Abstract

The rapid growth in industrialization steadily increased the energy demand. The world’s population ultimately depends on petroleum as a major share of fuel for transportation and industrialization. Even though it is widely used in various sectors, its emission into the atmosphere creates serious problems in the form of acid rain, smog, etc. This present experimental investigation highlights the utilization of Vachellia nilotica seed oil methyl ester (VNSOME) synthesized from Vachellia nilotica seed oil (VNSO) fueled in a diesel engine to assess the emission and performance characteristics. VNSOME is produced using the alkaline catalyst (NaOH) transesterification technique. Four different fuel blends of biodiesel, namely, VNSOME5, VNSOME10, VNSOME15, and VNSOME20, were prepared and fueled in an unmodified engine. The engine brake thermal efficiency is lower, the brake-specific fuel consumption (BSFC) using VNSOME20 is higher, and the temperature of exhaust gas emitted after combustion is increased. The thermal efficiency is reduced by 7.34% with increased BSFC and exhaust gas temperature (EGT) of 9.3 and 14.28%, respectively, as compared to diesel fuel. Similarly, using an optimized biodiesel blend (VNSOME20), the emission emitted such as HC and CO is reduced by 19.14 and 22.2%, respectively. However, the engine fueled with the VNSOME20 biodiesel blend increased the level of CO2 and NOx emitted into the atmosphere when compared to diesel fuel.

1. Introduction

Fossil fuels are largely used in industries, transportation, power plants, and automobiles. Industries and power plants use fossil fuels for power generation. Agricultural equipment such as pesticide sprayers and water pumps use compact engines, which are normally run by fossil fuels. Due to the rapid growth in the agricultural, industrial, and automobile sectors, the consumption of these fuels is increased. The demand for biofuels is rapidly increasing in view of depleting natural resources. These fossil fuels, especially diesel and petroleum, are extensively used for energy production. However, the emissions from the combustion of fuels are the principal causes of global warming and many environmental consequences. Various bio-oils are produced from biological resources, crops, byproducts from the forest, and feedstocks. The transesterification process or alcoholysis was the available best method to treat the oil to reduce the viscosity and remove the free fatty methyl ester acid and glycerol contents.1−8

Biodiesel is produced from various feedstocks of plants, including karanja, jatropha, soya bean, lemon seed, pumpkin seed, neem, pongamia, rape seed oils, etc. Oil obtained from conventional and nonconventional sources is also used to produce biodiesel.9−25 Ong et al.26 optimized the production of Calophyllum inophyllum biodiesel and studied the feasibility of its utilization in an internal combustion engine. The biodiesel production was optimized using RSM, and the operating parameters that include catalyst concentration, molar ratio, reaction time, and reaction temperature on yield were analyzed. The composition of biodiesel in diesel fuel varied from 10 to 50%. The results showed that, using 10% Calophyllum inophyllum in diesel fuel, BSFC and EGT were lower than those in diesel fuel, whereas NOx was higher than that in diesel fuel. The characterization and optimization of Calophyllum inophyllum–Ceiba pentandra oil were investigated by Ong et al.27 ANN and ACO techniques were used to optimize the process variables such as the methanol–oil ratio, catalyst concentration, and reaction time on biodiesel yield. The recent challenges and opportunities in the production of biodiesel derived from agricultural products and microalgae using ionic liquids were reviewed by Ong et al.28 Transesterification using microwave irradiation on the synthesis of biodiesel produced from Ceiba pentandra oil was optimized by Silitonga et al.29 The performance and emission characteristics of biodiesel–bioethanol and diesel blends in diesel engines using the K-Extreme learning method were studied by Silitonga et al.30

The influential effect of different Mimusops elangi methyl ester (MEME) fuel blends on the performance, emission, and combustion parameters of a DI diesel engine was studied by Krupakaran et al.31 In their study, the MEME was synthesized by the process of transesterification, and the test fuel blends were prepared with diesel in the volume of 10% (90% diesel–10% MEME), 20% (80% diesel–20% MEME), 30% (70% diesel–30% MEME), 40% (60% diesel–40% MEME), and 100% MEME. The fuel properties were evaluated and validated with the limits of ASTM standards. Engine test results revealed that, on operating the engine in the full load with 20MEME, the engine exhibited 5.12 and 4.18% higher BSEC and BTE, respectively, when correlated with base fuel (diesel). Results also indicated that the inside cylinder pressure developed and rate of heat release were superior while using 20MEME biodiesel blend at the full load condition. A significant reduction of HC (5.26%), CO (16.6%), and smoke (6.2%) resulted in juxtaposition with base fuel despite marginally higher CO2 (5.26%) and NOx (4.8%) at the maximum load of the engine operation.

The impact of oil derived from Cymbopogon martinii [Palmarosa methyl ester (PMO)] as an alternative fuel for a diesel engine was experimentally carried out by Sathiyamoorthy et al.32 The performance analysis showed that, compared to diesel, an extensive augmentation in BSFC was exhibited for PMO25 (7.41%), PMO50 (19.35%), and PMO100 (26.47%). The results of combustion revealed that the longer duration of combustion and shorter ignition delay were noticed with the use of PMO fuel blends, which are responsible for the considerable increment in the heat release and pressure of combustion. The test engine produces lower CO, HC, and smoke (19.02, 31.25, and 29.75%) for PMO100. Furthermore, a minimal increment in NOx (15.21%) was noticed for PMO blends contrasted with the base diesel fuel.

The impact of using Pithecellobium dulce biodiesel (PDBD) in lower concentrations blended with diesel fuel on the engine performance and emission characteristics was experimentally investigated by Sekhar et al.33 On a volume basis, three fuel blends, namely, PDBD5, PDBD10, and PDBD20, were prepared and fueled in an unmodified diesel engine. On comparing the test results of PDBD blends over diesel fuel, it was revealed that the PDBD20 fuel blend produced lower HC (17.64%), CO (19.64%), and NOx (6.73%). Finally, it was contemplated that the PDBD20 diesel blend could be a successful fuel for use in an unmodified engine.

The extraction of biodiesel from Oenothera lamarckiana oil (OLO) in a diesel engine with an engine power of 9 kW was experimentally carried out by Hoseini et al.34 to assess its performance and emissions. Two blends, namely, B10 and B20, along with diesel fuel, were tested with various engine loads. Results showed that, using the B20 blend, the SFC was lower than that in diesel fuel by about 6.8%. Similarly, by operating the engine at the full load condition, the HC and CO are lower compared to those of diesel by about 37.28 and 10.13%, respectively. However, with the engine operating at the peak load, the other emissions emitted, such as CO2 and NOx, were improved by about 7.9 and 4.6%, respectively.

Performance analysis on a diesel engine fueled with sand-apple-based biodiesel blends was experimentally carried out by Ogunkunle and Ahmed.35 Sand apple oil was blended in the volume concentration of 5, 10, 15, and 20 along with diesel fuel. The engine tests were implemented by changing the load of the engine from 0 to 100%. Results on performance revealed that increased BSFC and lower BTE were observed using the biodiesel blend.

The biodiesel synthesized from juliflora seed oil was exploited as an additional source of fuel in a DI diesel engine by Asokan et al.36 In their study, the experiments were conducted with four different blends (B20, B30, B40, and B100) along with pure diesel. The test engine outcomes detected that the B20 fuel exhibits marginally higher BSFC (3.7%) and lower BTE (6.7%) at 100% load than those of diesel. In regard to emission, the B20 fuel generates minimum HC, CO, and smoke and slightly higher NOx than diesel fuel at 100% loading condition. From the conclusion, they recommended that the B20 fuel be utilized as a substitute for traditional diesel fuel.

Lalambari (LA) oil-based biodiesel and their blends (LA20, LA40, LA60, LA80, and LA100) were tested on a CI engine to study the effect on performance, combustion, and exhaust emissions. Test outcomes revealed that there are a devaluation in BTE (by 4.4%) and an increase in BSFC (by 2.5%) for LA20 than diesel fuel while the engine is operated at the peak load (3.7 kW). Also, pressure and heat release during the combustion were lesser for all the LA blends at 100% load. Furthermore, a reduction in smoke emission of about 16.6% and marginal increase in CO2 of 3.5% were recorded for LA20 at 3.7 kW compared to diesel fuel. Finally, the test results proved that LA100 and their blends could be incorporated as an additional fuel source for CI engines.37

Vachellia nilotica belongs to a member of the Leguminosae family, which grows to around 15–18 and 2–3 m in height and diameter, respectively. Its color commonly determines the age of the bark. The slaty green color of the bark indicates that the tree is immature, while the black color indicates that the tree is mature. In a matured tree, longitudinal gaps uncovering the inward gray-pinkish slash, radiating a ruddy low-quality gum, were observed. The tree leaves are bi-pinnate, 3–10 sets and 1.3–3.8 cm long, leaflets of 10–20 sets and 2–5 mm in length. Flowers of the tree are in globulous heads with sparkling golden yellow shading and have a diameter of 1.2–1.5 cm. When the tree is immature, the pods are green and tomatoes, while the mature tree pods are dark greenish. Pods are indehiscent, profoundly choked between the seed and offering a necklace view and a length of 7–15 cm. The pod consists of 8–12 seeds, packed, elliptical, and misty brown colored with strong testa. The Vachellia nilotica can bloom and fruit in a few years (2–3 years) after the period of germination. After the high-precipitation years, the rapid growth of fruits occurs. Normally, blooming starts during the months of March and June, while the shaping of the pods happens between July and December. During the periods of June and November, the leaf falls after it is completely dry. The seed pods can drop from the tree between October and January.38,39

From the review of various literature, researchers are majorly focusing on various new-generation feedstocks to produce biodiesel. Researchers are also focusing on the various techniques to produce biodiesel along with the traditional method. The main objective of the study is to determine the physiochemical properties of Vachellia nilotica biodiesel and the feasibility of using the prepared fuel on performance and emission characteristics of diesel engine. This study mainly focuses on the extraction of biodiesel produced from Vachellia nilotica seed oil and the suitability of Vachellia nilotica seed oil methyl ester (VNSOME) in different concentrations blended into diesel fuel to assess the engine performance and emission produced during the combustion. A competitive study is carried out in the engine fueled with diesel, VNSOME5, VNSOME10, VNSOME15, and VNSOME20. As per the ASTM standards, the properties of biodiesel were estimated. It is also noted that the produced biodiesel is suggested as a novel feedstock as an alternative source for a diesel engine without any engine modification.

2. Materials and Methods

2.1. Extraction of Vachellia nilotica Seed Oil (VNSO)

The Vachellia nilotica seeds utilized in this study are collected from the agriculture fields of rural villages nearby Tirunelveli District, Tamil Nadu, India. Initially, screening is done to remove the dust particles and undersized particles, and the seeds are thoroughly washed with water. The washed seeds are heated at an air temperature of 50 °C to remove the moisture content using an air blower. Then, the seeds are fed into a mechanical expeller to extract the Vachellia nilotica seed oil (VNSO). Further, the VNSO is refined by evacuating sticky substances and then neutralized for the betterment of its purity.

2.2. Preparation of VNSOME through a Biodiesel Production Plant

The VNSOME is produced through a small-scale biodiesel plant at CSIR-CLRI, Chennai, India. The detailed procedure is discussed below:

The VNSOME is produced from the VNSO by a single-stage transesterification process due to the lower free fatty acid (2%) content.

Sodium hydroxide (NaOH) is used as a catalyst and methanol is used as a solvent for the synthesis of VNSO into VNSOME.

In the initial stages of the experimentation, the methoxide (CH3OH and NaOH) solution is prepared based on the free fatty acid in the VNSO.

Then, 5 L of VNSO is fed into the reaction heater 1 (RH1), as shown in Figure 1. Then, it is heated up to 60 °C. After reaching 60 °C, the methoxide solution is fed into the RH1 (Figure 1).

The mixture (VNSO and methoxide solution) is then maintained in the temperature range of 60–65 °C.

The process is carried out until the formation of glycerol. The glycerol formation can be identified by the appearance of brownish color during circulation.

After glycerol evolution, the admixture is allowed to settle for 3–5 h.

The VNSOME produced is at the top of the RH1, and the glycerol is settled at the bottom, and it is drained out.

Then, the VNSOME is fed into the water heater tank 1 (WH1), in which water is available at a temperature of 50 °C. Water washing of the product is performed in WH1, and then the VNSOME is fed into the drying heater tank 1 (DH1). In DH1, the VNSOME is heated up to 110 °C to remove the moisture content. Finally, the VNSOME is collected from the plant and stored in containers.

Figure 1.

Biodiesel plant.

2.3. Characterization of VNSOME

The chemical characterization of VNSOME has been performed to quantify the methyl esters present in the product. The characterization of VNSOME is analytically studied using Fourier transform infrared (FT-IR) spectrometry (test method: ASTM E1252) and gas chromatography–mass spectrometry (GC–MS) (test method: ASTM E2997-16).

2.3.1. GC–MS of VNSOM

Gas chromatography analysis of VNSOME is carried out to evaluate the composition of methyl esters in VNSOME. The working conditions of GC–MS are shown in Table 1.

Table 1. GC–MS Operating Conditions33.

| property | specification |

|---|---|

| injection | split ratio of 1:10 at 280 °C |

| column | capillary column Elite-5 |

| column dimension | 30 m × 0.25 mm i.d. × 250 μm film thickness |

| carrier gas | helium |

| column flow rate | 1 mL/min |

| detector | electron ionization |

| electron energy | 70 eV |

| mass range | 40–450 amu |

| oven temperature | initial temperature of 60 °C increased to 150 °C (hold for 2 min). Further, temperature is raised to 4 °C/min up to 280 °C and kept constant for 5 min with a total run time of 54.5 min. |

Table 2 shows the saturated and unsaturated methyl esters present in the VNSOME. From Table 2, it is clear that the VNSOME contains higher unsaturated fatty acid methyl esters (around 77.57%). Hence, the VNSOME is suitable for cold weather conditions.

Table 2. Fatty Acid Methyl Ester Composition of VNSOME.

| fatty acid methyl ester compound | molecular formula | composition (%) |

|---|---|---|

| linoleic acid methyl ester | C19H34O2 | 67.35 |

| elaidic acid methyl ester | C19H36O2 | 10.22 |

| total unsaturated fatty acid methyl esters | 77.57 | |

| palmitic acid methyl ester | C17H34O2 | 15.10 |

| isostearic acid methyl ester | C19H38O2 | 5.18 |

| arachidic acid methyl ester | C21H42O2 | 0.95 |

| behenic acid methyl ester | C23H46O2 | 0.66 |

| lignoceric acid methyl ester | C25H50O2 | 0.54 |

| total saturated fatty acid methyl esters | 22.43 | |

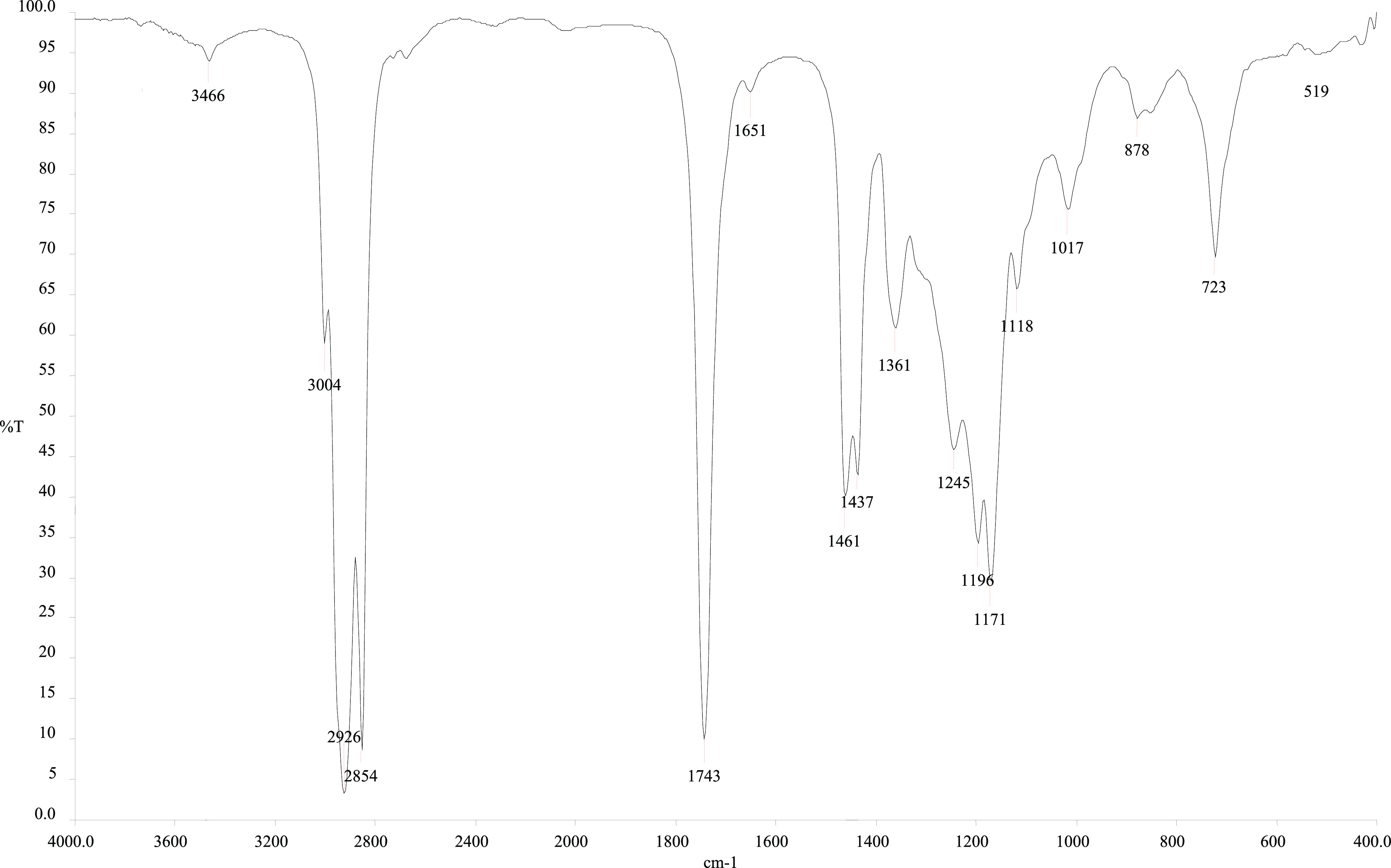

2.3.2. FT-IR Spectrometry of VNSOME

The FT-IR spectrometry results of Vachellia nilotica seed oil and the functional group with peak are tabulated in Table 3, and Figure 2 shows the FT-IR spectrum of VNSOME. The Perkin Elmer RXIFT-IR spectrometer was used to develop the VNSOME spectrum.33

Table 3. Functional Group and Peak Identification.

| wave number | functional group |

|---|---|

| 850–650 | phenols of aromatic group |

| 1300–1400 | C–O alcohols |

| 1500–1400 | C–C |

| 1750–1600 | C=O |

| 3000–2800 | CH stretching of CH3 and CH2 |

| 3400 | OH, NH, and water impurities |

Figure 2.

FT-IR spectra for VNSOME.

It can be observed that the peak detected at 3400 cm–1 clearly states the presence of −OH, −NH, and water impurities. Similarly, a stretch in −CH, CH3, and CH2 is found between the wavelength of 3000 and 2800 cm–1. There is a peak at 2926 and 2854 cm–1 suggesting the existence of CH3 and CH2. The presence of >C=O is found in the wavelength between 1750 and 1600 cm–1 as a peak is observed. The peak ranging from 1500 to 1400 cm–1 classifies the C–C stretching vibrations. Also, the C–O vibrations can be noticed between the wavelengths of 1300 and 1400 cm–1. The peaks of phenols of aromatic group vibration can be noticed with wavelength ranging from 850 to 650 cm–1.

2.4. Properties of VNSO and VNSOME

The VNSOME is mixed with diesel fuel on volume basis of 5, 10, 15, and 20% by using a lab stirrer (Remi RQ-121/D) at 750 rpm for 2 h. The physiochemical properties of the diesel fuel, VNSO, and VNSOME are analyzed based upon the ASTM D6751-02 standards, and they are represented in Table 4.

Table 4. Fuel Properties of VNSO and VNSOME.

|

Vachellia nilotica |

Ceiba pentandraa |

Papaver somniferum Lb |

|||||||

|---|---|---|---|---|---|---|---|---|---|

| property | diesel | VNSO | VNSOME | CCPO | CPME | RPSO | PSOME | limits | test method |

| kinematic viscosity at 40 °C (mm2/s) | 2.40 | 40.52 | 4.505 | 18.74 | 4.69 | 5.03 | 4.13 | 1.90–6.0 | ASTM D445 |

| fire point (°C) | 57 | 285 | 188 | NA | NA | NA | NA | ASTM D93 | |

| flash point (°C) | 46 | 237 | 185 | 186.5 | 158.5 | 234 | 172 | 130 min | ASTM D93 |

| pour point (°C) | –12 | 7 | –6 | NA | –2 | –14 | –13 | –15 to 10 | ASTM D97 |

| cloud point (°C) | 0 | 12 | 5 | NA | –3 | –12 | –15 | –3 to 12 | ASTM D2500 |

| copper strip corrosion | 1a | 1a | 1a | NA | 1a | NA | NA | class 3 | ASTM D130 |

| specific gravity at 15 °C | 0.825 | 0.885 | 0.860 | 0.906 | 0.883 | 0.919 | 0.874 | 0.86–0.90 | ASTM D1298 |

| cetane index | 53 | 57 | 62 | 53 | 58 | 47 (min) | ASTM D976 | ||

| calorific value (MJ/kg) | 41.30 | 36.88 | 38.5 | 38.672 | 40.276 | 39.6 | 40.365 | 39–43 | ASTM D240 |

| ash content (% by mass) | 0.012 | 0.0178 | 0.0165 | NA | NA | NA | NA | 0.02max | ASTM D129 |

| carbon residue (wt %) | 0.014 | 0.0260 | 0.0235 | NA | NA | NA | NA | 0.05max | ASTM D524 |

The calorific value (lower heating value) of VNSO and VNSOME is lower than that of the diesel fuel due to the existence of oxygen particles in the structure. The flash point of VNSO and VNSOME is detected to be 237 and 185 °C, respectively, making the products secure for transportation. Copper strip corrosion shows the value of class 1a for VNSO and VNSOME and is responsible for lower corrosiveness on the engine parts. Finally, it was found that the reaming fuel properties of VNSO and VNSOME are within the standard limits of ASTM D6751-02.

2.5. Test Engine and Experimentation

An experimental investigation is conducted on a stationary direct injection (DI) multifuel engine [single cylinder, four strokes, and compression ratio (CR) of 17.5:1]. It is loaded with an electrical dynamometer (eddy current type), and the engine is operated at 1500 rpm (constant speed). The details of the experimental test rig used in the present study are tabulated in Table 5, and Figure 3 shows the schematic diagram. On various engine loads, a series of experiments are carried out on the diesel engine using diesel fuel and biodiesel blends (VNSOME5, VNSOME10, VNSOME15, and VNSOME20). Exhaust gas temperature is measured using a K-type thermocouple attached to the tailpipe of the engine. The exhaust gas analyzer (AVL Digas 444) is connected to the tailpipe to determine the emissions (CO2, NOx, HC, and CO) produced during combustion of the test engine. The smoke emissions are assessed by the smoke meter (AVL 437). The range and accuracy of the instruments to measure the emissions produced (exhaust gas analyzer and smoke meter) are tabulated in Table 6.

Table 5. Test Engine Specifications.

| engine make | Kirloskar |

| capacity | 661 cc |

| engine type | single-cylinder, four-stroke, and multifuel engine |

| rated power | 3.5 kW (5 BHP) |

| compression ratio range | 12 to 18 |

| bore/stroke | 87.5/110 mm |

| type of cooling | water |

| engine rated speed | 1500 rpm |

| injection variation | 0–25° bTDC |

| injection pressure | 220 bar |

Figure 3.

Schematic diagram of the test engine setup.

Table 6. Range and Accuracy of Gas Analyzer and Smoke Meter.

| parameter to be measured | range | resolution/accuracy |

|---|---|---|

| CO2 | 0–20 vol % | 0.01 vol % |

| NOx | 0–5000 ppm | 1 ppm |

| HC | 0–20,000 ppm | 2 ppm |

| CO | 0–10 vol % | 0.01 vol % |

| smoke meter | ||

| smoke density | 0–100% | 0.01% |

3. Results and Discussions

3.1. Performance Analysis of VNSOME Blends

The performance analysis on a diesel engine operated at various loads using VNSOME blends and diesel fuel has been conducted, and the test results are discussed below:

The brake-specific fuel consumption (BSFC) of the engine using VNSOME fuel blends and diesel for different loads of engine operation is shown in Figure 4. For all the test fuels, the BSFC decreases as the loading is increased. On operating the engine at the maximum load, the BSFC of different concentration of biodiesel shows an increase of about 2.5, 4.8, 7.2, and 9.3% usingVNSOME5, VNSOME10, VNSOME15, and VNSOME20, respectively. Viscosity, specific gravity, and calorific value are the specific parameters of fuel properties that affect the BSFC of any type of diesel engine. From the results of BSFC, it is observed that BSFC from the engine fueled with VNSOME and its blends is higher than that with diesel fuel as the specific gravity and viscosity are higher.41,42 Also, it is noted from the properties of VNSOME such as higher viscosity, density of the prepared fuel, and its blends that have a lower calorific value.

Figure 4.

BSFC variation of the test fuels.

The BTE of the engine completely depends on the physical parameters such as evaporation, atomization, and combustion inside the cylinder. Figure 5 shows the disparity of brake thermal efficiency (BTE) related to different BP of the test engine at 1500 rpm. BTE is a function of BP and thermal input (product of volume flow rate and calorific value of the fuel). At a particular load of operation, the BP remains constant; hence, the BTE of the test fuels strongly depends on the calorific value.43−46 It is found that the increase in the blend concentration of VNSOME with diesel fuel decreases the calorific value and it is less compared to that of diesel fuel. Therefore, the BTE is lower than the diesel for all the VNSOME blends. At the BP of 3.5 kW, BTEs of VNSOME5, VNSOME10, VNSOME15, and VNSOME20 are 1.97, 5.49, 6.37, and 7.34%, respectively, lower than the diesel.

Figure 5.

BTE variation of the test fuels.

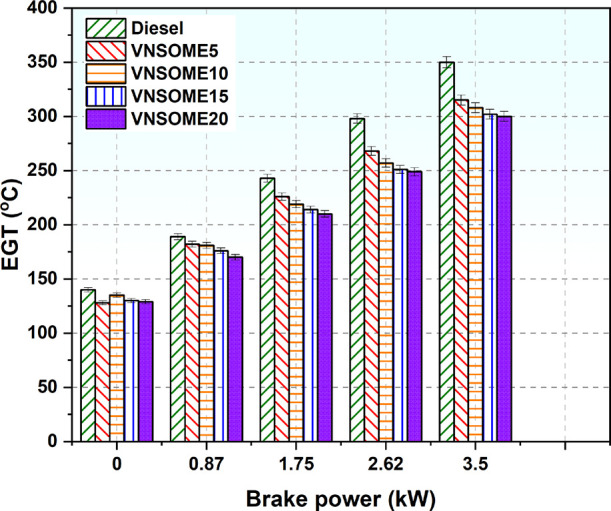

The exhaust gas temperature (EGT) of using VNSOME fuel blends and diesel for different loads of engine operation is shown in Figure 6. With increased loading condition, the EGT of test fuels increases. Similarly, with the increase in the blend of VNSOME with diesel, the EGT significantly increases at all load conditions. The enriched oxygen content available in the VNSOME blends improves the process of combustion, which resulted in greater EGT.47 At the maximum loading condition (3.5 kW), the EGTs of VNSOME5, VNSOME10, VNSOME15, and VNSOME20 are 3.22, 6.25, 9.63, and 14.28% higher than the EGT of the diesel fuel, respectively.

Figure 6.

EGT variation of the test fuels.

3.2. Exhaust Emission Analysis of VNSOME Blends

The engine exhausts emitted from the diesel engine such as hydrocarbons (HC), carbon monoxide (CO), oxides of nitrogen (NOx), smoke, and carbon dioxide (CO2) are analyzed for the VNSOME5, VNSOME10, VNSOME15, and VNSOME20 fuel blends in comparison with neat diesel, and the obtained results are discussed below:

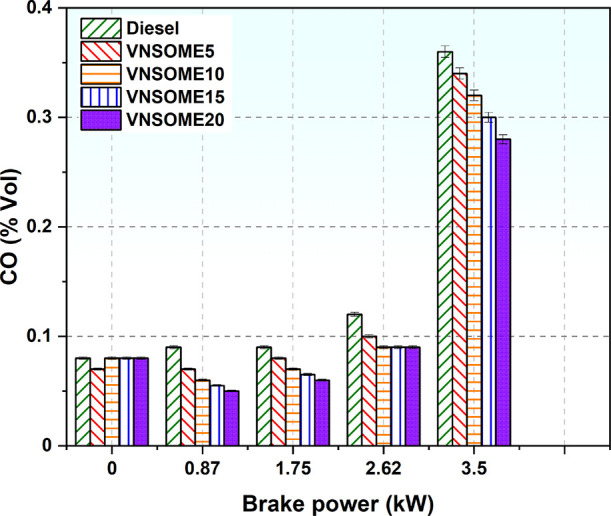

The variation in carbon monoxide (CO) emission in regard to BP is outlined in Figure 7. CO emission is higher at lower loads and is increased gradually at higher loads for all the test fuels. The possible increase in the CO emission at high loads is due to the rich fuel mixture present in the cylinder during combustion. The test outcomes revealed that the CO emission formed during the combustion with VNSOME fuel blends is lower than that with diesel fuel. At 3.5 kW, the VNSOME5, VNSOME10, VNSOME15, and VNSOME20 generates 5.55, 11.11, 16.66, and 22.22% lower CO emission when correlated to diesel fuel operation. The inbuilt oxygen composition in the VNSOME fuel blends improves the poststoichiometric combustion and thus lessens the CO emission.48,49

Figure 7.

CO emission variation of the test fuels.

The hydrocarbon (HC) deviation using VNSOME fuel blends and diesel for different loads of engine operation is displayed in Figure 8. From the pictorial view, it is very clear that the VNSOME fuel blends produce lower HC emission than diesel fuel. At the maximum load (3.5 kW), a reduction of 4.25, 8.51, 14.90, and 19.14% HC emission was depicted, respectively, for VNSOME5, VNSOME10, VNSOME15, and VNSOME20 in contrast with diesel. The oxygen composition in the VNSOME blends leads to enhance the combustion process, and it is responsible for the lower HC emission.50−52

Figure 8.

HC emission variation of the test fuels.

The formation of oxides of nitrogen (NOx) emitted after combustion using VNSOME fuel blends and diesel for different loads of engine operation is plotted in Figure 9. From Figure 9, it can be detected that the formation of oxides of nitrogen (NOx) is higher with VNSOME biodiesel blends with increased engine load. Also, it is found that the formation of NOx using diesel fuel is lower than that using VNSOME fuel blends. The oxygen content already available in the VNSOME fuel blend is the main cause of the increased formation of NOx. The availability of oxygen content present in the biodiesel blend leads to complete and enhanced combustion that simultaneously increased the combustion temperature.53−55 At 3.5 kW load, when compared to diesel fuel, the formation of NOx emission is found to be higher by about 1.94, 3.80, 5.60, and 7.34% for VNSOME5, VNSOME10, VNSOME15, and VNSOME20, respectively.

Figure 9.

NOx variation of the test fuels.

The fluctuation in smoke emission for the VNSOME fuel blends and diesel for different loads of engine operation is displayed in Figure 10. With the possible increase in the engine load, the smoke is also increased for all the test fuels since the smoke opacity strongly depends on engine load. In general, the smoke and NOx are trade-offs. The smoke emission was reduced by 4.42, 7.37, 9.30, and 11.20% for VNSOME5, VNSOME10, VNSOME15, and VNSOME20, respectively, in contrast with the pure diesel fuel at the maximum load (3.5 kW). The reduction in C–H ratio, superfluous oxygen composition, and absence of sulfur content in the VNSOME blends are the important causes of the effective reduction in smoke emissions.49,56,57

Figure 10.

Smoke variation of the test fuels.

The disparity of carbon dioxide (CO2) emission of the test fuels (VNSOME5, VNSOME10, VNSOME15, VNSOME20, and diesel fuel) at different BPs is exhibited in Figure 11. When the load increases in the test, the engine emits higher CO2 emissions for all the test fuels. At the full load (3.5 kW) condition, the VNSOME5, VNSOME10, VNSOME15, and VNSOME20 blends produce 2.34, 4.58, 6.01, and 7.40% higher CO2 emission compared to diesel fuel. This may be due to the improved combustion of VNSOME blends than diesel fuel.49

Figure 11.

CO2 variation of the test fuels.

4. Conclusions

In this study, an attempt was made to prepare the new biodiesel (VNSOME) fueled in a DI diesel engine for assessing the emission and performance characteristics. Based on the experimental results from the engine analysis, the conclusions are as follows:

The blends of VNSOME in diesel fuel exhibited lower BTEs using VNSOME in different volume concentrations on diesel compared to neat diesel fuel. For VNSOME20, 7.34% marginally lower BTE is detected at 3.5 kW. Similarly, higher BSFC and EGT were found for all the VNSOME blends.

The CO emissions produced from the engine tested with VNSOME in different volume concentrations are lower than that with neat diesel. At 3.5 kW, VNSOME20 emits 22.22% lower CO than that of diesel fuel.

The formation of HC from the engine with different blends of VNSOME fuel is significantly lower than that with neat diesel. The VNSOME20 fuel blend generates 19.14% lower HC compared to diesel fuel at the maximum load of the engine.

NOx emissions are marginally increased for VNSOME fuel blends. When compared to neat diesel, the NOx formed is higher by about 7.34% than the VNSOME20 blend with the engine operated at the peak load.

Using VNSOME fuel blends in the engine, the smoke emission is considerably reduced. There is an 11.20% reduction of smoke identified for VNSOME20 compared to diesel fuel at the full load of the engine.

CO2 emissions are slightly higher for all VNSOME fuel blends. At the full load (3.5 kW), VNSOME20 develops 7.40% higher CO2 than diesel fuel.

4.1. Future recommendations

It can be concluded that the biodiesel fuel blend (VNSOME20) was found to be an alternative source for diesel fuel and the diesel engine can be fueled with this blend without making any modification.

Author Contributions

The manuscript was written through contributions of all authors. All authors have given approval to the final version of the manuscript.

The authors declare no competing financial interest.

References

- Knothe G. Biodiesel and renewable diesel: a comparison. Prog. Energy Combust. Sci. 2010, 36, 364–373. 10.1016/j.pecs.2009.11.004. [DOI] [Google Scholar]

- Ma F.; Hanna M. A. Biodiesel production: a review. Bioresour. Technol. 1999, 70, 1–15. 10.1016/S0960-8524(99)00025-5. [DOI] [Google Scholar]

- Hoekman S. K.; Broch A.; Robbins C.; Ceniceros E.; Natarajan M. Review of biodiesel composition, properties, and specifications. Renewable Sustainable Energy Rev. 2012, 16, 143–169. 10.1016/j.rser.2011.07.143. [DOI] [Google Scholar]

- Leung D. Y. C.; Wu X.; Leung M. K. H. A review on biodiesel production using catalyzed transesterification. Appl. Energy 2010, 87, 1083–1095. 10.1016/j.apenergy.2009.10.006. [DOI] [Google Scholar]

- Mata T. M.; Martins A. A.; Caetano N. S. Microalgae for biodiesel production and other applications: a review. Renewable Sustainable Energy Rev. 2010, 14, 217–232. 10.1016/j.rser.2009.07.020. [DOI] [Google Scholar]

- Meher L. C.; Sagar D. V.; Naik S. N. Technical aspects of biodiesel production by transesterification—a review. Renewable Sustainable Energy Rev. 2006, 10, 248–268. 10.1016/j.rser.2004.09.002. [DOI] [Google Scholar]

- Tan T.; Lu J.; Nie K.; Deng L.; Wang F. Biodiesel production with immobilized lipase: a review. Biotechnol. Adv. 2010, 28, 628–634. 10.1016/j.biotechadv.2010.05.012. [DOI] [PubMed] [Google Scholar]

- Atadashi I. M.; Aroua M. K.; Aziz A. A. Biodiesel separation and purification: a review. Renewable Energy 2011, 36, 437–443. 10.1016/j.renene.2010.07.019. [DOI] [Google Scholar]

- Abbaszaadeh A.; Ghobadian B.; Omidkhah M. R.; Najafi G. Current biodiesel production technologies: A comparative review. Energy Convers. Manage. 2012, 63, 138–148. 10.1016/j.enconman.2012.02.027. [DOI] [Google Scholar]

- Basha S. A.; Gopal K. R.; Jebaraj S. A review on biodiesel production, combustion, emissions and performance. Renewable Sustainable Energy Rev. 2009, 13, 1628–1634. 10.1016/j.rser.2008.09.031. [DOI] [Google Scholar]

- Atabani A. E.; Silitonga A. S.; Badruddin I. A.; Mahlia T. M. I.; Masjuki H. H.; Mekhilef S. A comprehensive review on biodiesel as an alternative energy resource and its characteristics. Renewable Sustainable Energy Rev. 2012, 16, 2070–2093. 10.1016/j.rser.2012.01.003. [DOI] [Google Scholar]

- Haseeb A. S. M. A.; Fazal M. A.; Jahirul M. I.; Masjuki H. H. Compatibility of automotive materials in biodiesel: a review. Fuel 2011, 90, 922–931. 10.1016/j.fuel.2010.10.042. [DOI] [Google Scholar]

- Aransiola E. F.; Ojumu T. V.; Oyekola O. O.; Madzimbamuto T. F.; Ikhu-Omoregbe D. I. O. A review of current technology for biodiesel production: State of the art. Biomass Bioenergy 2014, 61, 276–297. 10.1016/j.biombioe.2013.11.014. [DOI] [Google Scholar]

- Jegannathan K. R.; Abang S.; Poncelet D.; Chan E. S.; Ravindra P. Production of biodiesel using immobilized lipase—a critical review. Crit. Rev. Biotechnol. 2008, 28, 253–264. 10.1080/07388550802428392. [DOI] [PubMed] [Google Scholar]

- Kouzu M.; Hidaka J.-s. Transesterification of vegetable oil into biodiesel catalyzed by CaO: a review. Fuel 2012, 93, 1–12. 10.1016/j.fuel.2011.09.015. [DOI] [Google Scholar]

- Ong H. C.; Mahlia T. M. I.; Masjuki H. H.; Norhasyima R. S. Comparison of palm oil, Jatropha curcas and Calophyllum inophyllum for biodiesel: A review. Renewable Sustainable Energy Rev. 2011, 15, 3501–3515. 10.1016/j.rser.2011.05.005. [DOI] [Google Scholar]

- Fadhil A. B.; Al-Tikrity E. T.; Khalaf A. M. Transesterification of non-edible oils over potassium acetate impregnated CaO solid base catalyst. Fuel 2018, 234, 81–93. 10.1016/j.fuel.2018.06.121. [DOI] [Google Scholar]

- Fadhil A. B.; Ahmed A. I. Ethanolysis of fish oil via optimized protocol and purification by dry washing of crude ethyl esters. J. Taiwan Inst. Chem. Eng. 2016, 58, 71–83. 10.1016/j.jtice.2015.06.010. [DOI] [Google Scholar]

- Ayoob A. K.; Fadhil A. B. Valorization of waste tires in the synthesis of an effective carbon based catalyst for biodiesel production from a mixture of non-edible oils. Fuel 2020, 264, 116754. 10.1016/j.fuel.2019.116754. [DOI] [Google Scholar]

- Ayoob A. K.; Fadhil A. B. Biodiesel production through transesterification of a mixture of non-edible oils over lithium supported on activated carbon derived from scrap tires. Energy Convers. Manage. 2019, 201, 112149. 10.1016/j.enconman.2019.112149. [DOI] [Google Scholar]

- Altikriti E. T.; Fadhil A. B.; Dheyab M. M. Two-step base catalyzed transesterification of chicken fat: Optimization of parameters. Energy Sources, Part A 2015, 37, 1861–1866. 10.1080/15567036.2012.654442. [DOI] [Google Scholar]

- Fadhil A. B.; Saeed I. K.; Saeed L. I.; Altamer M. H. Co-solvent ethanolysis of chicken waste: Optimization of parameters and characterization of biodiesel. Energy Sources, Part A 2016, 38, 2883–2890. 10.1080/15567036.2015.1065299. [DOI] [Google Scholar]

- Fadhil A. B.; Aziz A. M.; Altamer M. H. Optimization of methyl esters production from non-edible oils using activated carbon supported potassium hydroxide as a solid base catalyst. Arab. J. Basic Appl. Sci. 2018, 25, 56–65. 10.1080/25765299.2018.1449414. [DOI] [Google Scholar]

- Fadhil A. B.; Saeed L. I. Sulfonated tea waste: A low-cost adsorbent for purification of biodiesel. Int. J. Green Energy 2016, 13, 110–118. 10.1080/15435075.2014.896801. [DOI] [Google Scholar]

- Fadhil A. B.; Ahmed A. I. Production of mixed methyl/ethyl esters from waste fish oil through transesterification with mixed methanol/ethanol system. Chem. Eng. Commun. 2018, 205, 1157–1166. 10.1080/00986445.2018.1434514. [DOI] [Google Scholar]

- Ong H. C.; Masjuki H. H.; Mahlia T. M. I.; Silitonga A. S.; Chong W. T.; Leong K. Y. Optimization of biodiesel production and engine performance from high free fatty acid Calophyllum inophyllum oil in CI diesel engine. Energy Convers. Manage. 2014, 81, 30–40. 10.1016/j.enconman.2014.01.065. [DOI] [Google Scholar]

- Ong H. C.; Milano J.; Silitonga A. S.; Hassan M. H.; Shamsuddin A. H.; Wang C.-T.; Mahlia T. M. I.; Siswantoro J.; Kusumo F.; Sutrisno J. Biodiesel production from Calophyllum inophyllum-Ceiba pentandra oil mixture: Optimization and characterization. J. Cleaner Prod. 2019, 219, 183–198. 10.1016/j.jclepro.2019.02.048. [DOI] [Google Scholar]

- Ong H. C.; Tiong Y. W.; Goh B. H. H.; Gan Y. Y.; Mofijur M.; Fattah I. M. R.; Chong C. T.; Alam M. A.; Lee H. V.; Silitonga A. S.; Mahlia T. M. I. Recent advances in biodiesel production from agricultural products and microalgae using ionic liquids: Opportunities and challenges. Energy Convers. Manage. 2020, 228, 113647. 10.1016/j.enconman.2020.113647. [DOI] [Google Scholar]

- Silitonga A. S.; Shamsuddin A. H.; Mahlia T. M. I.; Milano J.; Kusumo F.; Siswantoro J.; Dharma S.; Sebayang A. H.; Masjuki H. H.; Ong H. C. Biodiesel synthesis from Ceiba pentandra oil by microwave irradiation-assisted transesterification: ELM modeling and optimization. Renewable Energy 2020, 146, 1278–1291. 10.1016/j.renene.2019.07.065. [DOI] [Google Scholar]

- Silitonga A. S.; Masjuki H. H.; Ong H. C.; Sebayang A. H.; Dharma S.; Kusumo F.; Siswantoro J.; Milano J.; Daud K.; Mahlia T. M. I.; Chen W.-H.; Sugiyanto B. Evaluation of the engine performance and exhaust emissions of biodiesel-bioethanol-diesel blends using kernel-based extreme learning machine. Energy 2018, 159, 1075–1087. 10.1016/j.energy.2018.06.202. [DOI] [Google Scholar]

- Krupakaran R. L.; Hariprasad T.; Gopalakrishna A. Impact of various blends of Mimusops elengi methyl esters on performance and emission characteristics of a diesel engine. Int. J. Green Energy 2018, 15, 415–426. 10.1080/15435075.2018.1469496. [DOI] [Google Scholar]

- Sathiyamoorthi R.; Sankaranarayanan G.; kumaar S. B. A.; Chiranjeevi T.; Kumar D. D. Experimental investigation on performance, combustion and emission characteristics of a single cylinder diesel engine fuelled by biodiesel derived from Cymbopogon Martinii. Renewable Energy 2019, 132, 394–415. 10.1016/j.renene.2018.08.001. [DOI] [Google Scholar]

- Sekhar S. C.; Karuppasamy K.; Sathyamurthy R.; Elkelawy M.; Bastawissi H. A. E. D.; Paramasivan P.; Sathiyamoorthy K.; Edison P. Emission analysis on compression ignition engine fueled with lower concentrations of Pithecellobium dulce biodiesel-diesel blends. Heat Transfer - Asian Res. 2019, 48, 254–269. 10.1002/htj.21381. [DOI] [Google Scholar]

- Hoseini S. S.; Najafi G.; Ghobadian B.; Mamat R.; Ebadi M. T.; Yusaf T. Characterization of biodiesel production (ultrasonic-assisted) from evening-primroses (Oenothera lamarckiana) as novel feedstock and its effect on CI engine parameters. Renewable Energy 2019, 130, 50–60. 10.1016/j.renene.2018.06.042. [DOI] [Google Scholar]

- Ogunkunle O.; Ahmed N. A. Performance evaluation of a diesel engine using blends of optimized yields of sand apple (Parinari polyandra) oil biodiesel. Renewable Energy 2019, 134, 1320–1331. 10.1016/j.renene.2018.09.040. [DOI] [Google Scholar]

- Asokan M. A.; Prabu S. S.; Bade P. K. K.; Nekkanti V. M.; Gutta S. S. G. Performance, combustion and emission characteristics of juliflora biodiesel fuelled DI diesel engine. Energy 2019, 173, 883–892. 10.1016/j.energy.2019.02.075. [DOI] [Google Scholar]

- Shrivastava P.; Verma T. N. An experimental investigation into engine characteristics fueled with Lal ambari biodiesel and its blends. Therm. Sci. Eng. Prog. 2020, 17, 100356. 10.1016/j.tsep.2019.100356. [DOI] [Google Scholar]

- Irani R.; Khaled K. L. Acacia nilotica gum: An Underutilized Food Commodity. Int. J. Curr. Res. 2015, 7, 14280–14288. [Google Scholar]

- Bargali K.; Bargali S. S. Acacia nilotica: a multipurpose leguminous plant. Nat. Sci. 2009, 7, 11–19. [Google Scholar]

- Bhuiya M. M. K.; Rasul M. G.; Khan M. M. K.; Ashwath N. Biodiesel production and characterisation of poppy (Papaver somniferum L.) seed oil methyl ester as a source of 2nd generation biodiesel feedstock. Ind. Crops Prod. 2020, 152, 112493. 10.1016/j.indcrop.2020.112493. [DOI] [Google Scholar]

- Chattopadhyay S.; Sen R. Fuel properties, engine performance and environmental benefits of biodiesel produced by a green process. Appl. Energy 2013, 105, 319–326. 10.1016/j.apenergy.2013.01.003. [DOI] [Google Scholar]

- Kumar T. S.; Kumar P. S.; Annamalai K. Experimental study on the performance and emission measures of direct injection diesel engine with Kapok methyl ester and its blends. Renewable Energy 2015, 74, 903–909. 10.1016/j.renene.2014.09.022. [DOI] [Google Scholar]

- Khiari K.; Awad S.; Loubar K.; Tarabet L.; Mahmoud R.; Tazerout M. Experimental investigation of pistacia lentiscus biodiesel as a fuel for direct injection diesel engine. Energy Convers. Manage. 2016, 108, 392–399. 10.1016/j.enconman.2015.11.021. [DOI] [Google Scholar]

- Nautiyal P.; Subramanian K. A.; Dastidar M. G.; Kumar A. Experimental assessment of performance, combustion and emissions of a compression ignition engine fuelled with Spirulina platensis biodiesel. Energy 2020, 193, 116861. 10.1016/j.energy.2019.116861. [DOI] [Google Scholar]

- Srihari S.; Thirumalini S.; Prashanth K. An experimental study on the performance and emission characteristics of PCCI-DI engine fuelled with diethyl ether-biodiesel-diesel blends. Renewable Energy 2017, 107, 440–447. 10.1016/j.renene.2017.01.015. [DOI] [Google Scholar]

- Raman L. A.; Deepanraj B.; Rajakumar S.; Sivasubramanian V. Experimental investigation on performance, combustion and emission analysis of a direct injection diesel engine fuelled with rapeseed oil biodiesel. Fuel 2019, 246, 69–74. 10.1016/j.fuel.2019.02.106. [DOI] [Google Scholar]

- Mishra S. R.; Mohanty M. K.; Panigrahi N.; Pattanaik A. K. Impact of Simarouba glauca biodiesel blends as a fuel on the performance and emission analysis in an unmodified DICI engine. Renewable Energy Focus 2018, 26, 11–16. 10.1016/j.ref.2018.05.002. [DOI] [Google Scholar]

- Sivaramakrishnan K. Investigation on performance and emission characteristics of a variable compression multi fuel engine fuelled with Karanja biodiesel–diesel blend. Egypt. J. Pet. 2018, 27, 177–186. 10.1016/j.ejpe.2017.03.001. [DOI] [Google Scholar]

- Sayin C.; Gumus M. Impact of compression ratio and injection parameters on the performance and emissions of a DI diesel engine fueled with biodiesel-blended diesel fuel. Appl. Therm. Eng. 2011, 31, 3182–3188. 10.1016/j.applthermaleng.2011.05.044. [DOI] [Google Scholar]

- Hasan M. M.; Rahman M. M. Performance and emission characteristics of biodiesel–diesel blend and environmental and economic impacts of biodiesel production: A review. Renewable Sustainable Energy Rev. 2017, 74, 938–948. 10.1016/j.rser.2017.03.045. [DOI] [Google Scholar]

- Kumar M. V.; Babu A. V.; Kumar P. R. The impacts on combustion, performance and emissions of biodiesel by using additives in direct injection diesel engine. Alexandria Eng. J. 2018, 57, 509–516. 10.1016/j.aej.2016.12.016. [DOI] [Google Scholar]

- Rahman S. M. A.; Van T. C.; Hossain F. M.; Jafari M.; Dowell A.; Islam M. A.; Nabi M. N.; Marchese A. J.; Tryner J.; Rainey T.; Ristovski Z. D. Fuel properties and emission characteristics of essential oil blends in a compression ignition engine. Fuel 2019, 238, 440–453. 10.1016/j.fuel.2018.10.136. [DOI] [Google Scholar]

- Baskar P.; Senthilkumar A. Effects of oxygen enriched combustion on pollution and performance characteristics of a diesel engine. Eng. Sci. Technol., Int. J. 2016, 19, 438–443. 10.1016/j.jestch.2015.08.011. [DOI] [Google Scholar]

- Shameer P. M.; Ramesh K. Experimental evaluation on performance, combustion behavior and influence of in-cylinder temperature on NOx emission in a D.I diesel engine using thermal imager for various alternate fuel blends. Energy 2017, 118, 1334–1344. 10.1016/j.energy.2016.11.017. [DOI] [Google Scholar]

- Di Y.; Cheung C. S.; Huang Z. Experimental investigation on regulated and unregulated emissions of a diesel engine fueled with ultra-low sulfur diesel fuel blended with biodiesel from waste cooking oil. Sci. Total Environ. 2009, 407, 835–846. 10.1016/j.scitotenv.2008.09.023. [DOI] [PubMed] [Google Scholar]

- Srinivas K.; Naik B. B.; Radha K. K. Performance and emission characteristics of VCR CI engine fueled with methyl ester of palm kernel oil and eucalyptus oil blends. Perspect. Sci. 2016, 8, 195–197. 10.1016/j.pisc.2016.04.030. [DOI] [Google Scholar]

- Kumar R. S.; Sureshkumar K.; Velraj R. Combustion, performance and emission characteristics of an unmodified diesel engine fueled with Manilkara Zapota Methyl Ester and its diesel blends. Appl. Therm. Eng. 2018, 139, 196–202. 10.1016/j.applthermaleng.2018.04.107. [DOI] [Google Scholar]