Abstract

Biosurfactants are in demand by the global market as natural commodities that can be added to commercial products or use in environmental applications. These biomolecules reduce the surface/interfacial tension between fluid phases and exhibit superior stability to chemical surfactants under different physico-chemical conditions. Biotechnological production of biosurfactants is still emerging. Fungi are promising producers of these molecules with unique chemical structures, such as sophorolipids, mannosylerythritol lipids, cellobiose lipids, xylolipids, polyol lipids and hydrophobins. In this review, we aimed to contextualize concepts related to fungal biosurfactant production and its application in industry and the environment. Concepts related to the thermodynamic and physico-chemical properties of biosurfactants are presented, which allows detailed analysis of their structural and application. Promising niches for isolating biosurfactant-producing fungi are presented, as well as screening methodologies are discussed. Finally, strategies related to process parameters and variables, simultaneous production, process optimization through statistical and genetic tools, downstream processing and some aspects of commercial products formulations are presented.

Keywords: Filamentous fungi, Yeasts, Biosurfactants, Bioprocess, Screening, Downstream

Introduction

Since the 1930s, chemical surfactants have been part of several commercial products. These molecules are structurally composed of a hydrophilic and a hydrophobic moiety, with variations in structure, which allows for applications in numerous environmental and industrial areas [1, 2]. Main physico-chemical action of surfactants is to reduce the surface and interfacial tension at the interfaces between immiscible liquids, solids and gases, allowing distinct phases to mix and interact [1, 3]. They play a diverse and significant role in various industrial market segments, including products currently in demand due to the COVID-19 pandemic [4, 5]. Several products contain a significant amount of surfactants in their composition, such as toothpastes, soaps, detergents, fabric softeners, etc. [3]. Most of the chemical surfactants are synthesized from petrochemicals products, which although economically viable, are ecologically undesirable [1, 3]. However, biotechnology and chemical companies are continuously engaged in research for safer and more environmentally friendly industrial bioprocesses preferably using ecological biomolecules with superior structural and functional properties [6, 7]. In this context, biosurfactants represent a sustainable alternative to these requirements, since they are naturally synthesized by biological systems such as plants and microorganisms, offering lower toxicity and higher degradability [6, 8, 9].

Bacterial biosurfactants (glycolipids, glycoproteins, lipopeptides) are produced by different strains mainly Pseudomonas and Bacillus strains, leading the largest volume of data and scientific output [10]. Fungal biosurfactants, in comparison, represent only 19% out of the total (12% from ascomycetes and 7% from basidiomycetes), while having the widest chemical structural variant of biosurfactants, some of these are produced exclusively by fungi, like sophorolipids, mannosylerythritol lipids, cellobiose lipids, xylolipids, lipid polyols and hydrophobins [11–13]. In general, fungal biosurfactants have chemical structures versatility and their properties allow a wide range of applications such as in personal care sector [14], food [15], agriculture [16], pharmaceutical [17], biomedicine [18], materials engineering [19], bioenergies [20] and environmental remediation [21, 22].

Both bacterial and fungal biosurfactant production is still quite restricted, due to the production and recovery costs that often are higher than chemical surfactants and the fact that most bioprocesses show low yield and productivity [23]. In summary, industrial biotechnology can minimize limitations inherent to each stage, including isolation, screening, growth and product yield optimization, downstream processing, recovery, purification and characterization of the products [24]. In this context, after the isolation of the fungal strain from different environments, several techniques based on direct and indirect measurement of surface tension and/or emulsifying activity can be applied to select producing strains [25]. In addition, the use of agro-industrial waste, non-conventional substrates and the optimization of bioprocess parameters through statistical designs have also been shown as a tool to enhance the viability of the production of these biomolecules [26, 27]. Downstream processing steps are also constantly being improved to ensure greater yields and better performance and to elucidate structural variants of these molecule [28, 29].

The purpose of this review is to collate information related to fungal biosurfactants and bioemulsifiers and determine the main types and properties of these molecules. The review evaluates the bioprocesses involved in biosurfactants production considering the entire innovation chain, from isolation sources and selection tests for producing microorganisms, cultivation parameters, process optimization through statistical and genetic tools, to downstream processing; in addition to their potential in formulating commercial products.

Structural classes, properties and applications

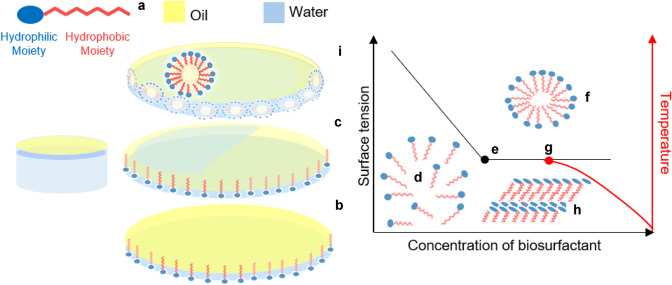

The versatility of the chemical structures of fungal biosurfactants is directly correlated to their biochemical composition and molecular weight, these macromolecules carryout physico-chemical and biological properties of biotechnological interest. Low molecular weight biosurfactants have their molar mass ranging between 0.5 and 1.5 kDa [30], while bioemulsifiers (high molecular weight) also known as Exopolysaccharides (EPS) can reach up to 500 kDa [31–33]. Figure 1 presents a schematic chart for understanding the action of biosurfactants and bioemulsifiers.

Fig. 1.

Biosurfactants are amphiphilic molecules, their composition consists of hydrophilic (carboxylic acids, alcohols, amino acids, phosphates, peptides, mono-, di- or polysaccharide cations or anions) and hydrophobic (hydrocarbon chains or saturated/unsaturated fatty acids) moieties (a). These molecules accumulate at phase interfaces of different polarities and stabilise heterogeneous phases (oil/air bubble droplets). b Thus, adsorption reduces the free energy per unit area needed to create a new surface, a reduction that is closely related to surface tension (liquid–air) and interfacial tension (liquid–liquid) [note the displacement of surface oil over water in c] [34]. Biosurfactant monomers (d) due to their self-assembly properties on reaching the Critical Micellar Concentration (CMC) (e), can form aggregated micellar structures (f) [35]. Micelle formation and solubility occur just above the Krafft temperature (g), i.e., the critical temperature at which micellar self-assembly occurs due to dissolution of the hydrated surfactant crystals (h) [36]. Bioemulsifiers are less effective in reducing surface tension and are involved in the formation and stabilization of emulsions between two immiscible phases (i) [31, 32]

In summary, the main function of surfactants is to decrease the tension at the fluid interfaces (liquid/liquid [emulsion] and liquid/air [foam]). Likewise, emulsifiers promote the formation of emulsions and steric stabilization at the interfaces of small drops of emulsions and foams, providing long-term stability [37]. It is known that some biomolecules have both properties, surfactants and emulsifiers [38]. Biosurfactant types include glycolipids, polyol lipids, proteins, carbohydrate–lipid–protein complexes, lipoproteins (or lipopeptides) and glycoproteins [12, 39].

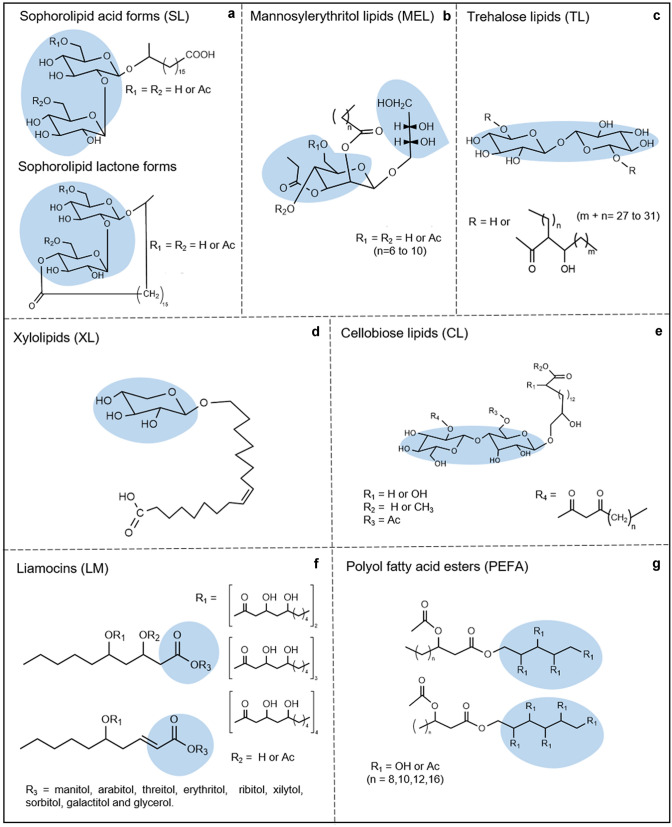

Figure 2 shows the classes of fungal biosurfactant glycolipids (low molecular weight) and polyol lipids based on their composition and chemical structure. Table 1 presents the classes of high molecular fungal biosurfactants based on their biochemical composition, structural characteristics and main producing microorganisms reported.

Fig. 2.

Chemical structure of fungal glycolipids and polyol lipids (adapted from [12] and [39]). The hydrophilic portions are highlighted in blue

Table 1.

Main high molecular weight fungal biosurfactants

| Group | Biosurfactant | Composition | Producer microorganism | References |

|---|---|---|---|---|

| Carbohydrate-lipid-protein complexes | Not classified | Molecules composed by the ligation of congeners of carbohydrates, lipids and proteins | Galactomyces pseudocandidum, Candida tropicalis and Geotrichum candidum | [40] |

| Aspergillus flavus | [41] | |||

| Penicillium citrinum | [42] | |||

| Aspergillus ustus | [43] | |||

| Lipopeptides (or lipoproteins) | Not classified | Molecules composed of proteins and lipids | Yarrowia lipolytica MTCC9520 | [44] |

| Penicillium chrysogenum SNP5 | [45] | |||

| Aspergillus mulundensis | [46] | |||

| Fusarium sp. | [47] | |||

| Polymeric-Glycoproteins | Liposan | Molecule composed of polysaccharide and protein | Y. lipolytica | [48] |

| Manoproteins | Mannose polymers covalently linked to the backbone main protein | Saccharomyces cerevisiae, | [49] | |

| Kluyveromyces marxianus | [50] | |||

| Yasan | Low-lipid polysaccharide-protein complex | Y. lipolytica | [51] |

Sophorolipids

Among fungal glycolipids, Sophorolipids (SL) has taken the lead industrially due to its high production yields, which can exceed 300 gL−1 and ample applicability in the industrial, environmental and health sectors [52]. SL has a hydrophilic portion of sophorose, a two β-1,2 glucose residues linked to a hydrophobic long fatty acid chain (C16 or C18), terminally or subterminally hydroxylated (Fig. 2a). SL are synthesized metabolically in two main forms, lactonic or acidic, that lead to a mixture of different congeners and quantities in the final production lines [53, 54]. Acidic SL are alicyclic and have a carboxylic acid group (COOH) at the end of the hydrophobic portion, while lactonic SL are cyclic with ester functionality [55, 56].

Although 20 or more congeners can occur of SL, generally a few forms are dominant [57]. The structures of SL can be modified through chemicals or enzymes [58], i.e., the combination of genetic manipulation techniques allows the modification in the hydrophilic and/or hydrophobic portions of the molecule [9]. The structural variation is due to the length and saturation of the fatty acid portion and acetylation of the sophorose, as well as the position of the hydroxyl group in both the lipid portion and the carbohydrate that is esterified with fatty alcohol [55, 59].

SL production occurs in several non-pathogenic yeasts, principally from Starmerella genus, which was previously classified as Candida and/or Torulopsis [60]. The diversity of species able to produce SL in this genus explains the SL production with different physico-chemical characteristics, since they have enzymes necessary to synthesize them when grown on hydrophobic substrates, forming fatty acids to be metabolized by β-oxidation [61].

The SL congeners profile produced by a microorganism can have different types and extensions of bioactivity, therefore, the use of purified SL does not attribute to it an unambiguous activity [62]. Recently, it was reported that the interfacial properties of acidic SL, such as leaching and chelating action, are pH dependent and can promote its application in hydrometallurgical extraction of metals and separation of ions and minerals through foam flotation, respectively [63]. Lactonic SL in comparison have lower CMC than acidic forms, being more hydrophobic and less soluble in water molecules [54], in the same way that acetylation decreases SL solubility [64]. In addition, lactonic SL have a better surface tension reduction compared to acid SL. However, both have recognized antimicrobial activity [65] and have already been proven to be prominent compounds with antimicrobial action in topical creams and for oral hygiene [56, 66].

In general, SL have broad antimicrobial activity against several bacterial (Escherichia coli, Pseudomonas aeruginosa, Staphylococcus aureus) [67–69] and fungal pathogens (Colletotrichum gloeosporioides, Fusarium verticilliodes, Fusarium oxysporum, Corynespora cassiicola and Trichophyton rubrum) [70, 71]. In addition, SL have antimicrobial action against Clostridium perfringens and Campylobacter jejuni and their association with lactic acid is a promising natural disinfectant in the poultry industry [72].

In addition to antimicrobial activity, when sophorolipids was added to the bioactive films composed of polylactic acid for food, it enhanced their thermomechanical properties [73]. In this context, SL are promising ingredients in the food industry as they also have emulsifying properties over edible oils and are stable at a wide range of pH, temperature and salinity [74]. Candida albicans SC5314 and Candida glabrata CBS138 sophorolipids have been reported to have emulsifying activities in olive oil, soy oil, almond oils and mustard by 40–50% [75]. In addition, SLs have sensory properties on the palate and responses induced in human taste buds cell cultures, enabling their application to modulate the taste of food and drugs [76].

Applied as adjuvants in antibiotic recovery processes (erythromycin and amoxicillin), SLs are alternatives for increasing the solubility and transferring to the organic phase through the formation of reverse micelles, in a liquid–liquid extraction processes [17]. SL were also used to remove tetracycline (88.2%), sulfadiazine (96.6%) and roxithromycin (100%) from soils contaminated by these antibiotics [21].

In agriculture, the addition of SL as adjuvants in pesticide formulations resulted in the US patent 2017/0094968 A1, which describes strategies on the use of SL to increase yield in the production of plants of agricultural interest [77]. SLs are also employed at preferably 100–500 g/ha, allowing a better formation of total biomass or improving harvestable parts in plants [77]. The Medicago sativa and Bidens pilosa plants when grown in soils augmented with SL had an increase in the growth of their shoots and roots, which may have been due to greater microbial activity in the soil after this addition [16].

In materials engineering, SL can be used as stabilizers and reducing/capping agents in the synthesis of metal-based nanomaterials, since they are generally used to improve colloidal stability in water or in aqueous solutions containing salt, many nanoparticles syntheses are carried out in organic media [78, 79]. SL use in the synthesis of copper (Cu) nanowires through hydrothermal synthesis, together with these nanomaterials, showed the potential for the substitution of components in transparent conductive electrodes [19].

The increase in the yield of enzymatic saccharification applied to vegetable biomass, as in wheat bran (20%) and steam-exploded wood (67%) was increased with the addition of SL in enzymatic cocktails, opening applications also aimed at bioethanol production [20, 80].

Mannosylerythritol lipids

The mannosylerythritol lipids (MEL) are composed of 4-O-d-mannopyranosyl-meso-erythritol with various patterns of acylation and acetylation, linked to fatty acid molecules (C8–C20) (Fig. 2b). Their structure may vary with the producing microorganism and the substrates used [26]. MEL have an oily appearance and according to the number of acetyl groups and their locations in the mannose, they are characterized as MEL-A (diacetylated in O-4 and O-6), MEL-B (monoacetylated in O-6), MEL-C (monoacetylated at O-4), MEL-d (deacetylated) [81] and MEL-A2 (triacetylated (O-2, O-4 and O-6) [82, 83]. The number of acyl groups in mannose and/or erythritol, and the length of the fatty acid chain, with its levels of saturation, may contribute to differences in several homologues of MEL [84, 85]. In this way, a detailed characterization of all structures derived from MEL is essential to identify their structure–function relationship and potential application. An MEL variant, with greater hydrophilicity, was identified with the presence of a mannitol instead of an erythritol residue in its structure [86].

MEL are well described for their self-assembling properties (sponge, cube and lamellar) that are influenced by carbohydrate stereochemistry [87]. These structures can form giant vesicles or nanostructures that can be applied as models in the cellular and molecular study processes [39]. MEL production is commonly described from fungi that belong to the Ustilaginales order [88]. Other species, such as Sporisorium sp. aff. sorghi [82], Pseudozyma spp. [28] and Schizonella melanogramma (MEL-A and -B) [89] are also described as MEL producers. As far as we known, the highest MEL (165 gL−1) production was obtained in batch-fed cultivation of Pseudozyma aphidis [90].

The elucidation of MEL synthesis pathways showed conserved mechanisms, in which a cluster of five conserved genes, including an acetyltransferase gene (mat1), a member of the family of the main facilitators mmf1, two acyltransferases (mac1 and mac2) and a glycosyl transferase gene (emt1) are present [91].

The MEL produced by Ustilago hordei differ from those secreted by Ustilago maydis, as they are mostly monoacetylated and contain a different mixture of acyl groups, although the MEL gene clusters of both species show a high degree of synergy (52%) and similarity (75%) to the respective genetic products [92]. These differences result from different catalytic activities of mat1 and mac1 acylation in the mannosylerythritol fraction at the C2 position, while mac2 promotes acylation at the C3 position. This indicates that the elucidation of these enzymes with different substrate specificities [106] may enable a specific MEL production [93].

The production of MEL-D (deacetylated) corresponds to a small fraction compared to other MEL congeners produced during cultivation. As far as it is known, there are no reports of mainly deacetylated MEL production by microorganisms [93]. However, alternative strategies are possible by enzymatic treatment of MEL-B with lipases [94] and genetic modification. The “interruption” of the mat1 gene in Pseudozyma hubeiensis (MEL-C producer) favours the production of MEL-D [95].

MEL-A produced by the endophytic fungus Ceriporia lacerate are potential adjuncts in environmental bioremediation, and these biomolecules showed a decrease in surface tension (31 mNm−1) and emulsifying activity in hydrocarbon contaminants (78.5%), soybeans (76.1%) and vacuum pump oil (77.4%) [84]. MEL-B and MEL-C can be applied in the formulation of biopesticides, as they are effective in altering the hydrophobicity of solid surfaces and inhibit germination of Magnaporthe grisea (rice blast) conidia [96].

MEL have excellent interfacial properties and pharmacological actions in drug administration [97], for this purpose MEL-A may be superior to MEL-B/C [81]. The formulation of fungal liposomes coated with chitosan modified with MEL-A can be considered as a promising delivery system, with enhanced antioxidant effects for bioactive compounds [98]. MEL-A have cytostatic activity to trigger apoptosis of B16 cells in vitro [99] and can dramatically increase gene transfection via membrane fusion [100]. In biomedical applications, MEL produced by Ustilago maydis CGMCC 5,203 were used for the synthesis of gold nanoparticles (AuNPs) and demonstrated cytotoxic potential against HepG2 cells [101].

MEL-A and B also showed antimicrobial activity against Gram-positive and Gram-negative bacteria [102], while MEL-A showed antibacterial activity against strains of Micrococcus luteus and S. aureus (FDA209P) and MEL-D against Enterococcus faecalis and E. faecium vancomycin-resistant (VRE) strains [103]. In addition, MEL can be used as additives to improve the functional properties of proteins and formulation of edible films for food. These surfactant–protein interactions in food systems ensure consistency, foam capacity and adequate food emulsifying activity [104]. In this sense, MEL addition for active films formulation based on starch provided greater flexibility, permeability to water vapor and hydrophilicity, favouring its use as an edible coating for food and biomedical devices [15].

MEL are also promising molecules for personal care products. Pseudozyma antarctica NBRC 10,736 MEL has been patented as a substitute for skin moisturizers, such as ceramide [105]. MEL-C produced by Pseudozyma hubeiensis have antioxidant effects and superior protective activity (30.3%) against oxidative stress in human skin cells compared to arbutin (13%), sunscreen and antioxidants [106]. In addition, MEL can be used as anti-melanogenic agents for effective skin lightening, as they significantly decrease the melanin content in primary normal human melanocytes [14].

Trehalose lipids and xylolipids

Trehalose lipids (TL) consist of a trehalose disaccharide linked by an ester bond to long-chain fatty acids (Fig. 2c). Only Fusarium fujikuroi was reported to be a TL producer with reducing surface tension (20.08 mNm−1). This filamentous fungus was isolated from soil samples contaminated with hydrocarbons [107]. TL are present as trehalose dimicolate in bacteria such as mycobacteria, Corynebacterium, Nocardia and Rhodococcus [108]. Most TL are found in these prokaryotes cell walls [109, 110], which can make it difficult to extract. In addition, most of these strains can exhibit slow growth and may be pathogenic. Consequently, TL still arouse less industrial interest via biotechnological production [3].

Xylolipids (XLs) on the other hand are composed of xylose monomers linked to fatty acids (Fig. 2d) and are secreted (at a reported 7.48 gL−1) by Pichia caribbica when grown in xylose-rich media. In addition, XLs reduce the surface tension to 35.9 mNm−1 with a CMC of 1 mgL−1 and have some antibacterial activity against S. aureus [111].

Cellobiose lipids

Cellobiose lipids (CL), also known as ustilagic acids, consist of cellobiose linked to the terminal hydroxyl group of a fatty acid (Fig. 2e) [112]. Under nitrogen starvation, the fungus U. maydis can produce CL and mannosylerythritol lipids in varying concentrations up to 30 gL−1, depending on the carbon source [88]. The studies of this class of biosurfactant are focused on two points. The first, is the structural characterization of the hydrophobic portion, and the second is its antimicrobial potential suggested by the involvement of the cytoplasmic membrane, by the inhibition of some enzymes, and by structural changes in the wall of sensitive microorganisms [113].

Ustilagomycetic yeasts of the genus Pseudozyma are commonly reported as producers of CL. Good examples are P. fusiformata [114], P. aphidis and P. hubeiensis [115]. The CL excreted by P. flocculosa, named flocculosine, are well known for their phytopathogenic action against powdery mildew [116], yeasts and Gram-positive bacteria commonly associated with human infections. The CL excreted by Sympodiomycopsis paphiopedili act against Cryptococcus terreus (45 μg mL−1) and Candida albicans (160 μg mL−1) [117] while those produced by Trichosporon porosum act against Candida albicans (0.2 mM) and Filobasidiella neoformans (0.03 mM) [118].

The CL produced by Cryptococcus humicola are additives for the formulation of colloids applied in the food and cosmetics industries [119]. Sodium salts improves the aqueous solubility of CLs and favours the formation of gels in alcoholic solution (ethanol or 1,3-butanediol) [119, 120]. CL from C. humicola, when added to poly (lactic acid) films, modifies the surface properties increasing, for example, its wettability [121].

Polyol lipids

Polyol lipids (PL) are considered to be an exclusive class of fungal biosurfactants. The main difference of the PL from other glycolipids is the replacement of the hydrophilic portion by a polyol (typically d-mannitol or d-arabitol) linked to an acetylated (R) -3-hydroxy fatty acid [122]. This class of biosurfactants comprises two groups of molecules, the Liamocins (LM), produced by Aureobasidium pullulans (Fig. 2f) [123], and the Polyol Fatty Acid Esters (PEFA), reported in Rhodotorula spp. (Fig. 2g) [124].

Several structures of LM are produced by Aureobasidium melanogenum [125]. The LM are only acylated in the polyol portion, while the PEFA can present different acetylation degrees in the polyol, in addition to an acetylation in the fatty acid portion [122]. Additionally, differences are found in the degree of acetylations in the PEFA depending on the producing fungus, which directly changes the surface properties of the molecule [126].

Regarding the physico-chemical properties, PL densities are higher than water, which favours the recovery of molecules. LM are commonly described as an oily compound, while PEFA have a viscous characteristic [12]. The small portions of the molecule can be modified by polyols supplementation in culture medium [127]. Different LM congeners with different polyol groups have antibacterial activity against strains of Streptococcus spp. [127].

In general, LM have a potential as a new antimicrobial agent group, particularly in prophylactic applications in which a broad spectrum antibiotic may not be the best option [128]. LM inhibits the formation of oral biofilms of S. mutans, S. sobrinus [129] and S. suis mainly by rupturing the pathogen’s cell membrane [130].

Limited information are reported on PEFA applicability. The ability to reduce surface tension and its emulsifying capacity are contrasting, but offer promising prospects for therapeutic and environmental applications [18, 131]. The PEFA produced by Rhodotorula paludigena have a high capacity to reduce surface tension (33.84 mNm−1) at low CMC (13.18 mgL−1) and they have a superior capacity than Tween 80 to emulsify diesel (77%) [131]. However, the PEFAs produced by R. babjevea reduce surface tension to a lesser extent and have a high capacity to emulsify diesel (70%) [18].

Lipopeptides

Lipopeptides (LPP) are composed of a portion of fatty acids with different degrees of branching and oxidation, linked to linear or circular oligopeptides. The peptide varies in number and type of amino acids [26]. Some fungi-produce LPP with active surface properties as described in Table 1. Fusarium sp. BS-8 produces LPP which reduced surface tension (32 mNm−1) at low CMC (≥ 1.2 gL−1) [47]. LPP produced by Mucor circinelloides also reduce the surface tension (26 mNm−1) and the viscosity of motor oil by 98.25%, contributing to potential applications in microbial enhanced oil recovery [132]. The cationic lipoprotein produced by Yarrowia lipolytica MTCC 9520 was applied as a stabilizing agent in the synthesis of silver nanoparticles, whose action was to prevent the formation of aggregates and facilitate nanoparticles production [44].

The LPP denoted scopularides produced by Scopulariopsis brevicaulis have activity against several tumour cell lines, i.e., anticancer activity, even at low concentrations (10 µg mL−1) [133]. Other LPP called eniatiatins are secreted by Fusarium, Verticillium and Halosarpheia. Eniatiatins are suggested for the treatment and prevention of atherosclerosis and hypercholesterolemia, since they inhibit the enzyme acyl-CoA:cholesterol acyltransferase and alter the concentration of intracellular ions, interrupting cellular metabolism [134].

Among other possible applications, those produced by Candida lipolytica UCP 0988 do not present toxicity against the germination of different vegetable seeds such as Brassica oleracea, Solanum gilo and Lactuca sativa [135], favouring germination in bioremediation soils containing traces of biosurfactants or enhancing water entry for seed germination [136]. In addition, these LPP do not present toxicity to the development of Artemia salina [135], a species of aquatic brine shrimp, enabling the application for remediation of aquatic environments [136].

Hydrophobins

Hydrophobins are globular proteins, with low molecular weight (< 20 kDa) and primary sequence of about 100–150 amino acids and have 8 cysteine residues that form 4 intramolecular disulfide bonds, stabilizing their tertiary structure and promoting surfactant and emulsifying activity [137, 138]. Hydrophobins are classified into two classes (I and II) according to their assembly characteristics at hydrophobic–hydrophilic interfaces, solubility and hydropathy. Class I hydrophobins form structures similar to amyloid fibrils, termed rodlet layers with a β-sheet conformation and are soluble only in strong acids, on the other hand, class II hydrophobins form regular crystalline structures with a random spiral conformation and can be easily dissolved with organic solvents or detergents [139, 140]. Some of these proteins may exhibit glycosylation [137, 139]. Although some hydrophobins can form oligomers as a strategy to increase their solubility in solution, others remain monomeric even at high concentrations [13, 141].

Class I hydrophobins were isolated from Schizophyllum commune (SC3) and class II hydrophobins from Trichoderma reesei (HFBI and HFBII) [138, 139], as well as, several ascomycetes and basidiomycetes capable of secreting hydrophobins in their cell wall, which has an ecological role related to local environment modification [13, 137]. It is believed that these hydrophobins assist hyphae to grow from a liquid phase into air by covering the surface of aerial hyphae with a hydrophobic layer. Likewise, spore dispersal, adhesion, pathogenesis, and breaking surface tension have been linked to hydrophobins [13, 137]. From a biotechnological perspective, due to their high surface activity and non-immunogenicity, hydrophobins have a versatility of applications as agents for solubilization and delivery of hydrophobic drugs, emulsifying agents for food, protein purification tags, tools for protein and cell immobilization, coatings for biomaterials, biosensors and, biomineralization templates [137, 140, 142]. Although there is a growing potential to manipulate hydrophobin variants for specific applications by protein engineering and heterologous expression in host cells, the insertion of these molecules into commercial applications is still limited due to low productivity, the need for additional steps for recovery and post-transcriptional modifications of the surfactant protein [137, 140].

Fungi-producing biosurfactants: bioprospecting and isolation sources

Fungi have ubiquitous habitat which can influence the production of different metabolites. The microbial ecology involved in the production of biosurfactants can indicate possible sites of isolation and/or application of the molecules obtained from these organisms. Several theories were proposed to explain the evolution behind microbial biosurfactant production. The first involves emulsification and solubilization of hydrophobic substrates to create a microenvironment favourable to the growth and production of the organisms [143]. The second, involves the adhesion-release of the cell to surfaces: when associated with the walls, they can regulate the properties of the cell surface, increasing the permeability of the membrane, for example. In this way, they use the property of active surface to detach themselves from unfavourable environments or in the search for new habitats with greater availability of nutrients [144]. The third, presenting antibiotic activity as a defence mechanism against possible competitors for substrates [145]. Fourth, as an energy reserve, since they can enter the catabolic process as a possible source of energy during periods of nutrient limitation [146, 147] and finally as protection for the microorganism against environments with high osmotic pressure, ionic imbalances and as protection against freeze/thaw cycles [148].

The isolation of fungi dependents on accessing environments where biosurfactant-producing strains are thriving. Although cultivable microorganisms represent less than 1% of the diversity of known microbial species [149], the bioprospecting of fungal strains by culture-dependent technique has enabled the discovery of new biosurfactant-producing strains [147] as well as novel biosurfactant structures [150]. Biosurfactant-producing fungi were isolated from hydrocarbon/petroleum contaminated soil samples [151], plant structures such as roots [40], stems [147], leaves [147], cones [152], flowers [150], fruits [153]; and animals such as porifers [43] and arthropods [154].

On the other hand, the search for biosurfactant-producing fungi can also be carried out through approaches that exploit extreme environments [155] and cultivation-independent techniques (metagenomics), as total environmental DNA can be examined at sequence level or be function-oriented [149, 156]. Functional metagenomics identifies genes or pathways in an environmental clone library by their functional activity (in this case, produce biosurfactants), providing an advantage over sequence-based screening, principally due to the fact that no prior knowledge of the gene sequence for target activity is required [157]. Likewise, metagenomics coupled with next-generation sequencing has enabled wider access to the diversity and function of many microorganisms in nature [158]. In addition, genetic information from non-culturable microorganisms can be exploited for enhanced biosurfactant development [149]. However, there are few published studies that employed metagenomics to prospect for biosurfactant-producing microorganisms [159]. The main limitation for metagenomic biosurfactant discovery may be due to the complex regulatory mechanisms involved in its production [156].

Biosurfactants in cold environments

Although extremophilic microorganisms are potential producers of biosurfactants, as they can excrete them for their colonization in adverse environment, biotechnological production from these microorganisms is virtually unexplored [160]. The bioprospecting of cold-adapted microorganisms has promoted the discovery of previously undescribed bacteria for biosurfactants production [161], however, studies focused on fungal strains remain scarce.

Filamentous fungi isolated from Antarctic soils such as Thelebolus sp. [33] and Phoma herbarum CCFEE 5080 produced EPS at 1.94 and 13.6 gL−1, respectively, that may act as necessary protection to microclimatic conditions, characterized by low temperatures, high thermal fluctuations and repeated freeze–thaw cycles [148]. Mortierella sp., isolated from arctic soils contaminated by hydrocarbons are suspected to produce biosurfactants [162], since new biomolecules (Malpininas and Malpibaldinas) with emulsifying properties were produced by zygomycetes such as Mortierella alpina ATCC32222 and DH187 [163]. In addition, extremophilic yeast Moesziomyces antarcticus (previously classified as Candida antarctica) produced biosurfactants such as mannosylerythritol lipids [164] and diacylmannosylerythritol [165], the latter interfered with ice paste formation as they have an anti-agglomeration effect and a high ice packing factor [161]. Among 68 yeasts isolated from Antarctic soils, only 11 produced biosurfactants, with Candida glaebosa as the most prominent [155]. Recently, other yeasts isolated from Antarctic marine and terrestrial environments such as Meyerozyma guilliermondii L21, Cryptococcus victoriae L92 and Leucosporidium scotti L120 have been reported as biosurfactant producers [166].

Research on biosurfactants produced by microorganisms in cold environments establishes a turning point for bioprocess work carried out at low temperatures, without the need for heating, and action on surfaces with low temperatures [164, 167]. Cold-adapted microorganisms are able to produce biosurfactants at low Krafft temperature (Fig. 1g), i.e., it allows their solubilization, micelle formation and application even at low temperatures [36]. Thus, these biosurfactants could be used as ingredients in antifreeze additives, cold detergents and to improve flow properties at freezing temperatures in biodiesel production [164]. However, the difficulty to mimic extreme conditions in vitro that allows the synthesis of the bioproduct is still a challenge to be overcome [160].

Screening of biosurfactant-producing fungi: methodologies and characterization

The presence of biosurfactants in culture media can be assessed by a various qualitative and/or quantitative methods that have different accuracy [168]. Generally, the screening tests depend on the analysis of microbial metabolites produced by fungal strain during or after cultivation [38]. These tests are based on direct measurement of surface tension, indirect methods of surface activity, emulsification index and/or cellular hydrophobicity [25]. The use of single techniques for screening can exclude strains that other techniques may have been able to detect [168]. The desired strains are those that produce biosurfactants with the lowest CMC values and with highest surface tension reduction or emulsification activity. In this regard, the screening tests must be developed and established considering the addition of inducing substrates under different processing conditions [38]. Methodologies are constantly being improved to screen high numbers of isolates and correlate the findings with available data [169, 170], as well as, for screening clones from metagenomic libraries [159]. Molecular techniques could be applied to screen strains with single gene clusters and islands of inherent production capacity, which would also facilitate the process and identification of similar gene sequences in other strains [171].

After selecting the producing strain, the fungal strain must be essentially identified from their genetic sequencing through the region of the Internal Transcribed Spacer (ITS) [151, 168]. The results should be compared with similar strains of the type of different species within the genus through multiple sequence alignment, ensuring unambiguous identification of the inoculum [168].

Surface tension measurement

In the last 20 years, measuring the surface/interfacial tension of culture supernatants and/or filtrates has been the main semi-quantitative parameter used to confirm the presence of biosurfactants [172, 173]. This methodology is sensitive, since the reduction in surface/interfacial tension is quantified until reaching the CMC, due to the saturation of this reduction, i.e., the numerical value obtained in the analysis only indicates if the microbial culture is producing biosurfactants or not. Therefore, it cannot be considered a quantitative parameter [9]. The positive criteria for biosurfactants production is the reduction of the surface tension to less than or equal to 35 mNm−1 [30].

The surface or interfacial tension can be measured by several methods (du Nouy Ring, Wilhelmy Plate, Spinning Drop, Pendent Drop), with the du Nouy Ring method being the most used. This determination is made by a tensiometer and/or goniometer [174, 175]. The main advantage of this method is accuracy and the absence of false-negative results [176, 177]. This technique requires specialized equipment and the analysis can be time-consuming, since simultaneous measurements are not possible and it requires an interval between each sample preparation (washing, wire buckling/platinum plate) [25, 178].

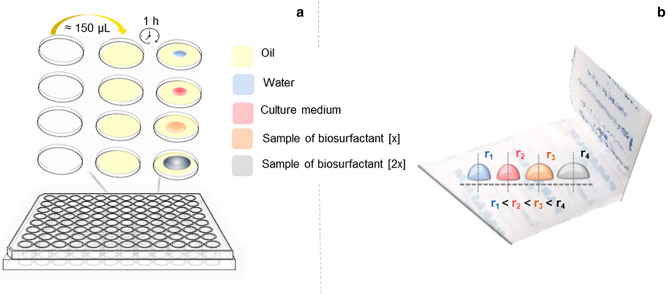

Drop collapse test

The drop collapse test is based on the collapse of a drop when in contact with a hydrophobic surface. There is a directly proportional correlation between the drop diameter and the surfactant concentration, also indicating a semi-quantitative parameter for the presence of biosurfactants [176, 179]. This assay can be carried out in 96-well microplates, which indicates high-throughput screening (Fig. 3a) [180, 181]. An adaptation of this method is the use of a hydrophobic surface of the commercial product parafilm-M™ (Parafilm-M Test) to facilitate visualization (Fig. 3b) [182]. Some authors have used methylene blue to stain samples to improve the visualization, as it does not influence in the drops shape [182, 183].

Fig. 3.

Collapse drop test occurs with the addition of oil and samples (3:1 v/v) to the wells of the microplate. First, oil is added to form a hydrophobic surface. Afterwards, drops of samples containing biosurfactants will collapse on contact with this surface as shown in a, and Parafilm-M test in b, where rn=1,2,3,4 = drop radius and n analyzed sample

The drop collapse/parafilm-M test is accurate in distinguishing between producing and non-producing strains, with few false-negatives. This test is a quick and simple test that does not require specialized equipment and can be performed with a small volume of sample [152, 178].

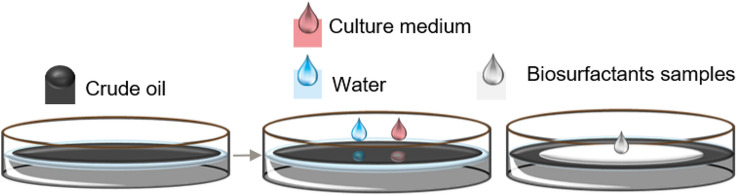

Oil spreading

The oil spreading test is based on the principle of decreasing the interfacial/superficial tension between the water and oil phases [178, 184]. If a biosurfactant is present, there will be a destabilization in the intermolecular forces of the water/oil interface with the active surface molecule, displacing the volume of the oil on the surface (Fig. 4) [178]. As the repulsion between the oil and water molecules is reduced, the oil is displaced in proportion to the biosurfactant concentration. Thus, a semi-quantitative parameter is provided for the selection of strains with the greatest production potential [185]. This methodology is considered sensitive, reliable, fast, and easy to perform. However, large volumes of waste are generated [43, 153, 186].

Fig. 4.

The oil spread test occurs with the addition of water and a smaller volume of oil to form a thin hydrophobic layer. Then, the test sample is added over the oil layer and provides the displacement of the area on the oil surface

Emulsification index

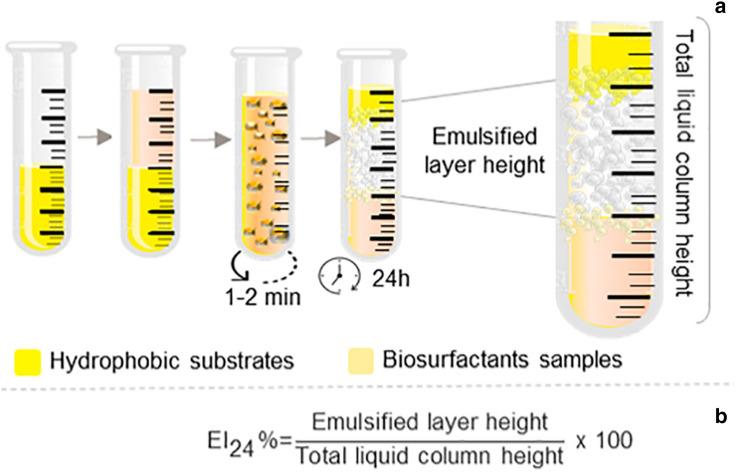

The emulsification activity was initially proposed through spectrophotometric analysis that require sophisticated equipment [48, 180]. However, the Emulsification Index (EI24) is a simpler, effective and commonly used method that consists of measuring the ratio between the emulsified volume and the total volume of the analysed sample (Fig. 5) [187]. Both methodologies are widely used [188, 189]. The EI24 is easy to perform and is considered as an appropriate indicator for strain screening, but a large volume of waste is produced [31].

Fig. 5.

EI24 test: addition of equal volumes (1:1) of hydrophobic substrates and samples containing biosurfactants in graduated tubes. Subsequently, the mixture is stirred at high speed, being maintained in the absence of disturbance for phase separation and stability of the formed emulsion (a). The emulsification percentage value can be measured according to (b)

The EI24 shows the molecule capacity in forming stable emulsions between different immiscible phases i.e., this index acts independently of the effect of surface tension of the medium to prevent drop coalescence [190]. Biosurfactants contained in the samples, upon contact with hydrophobic substrates, will reach an equilibrium phase between oil/water/biosurfactant system and promote solubilization to form emulsions [185, 191]. This functional property has been used to assess the biosurfactant ability to form and stabilize emulsions on different hydrophobic substrates, organic solvents and environmental conditions [35, 38, 192]. The emulsions stability is influenced by the compaction and size of the globules. Emulsions with low compaction and large globules generally show reduced stability [193]. An important characteristic in the emulsion stabilization is the adsorption of the emulsifier at the liquid–liquid interface [194].

The ability of a molecule to form stable emulsions is not always associated with the ability to reduce surface tension. It is suggested that strains producing biosurfactants are also producers of bioemulsifiers, but not the other way around [178, 195]. Therefore, the emulsification index provides a perspective on the production of bioemulsifiers by the selected isolates.

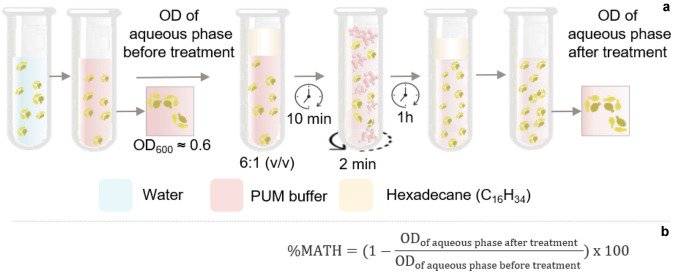

Cell adhesion to hydrocarbon hydrophobicity analysis

The Microbial Adhesion To Hydrocarbon (MATH) test is based on the cell surface hydrophobicity [196]. There is a direct correlation between the cell surface hydrophobicity and its adhesion in hydrocarbon droplets, which favours emulsification and assimilation of hydrophobic substrates (Fig. 6) [197, 198]. This test measures the partition of cells between the aqueous and hydrophobic phases. The fungus surface is considered hydrophobic when more than 50% of the cells migrate from the buffer (PUM—phosphate, urea, magnesium) to the hexadecane. On the other hand, it is considered hydrophilic when more than 50% of the cells remain in the buffer [199].

Fig. 6.

The microbial adhesion to hydrocarbon test is initiated by washing fungal cells to remove contaminants, followed by a resuspension in buffer solution (PUM) until reaching a standardized optical density (DO). Thereafter, the hydrocarbon is added, and the mixture is stirred. After complete separation of phases, the organic phase is removed, and the optical density is measured again (a). The percentage value of microbial cell adhesion to hydrocarbons is obtained as in (b)

Few reports were found in the literature for superficial hydrophobicity of filamentous fungi [200]. Therefore, it is necessary to search for new effective methodologies to improve on existing measurements of cellular hydrophobicity of filamentous fungi which is affected by differentiated mycelial growth, cultivation conditions and the physiological state of strains [138]. Sampling for the MATH may cause hyphae fragmentation, phase separation, possibly changes in hydrophobicity affecting standardization and resulting in incorrect measurements [201, 202].

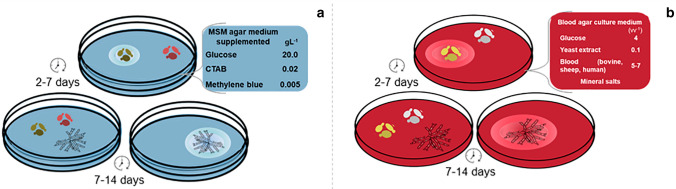

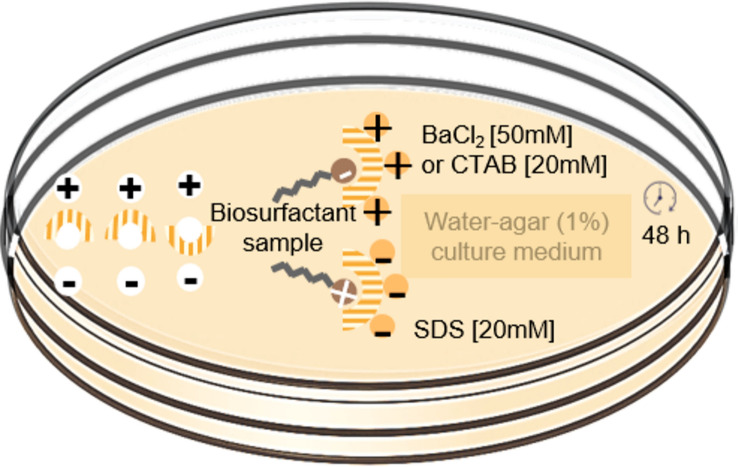

Methylene CTAB-Blue agar plate method and blood haemolysis

Methylene Blue Agar-CTAB method is selective for extracellular anionic biosurfactants, since halos formed in the culture are the result of insoluble salts produced between the anionic biosurfactant and the cationic detergent Cetyltrimethylammonium Bromide (CTAB) [203]. This test is qualitative, considered a primary screening study, easy to perform and to view responses (Fig. 7a) [40, 152, 204, 205].

Fig. 7.

Methylene blue-CTAB agar test (a) and blood hemolysis test (b). Biosurfactant-producing strains produce a halo when grown in a solid medium of defined composition. The cultivation period for obtaining the results varies according to culture strain

The CTAB assay is widely reported in the literature with consistent results for screening bacteria and yeasts. However, the CTAB method presents limitations for filamentous fungi, as it may underestimate positive results due to the spread of mycelial growth, production of metabolites involved in the dye degradation and dye absorption [205, 206].

The blood haemolysis test was developed for the selection of bacteria producing biosurfactants [207]. However, it has recently been used to prospect for filamentous fungi and yeasts producing biosurfactants (Fig. 7b) [40, 208, 209]. The haemolysis results from the lysis of erythrocytes due to disintegration of cell membranes due to activities of some surfactant [209, 210].

The limitations of the blood haemolysis test are related to difficulties in maintaining the culture conditions in the blood agar media that would favour the production of biosurfactants in addition to possible interference of microbial haemolysins with the results [154]. Low biosurfactant concentration produced can also present weak diffusion in the solid medium and favour the non-formation of halos [25]. Some results of blood haemolysis tests for fungi and yeasts have been shown to be false-negatives, as they have shown negative results for haemolysis while other positive results are obtained for different tests of surface activity and/or emulsification indexes [40, 67, 154]. Therefore, due to the variability of the results, other screening tests must be associated with blood haemolysis to corroborate biosurfactant production.

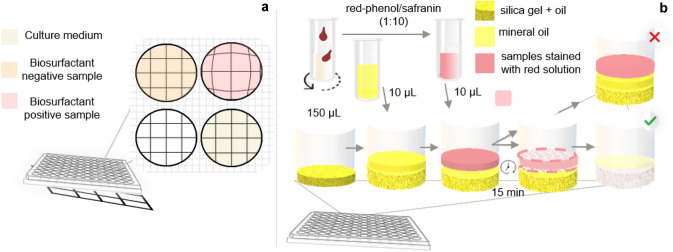

High-throughput screening, microplate and penetration assays

The application of two or more methods for preliminary confirmation of biosurfactant producer strains takes longer time, as does the interval between inoculation and production of biosurfactants. High-throughput screening involves the development and execution of rapid methods applied to a large number of isolates. Currently, there are only few screening procedures for biosurfactant detection considered as "high yielding". Microplate and penetration assays are carried out in 96-well microplates, which increases the number of tested strains and require lower sample volumes [25, 180, 211].

The samples analysed by microplate test are visually inspected. The test provides a qualitative result for biosurfactants presence due to the optical distortion promoted instantly in the image. If there are biosurfactants in its composition, the image formed on the microplate is modified (Fig. 8a) [204, 212]. On the other hand, the penetration test is colorimetric and involves two insoluble phases. The direct contact between these phases changes the analysed sample’s colour in the presence of biosurfactants, because it allows for the interaction between phases (Fig. 8b) [25].

Fig. 8.

Microplate assay is initiated by placing a grid paper under a microplate. The culture medium/water in a microplate well is considered to have a flat surface. A sample with biosurfactant will have a change at the well edge and the fluid surface will become concave, and consequently distorts the image (a). The penetration test occurs by adding a hydrophobic paste to the wells of the microplate, which is covered with mineral oil. Then, the sample is stained with red solution and added to the hydrophobic surface. The presence of biosurfactants is detected through its influence on the rupture of the barrier (interface) of the oil layer in the paste, which favors the entry of silica into the hydrophilic phase, and the upper phase changes the color from light red to cloudy white (b)

New production technologies

Biosurfactants are considered extracellular or cell membrane-associated secondary metabolites and have an ecological role similar to antibiotics and pigments that interact in membrane regulation [59, 154, 213]. However, some authors report that biosurfactant biosynthesis is associated with microbial growth when hydrophobic substrates are used, which indicates that these primary metabolites may also facilitate the absorption of substrates for fungi development [151, 198, 214]. Fungi have a more rigid and complex cell wall composition, i.e., they are more resistant to high concentrations of biosurfactants during cultivation, while bacteria have more sensitive cell structures [209, 215].

In most cases, fungal biosurfactants are produced by submerged cultures conducted in shaking flasks and/or bioreactors [216, 217]. Solid-state production is also promising [55] A recent study showed 39% of published research articles on biosurfactant production through solid cultivation are fungal, among which SL represent 14% and hydrophobins 2% of the types produced [55]. Solid-state cultivation promoted the production of hydrophobins by Purpureocillium lilacinum (34.8 mNm−1 and 1.3 mg of protein g−1), which did not occur in submerged culture [141]. Moreover, a 107% increase in yield was achieved in solid culture with complex substrate (sesame oil cake) compared to submerged culture using YMG medium for production of hydrophobins from Pleurotus ostreatus. [218].

Most studies on cultivation in solid medium for biosurfactant production are conducted in complex residues (agro-industrial) [218], which can make extraction difficult due to the greater diversity of interaction (product-medium and medium-solvent), maintaining residual impurities in the recovered extract [55]. In addition, solid-state cultivation scale presents challenges to be overcome on an industrial scale, such as the design of bioreactors that allow automated control and monitoring of parameters of the cultivation process [219, 220], as well as minimizing heterogeneity in terms of heat and mass transfers [55]. However, solid-state cultivations avoid possible problems associated with foaming or high viscosity commonly reported in submerged cultures [221].

Nutritional parameters and multiple metabolites

In general, culture medium is mainly composed of a carbon and nitrogen source plus macro and micronutrients [23], as well as, its price corresponds to about 10–30% out of total cost of the product [222]. Thus, culture medium composition may be considered the main cost reduction strategy in a bioprocess [23]. Likewise, the cultivation systems with multiple metabolite production have been reported as an effective approach to improve process profitability due to the use of more efficient types of bioreactors and substrates [19, 132].

Simultaneous production of biosurfactants and other bioproducts, using an integrated platform concept, can also be an economic strategy [18]. Garay et al. [223] reported the production of PEFA and intracellular triacylglycerols (TG) by Rhodotorula paludigena (20.9 gL−1 PEFA and 8.8 gL−1 TG) and Rhodotorula babjevae (11.2 gL−1 PEFA and 18.5 gL−1 TG). In optimized culture conditions, R. paludigena produced the highest yield of PEFA (48.5 gL−1) and intracellular lipids (16.9 gL−1) ever reported. The lipid sources produced are substrates for the biofuel production industry [131].

In other cases, biosurfactant production is also associated with the excretion of hydrolytic enzymes such as lipases, proteases and amylases [224, 225]. The fungus Pleurotus sajor-caju simultaneously produces biosurfactants (4.01 gL−1) and ligninolytic enzymes (laccase, manganese peroxidase and lignin peroxidase) in solid-state cultivation with sunflower seed husks as substrate [226]. In addition, P. antarctica PYCC 5048 produces MEL and xylanolitic enzymes from the direct conversion of xylan in a single step, without the need for enzymatic supplementation [227].

An unidentified yeast isolated from fresh rhizosphere samples of healthy planted crops have lipolytic activity and produce biosurfactants when grown on hydrophobic substrates [40]. Lipases and biosurfactants may act in synergism to favour the bioavailability of these substrates from the hydrolysis of complex biopolymers for cell growth [164]. If additional steps are necessary for the recovery of the produced co-products, harvesting two products (lipases and biosurfactants) in a single bioprocess can be a promising strategy to improve overall process profitability.

Carbon sources

The carbon sources initially provided and utilized in the culture medium interfere in different metabolic pathways for biosurfactant production [228]. The combination of energy sources, such as carbohydrates and lipids in culture medium, has been commonly reported [229, 230]. In this context, several sources of carbon can be used in culture media such as glucose, sucrose [231], xylose [227], inulin [131], cassava wastewater [28], cane molasses [232], soy molasses [233], glycerol [234] and hydrolyzates from restaurant food waste [235]. Additionally, lipid sources, such as refined vegetable oils and residual food frying oils [71, 208, 230, 236], wastewater from the oil industry [186, 237], motor oil [151] and animal fat [44, 238], have also been used. In addition, the carbon source supply directly influenced the chemical composition and surfactant properties of sophorolipids produced when S. bombicola was grown in biodiesel or rapeseed oil, with biodiesel a new esterified sophorolipid structure was produced with lower CMC value and surface tension [239].

In general, non-residual and non-traditional substrates showed low productivity values for sophorolipid production by S. bombicola even when supplemented with glucose. As examples, petroselinic acid (positional isomer of oleic acid) (0.24 gL−1 h−1) [240]; horse oil (composed of linoleic, palmitoleic fatty acids and unsaturated) (0.40 gL−1 h−1) [241]; castor oil (Ricinus) (0.20 gL−1 h−1) [242]; jatropha oil (Jatropha curcas) (0.03 gL−1 h−1), karanja oil (Pongamia) (0.03 gL−1 h−1) and neem oil (Azadirachta) (0.01 gL−1 h−1) [243]. This is probably due to the composition of fatty acids and also the presence of inhibitory compounds in these substrates [243].

Lignocellulosic hydrolyzates have been used to produce MEL and sophorolipids, although the presence of sugar dehydration, such as furfural and hydroxyl-methyl furfural had an inhibitory effect on the production [209, 244]. The hydrolyzates detoxification processes can partially remove those inhibitors [209, 230], since the yield of sophorolipids was doubled when hydrolysate from detoxified corn straw and oleic acid were used as carbon sources for S. bombicola [230].

A variety of agro-industrial by-products are reported for the production of biosurfactants through solid-state cultivation, such as oil cakes from the oil refining industry with the addition of beet molasses [220], soybean bran, husk, rice straw and bran [216, 245], wheat bran, soybean seeds, peanuts [246], grape residues and potato skins [247]. In this context, substrates for solid-state cultivation, as digestate from biowaste supplemented with glucose and fats (0.02 g g−1) and stearic acid (0.211 g g−1) showed low yield for sophorolipids production [248, 249].

Nitrogen sources

Different sources of inorganic and organic nitrogen can influence biosurfactants synthesis. The corn-steep liquor (CAS 66071-94-1), yeast extract and urea are organic sources, as well as nitrate and ammonium salts are inorganic sources commonly used [250, 251] Normally, during cell growth excess carbon and nitrogen sources is suggested, followed by depletion of the nitrogen source [29, 252]. The C/N ratio can interfere with biosurfactant production, so it is recommended to maintain a high C/N ratio during cultivation, observing a range of 16:1–18:1 [34, 193].

The physico-chemical properties of biosurfactant can be modified by providing different nitrogen sources. Inorganic nitrogen sources were more suitable than organic sources for the production of sophorolipids, this latter promoted preferably lactonic and low polarity sophorolipids [253], as well as the substitution of peptone for tryptone in the culture medium reduced the emulsification index of the biosurfactants produced by Aspergillus flavus [41].

Trace elements

Although natural by-products contain several nutrients due to their complex composition, the amounts of nutrients are suboptimal [254]. Supplementation with amino acids [163] and micronutrients such as magnesium, phosphorus, sodium, copper and manganese can meet these nutritional requirements and favour biosurfactant production [81, 84]. Optimizing the concentration of nutrients (phosphate salts, sulphates and chlorides) in the culture medium using response surface methodology increased MEL production at 61% by Ceriporia lacerate [84]. Culture media containing peptone, copper and manganese salts provided greater production of MEL-A homologues by P. aphidis ZJUDM34 compared to media without these microelements [81]. Metallic ions can influence the selective production of different sophorolipids by Wickerhamiella domercqiae, since lactonic congeners were mainly produced in the presence of Mg 2+ ions, while Fe 2+ ions promoted the production of acidic sophorolipids, as well as Cu+2 ions favoured maximum productivity (0.89 gL−1 h−1) [255]. The synthesis of sophorolipids by S. bombicola was increased by approximately 17% due to the addition of Mg2+, Mn2+, Cu2+ and principally Fe+2 to a specific concentration, decreasing slowly with additional increase of ion concentration [230].

Strategies for increasing yield and productivity

During biosurfactant production, cell aging, depletion of nutrients or the accumulation of product and/or by-products can inhibit cell activity and reduce biosurfactant production rate [256]. Process yield, chemical structures and physico-chemical properties vary according to substrates composition, producing-strains and cultivation system (batch, fed-batch, semi-continuous) [186, 257]. In addition, changes in cultivation parameters and conditions such as volume of inoculum and absence of agitation resulted in product with different emulsifying properties, surface activity and yield by Mucor hiemalis [208]. Table 2 shows a survey of the main components of the culture medium, parameters process and the kinetic values related to fungal biosurfactant production in agitated flasks, bench-top and pilot scale bioreactors.

Table 2.

Survey of fungal biosurfactants production parameters found in the literature

| Producer microorganism | Substrates (C/N) | Working volume (L) | Mixing (rpm) | Aeration (vvm) | pH/temperature (°C) | Volumetric productivity (gL−1 h−1) | Maximum yield (gL−1) | Surface tension (mNm−1) | References |

|---|---|---|---|---|---|---|---|---|---|

| Candida lipolytica | Animal fat (5%) and corn-steep liquor (2.5%) | 50.0 | 200 | ND | 5.3/28 | 0.30 | 40.00 | 25.00 | [136] |

| Candida tropicalis UCP0996 | Frying oil (2.5%), corn liquor (2.5%) and cane molasses (2.5%) | 25.0 | 200 | 1.0 | 5.5/28 | 0.06 | 7.36 | 27.48 | [232] |

| Candida sphaerica | Ground-nut oil refinery residue (9%) and corn-steep liquor (9%) | 20.0 | 150 | ND | 5.3/27 | 0.15 | 21.00 | 27.00 | [22] |

| Candida antarctica | Soybean oil (80 gL−1) and yeast extract (1 gL−1) | 2.0 | 200 | 1.0 | ND | 0.19 | 28.00 | 35.00 | [217] |

| Starmerella bombicola | Glucose (10%), sunflower acid oil (10%), yeast extract (4 gL−1) and urea (1 gL−1) | 2.0 | 550 | 1.0 | 3.5/30 | 0.27 | 51.50 | 35.50 | [59] |

| Starmerella bombicola | Glucose (100 gL−1) and corn-steep liquor (10 gL−1) | 2.5 | 800 | 1.0 | 3.9/25 | 1.55 | 342.00 | ND | [250] |

| Pseudozyma tsukubaensis | Cassava wastewater | 3.0 | 100/150 | 0.4 and 0.8 | ND | 0.02 | 1.26 | 26.00 | [28] |

| Rhodotorula paludigena | Glucose (150 gL−1) and yeast extract (1.5 gL−1) | 4.0 | ND | 1.0 | 6.5/27 | 0.12 | 20.90 | ND | [223] |

| Aureobasidium pullulans | Sucrose (50 gL−1), peptone (0.6 gL−1) and yeast extract (0.4 gL−1) | 0.7 | 300–1200 | 0.5 | 6.5–3.5/30 | 0.09 | 15.00 | ND | [252] |

| Cultivation of filamentous fungi in shake flasks | |||||||||

| Rhizopus arrhizus | Crude glycerol (3%) and corn-steep liquor (5%) | 150 | ND | 5.5/28 | 0.02 | 1.74 | 28.80 | [192] | |

| Fusarium sp. BS-8 | Sucrose (40 gL−1) and yeast extract (0.8 gL−1) | 150 | ND | 7.0/30 | 0.01 | 2.43 | ND | [47] | |

| Mucor hiemalis | Soybean oil waste (5%); sodium glutamate (1%) | 150 | ND | ND/28 | 0.08 | 7.73 | 32.00 | [208] | |

| Aspergillus niger |

Banana stalk powder (5.75 g), yeast extract (1 gL−1) and peptone (3 gL−1) |

ND | ND | 7.0/35 | 0.03 | 5.50 | ND | [27] | |

| Cunninghamella echinulata | Soybean oil waste (2%) and corn-steep liquor (8%) | 150 | ND | 5.5/28 | 0.04 | 5.18 | 31.70 | [251] | |

As a rule of thumb, 50 gL−1 is the minimum acceptable titre for any basic chemical produced and can be higher in many cases. Productivity below 2.0 gL−1 h−1 is generally unmarketable due to the high capital costs [258]. According to Table 2, only strains of S. bombicola show productivity and yield close to these titres, and the other strains under these conditions showed lower productivity. Filamentous fungi normally require long periods to reach maximum production and show lower yield compared to yeasts.

Studies showed that high biosurfactants yields can be achieved through fed-batch bioreactor cultivation with online variables control (dissolved oxygen concentration, pH and temperature, etc.) and also for variables available offline (concentration of specific medium components, substrate, etc.) [242, 259]. Changes in flow rates according to the feeding favour productivity and final yield [259]. Taking as an example the production of sophorolipids from S. bombicola, pulse feeding with biodiesel and glucose increased productivity to 1.55 gL−1 h−1 compared to 0.40 gL−1 h−1 when grown in shake flasks [239] and a productivity 1.45 gL−1 h−1 was achieved by continuous feeding of hydrophobic substrate and with intermittent pulses of glucose [250]. In addition, an increase in yield (14%) was achieved by propagating under fed batch conditions while exposing to ultrasonic waves, which is due to the phonophoretic effect that increases the permeability of the cell membrane and favours the absorption and conversion of nutrients [236]. Higher productivity (1.59 gL−1 h−1) was achieved through semi-continuous cultivation with integrated two-stage separation processes compared to fed batch production (1.25 gL−1 h−1) [257].

The inoculum is typically produced using pure cultures in media not necessarily the same as that used for production [260]. Bioprocesses for filamentous fungi are usually started with fungal spores which develop into hyphae branches and hyphal extensions to form structures called “pellets” [261]. The amount of inoculum supplied is about 3–10% of the working volume of the bioreactor, and it is expected that a larger volume can minimize the lag phase and produce a larger amount of biomass, which reduces the process time, consequently, the productivity of the bioreactor is increased [260]. Pre-treatments applied during inoculum preparation, such as application of an electric field after the development of Aspergillus brasiliensis spores in an electrochemical bioreactor, allowed the increase in production of bioemulsifier by 19.5% [194]. This was due to the fact that electric current promotes changes in the cell membrane and induces gene expression associated with the hydrophobin proteins that facilitates substrate uptake [194].

The ideal pH reported for biosurfactant production is slightly acid, preferably between 5 and 7 (Table 2). In some bioprocesses, the pH of the medium strongly influences biosurfactant production and the transport of various components across the cell membrane [55, 252]. The pH should be kept stable to avoid cell lysis, however, change in its value may trigger biosurfactant production, its value, however, is usually slightly reduced by the end of the cultivation [136, 252]. A strain of A. pullulans produced liamocins (15 gL−1) only after decreasing the pH of the culture broth from 6.0 to 3.5 [252]. In addition, low pH prevents microbial contamination of the culture medium and favours its maintenance through longer fermentation times [145].

Biosurfactant production processes are typically aerobic, requiring high rates of aeration and mixing during submerged cultivation. To enhance oxygen transfer rate in sophorolipids production, a 2:1 height/diameter ratio of the bioreactors is recommended [242, 262]. However, there are no studies related to fungal biosurfactant production with chemical engineering parameters, such as oxygen transfer coefficient (kLa). The effect of aeration rates has been less investigated as most studies are focused on the characterization and application of the molecules and not necessarily on the effects of aeration. Normally, dissolved oxygen is controlled between 25 and 50% saturation [217, 250]. High rates of aeration can increase the formation of foam, which hinders the recovery of the biosurfactant and decreases its yield [231, 263].

The mixing of the culture medium ensures a more homogenized system in submerged cultures, its application in solid cultures using filamentous fungi is limited due to the high shear stress [24]. There are few reports related to the effect of mixing speed on biosurfactant production. Intermittent mixing of the solid medium cultivated with S. bombicola for SL production increased substrate bioavailability and process yield (0.235 g/g) [220], possibly through minimizing mass/heat transfer problems. In submerged cultures for biosurfactants production carried out in agitation flasks, the mixture is performed by orbital agitation. Stirring speeds between 150 and 800 rpm have been commonly reported for fungal biosurfactant production [153, 238, 250], speeds of about 150 rpm are usual for filamentous strains to maintain cellular integrity and speeds above 200 rpm are easily achieved in cultures of agitated bioreactors [152, 192]. High stirring speeds are required when there is an increase in viscosity concomitant with biosurfactant production, which limits oxygen transfer [250].

The optimum culture temperature for both yeast and filamentous fungi is typically within the mesophilic range of 25–30 °C (Table 2). This condition is advantageous for the industry since it does not increase costs related to the cooling stages of the culture medium [136]. However, the thermophilic fungi Fusarium fujikuroi produces trehalose lipids with lower surface tension (20.08 mNm−1) at 47 °C [107] while psychotolerant yeasts isolated from cold environments produce biosurfactants at 20 °C [155].

Moisture is an important parameter in solid-state cultivation, as it influences microbial growth rate on the substrates and determines the process yield. Fungal cultures require water activity around 0.5–0.6 [55]. The ideal value for moisture depends on parameters such as size, porosity and composition of the substrate, as well as on the characteristics of the strains. Values between 45 and 75% have been reported for SL production from S. bombicola [220, 249].

Experimental design and response surface methodology

Statistical experimental designs allow the verification of the influence of multiple variables, individually or in relation to each other, and reduce the number of assays carried out. This method can indicate the most significant variables of the process and subsequently allow for optimizations [264].

The individual study of each independent variables (pH, agitation, nutrients, inoculum size) that have an effect on biosurfactant production can be a first strategy for optimization [128]. Alternatively, when more than five independent variables are investigated, the Plackett–Burman model can be used to assess variables that influence the system. This approach allows for optimizations in the fractional or complete experimental designs [128, 265]. The use of fractional experimental designs for example showed that yeast extract (2 gL−1) and wastewater from the olive oil industries [1.5% (w/w)] provided similar biosurfactant production by Aureobasidium thailandense as that of lauric acid ester [266].

The literature states that different parameters and components of the culture medium, when optimized by statistical models (response surface methodology), result in 1.65–4 times higher productivity compared to non-optimized media [6]. After optimizing the amount of substrate (waste cooking oil) and inoculum size through a central composite design for example, the yield of MEL by P. aphidis ZJUDM34 was sixfold higher (61.50 gL−1) compared to the non-optimized medium (10.25 gL−1) [267].

Genetic and metabolic engineering, an emerging alternative

An alternative to increase productivity and the development of new surfactants is through genetic improvements of strains [11, 23]. Genetic material can be modified by random mutation or by metabolic engineering [158]. Although it is conceivable that random mutation from techniques such as exposure to UV radiation, chemical components and base analogues has enabled the selection of mutant strains for biosurfactant production [228], only a single study was published on the use of mutagenic agent in fungi. It was reported that after exposed to the chemical mutagen (ethidium bromide) Aspergillus niger increased its yield of biosurfactant production by 43% [27].

Since 2014, the US 8,911,982 B2 patent granted the company Evonik the right to produce sophorolipids from genetically modified S. bombicola through the insertion and deletion of genes that overexpress enzymes involved in the synthesis of those compounds [268]. The majority of the production was directed to acidic sophorolipids (138 gL−1) through the deletion of the lactone esterase gene (Δsble) in S. bombicola, restricting biosynthesis of the lactonic forms [269]. Another example is mono-acylated and deacetylated MEL-D production by the deletion of an acyltransferase gene (PtMAC2) in Pseudozyma tsukubaensis. This gene recombination allowed the production of new mannosylerythritol lipid derivatives, maximizing their applicability in the industry [270].

The production of new structural variants of biosurfactants expands their application. A good example is the Bolaform (sophorosides), a compound that consists of a long hydrophobic spacer with hydrophilic groups at both ends. These changes increase the molecule’s solubility in water and the formation of micelles, thus improving the physico-chemical properties of the bioactive agent [271, 272]. The deletion of the acetyltransferase (Δat) and lactonase genes (Δlac) and the insertion of a second glycosyltransferase gene (Δugtbl) in S. bombicola promoted Bolaform product production [271]. In this context, the deletion of the putative alcohol oxidase gene fao1 from S. bombicola (ΔatΔsbleΔfao1) allowed the supply of fatty alcohols instead of fatty acids to the culture medium, favouring the production of Bolaform biosurfactant (20 gL−1) [272].

Although the heterologous production of fungal biosurfactants in bacteria is an interesting alternative, since it is easier and faster, the production of hydrophobins in bacterial host presents very low yields (10–100 mgL−1) and require additional steps for inclusion body purification such as denaturation/renaturation to recover the biosurfactant [140]. The yield in heterologous production of hydrophobin (330 mgL−1) in Pichia pastoris can be increased by 30-fold through an increase of 3 copies of the overexpressed gene chaperone protein Ero1p and a tenfold increase with the overexpression of the gene KAR2 encoding the endoplasmic reticulum resident chaperone protein [273]. The expression of hydrolytic enzymes, such as lipases, in biosurfactants producer fungi is a strategy for petroleum derivatives consumption. A 1.7-fold increase in MEL-B yield in a recombinant strain of P. tsukubaensi was achieved after the insertion of the lipase gene PaLIPAp (PaLIPA) from P. antarctica T-34 [274]. In addition, Saccharomyces cerevisiae were also used as an expression vector to produce rhamnolipids (a bacterial biosurfactants) through the insertion of genes from Pseudomonas aeruginosa [275] and sophorolipids from the expression of the glycosyltransferase (gtf-1) gene from C. bombicola [276]. This approach promoted glycosylation of lipids and increased the spectrum for use of substrates (including sterols) [276].

Metabolic flow analysis between wild and mutant strains of S. bombicola showed that an inadequate supply of intracellular acetyl-CoA in the mutant strain, as well as citrate metabolism, can negatively affect sophorolipids biosynthesis, since it is related to fatty acid metabolism [277]. However, the regulatory mechanisms that determine genomic analysis and attempts to induce the overproduction of biosurfactants can only be explored in a restricted way due to the wide structural variety of these molecules and biosynthesis pathways involved in production [156]. The application of advanced tools in genomics, transcriptomics, proteomics and metabolomics to elucidate complete biosynthetic pathways and their regulation in biosurfactant-producing strains, improves our understanding of the bottle necks in synthesis pathways of some metabolites, diverting most of the energy to the main metabolic pathways involved in the production of biosurfactant [171].

Biosurfactant downstream processing

Recovery and purification

The structural diversity of biosurfactants and their unknown thermodynamic data present additional challenges in relation to their recovery. Different molecular characteristics, such as location, ionic charge and solubility, significantly influence their recovery and purification [23, 278]. In general, downstream processing depends on biosurfactant itself and the purity required for application.

Biosurfactants associated with fungal cell membrane (or intracellular) require cell lysis or sonication to be released [279]. Application of ultrasound in biosurfactant recovery produced by Fusarium proliferatum increased the yield by 30% before extraction with a solvent [280]. On the other hand, when biosurfactants are already excreted in the medium, the fungal biomass can be separated by filtration and/or centrifugation, which allows better conditions for recovery of the bioproduct [208].

The recovery of extracellular biosurfactants includes acid precipitation with hydrochloric acid [281] followed by solvent extraction (ethyl acetate, acetone, ethanol) to remove lipid contaminants or residual carbohydrate compounds [110, 251]. The economic advantage of this process is the possibility to recover the solvent. An MEL recovery system (94% efficient) was developed by combining the following solvents: methanol/water/n-hexane (pH 2) [282].

The separation processes with membranes such as microfiltration and ultrafiltration are used to recover biosurfactants [63]. Ultrafiltration processes with high molecular weight membranes (100 kDa) facilitate the recovery and increase biosurfactants purity, which can be extended with a cross-flow filtration unit. At concentrations above CMC, biosurfactants increase their molecular weight due to the property of self-aggregation, forming micelles that favours retention in the membrane [28].

Several techniques, in particular foam fractionation, gravity separation and membrane separation, have been shown to be effective in the recovery of biosurfactants, since these techniques can become useful to avoid problems caused by product accumulation in the medium [29]. Furthermore, the integrated production and recovery of sophorolipids can be industrially promising, since it allowed the extension of the process time (480 h) with 93% efficiency in six separation cycles, reducing the probability of contamination and avoiding the addition of chemicals [283].

The production and integrated gravitational separation of biosurfactants allow continuous recovery of sophorolipids (86–280 g) of higher or lower density than the culture medium, while medium broth and cells are recirculated. This system provides reductions of up to 11% in the volume of the bioreactor [284]. An integrated system for the production and separation of sophorolipids by gravity in a bioreactor with double ventilation tubes and double sieve plates has been proposed [257]. The two-stage recovery system improved the purity of the sophorolipids by 23.3%, allowing the recycling of substrates and yeast cells, minimizing inhibition processes and increasing substrate rate consumption [257].