Abstract

Background

Noise-induced hearing loss is a well-known occupational disease that affects many fish harvesters from many fisheries worldwide, whose risk factor is prolonged exposure to hazardous noise levels. To date, academic research activities and regulatory bodies have not provided any comparative analysis among the existing methods to assess noise exposure levels of fish harvesters. This paper provides a comparison of four relevant assessment methods of noise exposure, examining the results of a measurement campaign performed onboard small fishing vessels from Newfoundland and Labrador.

Methods

We traveled onboard 11 vessels engaged in multiple fisheries from Newfoundland and Labrador and performed extensive noise exposure surveys using the simplified International Maritime Organization method, the full-day measurement method, and the two methods provided by ISO 9612:2009, the task-based method and job-based method (JBM).

Results

The results showed that the four methods yield similar values when the noise components are dominated by the engine and auxiliaries (steady-state sources); when noise components are dominated by the fishing gear, task-based method and the simplified International Maritime Organization method estimates are less accurate than JBM, using full-day measurements as baseline.

Conclusion

The JBM better assesses noise exposure in small-scale fisheries, where noise exposure has significant variance and uncertainties on the exposure levels are higher.

Keywords: Fishing safety, Noise measurement methods, Occupational noise exposure, Risk assessment

1. Introduction

Noise-induced hearing loss (NIHL) is a common occurrence in workplaces characterized by prolonged exposure to hazardous noise levels and frequent impulsive noise [1]. In particular, noise-induced hearing loss is a well-documented occupational illness for fish harvesting in the literature: studies have been conducted to test fishing workers for hearing threshold shifts [2,3] and to assess hospital contacts or work health history [[4], [5], [6]] of fish harvesters. This problem might potentially affect a tremendous amount of people worldwide. Indeed, the fishing industry is present in every coastal region worldwide, and 40,399,000 people were fish harvesters in 2016, an increase of 25% over the previous 20 years [7].

Exposure to hazardous noise levels can be assessed through noise measurements performed during fishing operations. This assessment is the first necessary step to implement risk-control measures in the workplace, and accuracy in the measurement and identification of hazardous noise levels are fundamental to tailor the control interventions. An analysis of the scientific literature on this matter highlights that few studies have been conducted on noise exposure assessment of fish harvesters. The outcomes of these studies do not define a clear and generalized course of action to mitigate noise exposure of fish harvesters, as they were performed in different parts of the world, for multiple fisheries, and using different methods of assessment. Most of the reported research activities on the assessment of noise exposure of fish harvesters used the task-based measurement (TBM) approach, where noise levels are measured in each work position and for each work task, and then the overall noise exposure is calculated considering the stationing time in those work positions and the duration of the tasks of a nominal working day. Zytoon [8] conducted extensive measures on 24 vessels; Peretti et al. [9] assessed the exposure on five small-size to medium-size vessels. The TBM approach is well suited for highly standardized works where a worker job can be split into a series of repetitive tasks [10], and it has been shown that it can be used to accurately assess noise exposure of workers in several occupations [[11], [12], [13]]. Alternatively, full-day personal dosimetry or full-day measurement (FDM) can be performed to assess an average day noise exposure level. According to this method, personal noise dosimeters are worn on the harvesters' bodies during normal fishing activities and monitor noise for the whole working day. Some scholars have used FDM to assess noise exposure on samples of fish harvesters: Paini et al. [2] studied noise exposure on small-size fisheries from Brazil; Levin et al. [3] on shrimp trawlers from the Mexico Gulf; Fulmer and Buchholz [14] on small-scale lobster fishers and gillnetters from Massachusetts; Zytoon [8] performed FDM for comparison with TBM assessment. Finally, a third method to assess noise exposure is the job-based method (JBM), that identifies jobs—intended as the overall occupational activity carried out by a worker during an entire working day—and extrapolates for each job a mean exposure level from a random sample of noise measurements performed during the working day [10]. To our knowledge, no research on fish harvesters’ exposures has been conducted using this method.

With regard to relevant international standards, there is no recommendation on what method should be used to assess noise exposures on fishing vessels. The Maritime Safety Committee of the International Maritime Organization (IMO), which is the main international body regulating safety at sea, does not regulate safety on fishing vessels. This is also reflected in the “Code on noise levels on ships” [15], which sets noise limits for different vessel spaces and noise exposure for crew members. It recommends using International Organization for Standardization (ISO) 9612 methods [10] for exposure assessment but also outlines a simplified IMO (sIMO) method to determine noise exposure of crew members, using noise levels measured in different vessel spaces during the sea trials and the crew standing time in these spaces. This code does not apply to fishing vessels but is used to assess noise exposure on larger commercial vessels [16]. On board a large harvester/processor, ISO and sIMO methods were used together by Neitzel et al. [17], where noise exposure levels of non–work-shifts (obtained via sIMO) and work-shifts (obtained via dosimetry) were combined to get the overall exposure.

This paper presents the results from surveys performed to assess occupational noise exposures of fish harvesters on small fishing vessels in the Canadian province of Newfoundland and Labrador (NL). We traveled on 11 fishing vessels during regular fishing trips and performed extensive noise exposure surveys, encompassing several types of fishing vessels, diverse in length—from open-deck skiffs to larger decked vessels—fishing gear, and fishing operations. On each vessel, the surveys were performed according to the TBM, JBM, FDM, and sIMO method. The noise exposure levels calculated with the TMB, JBM, and sIMO method were compared with the FDM-calculated levels, which is a measure of the true exposure of workers [10], to understand which method is the most accurate to determine occupational noise exposures on small fishing vessels and strengths and limitations of each method. The research presented in this paper is a part of a larger project that aims to mitigate occupational noise exposures of fish harvesters working on fishing vessels less than 24 m in overall length from the Canadian province of NL, also known as a small-scale fishing fleet.

2. Materials and methods

2.1. Sample of visited vessels

The authors traveled onboard 11 vessels from the NL small-scale fleet, surveying noise exposure of 34 fish harvesters engaged in seven different fisheries. The sample is presented in Table 1. To define a sampling regime, we studied the composition of the NL small-scale fishing fleet. Thus, the sample was composed of relevant cases that account for the variability of noise exposure in the fleet section considered. Parameters such as lengths, vessel layouts, and construction materials were considered because they influence the type of noise sources—i.e., propulsive engine, auxiliary machinery, fishing gear—and noise transmission on board. We also considered the work patterns of harvesting operations because occupational noise exposures depend on them. A detailed examination of the fleet composition was presented by Burella et al. [18].

Table 1.

Sample of visited vessels

| Vessel ID | Crew # | Length (m) | Boat type | Fishery | Gear | Engine power (Hp) | Engine type |

|---|---|---|---|---|---|---|---|

| FSH001 | 2 | 5.8 | Undecked,FRP∗ | Lobster | Pots | 115 | OB† |

| FSH002 | 2 | 10.7 | Decked,WD | Cod | Handline | 150 | IB |

| FSH003 | 2 | 10.7 | Decked,FRP | Cod | Gill net | 205 | IB |

| FSH004 | 3 | 11.9 | Decked,WD | Whelk | Pots | 306 | IB |

| FSH005 | 3 | 10.7 | Decked,WD | Crab | Pots | 217 | IB |

| FSH006 | 3 | 19.8 | Decked,FRP | Cod | Gill net | 624 | IB+GS |

| FSH007 | 3 | 10.7 | Decked,WD | Crab | Pots | 217 | IB |

| FSH008 | 5 | 15.5 | Decked,FRP | Crab | Pots | 340 | IB+GS |

| FSH009 | 5 | 18.3 | Decked,FRP | Capelin | Purse seine | 543 | IB+GS |

| FSH010 | 6 | 19.8 | Decked,FRP | Shrimp | Trawls | 624 | IB+GS |

| FSH011 | 2 | 5.8 | Undecked,FRP | Squid | Handline | 50 | OB |

FRP: fiberglass boat, WD: wooden boat.

OB: outboard motor, IB: inboard engine, GS: electric/hydraulic power generating set.

2.2. Ethics

This research was approved by the Interdisciplinary Committee on Ethics in Human Research (of Memorial University of Newfoundland. Ethics clearance required participation in the study to be voluntary, written, informed consent from participants, confidentiality, and feedback of results to participating skippers and crews.

2.3. Noise surveys

Noise measurements took place on board consenting vessels during regular fishing trips. Owner-operators provided information on the vessel characteristics via a pretrip questionnaire. Furthermore, we interviewed the vessel's crew about the typical fishing operations and work patterns of the fishing trip. After these, we developed a noise measurement plan, and we identified homogeneous noise exposure groups among all the fish harvesters working on the same vessel [10].

The noise-sampling instrumentation setup was composed of four Brüel & Kjær® Type 4448 personal noise dosimeters that were used during every fishing trip. Microphones were equipped with windscreens to avoid wind flow interference. The noise dosimeters were worn on the most exposed shoulder of the harvesters and used to perform personal noise dosimetry for the entire fishing trip. The actual composition of the working day activities—i.e., tasks and their duration—was extracted from debrief questionnaires that were compiled at the end of each fishing trip. In these questionnaires, harvesters were required to log their tasks during their working day. These logs were supplemented by one compiled by the researchers onboard to fill possible blanks.

Class 1 model 378B02 ICP handheld microphone by PCB Piezotronics® connected to a National Instruments® model A 9234 BNC input card was used to record sound pressure levels of onboard spaces, and the acquired data were processed using LabVIEW®. The microphones were used to map the noise levels existing in spaces of vessels at different vessels speed, as per the IMO noise code [15].

Before each trip, the dosimeters and handheld microphones were calibrated using a Larson Davis® calibrator model CAL200. All the equipment was holding a valid calibration certificate on and before August 2018, the date of the last survey trip.

2.4. Methods to assess occupational noise exposures

The measured data were processed to obtain the eight-hour A-weighted noise exposure level for noise exposure groups according to four methods:

-

•

The TBM and JBM as described in the ISO standard 9612:2009 (E) [10],

-

•

The FDM following the procedure illustrated in [19,20] for samples of sound exposure levels, and

-

•

The sIMO method as described in the “Code on noise levels on ships” [18].

According to TBM, noise exposure levels are calculated as follows:

| (1) |

| (2) |

where is the i-th sample of the A-weighted sound pressure level of measured samples for the m-th task, is the reference duration of the workday, and is the average duration of the m-th task. Duration of each sample is prescribed by the standard in accordance with the type of noise sources. is the total number of tasks performed on a working day.

The sIMO method [15] is similar to the ISO 9612 TBM, except that are substituted by the noise levels from the noise mapping of spaces where the crew is standing. The noise mapping was performed using the handheld microphone equipment during sea trials at two typical vessel speeds—full speed and slowdown—and used with crew standing time in the spaces to assess noise exposure according to Eqs (1), (2).

In the JBM, noise exposure levels are calculated for each job and each noise exposure group as follows:

| (3) |

| (4) |

where is the n-th sample of the A-weighted sound pressure level of measured samples associated with the job and is the effective duration of the working day. Thus, for each job, a representative random sample of is measured during the day, based on the contribution to the overall noise exposure. The actual size of the said sample depends on the number of workers in the homogeneous noise exposure group for that job.

Finally, the FDM requires using full-day measurments from workers of a homogeneous noise exposure group, performing the average using Eq. (3), and calculating the noise exposure levels, according to Eq. (4). This method is conceptually similar to the JBM, except for using 1-minute-long samples () from the full-day dosimeter measurements log of workers from a specific homogeneous noise exposure group instead of fewer random samples of longer duration.

Expanded uncertainties for the TBM and JBM were calculated as per the procedure in ISO 9612:2009 [10]. Because of the low number of full-day measurements available, we used an alternate methodology to calculate FDM expanded uncertainties than the one proposed in ISO 9612:2009 [10]. was obtained using the following uncertainty contributions formula:

| (8) |

| (9) |

where is the uncertainty contribution of the FDM samples obtained through the simplified procedure illustrated in [19,20], and are the sensitivity coefficient and uncertainty for the used instrumentation, respectively, and and are the sensitivity coefficient and uncertainty for the microphone position, respectively. To make FDM's expanded uncertainties comparable with the ones calculated for the TBM and JBM, we set , , and , as reported in the ISO 9612 standard [10]. No uncertainty evaluation is required for the sIMO method.

2.5. Analysis of measured data

In the JBM and TDM, to obtain the samples of time averaged sound pressure levels for each task and for each job, we used of the day activities logs to break down the composition of the dosimeters logs and extract the measured samples and durations.

We also calculated A-weighted sound pressure levels according to the FDM using the full working day 1-minute-long logs from the dosimeters.

Any spurious noise interference, such as deviation from the nominal working day or presence of impacts on the dosimeters' microphones, was removed from both dosimeter and handheld microphone measurements.

Table 2 shows the number of workers and noise level sample duration per homogeneous noise exposure group and method.

Table 2.

Numbers of workers and samples duration for each noise exposure group and each method used for assessing noise exposure on fishing vessels

| Vessel |

Noise exposure groups |

sIMO samples duration | |||||||

|---|---|---|---|---|---|---|---|---|---|

| ID | Skipper and crew/skipper |

Crew |

|||||||

| Number of workers | JBM samples duration | TBM samples duration | FDM samples duration | Number of workers | JBM samples duration | TBM samples duration | FDM samples duration | ||

| FSH001 | 2 | 15 minutes | 5 minutes | 1 minute | - | - | - | - | 1 minute |

| FSH002 | 2 | 15 minutes | 5 minutes | 1 minute | - | - | - | - | 1 minute |

| FSH003 | 1 | 15 minutes | 5 minutes | 1 minute | 1 | 15 minutes | 5 minutes | 1 minute | 1 minute |

| FSH004 | 1 | 15 minutes | 5 minutes | 1 minute | 2 | 15 minutes | 5 minutes | 1 minute | 1 minute |

| FSH005 | 1 | 15 minutes | 5 minutes | 1 minute | 2 | 15 minutes | 5 minutes | 1 minute | 1 minute |

| FSH006 | 1 | 15 minutes | 5 minutes | 1 minute | 2 | 15 minutes | 5 minutes | 1 minute | 1 minute |

| FSH007 | 1 | 15 minutes | 5 minutes | 1 minute | 2 | 15 minutes | 5 minutes | 1 minute | 1 minute |

| FSH008 | 1 | 15 minutes | 5 minutes | 1 minute | 4 | 15 minutes | 5 minutes | 1 minute | 1 minute |

| FSH009 | 1 | 15 minutes | 5 minutes | 1 minute | 4 | 15 minutes | 5 minutes | 1 minute | 1 minute |

| FSH010 | 1 | 15 minutes | 5 minutes | 1 minute | 5 | 15 minutes | 5 minutes | 1 minute | 1 minute |

| FSH011 | 2 | 15 minutes | 5 minutes | 1 minute | - | - | - | - | 1 minute |

FDM, full-day measurement; JBM, job-based method; sIMO, simplified International Maritime Organization; TBM, task-based method.

We compared the values obtained according to these four methods to evaluate differences, strengths, and limitations of each method when used to assess occupational noise exposure of fish harvesters.

3. Results

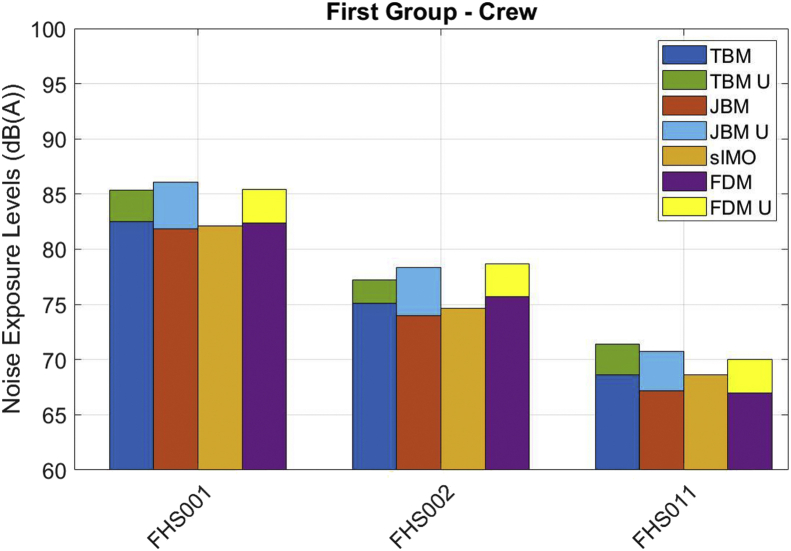

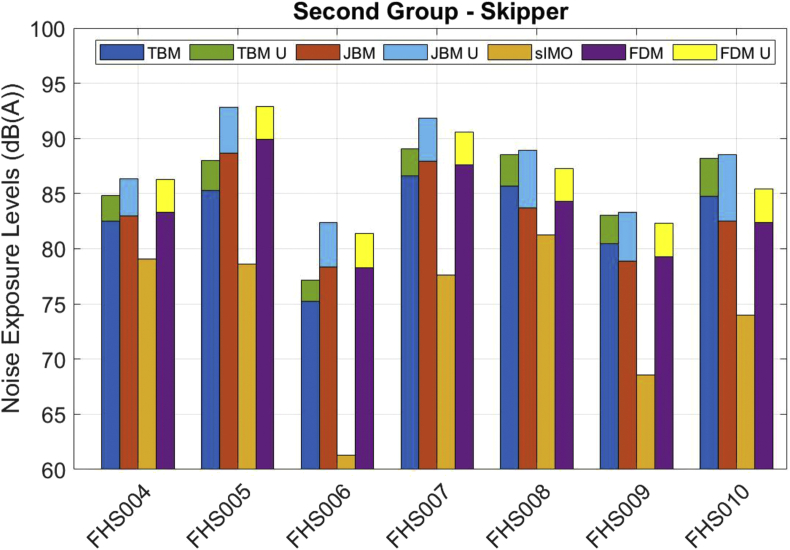

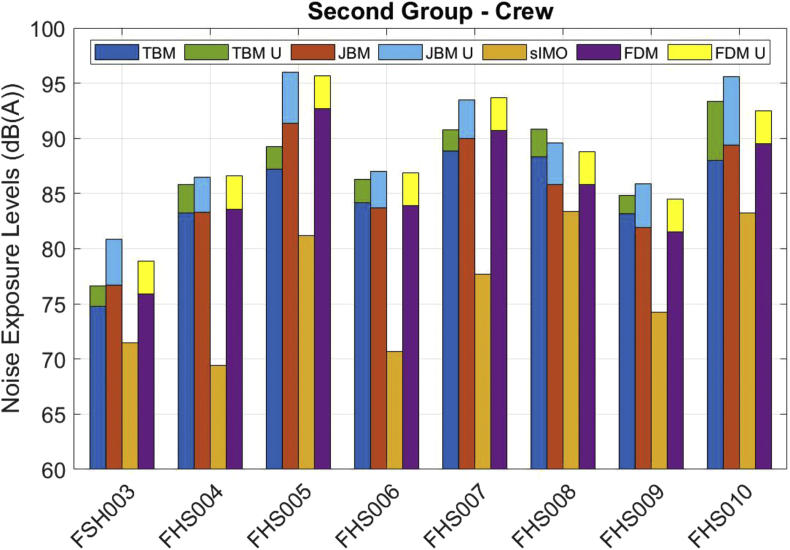

The results of the assessment of noise exposures using the four methods are reported in Fig. 1, Fig. 2, Fig. 3. The figures show the mean exposure values with the expanded uncertainty , which corresponds to the exact one-sided 95% upper confidence interval [19].

Fig. 1.

Eight-hour equivalent noise exposure levels and uncertainties U on the first group of vessels obtained with the four assessment methods. FDM, full-day measurement; JBM, job-based method; sIMO, simplified International Maritime Organization; TBM, task-based method; U, uncertainties.

Fig. 2.

Eight-hour equivalent noise exposure levels and uncertainties U of skippers on the second group of vessels obtained with the four assessment methods. FDM, full-day measurement; JBM, job-based method; sIMO, simplified International Maritime Organization; TBM, task-based method; U, uncertainties.

Fig. 3.

Eight-hour equivalent noise exposure levels and uncertainties U of crew members on the second group of vessels obtained with the four assessment methods. FDM, full-day measurement; JBM, job-based method; sIMO, simplified International Maritime Organization; TBM, task-based method; U, uncertainties.

The results in Fig. 1, Fig. 2, Fig. 3 are shown for two different groups of vessels, which were identified in a previous study where we performed an analysis of the sound sources on each vessel [18]: 1) vessels onboard which noise levels are mainly dominated by the engine and auxiliaries, such as small open boats, or decked vessels where light gear such as gill net or handline is used—FSH001, FSH002, and FSH011 belong to the first group; 2) vessels onboard which noise exposure is mainly dominated by fishing activities noise on the deck (handling and impacts of gear, deck machinery, catch, etc.), as onboard decked vessels that use heavy gear, such as crab pots, or trawls—FSH003, FSH004, FSH005, FSH006, FSH007, FHS008, FHS009, and FHS010 belongs to this group. In this group, noise exposures of skippers and crew members are analyzed separately. Detailed exposure levels are presented in the tabular form in Appendix A.

4. Discussion

The data presented in Fig. 1, Fig. 2, Fig. 3 highlight the risk of hazardous noise exposure (noise exposure levels above 85 dB(A) [21]) for personnel of vessels from the second group, especially in the case of crew members (Fig. 3).

In the following discussion, we consider the exposure levels reported using the FDM as a benchmark to assess the effectiveness of the other methods to assess noise exposure levels. The FDM considers the average daily exposure as measured by the dosimeter of a homogeneous noise exposure group over an entire working day, which is a measure of the true exposure of workers. Table 3 shows the difference in dB among the JBM, TBM, and sIMO method with the FDM. A difference of less than 1 dB is considered acceptable, as this is the standard uncertainty effect of the class 1 microphone used in this assessment [10].

Table 3.

Difference [dB] of noise exposure levels obtained via the TBM, JBM, sIMO method, and FDM. A reported negative difference means that the calculated level is lower than the corresponding FDM level

| Vessel ID | Difference of TBM with FDM |

Difference of JBM with FDM |

Difference of sIMO with FDM |

|||

|---|---|---|---|---|---|---|

| dB(A) | dB(A) | dB(A) | ||||

| First grouping: noise dominated by engine noise | ||||||

| FSH001 | All crew members | All crew members | All crew members | |||

| Lobster | 0.1 | −0.5 | −0.2 | |||

| FSH002 | All crew members | All crew members | All crew members | |||

| Cod | −0.6 | −1.7 | −1.1 | |||

| FSH011 | All crew members | All crew members | All crew members | |||

| Squid | 1.6 | 0.2 | 1.6 | |||

| Second grouping: noise dominated by noise of fishing activities | ||||||

| FSH003 | All Crew Members | All Crew Members | All Crew Members | |||

| Cod | −1.2 | 0.8 | −4.5 | |||

| FSH004 | Skipper | Crew | Skipper | Crew | Skipper | Crew |

| Whelk | −0.7 | −0.4 | −0.3 | −0.3 | −4.2 | −14.2 |

| FSH005 | Skipper | Crew | Skipper | Crew | Skipper | Crew |

| Crab | −5.5 | −4.7 | −1.4 | −1.3 | −11.3 | −11.5 |

| FSH006 | Skipper | Crew | Skipper | Crew | Skipper | Crew |

| Cod | −3.1 | 0.3 | 0.0 | −0.2 | −17.0 | −13.2 |

| FSH007 | Skipper | Crew | Skipper | Crew | Skipper | Crew |

| Crab | −1.8 | −1.1 | −0.7 | 0.3 | −10.0 | −13.0 |

| FSH008 | Skipper | Crew | Skipper | Crew | Skipper | Crew |

| Crab | 2.5 | 1.4 | 0.0 | −0.6 | −3.1 | −2.4 |

| FSH009 | Skipper | Crew | Skipper | Crew | Skipper | Crew |

| Caplin | 1.7 | 1.2 | 0.4 | −0.4 | −10.7 | −7.2 |

| FSH010 | Skipper | Crew | Skipper | Crew | Skipper | Crew |

| Shrimp | −1.4 | 2.3 | −0.1 | 0.1 | −8.4 | −6.2 |

FDM, full-day measurement; JBM, job-based method; sIMO, simplified International Maritime Organization; TBM, task-based method.

4.1. Noise exposure dominated by engine noise

The mean noise exposure values of Fig. 1 and the reported in Table 3 show that both the TBM and JBM are good estimators of the mean noise exposure level when compared with the noise exposure values obtained with FDM. JBM estimates are in general closer to FDM's, with always less than 1 dB, and similarly for between the TBM and FDM is generally greater.

The combined effect of the mean exposure level and uncertainty are leveling out the estimates of the JBM, TBM, and FDM. This behavior was already assessed in the study [8].

The prevalence of the propulsive engine and auxiliaries noise in the exposure is also supported the negligible difference between the sIMO method and FDM, as reported in Table 3. The sIMO method indeed considers only components of noise originating from the propulsive engine and auxiliaries as the samples of noise are obtained during sea trials, when only these sources are present.

4.2. Noise exposure dominated by fishing gear

In this case, the between the TBM and FDM is higher than the between the JBM and FDM, as reported in Table 1.

Although the sample of the TBM is obtained from noise levels measured during fishing operations with all the relevant noise components present, it fails to accurately represent the average exposure level, when compared with FDM. This is proven by TBM levels that differ from FDM's more than 1 dB in all the surveyed vessels, except for vessel FSH004. TBM assessment also gives narrower upper intervals of uncertainty, as shown in Fig. 2, Fig. 3, especially for crew members. This leads to a combined value of uncertainty and mean exposure levels that are lower than those of the JBM's method, in line with what is seen in the first group.

The between the JBM and FDM (see column 2 of Table 3) is generally smaller than the between the TBM and FDM. These values are lower than 1 dB for all the surveyed vessels, except for vessel FSH005. This is explained by the higher variability of the sample used in the JBM. This trend was expected because the dominating noise component arises from fishing operations that are highly variable in pattern and composition. Failure of the TBM to properly produce reliable exposure estimates in the presence of high noise level variability within tasks is confirmed in other works that assessed noise in other occupations [[22], [23], [24], [25]].

With regard to the sIMO, the data reported in Fig. 2 and in Table 1 show that this simplified method largely underestimates occupational noise exposure of fish harvesters, with always greater than 1 dB. This shows that when noise levels are dominated by nonstationary sources, the noise contributions from fishing gear and operations cannot be neglected. The between the sIMO and FDM calculated in Table 3 in the case of vessel FHS007 is particularly high (17 dB) due to the harsh weather during the survey.

4.3. Recommendations

According to the results presented in this paper, we can draw the following considerations:

-

•

TBM: This method is less time-consuming to implement than the JBM or the FDM. It only requires performing short time duration measures of noise exposure of tasks that compose a specified working activity, as opposed to the other two methods, that require more extensive and lengthy measurements. Nonetheless, this research shows a shortcoming in the ability to capture a proper estimate of noise exposure in the case of fishing activities. Differences between the TBM and FDM estimates are due to nonrepresentative samples of tasks that neglect the high degree of variability within the task. To be accurate, the job should be decomposed into a higher number of tasks [25], making it extremely difficult to implement for small-scale fishing operations. Hence, its application should be limited to the detection of the tasks related to high noise exposure.

-

•

JBM: This method requires a sample of noise exposure measurements having a fixed minimum cumulative duration. Samples must be representative of all noise components and, hence, requires a more extensive noise measurement program. Thus, because of the high variability of the noise components in the exposure, this research shows that the JBM captures the mean noise exposure levels and expanded uncertainty better than the TBM.

-

•

The sIMO method: This method is similar to the TBM, except for the use of noise levels of spaces obtained during sea trials instead of noise levels measured during specific tasks. The occupational noise exposure assessment performed according to this method is easy to implement and less time-consuming than the assessments performed according to the other methods. Noise mapping of spaces does not require the collection of a group of samples; the only required activity is the estimation of the time the workers spend performing a certain task. Unfortunately, this research shows that the sIMO method is not feasible to assess noise exposure, as it neglects noise components arising from the use of gear during fishing activities. Nonetheless, these components are dominant sources on several vessels.

-

•

FDM: This method calculates the average of the full-day measurements of noise exposure from personal noise dosimetry of a selected sample of workers. This method is the most time-consuming as it requires obtaining a measurement of noise exposure that spans for an entire work day. Measures are also more difficult to control due to their length in time, and they require the investigator to watch the tested workers closely to avoid the recording of spurious noise components.

We can conclude that the JBM is the most effective method to assess noise exposure on small fishing vessels and as it gives accurate results with a relatively small samples and takes into account the uncertainties in the measurement procedure and the high variance of noise exposure samples from fishing operations better than the other methods.

A limitation of the study is the sample size, which is not wide enough to be representative of the whole population of small-scale vessels form the province so that the consideration listed here might not be general. Nonetheless, these recommendations can be used for the assessment of noise exposure of similar cases as the one presented in this study and present a baseline for future similar research on the topic.

Funding

The authors acknowledge the support of the Newfoundland and Labrador Fish Harvesting Safety Association (NL-FHSA) and the SafetyNet Centre for Occupational Health and Safety.

This work was supported by Mitacs through the Mitacs Accelerate program.

Conflicts of interest

All authors have no conflicts of interest to declare.

Acknowledgments

The authors would like to thank Ms. Brenda Greenslade and Ms. Sharon Walsh from the Newfoundland and Labrador Fish Harvesting Safety Association (NL-FHSA), Mr. Mark Dolomount from the Professional Fish Harvesters Certification Board (PFHCB), and Dr. Barbara Neis from the SafetyNet Centre for Occupational Health and Safety of the Memorial University of Newfoundland for their kind help throughout the research activity. Special thanks go to all the vessel owners-operators and fish harvesters who allowed us to travel with them during their fishing trips and visit their vessels at the wharf.

Contributor Information

Giorgio Burella, Email: gburella@mun.ca.

Lorenzo Moro, Email: lmoro@mun.ca.

Appendix.A.

Numerical values of noise exposure for the used methods and uncertainties are reported in the tabular form for completeness in Table A-1, which corresponds to data presented in Fig. 1, Fig. 2, Fig. 3.

Table A-1.

Eight-hour equivalent noise exposure levels obtained with the four different methods and uncertainties

| Vessel ID | TBM |

JBM |

sIMO |

Full-day measurement |

|||

|---|---|---|---|---|---|---|---|

| dB(A) | dB(A) | dB(A) | dB(A) | ||||

| First grouping: noise dominated by engine noise | |||||||

| FSH001 | All crew members | All crew members | All crew members | All crew members | |||

| Lobster | 82.5 + 2.9 | 81.8 + 4.2 | 82.13 | 82.4 + 3.0 | |||

| FSH002 | All crew members | All crew members | All crew members | All crew members | |||

| Cod | 75.1 + 2.1 | 74.0 + 4.4 | 74.67 | 75.7 + 3.0 | |||

| FSH011 | All crew members | All crew members | All crew members | All crew members | |||

| Squid | 68.6 + 2.8 | 67.2 + 3.5 | 68.63 | 67.0 + 3.0 | |||

| Second grouping: noise dominated by noise of fishing activities | |||||||

| FSH003 | All crew members | All crew members | All crew members | All crew members | |||

| Cod | 74.8 + 1.9 | 76.7 + 4.2 | 71.44 | 75.9 + 3.0 | |||

| FSH004 | Skipper | Crew | Skipper | Crew | Skipper | Skipper | Crew |

| Whelk | 82.5 + 2.3 | 83.3 + 2.6 | 83.0 + 3.3 | 83.3 + 3.1 | 79.08 | 83.3 + 3.0 | 83.6 + 3.0 |

| FSH005 | Skipper | Crew | Skipper | Crew | Skipper | Skipper | Crew |

| Crab | 85.3 + 2.7 | 87.2 + 2.1 | 88.7 + 4.1 | 91.4 + 4.6 | 78.64 | 89.9 + 3.0 | 92.7 + 3.0 |

| FSH006 | Skipper | Crew | Skipper | Crew | Skipper | Skipper | Crew |

| Cod | 75.2 + 2.0 | 84.2 + 2.2 | 78.3 + 4.1 | 83.7 + 3.3 | 61.32 | 78.3 + 3.1 | 83.9 + 3.0 |

| FSH007 | Skipper | Crew | Skipper | Crew | Skipper | Skipper | Crew |

| Crab | 86.6 + 2.5 | 88.9 + 1.9 | 88.0 + 3.9 | 90.0 + 3.5 | 77.62 | 87.6 + 3.0 | 90.7 + 3.0 |

| FSH008 | Skipper | Crew | Skipper | Crew | Skipper | Skipper | Crew |

| Crab | 85.7 + 2.8 | 88.3 + 2.5 | 83.7 + 5.2 | 85.8 + 3.8 | 81.25 | 84.3 + 3.0 | 85.8 + 3.0 |

| FSH009 | Skipper | Crew | Skipper | Crew | Skipper | Skipper | Crew |

| Caplin | 80.5 + 2.5 | 83.2 + 1.6 | 78.9 + 4.4 | 81.9 + 4.0 | 68.57 | 79.3 + 3.0 | 81.5 + 3.0 |

| FSH010 | Skipper | Crew | Skipper | Crew | Skipper | Skipper | Crew |

| Shrimp | 84.8 + 3.5 | 88.0 + 5.3 | 82.5 + 6.0 | 89.4 + 6.2 | 73.98 | 82.4 + 3.0 | 89.5 + 3.0 |

References

- 1.National Institute for Occupational Safety and Health (NIOSH) National Institute for Occupational Safety and Health (NIOSH); Cincinnati, OH: 1998. Criteria for a recommended standard–occupational noise exposure. [Google Scholar]

- 2.Paini M.C., Morata T.C., Corteletti L.J., Albizu E., Marques J.M., Santos L. Audiological findings among workers from Brazilian small-scale fisheries. Ear Hear. 2009;30(1):8–15. doi: 10.1097/AUD.0b013e31818fba17. [DOI] [PubMed] [Google Scholar]

- 3.Levin J.L., Curry W.F., Shepherd S., Nalbone J.T., Nonnenmann M.W. Hearing loss and noise exposure among commercial fishermen in the gulf coast. J Occup Environ Med. 2016;58(3):306–313. doi: 10.1097/JOM.0000000000000642. [DOI] [PubMed] [Google Scholar]

- 4.Kaerlev L., Jensen A., Nielsen P., Olsen J., Hannerz H., Tuchsen F. Hospital contacts for noise-related hearing loss among Danish seafarers and fishermen: a population-based cohort study. Noise Heal. 2009;10(39):41. doi: 10.4103/1463-1741.40822. [DOI] [PubMed] [Google Scholar]

- 5.Novalbos J., Nogueroles P., Soriguer M., Piniella F. Occupational health in the andalusian fisheries sector. Occup Med (Chic Ill) 2008;58(2):141–143. doi: 10.1093/occmed/kqm156. [DOI] [PubMed] [Google Scholar]

- 6.Inaoka T., Kitano T., Nagano M., Miyakita T., Ueno T., Ohama N. Work history, health conditions and hearing loss of ishigaki fishermen. Nippon Eiseigaku Zasshi (Japanese J Hyg) 2011;47(5):923–933. doi: 10.1265/jjh.47.923. [DOI] [PubMed] [Google Scholar]

- 7.Food and Agriculture Organization (FAO) Food and Agriculture Organization (FAO); 2018. Fisheries and aquaculture statistics 2016; p. 104. [Google Scholar]

- 8.Zytoon M.A. Occupational noise exposure of fishermen aboard small and medium-scale fishing vessels. Int J Ind Ergon. 2013;43(6):487–494. [Google Scholar]

- 9.Peretti A., Nataletti P., Sisto R., Romana F., Tonazzo M., Bonfiglio P. Atti del Convegno dBA 2006– Rischi fisici negli ambienti di lavoro. Modena; Italy: 2006. Rumore e Vibrazioni nelle Imbarcazioni Adibite alla Pesca–parte 1. Misurazioni sui Pescherecci in Navigazione e Durante le Attivita’ di Pesca. Valutazione del Rischio; pp. 503–516. [Google Scholar]

- 10.International Organization for Standardization (ISO) International Organization for Standardization (ISO); 2009. ISO 9612:2009- Acoustics: determination of occupational noise exposure and estimation of noise-induced hearing impairment. [Google Scholar]

- 11.Seal A.B., Bise C.J. Case study using task-based, noise-exposure assessment methods to evaluate miner noise hazard. Min Eng. 2002;54(11):44–48. [Google Scholar]

- 12.Neitzel R., Yost M. Task-based assessment of occupational vibration and noise exposures in forestry workers. Am Ind Hyg Assoc J. 2002;63(5):617–627. doi: 10.1080/15428110208984748. [DOI] [PubMed] [Google Scholar]

- 13.Humann M.J., Sanderson W.T., Donham K.J., Kelly K.M. Task-based noise exposures for farmers involved in grain production. J Agric Saf Health. 2013;19(2):101–113. doi: 10.13031/jash.19.9540. [DOI] [PubMed] [Google Scholar]

- 14.Fulmer S., Buchholz B. Ergonomic exposure case studies in Massachusetts fishing vessels. Am J Ind Med. 2002;42(Suppl. 2):10–18. doi: 10.1002/ajim.10086. [DOI] [PubMed] [Google Scholar]

- 15.The Maritime Satefy committee (MSC) vol. 337. International Maritime Organization (IMO); 2012. p. 36. (Resolution MSC.337(91) Code on noise levels on board ships). [Google Scholar]

- 16.Turan O., Helvacioglu I.H., Insel M., Khalid H., Kurt R.E. Crew noise exposure on board ships and comparative study of applicable standards. Ships Offshore Struct. 2011;6(4):323–338. [Google Scholar]

- 17.Neitzel R.L., Berna B.E., Seixas N.S. Noise exposures aboard catcher/processor fishing vessels. Am J Ind Med. 2006;49(8):624–633. doi: 10.1002/ajim.20332. [DOI] [PubMed] [Google Scholar]

- 18.Burella G., Moro L., Colbourne B. Noise sources and hazardous noise levels on fishing vessels: the case of Newfoundland and Labrador’s fleet. Ocean Eng. 2019;173:116–130. [Google Scholar]

- 19.Grzebyk M., Thiéry L. Confidence intervals for the mean of sound exposure levels. Am Ind Hyg Assoc J. 2003;64(5):640–645. doi: 10.1202/430.1. [DOI] [PubMed] [Google Scholar]

- 20.Thiery L., Ognedal T. Note about the statistical background of the methods used in ISO/DIS 9612 to estimate the uncertainty of occupational noise exposure measurements. Acta Acust United with Acust. 2008;94(2):331–334. [Google Scholar]

- 21.Government of Newfoundland and Labrador . 2012. Occupational health and safety act. [Google Scholar]

- 22.Seixas N.S., Sheppard L., Neitzel R. Comparison of task-based estimates with full-shift measurements of noise exposure. Am Ind Hyg Assoc J. 2003;64(6):823–829. doi: 10.1202/524.1. [DOI] [PubMed] [Google Scholar]

- 23.Li N., Yang Q.L., Zeng L., Zhu L.L., Tao L.Y., Zhang H. Noise exposure assessment with task-based measurement in complex noise environment. Chin Med J (Engl) 2011;124(9):1346–1351. [PubMed] [Google Scholar]

- 24.Tao L., Zeng L., Wu K., Zhang H., Wu J., Zhao Y. Comparison of four task-based measurement indices with full-shift dosimetry in a complicated noise environment. Int J Ind Ergon. 2016;53:149–156. [Google Scholar]

- 25.Virji M.A., Woskie S.R., Waters M., Brueck S., Stancescu D., Gore R. Agreement between task-based estimates of the full-shift noise exposure and the full-shift noise dosimetry. Ann Occup Hyg. 2009;53(3):201–214. doi: 10.1093/annhyg/mep010. [DOI] [PubMed] [Google Scholar]