Abstract

The use of low intensity ultrasound has gotten surprising consideration over the last decade as a method for enhancing the catalytic activity of enzyme. Ultrasounds have the potential to significantly influence the activity of the enzymatic processes, provided that the energy input is not so high as to inactivate the enzyme. By providing the variation in parameters, various physical and chemical effects can be attained that can enhance the enzymatic reaction. Ultrasonic reactors are known for their application in bioprocesses. However, the potential of their applications is still limited broadly due to the lack of proper information about their operational and performance parameters. In this review, the detailed information about ultrasonic reactors is provided by defining the different types of reactors and number and position of ultrasonic transducers. Also, it includes mechanism of intensification and influence of ultrasonic parameters (intensity, duty cycle, and frequency) and enzymatic factors (enzyme concentration, temperature, and pH) on the catalytic activity of enzyme during ultrasound treatment.

Keywords: Ultrasound, Ultrasonic reactors, Enzyme kinetic, Enzymatic reaction, Sonochemical reaction

Introduction

The rapid growth in biotechnology is continually attracting new strategies and solutions for further advancement of bioprocess performances. Ultrasound has gotten surprising consideration over the last decade as a rapid method for enhancing the efficiency of bioprocesses (Nadar and Rathod 2017). Ultrasonication is a branch of acoustics that can be applied to solids, liquids, and gases at frequencies above the human hearing range. Ultrasound is defined as a sound wave having a frequency that exceeds the human ear’s hearing limit (20 kHz). In a somewhat arbitrary fashion, ultrasound is considered existing in one of two broad regimes termed (i) low intensity ultrasound and (ii) high intensity ultrasound (Saito et al. 2004). Low intensity ultrasound uses a low power density (< 0.1Wcm−2) and a high frequency (0.1 to 100MHz), whereas high intensity ultrasound uses a high-power density (> 1 Wcm−2) and lower frequencies (<0.1MHz) (Rokhina et al. 2009).

Ultrasound waves consist of a cyclic succession of expansion (rarefaction) and compression phases imparted by mechanical vibration (Tole and Ostensen 2005). Compression cycles exert a positive pressure and push the liquid molecules together, while expansion cycles exert a negative pressure and pull the molecules apart. This causes cavitation and bubble collapse process (Vernès et al. 2020). In the presence of the small solid surfaces (composite reactions), the collapse of bubbles near the solid surface leads to formation of microjets which improve the mass transfer and speed up the transport process. In the time interval of cavitation and bubble collapse, the temperature and pressure inside the bubble reach greater than 5000 K and 1000 atm (Bhangu and Ashokkumar 2017). As an effector of such local variation, ultrasounds have the potential to influence the activity of the enzymatic reactions, if the energy input is not so high as to inactivate the enzyme (Rojas et al. 2016). Ultrasounds (US) having frequencies ranging from 20 kHz to 5 MHz are a type of mechanical energy which do not shows ionizing radiation properties (Vartolomei et al. 2019). In earlier research, ultrasound having a frequency above 30 kHz was used as a method of enzyme inactivation in order to prevent the nutritive value of fruits and vegetables from undesirable effects (browning and off flavor), but recently, it has been found that activity of enzyme can be enhanced under milder condition of ultrasound irradiation. Enzymes are very sensitive to ultrasound treatment. An enzyme’s catalytic activity is affected due to the continuous generation of waves and cavitation bubbles that leads to alteration in the loop and domain regions of enzyme (Nadar and Rathod 2017).

An ultrasonic (US) reactor is a system used for the production of ultrasound. Different types of US reactor are employed for various applications dependent upon their special features. The occurrence of cavitation and acoustic streaming are the most important features of ultrasonic reactor design (Fang et al. 2018; Kumar et al. 2007a, 2007b). Acoustic streaming causes physical effects and also enhances chemical processing limited by mass transfer. Sonochemical reactors are applied in various chemical and physical processes such as biotechnology, chemical synthesis, wastewater treatment, polymers degradation, waste water treatment, extraction, emulsification, crystallization, petrochemical industries, and leaching (Asgharzadehahmadi et al. 2016; Sutkar and Gogate 2009). These reactors are very sensitive and unresistant to operational parameters. The proper knowledge and understanding of physical and chemical phenomena is required to control the operational parameters (Asgharzadehahmadi et al. 2016).

Over the past years, there have been relatively many review papers discussing the application of ultrasound in areas of chemical engineering, textile engineering, and medicine (Zhang 2017; Carovac et al. 2011). However, to date there have been relatively few review articles considering the use of ultrasound in bioprocess and biotechnology. An early review, that considered the manner in which ultrasound affects biotechnological process, was published by Sinisterra (1992) under the title “Application of ultrasound to biotechnology.” However, due to the unavailability of suitable published material at that time, the author of that work presented a number of unpublished examples of his own research (Sinisterra 1992). In 2003, Chisti reviewed published studies of reactions catalyzed by live cells using ultrasound, concentrating totally in that work on the enhancement effect of ultrasonic waves on live biological system and the design requirements for ultrasonic reactors (Chisti 2003). Rokhina et al. reviewed the use of low frequency ultrasound in biotechnology and focused mainly in areas where sonochemistry can be profitably connected with biotechnology (Rokhina et al. 2009). Recently, a mini review of the ultrasound-assisted intensification of enzyme activity has been published (Nadar and Rathod 2017). In that work, the authors presented an overview of the influence of ultrasonic parameters on enzyme activity along with preparation techniques for immobilization of ultrasound-irradiated enzyme(s) (Nadar and Rathod 2017).

The aim of the present review article is to provide a suitably deep yet widely accessible analysis of factors and developments associated with the exposure of enzymatic reactions to ultrasound. Also, we will briefly discuss the mechanism of enhancement of enzymatic activity and also provide in-depth knowledge about ultrasonic reactors and their types. Finally, ultrasonic and other factors that affect the enzyme activity will be discussed. This review will attempt to discuss all aspects and provide all the aspects related to enhancement of the activity of different enzymes within a single US generating platform. The information presented in this review will potentially be useful to those wishing to use US in bioprocess technologies, such as food processing, enzymatic conversions, chemical synthesis using enzyme, and for research scholars interested in fundamental studies of enzyme regulation using ultrasound.

Mechanism of enhancement of enzymatic activity using ultrasound

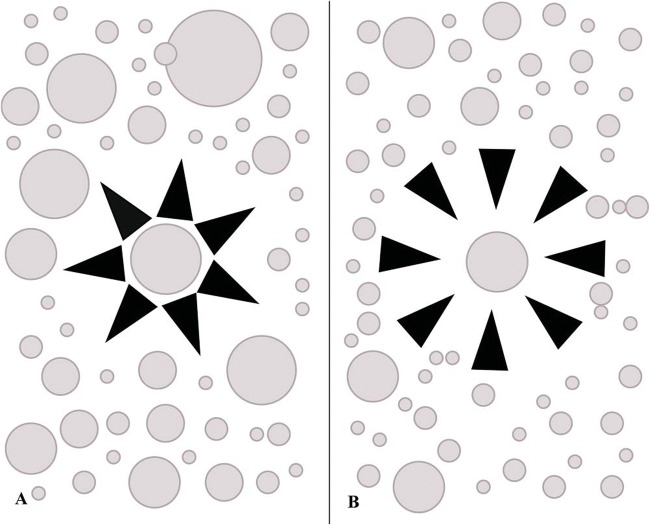

Introduction of ultrasound in liquid medium results in the cyclical generation of bubbles followed by their collapse. This process is termed as acoustic cavitation (Ashokkumar 2011). The process of cavitation is represented in Fig. 1. The collapse of bubbles leads to formation of microjets which improve the mass transfer and speed up the transport of solution reaction components (including the enzyme) both throughout solution and, also crucially, towards the solid or liquid interface (Yachmenev et al. 2002). Ultrasound energy can also change the secondary and tertiary structures of enzyme molecules in such a way as to affect the enzyme activity. A study conducted on β-D-glucosidase showed an increase in α-helix content and a decrease in parallel and antiparallel β-sheet of β-D-glucosidase upon the application of ultrasound with significant activation of enzyme activity (Sun et al. 2019). One additional feature that is often overlooked is that cavitation creates a hydrodynamic shear force in the liquid medium due to the quick breakdown of microbubbles, which helps in the deterioration of large materials into small particles, in this manner fundamentally expanding the surface zone for enzymatic attack (Dijkink and Ohl 2008; Badve et al. 2015).

Fig. 1.

Cavitation bubble formation. A Rarefaction. B Compression (Islam et al. 2014)

In principle, sonication can result in the formation of free radicals (involving hydrogen and hydroxyl group) due to the sonolysis of water with subsequent reaction and rearrangement to create super-oxides and hydrogen peroxide also taking place (Riesz and Kondo 1992; Riesz et al. 1985). These free radicals can interact with the amino acid residues of enzymes thereby damaging their chemical structure and decreasing the activity of the enzyme (Salvi et al. 2001; Dean et al. 1991). However, the probability of enzyme molecules interacting with these free radicals is small due to the typically low concentration of both the generated radical species and the enzyme itself. Ultrasonic shockwaves produced due to sudden collapse of microbubbles can also stabilize the enzyme by preventing the agglomeration of the enzyme to a precipitated form (Subhedar and Gogate 2013).

Ultrasonic reactors for enhancement of enzymatic reaction

An ultrasonic reactor is a system that has the capability to transform electrical energy into ultrasonic vibrations. A reactor consists of a generator, a transducer, and an application system (Khaire and Gogate 2021; Savin et al. 2007). The generator is the source of energy, and the transducer converts the energy produced by generator into mechanical energy in the form of vibrations (Cárcel et al. 2012). Magneto-strictive and piezoelectric transducers are the most common type of transducers used in ultrasonic reactors. Magneto-strictive transducers are made from high strength metallic alloys, and they are very stable, consistent, and resistant to degradation. However, piezoelectric transducers are most commonly used, because of their high energy transfer efficiency as compared to magneto-strictive transducers (Subhedar and Gogate 2013). Reactor efficiency can be enhanced by choosing an appropriate type of transducer and having sufficient knowledge about the number of transducers and their position in the reactor. Use of multiple transducers in the reactor helps to create a uniform distribution. Multiple transducers provide better control of hydrodynamic conditions, and they allow mixing and also yield the ability to use multiple frequencies. The use of ultrasonic waves always heats the solution and reactor during use. Therefore, cooling and temperature regulation of the system should also be carefully planned (Gogate and Patil 2017).

Types of ultrasonic reactors

Ultrasonic horns and ultrasonic baths are the most common type of ultrasonic reactor used for enhancement of enzymatic activity at laboratory scale. In the ultrasonic horn reactor, the transmitting element which submerges in the liquid medium consists of a horn linked to the transducer. Ultrasonic horn is an immersion type of reactor in which the ultrasonic waves are directly transmitted into the medium via the vibrating horn (Chemat and Khan 2011). Cavitation effects are very high close to the vibrating horn and decrease exponentially on moving away from the vibrating surface. The efficiency of horn type reactors is very low for large-scale operations as compared to reactors based on multiple transducers (Sabnis et al. 2020) Additionally, erosion of the horn tip can occur as a result of the high power applied to the horn, and particle peeling can increase the chance of stress induced fatigue failure (Gogate and Kabadi 2009). However, certain modifications can be made in the shape and position of the horn to increase the sonochemical yield. Barbell-shaped horns, donut-shaped ultrasonic horns, concentrator horns, and telsonic horns are some of the modified horn examples (He et al., 2015). However, for fundamental physical reasons, these horn designs are not powerful enough for scale up purposes because they lack the capacity for transmission of significant energy into large tank volumes (Subhedar and Gogate 2013). Horns can also be used longitudinally in the vessel for different applications. Longitudinal horns usually have higher surface area of irradiation in the medium, and the magnitude of energy efficiency in this type of ultrasonic is higher than the conventional one. Moreover, the broad irradiation area of longitudinal ultrasonic horns leads to uniform distribution of cavitational activity in the whole reactor volume, a situation which can be more beneficial in pilot scale, in comparison with simple ultrasonic horns (Gogate and Patil 2017).

Ultrasonic baths are also commonly used ultrasonic reactors in which transducers are attached at the bottom of the reactor and ultrasound irradiations are transmitted into the system indirectly through the base and/or walls of the bath (Dong et al. 2020). The cavitational intensity of ultrasonic baths is less as compared to ultrasonic horns because they are indirect irradiation-based ultrasonic reactors. They are generally applied where specific ultrasonic intensity is not required. The maximum operating capacity of the ultrasonic bath is about 3 l, but baths with higher capacity (up to 1000 l) are also possible with some modification in terms of larger number of transducers in different configurations. Although ultrasonic bath-type reactors are suitable for laboratory-scale to large-scale operations, there is a limit to the number of transducers that can be attached to the system for a large-scale operation (Asgharzadehahmadi et al. 2016). The design of dual frequency and triple-frequency flow-cell-type reactors are based on the use of multiple transducers, and they can be very effective in continuous operations (Kumar et al. 2007a, 2007b). These reactors produce a beat frequency inside a chamber that continually oscillates through the fluid in the chamber thereby ensuring constant processing. There are two sets of magneto-strictive transducers (i.e., three in each side) attached on the two opposite walls in a dual frequency flow cell. In the case of a triple frequency flow cell, there are three transducers attached in each set per side such that they have equal power dissipation on each side. The use of multiple transducers is helpful in concentrating the ultrasonic waves towards the central zone of vessel (Asgharzadehahmadi et al. 2016; Gogate and Kabadi 2009) (Table 1).

Table 1.

Comparison of cavitational yield in ultrasonic reactors (Gogate and Kabadi 2009)

| Type of reactor | Cavitational yield (mol/W) |

|---|---|

| Ultrasonic horn | 0.0005 |

| Ultrasonic bath | 0.01 |

| Dual frequency flow cell | 0.011 |

| Triple frequency flow cell | 0.018 |

| Longitudinal horn reactor | 0.077 |

Cavitation yield measurements can be determined as the amount of iodine liberated when potassium iodide solutions are subjected to ultrasound (Weissler’s reaction (Weissler et al., 1950)). The general unit for cavitational yield is μmol/(W/mL) where W is the power supplied in Watts.

Factors affecting enzymatic reactions

Ultrasonic frequency

The frequency of an ultrasound is an important factor for enzymatic reactions. The ultrasound frequency has a direct influence on the cavitation bubble collapse. Ultrasonic irradiation of enzyme at an optimum frequency can cause conformational changes in the enzyme’s protein structure leading to changes in its activity. Research was conducted on the effect of ultrasound frequency on cellulase activity, which shows the increase in cellulase activity due to low frequency ultrasound with short duration of time (de Carvalho Silvello et al. 2020). The researchers observed incremental increases in the catalytic activity of immobilized cellulose by 6.6, 14.8, 17.8, and 10.4% at frequencies of 18, 20, 24, and 26 kHz, respectively. This increase in catalytic activity was suggested to be due to the US energy’s ability to increase the surface area of substrate in contact with the immobilized enzyme molecules. However, a very slight decrease was observed in catalytic activity at 29 kHz which was suggested to be due to the rapid collapse of cavitation bubbles at these higher frequencies, leading to formation of excess heat (Wang et al. 2012a, 2012b). In other research, the effect of ultrasound frequency on alkaline protease catalytic activity was analyzed by exposing enzyme to three different frequencies 40, 80, and 100 kHz. The yields under ultrasound were better than that of shaking and at 80 kHz, and the highest yield was found. Thus, ultrasound irradiation using an optimum frequency facilitates improved results (Xiao et al. 2011).

Ultrasonic power or intensity

Ultrasonic intensity is an important factor which plays a major role in enhancing or inhibiting the effects of ultrasound on enzyme activity. Sun et al. (2019) conducted an experiment on the effect of ultrasonic intensity on β-d-glucosidase catalytic activity and found that the activity was increased with increasing ultrasonic intensity up to 181.5 W/cm2. However, in that study the authors found that the enzyme activity started decreasing after 181.5 W/cm2. These results indicated that use of low intensity ultrasound may create cavitation and mechanical oscillation which leads to conformational changes in enzyme and increase its contact with the substrate. Under the condition of high intensity ultrasound, inhibition of enzyme activity occurred. The reasons for this decrease were suggested to either due to the mechanical denaturation of the enzyme by US or its chemical denaturation due to interaction with free radicals in solution (Sun et al. 2019). In another study, the effect of ultrasound intensity on cellulase activity was explored by irradiating an enzyme to various intensities with maximum activity observed at 17.3W/cm2. The explanation for this was that low intensity ultrasound broke the weak chemical interactions (such as hydrogen bonds or Van der Waals forces) which allowed more rapid conformational alteration within the active site of enzyme (Subhedar and Gogate 2014).

Duty cycle

The duty cycle (DC) is another important parameter in ultrasound that can affect the enzyme activity, when we talk about pulsed or discontinuous ultrasound, DC is one of the things that we talk about with respect to pulsing the sound. A DC is on time to total time (Meunier et al. 2007). The use of a duty cycle (a discontinuous regular application) is more economical than designs based on continuous energy application. It keeps the temperature of the reaction sample at optimum levels and protects the enzyme from denaturation. It also helps to control the ultrasonic exposure of the enzyme and further leads to a reduction in energy consumption (Fretias et al., 2019). A study was conducted on β-d-glucosidase for evaluation of the effect of a duty cycle on its catalytic activity. The results indicated that the activity was enhanced when the duty cycle application fraction was between 33.33 and 40% of the total time. However, a slight decrease in yield was found when duty cycle ranged from 40 to 100%. The reason for the decrease in yield at higher duty cycle was due to extensive cavitation which affected the active conformation of the enzyme (Omar et al. 2017; Freitas et al., 2019). A lower duty cycle seems to be a better choice for the activation of an enzyme (Sun et al., 2019). In another study on lipase, the trialing of different duty cycles showed a maximum in enzyme activity at a DC of 66.67%. The exact reason for the observed maximum activity at a DC of 66.67% is unknown (Jadhav & Gogate, 2014).

Concentration of enzyme

Concentration of enzyme plays a critical role in analyzing the effects of ultrasound irradiation. At very low enzyme concentrations, the probability of enzyme molecules effectively interacting with micro streams generated due to acoustic cavitation is quite small (Liu et al., 2008; Nadar & Rathod, 2017). Conversely, above the optimum concentration, excessive enzyme molecules impede the energy-transfer process, thereby decreasing the available energy for cavitational phenomenon (Save et al., 1994). Excess enzyme molecules also increase the probability of forming aggregates of enzymes due to cavitation, which results in a lower degree of enhancement. Enzyme kinetics can also be affected by high enzyme concentrations with a relative decrease in the specific rate of reaction due to competition for substrate by enzyme molecules at high concentration of enzyme (Jadhav & Gogate, 2014).

pH and temperature

pH and temperature both play important roles in determining the effects of ultrasound irradiation-based enhancement of enzyme activity (Sun et al., 2019; Huang et al., 2017). Extremes of pH and temperature can lead to partial or complete inhibition of enzyme catalytic activity. Wei-ming Wang et al. (2012) investigated the effect of pH on the ultrasound enhancement of amylase activity applied for the enzymatic treatment of cotton fabric (Pan et al., 2001; Zhang et al., 2016). The authors found that treatment efficiency was significantly increased when pH values were increased to 6. However, antagonistic effects have been found for the catalytic activity of amylase at pH values above 6 (Wang et al., 2012). Souza et al. studied the effects of temperature on the activity of alpha amylase on ultrasound treatment (Souza et al., 2013a, b; Leaes et al., 2013). They observed three times increase in catalytic activity of alpha amylase when the temperature was increased by 40% with concomitant application of ultrasonic irradiation. The results indicated that the cavitation is higher at lower temperature and optimum temperature range is required to break strong interaction such as hydrogen bonding, dipole attractions, and Van der Waal forces existing between the substrate and active sites on the enzyme (Souza et al., 2013a, b).

Conclusion

In summary, low intensity ultrasound can be used as a tool for enhancement of enzymatic activity. It is a very effective tool for activation of enzymes by changing the structural conformation of the active site and can also be effective in improving the stability of enzymes, maximizing solution transportation, and preventing unwanted protein aggregation. Cavitation phenomenon (produced from ultrasound) can be utilized to attain higher reaction rates. Choosing an appropriate reactor is a critical task for specific enzymatic enhancement reactions. An ultrasonic reactor appears to be very effective for enzymatic intensification reactions. It is economically beneficial due to their special features such as acoustic cavitation and acoustic streaming. Parameters such as ultrasonic frequency, ultrasonic intensity, duty cycle, temperature, pH, and treatment time determine the activation or inhibition of enzyme. Controlling these parameters and maintaining uniform distribution of cavitational activity within the reactor is one of the important challenges to be faced in optimization and scaling-up of ultrasonic reactors. There is lack of proper information about the optimal enzyme working environment. Therefore, it is necessary to collect complete information on ultrasonic effects under various experimental conditions. This will be helpful in developing mathematical models for easy (easier) prediction of changes in the efficiency of the process.

Acknowledgements

We wish to show our appreciation to Institute of Chemical Technology, Mumbai, for providing us the right environment to write this review.

Footnotes

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Asgharzadehahmadi S, Raman AAA, Parthasarathy R, Sajjadi B (2016) Sonochemical reactors: review on features, advantages and limitations. Renew Sust Energ Rev 63:302–314. 10.1016/j.rser.2016.05.030

- Ashokkumar M (2011) The characterization of acoustic cavitation bubbles–an overview. Ultrason Sonochem 18(4):864–872. 10.1016/j.ultsonch.2010.11.016 [DOI] [PubMed]

- Badve MP, Alpar T, Pandit AB, Gogate PR, Csoka L (2015) Modeling the shear rate and pressure drop in a hydrodynamic cavitation reactor with experimental validation based on KI decomposition studies. Ultrason Sonochem 22:272–277. 10.1016/j.ultsonch.2014.05.017 [DOI] [PubMed]

- Bhangu, SK, Ashokkumar, M (2017). Theory of sonochemistry. In Sonochemistry 1–28 Springer, Cham. 10.1007/978-3-319-54271-3_1

- Cárcel JA, García-Pérez JV, Benedito J, Mulet A (2012) Food process innovation through new technologies: use of ultrasound. J Food Eng 110(2):200–207. 10.1016/j.jfoodeng.2011.05.038

- Carovac A, Smajlovic F, Junuzovic D (2011) Application of ultrasound in medicine. Acta Informatica Medica 19(3):168. 10.5455/aim.2011.19.168-171 [DOI] [PMC free article] [PubMed]

- Chemat F, Khan MK (2011) Applications of ultrasound in food technology: processing, preservation and extraction. Ultrason Sonochem 18(4):813–835. 10.1016/j.ultsonch.2010.11.023 [DOI] [PubMed]

- Chisti Y (2003) Sonobioreactors: using ultrasound for enhanced microbial productivity. Trends Biotechnol 21(2):89–93. 10.1016/s0167-7799(02)00033-1 [DOI] [PubMed]

- de Carvalho Silvello MA, Martínez J, Goldbeck R (2020) Low-frequency ultrasound with short application time improves cellulase activity and reducing sugars release. Appl Biochem Biotechnol:1–14. 10.1007/s12010-019-03148-1 [DOI] [PubMed]

- Dean RT, Hunt JV, Grant AJ, Yamamoto Y, Niki E (1991) Free radical damage to proteins: the influence of the relative localization of radical generation, antioxidants, and target proteins. Free Radic Biol Med 11(2):161–168. 10.1016/0891-5849(91)90167-2 [DOI] [PubMed]

- Dijkink R, Ohl CD (2008) Measurement of cavitation induced wall shear stress. Appl Phys Lett 93(25):254107. 10.1063/1.3046735

- Dong Z, Delacour C, Mc Carogher K, Udepurkar AP, Kuhn S (2020) Continuous ultrasonic reactors: design, mechanism and application. Materials 13(2):344. 10.3390/ma13020344 [DOI] [PMC free article] [PubMed]

- Fang Y, Yamamoto T, Komarov S (2018) Cavitation and acoustic streaming generated by different sonotrode tips. Ultrason Sonochem 48:79–87. 10.1016/j.ultsonch.2018.05.011 [DOI] [PubMed]

- Freitas VOD, Matte CR, Poppe JK, Rodrigues RC, Ayub MA (2019) Ultrasound-assisted transesterification of soybean oil using combi-lipase biocatalysts. Braz J Chem Eng 36(2):995–1005. 10.1590/0104-6632.20190362s20180455

- Gogate PR, Kabadi AM (2009) A review of applications of cavitation in biochemical engineering/biotechnology. Biochem Eng J 44(1):60–72. 10.1016/j.bej.2008.10.006

- Gogate, PR, Patil, PN (2017) Sonochemical reactors. In Sonochemistry (pp. 255-281). Springer, Cham. 10.1007/978-3-319-54271-3_10

- He T, Xin-Quan Y, Yang Z (2015) Optimization design for ultrasonic horn with large amplitude based on genetic algorithm. Journal of Vibroengineering 17(3):1157–1168. https://www.jvejournals.com/article/15636

- Huang G, Chen S, Dai C, Sun L, Sun W, Tang Y et al (2017) Effects of ultrasound on microbial growth and enzyme activity. Ultrason Sonochem 37:144–149. 10.1016/j.ultsonch.2016.12.018 [DOI] [PubMed]

- Islam MN, Zhang M, Adhikari B (2014) The inactivation of enzymes by ultrasound—a review of potential mechanisms. Food Rev Int 30(1):1–21. 10.1080/87559129.2013.853772

- Jadhav SH, Gogate PR (2014) Intensification in the activity of lipase enzyme using ultrasonic irradiation and stability studies. Ind Eng Chem Res 53:1377–1385. 10.1021/ie403419e

- Khaire RA, Gogate PR (2021) Understanding the role of different operating modes and ultrasonic reactor configurations for improved sonocrystallization of lactose. Chemical Engineering and Processing-Process Intensification 159:108212. 10.1016/j.cep.2020.108212

- Kumar A, Gogate PR, Pandit AB (2007a) Mapping of acoustic streaming in sonochemical reactors. Ind Eng Chem Res 46(13):4368–4373. 10.1021/ie060 575q

- Kumar A, Gogate PR, Pandit AB (2007b) Mapping the efficacy of new designs for large scale sonochemical reactors. Ultrason Sonochem 14(5):538–544. 10.1016/j.ultsonch.2006.11.005 [DOI] [PubMed]

- Leaes EX, Lima D, Miklasevicius L, Ramon AP, Dal Prá V, Bassaco MM et al (2013) Effect of ultrasound-assisted irradiation on the activities of α-amylase and amyloglucosidase. Biocatalysis and Agricultural Biotechnology 2(1):21–25. 10.1016/j.bcab.2012.08.003

- Liu Y, Jin Q, Shan L, Liu Y, Shen W, Wang X (2008) The effect of ultrasound on lipase-catalyzed hydrolysis of soy oil in solvent-free system. Ultrason Sonochem 15(4):402–407.10.1016/j.ultsonch.2007.09.013 [DOI] [PubMed]

- Meunier JM, Holland CK, Lindsell CJ, Shaw GJ (2007) Duty cycle dependence of ultrasound enhanced thrombolysis in a human clot model. Ultrasound Med Biol 33(4):576–583. 10.1016/j.ultrasmedbio.2006.10.010 [DOI] [PMC free article] [PubMed]

- Nadar SS, Rathod VK (2017) Ultrasound assisted intensification of enzyme activity and its properties: a mini-review. World J Microbiol Biotechnol 33(9):170. 10.1007/s11274-017-2322-6 [DOI] [PubMed]

- Omar, WSAW, Sulaiman, AZ, Ajit, A, Chisti, Y, Chor, ALT (2017) Effect of flow rate, duty cycle, amplitude, and treatment time of ultrasonic regimens towards Escherichia coli harbouring lipase. In IOP Conference Series: Materials Science and Engineering 206(1): 012021. IOP Publishing. 10.1088/1757-899X/206/1/012021

- Rokhina EV, Lens P, Virkutyte J (2009) Low-frequency ultrasound in biotechnology: state of the art. Trends Biotechnol 27(5):298–306. 10.1016/j.tibtech.2009.02.001 [DOI] [PubMed]

- Sabnis SS, Raikar R, Gogate PR (2020) Evaluation of different cavitational reactors for size reduction of DADPS. Ultrason Sonochem 69:105276. 10.1016/j.ultsonch.2020.105276 [DOI] [PubMed]

- Souza M, Mezadri ET, Zimmerman E et al (2013a) Evaluation of activity of a commercial amylase under ultrasound-assisted irradiation. UltrasonSonochem 20:89–94. 10.1016/j.ultsonch.2012.05.012 [DOI] [PubMed]

- Subhedar PB, Gogate PR (2013) Intensification of enzymatic hydrolysis of lignocellulose using ultrasound for efficient bioethanol production: a review. Ind Eng Chem Res 52(34):11816–11828. 10.1021/ie401286z

- Subhedar PB, Gogate PR (2014) Enhancing the activity of cellulase enzyme using ultrasonic irradiations. J Mol Catal B Enzym 101:108–114. 10.1016/j.molcatb.2014.01.002

- Sun Y, Zeng L, Xue Y, Yang T, Cheng Z, Sun P (2019) Effects of power ultrasound on the activity and structure of β-D-glucosidase with potentially aromaenhancingcapability. Food science & nutrition 7(6):2043–2049. https://doi.org/10.1002/fsn3.1035 [DOI] [PMC free article] [PubMed]

- Sutkar VS, Gogate PR (2009) Design aspects of sonochemical reactors: techniques for understanding cavitational activity distribution and effect of operating parameters. Chem Eng J 155(1-2):26–36 10.1016/j.cej.2009.07.021

- Tole, NM, Ostensen, H (2005) Basic physics of ultrasonographic imaging. World Health Organization. https://apps.who.int/iris/handle/10665/43179

- Vartolomei A, Calinescu I, Vinatoru M, Gavrila AI (2019) Intensification of the enzymatic esterification process by ultrasounds. Rev Chim 70(1):41–44. 10.37358/RC.19.1.6847

- Vernès, L, Vian, M, Chemat, F (2020). Ultrasound and microwave as green tools for solid-liquid extraction. In Liquid-Phase Extraction (pp. 355-374). Elsevier. 10.1016/b978-0-12-816911-7.00012-8

- Wang Z, Lin X, Li P, Zhang J, Wang S, Ma H (2012a) Effects of low intensity ultrasound on cellulase pretreatment. Bioresour Technol 117:222–227. 10.1016/j.biortech.2012.04.015 [DOI] [PubMed]

- Wang W, Yu B, Zhong C (2012b) Use of ultrasonic energy in the enzymatic desizing of cotton fabric. J Clean Prod 33:179–182. 10.1016/j.jclepro.2012.04.010

- Weissler A, Cooper HW, Snyder S (1950) Chemical effect of ultrasonic waves: oxidation of potassium iodide solution by carbon tetrachloride. J Am Chem Soc 72(4):1769–1775. 10.1021/ja01160a102

- Xiao Y, Yang L, Mao P, Zhao Z, Lin X (2011) Ultrasound-promoted enzymatic synthesis of troxerutin esters in nonaqueous solvents. Ultrason Sonochem 18(1):303–309. 10.1016/j.ultsonch.2010.06.010 [DOI] [PubMed]

- Yachmenev VG, Bertoniere NR, Blanchard EJ (2002) Intensification of the bio-processing of cotton textiles by combined enzyme/ultrasound treatment. J Chem Technol Biotechnol 77(5):559–567. 10.1002/jctb.579

- Zhang, Y (2017) Study on the ultrasonic application in chemistry and chemical engineering. In 2016 International Conference on Modern Management, Education Technology, and Social Science (MMETSS 2016). Atlantis Press.10.2991/mmetss-16.2017.79

- Zhang D, Luo Y, Chu S, Zhi Y, Wang B, Zhou P (2016) Enhancement of cellulase and xylanase production using pH-shift and dissolved oxygen control strategy with Streptomyces griseorubens JSD-1. Appl Biochem Biotechnol 178(2):338–352. 10.1007/s12010-015-1875-9 [DOI] [PubMed]