Abstract

Hydrogel microparticles (HMPs) are promising for biomedical applications, ranging from the therapeutic delivery of cells and drugs to the production of scaffolds for tissue repair and bioinks for 3D printing. Biologics (cells and drugs) can be encapsulated into HMPs of predefined shapes and sizes using a variety of fabrication techniques (batch emulsion, microfluidics, lithography, electrohydrodynamic (EHD) spraying and mechanical fragmentation). HMPs can be formulated in suspensions to deliver therapeutics, as aggregates of particles (granular hydrogels) to form microporous scaffolds that promote cell infiltration or embedded within a bulk hydrogel to obtain multiscale behaviours. HMP suspensions and granular hydrogels can be injected for minimally invasive delivery of biologics, and they exhibit modular properties when comprised of mixtures of distinct HMP populations. In this Review, we discuss the fabrication techniques that are available for fabricating HMPs, as well as the multiscale behaviours of HMP systems and their functional properties, highlighting their advantages over traditional bulk hydrogels. Furthermore, we discuss applications of HMPs in the fields of cell delivery, drug delivery, scaffold design and biofabrication.

Owing to their high water content, diverse properties and similarity to the native extracellular matrix (ECM), hydrogels are used as substrates for cell culture1, templates for tissue engineering2 and vehicles for drug and protein delivery3. Traditionally, hydrogels are cross-linked into continuous volumes (bulk hydrogels) with external dimensions at the millimetre scale or larger and a mesh size at the nanometre scale that permits molecule diffusion. A micrometre-scale porosity can be introduced into a bulk hydrogel using various processing techniques, such as porogen leaching4, cryogel formation5 or electrospinning6. However, bulk hydrogels are not always suited for their intended applications, particularly in cases in which injection is needed or smaller sizes are required.

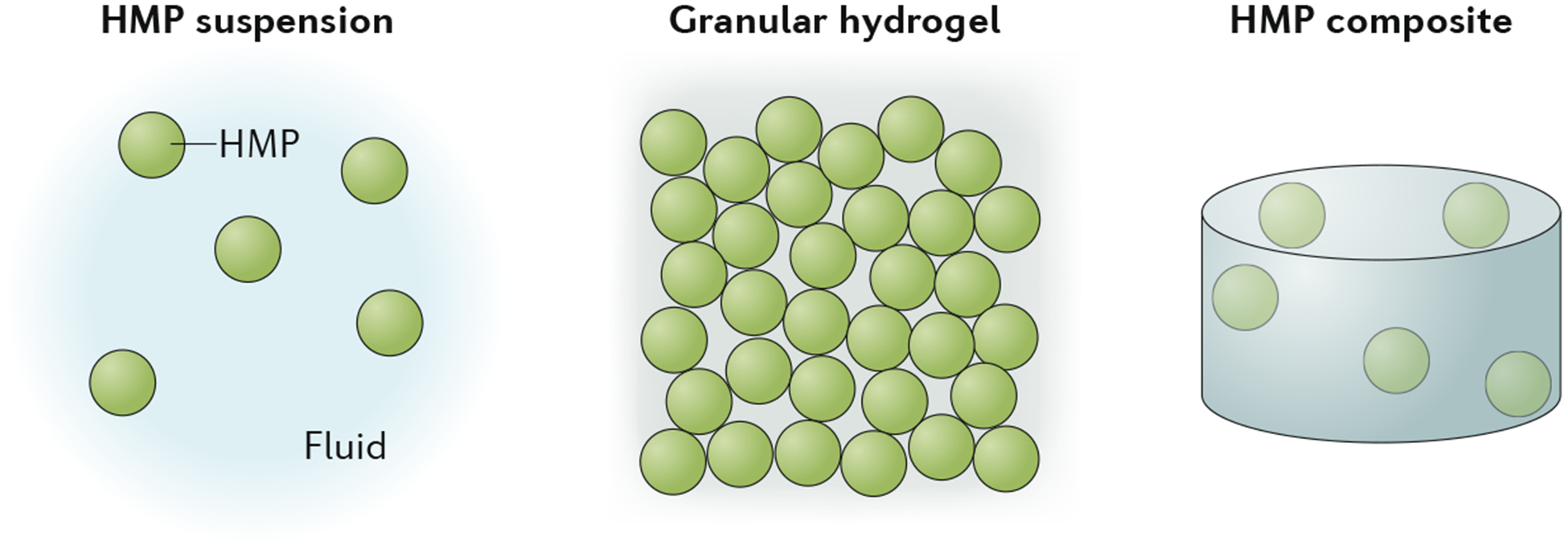

As an alternative, various techniques have been developed to fabricate hydrogels as microscale particles (~1–1,000 μm), called hydrogel microparticles (HMPs) or microgels. HMPs can be made from both natural and synthetic polymers, and can be fabricated into a variety of shapes and sizes using techniques that are often compatible with the encapsulation of biologics (for example, cells and drugs). Whereas the dynamics of polymers in solution, such as prior to hydrogel formation, are driven by thermal fluctuations, the larger HMPs are dominated by gravity, which allows for particle settling. HMPs can be utilized as distinct units or in aggregation; thus, we classify HMP systems into three categories: HMP suspensions, granular hydrogels and HMP composites (FIG. 1). In HMP suspensions, the HMPs reside in a fluid (liquid or air), with minimal interactions between particles. When the particle-packing density is increased and the particle–particle interactions that govern bulk assembly properties arise, HMPs form granular hydrogels. Granular hydrogels primarily exist in a jammed state, where they can range from a loose-packing configuration with high porosity to an ultraclose-packing state in which HMPs deform and the interstitial space collapses, resulting in a loss of microporosity. Finally, HMP composites are obtained when HMPs are embedded within a bulk hydrogel.

Fig. 1 |. Categories of hydrogel microparticles.

Hydrogel microparticles (HMPs) can be fabricated and used as distinct units or in aggregation. Their aggregates can be categorized as suspensions, granular hydrogels or composites if HMPs are embedded within a bulk hydrogel.

HMPs have a number of unique properties compared to bulk hydrogels that make them attractive for biomedical applications. First, their small size enables injection through small needles and catheters and inhalation of particles, which is advantageous for minimally invasive delivery of cells and biologics. The physical interactions between particles in granular systems often lead to a shear-thinning behaviour that permits injection and then a solid-like consistency after injection without the need for chemical modification7; however, interparticle cross-linking chemistries may also be incorporated to further alter the granular hydrogel properties8. Second, HMP systems are inherently modular, as multiple HMP populations with varying composition, size and contents can be mixed to create diverse materials9. Third, granular hydrogels can possess significant porosity (or void space) owing to the interstitial space between HMPs. The level of porosity scales with the size and packing density of HMPs and can be tuned to support cell proliferation and migration10.

In this Review, we discuss advances in the development of HMPs for biomedical applications. First, we introduce and compare methods used to fabricate HMPs, including batch and microfluidic emulsions, lithography, spraying and mechanical fragmentation. Then, we discuss the multiscale properties of HMP systems, including mechanical properties, injectability and porosity. Finally, we survey recent applications of HMP systems in cell delivery, drug delivery, scaffold building and biofabrication. The overall goal of this Review is to introduce the biomedical potential of these materials, as well as provide guidance for methods to fabricate and characterize them.

Fabrication of HMPs

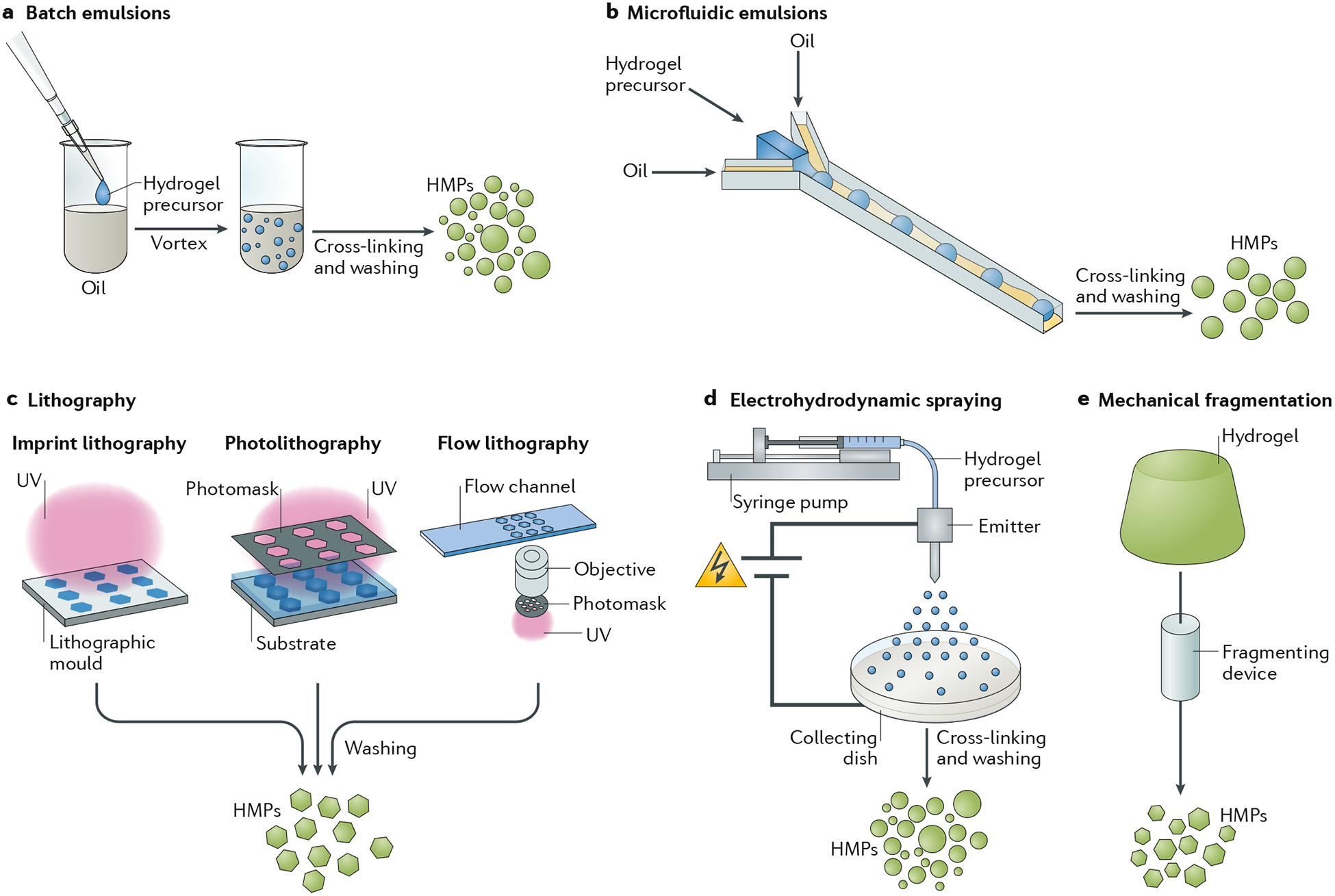

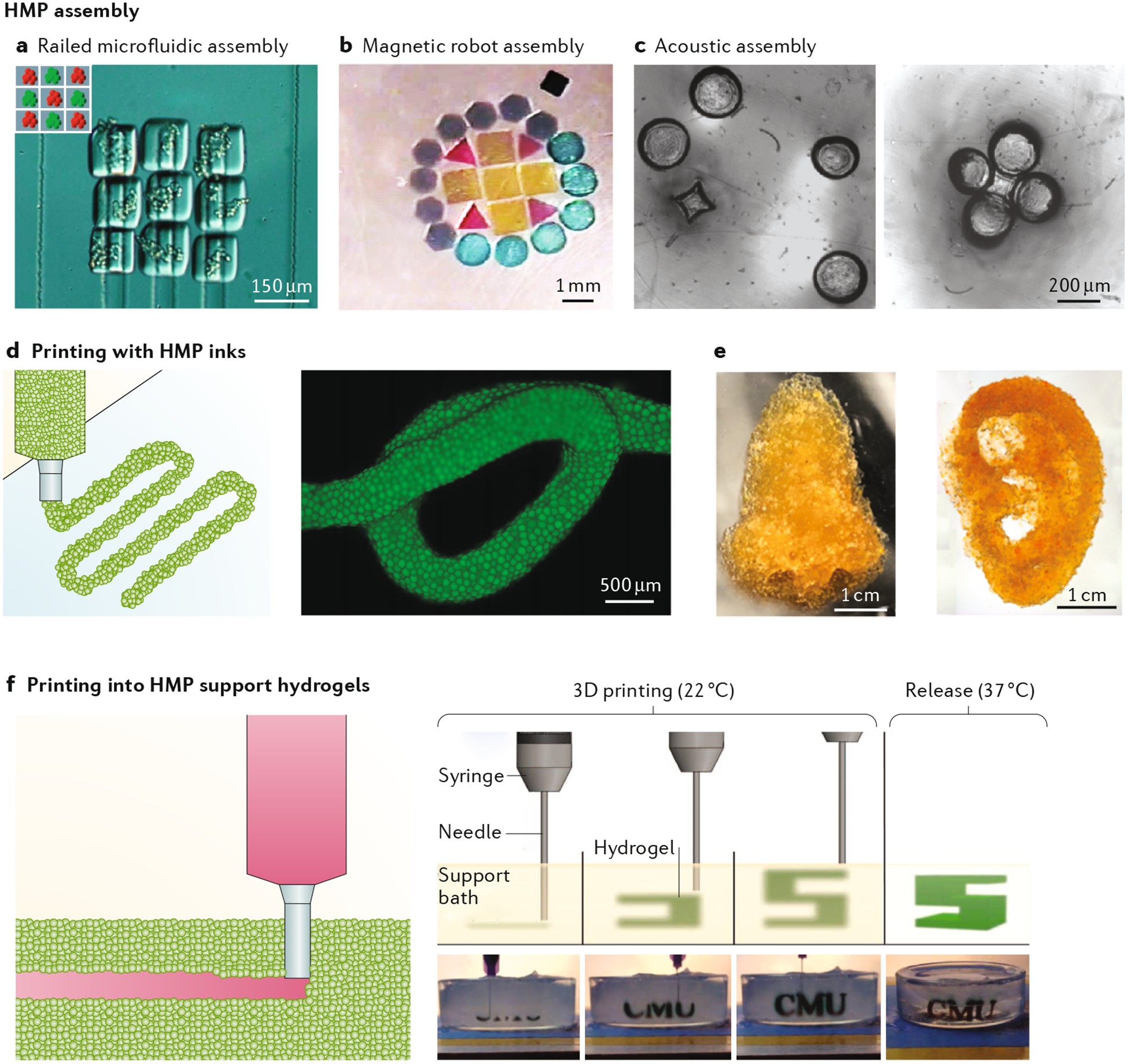

A variety of fabrication techniques can be used to fabricate HMPs across various hydrogel types and cross-linking methods (FIG. 2). We can categorize them as batch emulsions, microfluidic emulsions, lithography, EHD spraying and mechanical fragmentation. In general, these approaches include the formation of droplets of hydrogel precursors that are then cured into HMPs, the spatial control of light to cure HMPs from hydrogel precursor solutions or the disruption of bulk hydrogels into HMPs.

Fig. 2 |. Fabrication of hydrogel microparticles.

Examples of fabrication techniques include: a | Batch emulsions, in which immiscible liquids are mixed together (for example, water and oil) to generate droplets that can be cross-linked to form hydrogel microparticles (HMPs). b | Microfluidic emulsions, in which flow-focusing junctions are used to generate droplets that can be subsequently cross-linked to form HMPs. c | Lithography, in which masks or moulds are used as templates for hydrogels at the microscale. d | Electrohydrodynamic spraying, in which electrical forces are used to charge flowing solutions to form droplets that can then be cross-linked into hydrogels. e | Mechanical fragmentation techniques, in which mechanical energy is used to fragment preformed hydrogels into smaller particles. Blue shading refers to uncross-linked solution, green shading refers to cross-linked HMPs or hydrogel. UV, ultraviolet.

Approaches such as batch emulsions and mechanical fragmentation are popular because of their simplicity and the speed at which HMPs can be produced. However, more advanced strategies, such as microfluidic emulsions, lithography and EHD spraying, offer improved control over the formation of individual particles and have enabled the production of more monodisperse HMPs with variations in internal and external architectures. Key process parameters such as the rate of particle production and the particle size distribution can vary significantly across fabrication techniques: we outline these parameters in TABLE 1.

Table 1 |.

Key performance metrics for different techniques for the fabrication of hydrogel microparticles

| Production method | Particle size coefficient of variation* (CV%) | Minimum size range | Production rate | Particle geometry | Compatibility with cells |

|---|---|---|---|---|---|

| Batch emulsion | Large variation (>10%)11,230 | 1–10 μm17 | High (only limited by vessel size) | Spherical | Average (>80% viability)11,12 |

| Microfluidic emulsion | Low variation (1–2% possible)26 | 5–10 μm14,23,24,51 | Average (can be improved with parallel channels) | Spherical | Average (>80% viability)33,38,47 |

| Lithography | Low variation (1–3% possible)61,75,231 | <1 μm possible61,62 | Low (can be improved when integrated with microfluidics) | Arbitrary 2D and 3D geometries possible | High (>90%); no oil or surfactant required58,59 |

| Electrohydrodynamic spraying | Average variation >50%77,79,80 | 1–10 μm78 | Average | Spherical | Average (>80%)76,77 |

| Mechanical fragmentation | Average variation (2–8%)86 | 20–50 μm85,86 | High (only limited by vessel size) | Irregular | Unreported |

The coefficient of variation (CV%) is defined as the ratio of the standard deviation of particle size to the mean particle size.

Each fabrication technique imposes constraints on the hydrogels that can be processed. For example, the rheological behaviour and cross-linking mechanism of the hydrogel must be compatible with the chosen method. Thus, the fabrication technique should be selected based on its compatibility with the selected hydrogel, as well as on the desired HMP properties (such as size and dispersity) and access to specialized equipment (microfluidic emulsion, lithography and EHD spraying require more advanced equipment, whereas batch emulsions and fragmentation require relatively simple equipment). In this section, we discuss the strengths, limitations and compatibility with cell and drug encapsulation of each technique. We also highlight the hydrogel chemistry and cross-linking methods used in each fabrication approach, which are summarized in TABLE 2.

Table 2 |.

Hydrogel cross-linking chemistries used to generate hydrogel microparticles

| Base hydrogel | Chemical modification | Cross-linking method | Fabrication technique |

|---|---|---|---|

| Alginate | Unmodified77 | Ionic cross-linking with CaCl2 | EHD spraying |

| Unmodified47,112 | Ionic cross-linking in the presence of CaCl2 | Microfluidic emulsion | |

| Methacrylate232 | Radical polymerization (UV) | Microfluidic emulsion | |

| Gelatin | Unmodified86 | Temperature | Mechanical fragmentation |

| Methacrylate35,233 | Radical polymerization (UV) | Microfluidic emulsion | |

| Methacrylate194 | Temperature (cooling to 4 °C then radical polymerization (UV)) | Microfluidic emulsion | |

| Methacrylate58 | Radical polymerization (UV) | Lithography | |

| Hyaluronic acid | Methacrylate234 | Radical polymerization (UV) | Batch emulsion |

| Methacrylate67 | Radical polymerization (UV) | Lithography | |

| Acrylate103 | Radical polymerization (UV) | Microfluidic emulsion | |

| Norbornene7 | Thiol-ene reaction | Microfluidic emulsion | |

| Tyramine235 | Sequential enzymatic and radical polymerization (UV) | Lithography (two-photon) | |

| Tyramine + furan236 | Enzymatic cross-linking and/or Diels–Alder click chemistry | Microfluidic emulsion | |

| Vinyl ester69 | Thiol-ene reaction | Lithography (two-photon) | |

| Aldehyde + hydrazide237 | Hydrazone covalent cross-linking | Batch emulsion | |

| Methacrylate + tetrazole238 | Tetrazole–alkene photoclick chemistry (UV) | Microfluidic emulsion | |

| PEG | Acrylate59,239,240 | Radical polymerization (UV) | Microfluidic emulsion and lithography |

| Methacrylate34 | Radical polymerization (UV) | Lithography | |

| Norbornene195 | Thiol-ene reaction (UV) | EHD spraying | |

| Vinyl sulfone8 | Michael addition | Microfluidic emulsion | |

| Vinyl sulfone and thiol39,125 | Michael addition | Microfluidic emulsion | |

| Maleimide29,33,38 | Michael addition | Microfluidic emulsion | |

| PVA | Thiol and ene68 | Thiol-ene reaction (UV) | Lithography |

| Chitosan | Unmodified82 | Electrostatic interactions | EHD spraying |

| Silk/fibroin | Norbornene241 | Thiol-ene photoclick chemistry and β-sheet formation | Batch emulsion |

| Agarose | Unmodified7,37,242 | Temperature | Microfluidic emulsion |

EDH, electrohydrodynamic; PEG, poly(ethylene glycol); PVA, poly(vinyl alcohol); UV, ultraviolet.

Batch-emulsion techniques

Emulsion techniques use immiscible oil and aqueous hydrogel precursor solutions to generate droplets that can then be cross-linked into HMPs. In a batch process, an aqueous precursor solution containing the hydrogel prepolymer and an initiator and/or cross-linker is combined with the oil in a single container, potentially with a surfactant to stabilize the emulsion. Mechanical mixing is used to homogenize the solution and generate aqueous droplets surrounded by an oil phase (FIG. 2a). The extent and timing of mixing can influence the size and dispersity of the resulting droplets. The droplets are then cross-linked and the oil phase is removed using a series of washing, centrifugation and filtration steps. Several hydrogel cross-linking approaches are compatible with batch-emulsion techniques (TABLE 2). Photocross-linking is commonly used because external light sources induce cross-linking while the droplets of precursor solutions are suspended in the oil phase. For example, acrylated or methacrylated poly(ethylene glycol) (PEG) HMPs can be photocross-linked using radical polymerizations if a suitable initiator is included in the aqueous phase11. Alternatively, changes in temperature (cooling) can be used to cross-link thermosensitive hydrogels such as gelatin12.

The main advantages of batch-emulsion methods are their simplicity and the high particle-production rates, which are only limited by the container volume and by the ability to mix the emulsion. These methods are also compatible with biologics such as small molecules and growth factors, which can be simply dissolved in the hydrogel precursor solutions before the formation of the emulsion13. Batch-emulsion techniques have also been successfully used to encapsulate cells within HMPs through suspension in the aqueous solution prior to emulsification11·12.

One of the main limitations of batch emulsions is the polydispersity of the resulting HMPs, as there is limited control over the formation of individual particles14. This may also lead to batch-to-batch variations if the mixing procedures are not performed identically each time. The importance of polydispersity depends on the application: for example, when HMPs are used to release growth factors, diffusion may depend on their polydispersity and on particle sizes. It has been demonstrated that HMP populations with comparable mean diameters but prepared with either batch or microfluidic emulsions possess distinct release profiles, with greater variability in the population prepared by batch emulsion, which displays an earlier burst release of the encapsulated drug14. Further, HMP polydispersity makes it challenging to control the number of cells contained within each HMP; however, polydisperse HMP suspensions can be serially filtered with increasingly smaller filters to achieve a more monodisperse suspension15. If the batch-emulsion process is performed in a repeatable manner and its influence on HMP properties is understood, the drawbacks related to polydispersity can be minimal.

Although this method is used less frequently, HMPs can also be produced using all-aqueous, two-phase separation techniques16. Early work in this area leveraged phase-separation phenomena that occur through simple mixing of aqueous solutions of PEG and methacrylated dextran and subsequent cross-linking with light after separation17. PEG can also be used to form HMPs, exploiting phase separation above a lower critical solution temperature, including across a range of sizes with control over the thermodynamics and kinetics of the phase-separation process18. For example, HMPs were formed from reactive PEG derivatives that underwent thermally induced phase separation, and their size was dependent on the kinetics of gelation, influenced by temperature and pH19. Gelatin-based HMPs have also been fabricated with two-phase separation techniques exploiting the formation of simple coacervates in the presence of polyanions such as alginate under low-pH conditions20. For example, spontaneous HMP formation was observed following mixing of oxidized and methacrylated alginate and gelatin methacrylamide (GelMA) in aqueous solutions at low pH, resulting in a composite hydrogel system containing growth-factor-loaded GelMA compartments surrounded by an alginate bulk phase20.

Microfluidic-emulsion techniques

The limitations of batch-emulsion protocols motivated seminal studies in the early 2000s that demonstrated the potential of more controlled emulsions in HMP fabrication, such as in flow-focusing microfluidic devices21,22. Controlled droplet formation can be achieved by directing the flow of oils and aqueous solutions at intersection points, where shear forces and hydrophobic interactions induce the formation of aqueous droplets within an oil phase (FIG. 2b). Importantly, by varying the geometry of the intersection and the relative flow rates between the two phases, it is possible to control the droplet diameter, which is in the micrometre range (5–500 μm)23·24. In addition, if the flow rates are maintained, monodisperse particle populations with dispersity indexes as low as 1–2% can be produced25,26. As a result, microfluidic technology has been widely adopted to produce HMPs across a wide variety of hydrogels8,23,27 (TABLE 2). Microfluidic emulsions are also compatible with small-molecule or protein encapsulation; the improved size distribution offers greater control over subsequent release profiles13,14,28–30. In addition, by incorporating cells in the aqueous phase at a defined concentration, it is possible to predict and control the number of cells encapsulated in single HMPs31–33.

Microfluidic methods impose two main requirements on the hydrogel precursor solution. First, the solution must have a relatively low viscosity, so that it can be pumped through narrow microchannels at low pressures. Second, the droplets must cross-link rapidly during collection to prevent droplet coalescence. Many cross-linking strategies have been introduced in which droplets are cross-linked either ‘on-chip’ or ‘off-chip’; on-chip approaches are preferred because they limit droplet coalescence. Photocross-linking has been used with macromers such as polyethylene (glycol) diacrylate (PEGDA) and GelMA because they can be rapidly cross-linked using externally applied light34,35. Photoinitiated thiol-ene cross-linking has also been used to process HMPs, for example with norbornene-modified hyaluronic-acid and PEG macromers, which were cross-linked in the presence of dithiol cross-linkers and radical initiators7,36. Thermoresponsive hydrogels such as agarose can also be processed into HMPs by cooling the droplets during collection7,37.

Gelation of the hydrogel precursor can also be achieved through mixing or introduction of reactive components on-chip. Cross-linkers or initiators can be added to the oil phase, which subsequently diffuses into the aqueous phase to initiate cross-linking. For example, PEG maleimide HMPs have been fabricated by incorporating dithiol cross-linkers into the oil phase, where they can diffuse into the droplets to induce a Michael-addition reaction38. Advanced microfluidic devices can also be used to mix reactive components, for example using multiple flow-focusing junctions. The mixed aqueous phase can then be rapidly focused at a second emulsion junction for droplet formation and cross-linking over time. Using this approach, HMPs have been fabricated through a Michael-addition reaction between PEG thiol and PEG vinyl sulfone39. In a similar approach, degradable HMPs were formed through a reaction between cysteine-terminated, degradable matrix metalloproteinase (MMP)-sensitive cross-linkers and PEG vinyl sulfone8.

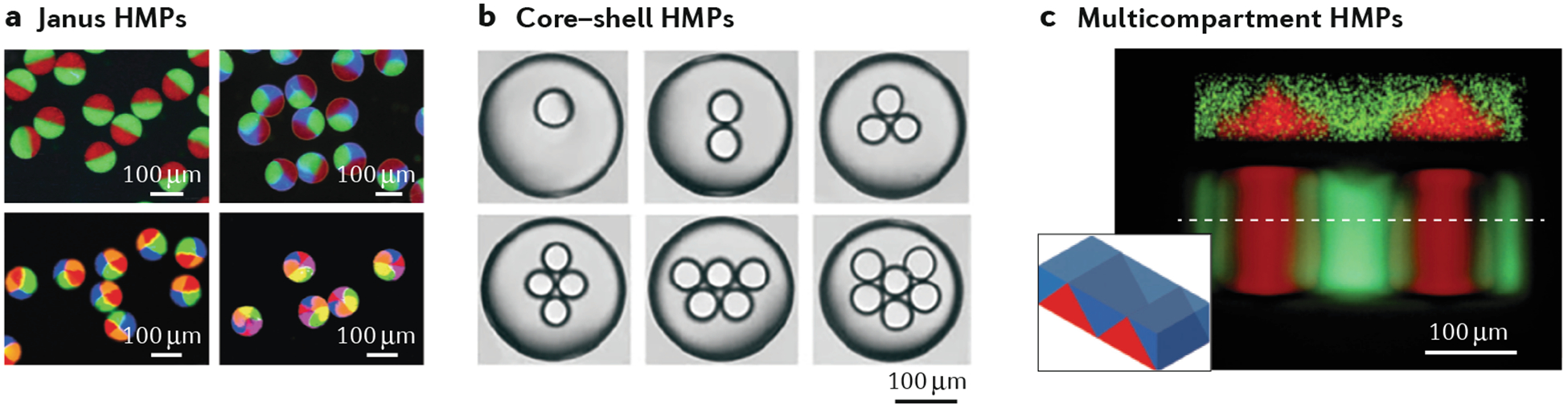

The main advantage of microfluidic approaches is the good control over the droplet-formation process, which can be precisely engineered by both designing microfluidic channels with specified geometries and controlling inputs such as flow rates. Typically, microfluidic junctions are made using microfabricated polydimethylsiloxane (PDMS) moulds that can be engineered to user-defined dimensions using soft lithography or 3D printing. Capillary-based microfluidic devices, in which glass capillaries are coaxially aligned in either co-flow or flow-focusing configurations, can also be used to generate microfluidic emulsions. A range of microfluidic techniques for generating compartmentalized HMPs have been developed40–42. For example, Janus HMPs were obtained by directing two aqueous solutions at a primary junction with laminar flow and then breaking them into droplets by further flow focusing at a secondary emulsion junction43 (FIG. 3a). Glass microcapillary devices can be used to form double emulsions, where particles of various internal complexities can be made, dependent upon the relative flow rates between the outer, middle and inner fluids25 (FIG. 3b). This high level of control over the droplet-formation process has enabled the formation of HMPs with either multiple drug-loaded compartments, where the drug-release rate from a particular compartment can be independently tuned by varying the hydrogel properties of that compartment and the overall release is based on the total release over time from all compartments44,45, or with structured co-cultures of cells46,47. A promising alternative is the design of centrifuge-based microfluidic devices to produce compartmental microparticles without oil, with the particle size controlled by the capillary diameter and centrifugal force48.

Fig. 3 |. Microfluidic and lithographic templating of compartmentalized hydrogel microparticles.

a | Microfluidic formation of Janus (multiple-sided) hydrogel microparticles (HMPs) containing up to six distinct compartments, which is achieved by using multibarrel microcapillaries123. b | Formation of structured core–shell HMPs containing multiple compartments using co-axial, flow-focusing, microcapillary needle arrangements42. c | Complex 3D structures fabricated using membrane-assisted photolithography, which facilitates sequential, layered polymerizations. The confocal microscopy image shows the cross section of the particle, the inset its 3D morphology56. Panel a is adapted from reF.123, panel b from reF.42, panel c from reF.56.

As an alternative to chip-based microfluidics, in-air microfluidic methods have been developed. In these methods, two microscale liquid streams are jetted together and forced to collide, leading to droplet formation49,50. Compared to microchannel-based on-chip techniques, higher liquid-flow rates can be achieved, which leads to faster particle-production rates (10–100 times faster). In addition, when reactive liquids are jetted towards each other (for example, alginate and calcium chloride), the HMPs can be directly deposited into 3D constructs. There is great potential in techniques such as these, which need to be further explored to exploit their advantages over other emulsion-based methods.

The major limitation of microfluidic approaches is that they are relatively low throughput compared to batch emulsions. This issue becomes exacerbated when attempting to produce smaller-diameter HMPs because the volumetric throughput decreases with the cube of the droplet diameter. However, higher throughput rates can be achieved using parallelized microfluidic devices containing multiple junctions on a single device51–54. To ensure that monodisperse particle populations are produced when using parallelized devices, the channel geometry must be designed to accommodate pressure drops and flow fluctuations throughout the device. For example, the successful encapsulation of viable cells within monodisperse PEG HMPs was demonstrated using a parallelized, double-layer PDMS device with a throughput six times higher than that of single-channel devices33. Microfluidic devices also classically produce spherical particles as a product of the surface-tension-driven droplet formation and alternative techniques may be needed if non-spherical particle geometries are desired.

Lithography

HMPs can also be produced using lithographic methods, in which photopolymerization is used to template hydrogels at the microscale. There are three main classes of lithography technologies: imprint lithography, photolithography and flow lithography55 (FIG. 2c). In imprint lithography, a hydrogel precursor is loaded into a templated mould with the negative features of the desired HMPs for cross-linking and then cured. Photolithography uses templated photomasks to selectively cure regions of a hydrogel precursor to form HMPs. Lastly, flow lithography uses a photomask to cure regions of a flowing hydrogel precursor solution at regular intervals to form HMPs. The main advantage of lithography technologies is that the geometrical features of the mask or mould can be tightly controlled, resulting in great control over the geometry and monodispersity of the HMPs56–58. In addition, lithographic approaches are widely compatible with cell encapsulation and no oil or surfactants are required to induce particle formation34,59.

Advances in microfabrication techniques have enabled the production of moulds and masks with features defined at the nanometre scale, making it possible to generate designer HMPs with tailored internal and external architectures that could not be achieved with other fabrication methods56–58,60–62. However, there are several constraints on the HMP geometries that can be obtained. Imprint-lithography approaches present the practical constraint of needing to remove the cross-linked HMPs from the mould, which limits the complexity of the achievable internal or external features. With photolithography, only relatively simple geometries such as cubes, cuboids, discs, bars and stars can be obtained55,61. To enable the production of HMPs with complex 3D geometries, multiphoton light sources have to be used63,64. Advanced lithographic assemblies that facilitate sequentially layered polymerization to produce complex 3D HMPs have also been developed56 (FIG. 3c).

A range of photocross-linking chemistries have been explored to produce HMPs using lithography (TABLE 2). The most commonly used hydrogels are acrylated or methacrylated PEGs, which are simple, tunable and biocompatible59,65,66. For example, PEGDA and poly(ethylene glycol) dimethacrylate (PEGMA) hydrogels can be cross-linked in seconds through photoinduced radical polymerization in the presence of a photoinitiator. Naturally derived hydrogels such as hyaluronic acid and gelatin can also be functionalized with reactive groups that make them processable by lithography58,67. Thiol-ene-based, step-growth photocross-linking approaches have been used to generate HMPs using modified poly(vinyl alcohol) (PVA)68 or hyaluronic acid vinyl ester with two-photon photolithography69.

A major challenge with lithography approaches is that they are relatively low throughput compared to other methods. Specifically, the particle-production rate is limited by the size of the moulds or masks that can be prepared using available microfabrication techniques and by the field of view of the light source or objective. Fast hydrogel curing times are generally preferred because they increase particle-production rates. For example, by increasing the number of functional groups on the macromer (for example, acrylate or norbornene) or the macromer concentration, the rate of polymerization and the final mechanical properties increased70–72. Further, increasing the light-source intensity or the initiator concentration (for example, I2959 for ultraviolet light and lithium phenyl-2,4,6-trimethylbenzoylphosphinate (LAP) for visible light) reduces the curing time required to reach a desired cross-linking density73,74. Flow-lithography techniques offer the greatest throughput because they can be integrated with microfluidic techniques61,65 and parallelized75. A method that is not widely adopted but has good performance is the particle replication in non-wetting templates (PRINT) system, which can produce HMPs with controlled sizes and shapes in a high-throughput manner through integration with a roll-to-roll manufacturing process that facilitates scalable particle-production rates62,66.

Electrohydrodynamic-spraying methods

EHD-spraying methods are less commonly used than the techniques discussed so far. During EHD spraying, a hydrogel precursor solution is extruded through a syringe while a voltage is applied at the needle tip. Beyond a critical threshold, the applied voltage overcomes the surface tension at the needle tip, leading to the formation of a charged jet of droplets that are attracted towards a collecting substrate76 (FIG. 2d). The droplets are then cross-linked in the collecting bath, and their size depends on parameters such as the applied voltage, needle diameter and polymer flow rate77, and can be as small as 1 μm78. However, achieving monodisperse particle populations is challenging, and dispersity indexes higher than 5% are often reported79,80. Alginate is widely used for EHD spraying because it can be directly sprayed into a calcium-chloride solution to induce immediate cross-linking of the droplets76,77,81. Chitosan HMPs have been processed by spraying into a tripolyphosphate solution to cross-link via electrostatic interactions82. Photocross-linkable hydrogels have been processed by spraying into a bath that is simultaneously exposed to light79,80. Finally, this technique is compatible with cell encapsulation76,77,83,84. Similar to emulsion approaches, the polydisperse particles can be passed through filters to achieve a more monodisperse population.

Mechanical-fragmentation methods

In mechanical-fragmentation methods, HMPs are produced by mechanically breaking a preformed bulk hydrogel into microscale particles (FIG. 2e). For example, a cross-linked hydrogel can be mechanically forced through a fine steel mesh to form smaller particles. The size of the HMPs can then be controlled through the pore size ofthe mesh. HMPs with diameters of 15–30 μm have been obtained this way85. Another simple fragmentation method involves breaking a cross-linked hydrogel into particles using a simple rotational blender. This method has been used to generate blended gelatin slurries composed of microparticles with diameters of120–300 μm86. The main advantages of microparticulation approaches are their speed and simplicity, which make it possible to rapidly generate large volumes of microparticles in a single process. However, a major limitation is that there is little control over the formation of individual particles, which results in polydisperse size distributions. It is also not clear whether these approaches are compatible with cell encapsulation, and, to the best of our knowledge, no studies on this aspect are available in the literature.

Properties of HMP systems

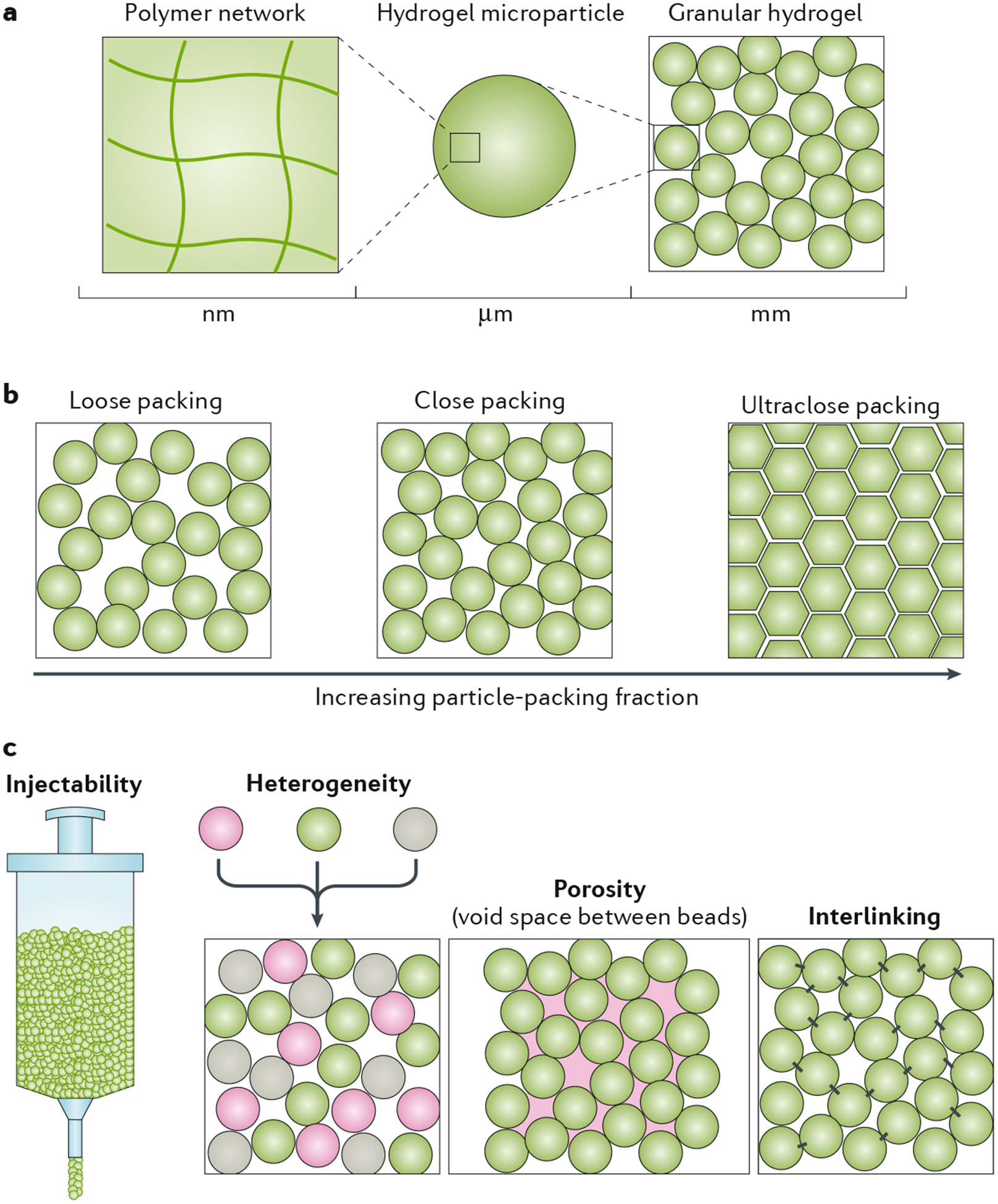

The physical properties of HMP systems are multiscale and depend on the properties of the individual HMPs, on their packing density and on the properties of the continuous phase. HMP suspensions, granular hydrogels and HMP composites each possess unique functional properties not present in bulk hydrogels. For example, HMP suspensions can be easily delivered through small needles or inhalers for minimally invasive delivery of cells and biologics. Granular hydrogels (FIG. 4) form particle scaffolds that open up new building approaches, including microporosity (owing to the interstitial space among HMPs) and scaffold modularity (owing to the mixing of multiple HMP populations)87. Granular hydrogels also display a shear-thinning behaviour that can be exploited for injectability and 3D printing applications9. In this section, we describe the different classes of HMP systems, with particular focus on their macroscale and microscale mechanics, porosity and diffusivity. We then describe some of the unique functional features of HMPs (injectability, heterogeneity and porosity) relevant for biomedical applications.

Fig. 4 |. Structure and properties of granular hydrogels.

a | Granular hydrogels have multiscale features, with the polymer network at the nanoscale, individual hydrogel microparticles (HMPs) at the microscale and the granular structure at the millimetre scale. b | When the particle-packing fraction of HMPs in a granular hydrogel increases, the system evolves from loose packing to close packing to, eventually, an ultraclose-packing state, in which the particles deform and void spaces collapse. The packing density affects physical properties such as porosity, transport and mechanical properties. c | Granular hydrogels have unique features, including injectability, heterogeneity (if different types of HMPs are mixed together) and porosity, which allows for passage through the structure. Interlinking between particles further stabilizes the structure.

Multiscale properties of HMP systems

HMP suspensions.

HMP suspensions comprise dilute HMPs in a fluid, such as liquid or air (FIG. 1). The macroscale mechanical and rheological behaviours of HMP suspensions are largely governed by the properties of the continuous phase because interparticle interactions are negligible. The individual mechanical properties of the HMPs within the system depend on the polymer type and density, as well as the extent of cross-linking between polymer chains. Due to the relatively low packing density of HMPs in suspensions, the overall system diffusivity is high; however, diffusivity within an individual HMP is governed by the polymer mesh size. The concept of microporosity does not apply to HMP suspensions because microporosity is defined in the context of a solid-like material, but the particle-packing density is too low in these systems. Larger and denser microparticles (usually larger than 10 μm in diameter) are less sensitive to thermal forces that lead to Brownian motion and more affected by gravitational forces. This, in conjugation with interparticle friction, promotes HMP settling and packing88–90. Therefore, under static, non-mixing, non-flow conditions, suspensions of HMPs greater than 10 μm readily settle into a jammed state and transition to a granular hydrogel. HMP suspensions are generally used for cell or drug delivery, when interactions between particles are not needed to achieve effective therapeutic outcomes.

Granular hydrogels.

Granular hydrogels (FIG. 4) comprise an agglomeration of HMPs in the jammed state, where the term ‘jammed’ implies that an inside particle can only move if its neighbouring particles also move91. Generally, granular materials are composed of solid particles that readily sediment and experience frictional forces between touching particles88,90. Interparticle friction among HMPs in granular hydrogels is attributed to polymer interactions on the surface of HMPs; the amount of friction is influenced by the polymer type, microparticle chemistry and properties of the continuous phase of the material (such as viscosity and polymer-solvent interactions)92. As the HMP-packing density reaches that of the jammed state, interparticle friction aids in the transition from a liquid-like to a solid-like state88. Looking at the properties of granular hydrogels across various length scales, the polymer network is important at the nanoscale and it can influence the properties of individual HMPs at the microscale and those of the granular hydrogel at the millimetre scale (FIG. 4a).

The jamming transition occurs when the particle-packing density (or particle-volume fraction, ϕ) is sufficiently high and under appropriate conditions of stress and temperature87,90. Reducing the continuous phase of the material can promote HMP packing towards the jammed state7. The resulting jammed system behaves as a solid-like mass of touching particles; the precise particle-packing density largely influences hydrogel dynamics. Classically, hard-sphere packing is categorized into three general ranges: random loose packing (ϕ > 0.58), random close packing (0.58 < ϕ < 0.64) and maximally jammed, perfect packing (ϕ ≈ 0.74). At ϕ ≈ 0.58, particles are minimally jammed but configurationally stable. At ϕ ≈ 0.64, particles are maximally jammed in a random configuration in which additional jamming would require particle deformation90,93. Thus, granular hydrogels of spherical HMPs theoretically lie within a range of ϕ ≈ [0.58–0.64]. In reality, however, HMP systems are much more complex, owing to HMP deformability, interparticle friction and non-spherical, non-uniform HMP shapes, all of which may allow for states with ϕ > 0.74 (REF94). External forces such as centripetal forces or compression can be used to reach a state of ultraclose packing (ϕ 1), in which the interstitial space begins to collapse and flat-faced facets form between touching, deformed HMPs (FIG. 4b). To understand these behaviours, numerical simulations have been used to study the packing of particles of heterogeneous shapes, sizes and deformability93,95,96.

Granular hydrogels can swell and compress more than bulk hydrogels, owing to their two-scale matrix structure: intraparticle polymer cross-linking makes up individual HMPs, whereas an interparticle microporous matrix is formed when particles are packed together. The intraparticle matrix is nearly identical to that of a bulk hydrogel, but the microporous scaffold is specific to the jammed state, in which touching particles form the interconnected secondary matrix. This two-scale structure results in a two-phase response to swelling and osmotic compression. Bulk hydrogels can only swell up to the capacity of their polymer matrix, whereas granular hydrogels comprising fully swollen HMPs may continue to swell into the interstitial space of the packed particles until particles begin to pull apart (transitioning towards an HMP suspension)92. By contrast, osmotic forces can make HMP suspensions transition to a granular hydrogel phase. Once the jammed state is reached, further compression past a critical force will expel solvent from the decreasing interstitial space until the granular hydrogel begins to behave as a solid bulk gel. Such phenomena are sensitive to HMP stiffness but not to HMP size92.

The particulate nature of granular hydrogels makes them respond differently than bulk hydrogels to uniaxial compression, indentation and shear tests. Viscoelastic materials such as bulk hydrogels fracture under an applied force surpassing the yield stress. Granular hydrogels behave in a similar way under exceedingly high compression, when particles are densely packed and deformed. However, below this critical threshold, local slipping and sliding of HMPs helps to accommodate the imposed stress89,92. Unlike homogeneous bulk hydrogels, granular hydrogels contain load-bearing force chains, which are paths of touching particles through which stress is transmitted; these chains govern the stability and flowability of the system. Over the range of strains at which granular hydrogels exhibit elastic behaviour, force-chain networks remain constant. However, in the plastic regime, force chains become dynamic and respond to changes in the external load to maintain stable stress states89,97. The surface area of the applied load dramatically influences the mechanical response of a granular system: a large surface-area compression may result in minimal HMP displacement, whereas a focused indentation can penetrate the scaffold without fracture by causing local particle displacement. Shear loading of granular hydrogels results in a higher loss modulus (viscous response) under low shear rates than in bulk hydrogels.

Many materials properties influence the mechanical response of granular hydrogels, including polymer type, HMP stiffness, HMP density, HMP charge and interparticle friction. Incorporating a heterogeneous population of HMPs can introduce other interparticle forces that contribute to the dynamics of granular gels, including electrostatic interactions and hydrophobic-hydrophilic interactions. Granular hydrogels that comprise heterogeneous particle sizes may contain ‘rattlers’ or ‘floaters’ (smaller particles that freely traverse the interstitial space of the scaffold)91,95; however, these should not significantly impact the jamming properties of the system. When an external force is applied to a granular hydrogel, interparticle friction reduces HMP rearrangement92. To fully immobilize particles and fix the packing configuration of a scaffold, HMPs may be cross-linked together to create what is referred to as a microporous annealed particle (MAP) scaffold8. Annealing between HMPs can be achieved using a number of covalent or non-covalent techniques. The mechanical properties of MAP scaffolds are different from those of non-annealed HMP systems10, and, although both systems behave as solids under low shear stress, non-annealed HMP systems flow under high shear stress. By contrast, MAP scaffolds reach a higher modulus and do not behave as a liquid at high shear stress unless the annealing chemistry is reversible or non-covalent. Note that MAP scaffolds do not match the mechanical properties of bulk hydrogels with a matching formulation, owing to the lower number of HMP contact points relative to polymer entanglement in a bulk network15,98. Material degradation kinetics can also be modulated by HMP annealing, which introduces a tunable degradation parameter that does not exactly mirror the properties of the non-porous matrix composing the HMPs. Additionally, by limiting HMP rearrangement, the void space microarchitecture of the scaffold becomes fixed, offering a more controllable infrastructure.

HMP composites.

In HMP composites, the particles are incorporated in a secondary material (such as a hydrogel) (FiG. 1). The mechanical properties of the secondary material typically dominate the behaviour of composite systems, unless the concentration of HMPs is substantial and depending on their size and density. Embedding HMPs in a hydrogel helps to stabilize individual HMPs: the hydrogel acts as a cement to hold HMPs together and can potentially introduce desirable chemical or molecular interactions. HMP composites can also be used to fabricate microporous bulk hydrogels by using the HMPs as a sacrificial porogen that is then washed out (for example, gelatin through heating and cooling steps) after cross-linking the bulk hydrogel phase99,100. The dual material inherent to HMP composites can also be exploited for a more complex mechanical behaviour. For example, HMP composites have been used to engineer mechanically tough hydrogels in which the dispersed microgel phase blunts crack propagation under load101. HMP composites can also be used to decouple the mechanical and biological properties of a hydrogel. For example, rather than simply increasing the cross-linking density of a hydrogel to make it tougher, which may influence cell behaviour, adding HMPs (such as stiff gellan-gum microgels) to a soft hydrogel was shown to increase its toughness102.

Functional properties of HMP systems

Injectability.

A noteworthy feature of HMP systems is that they can be injected using a syringe or catheter (FiG. 4). Preformed bulk hydrogels are challenging to deliver using minimally invasive techniques and must, instead, be shaped and implanted, often involving surgical incisions. Bulk hydrogels are normally only injectable as a homogeneous precursor solution that exhibits liquid-like (viscous) rheological properties until gelation is induced using in situ cross-linking approaches or through the incorporation of shear-thinning cross-links. By contrast, unannealed HMP systems are easily injectable due to their particulate nature and small particle size. Frictional, non-covalent and electrostatic forces among neighbouring HMPs affect their injectability and become increasingly influential as particle packing increases. For example, jammed granular hydrogels exhibit shear-thinning behaviour; thus, large injection forces allow HMPs to collectively flow as a fluid and, once the applied force is attenuated, the HMPs return to a viscoelastic solid state with gel-like rheological properties7. Gel stiffness may be further enhanced by annealing HMPs post injection8. The injectability of HMPs has been exploited for several applications, including wound healing and bioprinting, using a wide range of hydrogels. For example, modified hyaluronic-acid HMPs (made using microfluidics) were injected into ischaemic sites within cardiac9 and brain103 tissue in rats and mice, respectively, to promote wound healing in a minimally invasive way.

Particle jamming, which regularly occurs under syringe pressure, minimizes turbulent flow and allows HMPs to move as a plug during injection54,104 (FIG. 4c). When injected into a cavity, HMPs at appropriate packing fractions readily fill the space and take the shape of the cavity, similar to a precursor hydrogel solution; however, the viscoelasticity of particulate hydrogels minimizes their dispersion upon injection8,103. Note that unannealed, jammed HMPs behave as a solid unit when injected into tissues that experience low pressure, such as the skin; however, injection into pressurized, confined spaces, such as fluid-filled stroke cavities, may require post-injection HMP annealing to avoid backflow after the syringe is removed103. Annealing after injection into highly motile tissues, such as cardiac tissues, may also help to minimize particle dislodging9 but, depending on the formulation, is not always needed105.

Heterogeneity.

Incorporating intraparticle and/or interparticle heterogeneity introduces additional complexity to HMP systems that may elicit multifactorial effects at the particle or system level (FIG. 4c). Intraparticle heterogeneity may involve compartmentalizing individual HMPs, altering surface chemistries post production, layering individual HMPs or varying porosity within individual HMPs. Regarding interparticle heterogeneity, HMP species can differ from one another in a multitude of ways, including hydrogel formulation or cargo type. A heterogeneous material can be produced by simply mixing multiple HMP populations until particles are uniformly distributed. Macroscale anisotropy can be achieved by exploiting HMP jamming, which minimizes HMP mixing and allows for physical separation of different HMP agglomerations104. To demonstrate the potential complexity of HMP systems, consider a collection of spherical (100-μm) HMPs in an aqueous medium. In the jammed state, there are roughly 1,000 HMPs per μL of material. Scaling up, 1 mL of material would contain 1 million distinct HMPs. Thus, there is substantial room for incorporating HMP heterogeneity across various HMP systems.

Void space and porosity.

The interstitial space (or void space) among packed HMPs is referred to as the pores of the granular scaffold, and the size of the pores is pro-portional to the size of the HMPs. Thus, packed HMPs produce micrometre-sized pockets of interstitial space87. Cells with diameters on this length scale can, therefore, easily infiltrate and traverse a granular scaffold without needing to degrade the hydrogel, whereas degradation is often needed for cells to infiltrate a bulk hydrogel. Relative to non-porous hydrogels, the microporosity of granular hydrogels increases fluid-flow, mass-transport, permeability and cell-infiltration rates. The system can also accommodate other large entities, such as ECM proteins (which often exceed 200 kDa in size). A reduction in scaffold porosity generally correlates with a reduction in mass-transport rates. The average pore size of a scaffold is affected by HMP shapes and sizes, packing density and stiffness8,106. Depending on the degree of HMP jamming and softness, the application of a large external force may result in the collapse of the interstitial space, so that flat-faced facets form between touching, deformed particles94 (ultraclose packing in FIG. 4c).

Applications of HMPs

The properties of HMPs make them promising for numerous biomedical applications, several of which are covered in this section, including cell delivery, drug delivery, scaffold building and biofabrication. The ability to extrude HMP-based biomaterials from syringes or catheters is particularly important for their delivery to tissues. HMPs can be delivered, for example, by intraarticular injection or direct injection into tissues: the modes of delivery of HMPs to various tissues are summarized in FIG. 5.

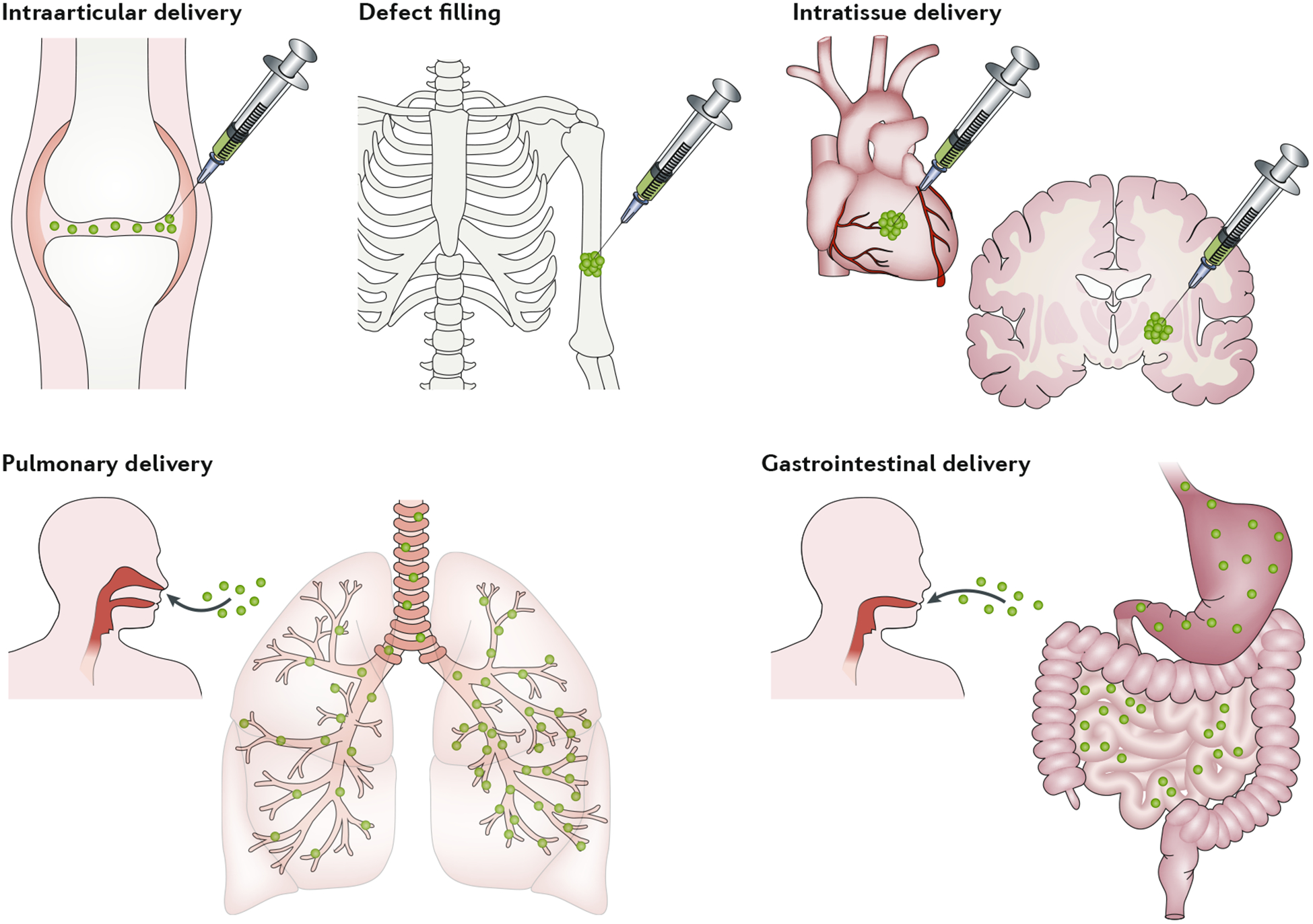

Fig. 5 |. Hydrogel microparticles delivery to various tissues in the body.

Examples of hydrogel microparticle delivery include: delivery to the intraarticular space; delivery to bone defects; intratissue delivery (for example, in the heart or brain); delivery to the lungs via aerosols; and delivery through the gastrointestinal tract to the intestine. Hydrogel microparticles can be delivered as suspensions, granular hydrogels or composites, and they may contain biologics, such as cells or drugs.

HMPs for cell delivery

The delivery of cells to damaged and diseased tissues holds tremendous potential for numerous applications; however, challenges — including limited cell survival and difficult engraftment of transplanted cells following delivery — has hampered progress in this area. This has led to increased interest in the use of delivery vehicles to enhance the integration, viability and function of injected cells107. Hydrogels emerged as a platform to increase the localization of cells at the target site following injection and to provide appropriate biophysical and biochemical cues to promote cellular integration and desired function108–111. The high water content and tunable properties of hydrogels further motivated their use in this area. Although significant progress has been made, challenges still remain; for example, the large diffusion lengths in bulk hydrogels may limit the oxygen and nutrients that reach transplanted cells. Further, the limited porosity and lack of injectability of many bulk hydrogels impede their use in several applications. These limitations have stimulated interest in the use of HMP systems for cell delivery. In this section, we describe concepts and advances in the use of HMPs for cell delivery and highlight some successful applications.

Cell encapsulation within HMPs.

As discussed, a range of HMP fabrication techniques are compatible with cell encapsulation (batch emulsion, microfluidic emulsion, lithography and EHD spraying). Microfluidic emulsions and lithography are often used due to the improved control over particle size and shape that they offer. By controlling process parameters such as the particle size and density of cells within the precursor solution, it is possible to precisely control the number of cells per HMP, down to the single-cell level33,112. In addition, by parallelizing channels, it is possible to generate cell-laden HMPs in a high-throughput manner33,75.

Cell encapsulation within HMPs offers several advantages compared to encapsulation within bulk hydrogels. A significant challenge with hydrogel-based cell encapsulation is the limited nutrient diffusion within core regions, which is exacerbated as the hydrogel size is increased to clinically relevant dimensions. A common approach to address this problem is the incorporation of nutrient microchannels into the hydrogel113–116; however, this can be technically challenging when an injectable material is desired. Packed HMP systems provide an alternative because the microporous interstitial space surrounding the particles enables diffusion. Additionally, granular scaffolds enhance vascularization when compared to bulk hydrogels in a variety of in vivo environments, which supports the engineering of thicker tissues8,103.

When considering the design of HMP cell-encapsulation techniques, it is important to consider both the process that is used to encapsulate the cells (in terms of achieving high viability) and the environment in which the cells are embedded (in terms of enabling function). The importance of the cellular microenvironment on cell function has emerged over the past decades: features such as the mechanics of the environment may change cellular mechanosensing, and the incorporation of ligands may enable cell adhesion1,117; thus, there is now a focus on these features when designing HMP environments. Further, properties such as HMP degradation may be important to control the timing of cell release or their integration with the surrounding tissue environment. This may happen through the incorporation of hydrolytic or enzymatic cross-links or even through the use of phototriggered degradation processes118. In some cases, cells are made to adhere to the outside of HMPs or between populations of HMPs for delivery to tissues instead of encapsulated.

The cytocompatibility of the HMP encapsulation process is regulated by the method of gelation and the presence of shear forces, radicals and chemicals that may be harmful to cells. This is mostly similar to encapsulation of cells within bulk hydrogels, although there are some differences due to the fabrication processes to scale down the HMPs. For example, the use of lithography for HMP cell encapsulation does not impose significant added constraints compared to cell encapsulation within bulk hydrogels, and cell viability within such systems is generally high, at >90%58,59. However, achieving high cell viability within microfluidic emulsions is not trivial and depends on several factors, including the total batch-processing time, the pH of the precursor solution, the medium used to achieve effective droplet formation and the level of shear experienced by the precursor solution while travelling through the microfluidic channels.

Several approaches can be employed to improve cell viability when designing chips for microfluidic emulsions. First, the width of the channels should be carefully considered, as narrower channels (35 μm) resulted in significantly decreased cell viability compared to wider channels (100 μm), with viabilities of 71% and 91%, respectively33. The length of exposure to potentially harsh oil and surfactants can also decrease cell viability. The traditional approach to separate HMPs from oil is to apply cycles of centrifugation and washing steps; however, these processes can impact cell viability and reduce the yield of collected particles. Recently, a range of on-chip filtration processes to rapidly separate cross-linked HMPs from the continuous oil phase have been developed, and significant improvements in cell viability (up to 20%) have been reported119,120. Double-microfluidic-emulsion water-oil-water approaches have been used to generate cell-laden GelMA HMPs containing an ultra-thin oil shell on the particle that quickly dewets upon transfer into an aqueous solution121. This reduces cell exposure to the oil phase, resulting in improved viability compared to conventional, single-emulsion approaches. Oil-free, all-aqueous microfluidic approaches can also be used to generate HMPs based on the immiscibility between specific aqueous phases (such as PEG (30% w/v), sodium alginate (1% w/v) and dextran (15% w/v)122). An oil-free, centrifuge-based microfluidic device was also developed that can produce alginate-based HMPs loaded with cells with viability as high as 70% (REFS48,123).

The distribution of cells within HMPs is another important consideration. Within emulsions, cell distributions may be influenced by HMP polydispersity (in batch emulsions) or long processing times (in microfluidics); however, increased control over the particle-production process and hydrogel cross-linking33,38,124 and techniques that prevent cell settling in the hydrogel precursor solution can improve control over cell distributions125. Achieving consistent cell distributions with EHD-spraying techniques can also be challenging because excessive voltages may lead to cell aggregation towards the periphery of the HMPs79. Lithography approaches generally result in homogeneous cell distributions across particles, although particle cross-linking must occur sufficiently fast to prevent cell settling within the uncross-linked hydrogel precursor58.

Applications of HMPs in cell delivery.

HMPs have been used in a variety of cell applications, typically either as HMP suspensions or as granular hydrogels (often with low particle-packing density). The cell-laden HMPs may be cultured in vitro prior to delivery or delivered soon after cell encapsulation, and approaches often include co-cultures of cells. One major advantage of using HMPs for cell delivery is that cells are protected during the delivery process. Although bulk hydrogels may be injectable by exploiting shear thinning, shear forces acting on cells during injection may impact their viability126,127.

The shear-thinning behaviour of bulk hydrogels is based on the relative motion of adjacent polymer chains, which results in the transfer of shear forces to cells encapsulated within the hydrogel. In contrast, when cells are encapsulated in HMPs, the relative motion between particles during injection, especially in granular hydrogels, results in limited force transfer, which could enhance cell viability during extrusion through small needles. Although not specifically explored in a HMP system, hydrogel cross-linking has been shown to enhance cell protection during injection: lightly cross-linked alginate (~30 Pa) enhanced cell survival compared to non-cross-linked solutions128. In many HMPs, encapsulated cells are surrounded by a stable hydrogel, which likely improves cell viability during syringe delivery.

One area that has garnered attention is the use of HMPs to deliver bone-marrow-derived stromal cells (BMSCs) for the repair of bone defects. For example, injectable osteogenic microtissues were generated by encapsulating BMSCs and bone morphogenetic protein-2 (BMP-2) within GelMA HMPs fabricated using a microfluidic emulsion device129. Cells proliferated within the HMPs and, following delivery into a bone defect, induced robust bone regeneration129. In a similar approach, BMSCs were encapsulated in chitosan-collagen HMPs using a batch emulsion and differentiated along an osteogenic lineage in vitro before being delivered into mouse calvarial defects130. Predifferentiation of cells within the HMPs enhanced bone defect repair compared to undifferentiated controls, which demonstrates how HMP technologies can be used to deliver preformed, engineered microtissues that are otherwise challenging to deliver using minimally invasive techniques. A synergistic enhancement of bone formation was also observed when BMSCs and bone marrow mononuclear cells were co-delivered by distinct chitosan-collagen HMP populations (fabricated by batch emulsion)131.

HMPs are also being explored as platforms for cell delivery in the repair of cartilage tissue. Early studies demonstrated that, following microencapsulation within HMPs, BMSCs differentiate along a chondrogenic lineage in the presence of the transforming growth factor β3 (TGF-β3)132,133. Promising in vitro studies also reported enhanced synthesis of cartilage matrix components in gelatin-norbornene HMPs (produced by microfluidic emulsion) compared to cartilage synthesis promoted by bulk hydrogels, which was attributed to the microporosity among particles134. HMP systems have also been explored as templates for directing the repair of cartilage defects. For example, cartilage ECM-derived particles were fabricated by performing a series of fragmentation pulverization, sieving and decellularization steps on fresh cartilage tissues135. Following seeding with BMSCs, the ECM-derived particles promoted the repair of osteochondral defects in a rabbit model. In a similar study, chitosan-based and cellulose-based ECM mimetic nanofibrous microparticles were seeded with BMSCs to promote cartilage regeneration following delivery into chondral defects136.

HMPs have also been explored as platforms for delivering cells to promote cardiac repair. In one approach, cardiac side population cells (a progenitor cell in the heart) were seeded onto the surface of GelMA HMPs made using microfluidic emulsions35. The cells adhered and proliferated on the surface of the HMPs, and the inclusion of a silica hydrogel coating on the HMPs provided protection against oxidative stress to promote survival following delivery in vivo35. In another study, it was demonstrated that the delivery of cardiac progenitor cells (CPCs) to the ischaemic myocardium using gelatin HMPs enhanced cell engraftment compared to CPC-only controls137. Interestingly, despite improvements in cell engraftment, only marginal improvements in cardiac function were observed compared to the results obtained delivering CPC controls.

HMPs can also be used for applications in which physical isolation of transplanted cells from the immune system is required to promote a therapeutic effect following delivery in vivo. For example, delivery of insulin-producing islets has been widely explored for the treatment of diabetes; however, overcoming premature immune rejection following transplantation has been a major challenge. HMPs are an ideal platform for islet transplantation because they can be used to provide an immunoprotective barrier; the shorter diffusion distances (compared to those of bulk hydrogels) ensure the efficient exchange of nutrients and oxygen with the surrounding tissue to maintain islet survival and enhance the transfer of insulin from the islets to the surrounding vasculature138. Islets encapsulated in alginate HMPs (fabricated using EHD spraying) can be used as a platform to achieve immunoisolation and enhance the therapeutic window following delivery139. Interestingly, a size-dependent immune response was observed, with larger particles (up to 1.9 mm in diameter) promoting a reduced foreign-body response and fibrosis compared to smaller particles (500 μm in diameter)139. An enhanced therapeutic window was achieved by co-delivering islets and PEG HMPs containing Fas ligand fabricated using microfluidic emulsions140. The Fas-ligand-containing HMPs localized immune suppression through selective apoptosis of adaptive immune cells, which, in turn, promoted survival of the transplanted islets.

Although not developed specifically for delivery to tissues, the ability to structurally organize cells with predefined arrangements using microfluidic emulsions and lithography has made it possible to engineer in vitro models that mimic the complexity of in vivo microenvironments. Core-shell assemblies are promising for models in which homotypic and heterotypic interactions need to be balanced. For example, HMPs containing hepatocytes in the core and fibroblasts in the shell enhance the production of liver-specific functions compared to isolated or unstructured co-cultures46. In another experiment, pneumatic-aided imprint lithography was used to fabricate HMPs that mimicked the structural and cellular organization of a liver lobule with radially aligned hepatocytes and endothelial cells encapsulated in collagen124. It was demonstrated that the hepatocytes cultured within the structured 3D model were more sensitive to acetaminophen than those in unstructured 2D and 3D cultures, highlighting the influence of cell-cell and cell-ECM interactions in regulating in vitro drug-toxicity screening.

HMPs for drug delivery

Hydrogels are very promising for the delivery of drugs (for example, small-molecule pharmaceuticals or growth factors), owing to their ability to protect, deliver and locally release bioactive factors in a controllable manner141, overcoming many of the limitations of traditional drug-administration methods (such as oral and intravenous) that often require high doses and repeated administration, and can lead to off-target effects. Traditionally, hydrogels for drug delivery have been macroscale bulk hydrogels, potentially delivered using minimally invasive techniques142,143 and with controlled-release profiles3; however, the use of HMP systems is growing, owing, as discussed, to their distinct advantages over macroscale hydrogels. The small size of HMPs enables minimally invasive delivery through small needles and catheters8 (FIG. 5), without the need for the specific in situ or shear-thinning cross-linking chemistries needed for the delivery of bulk hydrogels. Additionally, HMPs are highly versatile because multiple HMP populations can be easily combined to include multiple release profiles and degradation behaviours into a single injection9, which may be advantageous for many tissue-repair strategies to match biological signalling cascades. In this section, we discuss advances in the use of HMPs for drug delivery and highlight their increased versatility compared to traditional delivery strategies (FIG. 6).

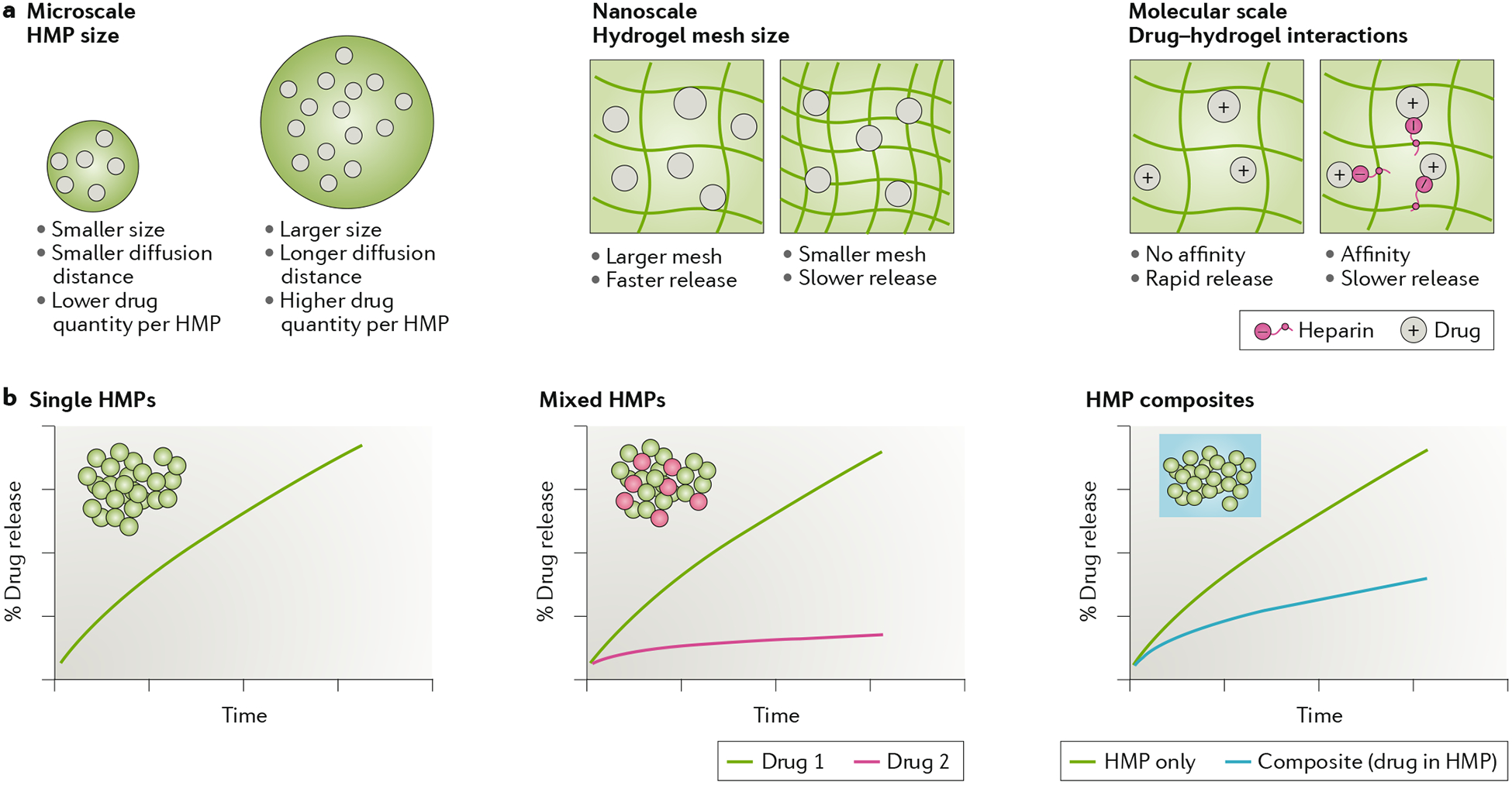

Fig. 6 |. Drug release from hydrogel microparticles.

a | General parameters that influence drug release from hydrogel microparticles (HMPs) are the particle size, network mesh size and molecular interactions between drug and hydrogel. b | Potential release profiles of drugs from HMPs for single HMP formulations, mixed HMP formulations to deliver multiple drugs and composites in which HMPs are embedded within a bulk hydrogel.

Controlling drug release from HMPs.

The design of HMPs for drug delivery resembles that of bulk hydrogels, and the different strategies for controlling drug loading and release from bulk gels can be adapted to HMPs3. However, there are unique features that apply only to HMPs or affect them more than bulk systems. For example, microscale features such as the particle size and shape influence the total volume of cargo that can be encapsulated (FIG. 6a). The particle diameter is an important consideration; larger particles display more sustained release due to larger diffusion distances and smaller surface per hydrogel volume compared to smaller particles144,145. At the nanoscale, the particle mesh size influences drug diffusion through the network, and the release profile is slower for smaller mesh sizes146,147. Smaller mesh sizes can be achieved by increasing the polymer concentration and cross-linking density during HMP formation. Finally, at the molecular scale, chemical interactions between the drug and hydrogel can be used to delay the release of cargo from the particle.

A range of interactions such as covalent conjugation and electrostatic and hydrophobic associations can be used to increase the drug-hydrogel affinity to control release3,148. For example, heparin, which is an important molecule in drug delivery because of its ability to reversibly bind proteins owing to its highly sulfated nature, has been incorporated into HMPs (using a batch-emulsion process) to sustain the delivery of BMP-2, vascular endothelial growth factor (VEGF) and basic fibroblast growth factor (FGF-2)149. Similar approaches can be adopted through sulfation of uronic acids that are present in commonly used hydrogels, such as hyaluronic acid and alginate150,151. For example, enhanced binding of growth factors within alginate HMPs has been achieved through sulfation152.

One advantage of using HMPs in drug delivery is that multiple particle populations can be mixed together to develop injectables with multifunctional behaviours. For example, two distinct drugs can be encapsulated in separate particle populations engineered with independent release profiles (FIG. 6b). Early work in this area demonstrated how the sequential release of distinct growth factors using HMP suspensions enhances tissue formation and repair153–155. Mixed particle populations containing different degradation behaviours can also be used to selectively deliver therapeutics in response to the local biological environment. For example, mixed hyaluronic-acid particle populations cross-linked with either stable or degradable cross-linkers (fabricated using a microfluidic emulsion) selectively degrade and release their cargo in response to the upregulated MMP activity present after myocardial infarction9. Further, spatial control over drug presentation following delivery is challenging to achieve using traditional injectable hydrogels. Recently, distinct populations of hyaluronic-acid HMPs formed using microfluidics were delivered in a spatially controlled manner by sequentially loading different particle populations into the syringe before injection104.

HMPs are often delivered as HMP composites, in which they are mixed into a secondary bulk hydrogel (FIG. 6b). Composite systems are appealing because they can address some of the limitations of both HMPs and macroscale hydrogels. For example, the secondary hydrogel can prevent particle migration from target sites when drug localization is required. As in heterogeneous particle systems, different drugs can be encapsulated into the HMPs and bulk hydrogels, with the drug release controlled by the independent properties of the two phases. Purely particle-based systems present short diffusion distances that can result in early ‘burst release’ of encapsulated drugs, whereas composite systems reduce burst effects by providing a secondary diffusional barrier around the particle phase156,157. HMP composites and bulk hydrogels are often exploited for their ability to trap cells in the hydrogel phase and drugs in the HMPs; HMPs loaded with growth factors have been used to direct the differentiation of stem cells encapsulated in the bulk hydrogel158,159. This makes it possible to create HMP composites containing distinct microscale and macroscale functionalities, with the growth-factor release controlled through HMP design, and the bulk hydrogel independently tunable to direct cell behaviour.

Applications of HMPs in drug delivery.

Due to their ease of injection and versatility, HMPs have been used in a wide variety of drug-delivery applications (FIG. 5). Many of the earliest applications were in the orthopaedic field, where HMP suspensions were used to provide sustained release of growth factors to promote bone and cartilage repair160,161. For example, genipin-cross-linked, gelatin-based microparticles, often made using batch emulsions, have been widely used to sustain the release of BMP-2 to promote bone repair162. Mixed particle populations have also shown promise for bone-repair applications. For example, the dual delivery of VEGF and BMP-2 using gelatin HMPs enhanced bone repair compared to the delivery of either factor alone163. In another example, oppositely charged chitosan particles formed using a batch emulsion were mixed to separately deliver osteoinductive and antibacterial factors in a sustained manner to promote bone regeneration164. The controlled delivery of chondroinductive factors, such as TGF-β1/3 and FGF-2 from gelatin particles, has been widely used for both cartilage-tissue engineering and cartilage-defect-repair applications165–167. HMP suspensions have also been explored for intraarticular delivery strategies: in a rat osteoarthritis model, degeneration of the articular surface was attenuated by delivering chitosan microparticles containing kartogenin (which can promote chondrogenesis) to the joint space168.

HMPs have also found utility in cardiac-repair applications, as they can be successfully delivered to the myocardium using minimally invasive, catheter-based strategies169. Following delivery, HMP suspensions provide sustained delivery of therapeutics to promote repair of the myocardium. For example, the sustained delivery of FGF from gelatin microspheres promoted angiogenesis and improved ventricular function in a model of myocardial infarction170,171 and polyethylene glycol/polybutylene tere-phthalate (PEG-PBT) HMPs loaded with VEGF demonstrated a therapeutic effect when delivered after myocardial infarction172. More recently, it was demonstrated that hydrolytically degradable, hyaluronic-acid HMPs (engineered using a microfluidic emulsion) loaded with interleukin-10 promoted cardiac repair following delivery through a shear-thinning supramolecular hydrogel173.

HMPs are commonly used for pulmonary-drug-delivery applications because they can be fabricated with sizes suitable for bronchial-airway delivery (~5 μm)174. Bulk hydrogels are not suitable for pulmonary delivery because of the risk of airway blockage. In an early experiment, alginate particles containing antitubercular drugs caused a nine-fold enhancement in drug bioavailability in the respiratory tract compared to bolus injection175. To facilitate sustained delivery to the lungs, therapeutics are often delivered via aerosols; aerodynamic particles with diameters of 0.5–5 μm are required for deep lung penetration176. Upon penetration into the airways, the dried drug-loaded particles swell and increase in size once they are deposited on the moist surfaces of the lung177. Final sizes of >5 μm are required to avoid premature uptake and clearance by alveolar macrophages174. Reduced clearance rates can also be achieved by using particles that are mucoadhesive to provide sustained therapeutic delivery within the respiratory tract178. PEG HMPs (made by batch emulsion) have been developed that degrade in response to proteases (such as MMP-2) that are overexpressed in a range of pulmonary diseases, such as lung cancer, tuberculosis and chronic obstructive pulmonary diseases179,180.

For many years, effective and reliable oral insulin-delivery strategies have been sought for the treatment of diabetes. Hydrogels have been widely explored because they can protect insulin from degradation during the passage through the stomach, and release it in the intestinal system for transfer into the blood-stream181. HMP suspensions are ideal for insulin delivery because they can be administered orally and their small size enables easy passage to the intestine, where they offer a substantial surface-area coverage following delivery. A large body of work has focused on developing pH-responsive particles that can protect insulin from degradation while passing through the low-pH environment of the stomach, and then release their cargo to the small intestine. where the pH is higher181. One example is poly(methacrylic acid) (PMAA), which contains free carboxylic-acid groups that undergo pH-dependent protonation and deprotonation that leads to swelling and deswelling182–184. To delay particle clearance, mucoadhesive polymers such as chitosan can be incorporated into the HMPs185–187. Glucose-responsive particles that can release insulin in response to hyperglycaemic conditions have also been developed82: chitosan HMPs containing insulin and nanocapsules loaded with glucose-specific enzymes were prepared using EHD spraying. Their swelling changed under hyperglycaemic conditions as a result of the enzymatic conversion of glucose to gluconic acid, which led to protonation.

HMPs are also used as platforms for delivering growth factors within cell aggregates and microtissues. For example, gelatin HMPs loaded with TGF-β3 were embedded within mesenchymal stem/stromal cell (MSC) microtissues. HMPs were mixed with the cell suspension and then centrifuged; following aggregation, the particles were evenly distributed throughout the microtissues and supported levels of chondrogenic differentiation comparable to those obtained by exogenous delivery of the growth factor in the culture media147,188,189. Similar approaches have been used to control morphogen presentation (BMP4/noggin) within pluripotent stem-cell aggregates, including cases in which spatial control of the HMPs within the microtissue influenced the spatial differentiation of cells190.

HMPs for building scaffolds

For nearly three decades, hydrogel scaffolds have been explored for numerous applications, including the repair and regeneration of tissues191,192. In many of these platforms for both in vitro and in vivo studies, cells are either embedded within the material during fabrication or seeded onto the scaffold after fabrication. Scaffolds must provide an environment that supports cell viability, enables desired cellular interactions (such as adhesion and remodelling), contains encapsulated soluble factors (such as growth factors, chemokines and cytokines) that control cellular outcomes and matches timescales relevant for tissue development and repair. Granular scaffolds are fabricated by packing HMPs until they reach a jammed state; as discussed, these systems are becoming popular because of their microporosity, injectability and tunability (FIG. 4). Granular scaffolds are inherently microporous, owing to the interstitial space among packed HMPs, which supports cellular invasion. By contrast, to allow for cell infiltration, bulk hydrogels must be engineered with features that permit material remodelling by the cells, which can lead to impaired mechanical properties over time. Granular scaffolds offer good potential for mechanical matching between tissue and scaffold, as well as long-lasting mechanical support for cells. This section explores the design of granular scaffolds and provides examples of their use.

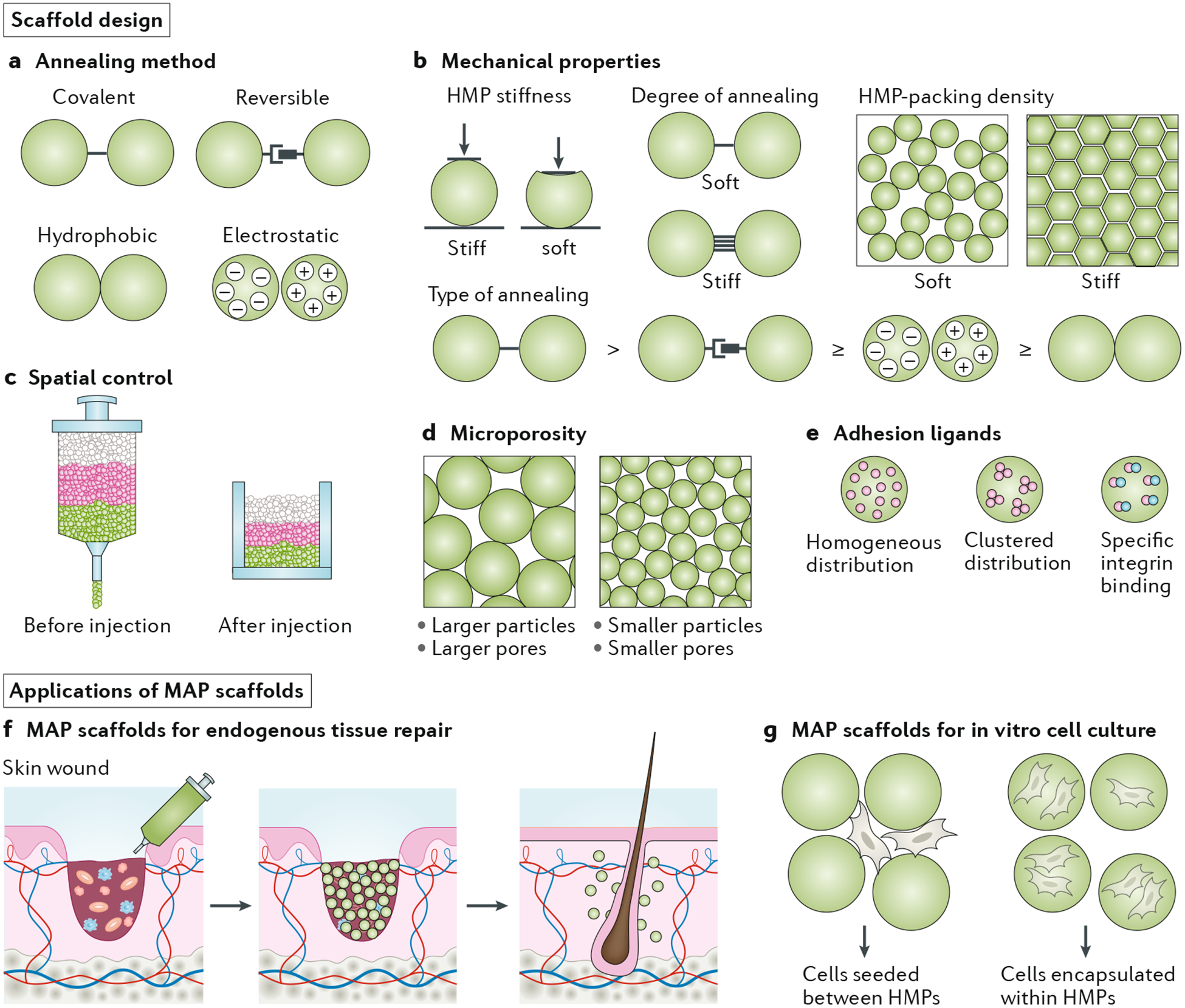

Designing granular scaffolds.