Highlights

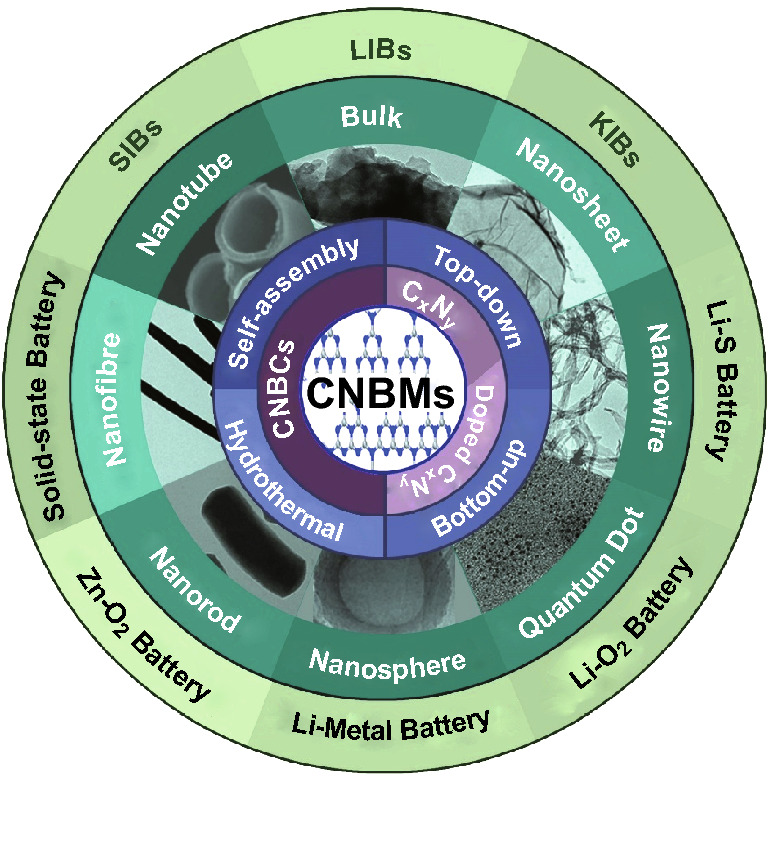

Comprehensive summary of crystalline structures and morphologies of carbon nitride-based materials (CNBMs).

Density functional theory computation for the design of functional CNBMs for rechargeable battery applications.

The experimental synthesis strategies of CNBMs for rechargeable battery application.

Keywords: Carbon nitrides, Metal-ion batteries, Density functional theory, g-C3N4, Anode

Abstract

Carbon nitrides (including CN, C2N, C3N, C3N4, C4N, and C5N) are a unique family of nitrogen-rich carbon materials with multiple beneficial properties in crystalline structures, morphologies, and electronic configurations. In this review, we provide a comprehensive review on these materials properties, theoretical advantages, the synthesis and modification strategies of different carbon nitride-based materials (CNBMs) and their application in existing and emerging rechargeable battery systems, such as lithium-ion batteries, sodium and potassium-ion batteries, lithium sulfur batteries, lithium oxygen batteries, lithium metal batteries, zinc-ion batteries, and solid-state batteries. The central theme of this review is to apply the theoretical and computational design to guide the experimental synthesis of CNBMs for energy storage, i.e., facilitate the application of first-principle studies and density functional theory for electrode material design, synthesis, and characterization of different CNBMs for the aforementioned rechargeable batteries. At last, we conclude with the challenges, and prospects of CNBMs, and propose future perspectives and strategies for further advancement of CNBMs for rechargeable batteries.

Introduction

Rechargeable metal ion batteries (MIBs) are one of the most reliable portable energy storage devices today because of their high power density, exceptional energy capacity, high cycling stability, and low self-discharge [1, 2]. Lithium-ion batteries (LIBs) remain the most developed and commercially viable alternative among all rechargeable batteries, and graphite is widely accepted as a preferred negative electrode (anode) material for LIBs [3]. Graphite is affordable, and it does not suffer significant volumetric changes (compared to other metal-based electrodes); it operates at a very low voltage close to that of lithium metal (~ 0.1 V) and exhibits moderately stable cycle life with a theoretical capacity of 372 mAh g (LiC6). Despite these positive characteristics, the performance of graphite is still very limited, and one of the effective ways to modulate its properties and electrochemical performance is through nitrogen doping [4]. Precisely, the work of Liu et al. showed that the N-doping of graphene results in improved conductivity and charge transfer, which boosts its performance and cyclability [5].

Carbon nitrides are a family of nitrogen-rich graphite analogues which contain a high nitrogen content and porous defect sites for effective charge transfer in energy storage devices [6, 7]. However, carbon nitrides are limited by poor electrical conductivity, chemical inertness, and ineffective intercalation/deintercalation process [8]. Due to these issues, several research studies have focused on the design of unique carbon-nitride-based materials (CNBMs), including pure carbon nitrides, doped carbon nitrides (DCNs) as well as carbon-nitride-based composites (CNBCs) [9]. Most of these reports have focused on g-C3N4 because it is easy to synthesize, low cost, environmentally safe, and it has a theoretical capacity of 524 mAh g−1 (Li2C3N4). In contrast, though other carbon nitride structures (such as CN, C2N, C3N, C4N, and C5N) which have been studied through density functional theory (DFT) calculations exhibit exceptional structural and electronic properties which demonstrates their capabilities as promising MIB electrode materials, they have attracted less attention.

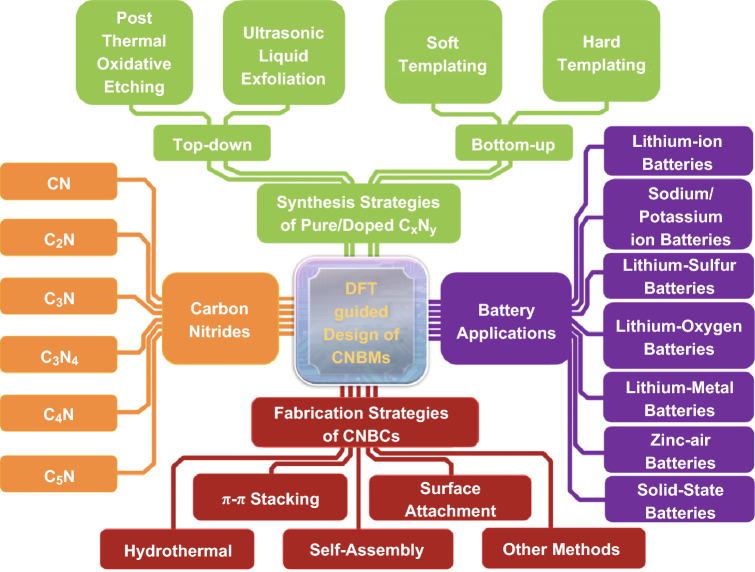

On the other hand, DFT has been adopted more and more in studying CNBMs and their electronic properties [10]. In fact, DFT could provide effective guidance for the synthesis of electrode materials and/or interpretation of the structure–performance relationship in energy storage devices, including LIBs, sodium- and potassium-ion batteries (SIBs and PIBs), lithium-sulfur batteries (Li–S), lithium-oxygen (Li-O2) batteries, lithium metal batteries (LMBs), zinc air batteries (ZABs), and solid-state batteries (SSBs). This review aims to comprehensively discuss the relationships between the structural and electronic properties and the MIB performance of pure carbon nitrides, doped carbon nitrides, and CNBCs, summaries the theoretical computation for the design of functional CNBMs for different rechargeable MIB applications, and generalizes the synthesis strategies of pure carbon nitrides and CNBCs for rechargeable metal ion battery application (Fig. 1). At the end of this work, we also offer a perspective on the existing challenges of carbon nitrides for energy storage devices and relevant resolving strategies.

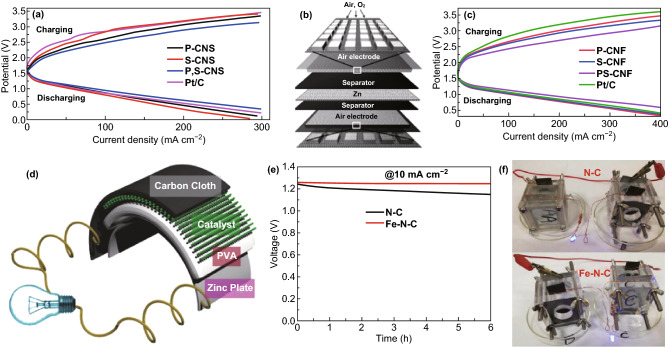

Fig. 1.

Overview of the main topics of this work, including DFT-guided design (symbolized by the “CPU” at the center), the molecular configuration of carbon nitrides (yellow block), the synthesis strategies of pure/doped carbon nitrides (green block), the fabrication strategies of CNBCs (red block) and the battery applications of CNBMs (purple block). (Color figure online)

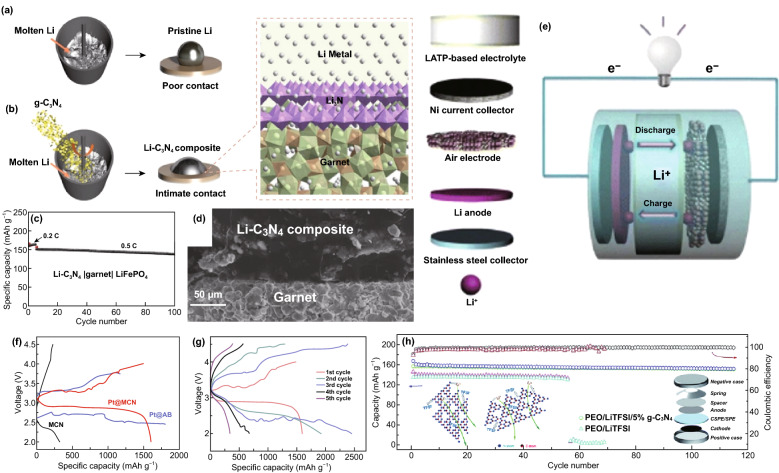

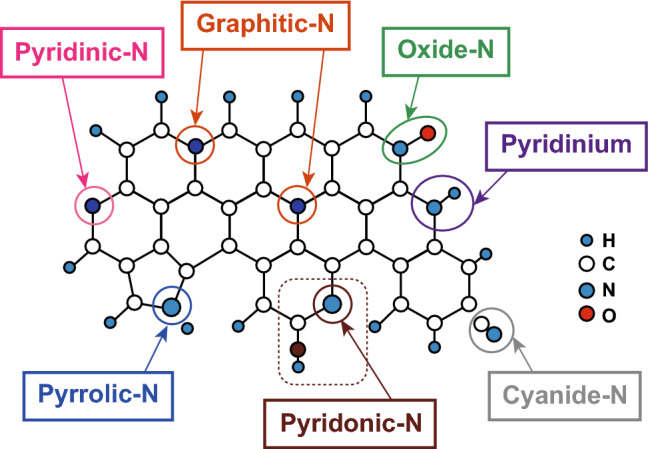

CNBMs

To study the carbon nitrides, we must begin by exploring their crystalline structure, structural and electronic properties, and functionality. Carbon nitrides are a family of nitrogen-rich carbon materials, and they have different crystalline structures and molecular configurations. Generally, there are seven types of nitrogen species (Fig. 2), with at least two most common species of nitrogen (the graphitic-N and pyridinic-N). The nature of the nitrogen and its percentage concentration has been proven to impact the electronic configuration and characteristic of the carbon nitride for different applications. The classification of carbon nitrides is often based on the carbon to nitrogen content (i.e., the C/N ratio) which is often associated with the degree of surface defects in their structure [11]. The carbon nitrides discussed in this review are categorized based on the dominant N species in their crystalline structure.

Fig. 2.

Common forms of nitrogen species in nitrogen-doped carbon materials. Reproduced with permission from Ref. [12]. Copyright permissions from Wiley–VCH. (Color figure online)

Pure Carbon Nitrides

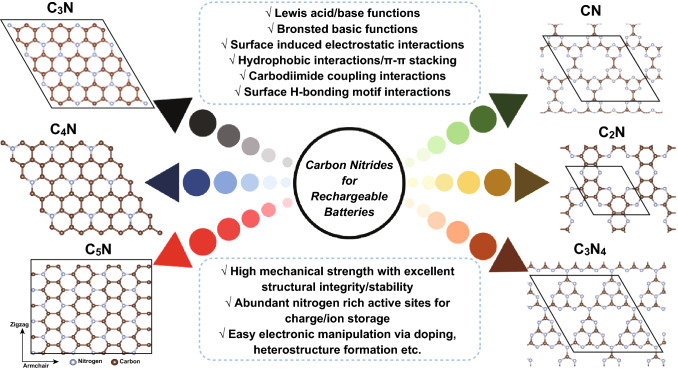

Based on their generic family molecular formula of CxNy, the carbon nitride family includes CN (C2N2, C3N3, C4N4), C2N, C3N, C3N2, C3N4, C3N5, C3N6, C3N7, C4N, C4N3, C5N, C6N6, C6N8, C9N4, C9N7, C10N3, C10N9, and C14N12 [11, 13]. All these carbon nitride materials possess some similarity with graphene in that they are all two-dimensional (2D) materials with sp2/sp3 hybridized conjugated C atoms [14], but they all exhibit different structural frameworks and C/N ratio. In this section of the review, we summarize the crystalline structure, surface functionalities, and electronic properties of different carbon nitrides, including pyridinic nitrogen-based carbon nitrides (CN, C2N, and C3N4) and graphitic nitrogen-based carbon nitrides (C3N, C4N, and C5N) (Fig. 3).

Fig. 3.

Geometric structures of the pyridinic and graphitic-N-based carbon nitrides reported for rechargeable batteries and their surface functionalities. The brown spheres represent carbon atoms, and the light blue one represents nitrogen atoms in the 2D carbon nitrides structures. (Color figure online)

Pyridinic Nitrogen-Based Carbon Nitrides (CN, C2N, C3N4)

Pyridinic-N is one of the edge site nitrogen species in an N-doped carbon material or carbon nitride. It is bonded to two carbon atoms and supplies one p electron to the π–π conjugated system of carbon [12]. Due to the co-ordination of pyridinic-N to 2 carbon atoms, it donates 4 electrons to the sp2 of each carbon atom along with a lone pair. Because of its superior electronegativity, it is able to pull π-electrons from the conjugated system of carbon, thereby making it negatively charged N-atom. When the π-conjugated system of carbon is broken (the aromaticity), a non-bonding pz orbital is formed, and this orbital can also be observed around defected carbon materials. Carbon materials that contain pyridinic-N can function as Lewis base because the pyridinic-N exhibits a negative charge on surrounding carbon atom, which makes them positively charged with a lone pair of electrons as a result of the non-bonding pz orbital [12]. The pyridinic-N-based carbon nitrides in this category include CN, C2N, and C3N4.

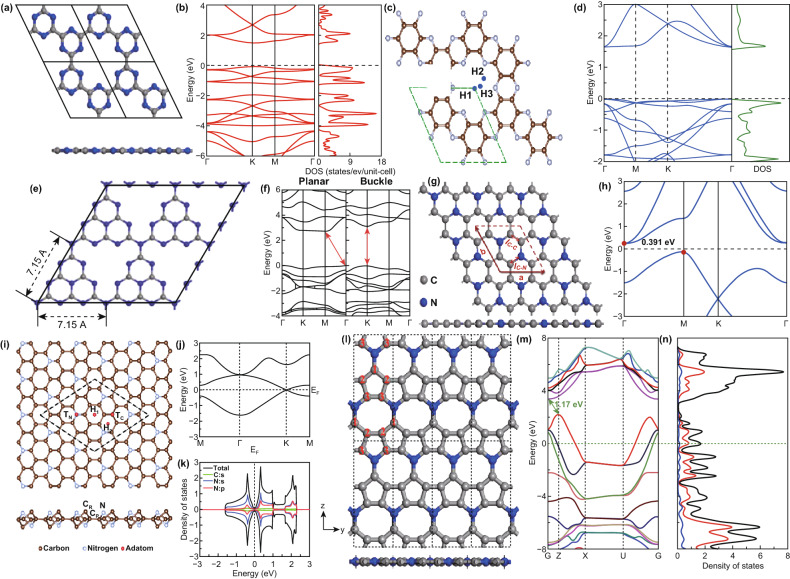

CN

CN exists in different compositions such as C2N2, C3N3, and C4N4, and the structure of these carbon nitride materials possesses round and uniform pores, six pyridinic nitrogens in each unit cell and a bandgap of ~ 1.5–1.6 eV (Fig. 4a, b) [15]. Most of the carbon nitrides contain both graphitic and pyridinic nitrogen except for CN. Due to its rich pyridinic nitrogen structure and absence of graphitic nitrogen, CN exhibits high structural stability, better conductivity and does not experience loss of crystallinity when it interacts with alkali metal ions like Li+.

Fig. 4.

a Top view and side view of the supercell (2 × 2) g-C3N3. b Band structure and total density of state for 1 × 1 g-C3N3. Reproduced with permission from Ref. [15]. c Relaxed structure of 2 × 2 C2N monolayer, H1, H2, and H3 are possible binding sites for transition metal atom doping on the C2N. d Band structure and density of states of C2N monolayer. Reproduced with permission from Ref. [28]. e Schematic structure of monolayer g-C3N4. Reproduced with permission from Ref. [18]. f Calculated band structures of monolayer g-C3N4 with planar or buckled topology. Reproduced with permission from Ref. [20]. g Optimized structure and h band structure of C3N monolayer. The unit cell is shown by the red dashed line. Reproduced with permission from Ref. [29]. i Top and side view of the atomic structure of monolayer C4N. The black dashed lines show the 3 × 3 × 1 supercell of monolayer C4N. Four adsorption sites were considered (H1, H2, TC, TN). j Electronic band structures and k PDOS of the unit cell of a pristine C4N monolayer. Reproduced with permission from Ref. [30]. l Top (upper) and side (lower) view of the atomic structure of C5N monolayer. The gray and blue balls represent C atoms and N atoms, respectively. m Band structure and n density of states (DOS) of C5N monolayer obtained from HSE06 calculations. The black, red, and blue lines denote the total DOS of C5N, the partial DOS of C atoms, and the partial DOS of N atoms, respectively. Reproduced with permission from Ref. [27]. Copyright permissions from Elsevier, Royal Society of Chemistry and Wiley–VCH. (Color figure online)

C2N

The structure of C2N exhibits sp2 hybridization, and it is filled with uniformly sized holes and one large hole at the center, which is due to the six-member nitrogen-containing ring (Fig. 4c). Like the structure of graphene, it possesses several benzene rings that are bridged by pyrazine rings, which have two nitrogen atoms opposite to each other [16]. Also, unlike graphene, which has a fully conjugated π–electron structure, the presence of nitrogen in the structure of C2N makes the π–electronic structure of its benzene rings isolated. Therefore, it has a flat band and exists as a semiconductor with a bandgap of 1.96 eV (Fig. 4d). Due to its wider structure and the abundance of several benzene and pyrazine rings, it is expected that it will possess several active sites for alkali metal ion storage. Moreover, the defect sites and higher nitrogen population of C2N suggest that it will exhibit superior conductivity to boron nitride (BN) [17].

C3N4

C3N4 carbon nitride is the most reported member of the carbon nitride family. It is composed of consistently repeated tri-s-triazine units having planar sp2-hybridized conjugation structures held together by van de Waals forces. It often occurs as bulk C3N4, which has a relatively low indirect bandgap of ~ 2.7 eV and an interplanar distance of 0.324 nm and can be functionalized to obtain other architectures such as the monolayer 2D sheet (Fig. 4e) [18]. This indirect bandgap of C3N4 highly has spurred massive interest in its application for several applications such as photocatalysis, oxygen evolution, reduction reactions, sensing devices, etc. However, the semiconductor property of bulk C3N4 limits the electronic conductivity for application in electronic devices [19]. Under buckling, the indirect bandgap of bulk C3N4 can be tuned into a direct bandgap material with superior electronic conductivity (Fig. 4f) [20]. This ability to easily modify the electronic and structural properties of C3N4 makes it one of the most preferred and widely applied carbon nitride structures [21].

Graphitic Nitrogen-Based Carbon Nitrides (C3N, C4N, and C5N)

Graphitic nitrogen is one of the most widely known forms of nitrogen. It has a nitrogen bonded to three carbon atoms, and it is the nitrogen-doped into the basal graphitic carbon plane of the material. Due to its superior negativity in comparison with carbon, it is possible for graphitic nitrogen to induce a positive charge on adjacent carbon, thereby making it readily active site for attraction to negatively charged species [22]. This makes it a commonly desired form of nitrogen doping, just like pyridinic nitrogen. The graphitic-N-based carbon nitrides, which we shall discuss in this review, include C3N, C4N, and C5N.

C3N

The structure of C3N contains well-defined homogenous rings with no large holes. It is a 2D honeycomb lattice configuration that displays a D6h-symmetry that facilitates high structural stability and superior thermal conductivity (Fig. 4g). It is a semiconductor which displays a unique molecular orbital with a low unoccupied molecular orbital gap (~ 2.7 eV) and an indirect bandgap of 0.39 eV (Fig. 4h) [23].

C4N

Compared to the atomic structure of another carbon nitride, the C4N structure is filled with sp3 hybridized species and due to the presence of 4 pz atomic orbitals in the projected electron density of states (PDOS), it exhibits a Dirac cone shape in its band structure like that of graphene (Fig. 4i, j). It is often called the dumbbell (DB) C4N and depending on the positions of the raised C/N atoms in its structure, two structural configurations exist, namely the DB C4N-I and the DB C4N-II. The former refers to a C4N monolayer structure in which the raised C/N atoms are located on the same side, while the latter is a C4N monolayer structure where C/N atoms are on opposite sides [24, 25]. These two configurations of C4N are semiconductors in nature and display a narrow and zero bandgap (Fig. 4k); however, this property can be tuned easily [24, 26].

C5N

C5N is the most recently reported graphitic-N-based carbon nitrides; like C4N, the atomic structure of C5N is filled with sp3 hybridized carbon atoms; however, it contains two cyclic rings of different sizes (Fig. 4l). A 5-membered carbon ring and an eight-membered carbon ring with two nitrogen atoms are opposite to each other, and these rings are side-by-side to each other (see the atomic structure of C5N in Fig. 4k). The C5N structure has some interesting features such as high chemical, mechanical and thermodynamic stability. Also, analysis of the band structure shows that the Fermi level is located below the valence-band maximum, which suggests it will be metallic and display superior conductivity than other carbon nitrides (Fig. 4m, n) [27].

Doped Carbon Nitrides

It has been proven that the metal ion storage capacity of an electrode material such as carbon nitride is significantly dependent on the electronic property. Most carbon nitrides are semiconductors, the electronic density of states (DOS) of the majority of the carbon nitrides possess a lone pair orbital of nitrogen at their Fermi level, and this leads to a large effective mass for hole/electron and results in poor electronic conductivity [19]. Therefore, doping is important for carbon nitride structures. Heteroatoms of elements at the top end of the periodic table such as sulfur, nitrogen, boron, and phosphorus, display narrow bandgap and lower high occupied molecular orbital, which signifies superior electronic conductivity. Therefore, replacing some of the carbon atoms in the crystalline structure of carbon nitrides with metallic or non-metallic atoms can boost their electronic conductivity and electron mobility. Doping also creates surface defects on the carbon nitride structure, and this is beneficial for effective charge transport.

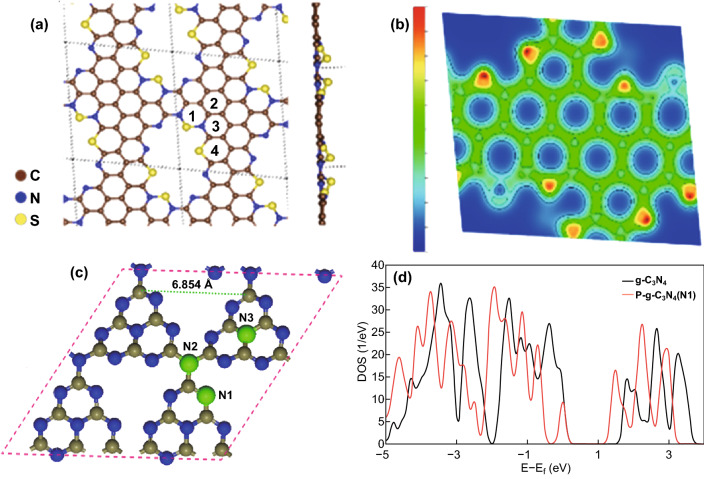

Three heteroatoms are commonly used to dope carbon nitrides. These are carbon, nitrogen, sulfur, and phosphorus. C doping in carbon nitrides can facilitate the formation of delocalized π-bonds, which can result in n − π* electronic transition due to interaction with inherent nitrogen, and this will boost the electronic conductivity and charge transfer. N and S doping have proven to enlarge the interlayer distance of carbon nitrides; this facilitates the adsorption of metal ions and improves the conductivity. Cha et al. reported S-doped mesoporous CN carbon nitride (Fig. 5a shows the optimized structure), and from the electron density profile presented in Fig. 5b, it is obvious that effective charge distribution can be achieved at S-doped sites [31]. Boron (B) and phosphorus (P) doping can decrease the indirect bandgap of semiconductor carbon nitrides and make them metallic. Molaei et al. studied the effect of doping C3N4 with phosphorus by replacing some of the N atoms with P atoms (Fig. 5c), and the DOS result shown in Fig. 5d confirms a shift of the Fermi level toward the conduction band. This suggests a narrowed band gap and enhanced electronic conductivity compared to pure C3N4 [32]. In summary, heteroatom doping of carbon nitrides is beneficial for boosting their electrical conductivity, improving charge transfer, enlarging their interlayer distance, and boosting metal ion storage.

Fig. 5.

a Optimized atomic structure of S-doped mesoporous CN (S-MCN). b Charge density profile of S-MCN, blue color—lowest electron density (0%), and red color—highest electron density (100%). Reproduced with permission from Ref. [31]. c Optimized structure g-C3N4 monolayer, showing possible P-doping sites. d DOS plots of P-doped g-C3N4 for P substitution at N1 and N2 sites. Reproduced with permission from Ref. [32]. Copyright permissions from American Chemical Society and Springer Nature. (Color figure online)

CNBCs

Although doping is an effective way of modulating the electronic conductivity of carbon nitrides, they are still limited by poor reversible capacity due to ineffective metal ion storage mechanisms and inadequate surface area. Most carbon nitrides are not able to achieve the desired performance in battery testing because the adsorption energy may be too strong for effective adsorption and desorption of metal ions or the diffusion barrier may be too high for easy metal ion transport. Also, apart from poor electronic conductivity, pure carbon nitrides are characterized by smaller surface area, which provides inadequate coverage for metal ion adsorption. CNBCs can solve these problems because combining pure carbon nitride with highly conductive materials like reduced graphene oxide (rGO) will produce a material with improved electronic conductivity and larger surface area. Moreover, the formation of CNBCs with high theoretical capacity metal oxides such as Fe2O3 will provide an anode material with an improved reversible capacity [33]. CNBCs can also be formed by combining pure carbon nitride with metal chalcogenides, perovskites, etc., for different metal-ion batteries. Hence, we summarize that an effective way to resolve the problems of poor reversible capacity and limited surface area is through CNBCs.

DFT-Guided Studies of CNBMs for Energy Storage Devices

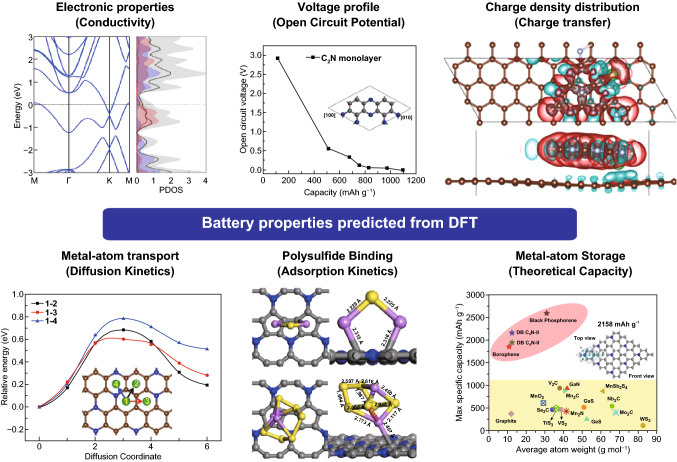

After the first discovery/synthesis of tri-s-triazine-based carbon nitride by Berzelius in 1834, the prediction and synthesis of beta-C3N4 in 1993, the discovery of other carbon nitride structures have largely depended on theoretical first-principle simulations. First-principle calculations allow researchers to calculate or predict the structures and properties of material before its synthesis. It can also be used to resolve the discrepancy between experimental measurements and theoretical calculations by considering various possible alkali-metal atom diffusion kinetics, including diffusions in the bulk structure, on the surface, in the defect rich sites, etc. [1, 34]. This prevents random experimental tests or synthesis, thereby facilitating materials discovery. Furthermore, modification strategies for improving the properties of prospective materials can be easily explored through first-principle calculations. DFT is one of the most common computational simulation methods. It is a very powerful tool used to predict different electrochemical parameters of electrode materials. DFT calculations can be used to determine the alkali-metal atom insertion voltage of electrode materials, calculate the migration energy barriers of the alkali-metal atom, and directly visualize the transport pathways and dynamics [35, 36]. In addition, the theoretical capacity of a potential electrode material can be predicted from DFT calculations by investigating the maximum metal atom loading on its structure. The adsorption energy of important molecules on the structure of electrode materials can also be calculated; for example, the adsorption of polysulfides on Li–S cathode materials. Crystal and surface defects are important properties of an electrode material because they impact the alkali-metal atom transport mechanism and pathways, and their effect can also be studied through first-principle calculations. Moreover, information on the intrinsic electronic conductivity and bandgap can be directly inferred from the calculated electronic density of states by observing the Fermi level, conduction, and valence bands. The important role of DFT calculations in CNBMs for energy storage devices includes the DFT-guided synthesis and the DFT-predicted electrochemical properties. In terms of DFT-guided synthesis, DFT studies can determine important synthesis parameters such as the formation energy, exfoliation energy, and cohesive energy of a CNBM. These are criteria that indicate the ease/feasibility of synthesizing a CNBM experimentally. DFT calculations can also provide an atomistic understanding of the interaction between the C/N and the adsorbed metal atom, which will reveal the structural limitations of the CNBMs and guide the synthesis of superior material. DFT studies also play a significant role in predicting fundamental electrochemical properties such as the bandgap, metal atom adsorption energy, open-circuit potential, charge transport kinetics, and theoretical capacity of the CNBMs. These parameters forecast the prospect of CNBMs for energy storage devices and reveal potential limitations that must be considered and improved upon. The electrochemical properties that can be predicted from DFT are summarized in Fig. 6.

Fig. 6.

Electrochemical properties of carbon nitrides can be predicted from DFT calculations. Reproduced with permission from [27, 37–40]. Copyright permissions from Elsevier, American Chemical Society, Wiley–VCH, and IOP Publishing. (Color figure online)

Theoretical Calculations on CNBMs for Energy Storage Devices

Density functional theory calculations are one of the most useful tools for discovery and electrochemical investigation of different carbon nitrides for rechargeable batteries [41]. In this section, we discuss different carbon nitrides that have been studied through DFT.

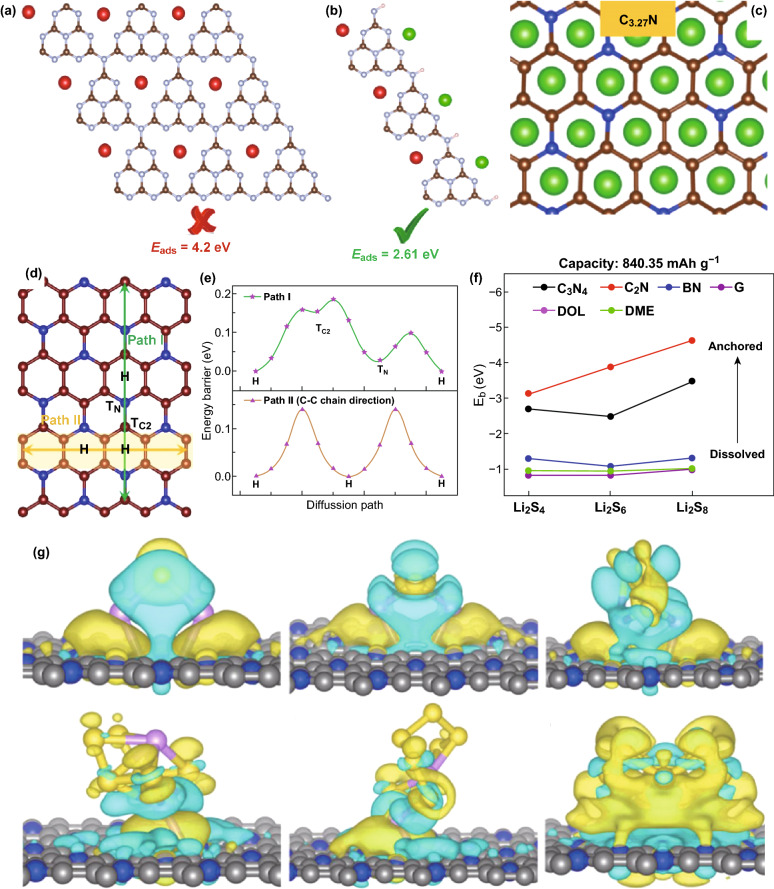

Pure Carbon Nitrides

Through DFT calculations, it was predicted that C3N4 carbon nitride could deliver a theoretical capacity of up to 524 mAh g−1 (Li2C3N4) [42], and this capacity has not been achieved in battery testing. Mao et al. [43], Veith et al. [44], and Hankel et al. [45] showed that this poor performance was due to the high content of graphitic nitrogen in its structure which resulted in ineffective intercalation. We reported the first C3N4 with reduced graphitic-N and increased pyridinic-N for LIBs, and our DFT calculations showed that unlike bulk/sheet C3N4 which adsorbs Li atom in the triangular pore at high energy of ~ 4 eV, a 1D-C3N4 fiber possesses lower Li binding energy (2.61 eV) at its edges. Hence, it can effectively adsorb/desorb Li atoms (Fig. 7a, b) [46]. Hui Pan reported a first-principle study on C3N4 carbon nitride nanotubes for LIBs and predicted that it could store Li atoms internally and externally due to its porous structure, which might make it better than other dimensions of carbon nitride [47].

Fig. 7.

Reversible Li active sites in a 2D-C3N4 sheet, and b 1D-C3N4 fiber. Green means reversible Li atoms and red means non-reversible Li atoms. c Top and side view of stable intercalation structures of n Li ions into C3N. Reproduced with permission from Ref. [40]. d Diffusion paths and e corresponding energy barriers of Li migration in C3N-S2. Reproduced with permission from Ref. [51]. f Binding energy of Li2S4/Li2S6/Li2S8 interacting with G, BN, C2N, C3N4 and DOL/DME solvent, respectively. Reproduced with permission from Ref. [17]. g Isosurfaces of charge density difference of Li2S, Li2S2, Li2S4, Li2S6, Li2S8, and S8 adsorbed on the surface of C5N with the isovalue of 0.003 A−3. Blue wireframes denote loss of electrons and yellow wireframes denote gain of electrons. Reproduced with permission from Ref. [27]. Copyright permissions from American Chemical Society, Elsevier and Wiley–VCH. (Color figure online)

Other carbon nitride structures have also been studied for LIBs through DFT. For example, Hankel et al. showed that although g-CN can deliver a high capacity of 454 mAh g−1. Its high Li binding energy of > 3 eV leads to ineffective intercalation/deintercalation and limits its prospects for LIBs [48]. The study of Hussain et al. on C2N-h2D showed that despite the pyridinic nitrogen, which facilitates Li storage, the high initial Li adsorption energy would result in poor battery performance [16]. By using a “pair of particle (metals) model,” Wu et al. [49] carried out a DFT study on C2N for LIBs and SIBs to show that C2N monolayer can achieve a capacity of 2939 and 2469 mAh g−1 for LIBs and SIBs with low diffusion barrier and an OCV of 0.45 V [16]. Liu et al. carried out a DFT study on different C3N compositions (C3N, C2.67N, and C3.33N) and showed that the drop in capacity experience by Xu et al. [50] was due to ineffective intercalation of Li. They concluded that C3.33N is the preferred C3N composition, and it delivered a reversible capacity of 840.35 mAh g−1 (Fig. 7c), operated at a low open-circuit potential of 0.12 V, and displayed superior electronic conductivity [40]. Guo et al. proposed other C3N allotropes (C3N-S1, C3N-S2, and C3N-S3) with unique electronic properties, and the C3N-S2 structure displayed the most feasible Li diffusion pathway with lower diffusion barrier (0.14 eV) for LIBs (Fig. 7d, e) [51]. Yang et al. also reported the first-principle study of two structural configurations of DB C4N as LIBs anode for LIBs, and they predicted that DB C4N-I and DB C4N-II could deliver high theoretical capacities of 1942 mAh g−1 (DB C4N-I) and 2158 mAh g−1 (DB C4N-II) [52].

DFT studies of pure carbon nitrides for large-sized metal ion batteries have also been reported. For instance, Weng et al. showed that pure C3N4 nanosheet displays high adsorption energy for Na-atom, but it shows an exceedingly high diffusion barrier, which makes it fail as a SIBs anode [53]. Moreover, through DFT we showed that thanks to the high pyridinic-N of 1D-C3N4 fiber it exhibits a high affinity for potassium ions, but it suffers from a rather high K-diffusion barrier which limits effective ion transport [54]. Bhuriyal et al. also reported the first-principle study of C3N monolayer as a promising anode material for SIBs and PIBs, and they showed that multilayer adsorption of the metal atoms generated a high capacity of 1072 mAh g−1 and low diffusion barrier of 0.03 and 0.07 eV for Na and K-ion [55]. Xu et al. showed that metal ion (Li, Na, and K) adsorption on C4N is an effective way to open the zero bandgap and modulate the electronic property because the adsorbed metal ion transfers charges to the surface of DB C4N [30].

Thanks to the nitrogen-rich structure, carbon nitrides have also been studied for Li–S and other battery systems. Li et al. reported that due to the accumulation of charges at the N–N bond of the C4N4 structure, it demonstrates superior lithium polysulfide species (LIPSs) anchorage than commercial electrolyte solvent molecules (DOL and DME) [56]. Zheng and co-workers compared the LIPSs anchoring property of graphene, boron nitride (BN), C2N, and C3N4 with commercial solvents and showed that C2N and C3N4 were the most effective due to their stronger binding energy (Fig. 7f) surface interaction with LiPSs via the Li-N/C-S bonds formed during their interaction [17]. Liang et al. also showed that interaction between LIPSs and polymeric C3N4 (p-C3N4) exhibits strong ionic bonding, electrostatic, and vdW interactions which are beneficial for altering the bonding and spatial configuration of LIPSs which then modifies their redox kinetics [57]. Meng et al. also reported that the abundant nitrogen species on the surface of C3N4 nanosheet is able to facilitate LiPSs anchoring by a surface chemical adsorption mechanism due to the formation of a Li-N bond [58]. Wang et al. reported a first-principle study on the application of C5N as a LIPSs host. The isosurfaces of charge density difference presented in Fig. 7g showed that it exhibits an effective physical/chemical adsorption property, which enables LIPSs anchoring and charge transfer to its surface [27]. Carbon nitrides have also been explored for metal-air batteries because of their unique properties. For example, Shinde et al. reported the prospect of C2N for zinc-air (Zn-Air) batteries and showed that the open holey structure of C2N enabled reversible oxygen reactions and improved the electronic conductivity [59]. Je et al. also carried out first-principle calculations on heptazine and triazine sourced C3N4 for non-aqueous Li-O2 battery, and the results showed that triazine was better because it delivered a higher overpotential. Interaction of C3N4 with LiO2 resulted in the formation of a Li-N bonding, which is dependent on the ratio of N in the material and greatly influences their overpotential [60].

Doped Carbon Nitrides

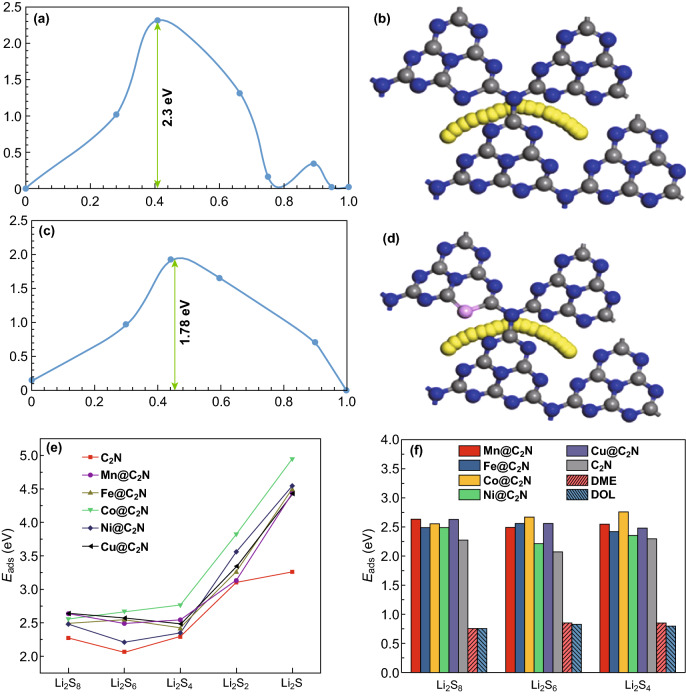

Theoretical study on doped carbon nitrides of different atomic compositions has been reported. For example, Nong et al. considered the effect of non-metal doping (boron, oxygen, and sulfur) and the impact of strain on the Li storage capacity and Li absorptivity of C3N. They reported that oxygen-doped C3N (ON–C3N) was the preferred dopant, it operated at 0.02 V and delivered a higher theoretical capacity of 534.42 mAh g−1 although it exhibited a high Li diffusion barrier of 0.78 eV, and this could be lowered by applying strain to the C3N structure [61]. Tian et al. also studied the effect of boron doping on the performance of C3N for alkali metal ion battery (Li, Na, and K) and showed that B4-doped C3N displays superior capacity, cycle, and thermal stability than pristine C3N [29]. Cha et al. showed that CN possesses a high Na adsorption energy, which can foster attraction of Na atoms into its structure for SIBs batteries [31]. Although Weng et al. [62] proved that C3N4 displays a very high Na-adsorption energy which limits its application for SIBs, the report of Molaei et al. on P-doped C3N4 showed that phosphorus doping is an effective way to decrease the high Na adsorption energy and diffusion barrier in C3N4 (Fig. 8a-d). The more P-atoms introduced into the structure of C3N4, the lower these energies [32]. Moreover, the work of Cha et al. [31] on Si-doped CN suggests that S-doping of carbon nitrides can successfully enlarge their interlayer distance for such large-sized metal-ion battery applications.

Fig. 8.

a Energy barrier for Na diffusion through g-C3N4, b corresponding Na diffusion path. c Energy barriers for Na diffusion through P-g-C3N4, d corresponding Na diffusion path. Reproduced with permission from Ref. [32]. e Adsorption energies of LiPSs on transition metal embedded C2N monolayers. f Adsorption energies of long-chain LiPSs with transition metal embedded C2N, 1,2-dimethoxyethane (DME) and 1,3-dioxolane (DOL). Reproduced with permission from Ref. [28]. Copyright permissions from Springer Nature and Elsevier. (Color figure online)

Doped carbon nitrides have also been studied for Li–S battery, Lin et al. studied the effect of transition metal doping (Mn, Fe, Co, Ni, and Cu) in C2N for improved immobilization of polysulfides in Li–S batteries, their results showed that a Lewis acid–base interaction which boosted LiPSs anchoring was established, and a significant charge was transferred from the transition metal dopant to the C2N monolayer with Co@C2N transferring the most in line with its superior adsorption energy (Fig. 8e, f) [28]. Zhao and co-workers reported confined single-atom Pt in holey g-C3N4, and DFT calculations showed that incorporation of single-atom Pt in holey g-C3N4 leads to improved electrical conductivity and a more stable structure with efficient electron and ionic transfer [63].

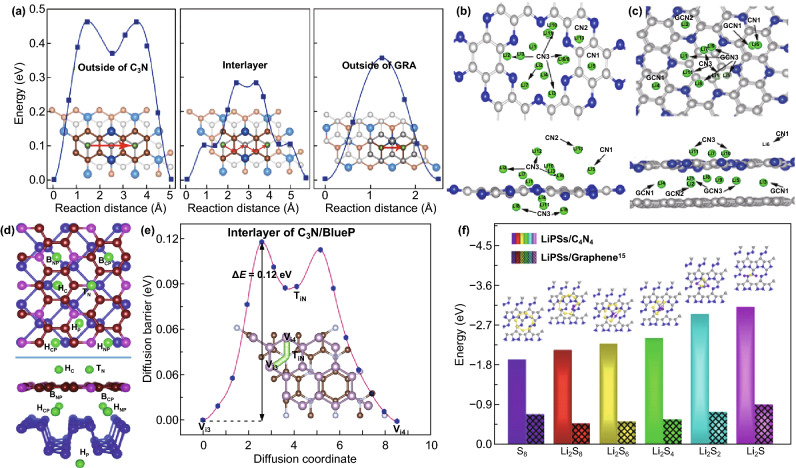

CNBCs

CNBCs with superior electronic conductivity and higher capacity have also been studied through DFT. For example, Wang et al. reported a DFT study of C3N/graphene heterostructure for LIBs and proved that the electrical conductivity and structural stability can be significantly improved. The heterostructure recorded a high theoretical capacity of 1079 mAh g−1, a low Li diffusion barrier of 0.28 eV at the interlayer (Fig. 9a), and operated at a low open-circuit voltage of 0.13 V [37]. Ding et al. reported the first-principle study of C2N/graphene bilayer for LIBs, and by using molecular dynamic (MD) simulations, they predicted that Li storage follows a two-step process, i.e., migration through the z-direction via the large hole in the center of the C2N structure and on to the surface of the C2N membrane. The structures of different compositions of the bilayer heterostructures are presented in Fig. 9b, c. [38]. Guo et al. [64] and Lin et al. [65] also reported a DFT study on C3N/phosphorene heterostructure for LIBs, while Bao et al. explored its potential for Li/Na battery. The three reports concluded that the design of such C3N/phosphorene heterostructure would not only address the issues of phosphorene but also alleviate the problems of C3N for Li/Na storage. Storage of Li-ions occurred at the outer surface and interlayer of the heterostructure (Fig. 9d, e) [66].

Fig. 9.

a Energy profiles for Li atom diffusion on C3N/GRA, along with the corresponding pathways denoted as red arrows. Carbon atoms from graphene—gray balls, carbon atoms from C3N—orange balls, nitrogen atoms—blue and lithium atoms—green. Reproduced with permission from Ref. [37]. b Top and side views of Li13–C2N structure; c top and side views of the Li11–C2N/graphene bilayer. Different adsorption sites are indicated as CN1, CN2, CN3, GCN1, GCN2, and GCN3 for both structures. Reproduced with permission from Ref. [38]. d Top and side views of the Li adsorption site on the C3N/P heterostructure (Li/C3N/P, C3N/Li/P, and C3N/P/Li). HC and TN sites are on the outer surface of C3N, and HP site is on the outer surface of phosphorene, HCP, HNP, BCP, and BNP sites are in the interlayer of the C3N/P heterostructure. Reproduced with permission from Ref. [64]. e Lithium migration pathway and corresponding energy profile through Path II of the interlayer of C3N/Blue P heterostructure. Reproduced with permission from Ref. [65]. f Adsorption energy for S8 cluster and LiPSs on C4N4 monolayer (bars without patterns) and graphene (bars with patterns), respectively. The insets on the pillars show S8 or Li2Sn/C4N4 structures generated by the principle of minimum energy. Reproduced with permission from Ref. [56]. Copyright permissions from Elsevier, American Chemical Society and Royal Society of Chemistry. (Color figure online)

DFT reports on CNBCs for Li–S batteries have also been widely reported. For instance, Liao and co-workers showed that the anchoring ability of C3N4 could be exploited in CNBCs [67]. Fan et al. also reported a carbon black blended g-C3N4 (g-C-coated) for Li–S battery and showed that two bonds (C-S and N-Li) are formed as a result of its interaction with LIPSs. These bonds inhibit the migration of LiPSs because it effectively binds to the LiPSs [68]. The work of Li et al. on porous C4N4 monolayer and C4N4/graphene composite for Li–S battery reported that LIPSs adsorption occurred by a chemisorption process and addition of graphene enhanced this process (Fig. 9f) [56]. Chen et al. studied the effect of transition metal (Fe, Ni, Cu, and Co)-doped g-C3N4/C composite for Li–S battery and showed that this would increase the electron mobility, while g-C3N4 will prevent polysulfide dissolution by anchoring LiPSs species [69]. In summary, DFT has been very key in the synthesis and electrochemical study of carbon nitrides for metal-ion batteries. Table 1 compares the DFT predicted parameters of carbon nitrides with commercial graphite anode for energy storage devices. From this table, it is obvious that most of the carbon nitrides can function as anode materials with superior theoretical capacity compared to graphite. These electrochemical properties have inspired researchers into the synthesis and fabrication of pure and doped carbon nitrides as well as CNBCs for energy storage devices.

Table 1.

Comparison of the DFT predicted parameters of pure carbon nitrides with commercial graphite for energy storage devices

| Materials | Conductivity | Capacity (mAh g−1) | Adsorption energy (eV) | Diffusion barrier (eV) | Operating voltage (V) |

|---|---|---|---|---|---|

| Graphite | Metallic |

372 (LIBs) 31 (SIBs) [70] 279 (PIBs) [71] |

1.1–1.29 (LIBs) [72] − 0.67 (SIBs) [73] − 0.44 to 2.0 (PIBs) [74] |

0.22 (LIBs) [75] 0.09–0.35 (SIBs) [76] 0.039 (PIBs) [77] |

0–0.5 (LIBs) [78] 0.3 (SIBs) [79] ~ 0.24 (PIBs) [80] |

| CN | Semi-conductor | 454 (LIBs) [48] | – 5.03 (LIBs) [48] | ~ 3 (LIBs) [45] | ~ 0.6 (LIBs) [81] |

| C2N | Semi-conductor |

2939 (LIBs) [49] 2469 (SIBs) [49] |

– 3.437 (LIBs) [49] – 2.868 (SIBs) [49] |

0.409 (LIBs) [49] 0.116 (SIBs) [49] |

0.452 (LIBs) [49] 0.458 (SIBs) [49] |

| C3N | Semi-conductor |

837.06 (LIBs) [40] 1072 (SIBs) [55] 1072 (PIBs) [55] |

− 0.01 (LIBs) [40] − 1.806 (SIBs) [55] – 2.230 (PIBs) [55] |

0.8 (LIBs) [40] 0.03 (SIBs) [55] 0.07 (PIBs) [55] |

0.15 (LIBs) [40] 0.13 (SIBs) [55] 0.26 (PIBs) [55] |

| C3N4 | Semi-conductor | 524 (LIBs) [44] | – 4.56 (LIBs) [45] | ~1.8 (LIBs) [47] | 0.8 (LIBs) [44] |

| C4N | Semi-conductor |

I—1942 (LIBs) [52] II -2158 (LIBs) [52] |

I—1.3 (LIBs) II—0.93 (LIBs) [52] |

I—0.26 [52] II—0.21 [52] |

I—0.60 [52] II—0.68 [52] |

| C5N | Metallic | N/A | N/A | N/A | N/A |

Synthesis Strategies of Pure and Doped Carbon Nitrides

The conclusions obtained from DFT studies showed that the poor performance of most CNBMs can be traced to high metal atom adsorption energy due to excess graphitic-N, which leads to irreversible intercalation/deintercalation, poor conductivity, and low charge transfer mobility, as well as inferior structural stability after metal atom adsorption. DFT calculations showed that these problems could be overcome by regulating the ratio of C/N in the structure and prioritizing pyridinic-N, heteroatom doping, and CNBCs design with other superior electrode materials. Inspired by these DFT conclusions, several researchers have modified the general experimental synthesis strategies to obtain CNMBs that exhibit the desired structural/electronic properties. Such modified experimental synthesis strategies that are motivated by the findings in DFT studies can be considered DFT-guided synthetic protocols. In this section, we summarize some significant DFT-guided synthesis strategies for CNBMs, including pure/doped carbon nitrides as well as CNBCs.

Top-Down Strategy

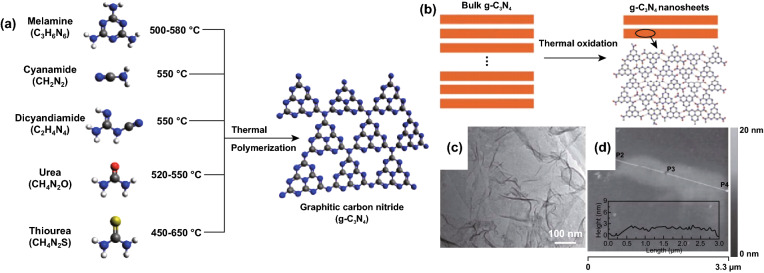

Carbon nitrides generally occur in the bulk state, and this form of carbon nitride is obtained via thermal decomposition of N-rich amine compounds such as melamine [82] (Fig. 10a). However, bulk carbon nitride suffers from the poor conductivity, limited surface area, and sluggish reaction kinetics [83, 84]. Bulk carbon nitride also contains excess graphitic-N which is proven to limit the performance of carbon nitrides in rechargeable batteries according to DFT conclusions. One way to regulate the C/N ratio and decrease the graphitic-N is by converting bulk carbon nitride to nanosheets and other morphologies. This can be achieved through the top-down strategy which is grouped into post-thermal oxidative etching and ultrasonic liquid exfoliation.

Fig. 10.

a Schematic illustration of one of the top-down synthesis approach (thermal polymerization) for g-C3N4 using different precursors. Black balls—carbon (C), blue balls—nitrogen (N), white balls—hydrogen (H), red balls—oxygen (O), and yellow balls—sulfur (S), respectively. Reproduced with permission from Ref. [84]. b Schematic of the synthesis of g-C3N4 nanosheets from bulk g-C3N4. In the atomic model, carbon atoms—gray balls, nitrogen atoms—blue balls and hydrogen atoms—red. c TEM image of g-C3N4 nanosheets. d Tapping-mode AFM image of a single g-C3N4 nanosheet deposited on the silicon wafer substrate. The inset is the height curve determined along the line between P1 and P4. Reproduced with permission from Ref. [88]. Copyright permissions from American Chemical Society and Wiley–VCH. (Color figure online)

Thermal Oxidation

As the name implies, this method involves the heat treatment of bulk carbon nitride at high temperature and it is an effective way to break the van der Waals forces which hold the layer of carbon nitride together. This process produces a sheet-like carbon nitride with large surface area, surface defects and adjusted layer thickness [22, 85]. As depicted in Fig. 10b, bulk g-C3N4 can be converted to g-C3N4 nanosheets via thermal oxidation and Fig. 10c, d shows that the layer thickness can also be regulated. Guo et al. reported the synthesis of graphite/sheet-like carbon nitride (CN) as well as nanotube, nanoribbon, and microsphere morphologies via thermal treatment [86, 87]. 2D-C3N carbon nitride with a needle-like morphology was also synthesized by via a direct solid-state reaction [23].

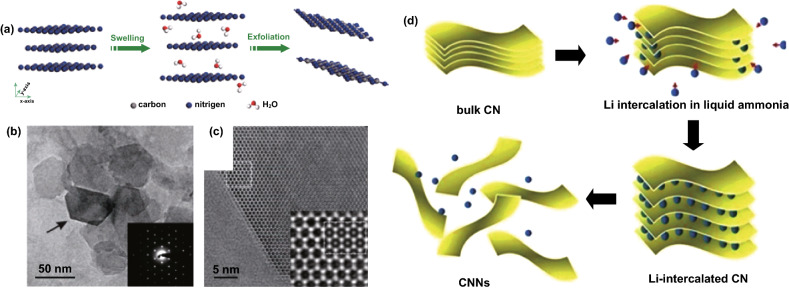

Ultrasonic Liquid Exfoliation

Another effective strategy to convert bulk multilayered carbon nitrides to few/single layer carbon nitrides is through the intercalation of solvent molecules through the bulk structure, thereby resulting in delamination (Fig. 11a). This liquid exfoliation process is effective for synthesizing nanosheets or flakes of carbon nitrides (Fig. 11b, c). Mahmood et al. reported the synthesis of two-dimensional C2N carbon nitride by a top-down (facile wet-chemical reaction) approach [89]. This process can also be achieved through lithiation exfoliation which uses Li ions as exfoliant to penetrate the layers of bulk carbon nitride and separate them to individual nanosheets (Fig. 11d).

Fig. 11.

a Schematic illustration of liquid-exfoliation process from bulk g-C3N4 to ultrathin nanosheets. Reproduced with permission from Ref. [90]. b TEM image of exfoliated ultrathin nanosheets, c higher magnification of a carbon nitride nanosheet edge viewed along [001]. Reproduced with permission from Ref. [91] d Schematic diagram of the lithiation and exfoliation of g-C3N4 nanosheets from bulk g-C3N4. Reproduced with permission from Ref. [92]. Copyright permissions from American Chemical Society. (Color figure online)

Bottom-Up Strategy

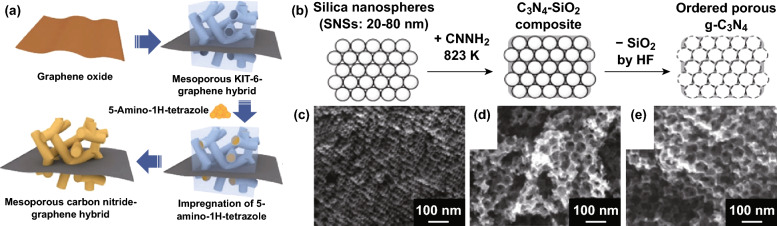

The bottom-up strategy or template-aided synthesis is divided into soft and hard templating method.

Hard Templating

Templates are often used as morphology directing agents during the synthesis of unique carbon nitride morphologies. Hard templates such as silica [93–95], anodic alumina oxide [96], and carbon [97] are often reported for synthesizing CNBMs. For instance, DFT studies showed that by increasing the N content in C3N4 to C3N5 the electrochemical properties can be improved. Recently, Kim et al. reported the synthesis of a graphene-like mesoporous carbon nitride C3N5 with superior electronic properties by using KIT-6 as a hard template [98]. Moreover, their DFT/electrochemical study showed that such composite can deliver excellent performance for energy storage devices [34]. The C3N5 sample showed outstanding interesting electrochemical properties, and it was combined with graphene oxide to form a composite (MCN-11). Figure 12a shows a scheme of the synthesis procedure of the C3N5 and the hybrid.

Fig. 12.

a Schematic representation of the synthesis protocol for synthesizing the mesoporous C3N5 and its graphene hybrid. Reproduced with permission from Ref. [98]. b Schematic illustration of the synthesis of ordered porous g-C3N4 by using close-packed silica nanospheres (SNSs) as the primary template. c–e FE-SEM images of porous g-C3N4 at different resolutions. Reproduced with permission from Ref. [93]. Copyright permissions from Wiley–VCH and Royal Society of Chemistry. (Color figure online)

Soft Templating

Templating materials which demonstrate self-assembling properties have also been employed for synthesizing carbon nitrides by using ionic liquids [99, 100], surfactants [101–103], and amphiphilic block polymers [102, 104]. Yong et al. reported the synthesis of a nanoporous carbon nitride by using ionic liquid as soft templates (Fig. 12b-e), and such carbon nitride structure demonstrated superior conductivity to bulk material [101]. In summary, by using the conclusions of DFT studies as a guide, the general experimental synthesis approach of carbon nitrides can be optimized to achieve carbon nitrides with regulated C/N ratio, increased pyridinic-N, superior structural stability, and conductivity for improved performance.

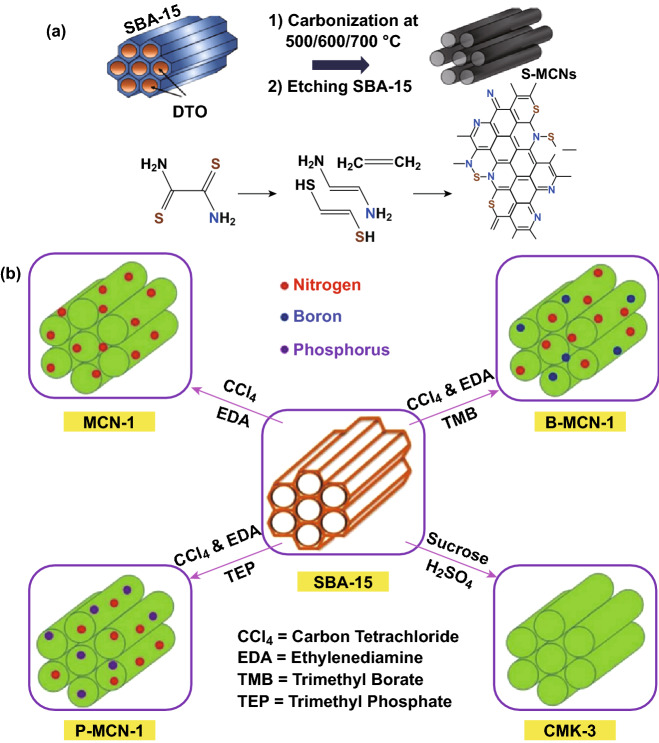

Fabrication Strategies of Doped Carbon Nitrides

The DFT study of Molaei et al. [32] proved that heteroatom doping of carbon nitride will boost the electronic conductivity and improve metal atom storage, and the DFT conclusion of this work motivated the Vinu group to report the synthesis of rod-like sulfur-doped mesoporous CN (S-CN) by a templating method (Fig. 13a) [31]. Phosphorus-doped mesoporous carbon nitride (P-MCN) was also synthesized via a simple template approach [105]. A schematic of the template synthesis method for heteroatom-doped mesoporous carbon nitrides is presented in Fig. 13b. To summarize, doped carbon nitrides can be synthesized through a combination of some top-down and bottom-up approaches which often involves the use of a salt of the heteroatom or a surfactant.

Fig. 13.

a Schematic of the synthesis procedure of S-MCN [31]. b Schematic of the template synthesis method for heteroatom-doped mesoporous carbon nitrides. Reproduced with permission from Ref. [105]. Copyright permission from American Chemical Society. (Color figure online)

Fabrication Strategies for CNBCs

DFT studies have proved that CNBCs design is another effective way to resolve the challenges of carbon nitrides because such CNBCs will demonstrate superior conductivity, better structural stability, and enhanced charge transfer. Therefore, in this section, we highlight some recent CNBCs that have been synthesized through commonly reported experimental synthesis strategies but inspired by the conclusions of DFT studies.

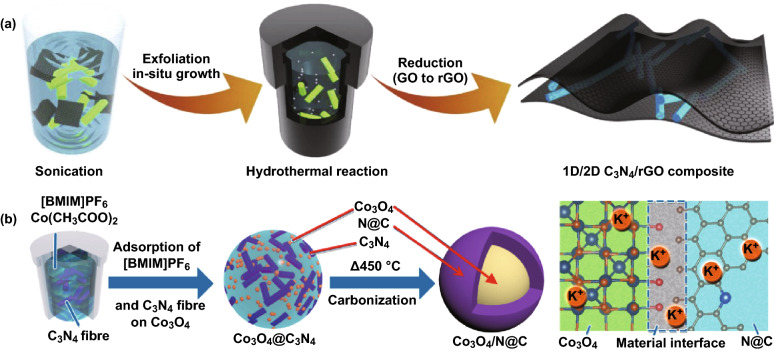

Hydrothermal Method

Hydrothermal method involves the controlled synthesis of a composite in a tightly sealed vessel under high temperature and pressure [106, 107]. Although 2D-C3N4 is widely reported for designing CNBCs, our DFT studies showed that 1D-C3N4 exhibits superior structural stability and metal storage capability than 2D-C3N4 [40]. Moreover, our comparative DFT study between 1D/2D C3N4/graphene and 1D/2D C3N4/graphene showed that 1D/2D will perform better [38]. These DFT conclusions motivated us to combine 1D-C3N4 with 2D-rGO for energy storage devices. Therefore, we reported the synthesis of a 1D/2D C3N4/rGO composite via a freeze-drying-assisted hydrothermal approach by deploying the π–π interaction between C3N4 and graphene [54]. Figure 14a shows the synthesis scheme of the composite. Guided by the result of our DFT calculations, we also reported the design of a composite of Co3O4@N–C derived from 1D-C3N4 via an ionic liquid-assisted solvothermal method [108]. Scheme illustration of the synthesis strategy is depicted in Fig. 14b.

Fig. 14.

a Schematic illustration of the synthesis of 1D/2D C3N4/rGO composite via a hydrothermal/freeze-drying method. Reproduced with permission from Ref. [54]. b Scheme illustrating suggested potassiation and depotassiation mechanism of the Co3O4@N–C electrode. Reproduced with permission from Ref. [108]. Copyright permission from Elsevier and American Chemical Society. (Color figure online)

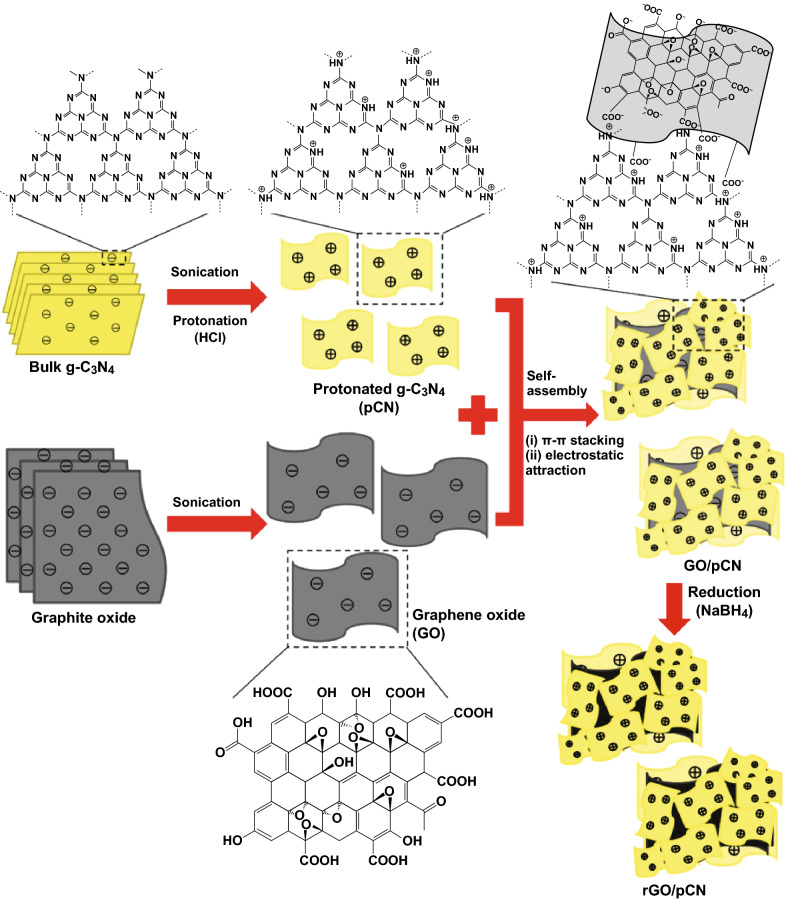

Self-Assembly Method

Due to their amphoteric nature, carbon nitrides possess tunable surface functional groups and surface charges which enable surface attachment with other functional materials such as graphene and other functional 2D materials [130]. Such structural interaction has been identified through the molecular dynamic simulation and DFT studies of Ding et al. and Wang et al. The heterostructure will display superior electronic conductivity and structural stability than the pure carbon nitride. This concept is employed in self-assembly synthesis of C3N4 and other CNBMs. Figure 15 shows a detailed schematic of the self-assembly approach for a surface modified C3N4 (pCN) with graphene oxide and reduced graphene oxide to achieve a GO/pCN and rGO/pCN composite, respectively [109].

Fig. 15.

Schematic diagram for the synthesis process of rGO/pCN samples via a combined ultrasonic dispersion and electrostatic self-assembly strategy followed by a NaBH4-reduction process. Reproduced with permission from Ref. [109]. Copyright permission from Elsevier. (Color figure online)

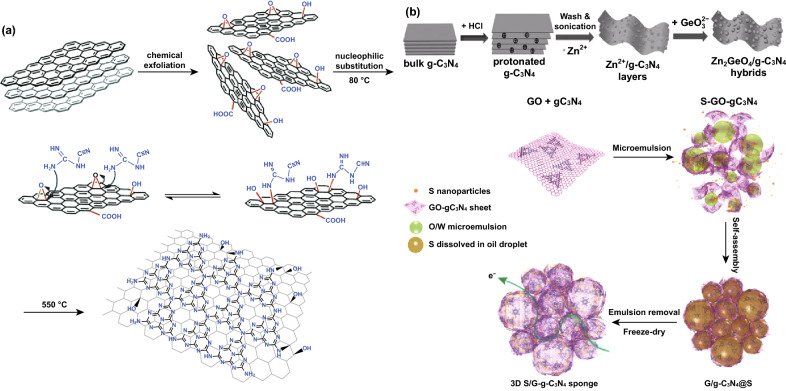

Other Composite Fabrication Strategies

CNBCs can also be designed by some other unique methods, and Fu et al. designed a 2D-2D g-C3N4-rGO hybrid via an in situ chemical method by initiating a nucleophilic reaction between epoxy groups on the surface of GO and amine/amide groups on dicyanamide-C2H4N4. The synthesis method is depicted in Fig. 16a, and through this approach, the problem of poor electrical conductivity, aggregation, and restacking was resolved [110]. Similarly, Li et al. reported the design of a Zn2GeO4/g-C3N4 composite by growing Zn2GeO4 NPs in-between the layers of g-C3N4 via a solution approach to inhibit agglomeration of Zn2GeO4 NPs and restacking of g-C3N4 (Fig. 16b). Zn2GeO4 also functioned as a spacer to enlarge the interlayer distance of g-C3N4 sheet enabling metal ion adsorption and improved conductivity [111]. Wang et al. reported the synthesis of a GO/g-C3N4 microsphere by an ethanol-assisted spray drying approach [112]. Zhang et al. also reported the design of a sponge-like free-standing 3D S/graphene@g-C3N4 hybrid using a microemulsion-assisted assembly method (Fig. 16c) [113].

Fig. 16.

a Illustration of the formation process of g-C3N4–rGO. Reproduced with permission from Ref. [110]. b Schematic of the synthesis process of the Zn2GeO4/g-C3N4 hybrids. Reproduced with permission from Ref. [111]. c Schematic illustration of the procedure for preparing S/GCN hybrid sponge. Reproduced with permission from Ref. [113]. Copyright permissions from Royal Society of Chemistry and Wiley–VCH. (Color figure online)

In summary, the advancement in experimental synthesis strategies of pure/doped carbon nitrides and CNBCs has been propelled by the conclusions of DFT studies on CNBMs. Precisely, DFT studies proposed that adjusting the C/N ratio, increasing the concentration of pyridinic-N, heteroatom doping and CNBCs design are effective ways to inhibit the problem of irreversible intercalation/deintercalation, poor conductivity, and instability experienced by pure layered CNBMs in rechargeable batteries. These conclusions from DFT studies have guided the experimental synthesis of CNBMs to fabricate functional CNBMs which exhibit the desired requirements and deliver superior battery performance.

Electrochemical Studies of CNBMs for Energy Storage Devices

The structural/electronic properties and surface functionalities of CNBMs qualify them as promising electrode materials for energy storage devices. In this section, we give an overview of experimental works on carbon nitrides for energy storage devices including LIBs, SIBs and PIBs, Li–S, LABs, LMBs, ZABs, and SSBs.

Lithium-Ion Batteries (LIBs)

LIBs offer benefits such as lightweight, superior energy density, and long cycle life [3, 114, 115]; CNBMs (pure/doped carbon nitrides and CNBCs) have been reported as electrodes.

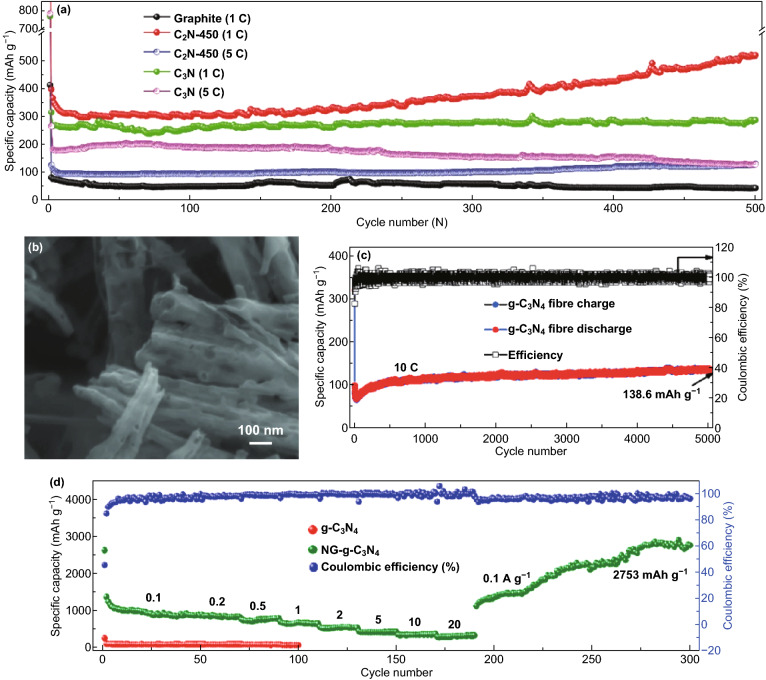

Pure Carbon Nitrides for LIBs

Due to the structural and electronic properties of carbon nitrides, different atomic composition of carbon nitrides has been studied for LIBs. Yin and co-workers reported C3N3 for LIBs but only a low reversible capacity of 197.8 mAh g−1 was obtained at 100 mA g−1 after 300 cycles and a ICE of 34.3% [81]. Xu et al. tested C2N (C2N-450) and C3N for LIBs and at 1C, C3N only retained 285.1 mAh g−1 after 500 cycles, while C2N‐450 maintained a reversible capacity of 516.1 mAh g−1 although it displayed large activation (Fig. 17a) [50]. Other carbon nitride compositions such as C4N and C5N have not been experimentally tested for any metal ion batteries.

Fig. 17.

a Long cycle life of C2N-450, C3N. Reproduced with permission from Ref. [50]. b SEM image of the 1D-g-C3N4 fiber. c Cycling performance of 1D-g-C3N4 fiber structure at a high current density of 10 C. Reproduced with permission from Ref. [46]. d Rate performance for ND-g-C3N4 electrode at current density of 0.1, 0.2, 0.5, 1, 2, 5, 10, and 20 A g−1 and galvanostatic discharge property for g-C3N4 electrode. Reproduced with permission from Ref. [8]. Copyright permissions from Wiley–VCH, and American Chemical Society. (Color figure online)

We reported the synthesis of a porous 1D-C3N4 fiber with large surface area and multiple active sites (see SEM image—Fig. 17b) for LIBs; a reversible capacity of 181.7 mAh g−1 was achieved at 0.5 C and 138.6 mAh g−1 at 10 C (Fig. 17c) [46]. Chen et al. also reported the application of C3N4 (ND-g-C3N4) for LIBs and obtained a capacity of 2753 mAh g−1 after 300 cycles) although significant activation occurred (Fig. 17d). To provide a brief summary, pure carbon nitrides of different crystalline structures have been reported for LIBs, and commendable performances have been recorded (Table 2). However, the issues of ineffective intercalation/deintercalation due to extremely high Li adsorption energy, high Li diffusion barrier, structural deformation, and loss of crystallinity has severely limited the exploitation of their full potential. Therefore, DCNs and CNBCs are necessary to achieve improved performance.

Table 2.

Pure and doped carbon nitrides for LIBs and SIBs

| Battery type | Materials | Synthesis | Morphology | Initial capacity (mAh g−1) | ICEa | Reversible capacity (mAh g−1) | References |

|---|---|---|---|---|---|---|---|

| LIBs | ND-g-C3N4 | Magnesiothermic denitriding method | Porous nanosheet | 2627 @ 100 mA/g | 45.7% | 2753 @ 300 cycles | [8] |

| CN-480–600 | Solid-state Wurtz reaction | Macroporous graphite-like | 575.7 @ 100 mA/g | 19.9% | 197.8 @ 300 cycles | [144] | |

| C2N-450 | Bottom-up wet-chemical reaction. | Stacked sheet | 1629.6 @ 0.1 C | 57.2% | 516.1 @ 500 cycles | [146] | |

| C3N | Bottom-up wet-chemical reaction. | Rod-like | 787.3 @ 0.1 C | 48.7% | 1C, 285.1 @ 500 cycles | [126] | |

| Li-C3N4 | Electrochemical and solid-state reactions | Sheet-like | 188 | – | 38 @ 6 cycles | [121] | |

| C6N8 (C3N4) | Thermal oxidation | – | 250 @ 30 mA/g | – | 50 @ 50 cycles | [122] | |

| 1D-C3N4 fiber | Polyaddition/polycondensation reaction | Porous layered fiber | 419.7 @ 0.5 C | 84.1% | 181.7 @ 200 cycles | [46] | |

| NGC | Carbonization | Graphene-like | 2749 @ 50 mA/g | 50.3% | 1143 @ 200 cycles | [145] | |

| P-MCN-1 | Template synthesis | Spherical particles | 2850 @ 1 A/g | 44.2% | 963 @ 1000 cycles | [105] | |

| SIBs | C6N8 (C3N4) | Thermal oxidation | – | 250 @ 30 mA/g | – | 10 @ 50 cycles | [122] |

| SIBs | S-MCN | Hard template approach | Rod-like morphology | ~850 @ 100 mA/g | 47% | 304.2 @ 100 cycles | [31] |

aICE Initial coulombic efficiency

CNBCs for LIBs

CNBCs can deliver superior structural/electronic properties, enhanced structural stability and extremely large surface area which will boost the overall LIBs performance. In this section, we highlight some significant CNBCs including binary CNBCs and ternary CNBCs.

Binary CNBCs for LIBs

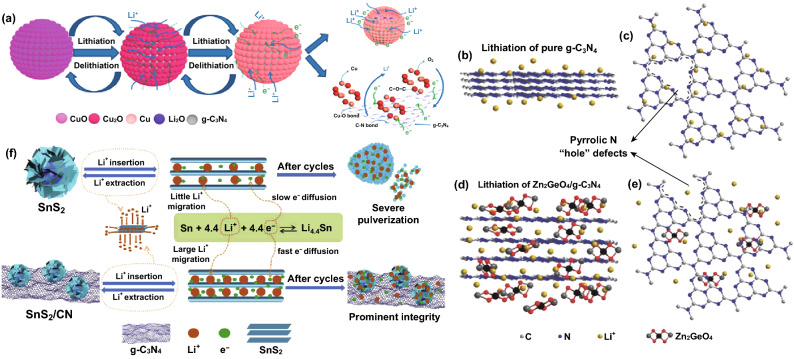

Binary CNBCs involving carbonaceous materials such as graphene oxide are commonly reported because of the inherent π–π stacking, extremely large surface area, surface functional groups, and electronic conductivity. For instance, Fu et al. [110] reported the application of a 2D-2D stacked g-C3N4-rGO hybrid for LIBs. The 2D-2D stacked g-C3N4-rGO hybrid achieved a reversible capacity of 1525 mAh g−1 at 100 mA g−1 and up to 943 mAh g−1 at 1000 mA g−1 [110]. Mohamed et al. designed a CuO/O-doped g-C3N4 composite which delivered a reversible capacity of 738 mAh g−1 after 100 cycles and 503 mAh g−1 after 500 cycles when tested at 100 and 1000 mA g−1, respectively. A depiction of the Li+ storage mechanism is shown in Fig. 18a [116]. Li et al. also reported the application of metal oxide-based composite—Zn2GeO4/g-C3N4 composite for LIBs. The lithium storage mechanism for g-C3N4 and the composite is depicted by the scheme provided in Fig. 18b-e. The composite exhibited a superior reversible capacity of 1370 mAh g−1 at 200 mA g−1 after 140 cycles [111]. Yin et al. designed a composite comprising of SnS2 anchored on g-C3N4 nanosheet, and the SnS2/CN composite followed the conversion and alloying/dealloying lithium storage mechanism (). Schematic of this storage mechanism is provided in Fig. 18f. A high reversible capacity of 444.7 mAh g−1 was delivered at 100 mA g−1 after 100 cycles with structural stability and no pulverization [117].

Fig. 18.

a Schematic description explaining the reaction mechanism of the CuO/O-doped g-C3N4 anode during the charge/discharge process. Reproduced with permission from Ref. [116]. Illustrations of pure (b, c) g-C3N4 and (d, e) Zn2GeO4/g-C3N4 hybrids for Li-insertion viewed from the (b, c) edge and (d, e) basal plan directions. Reproduced with permission from Ref. [111]. f Schematic illustration of the Li-ions diffusion and electronic transport in the SnS2 and SnS2/CN composite electrode during the charge/discharge processes. Reproduced with permission from Ref. [117]. Copyright permissions from Elsevier, Royal Society of Chemistry, American Chemical Society and Wiley–VCH. (Color figure online)

Ternary CNBCs for LIBs

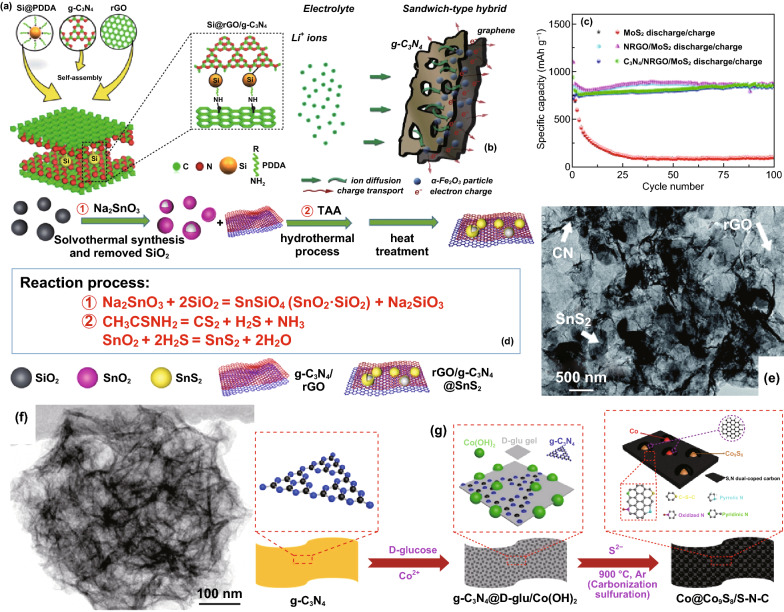

Ternary composites which can provide additional benefits than binary composites have also been reported. Wang et al. reported the application of a Si@rGO/g-C3N4 composite for LIBs. By taking advantage of the interfacial chemical bonding on functionalized rGO/g-C3N4, Si nanoparticles (NPS) were effectively anchored on 2D-composite of rGO/g-C3N4 (Fig. 19a), and such composite design resulted in a reversible capacity of 1354.8 and 799.6 mAh g−1 when cycled at 0.1 and 0.5 C, respectively [118]. Kong et al. also reported a red phosphorus/rGO-C3N4 composite which delivered a capacity of 1032.6 mA g−1 after 600 cycles when tested at 200 mA g−1 [119]. Shi et al. reported the synthesis of a Fe2O3/C3N4-graphene composite for LIBs. The Li storage mechanism of the Fe2O3/CN-G composite is depicted in Fig. 19b, a high reversible capacity of 980 mAh g−1 at 50 mA g−1 after 50 cycles along with a stable rate performance exceeding that of Fe2O3/G [120] (Table 3).

Fig. 19.

a Schematic reaction scheme of the Si@rGO/g-C3N4 hybrid and illustration of Si NPs anchored on rGO/g-C3N4 via strong covalent and hydrogen bonding formed during the pyrolysis process. Reproduced with permission from Ref. [118]. b Schematic diagram of ionic diffusion and charge transport in the porous Fe2O3/CN–G anode with a 2D sandwich-like nanosheet architecture. Reproduced with permission from Ref. [124]. c Cycle performance over the voltage range of 0.01–3.0 V vs. Li/Li+ at the same current density of 100 mA/g for MoS2, NRGO/MoS2, and C3N4/NRGO/MoS2. Reproduced with permission from Ref. [121]. d Schematic synthesis process of rGO/g-C3N4@SnS2. Reproduced with permission from Ref. [123]. e TEM micrograph of porous ternary composite architectures of reduced graphene oxide, SnS2, and CN (GSC6). Reproduced with permission from Ref. [122]. Copyright permissions from Royal Society of Chemistry, Elsevier, and Springer Nature. (Color figure online)

Table 3.

CNBCs for metal-ion batteries LIBs, SIBs and PIBs

| Battery type | Materials | Synthesis | Morphology | Initial capacity (mAh g−1) | ICEa | Reversible capacity (mAh g−1) | References |

|---|---|---|---|---|---|---|---|

| LIBs | huCP/g-C3N4 | Hydrothermal treatment | Carbon fibers with large pores and hollow structure | 1199 @ 1 A/g | ~ 93% | 1030 @ 1000 cycles | [147] |

| g-C3N4–rGO | In-situ chemical synthetic approach | 2D sheets | 3002 @ 100 mA/g | 57% | 1525 @ 50 cycles | [108] | |

| CN-rGO | Hydrothermal synthesis | 3D Sandwich architecture | 1632 @ 50 mA/g | 41.3% | 970 @ 300 cycles | [130] | |

| g-C3N4@rGO | Hydrothermal reaction | Spongy, porous, and tangled ultrathin sheets | 2731 @ 0.1 C | ~89% | 901 @ 50 cycles | [131] | |

| SN/CN | Hydrothermal | Cauliflower-like morphology | 733 @ 0.1 C | 55.4% | ~420 @ 60 cycles | [132] | |

| SnO2@C3N4 | Scalable solid-state reaction | Porous and wrinkled material | 1200 @ 0.1 C | ~50% | 550 @ 100 cycles | [149] | |

| TiO2@CNS (TCNS) | Self-assembly approach/hydrothermal | Spherical Core–shell particles | 359 @ 0.1 C | ~90% | 303 @ 125 cycles | [100] | |

| Zn2GeO4/g-C3N4 | Facile solution approach | ultrathin nanosheet. | 1068 @ 200 mA/g | 58.6% | 1370 @ 140 cycles | [109] | |

| LIBs | NiCo2O4/g-C3N4 | Facile ultrasonic treatment | Nanosheet structure | 1367 @ 100 mA/g | 84.5% | 1252 @ 100 cycles | [150] |

| Li4Ti5O12/g-C3N4 | Solvothermal method | Nanoparticles | 173.7 @ 0.5 C | – | 150.8 @ 502 cycles | [133] | |

| Nitrogen-doped LTO/C (NCLTO) | Thermal decomposition | Irregular sized nanoparticles | 189 @ 1 C | ~92% | 122 @ 500 cycles | [109] | |

| CuO/O-doped g-C3N4 | Hydrothermal | Nanospheres | 980 @ 100 mA/g | 94.7% | 738 @ 100 cycles | [101] | |

| 3D N-rich C3N4@MoS2 | Hydrothermal | Nanosphere | 2390 @ 0.1 C | ~74% | 857 @ 50 cycles | [154] | |

| MoS3/g-C3N4–H+/GO | Sonication/thermal treatment | 2D sheet-like structure | 1728 @ 0.1 mA/g | – | 1450 @ 200 cycles | [103] | |

| MoS2/g-C3N4 | Thermal treatment (calcination) | Spherical particles | 2467 @ 0.05 C | ~41% | 1204 @ 200 cycles | [175] | |

| WS2/g-C3N4 | Solid-state reaction | Nano-sized petal-like sheets | 1933.6 @ 100 mA/g | 63.6% | 622.7 @ 400 cycles | [156] | |

| SnS2/CN | Microwave hydrothermal method | Nanoflower | 1465.9 @ 100 mA/g | 47% | 383.8 | [153] | |

| Co1−xS@g-C3N4 | Solvothermal method | Spherical-like | ~1250 @ 0.1 A/g | ~55% | 789.59 @ 210 cycles | [155] | |

| C3N5/MoS2 | Soft- and hard templating methods | Highly ordered mesoporous nanosheet | 271 @ 100 mA/g | 60% | 193 @ 100 cycles | [112] | |

| SIBs | huCP/g-C3N4 | Hydrothermal treatment | Carbon fibers with large pores and hollow structure | 222 @ 0.1 A/g | – | 345 @ 380 cycles | [147] |

| N-doped MoC | Pyrolysis | Hollow microspheres | 1040 @0.16 A/g | – | 410@ 200 cycles | [172] | |

| Amorphous carbon nitride (ACN) | Copolymerization/direct carbonization | Uniform rhombic dodecahedral shape | 640 @ 83 mA/g | 67.2% | 175 @ 2000 cycles | [173] | |

| N-FLG-800 | Pyrolysis | 2D lamellar structure of with plenty of wrinkles | 256.7 @ 0.5 A/g | 83.5% | 211.3 @ 2000 cycles | [175] | |

| C/g-C3N4 | One-pot calcination | 2D-sheet-like structure | ~200 @ 0.4 A/g | 99 % | ~ 160 @ 400 cycles | [128] | |

| g-C3N4 film | Chemical vapor deposition (CVD) | 2D thin film | – | 98 % | ~6 Ah/g @ 500 cycles | [174] | |

| CN/MoS2-600 | Nanotemplating approach | Corrugated cardboard-like morphology | – | 70% | 605 | [98] | |

| C3N5/MoS2 | Combined soft- and hard templating methods | Ordered mesoporous nanosheet | 126 @ 100 mA/g | 46% | 54 @ 100 cycles | [112] | |

| PIBs | 1D/2D C3N4/rGO | Hydrothermal/freeze drying method | 1D-C3N4 rod infused in-between the 2D-sheet | 682.7 @ 0.5 A/g | 56.8% | 557.4 @ 50 cycles | [54] |

| PIBs | Co3O4@N–C | Ionic liquid-assisted solvothermal method | Spherical | 1229.2 @ 50 mA/g | 48.2% | 448.7 @ 40 cycles | [176] |

| LIBs | Si@rGO/g-C3N4 | Template-free self-assembly and pyrolysis process | Multilayered 3D framework | 1354.8 @ 0.5 C | 70.9% | 799.6 @ 1000 cycles | [159] |

| P/rGO-C3N4 | Ball milling | Nubby structure (40–200 nm) | 2423.4 @ 200 mA/g | 99% | 1032.6 @ 600 cycles | [160] | |

| rGO/g-C3N4/SnS2 (GSC6) | Hydrothermal route | 3D porous structure | 1073.1 @ 100 mA/g | 61.1% | 1118.6 @ 100 cycles | [122] | |

| rGO/g-C3N4@SnS2 | Solvothermal synthesis | Nano-spheres anchored on hybrid sheet | ~600 @ 800 mA/g | —— | 864.9 @ 1000 cycles | [164] | |

| MnO/C3N4/C | Sonication/calcination | 3D Porous sphere | 918.9 @ 0.5 C | 66% | 781.9 @ 86 cycles | [165] | |

| SnO2-TiO2-C3N4 | Self-assembly deposition | Microspherical shaped NPs | 853 @ 0.1 C | —— | 114.1 @ 20 cycles | [188] | |

| Co@Co9S8/S–N-C | Hydrothermal reaction and pyrolysis method | Porous structure with smooth-faced surfaces | 1033.25 @ 0.2 A/g | 60% | 652.1 @ 610 cycles | [166] |

aICE Initial coulombic efficiency

Ternary CNBCs involving metal chalcogenides such as MoS2 and SnS2 have also been studied. Hou et al. reported a C3N4/NRGO/MoS2 composite which exhibited a reversible capacity of 855 mAh g−1 after 100 cycles when tested at 100 mA g−1 (Fig. 19c) [121]. Shah et al. reported the design of a SnS2, rGO and g-C3N4 composite with intimate 2D-2D contact for LIBs. A stepwise detail of the synthesis method and the reaction processes involved is depicted in Fig. 19d. A reversible capacity of 1248.4 mAh g−1 was retained after 276 cycles at 100 mAg−1 [122]. Shi et al. also prepared a rGO/g-C3N4@SnS2 composite with effective surface contact of all constituents which can be seen from the TEM image (Fig. 19e). After 1000 cycles at 800 mA g−1, a reversible capacity of 864.9 mAh g−1 was retained [123].

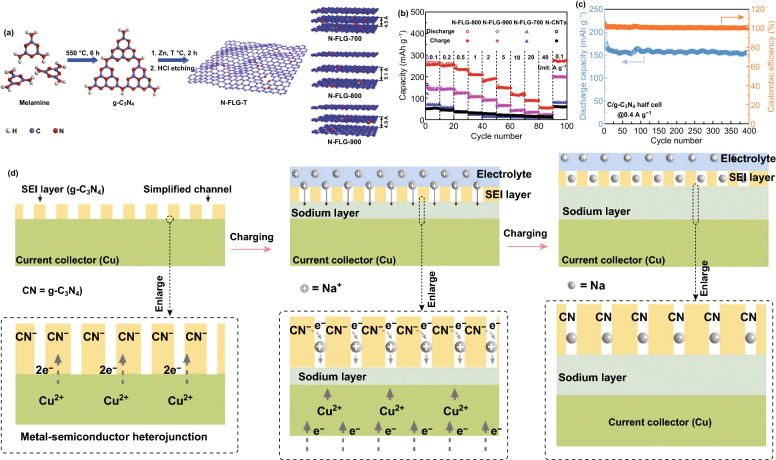

Sodium and Potassium-Ion Batteries (SIBs and PIBs)

Due to their large-sized ions, one of the major focus for sodium and potassium ion battery electrode materials is the enlargement of their interlayer distance. The low interlayer/d-spacing of graphite (0.334 nm) and its low theoretical capacity (279 mAh g−1) has limited its application in either of these two battery systems [125–127]. g-C3N4 can be a source of N-doped carbon with large interlayer distance; this approach was reported by Qiao et al. who successfully fabricated a series of N-doped graphene 2D-sheet with different interlayer distances (Fig. 20c). The optimized N-doped graphene sheet (N-FLG-800) delivered a superior rate capability of 56.6 mAh g−1 at a current density of 40 A g−1 (Fig. 20e) and outstanding long-cycle stability of 211.3 mAh g−1 after 2000 cycles at 0.5 A g−1 [128]. Weng et al. reported the synthesis of a C/g-C3N4 composite via a simple one-pot synthesis approach, and the composite delivered a capacity of 254 mAh g−1 at 0.1 A g−1 and 160 mAh g−1 at 0.4 A g−1 (see Fig. 20g) [53]. Recently, Chen et al. showed that coating the surface of copper metal current collector with a thin film of 2D-C3N4 can improve Na storage by inhibiting unwanted surface interaction with the liquid electrolyte. The Na+ storage mechanism is illustrated by the scheme in Fig. 20h. At an areal current density of 0.013 mA cm−2, a high areal capacity of 0.036 mAh cm−2 was achieved [129].

Fig. 20.

a Schematic illustration of the synthetic routes for the fabrication of N-FLG-T. b Rate capability of N–CNTs and N-FLG-T at various current densities. Reproduced with permission from Ref. [128]. c Cycling performance of C/g-C3N4 Na half cells at 0.4 A g−1. Reproduced with permission from Ref. [53]. d Illustration of the mechanism of the sodium storage in g-C3N4 film activated Cu foil. Reproduced with permission from Ref. [129]. Copyright permission from Wiley–VCH. (Color figure online)

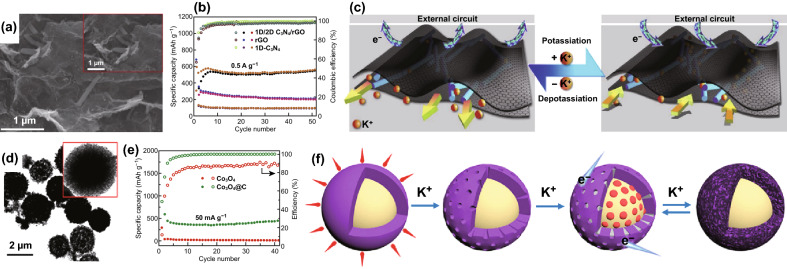

In the case of potassium-ion batteries (PIBs), we showed that the high K+ affinity of 1D-C3N4 fiber facilitates high initial PIBs capacity, but it suffers from poor cycle life and DFT study showed that this was due to the high potassium diffusion barrier and poor conductivity. Guided by this theoretical discovery, we combined 1D-C3N4 fiber with rGO and fabricated a 1D/2D C3N4/rGO composite (Fig. 21a—SEM) which exhibited a larger surface area, superior K+ diffusivity, and improved conductivity. The composite delivered a superior reversible capacity 557.4 mAh g−1 after 50 cycles with impressive cycle stability (Fig. 21b). The K-ion storage mechanism is depicted in Fig. 21c and shows the bi-directional transport of ions through the interlayer of the composite [54]. In our recent work, we resolved the inadequate interlayer spacing of Co3O4 by coating it with N-doped carbon sourced from 1D-C3N4 fiber. The Co3O4@N–C possessed a core–shell morphology (Fig. 21d) in which N–C at the surface of Co3O4 ensured effective transfer of attracted K+ to the Co3O4 core. The composite delivered a superior reversible capacity of 448.7 mAh g−1 unlike pure Co3O4 spheres which only recorded ~ 10 mAh g−1 after 40 cycles (Fig. 21e). The potassium storage mechanism of the composite is depicted in Fig. 21f.

Fig. 21.

a SEM image of 1D/2D C3N4/rGO. b Cycling performances and coulombic efficiency of 1D-C3N4, rGO and 1D/2D C3N4/rGO at of 0.5 A g−1. c Possible mechanism of potassium storage in the 1D/2D C3N4/rGO composite. Reproduced with permission from Ref. [54]. d TEM and e comparison of the cycle life of Co3O4 and Co3O4@N–C at 50 mA g−1. f Scheme illustrating suggested potassiation and depotassiation mechanism of the Co3O4@N-C electrode. Reproduced with permission from Ref. [108]. Copyright permissions from Elsevier and American Chemical Society. (Color figure online)

Lithium-Sulfur Batteries

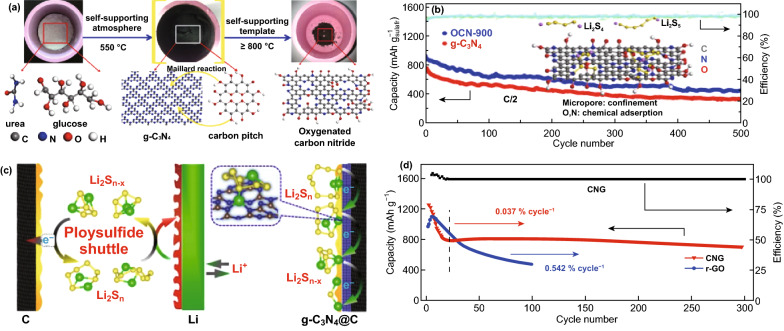

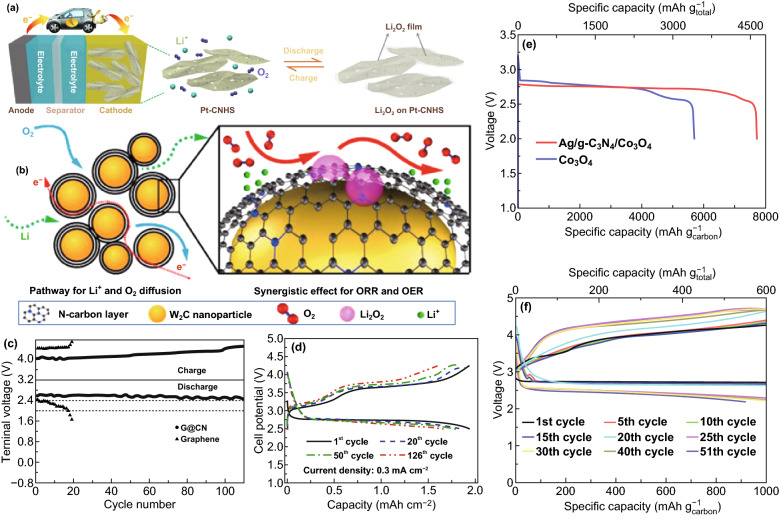

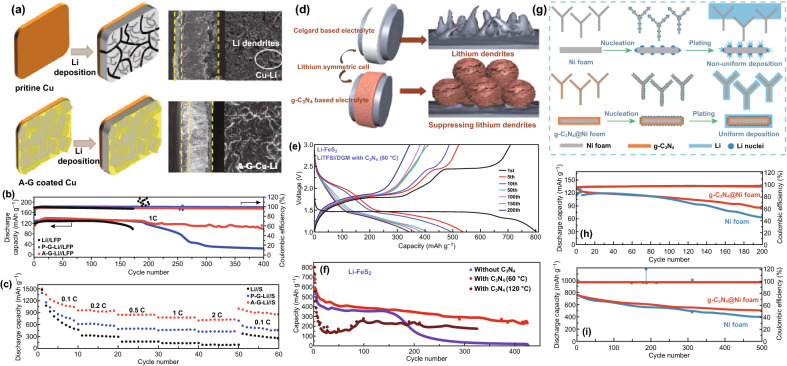

Carbon nitrides have proven to be effective at anchoring LiPSs in Li–S batteries, thereby inhibiting their dissolution in the electrolyte and boosting overall battery performance [134, 135]. Experimental battery studies on CNBMs as sulfur hosts for Li–S battery have confirmed the DFT predictions discussed earlier. For example, Liu et al. reported the application of a 2D graphene-like oxygenated C3N4 via a scalable one-step self-supporting solid-state pyrolysis process (Fig. 22a). The oxygen-rich functional groups possess strong chemical adsorption toward sulfur atoms; hence, they can inhibit the dissolution of polysulfides in Li–S electrolyte. As a cathode material, the resultant electrode delivered an initial columbic efficiency of 98% (S utilization of 84%) with a reversible capacity of 1407.6 mAh g−1 at C/20 (Fig. 22b) thanks to the surface functional groups [136].

Fig. 22.

a Schematic illustration of graphene-like oxygenated carbon nitride (OCN) prepared by one-step self-supporting solid-state pyrolysis. b Cycling performances of the OCN sample prepared at different conditions and g-C3N4 at C/2 after initial activation process to allow complete access of the electrolyte to the active material. Inset: OCN with adsorbed LiPSs molecules. Reproduced with permission from Ref. [136]. c Schematic of the mechanism for polysulfide adsorption by the g-C3N4@CFM cathode. Reproduced with permission from Ref. [67]. d Cycling performance of LiPSs on CNG and r-GO. Reproduced with permission from Ref. [57]. Copyright permissions from American Chemical Society and Wiley–VCH. (Color figure online)

Carbon coating for anchoring soluble polysulfides is an effective strategy to improve the conductivity of electrode materials in Li–S batteries [135]. Based on the conclusion of DFT calculations, Liao and co-workers showed that coating g-C3N4 on carbon-fiber mesh can serve as an effective anchoring strategy for LiPSs, and the g-C3N4@CFM electrode delivered 905 mAh g−1 at 0.1 C. Figure 22c shows the polysulfide adsorption mechanism of the composite electrode [67]. Liang et al. deployed polymeric C3N4 (p-C3N4) as a suitable cathode material to effectively attract LiPSs in common electrolyte solvents (1,3-dioxolane (DOL) and 1,2-dimethoxyethane (DME)). DFT calculations proved that interaction between p-C3N4 and LiPSs can alter the bonding and spatial configuration of the lithium polysulfides, which in turn tunes their redox kinetics. The results of Li–S battery testing in Fig. 22d showed that the electrode consisting of p-C3N4 and rGO (CNG) performed better than its individual constituents, improved stabilization, and kinetics of LiPSs and restrained shuttling effect [57].

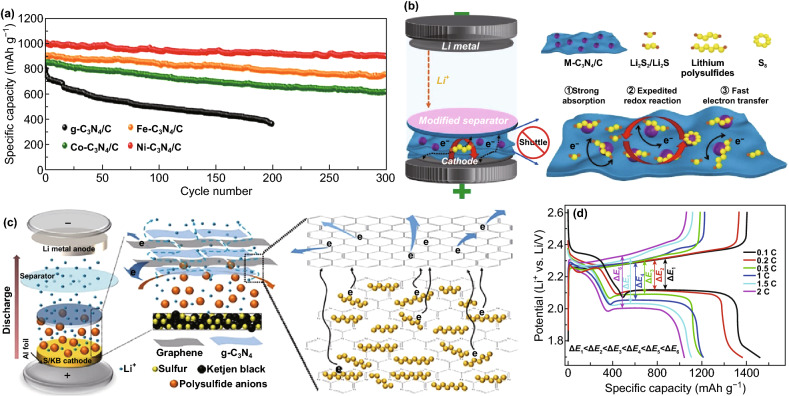

Coating of the commercial polypropylene separator with g-C3N4 is another strategy to facilitate LiPSs adsorption and effectively suppress polysulfide dissolution [134, 135]. Fan et al. reported the blending of commercial separator with carbon black (g-C-coated) and coating it on commercial glass fiber separator for LIPSs adsorption. The g-C3N4-coated separator showed better capacity retention in that after 400 cycles at 0.2 C, it could still deliver 773.2 mAh g−1, while the carbon-coated separator only had 611 mAh g−1 [68]. Chen et al. showed that coating of a transition metal (Fe, Ni, Cu, and Co) coordinated g-C3N4/C commercial separator improved LiPSs adsorption and performance. Experimental Li–S battery testing and DFT calculations concluded that Ni-modified C3N4 facilitated the LiPSs adsorption the best; hence, it outperformed the other metal modified C3N4/C-coated separators in terms of battery performance (Fig. 23a). A schematic of the polysulfide adsorption mechanism of the metal modified electrode is depicted in Fig. 23b. In terms of CNBCs, Qu et al. reported the use of graphene as a conductive material combined with C3N4 to form a g-C3N4/GS interlayer for a sulfur filled kejten black cathode for Li–S battery. Due to the electrostatic forces present as a result of π–π bonding between both materials, graphene and g-C3N4 heterogeneously intercalated with each in a closely packed fashion to form a laminated channel which inhibited diffusion of LiPSs toward the anode (Fig. 23c). The cathode material delivered a high reversible capacity (> 1200 mAh g−1) when cycled at 1 C and retained up to 50% of its capacity after 100 cycles. Moreover, from Fig. 23d a stable and consistent charge/discharge profile was maintained even when the electrode was cycled at various current densities [137]. To summarize the discussion on Li–S, CNBMs have been used for several functions in Li–S batteries and they have shown great promise as advanced electrode materials (Table 4). However, the percentage of S loading needs to be increased from an average of 50% to an average of ~ 80% for all CNBCs reports. Also, the binding mechanism and chemical interactions between the CNBMs and the binder need to be further investigated.

Fig. 23.

a Cycling performance of the heteroatom-doped-C3N4/C-modified separators at 0.5 A g−1. b Schematic illustration of the M-C3N4/C-modified separator to suppress the shuttle of polysulfides and expedite conversion reaction kinetics of polysulfides. Reproduced with permission from Ref. [69]. c Schematic of cell configuration with a laminated structure g-C3N4/GS cathode interlayer. d Charge/discharge profiles for the S/KB@C3N4/GS cathode at various scan rates. Reproduced with permission from Ref. [137]. Copyright permissions from Elsevier and Wiley–VCH. (Color figure online)

Table 4.

CNBMs (pure, doped, and CNBCs) for different functions in Li–S batteries

| Battery function | Materials | Synthesis | Morphology | Initial capacity (mAh g−1) | Sulfur loading | Reversible capacity (mAh g−1) | References |

|---|---|---|---|---|---|---|---|

| Cathode | OCN | One-step self-supporting solid-state pyrolysis (OSSP) | Free-standing 2D sheets | 1407.6 @ C/20 | 56 wt% | 447.3 @ 500 cycles | [177] |

| GCN | Chemical deposition method | Sheet-like morphology | 1250.1 @ C/0.05 | 70.4 wt% | 578.0 @ 750 cycles | [132] | |

| C-NC/GN/g-C3N4 | Low-temperature dissolution and high-temperature carbonization | 3D interconnected network ultrathin sheets | ~ 1270 @ 0.5 C | ~ 78.1 wt% | ~ 1130 @ 500 cycles | [178] | |

| CN@NSHPC | Double-solvent approach with controllable pyrolysis | Solid spheroidal nanoparticle | 1099 @ 0.1 C | 73% (1.7–2 mg/cm2) | 445 @ 500 cycles | [179] | |

| CN/MoS2 | Hydrothermal method | Laminar nanosheet | 1252 @ 0.5 C | 4 mg/cm2 | 680 @ 200 cycles | [184] | |

| rGO/g-C3N4/CNT | Ethanol-assisted spray-drying method | Microsphere-like structure | 1030 @ 0.2 C | 1.5 mg/cm2 | 820 @ 200 cycles | [182] | |

| 3D PCN@rGO | Hydrothermal and freeze-drying | Interconnected sheets stacked by several layers | 1240 @ 0.2 C | ~ 1.5 mg/cm2 | 1005 @ 170 cycles | [181] | |

| Sulfur host | C3N4@CFM | In situ coating method | Carbon fiber mesh | 905 @ 0.1 C | 0.6 mg/cm2 | 801 @ 100 cycles | [140] |

| C3N4/rGO aerogel (CG12) | Hydrothermal, freeze-drying method | Inter-connected thin nanosheets | 1024 @ 0.5 C | 80 wt% (~ 1 mg/cm2) | 770 @ 100 cycles | [138] | |

| MoS2/g-C3N4 | Melt-diffusion method | Multi-layered sheet like structure | 943 @ 1 C | ~ 1.5 mg/cm2 (59.1%) | 569 @ 400 cycles | [102] | |

| Facilitate LiPS redox | CNG (Polymeric g-C3N4 and rGO) | Simple cyro-drying and annealing process | Interconnected thin sheets | ~1250 @ ~ 330 mA/g | ~ 0.6 mg of sulfur on 1.2 mg of CNG or r-GO | over 700 @ 280 cycles | [131] |

| Separator coating for Li–S battery | |||||||

|---|---|---|---|---|---|---|---|

| Battery type | Materials | Synthesis | Morphology | Initial capacity (mAh g−1) | Sulfur loading | Reversible capacity (mAh g−1) | References |