Abstract

The behavior of an Oldroyd-B nanoliquid film sprayed on a stretching cylinder is investigated. The system also contains gyrotactic microorganisms with heat and mass transfer flow. Similarity transformations are used to make the governing equations non-dimensional ordinary differential equations and subsequently are solved through an efficient and powerful analytic technique namely homotopy analysis method (HAM). The roles of all dimensionless profiles and spray rate have been investigated. Velocity decreases with the magnetic field strength and Oldroyd-B nanofluid parameter. Temperature is increased with increasing the Brownian motion parameter while it is decreased with the increasing values of Prandtl and Reynolds numbers. Nanoparticle’s concentration is enhanced with the higher values of Reynolds number and activation energy parameter. Gyrotactic microorganism density increases with bioconvection Rayleigh number while it decreases with Peclet number. The film size naturally increases with the spray rate in a nonlinear way. A close agreement is achieved by comparing the present results with the published results.

Subject terms: Engineering, Materials science, Mathematics and computing, Nanoscience and technology, Physics

Introduction

The progress in non-Newtonian liquids has a great deal of importance in projects and emerging developments. Magnetohydrodynamics (MHD) applied to electrically conductive fluids primarily concerned with the results that can be obtained from the connection between fluid motion with any external magnetic field current. Albano et al.1 reported that metallurgy (form control, homogenization, sample levitation material), molten steel flow, planetary science and astrophysics, fusion reactors are some of non-Newtonian main applications. Various of fluids commonly used in industrial applications like poultry, cement, polymers, chemical, fermentation cycles, geothermal pools, pore drying, heat insulation, improved oil regeneration, etc., are non-Newtonian in nature. Khan and Nadeem2 analyzed the non-Newtonian Maxwell nanofluid flow past a linear/exponential stretching sheet in rotating system with double stratification, Arrhenius activation energy, temperature dependent thermal conductivity and thermophoresis. They used the bvp4c Matlab to evaluate the coupled ordinary differential equations and showed that rotation and stretching have remarkable effect on the velocity and temperature profiles. Khan and Nadeem3 presented the heat and mass transfer time dependent two-dimensional flow of bio-convective Maxwell nanofluid over an exponentially stretching sheet with viscous dissipation, external magnetic field, multiple slip conditions and chemical reaction. Due to the special behaviors, the Oldroyd-B fluid model is very important among the rate type fluids. Khan et al.4 explored the two- dimensional radiative Oldroyd-B nanofluid in transient flow past a permeable convectively heated stretching surface with gyrotactic microorganisms to explore that for the higher values of retardation parameter, velocity increases and heat transfer decreases. Khan et al.5 investigated dynamics with Cattaneo–Christov heat and mass flux theory of bioconvection Oldroyd-B nanofluid. Khan et al.6 investigated for the rotating flow of an Oldroyd-B fluid for improved thermal conduction and developed mass diffusion models. More detail on non-Newtonian fluids can be seen in the references7–26.

The cooling of liquid is enhanced by the nano-sized particles whose diameter ranges from nm. These nanoparticles are added into to the base fluid which enhance the cooling process, due to its higher heat transfer coefficient as compared to the conventional liquids. This mixture is called nanofluid. Choi and Bestman27 introduced the concept of nanofluid at Agronne National Laboratory, USA. Nanotechnology is one of the most interesting field nowadays. It is interesting due to its vast applications in medicine, electronics, solar cells, food, fuel cells, batteries etc. In simple, nanotechnology has made its way to every branch. The enhancement of the thermal properties of the liquids can be made by either metals or by metal oxides. It is often a special type of fluid with higher thermal conductivity than conventional host fluids (such as motor oil, glycols, water, etc.). Nanoparticles include metals (for example, aluminum, copper, nickel) and other elements (for example, carbon nanotubes, graphene, silicon carbide, calcium carbonate, titanium, etc.) as well as oxides (for example, alumina, titanium, silicone, silicon carbide, silicone carbonate, silicone, etc.). Buongiorno28 implemented a second phase nanofluid model in the awake of these models. Ellahi et al.29 investigated the heated couple stress bi-phase fluid with spherical particles of metal Hafnium. In that paper the flow bounded by two parallel plates is caused by solely the influence of pressure gradient in an axial direction. More studies on nanofluids can be found in the references30–45.

Entropy optimization in terms of irreversibility rate was investigated using thermodynamic second law. Entropy augmentation is used to illustrate the quality of various contexts in advanced and composition applications. Entropy is derived from the Greek word entropia, which means "change" or "movement in the direction of." The calculation of entropy is important because it categorizes the parameters for energy loss. Bejan46 introduced the concept of an entropy optimization problem. Khan et al.47 investigated entropy optimization in MHD viscous fluid flow using a stretchable sheet. Khan and Ali48 provided the modeling and simulation of entropy generation in dissipative cross materials with quartic autocatalysis. Further studies about entropy generation may be read in the references49–55.

Thin film flow is an important subject of research. Thin film fluids are used to produce different heat exchangers and chemical tools and these applications require a complete understanding of the motion procedure. Thin film fluids applications also include wire and fiber coating, preparation of polymers, etc. This motion is attached to the manufacturing of different types of sheets, either metal or plastic. In recent years, some researchers have considered working on this type of flow. Ellahi et al.56 studied the thin film coating on multi-fluid flow of a rotating disk suspended with nano-size silver and gold particles. More studies in this regard can be found in the references57–59.

Among the most significant indicators where the species does not usually respond to the chemical reactions are related with Arrhenius activation energy. The term energy activation was initially proposed by Arrhenius60. However, the minimum energy required for the operation of chemical reactions molecules or atoms is defined as energy activation. Perhaps for the first time, Bestman61 identified a primary model consisting of a limiting layer of fluid flow problems due to binary chemical reactions with Arrhenius activation energy. The emphasis here is on the flow of a binary chemical reacting fluid with Arrhenius activating energy and convective boundary conditions. The purpose of this work is to discuss the effect of activation energy on fluid flow and binary chemical reactions. The effect of frictional heating on binary chemical reactions can significantly reduce undue surface reactions and, as a result, improve deposition. Further studies can be found in the references62–64.

In food industry and many physiological fluid flow problems, the density of motile gyrotactic microorganisms is significant and this density of motile microorganisms plays a vital role in fluid flow. Bioconvection phenomena is a common phenomenon usually occurs in suspensions due to the up swimming of microorganisms that are marginally with high density than water. If the upper surface of the suspensions gets so dense due to the proliferation of microorganisms, then it becomes porous and the microorganisms collapse to cause bioconvection. The concept explains the formation of impulsive patterns and dense streaming formed at the concurrent boundary of more autonomously propelled microorganisms, nanoparticles, and buoyant forces. However, some forms that may constitute parts of these microorganisms are gravitaxis (describe the swimming motion against gravity), gyrotaxis (describe the way the swimming is guided through a balance between the physical torques generated by viscous drag and by gravity operating on an asymmetric distribution of mass within the organism) or oxytaxis (describe the swimming along an oxygen gradient). Supporting gyrotactic microorganisms for nanofluid helps to convert the mass to mix micro-scales and to increase the stability of nanofluids particularly in micro-volumes. The analysis highlights the principle of nanofluid bioconvection. Several researchers have investigated its numerous effects on fluid flow including nanofluid gyrotactic microorganisms which plays a very important role in increasing the greenhouse effects. Ghorai and Hill65 have shown stability and growth within a deep cavity with free stress on the side walls in the presence of gyrotactic microorganisms. Chamkha et al.66 investigated the radiation effects of gyrotactic microorganisms on a vertical plate with fluid variability in temperature on natural bioconvection flows. Rashad et al.67 studied a mixed bioconvection nanofluid flow with gyrotactic microorganisms through a thin vertical cylindrical under closed saturated porous medium using the transient mixed boundary layer convection. Hady et al.68 presented the unsteady bioconvection thermal boundary layer nanofluid flow in the presence of gyrotactic microorganisms on a stretching plate and a vertical cone in porous medium. More studies on bioconvection can be found in the references69–73.

It is observed that due to stretching cylinder the flow receives adequate attention. Wang74,75 was the first to study the steady-state incompressible viscous fluid across the growing hollow cylinder. Bachok and Ishak76 examined and reported the numerical flow and thermal transfer solution for the stretching cylinder. Chuhan et al.77 investigated the effects of magnetohydrodynamics and thermal radiation on the movement of fluid past a porous stretching cylinder. Irfan et al.78 studied the motion of a nanofluid past a stretching cylinder with heat transfer and magnetic field.

Literature has several interesting studies on stretching cylinder like references79,80 which are followed by the present study. Spraying phenomena occurs in the analysis and design of coating processes. This paper is unique in the sense that it investigates the film deposition of a bioconvection Oldroy-B nanofluid containing motile gyrotactic microorganisms on a stretching cylinder. In the present article, the steady two-dimensional, incompressible radiative flow of the Oldroy-B axisymmetric sprayed thin film nanofluid past a stretching cylinder is analyzed. The fluid flow problem is governed by the partial differential equations and are converted into ordinary ones by means of suitable similarity variables. Initially, Liao presented HAM81–83 in 1992. The solution of this method is fast convergent. Due to its rapid convergence, various researchers84–88 have used HAM to solve their fluid flow problems. The computed results concerning the effects of all the related parameters on all the profiles are presented graphically.

Problem formulation

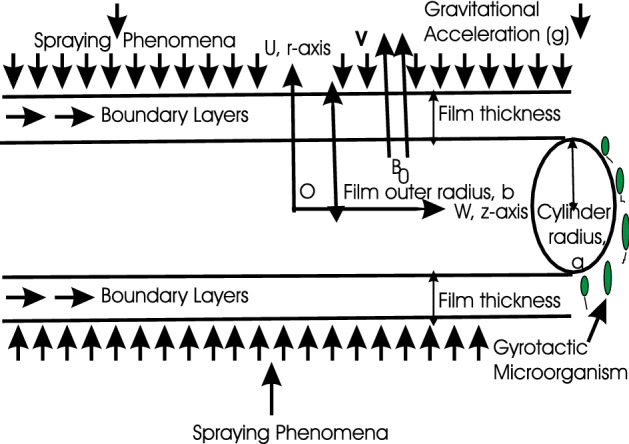

The steady, two-dimensional, and incompressible radiative Oldroyd-B and axisymmetric sprayed thin film nanofluid flow is considered past a stretching cylinder at . The flow is in the domain . The is taken along the axis of cylinder and is measured along the radial direction. The effects of the magnetic field are used in the direction of . Assuming induced magnetic field effects to be negligible. The expression is the surface velocity, where is the axial coordinate and is a proportional constant. As the material stretches, the cylinder's thickness decreases, but the cylinder's outer radius remains relatively constant. A radial axisymmetric spray with a velocity condenses as a film and is drawn in by the cylinder's outer surface (see Fig. 1).

Figure 1.

Geometry of the problem.

The basic governing equations for the fluid flow are as 56–59,74,75,79,80:

| 1 |

| 2 |

| 3 |

| 4 |

| 5 |

| 6 |

| 7 |

where is the film size.

According to the Rosseland approximation the thermally developed flow can be expressed as a modification2,

| 8 |

Introducing the transformation for non-dimensionless functions and similarity variable 74,79 as

| 9 |

At the outer radius of the film thickness

| 10 |

Equation (1) is satisfied through Eqs. (9, 10) whereas Eqs. (2)–(7) have the following form

| 11 |

| 12 |

| 13 |

| 14 |

with boundary conditions

| 15 |

The dimensionless parameters are defined as

| 16 |

The shear stress on the surface of the outer film is zero i.e.

| 17 |

And the shear stress on the cylinder is

| 18 |

The deposition velocity in terms of film thickness is given by

| 19 |

Mass flux is another interesting quantity which in connection with the deposition per axial length is

| 20 |

The normalized mass flux is

| 21 |

Physical quantities

The physical quantities of interests are given as following.

Skin friction coefficient

| 22 |

Nusselt number

| 23 |

Sherwood number

| 24 |

Local density motile flux

| 25 |

Analysis of entropy generation

For the bio-nanofluid system, the irreversibility formulation is

| 26 |

where R denotes the ideal gas constant and D represents the diffusivity.

In Eq. (26), the first term represents the irreversibility due to heat transfer, the second term is entropy generation due to viscous dissipation and third to six terms are irreversibility due to diffusion effect. The seventh term stands for the entropy generation due to magnetic field. The characteristic entropy generation rate is

| 27 |

Notice that irreversibility in scaled form is

| 28 |

Using Eqs. (9, 10), dimensional Eq. (28) converted into the following dimensionless form

| 29 |

where represents the entropy generation rate, are respectively the Brinkman number, diffusivity constant parameters due to nanoparticle and gyrotactic microorganism concentration and magnetic field parameter. ,, are respectively the dimensionless heat, nanoparticle concentration and microorganism concentration ratio variables.

Solution of the problem by homotopy analysis method (HAM)

Taking the initial guesses and the linear operators as

| 30 |

| 31 |

satisfying the properties as given below

| 32 |

| 33 |

| 34 |

| 35 |

where are the arbitrary constants.

The zeroth order form of the problems are given as

| 36 |

| 37 |

| 38 |

| 39 |

| 40 |

where is an embedding parameter in this case and are the non-zero auxiliary parameters. represent the none-linear operators and can be obtained through Eqs. (11)–(14) as follows

| 41 |

| 42 |

| 43 |

| 44 |

For and , the following results are obtained

| 45 |

Obviously, when is increased from , then vary from to . Through Taylor’s series expansion, the expressions in Eq. (45) become as the following

| 46 |

| 47 |

| 48 |

| 49 |

The convergence of the series in Eqs. (46)–(49) depend strongly upon . By considering that are selected properly so that the series in Eqs. (46)–(49) converge at , then the following simplifications are achieved

| 50 |

| 51 |

| 52 |

| 53 |

The result of the problems at order deformation can be constructed as follow

| 54 |

| 55 |

| 56 |

| 57 |

| 58 |

where and can be calculated as

| 59 |

| 60 |

| 61 |

| 62 |

.

The general solutions are

| 63 |

| 64 |

| 65 |

| 66 |

in which are the special solutions.

Results and discussion

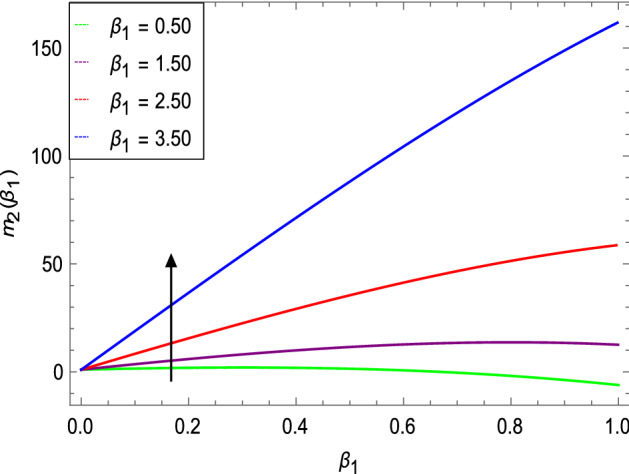

The dynamics of an Oldroyd-B nanoliquid coolant and shielding paint or film sprayed on a stretching cylinder is studied. The normalized spray rate which is functionally correlated with the film size is shown in Fig. 2. The film size naturally increases with the spray rate at once, but not in a linear fashion. If the spray is not uniform, the film's outer surface may be affected. It's interesting to note that the spray rate increases the thickness of the film in a non-linear way. The spray deposits an Oldroyd-B nanoliquid film on the stretching cylinder, which can be used to cool the extruded material to promote solidification via a water bath or coolant spraying. Spraying also improves cooling because it creates a thinner boundary layer.

Figure 2.

Spray rate as a function of β1.

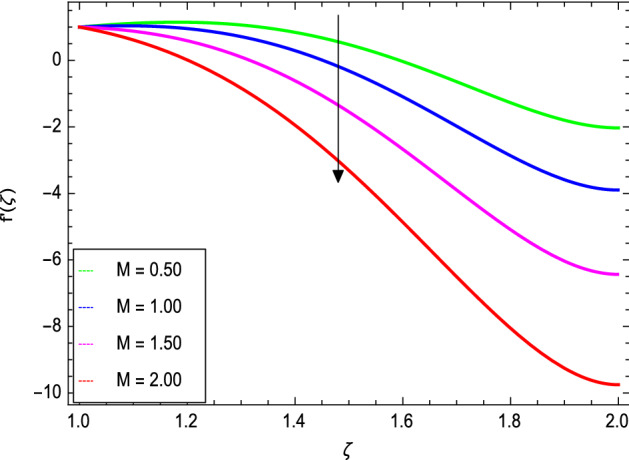

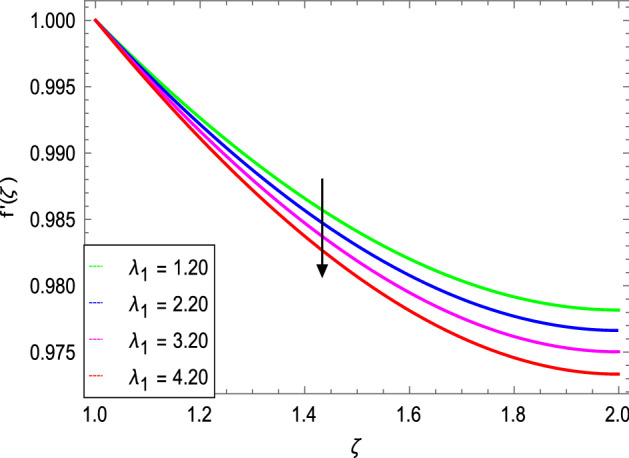

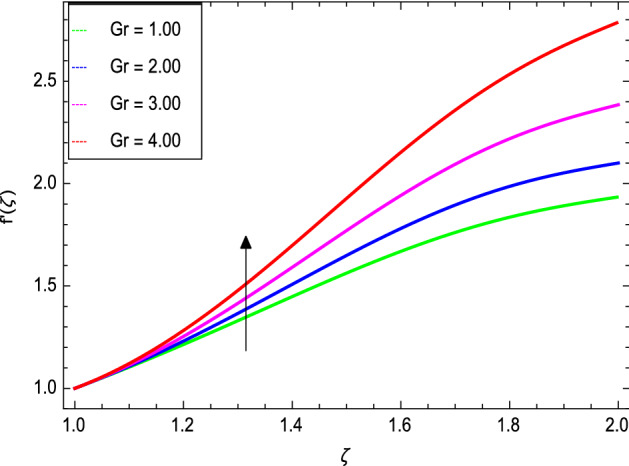

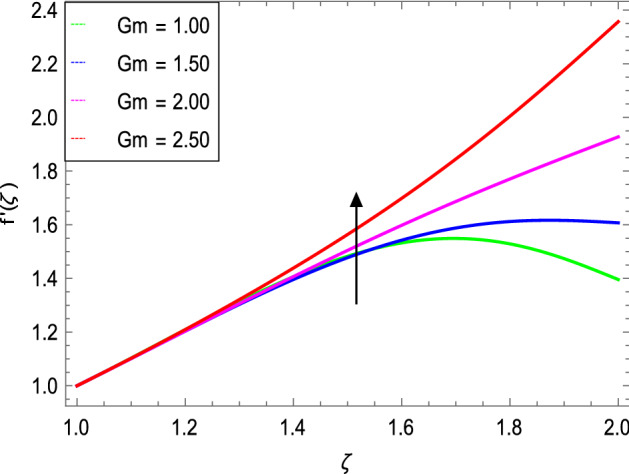

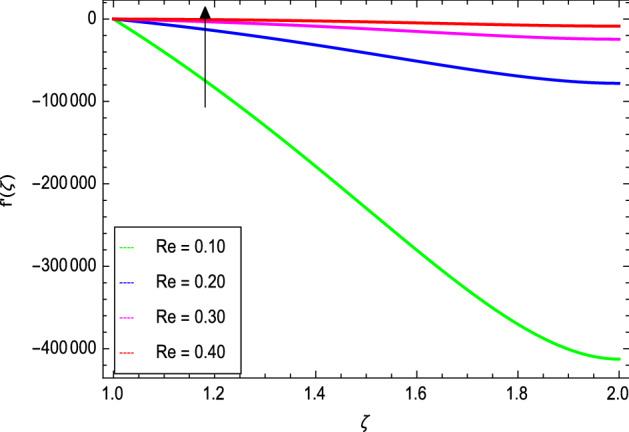

Figures 3 and 4 depict the effect of the magnetic field and Oldroyd-B nanofluid parameter on velocity profile. Figure 3 shows that the velocity decreases as the magnetic field parameter increases. In general, when a magnetic field is applied to a conduction-capable fluid flow, the momentum boundary layer becomes thin. The reason for this is that during this process, resistance forces known as Lorentz forces are produced, which have a negative impact on fluid flow. This force tends to slow the velocity of the nanofluid as it passes through the vertical surface. Figure 4 demonstrates that increasing the value of decreases the velocity and hence momentum boundary layer thickness decreases. Thermal Grashof number and solutal Grashof number effects on the velocity profile are shown in Figs. 5 and 6. The graphs show that the velocity is increased with and due to the dominant effects of the buoyancy force in the central region and generates changes in the velocity and high viscous effects across the walls. As a result, when increases, the concentration of the liquid film increases directly and hence the viscosity increases. Figure 7 shows the effects of Reynolds number on the velocity profile. The velocity is enhanced with the Reynolds number. The reason is that as the Reynolds number increases, the inertial force overcomes the flow regarding the viscous forces. High viscous forces are highly resistive to the fluid flow and with strong inertial forces, the flow of the boundary layer decreases. When is small, then it means there exists small inertial effect compared to that of viscous effect. Since so for = 0, the stretching rate tends to vanishing since the cylinder radius cannot be zero in the present case. Also, the thickness is made infinite for finite deposition rate and the steady form cannot exist.

Figure 3.

f′(ζ) as a function of M.

Figure 4.

f′(ζ) as a function of λ1.

Figure 5.

f′(ζ) as a function of Gr.

Figure 6.

f′(ζ) as a function of Gm.

Figure 7.

f′(ζ) as a function of Re.

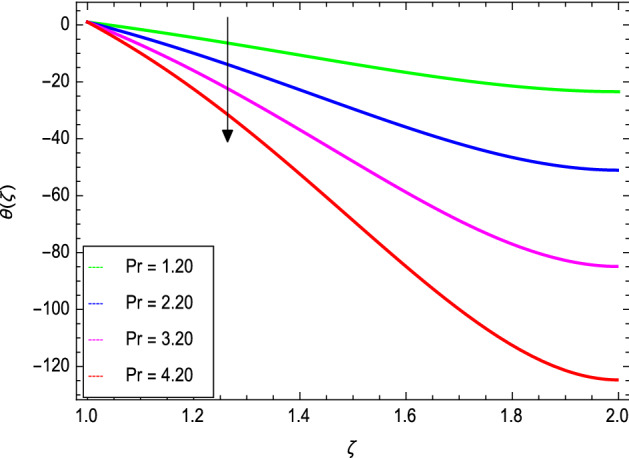

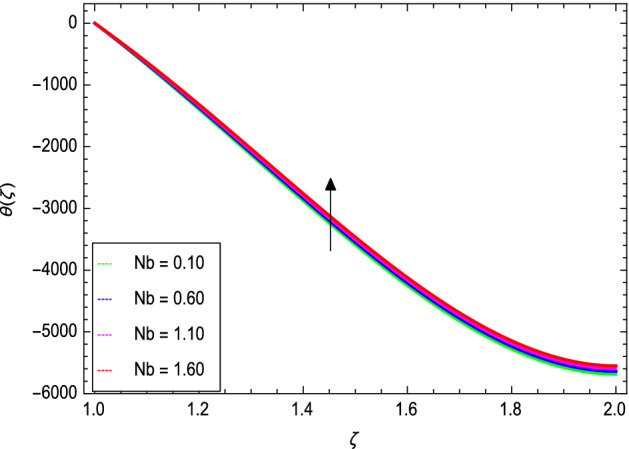

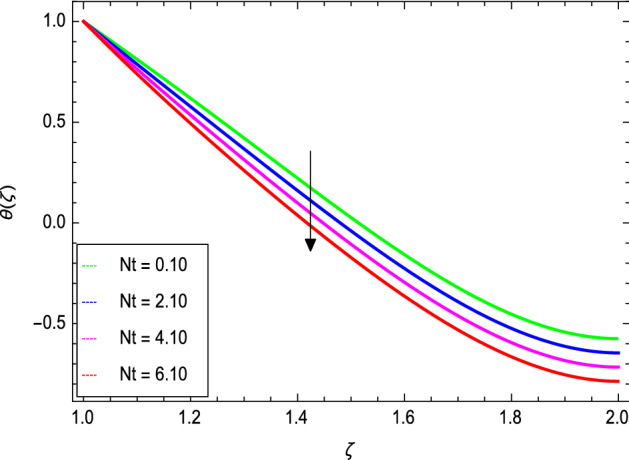

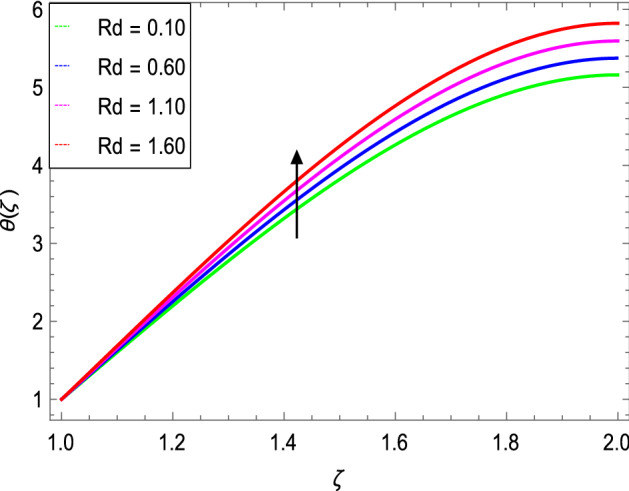

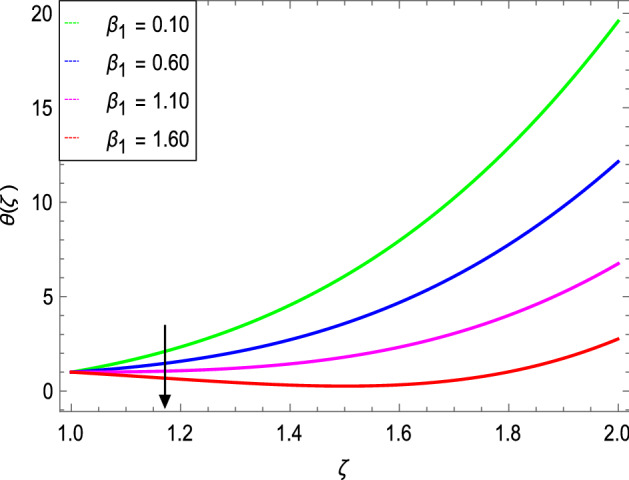

Figures 8 and 9 depict the effects of the magnetic field and Prandtl number on the temperature profile. Figure 8 reveals that increasing the values of the magnetic parameter , increases the temperature of the nanofluid. The magnetic field produces a resistive force that opposes the flow field and increases the thickness of the thermal boundary layer, consequently heat transfer increases. Figure 9 shows that the nanofluid temperature drops when the values of increases, thus the thermal boundary layer decreases for higher quantities of which shows that the effective cooling for nanofluid is achieved quickly. Given the relatively small size of the motion layer, the influence of a high Prandtl number is even clearer. The liquid retains a low thermal boundary layer for larger amounts of which leads to a thinner thermal boundary layer resulting in an increase in heat transfer rate on the surface. Figures 10 and 11 show the effects of the Brownian motion parameter and the thermophoresis parameter on the temperature profile. Figure 10 shows that the enhancement in temperature of the fluid is observed with the increasing values of which results in decrease in the friction of the free surface of nanoparticles. Figure 11 shows that the temperature of nanofluid decreases as the values increase. Thermophoresis is a phenomenon of the diffusion of particles because of a temperature gradient effect. The force that transfers nanoparticles to the ambient fluid due to the temperature gradient is called thermophoretic force. Increased thermophoretic force results in a wider transfer of nanoparticles to the fluid layer. Figures 12 and 13 show the impacts of thermal radiation parameter and film thickness parameter respectively on the temperature profile. As shown in Fig. 12, the radiation parameter is used to add heat to the temperature of the nanoparticles as the temperature of the nanofluid rises. The analysis of thermal radiation is essential in the cooling of the cylinder. The thin film parameter has a special role in the temperature distribution. The temperature of the thermal boundary surface is high and small along with the transverse distance. The film thickness parameter, as shown in Fig. 13, reduces the temperature for greater values. The heat transfer rate is improved by thinning the nanofluid. In the present case, however, it is depreciating. The reason for this is that as the thickness of the fluid film increases, so does the mass of the fluid, which exhausts the temperature. As a result, heat enters the fluid and the environment cools. Thick film fluid requires more heat than thin film fluid.

Figure 8.

θ(ζ) as a function of M.

Figure 9.

θ(ζ) as a function of Pr.

Figure 10.

θ(ζ) as a function of Nb.

Figure 11.

θ(ζ) as a function of Nt.

Figure 12.

θ(ζ) as a function of Rd.

Figure 13.

θ(ζ) as a function of β1.

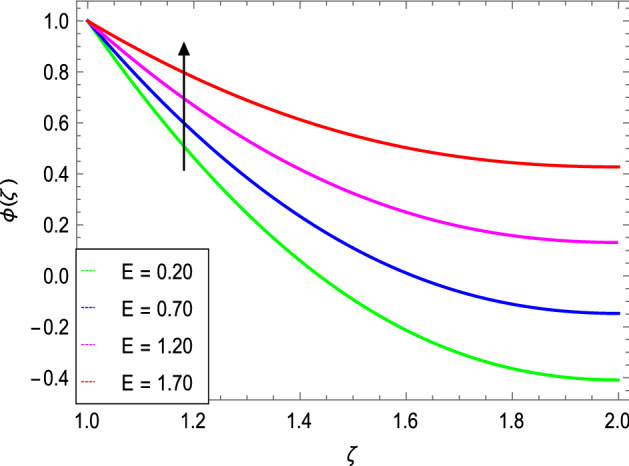

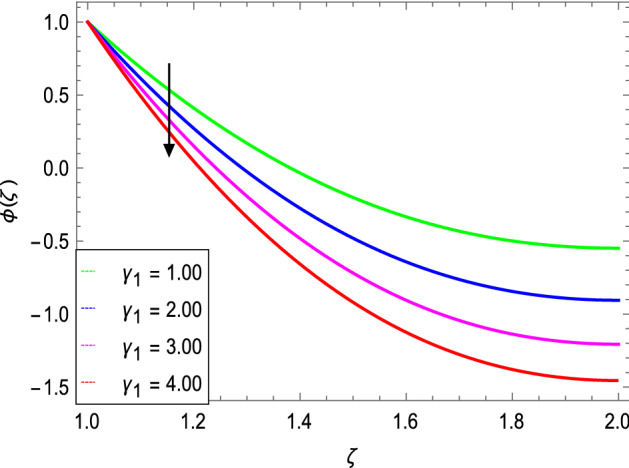

Figures 14 and 15 portray the influence of the activation energy parameter and the binary chemical reaction parameter on the concentration profile and show that it is incremented with larger values of E while it is decreased with enlarging values of respectively. The effect of Schmidt number on the nanoparticle’s concentration profile is presented in Fig. 16. The Schmidt number is related to the mass diffusions and therefore increases the mass diffusivity values leading to lessen down the nanoparticle’s concentration due to the less mass diffusion transportation as observed in Fig. 16.

Figure 14.

ϕ(ζ) as a function of E.

Figure 15.

ϕ(ζ) as a function of γ1.

Figure 16.

ϕ(ζ) as a function of Sc.

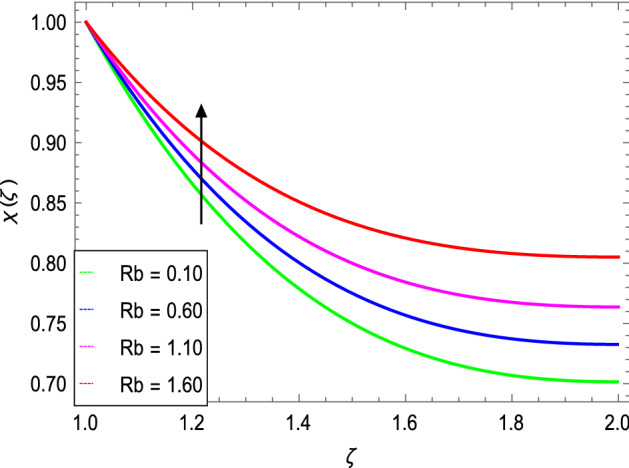

Figure 17 manifests the influence of Peclet number . It shows a decrement in the boundary layer thickness of the motile microorganisms. The maximum values of result a fall in the diffusivity of the microorganisms. Figure 18 portrays the influence of on motile microorganism’s density. It shows that increases with increasing the bioconvection Rayleigh number. The density of motile microorganisms is higher than that of liquid (water) and generally swims upwards to the outside (wall) of the cylinders.

Figure 17.

χ(ζ) as a function of Pe.

Figure 18.

χ(ζ) as a function of Rb.

The streamlines are the tangent curves to the local instantaneous velocity field. The formation of an inner mixing bolus within a fluid surrounded by streamlines is referred to as trapping. Figure 19 depicts the effect of the magnetic field parameter on the streamlines. It is shown that the number of the trapped boluses increases when the value of magnetic field parameter is 0.30 which shows that the flow velocity is highly influenced by the magnetic field. The compression of streamlines is high at the lower portion compared to that of upper portion at the surface of stretching cylinder.

Figure 19.

Streamlines for M = 0.30.

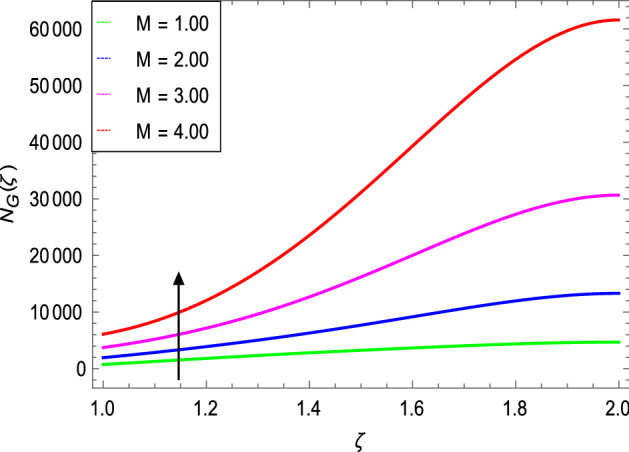

Figure 20 shows that the entropy generation increases as the magnetic field parameter increases. In general, increasing the magnetic field parameter causes a slight increase in entropy generation. Because the magnetic parameter has little influence on entropy generation, a wide difference in the magnetic field parameter results in a small variation in entropy.

Figure 20.

NG(ζ) as a function of M.

Comparison of the present work with published work

The present work is compared with the published work79 in Table 1 for various values of Oldroyd-B nanofluid parameter which shows the close agreement. In Tables 2, 3, 4 and 5, the different profiles show the different values including maximum and minimum for different parameters.

Table 1.

Comparison of the present research with published paper for .

| Published work80 | Present study | |

|---|---|---|

| 0.0 | 1.000000 | 1.000000 |

| 0.2 | 1.0518899 | 1.0518799 |

| 0.4 | 1.1019033 | 1.1019133 |

Table 2.

Variation in skin friction coefficient for

| 0.2 | 0.3 | 0.3 | 0.5 | 0.5 | 0.4231 |

| 0.6 | 0.3231 | ||||

| 1.0 | 0.2231 | ||||

| 0.5 | 0.1 | 0.1231 | |||

| 0.4 | 0.1231 | ||||

| 0.7 | 0.0231 | ||||

| 0.3 | 0.2 | 0.1031 | |||

| 0.4 | 0.1031 | ||||

| 0.6 | 0.1231 | ||||

| 0.3 | 0.1 | 0.0231 | |||

| 0.6 | 0.0231 | ||||

| 1.0 | 0.1230 | ||||

| 0.5 | 0.1 | 0.1201 | |||

| 1.0 | 0.1031 | ||||

| 2.0 | 0.0031 | ||||

| 0.5 | 0.1031 |

Table 3.

Variation in Nusselt number for

| 0.5 | 0.3 | 0.3 | 0.5 | 0.5 | 2.0 | 0.3 | 0.3 | 5.0 | 0.8 | 0.2764 |

| 0.2 | 0.2763 | |||||||||

| 0.6 | 0.2755 | |||||||||

| 1.0 | 0.2745 | |||||||||

| 0.1 | 0.2735 | |||||||||

| 0.4 | 0.2725 | |||||||||

| 0.7 | 0.2715 | |||||||||

| 0.2 | 0.2754 | |||||||||

| 0.4 | 0.2753 | |||||||||

| 0.6 | 0.2760 | |||||||||

| 0.1 | 0.2761 | |||||||||

| 0.4 | 0.2762 | |||||||||

| 0.7 | 0.2736 | |||||||||

| 0.1 | 0.2735 | |||||||||

| 1.0 | 0.2734 | |||||||||

| 2.0 | 0.2733 | |||||||||

| 0.1 | 0.2732 | |||||||||

| 1.0 | 0.2731 | |||||||||

| 2.0 | 0.2730 | |||||||||

| 1.0 | 0.2729 | |||||||||

| 3.0 | 0.2728 | |||||||||

| 5.0 | 0.2727 | |||||||||

| 0.1 | 0.2726 | |||||||||

| 0.4 | 0.2725 | |||||||||

| 0.8 | 0.2724 | |||||||||

| 1.0 | 0.2723 | |||||||||

| 2.0 | 0.2722 | |||||||||

| 3.0 | 0.2721 | |||||||||

| 0.1 | 0.2720 | |||||||||

| 0.3 | 0.2717 | |||||||||

| 0.5 | 0.2716 |

Table 4.

Variation in Sherwood number for .

| 0.5 | 0.3 | 0.3 | 0.5 | 0.5 | 2.0 | 0.3 | 0.3 | 5.0 | 0.1 | 0.15479 |

| 0.2 | 0.15478 | |||||||||

| 0.6 | 0.15477 | |||||||||

| 1.0 | 0.15476 | |||||||||

| 0.1 | 0.15475 | |||||||||

| 0.4 | 0.15474 | |||||||||

| 0.7 | 0.15473 | |||||||||

| 0.2 | 0.15472 | |||||||||

| 0.4 | 0.15471 | |||||||||

| 0.6 | 0.15470 | |||||||||

| 0.1 | 0.15469 | |||||||||

| 0.6 | 0.15468 | |||||||||

| 1.0 | 0.15467 | |||||||||

| 0.1 | 0.15468 | |||||||||

| 1.0 | 0.15467 | |||||||||

| 2.0 | 0.15466 | |||||||||

| 1.0 | 0.15465 | |||||||||

| 3.0 | 0.15464 | |||||||||

| 5.0 | 0.15463 | |||||||||

| 0.1 | 0.15462 | |||||||||

| 0.3 | 0.15461 | |||||||||

| 0.5 | 0.15460 | |||||||||

| 0.1 | 0.15459 | |||||||||

| 0.4 | 0.15458 | |||||||||

| 0.8 | 0.15457 | |||||||||

| 1.0 | 0.15456 | |||||||||

| 2.0 | 0.15455 | |||||||||

| 3.0 | 0.15454 | |||||||||

| 0.5 | 0.15453 | |||||||||

| 1.0 | 0.15452 | |||||||||

| 1.5 | 0.15451 |

Table 5.

Variation in motile microorganism density number for

| 0.5 | 0.3 | 0.3 | 0.5 | 0.5 | 1.0 | 0.1 | 0.3989 |

| 0.6 | 0.3988 | ||||||

| 1.0 | 0.3987 | ||||||

| 0.1 | 0.3986 | ||||||

| 0.4 | 0.3985 | ||||||

| 0.7 | 0.3984 | ||||||

| 0.2 | 0.3983 | ||||||

| 0.4 | 0.3982 | ||||||

| 0.6 | 0.3981 | ||||||

| 0.1 | 0.3980 | ||||||

| 0.6 | 0.3979 | ||||||

| 1.0 | 0.3978 | ||||||

| 0.1 | 0.3977 | ||||||

| 1.0 | 0.3976 | ||||||

| 2.0 | 0.3975 | ||||||

| 0.1 | 0.3974 | ||||||

| 0.5 | 0.3973 | ||||||

| 0.8 | 0.3972 | ||||||

| 0.2 | 0.3971 | ||||||

| 0.6 | 0.3970 | ||||||

| 1.0 | 0.3969 |

Conclusions

The heat and mass transfer flow of an Oldroyd-B nanoliquid film sprayed on a stretching cylinder containing gyrotactic microorganisms is investigated using similarity transformations. Thermodynamics and spraying phenomena are mathematically modeled and then analyzed using HAM solution with profiles such as spray rate, velocity, heat and mass transfer, and gyrotactic microorganism’s motion.

The summary of findings are as follows:

Spray rate increases with the film thickness nonlinearly.

The velocity profile shows decreasing behavior for magnetic field parameter, bioconvection Rayleigh number and Oldroyd-B nanofluid parameter while increases with thermal Grashof, solutal Grashof and Reynolds numbers.

The temperature increases with increasing the magnetic field, Brownian motion and thermal radiation parameters while it is decreased with the positive values of Prandtl number, film thickness and thermophoresis parameters.

The concentration profile shows an increasing behavior with the activation energy parameter while it decreases with increasing the thermal radiation, chemical reaction parameter and Schmidt number as well.

The gyrotactic microorganisms motion increases with increasing the bioconvection Rayleigh number while it is decreased with the Peclet and Lewis numbers.

The entropy generation increases with the magnetic field parameter.

Skin friction coefficient, heat and mass transfer rate, and motile density number consistently decrease with the different parameters.

Acknowledgements

The authors wish to thank the anonymous referees for their comments and suggestions. The authors acknowledge the financial support provided by the Center of Excellence in Theoretical and Computational Science (TaCS-CoE), KMUTT. Moreover, this research was supported by Research Center in Mathematics and Applied Mathematics, Chiang Mai University. The authors appreciate the financial support allotted by King Mongkut’s University of Technology Thonburi through the “KMUTT 55th Anniversary Commemorative Fund”. The first author is supported by the Petchra Pra Jom Klao Doctoral Scholarship Academic for PhD studies at KMUTT. The second author is thankful to the Higher Education Commission (HEC) Pakistan for providing the technical and financial support.

Abbreviations

Chemotaxis constant

Outer radius

Nanoparticles concentration

Nanoparticles concentration at the wall

Nanoparticles concentration beyond the surface

Magnetic field strength (N A−1 m−1)

Skin friction coefficient

Brownian diffusion coefficient (m2 s−1)

Mass diffusivity (m2 s−1)

Thermophoretic diffusion coefficient (m2 s−1)

Arrhenius activation energy parameter

Dimensional characteristic entropy generation

Dimensional entropy generation

Dimensionless velocity function

Acceleration due to gravity (m s−2)

Thermal Grashof number

Solutal Grashof number

Thermal conductivity parameter

Relaxation time coefficient

Retardation time coefficient

Mean absorption coefficient

Bioconvection Lewis number

Magnetic field parameter

Motile density of microorganisms

Motile density of microorganisms beyond the surface

Motile density microorganisms at the wall

Dimensionless Brownian motion parameter

Dimensionless entropy generation

Dimensionless thermophoresis parameter

Local Nusselt number

Pressure (kg m−1 s−2)

Peclet number

Prandtl number

Wall heat flux

Wall mass flux

Wall density flux

Bioconvection Rayleigh number

Local Reynolds number

Thermal radiation parameter

Schmidt number

Bioconvection Schmidt number

Sherwood number

Local motile microorganism density number

Temperature of the fluid (K)

Temperature at the outer radius of the film surface (K)

Temperature at the wall (K)

Velocity components (m s−1)

Radial axisymmetric spray velocity (m s−1)

Speed of gyrotactic cell

Greek symbols

Dimensionless similarity variable

Density of nanofluid (kg m−3)

Motile microorganism density (kg m−3)

Density of nanoparticles (kg m−3)

Deborah number on behalf of relaxation time

Deborah number on behalf of retardation time

Chemical reaction rate

Electrical conductivity (S m−1)

Stefan–Boltzmann constant (J K−1)

Dynamic viscosity (N s m−2)

Kinematic viscosity (m2 s−1)

Thermal diffusivity(m2 s−1)

Nondimensional film thickness parameter

Dimensionless motile microorganism’s concentration

Dimensionless nanoparticles concentration

Dimensionless temperature

Heat capacity of nanofluid (J K−1)

Heat capacity of nanoparticle (J K−1)

Ratio of heat capacity

Wall shear stress

Author contributions

N.S.K., A.H.U., Q.S., Z.U., U.W.H., P.K., W.K., A.B., P.T. and A.K. completed the research work.

Funding

This research is supported by the Petchra Pra Jom Klao Doctoral Scholarship for Ph.D. program of King Mongkut’s University of Technology Thonburi (KMUTT) [Grant No. 13/2562].

Data availability

Availability exists for the data upon request.

Competing interests

The authors declare no competing interests.

Footnotes

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Noor Saeed Khan, Email: noorsaeedkhankhattak@gmail.com.

Poom Kumam, Email: poom.kum@kmutt.ac.th.

References

- 1.Albano PG, Borghi CA, Cristofolini A, Fabbri M, Kishimoto Y, et al. Industrial applications of magnetohydrodynamics at the University of Bologna. Energy Convers. Manag. 2002;43:353–363. doi: 10.1016/S0196-8904(01)00102-9. [DOI] [Google Scholar]

- 2.Khan, M.N., & Nadeem, S. A comparative study between linear and exponential stretching sheet with double stratification of a rotating Maxwell nanofluid flow. Surfaces Interfaces22, 100886 (2020).

- 3.Khan MN, Nadeem S. Theoretical treatment of bio-convective Maxwell nanofluid over an exponentially stretching sheet. Can. J. Phys. 2020;98:732–741. doi: 10.1139/cjp-2019-0380. [DOI] [Google Scholar]

- 4.Khan, M.N., Nadeem, S., Ullah, N. & Saleem, A. Theoretical treatment of radiative Oldroyd-B nanofluid with microorganism pass an exponentially stretching sheet. Surfaces Interfaces21, 100686 (2020).

- 5.Khan, N.S., Shah, Q. & Sohail, A. Dynamics with Cattaneo–Christov heat and mass flux theory of bioconvection Oldroyd-B nanofluid. Adv. Mech. Eng. 2, 12(8), 1–20 (2020). [DOI] [PMC free article] [PubMed]

- 6.Khan WA, Irfan M, Khan M. An improved heat conduction and mass diffusion models for rotating flow of an Oldroyd-B fluid. Results Phys. 2017;7:3583–3589. doi: 10.1016/j.rinp.2017.08.068. [DOI] [Google Scholar]

- 7.Irfan, M., Khan, M., Khan, W. A., Alghamdi, M., & Ullah, M. Z. Influence of thermal-solutal stratifications and thermal aspects of non-linear radiation in stagnation point Oldroyd-B nanofluid flow. Int. Commun. Heat Mass. 116, 104636 (2020).

- 8.Khan M, Irfan M, Khan WA. Impact of nonlinear thermal radiation and gyrotactic microorganisms on the Magneto-Burgers nanofluid. Int. J. Mech. Sci. 2017;130:375–382. doi: 10.1016/j.ijmecsci.2017.06.030. [DOI] [Google Scholar]

- 9.Rafiq, K., Irfan, M., Khan, M., Anwar, M. S., & Khan, W. A. Arrhenius activation energy theory in radiative flow of Maxwell nanofluid. Phys. Scr. 96, 045002 (2021).

- 10.Irfan, M., Rafiq, K., Khan, M., Waqas, M., & Anwar, M. S. Theoretical analysis of new mass flux theory and Arrhenius activation energy in Carreau nanofluid with magnetic influence. Int. Commun. Heat Mass120, 105051 (2021).

- 11.Irfan M, Khan M, Khan WA. Impact of non-uniform heat sink/source and convective condition in radiative heat transfer to Oldroyd-B nanofluid: a revised proposed relation. Phys. Lett. A. 2019;383:376–382. doi: 10.1016/j.physleta.2018.10.040. [DOI] [Google Scholar]

- 12.Khan, W. A., Khan, M., & Malik, R. Three-dimensional flow of an Oldroyd-B nanofluid towards stretching surface with heat generation/absorption. PLoS One, 9, e105107 (2014). [DOI] [PMC free article] [PubMed]

- 13.Ahmad, S., Khan, M.N., & Nadeem, S. Mathematical analysis of heat and mass transfer in a Maxwell fluid with double stratification. Phys. Scr. 96, 025202 (2020).

- 14.Khan NS. Bioconvection in second grade nanofluid flow containing nanoparticles and gyrotactic microorganisms. Braz. J. Phys. 2018;43:227–241. doi: 10.1007/s13538-018-0567-7. [DOI] [Google Scholar]

- 15.Khan NS, Gul T, Khan MA, Bonyah E, Islam S. Mixed convection in gravity-driven thin film non-Newtonian nanofluids flow with gyrotactic microorganisms. Results Phys. 2017;7:4033–4049. doi: 10.1016/j.rinp.2017.10.017. [DOI] [Google Scholar]

- 16.Khan NS, Gul T, Islam S, Khan W. Thermophoresis and thermal radiation with heat and mass transfer in a magnetohydrodynamic thin film second-grade fluid of variable properties past a stretching sheet. Eur. Phys. J. Plus. 2017;32:11. doi: 10.1140/epjp/i2017-11277-3. [DOI] [Google Scholar]

- 17.Palwasha, Z., Khan, N.S., Shah, Z., Islam, S. & Bonyah, E. Study of two-dimensional boundary layer thin film fluid flow with variable thermo-physical properties in three dimensions space. AIP Adv. 8, 105318 (2018).

- 18.Khan NS, Gul T, Islam S, Khan A, Shah Z. Brownian motion and thermophoresis effects on MHD mixed convective thin film second-grade nanofluid flow with Hall effect and heat transfer past a stretching sheet. J. Nanofluids. 2017;6:812–829. doi: 10.1166/jon.2017.1383. [DOI] [Google Scholar]

- 19.Khan, N.S., Zuhra, S., Shah, Z., Bonyah, E., Khan, W.& Islam, S. Slip flow of Eyring-Powell nanoliquid film containing graphene nanoparticles. AIP Adv. 8, 115302 (2019).

- 20.Khan NS, Gul T, Kumam P, Shah Z, Islam S, Khan W, Zuhra S, Sohail A. Influence of inclined magnetic field on Carreau nanoliquid thin film flow and heat transfer with graphene nanoparticles. Energies. 2019;12:1459. doi: 10.3390/en12081459. [DOI] [Google Scholar]

- 21.Khan NS. Study of two-dimensional boundary layer flow of a thin film second grade fluid with variable thermo-physical properties in three dimensions space. Filomat. 2019;33:5387–5405. doi: 10.2298/FIL1916387K. [DOI] [Google Scholar]

- 22.Khan NS, Zuhra S. Boundary layer unsteady flow and heat transfer in a second grade thin film nanoliquid embedded with graphene nanoparticles past a stretching sheet. Adv. Mech. Eng. 2019;11:1–11. [Google Scholar]

- 23.Usman, A.H., Khan, N.S., Humphries, U.W., Shah, Z., Kumam, P., Khan, W., Khan, A., Rano, S.A. & Ullah, Z. Development of dynamic model and analytical analysis for the diffusion of different species in non-Newtonian nanofluid swirling flow. Front. Phys.8, 616790 (2021).

- 24.Liaqat, A., Asifa, T., Ali, R., Islam, S., Gul, T., Kumam, P., Mukhtar, S., Khan, N.S., Thounthong, P. A new analytical approach for the research of thin-film flow of magneto hydrodynamic fluid in the presence of thermal conductivity and variable viscosity. ZAMM J. Appl. Math. Mech. 101, e201900292 (2020).

- 25.Liaqat A, Khan NS, Ali R, Islam S, Kumam P, Thounthong P. Novel insights through the computational techniques in unsteady MHD second grade fluid dynamics with oscillatory boundary conditions. Heat Transf. 2020;50:2502–2524. [Google Scholar]

- 26.Zahra A, Mahanthesh B, Basir MFM, Imtiaz M, Mackolil J, Khan NS, Nabwey HA, Tlili I. Mixed radiated magneto Casson fluid flow with Arrhenius activation energy and Newtonian heating effects: Flow and sensitivity analysis. Alex. Eng. J. 2020;57:1019–1031. [Google Scholar]

- 27.Choi, S.U. & Eastman, J.A. Enhancing thermal conductivity of fluids with nanoparticles. Argonne Natl. Lab. IL (United States) (1995).

- 28.Buongiorno J. Convective transport in nanofluids. J. Heat Transf. 2006;128:240–250. doi: 10.1115/1.2150834. [DOI] [Google Scholar]

- 29.Ellahi R, Zeeshan A, Hussain F, Abbas T. Thermally charged MHD bi-phase flow coatings with non-Newtonian nanofluid and hafnium particles along slippery walls. Coatings. 2019;9:300. doi: 10.3390/coatings9050300. [DOI] [Google Scholar]

- 30.Zuhra S, Khan NS, Khan MA, Islam S, Khan W, Bonyah E. Flow and heat transfer in water based liquid film fluids dispensed with graphene nanoparticles. Results Phys. 2018;8:1143–1157. doi: 10.1016/j.rinp.2018.01.032. [DOI] [Google Scholar]

- 31.Khan NS, Shah Z, Shutaywi M, Kumam P, Thounthong P. A comprehensive study to the assessment of Arrhenius activation energy and binary chemical reaction in swirling flow. Sci. Rep. 2020;10:7868. doi: 10.1038/s41598-020-64712-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 32.Khan NS, Kumam P, Thounthong P. Computational approach to dynamic systems through similarity measure and homotopy analysis method for renewable energy. Curr. Comput.-Aided Drug Des. 2020;10:1086. [Google Scholar]

- 33.Khan NS, Shah Q, Sohail A, Kumam P, Thounthong P, Bhaumik A, Ullah Z. Lorentz forces effects on the interactions of nanoparticles in emerging mechanisms with innovative approach. Symmetry. 2020;12:1700. doi: 10.3390/sym12101700. [DOI] [Google Scholar]

- 34.Khan NS, Shah Q, Sohail A, Ullah Z, Kaewkhao A, Kumam P, Zubair S, Ullah N, Thounthong P. Rotating flow assessment of magnetized mixture fluid suspended with hybrid nanoparticles and chemical reactions of species. Sci. Rep. 2021;11:4448. doi: 10.1038/s41598-021-83910-w. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 35.Khan WA, Irfan M, Khan M, Alshomrani AS, Alzahrani AK, Alghamdi MS. Impact of chemical processes on magneto nanoparticle for the generalized Burgers fluid. J. Mol. Liq. 2017;234:201–208. doi: 10.1016/j.molliq.2017.03.078. [DOI] [Google Scholar]

- 36.Alshomrani AS, Irfan M, Salem A, Khan M. Chemically reactive flow and heat transfer of magnetite Oldroyd-B nanofluid subject to stratifications. Appl. Nanosci. 2018;8:1743–1754. doi: 10.1007/s13204-018-0846-1. [DOI] [Google Scholar]

- 37.Khan, M. N., Ullah, N., & Nadeem, S. Transient flow of Maxwell nanofluid over a shrinking surface: Numerical solutions and stability analysis. Surf. Interfaces. 22, 100829 (2021).

- 38.Ahmad, S., Nadeem, S., Muhammad, N., & Khan, M. N. Cattaneo–Christov heat flux model for stagnation point flow of micropolar nanofluid toward a nonlinear stretching surface with slip effects. J. Therm. Anal. Calorim. 1–13 (2020).

- 39.Khan M, Khan WA, Alshomrani AS. Non-linear radiative flow of three-dimensional Burgers nanofluid with new mass flux effect. Int. J. Heat Mass. 2016;101:570–576. doi: 10.1016/j.ijheatmasstransfer.2016.05.056. [DOI] [Google Scholar]

- 40.Khan WA, Ali M, Shahzad M, Sultan F, Irfan M, Asghar Z. A note on activation energy and magnetic dipole aspects for Cross nanofluid subjected to cylindrical surface. Appl. Nanosci. 2020;10:3235–3244. doi: 10.1007/s13204-019-01220-0. [DOI] [Google Scholar]

- 41.Khan, M. N., & Nadeem, S. MHD stagnation point flow of a Maxwell nanofluid over a shrinking sheet (multiple solution). Heat Transf. 1– 15 (2021).

- 42.Khan, W. A., Ali, M., Irfan, M., Khan, M., Shahzad, M., & Sultan, F. A rheological analysis of nanofluid subjected to melting heat transport characteristics. Appl. Nanosci. 1–10 (2019).

- 43.Khan WA, Ali M, Waqas M, Shahzad M, Sultan F, Irfan M. Importance of convective heat transfer in flow of non-Newtonian nanofluid featuring Brownian and thermophoretic diffusions. Int. J. Numer. Method H. 2019;29:4624–4641. doi: 10.1108/HFF-01-2019-0066. [DOI] [Google Scholar]

- 44.Irfan, M. Study of Brownian motion and thermophoretic diffusion on non-linear mixed convection flow of Carreau nanofluid subject to variable properties. Surf. Interfaces. 23, 100926 (2021).

- 45.Irfan M, Khan M, Khan WA, Ayaz M. Modern development on the features of magnetic field and heat sink/source in Maxwell nanofluid subject to convective heat transport. Phys. Lett. A. 2018;382:1992–2002. doi: 10.1016/j.physleta.2018.05.008. [DOI] [Google Scholar]

- 46.Bejan, A study of entropy generation in fundamental convective heat transfer. J. Heat Trans.101, 718–725 (1979).

- 47.Khan MI, Hayat T, Khan MI, Waqas M, Alsaedi A. Numerical simulation of hydromagnetic mixed convective radiative slip flow with variable fluid properties: A mathematical model for entropy generation. J. Phys. Chem. Solid. 2019;125:153–164. doi: 10.1016/j.jpcs.2018.10.015. [DOI] [Google Scholar]

- 48.Khan WA, Ali M. Recent developments in modeling and simulation of entropy generation for dissipative cross material with quartic autocatalysis. Appl. Phys. A. 2019;125:1–9. [Google Scholar]

- 49.Khan NS, Zuhra S, Shah Q. Entropy generation in two phase model for simulating flow and heat transfer of carbon nanotubes between rotating stretchable disks with cubic autocatalysis chemical reaction. Appl. Nanosci. 2019;9:1797–1822. doi: 10.1007/s13204-019-01017-1. [DOI] [Google Scholar]

- 50.Khan NS, Shah Q, Bhaumik A, Kumam P, Thounthong P, Amiri I. Entropy generation in bioconvection nanofluid flow between two stretchable rotating disks. Sci. Rep. 2020;10:4448. doi: 10.1038/s41598-020-61172-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 51.Khan NS, Shah Z, Islam S, Khan I, Alkanhal TA, Tlili I. Entropy generation in MHD mixed convection non-Newtonian second-grade nanoliquid thin film flow through a porous medium with chemical reaction and stratification. Entropy. 2019;21:139. doi: 10.3390/e21020139. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 52.Khan, N.S., Zuhra, S., Shah, Z., Bonyah, E., Khan, W., Islam, S. & Khan, A. Hall current and thermophoresis effects on magnetohydrodynamic mixed convective heat and mass transfer thin film flow. J. Phys. Commun. 3, 035009 (2019).

- 53.Khan NS, Kumam P, Thounthong P. Second law analysis with effects of Arrhenius activation energy and binary chemical reaction on nanofluid flow. Sci. Rep. 2020;10:1226. doi: 10.1038/s41598-020-57802-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 54.Khan NS, Kumam P, Thounthong P. Magnetic field promoted irreversible process of water based nanocomposites with heat and mass transfer flow. Sci. Rep. 2021;1:11692. doi: 10.1038/s41598-020-80554-0. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 55.Khan, N.S., Kumam, P. & Thounthong, P. Renewable energy technology for the sustainable development of thermal system with entropy measures. Int. J. Heat Mass Transf. 145, 118713 (2019).

- 56.Ellahi R, Zeeshan A, Hussain F, Abbas T. Study of shiny film coating on multi-fluid flows of a rotating disk suspended with nano-sized silver and gold particles: A comparative analysis. Coatings. 2018;8:422. doi: 10.3390/coatings8120422. [DOI] [Google Scholar]

- 57.Khan NS, Gul T, Islam S, Khan I, Alqahtani AM, Alshomrani AS. Magnetohydrodynamic nanoliquid thin film sprayed on a stretching cylinder with heat transfer. Appl. Sci. 2017;7:271. doi: 10.3390/app7030271. [DOI] [Google Scholar]

- 58.Palwasha Z, Islam S, Khan NS, Ayaz H. Non-Newtonian nanoliquids thin-film flow through a porous medium with magnetotactic microorganisms. Appl. Nanosci. 2018;8:1523–1544. doi: 10.1007/s13204-018-0834-5. [DOI] [Google Scholar]

- 59.Hartig, K. & Krisko, A.J. Inventors Cardinal CG Co, assignee. Thin film coating having transparent base layer. United States Patent US919, 133 (2005).

- 60.Arrhenius S. Über die Dissociationswärme und den Einfluss der Temperatur auf den Dissociationsgrad der Elektrolyte. Z. Phys. Chem. 1889;4:96–116. [Google Scholar]

- 61.Bestman AR. Natural convection boundary layer with suction and mass transfer in a porous medium. Int. J. Energy Res. 1990;14:389–396. doi: 10.1002/er.4440140403. [DOI] [Google Scholar]

- 62.Kumar, K. G., Baslem, A., Prasannakumara, B. C., Majdoubi, J., Rahimi-Gorji, M., & Nadeem, S. Significance of Arrhenius activation energy in flow and heat transfer of tangent hyperbolic fluid with zero mass flux condition. Microsyst. Technol. 1–10 (2020).

- 63.Alghamdi M. Significance of Arrhenius activation energy and binary chemical reaction in mixed convection flow of nanofluid due to a rotating disk. Coatings. 2020;10:86. doi: 10.3390/coatings10010086. [DOI] [Google Scholar]

- 64.Khan WA, Alshomrani AS, Alzahrani AK, Khan M, Irfan M. Impact of autocatalysis chemical reaction on nonlinear radiative heat transfer of unsteady three-dimensional Eyring-Powell magneto-nanofluid flow. Pramana. 2018;91:1–9. doi: 10.1007/s12043-018-1574-5. [DOI] [Google Scholar]

- 65.Ghorai S, Hill NA. Periodic arrays of gyrotactic plumes in bioconvection. Phys. Fluids. 2000;12:5–22. doi: 10.1063/1.870249. [DOI] [PubMed] [Google Scholar]

- 66.Chamkha AJ, Rashad AM, Kameswaran PK, Abdou MMM. Radiation effects on natural bioconvection flow of a nanofluid containing gyrotactic microorganisms past a vertical plate with streamwise temperature variation. J. Nanofluids. 2017;6:587–595. doi: 10.1166/jon.2017.1351. [DOI] [Google Scholar]

- 67.Rashad AM, Chamkha AJ, Mallikarjuna B, Abdou MMM. Mixed bioconvection flow of a nanofluid containing gyrotactic microorganisms past a vertical slender cylinder. Front. Heat Mass Transf. 2018;10:21. [Google Scholar]

- 68.Hady, F.M., Mohamed, R.A.; Mahdy, A. & Abo Zaid, O.A. Non-Darcy natural convection boundary layer flow over a vertical cone in porous media saturated with a nanofluid containing gyrotactic microorganisms with a convective boundary condition. J. Nanofluids 5, 765–773 (2016).

- 69.Nadeem S, Khan MN, Muhammad N, Ahmad S. Mathematical analysis of bio-convective micropolar nanofluid. J. Comput. Des. Eng. 2019;6:233–242. [Google Scholar]

- 70.Zuhra, S., Khan, N.S., Shah, Z., Islam, Z. & Bonyah, E. Simulation of bioconvection in the suspension of second grade nanofluid containing nanoparticles and gyrotactic microorganisms. AIP Adv. 8, 105210 (2018).

- 71.Zuhra S, Khan NS, Alam A, Islam S, Khan A. Buoyancy effects on nanoliquids film flow through a porous medium with gyrotactic microorganisms and cubic autocatalysis chemical reaction. Adv. Mech. Eng. 2020;12:1–17. doi: 10.1177/1687814019897510. [DOI] [Google Scholar]

- 72.Khan NS. Mixed convection in MHD second grade nanofluid flow through a porous medium containing nanoparticle and gyrotactic microorganisms with chemical reaction. Filomat. 2019;33:4627–4653. doi: 10.2298/FIL1914627K. [DOI] [Google Scholar]

- 73.Zuhra S, Khan NS, Islam S. Magnetohydrodynamic second grade nanofluid flow containing nanoparticles and gyrotactic microorganisms. Comput. Appl. Math. 2018;37:6332–6358. doi: 10.1007/s40314-018-0683-6. [DOI] [Google Scholar]

- 74.Wang CY. Fluid flow due to a stretching cylinder. Phys. Fluids. 1988;31:466–468. doi: 10.1063/1.866827. [DOI] [Google Scholar]

- 75.Wang CY. Liquid film sprayed on a stretching cylinder. Chem. Eng. Commun. 2006;193:869–878. doi: 10.1080/00986440500267352. [DOI] [Google Scholar]

- 76.Bachok N, Ishak A. Flow and heat transfer over a stretching cylinder with prescribed surface heat flux. Malaysian J. Math. Sci. 2010;4:159–169. [Google Scholar]

- 77.Chuhan DS, Rastogi P, Agrawal R. Magnetohydrodynamic flow and heat transfer in a porous medium along a stretching cylinder with radiation: Homotopy analysis method. Afrika Mat. 2014;25:115–134. doi: 10.1007/s13370-012-0102-x. [DOI] [Google Scholar]

- 78.Irfan M, Khan M, Khan WA, Sajid M. Thermal and solutal stratifications in flow of Oldroyd-B nanofluid with variable conductivity. Appl. Phys. A. 2018;124:674. doi: 10.1007/s00339-018-2086-3. [DOI] [Google Scholar]

- 79.Tlili I, Waqas H, Almaneea A, Khan SU, Imran M. Activation energy and second order slip in bioconvection of Oldroyd-B nanofluid over a stretching cylinder: A proposed mathematical model. Processes. 2019;7:914. doi: 10.3390/pr7120914. [DOI] [Google Scholar]

- 80.Hayat T, Waqas M, Shehzad SA, Alsaedi A. Mixed convection flow of viscoelastic nanofluid by a cylinder with variable thermal conductivity and heat source/sink. Int. J. Numer. Method H. 2016;26:214–234. doi: 10.1108/HFF-02-2015-0053. [DOI] [Google Scholar]

- 81.Liao, S.J. The Proposed Homotopy Analysis Method for the Solution of Nonlinear Problems. Ph.D. Thesis. (Shanghai Jiao Tong University, 1992).

- 82.Liao SJ. An explicit, totally analytic approximate solution for Blasius viscous flow problems. Int. J. Non-Linear Mech. 1999;34:759–778. doi: 10.1016/S0020-7462(98)00056-0. [DOI] [Google Scholar]

- 83.Liao S. Beyond Perturbation: Introduction to the Homotopy Analysis Method. CRC Press; 2003. [Google Scholar]

- 84.Khan M, Irfan M, Khan WA. Numerical assessment of solar energy aspects on 3D magneto-Carreau nanofluid: A revised proposed relation. Int. J. Hydrog. Energ. 2017;42:22054–22065. doi: 10.1016/j.ijhydene.2017.07.116. [DOI] [Google Scholar]

- 85.Rashidi, M.M., Siddiqui, A.M. & Asadi, M. Application of homotopy analysis method to the unsteady squeezing flow of a second-grade fluid between circular plates. Math. Probl. Eng. 2010, 706840 (2010).

- 86.Khan WA, Khan M, Irfan M, Alshomrani AS. Impact of melting heat transfer and nonlinear radiative heat flux mechanisms for the generalized Burgers fluids. Results Phys. 2017;7:4025–4032. doi: 10.1016/j.rinp.2017.10.004. [DOI] [Google Scholar]

- 87.Zuhra S, Khan NS, Islam S, Nawaz R. Complexiton solutions for complex KdV equation by optimal homotopy asymptotic method. Filomat. 2020;33:6195–6211. doi: 10.2298/FIL1919195Z. [DOI] [Google Scholar]

- 88.Khan, N.S., Ali, L, Ali, R., Kumam, P. & Thounthong, P. A novel algorithm for the computation of systems containing different types of integral and integro-differential equations. Heat Transf. 50(4), 3065–3078 (2020).

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Availability exists for the data upon request.