Abstract

Hollow sandcrete blocks constitute more than 90% of residential building construction in developing countries especially in West Africa. Over-reliance on dredged river sands and conventional ordinary Portland cement (OPC) contributes to environmental degradation and post-construction problems such as swelling and shrinkage-induced cracks prevalent in construction projects. The study investigates potential utilization of locally available materials such as laterite, calcite and calcined clay as ternary and quaternary blends to replace cement and quarry dust as 100% replacement of river sand with the aid of Taguchi-Response surface methodology approach. Optimum ternary blend of 24% calcined clay +1% calcite +75% OPC is recommended to achieve volume stability, higher compressive strength and higher flexural load capacity. Alternatively, ternary blends of 24% calcite +4% calcined clay +72% OPC can also be utilized. The improved mechanical properties were attributed to the Na- and Ca-rich aluminosilicates provided by the blended cements. Successful utilization of ternary and quaternary blended cements to produce stronger, durable and eco-friendly sandcrete blocks depends on utilization of high binder-to-aggregate ratio, optimal combination of the constituents, appropriate water-cement ratio and curing/production method. Partial and 100% replacement of river sand with granite dust is possible and contributes to reduction of environmental problems caused by river dredging as well as cleaner, ecofriendly construction. Ternary and quaternary blended cements is recommended to avert post-construction problems such as swelling and shrinkage-induced cracks prevalent in construction projects.

Keywords: Sandcrete block, Calcite, Calcined clay, Construction, Ternary blended cement, Quarry dust, Quaternary blended cement

Sandcrete block; Calcite; Calcined clay; Ternary blended cement; Quarry dust; Quaternary blended cement

1. Introduction

Hollow sandcrete blocks are traditional materials that have been utilized in construction of residential buildings for several decades. Sandcrete block is a composite material comprising a binding agent (cement) and fine aggregate. These conventional blocks utilize huge amount of ordinary portland cement (OPC) to achieve high compressive strength among other requirements. Reduction of cement content in sandcrete blocks contributes to carbon emission reduction of residential buildings [1, 2, 3, 4]. In addition, utilization of conventional river sand in sandcerete production contributes to resource depletion and erosion of lands near riverbanks. Besides, sandcrete blocks are susceptible to water ingress during exposure to the environment even after plastering [5]. To mitigate these shortcomings, ternary blended cement derived from locally available pozzolanic materials is being explored as potential cement replacement while quarry dust is utilized as 100% replacement for river sand. Replacement of OPC and river sand, partially or wholly, in production of hollow sandcrete blocks with local pozzolanic cementitious materials is also desirable to achieve eco-friendly production, resource conservation and economic design.

1.1. Review of literature

Based on literature review, several pozzolanic waste materials have been utilized as cement replacement in block/brick production such as sewage sludge ash, fly ash, metakaolin, waste clay bricks, ceramic and tile wastes, crushed waste calcined clay bricks, ceramic sludge to mention a few [6, 7, 8, 9, 10, 11]. In addition, several waste materials have been utilized as aggregates in block/brick production such as quarry dust, waste crushed glass, polyethylene wastes and waste tyre rubber, construction and demolition wastes and waste tyre rubbers [12, 13, 14, 15, 16, 17]. It was observed that cement reduction and replacement of natural aggregates in solid/hollow block/brick production is possible without sacrificing their quality as displayed in Figure 1. The highest compressive strength of 32.7 MPa was obtained with solid block which utilized sewage sludge ash (SSA) and waste glass (WG) as partial cement and sand replacement respectively using the dry mix method [6]. Therefore, dry mixing production of hollow block is recommended to improve the compressive strength (CS) of hollow blocks. It was also followed by solid concrete blocks manufactured with waste glass (WG) as 10% cement replacement, and HDPE (high-density polyethylene) and LDPE (low-density polyethylene) as 3% sand replacement with CS ranging from 18.5-19.5 MPa [18]. Comparatively, solid blocks exhibited higher compressive strength than hollow blocks. Therefore, in building projects where higher CS is required, solid blocks are recommended.

Figure 1.

Comparison of compressive strength of blocks made with different materials.

Furthermore, lateritic blocks stabilized with cement, hydrated lime and bone ash exhibited higher CS of 3.6–11.8 MPa compared to hollow blocks with CS range of 1.9–3.6 MPa and also met the minimum CS of 2.5 MPa required for structural load-bearing blocks stipulated by Standards Organisation of Nigeria [19]. However, durability tests are required to ascertain their suitability, which is scarce in literature. Hollow blocks which met the minimum CS requirements were constructed with combination of 70% quarry dust and 30% laterite as complete sand replacement, 100% quarry dust and crumb rubber (CR) as fine aggregate replacement respectively [13, 20].

In addition, it was observed that partial replacement of sand with quarry dust yields slightly higher CS of 2.5 MPa than 100% QD sand replacement of 2.03 MPa [20]. Surprisingly, hollow sandcerete block produced in a recent study with 100% QD [21] met the minimum CS because it was produced at a 0.5 w/c ratio which was lower than 0.58 used in another study [20]. This implies the CS of hollow blocks is affected by both percentage aggregate replacement and water-cement ratio. In addition, properties of hollow blocks were also revealed to be affected by binder-aggregate ratio with lower binder-aggregate ratio of 1:6 exhibiting higher CS of 2.35 MPa compared to 1:8 with CS of 1.9 MPa [22]. In addition, hollow blocks cured by room drying exhibited higher CS compared to conventional sun-dried hollow blocks [23]. The improvement was attributed to enhanced pozzolanic reaction in room drying and prevention of rapid loss of water which occurred in sun drying curing method. In summary, the performance of hollow blocks is affected by percentage aggregate replacement, water-cement ratio, binder-aggregate ratio, and curing/production method. Also, Figure 2 revealed that hollow blocks offer the benefit of lightweight due to the lower dry density compared to solid concrete blocks because of the air cavity in their structure and can be utilized in lightweight construction.

Figure 2.

Comparison of dry bulk density of blocks made with different materials.

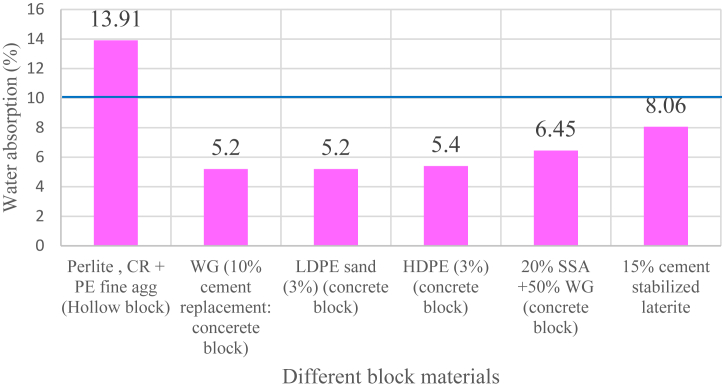

The hollow block constructed with perlite, crumb rubber and polyethylene recorded the lowest dry density and may be suitable for lightweight construction applications since it met the <1682 kg/m3 requirement for lightweight hollow blocks [24]. Also, applications of quarry dust and laterite, separately and combined, contributes to weight reduction and met the 1500 kg/m3 requirement for load-bearing hollow blocks [25]. Conversely, solid blocks result in higher dry density compared to hollow blocks which can result in higher building load and foundation cost. Figure 3 showed the water absorption of different blocks. Based on 10% maximum water absorption limit stipulated by IS-2185 [25], concrete blocks and stabilized bricks constructed with 10% WG, LDPE, HDPE, SSA and WG, and laterite can be utilized in production of load-bearing solid and hollow blocks for building/construction applications. The lightweight hollow block of CR and PE is unsuitable for hollow blocks except construction applications where it is not exposed to moisture ingress.

Figure 3.

Comparison of water absorption of blocks made with different materials.

Ternary blend of various pozzolanic waste materials have been found useful to reduce autogenous shrinkage, improves early strength, mechanical properties, stability and durability of conventional blocks/mortars [26, 27, 28]. Such pozzolanic waste materials include, but are not limited to, waste glass, fly ash, slag, limestone, metakaolin, rice husk ash and calcined clay. In addition, quaternary blends of metakaolin, biomass, granite powder with cement is useful for improved compactability and compressive strength as well as cost reduction [29]. Therefore, utilization of such pozzolanic waste materials has been recognized as the best strategy for reduction of CO2 emission of cement and construction industries as well as reduction of landfilled wastes [1, 30, 31, 32]. In addition, ternary and quaternary blends portend opportunities to maximize individual benefits of individual SCMs. While fine limestone improves durability by reducing steel corrosion at low water/binder ratio of 1:4, calcined clay increases pozzolanicity and improves sulphate resistance [33, 34, 35, 36].

Limestone, clay and laterite are materials that are readily available in Nigeria and many developing countries in Africa, China and India [1, 37, 38]. Limestone calcined clay has superior durability performance compared to OPC and comparable strength development owing to denser microstructure attributed to pozzolanic C-A-S-H from calcined clay [39, 40]. In addition, limestone calcined clay cement blend mitigates alkali silica reaction (ASR) expansion in mortar due to the combined effects of high Ca/Si ASR products formation and reduction in pore solution alkalinity [41]. ASR is the chemical reaction between hydroxyl ions in concrete pore solution and reactive silica minerals in aggregate. ASR is initiated by dissolution of reactive aggregate silica minerals to form ASR gel by the incorporation of alkalis in pore solution resulting in water absorption, volume increase/expansion and concrete cracking [41]. Effective utilization of appropriate ternary and quaternary blends can efficiently mitigate ASR expansion by reduction of alkali content, reduction of ion migration due to dense microstructure and reduction of dissolution of reactive silica in aggregates [42, 43].

1.2. Taguchi and response surface methodology

Taguchi is a robust optimization and quality control method which was introduced to improve the manufacturability and reliability of products. Taguchi method, invented in the 1950s by a Japanese engineer and statistician named Genichi Taguchi, aims to produce high quality product rapidly at low development and manufacturing cost to the manufacturer by utilizing minimum number of experiments within permissible limits of factors and levels. In addition, it utilizes special matrix of experiments called orthogonal arrays to design experiments which enables evaluation of factor/parameter effects as well as their signal-to-noise (S/N) ratios. The benefits of such approach are reduction of time and cost of product development without compromising product quality and customer satisfaction. Taguchi optimization has been utilized extensively in various industries such automobile, telecommunication, manufacturing and airline industries to mention a few [44, 45, 46, 47]. Recently, Taguchi method is gradually being appreciated in the construction industry and has been utilized in sandcrete block, geopolymer concrete, pervious concrete pavement and asphalt mixtures optimization to mention a few [48, 49, 50, 51]. However, successful application of Taguchi method is hinged on identification and selection of important parameters/factors and their levels, selection of appropriate orthogonal arrays, knowledge of statistics and interpretation of the results.

On the other hand, response surface methodology (RSM) is a fast, efficient, and user-friendly statistical method with advanced graphical user interface that facilitates both 2D and 3D visualization of interactive effects of the selected experimental factors. Like Taguchi method, RSM is also utilized for experimental design and allows for predictive model building, factor effects evaluation, identification of significant parameters and optimum condition search [5, 52]. RSM has also been applied extensively in diverse manufacturing processes such as biodiesel production, machining processes, aluminium composites for the automobile and aerospace industry to mention a few [53, 54, 55]. Recently, RSM is gradually being embraced by the construction industry experts and has been utilized in production of concrete blocks, sandcrete blocks, foamed concrete, roller compacted concrete pavement, ultra-high performance concrete, concrete with pozzolanic admixtures and steel fibre reinforced concrete to mention a few [5, 56, 57, 58, 59, 60, 61].

In contrast to Taguchi, RSM does not require extensive statistically knowledge and allows 3D graphical visualization of factor interactions which is limited to 2D in Taguchi. However, a major disadvantage of RSM is that it often requires longer experimental runs which is cost and time-consuming requires selection of appropriate user interface for treatments and optimization of the experimental data. To combine the benefits of both Taguchi and RSM, the hybrid Taguchi-RSM approach was utilized in the modelling and optimization of experimental data. Taguchi method was utilized to design the experiments while mixture design interface of RSM was utilized in modelling and optimization. There is scarcity of application of hybrid Taguchi-RSM approach in civil engineering in literature and available few is limited to recycled concrete and industrial processes [62, 63, 64].

Though recent studies have shown successful application of laterite as partial or complete replacement of river sand in bricks and solid blocks with comparable or even higher compressive strength than control [21, 65, 66, 67], there is scarce application of laterite as cement replacement in literature. In addition, there is dearth of blends of laterite, calcite and calcined clay as cement replacements in sandcrete blocks. Therefore, this study investigates ternary and quaternary blended cement comprising laterite, calcined clay and calcite as partial cement replacement in sandcrete hollow blocks. In addition, quarry dust was utilized as 100% replacement of river sand. The objectives of this study are to investigate the optimum replacement of cement with quaternary or ternary combinations of laterite, calcined clay and calcite in sandcrete hollow blocks. This study is significant because blended cements have the potential to overcome durability problems of hollow blocks, contributes to CO2 emission reduction and reduces landfilling of pozzolanic waste materials. Also, utilization of quarry dust has the potential to reduce river sand depletion and prevent disposal of hazardous quarry dust into the environment.

2. Methods and materials

2.1. Materials

The ordinary portland cement (OPC) utilized was obtained from the local market in Ado Ekiti while the quarry dust was obtained from Ijere in Ekiti State, calcined clay and laterite were obtained from Ire, Ekiti State and calcite from Auchi-Igara region of Edo State in Nigeria. The experimental materials displayed in Figure 4 were obtained from within Ekiti State, Nigeria. The laterite was grinded and sieved to obtain its fine contents before it was utilized as cement replacement. The specific gravity of the materials was determined using pycnometer method as shown in Figure 5 and their particle size distribution is displayed in Figure 6. The mix proportion for the hollow block is displayed in Table 1. Clay soil excavated from the ground was collected in sacks and dried for two weeks to remove moisture before firing. Thereafter, they were molded into clay balls, laid in crucibles before placement in muffle furnace for calcination at 900 °C for two (2) hours.

Figure 4.

Experimental materials for hollow block production (a) Calcined clay (b) Calcite (c) Laterite (d) Quarry dust (e) Ordinary Portland cement.

Figure 5.

Pycnometer bottles utilized in determination of specific gravity of (a) Calcite (b) Calcined clay (c) Quarry dust by pycnometer method.

Figure 6.

Particle size distribution of calcined clay, quarry dust (stone dust), laterite and calcite.

Table 1.

Hollow block mix composition.

| Exp. runs | Binder/agg | Total binder | Laterite (kg) | Cement (kg) | Calcined clay (kg) | Calcite (kg) | Water (kg) | Quarry dust (fine aggregate) |

|---|---|---|---|---|---|---|---|---|

| 1 | 0.167 | 3.76 | 9.02 | 6.76 | 6.76 | 0 | 7.18 | 112.46 |

| 2 | 0.167 | 3.76 | 4.509 | 11.2725 | 0 | 6.76 | 7.88 | 112.46 |

| 3 | 0.125 | 2.81 | 0 | 16.88 | 0 | 0 | 6.7 | 118.13 |

| 4 | 0.125 | 2.81 | 6.75 | 2.53 | 2.53 | 5.06 | 7.76 | 118.13 |

| 5 | 0.25 | 5.63 | 13.5 | 15.19 | 0 | 5.063 | 6.66 | 101.25 |

| 6 | 0.25 | 5.63 | 6.75 | 21.94 | 5.06 | 0 | 9.72 | 101.25 |

| 7 | 0.125 | 2.81 | 3.38 | 5.91 | 5.06 | 2.53 | 8.46 | 118.13 |

| 8 | 0.25 | 5.63 | 0 | 13.5 | 10.13 | 10.13 | 12.14 | 101.25 |

| 9 | 0.167 | 3.76 | 0 | 15.78 | 3.38 | 3.38 | 10.68 | 112.46 |

2.2. Experimental design

The alternative supplementary cementitious materials namely laterite, calcite, and calcined clay, for the hollow block materials were designed using L9 (34) Taguchi orthogonal array to reduce cement content as displayed in Table 2. Each experimental run of the nine blended cements was designed to ensure each row contains a total sum of 100% ASCM/Cement content while cement content was limited to a minimum of 30% and a maximum of 100%. Optimization of the ternary/quaternary cement blend was done in Response Surface Methodology. Taguchi is useful in reducing the number of experimental runs while RSM is helpful in displaying the interactive effects of the constituent, optimization of the constituents as well as identification of the major factors. Also, both calcite and calcined clay were limited to a maximum of 30% and laterite was capped at 40% maximum. In addition, quarry dust replacement of conventional river sand was limited to 100%. Each experimental run of hollow block was designed with a variable binder-to aggregate ratio of between 1:6–1:8 which is commonly utilized in the building industry. A minimum of six (6) hollow blocks were cast for each experimental run as shown in Table 3 making a total of 54 blocks.

Table 2.

L9 (34) Orthogonal Array for ternary and quaternary blended cements in hollow brick.

| Experiment runs | Laterite (%) | Calcite (%) | Calcined clay (%) | Cement (%) |

|---|---|---|---|---|

| 1 | 40 | 0 | 30 | 30 |

| 2 | 20 | 30 | 0 | 50 |

| 3 | 0 | 0 | 0 | 100 |

| 4 | 40 | 30 | 15 | 15 |

| 5 | 40 | 15 | 0 | 45 |

| 6 | 20 | 0 | 15 | 65 |

| 7 | 20 | 15 | 30 | 35 |

| 8 | 0 | 30 | 30 | 40 |

| 9 | 0 | 15 | 15 | 70 |

Table 3.

Hollow block experimental sample programme.

| Test | Duration (days) | Number of samples |

|---|---|---|

| Bulk density | 28 | 3 |

| Shrinkage | Every 2 days up to 28 days | |

| Compression strength | 28 | |

| Flexural load capacity | 28 | 3 |

The materials for each experiment were weighed out and manually mixed by hand. After thoroughly manually mixing the materials, the resulting mix was poured into the six inches block moulds and each block was mechanically compacted by an automatic vibro-compactor for few seconds to remove/reduce any voids in the hollow block displayed in Figure 7 (a). The manufactured bricks were then placed on a wooden pallette and covered with damp sacks for twenty-four (24) hours to prevent moisture loss and cracking from direct heat from sunlight as displayed in Figure 7 (b). The sacks were removed after twenty-four (24) hours and the blocks were cured by spraying them twice every day, first between 6-8 am in the morning and afternoon, for twenty-eight days. The mechanical properties such as compressive strength, flexural load capacity were carried out in the Concrete Laboratory of Department of Civil Engineering, Ekiti State University, Nigeria as well as bulk density and weight measurements as shown in Figure 8. The mean value of three samples were recorded and reported for each hollow block property for each experimental run.

Figure 7.

(a) Automated hollow block vibrated compaction (b) Hollow block placement on wooden pallette for curing in natural air and sunlight.

Figure 8.

Experimental tests for hollow blocks (a) Compressive strength test (b) Flexural load capacity test with Servo-Plus compression machine (c) Manual width shrinkage measurement with vernier caliper.

Compression strength test was done by placing a smooth surface wood (serving as base plate) at the bottom of the hollow concrete block and a steel with length and width similar to the blocks was placed at the top of each specimen block so as to ensure uniform distribution of load for accurate crushing. The compression test was done to failure and the maximum load was recorded. Compressive strength was determined by dividing the maximum load by the effective cross-section of the hollow block. Flexural load capacity of the hollow was determined using four-point test method. Two supports were placed at 75mm from the extreme ends of the block base. The distance between the supports was 300, which was divided into 3 equal segments to place the two upper point loads. The flexural test was done continuously until complete failure and the maximum load recorded was regarded as the flexural load capacity of the hollow block. Drying shrinkage was taken by direct measurement with the aid of vernier caliper. Drying shrinkage measurement was taken every two days up to 28 days for each experimental run. Bulk density and weight of hollow blocks were determined in dry state using a weighing balance after 28 days of curing. The Taguchi experimental result was then inputed into the mixture design of Design of Expert software and was optimized using response surface methodology. The pozzolanic contents of laterite, calcite, calcined clay and cement (SiO2 + Al2O3 + Fe2O3) were 94.6%, 7.12%, 82.5% and 28.47% as shown in Table 4. This implies the pozzolanic contents of laterite and calcined clay were higher than cement. However, the two materials have low calcium content. Therefore, calcite is useful to supply the calcium required for hydration like OPC which has higher CaO content of 62.50% compared to 51.40% for calcite. These results imply laterite and calcined play more cementitious roles while calcite plays more filler roles supplying calcium ions needed for hydration. Utilization of limestone as 10–30% filler replacement of cement has been suggested to produce low-carbon cement with advanced performance [68]. The filler role of calcined clay was also emphasized by a recent study [69].

Table 4.

Chemical composition of cement and cementitious materials.

| Oxides | Laterite [23] | Calcite [56] | Calcined clay [5] | Cement [56] |

|---|---|---|---|---|

| SiO2 | 67.9 | 5.82 | 54.97 | 20.99 |

| Al2O3 | 20.1 | 0.58 | 20.11 | 4.18 |

| Fe2O3 | 6.6 | 0.72 | 7.50 | 3.30 |

| MgO | 1.1 | 0.50 | 0.51 | 1.87 |

| CaO | 0.2 | 51.40 | 0.10 | 62.50 |

| P2O5 | 0.4 | - | 0.22 | - |

| K2O | 1.9 | 0.18 | 0.13 | 0.92 |

| TiO2 | 1.0 | - | 0.01 | - |

| Na2O | 0.4 | 0.04 | 1.88 | 0.37 |

| MnO | 0.1 | - | 0.04 | - |

| LOI | - | 0.18 | 5.21 | 1.53 |

3. Results and discussion

3.1. Perturbation plots of input factors

Figure 9 (a) showed the influence of the individual input factors on the weight of hollow sandcrete blocks. Linear reduction in weight occurred with increasing calcined clay content while non-linear reduction occurred with increased laterite content. Conversely, weight of the blocks increases with increased calcite and cement contents. Similar relationship was exhibited with bulk density in Figure 9 (b). Also, Figure 9 (c) showed the influence of input factors on the CS. CS reduced significantly with increased laterite content while minimal CS reduction occurred with increased calcite content. In contrast, CS increase was recorded with increased calcined clay and cement contents. Figure 9 (d) displayed the influence of the input factors on the flexural load. Increased flexural load was exhibited with increased cement content while flexural load reduction occurred with laterite, calcite and calcined clay.

Figure 9.

Perturbation plots of (a) Weight vs Deviation from reference blend (b) Bulk density vs Deviation from reference blend (c) Compressive strength vs Deviation from reference blend (d) Flexural load vs Deviation from reference blend (e) Width shrinkage vs Deviation from reference blend due to laterite (A), calcite (B), calcined clay (C) and cement (D).

However, slight reduction was recorded with calcined clay. Figure 9 (e) displayed the influence of input factors on the width shrinkage/expansion. While increasing laterite and cement content caused expansion, both calcite and calcined clay cause reduction of expansion (that is shrinkage). This implies careful combination of these materials to produce blended cements is required to avoid post-construction maintenance problems such as swelling and cracking.

3.2. Width of hollow sandcrete blocks with curing days

The width dimensions of the hollow sandcrete blocks with curing age is displayed in Figure 10. It was observed that run 8 containing 30% calcite and 30% calcined clay exhibited the highest width stability with shrinkage slope of 0 mm/mm as displayed in Table 5 and was closely followed by runs 7 with shrinkage slope of 0.0009 mm/mm and contains 20% laterite, 15% calcite and 30% calcined clay. The shrinkage slope of the two runs was better (smaller) than the control shrinkage slope of 0.006. This implies utilization of 100% cement alone in sandcrete blocks promotes high level of width expansion which is undesirable. Experiment runs 9, 6, 1 and 5 also exhibited width expansion but their shrinkage slope values of 0.0023, 0.0025, 0.0035 and 0.0039 and 0.0044 mm/mm respectively were lower compared to the control value of 0.006 mm/mm. In contrast, runs 4 and 2 exhibited width shrinkage with shrinkage slope of -0.001 and -0.0035 respectively. This implies ternary blends of calcined clay and calcite can be utilized to replace cement in production of stable hollow sandcrete blocks especially where width stability is of high importance. Alternatively, 20% laterite, 15% calcite and 30% calcined clay can also be utilized. Utilization of ternary mixtures of laterite and calcined clay alone with cement results in expansion as shown in runs 1 and 6 while ternary mixtures of laterite and calcite result in shrinkage as shown in runs 2. To avert both shrinkage and expansion and ensure width stability, the three pozzolanic materials may be utilized. However, the proportion of laterite should be preferably between 10-20% while the proportion of the calcite and calcined clay could be higher.

Figure 10.

Width shrinkage of hollow concrete blocks.

Table 5.

Taguchi experimental results.

| Runs | Weight (kg) | Bulk density (Kg/m3) | CS (MPa) | Flexural load (kN) | Shrinkage slope (mm/mm) |

|---|---|---|---|---|---|

| 1 | 17.45 | 2068.54 | 0.35 | 3.512 | 0.0039 |

| 2 | 19.95 | 2364.84 | 1.22 | 13.123 | -0.0035 |

| 3 | 18.36 | 2176.00 | 1.41 | 17.97 | 0.006 |

| 4 | 17.23 | 2042.47 | 0.22 | 0 | -0.001 |

| 5 | 19.01 | 2252.64 | 1.49 | 15.903 | 0.0044 |

| 6 | 16.68 | 1976.89 | 1.06 | 20.131 | 0.0025 |

| 7 | 17.50 | 2074.07 | 0.57 | 5.01 | 0.0009 |

| 8 | 17.95 | 2127.80 | 1.25 | 15.815 | 0 |

| 9 | 20.05 | 2376.69 | 2.31 | 25.403 | 0.0023 |

The interaction plots for width shrinkage are displayed in Figure 11 (a), (b), (c) and positive slope implies shrinkage while negative slope refers to expansion. Figure 11 (a) revealed that at 0% laterite content, cement causes expansion. However, with laterite addition up to 10% and at reduced cement of 62%, the expansion reduced slightly. Width stability was achieved between 10-15% laterite content at corresponding cement content of 57%–62%. Beyond this point, significant expansion occurred in hollow sandcrete blocks up to about 40% laterite content with further cement reduction to 32%. This implies laterite cementitious content should be limited to between 10-15% in hollow sandcrete bricks where minimal expansion is allowed. The expansion is due to the reactive silica in the laterite. To fully maximize laterite usage, pretreatment of laterite is recommended before usage to minimize the ASR expansion.

Figure 11.

Interaction effects of (a) Laterite and cement (b) Calcite and calcined clay on width shrinkage of hollow blocks.

Figure 11 (b) revealed that utilization of calcium clay alone with cement without calcite causes shrinkage of the hollow blocks. With increased calcite addition up to approximately 13% which correspond to calcite clay reduction up to 16%, expansion occurred. With further calcite content addition up to 28% and calcined clay reduction to 0%, shrinkage occurred in the hollow bricks. Figure 11(b) and Figure 9 (e) indicate calcite caused more shrinkage compared to calcined clay. However, zero-shrinkage is almost impossible in construction practice. Therefore, recommended dosages of ternary and quaternary blends are displayed in Table 6 for zero shrinkage and minimal expansion project requirements. A recent study reported high shrinkage when clay aggregate alone was utilized in brick production and shrinkage reduction at optimum addition of 30% laterite to clay [31]. Another study also observed volumetric deformations with the use of calcined clay and were attributed to both the chemical and autogenous shrinkage accompanied with expansion due to heat released during hydration [32]. This implies calcined clay could cause both expansion and shrinkage possibly depending on the percentage utilization and requires appropriate combination with calcite to mitigate shrinkage.

Table 6.

Recommended mix of ternary and quaternary cements.

| Project requirement | Calcite (%) | Calcined clay (%) | Laterite (%) | Cement (%) |

|---|---|---|---|---|

| Zero shrinkage | 1 | 24 | - | 75 |

| Zero shrinkage | 24 | 4 | - | 72 |

| Minimal expansion | 13 | 15 | 13 | 59 |

This finding is crucial for construction projects which utilize clay as aggregates and both clay and calcined clay as cementitious materials.

3.3. Weight and bulk density of hollow sandcrete blocks

Figure 12 (a) showed a curved reduction in weight of the hollow sandcrete blocks with increased laterite replacement of cement. The weight of the block was constant from approximately 28% laterite content to 35% laterite content. The weight reduction is attributed to the lower specific gravity of the laterite compared to cement and is an additional desirable benefit which is useful in lightweight construction. Conversely, an increasing positive linear relationship was observed between weight of block and increasing calcite replacement of calcined clay in Figure 12 (b). The weight increase is attributed to the higher bulk density of calcite derived from limestone compared to calcined clay. Furthermore, from Table 5, the highest weight of 20.05 kg and bulk density of 2376.7 kg/m3 was recorded by run 9 containing 15% calcite. The values were higher than control values of 18.36 kg and 2176 kg/m3 even though control has higher binder/aggregate ratio. Comparatively, hollow sandcrete blocks prepared with ternary blends at lower binder/aggregate ratio of 1:4 and 1:6 in runs 1, 2 6 and 8 and 35–60% cement replacement recorded lower weight and bulk density. In addition, hollow sandcrete blocks produced with quaternary cement blends utilized in runs 4 and 7 exhibited weight reduction. This implies ternary blends at lower binder/aggregate ratio and quaternary cement blends at higher binder/aggregate ratio can be utilized to achieve lightweight construction.

Figure 12.

Interaction effects of (a) Laterite and cement (b) Calcite and calcined clay on weight of hollow sandcrete block.

3.4. Compressive strength of hollow sandcrete block

Figure 13 (a) showed significant non-linear reduction in CS with increasing cement replacement using laterite. This implies high volume laterite as cement replacement is detrimental to CS development which is not recommended. In addition, Figure 13 (b) displayed decreasing non-linear CS with calcite replacement of calcined clay up to 17.5% calcite before increasing thereafter. Comparison of the two graphs revealed that calcined clay contributes more to CS development compared to calcite. Though higher calcined clay and calcite is desirable, they are limited by their tendency to increase shrinkage in concrete products as depicted in Figure 11 (b). Hollow sandcrete block containing 15% calcite and 15% calcined clay (runs 9) achieved CS of 2.31 MPa which was 63.8% higher than the control (runs 5) with 100% OPC utilization which recorded lower CS of 1.41 MPa as shown in Table 5. The CS recorded for 450 × 225 × 150 mm hollow sandcrete block in this study was greater than CS of 0.19–1.59 MPa reported for commercial pure OPC sandcrete blocks of higher dimension of 450 × 225 × 225 mm in Nigeria [70, 71, 72]. This implies equal combination of calcined clay and calcite (1:1) can be utilized to replace 30% of cement in production of hollow sandcrete block with significant CS improvement. The CS achieved complied with the Nigerian National Building Code [73] requirement of 1.7–2 MPa and 1.75–2 MPa recommended by Nzeh [74] for hollow sandcrete blocks.

Figure 13.

Interaction effects of (a) laterite and cement (b) calcite and calcined clay on compressive strength of hollow sandcrete block.

Similarly, hollow sandcrete block containing 40% laterite and 15% calcite achieved CS of 1.49 MPa which was 5.7% greater than control value. Even though runs 9 was prepared at higher binder/aggregate ratio of 0.167 (1:6), which implies lower cementitious content, it still recorded higher CS to control produced at lower binder/aggregate ratio of 0.25 (1:4) and 100% OPC. This implies approximately 1.5 times the recorded CS (3.4 MPa) would have been achieved at lower binder/aggregate ratio of 1: 4 even at 100% quarry dust replacement of sand. This CS would have met the 2.5 MPa CS stipulated for 150 mm sandcrete blocks by Standard Organization of Nigeria [75] and a recent study [70]. Also, higher CS of at least 4 MPa could also be achieved at higher binder ratios of 1:2 to 1:3 and partial replacement of quarry dust with a pozzolanic aggregate [76, 77, 78]. CS increase factor of 1.23 was recorded in a study at 70% quarry dust and 30% laterite replacement of sand compared to 100% quarry dust replacement of river sand [20].

The significant CS improvement in the hollow sandcrete block produced with ternary blend of 15% calcined clay and 15% calcite with 70% OPC can be attributed to the approximately equal calcium-aluminosilicate content from calcite and the sodium-aluminosilicate contents from calcined clay. From a chemical point of view, mixing of Ca-rich aluminosilicate calcite and silica-rich aluminosilicate calcined clay is synonymous with geopolymer synthesis of sodium (alumino) silicate hydrate (N-A-S-(H)) gel and calcium (alumino) silicate hydrate (C-A-S-H) gel which is beneficial for CS improvement [79]. In contrast, the lower CS of hollow block produced with 40% laterite and 15% calcite implies excessive silica in the cementitious matrix resulting in lower CS. Recent studies reported that excessive silica content (laterite) contributes to CS reduction [80, 81].

3.5. Flexural load capacity of hollow sandcrete block

Figure 14 (a) indicated negative linear reduction in flexural load of the hollow sandcrete blocks with increasing laterite replacement of cement from 0-40%. Within the same range of 28% cement replacement, 74% reduction in flexural load was exhibited by laterite while only 32% reduction was exhibited with combined calcite and calcined clay replacement of cement as displayed in Figure 14 (b). This implies combined application of calcite and calcined clay is preferable to high laterite inclusion to avoid significant reduction of flexural capacity of structures. In addition, experimental results revealed that hollow block made with 15% calcite and 15% calcined clay (runs 9) achieved 41% higher flexural load capacity compared to the 100% OPC control blocks. Conversely, ternary cement blends of laterite and calcite (runs 2 and 5) yielded lower flexural load capacity of 13.1–15.9 kN compared to control. This implies ternary cement blends of calcined clay and calcite can be utilized to obtain higher flexural load capacity for hollow sandcrete blocks. However, very high cement replacement (60%) with ternary cement blends of calcined clay and calcite caused 13.8% reduction in flexural strength even at 1:4 binder/aggregate ratio. Therefore, moderate cement replacement with ternary cement blends is recommended to avoid loss of flexural load capacity in the hollow sandcrete blocks. Utilization of both natural and synthetic fibres is also suggested to improve the load-bearing capacity and toughness of hollow sandcrete blocks as building material [82, 83, 84].

Figure 14.

Interaction effects of (a) Laterite and cement (b) Calcite and calcined clay on flexural load of hollow sandcrete blocks.

3.6. Diagnostic plots and optimization of input factors and responses

The adequacy of the model was evaluated using the plots of residual and externally studentized residuals as shown in Figure 15. Majority of the predicted values were close to the straight line in Figure 15 (a) and (c) which indicates that the residual of the response is normally distributed [5, 85]. Also, the plots of the residuals vs predicted values for both CS and shrinkage slope were within the two red lines depicted in Figure 15 (b) and (d). It was observed that the R2 value of 0.9999 of the width shrinkage slope model was very close to 1 (unity) followed by that of the compressive strength model with R2 value of 0.9903 and p-value of 0.0287. With p-values < 0.05, these results indicate that the models are significant and can be utilized.

Figure 15.

Diagnostic plots of (a) Predicted compressive strength vs Actual compressive strength (b) Externally studentized residuals of actual compressive strength vs Predicted compressive strength (c) Predicted shrinkage slope vs Actual shrinkage slope (d) Externally studentized residuals of actual shrinkage slope vs Predicted shrinkage slope of hollow blocks.

Furthermore, Taguchi-RSM optimization gave an undesirable optimization of 40% laterite and 30% calcite which can cause shrinkage due to the high laterite content and significant reduction in CS and flexural load capacity. However, evaluation of the Taguchi experimental results combined with the interaction plots revealed that zero shrinkage can be achieved with ternary combination of 1% calcite +24% calcined clay +75% OPC or 24% calcite +4% calcined clay +72% OPC. Ternary blended cement with higher calcined clay is recommended because it gives higher CS and higher flexural load capacity. However, zero shrinkage is difficult to accomplish in construction practice. Therefore, where minimal expansion is allowed, quaternary combination of 13% calcite +15% calcined clay +13% laterite is also recommended. The ternary and quaternary blends are <50–65% cement replacement recommended in recent studies to avoid hydration inhibition [30, 36].

4. Conclusion

This study has shown the potential application of local materials such as calcined clay, calcite and laterite as cement replacement and quarry dust as river sand 100% replacement to improve the sustainability of hollow sandcrete block production. The major findings from this study are as follows:

-

1.

To achieve stable hollow sandcrete blocks with zero shrinkage, higher compressive strength, higher flexural load capacity for lightweight construction, optimum ternary blend of 1% calcite +24% calcined clay +75% OPC is recommended. Alternatively, ternary blend of 24% calcite +4% calcined clay +72% OPC can also be utilized to achieve zero shrinkage.

-

2.

Where minimal expansion is allowed in hollow sandcrete bricks, quaternary blend of 13% calcite +15% calcined clay +13% laterite +59% OPC can also be utilized.

-

3.

While calcined clay contributes significantly to CS development, calcite contributes to expansion reduction (shrinkage) and laterite causes expansion. Therefore, careful combination and utilization of these materials is important to avoid post-construction problems such as swelling (expansion) and shrinkage-induced cracks.

-

4.

Utilization of binary, ternary and quaternary blended cements contribute to CO2 reduction with OPC replacement and can be utilized in production of strong, durable and eco-friendly hollow sandcrete blocks for residential building construction.

-

5.

While partial replacement of river sand with quarry dust is recommended, 100% replacement is possible and both replacements contribute to cleaner, ecofriendly construction.

Declarations

Author contribution statement

A. O. Sojobi: Conceived and designed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data; Wrote the paper.

T.F. Awolusi & G.B. Aina: Performed the experiments.

O.L. Oke & Oguntayo D.O.: Contributed reagents, materials, analysis tools or data.

M. Oladokun: Analyzed and interpreted the data.

Funding statement

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Data availability statement

Data will be made available on request.

Declaration of interests statement

The authors declare no conflict of interest.

Additional information

No additional information is available for this paper.

Acknowledgements

The first author appreciates the post-doctoral fellowship granted him in the Department of Civil and Environmental Engineering of The Hong Kong Polytechnic University. All the authors appreciate the Management of Ekiti State University for the equipment provided at the Concrete Laboratory of Department of Civil Engineering, Ekiti State University, Nigeria. The authors appreciate the support given by the Director of the Ekiti State University Block Industry. The reviewers are also appreciated for their comments which led to significant improvement of the manuscript.

References

- 1.Scrivener K., Martirena F., Bishnoi S., Maity S. Calcined clay limestone cements (LC3) Cem. Concr. Res. 2018;114:49–56. [Google Scholar]

- 2.Teng Y., Pan W. Systematic embodied carbon assessment and reduction of prefabricated high-rise public residential buildings in Hong Kong. J. Clean. Prod. 2019;238:1–15. [Google Scholar]

- 3.UN-Environment, Scrivener K., John V., Gartner E. Eco-efficient cements: potential economically viable solutions for a low-CO2 cement-based materials industry. Cem. Concr. Res. 2018;114:2–26. [Google Scholar]

- 4.Wang X., Chen D., Ren Z. Global warming and its implication to emission reduction strategies for residential buildings. Build. Environ. 2011;46:871–883. [Google Scholar]

- 5.Awolusi T.F., Oke L., Akinkurolere O.O., Ubani D.P., Bamisaye R.T., Aluko O.G. The application of response surface methodology in understanding the compressive strength and water absorption capacity of sandcrete blocks. Silicon. 2020:1–10. [Google Scholar]

- 6.Chen Z., Li J.S., Poon C.S. Combined use of sewage sludge ash and recycled glass cullet for the production of concrete blocks. J. Clean. Prod. 2018;171:1447–1459. [Google Scholar]

- 7.Cheng H. Reuse research progress on waste clay brick. Proc. Environ. Sci. 2016;31:218–226. [Google Scholar]

- 8.De Sailva G.H.M.J., Hansamali E. Eco-friendly fired clay bricks incorporated with porcelain ceramic sludge. Constr. Build. Mater. 2019;228:1–10. [Google Scholar]

- 9.Filho R.D.T., Goncalves J.P., Americano B.B., Fairbairn E.M.R. Potential for use of crushed waste calcined-clay brick as a supplementary cementitious material in Brazil. Cem. Concr. Res. 2007;37:1357–1365. [Google Scholar]

- 10.Lee G., Ling T.C., Wong Y.-L., Poon C. Effects of crushed glass cullet sizes, casting methods and pozzolanic materials on ASR of concrete blocks. Constr. Build. Mater. 2011;25:2611–2618. [Google Scholar]

- 11.Meng Y., Ling T.C., Mo K. Recycling of wastes for value-added applications in concrete blocks: an Overview. Resour. Conserv. Recy. 2018;138:298–312. [Google Scholar]

- 12.Akinyele J.O., Igba U.T., Ayorinde T.O., Jimoh P.O. Structural efficiency of burnt clay bricks containing waste crushed glass and polypropylene granules. Case Stud. Const. Mater. 2020;13:1–11. [Google Scholar]

- 13.Al-Tamimi A.S., Al-Amoudi O.S.B., Al-Osta M.A., Ali M.R., Ahmad A. Effect of insulation materials and cavity layout on heat transfer of concrete masonry hollow blocks. Constr. Build. Mater. 2020;254:1–19. [Google Scholar]

- 14.Fraile-Garcia E., Ferrero-Cabello J., Mendivil-Giro M., Vicente-Navarro A.S. Thermal behaviour of hollow blocks and bricks made of concrete doped with waste tyre rubber. Constr. Build. Mater. 2018;176:193–200. [Google Scholar]

- 15.Gencil O., Erdugmus E., Sutcu M., Oren O.H., Gencil O. Effects of concrete waste on characteristics of structural fifired clay bricks. Constr. Build. Mater. 2020;255:1–12. [Google Scholar]

- 16.Paihte P.L., Lalngaihawma A.C., Saini G. Recycled Aggregate filled waste plastic bottles as a replacement of Bricks. Mater. Today Proceed. 2019;15:663–668. [Google Scholar]

- 17.Seco A., Omer J., Marcelino S., Espuelas S., Prieto E. Sustainable unfired bricks manufacturing from construction and demolition wastes. Constr. Build. Mater. 2018;167:154–165. [Google Scholar]

- 18.Chidiac S.E., Mihaljevic S.N. Performance of dry cast concrete blocks containing waste glass powder or polyethylene aggregates. Cem. Concr. Compos. 2011;33:855–863. [Google Scholar]

- 19.SON . 2004. Standards for Sandcrete Blocks, Standard Organization of Nigeria, Lagos. [Google Scholar]

- 20.Okafor F.O., Egbe E.A. Structural properties of laterite - quarry dust cement blocks. J. Arch Civ Eng. 2016;3(3):12–17. [Google Scholar]

- 21.Akinyemi B.A., Elijah A., Oluwasegun A., Akpenpuun D.T., Glory O. The use of red earth, lateritic soils and quarry dust as an alternative building material in sandcrete block. Sci. Afr. 2020;7:1–7. [Google Scholar]

- 22.Popoola O.C., Ayebokiki S.T., Gambo M.D. Study of compressive strength characteristics of hollow sandcrete blocks partially replaced by saw dust ash. IOSR J. Eng. 2015;5(5):30–34. [Google Scholar]

- 23.Obianyo I.I., Onwualu A.P., Soboyejo A.B.O. Mechanical behaviour of lateritic soil stabilized with bone ashand hydrated lime for sustainable building applications. Case Stud. Const. Mater. 2020;12:1–12. [Google Scholar]

- 24.ASTM-C90 . ASTM International; United States: 2009. Standard Specification for Loadbearing concrete Masonry Units. [Google Scholar]

- 25.IS-2185, Concrete Masonry Units-Specification (Part 1) Hollow and Solid concrete Blocks. Bureau of Indian Standards; New Delhi: 2005. [Google Scholar]

- 26.Hu X., Shi C., Shi Z., Tong B., Wang D. Early age shrinkage and heat of hydration of cement-fly ash-slag ternary blends. Constr. Build. Mater. 2017;153:857–865. [Google Scholar]

- 27.Roziere E., Medjigbodo G., Izoret L., Loukili A. Hydration and durability of ternary binders based on metakaolin and limestone filler. In: Bishnoi S., editor. Calcined Clays for Sustainable Concrete. Springer; Singapore: 2020. [Google Scholar]

- 28.Younes M.M., Abdel-Rahman H.A., Khattab M.M. Utilization of rice husk ash and waste glass in the production of ternary blended cement mortar composites. J. Build. Eng. 2018;20:42–50. [Google Scholar]

- 29.Rojo-Lopez G., Nunes S., Gonzalez-Fonteboa B., Martinez-Abella F. Quaternary blends of portland cement, metakaolin, biomass ash and granite powder for production of self-compacting concrete. J. Clean. Prod. 2020;266:1–14. [Google Scholar]

- 30.Avet F., Scrivener K. Investigation of the calcined kaolinite content on the hydration of limestone calcined clay cement (LC3) Cem. Concr. Res. 2018;107:124–135. [Google Scholar]

- 31.Liew K.M., Sojobi A.O., Zhang L.W. Green concrete: prospects and challenges. Constr. Build. Mater. 2017;156:1063–1095. [Google Scholar]

- 32.Miller S.A., John V.M., Pacca S.A., Horvath A. Carbon dioxide reduction potential in the global cement industry by 2050. Cem. Concr. Res. 2018;114:115–124. [Google Scholar]

- 33.Briendl L.G., Mittermayr F., Baldermann A., Steindl F.R., Sakoparnig M., Letofsky-Papst I., Galan I. Early hydration of cementitious systems accelerated by aluminium sulphate: effect of fine limestone. Cem. Concr. Res. 2020;134:1–14. [Google Scholar]

- 34.Li C., Jiang L., Li S. Effect of limestone powder addition on threshold chloride concentration for steel corrosion in reinforced concrete. Cem. Concr. Res. 2020;131:1–9. [Google Scholar]

- 35.Nadelman E.I., Kurtis K.E. Durability of Portland-limestone cement-based materials to physical salt attack. Cem. Concr. Res. 2019;125:1–11. [Google Scholar]

- 36.Shi Z., Ferreino S., Lothenbach B., Geiker M.R., Kunther W., Kaufmann J., Herfort D., Skibsted J. Sulfate resistance of calcined clay – limestone – Portland cements. Cem. Concr. Res. 2019;116:238–251. [Google Scholar]

- 37.Krishnan S., Bishnoi S. A numerical approach for designing composite cements with calcined clay and limestone. Cem. Concr. Res. 2020;138:1–9. [Google Scholar]

- 38.Sojobi A.O., Aladegboye O.J., Awolusi T.F. Green interlocking paving units. Constr. Build. Mater. 2018;173:600–614. [Google Scholar]

- 39.Dhandapani Y., Sakthivel T., Santhanam M., Gettu R., Pillai R.G. Mechanical properties and durability performance of concretes with limestone calcined clay cement (LC3) Cem. Concr. Res. 2018;107:136–151. [Google Scholar]

- 40.Dhandapani Y., Santhanam M. Investigation on the microstructure-related characteristics to elucidate performance of composite cement with limestone-calcined clay combination. Cem. Concr. Res. 2020;129:1–22. [Google Scholar]

- 41.Nguyen Q.D., Kim T., Castel A. Mitigation of alkali-silica reaction by limestone calcined clay cement (LC3) Cem. Concr. Res. 2020;137:1–14. [Google Scholar]

- 42.Aquino W., Lange D.A., Olek J. The influence of metakaolin and silica fume on the chemistry of alkali-silica reaction products. Cem. Concr. Compos. 2001;23:485–493. [Google Scholar]

- 43.Turk K., Kina C., Bagdiken M. Use of binary and ternary cementitious blends of F Class flfly-ash and limestone powder to mitigate alkali-silica reaction risk. Constr. Build. Mater. 2017;151:422–427. [Google Scholar]

- 44.Jalalian M., Gholami S., Ramezanian R. Analyzing the trade-off between CO2 emissions and passenger service level in the airline industry: mathematical modeling and constructive heuristic. J. Clean. Prod. 2019;206:251–266. [Google Scholar]

- 45.Jeon B.J., Kim Y.H., Lee K.S., Cha S.W., Nam G.J., Park C.Y., Lee G.J. Parameter design of a coaxial cable insulation manufacturing process using axiomatic design and the Taguchi method. Polym. Plast. Technol. Eng. 2008;47(8):785–790. [Google Scholar]

- 46.Nalbant N., Gokkaya H., Sur G. Application of Taguchi method in the optimization of cutting parameters for surface roughness in turning. Mater. Des. 2007;28:1379–1385. [Google Scholar]

- 47.Subulan K., Cakmakci M. A feasibility study using simulation-based optimization and Taguchi experimental design method for material handling—transfer system in the automobile industry. Int. J. Adv. Manuf. Technol. 2012;59:433–443. [Google Scholar]

- 48.Dave S.V., Bhogayata A. The strength-oriented mix design for geopolymer concrete using Taguchi method and Indian concrete mix design code. Constr. Build. Mater. 2020;262:1–12. [Google Scholar]

- 49.Hosseinpour-Lonbar M., Alavi M.Z., Palassi M. Selection of asphalt mix with optimal fracture properties at intermediate temperature using Taguchi method for design of experiment. Constr. Build. Mater. 2020;262:1–10. [Google Scholar]

- 50.Ikeagwuani C.C., Nwonu D.C., Ugwu C.K., Agu C.C. Process parameters optimization for eco-friendly high strength sandcrete block using Taguchi method. Heliyon. 2020;6 doi: 10.1016/j.heliyon.2020.e04276. 1-14. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 51.Joshaghani A., Ramezanianpour A., Ataei O., Golroo A. Optimizing pervious concrete pavement mixture design by using the Taguchi method. Constr. Build. Mater. 2015;101:317–325. [Google Scholar]

- 52.Bashar S., Veerendrakumar C., Muhd F. Rubbercrete mixture optimization using response surface methodology. J. Clean. Prod. 2018;171:1605–1621. [Google Scholar]

- 53.Betiku E., Ajala S.O. Modeling and optimization of Thevetia peruviana (yellow oleander) oil biodiesel synthesis via Musa paradisiacal (plantain) peels as heterogeneous base catalyst: a case of artificial neural network vs. response surface methodology. Ind. Crops Prod. 2014;53:314–322. [Google Scholar]

- 54.Mohit H., Selvan V.A.M. Optimization of the tensile strength of sintered Al6061/SiC nanocomposites using response surface methodology. Mater. Today Proceed. 2020;27:2801–2805. [Google Scholar]

- 55.Tosun N., Cogun C., Tosun G. A study on kerf and material removal rate in wire electrical discharge machining based on Taguchi method. J. Mater. Process. Tech. 2004;152:316–322. [Google Scholar]

- 56.Awolusi T.F., Oke O.L., Akinkurolere O.O., Sojobi A.O. Application of response surface methodology: predicting and optimizing the properties of concrete containing steel fibre extracted from waste tires with limestone powder as filler. Case Stud. Const. Mater. 2019;10:1–21. [Google Scholar]

- 57.Ferdosian I., Camoes A. Eco-efficient ultra-high-performance concrete development by means of response surface methodology. Cem. Concr. Compos. 2017;84:146–156. [Google Scholar]

- 58.Jitendra K., Khed V.C. Optimization of concrete blocks with high volume fly ash and foundry Sand. Mater. Today Proceed. 2020;27:1172–1179. [Google Scholar]

- 59.Nambiar E.K.K., Ramamurthy K. Models relating mixture composition to the density and strength of foam concrete using response surface methodology. Cem. Concr. Compos. 2006;28:752–760. [Google Scholar]

- 60.Rooholamini H., Hassani A., Aliha M.R.M. Evaluating the effect of macro-synthetic fibre on the mechanical properties of roller-compacted concrete pavement using response surface methodology. Constr. Build. Mater. 2018;159:517–529. [Google Scholar]

- 61.Vasudevan S., Poornima V., Balachandran M. Influence of admixtures on properties of concrete and optimization using response surface methodology. Mater. Today Proceed. 2020;24:650–661. [Google Scholar]

- 62.Ashengroph M., Nahvi I., Amini J. Application of Taguchi design and Response surface methodology for improving conversion of isoeugenol into vanillin by resting cells of Psychrobacter sp. CSW4, Iran. J. Pharm. Res. 2013;12(3):411–421. [PMC free article] [PubMed] [Google Scholar]

- 63.de Freitas A.P.B.R., de Freitas L.V., Loures C.C.A., Gonçalves L.G., Silva M.B. Response surface method and Taguchi Orthogonal Array applied to phenolic wastewater by advanced oxidation process (AOP) Am. J. Theor. Appl. Stat. 2014;3(6-1):35–41. [Google Scholar]

- 64.Zhang L.W., Sojobi A.O., Kodur V.K.R., Liew K.M. Effective utilization and recycling of mixed recycled aggregates for a greener environment. J. Clean. Prod. 2019;236:1–27. [Google Scholar]

- 65.Awoyera P.O., Akinmusuru J.O., Ndambuki J.M. Green concrete production with ceramic wastes and laterite. Constr. Build. Mater. 2016;117:29–36. [Google Scholar]

- 66.Bodian S., Faye M., Sene N., Sambou V., Limam O., Thiam A. Thermo-mechanical behavior of unfifired bricks and fifired bricks made from a mixture of clay soil and laterite. J. Build. Eng. 2018;18:172–179. [Google Scholar]

- 67.Yaragal S.C., Gowda S.N.B., Rajasekaran C. Characterization and performance of processed lateritic fine aggregates in cement mortars and concretes. Constr. Build. Mater. 2019;200:10–25. [Google Scholar]

- 68.John V.M., Damineli B.L., Qualtrone M., Pileggi R.G. Fillers in cementitious materials — experience, recent advances and future Potential. Cem. Concr. Res. 2018;115:65–78. [Google Scholar]

- 69.Zunino F., Scrivener K. The influence of the filler effect on the sulfate requirement of blended cements. Cem. Concr. Res. 2019;126:1–10. [Google Scholar]

- 70.Ajao A.M., Ogunbayo B.F., Ogundipe K.E., Bamigboye G.O., Ogunde A.O., Tunji-Olayeni P.F. Assessment of sandcrete blocks manufacturers' compliance to minimum standard requirements by standard organisation of Nigeria in southwest, Nigeria. Int. J. Appl. Eng. Res. 2018;13(6):4162–4172. [Google Scholar]

- 71.Ambrose E.E., Etim R.K., Koffi N.E. Quality assessment of commercially produced sandcrete blocks in part of Akwa Ibom State, Nigeria. Nig. J. Tech. 2019;38:3. [Google Scholar]

- 72.Odeyemi S.O., Akinpelu M.A., Atoyebi O.D., Orire K.J. Quality assessment of sandcrete blocks produces in Adeta, Kwara State, Nigeria. Nig. J. Tech. 2018;37(1):53–59. [Google Scholar]

- 73.FRN . first ed. Lexis Nexis, Butterworths; South Africa: 2006. National Building Code, Federal Republic of Nigeria. [Google Scholar]

- 74.Nzeh R., Nzeh R.E. Department of Civil Engineering, University of Nigeria; Nsukka, Nigeria: 2008. Standardization of Sandcrete-Block’s Strength through Mathematical Modelling and Precision. PhD Thesis, Dept. Civ Eng, University of Nigeria, Nsukka. [Google Scholar]

- 75.SON . Standard Organisation of Nigeria; Lagos, Nigeria: 2007. Nigerian Industrial Standard: Standard for Sandcrete Blocks, NIS 87. [Google Scholar]

- 76.Anya C.U., Osadebe N.N. Effect of partial replacement of sand with quarry dust on the structural characteristics of sandcrete bricks. Nig. J. Tech. 2015;34(4):679–684. [Google Scholar]

- 77.Lokeshwari M., Jagadish K.S. Eco-friendly use of granite fines waste in building blocks. Proc. Environ. Sci. 2016;35:618–623. [Google Scholar]

- 78.Singh S., Khan S., Khandelwal R., Chugh A., Nagar R. Performance of sustainable concrete containing granite cutting waste. J. Clean. Prod. 2016;119:86–98. [Google Scholar]

- 79.Lemougna P., Wang K., Tang Q., Kamseu E., Billong N., Melo U., Cui X. Effect of slag and calcium carbonate addition on the development of geopolymer from indurated laterite. Appl. Clay Sci. 2017;148:109–117. [Google Scholar]

- 80.Khan K., Ullah M.F., Shahzada K., Amin M.N., Bibi T., Wahab N., Aljaafari A. Effective use of micro-silica extracted from rice husk ash for the production of high-performance and sustainable cement mortar. Constr. Build. Mater. 2020;258:1–12. [Google Scholar]

- 81.Yaragal S.C., Gowda S.N.B., Rajasekaran C. Characterization and performance of processed lateritic fine aggregates in cement mortars and concretes. Constr. Build. Mater. 2019;200:10–25. [Google Scholar]

- 82.Binici H., Aksogan O., Shah T. Investigation of fibre reinforced mud brick as a building material. Constr. Build. Mater. 2005;19:313–318. [Google Scholar]

- 83.Kumi-Larbi A., Yunana D., Kamsouloum P., Webster M., Wilson D.C., Cheeseman C. Recycling waste plastics in developing countries: use of low-density polyethylene water sachets to form plastic bonded sand blocks. Waste Manag. 2018;80:112–118. doi: 10.1016/j.wasman.2018.09.003. [DOI] [PubMed] [Google Scholar]

- 84.Opoku R., Obeng G.Y., Darkira J., Kwofie S. Minimizing heat transmission loads and improving energy efficiency of building envelopes in sub-Saharan Africa using bio-based composite materials. Sci. Afr. 2020;8:1–13. [Google Scholar]

- 85.Khare M., Gupta R.K., Bhardwaj B. Dry sliding wear behavior of Al 7075/Al2O3/B4C composites using mathematical modeling and statistical analysis. Mater. Res. Express. 2019;6(12):126512. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data will be made available on request.