Abstract

High-entropy alloys (HEAs) are broadly explored from the perspective of mechanical, corrosion-resistance, catalytic, structural, superconducting, magnetic properties, and so on. In magnetic HEAs, 3d transition metals or rare-earth elements are well-studied compositional elements. We researched a magnetic HEA containing Fe combined with 4d and 5d transition metals, which has not been well investigated, and found a new dual-phase face-centered-cubic (fcc) HEA FeRhIrPdPt. The structural, magnetic, and transport properties were evaluated by assuming that FeRhIrPdPt is a mixture of FeRh4, FeIr4, FePd4, and FePt4, all with the fcc structure. The dual-phase is composed of a Rh- and Ir-rich main phase and a Pd- and Pt-rich minor one. FeRh4 and FeIr4 show spin freezings at low temperatures, while FePd4 and FePt4 are ferromagnetic. Two magnetic features can characterize FeRhIrPdPt. One is the canonical spin-glass transition at 90 K, and the other is a ferromagnetic correlation that appears below 300 K. The main and minor phases were responsible for the spin-glass transition and the ferromagnetic correlation below 300 K, respectively.

Keywords: high-entropy alloys, Fe, 4d and 5d transition metals, magnetic properties, dual-phase

1. Introduction

High-entropy alloys (HEAs) were initially proposed for simple crystal structures such as face-centered cubic (fcc), body-centered cubic (bcc), and hexagonal close packing (hcp), in which more than five elements, each having an atomic fraction between 5% and 35%, randomly occupy one crystallographic site [1,2]. The HEA concept is now adopted in various crystal structures [3,4]. The high-entropy state contributes to the stability of the solid solution with the desired crystal structure through the relatively large mixing entropy. For example, (Gd1/6Tb1/6Dy1/6Tm1/6Yb1/6Lu1/6)2Si2O7 disilicate shows outstanding thermal stability, which is ascribed to the high-entropy state at the rare-earth site [5]. The significant atomic disorder leads to the severe lattice distortion effect. In particular, bcc HEAs show superior mechanical properties, attracting a great deal of interest. There is also growing interest in the study of HEAs with high ductility, refractory HEAs, those demonstrating superconductivity, as well as HEAs used in anti-corrosion coatings, biomaterials, catalysts, shape memory alloys, magnetic refrigeration materials, and so on [6,7,8,9,10,11,12,13,14,15].

In some HEAs containing 3d transition (Cr, Mn, Fe, Co, and Ni) or rare-earth metals, the magnetic properties are well investigated. AlxCoCrFeNi exhibits a structural change from fcc to bcc through the mixture of fcc and bcc as x is increased [16]. Al-free CoCrFeNi is ferromagnetic below 120 K, and the Curie temperature TC tends to be enhanced above room temperature with increasing Al content. In some compositions, spin freezing appears at low temperatures, which is detected as the irreversible magnetization between zero-field-cooled (ZFC) and field-cooled (FC) states. The electrical resistivity of AlxCoCrFeNi shows metallic temperature dependence, whereas it is rather small due to atomic disorder. NiFeCoCrPd and NiFeCoCrMn Cantor–Wu alloys are famous equimolar HEAs. Both alloys are ferromagnets with TC = 440 K for NiFeCoCrPd and TC = 38 K for NiFeCoCrMn, respectively [17,18]. NiFeCoCrMn also shows a spin-glass behavior. The temperature dependences of the electrical resistivity of Cantor–Wu alloys are also weak but metallic. Although the almost-magnetic HEAs display ferromagnetism, Cr20MnxFeyCo20Niz (x + y + z = 60) is reported to be an antiferromagnet with the transition temperature ranging from 80 to 190 K, depending on the composition [19]. As for rare-earth-based HEAs, Gd20Dy20Er20Ho20Tb20 forms a single-phase hcp structure and shows relatively good magnetocaloric properties [15].

Research into HEA magnetic materials also shows a growing interest in tailoring magnetic properties by changing the microstructure, especially in dual-phase HEAs as in the present study. In Fe15Co15Ni20Mn20Cu30, a spinodal decomposition occurs after heat treatment [20]. The spinodally decomposed HEA possesses enhanced TC and magnetization by 48% and 70%, respectively, compared to the homogenized single-phase state. The control of magnetic properties was also achieved in dual-phase CoFeNi0.5Cr0.5-Alx (x = 0, 1.0, and 1.5) or multiphase Al0.1(Fe1+xCoCr1−xMn)0.9 (x = 0, 0.2, 0.4, 0.6, and 0.8) HEAs [21,22]. The magnetic phases contained in the dual-phase HEAs independently exhibit their magnetic properties.

Up to now, HEAs containing Fe combined with 4d and 5d transition metals, such as Rh, Ir, Pd, and Pt, have not been well investigated. Here we show the results of the new equimolar FeRhIrPdPt. We found that this HEA forms a dual-phase fcc structure, which shows a spin-glass transition at approximately 90 K and a ferromagnetic correlation below 300 K. The phase assignment of these two characteristic magnetic properties was performed by employing FeRh4, FeIr4, FePd4, and FePt4 under the assumption that FeRhIrPdPt is a mixture of the four binary alloys with fcc structure. This article reports structural investigations of FeRhIrPdPt, FeRh4, FeIr4, FePd4, and FePt4. The magnetic and transport properties of these alloys were examined by measuring the temperature dependences of magnetization, isothermal magnetization curve, and electrical resistivity.

2. Materials and Methods

Polycrystalline samples, as listed in Table 1, were prepared by a homemade arc furnace using constituent elements Fe (99.9%), Rh (99.9%), Ir (99.99%), Pd (99.9%), and Pt (99.9%) under an Ar atmosphere. The elemental metals were arc-melted to button-shaped samples with a mass of 1.5 g and quenched on a water-chilled Cu hearth. The samples were flipped and remelted several times to ensure homogeneity. In this study, all samples received neither heat treatment nor deformation (e.g., rolling). Room-temperature X-ray diffraction (XRD) patterns of as-cast samples were collected using an X-ray diffractometer (XRD-7000L, Shimadzu, Kyoto, Japan) with Cu-Kα radiation in Bragg–Brentano geometry. We used thin slabs cut from the samples due to their high ductility.

Table 1.

Chemical compositions determined by energy-dispersive X-ray spectroscopy and lattice parameters of the prepared samples.

| Sample | Composition | Lattice Parameter (Å) |

|---|---|---|

| FeRh4 | Fe19.2(8)Rh80.8(8) | 3.782(1) |

| FeIr4 | Fe18.5(6)Ir81.5(6) | 3.807(1) |

| FePd4 | Fe19.3(9)Pd80.7(9) | 3.858(1) |

| FePt4 | Fe19.2(6)Pt80.8(6) | 3.871(2) |

| FeIrRhPtPd | main: Fe15.8(5)Rh24.5(5)Ir32.6(1)Pd10.7(6)Pt16.4(6) minor: Fe23.7(7)Rh14.0(8)Ir5.4(9)Pd32.5(9)Pt24.4(6) |

3.834(1) |

The metallographic examination of the prepared sample was carried out by a field-emission scanning electron microscope (FE-SEM; JSM-7100F, JEOL, Akishima, Japan). The atomic composition in each sample area was investigated by an energy-dispersive X-ray (EDX) spectrometer equipped to the FE-SEM by averaging several data collection points. The elemental mappings of FeRhIrPdPt were also obtained by the EDX spectrometer.

The temperature dependence of dc magnetic susceptibility χdc(T) between 50 K and 400 K and the isothermal magnetization curve were measured by VersaLab (Quantum Design, San Diego, CA, USA). The temperature dependence of ac magnetic susceptibility χac(T) between 70 K and 170 K under the ac field of 15 Oe and the frequency ranging from 20 Hz to 5 kHz was also measured using this apparatus. χdc(T) below 100 K and the isothermal magnetization curve at 2 K were measured by MPMS3 (Quantum Design, San Diego, CA, USA). The high-temperature χdc(T) between 400 K and 450 K was checked by a vibrating sample magnetometer (BHV-50H, Riken Denshi, Yutenji, Japan). The temperature dependence of electrical resistivity ρ (T) between 3 K and 300 K was measured by a dc four-probe method using a homemade system in a GM refrigerator (UW404, Ulvac cryogenics, Kyoto, Japan). In this equipment, we also measured χac(T) between 3 K and 300 K under the ac field of 5 Oe at 800 Hz.

3. Results and Discussion

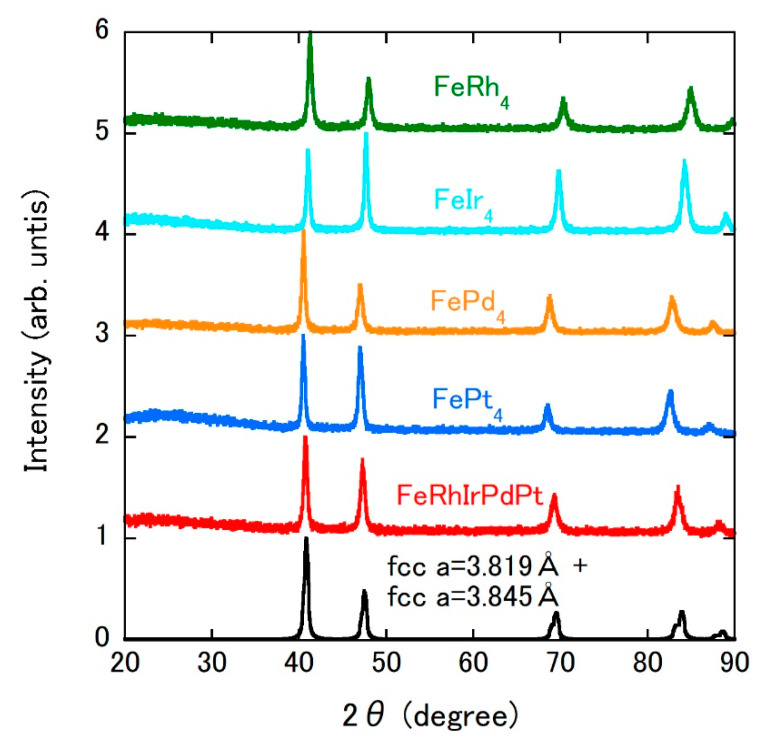

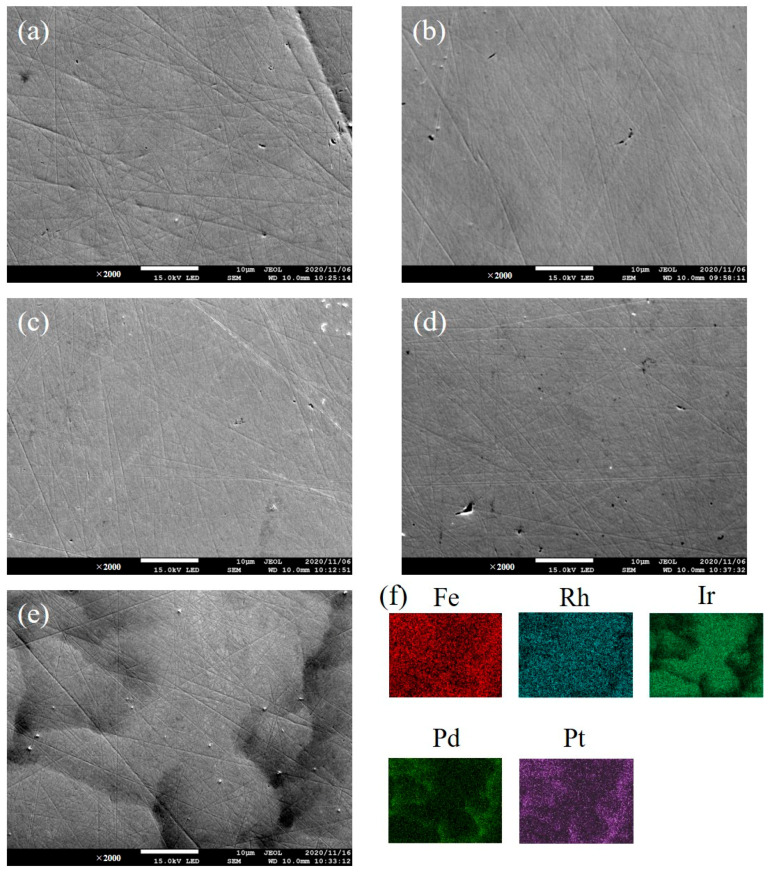

Figure 1 shows the XRD patterns of prepared samples. In each pattern, the diffraction peak positions match those of the fcc structure with the lattice parameters listed in Table 1. The lattice parameters were determined by the unit cell parameter refinement program CellCalc [23]. In the binary alloys, the lattice parameter decreases from FePt4, FePd4, and FeIr4 to FeRh4. The lattice parameter of FeRhIrPdPt is almost intermediate between those of FePd4 and FeIr4. SEM images of the studied samples are displayed in Figure 2a–e. The images of all binary alloys demonstrate their single-phase nature (Figure 2a–d). In each alloy, the chemical composition determined by EDX analysis is consistent with the starting composition listed in Table 1. In contrast, the SEM image of FeRhIrPdPt shows the main phase with the bright image (70 vol.%, 74 wt.%), accompanying the minor phase (30 vol.%, 26 wt.%) precipitated between grain boundaries of the main phase (see the dark image in Figure 2e). Figure 2f shows the elemental mappings of FeRhIrPdPt, especially the Ir and Pd mappings that support the dual-phase nature. For further elucidation of the dual-phase nature in FeRhIrPdPt, transmission electron microscopy images and selected area electron diffraction patterns are desirable. As shown in Table 1, compared to the ideal composition Fe20Rh20Ir20Pd20Pt20, one can say that the main (minor) phase is Rh- and Ir-rich (Pd- and Pt-rich) alloy. We guess that the minor phase also forms an fcc structure with a lattice parameter close to that of the main phase because no extra XRD peak other than the fcc structure in Figure 1 was observed. We tried simulating the XRD pattern of FeRhIrPdPt by the superposition of the main and minor phases. The lattice parameter of each phase was estimated by the composition-weighted average of FeRh4, FeIr4, FePd4, and FePt4. The obtained parameters are 3.819 Å for the main phase and 3.845 Å for the minor one. The resultant XRD pattern calculated using PowderCell 2.3 software [24] with the weight fractions mentioned above is shown in Figure 1. The simulated pattern agrees with the experimental one.

Figure 1.

X-ray diffraction patterns of FeRh4, FeIr4, FePd4, FePt4, and FeRhIrPdPt. The simulated pattern for FeRhIrPdPt is also shown. The origin of each pattern is shifted by an integer value for clarity.

Figure 2.

SEM images of (a) FeRh4, (b) FeIr4, (c) FePd4, (d) FePt4, and (e) FeRhIrPdPt, respectively. (f) Elemental mappings of FeRhIrPdPt.

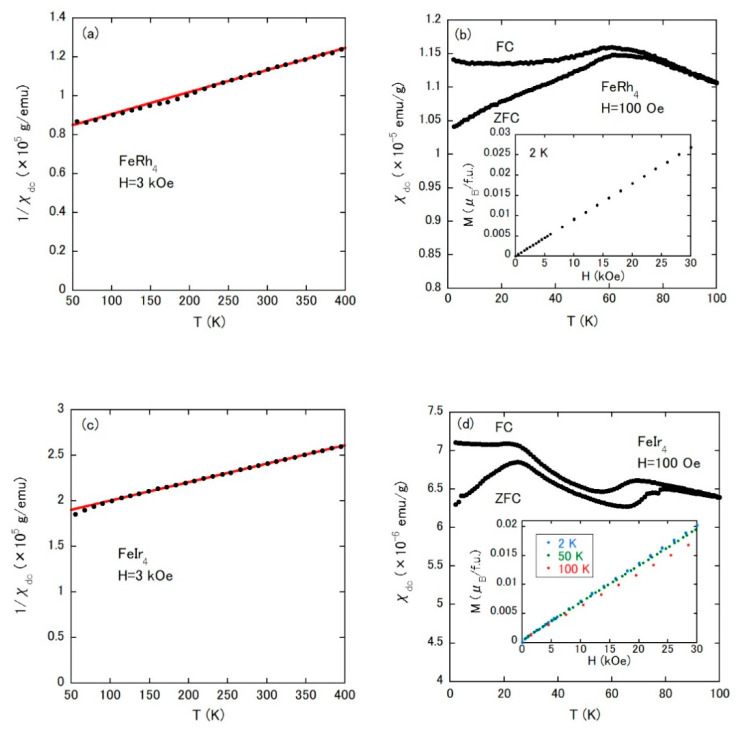

Next, we discuss the static and dynamic magnetic properties within the framework of molecular field. The magnetic properties investigated by χdc(T) and M–H (M: magnetization, H: external field) curve measurements are summarized in Figure 3a–d for FeRh4 and FeIr4. As shown in Figure 3a,c, the 1/χdc(T) of FeRh4 and FeIr4 show linear temperature dependences (red lines), which are well-described by the Curie–Weiss law as follows:

| χdc (T) = C/(T − ΘCW), | (1) |

where C is the Curie constant and ΘCW is the Weiss temperature. The effective magnetic moment μeff is derived from C. μeff and ΘCW were obtained as listed in Table 2. In each alloy, the value of μeff per Fe atom is close to that of the Fe3+ ion (5.92μB), which means a well-localized magnetic moment, and the negative ΘCW indicates a dominance of antiferromagnetic (AFM) interaction between Fe atoms. The low-temperature χdc(T) under ZFC and FC conditions with H = 100 Oe for FeRh4 is given in Figure 3b. Irreversibility between the temperature dependences of ZFC and FC magnetization is common in spin-glass materials. Additionally, the isothermal M–H curve at 2 K demonstrates a featureless magnetization process (see the inset of Figure 3b). FeIr4 also shows a spin-glass-like behavior (Figure 3d), whereas there are two anomalies, for example, at approximately 23 and 69 K in χdc(T) under the FC state. The comparison of M–H curves in the inset of Figure 3d suggests no pronounced feature characteristic for ferromagnetic (FM) or AFM ordering.

Figure 3.

(a) Temperature dependence of 1/χdc under an external field of 3 kOe for FeRh4. (b) Temperature dependence of χdc under ZFC and FC conditions with an external field of 100 Oe for FeRh4. The inset is the isothermal M–H curve at low temperature. (c,d) Experimental results of FeIr4, corresponding to (a,b), respectively.

Table 2.

Magnetism, magnetic ordering temperature, effective magnetic moment μeff, Weiss temperature ΘCW, and electrical resistivity ρ at room temperature (RT) of prepared samples. SG, FM, and FM corr. refer to spin-glass, ferromagnetism, and ferromagnetic correlation below 300 K, respectively. Tf and TC are spin-freezing and Curie temperatures, respectively. Tf is the temperature where field-cooled magnetization under the external field of 100 Oe shows the hump.

| Sample | Magnetism | Magnetic Ordering Temperature (K) | μeff (μB/Fe) | ΘCW (K) | ρ (RT) (μΩcm) |

|---|---|---|---|---|---|

| FeRh4 | SG | Tf = 59 | 5.74 | −700 | 39.0 |

| FeIr4 | SG | Tf = 23, 69 | 5.71 | −890 | 21.2 |

| FePd4 | FM | TC = 393 | 5.44 | 409 | 59.5 |

| FePt4 | FM | TC = 177, 317 | 4.11 | 272 | 107 |

| FeRhIrPdPt | SG +FM corr. |

Tf = 90 | 3.40 | 308 | 70.8 |

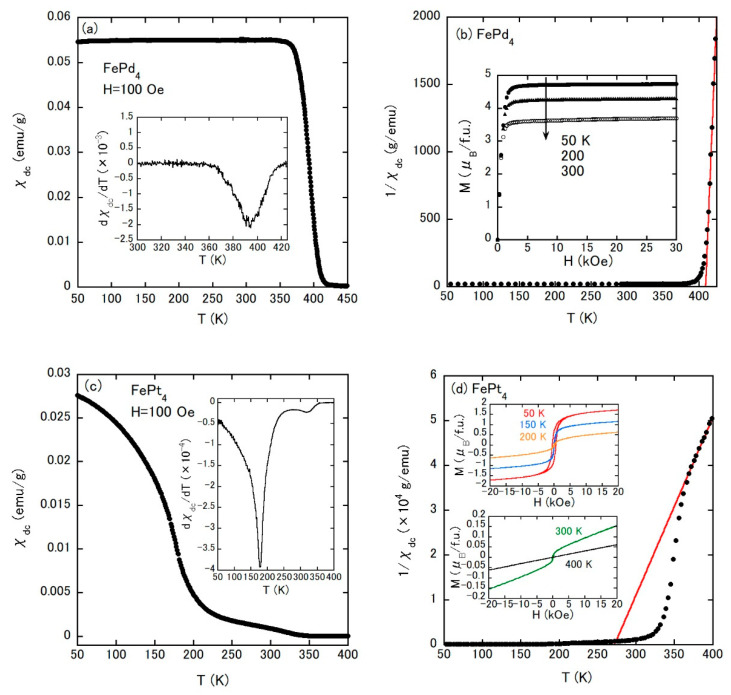

FePd4 and FePt4 show FM transitions, which are observed as rapid increases of χdc(T) below approximately 400 K and 200 K, respectively (Figure 4a,c). For FePt4, an additional transition is observed at 317 K, which can be confirmed by the small anomaly in the temperature derivative of χdc (see the inset of Figure 4c). The FM nature of these alloys was also checked by the M–H curves, as shown in the insets of Figure 4b,d. Although the M–H curves of FePd4 measured in increasing and decreasing H show no noticeable difference, a small hysteresis appears in FePt4. The 300 K isothermal M–H curve of FePt4 already displays an FM feature. Thus, the additional anomaly at 317 K can be ascribed to the entrance into the FM state. We note here that FeIr4, the alloy between Fe and 5d element, also possesses two magnetic anomalies. The TC of each ferromagnet was determined as a minimum on the temperature derivative of χdc(T) (see the inset of Figure 4a or Figure 4c). This procedure is frequently employed in ferromagnets [25,26,27]. The χdc(T)s of FePd4 and FePt4 also show Curie–Weiss behaviors above their TCs (red lines in Figure 4b,d). The value of each μeff supports the localized magnetic moment for the Fe atom, and the positive ΘCW is consistent with the FM ground state.

Figure 4.

(a) Temperature dependence of χdc under an external field of 100 Oe for FePd4. The inset is the temperature derivative of χdc. (b) Temperature dependence of 1/χdc of FePd4. The inset shows the isothermal magnetization curves of FePd4 at 50, 200, and 300 K. (c) Temperature dependence of χdc under an external field of 100 Oe for FePt4. The inset is the temperature derivative of χdc. (d) Temperature dependence of 1/χdc of FePt4. The insets are the isothermal magnetization curves of FePt4 at 50, 150, 200, 300, and 400 K.

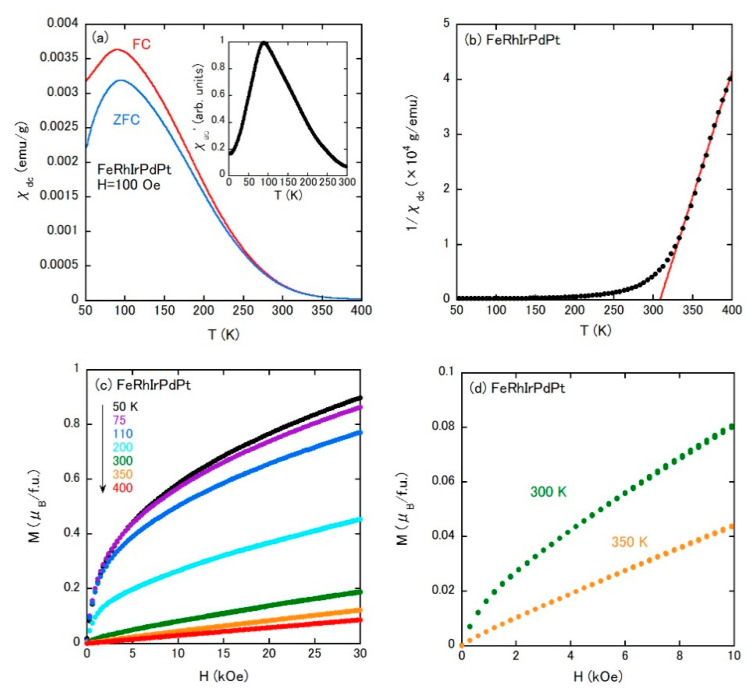

For FeRhIrPdPt, χdc was measured as a function of temperature under ZFC and FC protocols with an external magnetic field of 100 Oe (Figure 5a). Both χdc(T)s show broad peaks at approximately 90 K, associated with the difference between ZFC and FC data, due to a spin-glass transition as mentioned below. Besides, the irreversible χdc(T) between ZFC and FC states already appears below approximately 300 K, which suggests a growth of some magnetic correlation. The inverse χdc(T) shows the straight line above 325 K and can be explained by the Curie–Weiss law with μeff = 3.40μB/Fe and ΘCW = 308 K (Figure 5b). The effective moment slightly smaller than those of binary alloys is probably due to the influence of the dual phase. The positive ΘCW indicates the presence of FM correlation. Note that ΘCW is comparable to 300 K, below which the irreversible χdc(T) grows. So, the irreversibility of a magnetic domain could be responsible for the difference of χdc(T) between ZFC and FC below 300 K. The FM correlation is further supported by the M–H curves depicted in Figure 5c,d. Although the isothermal magnetization at 350 K shows a paramagnetic behavior, a rather rapid increase of magnetization at the lower field appears below 300 K, close to ΘCW. With decreasing temperature, the rapid increase at the lower field is pronounced, whereas no saturation is confirmed, which indicates an additional contribution of paramagnetic moments. There seem to be two characteristic temperatures in the magnetism of FeRhIrPdPt: 90 K (spin-glass transition) and 300 K (FM correlation). Especially for the latter temperature, it may be important to investigate a possible long-range ordering. χac(T) is a useful tool for this because the real part of χac(T) can often distinguish respective magnetic ordering as a peak, even in the case that a large χdc anomaly due to a strong magnetic interaction masks a small anomaly by a minor magnetic ordering [28,29]. The inset of Figure 5a presents the real part of ac magnetization χac′(T) between 3 K and 300 K, showing no anomaly except for the broad peak due to the spin-glass transition. Therefore, the FM correlation below 300 K would not evolve into a long-range ordering. We note that a similar phenomenon was also observed in another magnetic compound, and is ascribed to an inhomogeneous magnetic state [30,31].

Figure 5.

(a) Temperature dependence of χdc measured under ZFC and FC conditions for FeRhIrPdPt. The external field is 100 Oe. The inset is the temperature dependence of the real part of the ac susceptibility χac′(T) of FeRhIrPdPt under an ac field of 5 Oe at 800 Hz. (b) Temperature dependence of 1/χdc measured under FC condition for FeRhIrPdPt. Isothermal magnetization curves of FeRhIrPdPt at 50, 75, 110, 200, 300, 350, and 400 K for (c) and at 300 K and 350 K with expanded scale for (d).

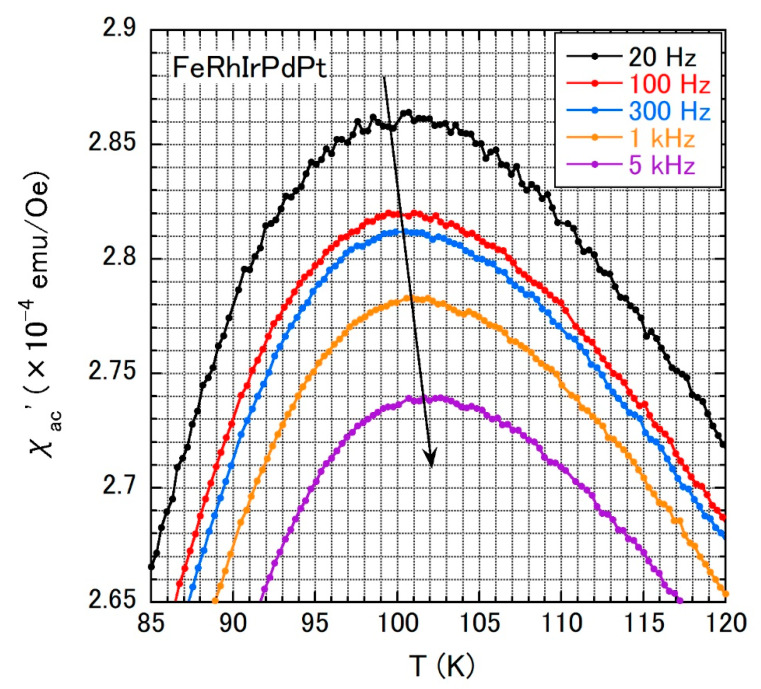

To assess the possible spin-glass transition in FeRhIrPdPt, we measured χac′(T) under several ac frequencies, as shown in Figure 6. χac′(T) shows a broad peak at Tf_ac, and as anticipated for a spin-glass transition, Tf_ac slightly shifts to higher temperatures as the frequency is increased. We employed two models to explain the shift quantitatively [32]. One is the Vogel–Fulcher law, expressed by

| τ = τ0∙exp [Ea/(kB(Tf_ac − TSG))]. | (2) |

Figure 6.

Temperature dependences of χac′ under ac frequencies of 20 Hz, 100 Hz, 300 Hz, 1 kHz, and 5 kHz for FeRhIrPdPt. The arrow is a guide to the eyes.

The other model is the critical scaling approach, as follows:

| τ = τ0∙[Tf_ac/TSG − 1]−zv. | (3) |

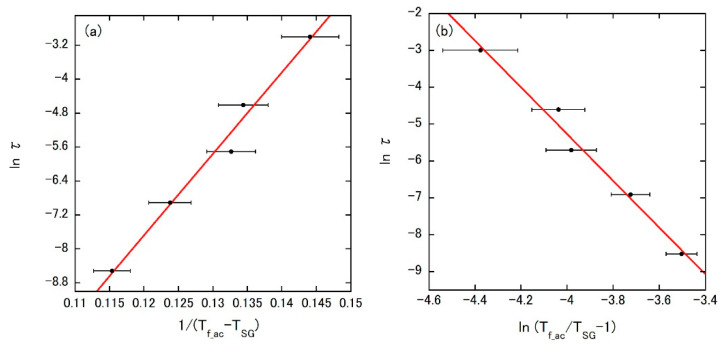

In these equations, τ, τ0, Ea, TSG, zv, and kB are the inverse ac frequency, the spin relaxation time, the activation energy, the spin-glass temperature, the dynamical critical exponent, and the Boltzmann constant, respectively. Figure 7a is the ln τ vs. 1/(Tf_ac − TSG) plot by the Vogel–Fulcher law, which yields the parameters listed in Table 3. The relations Ea ~ 2Tf_ac and τ0 on the order of 10−14 s are consistent with those found in many canonical spin-glass systems [33,34]. The fitting result by the critical scaling approach is given in Figure 7b with a ln τ vs. ln(Tf_ac/TSG − 1) plot. The obtained parameters again fall in the typical range for spin-glass systems [32]. Furthermore, the Mydosh parameter K defined by ΔTf_ac/Tf_aclog(Δf) (where f is the ac frequency) is 0.007, comparable to those of canonical spin-glasses such as CuMn and AgMn [35]. Thus, FeRhIrPdPt can be regarded as a canonical spin-glass HEA.

Figure 7.

Fitting results of Tf_ac shift in χac′(T) using (a) Vogel–Fulcher law and (b) critical scaling approach for FeRhIrPdPt, respectively.

Table 3.

Fitting parameters obtained by Vogel–Fulcher law and critical scaling approach for FeRhIrPdPt.

| Model | τ0 (s) | Ea (K) | TSG (K) | zv |

|---|---|---|---|---|

| Vogel–Fulcher law | 4.8 × 10−14 | 192 | 93 | - |

| Critical scaling approach | 5.1 × 10−14 | - | 90 | 6.3 |

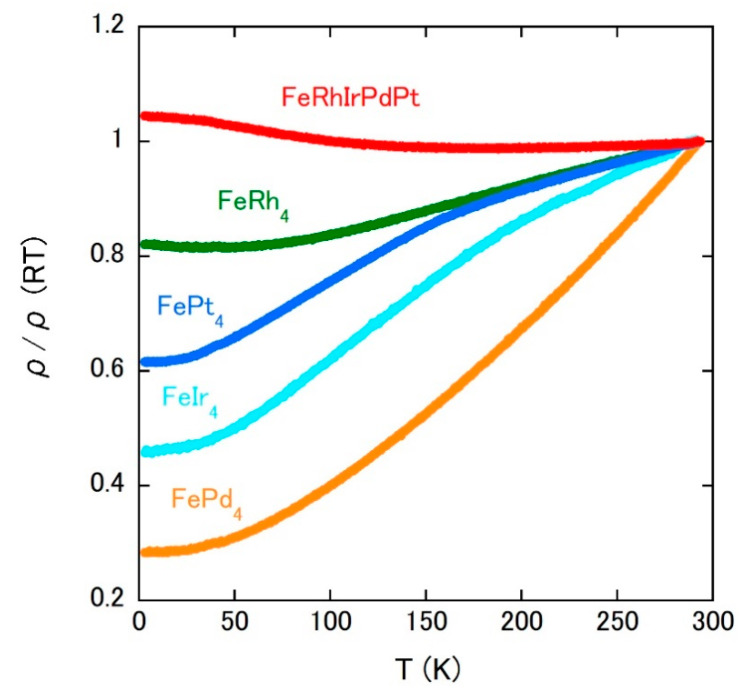

Figure 8 shows the ρ (T) of investigated alloys. Each ρ is normalized by the room-temperature value listed in Table 2. The binary alloys show the metallic behavior; ρ decreases as the temperature is lowered. For the disordered FePd4, the temperature dependence is rather large in the ferromagnetic state, which is also observed in the other disordered ferromagnets [36]. Contrasted to the metallic behavior of binary alloys, ρ of FeRhIrPdPt slightly increases on cooling, which is a signature of carrier localization and may be due to the atomic disorder higher than those in the binary alloys. It should be noted that the other spin-glass HEAs show metallic temperature dependences [16,18,37].

Figure 8.

Temperature dependences of electrical resistivity of FeRh4, FeIr4, FePd4, FePt4, and FeRhIrPdPt.

Here we discuss the dual-phase formation in FeRhIrPdPt. Compared to the ideal equimolar Fe20Rh20Ir20Pd20Pt20, the EDX analysis indicates that the main phase is rich in Rh and Ir and poor in Fe, Pd, and Pt, whereas the minor phase shows the reverse tendency (see also Table 1). The enthalpy of formation ΔHf of each binary compound for constituent elements [38] calculated by Troparevsky et al. can explain the dual-phase formation. Table 4 presents the ΔHf of stable binary alloy for each component. Although Fe tends to form an alloy with all elements because all pairs Fe–Rh, Fe–Ir, Fe–Pd, and Fe–Pt show negative ΔHf, Fe–Pd and Fe–Pt pairings would be more robust. Furthermore, alloying between Ir and Rh (Pt and Pd) is also favored. These facts based on the pairwise ΔHf can explain the dominant elements in each phase of FeRhIrPdPt. A similar discussion has been found in AuPdAgPtCu, also showing a dual-phase microstructure [39]. All binary alloys of noble metals (Rh, Ir, Pd, and Pt) with 1:1 composition form fcc [40,41]. Furthermore, many noble metal HEAs (e.g., PdPtRhIrCuNi and PdPtRhRuCe) are reported to be fcc alloys [39,42]. Therefore, the fcc FeRhIrPdPt would be deeply related to the existing phase diagrams of noble metals.

Table 4.

Enthalpies of each binary compound. The unit is meV/atom. Data from [38].

| Fe | Rh | Ir | Pd | Pt | |

|---|---|---|---|---|---|

| Fe | 0 | −57 | −63 | −116 | −244 |

| Rh | −57 | 0 | −21 | 37 | −24 |

| Ir | −63 | −21 | 0 | 40 | 11 |

| Pd | −116 | 37 | 40 | 0 | −36 |

| Pt | −244 | −24 | 11 | −36 | 0 |

It is straightforward that the main and minor phases of FeRhIrPdPt independently exhibit their magnetism as in the other dual-phase HEA magnetic materials. The magnetic properties of FeRhIrPdPt can be characterized by the canonical spin-glass plus high-temperature FM correlation. So, in FeRhIrPdPt, the different phases would be responsible for the spin-glass transition and the high-temperature FM correlation. In the binary alloys, FeRh4 and FeIr4 are spin-glass materials, while FePd4 and FePt4 are ferromagnets. Based on the atomic ratios in the dual-phase of FeRhIrPdPt, we speculate that the main phase rich in Rh and Ir and minor one rich in Pd and Pt exhibit the spin-glass transition and the FM correlation, respectively. As mentioned in the Introduction, dual-phase HEAs would be useful in tailoring magnetic properties via a change of microstructure. In this case, the occurrence of spinodal decomposition is mainly responsible for the change of microstructure. Although the as-cast dual-phase HEA was investigated in this study, it is important to understand the thermal stability of the alloy in order to understand and control the microstructure. This is a future task. The other interesting aspect of dual-phase HEAs is a possible multifunctional magnetic material, in which two magnetic phases offer different magnetic functions.

4. Summary

We synthesized the new dual-phase fcc HEA FeRhIrPdPt and evaluated its structural, magnetic, and transport properties by assuming that the HEA is a mixture of FeRh4, FeIr4, FePd4, and FePt4, all with fcc structure. The dual-phase alloy is composed of a Rh- and Ir-rich main phase with 70 vol.% (74 wt.%) and a Pd- and Pt-rich minor one with 30 vol.% (26 wt.%). The minor phase could also form an fcc structure with a lattice parameter near that of the main phase. In the binary alloys, FeRh4 and FeIr4 are spin-glass materials dominated by antiferromagnetic interactions, whereas FePd4 and FePt4 are ferromagnetic. FeRhIrPdPt can be characterized by two magnetic features: one is the canonical spin-glass transition at 90 K, and the other is the ferromagnetic correlation revealed by the irreversible χdc(T) under ZFC and FC conditions below 300 K. The latter correlation would not lead to long-range magnetic ordering. Based on each chemical composition of the dual-phase alloy, the main and minor phases would be responsible for the spin-glass transition and the ferromagnetic correlation at high temperatures, respectively. The temperature dependence of the electrical resistivity of FeRhIrPdPt indicates weak carrier localization, which is contrasted with the metallic behaviors of binary alloys. The dual-phase formation of FeRhIrPdPt can be discussed based on the pairwise formation enthalpies of the binary alloys.

Acknowledgments

J.K. is grateful for the support provided by Comprehensive Research Organization of Fukuoka Institute of Technology.

Author Contributions

Conceptualization, J.K.; methodology, J.K.; formal analysis, J.K.; investigation, K.B., N.I., T.N., and J.K.; writing—original draft preparation, J.K.; writing—review and editing, T.N. and J.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data sharing is not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Footnotes

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- 1.Gao M.C., Yeh J.-W., Liaw P.K., Zhang Y. High-Entropy Alloys: Fundamentals and Applications. Springer; Cham, Switzerland: 2015. [Google Scholar]

- 2.Murty B.S., Yeh J.-W., Ranganathan S., Bhattacharjee P.P. High-Entropy Alloys. 2nd ed. Elsevier; Amsterdam, The Netherlands: 2019. [Google Scholar]

- 3.Musicό B.L., Gilbert D., Ward T.Z., Page K., George E., Yan J., Mandrus D., Keppens V. The emergent field of high entropy oxides: Design, prospects, challenges, and opportunities for tailoring material properties. APL Mater. 2020;8:040912. doi: 10.1063/5.0003149. [DOI] [Google Scholar]

- 4.Jiang B., Yu Y., Cui J., Liu X., Xie L., Liao J., Zhang Q., Huang Y., Ning S., Jia B., et al. High-entropy-stabilized chalcogenides with high thermoelectric performance. Science. 2021;371:830–834. doi: 10.1126/science.abe1292. [DOI] [PubMed] [Google Scholar]

- 5.Sun L., Luo Y., Ren X., Gao Z., Du T., Wu Z., Wang J. A multicomponent γ-type (Gd1/6Tb1/6Dy1/6Tm1/6Yb1/6Lu1/6)2Si2O7 disilicate with outstanding thermal stability. Mater. Res. Lett. 2020;8:424–430. doi: 10.1080/21663831.2020.1783007. [DOI] [Google Scholar]

- 6.Zhou Y.J., Zhang Y., Wang Y.L., Chen G.L. Microstructure and compressive properties of multicomponent Alx(TiVCrMnFeCoNiCu)100−x high-entropy alloys. Mater. Sci. Eng. A. 2007;454–455:260–265. doi: 10.1016/j.msea.2006.11.049. [DOI] [Google Scholar]

- 7.Senkov O.N., Wilks G.B., Miracle D.B., Chuang C.P., Liaw P.K. Refractory high-entropy alloys. Intermetallics. 2010;18:1758–1765. doi: 10.1016/j.intermet.2010.05.014. [DOI] [Google Scholar]

- 8.Sun L., Cava R.J. High-entropy alloy superconductors: Status, opportunities, and challenges. Phys. Rev. Mater. 2019;3:090301. doi: 10.1103/PhysRevMaterials.3.090301. [DOI] [Google Scholar]

- 9.Ishizu N., Kitagawa J. New high-entropy alloy superconductor Hf21Nb25Ti15V15Zr24. Res. Phys. 2019;13:102275. doi: 10.1016/j.rinp.2019.102275. [DOI] [Google Scholar]

- 10.Kitagawa J., Hamamoto S., Ishizu N. Cutting Edge of High-Entropy Alloy Superconductors from the Perspective of Materials Research. Metals. 2020;10:1078. doi: 10.3390/met10081078. [DOI] [Google Scholar]

- 11.Shi Y., Yang B., Liaw P.K. Corrosion-resistant high-entropy alloys: A review. Metals. 2017;7:43. doi: 10.3390/met7020043. [DOI] [Google Scholar]

- 12.Todai M., Nagase T., Hori T., Matsugaki A., Sekita A., Nakano T. Novel TiNbTaZrMo high-entropy alloys for metallic biomaterials. Scr. Mater. 2017;129:65–68. doi: 10.1016/j.scriptamat.2016.10.028. [DOI] [Google Scholar]

- 13.Xie P., Yao Y., Huang Z., Liu Z., Zhang J., Li T., Wang G., Shahbazian-Yassar R., Hu L., Wang C. Highly efficient decomposition of ammonia using high-entropy alloy catalysts. Nat. Commun. 2019;10:4011. doi: 10.1038/s41467-019-11848-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Firstov G.S., Kosorukova T.A., Koval Y.N., Odnosum V.V. High Entropy Shape Memory Alloys. Mater. Today Proc. 2015;2:S499–S503. doi: 10.1016/j.matpr.2015.07.335. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Yuan Y., Wu Y., Tong X., Zhang H., Wang H., Liu X.J., Ma L., Suo H.L., Lu Z.P. Rare-earth high-entropy alloys with giant magnetocaloric effect. Acta Mater. 2017;125:481–489. doi: 10.1016/j.actamat.2016.12.021. [DOI] [Google Scholar]

- 16.Kao Y.-F., Chen S.-K., Chen T.-J., Chu P.-C., Yeh J.-W., Lin S.-J. Electrical, magnetic, and Hall properties of AlxCoCrFeNi high-entropy alloys. J. Alloys Compd. 2011;509:1607–1614. doi: 10.1016/j.jallcom.2010.10.210. [DOI] [Google Scholar]

- 17.Billington D., James A.D.N., Harris-Lee E.I., Lagos D.A., O’Neill D., Tsuda N., Toyoki K., Kotani Y., Nakamura T., Bei H., et al. Bulk and element-specific magnetism of medium-entropy and high-entropy Cantor-Wu alloys. Phys. Rev. B. 2020;102:174405. doi: 10.1103/PhysRevB.102.174405. [DOI] [Google Scholar]

- 18.Schneeweiss O., Friák M., Dudová M., Holec D., Šob M., Kriegner D., Holý V., Beran P., George E.P., Neugebauer J., et al. Magnetic properties of the CrMnFeCoNi high-entropy alloy. Phys. Rev. B. 2017;96:014437. doi: 10.1103/PhysRevB.96.014437. [DOI] [Google Scholar]

- 19.Wu X., Li Z., Rao Z., Ikeda Y., Dutta B., Körmann F., Neugebauer J., Raabe D. Role of magnetic ordering for the design of quinary TWIP-TRIP high entropy alloys. Phys. Rev. Mater. 2020;4:033601. doi: 10.1103/PhysRevMaterials.4.033601. [DOI] [Google Scholar]

- 20.Rao Z., Dutta B., Körmann F., Lu W., Zhou X., Liu C., Kwiatkowski da Silva A., Wiedwald U., Spasova M., Farle M., et al. Beyond Solid Solution High-Entropy Alloys: Tailoring Magnetic Properties via Spinodal Decomposition. Adv. Funct. Mater. 2021;31:2007668. doi: 10.1002/adfm.202007668. [DOI] [Google Scholar]

- 21.Quintana-Nedelcos A., Leong Z., Morley N.A. Study of dual-phase functionalisation of NiCoFeCr-Alx multicomponent alloys for the enhancement of magnetic properties and magneto-caloric effect. Mater. Today Energy. 2021;20:100621. doi: 10.1016/j.mtener.2020.100621. [DOI] [Google Scholar]

- 22.Jung C., Kang K., Marshal A., Pradeep K.G., Seol J.-B., Lee H.M., Choi P.-P. Effects of phase composition and elemental partitioning on soft magnetic properties of AlFeCoCrMn high entropy alloys. Acta Mater. 2019;171:31–39. doi: 10.1016/j.actamat.2019.04.007. [DOI] [Google Scholar]

- 23.Miura H. A unit cell parameter refinement program on windows computer. J. Crystallogr. 2003;45:145–147. [Google Scholar]

- 24.Nolze G., Kraus W. PowderCell 2.0 for Windows. Powder Diffr. 1998;13:256–259. [Google Scholar]

- 25.Yu M.-H., Lewis L.H., Moodenbaugh A.R. Large magnetic entropy change in the metallic antiperovskite Mn3GaC. J. Appl. Phys. 2003;93:10128–10130. doi: 10.1063/1.1574591. [DOI] [Google Scholar]

- 26.Kitagawa J., Skaguchi K. New room-temperature ferromagnet: B-added Pd0.75Mn0.25 alloy. J. Magn. Magn. Mater. 2018;468:115–122. doi: 10.1016/j.jmmm.2018.07.087. [DOI] [Google Scholar]

- 27.Miyahara J., Shirakawa N., Setoguchi Y., Tsubota M., Kuroiwa K., Kitagawa J. Hill Plot Focusing on Ce Compounds with High Magnetic Ordering Temperatures and Consequent Study of Ce2AuP3. J. Supercond. Nov. Magn. 2018;31:3559–3564. doi: 10.1007/s10948-018-4624-9. [DOI] [Google Scholar]

- 28.Kitagawa J., Terada H., Shirakawa N., Tsubota M., Nose A., Tanaka S. Composition effect in ferromagnetic properties of Tb3Co3Ga. Res. Phys. 2019;15:102591. doi: 10.1016/j.rinp.2019.102591. [DOI] [Google Scholar]

- 29.Tanaka S., Terada H., Shirakawa N., Tsubota M., Kitagawa J. The Impact of the Composition Effect on Ferromagnetic Properties of Tb2Co2Ga. Metals. 2019;9:1242. doi: 10.3390/met9121242. [DOI] [Google Scholar]

- 30.Dhar S.K., Kulkarni R., Manfrinetti P., Fornasini M.L., Bernini C. Structure and magnetic properties of RCu4Mn (R=La-Gd) Phys. Rev. B. 2008;77:054424. doi: 10.1103/PhysRevB.77.054424. [DOI] [Google Scholar]

- 31.Marcano N., Gómez Sal J.C., Espeso J.I., De Teresa J.M., Algarabel P.A., Paulsen C., Iglesias J.R. Mesoscopic Magnetic States in Metallic Alloys with Strong Electronic Correlations: A Percolative Scenario for CeNi1−xCux. Phys. Rev. Lett. 2007;98:166406. doi: 10.1103/PhysRevLett.98.166406. [DOI] [PubMed] [Google Scholar]

- 32.Kroder J., Gooth J., Schnelle W., Fecher G.H., Felser C. Observation of spin glass behavior in chiral Mn48Fe34Si18 with a β-Mn related structure. AIP Adv. 2019;9:055327. doi: 10.1063/1.5089191. [DOI] [Google Scholar]

- 33.Souletie J., Tholence J.L. Critical slowing down in spin glasses and other glasses: Fulcher versus power law. Phys. Rev. B. 1985;32:516–519. doi: 10.1103/PhysRevB.32.516. [DOI] [PubMed] [Google Scholar]

- 34.Mukherjee S., Garg A., Gupta R. Spin glass-like phase below ∼210 K in magnetoelectric gallium ferrite. Appl. Phys. Lett. 2012;100:112904. doi: 10.1063/1.3693400. [DOI] [Google Scholar]

- 35.Mydosh J.A. Spin Glasses: An Experimental Introduction. Taylor & Francis; London, UK: 1993. [Google Scholar]

- 36.Kitagawa J., Sakaguchi K., Hara T., Hirano F., Shirakawa N., Tsubota M. Interstitial Atom Engineering in Magnetic Materials. Metals. 2020;10:1644. doi: 10.3390/met10121644. [DOI] [Google Scholar]

- 37.Jin K., Sales B.C., Stocks G.M., Samolyuk G.D., Daene M., Weber W.J., Zhang Y., Bei H. Tailoring the physical properties of Ni-based single-phase equiatomic alloys by modifying the chemical complexity. Sci. Rep. 2016;6:20159. doi: 10.1038/srep20159. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 38.Troparevsky M.C., Morris J.R., Kent P.R.C., Lupini A.R., Stocks G.M. Criteria for Predicting the Formation of Single-Phase High-Entropy Alloys. Phys. Rev. X. 2015;5:011041. doi: 10.1103/PhysRevX.5.011041. [DOI] [Google Scholar]

- 39.Sohn S., Liu Y., Liu J., Gong P., Prades-Rodel S., Blatter A., Scanley B.E., Broadbridge C.C., Schroers J. Noble metal high entropy alloys. Scr. Mater. 2017;126:29–32. doi: 10.1016/j.scriptamat.2016.08.017. [DOI] [Google Scholar]

- 40.Yusenko K.V., Khandarkhaeva S., Bykov M., Fedotenko T., Hanfland M., Sukhikh A., Gromilov S.A., Dubrovinsky L.S. Face-Centered Cubic Refractory Alloys Prepared from Single-Source Precursors. Materials. 2020;13:1418. doi: 10.3390/ma13061418. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 41.Yusenko K.V., Riva S., Carvalho P.A., Yusenko M.V., Arnaboldi S., Sukhikh A.S., Hanfland M., Gromilov S.A. First hexagonal close packed high-entropy alloy with outstanding stability under extreme conditions and electrocatalytic activity for methanol oxidation. Scr. Mater. 2017;138:22–27. doi: 10.1016/j.scriptamat.2017.05.022. [DOI] [Google Scholar]

- 42.Moghaddam A.O., Trofimov E.A. Toward expanding the realm of high entropy materials to platinum group metals: A review. J. Alloys Compd. 2021;851:156838. doi: 10.1016/j.jallcom.2020.156838. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data sharing is not applicable.