Abstract

To investigate the effects of electrolyzed water treatment on the qualities of rice noodles prepared with semidry- milled rice flour, pasting properties and thermal properties of rice flour, and the cooking and textural properties of rice noodles were determined. Higher peak viscosity and lower melting enthalpy were observed in electrolyzed water (EW) treated rice flour. The hardness, gumminess and chewiness of rice noodle in slightly acidic electrolyzed water treated rice noodles with available chlorine concentration (ACC) 20.32 mg/L were increased significantly (p < 0.05). The cooking loss decreased significantly in strong acidic electrolyzed water treated noodles with ACC 10.09 mg/L treatment (p < 0.05). The results indicated that EW could promote the gelatinization of rice flour, and improve the textural qualities of rice noodles. Therefore EW was appropriate to be used in rice noodle production.

Keywords: Electrolyzed water, Qualities, Rice noodles, Semidry-milling, Rice flours

Introduction

Rice noodles, which are made from rice flour, play an important role in the daily diet and are widely eaten in most Asian countries. Nowadays the pace of people’s living is speeding up and the demand for convenience food is increasing. Rice noodles are rich in carbohydrate and protein, which can supply humans with more energy, and thus rice noodles are the best choice (Supakornchuwong and Suwannaporn, 2012).

The rice flour preparation methods have effects on noodle quality. Wet-milling is traditionally used in the production of rice pulp or rice flour with an ideal particle size, which produces noodles with a smoother texture. The content of damaged starch was significantly lower in wet-milled flour, which is considered to be desirable in rice noodle production (Tong et al., 2015). However, the large quantity of waste water is a big environment problem, and the long soaking time resulted in a loss of nutrient as well as bacteria growth in rice, which had bad effects on product quality (Charles et al., 2007). Dry-milling could minimize the waste water disposal problem. However, the particle size of rice flour made by dry-milling was unsatisfactory, and the final product exhibited poorer organoleptic quality (Jitranut and Jirarat, 2016).

An emerging process involves the use of semidry-milling has been applicated. Previous research showed that semidry-milling at 30% moisture had improvement effects on characteristics of rice flour by decreasing the content of damaged starch, and could protect the integrity of starch granules and improve the whiteness of rice flour, and the rice noodles produced by rice flour with semidry-milling at 30% moisture exhibited better textural and cooking qualities than dry-milled rice noodles (Tong et al., 2014). However, compared with wet-milling rice flour, the pasting properties of semidry-milled rice flour still need to be improved, previous research showed that lower peak viscosity was observed in semidry-milled rice flour, which indicated the large starch granule was different to gelatinize. Moreover, the textural qualities of rice noodles, which include hardness and chewiness, were smaller for noodles (Tong et al., 2014). Therefore, the development of effective methods to improve the rice noodle quality based on semidry- milling is an ongoing subject of interest.

Electrolyzed water (EW) has been widely used in the food processing industries. EW can be made by electrolyzing dilute salt or hydrochloric acid solution, and can be divided into acidic and alkaline electrolyzed water based on the pH. EW has been used in the manufacture of food products. Previous research showed that the texture of tofu processed by adding EW was softer than tap water treatment (Hara et al., 2003a). Noodles produced by kneading wheat flour with acidic electrolyzed water were harder and springier than tap water treatment (Hara et al., 2003b). The texture of cooked age rice can be improved by using alkaline electrolyzed water (Al-Haq et al., 2005). Therefore, EW can be used for kneading to improve the quality of processed foods without adding any food additives. Previous research showed that pasting properties were changed when wheat starch was heated in electrolyzed water, and acidic electrolyzed water was more effective than alkaline electrolyzed water in modifying the pasting properties of wheat starch (Al-Haq et al., 2005). However, literature review does not show any studies using EW in rice noodle production.

The objective of this study was to investigate the improvement effects of electrolyzed water on pasting properties of rice flour and the quality of rice noodles.

Materials and methods

Materials

The indica rice (Hunan fragrant rice variety, harvested in 2018.07) used in the study was provided by Jinjian Cereals Industry co., Ltd. (Changde, China). The moisture and protein content of rice were 12.46% and 7.22% (dry basis), respectively.

Preparation of semidry-milled rice flour

Rice was hydrated before milling (Tong et al., 2015). Water addition amount used for hydration was calculated based on the formula: Water addition amount (mL) = W(M1 − M0)/(1 − M1), W-sample weight, g; M1-moisture of rice after hydration, %; M0-moisture of rice before hydration, %. The moisture of rice used in the study changed to 30% after hydration. Then the rice samples were ground into flour using a cyclone mill and passed through a 100 mesh sieve (CT410, FOSS Scino (Suzhou) Co., Ltd., Suzhou, China). The damage starch content was between 2 and 3%, according to Tong et al. (2015). All rice flours were freeze-dried to obtain the rice flour below 5% moisture and stored at 4 °C for uses.

Preparation of electrolyzed water

Electrolyzed water (EW) was prepared using an EW generator (model XY-L-150, Xinyu Optics-Mechanics-Electricity Co. Ltd., Baoji, China). The electrolyzed water was collected from the outlet, and used immediately in the experiments. In this study, electrolyzed water with different physicochemical indexes was used, and this was prepared by adjusting the concentration of the electrolysis solution. The pH values of electrolyzed water were measured with a No. 6503 pH electrode (Lohand Biological Instrument Co. Ltd., Hangzhou, China). The ACC of electrolyzed water was determined by iodometry (Block, 1983). The electrolyzed water used in the study includes: strong acidic electrolyzed water (StAEW) with pH 2.98 and available chlorine concentration(ACC) 10.15 mg/L; StAEW with pH 2.98 and ACC 20.17 mg/L; StAEW with pH 2.98 and ACC 30.23 mg/L; slightly acidic electrolyzed water (SAEW) with pH 5.02 and ACC 10.09 mg/L; SAEW with pH 5.02 and ACC 20.32 mg/L; SAEW with pH 5.02 and ACC 30.47 mg/L.

Preparation of rice noodles

To prepare rice noodle control, 100 g freeze-dried rice flour was mixed with 100 mL deionized water to make rice milk. Pouring the rice milk into the stainless steel pan to steam at 100 °C for 20 min. The rice dough is tightly packed through a dough forming machine (JCXZ, Beijing Dongfu Jiuheng Instrument Technology Co., Ltd., Beijing, China). Then the rice noodle was extruded from the dough using a rice-noodle machine (Senchao Machinery Equipment Manufacturing Co., Ltd., Xingtai, China), and the diameter of the round noodle was 3 mm. In electrolyzed water treatment, 50 mL deionized water and 50 mL electrolyzed water was used instead of 100 mL deionized water to make rice milk, the other steps to make noodles were the same as previously mentioned.

Determination of pasting properties of rice flour

Pasting properties of rice flour were analyzed in triplicate with an RVA (RVA-TecMaster, Perten, Sweden) following the method described by Xie et al. (2015) with modification. Briefly, 3.14 g of rice flour (4.10% moisture basis) was mixed in 25.36 mL of deionized water or electrolyzed water. The mixture was kept at 50 °C for 1 min, then heated to 95 °C in 3.7 min, kept for 2.5 min, and cooled to 50 °C in 3.8 min, kept for 1 min. Viscosity was recorded as centipoise, including peak viscosity, trough viscosity, breakdown value (peak minus trough viscosity values), final viscosity, setback value (final minus trough viscosity values).

Determination of thermal properties of rice flour

Thermal properties of rice flour were analyzed in triplicate with a DSC (DSC-Q200, TA, USA) following the method described by Xie et al. (2015) with modification. Briefly, 3.0 mg of rice flour was weighed into a 40 μL aluminium pan, and deionized water or electrolyzed water was added to give a sample-to-water weight ratio of 1:2. The pan was sealed and held at 4 °C overnight before analysis. The pan was heated at a rate of 10 °C/min from 20 to 100 °C. An empty aluminium pan was used as a reference. To (onset temperature), Tp (peak temperature), Tc (conclusion temperature), and ΔH (enthalpy of gelatinization) were calculated automatically with the equipped software (TA Universal Analysis).

Determination of cooking qualities of rice noodles

Cooking qualities of rice noodles were analyzed following the method described by Tong et al. (2015) with modification. Briefly, 10 g of rice noodles were boiled in 150 mL deionized water for 2 min, followed by draining for 5 min, and the weight was recorded. The cooking water was collected and dried at 105 °C to a constant weight. Water absorption and cooking loss were calculated as follows:

Textural quality analysis of cooked rice noodles

The textural quality of cooked rice noodles was analyzed using a Texture Analyser (TA.HD Plus, Stable Micro System Ltd., Godalming, England) following the method described by Tong et al. (2015) with modification. Briefly, 10 g of rice noodles were cooked in 150 mL boiling deionized water for 2 min, followed by cooling with deionized water at room temperature, and kept at 4 °C for 2 h before analysis. Rice noodles with 15 cm in length and similar diameter were prepared, and specific measuring parameters were as follows: P/SPR probes with the measuring speed of 60.0 mm/min, 50% degree of deformation, trigger force of 0.5 N. Fifteen samples for each treatment were measured and the values were averaged.

Statistical analysis

For each treatment, the means of independent replication trials were calculated. A one-way analysis of variance (ANOVA) was used to determine the significance of differences between treatments at the same pH value (SPSS 22.0). The t-test was used to determine the significance of differences between treatments at the same ACC level (SPSS 22.0). Dunnett post hoc test was conducted between each EW treatment to control (SPSS 22.0). Statistical significance was set at a p value of < 0.05.

Results and discussion

The effect of electrolyzed water on the pasting properties of rice flour

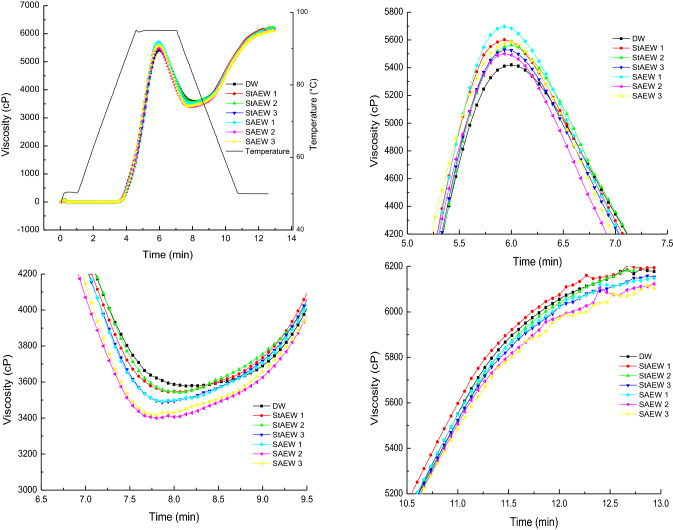

Pasting curves of rice flour in different physicochemical indexes of electrolyzed water were shown in Fig. 1, and pasting properties of rice flour in the presence of electrolyzed water were shown in Table 1. The ANOVA results showed that, at the same pH value, the pasting properties of rice flour treated by electrolyzed water with different ACC did not show significant differences (p > 0.05). The t-test result showed that, at the same ACC, the pasting properties of rice flour treated by electrolyzed water with pH 2.98 and pH 5.02 showed significant difference (p < 0.05). The Dunnett post hoc test between each EW treatment to control showed that, the breakdown value of rice flour treated by acidic electrolyzed water was significantly higher than control (p < 0.05).

Fig. 1.

Pasting curves of rice flour in different physicochemical indexes of electrolyzed water. StAEW 1: strong acidic electrolyzed water (StAEW) with pH 2.98 and available chlorine concentration(ACC) 10.15 mg/L; StAEW 2: StAEW with pH 2.98 and ACC 20.17 mg/L; StAEW 3: StAEW with pH 2.98 and ACC 30.23 mg/L; SAEW 1: slightly acidic electrolyzed water (SAEW) with pH 5.02 and ACC 10.09 mg/L; SAEW 2: SAEW with pH 5.02 and ACC 20.32 mg/L; SAEW 3: SAEW with pH 5.02 and ACC 30.47 mg/L; DW: deionized water

Table 1.

Pasting properties of rice flour in the presence of electrolyzed water

| Treatment | pH | ACC (mg/L) | Peak viscosity (cP) | Trough viscosity (cP) | Breakdown value (cP) | Final viscosity (cP) | Setback value (cP) |

|---|---|---|---|---|---|---|---|

| DW | 7.44 | ND | 5421.00 ± 38.18 | 3578.00 ± 7.07 | 1843.00 ± 45.25 | 6178 ± 0 | 2600.00 ± 7.07 |

| StAEW 1 | 2.98 | 10.15 | 5602.00 ± 9.90 aA | 3543.00 ± 29.70 aA | 2059.00 ± 39.60 aA* | 6194.50 ± 13.44 aA | 2651.50 ± 16.26 aA |

| StAEW 2 | 2.98 | 20.17 | 5563.50 ± 62.93 aA | 3542.50 ± 64.35 aA | 2021.00 ± 1.41 aA* | 6207.50 ± 10.61 aA | 2665.00 ± 74.95 aA |

| StAEW 3 | 2.98 | 30.23 | 5534.00 ± 113.14 aA | 3491.00 ± 66.47 aA | 2043.00 ± 46.67 aA* | 6153.50 ± 31.82 aA | 2662.50 ± 34.65 aA |

| SAEW 1 | 5.02 | 10.09 | 5697.50 ± 54.45 aA | 3496.50 ± 84.15 aA | 2201.00 ± 29.70 aA* | 6148.00 ± 50.91 aA | 2651.50 ± 33.23 aA |

| SAEW 2 | 5.02 | 20.32 | 5467.00 ± 25.46 aA | 3397.50 ± 62.93 aA | 2069.50 ± 88.39 aA* | 6136.00 ± 7.07 aB | 2738.50 ± 55.86 aA* |

| SAEW 3 | 5.02 | 30.47 | 5587.50 ± 267.99 aA | 3415.50 ± 207.18 aA | 2172.00 ± 60.81 aA* | 6102.50 ± 161.93 aA | 2687.00 ± 45.25 aA |

Values are means ± standard deviations, n = 3

StAEW strong acidic electrolyzed water, SAEW slightly acidic electrolyzed water, DW deionized water, ACC available chlorine concentration, ND not detected

*Next to a value in each column indicate significant differences of electrolyzed water treatments to control (p < 0.05)

Lower case letters next to a value in each column indicate significant differences of treatments at the same pH values (p < 0.05)

Upper case letters next to a value in each column indicate significant differences of treatments at the same ACC values (p < 0.05)

When the rice flour solution was heated, the hydrogen bond between starch granules weakened, and the starch granules absorb water, which leads to an increase of viscosity until the peak viscosity was reached. With the continued increase of temperature, the starch particles keep swollen until broken, and with the release of starch, the viscosity decreased. During the cooling procedure, amylose starch retrogradation, during which hydrogen bonds re-formed, and the viscosity increased.

An increase of peak viscosity and decrease of trough viscosity in acid electrolyzed water treated rice flour was observed, and two reasons might account for the phenomenon. One might be more water absorbed by rice flour during heating, and the starch particles keep swollen after addition of acid electrolyzed water. Sato and coworkers (Sato et al., 1994) once observed the effect of soaking time on the water content of rice, and the result showed that when the soaking time was in 30 min, acidic electrolyzed water showed promotion effect on water absorption of rice. Ohishi and coworkers (Ohishi et al., 2007) reported that during heating process, more water was absorbed in starch granules with acid treatment than distilled water treatment, and in the presence of acid, the structure of the starch became more fragile by stirring, resulting in the decrease of trough viscosity and the increase of breakdown value (Ohishi et al., 2007; Wang et al., 2000). The other might be that oxidation-induced cross linking of starch molecules, since acidic electrolyzed water possess oxidizing properties (Liao et al., 2007). The result of pasting properties of rice flours is in line with Ding et al. (2015) who reported increased in peak viscosity of rice flour after ozone treatment, which also possess oxidizing properties.

Mizukami and coworkers (Mizukami et al., 1996) reported that the final viscosity of starch by RVA measurement was relevant to the quality of cooked rice when it was cooled. As shown in Table 1, the final viscosity of the paste with SAEW treatment was lower than deionized water treatment. It was suggested that cooked rice with SAEW might exhibit less tendency of retrogradation. Wang et al. (2000) also confirmed that acidic rice flour paste exhibited less tendency of retrogradation, which due to the short-chain starch molecules appeared as a result of acid hydrolysis.

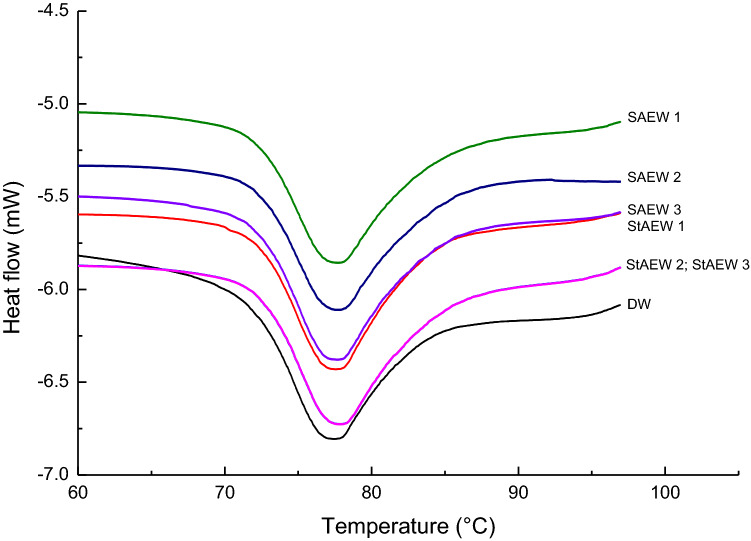

The effect of electrolyzed water on the thermal properties of rice flour

DSC curves of rice flour with the addition of electrolyzed water was shown in Fig. 2, and the effect of electrolyzed water addition on thermal properties of rice flour was shown in Table 2. The ANOVA results showed that, at pH 2.98, the onset and peak temperature of rice flour treated by EW of ACC 30.23 mg/L were significantly higher than ACC 10.15 mg/L treatment (p < 0.05). The t-test result showed that, at ACC of 30 mg/L, the onset and peak temperature of rice flour treated by EW of pH 2.98 were significantly higher than pH 5.02 treatment (p < 0.05). The Dunnett post hoc test result showed that the ΔH of rice flour of electrolyzed water treatment decreased significantly (p < 0.05), except StAEW 2 treatment.

Fig. 2.

DSC curves of rice flour with the addition of electrolyzed water. StAEW 1: strong acidic electrolyzed water (StAEW) with pH 2.98 and available chlorine concentration(ACC) 10.15 mg/L; StAEW 2: StAEW with pH 2.98 and ACC 20.17 mg/L; StAEW 3: StAEW with pH 2.98 and ACC 30.23 mg/L; SAEW 1: slightly acidic electrolyzed water (SAEW) with pH 5.02 and ACC 10.09 mg/L; SAEW 2: SAEW with pH 5.02 and ACC 20.32 mg/L; SAEW 3: SAEW with pH 5.02 and ACC 30.47 mg/L; DW: deionized water

Table 2.

Effect of electrolyzed water addition on thermal properties of rice flour

| Treatment | pH | ACC (mg/L) | Onset temperature (°C) | Peak temperature (°C) | Conclusion temperature (°C) | ΔH (J/g) |

|---|---|---|---|---|---|---|

| DW | 7.44 | ND | 71.81 ± 0.16 | 77.09 ± 0.23 | 74.45 ± 0.58 | 14.32 ± 0.05 |

| StAEW 1 | 2.98 | 10.15 | 72.19 ± 0.14 bA | 77.53 ± 0.20 bA | 74.39 ± 0.16 aA | 12.89 ± 0.29 cA* |

| StAEW 2 | 2.98 | 20.17 | 72.28 ± 0.07 bA* | 77.70 ± 0.16 abA* | 75.11 ± 1.18 aA | 14.17 ± 0.10 aA |

| StAEW 3 | 2.98 | 30.23 | 72.70 ± 0.01 aA* | 77.98 ± 0.21 aA* | 74.08 ± 0.08 aA | 13.61 ± 0.21 bA* |

| SAEW 1 | 5.02 | 10.09 | 72.20 ± 0.23 aA | 77.60 ± 0.27 aA | 74.17 ± 0.72 aA | 13.05 ± 0.03 bA* |

| SAEW 2 | 5.02 | 20.32 | 72.32 ± 0.23 aA* | 77.68 ± 0.26 aA | 74.29 ± 0.77 aA | 11.85 ± 0.28 cB* |

| SAEW 3 | 5.02 | 30.47 | 72.27 ± 0.08 aB* | 77.48 ± 0.15 aB | 74.48 ± 0.72 aA | 13.78 ± 0.03 aA* |

Values are means ± standard deviations, n = 3

StAEW strong acidic electrolyzed water, SAEW slightly acidic electrolyzed water, DW deionized water, ACC available chlorine concentration, ND not detected

*Next to a value in each column indicate significant differences of electrolyzed water treatments to control (p < 0.05)

Lower case letters next to a value in each column indicate significant differences of treatments at the same pH values (p < 0.05)

Upper case letters next to a value in each column indicate significant differences of treatments at the same ACC values (p < 0.05)

The study showed that under strong acidic condition, the To and Tp of rice flour increased with increase in the ACC of electrolyzed water, and under higher ACC condition, the To and Tp of rice flour increased with decrease in the pH of electrolyzed water. For those with higher onset temperature and peak temperature, it indicates that water permeates and diffuses into starch particles slowly during gelatinization, thus delaying the phase change. This was in line with the study done by Sakkara et al. (2020), who once observed maize starch showed reduced hydrophilicity under strong acidic conditions. Sun and coworkers (Sun et al., 2013) observed an increase in gelatinization temperature of starch after AH-HMT (acid hydrolysis combined with heat moisture treatment). It was suggested that the increase in To and Tp were related to the reorientation of the starch granules and crystalline reorganization.

The melting enthalpy of rice flour is independent of the onset, peak and conclusion temperature. The enthalpy values (ΔH) represent the number of double helices that unravel and melt during gelatinization (Cooke and Gidley, 1992). The higher enthalpy gelatinization value indicated more heat was needed to melt the rice powder crystals (Wu et al., 2015). It was assumed that electrolyzed water treatments tend to disrupt the crystallinity of starch, and some of the double helices present in crystalline and non-crystalline regions of the starch granule have been damaged during electrolyzed water treatment (Sun et al., 2013).

The effect of electrolyzed water on the cooking qualities of rice noodles

The effect of electrolyzed water on the cooking qualities of rice noodles was shown in Table 3. According to the ANOVA result, at the same pH value, the cooking loss of rice noodles treated by EW with ACC 10 mg/L were significantly lower than ACC 30 mg/L treatments (p < 0.05). According to the t-test result, at ACC levels of 10 mg/L and 20 mg/L, the cooking loss of rice noodles treated by EW with pH 2.98 was significantly lower than pH 5.02 treatment (p < 0.05). The Dunnett post hoc test result showed that the cooking loss of rice noodles treated by EW with pH 2.98 and ACC 10.15 mg/L was significantly lower than control (p < 0.05).

Table 3.

The effect of electrolyzed water on the cooking qualities of rice noodles

| Treatment | pH | ACC (mg/L) | Cooking loss (%) | Water absorption (%) |

|---|---|---|---|---|

| DW | 7.44 | ND | 4.20 ± 0.32 | 26.97 ± 5.09 |

| StAEW 1 | 2.98 | 10.15 | 2.69 ± 0.59 bB* | 23.00 ± 0.69 bA |

| StAEW 2 | 2.98 | 20.17 | 3.49 ± 0.38 abB | 31.03 ± 0.01 aA |

| StAEW 3 | 2.98 | 30.23 | 5.08 ± 1.92 aA | 34.00 ± 2.59 aA |

| SAEW 1 | 5.02 | 10.09 | 3.57 ± 0.33 bA | 29.62 ± 3.78 aA |

| SAEW 2 | 5.02 | 20.32 | 4.38 ± 0.52 aA | 21.17 ± 8.08 aA |

| SAEW 3 | 5.02 | 30.47 | 4.52 ± 0.58 aA | 20.36 ± 0.49 aA |

Values are means ± standard deviations, n = 3

StAEW strong acidic electrolyzed water, SAEW slightly acidic electrolyzed water, DW deionized water, ACC available chlorine concentration, ND not detected

*Next to a value in each column indicate significant differences of electrolyzed water treatments to control (p < 0.05)

Lower case letters next to a value in each column indicate significant differences of treatments at the same pH values (p < 0.05)

Upper case letters next to a value in each column indicate significant differences of treatments at the same ACC values (p < 0.05)

Cooking loss is the solid loss in the cooking water, and it is an important factor that determines the cooking quality of final product and indicates the capability of a product to resistant to the structural breakdown during cooking (Ahmed et al., 2016). In the present study, at the same pH level, the cooking loss increased with the increasing ACC value, this would be related to the amount of the soluble protein increased with higher concentration of available chlorine (Watanuki et al., 2004). According to literature, less than 7–8% cooking loss is acceptable (Ko et al., 2015). In the present study, the rice noodles were made from semidry- milled rice flour, and previous researches showed that semidry milling has a protective effect on the integrity of starch granules (Heo et al., 2013; Tong et al., 2015). The cooking qualities of rice noodles made by semidry milling rice flour and involved using electrolyzed water are acceptable.

The effect of electrolyzed water on the textural properties of rice noodles

The effect of electrolyzed water on the textural properties of rice noodles was shown in Table 4. The ANOVA results showed that, at pH 2.98, the hardness, gumminess of rice noodles treated by EW with ACC 30.23 mg/L were significantly higher, whereas adhesiveness and cohension were significantly lower than ACC 10.15 mg/L treatment, (p < 0.05). The t-test results showed that, at the ACC level of 10 mg/L and 20 mg/L, the hardness and gumminess of rice noodles treated by EW with pH of 5.02 were higher, whereas springiness was lower than pH 2.98 treatment (p < 0.05). The Dunnett post hoc test result showed that the adhesiveness of rice noodles of EW treatment was significantly higher than control (p < 0.05).

Table 4.

The effect of electrolyzed water on the texture properties of rice noodles

| Treatment | pH | ACC (mg/L) | Hardness (g) | Adhesiveness (-g s) | Resilience (%) | Cohesion | Springiness (%) | Gumminess (g) | Chewiness (g) |

|---|---|---|---|---|---|---|---|---|---|

| DW | 7.44 | ND | 4713.42 ± 801.70 | 76.99 ± 21.59 | 50.50 ± 3.28 | 0.69 ± 0.04 | 87.87 ± 3.53 | 3219.96 ± 388.95 | 2836.56 ± 412.04 |

| StAEW 1 | 2.98 | 10.15 | 4608.02 ± 381.27 bB | 208.74 ± 33.00 bA* | 46.47 ± 2.92 aA | 0.73 ± 0.02 aA | 86.05 ± 1.90 aA | 3338.31 ± 224.91 bB | 2875.09 ± 238.95 aA |

| StAEW 2 | 2.98 | 20.17 | 5108.45 ± 626.49 aB | 179.56 ± 30.35 bA* | 47.66 ± 3.04 aA | 0.71 ± 0.02 aA | 86.36 ± 4.56 aA | 3629.13 ± 356.49 aB | 3142.59 ± 415.65 aB |

| StAEW 3 | 2.98 | 30.23 | 5435.38 ± 631.77 aA | 146.07 ± 60.52 aA* | 44.71 ± 5.39 aA* | 0.67 ± 0.04 bA | 84.34 ± 5.74 aA | 3625.87 ± 266.44 aA | 3066.65 ± 385.38 aA |

| SAEW 1 | 5.02 | 10.09 | 5599.50 ± 816.05 abA* | 225.58 ± 63.20 bA* | 43.81 ± 5.92 bA* | 0.67 ± 0.04 bB | 82.34 ± 4.53 aB* | 3720.75 ± 395.85 bA* | 3067.37 ± 423.48 bA |

| SAEW 2 | 5.02 | 20.32 | 6225.81 ± 889.00 aA* | 206.78 ± 66.08 abA* | 50.06 ± 4.09 aA | 0.71 ± 0.03 aA | 82.80 ± 3.55 aB* | 4423.60 ± 554.82 aA* | 3667.78 ± 528.12 aA* |

| SAEW 3 | 5.02 | 30.47 | 5338.85 ± 792.48 bA | 163.03 ± 30.41 aA* | 46.86 ± 5.95 abA | 0.68 ± 0.04 abA | 83.11 ± 4.61 aA* | 3620.84 ± 432.43 bA | 3017.76 ± 451.24 bA |

Values are means ± standard deviations, n = 15

StAEW strong acidic electrolyzed water, SAEW slightly acidic electrolyzed water, DW deionized water, ACC available chlorine concentration, ND not detected

*Next to a value in each column indicate significant differences of electrolyzed water treatments to control (p < 0.05)

Lower case letters next to a value in each column indicate significant differences of treatments at the same pH values (p < 0.05)

Upper case letters next to a value in each column indicate significant differences of treatments at the same ACC values (p < 0.05)

Sozer and Kaya (2008) reported that protein molecules are positively charged, and starch molecules are negatively charged under acidic pH, and electrostatic interactions between proteins and starch may readily occur, which enhanced starch-protein interactions. The acidic pH of electrolyzed water may contribute to the increase of hardness of rice noodles.

Ahmed et al. (2016) reported that chewiness and hardness of rice noodles made from flour with smaller particle size were higher than those made from flour with larger particle size, characterizing better quality, which due to the quick and complete gelatinization of smaller particle size (Hatcher et al., 2002). Similarly, in the research, the results showed that peak viscosity of rice flour of electrolyzed water treatment increased, which indicated that electrolyzed water promoted water absorption of rice flour. More water and heat is entered into the starch granule cores of the flour with electrolyzed water, thus the flour gelatinized more thoroughly.

Acknowledgements

This work was supported by Laboratory of Agro-Products Processing, Ministry of Agriculture and Rural Affairs, the Key Disciplines Construction Foundation of the “1331” Project of Shanxi Province (Grant Number 098-091704), and the Fund for Shanxi Key Subjects Construction (FSKSC).

Declarations

Conflict of interest

The authors declare no conflict of interest.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Rui Liu, Email: liuruiycu@126.com.

Zhang-Long Yu, Email: y_zl1230@163.com.

Yuan-Lin Sun, Email: sunyuanlinycu@126.com.

Li-Tao Tong, Email: 576295668@qq.com.

Li-Ya Liu, Email: 604368127@qq.com.

Li-Li Wang, Email: 331455751@qq.com.

Xian-Rong Zhou, Email: lrui5188@126.com.

Su-Mei Zhou, Email: allie@ycu.edu.cn.

References

- Ahmed I, Qazi IM, Li Z, Ullah J. Rice noodles: materials, processing and quality evaluation. Proceedings of the Pakistan Academy of Sciences: B. Life and Environmental Sciences. 2016;53:215–238. [Google Scholar]

- Al-Haq MI, Sugiyama J, Isobe S. Applications of electrolyzed water in agriculture & food industries. Food Science and Technology Research. 2005;11:135–150. doi: 10.3136/fstr.11.135. [DOI] [Google Scholar]

- Block SS. Sterilants, disinfectants and antiseptics. In: Block SS, editor. Disinfection, Sterilization, and Preservation. Philadelphia, USA: Lea and Febiger; 1983. pp. 157–160. [Google Scholar]

- Charles AL, Huang TC, Lai PY, Chen CC, Lee PP, Chang YH. Study of wheat flour–cassava starch composite mix and the function of cassava mucilage in Chinese noodles. Food Hydrocolloids. 2007;21:368–378. doi: 10.1016/j.foodhyd.2006.04.008. [DOI] [Google Scholar]

- Cooke D, Gidley MJ. Loss of crystallinity and molecular order during starch gelatinization: origin of the enthalpic transition. Carbohydrate Research. 1992;227:103–112. doi: 10.1016/0008-6215(92)85063-6. [DOI] [Google Scholar]

- Ding W, Wang Y, Zhang W, Shi Y, Wang D. Effect of ozone treatment on physicochemical properties of waxy rice flour and waxy rice starch. International Journal of Food Science and Technology. 2015;50:744–749. doi: 10.1111/ijfs.12691. [DOI] [Google Scholar]

- Hara Y, Matsuda H, Arai E. Effects of weakly electrolyzed water on properties of tofu (soybean curd) Food Science and Technology Research. 2003;9:332–337. doi: 10.3136/fstr.9.332. [DOI] [Google Scholar]

- Hara Y, Watanuki A, Arai E. Effects of weakly electrolyzed water on properties of Japanese wheat noodles (udon) Food Science and Technology Research. 2003;9:320–326. doi: 10.3136/fstr.9.320. [DOI] [Google Scholar]

- Hatcher DW, Anderson MJ, Desjardins RG, Edwards NM, Dexter JE. Effects of flour particle size and starch damage on processing and quality of white salted noodles. Cereal Chemistry. 2002;79:64–71. doi: 10.1094/CCHEM.2002.79.1.64. [DOI] [Google Scholar]

- Heo S, Lee SM, Shim JH, Yoo SH, Lee S. Effect of dry- and wet-milled rice flours on the quality attributes of gluten-free dough and noodles. Journal of Food Engineering. 2013;116:213–217. doi: 10.1016/j.jfoodeng.2012.11.017. [DOI] [Google Scholar]

- Jitranut L, Jirarat A. Effects of dry-milling and wet-milling on chemical, physical and gelatinization properties of rice flour. Rice Science. 2016;23:274–281. doi: 10.1016/j.rsci.2016.08.005. [DOI] [Google Scholar]

- Ko JA, Kim HS, Baek HH, Park HJ. Effects of hydroxypropyl methylcellulose and temperature of dough water on the rice noodle quality. Food Science and Technology Research. 2015;21:129–135. doi: 10.3136/fstr.21.129. [DOI] [Google Scholar]

- Liao LB, Chen WM, Xiao XM. The generation and inactivation mechanism of oxidation–reduction potential of electrolyzed oxidizing water. Journal of Food Engineering. 2007;78:1326–1332. doi: 10.1016/j.jfoodeng.2006.01.004. [DOI] [Google Scholar]

- Mizukami H, Hizukuri S, Takeda Y. Structures and pasting properties of starches from new characteristic rice cultivars. Journal of Applied Glycoscience. 1996;43:15–23. [Google Scholar]

- Ohishi K, Kasai M, Shimada A, Hatae K. Effects of acetic acid on the rice gelatinization and pasting properties of rice starch during cooking. Food Research International. 2007;40:224–231. doi: 10.1016/j.foodres.2006.10.005. [DOI] [Google Scholar]

- Sakkara S, Nataraj D, Venkatesh K, Xu Y, Patil JH, Reddy N. Effect of pH on the physicochemical properties of starch films. Journal of Applied Polymer Science. 2020;137:1–7. doi: 10.1002/app.48563. [DOI] [Google Scholar]

- Sato Y, Noguchi S, Takahashi S, Naito F. The properties of cooked rice with electrolyzed water and its soaking condition. Journal of Home Economics of Japan. 1994;45:343–348. [Google Scholar]

- Sozer N, Kaya A. The effect of cooking water composition on textural and cooking properties of spaghetti. International Journal of Food Properties. 2008;11:351–362. doi: 10.1080/10942910701409260. [DOI] [Google Scholar]

- Sun Q, Zhu X, Si F, Xiong L. Effect of acid hydrolysis combined with heat moisture treatment on structure and physicochemical properties of corn starch. Journal of Food Science and Technology. 2013;52:375–382. doi: 10.1007/s13197-013-0998-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Supakornchuwong C, Suwannaporn P. Attitudes toward rice compared with potatoes and pasta among British, French, Dutch and Belgian consumers. Journal of Sensory Studies. 2012;27:71–77. doi: 10.1111/j.1745-459X.2011.00369.x. [DOI] [Google Scholar]

- Tong L, Gao X, Wang L, Yi C, Zhou S. Preparation of fresh rice noodles using rice prepared by tempering moisture and semi-dry milling method and determination of its quality. Transactions of the Chinese Society of Agricultural Engineering. 2014;30:332–338. [Google Scholar]

- Tong LT, Gao XX, Lin LZ, Liu YJ, Zhong K, Liu LY, Zhou XR, Wang L, Zhou SM. Effects of semidry flour milling on the quality attributes of rice flour and rice noodles in China. Journal of Cereal Science. 2015;62:45–49. doi: 10.1016/j.jcs.2014.12.007. [DOI] [Google Scholar]

- Wang HH, Sun DW, Zeng Q, Lu Y. Effect of pH, corn starch and phosphates on the pasting properties of rice flour. Journal of Food Engineering. 2000;46:133–138. doi: 10.1016/S0260-8774(00)00077-7. [DOI] [Google Scholar]

- Watanuki A, Hara Y, Arai E. Effect of weakly electrolyzed water on the physical properties of rice-flour-bread. Journal of Cookery Science of Japan. 2004;37:352–359. [Google Scholar]

- Wu W, Zhu H, Wang Y, Li Y. The gelatinization and resuscitation properties of rice with DSC. Food Science and Technology. 2015;40:165–168. [Google Scholar]

- Xie L, He X, Duan B, Tang S, Luo J, Jiao G, Shao G, Wei X, Sheng Z, Hu P. Optimization of near-infrared reflectance model in measuring gelatinization characteristics of rice flour using RVA (rapid viscosity analyzer) and DSC (differential scanning calorimeter) Cereal Chemistry. 2015;92:522–528. doi: 10.1094/CCHEM-08-14-0171-R. [DOI] [Google Scholar]