Abstract

Saccharides are the most common carbon source for Streptococcus thermophilus, which is a widely used bacterium in the production of fermented dairy products. The performance of the strain is influenced by the consumption of different saccharides during fermentation. Therefore, a precise measurement of the concentrations of saccharides in the fermentation media is essential. An 18-min long method with limits of quantitation in the range of 0.159–0.704 mg/L and with 13C labelled internal standards employing hydrophilic interaction chromatography coupled to mass spectrometric detection-(HILIC-LC-MS) allowed for simultaneous quantification of five saccharides: fructose, glucose, galactose, sucrose, and lactose in the fermentation samples. The method included a four-step sample preparation protocol, which could be easily applied to high-throughput analysis. The developed method was validated and applied to the fermentation samples produced by Streptococcus thermophilus.

Keywords: saccharides, HILIC-LC-MS, Streptococcus thermophilus, fermentation

1. Introduction

Streptococcus thermophilus is a gram-positive facultative anaerobic bacterium mostly known for its role in the production of fermented dairy products. As a part of the lactic acid bacteria (LAB) group, it is a widely studied and well-known microorganism. As production of lactic acid by S. thermophilus is dependent on carbohydrate utilisation, the choice of available carbohydrate is usually dictated by strain ability to digest certain disaccharides—mainly sucrose and lactose [1]. Bacterial consumption of monosaccharides—fructose, glucose. and galactose, was found to be suppressed in most common strains. Nevertheless, the mutant strains, able to consume monosaccharides, were created to study the alternative ways for lactic acid production by utilisation of low-molecular carbohydrates [2,3,4].

Carbohydrates are a vast class of chemical compounds with a similar structure comprised of either furanose or pyranose skeleton core. Carbohydrate analysis employing chromatography has a long history starting from paper partition chromatography of selected monosaccharides in 1949 [5]. The advances in the chromatographic field have helped to achieve better separation and selectivity [6,7]. The main path to analyse carbohydrates was to use either gas chromatography with derivatisation of saccharides or liquid chromatography employing ion-exchange resins [8]. The development of novel stationary phases for both gas and liquid chromatography increased the number of applications where carbohydrate analysis could be performed from samples obtained from various sources, i.e., raw nutritional materials, animals, bacteria, humans, and so forth [9,10,11,12]. At the same time, developments in ion chromatography and electrophoresis allowed to measure carbohydrates in similar matrices creating the alternative ways for the measurements of saccharides [13,14,15,16]. Nowadays, the most commonly used method is to measure carbohydrates to use ion-exchange resin with a refractive index (RI) detector, as carbohydrates do not have any chromophores. The use of this combination is shown in Association of Official Analytical Chemists (AOAC) or International Organization for Standardization (ISO) methods [17]. The main disadvantage with RI-based detection is a relatively low selectivity, sensitivity, and elution program restriction compared to more advanced detection techniques such as evaporative light scattering detector (ELSD) [18,19], charged aerosol detection (CAD) [20] or mass spectrometric (MS) detector [21,22,23]. Out of advanced methods, MS-based detection offers the most selectivity as active mass filtration could clean up a substantial portion of noise interference originated from the sample matrix [24]. Therefore, the liquid chromatography coupled to mass spectrometer (LC-MS) system became a prominent choice to perform carbohydrate analysis with little to no extensive sample preparation [25,26].

The aim of this work was to develop and validate a rapid and sensitive method for the quantitative determination of five saccharides: fructose, glucose, galactose, sucrose, and lactose, by employing a rapid, selective, and sensitive methodology based on hydrophilic interaction chromatography coupled to mass spectrometric detection (HILIC-LC-MS) and isotopically labelled glucose and lactose as internal standards. The method development included optimisation of sample preparation, validation and application of the method towards the determination of carbohydrates metabolised by S. thermophilus in fermentation broth samples.

2. Results and Discussion

2.1. Chromatographic and Mass Spectrometric Optimisation

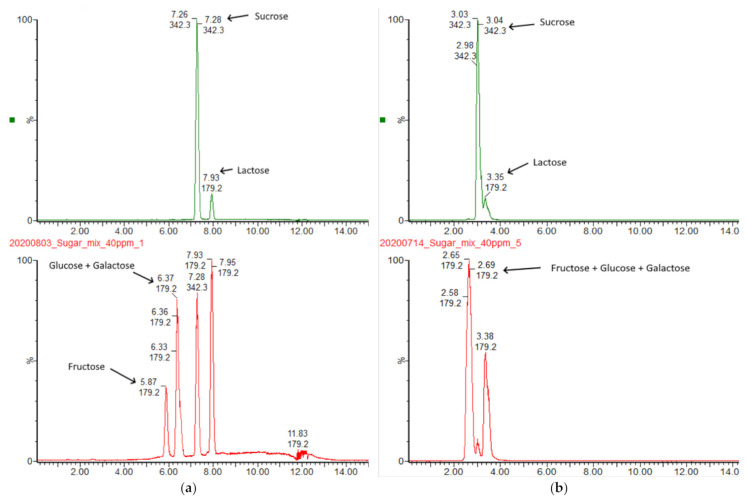

The initial screening involved testing of the performance of several columns with hydrophilic interaction (HILIC) stationary phase. The testing of Waters BEH HILIC and BEH Amide revealed that even though the columns are clearly capable of separation between mono- and disaccharides, the inter-class separation of closely matched carbohydrates is impossible (Figure 1).

Figure 1.

(a) Separation of mono- and disaccharides on Waters BEH Amide column with mobile phases containing 0.1% NH4OH; The elution was achieved using gradient elution at 170 µL/min flow rate. Solvents were: A—MilliQ + 0.1% NH4OH, B—MeCN + 0.1% NH4OH. Gradient program was: 0.0–10 min linear ramp 0.1–60% A, 10.01–25.00 hold at 0.1% A. The detection was performed in Single-Ion-Reaction (SIR) mode (b) Separation of mono- and disaccharides on Waters BEH HILIC column with mobile phases containing neat solvents. The elution was achieved using gradient elution at 170 µL/min flow rate. Solvents were: A—MilliQ, B—MeCN. Gradient program was: 0.0–20 min linear ramp 0.1–40% A, 20.01–30.00 hold at 0.1% A. The detection was performed in Single-Ion-Reaction (SIR) mode at a concentration level of 10 µg/mL for all saccharides.

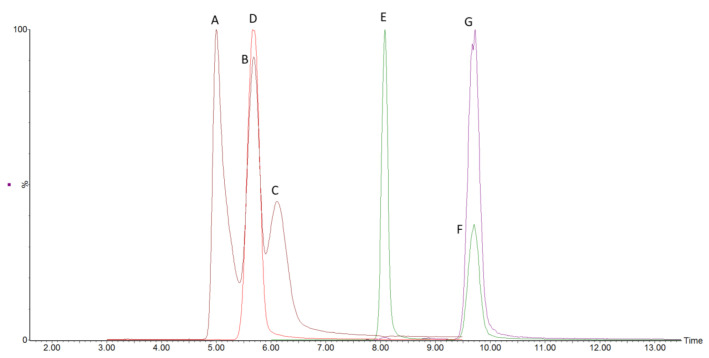

During method scouting, it became evident that BEH HILIC column could not achieve an acceptable separation of 3 monosaccharides of interest. Employing Waters BEH Amide column showed the separation between fructose and glucose-galactose pair close to the baseline. The separation of the glucose-galactose pair requires more resolving power as the epimer separation is proven to be complex. The acceptable separation between epimers was reached using Phenomenex Luna Omega Sugar column, which allowed a repeatable and precise determination of closely eluting glucose and galactose (Figure 2).

Figure 2.

The representative chromatogram of separated mono- and disaccharides with internal 13C-labeled standards on the Luna Omega Sugar column. Peaks are labelled as: A—fructose, B—glucose, C—galactose, D—glucose-13C6, E—sucrose, F—lactose and G—lactose-13C6. Peak heights are normalised.

To improve the sensitivity of measured analytes, the decision to enrich the mobile phases with guanidine hydrochloride solution was made to facilitate the formation of [M + Cl]− adduct instead of [M-H]- ion. The addition of chloride ion to saccharide molecules provided better ionisation, cleaner spectra at the baseline level (Table S1). It thus decreased the amount of sample injected on the column to achieve a satisfactory chromatographic and mass spectrometric result [27,28]. The variations in flow rate were also studied as the mock-up method was transferred from the column with a larger inner diameter, making it incompatible with the current column choice. Therefore, several different flow rates were evaluated to achieve optimal separation between all analytes: 300, 313 and 350 µL/min (Figure S1–S3). The flow rate 313 µL/min resulted in the most optimal separation among targeted carbohydrates. The column temperature was also studied, and two temperatures were tested: 25 and 35 °C. The higher temperature was ruled out as unfavoured due to more unsatisfactory performance in terms of chromatographic separations, which was in accordance with reports in the literature [29].

2.2. Sample Preparation Optimisation and Measurement of Fermentation Samples

Several variants of sample preparation were proposed during initial consideration for adequate sample preparation for maximum elimination of matrix components (Table 1).

Table 1.

Comparison of sample preparation protocols.

| Protocol Nr. | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Step 1 | Dilute 100 times with MilliQ | Dilute 50 times with MilliQ | ||||

| Step 2 | Centrifuge at 14000 rpm for 10 min | |||||

| Step 3 | Filter through 0.2 µm filter | Dilute 2 times with MeCN: MilliQ mixture containing 13C ISTD | Pass through 1 kDa MWCO filter | Pass through 3 kDa MWCO filter | Dilute 4 times with MeCN: MilliQ mixture containing 13C ISTD | |

| Step 4 | Dilute 2 times with MeCN: MilliQ mixture containing 13C ISTD | Pass through Isolute PLD+ cartridge | Pass through Isolute NH2 cartridge | Dilute 2 times with MeCN: MilliQ mixture containing C13 ISTD | Pass through Isolute NH2 cartridge | |

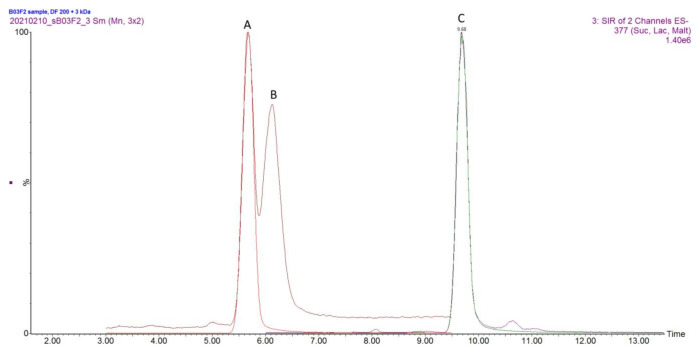

As the protocols were being tested firstly with a simulated matrix composed of chemically defined medium (CDM) [30] and external standards, it was found that variants 2, 3, 4 and 6 did not produce expected results as analytes were detected in lower amount compared to other protocols or no analytes of interest were found during the measurement (Table S2). Protocol nr 1 and 5 were chosen for additional evaluation as their performance with simulated matrix was found to be acceptable. The optimised protocols nr. 1 and 5 were applied towards harvested fermentation broth. It was found that protocol nr 1 produced a higher number of impurities which negatively affected MS performance by leaving more residue on the source cone compared to protocol nr 5, which included the usage of molecular weight cut-off filters (Figure 3).

Figure 3.

The overlaid chromatogram of the fermented sample subjected to extraction protocol nr. 5. Peaks are labelled as follows: A—Glucose and Glucose-13C6, B—Galactose, C—Lactose and Lactose-13C6.

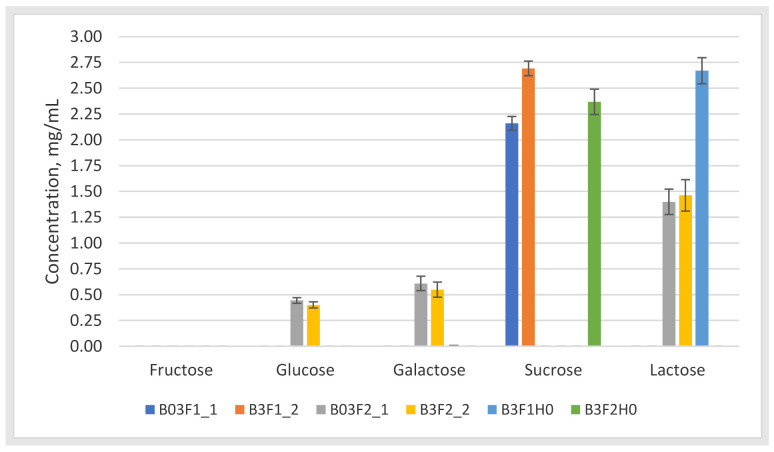

After sample preparation protocol optimisation was completed and sample preparation protocol nr 5 was chosen as the primary option to perform sample preparation. Six samples obtained during the fermentation process at different time points were analysed for carbohydrate content (Table 2).

Table 2.

Description of the harvested fermentation samples produced by S. thermophilus.

| Sample Name | Sampling Time Point, h | Carbohydrate Source |

|---|---|---|

| BO3F1_1 | 24 | Sucrose |

| B3F1_2 | 24 | Sucrose |

| BO3F2_1 | 24 | Lactose |

| B3F2_2 | 24 | Lactose |

| B3F1H0 | 0 | Lactose |

| B3F2H0 | 0 | Sucrose |

The samples were injected in triplicates. (Figure 4).

Figure 4.

Quantified carbohydrates (mg/mL) in the measured samples. The bars represent the concentration levels of the found saccharides in the fermentation samples. The sample naming follows B stands for batch fermentation; number 3 or 03 states the number of experiments, F1 or F2 states the reactor number and _1 or_2 states the number of parallel. H0 denotes 0 h sampling point.

It was found that neither of the samples contained fructose at levels exceeding the limit of quantification. Other samples contained either sucrose or lactose at a higher concentration due to its presence in CDM. It was shown in samples B03F2_1 and B3F2_2 that the bacterium was able to produce monosaccharides by breaking down larger saccharide. In other samples, no by-products of disaccharide breakdown were detected, which could indicate that bacteria would utilise either sucrose or lactose as a carbon source for the production of other molecules such as organic acids. The results were subjected to carbon balance calculations based solely on the saccharide content in the fermented and blank samples. The calculations showed that measured saccharide content is correlatable with calculations e.g., carbon balance calculation errors were 25.6 ± 16.1% (n = 6) on average between fermented samples. The obtained values were found to be acceptable as calculations did not take into the account presence of other organic materials commonly present in the fermentation broth.

2.3. Validation Results

When the development and optimisation of methodology were finished, validation was performed to evaluate the method linear range, limits of detection and quantifications, recoveries and the stability of prepared samples. First of all, linear range and linearity were evaluated via the repeated measurements of standard solutions consisting of 8 individual points obtained from stock’s serial dilution (Table 3).

Table 3.

The linear range, regression equation, limits of detection. and quantification of five saccharides.

| Analyte | Linear Range, µg/ml | Linear Regression | R2 | LoD 1, mg/L | LoQ 2, mg/L |

|---|---|---|---|---|---|

| Fructose | 0.77–49.88 | y = 1.3611x + 0.9873 | 0.9974 | 0.189 | 0.629 |

| Glucose | 0.51–64.80 | y = 0.6921x + 0.0765 | 0.9993 | 0.080 | 0.268 |

| Galactose | 0.39–49.60 | y = 0.3764x − 0.0112 | 0.9958 | 0.067 | 0.220 |

| Sucrose | 0.93–59.75 | y = 1.2610x + 0.9776 | 0.9935 | 0.232 | 0.704 |

| Lactose | 0.38–49.10 | y = 1.0851x − 0.0076 | 0.9996 | 0.048 | 0.159 |

1 LoD = Blank mean value + 3.3*standard deviation at LLOQ; 2 LoQ = Blank mean value + 10* standard deviation at LLOQ.

After linearity was found to be acceptable (R2 ≥ 0.99 or higher) for all sugars in this study, the repeatability of the method was studied. Repeatability of retention times and peak areas were studied first with six replicate injections of standard solution (Table 4). The repeatability of the method was studied across four independent days to confirm the stability of the retentions time and peak areas of the analytes.

Table 4.

Repeatability of retention times and peak areas of measured carbohydrates.

| Analyte | Mass of Measured Ion, m/z | Retention Time, min | Retention Time RSD, % | Peak Area RSD % | ||

|---|---|---|---|---|---|---|

| Inter-Day, % (n = 6) | Intra-Day, % (n = 4) | Inter-Day, % (n = 6), | Intra-Day, % (n = 4) | |||

| Fructose | 215 | 5.06 | 0.26 | 1.27 | 2.90 | 3.75 |

| Glucose | 215 | 5.75 | 0.42 | 1.59 | 2.69 | 4.01 |

| Galactose | 215 | 6.18 | 0.50 | 1.50 | 3.62 | 3.28 |

| Sucrose | 377 | 8.16 | 0.23 | 1.32 | 3.46 | 2.96 |

| Lactose | 377 | 9.81 | 0.19 | 1.60 | 4.70 | 2.40 |

| Glucose—13C6 | 221 | 5.70 | 0.39 | 0.59 | 2.13 | 1.48 |

| Lactose—13C6 | 383 | 9.73 | 0.44 | 0.50 | 4.63 | 2.23 |

Recovery of the sample preparation was determined by analysing fermentation samples, whereas 13C-internal standards were spiked prior to sample preparation steps and compared to sample preparation procedure where 13C-internal standards were added in the last stage of the procedure. Recovery was calculated according to Equation (1):

| Recovery = Peak area in a spiked sample/Peak area in a non-spiked sample ∗ 100 | (1) |

The recovery experiments consisted of injections of 2 samples in triplicate. The recorded recovery values were 103.73 ± 1.69% and 111.04 ± 2.80% for 13C-labeled glucose and 13C-labeled lactose, respectively. The obtained values are in the ±20% range. Furthermore, we have investigated the stability of the prepared standard solutions in a ready-to-use form stored at +4 and −20 °C. The prepared standards were stable at +4 degrees for one week whereas peak area of analytes has not changed by more than 5%. The analytes stored at −20 degrees for 1 month showed stable retention factors or all measured compound except for sucrose, which response factor after 1 month of storage at −20 °C had changed by 15%.

3. Materials and Methods

3.1. Reagents and Chemicals

Standards of mono- and disaccharides: d-fructose, d-glucose, d-galactose, d-(+)-sucrose, d-lactose monohydrate, and ammonia solution (25%, LC-MS LiChropur™ grade) were obtained from Sigma-Aldrich (Darmstadt, Germany). Glucose-13C6 (Glu-13C6, U-13C6, 99%, chemical purity 98%) and lactose monohydrate (Lac-13C6, UL-13C6glc, 98%+) were procured from Cambridge Isotope Laboratories Inc. (Tewksbury, MA, USA). Ultrapure water (18.2 MΩ.cm) was prepared with MilliQ® Direct-Q® UV (Merck KGaA, Darmstadt, Germany). Acetonitrile (MeCN; LiChrosolv, HPLC gradient grade), and guanidine hydrochloride (GuHCl; ≥99%) were acquired from Sigma-Aldrich (Darmstadt, Germany). Biotage Isolute® PLD+, C18 and NH2 were procured from Biotage Sweden AB (Uppsala, Sweden). Amicon Ultra-0.5 centrifugal filter unit (3 kDa) and Millex-LCR filters (Pore size 0.2 µm, Filter Dimension 13 mm) were obtained from Merck KGaA (Darmstadt, Germany) and Microsep Advance Centrifugal Devices with Omega Membrane 1K filter unit was purchased from Pall Corporation (Port Washington, NY, USA).

3.2. Preparation of Standard Solutions

The stock solution of each individual saccharide was prepared in MilliQ® water and stored at −20 °C. Solutions of isotopically labelled standards were dissolved in aqueous MeCN (50%, v/v) and stored at −50 °C. Working solutions for the determination of analytes were prepared firstly by diluting the stock solution with 100% MeCN, and after each working solution was prepared in aqueous MeCN (50%, v/v) water. Calibration curves were built for fructose (0.39–49.875 ppm), glucose (0.506–64.800 ppm), galactose (0.388–49.600 ppm), sucrose (0.467–59.750 ppm) and lactose (0.384–49.100 ppm). Glucose-13C6 and lactose-13C6 were added prior to injection to the autosampler vial, and their concentration in the vial was set at 15.925 and 12.825 ppm, respectively. The calculations of calibration curves used response factors, which were calculated according to Equation (2).

| Response Factor (RF) = Area of analytes × (Concentration of internal standard/Area of internal standard) | (2) |

Calibration curves were built using eight-point measurements of serially diluted standards. The regression was found by fitting a point to a linear equation.

3.3. Liquid Chromatography

Samples were analysed using a Waters UPLC® system (Waters Corporation, Milford, MA, USA) coupled with a Waters Quattro Premier XE Mass Spectrometer equipped with ZSpray™ Source and controlled by Waters MassLynx™ 4.1 (V4.1 SCN805, Waters Corporation, Milford, MA). Mobile phases were as follows: (A) 99% MilliQ® + 1% MeCN + 1 mg/L of GuHCl and (B) 99% MeCN + 1% MilliQ® + 1 mg/L of GuHCl. Weak needle wash was composed of 10% MilliQ® in MeCN (v/v), and strong wash needle consisted of 10% MeCN in MilliQ® (v/v). Seal wash was aqueous MeCN (50%, v/v). Samples were stored at an autosampler which held temperature at 8 °C. The injection volume was 2 µL. Several columns were tested: Waters Acquity UPLC® BEH HILIC (2.1 × 100 mm, 1.7 µm, Waters Corporation, Milford, MA), Waters XBridge® BEH Amide XP (3.0 × 150 mm, 2.5 µm, Waters Corporation, Milford, MA), Phenomenex Luna Omega Sugar column (2.1 × 150 mm, 100 Å, 3 µm, Phenomenex Inc., Torrance, CA, USA). To prevent harm to any analytical column, ACQUITY UPLC Column in-line filter unit (Waters Corporation, Milford, MA) with installed 0.2 µm stainless steel filter was used in all experiments with all tested columns. The column temperature was held at 25 degrees of Celsius for the duration of all experiments. The gradient was as follows: 0–10 min linear gradient 10–25% A, 10–12 min hold at 25% A, 12.01–14 min hold at 35% A, 14.01–18 min hold at 10% A. Flow rate was set at 313 µL/min.

3.4. Mass Spectrometry

The analytes were ionised under negative electrospray ionisation conditions with optimised source conditions. The source temperature was set at 120 °C, high-purity nitrogen was fed into the source at 50 L/h (cone) and 800 L/h (desolvation) and heated to 350 °C. The capillary voltage was set at −2.3 kV, cone voltage at 25 V and extractor voltage 3 V. The values for efficient ionisation were found by infusing a standard solution of individual saccharide (ca 25 ppm) in 50% aqueous MeCN (v/v) at the combined flow from UPLC and integrated syringe pump at 250 µL/min. For measurement of analytes, single ion monitoring (SIR) experiments were chosen as saccharides possess no valuable fragments for ubiquitous identification, therefore, making it unnecessary to perform multiple reaction monitoring (MRM) type of experiments. The SIR channels were based on molecular ion with added chloride as [M+Cl]-. Data acquisition was performed in Waters MassLynx™ V4.1 (SCN805, Waters Corporation, Milford, MA, USA). Data analysis was performed in Waters QuanLynx™ V4.1 (SCN805, Waters Corporation, Milford, MA, USA) and Microsoft Excel (Microsoft 365 Apps for enterprise).

3.5. Bioreactor Experiments, Bacteria Growth Description

Streptococcus thermophilus was inoculated into fresh M17 medium (lactose as carbon source) at the rate of 1e7 cfu/mL (1%) and cultivated until OD600 reached a value of 0.8. Then the culture was inoculated into a bioreactor containing 300 mL of CDM achieving 100-fold dilution. CDM contained either sucrose or lactose as a carbon source. Cultivation was conducted in anaerobic conditions maintained by the constant flow of N2 into the medium flask and N2:CO2 mixture (80:20, v/v) into the reactor vessel at 150 and 300 mL/min, respectively.

Culture outgrowth was monitored by the rate of medium acidification and using the turbidimetric sensor. After 7 h of batch growth, the stability of culture was achieved, and flowthrough was initiated with a dilution rate of 0.25 h−1. The flow was maintained for 20 h, ensuring culture stabilisation. At the chemostat point, the culture samples were taken for subsequent analysis. HPLC samples were centrifuged at 14,000 rpm for 10 min. Supernatants were frozen and stored at −20 °C.

3.6. Sample Preparation

Frozen samples were fully thawed at room temperature until a clear solution was obtained. Thawed samples were serially diluted 100-fold before further steps. Diluted samples (1000 µL) were firstly centrifuged at 14,000 rpm for 10 min to remove any remaining solid residue. The supernatant (500 µL) was then transferred to a 3 kDa molecular weight cut-off (MWCO) filter (Amicon® Ultra-0.5, Merck KGaA, Germany). The MWCO filter was then centrifuged at 14,000 rpm for 20 min. The supernatant obtained was diluted with a 50% aqueous MeCN (v/v) mixture containing Glu-13C6 and Lac-13C6 2-fold before analysis.

3.7. Method Validation

The developed method was assessed for linearity (as a correlation coefficient of R2 of calibration curve), the limit of detection and quantification (as the standard deviation of the measured sample at the lowest calibration points multiplied by 3 or 10, respectively), recovery (as spiked sample vs. un-spiked) and matrix effect [31].

4. Conclusions

In summary, we have developed the HILIC-LC-MS method for the rapid and simultaneous determination of five saccharides in just 18 min without employing complex sample preparations steps. The methodology can be applied to the simplest instrumentation consisting of liquid chromatograph and single quadrupole mass detector. The addition of a common mobile phase additive such as guanidine hydrochloride is a viable option to increase signal insensitivities while reducing the baseline noise. The mass spectrometric detection helps with the selectivity of the methodology as mass spectrometer could filter out matrix interfering components thus providing cleaner and unambiguous spectra. The simultaneous measurement of fructose, glucose, galactose, sucrose, and lactose could be done in a fraction of time and less consumed solvent compared to classical methods used elsewhere [10,11,16,32]. The method developed here suits for both to identify and characterise the metabolism of various starter cultures (like here with Streptococcus thermophilus) as well as to detect the sugar profile of different food matrices. Furthermore, the monosaccharide quantities could be used in a calculation of the carbon balance in a single cell model (SCM) to assess the productivity of the strain during fermentation. The applicability of the method for quantification of the larger oligosaccharide chains together with smaller saccharides, for example, to analyse their consumption by gut microbiota, could be further determined in the future.

Acknowledgments

Authors would like to acknowledge Tiina Kriščiunaite and Georg Arju for input in the editing of the manuscript.

Supplementary Materials

Figure S1: The chromatogram of 5 saccharides subjected to the optimised gradient elution program with flow rate of 300 µL/min, Figure S2: The chromatogram of 5 saccharides subjected to the optimised gradient elution program with flow rate of 313 µL/min, Figure S3: The chromatogram of 5 saccharides subjected to the optimised gradient elution program with flow rate of 350 µL/min, Table S1: The peak areas of analytes while using neat solvents or solvents with added guanidine hydrochloride, Table S2: The peak areas of five saccharides in this study subjected to different extraction protocol in order to perform the sample preparation optimisation.

Author Contributions

Conceptualisation, D.P., V.K. and R.V.; methodology, D.P.; software, V.K.; validation, D.P. and V.K.; formal analysis, D.P. and V.K.; investigation, D.P., V.K. and J.M.; resources, V.K. and J.M.; data curation, D.P. and V.K.; writing—original draft preparation, D.P.; writing—review and editing, J.M., M.-L.K., R.V.; visualisation, D.P.; supervision, R.V.; project administration, D.P.; funding acquisition, M.-L.K. and R.V. All authors have read and agreed to the published version of the manuscript.

Funding

This study was supported by ERDF and Estonian Research Council via project RESTA16.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

Sample Availability

Not available.

Footnotes

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- 1.Hutkins R., Goh Y.J. Encyclopedia of Food Microbiology. Elsevier; Amsterdam, The Netherlands: 2014. STREPTOCOCCUS | Streptococcus thermophilus; pp. 554–559. [Google Scholar]

- 2.Thomas T.D., Crow V.L. Lactose and Sucrose Utilization by Streptococcus Thermophilus. FEMS Microbiol. Lett. 1983;17:13–17. doi: 10.1111/j.1574-6968.1983.tb00362.x. [DOI] [Google Scholar]

- 3.Sobowale A.A., Efuntoye M.O., Adesetan O.O. Energy Sources of Yoghurt Bacteria and Enhancement of Their Galactose Uptake. Afr. J. Biotechnol. 2011;10:4457–4463. doi: 10.4314/ajb.v10i21. [DOI] [Google Scholar]

- 4.Robitaille G., Moineau S., St-Gelais D., Vadeboncoeur C., Britten M. Galactose Metabolism and Capsule Formation in a Recombinant Strain of Streptococcus Thermophilus with a Galactose-Fermenting Phenotype. J. Dairy Sci. 2007;90:4051–4057. doi: 10.3168/jds.2007-0140. [DOI] [PubMed] [Google Scholar]

- 5.Jermyn M.A., Isherwood F.A. Improved Separation of Sugars on the Paper Partition Chromatogram. Biochem. J. 1949;44:402–407. doi: 10.1042/bj0440402. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Noggle G.R., Zill L.P. The Biosynthesis of Carbon-14-Labeled Compounds. III. The Separation and Isolation of Sugars by Ion-Exchange Chromatography1. Plant Physiol. 1953;28:731–735. doi: 10.1104/pp.28.4.731. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Bishop C.T., Cooper F. Separation Of Carbohydrate Derivatives By Gas–Liquid Partition Chromatography. Can. J. Chem. 1960 doi: 10.1139/v60-054. [DOI] [PubMed] [Google Scholar]

- 8.Wheaton R.M., Bauman W.C. Ion Exclusion—A Unit Operation Utilizing Ion Exchange Materials. Ind. Eng. Chem. 1953;45:228–233. doi: 10.1021/ie50517a067. [DOI] [Google Scholar]

- 9.Weiß K., Alt M. Determination of Single Sugars, Including Inulin, in Plants and Feed Materials by High-Performance Liquid Chromatography and Refraction Index Detection. Fermentation. 2017;3:36. doi: 10.3390/fermentation3030036. [DOI] [Google Scholar]

- 10.Correia D.M., Dias L.G., Veloso A.C.A., Dias T., Rocha I., Rodrigues L.R., Peres A.M. Dietary Sugars Analysis: Quantification of Fructooligossacharides during Fermentation by HPLC-RI Method. Front. Nutr. 2014;1 doi: 10.3389/fnut.2014.00011. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Zielinski A.A.F., Braga C.M., Demiate I.M., Beltrame F.L., Nogueira A., Wosiacki G. Development and Optimization of a HPLC-RI Method for the Determination of Major Sugars in Apple Juice and Evaluation of the Effect of the Ripening Stage. Food Sci. Technol. 2014;34:38–43. doi: 10.1590/S0101-20612014005000003. [DOI] [Google Scholar]

- 12.Montesano D., Cossignani L., Giua L., Urbani E., Simonetti M.S., Blasi F. A Simple HPLC-ELSD Method for Sugar Analysis in Goji Berry. [(accessed on 2 February 2021)]; Available online: https://www.hindawi.com/journals/jchem/2016/6271808/

- 13.Oliver J.D., Sutton A.T., Karu N., Phillips M., Markham J., Peiris P., Hilder E.F., Castignolles P. Simple and Robust Monitoring of Ethanol Fermentations by Capillary Electrophoresis. Biotechnol. Appl. Biochem. 2015;62:329–342. doi: 10.1002/bab.1269. [DOI] [PubMed] [Google Scholar]

- 14.Herber W.K., Robinett R.S.R. Determination of Carbon Sources in Fermentation Media Using High-Performance Anion-Exchange Liquid Chromatography and Pulsed Amperometric Detection. J. Chromatogr. A. 1994;676:287–295. doi: 10.1016/0021-9673(94)80428-1. [DOI] [Google Scholar]

- 15.Robinett R.S.R., Herber W.K. Analysis of Substrates and Metabolites in Fermentation Broth by Ion Chromatography. J. Chromatogr. A. 1994;671:315–322. doi: 10.1016/0021-9673(94)80256-4. [DOI] [Google Scholar]

- 16.Oliver J.D., Gaborieau M., Hilder E.F., Castignolles P. Simple and Robust Determination of Monosaccharides in Plant Fibers in Complex Mixtures by Capillary Electrophoresis and High Performance Liquid Chromatography. J. Chromatogr. A. 2013;1291:179–186. doi: 10.1016/j.chroma.2013.03.041. [DOI] [PubMed] [Google Scholar]

- 17.Krol J. Simple Sugar Analysis by HPLC Using Refractive Index Detection. [(accessed on 2 February 2021)]; Available online: http://www.waters.com/waters/library.htm?lid=1543489.

- 18.Schuster-Wolff-Bühring R., Michel R., Hinrichs J. A New Liquid Chromatography Method for the Simultaneous and Sensitive Quantification of Lactose and Lactulose in Milk. Dairy Sci. Technol. 2011;91:27–37. doi: 10.1051/dst/2010034. [DOI] [Google Scholar]

- 19.Clement A., Yong D., Brechet C. Simultaneous Identification of Sugars by HPLC Using Evaporative Light Scattering Detection (ELSD) and Refractive Index Detection (RI). Application to Plant Tissues. J. Liq. Chromatogr. 1992;15:805–817. doi: 10.1080/10826079208018836. [DOI] [Google Scholar]

- 20.Zhang Q., Bailey B., Thomas D., Plante M., Acworth I. Direct Carbohydrate Analysis in Beverages and Foods Using Pulsed Amperometric Detection or Charged Aerosol Detection. Thermo Fisher Scientific; Chelmsford, MA, USA: 2015. p. 7. [Google Scholar]

- 21.Gervasoni J., Primiano A., Graziani C., Scaldaferri F., Gasbarrini A., Urbani A., Persichilli S. Validation of UPLC-MS/MS Method for Determination of Urinary Lactulose/Mannitol. Molecules. 2018;23:2705. doi: 10.3390/molecules23102705. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Rego A., Jesus S., Motta C., Delgado I., Teixeira R., Galhano dos Santos R., Castanheira I. Quantification by LC-MS/MS of Individual Sugars in Fruit Juice Consumed in Portugal. J. Phys. Conf. Ser. 2018;1065:232004. doi: 10.1088/1742-6596/1065/23/232004. [DOI] [Google Scholar]

- 23.Bawazeer S., Muhsen Ali A., Alhawiti A., Khalaf A., Gibson C., Tusiimire J., Watson D.G. A Method for the Analysis of Sugars in Biological Systems Using Reductive Amination in Combination with Hydrophilic Interaction Chromatography and High Resolution Mass Spectrometry. Talanta. 2017;166:75–80. doi: 10.1016/j.talanta.2017.01.038. [DOI] [PubMed] [Google Scholar]

- 24.Gleave M. The Strengths of Mass Spectrometry Are Not Just Sensitivity and Selectivity. Bioanalysis. 2011;3:245–247. doi: 10.4155/bio.10.195. [DOI] [PubMed] [Google Scholar]

- 25.Fountain K.J., Hudalla C., Grumbach E.S., McCabe D., Morrison D. Analysis of Carbohydrates by UltraPerformance Liquid Chromatography and Mass Spectrometry. [(accessed on 3 February 2021)]; Available online: https://www.waters.com/nextgen/ee/en/library/application-notes/2009/analysis-of-carbohydrates-by-uplc-and-mass-spectrometry.html.

- 26.Thacker J.B., Schug K.A. Quantitative Determination of Fructose, Glucose, and Sucrose in Hard Ciders and Apple Juice by LC–MS/MS. Sep. Sci. PLUS. 2020;3:286–293. doi: 10.1002/sscp.202000033. [DOI] [Google Scholar]

- 27.Boutegrabet L., Kanawati B., Gebefügi I., Peyron D., Cayot P., Gougeon R.D., Schmitt-Kopplin P. Attachment of Chloride Anion to Sugars: Mechanistic Investigation and Discovery of a New Dopant for Efficient Sugar Ionization/Detection in Mass Spectrometers. Chem. Weinh. Bergstr. Ger. 2012;18:13059–13067. doi: 10.1002/chem.201103788. [DOI] [PubMed] [Google Scholar]

- 28.Jiang Y., Cole R.B. Oligosaccharide Analysis Using Anion Attachment in Negative Mode Electrospray Mass Spectrometry. J. Am. Soc. Mass Spectrom. 2005;16:60–70. doi: 10.1016/j.jasms.2004.09.006. [DOI] [PubMed] [Google Scholar]

- 29.Jenkins K. HILIC Separation of Carbohydrates Using BEH Amide Particle Technology. [(accessed on 3 March 2021)]; Available online: https://www.chromatographytoday.com/article/bioanalytical/40/waters-corporation/hilic-separation-of-carbohydrates-using-beh-amide-particle-technology/1959.

- 30.Letort C., Juillard V. Development of a Minimal Chemically-Defined Medium for the Exponential Growth of Streptococcus Thermophilus. J. Appl. Microbiol. 2001;91:1023–1029. doi: 10.1046/j.1365-2672.2001.01469.x. [DOI] [PubMed] [Google Scholar]

- 31.Kruve A., Rebane R., Kipper K., Oldekop M.-L., Evard H., Herodes K., Ravio P., Leito I. Tutorial Review on Validation of Liquid Chromatography–Mass Spectrometry Methods: Part II. Anal. Chim. Acta. 2015;870:8–28. doi: 10.1016/j.aca.2015.02.016. [DOI] [PubMed] [Google Scholar]

- 32.Xu W., Liang L., Zhu M. Determination of Sugars in Molasses by HPLC Following Solid-Phase Extraction. Int. J. Food Prop. 2015;18:547–557. doi: 10.1080/10942912.2013.837064. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Data Availability Statement

Data is contained within the article.