Abstract

The current dominating production and consumption model is based on the linear economy (LE) model, within which raw materials are extracted-processed-consumed-discarded. A circular economy (CE) constitutes a regenerative systemic approach to economic development which views waste as a valuable resource to be reprocessed back into the economy. In order to understand the circular strategy for a systemic change from an LE to a CE as a means of resolving the issue of plastic waste, this research aims to map current circular strategy trends across the system perspective contained in the literature relating to plastic CE literature. The novelty of the research lies in the mapping and review of the distribution of comprehensive circular strategies within the 9R framework across the entire system perspective (e.g. micro-meso-macro) down to its sub-levels in the literature on a plastic CE. The bibliographic mapping and systematic literature review iindicateed that the majority of the research focused on recycle (R8), followed by refuse (R0), reuse (R3), and reduce (R2). Certain circular strategies are more appropriate to handling certain plastic materials, despite CE's favoring of prevention and recycling over incineration. Recover (R9) is often used to process mixed and contaminated plastic. Recycling (R8) is the most popular circular strategy and the most applicable to plastic material with three recycle trends, namely; mechanical recycling, chemical recycling and DRAM (Distributed-Recycling-and-Additive-Manufacturing). Prolonging the product life through refurbishing (R5) is not applicable to plastic due to its material limitations. Reduce (R2) popularity as circular strategy reflects the preference to reduce consumption, either by launching campaigns to prevent waste or increasing production efficiency. Research on Rethink (R1) has largely focused on rethinking product design, consumer and organization behavior and perceptions of CE. Refuse (R0) strategy is an adoption of bio-based plastics which have a similar function to fossil-based plastics.

Keywords: Circular economy, 9R framework, System perspective, Plastic, Circular strategy

Circular Economy, 9R framework, System Perspective, Plastic, Circular Strategy.

1. Introduction

The current dominating production and consumption model is based on the linear economy (LE) model, within which raw materials are extracted from the environment, processed to become products, used and, finally, discarded [148]. In 2016, between 19 to 23 million metric tons of plastic waste were estimated to have entered the global aquatic ecosystem which represented an increase on the previous estimate of 4.8–12.7 million metric tons in 2010 [103]. It is, therefore, important to transform the current linear economy into a closed-loop circular system [20].

A circular economy (CE) constitutes a regenerative systemic approach to economic development which views waste as a valuable resource to be reprocessed back into the economy to the potential benefit of business, environment, and society [49, 246]. Failure in implementing systemic change could result in the misunderstanding and subversion of CE principals resulting in stakeholders implementing nothing more than minimum change [114]. One example would be a company that adopts waste recycling practice rather than rethinking its product design; or refusing to use fossil-based plastic, thereby preventing waste generation, as a means of preserving the status-quo vis-à-vis modes of production and consumption.

The transition from an LE to a CE requires the implementation of a strategy across the production chain culminating in systemic change. Circularity strategies, or the R framework, represents the core principle and know-how through which a CE [20, 73, 113] minimizes resource consumption and waste generation [179]. There are several known R frameworks or circular strategies, namely; 3R, 4R and 9R. The 3R framework consists of reduce-reuse-recycle [20, 73, 113], while the 4R framework comprises reduce-reuse-recycle-recover [58]. Of all the R frameworks, the most comprehensive collection strategy is the 9R Framework, or Circular Strategy [175], which is a hierarchical collection of circular principles with the closest state to LE being recover (R9), followed by recycle (R8), repurpose (R7), remanufacture (R6), refurbish (R5), repair (R4), reuse (R3), reduce (R2), rethink (R1), and, finally, refuse (R0). The last mentioned is the state closest to a CE [175]. With regard to systemic change, the implementation of a CE occurs at three levels, referred to as the micro-meso-macro system perspectives [60, 102, 204].

A review of the previous research into the literature on CE confirmed that it focuses on only one aspect of systemic change (micro-meso-macro). Previous literature reviews focused solely on one aspect of the micro system such as the product level [24, 223] or the company level [78, 162, 173, 196, 208, 226]. Other literature reviews centred on the meso system at the industrial level [126, 141]. Certain literature included all levels of systemic change (micro-meso-macro) but only incorporated limited circular strategies such as maintain, reuse, remanufacture, and recycle [202] or reduce-reuse-recycle-recover (4R Framework) [114].

In order to understand the circular strategy for a systemic change from an LE to a CE as a means of resolving the issue of plastic waste, this research aims to map current circular strategy trends across the system perspective contained in the literature relating to plastic CE literature. This study proposes the systemic change perspective as the combination of the research by Saidani (2018) and Kirchherr (2017), while the circular strategy will employ the 9R framework [175]. The novelty of the research lies in the mapping and review of the distribution of comprehensive circular strategies within the 9R framework across the entire system perspective (e.g. micro-meso-macro) down to its sub-levels in the literature on a plastic CE.

Within this study, bibliographic mapping involving the use of a VOSviewer complemented by a systematic literature review. The emerging research trend initially identified by bibliographic mapping can be used to design a detailed in-depth analysis of this systematic review through the use of a system perspective and 9R framework as part of a Circular Strategy. Widely used CE strategies can be identified and employed to determine the level of transition from an LE to a CE at the micro-meso-macro levels down to their sub-levels. The distribution of circular strategy within the system perspective in the literature will use 9R frameworks.

This study is organized into five parts. Section 1 highlights the background and contains a literature review. Section 2 contains the research methodology and iterative approach employed to categorize the literature on plastic CE. Section 3 presents the visualization results of the VOSviewer-generated bibliographic map. Section 4 elaborates the findings of the systemic literature review. Section 5 features the conclusion, while Section 6 outlines the research limits and suggests possible areas for future research.

2. Methodology

The research was conducted using bibliographic mapping and complemented by a systematic literature review. Bibliographic mapping tools can enable the processing of the abundant information produced by the rapid pace of research by facilitating the tracking of research evolution and emerging trends [214]. However, despite further advances in text mining and machine learning techniques, bibliographic mapping is limited as far as providing in-depth analysis is concerned. Consequently, a systematic literature review was also undertaken to complement bibliographic mapping. The emerging trend initially identified by bibliographic mapping can be used to design a detailed in-depth analysis of the systematic review.

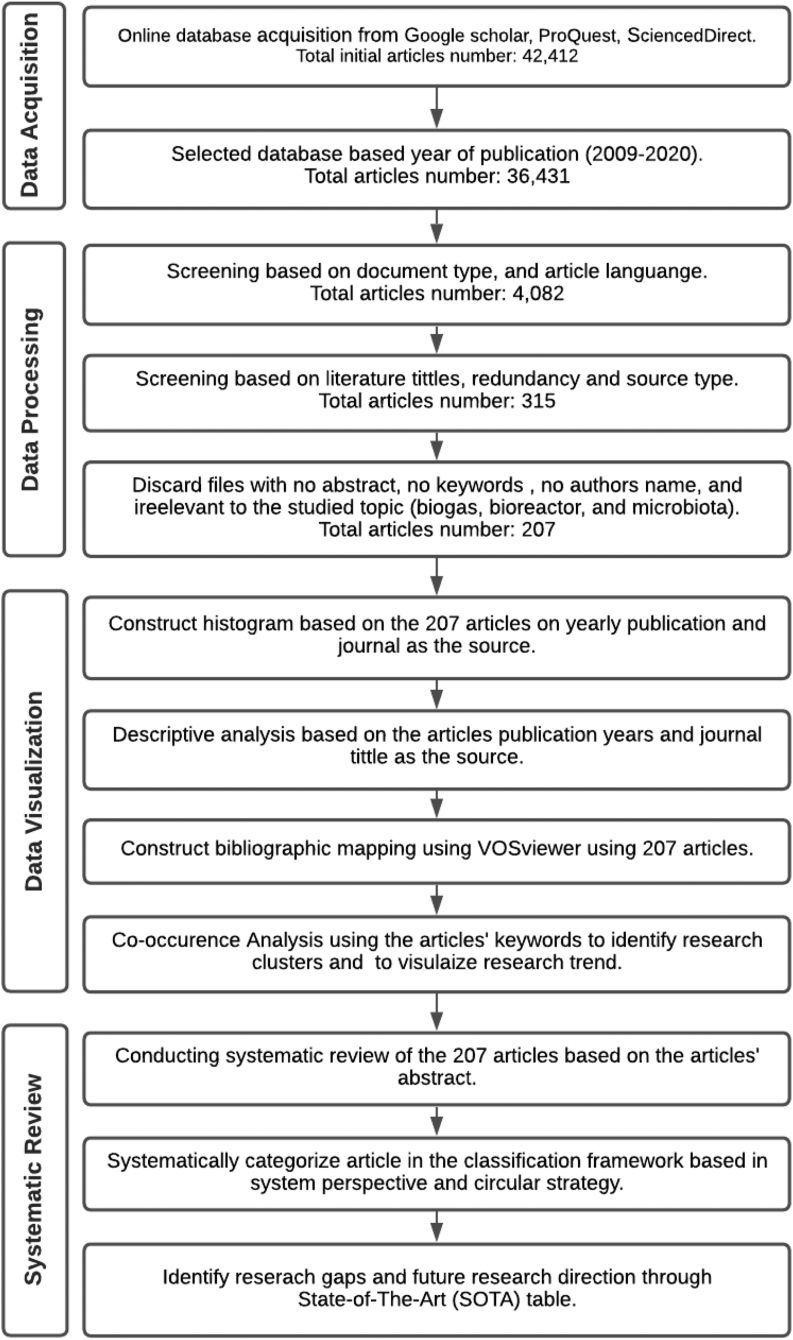

The bibliographic analysis is based on a general methodological flowchart [179] which involves three steps, namely; data acquisition, followed by data processing, and, finally, visual output. The justification for following the flows contained in this framework is that they are reproducible, flexible and appear in other bibliographical mapping papers using the same method [97, 251].

Figure 1 shows the methodological framework of the literature review undertaken for this paper. The first step consisted of conducting a search of an online database using a general keyword. Initial data acquisition involved accessing Goggle Scholar, ProQuest, and ScienceDirect. Using a combination of the keywords “Circular Economy” and “Plastic”, an initial 42,412 articles were screened on the basis of having been published between 2009 and 2020 to produce a reduced total of 36,431 articles.

Figure 1.

Methodology framework used to review the plastic circular economy literature.

The second step involved data processing and screening conducted on the basis of the type of academic article written in English which further reduced the total number to one of 4,082 articles. In order to avoid the inclusion of redundant articles from various online sources another screening process was completed based on title, redundancy and source type (Scopus index of peer-reviewed journals). The justification for making exclusive use of Scopus-indexed journals lay in the fact that the VOSviewer can only process articles from either Scopus or Web of Science. This fact constitutes one of the limitations of this research. The screening resulted in a total of 315 articles whose abstracts, keywords, authors, years of publications, and source journals were downloaded from the Scopus website in CSV downloadable format. Each article abstract was manually checked for relevance with redundant studies on such topics as biogas, bioreactors and microbiota being removed. Articles with no abstract, keywords, or author names were also removed from the literature database. This process resulted in the final data amounting to 207 articles.

The third step, visualization output of the final data, involved descriptive analysis and bibliographic mapping using a VOSviewer. Descriptive analysis was conducted to enable comprehension of the data distribution by constructing a histogram based on the year of publication and journal source. Bibliographic mapping was conducted using the final article database that had been checked, corrected and screened by the VOSviewer using in-app algorithms to create the output visual file. The justification for using the VOSviewer lay in its being an open-source Java-based package allowing the user to visualize in the form of bibliometric maps which enable trend analysis [235]. The visualization employed a co-occurrence analysis of the articles' keywords to identify research clusters and, subsequently, investigate the emerging research trend. The use of keywords reflected each article's core content and research topic development [225].

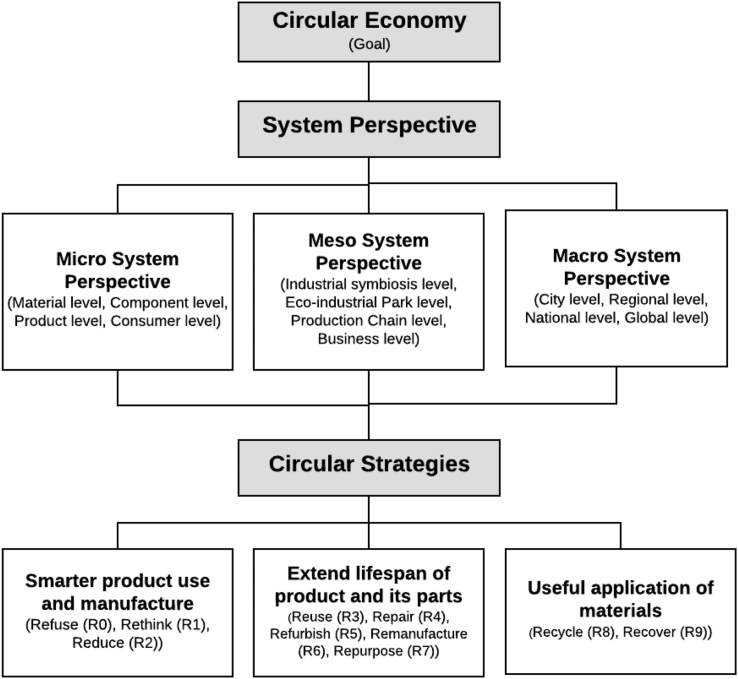

The fourth step was a systematic review of article abstracts and a content analysis of the literature abstracts to identify and classify those which are state-of-the-art. The database was subsequently classified using a classification framework based on the system perspective and 9R Framework (or Circular Strategy) contained in Figure 2. A systematic literature review was also conducted to complement bibliographic mapping. The emerging trend initially highlighted by this means can be used to design a detailed in-depth analysis of systematic reviews to identify research gaps requiring further work in addition to the direction of future research. This study employs the circular strategy of the 9R Framework [175] across the systemic change perspective [202].

Figure 2.

The proposed classifications of plastic circular economy literature.

2.1. System perspective within the circular economy

The system perspective, or systemic change, within the CE pertains to those system levels that will be fundamentally changed when transitioning from an LE to a CE [114]. A business or region striving to achieve sustainable development and enhance its circularity can do so by means of transition stages. The transition to a CE as a system occurs at three levels: micro-meso-macro system perspectives [60, 102, 114, 204]. The macro-system focuses on the fundamental change in the entire economic structure. The meso-system highlights the transition and adjustment to the CE at the industrial level [92, 216]. The micro-system seeks to improve the circularity of the product or consumer levels [102, 204] (see Table 1).

Table 1.

Review of previous literature on the plastic circular economy.

| # | Study | Focus |

|---|---|---|

| 1. | Ghisellini et al. (2016) [73] | Summary of 155 articles on CE. |

| 2. | Lieder and Rashid (2016) [126] | CE manufacturing industry. |

| 3. | Kirchherr et al. (2017) [114] | Analysis of 114 definitions of CE. |

| 4 | Gregorio et al. (2018) [78] | Trends of bio, green, and CE. |

| 5 | Okorie et al. (2018) [162] | Digitalization in CE. |

| 6 | Saidani et al. (2018) [202] | Taxonomy of CE indicators. |

| 7 | Spierling et al. (2019) [224] | Bioplastic in CE. |

| 8 | Bungaard and Huulgaard (2019) [24] | Luxury product and its links to CE. |

| 9 | Paes et al. (2019) | SWOT (Strength-Weakness-Opportunity-Threat) analysis of organic waste management. |

| 10 | Meherishi et al. (2019) [141] | Sustainable Packaging for Supply Chain Management in CE. |

| 11 | Pieroni et al. (2019) [173] | Business model innovation for CE. |

| 12 | Rosa et al. (2019) [196] | Circular Business Model. |

| 13 | Sassanelli et al. (2019) [208] | CE performance assessment method. |

| 14 | Thorley et al. (2019) [226] | CE impact towards SME. |

| 15 | Sanchez et al. (2020) [206] | Analyzing articles on DRAM (Distributed Recycling and Additive Manufacturing) in CE. |

| 16 | Qureshi et al. (2020) [181] | Pyrolysis for plastic waste |

Two previous literature reviews classified system perspectives in the CE; one based on the 114 definitions of the CE [114], the other on the taxonomy of CE indicators [202]. Table 2 displays the system perspectives of previous research and that presented here, both of which classify the system perspectives as micro-meso-macro, yet which differ at the sub-level.

Table 2.

CE system perspectives for this research.

| Authors | Macro-System Perspective/Levels | Meso-System Perspective/Levels | Micro-System Perspective/Levels |

|---|---|---|---|

| Kirchherr et al. (2017) 114 |

|

|

|

| Saidani et al. (2018) 202 |

|

|

|

| This research |

|

|

|

Micro-system perspective sub-levels based on the 114 CE definitions [114] consist of product, company and customer levels [99, 204]. The meso-system consists of eco-industrial parks [92, 216] and the regional level [70, 125]. The macro-system consists of global, national, and industrial structure levels. Meanwhile, based on the CE indicator taxonomy [202], micro-system perspective sub-levels consisting of product, component, and material levels [202]. The meso-system comprises business and industrial symbiotic levels. The macro-system includes city, regional and national levels. Certain sub-levels are mentioned only in one literature source, while others are contained in both sources. The differences are due to the various sources of classification within the system perspective: some based on the circular indicators identified in both the academic and grey literature developed by scholars, governmental agencies, and consulting companies [202]; others based solely on the 114 CE definitions [114].

Based on the background above, this research will combine both system perspectives [114, 202] and add a new production chain sub-level to review the distribution of CE implementation across the plastics industry from a system perspective within the current CE literature. The micro-system will consist of material, component, and product levels [202], together with the customer level [202]. The material level will focus on improving circularity of the element's composition. The component level focuses on adjustment of the CE at the ingredient level. The product level centers on improving circularity while still satisfying customer needs. The customer level focuses on the socio-demographic breakdown of the product's consumers and the nature of sustainable consumption. The meso-system deals with industrial symbiosis, eco-industrial parks [202], production chain level and the business level [114]. The business level focuses on the adjustment to improve circularity at the company level. The production chain level centers on the transition to a CE at the supply chain level. Industrial symbiosis is the merger of two or more different industries where each tries to achieve optimal access to material components and material elements [13, 189]. An eco-industrial park is a business that cooperates with locals to share resources efficiently and reduce waste in order to promote economic prosperity, improve environmental quality and enhance human resources for the local community [167]. A macro-system will consist of city, regional and national levels [114] combined with the global level [202]. City, regional and national levels focus on the fundamental change to the CE of administration at these levels. The global level focuses on the transition to the CE at the multi-national level and across borders.

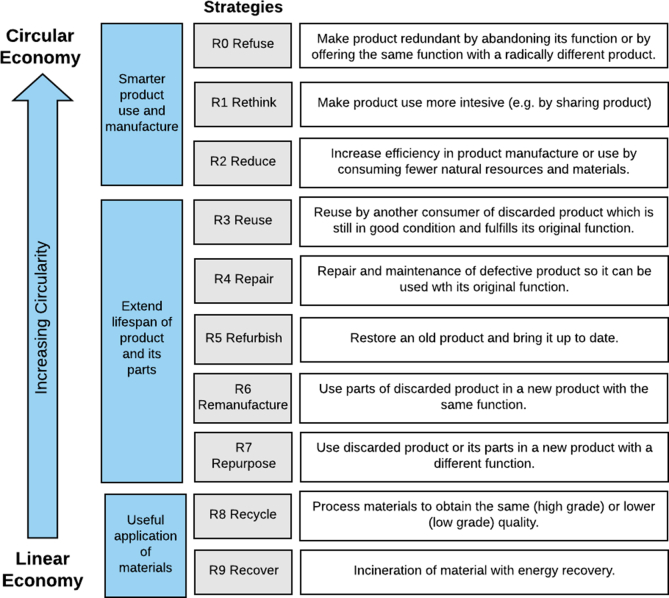

2.2. Circular economy strategies

CE strategies outline the R strategy necessary to transform LE to a CE [175] and are ordered from R0 to R9 based on their level of priority in the LE to CE transition as shown in Figure 3. R0 signifies the closest state to CE,while R9 indicates the closest state to LE. Adopting the circular recycling strategy (R8) means that the system is predominanttly under LE. Meanwhile, implementing circular reduction strategies (R2) means the closer the transition to the CE model.

Figure 3.

Framework for CE strategies [175].

The circular strategies of smarter product use and manufacturing framework comprise recovery (R9) and recycling (R8) [175]. The CE principle is that of extracting the maximum value from material at the end-of-life (EoL) [48]. Recycling is the most widely-known circular strategy, although it represents only one of the options and is closer to the LE after recovery (R9) than the CE [175]. The recycling strategy includes mechanical recycling, chemical recycling and DRAM. DRAM involves producing objects from 3D models by joining materials layer-by -ayer using 3D manufacturing processes [206]. Mechanical recycling involves the application of physical treatment to reduce a product to its material level, thereby enabling it to be remade [7, 175]. Chemical recycling produces chemical feedstock in the form of solid, liquid, and gaseous fuels [7].

Extending the lifespan of the product and its parts requires circular strategies of repurpose (R7), remanufacture (R6), refurbish (R5), repair (R4), and reuse (R3). Reuse and remanufacture are two of the circularity loops in the CE butterfly diagram of the technical materials produced by the practitioner [49]. However, there is a limit to prolonging the product life of items manufactured from plastic and it cannot constitute a mainstream practice [85].

Smarter product use and manufacturing frameworks apply circular strategies of refuse (R0), rethink (R1), and reduce (R2). Refuse (R0) is the closest circular strategy in the production chain to CE [175]. In this research, the use of bio-based plastic as the CE strategy of “refuse” (R0) is included since the adoption of such plastic, which performs a similar function, can render conventional plastic redundant. Degradable bio-based plastic can be manufactured from renewable materials, including plant materials [88], thus allowing microbes to break down the bioplastic complex molecular structure and produce CO2. Examples of biodegradable bio-based plastics are PLA (Polylactic acid), PHA (Polyhydroxyalkanoates), PBS (Polybutylene succinate), and starch blends. Biodegradable plastic can also be produced solely from petrochemicals using additives to facilitate its breaking down, but it remains a fossil-based plastic [57]. Examples of petrochemical-based biodegradable plastics include PBAT (Polybutylene Adipate Terephthalate) and PCL (Polycaprolactone).

3. Analysis

3.1. Descriptive analysis of the data

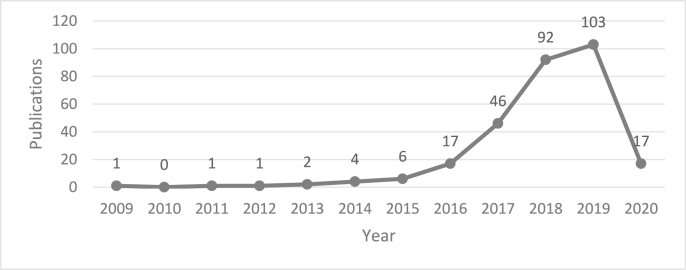

Descriptive analysis of bibliographic data can promote an understanding of data distribution. Figure 4 contains the distribution of articles from 2009 to 2020. Initially, between 2009 and 2013, only one or two articles were published. However, from 2014 to 2016, there was an increase in the number of articles in line with the European Union's new Circular Economy Package [59]. Furthermore, it is important to note the exponential increase in 2017 when the number of articles on the plastic circular economy almost trebled. This increased research interest might be due, in part, to the New Plastic Economy project and Ellen MacArthur Foundation initiatives which aim to develop a more circular economic model [246]. The upward trend continued until 2019 when the number of published articles rose to the unprecedented annual total of 103. China's new regulation of July 2017 banning solid waste imports (including plastics, paper products, and textiles, among others) from foreign countries and its impact on the global plastic waste trade [22] might have contributed to the increased interest in plastic CE as a research topic. Analyzing the trend retrospectively, there is a possibility that, in subsequent years, more articles will be published on the plastic circular economy since the topic is new and relevant to current events. However, the sharp decline in yearly publication in 2020 might be in part due to the shifting research interest moving into the topic of pandemic. In addition, not all publication in 2020 are considered with the research on the end of 2019 and throughout 2020 are presented as projection.

Figure 4.

The annual number of publications from 2009 to 2020.

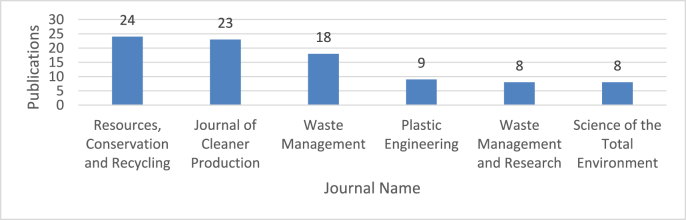

Figure 5 contains a quantitative measurement of the top six journal sources. The leading journal for plastic CE research is Resources, Conservation, and Recycling with 24 articles, followed by the Journal of Cleaner Production with 23 articles and Waste Management with 18 articles, respectively. Meanwhile, Plastic Engineering, Waste Management∗, as well as Research and Science of the Total Environment each have an average of eight articles. The journals Resources; Conservation and Recycling; and Journal of Cleaner Production contain more topics on the CE compared to other journals. This is due to both journals addressing a wide variety of topics on sustainability and their high Scopus ranking. Resources, Conservation and Recycling, in particular, emphasizes the transitional process towards sustainable production and consumption systems in line with the definition used within the Circular Economy. The Journal of Cleaner Production addresses the issues of preventing waste production, improving resource use efficiency and promoting a more sustainable society which are similar to Circular Economy principles. In addition, the Scopus ranking of both journals is very high at Q1 which explains the preference of numerous researchers for submitting articles to these journals compared to others such as Plastic Engineering (Q4) and Waste management and Research (Q2).

Figure 5.

Quantitative measurements of the six leading journal sources from 2009 to 2020.

3.2. Bibliographic mapping using VOSviewer keywords co-occurrence analysis

A keyword co-occurrence network is useful for the purposes of knowledge mapping [182] since keywords reflect the research topic development and core content of an article [225]. The author's keywords in the literature database determine the co-occurrence frequencies in the VOSviewer. Table 3 shows that of 823 keywords, only 22 satisfied the condition of appearing in a minimum of five publications which, expressed statistically, represents a frequency of 2.67% (22/823∗100%). The justification for adopting this minimum occurrence level for the keyword is that the more frequently it occurred, the more popular the research topic.

Table 3.

Co-occurrence and total link strength of the most common keywords.

| # | Selected Keywords | Cluster Number | Occurrences | Total link strength | Average Publication Year |

|---|---|---|---|---|---|

| 1 | Circular economy | 3 | 135 | 134 | 2018 |

| 2 | Recycling | 2 | 42 | 67 | 2018 |

| 3 | Waste plastic | 2 | 6 | 27 | 2019 |

| 4 | Polymers | 2 | 5 | 25 | 2019 |

| 5 | Upcycle | 2 | 5 | 25 | 2019 |

| 6 | Plastic waste | 4 | 12 | 24 | 2019 |

| 7 | Additive manufacturing | 2 | 6 | 21 | 2019 |

| 8 | Plastic | 1 | 10 | 20 | 2018 |

| 9 | Plastics | 4 | 12 | 19 | 2017 |

| 10 | Waste | 1 | 10 | 18 | 2017 |

| 11 | Plastic recycling | 4 | 9 | 17 | 2019 |

| 12 | Sustainability | 1 | 14 | 16 | 2018 |

| 13 | Life cycle assessment | 3 | 10 | 14 | 2018 |

| 14 | Waste management | 3 | 11 | 14 | 2018 |

| 15 | Bioplastics | 1 | 8 | 13 | 2019 |

| 16 | Packaging | 1 | 6 | 13 | 2019 |

| 17 | 3d printing | 2 | 5 | 12 | 2019 |

| 18 | Pyrolysis | 4 | 8 | 11 | 2019 |

| 19 | Recovery | 4 | 5 | 8 | 2017 |

| 20 | Contamination | 3 | 5 | 7 | 2019 |

| 21 | LCA | 1 | 5 | 7 | 2018 |

| 22 | Municipal solid waste | 3 | 6 | 6 | 2017 |

This study found "Circular Economy" to be the most important keyword with a total link strength of 134 and the largest circle size at 135 co-occurrences in the dataset. The "Circular Economy" keyword links all the keywords in the map, thereby justifying its large total link strength. The vast array of networks for this keyword is justified since both it is used as one of the research keyword during online literature data acquisition. The second most important is "Recycling", with a total link strength of 67 and 42 co-occurrences. The keyword "recycling" has links to most map keywords except for the following: plastic recycling, contamination, life cycle assessment, and bioplastic.

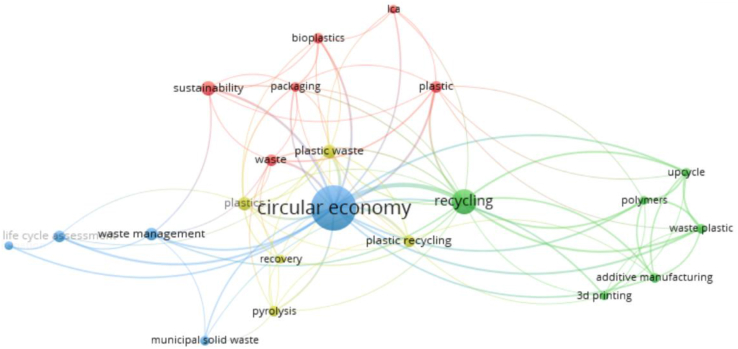

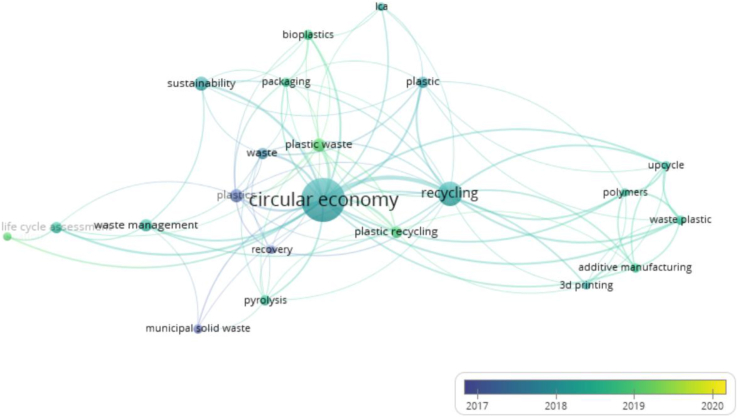

VOSviewer visualization resulted in two different maps, namely: the network and overlay visualization maps. Both visualizations incorporate the use of a two-dimensional distance-based map that indicates the strength of the items' relationship based on their distance [235]. A larger distance indicates a weak association and vice-versa. In contrast, a shorter distance signifies greater strength of the relationship. A keyword is indicated by a label and a circle whose size signifies its importance [235]. The bibliographic mapping of overlay visualization is identical to network visualization, although different colors are used to indicate distinct information. The network visualization conveys the information of keywords cluster groups, while the overlay visualization conveys the information of average annual publication of each keyword.

Figure 6 contains network visualization groups of closely related keywords shown in different colors indicating the cluster to which they belong. It identifies four keyword network clusters from the network visualization. Meanwhile, within overlay visualization (Figure 7), the circle labels are colored according to the average annual publication of the keyword. To represent the average publication year, purple was used for 2017 and yellow for 2020. Figure 7 contains the keywords mentioned in the average number of articles published between 2018 and 2019.

Figure 6.

Co-occurrence of keyword network visualization.

Figure 7.

Co-occurrence of keyword overlay visualization based on average publications per year.

The following constitutes an analysis of the identified research clusters within network visualization. The first cluster (shown in red) contains certain keywords including “bioplastic”, “LCA”, “packaging”, “plastic”, “sustainability”, and “waste”. This cluster pertains to reviewing the life cycle assessments of plastic material and its substitution by bio-plastic to render it more sustainable. Bioplastics perform a similar function, thereby rendering conventional plastic unnecessary. Substitution of conventional plastic by bioplastics is similar to the circular strategy relating to refuse (R0) of offering similar functions but with different products. “Refuse” is the closest circular strategy in the production chain to the CE [175]. Overlay visualization shows the publication year (2018) for this cluster when the keywords “LCA”, “sustainability” and “plastic” were trending, followed by “bioplastic” and “packaging” which did so in the following year. This phenomenon is reflected in the more intense focus on the issue of plastic waste in the marine environment during 2018 and 2019.

The second cluster (shown in green) contained the keywords “3D printing”, “additive manufacturing”, “polymers”, “recycling”, “upcycle”, and “waste plastic” and is concerned with recycling (R8), either through downcycling or upcycling. In the recycling process, material value is often partially lost or downgraded, while the upcycling process increases value by upgrading the product used [219]. Additive manufacturing is a process of producing objects from 3D models [206]. In upcycling, using the latest technology in 3D printing, the plastic waste is recycled into added-value products through additive manufacturing. In overlay visualization, the keyword “recycle” was trending in 2018 with additive manufacturing, while those of “3D printer” and “upcycle” gradually gained popularity in publications during in the following year.

The third cluster (shown in blue), containing the keywords “circular economy”, “contamination”, “life cycle assessment”, “municipal solid waste”, and “waste management”, concerns the management of municipal solid waste to reduce contamination using a CE. Reduce (R2) constitutes a circular strategy to decrease resource consumption [175] which is achievable through waste prevention campaigns or greater production efficiency. Overlay visualization shows this cluster to contain multiple trending research topics emerging in 2018, one of which is “circular economy”, in addition to “recycling”, “sustainability”, “life cycle assessment”, and “waste management”.

The fourth cluster (shown in yellow) contained “plastic recycling”, “plastic waste”, “plastics”, “pyrolysis”, and “recovery” and concerned “plastic waste recovery” and “treatment through chemical recycling” such as pyrolysis. Pyrolysis is one form of chemical recycling that converts plastic waste into energy in the form of solid, liquid, and gaseous fuels [145]. Recovery (R9), another popular circular principle in the management of post-consumer plastic-waste, was based on energy recovery through material oxidation [228] to produce heat, power, oils, and disposable by-products [7]. Therefore, incineration for energy is classified as the recovery strategy. Overlay visualization shows that one of the earliest core topics of plastic CE articles in 2017 pertains to municipal solid waste, plastic waste and recovery.

4. Result

This section contains the result of the systematic literature review relating to the distribution of circular strategy within the whole system perspective contained in the plastic CE literature which is classified in the SOTA (State-of-The-Art) table. This table enables researchers to identify gaps in the existing research and the need for further future investigation. Widely-used CE strategies can be identified and employed to determine the level of transition from the LE to the CE in the system perspective. Table 4 shows the distribution of circular strategy across the system perspective in the existing literature.

Table 4.

State of the art system perspective of the transition towards a plastic circular economy.

| Circular Strategies (9R Framework) | Micro-system perspective |

Meso-system perspective |

Macro-system perspective |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Material | Component | Product | Consumer | Businesses | Production Chain | Industrial Symbiosis | Eco-Industrial Park | City | Regional | National | Global | |

| Recover (R9) | 2 | 1 | 1 | 1 | 2 | - | 1 | - | 1 | 2 | 2 | - |

| Recycle (R8) | 31 | 6 | 35 | 6 | 11 | 12 | 3 | 4 | 6 | 7 | 12 | 8 |

| Repurpose (R7) | 1 | - | 1 | - | - | - | - | 1 | - | - | - | - |

| Remanufacture (R6) | - | 1 | - | - | - | - | - | - | - | 1 | - | - |

| Refurbish (R5) | - | - | - | - | - | - | - | - | - | - | - | - |

| Repair (R4) | - | - | 2 | - | - | - | - | - | - | - | - | - |

| Reuse (R3) | 5 | 1 | 4 | 1 | 1 | 1 | 1 | - | 2 | 2 | 2 | 1 |

| Reduce (R2) | 2 | - | 1 | 2 | 1 | 1 | 1 | 1 | 1 | 2 | 2 | 8 |

| Rethink (R1) | 1 | - | 2 | 2 | 2 | - | - | 1 | 1 | - | - | 2 |

| Refuse (R0) | 22 | 1 | 6 | 4 | - | 3 | - | - | - | - | - | 2 |

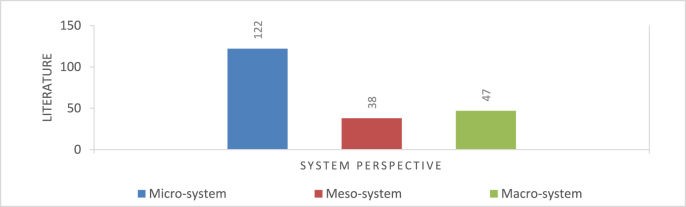

For classification of this systemic literature review, a source can only be classified as falling within one of the CE system perspectives. The total number (n) of works was 207. Statistically, most previous literature reviews focused on the microsystem at 59% (122/207∗100%). The second most common theme was the macro-system at 23% (47/207∗100%), while the meso-system occupied third place at 18% (38/207∗100%). Overall, the meso-system accounted for the smallest share of the literature compared to other system perspectives.

Based on the dimension with the least amount of reviews, the meso-system perspective suffered from a research gap (Figure 8). A further breakdown in the system perspective categorization sub-levels is as follows.

-

a.

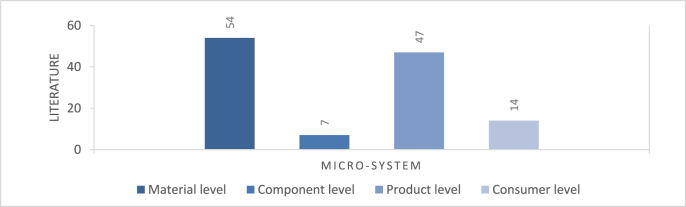

From the micro-system perspective, the distribution of literature was one of 54 texts at the material level, 7 texts at the component level, 47 texts at the product level, and 14 texts at the consumer level. Furthermore, the product level represented the largest proportion of system perspective literature, while the component level was the smallest (Figure 9).

-

b.

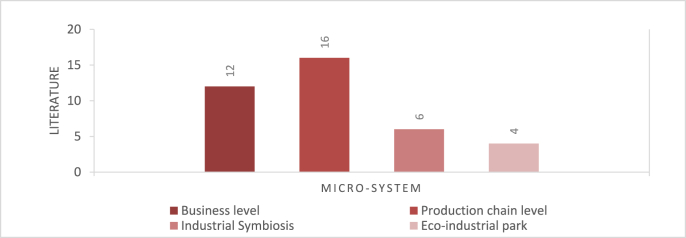

From the meso-system perspective, the distribution of literature consists of 12 texts at the business level, 16 texts at the production chain level, 6 texts at the industrial symbiosis level, and 4 texts at the eco-industrial park level. The industrial symbiosis level represented the largest proportion of texts, while the eco-industrial park was the smallest (Figure 10).

-

c.

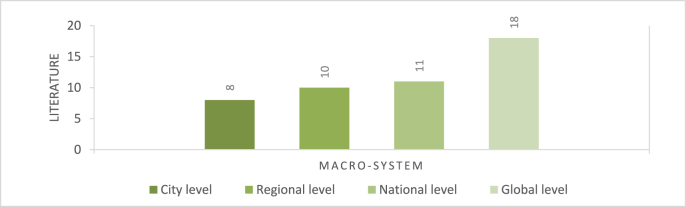

From the macro-system perspective, the distribution of literature consists of 8 texts at city level, 10 texts at regional level, 11 texts at national level, and 18 texts at the global level. The national level represented the largest proportion of texts, while the city level represented the smallest (Figure 11).

Figure 8.

Distribution of texts across all system perspective of plastic CE.

Figure 9.

Distribution of texts across micro-system sub-levels.

Figure 10.

Distribution of texts across meso-system sub-levels.

Figure 11.

Distribution of texts across macro-system sublevels.

The component, eco-industrial park, and city levels had the smallest proportion of texts in their respective system perspectives. Therefore, they constitute research gaps in the literature on plastic CE which could be the focus of future investigation.

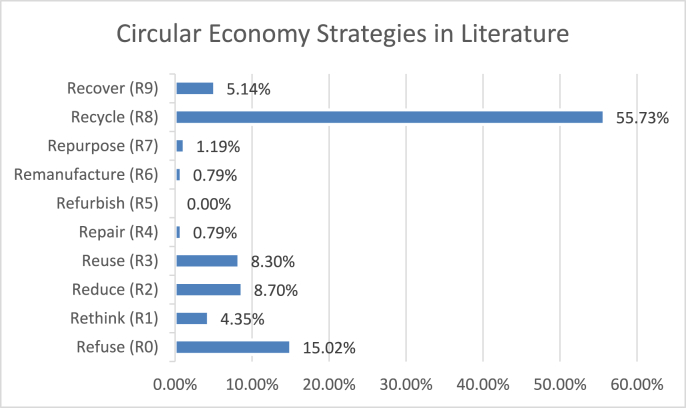

For the purposes of classification into the circular strategy, a total population (n) of 253 was arrived at after adding all the identified 9R framework in each text (13 + 141 + 3 + 2 + 0 + 2 + 21 + 22 + 11 + 38). A text can use one or more circular strategies. Statistically, it was found that the most common circular strategy was recycle (R8) at 55.73% (141/253), followed by refuse (R0) at 15.02% (38/253), reduce (R2) at 8.70% (22/253), reuse (R3) at 8.30% (21/253), recovery (R9) at 5.14% (13/253), rethink (R1) at 4.35% (11/253), repurpose (R7) at 1.19% (3/253), remanufacture (R6) at 0.79% (2/253), and repair (R4) at 0.79% (2/253). Meanwhile, the least popular strategy was refurbish (R5) at 0% (0/253). Figure 12 displays the identified circular strategies in the texts.

Figure 12.

Bar chart of circular strategies identified in texts.

4.1. Micro-system perspective circular strategy for plastic

4.1.1. Material level

Research into plastic CE at the material level mostly consists of circular strategies with the majority focusing on refuse (R0) with 23 articles, and recycle (R8) with 30 articles. In the articles relating to rethink (R1) reduce (R2), and reuse (R3) strategies are sparsely implemented, while no research was found on repair (R4), refurbish (R5) and remanufacture (R6) at the plastic material level. Table 5 shown the distribution of literature of circular strategy at the material level.

Table 5.

Circular strategy at the material level.

| Material Level | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| References | R0 | R1 | R2 | R3 | R4 | R5 | R6 | R7 | R8 | R9 | Research |

| [8] | X | X | PHAs production technical feasibility. | ||||||||

| [10] | X | BPA MFA in Norway. | |||||||||

| [11] | X | Polymer recycling technology | |||||||||

| [14] | X | Microwave-assisted recycling LDPE. | |||||||||

| [16] | X | Improving biotechnological upcycling processes. | |||||||||

| [17] | X | PHA-production technical and economic feasibility. | |||||||||

| [29] | X | Compounding food waste with PLA. | |||||||||

| [30] | X | Material design for bio-based Polymer Cosmetic packaging. | |||||||||

| [38] | X | Different blend ratios of PP/mixed post-consumer recycled polyolefin materials. | |||||||||

| [40] | X | Polymeric blends design. | |||||||||

| [41] | X | PET depolymerization using enzymes. | |||||||||

| [42] | X | PET recycling with enzymes as catalyst. | |||||||||

| [47] | X | Bio-derived polymer from citrus waste. | |||||||||

| [55] | X | Household plastic contamination. | |||||||||

| [79] | X | CO2-based monomers & polymers transformation routes. | |||||||||

| [90] | X | X | Performance and recyclability improvement strategy in bio-based plastics. | ||||||||

| [93] | X | Innovative process to recycle hydrocarbon polymer. | |||||||||

| [98] | X | Multilayer EVOH/HDPE rigid packaging. | |||||||||

| [99] | X | Variational effects in mixed recycled material. | |||||||||

| [119] | X | Utilization potential of Polyolefin-rich from wet mechanical processing pilot plants. | |||||||||

| [128] | X | Reimagining green chemistry towards circular material. | |||||||||

| [130] | X | Review of industrial enzymes within the sustainable approach to chemical synthesis. | |||||||||

| [142] | X | X | CF life cycle cost model. | ||||||||

| [143] | X | X | PA-12 reprocessing by injection molding. | ||||||||

| [144] | X | X | Cement kiln incineration and chemical recycling for PET, HDPE, LDPE, PP and PS. | ||||||||

| [156] | X | Modification of natural polymer with thermoplastic properties. | |||||||||

| [159] | X | Possibility of biotransformation and biodegradation of fossil-plastics. | |||||||||

| [163] | X | Agricultural and plastic waste for affordable homes. | |||||||||

| [164] | X | Integrated biodegradation strategy of waste-to-wealth. | |||||||||

| [166] | X | PLA production technologies, challenge and future opportunities. | |||||||||

| [168] | X | Hydrothermal processing chemical recycling. | |||||||||

| [170] | X | Bioplastic as a substitute to fossil based on its chemical functionalities. | |||||||||

| [177] | X | Bio-based plastic standardized labelling, sorting, and coordinated regulation. | |||||||||

| [181] | X | Opportunities and challenges of pyrolysis for plastic waste. | |||||||||

| [186] | X | X | Trade of feedstock material model | ||||||||

| [187] | X | Recycled polymers 3D printing. | |||||||||

| [194] | X | PLA as substitute for fossil-plastics | |||||||||

| [199] | X | Degradation characteristics of bioplastic material. | |||||||||

| [207] | X | X | Development of bioplastic with full-chemical recyclability. | ||||||||

| [211] | X | X | Rethink material recycling of flame retardant additives. | ||||||||

| [212] | X | Challenges of recovering plastic from electronic waste. | |||||||||

| [213] | X | X | X | Material efficiency in manufacturing and waste segregation. | |||||||

| [215] | X | X | Converting biomass into fuels, commodity chemicals and bioplastics. | ||||||||

| [217] | X | Substitute capacity and commercial viability of bio-based plastics. | |||||||||

| [218] | X | Framework for polymeric material reuse. | |||||||||

| [222] | X | Multi-step pyrolysis to recover energy and chemicals. | |||||||||

| [232] | X | Bioplastics derived from microalgae cultivation. | |||||||||

| [238] | X | Combining 3D printing with biomaterials. | |||||||||

| [249] | X | Gigabot to optimize recycled material. | |||||||||

| [250] | X | RepRapable Recyclebot. | |||||||||

| [253] | X | Recovering materials from pharmaceutical blister packaging. | |||||||||

| [255] | X | Fiber-reinforced polymer manufacturing. | |||||||||

| [258] | X | Novel development of SPC. | |||||||||

| TOTAL | 22 | 1 | 2 | 5 | 0 | 0 | 0 | 1 | 31 | 2 | |

LEGEND: R0 = Refuse; R1 = Rethink; R2 = Reduce; R3 = Reuse; R4 = Repair; R5 = Refurbish; R6 = Remanufacture; R7 = Repurpose; R8 = Recycle; R9 = Recover.

Refuse (R0) is the second most popular strategy due to the adoption of bioplastics with many texts on the subject published in 2019. Two texts focused on bioplastic as a substitute for fossil-based materials in terms of its chemical functionalities [170], upcycling process [16], and low environmental impact with particular regard to the food packaging applications of PLA material [194]. Extensive research into bioplastics focuses on the development of bioplastic production, namely; bio-derived polymer extracted from citrus waste [47] and sludge cellulose plastic composite (SPC) [258]. Furthermore, bioplastic from microalgae cultivation exploits agricultural run-off and urban wastewater as feedstock [232], cosmetic packaging made from bio-based polymer [30], converts biomass into bio-plastic [215], and combines 3D printing with biomaterials [238]. Several pieces of research have investigated the biodegradability [164] and degradation characteristics of bio-plastics [199]. A considerable body of literature covers the development of bio-based plastic polylactic acid (PLA) and polyhydroxyalkanoates (PHA), focusing on its substitution and commercial viability [217], PHA production feasibility [8], PHA economic feasibility [17], and the compounding of food waste with PLA [29]. Moreover, its standardized labeling, sorting, and coordinated regulation [177], production technologies, challenge and future opportunities [166] have also been covered. The remaining literature at the material level has focused on improving bioplastic polymer performance [90], chemical recyclability [207], and chemical synthesis [130]. One article described the potential processing and modification of natural polymer with thermoplastic properties [156].

Other strategies utilized at the material level include rethink (R1) reduce (R2), and reuse (R3). The main focus of the rethink (R1) strategy lies in rethinking the recycling of material additives to produce secondary material [211]. The Reduce (R2) strategy can be achieved through production efficiency to reduce resource consumption during material manufacturing [255] and segregate waste into high quality circulated raw material [213]. The focus on reuse (R3) covers an array of topics from polymeric material reuse [218], through the carbon fibre (CF) life cycle cost model [142], to feedstock material trade modelling to encourage private investment [186].

Recover (R9) is also used as a circular strategy at the material level. Certain plastic types PET (Polyethylene Terephthalate), HDPE (High-density Polyethylene), LDPE (Low-density Polyethylene), PP (Polypropylene), and PS (Polystyrene) are incompatible with chemical recycling. Therefore, incineration and mechanical recycling are preferred due to their lower global warming impact [144]. Contaminants such as bisphenol A (BPA) can be destroyed during incineration making it the form of waste-handling causing the least environmental emissions [10]. Thus, despite CE's favoring of prevention and recycling over incineration or landfilling, some circular strategies are more appropriate to managing certain plastic waste materials.

The articles on recycling (R8) form the majority of research into the material level. The topics focus on polymer recycling [11], wet mechanical processing pilot plants [119], and pharmaceutical waste [253]. Recovering materials for recycling includes transforming electronical waste and compounded polycarbonate into pellets [212] and pharmaceutical blister packaging using switchable hydrophilicity solvents [253]. Two pieces of research investigated polymeric blend properties that include the design of polymeric blends [40] and polypropylene/mixed post-consumer recycled polyolefin materials at different blend ratios [38]. Regarding physical contaminants, metal substances should be removed during the recycling process as increasing recycling rates may lead to higher metal concentrations in recycled materials [55].

The literature proposed a variety of chemical recycling and DRAM options at the material level. The chemical recycling options include multi-step pyrolysis [222], using enzymes as catalyst for disseminating PET [41], and PET depolymerization using enzymes via glycolysis reactions [42]. Other topics include chemical recycling by means of hydrothermal processing of waste plastic fractions [168], reimagining green chemistry in relation to its circular material [128], the opportunities for and challenges of plastic waste pyrolysis [181]. One article discussed microwave-assisted recycling LDPE waste into value-added chemicals [14]. Another option is to process high-density plastic waste using hydrothermal processing [169]. DRAM at the material level covers the topics of: recycled 3D printing polymers [187]; polyamide 12 (PA-12) reprocessing by injection moulding [143]; combining 3D printing with biomaterials to produce bioplastics [238]; gigabot development to optimize recycled material [249]; exploring potential, design, fabrication and operation of a RepRapable Recyclebot [250].

4.1.2. Component level

The component level overwhelmingly focuses on the recycle (R8) strategy in six articles. Refuse (R0), reuse (R3), remanufacture (R6) and recover (R9) strategies each only appear in one article. No research was found relating to rethink (R1), reduce (R2) and remanufacture (R4) (R5) and (R7) at the plastic component level. Refuse (R0) strategy is used in the bio-composite market for biodegradable polymeric matrices from agriculture waste [6]. Table 6 shown the distribution of literature of circular strategy at the component level. Reuse (R3) strategy is applied to glass fibre reinforced plastic waste treatment technology and the reuse potential of composites [105]. Remanufacture (R6) is evidently used for composite performance analysis of remanufacturing involving recycled short carbon fibres with the HiPerDif method [134]. Recycling (R8) strategy is largely used to process composites as follows. Plastic composite evaluation based on multiple properties [81]; automated plastic sorting using miniaturized handheld near-infra red (NIR) spectrometers [185], recycling strategies employing SWOT analyses of component recycling for WEEE (Waste from Electrical and Electronic Equipment) plastic [243]; Recover (R9) primarily used for wood-plastic composites (WPC) end-life treatment rather than recycling (R8) due to the lack of secondary material markets [220].

Table 6.

Circular strategy at the component level.

| Circular Strategy at the Component Level | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| References | R0 | R1 | R2 | R3 | R4 | R5 | R6 | R7 | R8 | R9 | Research |

| [6] | X | Bio-composite market for biodegradable polymeric matrices from agriculture waste. | |||||||||

| [81] | X | Plastic composite evaluation based on multiple properties. | |||||||||

| [105] | X | X | Glass fibre reinforced plastic waste treatment technology and reuse potential of composites. | ||||||||

| [134] | X | X | Analyse performance of composites remanufactured from recycled short carbon fibres with the HiPerDif method. | ||||||||

| [185] | X | Urban automated plastic sorting. | |||||||||

| [220] | X | X | WPC incinerated end-life treatment. | ||||||||

| [243] | X | Recycling strategies SWOT analysis for component recycling for WEEE plastic. | |||||||||

| TOTAL | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 6 | 1 | |

LEGEND: R0 = Refuse; R1 = Rethink; R2 = Reduce; R3 = Reuse; R4 = Repair; R5 = Refurbish; R6 = Remanufacture; R7 = Repurpose; R8 = Recycle; R9 = Recover.

4.1.3. Product level

Most of the circular strategies are present in the research into plastic CE at the product level. The limitation in this case is that no research on refurbish (R5) and remanufacture (R6) was found to exist. The majority are on recycle (R8) with 35 articles, followed by refuse (R0) with six articles, and reuse (R3) with four articles. The remaining articles cover circular strategies of rethink (R1) reduce (R2), repair (R4), repurpose (R7) and recover (R9). Table 7 shown the distribution of literature of circular strategy at the product level.

Table 7.

Circular strategy at the product level.

| Product Level | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| References | R0 | R1 | R2 | R3 | R4 | R5 | R6 | R7 | R8 | R9 | Research |

| [4] | X | X | Bioplastic risk. | ||||||||

| [9] | X | LCA recycled plastic diesel fuel filter | |||||||||

| [26] | X | LCA of 3D printer FPF. | |||||||||

| [27] | X | Thermochemical conversion from landfill. | |||||||||

| [33] | X | Product design & eco-design packaging | |||||||||

| [35] | X | X | Single-use tableware. | ||||||||

| [50] | X | Agricultural polymer container pesticide residue. | |||||||||

| [53] | X | Thermal degradation of resource-separated plastics HHW. | |||||||||

| [54] | X | Thermal degradation of HHW in Denmark. | |||||||||

| [61] | X | Recycling potential in Denmark. | |||||||||

| [66] | X | Product design made from waste | |||||||||

| [67] | X | Biodegradable tableware | |||||||||

| [72] | X | Recycled product chemical safety on food packaging. | |||||||||

| [76] | X | PLA for novel packaging application. | |||||||||

| [89] | X | Cotton polyester textile recycling into a novel cellulose fibres. | |||||||||

| [96] | X | X | X | Comparison with upcycling plastic scrap. | |||||||

| [101] | X | X | Typology to measuring recyclates feedstock quality. | ||||||||

| [109] | X | X | Helicopter canopy lifecycle. | ||||||||

| [122] | X | Single-use infant feeding bottle. | |||||||||

| [127] | X | Biodegradable plastic product design. | |||||||||

| [138] | X | Thermo-chemical exploitation of plastic. | |||||||||

| [140] | X | Product design using sharing economy and IoT concept. | |||||||||

| [146] | X | Reusing secondary material from landfills to manufature bricks in Italy. | |||||||||

| [151] | X | Bricks made from plastic waste. | |||||||||

| [152] | X | Sequential pyrolysis and catalytic chemical vapour deposition of plastic waste. | |||||||||

| [153] | X | Bioplastic used in circular cosmetic dermatology and packaging. | |||||||||

| [157] | X | Chemical-ultrasonic treatment of Multilayer Flexible Packaging Waste (MFPW). | |||||||||

| [161] | X | Product policy and design measures of ICT. | |||||||||

| [172] | X | Decontamination of agrochemical. | |||||||||

| [183] | X | New products made from recycled polymer. | |||||||||

| [184] | X | Different approaches to recycled polymer use. | |||||||||

| [192] | X | Guidance to incorporate recycled plastics into new E&EE. | |||||||||

| [195] | X | X | Leveraging waste reclaimed from water. | ||||||||

| [197] | X | Construction products made from plastic. | |||||||||

| [203] | X | Societal challenge of plastic packaging. | |||||||||

| [210] | X | Innovative plastic product development for food packaging design. | |||||||||

| [221] | X | Car door material LCA.audit | |||||||||

| [223] | X | Literature review of bioplastic. | |||||||||

| [229] | X | Reusable plastic crates in Italy. | |||||||||

| [230] | X | Single-use black LCA plastic life cycle. | |||||||||

| [231] | X | Plastic food packaging development. | |||||||||

| [239] | X | eDIM (ease of disassembly matrix) using LCD Monitor. | |||||||||

| [240] | X | Circular construct on product implementation. | |||||||||

| [245] | X | Recycling plastic used in air purifiers. | |||||||||

| [257] | X | Upcycling using recyclebot. | |||||||||

| TOTAL | 6 | 2 | 1 | 4 | 2 | 0 | 0 | 1 | 35 | 1 | |

LEGEND: R0 = Refuse; R1 = Rethink; R2 = Reduce; R3 = Reuse; R4 = Repair; R5 = Refurbish; R6 = Remanufacture; R7 = Repurpose; R8 = Recycle; R9 = Recover.

At the product level, Refuse (R0) strategy addresses mainly the replacing of fossil-plastics with bioplastics having a similar function. Two pieces focused on the performance comparison between a fossil-based plastic product and biodegradable single-use tableware [35, 67]. Two articles focus on novel products as an innovative approach to a more circular cosmetic dermatology and packaging [153] and PLA for novel consumer packaging application [76]. The literature on bioplastic focused on the issue of risks associated with its use [4, 223].

Rethink (R1) strategy at the main product level focuses on rethinking product design to render it more sustainable. Rethinking product design innovation can involve the use of waste [66], sharing economy and the internet of things concept to enable CE [140]. Reduce (R2) strategy reflects the circular preference to reduce raw material consumption during production through innovative plastic packaging design [210]. At product level, the topic focuses on reuse (R3) of recycled plastic to produce bricks [146], and reusable plastic crates [229]. Other topics include the consideration of product reusability throughout its lifecycle when designing products for helicopter canopies [109].

Repair (R4) involves making defective products useable and has its original function in maintenance [175]. Research at the product level focuses on product design disassembly evaluation using ease of Disassembly Metrics through the case study of LCD Monitor [239]. The other article measuring recyclates feedstock quality employed the example of a single-use plastic bottle [101]. There is one piece of research which compares remanufacture (R6), recycle (R8), and recover (R9) in upcycling plastic scrap [96].

Recycle (R8) forms the largest portion of circular strategy at the product level with the topics encompassing recycled products, chemical recycling, DRAM, decontamination, product lifecycle and product design. Three articles focused on recycled products: recycled polymers [184], bricks made from plastic waste [151], air purifiers [245], and construction products made from plastic [197]. Another article provides guidance to manufacturers looking to incorporate recycled plastics in new electrical and electronic equipment (E&EE) [192]. The articles on household waste (HHW) focused on HHW recycling in Denmark [54], thermal degradation, and the mechanical properties of resource-separated plastic HHW [53]. One article assess CE of plastic bottle in the USA at a product systemic level [133].

Chemical recycling options at the product level encompass thermo-chemical exploitation of plastic [138], thermochemical conversion from landfill [27], chemical-ultrasonic treatment of different types of Multilayer Flexible Packaging Waste [157], sequential pyrolysis and catalytic chemical vapor deposition [152]. The DRAM option at the product level include; upcycling using recyclebot, an open-source waste plastic extruder [257] and 3D printer FPF (Fused Particle Fabrication) lifecycle [26]. The articles on plastic decontamination of secondary material comprise agrochemical decontamination [172], pesticide residue in agricultural polymer containers [50], and recycled product chemical safety relating to food packaging [72]. Three articles focused on the product lifecycle of single-use black plastic [230], car door material [221], and plastic diesel fuel filters made from recycled polymide [9].

Articles of product design include topics such as single use feeding bottles [122], plastic food packaging development 231], biodegradable plastic product design [127], and product policy and design measures of information and communication technologies (ICT) [161]. Product design and eco-design packaging replaces eucalyptus wood sheets with plastic compound alternatives composed of virgin and recycled PP [33]. Other articles focus on cotton polyester textile recycling to produce a novel cellulose fibre [89]. The articles on PCPW (Post-Consumer Plastic Waste) product design focused on large-scale industrial trials of new products [183] and the plastic waste recyclability characteristics of Danish recycling centers [61]. The rest of the articles on product recycling cover topics such as societal challenges from plastic packaging [203], implementing circular construction of products [240], and leveraging waste reclaimed or diverted from water for products and marketing [195].

4.1.4. Customer level

At the customer level the circular strategy of Refuse (R0) largely relates to the customer perception of using bioplastics as opposed to fossil plastic with the following focus. users' emotional experiences resulting from interaction with sustainable materials [14]; psychological drivers of market acceptance of bioplastics [36]; consumer perceptions of bioplastic [200]; a bioplastic market review and the latest solution resulting from the use of bioplastic packaging materials [45]. Table 8 shown the distribution of literature of circular strategy at the customer level.

Table 8.

Circular strategy at the consumer level.

| Circular Strategy at the Consumer Level | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| References | R0 | R1 | R2 | R3 | R4 | R5 | R6 | R7 | R8 | R9 | Research |

| [14] | X | X | Users' emotional experiences resulting from interaction with sustainable materials. | ||||||||

| [15] | X | Recycling limitation and impacts to health and safety. | |||||||||

| [18] | X | Consumer's perception of environmentally sustainable beverage containers and compared it with LCA. | |||||||||

| [31] | X | Waste sorting manual vs. technical and health risk for workers | |||||||||

| [36] | X | Psychological driver for market acceptance for bioplastic. | |||||||||

| [45] | X | Bioplastic market review and the latest solution bioplastic packaging materials | |||||||||

| [82] | X | Raising awareness of plastic waste through practical session among interdisciplinary audience. | |||||||||

| [120] | X | Mass flow analysis of plastic & paper for childhood exposure to hazardous chemical in recycled material. | |||||||||

| [135] | X | Behavioral response to plastic produces in Dutch. | |||||||||

| [137] | X | Stakeholders' perception and viability of 3D printing as a CE enabler at the local level. | |||||||||

| [158] | X | Value-adding by informal waste collector in developing economies. | |||||||||

| [200] | X | Consumer perception to bioplastic. | |||||||||

| [205] | X | Plastic bottles reduce-reuse-recycle campaign in university. | |||||||||

| [248] | X | Behavioral change on marine litter mitigation. | |||||||||

| [259] | X | Waste prevention behavior for plastic bottle. | |||||||||

| TOTAL | 4 | 2 | 2 | 1 | 0 | 0 | 0 | 0 | 6 | 1 | |

LEGEND: R0 = Refuse; R1 = Rethink; R2 = Reduce; R3 = Reuse; R4 = Repair; R5 = Refurbish; R6 = Remanufacture; R7 = Repurpose; R8 = Recycle; R9 = Recover.

Rethink (R1) strategy focuses on raising awareness of the research focus on consumers’ perceptions of environmentally sustainable beverage containers and comparing it with LCA [18]. Raising awareness of plastic waste is undertaken through practical sessions involving interdisciplinary participants [82].

Reduce (R2) strategy highlights the following initiatives to prevent waste generation: university-based plastic bottle reduce-reuse-recycle campaigns [205]; behavioral change in terms of reducing marine pollution [248]; and effecting changed behavior with regard to plastic bottle waste prevention [259].

Recycling (R8) strategy at the customer level focuses on recycled product impact on health with particular reference to the following: recycling limitations and impacts on health and safety [15]; waste sorting manuals vs. technical and health risks for workers [31], mass flow analysis of plastic and paper in relation to childhood exposure to hazardous chemicals in recycled material [120]; behavioral response to plastic products in the Netherlands [135]; and stakeholder perceptions and viability of 3D printing as a CE enabler at the local level [137]. To reduce the adverse effect on human health from the increase adoption of recycling, the CE should be based on sustainable and clean resource flows [121].

4.2. Meso-system perspective circular strategy for plastic

4.2.1. Business level

The main focus of the circular strategy at the business level is on recycling (R8) with research gaps in the areas of refuse (R0), and strategies aimed at extending product lifespan. Table 9 shown the distribution of literature of circular strategy at the business level. One article reviewied distributed recycling using a 3D process chain [206]. Another dealt with chemical recycling of plastic waste-to-fuel from disused landfills within the EU [65]. The remaining articles covered the following topics related to mechanical recycling: healthcare waste analysis using the case study of a general public hospital in Pakistan [5]; an analysis of the life cycle of agricultural plastic waste (APW) [28]; the framework integrating an AI/DB (Artificial Intelligence Database) interface into the DSC-TGA (Differential Scanning Calorimetry-Thermogravimetric Analysis) system with a virgin-recycled mixing ratio database beneficial to the manufacturer [71]; optimizing recycling management in terms of emptying holding containers [129]; and plant bottle packaging company programs in China [188].

Table 9.

Circular strategy at the business level.

| Circular Strategy at the Business Level | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| References | R0 | R1 | R2 | R3 | R4 | R5 | R6 | R7 | R8 | R9 | Research |

| [5] | X | Healthcare waste analysis using case study of general public hospital in Pakistan. | |||||||||

| [28] | X | APW life cycle analysis. | |||||||||

| [34] | X | “Waste-to-resources” opportunities in plastic and food supply chain waste. | |||||||||

| [65] | X | Plastic waste-to-fuel recycling from old landfills in EU. | |||||||||

| [71] | X | Framework combines AI/DB interface into DSC-TGA system with database of mix virgin-recycled ratio. | |||||||||

| [100] | X | X | Propose improvement of Recyclability Benefit Rate and the Recycled Content Benefit Rate indicators. | ||||||||

| [112] | X | Organization behaviour to CE in Belgium. | |||||||||

| [117] | X | X | Fuel mixture using contaminated plastic for incinerator. | ||||||||

| [129] | X | Optimize recycling management in terms of emptying containers holding. | |||||||||

| [188] | X | Plant bottle packaging company program in China. | |||||||||

| [198] | X | Indicators for Circular Business Model using case study of companies in Brazil. | |||||||||

| [206] | X | Review of DRAM using a 3D process chain. | |||||||||

| [227] | X | Composition analysis of waste produced during a flight using case study of 27 flights in Cyprus. | |||||||||

| [254] | X | X | For municipal household waste, the largest value creation potential is at waste reuse (economically, socially, and environmentally). | ||||||||

| TOTAL | 0 | 2 | 1 | 1 | 0 | 0 | 0 | 0 | 11 | 2 | |

LEGEND: R0 = Refuse; R1 = Rethink; R2 = Reduce; R3 = Reuse; R4 = Repair; R5 = Refurbish; R6 = Remanufacture; R7 = Repurpose; R8 = Recycle; R9 = Recover.

A discussion of Rethinking (R1) organization behavior with regard to CE can be found in these articles. Indicators for Circular Business Model are used in a case study of companies in Brazil [198], while the relationship between Organization behaviour and CE draws on an example from Belgium [112]. Waste reduction (R2) represents the research focus of a composition analysis of waste produced during commercial flights using a case study of 27 such journeys to and from Cyprus [227]. Reuse (R3) and recycle (R8) appear in the research on municipal household waste, where the largest value creation potential (economic, social, and environmental) is that of waste reuse [254]. Several papers refer to the use of energy recovery (R9) to process unrecyclable, contaminated, and mixed plastic waste [100, 117] and propose improvements in Recyclability Benefit Rate and the Recycled Content Benefit Rate indicators [100] and use of a fuel mixture containing contaminated plastic for incineration [117].

4.2.2. Production chain level

Refuse (R0) strategy is covered in three articles relating to the production chain level with the following focus: designing for Recycling (DfR) to address bio-based polymers and recycling infrastructure system constraints [95]; a collaborative value chain for circular business models [111]; investigations into the structure of potential Organic Fraction of Municipal Solid Waste (OFMSW) supply chains to identify bottlenecks (bioplastic) [178], the role of Reduce (R2) strategy in the optimization of end-to-end supply network design to reduce waste in Scottish agriculture [190]; and Reuse (R3) strategy in relation to the legacy additives in the plastic waste stream resulting from improper disposal, treatment option and regulation [244]. Table 10 shown the distribution of literature of circular strategy at the production chain level.

Table 10.

Circular strategy at the production chain level.

| Circular Strategy at the Production Chain Level | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| References | R0 | R1 | R2 | R3 | R4 | R5 | R6 | R7 | R8 | R9 | Research |

| [19] | X | Innovative value co-creation through collaboration model in garden market plastic films. | |||||||||

| [23] | X | PCPW Recycling network level of types & material. | |||||||||

| [32] | X | Eco-design along the production chain. | |||||||||

| [85] | X | PCPW focus on stakeholders' value chain. | |||||||||

| [86] | X | Integrating systemic thinking in value chain of stakeholders for PCPW. | |||||||||

| [95] | X | Designing for Recycling (DfR) for bio-based polymers and recycling infrastructure system constraints. | |||||||||

| [111] | X | X | Collaborative value chain for circular business model. | ||||||||

| [165] | X | Distributed plastic recycling using 3D printer using closed supply chain network. | |||||||||

| [178] | X | X | Investigate the structure of potential supply chain of OFMSW to identify bottlenecks (bioplastic) | ||||||||

| [190] | X | X | Optimization on end-to-end supply network design to reduce waste in Scotland agriculture. | ||||||||

| [233] | X | Islamabad and Rawalpindi industrial circular plastic consumption cycle. | |||||||||

| [244] | X | X | Legacy additives in the plastic waste stream from improper disposal, treatment option and regulation. | ||||||||

| [139] | X | Mathematical modelling of supply chain complexity to identify possible optimum recycling centres. | |||||||||

| TOTAL | 3 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 12 | 0 | |

LEGEND: R0 = Refuse; R1 = Rethink; R2 = Reduce; R3 = Reuse; R4 = Repair; R5 = Refurbish; R6 = Remanufacture; R7 = Repurpose; R8 = Recycle; R9 = Recover.

Recycle (R8) constituted the predominant strategy of at the production chain level with the following topics: innovative value co-creation through a collaboration model in market garden plastic films [19]; eco-design throughout the production chain [32]; “Waste-to-resources” opportunities using plastic and food supply chain waste [34]; the value-adding of informal waste collectors in developing economies [158]; distributed plastic recycling using 3D printers within a closed supply chain network [165]; industrial circular plastic consumption cycles in Islamabad and Rawalpindi [233]; mathematical modelling of supply chain complexity to identify potential optimum recycling centres [139]; research focus on three PCPW topics - PCPW Recycling network levels, types and materials [23]; PCPW focus on stakeholder value chains [85]; and integrating systemic thinking in the value chain of stakeholders for PCPW [86].

4.2.3. Industrial symbiosis level

Industrial symbiosis is a merger of two or more different industries to find optimal access to material components and process waste [12], similar to CE. Research at the industrial symbiosis level covers only reduce (R2), reuse (R3), recycle (R8) and recover (R9) within the following topics: the UK Plastic Pact for recycling collective initiative [74]; PCPW material flow analysis of the Swiss waste management system's industrial ecology [91]; an industrial symbiosis model of electrical cable reuse [136]; the life cycle assessment of household waste collected at eight recycling centers in Denmark [65]; an examination of Extended Producer Responsibility (EPR) in South Korea [104]; organization behaviour relating to CE in Belgium [112]; and Chinese plastic recycling industries (CPRI) [131]. Table 11 shown the distribution of literature of circular strategy at the industrial symbiosis level.

Table 11.

Circular strategy at the industrial symbiosis level.

| Circular Strategy at the Industrial Symbiosis Level | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| References | R0 | R1 | R2 | R3 | R4 | R5 | R6 | R7 | R8 | R9 | Research |

| [65] | X | Life cycle assessment of residential household waste collected at 8 recycling centers in Denmark. | |||||||||

| [74] | X | UK Plastic Pact for recycling collective initiative. | |||||||||

| [91] | X | PCPW material flow analysis of Swiss waste management system industrial ecology. | |||||||||

| [104] | X | Examines extended producer responsibility in South Korea. | |||||||||

| [131] | X | CPRI | |||||||||

| [136] | X | Industrial symbiosis model of electrical cable reuse. | |||||||||

| TOTAL | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 3 | 1 | |

LEGEND: R0 = Refuse; R1 = Rethink; R2 = Reduce; R3 = Reuse; R4 = Repair; R5 = Refurbish; R6 = Remanufacture; R7 = Repurpose; R8 = Recycle; R9 = Recover.

4.2.4. Eco-industrial park level

Mechanical recycling dominates circular strategy at the eco-industrial level; PCPW industrial park construction [252] and pilot CE implementation in suburban steel plants recycling plastic waste in China [256]. One text examines locally-managed chemical recycling using appropriate technology within rural communities in Uganda [107]. The article outlining the New Plastics Economy and launching a Circular Design guide to help industry transition from LE to CE uses the reduce-reuse-remanufacture-recycle strategy [75]. Table 12 shown the distribution of literature of circular strategy at the eco-industrial park level.

Table 12.

Circular strategy at the eco-industrial park level.

| Circular Strategy at the Eco-Industrial Park Level | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| References | R0 | R1 | R2 | R3 | R4 | R5 | R6 | R7 | R8 | R9 | Research |

| [75] | X | X | X | X | Outline for New Plastics Economy & launch a Circular Design guide to help industry transition from LE to CE. | ||||||

| [107] | X | Locally produced waste-to-fuel using appropriate technology in rural communities in Uganda. | |||||||||

| [252] | X | PCPW Industrial park construction. | |||||||||

| [256] | X | Pilot CE implementation in suburban steel plant recycles including plastic waste in China. | |||||||||

| TOTAL | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 1 | 4 | 0 | |

LEGEND: R0 = Refuse; R1 = Rethink; R2 = Reduce; R3 = Reuse; R4 = Repair; R5 = Refurbish; R6 = Remanufacture; R7 = Repurpose; R8 = Recycle; R9 = Recover.

4.3. Macro-system perspective circular strategy for plastic

4.3.1. City level

The research at the city level predominantly uses a recycling strategy. Examples include: waste-to-wealth of post-war communities in Sri Lanka based on recycling plastic [37]; 3D printing disruption to the existing material value chain in the London Metropolitan Area [69]; and a Multi-Waste plant established to process municipal waste by means of pyrolysis and anaerobic digestion [94]. Rethink (R1) strategy is applied as part of the urban assessment of historical circular cities [77]. Reuse (R3) and recycle (R8) are used with the urban waste circular business model by integrating 4.0 technology and 3D printing technology [160]. Waste reduce (R2) depends on the socio-demographic characteristics that affect the plastic waste generation within a Czech municipality [201]. The design of urban biorefinery in Bangkok [209] incorporates both recycling (R8) and energy recovery through incineration (R9). Table 13 shown the distribution of literature of circular strategy at the city level.

Table 13.

Circular strategy at the city level.

| Circular Strategy at the City Level | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| References | R0 | R1 | R2 | R3 | R4 | R5 | R6 | R7 | R8 | R9 | Research |

| [37] | X | Waste-to-wealth of post-war communities in Sri Lanka by recycling plastic. | |||||||||

| [69] | X | 3D printing disruption to the existing material value chain in London Metropolitan Area. | |||||||||

| [77] | X | Urban assessment of historical circular cities | |||||||||

| [87] | X | Three different collection schemes which affect quantity and quality of recycling in England. | |||||||||

| [94] | X | Multi-Waste plant to process municipal waste through pyrolysis and anaerobic digestion. | |||||||||

| [160] | X | X | Urban waste circular business model by integrating industry 4.0 technologies and 3D printing technology. | ||||||||

| [201] | X | socio-demographic characteristics that affect plastic waste generation in Czech municipality. | |||||||||

| [209] | X | X | Design of urban biorefinery in Bangkok by integrating plastic and paper recycling processes. | ||||||||

| TOTAL | 0 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 6 | 1 | |

LEGEND: R0 = Refuse; R1 = Rethink; R2 = Reduce; R3 = Reuse; R4 = Repair; R5 = Refurbish; R6 = Remanufacture; R7 = Repurpose; R8 = Recycle; R9 = Recover.

4.3.2. Regional level

Reduce (R2) strategy at the regional level is identified in two articles, namely; Landfill mining (LFM) in the Baltic region to reduce disposed waste [25] and South Italy Farmers' attitudes towards policy, subsidies, and tax credits to reduce plastic waste [43]. A Reuse (R3) and Recycle (R8) combination is available at part of the "Pay-as-you-throw" (PAYT) scheme in the County of Aschaffenburg, Germany [154]. Table 14 shown the distribution of literature of circular strategy at the regional level.

Table 14.

Circular strategy at the regional level.

| Circular Strategy at the Regional Level | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| References | R0 | R1 | R2 | R3 | R4 | R5 | R6 | R7 | R8 | R9 | Research |

| [1] | X | Exploratory study of Abloradgei dumpsite in Ghana. | |||||||||

| [3] | X | Collection process of recyclable materials in year 2004–2011 in 103 Italian provinces. | |||||||||

| [25] | X | LFM in the Baltic region to reduce disposed waste. | |||||||||

| [43] | X | Farmers' attitudes towards policy, subsidies, and tax credits to reduce plastic waste. | |||||||||

| [116] | X | Lower Austrian waste management system by introducing 'catch-all-plastics-bin'. | |||||||||

| [124] | X | X | X | Extent of toxic chemical BDEs (Brominated Diphenyl Ether flame retardants) enter secondary product chains. | |||||||

| [147] | X | X | Nordic Region plastic value chain and mapping major actors, interactions and barriers to material flow. | ||||||||

| [154] | X | X | "Pay-as-you-throw" scheme contributes to material reuse and recycling in German county. | ||||||||

| [242] | X | X | In Päijät-Häme region, significant portion of plastic material flows to energy production instead of recycling. | ||||||||

| TOTAL | 0 | 0 | 2 | 2 | 0 | 0 | 1 | 0 | 7 | 2 | |

LEGEND: R0 = Refuse; R1 = Rethink; R2 = Reduce; R3 = Reuse; R4 = Repair; R5 = Refurbish; R6 = Remanufacture; R7 = Repurpose; R8 = Recycle; R9 = Recover.

The most common strategy at the regional level is recycling (R8) featuring various topics. These include Three different collection schemes which affect quantity and quality of recycling in England [87]; Exploratory study of Abloradgei dumpsite in Ghana [1]; Collection process of recyclable materials between 2004 and 2011 in 103 Italian provinces [3]; and Lower Austrian waste management system involving the introduction of a 'catch-all-plastics-bin' [116].

The combination of Recover (R9) and Recycle (R8) strategies can be found in two articles at the regional level; Nordic Region plastic value chain and mapping major actors, interactions and barriers to material flow [147] and In Päijät-Häme region, Finland, significant portion of plastic material flows to energy production instead of recycling [242].

4.3.3. National level