Abstract

This review discusses the contribution of physical vapor deposition (PVD) processes to the development of electrochemical energy storage systems with emphasis on solid‐state batteries. A brief overview of different PVD technologies and details highlighting the utility of PVD for the fabrication and characterization of individual battery materials are provided. In this context, the key methods that have been developed for the fabrication of solid electrolytes and active electrode materials with well‐defined properties are described, and demonstrations of how these techniques facilitate the in‐depth understanding of fundamental material properties and interfacial phenomena as well as the development of new materials are provided. Beyond the discussion of single components and interfaces, the progress on the device scale is also presented. State‐of‐the‐art solid‐state batteries, both academic and commercial types, are assessed in view of energy and power density as well as long‐term stability. Finally, recent efforts to improve the power and energy density through the development of 3D‐structured cells and the investigation of bulk cells are discussed.

Keywords: interface, physical vapor deposition, solid‐state battery, thin film electrode, thin film electrolyte

The review discusses how the development of electrochemical energy storage systems and particularly solid‐state batteries can benefit from physical vapor deposition processes, from the basic understanding of the structure and properties of individual materials and their interfaces to the processing and fabrication of complete batteries.

1. Introduction

Advanced electrochemical energy storage is internationally considered as one of the disruptive technologies of the future.[ 1 ] The introduction of lithium ion battery technology boosted the available energy density of battery packs, and tremendous progress regarding the performance of lithium ion batteries has been achieved in the past decades to enable even very demanding applications for energy storage, such as, electric vehicles. Still, the demand for even higher storage capacity, faster charging rates, prolonged operational life, and more stringent safety standards require the development of more powerful electrochemical energy storage concepts. These challenges perpetuate vigorous research efforts on all levels of battery development, which remains one of the focal points of energy research.

In this review it is shown how the development of electrochemical energy storage systems can benefit from physical vapor deposition (PVD) processes, from the basic understanding of the structure and properties of individual materials and their interfaces to the processing and fabrication of complete batteries. PVD is a process in which material is deposited from the gas phase. Its key advantage is the creation of dense solid layers with a tunable thickness, adjustable and controlled composition, crystallinity and crystal orientation. Further, the risk of contamination is minimal due to the absence of organic reactants, and there is the option to sequentially deposit several materials to form well‐defined multilayer systems. One of the unique advantages of PVD is the operation at significantly lower processing temperatures relative to the densification of materials by conventional heat treatment due to the higher energy of the species in the gas phase. This is particularly important (or even essential) when two materials to be processed as adjacent layers are prone to mutual interdiffusion or detrimental chemical reactions.

PVD techniques are highly useful for addressing various aspects of development within a broad spectrum of battery concepts.[ 2 ] However, in this review, the authors focus mainly on ceramic solid‐state battery research and development for which PVD methods have shown to unfold their full potential. Therefore, the discussion includes lithium metal and Li‐ion batteries, but it does not touch upon Li‐sulfur or Li‐oxygen systems.

Following a brief overview of different PVD technologies, the application of PVD for processing of individual battery materials is discussed in detail. We summarize the key processes that have been developed for the fabrication of solid electrolytes as well as active electrode materials with different crystalline structures and analyze how the processing conditions affect the resulting material characteristics. PVD techniques can be utilized to expand the fundamental understanding of battery materials (such as, e.g., the influence of the crystalline structure, crystal orientation and defects on the electronic and ionic conductivity, electrochemical performance, and underlying material transformations). Further, the application of PVD for the development of novel materials via the generation of material libraries that enable high‐throughput material screening is illustrated. The fabrication of thin film battery components, such as thin separator layers and various coatings for different battery designs, is also discussed.

With respect to the complex interfacial phenomena encountered in solid‐state batteries we present work that demonstrates how PVD facilitates both understanding and optimization of interfaces between different battery materials. Due to the possibility of sequentially depositing planar layers at low temperatures, PVD is ideally suited for fabricating model systems to investigate interfaces between solid materials. Model systems obtained via PVD techniques enable the deconvolution of interfacial phenomena that occur during processing and operation. Aside from discussing fundamental studies of interfacial properties, we describe the application of PVD for the production of thin functional layers, which improve the properties of the interfaces. More specifically, protective coatings that prevent chemical or electrochemical reactions between battery materials during processing or operation are described as well as adhesive coatings, which improve the contact between the materials and thus minimize the interfacial resistance.

Due to its ability to control the properties of individual materials and their interfaces, and by allowing the fabrication of multi‐layer structures, PVD technology is an excellent tool for the development of thin film batteries, which are also described in this review. Properties of state‐of‐the‐art commercial thin film batteries are briefly discussed as well as ongoing efforts to further improve the battery performance and also enable cell designs for specialty applications. Finally, to provide a comprehensive overview of processing issues with respect to the development of ceramic batteries, a brief summary regarding the progress of bulk battery cell development to date is provided.

2. Physical Vapor Deposition

2.1. Methods

PVD refers to a variety of vacuum techniques used to deposit thin films by the transport of material from a condensed matter source via the gas phase to another surface that shall be coated. The physical properties of the material generally do not change. In contrast to conventional ceramic processing, where materials have to be heat‐treated or densified at high temperatures (above roughly 50–75% of the melting temperature of the material[ 3 ]), PVD can provide dense and crystalline films at significantly lower temperatures. This is especially advantageous in setups where element interdiffusion between adjacent layers is detrimental and has to be avoided, for example, for model systems that are applied to study interfacial phenomena. As an example, a sintering temperature of at least 1400 °C is needed for the densification of screen‐printed yttria‐stabilized zirconia,[ 4 ] whereas comparably dense layers are obtained at 800 °C by PVD.[ 5 ]

PVD techniques generally involve processes featuring a ballistic transport of material. Ballistic transport means a transfer of material from the source to the sample without any or only very few collisions with other atoms, ions or molecules. The species transferred from the condensed phase to the gas phase obtain energy from the material source, which is the basis for the creation of dense layers compared to conventional heat treatment during ceramic processing. This energy gain has to be preserved until the gas species hit the sample surface. Hence, a ballistic transport requires a mean free path of roughly a couple of centimeters to a couple of decimeters. This implies pressure ranges of less than about 1 to 10 Pa.[ 6 ]

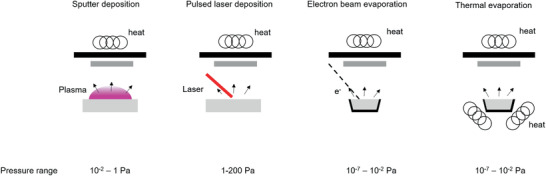

The deposition rates in PVD‐processes are highly dependent on the processing conditions and typically range between 1 and 100 nm s−1. Accordingly, this leads to layer thicknesses from a few nanometers to hundreds micrometers with process times varying from fractions of seconds to hours. For solid‐state battery research, the most important PVD processes are sputtering, pulsed laser deposition (PLD) and evaporation (thermal and electron beam) techniques. Simplified schemes of the single processes are shown in Figure 1 . Sputter deposition and evaporation processes are already well‐established in industrial processes (thermal insulation on architectural glass, wear‐resistant tools) due to their ability to coat large areas, including roll‐to‐roll processes, whereas PLD was limited to small substrate sizes for many years. In the last decade, the available areas for coating increased up to 300 mm diameter. This improvement was realized by beam widening and shaping, with orders of magnitude higher output powers compared to typical PLD laser systems for research.[ 7 ]

Figure 1.

Schematic illustration of different PVD techniques.

Vacuum and energy uptake during the phase transition from the condensed phase to the gas phase are important aspects and are discussed in more detail in the energy considerations in the following sections in which the fundamental characteristics of widely applied PVD techniques are described.

2.1.1. Sputter Deposition

Sputtering is the acceleration of gas ions on the surface of the material source where the material is spalled off/atomized. A high electric field is used to create a plasma. The setup for sputtering features an electrical current flow. A direct current (d.c.) method can be utilized for reasonably conductive material sources, whereas radio frequency (r.f.) currents are required in the case of electrical insulators. Plasmas are comparatively difficult to describe, as they can exist in thermal non‐equilibrium conditions. The electric field properties and intricacies of the sputter setup influence the generation of the plasma, especially the temperature, which in turn directly affects the velocity and energy distribution and also the collision cross sections of the species in the gas phase.[ 8 ] In general, the energy of the particles in the vapor phase during sputtering is higher compared to conventional evaporation due to the energy stemming from the high electric field,[ 9 ] so that deposition can be carried out at higher background pressures.

So‐called reactive sputtering processes represent a special case. Here, a gas with a slightly higher pressure than what would be common for conventional PVD is supplied, and the species sputtered from the target react with the gas molecules, thus forming new compositions. Therefore, reactive sputtering differs in two major aspects from the sputtering process described above: i) The target, gas, and layer composition are not identical, in contrast to conventional PVD; ii) the sputtered species collide with the gas molecules, which is intentional, in order to interact/react with them. Therefore, it is necessary to change the process, for example, to increase slightly the gas pressure, which allows more collisions. Thus, the gas transport behavior is shifted to a transition regime between a purely ballistic regime and a purely diffuse regime.

2.1.2. Evaporation Techniques

The most well‐known process for transferring material from a condensed phase to a gas phase is evaporation, resulting in a gas phase above the condensed phase. In an ideal case the gaseous species are in at least a local thermal equilibrium, and their velocities can be described by a Maxwell–Boltzmann distribution, although deviations from classical statistical mechanics were also reported.[ 10 ] Temperature is a significant parameter for the velocity distribution and thus for the energy distribution of the particles hitting the sample surface during deposition.

The most common method for evaporation is Joule heating, by which electrical energy is converted into heat by a resistor. This setup is limited to temperatures that are lower than the melting points of the crucibles and heating wires. By contrast, electron beam evaporation is also capable of evaporating refractory materials like highly temperature‐resistant ceramics. A focused electron beam is wobbled along the source material surface for heating. Further, effusion or Knudsen cells are specifically designed evaporation devices through which the vapor beam may be generated by Joule heat, but a directed beam is created by effusion.

While evaporation is one of the simplest methods to transfer materials in a gaseous phase, it is not universally applicable to the deposition of multicomponent compounds. Major problems arise if the compound to be evaporated melts incongruently, which may lead to variations in the compositions of the molten phase and the gas phase.[ 11 ]

2.1.3. Pulsed Laser Deposition

PLD evaporates and ionizes the material through one or a series of high energy laser pulses. The problem of compositional changes often encountered with evaporation processes practically does not arise. Therefore, PLD is favorable for the stoichiometric deposition of materials. As the laser light is focused on a small spot, only small areas of a sample can be coated in a homogeneous manner. The area‐specific power density of the laser pulse can be as high as 1015 W m−2, assuming pulses of 10 J in10 ns on an area of 1 mm2. This can be compared with the energy dissipation of 1020 W of a nuclear bomb,[ 12 ] which also highlights the difficulty of scaling up PLD to coat large areas. The fact that PLD does not only evaporate the material, but also ionize the vapor, illustrates the high vapor particle energy during processing,[ 13 ] which enables deposition at higher pressures, similar to sputtering processes. Therefore, reactive gases, which play an important role in the deposition of oxides, can be introduced into the deposition chamber.

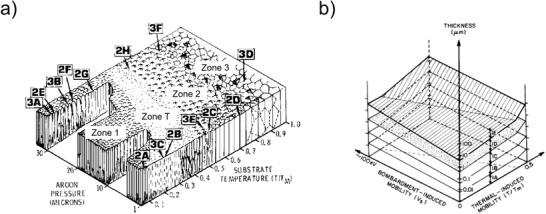

2.2. Thin Film Growth

The morphology developing during thin film growth depends on several factors, which are related to the mobility of the atoms on the substrate surface. Zone growth models (ZGM) were developed to describe the most important parameters. The most widely known ZGM is most likely the model developed for thick sputtered films by Thornton, which takes into account the process pressure and the ratio between the deposition temperature T and the melting temperature of the sputtered material T m (T/T m) as the factors defining the film growth (Figure 2a).[ 14 ] Four zones are described in the model:

Figure 2.

Zone growth models from a) Thornton, Reproduced with permission.[ 14 ] AIP Publishing. b) Messier et al. Reproduced with permission.[ 15 ] Copyright 1984, American Vacuum Society.

-

‐

Zone 1 (T/T m < 0.1): Low adatom mobility, small grains separated by voids.

-

‐

Transition zone (0.1 < T/T m < 0.3): Dense arrays of fibrous grains.

-

‐

Zone 2 (0.3–0.5 < T/T m < 0.75): Columnar grains, grain boundary migration, and recrystallization possible.

-

‐

Zone 3 (0.75 < T/T m): Flat grain tops with grooved grain boundaries.

Messier et al. further developed the model for T/T m < 0.3–0.5 including films with a thickness below 1 µm.[ 15 ] The five zones 1A, 1B, 1C, 1D, and 1E correspond to the growth of clusters with column sizes of 1–3, 5–20, 20–40, 50–200, and 200–400 nm, respectively (Figure 2b).[ 15 ] The nanostructured/amorphous nature of thin films with high‐melting compositions can be explained with this model. In the model developed by Messier et al., the bombardment‐induced mobility, which can be practically implemented by ion‐beam assistance or bias sputtering, was also mentioned as one factor that can improve the crystallization of thin films.[ 15 ]

The deposition temperature and the energy of the impinging particles further influence the interface formation between the substrate and the thin film.[ 16 ] The smaller these factors are, the smaller the resulting interface thickness becomes and vice versa. In order to deposit epitaxial thin films, the interface formation between the substrate and the thin film should be limited to a minimum. However, substrate heating is necessary to enable a sufficient mobility of the deposited atoms and thus the growth of a 2D film. Epitaxial growth can be realized more effectively by PLD or evaporation.

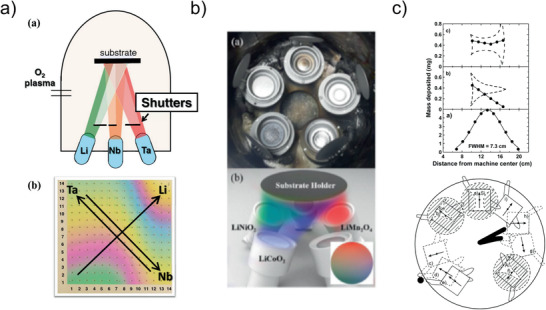

2.3. Material Development Facilitated by Physical Vapor Deposition

PVD techniques provide unique possibilities for high through‐put screening of novel materials and thus the generation of material libraries, which is one key task in current battery research. Films with tunable thickness, multielement composition, and composition gradients can be deposited in a controlled way. The thin film geometry is perfectly suitable for rapid screening by a wide variety of characterization techniques. Recent developments in automatization of analytical processes[ 17 ] and data processing in combination with well‐established technologies for thin film patterning, such as lithography, enable compiling large databases, which can be applied for machine learning processes. In addition to the development of battery components, which is discussed in more detail in the next chapter, the application of thin film libraries is well established for material development for photoelectrochemical water splitting,[ 18 ] shape memory alloys,[ 19 ] transparent conductive oxides,[ 20 ] and several other technologies. For further reading on this subject a review by Kafizas and Parkin is recommended.[ 21 ]

Typical techniques for the deposition of material libraries are shown in Figure 3 . The use of different material sources with different tilt angles/orientations will lead to a gradient due to the typical cosine distribution of the film thickness in PVD, provided that the substrate is not rotated. The slope of the gradient depends on the tilt angle of the sources. In Figure 3 examples for realizing such a gradient with effusion cells (Figure 3a) as well as in sputtering processes (Figure 3b) are shown. Intermixing of different materials by fast rotation of the substrate over different sputtering targets, as presented in Figure 3c, is also a possibility. In this case, the amount of material deposited from each target is controlled by using different shadow masks, where each mask causes a characteristic concentration curve.

Figure 3.

Different technical setups for the generation of material libraries by PVD. a) Setup for deposition of interlayers by using Knudsen‐effusion cells and oxygen plasma (top) and the generated sample from Li—Ta—Nb (bottom). Reproduced with permission.[ 22 ] Copyright 2015, ECS. b) Setup for sputter deposition of up to five different materials at once, equipped for LiNiO2‐LiCoO2‐LiMnO2 gradients. Reproduced with permission.[ 23 ] Copyright 2016, Elsevier. c) Effect of shadow masks to generate gradients(top) in a setup for up to 3 elements (Si—Sn—Al) (bottom). Reproduced with permission.[ 24 ] Copyright 2002, American Chemical Society.

3. Deposition and Properties of Thin Film Battery Components

The deposition of thin films with defined composition, crystallinity, orientation, and thickness is the key to a deeper understanding of material properties. However, the processing parameters have to be carefully adjusted to obtain appropriate samples. As already explained in Section 2.2, the degree of crystallization can be controlled very precisely by PVD, which enables the investigation of materials in their crystalline or amorphous state. However, the crystallization, which is a crucial step for a wide variety of battery materials, is carried out via heating, either in situ or in a post‐annealing step, which means that detrimental diffusion/reactions into/with the substrate material can occur. Further, if the substrate and the deposited layer are not compatible due to different coefficients of thermal expansion (CTE), bond character and/or lattice parameters, the risk of defects is increased with increasing treatment temperature. Therefore, a decrease of the deposition temperature, for example, by application of a bias voltage during a sputter process, is always desirable in thin film research.

The thin films deposited by PVD processes are free of organic additives and solvents and have a defined surface area, which allows relatively straightforward measurements of fundamental electrical and electrochemical properties. Further, PVD methods are suitable for the fabrication of films grown epitaxially or with preferred orientation, enabling the determination of material properties along a defined crystallographic axis. In addition, the analysis of chemical information, for example, by secondary ion mass spectrometry (SIMS) and X‐ray photoelectron spectroscopy (XPS), for thin film geometries is facilitated considerably.

Material libraries generated with PVD processes can be applied for high‐throughput material screening, which can accelerate the development of new compositions with enhanced electrochemical properties.

3.1. Deposition and Properties of Thin Film Electrolytes

The electrolyte plays a fundamental role in all types of batteries. In addition to ideally exhibiting a high Li‐ion conductivity and a low electronic conductivity it also should not form detrimental interfaces (e.g., by reaction) with electrode materials. The electrolyte does not take part in the electrochemical reaction, and therefore its mass should be reduced as much as possible to maximize the energy density of the cells. This can be realized by deposition of thin film electrolytes. Processing of thin films by PVD methods for the most common glass/ceramic electrolytes is discussed in this section.

3.1.1. Li3PO4‐ xNx

The amorphous, partially nitrated phosphate Li3PO4‐ xNx (LiPON) was first described as a good lithium ion conductor by Bates et al. in 1996.[ 25 ] In general, LiPON is deposited by an r.f. sputter deposition process from a Li3PO4 target by using nitrogen as a reactive sputter gas without substrate heating. PVD is considered to be the only technique to obtain LiPON layers with sufficient conductivity and satisfactory performance.

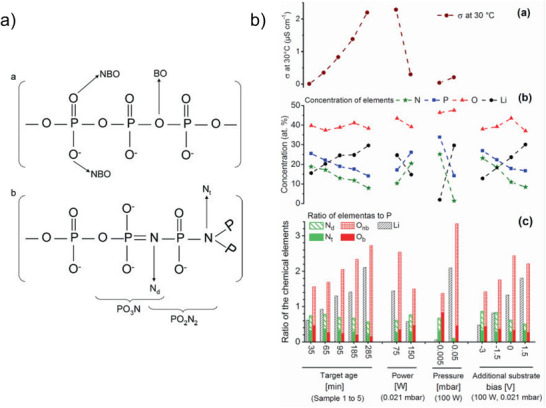

The reported key properties of LiPON are an ionic conductivity of about 2 × 10−6 S cm−1 and an activation energy of about 0.55 eV.[ 25 , 26 ] Amorphous Li3PO4 thin films showed a conductivity of 6.3 × 10−8 S cm−1 and an activation energy of 0.67 eV.[ 26 ] The highest conductivities reported for LiPON to date are 9.4 × 10−6[ 27 ] and 9.78 × 10−6 S cm−1.[ 28 ] On the other hand, the conductivities for crystalline Li3PO4 and LiPON are 4.2 × 10−18 and 1.4 × 10−13 S cm−1, respectively.[ 29 ] In order to keep the thin films in the highly conductive amorphous state, substrate heating is not applied during LiPON deposition. The low deposition temperatures are beneficial for battery fabrication, as they prevent severe element interdiffusion, which is typically observed at high processing temperatures. Extensive work was done to deposit LiPON thin films with different sputter parameters, such as sputter power,[ 30 , 31 ] pressure,[ 30 , 32 ] nitrogen flow rate,[ 33 ] bias voltage, and substrate temperature.[ 34 ] The objective was to elucidate the influence of the chemical structure on the ionic conductivity. Different chemical features, such as the N/P, Li/P, and Li/O ratio, as well as structural features, such as the ratio between triply coordinated nitrogen (Nt) and doubly coordinated nitrogen (Nd), the amount of bridging oxygen atoms (Figure 4a), etc., were discussed as the potential cause of high conductivity. However, although all chemical and structural features show trends when investigated as a single parameter, combined studies showed that the conductivity cannot be correlated with one single structural feature.[ 28 , 35 ] Hamedi Jouybari et al. concluded from their study that it is more likely that sufficient amounts of nitrogen and lithium incorporated in the structure and a low amount of bridging oxygen increase the conductivity (Figure 4b).[ 35 ] These results were confirmed by theoretical and experimental work by Lacivita et al. on the structural features of LiPON. Their studies do not support the existence of Nt in the structure.[ 36 ] Their work suggests the existence of apical N (Na) as the main structural feature that enables high ionic conductivity. The calculation fits neutron and infrared‐spectroscopy data very well, and a comparison of their results with conductivity data from the literature shows good agreement. However, this detailed study did not provide a complete explanation of the experimentally observed XPS spectra, which were mainly used to determine the structural features, and also did not explain some of the experimentally determined conductivity values, for example, the high conductivity of 9.78 × 10−6 S cm−1 published by Mani et al.[ 28 ]

Figure 4.

a) Structural features of LiPON, NBO = non‐bridging oxygen, BO = bridging oxygen, Nd = di‐coordinated nitrogen, Nt = tri‐coordinated nitrogen. Reproduced with permission.[ 37 ] Copyright 2012, Elsevier. b) Correlation of various chemical and structural features with Li‐ion conductivity in LiPON thin films. Reproduced with permission.[ 35 ] Copyright 2018, Elsevier.

While LiPON thin film fabrication employs a sintered Li3PO4 target in most studies, a few reports discussed the deposition from powder targets. Nimisha et al. and Suzuki et al. obtained LiPON thin films with conductivities of 1.1 × 10−6[ 38 ] and 3.1 × 10−6 S cm−1,[ 39 ] respectively, which is similar to values commonly published in the literature. On the other hand, a significant increase in the ionic conductivity was realized by adding Li2O to the powder target, so that conductivities of up to 6.4 × 10−6 S cm−1 could be achieved. However, the Li2O rich film showed more severe degradation after exposure to air, as pronounced particle growth, cracks and exfoliation were observed by scanning electron microscopy (SEM) analysis after 20 days.[ 40 ]

LiPON films were also grown by PLD from a Li3PO4 target in a flowing N2 atmosphere. A high pressure of about 267 Pa and a high laser fluence in the range of 15–20 J cm−2 were necessary to incorporate a sufficient amount of nitrogen into the glassy state, so that conductivities of up to 1.67 × 10−6 S cm−1 could be obtained.[ 41 ] These observations are complementary with the low conductivities obtained from studies with lower nitrogen pressure and laser fluence.[ 42 , 43 ] Nitrogen‐free Li3PO4 deposited by PLD yielded conductivities of up to 4 × 10−7 S cm−1.[ 42 ]

Electron beam evaporation processes supported by a nitrogen plasma represent another technique that can be applied for LiPON deposition. Different studies with varying plasma parameters revealed a maximum conductivity of 6 × 10−7 S cm−1.[ 44 ]

3.1.2. Garnet

Li‐rich garnets, such as Li5La3Ta2O12 (LLTaO) and Li7La3Zr2O12 (LLZ), were first described by Thangadurai et al.[ 45 ] and Murugan et al.,[ 46 ] who demonstrated that these materials exhibit high bulk ionic conductivities in the range from 10−6 S cm−1 (LLTaO) to 10−4 S cm−1 (LLZ). LLZ forms either a cubic phase with high ionic conductivity (up to 1.8 × 10−3 S cm−1[ 47 ]) or a tetragonal phase with a conductivity of up to 2.3 × 10−5 S cm−1 depending on the composition and synthesis temperature.[ 48 ] Various substitutions can be carried out while maintaining the garnet structure. The most common options are: the substitution of the Li‐site by Al3+ and Ga3+, the substitution of the La‐site by Ca2+, Sr2+, and Ba2+, and the substitution of the Zr/Ta‐site by Nb5+. Through these substitutions the amount of Li‐ion vacancies can be tuned precisely, and the cubic phase is stabilized. Thus, the ionic conductivity can be maximized. More details about substitutions are summarized in two review papers.[ 49 ]

Several attempts were made to deposit garnet structured materials by PVD processes. The proper selection of the deposition temperature in conjunction with the substrate temperature is a major challenge for the garnet deposition. Zr‐containing garnets are thermodynamically stable above 600–700 °C. At lower temperatures, amorphous phases, which exhibit low ionic conductivity, or La2Zr2O7 as the main phase were detected. At higher temperatures, a significant Li‐loss can occur due to the combination of vacuum, high temperature, and the unfavorable surface to volume ratio of thin films. The necessary temperature treatment (either during deposition or in a post‐annealing process) and the relatively high CTE of LLZ of about 15 × 10−6 K−1[ 50 ] limit the choice of suitable substrate materials. Matching CTEs help avoiding thermomechanical tensile/compressive stresses and are therefore necessary to obtain thin films without cracks and spalls, which is essential for electrolyte layers.

The first publication that demonstrated the fabrication of a garnet structure with a reasonable ionic conductivity was based on the epitaxial deposition of LLZ by PLD on a Gd3Ga5O12 substrate, which itself exhibits a garnet structure.[ 51 ] Further successful depositions via PLD were carried out on MgO substrates. Saccoccio et al. deposited Li6.4La3Zr1.4Ta0.6O12 at different temperatures followed by post‐annealing at 600 °C.[ 52 ] A different approach consisted of depositing Li6.25Al0.25La3Zr2O12, alternating with Li3N layers to balance the Li‐loss during annealing, which was carried out at 660 °C.[ 53 ]

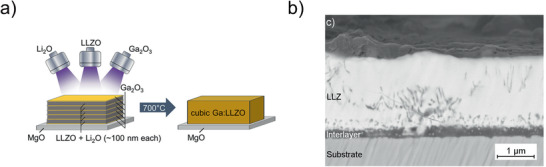

A confocal sputtering approach was applied to deposit Ga‐ and Al‐substituted LLZ on MgO substrates.[ 54 , 55 ] Three targets, namely LLZ, Li2O and either Ga2O3 or Al were used, and a sequential deposition of single layers was performed (Figure 5a). The thin films were deposited at room temperature and subsequently annealed at 700 °C to crystallize the garnet structure. Using sputter deposition from a Li6.6La3Zr1.6Ta0.4O12 target, LLZ thin films were also obtained on stainless steel substrates at a substrate temperature of 700 °C.[ 56 ] In this case, a severe reaction between the thin film and the steel substrate was observed, which produced a Li—Al—O interfacial layer (Figure 5b). For both sputtering and PLD, a temperature between 600 °C and 700 °C is necessary during deposition or post‐annealing to obtain garnet structured LLZ. When a Zr‐free garnet structure is to be deposited, lower temperatures are sufficient for crystallization.[ 57 , 58 ] Reinacher et al. deposited Li6BaLa2Ta2O12 at 550 °C with a target that was enriched with 5 mol% Li2O to compensate for possible Li‐loss during deposition.[ 57 ] The processes are also sensitive to the type of substrate. If inert material, such as MgO, is not used, reactions with the substrate are observed. Deposition on LiCoO2 (LCO) showed strong diffusion of Co into the garnet thin film.[ 59 ] Therefore, a diffusion barrier had to be implemented.[ 55 ]

Figure 5.

a) Multilayer deposition of Ga2O3 and co‐sputtered Li2O+LLZ layers which react to cubic LLZ after annealing at 700 °C. Reproduced with permission.[ 54 ] Copyright 2018, American Chemical Society. b) Sputter deposition of garnet structured thin films on steel substrate at 700 °C leads to interlayer formation. Reproduced with permission.[ 56 ] Copyright 2016, Elsevier.

The ionic conductivity of PVD‐grown LLZ films with different orientation was 1.0 × 10−5 S cm−1 and 2.5 × 10−6 S cm−1 for the (111) and (100) orientation, respectively, with corresponding activation energies of 0.52 and 0.55 eV. These values are inferior to those of bulk LLZ, which is commonly observed for thin films, and could be explained by the loss of lithium during deposition.[ 51 ] The highest conductivity of 1.2 × 10−4 S cm−1 was observed for a sputter deposition process at 700 °C.[ 56 ] In general, the conductivity values of the thin films are lower than for comparable bulk material. It can be speculated that the relatively low crystallization temperatures prevent the crystallization of large grains and thus increase the overall grain boundary resistance.

Besides PVD, chemical vapor deposition (CVD) was applied successfully to deposit tetragonal LLZ as well as Zr‐free LLTaO with sufficiently high conductivities of 4.2 × 10−6 and 3.8 × 10−5 S cm−1, respectively.[ 60 ] These values are close to those obtained with the bulk materials. LLZ thin films with a garnet structure synthesized by wet‐chemical methods, for example, sol–gel processes, have even lower conductivity values than thin films generated by PVD.[ 61 , 62 ] For example, the maximum value for a thin LLZ film deposited by a sol–gel process with subsequent annealing at 900 °C was 2.4 × 10−6 S cm−1.[ 61 ]

3.1.3. NaSICON

The abbreviation NaSICON, which stands for Na‐Super‐Ionic‐CONductor, describes a class of compounds with a stable 3D framework consisting of two types of transition metal‐oxygen (MO6 and M'O6) octahedra that share all corners with either sulfate, phosphate, silicate or arsenate tetrahedra. The first NaSICON solid electrolytes with Na‐ion conductivity were described in 1976 by Goodenough[ 63 ] and Hong.[ 64 ] The same type of structure was reported later to also show a reasonable Li‐ion conductivity. Particularly, the materials with the composition Li1+ xAlxM2‐ x(PO4)3 (M = Ge,Ti) demonstrate Li‐ion conductivities as high as 7.4 × 10−4 S cm−1 for Li1+ xAlxTi2‐ x(PO4)3 (LATP, x = 0.3)[ 65 ] and 2.4 × 10−4 S cm−1 for Li1+ xAlxGeM2‐ x(PO4)3 (LAGP, x = 0.5).[ 66 ] The lower sintering temperature of these materials compared to other ceramic electrolytes is an important advantage. Dense ceramics with high ionic conductivities can be obtained by sintering at 850 °C (LAGP)[ 67 ] and 880 °C (LATP).[ 68 ]

A crystalline LAGP thin film was obtained by sputtering from a ceramic LAGP target at 500 and 600 °C. At lower temperatures a secondary phase consisting of AlPO4 was observed.[ 69 ] Tan et al. deposited Li—Al—Ti—P—O—N thin films in a temperature range between 25 and 500 °C.[ 70 ] The as‐deposited films were amorphous with an increasing fraction of nanocrystalline domains in response to increasing deposition temperature. The ionic conductivities improved with increasing substrate temperature, showing a maximum of about 1.2 × 10−5 S cm−1 at 30 °C for a sample deposited at 500 °C with simultaneous reduction of the activation energy from 0.63 eV (deposition at 25 °C) to 0.44 eV. The Li‐ion transference number was calculated to be 0.9999 based on a polarization measurement. Hebb–Wagner measurements showed a low electronic conductivity in the range of 7.5 × 10−12 to 4.9 × 10−11 S cm−1.[ 70 ] The thin film was applied in a battery consisting of a NMC111 cathode and a metallic lithium anode, which showed a discharge capacity of about 127 mAh g−1 after 100 cycles.[ 71 ]

Recently, Hofmann et al. studied the crystallization behavior of LATP deposited by a PLD process. The deposition was first carried out on different substrates, namely, MgO, YSZ, Al2O3, and n‐doped Si, among which n‐doped Si showed the lowest amount of secondary phases. In a second step the deposition at elevated temperatures as well as the post‐crystallization of films deposited without heating were investigated. High temperature X‐ray diffraction studies revealed the formation of the NaSICON phase between 650 and 825 °C. Further, secondary phases were observed at 850 °C due to element interdiffusion between the substrate and the thin film. Crystallization studies of amorphous films at 750 °C showed that only short dwell times were necessary for the formation of the NaSICON structure.[ 72 ]

3.1.4. Perovskites

The perovskite Li3 xLa2/3‐ x ‐1/3‐2 xTiO3 (LLT, x = 0.11), which was discovered by Inaguma et al., shows a high bulk conductivity of 1 × 10−3 S cm−1, but the total conductivity of this material is typically lower due to the low grain boundary conductivity of 7.5 × 10−5 S cm−1.[ 73 ] The bulk conductivity of the perovskite structure can be tuned via substitution, for example, by Sr on an A(Li/La)‐site or by Al, Ta, Zr, Nb on a B‐Site(Ti).[ 74 ]

PVD of LLT was mainly carried out by PLD processes,[ 75 , 76 , 77 , 78 , 79 ] whereas only a few publications focused on sputtering[ 80 , 81 ] or evaporation processes.[ 82 ]

The deposition temperature is a crucial parameter for the conductivity of LLT thin films deposited by PLD. Below 700 °C, either during deposition or annealing, the thin films remain in an amorphous state, enabling higher ionic conductivities due to the absence of grain boundaries. Lee and Ahn reported 400 °C as an ideal deposition temperature.[ 76 , 79 ] Post‐annealing after deposition at 500 °C did not show a significant improvement of the ionic conductivity.[ 75 ] Controlling the oxygen partial pressure and the deposition temperature led to ionic conductivities of up to 3.0 × 10−4 S cm−1 at room temperature.[ 79 ] Furusawa et al. investigated the ionic conductivity for the composition LixLa(2‐ x )/3TiO3 while varying the Li‐content (0.1 ≤ x ≤ 0.5) and the crystallinity. Amorphous thin films demonstrated higher ionic conductivities than the comparable polycrystalline samples, reaching up to 1.252 × 10−3 S cm−1 for x = 0.5.[ 78 ] In accordance with the temperature range for amorphous thin films, epitaxial layers of LLT were deposited on SrTiO3 (STO) single crystals at substrate temperatures of 800 °C and above.[ 77 ] The conductivity of these films was 5.63 × 10−5 S cm−1 at room temperature for STO(111).[ 77 ] Sputter deposited films show a perovskite main phase with an increasing amount of secondary phases with increasing deposition temperature and a total conductivity of 5.25 × 10−5 S cm−1.[ 80 ] Films deposited by electron beam evaporation exhibited an ionic conductivity of 1.8 × 10−7 S cm−1 for the as‐deposited phase.[ 82 ] Post‐annealing at 100 °C increased the resistance of the thin film.[ 82 ]

3.2. Deposition and Properties of Thin Film Electrodes

In this chapter the discussion of the processing‐property relationships of electrode active materials is focused on materials that were already published in the context of all‐solid‐state batteries. Reviews about thin films for battery components deposited by different techniques (not exclusively by PVD)[ 2 ] as well as by PLD[ 83 ] are recommended for further reading.

3.2.1. Intercalation Materials

The most important group of electrodes are the intercalation materials. In state‐of‐the‐art batteries both electrodes typically include intercalation‐type active materials, such as graphite and Li4Ti5O12 (LTO) for the negative electrodes and LCO and LiFePO4 (LFP) for the positive electrodes. For most intercalation electrodes, the crystallization behavior of the layers is different for PLD and sputter processes, because the electrochemical properties of the materials are dependent on the oxidation state of the transition metal ions. With PLD higher oxygen partial pressures can be realized, and therefore the crystallization of the material is usually achieved by in situ heating during deposition, whereas sputter‐processes are typically carried out without active heating, and crystallization occurs during a post‐annealing step.

Electrode Materials with a Layered Structure

Layered materials with a general composition of Li(NixMnyCoz)O2 (NMC, with x+y+z = 1) are commonly used cathode active materials (CAMs) in state‐of‐the‐art lithium‐ion batteries. The most investigated material of this family is LCO, which crystallizes analogously to a layered α‐NaFeO2‐structure, and has a theoretical capacity of about 148 mAh g−1 (about 70 μAh cm−2 µm−1) and a potential of about 3.8 V vs Li/Li+.[ 84 ] Due to the importance of LCO as a CAM in commercial batteries, it attracted an immense research interest including PVD processes, which have been investigated for almost 30 years. A detailed overview of sputter deposition and PLD of LCO thin films is given in the publication put forward by Julien et al.[ 83 , 85 ] Therefore, only the most important and most recent developments will be reviewed in detail in this work.

By applying PLD, crystalline LCO films with satisfactory electrochemical properties, i.e., high discharge capacities and stable cycling behavior, can be obtained at temperatures of 600 °C.[ 86 , 87 ] An oxygen pressure of about 6.7 Pa during the deposition process provided films with a discharge capacity of about 57 μAh cm−2 µm−1 after 20 cycles, while higher pressures of about 40 Pa were found to be detrimental for the electrochemical performance due to an unfavorable crystal orientation.[ 87 ] LCO thin films deposited by sputter deposition showed the best electrochemical performance, as indicated by sufficient long‐term stability during cycling when post‐annealed at 700 °C.[ 88 ]

Crystalline LCO films can be obtained by sputtering processes at even lower temperatures if a bias voltage is applied to enhance the crystallinity, as was successfully demonstrated for LCO films deposited on aluminum substrates.[ 89 ] Cells with liquid as well as solid‐state electrolyte showed discharge capacities of about 50 μAh cm−2 µm−1 after a post‐annealing step at 500 °C.[ 89 ] This value is lower than for high temperature‐crystallized LCO thin films. The high values obtained with LCO thin films crystallized at about 700 °C could also not be achieved with other low‐temperature techniques.[ 90 ]

Since LCO has a layered structure, its ionic conduction is highly anisotropic and it depends on the orientation of the deposited layer. For LCO deposited on Pt‐ and Au‐coated alumina substrates Bates et al. observed that the orientation is changing from the unfavorable (003) to the more favorable (101) orientation with increasing layer thickness.[ 91 ] This assumption is rationalized by a minimization of the surface energy for very thin films and a minimization of volume strain for thicker films.[ 91 ] However, this effect depends strongly on the substrate material.[ 92 ] The film orientation can also be controlled by the deposition of epitaxial LCO, which can be obtained by PLD processes with substrates made of STO,[ 93 ] (110)Pt,[ 94 , 95 ] and (110)Au,[ 95 ] respectively.

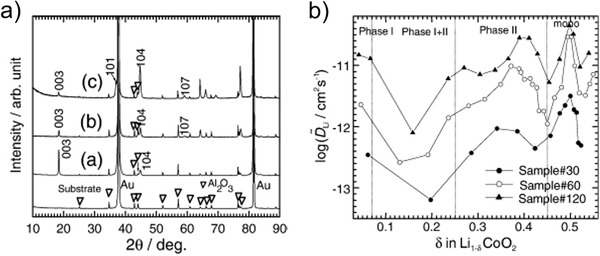

Orientation‐dependent Li+ diffusion coefficients were determined for LCO thin films deposited on Au‐coated alumina with thicknesses between 0.31 and 1.35 µm.[ 96 ] In agreement with the work of Bates et al.,[ 91 ] the orientations of the thin films were dependent on the film thickness, showing a (003) orientation and (104) orientation for the thinner and thicker films, respectively (Figure 6a). The diffusion coefficients were determined via different techniques, namely galvanostatic intermittent titration technique (GITT), potentiostatic intermittent titration technique, electrochemical impedance spectroscopy, and cyclic voltammetry (CV). GITT measurements revealed that the Li‐ion diffusion was most favorable for the (104) oriented thin film (Figure 6b).[ 38 , 39 ]

Figure 6.

a) Change of preferred orientation of LCO thin films deposited for 30 min (denoted as (a), thickness ≈0.31 µm), 60 min (denoted as (b), thickness ≈0.77 µm), and 120 min (denoted as (c), thickness ≈1.35 µm) and b) correlated diffusion coefficients as a function of the amount of Li intercalated into the LCO structure as determined by GITT. Reproduced with permission.[ 96 ] Copyright 2008, Elsevier.

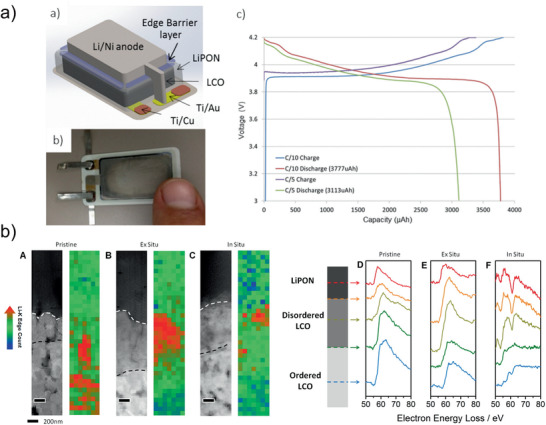

Thicker LCO films are required to increase the total capacity of thin‐film batteries. All‐solid‐state cells with a 10 µm thick LCO cathode obtained by sputter deposition showed high discharge capacities of about 45 μAh cm−2 µm−1 at a discharge rate of 1 C. Increasing the cell footprint to an area of 5.89 cm2 yielded a total discharge capacity of 3777 μAh (Figure 7a).[ 97 ] However, in a similar study with thin‐film batteries deposited by PLD cracks were observed in films with a thickness of about 12.5 µm after cycling.[ 98 ]

Figure 7.

a) Illustration, photograph, and electrochemical cycling data for a large‐scale thin‐film battery with a thick LiCoO2 electrode. Reproduced with permission.[ 97 ] Copyright 2017, Elsevier. b) In situ TEM showing degradation of LiCoO2 thin film in an all‐solid‐state battery during cycling at elevated temperatures. Reproduced with permission.[ 101 ] Copyright 2016, American Chemical Society.

LCO‐based thin‐film batteries showed strong degradation during cycling at elevated temperatures.[ 99 ] For example, while the discharge capacity remained very stable over 140 cycles at 25 and 50 °C, a ≈20% and ≈40% loss was observed at 100 and 150 °C, respectively. This can be explained by the formation of a disordered LCO phase at the LCO/LiPON interphase.[ 100 , 101 ] In situ STEM‐EELS indicated that the phase consisted of Li2O and CoO, which formed during LCO decomposition (Figure 7b).[ 101 ] This layer grew to a thickness of 4 µm after 250 cycles at 80 °C,[ 100 ] which explains the rapid degradation of thin‐film batteries at such elevated temperatures.

Layered NMC materials in which Co is substituted by Ni and/or Mn in the α‐NaFeO2 structure gradually replace LCO as CAMs due to their higher capacities (e.g., 160 mAh g−1 for LiNi1/3Mn1/3Co1/3O2 [ 84 ]) and gain increasing importance also in PVD research.

PLD of NMC thin films was reported by several groups. The oxygen partial pressure and the applied deposition temperature were varied in a very broad range from 3.3 to 266 Pa.[ 102 , 103 ] The applied deposition temperature ranged from 450 °C to 750 °C to achieve crystalline thin films,[ 102 , 103 ] whereby temperatures of 700 °C and higher were required to achieve high discharge capacities and low degradation during cycling.

For sputter deposition processes for the fabrication of NMC thin films, the temperature for post‐annealing typically ranges from 400 to 800 °C, showing improved electrochemical properties at higher temperatures,[ 71 , 104 , 105 , 106 ] whereas the poorly crystallized phase showed fast deterioration of the discharge capacity. An approximate capacity loss of 80% over 200 cycles at 50 µA µm−1 cm−2 was observed in a half‐cell configuration.[ 107 ] However, thin films were Li‐deficient after post‐annealing in those cases where a Li‐excess in the sputter target was not provided.[ 105 , 106 ] Nevertheless, even for Li‐deficient thin films high initial discharge capacities of up to 202 mAh g−1 were observed for NMC111 during cycling with liquid electrolyte between 2.8 V and 4.5 V.[ 106 ]

Electrodes with a Spinel Structure

The manganese spinel LiMn2O4 (LMO) is an attractive cathode material due to the abundance and non‐toxicity of the composing elements. The theoretical capacity of LMO is 148 mAh g−1. However, only 100–120 mAh g−1 can be practically realized because of the structural instability due to the Jahn–Teller distortion.[ 84 ]

The Li—Mn—O phase diagram is quite complex. Different compositions are possible depending on the deposition conditions.[ 108 , 109 ] The range of deposition parameters is quite large in comparison to other intercalation electrodes. PLD is carried out at temperatures between 300 and 650 °C and oxygen pressures between 2.66 and 30 Pa.[ 110 ]

LMO electrodes were sputter‐deposited without active heating, followed by post‐annealing between 600 and 750 °C.[ 111 , 112 , 113 ] Dudney et al. showed that amorphous and nanocrystalline thin films are Mn‐deficient and that the degree of deficiency is dependent on the oxygen partial pressure.[ 108 ] It is remarkable that the amorphous layers partly yield higher discharge capacities in all‐solid‐state batteries compared to the crystallized phase.[ 108 ] At cell potentials above 3 V a capacity of 100–150 mAh g−1 was observed for the amorphous material, whereas stoichiometrically comparable crystalline compositions yielded 20–50 mAh g−1 at best.

Substitution of manganese by nickel in the LMO structure introduces a high‐voltage Ni2+/Ni4+ redox couple with the potential of 4.7 V,[ 114 ] resulting in a high‐voltage LiNi0.5Mn1.5O4 (LNMO) cathode material. Therefore, the deposition and the properties of LNMO thin films have been the focus of several publications.

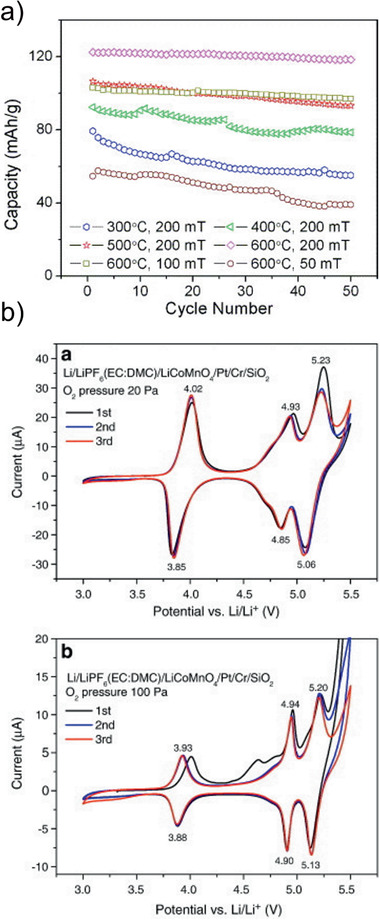

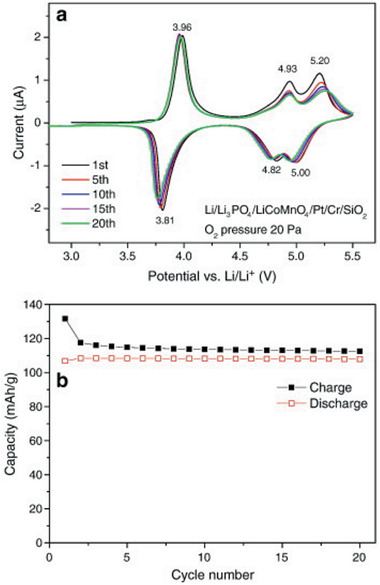

The only systematic study of LNMO deposition by PLD was performed by Xia et al. who demonstrated that an oxygen pressure of about 26.6 Pa and deposition temperature of 600 °C are the optimal process parameters, resulting in films with high initial capacities of 122.5 mAh g−1 for the first cycle and a capacity retention of 96% after 50 cycles in liquid electrolyte cells (Figure 8a).[ 115 ]

Figure 8.

a) Discharge capacity of LNMO deposited by PLD thin films as a function of the deposition parameters. Cycled with 1 m LiPF6 in EC/DEC (1:1) and Li‐counter electrode between 3 and 5 V. Reproduced with permission.[ 115 ] Copyright 2007, Elsevier. b) Cyclic voltammograms of LCMO thin films cycled with 1 m LiPF6 in EC/DEC (1:1) with a Li counter electrode at a sweep rate of 0.5 mV s−1. Reproduced with permission.[ 116 ] Copyright 2014, Elsevier.

LNMO films can be also obtained via sputter deposition. However, the layers deposited at low temperature exhibit poor crystallinity, and have to be heated during deposition or post annealed to increase the crystallinity. The choice of the processing parameters is thereby highly dependent on the substrate. If inert substrates, such as Pt/Al2O3 and Pt/Si, were used, the LNMO films can be deposited without heating, and can be post annealed at temperatures of about 700–750 °C, resulting in electrode layers with satisfactory electrochemical properties.[ 117 , 118 ] If stainless steel was used as a substrate, the annealing temperatures would have to be lowered to about 500–600 °C to avoid the substrate oxidation.[ 119 , 120 ] These temperature are, however, not sufficient for the LNMO crystallization, as the samples annealed at 550 °C still show relatively low capacities (<100 mAh g−1) and strong degradation, as evident from an observed discharge capacity loss of 53.1% over 150 cycles.[ 120 ]

Li‐content variation in the sputter target revealed that a stoichiometric target leads to the formation of Li2MnO3 and LiMnO2 in the resulting thin film, whereas the thin films deposited from a target with low Li‐content (Li0.5Ni0.5Mn1.5O4) show low discharge capacities.[ 117 ] The highest discharge capacity of about 58 μAh cm−2 µm−1 during cycling with liquid electrolyte was obtained for a film deposited with a Li0.75Ni0.5Mn1. 5O4 sputter target with reduced Li‐content.[ 117 ]

Cobalt‐substitution in LMO leads to a 5 V cathode material due to the Co3+/Co4+ redox couple.[ 121 ] LiCoMnO4 (LCMO) thin films were deposited by PLD between 500 °C and 700 °C.[ 116 , 122 , 123 ] A lower oxygen deficiency in the structure was reported as a consequence of increased oxygen pressure. Optimal deposition pressures of 100–200 Pa were suggested (Figure 8b).[ 116 ] LCMO films deposited at lower oxygen pressures of 6.6 Pa showed stronger degradation during electrochemical cycling, specifically, a discharge capacity loss of approximately 30% over 20 cycles, compared to films deposited at 100 Pa.[ 123 ] While films obtained at higher oxygen partial pressures showed a more distinct high‐voltage behavior in liquid electrolytes, higher discharge capacities in all‐solid‐state batteries with a Li anode and a LiPON electrolyte were observed for LCMO films deposited at 20 Pa.[ 116 ] LCMO thin films reported in another publication and cycled with lower cut‐off voltages exhibited remarkably high discharge capacities of 340 mAh g−1 (cycling with liquid electrolyte between 1.5 V and 4.5 V)[ 123 ] and 362 mAh g−1 (cycling in all‐solid‐state battery with a Li anode and a LiPON electrolyte between 1.4 V and 5 V).[ 122 ]

Other Active Electrode Material Structures

Olivine‐structured lithium transition‐metal phosphates LiMPO4 (M = Fe, Mn, Co, Ni) are a popular class of cathode materials with a capacity of about 170 mAh g−1 and high stability during electrochemical cycling. Particularly, LiFePO4 (LFP) with an operating potential of 3.45 V is a commercial low‐cost CAM with very high chemical and electrochemical stability. The operation potential and therefore the energy density of olivine CAMs increase as follows: Fe < Mn < Co < Ni. The major drawback of all olivine materials is their low electronic and ionic conductivity. An electronic conductivity of ≈10−9 S cm−1[ 124 ] and Li+ diffusion coefficients of about 10−13–10−14 cm2 s−1 were reported for LFP applying different measurement techniques.[ 125 ]

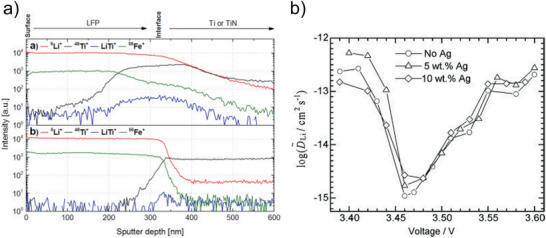

To avoid the oxidation of Fe2+, LFP thin films have to be crystallized in an atmosphere with low oxygen pressure, which is typically achieved by a post‐annealing step for both sputtering and PLD. The formation of crystalline olivine phases with satisfactory electrochemical properties was reported for annealing temperatures ranging from 500 to 700 °C.[ 126 , 127 , 128 ] Metallic iron precipitates on the surface of LFP thin films after the crystallization step were observed for MgO,[ 129 ] Si[ 130 ] and Ti[ 131 ] substrates. In the latter case, SIMS measurements revealed an interdiffusion of Ti into the LFP layer, which probably led to the formation of the precipitates. The application of a TiN layer as a diffusion barrier enabled the deposition of pure LFP thin films (Figure 9a).[ 131 ]

Figure 9.

a) SIMS depth profile of LFP deposited on metallic Ti showing strong interdiffusion of Ti into the LFP thin film (top) and of suppressed Ti‐diffusion by implementation of a TiN diffusion barrier layer. Reproduced with permission.[ 131 ] Copyright 2015, Elsevier. b) Diffusion coefficient for Li+ determined by EIS in LFP thin films with varying Ag content as function of voltage. Reproduced with permission.[ 128 ] Copyright 2009, Elsevier.

The capacity utilization of Li in pure LFP thin films is typically very poor. To date, only Yada et al. reported the formation of a thin LFP film by PLD with a capacity that is close to the theoretical value without any conductive additives present.[ 127 ] However, the film thickness was only 50 nm, and the total capacity achieved during cycling in liquid electrolyte between 3.0 and 4.0 V was only about 0.4 μAh. The introduction of conductive species like carbon or silver into the electrode layers can increase the electronic conductivity of LFP and improve its cycling behavior. For sputter deposition processes this approach was realized by using carbon‐ or silver‐containing deposition targets. Thin films deposited by sputter deposition from C‐rich targets showed only a small temperature window for single phase LFP due to secondary phase formation. Post‐annealing at 500 °C yielded a minor amount of secondary phases leading to discharge capacities of up to 170 mAh g−1 depending on other deposition parameters, for example, substrate bias.[ 132 ] Sputter deposition at 600 °C led to the formation of additional phases besides LFP due to a carbothermal reaction.[ 133 ] As a result of this reaction a 3D structure was formed, and the capacity was greatly increased to 160 mAh g−1.[ 133 ]

The introduction of silver enables a higher tolerance with respect to the annealing temperature. LFP thin films were obtained without secondary phases by performing PLD at 600 °C[ 134 ] and by sputter deposition and subsequent annealing at 700 °C for 1 h in Ar/H2.[ 128 ] The samples that were deposited by PLD showed discharge capacities that were close to the theoretical limit when the cut‐off voltages were extended to the range from 2.5 to 4.5 V.[ 134 ] The thin films deposited by sputtering showed an increase in the discharge capacity from 30 to 60 mAh g−1 due to the addition of 10 wt% silver.[ 128 ] The diffusion coefficients determined for these samples were nearly independent of the silver content (Figure 9b).[ 128 ]

The high‐voltage material LiCoPO4 showed low discharge capacities of less than 12 μAh cm−2 µm−1 in the form of phase pure thin films.[ 135 ] LiMnPO4 was deposited by PLD at varying substrate temperatures and deposition pressures, yielding the highest discharge currents for the films deposited at a substrate temperature of 600 °C and 100 Pa Ar. The highest reported capacities, which were determined in a thin‐film cell with a LiPON electrolyte and a Li anode, were 28 ± 3 mAh g−1, which is 16% of the theoretical capacity.[ 136 ] The low capacity was explained by the low Li+ diffusion coefficient of 3 × 10−17 cm2 s−1 as determined by CV.[ 136 ]

The zero‐strain material Li4Ti5O12 (LTO) has a spinel structure and a theoretical capacity of about 175 and 293 mAh g−1 corresponding to the intercalation of 3 or 5 Li‐ions, respectively.[ 137 ] For PLD processes, 700 °C was determined as the ideal deposition temperature to obtain well‐crystallized thin films.[ 138 ] Phase pure LTO was formed at oxygen pressures of 1.3 × 10−2 Pa[ 139 ] and 3 Pa,[ 140 ] whereas the formation of LiTi2O4 took place at 1.3 × 10−4 Pa,[ 139 ] and secondary phases were formed at 6 Pa and above.[ 140 ] A full all‐solid‐state battery with a LTO thin‐film cathode deposited by PLD on a LLZ pellet at 500 °C and a Li‐foil anode was cycled at low C‐rates (highest C‐rate = 0.15C), and showed discharge capacities close to the theoretical value of LTO at 0.015C.[ 141 ]

Sputter deposition was mainly carried out without substrate heating and subsequent annealing of the samples. Temperatures of about 1000–1100 °C yielded the formation of TiO2 (rutile structure) secondary phases,[ 142 ] whereas at lower temperatures pure LTO was identified.[ 142 , 143 , 144 ] The addition of Li2O during sputtering increased the amount of Li in the film after annealing.[ 143 ]

Deposition by ion beam sputtering yielded the highest crystallinity when the film was deposited at 600 °C and an oxygen partial pressure of 3 × 10−4 mbar was employed.[ 144 ] Li‐diffusion coefficients were determined on these films by CV, galvanostatic potentiometry and GITT.[ 144 ] All values were in the range of 10−12 cm2 s−1, which is in agreement with the values obtained with NMR measurements on powder samples.[ 145 ]

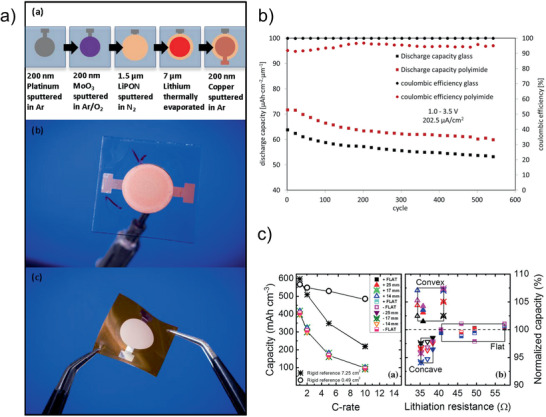

MoO3 and V2O5 are electrode materials with high capacities of up to 280 and 147 mAh g−1, respectively. Due to their intermediate redox potential, they can be applied either as positive or negative electrode materials in different types of batteries. Both materials are very attractive as electrodes for thin film batteries, because a crystallization of the phase is not necessary, and therefore, the deposition can be carried out on polymer substrates as well.

MoO3 cathodes for thin film batteries were sputtered either from MoO3 targets[ 146 , 147 ] or by reactive sputtering with oxygen from a Mo target.[ 148 ] The resulting all‐solid‐state batteries showed good cycling behavior even with thicker electrodes. A 4.66 µm thick film allowed for the utilization of 81.7% of its volumetric discharge capacity relative to an otherwise identical 1 µm thick film.[ 147 ] For comparison, similar cells with LCO cathodes rapidly deteriorated, losing 50% of the initial capacity within 100 cycles at an elevated temperature of 150 °C, whereas a stable capacity for more than 10000 cycles were achieved with a MoO3 cathode.[ 146 ]

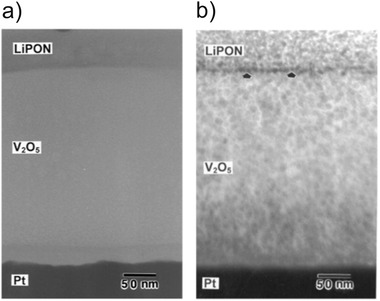

V2O5 cathodes for thin‐film batteries were deposited either by reactive sputtering with a vanadium target in the presence of oxygen[ 149 , 150 ] or by thermal evaporation of V2O5.[ 151 , 152 ] Aside from the commonly used Pt‐coated silicon wafer substrate,[ 149 ] the deposition was also carried out on stainless steel[ 150 , 152 ] as well as on flexible aluminum substrates.[ 151 ] Structural analysis of a V2O5/LiPON/Li battery after 450 cycles at room temperature revealed the formation of nanocrystals on both the V2O5 cathode and the LiPON electrolyte (Figure 10 ).[ 149 ]

Figure 10.

Cross section bright field TEM of the cathode part of a V2O5/LiPON/Li battery a) as deposited b) after 450 charge/discharge cycles. The initially amorphous phases V2O5 and LiPON show signs of crystallization after electrochemical cycling. Reproduced with permission.[ 149 ] Copyright 2003, American Vacuum Society.

3.2.2. Alloy Electrodes

Materials that are able to store lithium via an alloying mechanism are the subject of intensive research activities, as they can function as anodes with a high energy density for future battery concepts including solid‐state batteries. Currently, the most frequently used anode in all‐solid‐state batteries is made of Li metal, which is applied in thin‐film batteries by a vapor deposition process.[ 153 ] However, details about the vapor deposition process are rarely reported, and the influence of the Li‐anode application in thin‐film cells has not been discussed in the literature yet. For bulk‐type batteries, the Li metal anode is usually applied as a foil. Details about the interface between Li metal and solid electrolytes are given in Section 4.2.

Silicon, tin and germanium are the most popular alloying anode materials due to their availability, relative stability, high theoretical capacity and low potential (4200 mAh g−1/0.4 V, 994 mAh g−1/0.6 V and 1625 mAh g−1/0.5 V for Si, Sn, and Ge, respectively).[ 154 ] These materials have also been investigated in combination with solid electrolytes as buffer layers between the electrolyte and the Li metal anode.[ 155 , 156 , 157 , 158 ]

As in part determined by their melting temperature, thin films deposited by sputtering or evaporation without active substrate heating are amorphous in the case of Si und Ge and crystalline in the case of Sn. All materials show a large volume variation during electrochemical cycling (Si: 420%, Ge: 370%, Sn: 260%).[ 154 ]

Silicon electrodes show large irreversible capacity losses of roughly 500–1000 mAh g−1 during the first 5–10 cycles,[ 159 , 160 ] which can be attributed to their substantial expansion during lithiation and the associated loss of contact in the electrode. Similar observations were reported for Ge electrodes, albeit with smaller relative losses.[ 161 ] The expansion effect becomes more severe with increasing film thickness for both materials.[ 160 , 161 ] Roughening thin films either by using a rough substrate[ 162 ] or by nanostructuring[ 163 ] could counteract the degradation during cycling test to a certain degree. For further reading a recently published review about silicon thin films as battery anodes is recommended.[ 164 ]

Silicon films deposited by sputter deposition were investigated as anodes in thin‐film all‐solid‐state batteries.[ 157 , 158 ] Thin‐film cells with a lithium anode, a B‐doped LiPON electrolyte and a thin silicon cathode exhibited a reversible capacity of about 571 μAh cm−2 µm−1 for 1500 cycles when cycled in an all‐solid‐state battery with a lithium anode and a B‐doped LiPON electrolyte between 0.05 and 1 V.[ 158 ] Microbatteries with an amorphous lithium titanium oxysulfide cathode, a LiPON electrolyte and a silicon anode showed a mean capacity fade of 0.015% per cycle over 200 cycles.[ 157 ]

Similarly to Si, pure Sn thin films also suffered high capacity losses during the first cycles, as more than 20% of the initial capacity faded during the first 10 cycles.[ 165 ] To optimize the performance of the alloying electrodes and to identify materials with an increased cycling stability, Dahn et al. investigated numerous binary allows of Si and Sn by combinatorial sputtering using the sputtering system described in Figure 3c. These materials were tested in liquid electrolyte cells and are shown here to demonstrate the potential for application of PVD to generate material libraries. For the Si1‐ xSnx system the researchers identified compositions with high silicon content demonstrating a discharge capacity of up to 3500 mAh g−1 and reduced irreversible capacity losses (<15%). At low Sn concentrations the alloy remains amorphous during charge and discharge and there is no tendency toward particle growth for higher Sn‐contents.[ 166 ]

Binary Si‐Ag[ 167 ] and Si‐Zn[ 168 ] systems were investigated as alloy anodes by the same approach using thin‐film material libraries. During operation, a different behavior was identified for Ag compared to Zn. Ag was found to segregate into domains with an increasing size during cycling, thus severely compromising the initially alloyed structure. In contrast, Zn formed a dimensionally stable nanocrystalline dispersion in silicon, which acted as a confining matrix, and thus the degradation of silicon due to its volume changes was minimized. However, a continuous amorphous phase that does not undergo crystallization processes, as it is found in Sn‐Si, was identified as the most beneficial alloy anode.[ 169 ]

A similar principle of adding an electrochemically inactive element to generate a mechanically stable and chemically inert backbone was also investigated by means of thin‐film libraries for the following systems: Si—Fe,[ 170 , 171 ] Si—Co,[ 172 ] Si—B,[ 173 ] Si—M (M = Cr+Ni, Fe, Mn),[ 174 ] and Si—Ni.[ 175 ] For Si—Co,[ 172 ] Si—Fe, Si—Mn, and Si—Cr+Ni thin layer electrodes capacity fading was observed,[ 174 ] which was attributed to the formation of inactive silicides due to complete electrochemical inactivity at a concentration of 50 at% Si. The formation of inactive FeSi2 was confirmed also in subsequent work.[ 170 ] The capacity drop observed for the Si—Ni system was attributed to the voltage suppression due to internal stress–voltage coupling.[ 175 ] In the Si—B system neither the formation of detrimental phases nor a capacity drop was observed, and in contrast to the transition metal systems, only a minor voltage shift due to voltage‐stress coupling was detected.

Tin‐containing anodes with a general composition of Sn—M—C (M = Co, Ti, V) were also investigated by means of material libraries generated by sputter deposition. The selected materials showed an amorphous region in combination with tin, whereas other transition metals, such as Cr, Mn, Fe, Ni, and Cu formed crystalline phases.[ 176 ] Detailed investigations of the ternary systems with carbon showed that only Sn—Co—C is a suitable candidate for advanced battery anodes, because transition metal carbides cannot be formed. Such a formation would lead to a detrimental phase separation of tin.[ 177 ] Initial investigations showed that in (Sn0.55Co0.45)1‐ yCy for y = 0.4 a stable amorphous phase with a capacity of about 700 mAh g−1 was formed, which remained amorphous during electrochemical cycling.[ 178 ] Further studies revealed stable cycling behavior also for similar phases, which were synthesized by mechanical methods as opposed to sputtering, but yielded lower specific capacities of 270 or 450 mAh g−1. This behavior was attributed to different particle sizes obtained by different synthesis methods.[ 179 ]

3.2.3. Conversion‐Type Electrode Materials

Conversion materials have the general formula MxAy where M is a metal, mainly from the group of transition metals (Ti, V, Cr, Mn, Fe, Co, Ni, Sn, Zn, …) and A is an anion, mainly from the group O, N, F, S, P. As indicated by the name, conversion materials undergo the full conversion of the metal from oxidized to its metallic state (MxAy + (y × n) Li+ → x M + y LinA). Such transformations often accommodate more than one Li atom per metal atom, resulting in very high capacities and energy densities. A general overview about conversion anodes can be found in the publication by Cabana et al.,[ 180 ] and a general review about nitrides and carbides for energy conversion was published by Zhong et al.[ 181 ]

Various PVD techniques have been employed to deposit thin layers of conversion materials either as battery components or as model systems to investigate the mechanism of the material transformation during operation. PVD processing of conversion electrodes is mainly applicable for oxides and nitrides due to the fact that these types of materials can be easily deposited by reactive processes from metallic targets.

The main drawbacks of conversion materials are the significant chemical reorganization during reactions and generally poor ionic and electronic conductivity. The consequence is a substantial potential hysteresis and poor capacity retention, both hampering the application of these materials as anodes. Understanding the mechanisms of underlying material transformations and finding ways to improve the electrode performance has been one important task in PVD‐process based research.

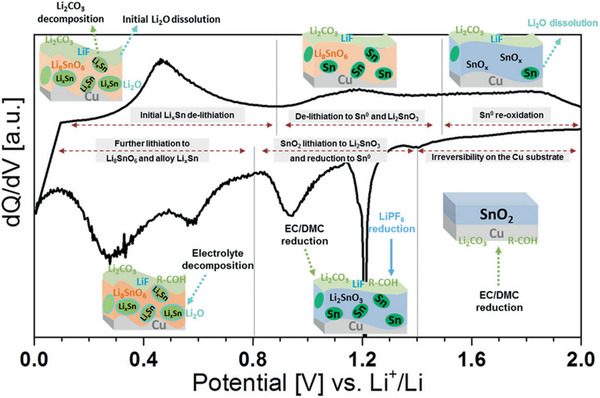

SnO2 is among the most attractive conversion electrodes due to its high theoretical capacity of 1491 mAh g−1 provided by the incorporation of up to 8.4 Li‐ions per formula unit in sequential conversion and alloying processes. A review about SnO2‐based conversion anodes was published by Zoller et al.[ 182 ] Unfortunately, thin films show rapid capacity fade when cycled with liquid electrolytes.[ 183 ] For SnO2 deposited by PLD, a discharge capacity of 1426 mAh g−1 was reached during the first cycle, whereas within 50 cycles the capacity was decreased to 564 mAh g−1.[ 184 ] Using thin amorphous SnO2 films deposited as a model electrode by d.c. magnetron sputtering, Ferraresi et al. were able to identify various intermediate conversion and alloy reactions taking place during lithiation/delithiation of tin oxide, and elucidated their impact on the total reversibility of the process.[ 185 ] XPS and SEM analysis at several charged and discharged states, corroborated by density functional theory calculations, revealed that Li2SnO3 and Li8SnO6 were formed as intermediate phases during the lithiation process (Figure 11 ).[ 185 ]

Figure 11.

Reactions and phase formation occurring at different potentials versus Li/Li+ during lithiation/delithiation of a SnO2 thin‐film electrode. Reproduced with permission.[ 185 ] Copyright 2018, American Chemical Society.

A thin film battery consisting of a LMO cathode, a LiPON electrolyte and an SnO2 anode showed a strong capacity loss of about 60% after 50 cycles, which was attributed to the poor performance of the SnO2 anode.[ 113 ] PLD of a nanocomposite consisting of alternating amorphous SnO2 with 60 nm thickness and TiO2 with 10 nm thickness afforded a capacity of about 160 μAh cm−2 for a 210 nm thick composite cycled with liquid electrolyte for 200 cycles.[ 183 ] A pure SnO2 thin film with the same thickness showed severe cracking after cycling, whereas the multilayer structure remained intact. The increased capacity retention of the multilayer system was attributed to the mechanical constraint of the SnO2 layers.[ 183 ]

Nitrides are particularly attractive as conversion‐type electrodes, because ionically conductive Li3N with a Li‐ion conductivity of up to 1.2 × 10−3 S cm−1[ 186 ] is formed as a reaction product. This formation establishes a Li‐ion conduction path inside the anode, in contrast to insulating Li2O formed during conversion of oxide materials. SnNx thin films deposited by a reactive sputtering process yielded capacities of up to 700 μAh cm−2 µm−1 for the compositions Sn:N = 1:1 and Sn:N = 3:4 in cells with liquid electrolyte.[ 187 ] Long‐term cycling showed a better performance in case of the 1:1‐composition, although a strong degradation within the first 100 cycles was also observed. It was shown that the reduction of the cut‐off potential from 2 to 0.8 V reduces the capacity of the SnN film to about 80% of its initial value but significantly improves the cycling stability. Even the thickest film, which rapidly delaminated when cycled to its full capacity, could be cycled for 120 cycles without significant capacity loss in the reduced potential range.[ 187 ]

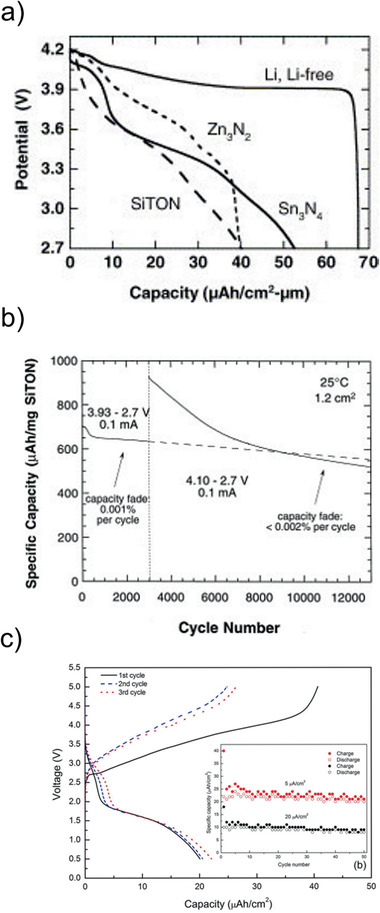

By employing sputtering, Dudney[ 188 ] and Neudecker et al.[ 189 ] have provided the first evidence that Sn3N4 layers can be used as anodes in all‐solid‐state cells. However, the discharge capacities of the cells built with a LiPON electrolyte, a LCO cathode and a Sn3N4 anode were still inferior to similar “anode‐free” cells or cells with a Li‐anode (Figure 12a).[ 188 , 189 ] A Sn3N4 anode was shown to be superior to comparable Zn3N2, Sn3S4 and InNx anodes.[ 188 , 189 ] In another example published by Li et al., a LCO/LiPON/SnNx cell fabricated using various sputtering processes showed a maximum discharge capacity at 60 °C, whereas the discharge capacity decreased upon further increasing the temperature. Constant discharge capacities were observed during cycling at 20 and 100 °C for 15 cycles.[ 190 ]

Figure 12.

Cycling properties of thin‐film all‐solid‐state batteries with conversion‐type thin‐film anode. a) Discharge curve of SiTON, Zn3N4 and Sn3N4 conversion anode in comparison to in‐situ plated Li‐anode. Reproduced with permission.[ 188 ] Copyright 2005, Elsevier b) long‐term cycling of a SiTON/LiPON/LCO thin‐film battery. Reproduced with permission.[ 191 ] Copyright 1999, Elsevier. c) Charge–discharge curve at low current density and cycling performance at high and low current density of a ZnO/LiPON/LMO thin‐film battery. Reproduced with permission.[ 196 ] Copyright 2018, Elsevier.

Silicon tin oxynitride (SiTON) is another conversion material with promising performance characteristics as a negative electrode in solid‐state batteries. Amorphous SiTON films can be deposited by r.f. sputtering from a SnSiO3 target in a nitrogen plasma.[ 191 ] Full LCO/LiPON/SiTON cells showed a discharge capacity of 340 mAh g−1 (with respect to the anode) without annealing. Exposure of the cell to 250 °C (the temperature required for soldering targeted as a possible application for the cell) resulted in an improved discharge capacity of up to 450 mAh g−1. The cells showed a low capacity fade of 0.001% per cycle when cycled between 2.7 and 3.93 V and 0.002% per cycle when cycled between 2.7 and 4.1 V (Figure 12b). The latter condition detrimentally affected the cycling stability but increased the discharge capacity by almost 50 mAh g−1.

Besides tin‐based materials, titania‐based compounds attracted attention as conversion‐type electrode materials. TiO2 anodes can be easily obtained by a reactive d.c. sputtering process with oxygen. Generally, the crystal structure of sputtered TiO2 thin films can be adjusted by controlling the oxygen partial pressure and total pressure during deposition.[ 192 ] However, the maximum capacity obtained in liquid electrolyte cells was only 330 mAh g−1 at 0.2 C,[ 192 ] which is relatively low in comparison to other anode materials. A 200 nm thick amorphous TiO2 film was used as an anode in a battery based on a 250 nm thick NMC111 cathode and a LiPON electrolyte.[ 193 ] This cell showed an initial discharge capacity of 52 μAh cm−2 µm−1, and still exhibited 86% of the initial capacity after 100 cycles. The cell showed high polarization due to the absence of conductive additives in the electrodes. Therefore, cycling was carried out between 3 and 5 V. The high upper cut‐off voltage can lead to degradation of the cathode, which could explain the low capacity as well as the deterioration of the cell.[ 193 ]

ZnO is another interesting type of anode material in which a conversion reaction to Zn and Li2O is followed by alloying of Zn and Li, which theoretically enables the accommodation of up to 3 Li ions per unit structure. Studies on thin ZnO films deposited by PLD and sputtering from ceramic targets showed, however, that a large amount of capacity, e.g., 55% or 44% was lost during the first charge cycle for undoped ZnO layers.[ 194 , 195 ] Doping with Al is an efficient means to improve the cycling performance of such sputtered thin films. Doping up to 3 wt% Al increased the cycling stability within the first 40 cycles significantly, so that capacities of about 500 mAh g−1 could be obtained.[ 195 ] However, higher amounts of Al dopants have a detrimental effect on the electrode performance. The electronic conductivity was improved by Al doping up to 3 wt%, as was confirmed by Hall measurements. The introduced Al is converted into electrochemically inert nanocrystalline Al2O3 after the first lithiation and delithiation process. It was assumed that these nanocrystals influence the cycling behavior of ZnO directly, most likely through their function as a stress releaser.[ 195 ] Aside from investigations on individual layers, ZnO was also tested as a negative electrode in full solid‐state cells. A thin film battery based on an amorphous LMO cathode, a LiPON electrolyte and a ZnO anode showed a low discharge capacity of 22 μAh cm−2, which was mainly attributed to the amorphous nature of the cathode.[ 196 ] A beneficial effect of using ZnO instead of metallic Li anodes is the stability of cells in air. Thus the cells protected by a LiPON layer without any additional sealing were cycled 50 times in air without significant capacity loss (Figure 12c).[ 196 ]

4. Interfaces—Model Systems and Modifications

Interfacial processes play a central role in any electrochemical energy storage system. Therefore, understanding and optimization of interfaces between different battery materials have always been the focus of PVD research. Due to the possibility of producing thin layers with a defined thickness, chemical composition, phase composition, and crystallinity as well the option of sequentially depositing multiple layers, various PVD processes are ideally suited to fabricate model systems to study interfacial phenomena. Comparatively low process temperatures in PVD methods are often of advantage for obtaining clean defined interfaces between solid materials that would otherwise require high temperature sintering with possible side reactions. Further, the layered geometry of the obtained systems is well suited for the characterization of the structure and composition with advanced analytics (e.g., XPS, SIMS and SEM) in combination with electroanalytical techniques, providing deeper insights into the structure as well as charge transfer and transport properties of various interfaces. Besides fundamental studies of interfacial properties, PVD is frequently applied to produce thin functional layers to improve the properties of the interfaces, such as protective coatings to prevent chemical or electrochemical reactions between battery materials during processing or operation, or coatings to improve the contact between the materials and minimize the interfacial resistance.

This section provides an overview of examples of PVD processes applied for the investigation and optimization of interfaces between active electrode materials and electrolytes.

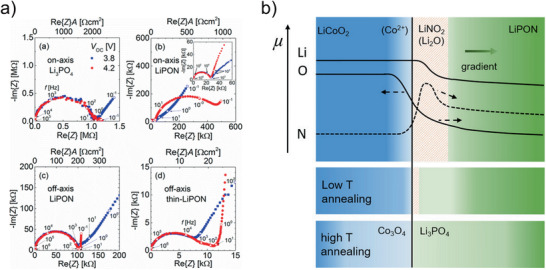

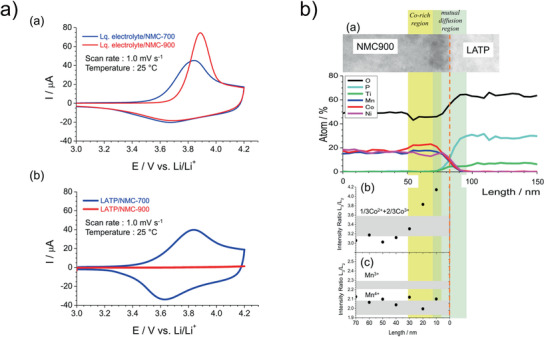

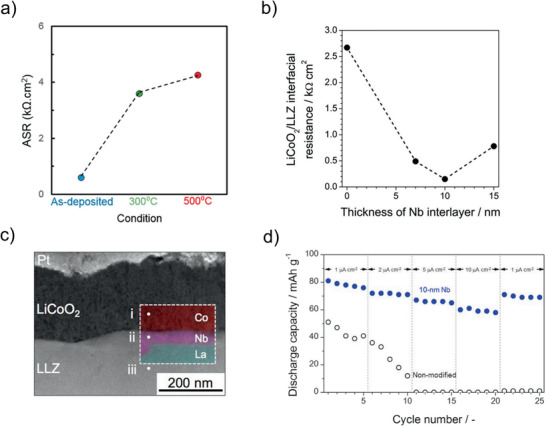

4.1. Interfaces between Cathodes and Solid Electrolytes