Abstract

The main objective of this study was to evaluate the kinetics of moisture and oil uptake during chorizo deep-fat frying as compared to atmospheric and vacuum conditions. The conditions in the process were 90, 120, and 150°C for vacuum frying and 160, 170, and 180°C for atmospheric frying. The kinetics of moisture loss during atmospheric and vacuum frying was studied from the analytical solution of Fick's second law for cylinder geometry. Oil absorption was also determined using a first-order kinetic model. The moisture content decreased by 33.72% at the maximum process temperature and time during vacuum frying (150°C, 360 s), as compared to the atmospheric frying, which was 28.61% (180°C). The oil content at the end of the process (360 s) was 27.79% (90°C), 27.31% (120°C), and 24.82% (150°C) for vacuum-fried chorizos, and higher values were obtained in the atmospheric frying, obtaining values of 34.45% (160°C), 31.36% (170°C), and 28.47% (180°C) (p < 0.05). In summary, the vacuum frying yielded sausages with a lower final oil percentage and higher moisture content; these results are promising because they may influence consumer preference for sensory parameters.

1. Introduction

Frying is one of the oldest and most popular cooking methods. This process consists of subjecting food to a cooking process by immersion in oil or fat at a temperature above the boiling point of water, normally between 150 and 200°C [1, 2]. Oil absorption is one of the most important quality parameters of fried foods. Oil consumption poses major health problems, such as coronary heart disease, cancer, diabetes, and hypertension [3], and is irreconcilable with consumer awareness of healthier, low-fat food products [4].

Moisture loss and fat absorption are two important mass transports that occur during frying. These two processes can be adjusted by changing the raw material properties and frying conditions to modify the quality and nutritional attributes of fried products [5].

When food is immersed in hot oil, heat transfer occurs by two mechanisms: convection from the oil to the surface of the food and conduction from the surface to the interior of the food [6]. This heat transfer evaporates part of the water present in the food, which escapes to the surface through concentration and pressure gradients. Moisture vaporization influences physical and chemical changes, such as starch gelatinization, protein denaturation, browning, pore and crust formation, and shrinkage/swelling [7–9].

Chorizo is a Colombian meat product that is traditionally consumed in various forms. A cured raw sausage of Spanish origin, its preparation has spread throughout the world; its formulation and preparation vary according to country and even region [10, 11]. According to Colombian Technical Standard NTC 1325, chorizo is a fresh, raw, and processed meat product obtained by grinding or mincing cooked and matured meat, together with fat and other permitted substances [12]. Vacuum frying is a technological alternative that improves the conditions of the frying process, while maintaining the sensory properties and product quality [13]. This technology consists of immersing food in hot oil in an airtight container, where the process pressure is below the atmospheric pressure, so time is shorter and temperature is lower than that in atmospheric frying [14]. Operating at low process temperatures confers advantages such as preservation of flavor and nutrients, as well as protection of oil quality and reduction in the generation of toxic compounds [15–17].

Some studies have reported the use of mathematical models to describe, predict, and optimize the kinetic behavior of foods during the frying process. Fick's law has been used to describe the process of moisture diffusion and as a basis for optimizing processing conditions for different fried foods [18, 19]. Authors such as [20–24] applied this diffusive model during frying of pea chips, potato strips, yucca slices, peas and banana slices, and sweet potato slices, respectively.

Although frying is a commonly used process, its quantitative analysis in the engineering field is limited to food matrices of meat origin, where vegetable products are mainly studied to evaluate transport phenomena [25]. The use of mathematical models to predict mass transfer kinetics has been widely applied in food matrices of plant origin since there is a greater possibility of mass exchange, which would represent a greater adjustment to the mathematical model.

Suaterna [26] showed that foods of animal origin have tissues with spaces or intracellular pores that prevent the entry of oil (heating medium) during frying, while the intracellular space of plant tissues is full of air, allowing more oil collection. It is worth mentioning that different studies have been carried out for the effect of frying on fresh meat and some derived foods, including studies carried out by Candela et al. [27], Makinson et al. [28], and Sheard et al. [29].

There are also studies by Yildiz and Dincer [30] and Sobowale et al. [31] on sausage frying. In addition, snacks, such as potato chips or tortillas, are the most studied fried products, but information on transport phenomena in fried meat products is scarce. For this reason, this study looked at mass transfer kinetics during atmospheric and vacuum frying of a chorizo-type meat product. So far, there are no publications in the literature on immersion frying chorizo, making this study important since it will provide more scientific information on the kinetics of water loss and oil absorption during vacuum and atmospheric frying. Therefore, the objective of this study was to study mass transfer during vacuum and atmospheric frying of chorizo.

2. Materials and Methods

2.1. Raw Materials

The beef, pork fat, and vegetables were purchased from a local supermarket in the city of Cartagena. The other inputs were purchased from a specialized company (Insumos y Equipos JR S.A.S., Cartagena de Indias, Colombia). Palm vegetable oil with antioxidants (TBHQ or BHT) was used (Famar S.A, Santa Marta, Colombia). The oil was fresh and was replaced for all frying conditions.

2.2. Elaboration of Chorizos

Beef that was previously cleaned and weighed was used to make the chorizos. Subsequently, the grinding process was carried out with a 10 mm thick disc grinder. The grinding temperature of the process was not higher than 7°C to avoid protein denaturation [32].

The ground meat was weighed with the pork fat already chopped and ground (15% of the weight of the meat) for the calculation. In this way, the chorizo was formulated according to the concentration allowed by Colombian Technical Standard NTC 1325: beef (100%): pork fat (15%), ice (10%), sodium chloride (1.6%), pepper (0.5%), liquid smoke (0.15%), Welsh onion (5%), garlic (1.5%), nitrite (1.5%), polyphosphate (0.4%), and ascorbic acid (0.045%).

The kneading and mixing of the nonmeat raw materials (seasonings and additives) were carried out manually to obtain a homogeneous dough. Once the dough was obtained, the sausage was produced in a hydraulic stuffer, using natural casing; the tying was done manually. After the stuffing process, the sausages were subjected to a blanching process until the core of the sausages reached a temperature of ±72°C. Then, the sausages were immediately dried and subjected to heat shock. Finally, they were allowed to rest and refrigerated (4°C) for 16 h. Once the chorizos were prepared, the experiments were carried out.

2.3. Vacuum Frying

The frying of the samples under vacuum conditions was carried out with a Gastrovac® (Cocina Internacional, Barcelona), 40 × 26 × 46 cm, with a maximum capacity of 10.5 L. The maximum vacuum pressure used in the equipment was 30 kPa; the oil temperatures were 90°C, 120°C, and 150°C; the frying times were between 90 and 360 s, established by means of preliminary tests. 10 pieces of chorizo were used for each frying, 100 mm long × 15 mm wide, and the weight was 100 g approx. The food : oil ratio was 1000 g : 4 L.

To start the vacuum frying process, the chorizos were placed in a basket that was attached to the handle of the lid, the fryer and the vacuum valve were closed, pressure was applied to the lid to stabilize the vacuum pressure, and, once the pressure was reached, the samples were immersed in hot oil. The temperature and time were previously programmed. Once the frying process was finished, the samples were removed from the oil, the vacuum valve was opened to balance the pressure, and the samples were removed.

2.4. Atmospheric Frying

The frying at atmospheric pressure was done in a Professional Digital Waring Pro Df250b Fryer, 1800 Watts, with a capacity of 5 L. The frying times were between 90 and 360 s, and the oil temperatures were established by preliminary tests at 160°C, 170°C, and 180°C. The chorizos were drained into a wire mesh basket for further analysis. 10 pieces of chorizo were used for each frying, 100 mm long × 15 mm wide, and the weight was 100 g approx. The food : oil ratio was 1000 g : 4 L.

The frying by immersion was carried out in a discontinuous way: the fryer was connected to the electrical source, the temperature and time were established in the control panel, and vegetable oil was placed in a stainless steel container. Once the temperature was reached, the chorizos were placed in lots of three units in a mesh basket and immersed in the oil, and the lid was placed. The fried chorizos were left to rest for 5 min outside the fryer basket and passed through absorbent paper where they were drained for 5 min. This process was repeated three times with each temperature time, similar to Marcano et al. [33].

2.5. Determination of Moisture and Oil Content

The determination of moisture loss was calculated according to AOAC 925.10 [34], and the Soxhlet method was applied to determine the fat content with extraction with light petroleum (benzine) according to AOAC 920.85 [34]. All measurements were taken in triplicate.

2.6. Mathematical Modeling

A first-order kinetic model was chosen to describe the phenomena of mass transfer with concentration differences within the frying process, taking into account the following assumptions: (1) the oil temperature is constant during frying, (2) the initial concentration of water in chorizos is uniform, and (3) the two flows were considered independent of each other.

The effective diffusion coefficients for each temperature of the process were obtained from the analytical solution to Fick's second law for the geometry of the cylinder and in an unstable state, using constant diffusion.

2.7. Kinetics of Moisture Loss

To calculate the diffusion coefficients of the fried sausages in different processes (atmospheric and vacuum), a second-order mathematical model describing the mass transfer with concentration differences was used:

| (1) |

The moisture concentration can be normalized according to the following equation [21]:

| (2) |

M t is the moisture content in time t, Me is equilibrium moisture content, Mo is for initial moisture content, and Fick's second law was used, described for the geometry of a cylinder proposed by Melquíades et al. [35]:

| (3) |

Assuming that Me at time t is equal to zero (0), it was discarded. To determine the effective moisture diffusion coefficient (Da), the linearization of Equation (3) was done by applying logarithm and adjusting it to a straight line y = mt + b:

| (4) |

On the other hand, the influence of the frying temperature on the effective diffusion coefficient had an Arrhenius-type behavior according to the following equation:

| (5) |

By linearizing the equation and applying the natural logarithm of the graph LnDa vs. T (k), Ea was estimated from the value of the slope.

To determine the mass transfer coefficient of chorizos, Lewis' first-order model was used:

| (6) |

K c is mass transfer coefficient and t is time.

2.8. Kinetics of Oil Uptake

For the fat uptake modeling, a first-order kinetic model was used, which is the first-order kinetic model recommended by Krokida et al. [36],

| (7) |

O∗ is the oil content in time t, Oeq is the equilibrium oil content in time t = ∞, and K represents the specific rate of oil uptake for the first-order model. In the model, at t = 0, the oil content is zero, and, for longer times, the oil content reaches the value of equilibrium. Equation (7) was linearized, and a natural logarithm was applied on both sides. From the graph, the speed of oil uptake was calculated. This model gave acceptable accuracy between calculated and experimental values for all cases [37].

The relationship for the variation of equilibrium oil content, Oeq, with frying temperature T can be described using an Arrhenius-type relationship to obtain the activation energy [38]:

| (8) |

A is a reaction rate of the model parameters, A0 is the preexponential factor, Ea is the activation energy, R is the universal gas constant, and T is the absolute temperature. The linearization of Equation (8) and graph Ln Oeq vs. 1/T gave the linear slope, which allowed us to calculate the activation energy. To minimize errors, the root equation was used:

| (9) |

In the above equation, N is the number of data points, Vexp is the experiment value, and Vfitted is the calculated value. Models based on Fick's law were adjusted to the experimental data.

2.9. Statistical Analysis

The data processing was carried out with the statistical program STATGRAPHICS Centurion 16.1.15 (Corporation, U.S.A.) on Windows 8. The existence or lack of statistically significant differences of each evaluated parameter was determined through a completely randomized analysis of variance (ANOVA) and multiple comparisons, at a significance level of 5% (p ≤ 0.05).

3. Results and Discussion

3.1. Kinetics of Moisture Loss

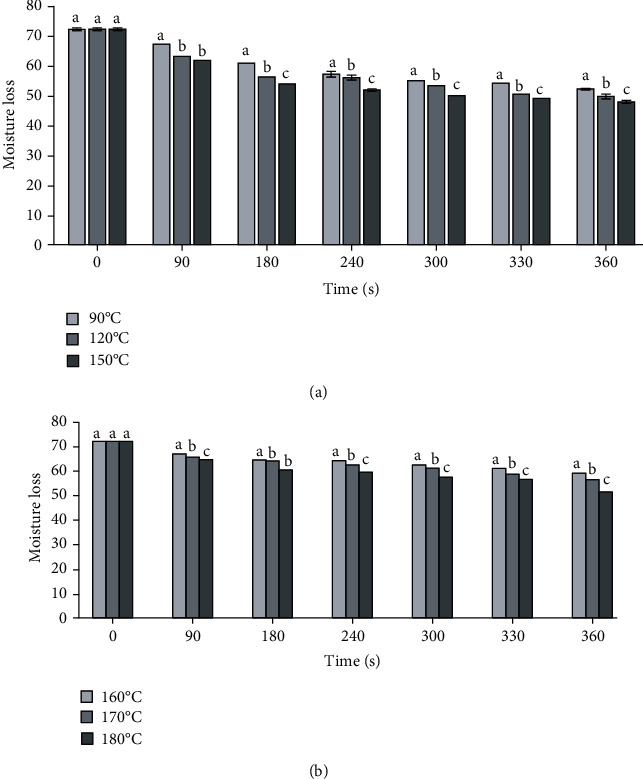

Figure 1 shows the kinetic movement of moisture loss from the chorizos during the vacuum and atmospheric frying processes. The curves between the different process temperatures presented a similar behavior, showing a direct relationship with time and temperature, i.e., as these variables increased, the moisture content of the chorizos during frying decreased (Figures 1(a) and 1(b)), with water evaporation being more noticeable at higher temperatures. The way in which a biological material loses water during frying is related to the physicochemical changes that occur in the cellular structure, which, in turn, are related to the processing temperature and time. This phenomenon was also observed by Sobowale et al. [31] during the frying of sausages, who stated that the moisture content of a meat product decreased with increasing temperatures and frying times. The application of higher frying temperatures saw a significant reduction in moisture content in both processes (vacuum and atmospheric).

Figure 1.

Moisture loss of chorizos vs. the frying time for each temperature: (a) vacuum frying and (b) atmospheric frying.

In addition, the moisture content was reduced by 33.72% at a temperature of 150°C and 360 s of processing time during vacuum frying, as compared to atmospheric frying, which was 28.61%. When analyzing the lower temperatures and longer frying times in both processes, the frying of chorizos at atmospheric pressure presented an average of 11% lower final moisture content (p < 0.05). Likewise, the moisture content of the chorizos at lower vacuum frying temperatures, independent of the processing time, was similar to the moisture content of the chorizos at atmospheric temperature, which means that it is possible to obtain chorizos with the same moisture content by applying lower process temperatures under vacuum conditions.

At intermediate vacuum temperatures (90°C) and a time of 240 s, the moisture content of the chorizos was similar in atmospheric conditions (170°C, 360 s) (p < 0.05); once again, the vacuum frying had similar moisture contents in shorter processing times. These results were obtained by Faloye et al. [39] for chicken nuggets, demonstrating that the moisture content decreased significantly with increasing temperatures and frying times, regardless of the thickness of the sample used. Previous studies on chorizo frying were carried out by Acevedo et al. [40], demonstrating that the factor that most influenced the dehydration of chorizos after vacuum frying was temperature, which in combination with processing time directly influences moisture loss.

Table 1 shows that the behavior of the diffusion coefficient in sausages fried at atmospheric pressure and under vacuum was higher when higher process temperatures were applied. Also, during atmospheric frying, this parameter was lower under atmospheric conditions than that seen with the vacuum application. That is, the effect of vacuum (30 kPa) produced expansion in the pores of the chorizo, which mobilized free water molecules faster because of the decrease in the boiling point of water.

Table 1.

Moisture transfer parameters of vacuum and atmospheric pressure fried chorizos, diffusivity, and convective moisture coefficient.

| Type of frying | T (°C) | D a (m2/s) | K c (m/s) | R 2 | E a (kJ/mol·K) |

|---|---|---|---|---|---|

| Vacuum frying | 90 | 3.50 × 10−8 | 9 × 10−4 | 0.98 | 4.3 |

| 120 | 3.89 × 10−8 | 10 × 10−4 | 0.97 | ||

| 150 | 4.28 × 10−8 | 11 × 10−4 | 0.95 | ||

|

| |||||

| Atmospheric frying | 160 | 1.95 × 10−8 | 5 × 10−4 | 0.95 | 38.25 |

| 170 | 2.33 × 10−8 | 6 × 10−4 | 0.95 | ||

| 180 | 3.11 × 10−8 | 8 × 10−4 | 0.94 | ||

Yildiz and Dincer [30] obtained lower diffusion coefficients (4.101 × 10−9 m2/s) during the frying of cylindrical sausages at 180°C. These authors stated that temperature has an enormous influence on diffusion because of the driving force for mass transfer provided by the conversion of water into steam, which is forced out of the pores of the matrix.

Similar results were reported by Nasiri et al. [41], who stated that the effective moisture diffusivity of shrimp nuggets ranged from 2.05 × 10−8 to 5.71 × 10−8 m2/s with R2 between 0.91 and 0.98. The frying temperature had a positive effect on the effective diffusivity of moisture, increasing with increasing oil temperatures. Sosa-Morales et al. [42] obtained lower diffusion coefficients during pork frying (plate shape), within the range of 1.5 × 10−9 to 30.2 × 10−9 m2/s, estimated between 90 and 110°C. The observed differences in moisture diffusivity could have been due to the effect of the different formulation of the chorizo and different food ingredients.

Osorio et al. [20] agreed with the effect of pressure on moisture diffusivity in fried peas at 140, 160, and 180°C, obtaining values between 1.62 ± 0.12 and 2.61 ± 0.23 × 10−8 m2/s for 78 kPa, 2.01 ± 0.24 and 2.86 ± 0.16 × 10−8 m2/s for 43 kPa, and 2.42 ± 0.18 and 3.44 ± 0.31 × 10−8 for 9 kPa m2/s. These authors indicated that the higher the vacuum, the higher the drying speed, and the shorter the processing times. An increase in pressure results in low diffusivity values; that is, at moderately low pressures, the diffusion coefficient of gases is inversely proportional to pressure or density. This fact is attributed to variation in the density of gases.

On the other hand, as the pressure decreases, the boiling point of the water decreases, and, as a result, the water contained in the product will start to vaporize faster from the inside of the food. This explains the values obtained in the convective coefficient or rate of water loss, where its dependence on temperature was observed. Higher values were seen with vacuum frying because of the effect of pressure, which indicates a higher speed of vaporization [22].

For the moisture loss kinetic constants, it was observed that they increased with increasing temperatures in both types of frying; however, the vacuum frying was higher on average by 36%. Similar data were reported by Barrios et al. [43] with calculated Kc coefficients during pea frying at temperatures of 160, 180, and 200°C, reporting maximum values of 1.25 × 10−2, 1.44 × 10−2, and 1.94 × 10−2 m/s.

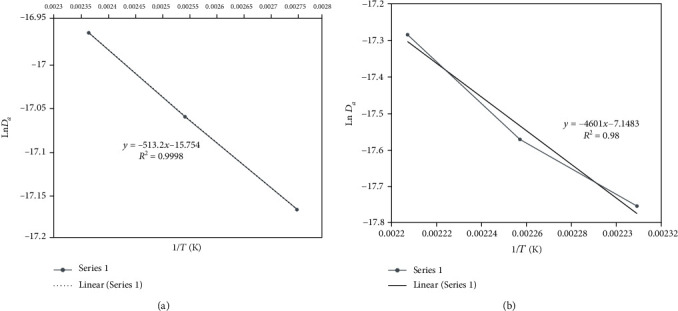

The activation energy (Ea) of the immersion frying operation was determined from the diffusion coefficient that fit the Arrhenius equation because of dependence on temperature [43]. Figure 2 shows the relationship with Ln Da (m2/s) as a function of 1/T (K−1), where the value of the activation energy with the slope of the line was calculated. Sobowale et al. [31] reported activation energies of 71.04 to 77.76 kJ/mol and 65.82 to 67.2 kJ/mol for temperatures of 150, 170, and 190°C, respectively, for frying goat meat sausages. The activation energy increased significantly with increasing temperatures. The lower activation energies indicated that sausage frying requires less energy and that the process is less sensitive and dependent on temperature changes [44].

Figure 2.

Logarithm of effective moisture diffusivity vs. absolute frying temperature: (a) vacuum frying and (b) atmospheric frying.

The vacuum (pressure of 30 kPa) and lower temperatures (of 150°C) resulted in an energy requirement to start the diffusion process that was much lower than that with normal pressures (1 atm). The activation energy (Ea) was 4.3 kJ/mol for the vacuum pressure and 38.25 kJ/mol for the atmospheric pressure, with determination coefficients of 0.99 and 0.98, respectively (Table 1). Ortega and Montes [22] reported activation energies (Ea) of 70.9424 kJ/kmol (R2 = 0.9905) for a pressure of 78 kPa and 23.2 kJ/kmol (R2 = 0.8673) for a pressure of 9 kPa, with frying temperatures of 140, 160, and 180°C for atmospheric pressure and 90, 110, and 130°C for vacuum pressure, with a time of 1000 s for both pressures. Barrios et al. [43] indicated that the activation energy of this phenomenon comes from the thermal energy of the fluid (oil), observing that, as the system is emptied, less Ea is required to start the process.

3.2. Kinetics of Oil Uptake

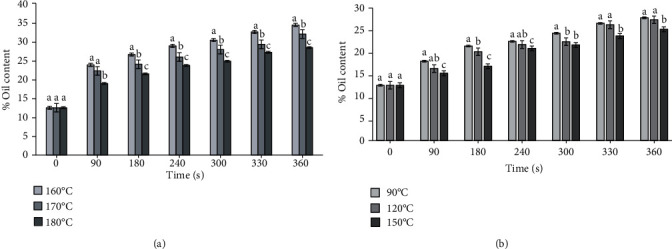

The oil content at the end of the process (360 s) was 27.79% (90°C), 27.31% (120°C), and 24.82% (150°C) for the vacuum-fried chorizos, and higher values were obtained in the atmospheric frying, obtaining values of 34.45% (160°C), 31.36% (170°C), and 28.47% (180°C) (p < 0.05). Also, during the atmospheric frying at 180°C and maximum frying time, the final oil content in the chorizos was similar to the content with a frying temperature of 160°C and time of 240 s. In addition, at the maximum processing temperature and time, a lower oil percentage, 21.00% and 11.20%, was obtained than that with temperatures of 160°C and 170°C, respectively (Figure 3(a)) (p < 0.05).

Figure 3.

Kinetics of oil uptake: (a) vacuum frying and (b) atmospheric frying.

The maximum difference between the experiment and regression values was 1.21% for the atmospheric frying and 1.23 for the vacuum frying, demonstrating excellent agreement between the data (Figures 3(a) and 3(b)). These results were similar to those of Sobowale et al. [31] for goat meat sausage frying, who reported higher oil contents with increasing frying temperatures and times, going from 19.38% to 36.0 2% at 170°C, 3 min and 9 min, respectively.

On the other hand, the vacuum frying at temperatures of 90°C and 120°C presented the same behavior for the fat absorption kinetics. On the other hand, at higher process temperatures (150°C), the final oil percentage was lower on average by 11% than that with the other two temperatures (90°C and 120°C) (Figure 3(b)). Yildiz and Dincer [30] also reported this same trend in frying cylindrical sausages, stating that the oil content increased with increasing the frying time. Faloye et al. [39] also demonstrated that oil content increased when the frying temperature increased from 155 to 175°C for 5 min in chicken nuggets. Thus, at higher temperatures, there tends to be faster development of the solid crust, which increases oil absorption, especially during cooling.

In general, it was found that fat absorption increased, while moisture content was significantly reduced in both frying types (atmospheric and vacuum). As the temperature decreased for a processing time, the oil content increased in the chorizos. For the vacuum frying, when the oil uptake decreased from 90°C to 150°C with a time of 240 s, the same behavior was shown for frying at atmospheric pressure.

Teruel et al. [45] reached the same conclusion when they studied the vacuum effect on chicken nugget frying. This can be explained by the phenomenon of pressurization that occurs after frying and before the cooling stage. Once the food is removed, the internal pressure of the pores begins to increase until equilibrium with the external environment is reached, at which time the oil and air (gas) on the surface of the food begin to penetrate the empty spaces [46].

Because of the difference in pressure at that time, the diffusivity of air is much higher than that of water, and, therefore, air begins to occupy those spaces, preventing oil from entering the food; in the cooling stage, like in atmospheric frying, oil located on the surface of food continues to penetrate the pores in vacuum frying, with the difference that, with this technology, oil adheres to a lesser degree on the surface of the product, so there is less oil available to penetrate during this stage [47].

There are some factors that influence oil uptake in foods, such as the quality and composition of oil, surfactants produced by oxidation, frying temperature, shape of the food, moisture content, and porosity and process conditions [22].

Bermúdez et al. [23] used the same temperatures used in this study under atmospheric conditions and reported similar results when frying banana slices. Barrios et al. [43] reported that, at a temperature of 160°C, the highest uptake value of 0.343 g oil/g dry solid was seen, which decreased by 9.621% at 180°C and 18.367% at 200°C.

A lower fat content was observed during the vacuum frying. A similar behavior was found by Urbano et al. [48] who carried out vacuum frying at 100, 120, 130, and 140°C and compared it with atmospheric pressure (165°C), indicating that using reduced pressures means the oil uptake decreases.

3.3. Parameters of Oil Uptake Kinetics

Table 2 shows the parameters describing the oil uptake kinetics for the vacuum and atmospheric frying. The temperature had an inverse and significant effect on the rate of oil uptake, i.e., a decrease in the rate of oil uptake was seen with increasing temperatures. The K values ranged from 4.7 × 10−3 at 90°C (R2 = 0.99) to 4.5 × 10−3 s−1 (R2 = 0.88) at 150°C (under vacuum conditions) and from 6.4 × 10−3 at 160°C (R2 = 0.93) to 6.4 × 10−3 s−1 (R2 = 0.86) at 180°C (under atmospheric conditions).

Table 2.

Parameters describing oil uptake kinetics of chorizos and activation energy with Arrhenius type fitting.

| Frying type | T (°C) | Oil absorption speed | Calculation of the activation energy | ||||||

|---|---|---|---|---|---|---|---|---|---|

| K(s−1 × 10−3) | R 2 | %RSM | 1/T (K−1∗10−3) | O eq | Slope (m) | R (kJ mol/K) | E a (kJ/mol) | ||

| Vacuum frying (30 kPa) | 90 | 4.7 | 0.99 | 0.10 | 2.75 | 27.79 | 283.25 | 8.31 | -2.35 |

| 120 | 3.8 | 0.98 | 0.109 | 2.54 | 27.31 | ||||

| 150 | 4.5 | 0.88 | 0.069 | 2.36 | 24.83 | ||||

|

| |||||||||

| Atmospheric frying | 160 | 6.4 | 0.93 | 0.095 | 2.31 | 34.45 | 1871.8 | 8.31 | -15.54 |

| 170 | 6.0 | 0.93 | 0.132 | 2.26 | 31.36 | ||||

| 180 | 6.4 | 0.86 | 0.091 | 2.21 | 28.47 | ||||

A different behavior was seen by Nasiri et al. [41] during shrimp nugget frying, obtaining an increase in a range between 3.5 × 10−3 and 7.8 × 10−3 s−1. It should be noted that the rate of oil uptake depends on the main process variables, such as oil temperature, type of product, pretreatment applied, frying conditions, product width, and type of oil [29, 32, 49]. In addition, the decrease in the speed constant was due to the rapid formation of the crust at high temperatures, a fact that would explain the results found for chorizos. The values of the root mean square (%RSM) and the coefficient of determination R2 indicated a good fit of the kinetic model with the experiment data. For the calculation of the activation energy, the Oeq values were used for the maximum oil content uptake by the chorizos under different frying conditions and the maximum time used in the experiment. The oil content at equilibrium () decreased when the oil temperature increased. This result agrees with the results of [22, 41], who studied mass transfer parameters for shrimp and nugget frying of yucca, respectively. The negative activation energy values for the oil uptake showed a decreasing trend with increasing temperatures. Similar results were reported by Ortega and Montes [22] for nugget frying of yucca slices, obtaining values of −10.25 ± 2.52, −2.77 ± 0.66, and −17.22 ± 3.75 kJ/mol for control and blanched and osmodehydrated samples.

4. Conclusion

Both frying types had a moisture content in the sausages that decreased gradually as the temperature and processing time increased. In addition, the moisture content during vacuum frying was reduced by 33.72% at the maximum temperature and processing time, as compared to the atmospheric frying, which was 28.61%. The vacuum frying had similar moisture contents in the shorter processing times. Also, the behavior of the diffusion coefficient in the sausages fried at atmospheric pressure and under vacuum was higher when higher process temperatures were applied. In addition, this parameter was lower under atmospheric conditions. Similarly, at the maximum process temperature and time (180°C and 360 s), a lower percentage of oil was obtained than that with the temperatures of 160°C and 170°C, 21.00% and 11.20%, respectively (Figure 3(a)).

Acknowledgments

The authors of this research are grateful to the Modeling and Application of Advanced Oxidation Processes research group and to the Agricultural and Agroindustrial Development research group (IDAA) at the University of Cartagena for their support in providing reagents and experiment equipment. This research was funded by Quinta Convocatoria de Proyectos de Investigación, Para semilleros de estudiantes de pregrado, adscritos a Grupos de Investigación Visibles (Categorizados o Reconocidos) en la Plataforma Científica del Departamento Administrativo de Ciencias, Tecnología e Innovación - Colciencias y avalada por la Universidad de Cartagena mediante la Resolución número 00473 del 2 de marzo de 2016.

Data Availability

The data used as references in this study have been indicated in the reference repository (name of authors, year of publication, title of the document, journal, and number of pages).

Conflicts of Interest

The authors declare that there is no conflict of interest in relation to the publication of this study.

References

- 1.Gouyo T., Rondet É., Mestres C., Hofleitner C., Bohuon P. Microstructure analysis of crust during deep-fat or hot-air frying to understand French fry texture. Journal of Food Engineering. 2021;298, article 110484 doi: 10.1016/j.jfoodeng.2021.110484. [DOI] [Google Scholar]

- 2.Turan S., Keskin S., Solak R. Determination of the changes in sunflower oil during frying of leavened doughs using response surface methodology. Journal of Food Science and Technology. 2021;2021:1–10. doi: 10.1007/s13197-021-04980-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Gil Á. In: Tratado de Nutrición. 2nd. Ruiz M. D., editor. Madrid: medica panamericana; 2010. [Google Scholar]

- 4.Maity T., Bawa A. S., Raju P. S. Effect of vacuum frying on changes in quality attributes of jackfruit (Artocarpus heterophyllus) bulb slices. International Journal of Food Science. 2014;2014:8. doi: 10.1155/2014/752047.752047 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Zhang W., Chen J., Yue Y., Zhu Z., Liao E., Xia W. Modelling the mass transfer kinetics of battered and breaded fish nuggets during deep-fat frying at different frying temperatures. Journal of Food Quality. 2020;2020:8. doi: 10.1155/2020/8874163.8874163 [DOI] [Google Scholar]

- 6.Omotosho O. E., Laditan O. C., Adedipe O. E., Olugbuyiro J. A. O. Effect of deep-fat frying on the vitamins, proximate and mineral contents of colocasia esculenta using various oils. Pakistan Journal of Biological Sciences. 2015;18(6):295–299. doi: 10.3923/pjbs.2015.295.299. [DOI] [Google Scholar]

- 7.Hase S. L., Linares A. R. Cinética de pérdida de agua y ganancia de aceite de snacks fritos de mandioca. Revista de Ciencia y Tecnología. 2018;29:35–44. [Google Scholar]

- 8.Yagua C. V., Moreira R. G. Physical and thermal properties of potato chips during vacuum frying. Journal of Food Engineering. 2011;104(2):272–283. doi: 10.1016/j.jfoodeng.2010.12.018. [DOI] [Google Scholar]

- 9.Caro A. D., Sampayo S. P., Acevedo D., Montero P. M., Martelo R. J. Mass transfer and colour analysis during vacuum frying of Colombian coastal carimañola. International Journal of Food Science. 2020;2020:11. doi: 10.1155/2020/9816204.9816204 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Jiménez-Colmenero F., Triki M., Herrero A. M., Rodríguez-Salas L., Ruiz-Capillas C. Healthy oil combination stabilized in a konjac matrix as pork fat replacement in low-fat, PUFA-enriched, dry fermented sausages. LWT-Food Science and Technology. 2013;5:158–163. doi: 10.1016/j.lwt.2012.10.016. [DOI] [Google Scholar]

- 11.Cruz-Bacab L., Baeza-Mendoza L., Pérez-Robles L., Martínez-Molina I. Evaluación sensorial de embutido tipo chorizo a base de carne de conejo. Abanico Veterinario. 2018;8(1):102–111. [Google Scholar]

- 12.Hleap-Zapata J. I., Romero-Quintana L., Botina-Cárdenas J., Martínez-Martínez C. A., Valenciano-Pulido Y., Higuita-Diaz K. Effect of the partial replacement of wheat flour with turmeric flour (Curcuma longa) on the physicochemical and sensory properties of a common chorizo. DYNA. 2020;87(214):46–52. doi: 10.15446/dyna.v87n214.83722. [DOI] [Google Scholar]

- 13.Diamante L. M., Shi S., Hellmann A., Busch J. Vacuum frying foods: products, process and optimization. International Food Research Journal. 2015;22(1):15–22. [Google Scholar]

- 14.Moreira R. G. Vacuum frying versus conventional frying - an overview. European Journal of Lipid Science and Technology. 2014;116(6):723–734. doi: 10.1002/ejlt.201300272. [DOI] [Google Scholar]

- 15.Da Silva P. F., Moreira R. G. Vacuum frying of high-quality fruit and vegetable-based snacks. LWT-Food Science and Technology. 2008;41(10):1758–1767. doi: 10.1016/j.lwt.2008.01.016. [DOI] [Google Scholar]

- 16.Andrés-Bello A., García-Segovia P., Martínez-Monzó J. Vacuum frying process of gilthead sea bream (Sparus aurata) fillets. Innovative Food Science & Emerging Technologies. 2010;11(4):630–636. doi: 10.1016/j.ifset.2010.06.002. [DOI] [Google Scholar]

- 17.Clerjon S., Kondjoyan A., Bonny J. M., et al. Oil uptake by beef during pan frying: impact on fatty acid composition. Meat Science. 2012;91(1):79–87. doi: 10.1016/j.meatsci.2011.12.009. [DOI] [PubMed] [Google Scholar]

- 18.Esan T. A., Sobukola O. P., Sanni L. O., Bakare H. A., Muñoz L. Process optimization by response surface methodology and quality attributes of vacuum fried yellow fleshed sweetpotato (Ipomoea batatas L.) chips. Food and Bioproducts Processing. 2015;95:27–37. doi: 10.1016/j.fbp.2015.03.008. [DOI] [Google Scholar]

- 19.Neethu K. C., Sharma A. K., Pushpadass H. A., Emerald F. M. E., Manjunatha M. Prediction of convective heat transfer coefficient during deep-fat frying of pantoa using neurocomputing approaches. Innovative Food Science and Emerging Technologies. 2016;34:275–284. doi: 10.1016/j.ifset.2016.02.012. [DOI] [Google Scholar]

- 20.Osorio O., Rodríguez G., Castellanos F., Chávez A. Procesamiento de Arvejas (Pisum sativum L.). Parte 3: Cinética de Pérdida de Agua en Chips de Arveja en Condiciones de Fritura Convencional y a Vacío. Información Tecnológica. 2016;27(4):33–42. doi: 10.4067/S0718-07642016000400004. [DOI] [Google Scholar]

- 21.Moyano P. C., Berna A. Z. Modeling water loss during frying of potato strips: effect of solute impregnation. Drying Technology. 2007;20(7):1303–1318. doi: 10.1081/drt-120005854. [DOI] [Google Scholar]

- 22.Ortega F. A., Montes E. J. Parámetros cinéticos de transferencia de masa durante el freído por inmersión de rodajas de yuca (Manihot esculenta Crantz) Ingeniería y Competitividad. 2014;16(2):247–255. [Google Scholar]

- 23.Bermúdez A. A., Romero P. R., Arrazola G. A. Pérdida de humedad y absorción de aceite durante fritura de tajadas de plátano (Musa paradisiaca L.) Biotecnología en el Sector Agropecuario y Agroindustrial. 2016;14(2):p. 119. doi: 10.18684/BSAA(14)119-124. [DOI] [Google Scholar]

- 24.Pedreschi F., Hernández P., Figueroa C., Moyano P. Modeling water loss during frying of potato slices. International Journal of Food Properties. 2005;8(2):289–299. doi: 10.1081/JFP-200059480. [DOI] [Google Scholar]

- 25.Tirado D. F., Acevedo D., Guzmán L. E. Coeficientes convectivos de transferencia de calor durante el freído de láminas de tilapia (Oreochromis niloticus) Información Tecnológica. 2013;24(6):41–46. doi: 10.4067/s0718-07642013000600007. [DOI] [Google Scholar]

- 26.Suaterna A. C. La fritura de los alimentos: pérdida y ganancia de nutrientes en los alimentos fritos. Perspectivas En Nutrición Humana. 2011;10(1):77–88. [Google Scholar]

- 27.Candela M., Astiasáran I., Bello J. Deep-fat frying modifies high-fat fish lipid fraction. Journal of Agricultural and Food Chemistry. 1998;46(7):2793–2796. doi: 10.1021/jf9709616. [DOI] [Google Scholar]

- 28.Makinson J. H., Greenfield H., Wong M. L., Wills R. B. H. Fat uptake during deep-fat frying of coated and uncoated foods. Journal of Food Composition and Analysis. 1987;1(1):93–101. doi: 10.1016/0889-1575(87)90017-2. [DOI] [Google Scholar]

- 29.Sheard P. R., Nute G. R., Chappell A. G. The effect of cooking on the chemical composition of meat products with special reference to fat loss. Meat Science. 1998;49(2):175–191. doi: 10.1016/S0309-1740(97)00137-X. [DOI] [PubMed] [Google Scholar]

- 30.Yildiz M., Dincer I. Modelling the heat and mass transfer analysis during oil-frying of cylindrical sausages. International Journal of Energy Research. 1995;19(7):555–565. doi: 10.1002/er.4440190702. [DOI] [Google Scholar]

- 31.Sobowale S. S., Olayanju T. A., Mulaba-Bafubiandi A. F. Process optimization and kinetics of deep fat frying conditions of sausage processed from goat meat using response surface methodology. Food Science & Nutrition. 2019;7(10):3161–3175. doi: 10.1002/fsn3.1145. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 32.Hleap J., Velasco V. Physicochemical parameters during storage of sausages made from red tilapia (Oreochromis sp.) Biotecnología en el Sector Agropecuario y Agroindustrial. 2012;10(1):42–50. [Google Scholar]

- 33.Marcano J., La Rosa Y., Salinas N. Influence of the deep fat frying process on the lipid profile of the fat contained in the “french” type fried potato using palm olein. Grasas y Aceites. 2010;61(1):24–29. doi: 10.3989/gya.053309. [DOI] [Google Scholar]

- 34.AOAC. Official Methods of Analysis. 19th. Arlington, VA, USA: AOAC; 2012. [Google Scholar]

- 35.Melquíades Y. I., López C., Rosas M. E. Estudio de la cinética de rehidratación de zanahoria (Daucus carota) deshidratadas. Información Tecnológica. 2009;20(3):65–72. doi: 10.4067/S0718-07642009000300009. [DOI] [Google Scholar]

- 36.Krokida M. K., Oreopoulou V., Maroulis Z. B. Water loss and oil uptake as a function of frying time. Journal of Food Engineering. 2000;44(1):39–46. doi: 10.1016/S0260-8774(99)00163-6. [DOI] [Google Scholar]

- 37.Krokida M. K., Oreopoulou V., Maroulis Z. B., Marinos-Kouris D. Effect of pre-drying on quality of French fries. Journal of Food Engineering. 2001;49(4):347–354. doi: 10.1016/S0260-8774(00)00233-8. [DOI] [Google Scholar]

- 38.Troncoso E., Pedreschi F. Modeling water loss and oil uptake during vacuum frying of pre-treated potato slices. LWT - Food Science and Technology. 2009;42(6):1164–1173. doi: 10.1016/j.lwt.2009.01.008. [DOI] [Google Scholar]

- 39.Faloye O. R., Sobukola O. P., Shittu T. A., Bakare H. A. Influence of frying parameters and optimization of deep fat frying conditions on the physicochemical and textural properties of chicken nuggets from FUNAAB-alpha broilers. SN Applied Sciences. 2021;3(2):1–17. doi: 10.1007/s42452-021-04249-5. [DOI] [Google Scholar]

- 40.Acevedo D., Castillo P. M., Díaz S. T. Pérdida de humedad y absorción de aceite en la fritura a vacío de un producto cárnico tipo chorizo con incorporación de harina de garbanzo (Cicer arietum) @LIMENTECH, Ciencia y Tecnología Alimentaria. 2017;15(2):5–15. doi: 10.24054/16927125.v2.n2.2017.2964. [DOI] [Google Scholar]

- 41.Nasiri F., Mohebbi M., Yazdi F., Haddad M. Kinetic modeling of mass transfer during deep fat frying of shrimp nugget prepared without a pre-frying step. Food and Bioproducts Processing. 2011;89(3):241–247. doi: 10.1016/j.fbp.2010.11.009. [DOI] [Google Scholar]

- 42.Sosa-Morales M. E., Orzuna-Espíritu R., Vélez-Ruiz J. F. Mass, thermal and quality aspects of deep-fat frying of pork meat. Journal of Food Engineering. 2006;77(3):731–738. doi: 10.1016/j.jfoodeng.2005.07.033. [DOI] [Google Scholar]

- 43.Barrios L., Osorio O., Cerón A. Estudio de las cinéticas de pérdida de agua y absorción de aceite durante la fritura de arveja (Pisum sativum L.) Acta Agronómica. 2016;65(3):1–16. doi: 10.15446/acag.v65n3.49188. [DOI] [Google Scholar]

- 44.Vitrac O., Dufour D., Trystram G., Raoult-Wack A. L. Characterization of heat and mass transfer during deep-fat frying and its effect on cassava chip quality. Journal of Food Engineering. 2002;53(2):161–176. doi: 10.1016/S0260-8774(01)00153-4. [DOI] [Google Scholar]

- 45.Teruel M. R., García-Segovia P., Martínez-Monzó J., Linares M. B., Garrido M. D. Use of vacuum-frying in chicken nugget processing. Innovative Food Science and Emerging Technologies. 2014;26:482–489. doi: 10.1016/j.ifset.2014.06.005. [DOI] [Google Scholar]

- 46.Cazar E. Optimización del proceso de elaboración de snacks de piña (Ananas comosus) mediante la combinación de diferentes condiciones de pretratamiento y fritura al vacío. Escuela Politécnica Nacional, tesis pregrado: Quito, Ecuador; 2015. [Google Scholar]

- 47.Garayo J., Moreira R. Vacuum frying of potato chips. Journal of Food Engineering. 2002;55(2):181–191. doi: 10.1016/S0260-8774(02)00062-6. [DOI] [Google Scholar]

- 48.Urbano A. M., García P., Martínez J. Evaluación del comportamiento de yuca (Manhiot esculeta Cranz) en el proceso de fritura a vacío de chips. Universidad Politécnica de Valencia, tesis; 2012. [Google Scholar]

- 49.Ansarifar E., Mohebbi M., Hahidi F., Varidi M. Effect of chitosan addition on kinetic of mass transfer during deep fat frying of Kurdish cheese nugget. Journal of Health Sciences and Technology. 2018;2(1):15–22. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

The data used as references in this study have been indicated in the reference repository (name of authors, year of publication, title of the document, journal, and number of pages).