Abstract

4D printing is inspired by embedded product designs to produce stimuli-responsive consumables fabricated by available commercial 3D printers. Although significant progress on smart material performance has been made and different studies have focused on new strategies and process improvements in typical additive manufacturing. Herein, the proposed review article discusses material arrangements for 4D printing, highlighting the structural evolvement mechanism, the behavior of deformation, and their prospective implementation with respect. Starting from a generalized idea, and fundamental workflow, together with a graphical manifestation of the 4D printing concept, and 4D printing for shape-memory materials (SMMs), self-fitting wearables based on shape memory alloys (SMAs) are reviewed exclusively. Furthermore, the capabilities of single and multiple materials mechanisms for shape-shifting behavior are summarized. Finally, we explored the future application potential under succeeding context: SMA-based knitted garments, transforming food, and relevant sectors wise development and proceedings with the advancement in smart materials. We determined our review by aiming our future directions such as the “dream it and make it feasible” technology.

Graphical abstract

Keywords: 3D Printing, 4D Printing, Smart materials, Stimulus-responsive materials, Shape memory materials

Introduction

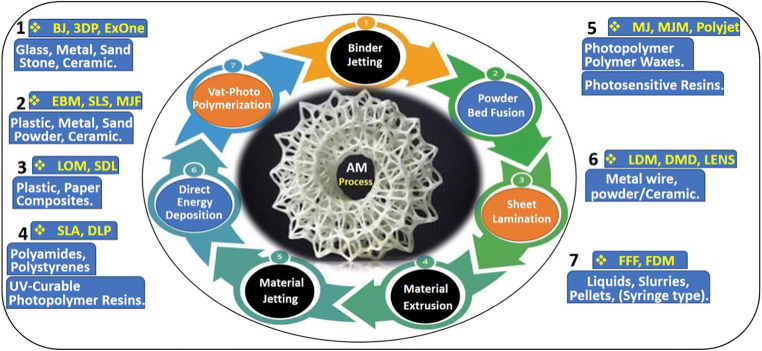

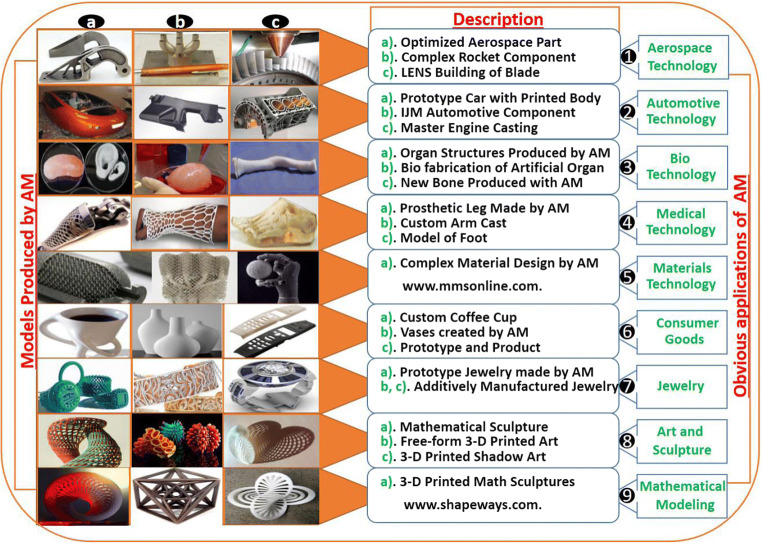

3D printing or additive manufacturing technology is indenting to transform the manufacturing world due to its potential to create any shape, size and geometry. Additive manufacturing first patent [1] was formally designated by ASTM “American Society for Testing Materials” for an extensive range of materials, systems, and corresponding products. Additive manufacturing is widely used in aviation [2] organizational relationships and procedures between enterprises [3]. Innovative framework for AM technology 3D printing implications for STEM (Science, Technology, Engineering, and Mathematics-related topics) education in the first decade of the 21 century [4]. Martin Stevens, CEO of IT IS 3D company overview [5], the technology can’t be successively enhanced but also the workforce of the future [6]. This approach has become the advance of learning classes [7] through experiments [8] and awareness [9] on additive manufacturing information [10] [11]. Educational, innovation process followed 3D printing throughout states an extensive review. However, the strong interest was shown in 4D printing of the US Army, Europe, and Asia such as China. Almost over 50 Chinese universities including Tsinghua University, Xian Jiao Tong University, HUST, and the South China University of Technology work on 3D and 4D printing. Perhaps, the most recent headway leaves Northwestern University, where experts have built up an advanced 3D printer that is fit for printing a grown-up human-sized item in a couple of hours. The three primary areas of additive manufacturing are university, industry, and government sectors, which all implement innovative strategies [5]. 3D and 4D printing research start to be acknowledged in academic circles, and particularly, additive manufacturing is regarded to be one main trigger to change and evolve in defense sector in the twenty-first century. ASTM internationally differentiated additive manufacturing technique into seven categories; typical materials and their alternative names are given in Fig. 1. 3D and 4D printing consumption are the basic way to make an example. The strategic applications of additive manufacturing include rapid tooling, rapid prototyping, and rapid manufacturing.

Fig. 1.

Classification, specific tech, and materials of AM processes by ASTM standards (Opted from www.hybridmanutech.com)

Significantly, AM technology proves its tremendous influence in the field of manufacturing of specified material such as layer to layer hybrid materials, functionally graded and multiple materials.

Inside the review, our prime focus is to highlight the enormous application and exploring the capabilities of 4D printing technology of additive manufacturing technology to achieve a better understanding of this technique. The review is organized into four sections: Section 1 is for technological advent, the fundamental concept, workflow of AM, printing challenges for the basis of 4D printing, and the graphical manifestation of 4D printing concept materials expressed in confines of Section 2. In Section 3, broaden details on the materials and capabilities of single and multiple responses of materials are discussed. In addition, there are insights into shape-memory materials (SMMs), their mechanism, features, and behaviors for 4D printing. Section 4 is about 4D printing potential applications, and relevant sectors wise developments, extensions, and alternatives in the AM. At long last, the end is built up 4D printing approach practicality followed with the aid of a promising research viewpoint.

Additive Manufacturing (fundamental concept and workflow)

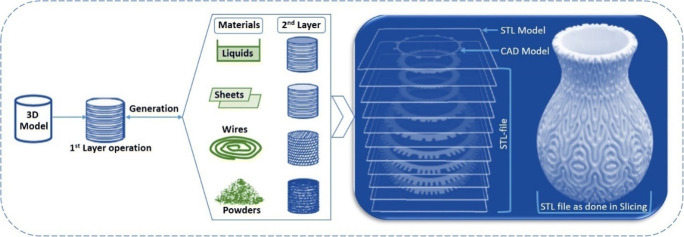

3D printing, also known as additive manufacturing, is a method of manufacturing parts directly from digital models by layering material. It is regarded as the “third industrial revolution” core technology. As shown in Fig. 2, AM is based on the principle of “layer by layer” manufacturing. Using metals, plastics, and ceramics, a method for creating products can be designed with the preferred spatial arrangement, starting with a 3D file/model and partitioning it into slices. Each slice is fixed to the x and y path, the major AM file format of the design, print and finish, by instructions on the head of the printer in the first 3D printing process. The Z motor, commanded by the G code, conveys a small portion of the top one inch up after the 3D printer completes a slice. The subsequent slice of the top line lays another layer of material. Later, it will use a layer to layer as far up the object as possible until it is finished.

Fig. 2.

Schematic representation of working and STL file as done by layer with the aid of layer. Source: teplogi.ru

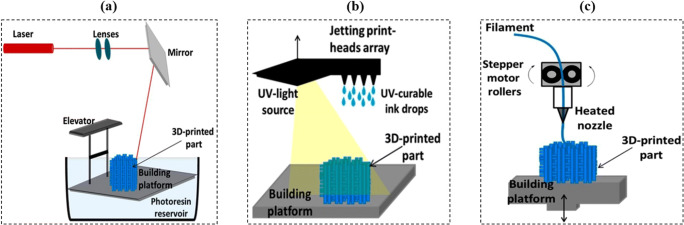

The procedure begins off evolved with a 3D solid modeling software file that could emerge out of any 3D computer-aided design (PC Supported Structure) application. The file must be changed over into a “standard” 3D format along with .STL (Standard Tessellation Language) position. In recent years, .STL has been the most well-known 3D printer file format, however, there are now additional well-known options such as .AMF. When it is certain that the piece is manufactural of a cutting procedure which is used in the 3D file. This procedure is maybe the very essential phase of the added substance fabricating process since it is the partition of the 3D model that empowers it to be produced by progressive layers of materials. According to the ISO standard (ISO 52900), the addition of a substance is described as “assembling forms using an additional approach, which are used to construct a model by developing progressive layers or units [12–14]. It can “print” in plastic, metal, nylon, and over a hundred different materials. It has numerous focal points over customary assembling processes like the opportunity of structure, multifaceted nature for nothing and lightweight design. The most well-known 3DP advancements realized today are schematically introduced in Fig. 3 along with the associated sections. In the sequence of printing techniques, the one is the laser-assisted stereolithography (SLA), also called vat polymerization, uses at least one laser beams to fix slender layers of fluid photopolymer pitches [15–17]. Charles W. Hall invented stereolithography, which is generally considered a developed 3D printing system, particularly combined with an additional invention for the photo-polymerization of liquid photopolymers using ultraviolet radiation. SLA is aimed at models toward improving the design because of the situation under various favorable circumstances, for example, speed and modernity. Inkjet printing is a drop-on technology, where weights and voltage beads start photo resin beads from a print head [18, 19]. The fluid, which commonly includes ultraviolet (UV) - which defines a treatable acrylate as soon as it is exposed to a UV source [15, 20].

Fig. 3.

Schematic details showing a specific 3D printing framework: a laser-assisted stereolithography (SLA), b inkjet printing, c fused deposition modeling (FDM)

Fused deposition modeling (FDM) as properly as direct ink composing is the suitable extrusion primarily conventional on additive manufacturing varieties for 4D printing. In the FDM process, the thermoplastic fiber is embedded via the warm nozzle that melts the material in the process of a semi-molten state. The liquid fiber is placed on the X-Y axis in such a shape that is equipped and tightened with the aid of cooling. After an isolation layer is assembled, the print head goes down or the plate strikes in the Z-axis to confirm the ensuing new layer on the top [15, 16, 21]. To restrict the impact of warm shrinkage, ensuing in vulnerable interlayer grip and mechanical demonstration, FDM machines empower the trade of managed cooling prices utilizing the assembly phase temperature [15, 22]. FDM machines, their assembly, and adaptation variations allow streamlined and easy setup. Therefore, the ability of the barrier relaxes the filament through the shrinking nozzles [22, 23], or additional printing contemporary apparatuses on the current device[23, 24].

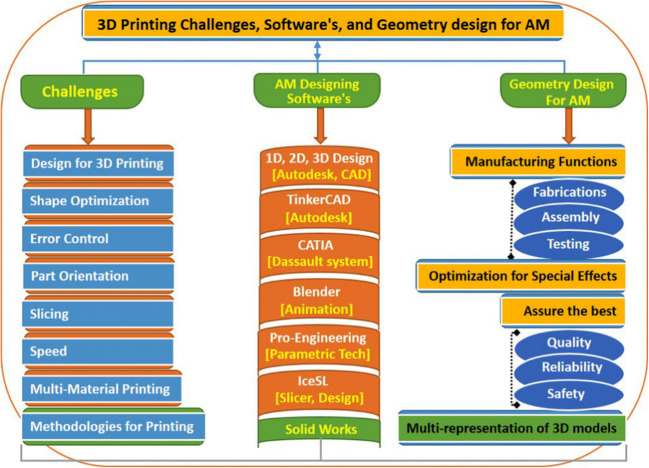

Printing challenges

Till now, undoubtedly additive manufacturing proves itself as a very productive approach with countless benefits. However, it has several limitations, including a lack of understanding, material availability, and design formulation. Also, this technology faces great limitations in its software application process and controlling standards. A 3D printer is a sort of industrial robot. AM will exchange the entire manufacturing creativity quickly and even exchange the philosophy of product consumption. 3D printing technology is capable of providing a content material layer via a layer, as a result of taking steps to produce the part. This process would involve transferring input from the material to the object completion after identifying challenges in key areas of 3D printing. The demanding situations are real and few of them have been addressed at all regarding computer-aided design (CAD) [25]. Our perspectives on technology in the era of additive manufacturing are depicted in Fig. 4.

Fig. 4.

Design exploration for additive manufacturing: the barriers, challenges and 3D design/modeling software

In any case, there are numerous software applications for generating support structures; however, there is the gap, absence of knowledge. Which one is preferred software than the opposition within the period of assemblies, designing, and structures using CURA and Slic3r for FDM processes? For future work, 3D printing is likely to offer both challenges and opportunities. AM brings obscure abilities to the advancement of another product, tasks, and the status of approaching engineering and technology [26]. AM has many advantages; however, the problem is that most of the components assembled are secure and unstable with the emissions of transferring assemblies [27]. 3D printing already attracted the attention of researchers, and from now on, there is a dire intention to grow a 4D printing that is not been witnessed until now.

4D printing

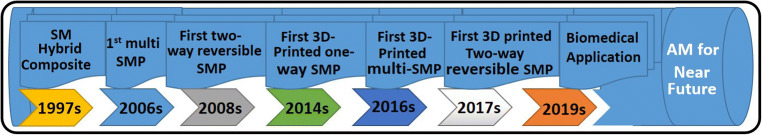

The printing of smart materials that respond to external stimuli is referred to as 4D printing. The historical backdrop of 4D printing is a short one, and the concept became delivered in 2012 by Skylar Tibbets [28]. From that point onward, 4D printing has equated to 3D printing, despite the fact that 4D printing has evolved into a novel branch of 3D printing [29, 30]. This determines an adaptable material content that can be approached in a variety of shapes depending on the stimulus difference [31]. This sort of approach explains why the concept of actuality compromises an environment-friendly route and 4D modifications right here over time [32]. This technology led the possibility of a massive evolution in space applications, manufacturing industries, deployable structures, security, biomedical technologies [33], and a variety of other fields by adding time as a fourth dimension [34]. Production-manufacturing 4D has a new prospect multi-material property in a single print as any 1D strand in 3D form, or its activation strength represented as any 2D surface in 3D format water can be used to convert printed materials. Figure 5 depicts the progress of additive manufacturing techniques. Although some recent discoveries have proved to be capable, but there are still some challenges to overcome [35–37].

Fig. 5.

3D-4D fabrication evolution and advancement of AM techniques

Graphical manifestation of 4DP concept

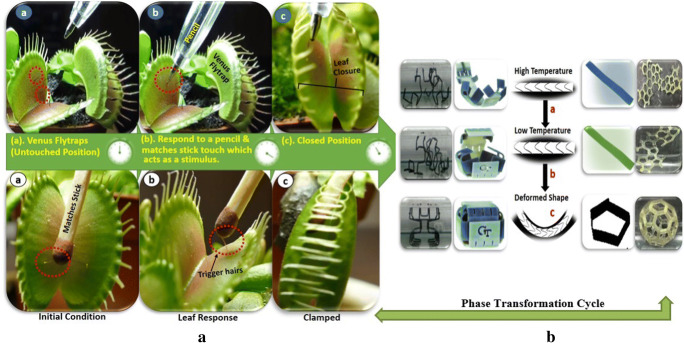

4D graphical summary set forth a path to the complete method comprehension. At the organismal level, plants and materials respond to ecological upgrades by different methods. This ability of a 4D created object to change shape is conditional on the stimuli that exposed it in different ways. Leaves skin is a wonderful example of the concept of 4D printing with Venus flytrap and a similar plant sensational approach. An important element of the folding itself is the collision. The folding structure is the arrangement of the specific parts of the contract, after which the block similarly folds tightly into the desired structures. A Venus flytrap accountable for nature-induced stimuli sticks to leaves/matches in 100ms to near-capture insects. Fig. 6a shows what happens when worms come into contact with leaves due to pores and skin. Warm them up a little, as shown in Fig. 6b, so they can carry out a folding sequence on their own and build a 3D object. The scenario now is possible to print gadgets that exchange their form at a particular time: the improvement was called “4D printing.” In the meantime, the unique flat object is produced with a 3D printer. Recently, the smart material of AM was one of the wise choices to respond to stimuli, and active research insisted on overcoming certain responsibilities. External stimuli inclusive of power, pressure, temperature, moisture, pH, or mechanical pressure reveal upon self-motivated and the time-established sensational behavior of several materials. On the smart material, they are warm and contemporary, while returning to their authentic shape, the material in warm water ought to convert it to the 4D-printing shape.

Fig. 6.

a Pre- and post-operative imaging of Venus flytrap: (A) From a temporary shape of Venus flytrap, (B) to impermanent shape b, and (C) to everlasting form c. Replicated from Ref. www.nature.com/nature with consent. b Phase Change Cycle: unfolding and object recovery, the three key capabilities of the technology in this regard are: machine-material and third is a geometry program.

Touch sensing leaves

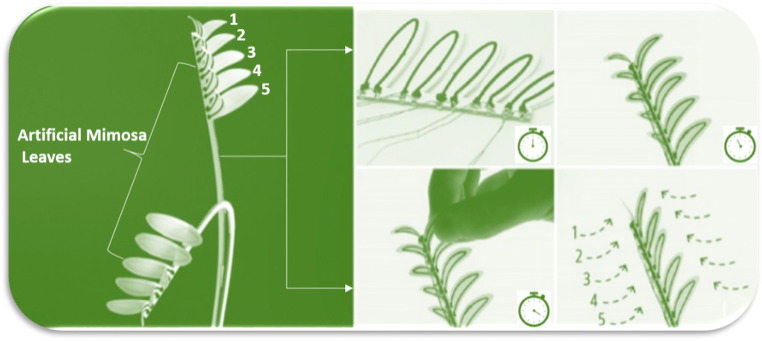

If the capacitance of the conductive material varies, it will interact with some other conductive object. This approves us to sense fingerprints on patterned paper. As shown in Fig. 7 in Mimosa, touch-sensitive and a sequentially actuated branch of a mimosa, when touching a leaf in the mimosa, open the continuous times to see each pair of leaves one by one.

Fig. 7.

Artificial mimosa tree leaves

Materials

Until 2008, all volume printers could use only one type of plastic (ABC); the material, such as any hydrogel, water, gypsum, nylon, chocolate, and concrete, can be effectively distinguished for three-dimensional printing. The idea of smart, flexible, and intelligent materials and structures has been around since the mid-1980s, and these materials have the potential to be smart, sharp, active, and sophisticated. There are many types of materials, and as we know, plastic, metal, and ceramics are not suitable for 4D printing and not suitable for external stimulation. The reason behind it is not a smart material and has no stimulus-response performance. If it is a smart material but it is not suitable for 4D printing, it may have no printability. Because it is not conductive to external inputs, it is rarely used as a condition for 4D printing. Water and temperature are external stimuli which are the requirement for 4D printing of materials that are able to generate a sensible reaction for further process. Subsequently, the 4D printing materials essentially hold on dual key abilities which are smartness and printability [38–40]. The stack of physical couplings can be obtained by acquiring smart objects or by the extension with the help of smart structures. One way to isolate smart content (Fig. 8) is to represent the photochromic content/composition as the input light and the color associated with the output. Based on gains, they react to inputs by creating specific outputs, and their outputs react by affecting inputs.

Fig. 8.

Schematic showing classification of smart materials

Table 1 review the growths for a calm assessment.

Table 1.

Summary of progressive materials approaches for AM

| Material term | Materials | Applications | |

|---|---|---|---|

| Conductive materials | Materials based on metals | Liquid metals,metal nanoparticles,in situ reactive metal inks | Aerospace, automobiles, biomedicine, textiles, etc. Electronics, sensors, micro-batteries |

| Supplementary conductive materials | Lithium-ion zinc, carbon-based materials | ||

| Smart materials | Shape-shifting material | Shape-shifting glasses, proteins, hydrogels | Soft micro-robotics, biomedical, biological imaging, piezoelectric devices |

| Piezoelectric materials | (BaTiO3, BTO), polyvinylidene fluoride (PVDF) |

Digital materials, smart materials, and smart structures

Digital material

Digital material is an extensible displaying and programming framework to help the portrayal and reenactment of material structure; it tends to be utilized to make a practical model. For instance, digital material as an individual set of components is made out of several materials that can occur in all sizes and shapes. Also, numerous elastomers of digital materials can imitate popular plastics, and produce realistic details for the special form of applications. The practical result of the use of digital material spherical voxel is the possibility of producing multi-material objects with micro scale precision [41].

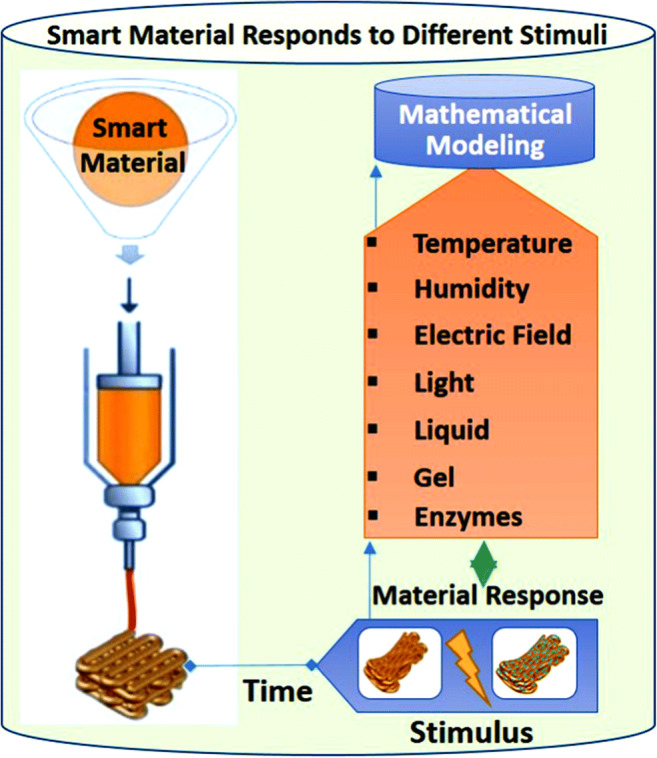

Smart materials

Sensor, actuator, and control system are the key components of a smart system. Advanced materials and nano-materials also are the name of smart materials or core aspects of 4D printing technology [42]. The one material that carries out a mess of sensing and actuation capabilities that may be coupled to a structure or framework. Self-detection, self-controlled, and shock absorbers are the properties of smart materials. Smart materials come up with new dimensions in addition to design possibilities for precision, structures, and systems to sort new practical applications. The materials most commonly used as a result of 3D printers are situated nylon, ABS plastic, resin, wax, and polycarbonate, etc. Although, in contrast to 3D printing, smart materials are used in 4D technology for example, piezoelectric, electrostriction, thermoelectric, and shape memory alloys. After material selection hardware has a key role in the printing process. 4D printing requires further development of modeling software than the one used for 3D printing. With a 3D printer and materials, the concept of the product’s configuration can be designed and reproduced anywhere on the globe.

Smart structures

Through a few forms of altering, one can experience out stimuli and responses. As we know, smart structures can rapidly change the behavior of a measuring device consists of a sensor, and their shape, self-healing, sensing, and decision-making systems to control vibration as well the controller used to grow from it. Setting a smart structure shown in Fig. 9 recognition gained as a field of smart materials and construction will increase the intensity and time of research domain additive articles, which will increase the intensity and time of the order, emphasizing multi-departmental efforts. The production continued and science and engineering faced the challenge. Recently, smart materials were substantially developed [28, 43–46]. Conduct of magneto-mechanical, opto-mechanical that escorts a coupled reaction to more than one record, is an example of multifunctional materials.

Fig. 9.

The flow of smart material structures (SMS)

Capabilities of single and multiple materials

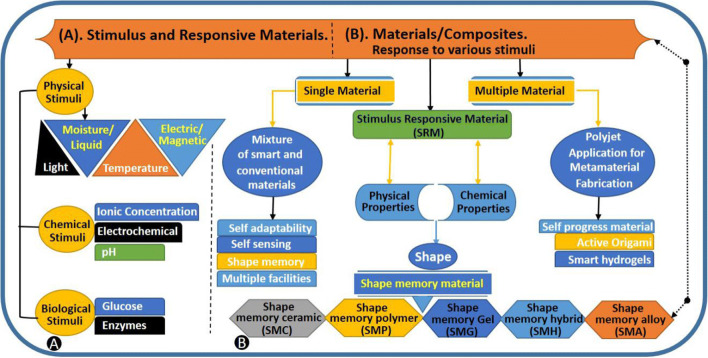

Additive manufacturing need to work with multiple different materials, and recently, within the 4D printing area, the smart material will assume a significant role for printed structures of single or multiple materials. The smart material category shape memory polymers (SMPs) and shape memory alloy (SMAs) materials are single materials [47–49]; moreover, active origami, self-progress, and electroactive polymers (EAPs) [50] are instances of 4D printing multi-materials. Here the significance of multi-material printing has no shape or form that will be sufficiently simple. 4D printing, including a novel technology, can trace the shape of these materials, reveal great insight into how to fold, and reduce large objects to small volumes. The transformation regarding 4D printing of single and multiple smart materials based on the limiting factor of adjustments is mentioned in Fig. 10b.

Fig. 10.

4D printed materials related enhancements and structures response to several stimuli

Stimulus

The stimulus is the main imperative for the formation of functions, features, and the state of the hidden structure. It can be divided into physical-chemical and biological families as presented in Fig. 10a. Physical stimuli refer to temperature, humidity, light, magnetism, and electrical power. The system shows chemical stimuli responsive properties including pH, molecular quality, and chemical concoctions. In 4D printing, researchers have used different stimuli to stimulate printed parts, including water [51, 52], heat [53, 54], a combination of heat and light [55], and the merger of water and temperature [56].

4D printing applies smart materials to manufacture advanced structures accomplished of dynamically altering conformation for numerous applications. In 3D and 4D printing development, it is necessary to realize future research and investment in core areas including materials, printer frameworks, and product markets in research and investment. Likewise, adaptive and dynamic response to structures and products is now the time to make smart systems without investing or adding additional components. Similar materials were suitable for stimuli responsible for intelligent and smart applications [57, 58]. The technological notable AM concept for the rudimentary 4D printing form is last but not THE least.

Self-actuation capacity and self-assembly

The forename “self-actuation” is closely associated with altering sizes as well as objects based on smart materials, such as thermal expansion coefficient and thermal conductivity. Various provocative and de-swelling ratios of bi-layer composite beams on behalf of temporal and spatial inflammation become accomplished over and done with smart materials [59]. The concept of self-assembly is the basis of 4D printing which has adjustment inside the smart structure itself. Tibbits established the capability to shake a flask containing separate parts and then assemble the individual pieces themselves after they came in contact [60]. The term self-folding relates to the effect of folding self-assembly procedures such as rotating or rolling, using the shape of a circle or the use of thin sheets made of cylindrical tubes. Installation instructions are another part of building self-assembly and 3D detailing algorithms. In these algorithms, an important design attribute for 4D printing can be done in a very easy way. It is generated by using the experimental structure and implanted a new feeling through the new technology and viable digital development through the setup and new technology of the computer code. Be able to describe any geometry such as 1D, 2D, or 3D installations using single or paired lines [43]. Folding and self-assembly mechanisms close linked to further stimulate variation in clinical study on proteins and cells.

Self-healing capacity and self-diagnose ability

Their recent work concerning graphene’s ability toward developing self-healing excellent properties was established on self-healing material. Potential applications in these areas could damage 3D printing materials and restore their original function because of the ability to repair such soft robotics, flexible electronics, and biological devices. Self-healing is the ability to repair these internal features after repairing and damaging the material itself and extending its life considerably. Thus three basic healing functions are executed internally, capsule-based and primarily to provide self-healing capability in 4D printing. Insider leads technique recovering destruction finished the reversibility of the so-called relationship healing agent in the content matrix. In the human body’s vascular system, micro-channels are introduced at a location in a polymer matrix for agent delivery healing [61]. Dedicated self-healing materials are key features for product performance, material safety, texture extension durability, and improved fatigue coatings. In the case of most self-diagnostic approaches which are controlled to assess responsibility aspects while targeted to include physical fundamentals in a material or design, moreover, self-diagnosis and self-sensing stress, load, etc. are the applications of self-diagnostic materials. Detection of variables such as stress, strain, pressure, vibration, impact, corrosion, and temperature is extensively investigated through an optical fiber. The self-sensing feature is useful for adding materials for advanced precaution. This feature is situated dynamically researching at the Georgia Institute of Technology (GIT) designed for sensor progress established on the phototropic influence [62]. Prominent applications of self-diagnostic capability are active in researching targeted drug delivery systems for cancer treatment. For safety, avoiding being controlled drug delivery methods through stimulants is more reliable for drug delivery variations.

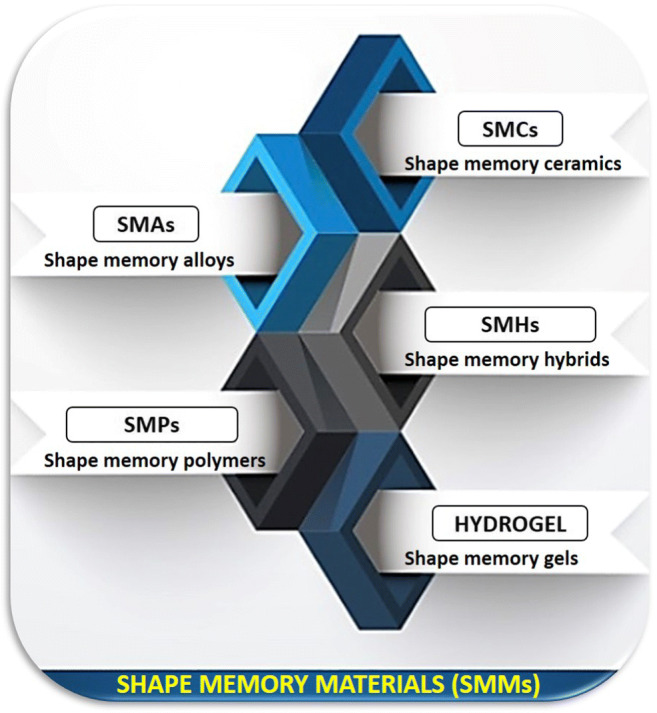

Shape memory materials (SMMs)

In any case, shape memory materials are characterized by unique objects as shown in Fig. 11. Here, situated Shape Memory Alloys (SMAs) and Shape Memory Polymers (SMPs) are rumored to be near among the most unusual shape memory and shape recovery features.

Fig. 11.

Schematic of shape memory materials for 4D printing

Shape memory alloys (SMAs)

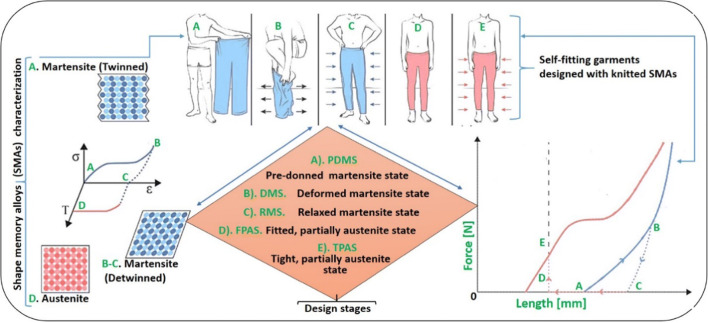

Shape memory alloys (SMAs) engineering materials are stained in a range of physical applications, which were widely calculated for the first time in the late 1960s. SMAs, called magnet-responsive or ferromagnetic shape memory alloys in front of an attractive field when changing measurement and configuration, begun in 1996 at MIT by Ullakko [62]. This alloy is an unusual form of memory behavior due to thermoelastic martensitic change, which is produced from austenite-to-austenite-to-martensite phase change at atomic temperature. At high temperatures, austenite becomes martensitic, while at low temperatures, austenite becomes martensitic. A martensitic segment is achieved as a result of cooling a high-temperature material in the alloys. The stimulus responsible alloys descent possessed by dual classes, which are thermo-responsive and responsible magnets. One of the most encouraging functional material frameworks for enabling fabrics is the NiTi-based SMA. This combines a variety of high vitality thicknesses, and provides excessive actuation and displacement possibilities. Particularly the especially self-fitting application uses the format memory effect of NiTi-based SMAs as depicted in Fig. 12.

Fig. 12.

The guides of actuators formed by mechanical heat conduction of SMA are explained by the stress obtained by the change in the material crystal structure

Shape memory polymers (SMPs)

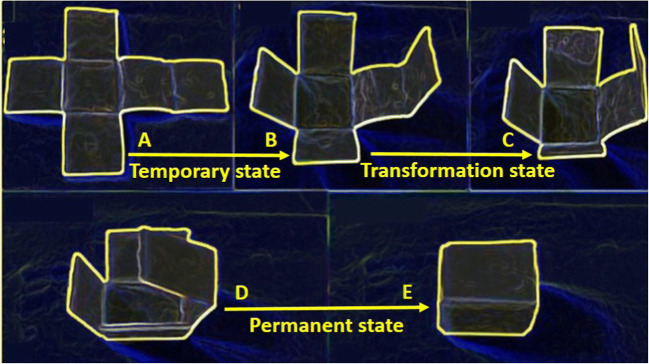

Shape memory polymer (SMPs) can be customized to arrange a foreordained management and return the structure to the front of external stimuli when recalling these cultivations [63]. Shape memory polymers can place dual occasionally three shapes proceeding display for a stimulus. The double component method, twin description mechanism, moreover unfinished transfer mechanism initiative shape memory consequence in SMPs [64]. The shape exists based on proceeding a specific shape memory polymer glass change temperature (Tg) which is unique when contrasted with shape memory compounds. Further down glass temperature (Tg) when the atom’s snapshot in the polished region is considerably low. The full-form memory effect reported in this paper can be seen to fit as a fiddle memory polymer when it is has a temperature (Tg) as shown in Fig. 13. The flexible concentration of polymer chains while driving the tension aerogel system in SMPs. Low cost, lightweight, and dominant recoverability stay as the key features of SMPs.

Fig. 13.

The shape of an SMP 3D cube while heated using an IR-light. An entire pattern of shape transformation be present shown in a periodic arrangement by temporary to a permanent state

Shape memory hybrids (SMH)

A shape memory hybrid (SMH) is prepared for the elastic wipe and cupric sulfate pentahydrate, showing a lattice and reservoirs individually a rapid H2O responsive process of getting a better shape. The SMP remains intended as latest literature [65], metal, natural, and anonymous processes, at the moment that it can be picked up for an imperative application to export a shape memory hybrid. SMH and SMPS; however, it seems to be argued by different objects such as forgeries and protections in the composition. They also give solid aptitudes and chemical data in contrast to SMAs, which require solid aptitudes and chemical data.

Shape memory ceramics

Ceramics have the shape memory effect, and in addition to MIT 2013, shape memory consumptions prompted the pack to announce ceramics manufacturing [53]. Shape memory ceramics (SMC’s) comparative martensitic progression which modifies the monoclinical structure of the tetragonal system. Ceramic production based on lead zirconatetitanate (Pb (ZR, Ti)O3, PZT) as antiferroelectric shape memory (AFE) composite gesture exhibited considerable isotropic volumetric shape memory performance.

Shape memory gels

Shape Memory Gel (SMG) is among the most remarkable types of soft materials, with some unique characteristics. Smart gels show expansion and constriction to change the general self-adoptable, macromolecular physical, or artificially interconnected system structure of the polymer. Probably this gel is acceptable for both medicinal and other applications like 3D bio-printing and unique reactions, utilities, and their enhancements in water [66]. Lee et al. generate electroactive hydrogels (EAH) exhibiting the bow favored by the electric field. This gel is cross-linked by PAA bile DA (Mn = 700 g mol-1) and printed with a small-scale stereolithography (PμSL) process [67].

Mechanism, feature and shape-shifting materials behaviors

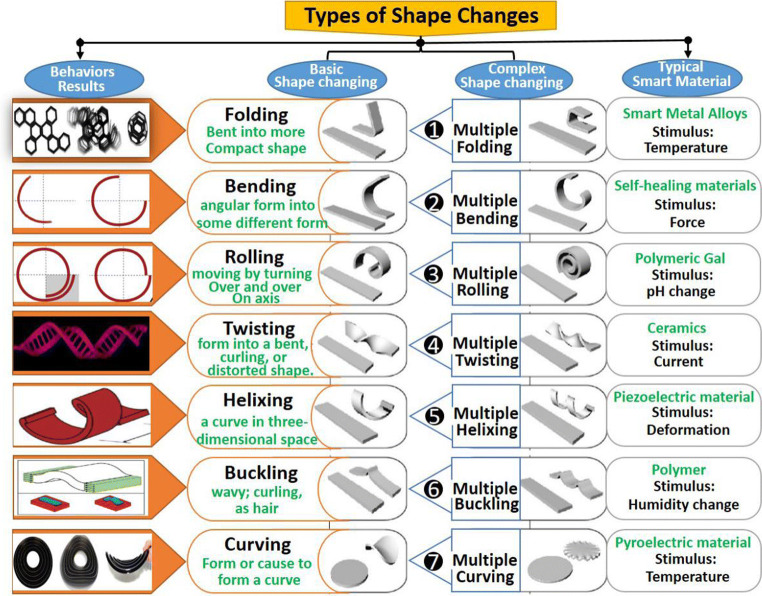

Determine the advantage of functional active shapes that can be achieved by a few mechanisms, for example, printed 4D material and printed useful material. Most investigations change the mechanism by shifting the extension mechanism and shape memory effect [68, 69]. As an emerging technology, the quantity of shape-shifting materials and behaviors is considered in 4D printing during the most recent couple of years based on several advanced technologies shown in Fig. 14. One of the main issues with 4D printing is effective shape changing; the manufacturing process is concerned with surface features and totally affects the qualities of the shape-shifting mechanisms-stimuli. The following concludes the conduct of two groups’ shape-change, the first involves the primary shape transformation and complex shape change, and the second group sets the shape behavior results and typical smart material. For many purposes, a 4D printing procedure perhaps used to stay away from straightforwardly printing an entangled 3D model. However, the secondary measurement element can be achieved when printed early and shortly after it is empowered for distinct dimensions in the target area. In breathtaking research characterized by shape-shifting behavior Liu et al. [76], further to the third dimension, obtainable printed among varied common approaches such as inkjet photolithography and roll-up which can add the required significance or purposes to the 2D sub otherwise lower layer from 2D to 3D. Future investigations may focus on combining sequential and parallel blends attributed to various shape-moving sorts and measurements. For example, the convoluted 3D design could be created as a result of bending and rotating from a 2D substrate as designed series. And during current progressive shift evaluation, the collecting procedure is limited regardless of whether a 4D printing produces deformation [77–79]. Therefore, different successive shape-shifting kinds and their combos can be studied with it forthcoming lookup involved extent. The typical smart materials are presented in Fig. 14. It can be used in 3D printing as smart materials to yield objects that can alter over time giving 4D-printed objects.

Fig. 14.

Basic modes of shape-shifting, typical smart materials in 4D printing process [28, 52, 70–75]

The introduced shape-shifting method presents a route to the manufacturing of these functionality-induced materials which have a wide range of applications in biotech, electronics, engineering manufacturing, and AM era.

Food, 3D-printed vegetable meat

Nova meat is a startup focusing on food tech. Nova meat, the first 3D vegetable meat to be printed beginning a 3D printer. Giuseppe Scionti the inventor of the first 3D printed plant-based beefsteak, CEO of Nova meat, based his company in Barcelona. Scionti developed the basic meat substitute using a vegetable protein found in the real meat of replicating protein complexes and is soon working to prepare meat alternatives. He sculpts a piece of artificial meat with a red paste he has introduced in his 3D printer through a nozzle attached to the end of the printer. This technology is designed to create a meat alternative that can use bio-printing strategies and adapt them, based on different food delivery systems in the near future, that is healthy, more efficient, and more sustainable for the environment.

Isolation rooms via 3D printing technology

China makes isolation rooms with 3D printing technology which they can utilize to treat patients with coronavirus to their easy movement and also moved to areas where insulation is more advanced. Within 2 h, a Shanghai-based company has used 3D printing technology to build isolation rooms, using recycled material, for a hospital treating coronavirus patients in Xian Ning, central China’s southeastern Hubei province.

Chocolate 3D printing studio

The Mona Lisa 3D Printing studio of the Barry Callebaut Group; is the world’s first chocolate to use 3D printing technology to create a unique and original masterpiece inspired by cocoa flowers. Before transforming the product into a 3D digital prototype with samples, a new technology customizes their chocolate decoration with unique design, shape, and size preferences. Once the prototype is approved, the final product can be submitted on a more rapid scale. The creations can be used for desserts, confectionery, hot drinks, and cakes. Furthermore, the printed thousands of parts in advanced precision technology made a custom, while maintaining a hand-made appearance.

4D printing potential applications

Potential motivation on printed structures can be effectively assigned with decreasing price and reduced effort [79]. Attributable to unmistakable focal points and complex design choices, presumably 4D printing will assume a fantastic role in a not so distant future. Self-acting actuators have to enable to allow researchers to face plan smart devices beyond printed batteries and vitality bases. A purpose of 4D printing is taken in consideration in several fields, for organ and tissue building, biological, electronic security [80], specially designed surface considering optics and soft actuators, smart valves, and smart clothing [81]. Many applications will be possible with this over the top innovation on development in the near future.

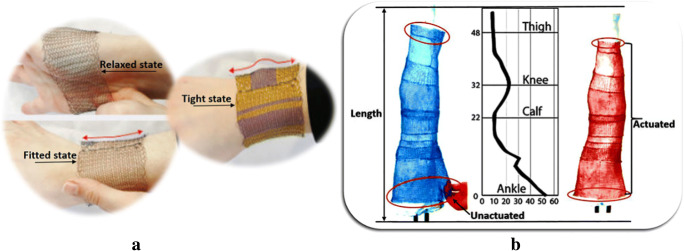

SMA-based knitted garments

In recent years, AM offers have been increased during the creative process, for prototyping the use of 3D printing in the fashion industry or even for production, manufacturing a wide range of fashion possibilities. A leap forward creation in wearable innovation can change how we collaborate with the garments which we wear each day. The creativity characterized by shape-changing fabrics powdered controlled uniquely over body heat, the circumstance especially energizing since it takes care of two critical issues at the same time. The product area of how to provide functional actuation or movement without using a considerable amount of power or heat and how the body has irregular shapes in order to produce useful, provocative or stimulating movement without adhering to a cloth or a dress. As appeared in Fig. 15, the textiles carry after normal weaves, except for those shape memory alloys (SMAs) which are made when heated using a unique assortment of active materials. This provides a chance to make articles of clothing that can truly change after some time, and has huge ramifications for clinical and fashion industry and business applications.

Fig. 15.

Self-fitting wearables dependent on active materials, for instance, shape-changing materials controlled uniquely by body heat, (a). A wrist sleeve was planned to utilize an SMA knitted actuator design, shape-changing textile powder distinctly by body heat, (b). The finished self-fitting piece of clothing is portrayed in un-actuated and actuated

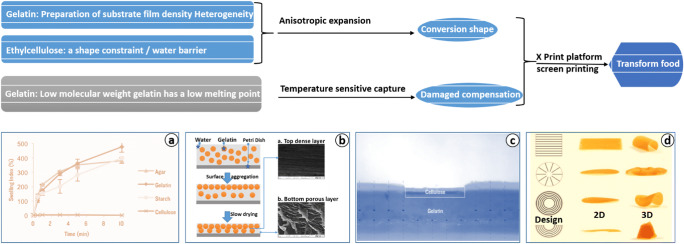

Transforming food

Through the interaction of water in cooking, the food is converted from 2D to 3D. The boundaries of technology and the transfer of inspiration are very limited in the choice of edible food ingredients, and their shape changes cannot achieve great functions. Designing the material composition program in the process of deforming food is very useful for our experiments on bright programmable materials Fig. 16.

Fig. 16.

Overhead phase of Cooking from 2D to 3D through the interaction of water: a Comparison of the expansion index of various food materials at 20°C, b different gelatin film formation, c cellulose barriers on gelatin, d folding design expending two-dimensional and three-dimensional

Relevant sectors wise developments, (extensions and alternatives in additive manufacturing)

The key motivation to use a 3D printer is for more than 90% of growth product life, material utilization, lighter, and stronger. In the early 1990s, Kruth [82] classified three additives from different additive manufacturing processes: liquid-, powder-, and solid-based systems. AM development rating, comprising research including trading approaches, was submitted by Shay Williams, AM’s schema [83]. For instance, the FDM technique works by extruding thermoplastic materials and building a 3D texture layer through a phase semi-melting material setting [84]. In this section, we will emphasize the importance of field wise applications and developments such as shown in Fig. 17. Moreover, AM outcomes should logically put forward a benefit to. Additive manufacturing technologies have been acclaimed in the aerospace and automotive sectors due to their unique skills in lightweight design, and designers have no unusual goal and that traditional parts are easy to reproduce assembly work. Furthermore, studies are reviewed which were about an integrated analysis, and the strength of products made in the unique capabilities of AM processes which contains the design flexibility, geometric complexity cost, and dimensional accuracy.

Fig. 17.

Schematic application of AM overview in the relevant economic sector

As a conclusion, this research work has attempted to provide the reader with a perspective on the additive manufacturing and the technological bases utilize, uses favorable circumstances, and confinements of these advances.

Concluding remarks

In this paper, the state of the art graphical manifestation is used to review the additive manufacturing process, materials, shape-shifting materials behaviors, evaluation of additive manufacturing technologies for 4D printing, and potential research needs. In the main, 3D and 4D are two names for the same technology; 4D is a new shape, design, or structure created using 3D printers. In contrast to 3D, 4D printing has the potential to assemble with parts that are capable to vary their response with properties including functions according to their environmental conditions accordingly. It is noteworthy to mention that 4D printing enables us to produce the transformation in the size and shape (twisting, bending, and folding) of the materials even after the printing.

Henceforward, in this paper, 4D printing technology is possible and is positive to change the world as we described in the potential application and relevant sector-wise development. Some concluding remarks are given below for better understanding.

On behalf of the different experiments conducted, varied researches have used the ideas of self-assembly, shape memory polymers, and hydrogels and few have used the forthcoming technology of the water-absorbing materials to demonstrate their experiments.

Above and beyond, the self-assembly landscape as concerns 4D printing resolves to moderate the developed time and labor that continue to be beneficial for the future hazard.

The products should not be discarded when they come up short, rather, allow self-correct containing self-prepare directed toward satisfying the novel needs.

In both 3D and 4D printing process, additive manufacturing involved to create a new product according to the design model. Time factor in 4D printing innovation is a component for additional measurement in 3D printing that makes 4D printing.

Currently, not all materials are smart materials with the feature of shape-changing capabilities. We summarized that the researchers are producing final materials that can be implemented in potential applications, like scientific and technical applications.

Acknowledgments

The authors are grateful for the constructive feedback and suggestions given by the anonymous referees, which sought to increase the paper's quality.

Author contribution

All authors contributed equally to this work.

Funding

This research is supported by National Natural Science Foundation of China (No. 51675226); Key Scientific and Technological Research Project of Jilin Province (No. 20180201055GX); Project of the International Science and Technology Cooperation of Jilin Province (No. 20170414043GH); Industrial Innovation Project of Jilin Province (No.20150204037SF).

Data availability

The fact used to support the outcomes of this study is contained inside the paper.

Declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

All authors consent to the publications of the manuscript in this journal.

Conflict of interest

The authors declare no competing interests.

Footnotes

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- 1.Hull CW (1986) Apparatus for production of three-dimensional objects by stereolithography. U.S. Patent No 4,575,300. Washington DC: Patent and Trademak Office. U.S. Pat. No 4,575,300

- 2.Walter M, Holmström J, Yrjölä H (2004) Rapid manufacturing and its impact on supply chain management. Proc Logist Res Netw Annu Conf

- 3.D’Aveni RA (2013) 3-D printing will change the world. Harv Bus Rev 91

- 4.Mercuri R, Meredith K (2014) An educational venture into 3D Printing. In: ISEC 2014 - 4th IEEE Integrated STEM Education Conference

- 5.Sharma RS, Singhal I, Gupta S. Innovative training framework for additive manufacturing ecosystem to accelerate adoption of three-dimensional printing technologies. 3D Print Addit Manuf 5. 2018;5:170–179. doi: 10.1089/3dp.2017.0003. [DOI] [Google Scholar]

- 6.Corum K, Garofalo J. Using digital fabrication to support student learning. 3D Print Addit Manuf. 2015;2:50–55. doi: 10.1089/3dp.2015.0008. [DOI] [Google Scholar]

- 7.Go J, Hart AJ. A framework for teaching the fundamentals of additive manufacturing and enabling rapid innovation. Addit Manuf. 2016;10:76–87. doi: 10.1016/j.addma.2016.03.001. [DOI] [Google Scholar]

- 8.Bull G, Haj-Hariri H, Atkins R, Moran P. An educational framework for digital manufacturing in schools. 3D Print Addit Manuf 2. 2015;2:42–49. doi: 10.1089/3dp.2015.0009. [DOI] [Google Scholar]

- 9.Cotteleer MJ (2014) 3D opportunity: additive manufacturing paths to performance, innovation, and growth. In: SIMT Additive Manufacturirng Symposium

- 10.Gibson I, Rosen D, Stucker B (2015) Additive Manufacturing Technologies

- 11.Diegel O, Nordin A, Motte D (2019) Additive Manufacturing Technologies

- 12.Rosenberg B (2008) Rapid prototyping to rapid manufacturing. Aerosp Eng Manuf 28

- 13.Rosen DW (2007) Stereolithography and rapid prototyping. In: BioNanoFluidic MEMS

- 14.Jiménez M, Romero L, Domínguez IA, Espinosa MM, Domínguez M. Additive manufacturing technologies: an overview about 3D printing methods and future prospects. Complexity. 2019;2019:1–30. doi: 10.1155/2019/9656938. [DOI] [Google Scholar]

- 15.Hofmann M. 3D printing gets a boost and opportunities with polymer materials. ACS Macro Lett. 2014;3:382–386. doi: 10.1021/mz4006556. [DOI] [PubMed] [Google Scholar]

- 16.ASTM (2013) Standard terminology for additive manufacturing technologies. Astm Int 44

- 17.ASTM International (2013) F2792-12a - Standard terminology for additive manufacturing technologies

- 18.Jain P, Kuthe AM (2013) Feasibility study of manufacturing using rapid prototyping: FDM approach. In: Procedia Engineering

- 19.Sweet RG. High frequency recording with electrostatically deflected ink jets. Rev Sci Instrum. 1965;36:136. doi: 10.1063/1.1719502. [DOI] [Google Scholar]

- 20.Barclift MW, Williams CB (2012) Examining variability in the mechanical properties of parts manufactured via polyjet direct 3D printing. In: 23rd Annual International Solid Freeform Fabrication Symposium - An Additive Manufacturing Conference, SFF 2012

- 21.Aliheidari N, Christ J, Ameli A, et al (2017) Optimizing fused deposition modeling 3D printing process for fracture resistance. In: Annual Technical Conference - ANTEC, Conference Proceedings

- 22.Yang Y, Chen Y, Wei Y, Li Y. 3D printing of shape memory polymer for functional part fabrication. Int J Adv Manuf Technol. 2016;84:2079–2095. doi: 10.1007/s00170-015-7843-2. [DOI] [Google Scholar]

- 23.Postiglione G, Natale G, Griffini G, Levi M, Turri S. Conductive 3D microstructures by direct 3D printing of polymer/carbon nanotube nanocomposites via liquid deposition modeling. Compos Part A Appl Sci Manuf. 2015;76:110–114. doi: 10.1016/j.compositesa.2015.05.014. [DOI] [Google Scholar]

- 24.Highley CB, Rodell CB, Burdick JA. Direct 3D Printing of shear-thinning hydrogels into self-healing hydrogels. Adv Mater. 2015;27:5075–5079. doi: 10.1002/adma.201501234. [DOI] [PubMed] [Google Scholar]

- 25.Piegl LA. Ten challenges in computer-aided design. CAD Comput Aided Des. 2005;37:470. doi: 10.1016/j.cad.2004.08.012. [DOI] [Google Scholar]

- 26.Gao W, Zhang Y, Ramanujan D, Ramani K, Chen Y, Williams CB, Wang CCL, Shin YC, Zhang S, Zavattieri PD. The status, challenges, and future of additive manufacturing in engineering. CAD Comput Aided Des. 2015;69:65–89. doi: 10.1016/j.cad.2015.04.001. [DOI] [Google Scholar]

- 27.Maidin SB, Campbell I, Pei E. Development of a design feature database to support design for additive manufacturing. Assem Autom. 2012;32:235–244. doi: 10.1108/01445151211244375. [DOI] [Google Scholar]

- 28.Tibbits S. 4D printing: multi-material shape change. Archit Des. 2014;84:116–121. doi: 10.1002/ad.1710. [DOI] [Google Scholar]

- 29.Nkomo NZ (2018) A review of 4D printing technology and future trends. In: 11th South African Conference on Computational and Applied Mechanics, SACAM 2018. South African Association for Theoretical and Applied Mechanics (SAAM), pp 202–211

- 30.Wu JJ, Huang LM, Zhao Q, Xie T. 4D printing: history and recent progress. Chinese J Polym Sci English Ed. 2018;36:563–575. doi: 10.1007/s10118-018-2089-8. [DOI] [Google Scholar]

- 31.Kamble DN. A Review on 4D Printing Technology. Int J Res Appl Sci Eng Technol. 2019;7:266–273. doi: 10.22214/ijraset.2019.11043. [DOI] [Google Scholar]

- 32.Choi J, Kwon OC, Jo W, Lee HJ, Moon MW. 4D printing technology: a review. 3D Print. Addit Manuf. 2015;2:159–167. [Google Scholar]

- 33.Kumar SB, Jeevamalar J, Ramu P, Suresh G, Senthilnathan K (2020) Evaluation in 4D printing – a review. Mater Today Proc. 10.1016/j.matpr.2020.07.335

- 34.Mostakim K, Masuk NI, Hasan MR, Islam MS. 4D printing technology, modern era: a short review. Int J Energy Technol. 2020;92:111. doi: 10.32438//ijet.203015. [DOI] [Google Scholar]

- 35.Lu H, Luo X, Chen T, et al. Recent progress of 4D printing technology. Hangkong Cailiao Xuebao/J Aeronaut Mater. 2019;39:1–9. doi: 10.11868/j.issn.1005-5053.2018.000041. [DOI] [Google Scholar]

- 36.Chu H, Yang W, Sun L, Cai S, Yang R, Liang W, Yu H, Liu L (2020) 4D printing: a review on recent progresses. Micromachines 11 [DOI] [PMC free article] [PubMed]

- 37.Singholi AKS, Sharma A. Review: recent advancement and research possibilities in 4D printing technology. Mater Werkst. 2020;51:1332–1340. doi: 10.1002/mawe.202000008. [DOI] [Google Scholar]

- 38.Khoo ZX, Teoh JEM, Liu Y, Chua CK, Yang S, An J, Leong KF, Yeong WY. 3D printing of smart materials: a review on recent progresses in 4D printing. Virtual Phys Prototyp. 2015;10:103–122. doi: 10.1080/17452759.2015.1097054. [DOI] [Google Scholar]

- 39.Tang WN, Park SS, You BS. Effect of the Zn content on the microstructure and mechanical properties of indirect-extruded Mg-5Sn-xZn alloys. Mater Des. 2011;32:3537–3543. doi: 10.1016/j.matdes.2011.02.012. [DOI] [Google Scholar]

- 40.Meng H, Li G. A review of stimuli-responsive shape memory polymer composites. Polymer (Guildf) 2013;54:2199–2221. doi: 10.1016/j.polymer.2013.02.023. [DOI] [Google Scholar]

- 41.Hiller J, Lipson H. Design and analysis of digital materials for physical 3D voxel printing. Rapid Prototyp J. 2009;15:137–149. doi: 10.1108/13552540910943441. [DOI] [Google Scholar]

- 42.Choi J, Kwon OC, Jo W et al (2015) 4D printing technology: a review. 3D Print Addit Manuf 2

- 43.Tibbits S. Design to self-assembly. Archit Des. 2012;82:68–73. doi: 10.1002/ad.1381. [DOI] [Google Scholar]

- 44.Lewis JA. Direct ink writing of 3D functional materials. Adv Funct Mater. 2006;16:2193–2204. doi: 10.1002/adfm.200600434. [DOI] [Google Scholar]

- 45.Sun K, Wei TS, Ahn BY, Seo JY, Dillon SJ, Lewis JA. 3D printing of interdigitated Li-ion microbattery architectures. Adv Mater. 2013;25:4539–4543. doi: 10.1002/adma.201301036. [DOI] [PubMed] [Google Scholar]

- 46.Hardin JO, Ober TJ, Valentine AD, Lewis JA (2015) 3D printing: microfluidic printheads for multimaterial 3D printing of viscoelastic inks (Adv. Mater. 21/2015). Adv Mater 27:. 10.1002/adma.201570145, 27 [DOI] [PubMed]

- 47.Yu K, Ritchie A, Mao Y, et al (2015) Controlled sequential shape changing components by 3D printing of shape memory polymer multimaterials. In: Procedia IUTAM,

- 48.Meier H, Haberland C, Frenzel J (2012) Structural and functional properties of NiTi shape memory alloys produced by Selective Laser Melting. In: Innovative Developments in Virtual and Physical Prototyping - Proceedings of the 5th International Conference on Advanced Research and Rapid Prototyping

- 49.Dadbakhsh S, Speirs M, Kruth JP, Schrooten J, Luyten J, van Humbeeck J. Effect of SLM parameters on transformation temperatures of shape memory nickel titanium parts. Adv Eng Mater. 2014;16:1140–1146. doi: 10.1002/adem.201300558. [DOI] [Google Scholar]

- 50.Rossiter J, Walters P (2009) Stoimenov B (2009) Printing 3D dielectric elastomer actuators for soft robotics. In: Electroactive Polymer Actuators and Devices (EAPAD)

- 51.Behl M, Razzaq MY, Lendlein A (2010) Multifunctional shape-memory polymers. Adv Mater 22 [DOI] [PubMed]

- 52.Sydney Gladman A, Matsumoto EA, Nuzzo RG, Mahadevan L, Lewis JA. Biomimetic 4D printing. Nat Mater. 2016;15:413–418. doi: 10.1038/nmat4544. [DOI] [PubMed] [Google Scholar]

- 53.Bogue R. Smart materials: a review of capabilities and applications. Assem Autom. 2014;34:16–22. doi: 10.1108/AA-10-2013-094. [DOI] [Google Scholar]

- 54.Yu K, Dunn ML, Qi HJ. Digital manufacture of shape changing components. Extrem Mech Lett. 2015;4:9–17. doi: 10.1016/j.eml.2015.07.005. [DOI] [Google Scholar]

- 55.Kuksenok O, Balazs AC. Stimuli-responsive behavior of composites integrating thermo-responsive gels with photo-responsive fibers. Mater Horizons. 2016;3:53–62. doi: 10.1039/c5mh00212e. [DOI] [Google Scholar]

- 56.Bakarich SE, Gorkin R, Panhuis M In Het, Spinks GM (2015) 4D printing with mechanically robust, thermally actuating hydrogels. Macromol Rapid Commun 36:. 10.1002/marc.201500079, 1211, 1217 [DOI] [PubMed]

- 57.Shafranek RT, Millik SC, Smith PT, Lee CU, Boydston AJ, Nelson A. Stimuli-responsive materials in additive manufacturing. Prog Polym Sci. 2019;93:36–67. doi: 10.1016/j.progpolymsci.2019.03.002. [DOI] [Google Scholar]

- 58.Sun L, Huang WM, Ding Z, Zhao Y, Wang CC, Purnawali H, Tang C. Stimulus-responsive shape memory materials: a review. Mater Des. 2012;33:577–640. doi: 10.1016/j.matdes.2011.04.065. [DOI] [Google Scholar]

- 59.Zolfagharian A, Kaynak A, Khoo SY, Kouzani A. Pattern-driven 4D printing. Sensors Actuators A Phys. 2018;274:231–243. doi: 10.1016/j.sna.2018.03.034. [DOI] [Google Scholar]

- 60.Tibbits S, Cheung K. Programmable materials for architectural assembly and automation. Assem Autom. 2012;32:216–225. doi: 10.1108/01445151211244348. [DOI] [Google Scholar]

- 61.Bekas DG, Tsirka K, Baltzis D, Paipetis AS. Self-healing materials: a review of advances in materials, evaluation, characterization and monitoring techniques. Compos Part B Eng. 2016;87:92–119. doi: 10.1016/j.compositesb.2015.09.057. [DOI] [Google Scholar]

- 62.Rastogi P, Kandasubramanian B. Breakthrough in the printing tactics for stimuli-responsive materials: 4D printing. Chem Eng J. 2019;366:264–304. doi: 10.1016/j.cej.2019.02.085. [DOI] [Google Scholar]

- 63.Raasch J, Ivey M, Aldrich D, Nobes DS, Ayranci C. Characterization of polyurethane shape memory polymer processed by material extrusion additive manufacturing. Addit Manuf. 2015;8:141. doi: 10.1016/j.addma.2015.09.004. [DOI] [Google Scholar]

- 64.Huang WM, Zhao Y, Wang CC, Ding Z, Purnawali H, Tang C, Zhang JL (2012) Thermo/chemo-responsive shape memory effect in polymers: a sketch of working mechanisms, fundamentals and optimization. J Polym Res 19

- 65.Weiss RA, Izzo E, Mandelbaum S. New design of shape memory polymers: mixtures of an elastomeric ionomer and low molar mass fatty acids and their salts. Macromolecules. 2008;41:2978–2980. doi: 10.1021/ma8001774. [DOI] [Google Scholar]

- 66.Dickey MD. Shaped after print. Nat Mater. 2016;15:15–380. doi: 10.1038/nmat4608. [DOI] [PubMed] [Google Scholar]

- 67.Han D, Farino C, Yang C, Scott T, Browe D, Choi W, Freeman JW, Lee H (2018) Soft robotic manipulation and locomotion with a 3D printed electroactive hydrogel. ACS Appl Mater Interfaces 10:. 10.1021/acsami.8b04250, 10, 17512, 17518 [DOI] [PubMed]

- 68.Ge Q, Sakhaei AH, Lee H, Dunn CK, Fang NX, Dunn ML (2016) Multimaterial 4D printing with tailorable shape memory polymers. Sci Rep 6. 10.1038/srep31110 [DOI] [PMC free article] [PubMed]

- 69.Sundaram S, Kim DS, Baldo MA, Hayward RC, Matusik W (2017) 3D-printed self-folding electronics. ACS Appl Mater Interfaces 9. 9:32290–32298. 10.1021/acsami.7b10443 [DOI] [PubMed]

- 70.Ge Q, Dunn CK, Qi HJ, Dunn ML. Active origami by 4D printing. Smart Mater Struct. 2014;23:094007. doi: 10.1088/0964-1726/23/9/094007. [DOI] [Google Scholar]

- 71.Ionov L. 3D microfabrication using stimuli-responsive self-folding polymer films. Polym Rev. 2013;53:92–107. doi: 10.1080/15583724.2012.751923. [DOI] [Google Scholar]

- 72.Wu J, Yuan C, Ding Z, Isakov M, Mao Y, Wang T, Dunn ML, Qi HJ (2016) Multi-shape active composites by 3D printing of digital shape memory polymers. Sci Rep 6. 10.1038/srep24224 [DOI] [PMC free article] [PubMed]

- 73.Ge Q, Qi HJ, Dunn ML. Active materials by four-dimension printing. Appl Phys Lett. 2013;103:131901. doi: 10.1063/1.4819837. [DOI] [Google Scholar]

- 74.Wang W, Yao L, Zhang T, et al. Transformative appetite: shape-changing food transforms from 2D to 3D by water interaction through cooking. In: Conference on Human Factors in Computing Systems - Proceedings; 2017. [Google Scholar]

- 75.Sharon E, Efrati E. The mechanics of non-Euclidean plates. Soft Matter. 2010;6:5693. doi: 10.1039/c0sm00479k. [DOI] [Google Scholar]

- 76.Liu Y, Genzer J, Dickey MD. “2D or not 2D”: Shape-programming polymer sheets. Prog Polym Sci. 2016;52:79–106. doi: 10.1016/j.progpolymsci.2015.09.001. [DOI] [Google Scholar]

- 77.Mao Y, Yu K, Isakov MS, Wu J, Dunn ML, Jerry Qi H (2015) Sequential self-folding structures by 3D printed digital shape memory polymers. Sci Rep 5. 5. 10.1038/srep13616 [DOI] [PMC free article] [PubMed]

- 78.Baker AB, Wass DF, Trask RS. 4D sequential actuation: combining ionoprinting and redox chemistry in hydrogels. Smart Mater Struct. 2016;25:10LT02. doi: 10.1088/0964-1726/25/10/10LT02. [DOI] [Google Scholar]

- 79.Felton SM, Tolley MT, Shin B, Onal CD, Demaine ED, Rus D, Wood RJ. Self-folding with shape memory composites. Soft Matter. 2013;9:7688. doi: 10.1039/c3sm51003d. [DOI] [Google Scholar]

- 80.Ivanova O, Elliott A, Campbell T, Williams CB. Unclonable security features for additive manufacturing. Addit Manuf. 2014;1:24–31. doi: 10.1016/j.addma.2014.07.001. [DOI] [Google Scholar]

- 81.Zolfagharian A, Kouzani AZ, Khoo SY, et al (2016) Evolution of 3D printed soft actuators. Sensors Actuators, A Phys. 250

- 82.Kruth JP. Material incress manufacturing by rapid prototyping techniques. CIRP Ann - Manuf Technol. 1991;40:603–614. doi: 10.1016/S0007-8506(07)61136-6. [DOI] [Google Scholar]

- 83.Williams CB, Mistree F, Rosen DW (2011) A functional classification framework for the conceptual design of additive manufacturing technologies. J Mech Des Trans ASME 133. 10.1115/1.4005231

- 84.Jo W, Kim DH, Lee JS, Lee HJ, Moon MW. 3D printed tactile pattern formation on paper with thermal reflow method. RSC Adv. 2014;4:31764–31770. doi: 10.1039/c4ra02822h. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

The fact used to support the outcomes of this study is contained inside the paper.