Highlights

-

•

Recent advances in ultrasound combined processes are detailed.

-

•

Hybrid combination of ultrasound with conventional techniques.

-

•

Innovative combinations of ultrasound with modern techniques.

-

•

Ultrasound combination techniques as efficient tool for food processing.

Keywords: Ultrasound, Combination, Hybrid, Innovative techniques, Intensification, Mechanisms

Abstract

Ultrasound has a significant effect on the rate of various processes in food, perfume, cosmetic, pharmaceutical, bio-fuel, materials, or fine chemical industries, despite some shortcomings. Combination with other conventional or innovative techniques can overcome these limitations, enhance energy, momentum and mass transfer, and has been successfully demonstrated in many recent studies. Various ultrasound combined hybrid and innovative techniques are systematically summarized in this review for the first time. Ultrasound can be combined with diverse conventional techniques including Soxhlet, Clevenger, enzyme, hydrotropes, ionic liquids, Deep Eutectic Solvents (DES) or Natural Deep Eutectic Solvents (NADES), to enhance mixing and micro-mixing, reduced thermal and concentration gradients, and selective extraction. Moreover, combinations of ultrasound with other innovative techniques such as microwave, extrusion, supercritical fluid, subcritical and pressure liquids, Instant controlled pressure drop (DIC), Pulsed Electric Field (PEF), Ultra-Violet (UV) or Infra-Red (IR) radiations, Counter-current chromatography (CCC), or centrifugal partition chromatographs (CPC) can enable reduced equipment size, faster response to process control, faster start-up, increased production, and elimination of process steps. The theories and applications of these ultrasound combined hybrid and innovative techniques as well as their advantages and limitations are compared, and further perspectives are proposed. This review provides new insights into advances in ultrasound combined techniques and their application at research, educational, and industrial level in modern food and plant-based chemistry.

1. Introduction

Processing under extreme or non-classical conditions is currently a dynamically developing area in applied research and industry. Alternatives to conventional transformation, preservation and extraction procedures may increase production efficiency and contribute to environmental preservation by reducing the use of water, energy and generation of hazardous substances. Ultrasound is a key versatile technology in achieving principles of sustainable “green” chemistry and extraction [1], [2]. Using ultrasound, full process of extraction could be completed in minutes with high reproducibility, reducing the consumption of solvent, simplifying manipulation and work-up, eliminating post-treatment of waste water, and consuming only a fraction of the fossil energy normally needed for a conventional process or extraction method such as Soxhlet extraction or Clevenger distillation. Although ultrasound has many advantages in term of mass transfer, there are still some obvious flaws, resulting in unsatisfactory results in certain cases such as degradation of secondary and primary metabolites [3]. Ultrasound is not a heating technique, so it's not ideally suited for the heat transfer, and cannot be used for macro-mixing, therefore, is not ideally suited for the momentum transfer.

This is the first report where ultrasound combined techniques have been summarized systematically with regard to processing and extraction techniques for food and natural extracts and products. Discussions focus on development of combined hybrid and innovative techniques, type of process obtained, driving forces and working mechanisms and the improvement on the yield, selectivity and total production line have also been discussed. This review does not include the discussion on ultrasound cavitation theory [4], guidelines of good practice for ultrasound [5], and application of ultrasound in food technology [6] as excellent reviews can be found elsewhere. This review presents a complete picture of current knowledge on combined hybrid and innovative techniques for processing and extraction as success stories for research, education and at industrial scale. The readers like chemists, biochemists, chemical engineers, physicians, and food technologists even from academia or industry will find the major combined techniques obtained by (1) improving and optimization of existing processes; (2) using non-dedicated equipment; and (3) innovation in processes and procedures.

2. Towards process intensification: From individual to combined techniques

Process intensification is one of the major concerns of current industries, whatever the sector of activity may be. Nowadays, the requirement for food industry no longer only meets the economic considerations but also at the necessity of developing processes which guarantee optimal efficiency in a sustainable approach.

The development of food products makes use of different processing, extraction and preservation technologies. This is because these products are complex mixtures of a large panel of compounds including proteins, sugars, lipids, vitamins, aromas, antioxidants, etc. Before such products can be commercialized and consumed, they have to be processed, transformed and preserved for food ready meals and extracted for food ingredients.

Conventional processing and extraction techniques have long been used to obtain food ingredients and develop finished dairy products. Nevertheless, these procedures are accompanied by several drawbacks including their low performance, possible degradation of thermolabile compounds as well as their high energy consumption [7], [8], [9].

Industries are constantly searching for efficient technologies with sustainable and green values to meet consumers and regulations requirements. Process intensification can be achieved through the exploitation of existing conventional and innovative processes and the exploration of combined technologies potential. In other words, when existing technologies are not efficient enough to ensure acceptable performance, it is recommended to intensify and assist the process with innovative technologies.

Ultrasound (US) has been considered as an innovative and promising technique of the 21st century. This technique has been increasingly used in the alimentary field including processing (crystallization, drying, filtration, cutting, etc.), preservation (inactivation of microorganisms and enzymes) and extraction processes [10], [11], [12]. These applications have already been listed in many reviews and scientific articles. The significance of US is clearly depicted from the results of a simple search on Science Direct which returned 63,588 documents on this topic, where 17,852 deal with US application for the extraction of food ingredients. This number of studies proves the relevance of US in this domain, especially in the extraction of natural products and ingredients. Power US performance relies on their positive contribution in terms of extraction kinetics, selectivity, rapidity, reduced solvent consumption and waste/CO2 emissions compared to conventional techniques [13], [14], [15], [16], [17], [18], [19]. Nowadays, ultrasonic technology represents a well-established method used at both laboratory and industrial scales. The growing number of ultrasonic patents indicates the increasing interest on this technique at industrial scale.

Different other innovative technologies were developed and valorized in food industry, especially for the extraction of food ingredients. Among these techniques, we find Microwave-Assisted Extraction (MAE), Pressurized Liquid Extraction (PLE), Supercritical Fluid Extraction (SFE) and Instantaneous Controlled Pressure Drop (DIC), etc.

Table 1 summarizes the most common conventional and innovative extraction processes, details their working principle and processing mechanism and presents their main advantages and limitations. As presented in this table, each technology presents certain advantages as well as considerable limitations, which justifies the interest increasingly given to combined techniques. Coupling different techniques may offer the solution to ensure optimal performance and provide products and ingredients of higher quality and in the meantime enhance competition of industries to be more ecologic, economic and innovative.

Table 1.

The main innovative techniques used for the extraction of natural materials.

| Technology | Working principle | Processing mechanism | Advantages | Limitations |

|---|---|---|---|---|

| Pressing-extrusion | The extrusion process consists in pushing materials through a die, aided by the pressure induced by one or two rotating screw(s) (single- or twin-screw extruder). The classical extrusion process only implies thermomechanical phenomena. When chemical reactions are induced in the extruder, a reactive extrusion process takes place [20] | Intense mixing and mechanical destructuring of biomaterials provided by screws both facilitate access to inner structures and their contents. As a result, extraction efficiency is significantly increased [20]. |

|

|

| Ultrasound-Assisted Extraction (UAE) | Cavitation through ultrasonic mechanical waves which have the property to spread in elastic medium such as extraction solvents [4]. | The implosion of cavitational bubbles generates micro-jets of extreme conditions of pressure and temperature to breakdown cell membranes. This results in enhanced porosity and accelerated solvent penetration into the biological material [3], [22], [23]. | ||

| Microwave-Assisted Extraction (MAE) | Absorption of microwave energy by the treated material through molecular interaction with the electromagnetic field [32], [33]. | It consists of a non-contact energy transfer process from electromagnetic energy into thermal energy. This energy conversion is based on two mechanisms: ionic conduction and dipole rotation [34]Microwave heating of the moisture inside the treated biomaterial results in high pressure on the cell wall resulting in their mechanical rupture. This is presumed to enhance solvent penetration into the inner tissues and to improve extraction yields and selectivity [32], [33]. |

|

|

| Pressurized Liquid Extraction (PLE) | A process which employs an extraction solvent at high temperature and pressure, below their respective critical points [35], [36]. | High conditions of temperature and pressure modify solvent physicochemical properties including surface tension, density, viscosity, diffusivity, and dielectric constant. As a result, solvent solubilization and extraction abilities will be improved. Moreover, when increasing temperature, intermolecular interactions (Van der Waals forces, hydrogen bonding and dipole attraction) that bind the targeted compound to its containing structure are considerably reduced. Thus, targeted molecules become easier to extract [35], [36] |

|

|

| Supercritical Fluid Extraction (SFE) | A fluid is consideredto be in its supercritical state when it is both heated above its critical temperature (Tc) and pressurized above its critical pressure (Pc) [1]. | Interest in SFE technique relies on supercritical fluid’s interesting properties. On the one hand, these solvents have a density close to liquids, implying that they have a solubilization power close to liquids. On the other hand, their viscosity is close to gases and their diffusivity is intermediary between liquids and gases, leading to an increase of mass transfer between the targeted molecule and the supercritical fluid. Therefore, working with supercritical fluids offers the possibility of modulating solvent selectivity [1] |

|

|

| Instant controlled pressure drop (DIC) process | DIC process involves a thermomechanical processing induced by subjecting the material to a fast transition from high steam pressure to vacuum [24]. | The creation of vacuum condition represents the first step of DIC extraction, followed by injecting high pressure saturated steam into the biomaterial for few seconds. The third DIC-stage consists of a sudden pressure drop towards vacuum (about 5 kPa with at a rate higher than 0.5 MPa/s) This pressure-drop triggers:

|

|

Possible degradation of thermolabile analytes [24] |

| Pulsed Electric Field (PEF) Extraction | PEF process is the application of repetitive short pulses with high voltage into a material held between two electrodes [40], [41]. | PEF extraction efficiency relies on the mechanism of “electroporation”, called also “electro-permeabilization”. Indeed, the application of an electric field induces the formation of pores into cell membranes. Consequently, membrane permeability and diffusion efficiency of targeted compounds increase significantly [40], [42] |

|

|

| High intensity light assisted extraction | A non-thermal method that employs Ultra-Violet (UV) rays of short wave-length and high energy. The penetrating pulses rich in UV last a few hundreds of microseconds [43], [44]. | Synthesis of secondary metabolites, playing the role of defense compounds, is usually triggered by biotic and abiotic stresses. The high intensity light, particularly in the UV region, represents an abiotic stress for plant cells. [43], [45]Furthermore, these UV-rays could physically breakdown cell walls or membranes and thereby enhance the release of cells contents into the surrounding extraction solvent [45] |

|

The strong pulse light treatment induces photochemical effects including chemical modifications, DNA cleavage, protein denaturation, etc. This way, this excessive treatment prevents cells to replicate. UVB and UVC are the most damaging wavelengths of UV light, causing direct DNA damage. As for UVA, it is less effective, causing indirect damage to cells through the production of reactive oxygen species that may damage DNA, proteins and lipids [48], [49] |

Different conventional methods can be coupled to US, such as Soxhlet, Clevenger and enzymatic extraction. US can also be coupled to other innovative sustainable “green” techniques including MAE, PLE, SFE and DIC etc.

These different combinations will permit the development of high process intensification, making use of physical and/or chemical phenomena different from those involved in individual processes.

This review provides at first a complete picture of the US necessary theoretical background (theory and mode of action). Then, it presents a summary of all current knowledge on the combination of conventional and innovative techniques with US technology for the intensification of extraction from food and natural products. Some examples of successful combinations are provided. Driving forces and working mechanisms are also discussed. The last part is devoted to the most common combinations developed for food processing and preservation.

3. Ultrasound-Assisted extraction and processing: Principle and mechanisms

Ultrasound can be defined as mechanical waves which are able to spread in elastic medium such as liquids [4]. Ultrasound (US) frequency is one the most important physical characteristics of ultrasonic waves, which ranges between 20 kHz and 10 MHz, above the human hearing range (from 16 Hz to 20 kHz) [50]. Given this large range of frequencies, two zones can be distinguished:

-

(i)

Diagnostic US characterized by high frequencies (from 2 MHz to 10 MHz) and low ultrasonic power (P < 1 W). In this frequency and power range, there is no destructive effect into the medium. The desired effect is only to characterize the medium by measuring the submitted modification of the ultrasonic wave during its propagation into the medium [50], [51], [52].

-

(ii)

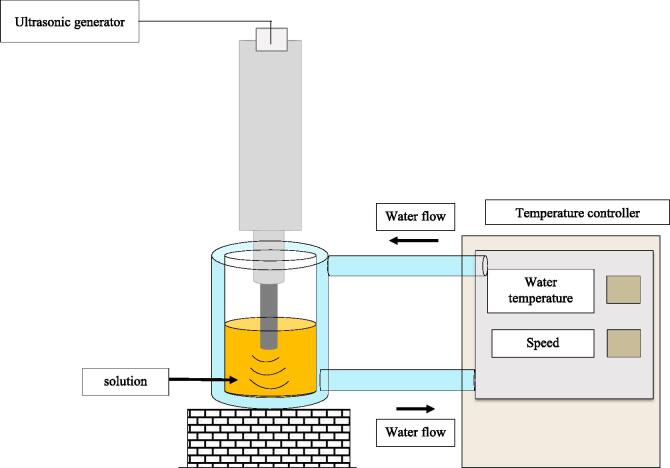

Power US characterized by low frequencies (from 20 kHz to 100 kHz) and high ultrasonic power (P > 10 W) [50]. Contrary to diagnostic US, high power promotes physical and chemical effects by creating sufficient interaction between the ultrasonic wave and the elastic medium. Physical impacts are essentially observed at low frequencies (from 20 kHz to 100 kHz). This frequency range is widely valorized in solid–liquid extraction. The extended range of power US frequencies (up to 2 MHz) is used in sonochemistry. Different chemical impacts can be observed in this frequency range, mainly the formation of radicals [51]. Frequencies most commonly applied in solid–liquid extraction of food ingredients are 20, 25 and 40 kHz. At these frequencies, US contribution relies on its physical effects. US impacts, behind the enhancement of extraction performances can be summarized as follows [53].

-

(i)

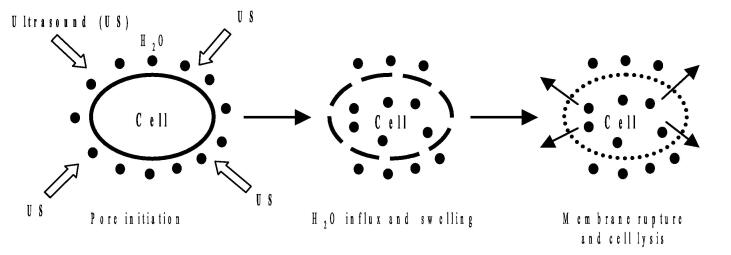

Increased mass transfer and improved accessibility to cells and inner structures, due to extreme conditions of temperature and pressure generated during bubble collapse events resulting in cells damage and thinning of membranes layers.

-

(ii)

Enhanced diffusion of solvent into the matrix, due to the creation of pores into membranes which gives access to the underlying tissues. Hydration and swelling of the matrix further enlarge pores and promote access.

-

(iii)

Improved diffusion of the solutes present within pores due to shear forces, microscopic turbulence and agitation as well as inter-particle collision resulting from the propagation of ultrasonic wave and the implosion of cavitation bubbles.

-

(iv)

Increased surface area of matrix as a result of shock waves and microjets directed towards the matrix surface.

Mechanisms behind those positive impacts are beginning to be unraveled owing to the growing interest in the comprehension of US-related physical impacts.

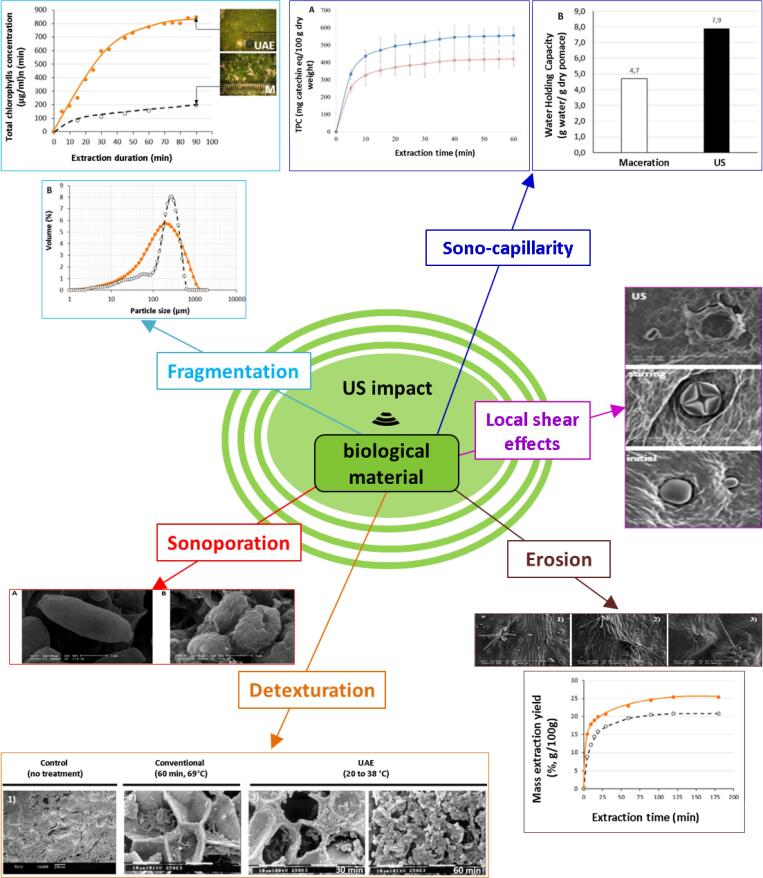

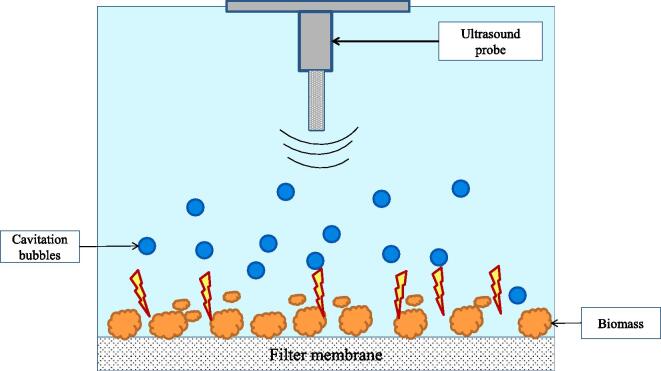

Overall, US-induced impacts can be attributed to the cavitation phenomenon referring to bubble formation, growth and implosion during the propagation of the ultrasonic wave into an elastic medium [4], [22], [30], [52]. Bubble implosion results in the creation of hot spot with extreme conditions of temperature (up to 5000 K) and pressure (up to 5000 atm), which explains their extremely high reactivity [22], [29], [52], [54], [55], [56]. Occurring at or near a solid surface, the bubble collapse is asymmetric generating micro-jets and shock waves directed towards the solid surface [57]. This results in disruption of cell walls, particle size reduction, and enhanced mass transfer across cell membranes as well as an excellent penetration of the extraction solvent [3], [9], [58], [59]. Shear forces and the resulting inter-particle collisions have also been reported to accelerate the diffusion of matrix-contained compounds [26], [51].

Shirsath et al (2012) have defined cell disruption and breaking as the major mechanism of action of US when applied on plant solid–liquid extraction. The formed cracks increase the plant tissues permeability and thus enhance the solvent penetration into the inner plant tissues as well as the release of their content [17]. Nevertheless, US mode of action appears to be a much more complicated process than that proposed by Shirsath and coworkers. It has been found that completely different physical impacts can be observed, depending on US parameters and particularly on the nature of plant matrices.

These different mechanisms were summarized in a review published by Chemat et al [1]. As explained in this review, depending on their structure, cell walls can be slightly or highly impacted by the cavitation phenomenon. This means that US-related effects can range from removing small particles or structures from the surface (erosion) to creating pores (sonoporation) or even deep fractures within the raw material (fragmentation). These effects are presumed to enhance solvent penetration into inner structures and in meantime favor the release of targeted compounds [60], [61], [62]. Furthermore, strong shear forces and turbulence, resulting from the propagation of US wave, seem to further accelerate exchange between raw material and the surrounding extraction solvent. These mechanisms result in “the increase of depth and velocity of penetration of solvent within plant inner structures”, referring to the ultrasonic capillary effect (UCE) [1]. This mechanism is associated to the increase in the swelling index and the hydration of plant material which enhance the extraction performances. A total detexturation of plant structures can be also observed due to US application [63].

Noteworthy, almost all studies dealing with US-induced mechanisms proposed a single physical mechanism behind the ultrasound observed effects. These individual mechanisms are summarized in Fig. 1 Fig. 2.

Fig. 1.

Reported US impacts on plant tissues.

Fig. 2.

Mechanism of ultrasound-induced cell damage.

Nevertheless, a study conducted by Khadhraoui et al. (2018) showed that US impacted rosemary leaves, not by a single mechanism but by a chain detexturation mechanism where six physical impacts occurred in a special order: local erosion, shear forces, sonoporation, fragmentation, capillary effect, and detexturation [27]. Together, these different mechanisms contributed to maximize yields of extraction by increasing the surface area contact between water and leaf components. A recent study conducted by the same team [28] further pointed out the complexity of ultrasonic mode of action. Findings presented in this article demonstrated that, at the same experimental conditions, US acts through different mechanisms when applied on blackcurrant, bitter orange and artichoke leaves. The case of artichoke leaf has particularly shed the light on the complexity of plant matrices behavior in response to US treatment. For the same plant and the same specialized structure, considerable differences were noticed between upper and lower surfaces [28]. Based on these different studies, it can be concluded that US has a highly complex mode of action. This represents the main limitation of this technology, since its performance could be extremely limited by matrices resistance level. Therefore, US combination with other conventional or innovative techniques may be useful in addressing this limitation.

4. Combination of US with conventional extraction techniques: Hybrid techniques

Most common combinations of US with conventional techniques are presented and discussed in this section. Table 2 gives examples of recent applications of these hybrid combinations.

Table 2.

Examples of conventional techniques coupled to US for the extraction of natural materials.

| Technique | Matrix | Targeted compound | Device diagram | Combination impact | Ref |

|---|---|---|---|---|---|

| Ultrasound assisted Soxhlet extraction: Sono-Soxhlet | Olives | Lipids |  |

Improvements in extraction time over conventional Soxhlet technique. | [64] |

| Ultrasound assisted hydro-distillationSono-Clevenger | Iberis amara seeds | Volatil aromatic compounds |  |

Higher extraction efficiency compared with traditional techniques | [67] |

| Ultrasound assisted enzymatic extraction | Sesame bran | Protein and phenolic compounds |  |

Higher protein yield and higher antioxidant capacity value compared with the combined ultrasound-assisted enzymatic extraction | [71] |

4.1. Ultrasound assisted Soxhlet extraction: Sono-Soxhlet

Fats and oils are traditionally extracted from the biomass matrix using the Soxhlet extraction. Invented in 1879, this apparatus has been widely used in various fields such as environmental applications, foodstuffs and also pharmaceuticals. Its principle is relatively easy and proceeds by an iterative percolation of condensed vapors of a boiled solvent, generally n-hexane. Nevertheless, Soxhlet extraction has some disadvantages such as a long operation time (several hours), large solvent volumes, evaporation and a concentration step needed at the end of the extraction. It is also inadequate for thermolabile analytes. There are only few processes in the literature that have reported the combination of Soxhlet extraction with innovative techniques, such as ultrasound, for the acceleration of fat and oil extraction.

The team of Luque de Castro (1998) [64] developed original Sono-Soxhlet methods. US is applied outside or inside the extraction chamber to enhance the solid–liquid extraction and migration of metabolites from solid matrix to solvent [29]. Sono-Soxhlet combines the advantages of the extraction performed with Soxhlet (extraction repeated by a fresh solvent) and enhanced mass transfer with US (reduction of extraction time). Hence, it ensures a complete, rapid, and accurate extraction of samples. This system has been successfully used for the extraction of the oil and the fatty acid from oleaginous seeds, lipids from sausage products, fat from cheese and bakery products.

4.2. Ultrasound assisted Clevenger distillation: Sono-Clevenger

The traditional method used to isolate volatile compounds such as essential oils from plant material (herbs, spices, barks, fruits…) is alembic distillation which, in chemistry laboratories, is also called Clevenger distillation. This method proceeds by the iterative distillation and boiling of the aromatic matrix in recondensed water vapor, and generally uses large quantities of water and energy. The extraction time can vary from 6 to 24 h. During distillation, fragrant plants exposed to boiling water or steam, release their essential oils through evaporation. Essential oil recovery is facilitated by distillation of two immiscible liquids, namely, water and the essential oil. This is based on the principle that, at the boiling temperature, the combined vapor pressures equal the ambient pressure. Thus, the essential oil ingredients, for which boiling points normally range from 200 to 300 °C, are evaporated at a temperature close to that of water. As steam and essential oil vapors are condensed, both are collected and separated in a vessel, traditionally called the “Florentine flask”. The essential oil, being lighter than water, floats at the top while water stays at the bottom and is separated.

Historically, there have been three types of distillation: water distillation, water-steam distillation and steam distillation. In addition, there are numerous other improved methods of producing natural fragrances and essential oils including turbo-distillation, hydro-diffusion, vacuum-distillation, continuous-distillation and dry-distillation. All these conventional extraction techniques have important drawbacks, such as low yields, formation of by-products and limited stability. The elevated temperatures and prolonged extraction time can cause chemical modifications in the essential oil components and often a loss of the most volatile molecules.

With the growing of flavor and fragrance industry and the increasing demand for more natural products, the need for novel extraction methods has become more intense. The combination of ultrasound with Clevenger or alembic distillation has attracted growing interest in the past few years. This has resulted in the development of Sono-Clevenger [65] specifically aimed for obtaining essential oils from plant materials. Sono-Clevenger is an original combination of ultrasound cavitation and Clevenger distillation at atmospheric or reduced pressure (Table 2). It provides yields comparable to those obtained by traditional hydro distillation but with reduced extraction times and enhanced quality. The thermally sensitive crude materials seem to be preserved with this method, in contrast to conventional Clevenger distillation. Ultrasound causes an internal convection movement of the solute in the solvent, which improves the mass transfer rate in the distillation process. Accelerated volatilization of plant aromatic compounds can then be observed [66].

Liu et al [67] determined the optimal condition of Sono-Clevenger for the extraction of essential oil (EO) from Iberis amara seeds using the surface response methodology. They also compared the efficiency of this treatment with traditional methods such as hydro distillation or steam distillation. It was observed that the extraction efficiency markedly increased with the assistance of ultrasound compared with traditional techniques. Oils obtained with the three techniques have slightly different but good effects: antioxidant and anti-inflammatory effects, cytotoxicity on human colon cancer, and antibacterial effects.

Few studies using ultrasound technique for the extraction of volatile substances from plants have been published. Tekin et al in 2015 [68] showed that ultrasonic bath assisted extraction can improve the EO yield of cloves. A significant effect on the amount of essential oil distilled as a function of the power of the ultrasound used can also be observed using this technique.

However, when the power used is too high, labile compounds may disintegrate due to the increase in local temperature and pressure in the solvent induced by the intensive use of ultrasound. A possible negative effect on the EO yield should therefore be considered [3]. For example, ultrasonic pre-treatment has been found to improve EO yield in mint leaves and marjoram, while no significant impact was found for chamomile flowers [69]. Therefore, the effect of ultrasound on EO extraction depends on the power of the ultrasound as well as the raw material.

4.3. Ultrasound assisted enzyme extraction

Ultrasound-assisted enzyme extraction (UAEE) is an efficient and environment friendly technique that generally gives high yields with low energy consumption. These combinations are of paramount importance in selecting the best operating conditions for scalable and cost-efficient plant material extractions to achieve excellent yields and minimize degradation. It is well known that ultrasound can either activate or denature enzymes. In each case, the parameters to be used must be optimized in order to obtain the desired results.

The increase of enzymes activity under mild ultrasonic irradiation when the shear force, temperature, pressure, and production of radicals are limited by controlling power and irradiating time, is well described in the literature [70].

In 2019 an ecofriendly process based on an enzyme-assisted extraction coupled with ultrasound extraction is proposed to obtain active compounds. Görgüç et al [71] have studied the effect of enzyme and ultrasound-assisted enzyme extraction on recovery of protein and antioxidant compounds from sesame bran using response surface methodology. Enzymatic and ultrasound assisted extraction methods increased the protein yield, total phenolic content and antioxidant capacities compared to the standard alkaline extraction method. The highest protein yield was obtained with the combined ultrasound-assisted enzymatic extraction.

5. Ultrasound-Assisted extraction (UAE) using green solvents

Most promising combinations of US with green solvents are presented in this section. Table 3 gives examples of recent applications of UAE using green solvents.

Table 3.

Recent applications of UAE using green solvents (hydrotropes, DESs and NADESs).

| Technique | Matrix | Targeted compound | Device diagram | Combination impact | Ref |

|---|---|---|---|---|---|

| Ultrasound assisted hydrotropic extraction | Leaves of palmarosa | Geraniol |  |

Increased extraction efficiency of geraniol from the leaves of palmarosa. | [73] |

| Ultrasound assisted ionic liquid extraction | Orange peel | Carotenoids |  |

Higher extraction efficiency and significantly reduced extraction time | [78] |

| Ultrasound assisted deep eutectic solvent extraction | Buckwheat sprouts | Flavonoids |  |

Higher extraction efficiency of flavonoid | [91] |

| Ultrasound assisted Natural Deep eutectic solvent extraction | Wine lees | Anthocyanins | Higher extraction efficiency of wine lees anthocyanins | [93] |

5.1. Ultrasound assisted hydrotropic extraction (UAHE)

Hydrotropy phenomenon can be defined as the increase in solubility of organic compounds that are insoluble or sparingly soluble in water in aqueous solutions in the presence of highly water-soluble organic salts, called also hydrotropes. The increase in solubility of an organic solute such as esters, alcohols, aldehydes, ketones, hydrocarbons and fats is a function of the hydrotropic concentration. This phenomenon depends not only on hydrotrope nature, but also on the solute nature [72].

Although hydrotropes were first studied in biochemistry, their role and applicability have been the subject of numerous studies in chemistry. Hydrotropes are composed of two parts: hydrophilic and hydrophobic. They don’t form micelles, but they self-aggregate gradually. They are characterized by a concentration threshold at which the solubility of hydrophobic compounds increases significantly: this threshold is called the minimum hydrotropic concentration (MHC).

Hydrotropes are widely used for the solubilization of drugs, but also as extraction agents for fragrances, for the separation of near boiling liquid mixtures by distillation or in the field of liquid–liquid extraction. The high solubilization capacity and selectivity of hydrotropic solubilization can be used for the extraction of water-insoluble bioactive compounds. In 2018, Thakker et al [73] used for the selective isolation of geraniol from the leaves of Cymbopogan martini, a newer concept of combining hydrotropic extraction with ultrasound to reduce time of extraction and hydrotropic requirement, while maintaining the quality of the product. Various parameters, such as ultrasound amplitude, cycle time and the volume and concentration of the hydrotropic solution, as well as the extraction time were studied in order to optimize the experimental conditions affecting the Ultrasound assisted hydrotropic extraction (UAHE). The results led to improvements in product yield compared to hydrotropic extraction without sonication, as well as a reduction in extraction time and a decrease in hydrotrope consumption. A synergistic effect between hydrotrope and ultrasound was thus demonstrated. This new eco-extraction method can be used to extract valuable compounds from various plants.

5.2. Ultrasound assisted ionic liquid extraction (UAILE)

Ionic liquids (ILs) are commonly defined as a class of salts, as a group of nonmolecular solvents prepared by the combination of organic cations and organic or inorganic anions showing melting points lower than their former constituents close to 100 °C [74]. ILs were first observed by Paul Walden in 1914 in the case of ethylammonium nitrate [EtNH3][NO3] which was obtained through the neutralization of ethylamine with concentrated nitric acid [75]. Among ILs properties of interest are their non– inflammability, thermal stability, low vapor pressure, and especially their impressive tunability and synthetic versatility [76]. It was only in 2007, that this solvent was used for the extraction of bioactive compounds. From this year forward, a great interest for IL as extraction medium was observed with a steady increase in the number of published manuscripts [77]. Murador et al [78] used ultrasound assisted ionic liquid extraction (UAILE) for the extraction of carotenoids from orange peel. The aim of this work was to develop an effective, rapid and environment friendly ionic liquid-based ultrasound assisted approach for the extraction of active compounds. The authors had to optimize a number of parameters such as ionic liquid concentration, soak time, solid–liquid ratio, ultrasound power, time and the number of extraction cycles. A comparison was made between extractions carried out in ionic liquid alone, in acetone and in ionic liquid combined with ultrasounds. The followed approach (UAILE) provided higher extraction efficiency and significantly reduced time and energy consumption. This environmentally friendly method can thus be applied for the extraction a wide range of active compounds.

5.3. Ultrasound assisted DES or NADES extraction (UADESE or UANADESE)

Historically, Deep Eutectic Solvents (DESs) were firstly observed by Abbott and coworkers in 2003 [79]. DESs can be prepared by mixing solid compounds which form a eutectic mixture with a melting point lower than either of the individual components melting points [80]. This is mainly due to the generation of intermolecular hydrogen bonds between hydrogen bond acceptor (HBA) and hydrogen bond donor (HBD). Choline chloride represents the most reported HBA in scientific literature. This molecule has the ability to form hydrogen bonds with most HBD. Produced on a large scale for animal supplementation, Choline chloride is a low-cost and biodegradable derivative of vitamin B4. Moreover, its non– toxicity makes it an ideal candidate for the synthesis of green solvents. Overall, DESs share many physicochemical properties with ILs (high viscosity, low volatility, non-inflammability, chemical and thermal stability) [80]. Moreover, they present some advantages over ILs mainly the ease of their storage and synthesis as well as the low cost of their starting materials. To further meet the principles of green chemistry proposed by Anastas and Warner [2], natural sources of DESs attracted great attention in replacement of synthetic compounds [81] giving rise to a new class of DESs, namely Natural Deep Eutectic Solvents (NADESs). As in the case of DESs, NADESs are mixtures of compounds that have a much lower melting point than that of any of their individual components [82].

Besides all the advantages of DESs, NADESs are considered as environment friendly and ‘readily biodegradable’ due to the natural origin of their components [82], [83] and consequently obtained extracts can be safely used in food, pharmaceutical and cosmetics industries [84]. These new green solvents were firstly introduced by Choi and coworkers who defined them as the third liquid phase naturally occurring in all living organisms and cells [85]. According to Choi [85], this third liquid is capable of dissolving a number of natural molecules that are poorly soluble in water and lipids such as taxol and rutin as well as proteins, explaining thus many biological phenomena such as the biosynthesis of molecules that are soluble in neither water nor lipids. The compounds found to form this liquid phase are primary metabolites like organic acids (lactic, malic, citric acids, etc.), sugars (glucose, fructose, sucrose, etc.); amino acids, choline chloride, etc. [86], [87]. These natural compounds play key roles in biological processes such as drought resistance, cryoprotection and defense against external attacks [88], [89]. Noteworthy, according to the nature of their components, NADESs can be classified into four groups: (i) Derivatives from organic acids, (ii) Derivatives from choline chloride, (iii) Mixtures of sugars and (iv) other combinations [90].

Recent studies prove the effectiveness of DES and NADES in the extraction of natural products and the valorization of by-products of the food industry. For example, DES coupled with ultrasound-assisted extraction are evaluated and optimized for the extraction of major flavonoids from common buckwheat sprouts. Mansur et al [91] show that the extraction efficiency is even higher than that achieved with methanol for the extraction of these compounds. The optimized extraction procedure is reliable and efficient for the extraction of major flavonoids from common buckwheat sprouts. Chanioti et al [92] employed natural deep eutectic solvents and innovative extraction techniques for the extraction of phenolic compounds from olive pomace. The NADESs offering sustainability, biodegradability, compositional flexibility and extractability of bioactive compounds, highlight their potential to be utilized as green solvents for the extraction of phenolic compounds from olive pomace. Moreover, if they are combined with novel extraction assisted methods (e.g. microwave, ultrasound etc), high extraction efficiencies can be achieved in significantly reduced time. These studies have demonstrated the improvement in the extraction of phenolic compounds compared to conventional solvents (e.g. aqueous ethanol and water). As another example we can observe the use of NADES combined with ultrasound for the extraction of anthocyanins from wine lees [93]. A NADES based on chlorine chloride with malic acid as hydrogen bond donor is selected as the most promising, which allowed a more efficient extraction of anthocyanins from wine lees compared to a conventional solvent. Bosiljkov et al [93] combined this NADES with ultrasound and showed that this approach using green NADES solvents and ultrasound as an alternative energy source could be a good choice for the design of environmentally friendly extraction methods for the recovery of plant phenolic compounds.

6. US coupled with innovative extraction techniques

6.1. Combination of US with pressing-extrusion

Mechanical pressing is increasingly used in a great number of applications in the food domain particularly for juice and oil extraction [21]. The extrusion process consists of pushing materials through a die, aided by the pressure induced by one or two rotating screw(s) (single- or twin-screw extruder). The classical extrusion process only implies thermomechanical phenomena. When chemical reactions are induced in the extruder, a reactive extrusion process takes place [20]. This solvent-free process could be considered as an interesting alternative to solvent extraction. This is because the obtained extracts are of higher quality and do not contain any solvent traces. In order to achieve better extraction yields, research has recently focused on the combination of extrusion with other solvent extraction processes [21]. Many studies proved that US application has a significant positive effect on oil extraction in terms of extraction kinetics and yields [94], [95], [96]. Milenković et al (2018) explored the potential of US as a subsequent treatment to mechanical pressing from sunflower seeds (table 4). After pressing process, the cake contains a certain amount of residual oil. The authors claimed that US application improved extraction kinetics and oil diffusion from the mass of the cake to the extracting solvent, compared to conventional Soxhlet extraction [97].

Table 4.

Examples of US-innovative techniques combinations for the extraction of natural materials.

| Technique | Matrix | Targeted compound | Type of combination | Device diagram | Combination impact | Ref |

|---|---|---|---|---|---|---|

| US combined with mechanical pressing | Sunflower seed | Oil | In line |  |

US application improved extraction kinetics and oil diffusion from the mass of the cake to the extracting solvent, compared to conventional Soxhlet extraction. | [97] |

| Ultrasound-Microwave Assisted Extraction (UMAE) | Sorghum husk | Natural colorants | Direct in situ (DIS) |  |

Significantly improved extraction yield and better dyeing properties of sorghum husk extracts. | [105] |

| Sweet potatoes (Ipomoea batatas L.) | Prebiotic oligosaccharides | Direct in situ (DIS) | Higher extraction efficiency compared to theconventional hot-water extraction, microwave-assisted extraction (MAE), and ultrasound assisted extraction (UAE) methods. | [106] | ||

| Lotus seed starch-green tea polyphenol complex | Preparation of starch-polyphenol complex | Direct in situ (DIS) | Increased extraction yield of the complex. | [107] | ||

| Potato pulp | Pectin | Direct in situ (DIS) | Increased extraction efficiency of potato pectin. | [107] | ||

| Alternate Microwave/Ultrasound with DES | Schisandra Chinensis fruit | Polysaccharides and essential oil | Alternating US/MW digestion | Higher polysaccharide and essential oils yields. | [109] | |

| Ultrasound Microwave- assisted enzymatic extraction (UMAEE) | Lentinus edodes | Polysaccharides | In line |  |

Higher extraction yields of polysaccharides content compared to conventional techniques. | [110] |

| Laminaria | Monoiodo-tyrosine (MIT) and Diiodo-tyrosine (DIT) | In line |  |

An efficient method to extract MIT and DIT from Laminaria. Both US and MW radiation can destroy the laminaria cell walls which improves access and extractability of targeted compounds. | [111] | |

| US combined with pressurized liquid | Sugar beet pulp | Pectin-enriched materials | In line |  |

Higher extraction yield and improved functional properties obtained with subcritical water extraction. | [112] |

| Pomegranate peel | Phenolic compounds | Direct in situ (DIS) |  |

Higher extraction yield Reduced extraction time and temperature | [113] | |

| Fragrant oil from red pepper seed | Residual propane | In line |  |

US was efficient in solvent residue removal. Treated oil presents good oxidation stability and quality. | [114] | |

| US combined with supercritical CO2 | Agave salmiana bagasse | Antioxidants and saponins | Direct in situ (DIS) |  |

Increased extraction yield in terms of antioxidants and saponins contents. | [119] |

| Ginger rhizomes | Pungent compounds | Direct in situ (DIS) | Improved extraction yield of pungent compounds from ginger. | [118] | ||

| Iberis amara seeds | Cucurbitacin E (CuE) | Direct in situ (DIS) | The introduction of ultrasound to supercritical CO2 extraction enhanced CuE yield and reduced operation time as well as the amount of CO2 consumed. | [67] | ||

| Instant controlled pressure drop (DIC) combined with US | Orange peels | Antioxidants | In line |  |

The highest yield of antioxidants with best kinetics is obtained by coupling both treatments. | [39] |

| Steviarebaudiana bertoni leaves | Rebaudioside A, Vitamin B6 and vitamin B1. | In line |  |

DIC pre-treatment has a significant positive effect on the extraction of Rebaudioside A, Vitamin B6 and vitamin B1. | [122] | |

| Pulsed Electric Field (PEF) combined with US | Almond seeds | Phenolics, flavonoids, condensed tannins and anthocyanins, antioxidant activity and volatile compounds | In line |  |

Combined treatment (PEF–US) has attained the highest value of total phenolics, total flavonoids, condense tannins, anthocyanin contents and antioxidant activity in DPPH, reducing power and metal chelating activity than all other treatments. | [124] |

| UV-C Radiation Combined with UAE | Cherry Tomato (Lycopersicon esculentum) | Lycopene | In line |  |

Extracted obtained from the irradiated tomatoes presented 5.8 times more lycopene content. | [126] |

| Tomatoes | Bioactive compounds | Direct in situ (DIS) | This postharvest non-thermal treatment resulted in increased lycopene, total phenols, vitamin C, hydrophilic and lipophilic antioxidant activities during storage. | [125] | ||

| US coupled with CCC and CPC | Paeonia lactiflora Pall roots | Albiflorin, benzoylpaeoniflorin, paeoniflorin, and galloylpaeoniflorin) | In line |  |

The four targeted compounds were successfully extracted. Compared with conventional extraction methods, this combination offers the advantages of automationand systematic extraction and isolation of natural products. | [131] |

6.2. Combination of US and MW

Microwave (MW) process relies on a non-contact energy transfer from electromagnetic energy into thermal energy. This energy conversion is based on two mechanisms: ionic conduction and dipole rotation. In other words, MW nonionizing radiation induces molecular motion through migration of ions and rotation of dipoles [34]. The overall advantages in applying MW include: faster energy absorption by the treated material, reduced thermal gradients and selective heating [98]. Furthermore, MW heating of the moisture inside the treated biomaterial causes high pressure on the cell wall resulting in their mechanical rupture. Solvent penetration into the inner tissues is therefore enhanced. Higher extraction yields and selectivity can be thus achieved [32], [33].

The combination of UAE and MW-assisted extraction (MAE) is one of the most promising combinations. These techniques can be either performed as single reactor configuration or via two separately connected reactors, which can be operated simultaneously or successively [24].

Ultrasound Microwave-Assisted Extraction (UMAE) has been successfully used for the extraction of bioactive compounds from different biomaterials [99], [100], [101], [102], [103], [104], [105], [106], [107], [108].

Some of these recent applications are presented in Table 4, giving more details concerning systems used and combination-associated impacts.

Wizi and coworkers (2018) explored simultaneous UMAE system through a direct in situ configuration (Table 4) for solid–liquid extraction from sorghum husk. Apart from a significantly improved extraction yield, the authors claimed that this combination ensured extracts with better dyeing properties [104]. The same configuration was successfully used to extract prebiotic oligosaccharides contained in sweet potatoes (Ipomoea batatas L.) [105] and to prepare starch-polyphenol complex from Lotus seed starch suspensions with added green tea polyphenols [106]. In both cases, the combined irradiation gave better extraction yields compared to conventional techniques.

UMAE combined with acid extraction increased extraction efficiency of potato pectin [107]. Significant performance gain was also noticed by Li and coworkers (2019) who have explored the potential of alternating US and MW to extract polysaccharides and essential oil from Schisandra Chinensis fruit [108]. Ultrasound Microwave-assisted enzymatic extraction (UMAEE) was used to obtain polysaccharides from Lentinus edodes. Although performed in separate steps, this combination was proved to considerably increase polysaccharides contents [109]. Wang et al (2019) applied UMAEE for Monoiodo-tyrosine (MIT) and Diiodo-tyrosine (DIT) extraction from Laminaria. This sequential treatment was proved to be an efficient method to extract MIT and DIT. US and MW positive contribution is related to the destruction of the laminaria cell walls which improves access and extractability of target compounds [110]. To summarize, all cited studies showed that US combined, simultaneously or successively, with MW radiation exhibit higher efficiency in shorter extraction time. This cost-effective combination has a great potential for application in solid–liquid extraction.

US-associated cavitation phenomenon promotes the release of targeted compounds through the physical damage of cell walls and membrane layers [98]. This results in increased mass transfer and accelerated solvent penetration. Concerning MW radiation, it is presumed to heat the biomaterial very quickly inducing the migration of dissolved molecules. Hence, simultaneous or successive US/MW treatment allows to achieve higher extraction efficiency [24], [98].

6.3. Combination of US with pressurized liquids

Pressurized-liquid extraction (PLE) is also called accelerated solvent extraction (ASE), pressurized hot solvent extraction (PHSE), high-pressure solvent extraction (HPSE), high-pressure high-temperature solvent extraction (HPHTSE), and subcritical solvent extraction (SSE). This extraction technique employs an extraction solvent at high temperature and pressure, below their respective critical points [35], [36]. At these high conditions of temperature and pressure, solvent physicochemical properties including surface tension, density, viscosity, diffusivity, and dielectric constant are significantly modified. This results in enhanced solubilization and extraction abilities. Moreover, when increasing temperature, intermolecular interactions (Van der Waals forces, hydrogen bonding and dipole attraction) that bind the targeted compound to its containing structure are drastically reduced. This makes their extraction easier [35], [36].

Even though this extraction technique improves solvent properties, accessibility to inner structures still represent a limiting factor especially when biological barriers are particularly difficult to overcome. For this, its combination with US appears of great interest since the latter has been proved to enhance accessibility through cell disruption and membranes thinning. Different solvents (water, ethanol, hydro-alcoholic mixtures, etc.) have been used, at their subcritical state, in combination with US. Chen and coworkers [111] have successfully extracted pectin-enriched material from sugar beet pulp by ultrasonic pre-treatment combined with subcritical water extraction (Table 4). These two techniques were performed in separate steps. As a result, higher extraction yields and extracts with improved functional properties (pasting temperature, gelatinization temperature and enthalpy, etc.) were obtained.

This combination was also performed for the extraction of phenolic compounds from pomegranate peel [112]. In this study, ultrasonic treatment and subcritical solvent extraction were carried out simultaneously (Table 4). Results showed higher extraction yields achieved in reduced extraction time and at lower temperature.

Liu et al (2020) have used ultrasonic treatment to remove the residual solvent from red pepper seed oil obtained by subcritical propane extraction (Table 4). US application allowed the removal of residual propane. The overall combination provided red pepper oil with good oxidation stability and high quality [113]. It can be concluded from these examples that whatever the type of combination (in line or in situ), US and subcritical solvent extraction offer great advantages in terms of extraction yields, time and energy saving.

6.4. Combination of US with supercritical fluids

Supercritical fluid extraction (SFE) is a high-pressure extraction method which employs an extraction solvent in the supercritical state [114]. A fluid is considered in its supercritical state when it is both, heated above its critical temperature (Tc) and pressurized above its critical pressure (Pc) [1]. Supercritical fluids (SCF) have particular gas-like and liquid-like properties. Their viscosity is close to gases and their diffusivity is intermediary between liquids and gases [1]. Hence, a SCF has the ability to penetrate through solid matrices like a gas, and to dissolve targeted compounds like a liquid [115]. Moreover, SCF density can be easily tuned via the variation of pressure or temperature. All these characteristics make SCF efficient solvents providing a certain degree of selectivity and a high recovery of compounds in a short time [1], [114]. Carbon dioxide (CO2) is the most commonly used SCF. Among the properties of interest of CO2 are its nontoxicity, noninflammability, chemical inertness and easily separable nature after extraction. Furthermore, SFE using CO2 is adapted to the extraction of thermolabile compounds since it employs low temperatures, compared to other conventional techniques [115]. Overall, SFE offers several advantages over conventional extraction techniques, including enhanced extraction kinetics and improved extraction selectivity as well as the absence of solvent residue [116]. This technique presents yet some disadvantages such as low extraction yields and high cost compared to some conventional processes [116]. Hence, US assistance may be useful in addressing these limitations.

Combination of US with CO2, using the system presented in Table 4, resulted in improved extraction yield of pungent compounds from ginger rhizomes. This performance gain could be explained by US-induced cellular damage, highlighted with SEM observations of treated ginger rhizomes. This results in doubled diffusivity of targeted compounds in the initial stages of extraction [117]. Higher extraction yield of antioxidants and saponins from agave bagasse was also obtained using ultrasonically-assisted supercritical CO2 extraction. In this case, the use of a multiplate ultrasound transducer allowed to avoid the compaction phenomenon within the extraction cell and to intensify the extraction process through US positive contribution [118].

The introduction of US to supercritical CO2 extraction enhanced Cucurbitacin E yield from Iberis amara seeds. Moreover, this combination allowed to reduce operation time as well as the amount of CO2 consumed [113]. To conclude, many studies proved that the combination of US and SFE is a promising alternative to conventional extraction processes. US introduction, on one hand, is of great interest since it offers many advantages, including the reduction of pressure, temperature, the flow rate of CO2 and the overall extraction time while enhancing mass transfer rate and providing higher extraction yields [53]. On the other hand, better stability of CO2, due to its inert nature and process operation at low temperature leads to minimal damage of thermally sensitive compounds [53].

6.5. Combination of US with DIC process

The Instantaneous Controlled Pressure Drop process, abbreviated as DIC according to the French expression “Détente Instantanée Contrôlée,” was developed by Allaf et al. (1993) [119]. DIC extraction consists of a thermomechanical processing which usually starts by creating a vacuum condition, followed by injecting steam into the material for several seconds, then proceeding to a sudden pressure drop towards vacuum [24], [120].

This pressure-drop triggers [3], [120]:

-

▪

A rapid auto-vaporization of the moisture inside the treated material, which results in an expansion of the treated material.

-

▪

The instantaneous cooling of the biomaterial.

-

▪

A swelling or even rupture of cell walls resulting in higher porosity and enhanced accessibility and extraction kinetics.

Noteworthy, solute diffusion in the solvent inside the pore is generally considered to be the limiting process within the expanded structure. Coupled to US, internal transfer of solute present within the pore can likewise be intensified by inducing convection transfer rather than diffusion [120].

Allaf et al (2013) [39] coupled DIC pre-treatment and UAE to intensify antioxidants extraction from orange peels (Table 4). The highest yield of antioxidants with best kinetics is obtained by coupling both treatments. DIC combined to UAE also gave satisfying amounts of rebaudioside A, vitamin B1 and vitamin B6 from Steviarebaudiana bertoni leaves. Swell drying by DIC significantly improved the yields of the three bioactive components [121].

6.6. Combination of US with pulsed electric field

Pulsed electric field (PEF) technique consists of the application of repetitive short pulses with high voltage into a material held between two electrodes [40], [41]. The driving force behind PEF efficiency in solid–liquid extraction is the electrical breakage of cellular membranes, also referred as “electroporation” or “electropermeabilization” [40]. In other words, the application of an electric field induces the formation of pores inside the membrane, thus increasing its permeability [42]. Higher extraction kinetics can be therefore reached.

PEF technique is a nonthermal method which is less destructive relative to other methods of cell damage. This means that this method allows a selective extraction while preserving the color, flavor, vitamin C content, etc. [122].

Nevertheless, PEF presents some shortcomings related to the difficulty of using it with conductive materials as well as the necessity to be combined with other techniques to recover acceptable yields of specific compounds of interest from raw material [33].

As an example of this promising combination, different bioactive compounds (phenolics, flavonoids, condense tannins and anthocyanins, antioxidant activity and volatile compounds) were successfully extracted from almond seeds using PEF coupled to US treatment. It has been demonstrated in this study that combined treatment (PEF–US) allowed to attain the highest value of total phenolics, total flavonoids, condense tannins, anthocyanin contents and antioxidant activity in DPPH, reducing power and metal chelating activity compared to other treatments [123].

6.7. Combination of US with UV-C radiation

UV-C radiation is a non-thermal method that employs Ultra-Violet (UV) rays of short wave-length and high energy. The penetrating pulses rich in UV last a few hundreds of microseconds [43], [44]. On the one hand, synthesis of secondary metabolites, playing the role of defense compounds, is usually triggered by biotic and abiotic stresses. The high intensity light, particularly in the UV region, represents an abiotic stress for plant cells [43], [45]. Consequently, the synthesis of secondary metabolites can be considerably improved when UV-C radiation is employed as a pre-treatment prior to solid–liquid extraction. On the other hand, when applied during solid–liquid extraction, these UV-rays could physically breakdown cell walls and thereby enhance the release of cells contents into the surrounding extraction solvent [45]. Coupling UV-C with US could be a very promising method for faster extraction and better efficiency. Esua et al (2019) [124] investigated the effect of simultaneous UV-C radiation and US postharvest treatment on tomato bioactive compounds during 28 days storage period. Results demonstrated that this non-thermal treatment resulted in increased lycopene, total phenols, vitamin C as well as hydrophilic and lipophilic antioxidant activities.

In a study conducted by Lima and coworkers, cherry tomatoes were first submitted to UV-C radiation [125]. The powder of irradiated tomatoes was then submitted to UAE. Interestingly, extracts obtained from the irradiated tomatoes presented 5.8 times more lycopene content compared to control samples. Therefore, combining UV-C and US simultaneously or in separate steps appears to be of great interest. It is noteworthy that, despite its great potential, this combination has not yet been adequately exploited.

6.8. Combination of US with CCC and CPC

The separation and isolation of extracted natural compounds from a complex extract is a key step which needs to be fully mastered. Different chromatographic techniques were developed and used for this purpose, including gas chromatography (GC), supercritical fluid chromatography (SFC) and liquid chromatography (LC) [126], [127]. Counter-current chromatography (CCC) belongs to the family of LC. The most important feature of CCC is that it uses a support-free liquid mobile phase. Both the mobile and the stationary phase are liquid [128], [129]. CCC offers, on one hand, a great advantage related to the elimination of irreversible adsorption of the sample onto a solid support [130]. On the other hand, the liquid nature of the stationary phase imposes the design of specific hydrodynamic and hydrostatic columns [131], [132]. It is important to note that CCC term is now being used only to refer to hydrodynamic columns. As for hydrostatic ones, they are called centrifugal partition chromatographs (CPC), coming from the patented trade name of the Japanese Sanki company [132]. Compounds separated by CCC and CPC using the same two-phase solvent system are generally different. Hence, combining CCC and CPC can improve the separation efficiency [133]. Zhang and coworkers [130] developed an ultrasound-assisted dynamic extraction system coupled with CCC and CPC for simultaneous extraction and isolation of natural compounds from white peony roots (Table 4). Results showed that targeted compounds were successfully extracted. Furthermore, compared with conventional extraction methods, this combination offers the advantages of automation and systematic extraction and isolation of natural products.

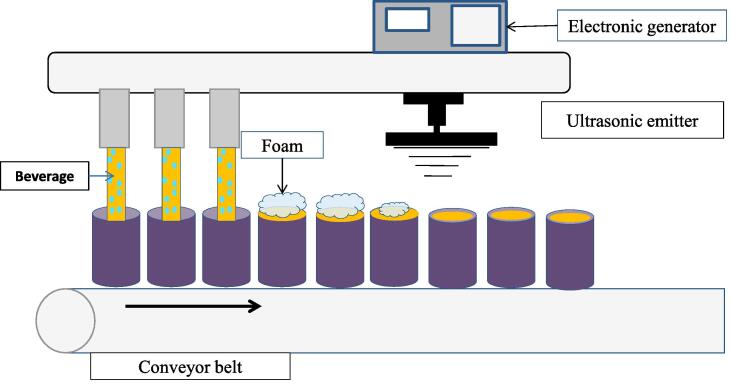

7. Ultrasound combined hybrid and innovative techniques for food processing

Ultrasound combined hybrid and innovative techniques are also use for food processing (Table 5).

Table 5.

Ultrasound combined hybrid and innovative techniques in Food Processing.

| Technique | Product | Condition | Salient findings | Reference |

|---|---|---|---|---|

| Frying | ||||

| US assisted osmotic dehydration (UAOD) as a pretreatment, followed by frying | Potatoes | Pretreatment conditions: 90 min Osmotic dehydration, 30 min UAOD, using 15% sodium chloride/50% sucrose solution prior to frying(170 °C) for 2–6 min | By 12.5% (db), UAOD reduced the oil content of fried potatoes, compared to untreated fried potatoes, at the end of frying. No significant difference between OD & UAOD in oil uptake reduction in fried potatoes. UAOD improved color of French fries and shortened the pretreatment duration of OD by about 67%. | [137] |

| ultrasonic-assisted frying | Meatballs | US power: 0, 200, 400, 600 and 800 WFrequency: 20 kHz applied during frying (12 min, 160 °C). | US-assisted frying was concluded as a potential approach in improving overall flavor of fried meatballs. US treatment significantly increased thiobarbituric acid reactive substances and decreased free fatty acids. US-fryingincreased the contents of 7 free amino acids including Lys, Glu, Gly, Ala, Tyr, Ser and Cys. Showed a positive impact on nucleotides formation and can enhance a more desirable flavor within 400 W. | [140] |

| US as a pretreatment before frying | Fried potatoes | Potato sticks in water treated with US. Frequency: 35 and 130 kHz) US power densities: 0, 9.5, 47.6 and 95.2 W/kg, Intensities: 10, 50 and 100% and water temperatures (30 and 42 °C). Followed by frying in refined sunflower oil (171 ± 1 °C) | At lower frequencies, US more effective in modification of weight gain, moisture and electrical conductivity during soaking, and on fried potatoes color. Soaking temperature had an impact on US effect. Treatment led to changes in total acrylamide content in fried potatoes. | [139] |

| Mushroom (Agaricus bisporus) chips | Vacuum frying (VF) Microwave vacuum frying (MVF) US assisted microwave vacuum frying (UMVF) | Microwave power: 800, 900 and 1000 WFrying temperature: 80, 85 and 90 ℃.US balancing sources: 120 W, 28 kHz. The frying temperature and vacuum pressure were set at 90 ℃ and 12 ± 1 kPa respectively | Optimum condition (1000 W, 90 ℃), gave higher moisture evaporation rate and low oil content. UMVF could reduce oil content (16–20%)compared to other treatments. UMVF chips: Better texture, most acceptable color, best matrices, accelerated frying, comparatively lower uptake of oil. | [141] |

| Fermentation | ||||

| US assisted fermentation | Lebanese apples | Microorganism: Hanseniaspora sp. yeast. US: 100 W, 40 kHz, power supply (220 V), Cyclic mode, variable periods of US pulses duration (0.5–2 s), followed by 6 s pauses. | Optimal US pulse duration on the yeast growth rate: 0.5 s followed by 6 s rest period, and during 6 h of both lag and log phases. Compared to untreated samples, US parameters resulted in faster glucose consumption in the medium during the fermentation. A significant enhancement in biomass growth and consumption of glucose, accompanied by significant decrease in the ethanol yield. | [142] |

| US assisted dough fermentation | Wheat dough | Bag with dough place in an US bath(40 kHz). Bath temperature maintained at 36–38 °C. Ultrasonic power density: from 15.38 W/L to 38.46 W/LTreatment time:20 min-50 min. Dough fermentation in tank: 40 min, 36 °C and 83% R.H. | US assisted dough fermentation improved the quality of the steamed bread. Fresh steamed bread hardness reduced by 22.4%.Specific volume enhancement: 6.7% at US power density; 23.08 W/L, 40 min. During storage, bread prepared by using US was softer compared to control. Springiness was lower when storage time under 48 h. | [144] |

| US assisted fermentation | Soyabean meal | US power density; 0.08 W/mL, Frequency:33 kHz Treatment time:1 hBacillus subtilis | Enhancement compared to control (peptide contents:31.27%; soluble protein :18.79%).Antioxidant activity and functional properties enhanced with US. | [145] |

| Freezing/crystallization | ||||

| US during immersion freezing | Broccoli | 30 kHz, 150 W; 20 kHz, 175 W for 120–180 sec. | Microstructure and textural firmness were better than the normal immersion freezing. Drip loss was noticed to be minimised. US was found to be promising. | [170] |

| US assisted immersion freezing | Fish | Immersion freezing tank (−25 ± 0.5 °C), 30 kHz, 0–175 W. US (On and off 30 s) On: 30 sec on/30 s off) 9 min cycle | Samples had smaller ice crystals compared to air freezing and immersion freezing, resulting in less deterioration of tissues of muscle during storage. During storage, compared to the other methods, lower total volatile basic nitrogen values and thiobarbituric acid reactive substance were observed. | [171] |

| US assisted immersion freezing | Mushrooms | Frequency: 20 kHz; US intensity: 0.13 W cm−2, 0.27 W cm−2 and 0.39 W cm−2 | US (20 kHz, 0.39 W cm−2) reduced freezing time by 40%.Reduction in peroxidase enzyme activities and polyphenol oxidase and drip loss. Improved whiteness index, chroma and textural hardness value. | [173] |

| US assisted immersion freezing | Potatoes | 35 kHz0.32 W/g, 8 s,-0.5, −2.0 and −3.0 ℃ | Nucleation was anticipated and freezing time was reduced. At −2.0℃, the shortest time was observed. | [174] |

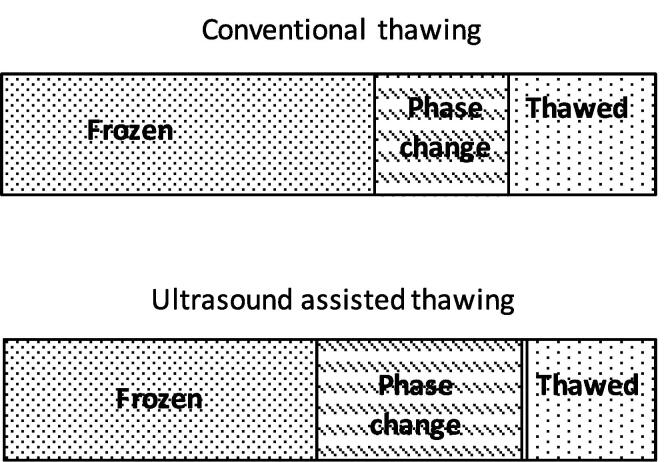

| Defrosting/ thawing | ||||

| Ultasound assisted thawing (UAT) | Bighead carp | 28 kHz, 0.135 W/mL, slow freezing(-18 °C) / fast freezing (-100 °C liquid nitrogen) frozen for 30 d at −18 °C, followed by water immersion thawing, air thawing and ultrasound assisted thawing. | Compared to water and air thawing, UAT drastically reduced thawing time. UAT was helpful in preserving the pH, color and lipid oxidation. Fast freezing UAT and Water immersion thawing, showed maximum muscle tissue destruction and water loss. UAT was found to be the best thawing method for big head carp which had undergone slow freezing. | [177] |

| UAT | Mango pulp | 28 kHz, UAT (intensities: 0.037, 0.074 and 0.123 W/mL in water bath at 4 ± 1 °C and 25 ± 1 °C, respectively | US was found to be a prospective alternative to conventional method of thawing. When compared with conventional method, a reduction in time by 16–64% was observed and more phenolic acids were obtained. US thawing (25 °C) reduced thawing time by 51–73% when compared with 4 °C. US intensities (0.074–0.123 W/mL) at 25 °C resulted in better thawing efficiency and nutritional quality. | [178] |

| Ultrasound assisted vacuum thawing (UVT) | Red seabream (Pagrus major) | UT; 200 W, 40 kHzUVT: 0.06 MPa, 0 °C, 200 W, 40 kHz | UVT samples showed poor viscoelasticity, the reason was considered to be the less denaturation of muscle proteins. Microwave assisted vacuum thawing (MVT) showed a viscoelasticity similar to fresh sample. UVT samples showed that the secondary structure was retained, while with MVT, non-uniform structure was observed. UVT and MVT were mentioned to have the potential to improve physicochemical properties of protein during thawing. | [177] |

| Low intensity ultrasound assisted thawing | Pork Longissimus dorsi muscle | 25 kHz. 0.2, 0.4, and 0.6 W/cm2 | US shortened thawing time by 87% through thawing from −5 to −1°C compared to air thawing. Ultrasound assisted thawing did not damage the textural and technological attributes. | [179] |

| Drying | ||||

| US pretreatment followed by hot air and freeze drying | Carrot discs | Probe system, 20 kHz, Amplitude: 24.4, 42.7 and 61.0 μm. Processing time: 3 and 10 min. Hot air drying (60 °C, 0.3 m/s). | Higher carotenoids and polyacetylenes retention in US pre-treated samples. US pre-treatment, a potential alternative to blanching, before drying carrots. | [180] |

| Hot air convective drying with contacting ultrasound system | Garlic slices | Sonication: 1513.5 W/m2Air velocity: 2.5 m/s Temperature: 50 °C, 60 °C and 70 °C. | Contacting US reduced drying time, enhanced water diffusion and reduced quality loss. Organosulfur compounds were better preserved, browning was minimized. | [181] |

| Airborne ultrasound assisted convective drying | Potato | 25 kHz, 100 and 200 W, air velocity 4 m/s, 50 °C | US reduced processing time from 5 to 3 h. US lowered energy consumption and helped retain quality parameter. | [182] |

| Ultrasound combined vacuum pretreatment(UVP) and convective drying | Okra | 25 kHz, P = 80, 200 and 320 W, T = 25 °C, t = 5, 10 and15 min. Optimised (250 W, 0.5 cm thickness and ultrasonic treatment for 15 min) | UVP enhanced convective drying, maintained the physicochemical properties and also reduced the energy consumption. | [183] |

| Cooking | ||||

| US assisted cooking | Spiced beef | Power levels: 0, 400, 600, 800 and 1000 W. Frequency: 20 kHzCooking time 120 min. | Permeability of NaCl enhanced due to. High power US resulted in increase in the lipid oxidation, which helped in strengthening the volatile compounds. At 800 W, US improved chemical profiles of spiced beef flavour and taste | [185] |

| US assisted cooking | Spiced beef | Power level: 0, 400, 600, 800 and 1000, Frequency: 20 kHz, Cooking time (80, 100 and 120 min) | US improved salt penetration, affected tenderness and water holding capacity of spiced beef was improved. | [186] |

| US assisted cooking | Mortadella | US 25 kHz | US improved the cooking process,accelerated increase in internal temperature and more homogeneity were observed in the mortadellas. US did not accelerate protein and lipid oxidation and no color changes were observed and did not affect the microbiological quality. Positive effects of US on gel formation were found as an increase in hardness and chewiness was reported. | [187] |

| Combination of US and temperature hydration | White kidney beans | Hydration using US (28 W/L volumetric power), 45 kHz and temperatures (25, 35, 45 and 55C). | Both temperature and US enhanced the hydration process. When in combination, ultrasound effect decreased with increasing temperature of soaking. The cooking process was not affected by both the different temperatures and ultrasound. | [188] |

| US assisted cooking | Mortadella | US 25 kHz | US improved the cooking process, accelerated increase in internal temperature and more homogeneity were observed in the mortadellas. US did not accelerate protein and lipid oxidation and no color changes were observed and did not affect the microbiological quality. Positive effects of US on gel formation were found as an increase in hardness and chewiness was reported. | [187] |

| Filtration | ||||

| US assisted cross flow ultrafiltration | Skim milk | Small angle X ray scattering Cross-Flow US-coupled Filtration CellUS intensity: 0.6 to 2.9 W cm−2 . | Feed milk viscosity not affected at 20 kHz, 2 W cm−2. US improved filtration. Partial disruption of concentrated layer occurred by US, accelerating permeate flux. The effect of ultrasound was found to decrease when the feed concentration increased. US was found to be promising as the formation of reversible fouling layer was limited, therefore higher permeate flux was induced. | [193] |

| US assisted cross flow ultrafiltration | Skim milk | Small angle X ray scattering Cross-Flow US-coupled Filtration CellUS intensity: 0.6 to 2.9 W cm−2 . | Feed milk viscosity not affected at 20 kHz, 2 W cm−2. US improved filtration. Partial disruption of concentrated layer occurred by US, accelerating permeate flux. The effect of ultrasound was found to decrease when the feed concentration increased. US was found to be promising as the formation of reversible fouling layer was limited, therefore higher permeate flux was induced. | [194] |

| US assisted defouling | Whey solution | 50 kHz, 300 W, 55 kPa, 20–22°C. Membrane: Cross flow UF. | 112% flux recovery. Ultrasound led to physical cleaning. Surfactant along with ultrasound showed a synergistic effect. | [195] |

| US assisted defouling | Soyabean protein | 40 kHz, (0, 1.43, 2.13, 3.57 W.cm -2) Power, (20, 30, 40, 50, 60, 70 kPa) operating pressure, | Permeate flux: 86.3 kg.m-2h−1 Frequency: 23 kHz, 3.57 Wcm−2. US leads to formation of cracks on membrane surface. Polyvinylidenefluoride (PVDF) membrane more resistant compared to other membranes. | [196] |

| US assisted defouling | Carrot juice | 20 kHz, 400, 600, 800, 1000 W, 0.2, 0.5 bar. Microfiltration system with PVDF | US enhanced the flux. US reduced diphasic nature of juice, affected fouling. @ 1000 W, 100 ml solution, 30 min sonication | [191] |

| US-assisted emulsification | ||||

| US assisted emulsification | Mustard oil in water | Ultrasonic power amplitude of 40%, 30 min, Hydrophilic lipophilic balance value of 10, Ψs of 0.08 (8%, v/v), Ψo of 0.1 (10%, v/ v) | Good emulsion stability (up to 3 months). Only physical effects of US were observed and no changes in molecular structure of oil were seen. | [198] |

| High intensity US | Whipped cream | US 20 kHz (100 and 300 W) for 0, 5, 10 and 15 min (Pulse on-time: 2 s, off-time: 4 s). | US enhanced the quality and properties of whipped cream up to a particular US input energy. Protein chains underwent denaturation, and opened to cover fat cells, enhancing the properties. | [199] |

| Pickling/brining | ||||

| US assisted brining | Chinese cabbage | 35 kHz, NaCl (10, 15, and 20% w/w), 1:10 (sample: salt solution), 25 °C(room temperature). Samples removed at 0, 30, 60, 90, 120, 150, and 180 min and wrapped in absorbent paper for 2 min to remove excess solution | US enhanced the cabbage hardness and chewiness, improved brining process, gave a homogenous salt distribution and improved Kimchi quality. | [201] |

| High intensity US | Pork meat (Longissimus dorsi) | US: 40 kHz; 37.5 W/dm3NaCl concentration :50, 100, 150, 200, 240 and 280 kg NaCl/m3Brining:15, 30, 45, 60, 90 and 120 min. Water immersion: 20 s, blotting followed by wrapping in plastic waterproof film. Storage :18 ± 0.5 ⁰C. | US significantly influenced salt gain and enhanced brining. Reduced brining time. Gave uniform salt distribution. | [202] |

| US assisted diffusion | Pork | 70 W, 20 kHz, Ultrasonic power: 9.29 and 54.9 W cm−2. | ||

| 5% NaCl/ Salt replacer, brining time 120 min. | US enhanced the salt diffusion into the matrix, compared to static brining. US brined samples, improved the texture of brined samples both with NaCl and salt replacer. | [203] | ||

| Sterilization | ||||

| US assisted pasteurisation | Juices | Designing of batch ultrasonic reactor. | [205] | |

| Frequency: 20 kHzAmplitude: 45%E.coli and S.aureus. | E. coli inactivation: 60 °C, Staphylococcus aureus: 62 °C. 5-log microbial reduction achieved in 0.38 min and 0.55 min, respectively. US damaged cell structure leading to inactivation of microbes. Pasteurisation time reduced. No negative impacts on organoleptic characteristics and nutritional properties. | |||