Abstract

Fish production worldwide has increased over the years due to increased populations and interest from consumers. This has led to an increase in the waste produced by this industry, with viscera being particularly notable as one of the main sources of negative environmental impact. This study will determine the environmental impact created when obtaining dry chemical silage from the viscera of red tilapia (Oreochromis spp.), using ecological footprint methodology as an indicator of sustainability. This process allows approximately 30% of CO2 emissions to be mitigated compared to those generated when fresh viscera are dumped into shallow landfills, while implementing actions that improve the process such as biogas production from waste and solar drying of the final product can mitigate approximately 86% of its environmental impact, when compared to the disposal of fresh viscera. It was concluded that the production of dry chemical silage using alternative drying energy is environmentally sustainable.

Keywords: Ecological footprint, Chemical silage, Red tilapia, Organic waste, Solar drying

Ecological footprint, Chemical silage, Red tilapia, Organic waste, Solar drying.

1. Introduction

The production of fish worldwide has increased over the years, due to an increase in the population and in consumer interest for this type of product as a result of its nutritional benefits (Heller and Keoleian, 2015; Pullin et al., 2007). This is how aquaculture has recently become one of the industries with the highest development indices (Fuentes-Santos et al., 2017), reaching 171 million tons in 2018 according to the United Nations Food and Agriculture Organization (FAO, 2018). In Colombia, it is estimated that fish production increased by 9% in 2018, with red tilapia (Oreochromis spp.) representing 62% of total production (Ministerio de Agricultura, 2018). This increase in production is accompanied by the generation of waste, which represents 65% of total production, causing environmental deterioration due to inadequate final disposal (Martínez-Alvarez et al., 2015).

In this context, silage represents an alternative use for some of the fish farming industry's most polluting waste (van't Land et al., 2017). This process is carried out by adding lactic acid microorganisms, organic or inorganic acid, which reduce the level of microorganisms that cause deterioration and activate endogenous enzymes, causing protein lysis, favoring the formation of peptides and amino acids of interest (Olsen and Toppe, 2017). This product is generally obtained in liquid form, however, there are disadvantages to using it in dry diets due to its moisture content (Madage et al., 2015). Therefore, drying processes are often used, increasing the concentration of its macro components such as protein, fat, and some organic acids (Olsen and Toppe, 2017). Although silage is an alternative to using by-products, it comprises a series of stages that involve different factors that directly or indirectly cause environmental deterioration (Suarez et al., 2018), especially when the aim is to create a dry product (Camaño et al., 2020).

The economic growth of many nations at the global level is associated with the depletion of natural resources, with the current human demand for water, food, infrastructure, and energy exerting ecological pressure on the planet. This leads to a variety of factors that damage the environment, such as the depletion of natural resources, the generation of waste and the emission of greenhouse gases (Ahmed and Wang, 2019). Activities that involve the use of these resources gradually increase to the level that they cause environmental damage; this is how the availability of natural resources (biocapacity) is limited, as there is insufficient capacity to counteract the impact caused by the creation of waste (Sharif et al., 2020).

As a result, the world has faced great challenges to the preservation of natural resources over the past few decades (Ibidhi et al., 2017). Currently, issues concerning sustainable development are becoming more prevalent and interest in these is increasing; this is reflected in the energy and environmental policy changes that have been occurring in many countries (Sharif et al., 2020). As a result of this, a variety of methods have emerged that allow environmental degradation to be monitored, evaluating the impact of various processes. This includes monitoring ecological footprints, which is a method capable of generating a clear perspective of processes' and even countries’ sustainability (Syrovátka, 2020).

Ecological footprint is a method of calculating the effect of anthropogenic activities on land, water, forest products, infrastructure and carbon footprints (Ahmed et al., 2020). This method is currently one of the most widely used sustainability indicators because it produces comparable, reliable and comprehensive responses (Jóhannesson et al., 2018; Ahmed and Wang, 2019). It also estimates the effects of human activity on the environment, establishing the amount of hectares of land and water worldwide that are necessary to produce and mitigate the waste generated in the consumption of natural resources (Ahmed and Wang, 2019). The ecological footprint is therefore used to evaluate the environmental impact in optimization processes, allowing each stage to be analyzed, identifying the phenomena that generate the greatest impact and implementing reduction strategies that improve the process ecological impact (Gwehenberger and Narodoslawsky, 2007a, Gwehenberger and Narodoslawsky, 2007b).

Chemical fish silage has been considered as a great alternative for the total or partial replacement of conventional protein sources in animal feed production and has been widely reported in many research studies. However, no studies have yet been reported that quantify the environmental impact of obtaining either liquid or dry chemical silage. Thus, the objective of this study was to determine the environmental impact created when obtaining dry chemical silage (DCS) from the viscera of red tilapia (Oreochromis spp.), using the ecological footprint methodology as an indicator of sustainability.

2. Materials and methods

2.1. Case study

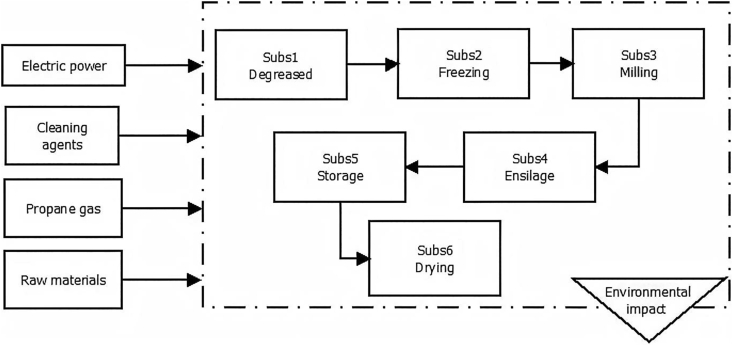

The study system aims to obtain DCS from the viscera of red tilapia (Oreochromis spp.), which involves different processes. Fresh viscera were supplied by El Gaitero fish farm, located in the municipality of San Jerónimo, Antioquia-Colombia (6°26′30″N 75°43′40″W), and they were processed in laboratory of group Nutrición y Tecnología de Alimentos (NUTEC) located in Medellín, Antioquia-Colombia. Figure 1 shows the different stages of the process of obtaining this product, including the overall inputs and outputs throughout the system as well as its delimitation. 6 subsystems were considered which represent the main stages of the process described according to the methodology described by Arias et al. (2017) and Suarez et al. (2018).

Figure 1.

Limit of the dry chemical silage manufacturing process.

Subsystem 1 (Subs1): This refers to the viscera degreasing stage, which consisted of heating the fresh viscera to 67 °C for a period of 30 minutes, successfully separating most of the lipid content by decantation.

Subsystem 2 (Subs2): This involves freezing the previously degreased material in order to solidify the remaining lipid content over a period of 24 h, eventually separating the frozen lipid phase from the protein-rich aqueous phase.

Subsystem 3 (Subs3): This consisted of crushing the protein-rich material obtained in subsystem 2. A knife mill (Black and Decker, USA) was used for this and a completely homogeneous material was obtained and arranged in plastic containers.

Subsystem 4 (Subs4): At this stage, the necessary additives were mixed with the homogenized viscera to initiate the hydrolysis and acidification processes. 97% sulfuric acid (Merck, Germany), 85% formic acid (Merck, Germany) and other additives were used for this, including Butyl hydroxy toluene (BHT) (Tecnas SA, Colombia) and potassium sorbate (Tecnas SA, Colombia) as an antioxidant and preservative respectively. Table 1 shows the formulation used for the chemical silage process.

Table 1.

Chemical silage formulation.

| Raw material | % |

|---|---|

| Homogenized viscera | 98,68 |

| 97% Sulfuric acid | 0,03 |

| 85% Formic acid | 1,16 |

| BHT | 0,002 |

| Potassium sorbate | 0,12 |

Subsystem 5 (Subs5): This is the storage stage, which lasts for a period of 8 days, during which the pH decreases to values of 4 or lower. At this stage, airtight conditions must be maintained to prevent oxygen from entering the containers and putrefactive microorganisms from spreading (Suarez et al., 2018).

Subsystem 6 (Subs6): At this stage, the convective drying process was carried out in a forced air oven (Thermo Scientific™, USA) at 60 °C for 24 hours until a moisture content of 10% is reached.

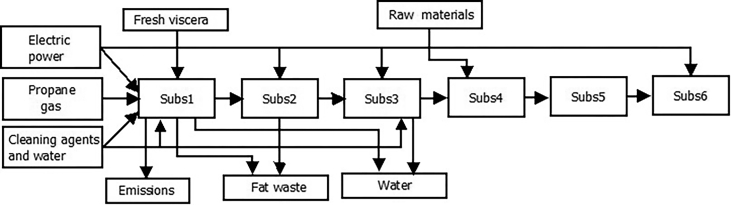

Meanwhile, Figure 2 shows all the subsystems with the inputs and outputs specified in each operation, in order to evaluate the environmental impact of each of these. These include electric power and caloric energy inputs, cleaning agents, additives and outputs such as lipid waste generation and cleaning water.

Figure 2.

Flow diagram of input and output of the dry chemical silage manufacturing process.

2.2. Assumptions and limitations

The following premises were considered for the present study:

-

1)

The DCS manufacturing process was carried out on El Gaitero fish farm, located in the municipality of San Jerónimo, Antioquia-Colombia, where the fresh viscera come from. This was done to avoid the negative environmental impact caused by transport, as this process is intended to be carried out on the fish farms where the fish originate.

-

2)

The impact of buildings was not taken into account in our calculations as they have a long service life.

-

3)

The environmental impact of industrial equipment was not included in the environmental analysis due to limitations in obtaining data from manufacturing processes. However, it has been shown that these do not significantly affect the environmental impact because they have long service lives (Perez-Martinez et al., 2018).

-

4)

Subs6 considers water vapor molecules to be the only compounds emitted into the environment as a result of the drying process, since at this stage the system does not reach the temperatures required to evaporate other compounds.

2.3. Calculation of environmental impact

To analyze the environmental impact of the process of manufacturing dry chemical silage, the ecological footprint study was used. This methodology was carried out as established by Gwehenberger and Narodoslawsky, 2007a, Gwehenberger and Narodoslawsky, 2007b and Krotscheck and Narodoslawsky (1996), in which calculation models are used to estimate the ecological impact of each activity shown in Figure 1. This makes calculations more precise as a large set of information is required and limitations that exist due to the use of international databases are reduced (Mamouni Limnios et al., 2009). To calculate the ecological footprint of the process, one ton of DCS was the fundamental unit. The environmental impact values of the inputs and outputs of each stage of the process were normalized to the same unit (Ha/ton) which indicates the number of hectares of forest necessary to replenish the CO2 produced during the process.

Seven calculation models based on IPCC (Intergovernmental Panel on Climate Change) (IPCC, 2006) reports were used. Eq. (1) was used to calculate the environmental impact (EI) caused by the organic compounds (OC) used or generated within the process. This was carried out in accordance with the provisions of the Intergovernmental Panel on Climate Change (IPCC) guidelines, where AOR corresponds to the amount of organic residue, CFM to the correction factor for methane gas (CH4) that depends on the process associated with solid waste management in a particular sector (IPCC, 2006), DOC represents the fraction of degradable organic carbon in the residue that can be subject to biochemical decomposition (IPCC, 1996), DCOF is the fraction of DCO not assimilated or that degrades very slowly (IPCC, 2006), F and R correspond to the fraction of CH4 in the landfill gas and the fraction of CH4 recovered respectively. The CH4 oxidation factor is represented by OX, the global warming potential of methane (GWP) was used for a period of 100 years (IPCC, 2014) and FF corresponds to the CO2 fixing factor for the region established within the environmental analysis (IDEAM, 2011). The coefficients 16 and 12 are the molecular weights of methane CH4 and C, respectively.

| (1) |

The environmental impact of the input of electrical power at different stages was calculated using Eq. (2), where EEG corresponds to the expenditure of electrical power (e) at each stage of the process and EEE is the factor of CO2 emissions caused by one kW-h of energy.

| (2) |

In subs1 the degreasing process is carried out through heating with propane gas. Its impact is calculated using Eq. (3), where RVC3H8 is the required volume of gas for the process, EBp is the embodied energy of the process of obtaining propane gas, DR is the distance traveled by transport, Rc is fuel efficiency and C is the amount of propane gas, while CO2 emissions from fuel are represented by EC. In addition to this, this subsystem also involves CO2 generation due to the propane gas combustion process, whose impact was calculated using Eq. (4), where CFC3H8 corresponds to the conversion factor for propane gas and EFC3H8 represents CO2 emission factor.

| (3) |

| (4) |

For subsystems 1 and 3 it is necessary to include an input flow corresponding to cleaning water. The impact caused by the supply of water was calculated using Eq. (5), in which WL corresponds to the liters of water required in the process (a) and EBW is the embodied energy for the water supply. However, the use of water is accompanied by an environmental impact associated with its eventual disposal, which is calculated using Eq. (6), where RWL corresponds to the volume of residual water obtained in the cleaning process, COBOD5 to the biochemical demand for oxygen from the degradable fraction of wastewater (IPCC, 2006), and MPCCH4 to the maximum methane production capacity of this fraction.

| (5) |

| (6) |

For the environmental impacts associated with production ingredients and other input flows in the different subsystems, Eq. (7) is used, where RQI is the required quantity of product (pi), EBPI corresponds to the embodied energy of the manufacture of the product and CI corresponds to the maximum amount in transporting the product.

| (7) |

2.4. Physicochemical analysis

The analytical methods established by the AOAC (Association of Official Analytical Chemists) (AOAC, 2000) were used to determine the bromatological characterization of fresh viscera and wet and dry chemical silage. The moisture content was determined using the methodology established in standard 930.15, drying the sample at 105 °C (Thermo Scientific™, USA) for 8 hours. The ashes were analyzed according to standard 942.05 by calcining the samples at 550 °C (Terrigeno, Colombia) for 7 hours. Fat analysis was performed according to standard 920.39 (Radlys, USA). Protein was determined by the Kjeldahl method (Velp Scientifica, Italy), standard 954.01, while carbohydrates (CHO) were determined by subtracting the other components mentioned from one hundred percent (Spanopoulos-Hernandez et al., 2010).

3. Results and discussion

Table 2 shows the bromatological composition of the matrices involved in the process, as well as that of the final product, highlighting the variation of important macro components such as fat and protein throughout the stages. Through the proposed elaboration process it was possible to obtain a product with the typical physical characteristics of a wet chemical silage (Arias et al., 2017; Suarez et al., 2018). In addition, it is evident that the DCS has significant potential as alternative raw protein material for animal feed, as it meets the required protein and fat levels, making it a product of great interest as it would allow the fish farming industry's waste to be meaningfully used (Camaño et al., 2020; Goddard and Perret, 2005).

Table 2.

Bromatological composition of fresh viscera, chemical silage, and dry chemical silage (%).

| Nutrient | Fresh Viscera | Chemical silage | DCS |

|---|---|---|---|

| Moisture | 61,36 ± 0,29 | 81,27 ± 0,09 | 10,20 ± 0,10 |

| Protein | 4,03 ± 0,10 | 6,85 ± 0,04 | 48,89 ± 0,51 |

| Fat | 32,93 ± 0,04 | 9,08 ± 0,01 | 31,58 ± 0,13 |

| Ash | 0,67 ± 0,04 | 2,69 ± 0,01 | 8,85 ± 0,02 |

| CHO | 0,98 ± 0,09 | 0,11 ± 0,02 | 0,48 ± 0,04 |

Table 3 outlines an inventory analysis of each of the dry chemical silage obtaining process subsystems, detailing the inputs and outputs at each of the stages with the respective quantity used to produce one ton of DCS. The reported values were calculated using Eqs. (1), (2), (3), (4), (5), (6), and (7). In addition, it includes an environmental impact value for each of the material and energy flows. The fresh viscera present in subs 1 show a value corresponding to -10,1482920 ha/ton; this is a negative value because it corresponds to a by-product of the fish farming industry that, if unused, generates an environmental impact equivalent to this magnitude. When used for preparing DCS, this impact on the environment is avoided. Similar behaviors were reported by Malakahmad et al. (2017), where the environmental impact of different processes for the disposal of organic waste was determined, finding that the CO2 emissions avoided for anaerobic digestion were considerably higher than the total CO2 emissions of the process, resulting in negative values.

Table 3.

Inventory analysis and environmental impact.

| Subs 1 | ||

|---|---|---|

| Inputs | Quantity | ∗EI (ha/ton) |

| Fresh viscera (Kg) | 6589,80 | -10,1482920 |

| Electric power (KW-h) | 3 | 0,0000587 |

| Propane (m3) | 1 | 0,0000710 |

| Water (L) | 2000 | 0,1095867 |

| Soap (Kg) |

50 |

0,0006728 |

|

Outputs |

Quantity |

EI (ha/ton) |

| Degreased viscera (Kg) | 4806,70 | 0 |

| CO2 (Kg) | 6379,80 | 0,7595000 |

| Cleaning water (L) | 2050 | 1,0250000 |

| Organic waste (Kg) |

1783,10 |

2,7459740 |

| Subs 2 | ||

|

Inputs |

Quantity |

EI (ha/ton) |

| Degreased viscera (Kg) | 4806,66 | 0 |

| Electric power (KW-h) |

0,0025 |

4,8923E-08 |

|

Outputs |

Quantity |

EI (ha/ton) |

| Degreased viscera (Kg) | 4440,96 | 0 |

| Organic waste (Kg) |

365,70 |

0,5631780 |

| Subs 3 | ||

|

Inputs |

Quantity |

EI (ha/ton) |

| Degreased viscera (Kg) | 4440,96 | 0 |

| Electric power (KW-h) | 0,1619 | 3,1682E-06 |

| Water (L) | 1400 | 0,0767107 |

| Soap (Kg) |

20 |

0,0006569 |

|

Outputs |

Quantity |

EI (ha/ton) |

| Homogenized viscera (Kg) | 4440,96 | 0 |

| Cleaning water (L) |

1420 |

0,710000 |

| Subs 4 | ||

|

Inputs |

Quantity |

EI (ha/ton) |

| Homogenized viscera | 4440,96 | 0 |

| Sulfuric acid 97% | 1,35 | 0,0002328 |

| Formic acid 85% | 52,20 | 3,3806E-06 |

| BHT | 0,09 | 1,0631E-06 |

| Potassium sorbate |

5,40 |

6,3787E-05 |

|

Outputs |

Quantity |

EI (ha/ton) |

| Pre-silage (Kg) |

4500 |

0 |

| Subs 5 | ||

|

Inputs |

Quantity |

EI (ha/ton) |

| Pre-silage (Kg) |

4500 |

0 |

|

Outputs |

Quantity |

EI (ha/ton) |

| Silage (Kg) |

4500 |

0 |

| Subs 6 | ||

|

Inputs |

Quantity |

EI (ha/ton) |

| Silage (Kg) | 4500 | 0 |

| Electric power (KW-h) |

67266 |

1,3163316 |

|

Outputs |

Quantity |

EI (ha/ton) |

| Dry silage (Ton) | 1 | 0 |

| TOTAL (Ha/Ton) | -2,8402475 | |

Red environmental impact values mean environmental deterioration, and black environmental impact values mean environmental benefit.

The total environmental impact delivered a value of -2,8402475 ha/ton, which indicates that the process of manufacturing DCS allows approximately 30% of CO2 emissions to be mitigated, compared to those generated in the environment when fresh viscera are dumped in shallow landfills (10,1482920 ha/ton). This result is highly relevant as the fish farming industry generates approximately 0,07 million tons of waste per year (Cakar et al., 2020), corresponding to 0,02 million tons of CO2 equivalent, which could be mitigated with alternative harvesting processes such as silage (Tian et al., 2012). However, during the multiple stages of the silage process, CO2 emissions are generated due to the inputs and outputs. It is therefore important to analyze each one in detail to identify possible process improvements from an environmental perspective.

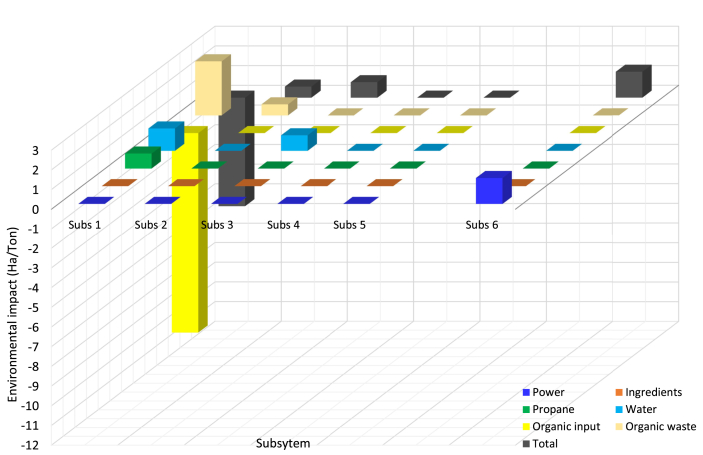

Figure 3 shows the environmental impact of the process subsystems with each of the input and output categories, as well as the total of each one. Similar inputs and outputs were consolidated within the categories; the impact of propane includes CO2 emissions produced during combustion and the impact of water includes emissions of input water for cleaning and the eventual disposal of this. For subs 1, we can see that organic waste represents the greatest environmental impact with 59% of the total CO2 emissions in this stage, followed by water with 24% and finally propane with 16%. Likewise, organic waste represented the highest CO2 emission (99,99%) for subs 2. In the case of subs 3, the water intake and water disposal represent 99,91% of total CO2 emissions at the crushing stage. Low environmental impact was registered at the silage stage (subs 4), since low percentages of raw materials were used, except for the homogenized viscera (Table 1). In subs 5, there are no CO2 emissions to the environment, since this is the product's hermetic storage stage, where there are no inflows or outflows. Finally, in subs 6 the electrical power necessary for drying is the only factor that affects the environment.

Figure 3.

Environmental impact of the subsystems of the dry chemical silage manufacturing process.

Based on the foregoing, the disposal of organic waste and the energy required for the drying stage were identified as the process input and output flows that have the greatest environmental impact, with 63% and 18% respectively. This requires alternatives to be proposed to improve the process from an environmental point of view. For example, organic waste can be used to produce biogas. Bulatov et al. (2019) and Kafle et al. (2013) reported that the waste from the fish farming industry is a potential substrate for obtaining alternative energies such as biogas. In addition, it has been shown that lipid waste can be used in the preparation of diets for animal feed as reported by Goosen et al. (2014) and Güllü et al. (2014), who found that the recovered oil can be a food ingredient that does not present significant modifications in the productive variables of the evaluated species. On the other hand, conventional drying technologies are expensive and have a high environmental impact, which is why alternative technologies such as solar drying have been pursued, as these are inexpensive while not significantly modifying the characteristics of the final product (Goddard and Perret, 2005). Likewise, the optimal drying conditions for chemical silage made from red tilapia viscera (Oreochromis spp.) have been reported through the use of a direct solar dryer, achieving the physicochemical and microbiological characteristics for the product's stability (Camaño et al., 2020). As a result of the foregoing, an alternative scenario was proposed, modifying the main sources of contamination of the original process, and calculating the reduction of the environmental impact based on these modifications.

Table 4 shows a comparison between the original scenario and the alternative scenario, with the above modifications. In terms of the disposal of organic waste in the alternative scenario, a value of -1,3236608 ha/ton was obtained, which indicates a significant reduction in environmental impact compared to the original process, as the use of the waste for obtaining biogas has been used to combat adverse effects on the environment, showing viability in sustainable processes (Bulatov et al., 2019). On the other hand, at the drying stage a mitigation of 100% of CO2 emissions caused in the original process can be achieved. This is because the solar energy used in the alternative scenario is an abundant, renewable and free source, making it one of the most promising alternatives to reduce the environmental impact of drying processes (Fudholi et al., 2015; Tiwari, 2016). Finally, the alternative scenario total environmental impact was -8,7893919 ha/ton, corresponding to an 86% reduction in environmental impact. This was 2,8 times greater than the obtained in the original scenario (30%). This indicates that the use of waste from the fish farming industry to obtain DCS by implementing alternative technologies for its production is possible from both an environmental and technological perspective, as this waste can create added value products that could supply protein raw materials for animal feed, with the environmental aspect being one of the fundamental axes in sustainable production processes.

Table 4.

Comparison of the environmental impact of the organic waste disposal and the drying process in the different scenarios.

| Original scenario | EI (Ha/ton) | Alternative scenario | EI (Ha/ton) | |

|---|---|---|---|---|

| disposal organic waste | Dumped in shallow landfills | 3,3091520 | Biogas production | -1,3236608 |

| Drying process | Convective drying | 1,3163316 | Solar drying | 0 |

4. Conclusions

The implementation of the ecological footprint as an environmental assessment method of a process to obtain dry chemical silage from red tilapia viscera (Oreochromis spp.) allowed the true environmental impact of the use of these residues to be quantified, identifying the stages and input and output flows with the highest levels of CO2 emissions, which was useful for implementing new alternative technologies that optimize deterioration, resulting in a technologically and environmentally stable process. In addition to this, the organic waste involved in the process of obtaining DCS proved to be the main source of CO2 emissions. However, it has been shown that this has a high potential to produce alternative energy such as biogas.

The production of DCS with the use of alternative drying energies such as solar drying, proved to be a sustainable process from an environmental perspective, in addition to being a product with added commercial value with ideal characteristics to be used as a substitute for protein raw materials in the animal feed industry.

Future research on the implementation of other environmental quantification methods in the process of obtaining chemical fish silage and their comparisons, as well as the quantification of the environmental impact in feeding different animal species with chemical silage could be of interest.

Declarations

Author contribution statement

Yhoan S. Gaviria G. & Jairo A. Camaño E: performed the experiments; analyzed and interpreted the data; wrote the paper.

Jose E. Zapata M.: conceived and designed the experiments; analyzed and interpreted the data; contributed reagents, materials, analysis tools or data; wrote the paper.

Funding statement

This work was supported by COLCIENCIAS (1115-745-58746).

Data availability statement

Data will be made available on request.

Declaration of interests statement

The authors declare no conflict of interest.

Additional information

No additional information is available for this paper.

References

- Ahmed Z., Asghar M.M., Malik M.N., Nawaz K. Moving towards a sustainable environment: the dynamic linkage between natural resources, human capital, urbanization, economic growth, and ecological footprint in China. Resour. Pol. 2020;67(April):101677. [Forthcoming] [Google Scholar]

- Ahmed Z., Wang Z. Investigating the impact of human capital on the ecological footprint in India: an empirical analysis. Environ. Sci. Pollut. Control Ser. 2019;26(26):26782–26796. doi: 10.1007/s11356-019-05911-7. [DOI] [PubMed] [Google Scholar]

- AOAC . 17a editio. Association of Official Analysis Chemists International; 2000. Official Methods of Analysis of AOAC International. [Google Scholar]

- Arias L., Gómez L.J., Zapata J.E. Efecto de temperatura-tiempo sobre los lípidos extraídos de VÍsceras de tilapia roja (Oreochromis sp.) utilizando un proceso de calentamiento-congelación. Inf. Tecnol. 2017;28(5):131–142. [Google Scholar]

- Bulatov N.K., Sarzhanov D.K., Elubaev S.Z., Suleymenov T.B., Kasymzhanova K.S., Balabayev O.T. Model of effective system of processing of organic wastes in biogas and environmental fuel production plant. Food Bioprod. Process. 2019;115:194–207. [Google Scholar]

- Cakar B., Aydin S., Varank G., Ozcan H.K. Assessment of environmental impact of FOOD waste in Turkey. J. Clean. Prod. 2020;244:118846. [Google Scholar]

- Camaño J.A., Rivera A.M., Zapata J.E. Efecto del espesor de película y de la ubicación de la muestra en un secador solar directo, sobre la cinética de secado de ensilado de vísceras de tilapia roja (Oreochromis sp) Inf. Tecnol. 2020;31(1):53–66. [Google Scholar]

- FAO . 2018. The State of World Fisheries and Aquaculture. Meeting the Sustainable Development Goals. [Google Scholar]

- Fudholi A., Sopian K., Bakhtyar B., Gabbasa M., Othman M.Y., Ruslan M.H. Review of solar drying systems with air based solar collectors in Malaysia. Renew. Sustain. Energy Rev. 2015;51:1191–1204. [Google Scholar]

- Fuentes-Santos I., Cubillo A.M., Labarta U. A bioeconomic approach to optimize mussel culture production. Rev. Aquacult. 2017;9(2):125–140. [Google Scholar]

- Goddard J.S., Perret J.S.M. Co-drying fish silage for use in aquafeeds. Anim. Feed Sci. Technol. 2005;118(3–4):337–342. [Google Scholar]

- Goosen N.J., de Wet L.F., Görgens J.F., Jacobs K., de Bruyn A. Fish silage oil from rainbow trout processing waste as alternative to conventional fish oil in formulated diets for Mozambique tilapia Oreochromis mossambicus. Anim. Feed Sci. Technol. 2014;188:74–84. [Google Scholar]

- Güllü K., Acar Ü., Tezel R., Yozukmaz A. Replacement of fish meal with fish processing by-product silage in diets for the rainbow trout, Oncorhynchus mykiss. Pakistan J. Zool. 2014;46(6):1697–1703. [Google Scholar]

- Gwehenberger G., Narodoslawsky M. The Sustainable Process Index SPI as an engineer’s tool for environmental impact assessment of processes: the sugar industry as a case study. WIT Trans. Ecol. Environ. 2007;102:333–340. [Google Scholar]

- Gwehenberger Gernot, Narodoslawsky M. The ecological impact of the sugar sector- Aspects of the change of a key industrial sector in Europe. Comput. Aided Chem. Eng. 2007;24:1029–1034. [Google Scholar]

- Heller M.C., Keoleian G.A. Greenhouse gas emission estimates of U.S. Dietary choices and food loss. J. Ind. Ecol. 2015;19(3):391–401. [Google Scholar]

- Ibidhi R., Hoekstra A.Y., Gerbens-Leenes P.W., Chouchane H. Water, land and carbon footprints of sheep and chicken meat produced in Tunisia under different farming systems. Ecol. Indicat. 2017;77:304–313. [Google Scholar]

- IDEAM . 2011. Estimación de las emisiones de dióxido de carbono generadas por deforestación durante el periodo 2005-2010. [Google Scholar]

- IPCC . Vol. 63. 1996. Directrices para los inventarios nacionales de gases de efecto invernadero - Desperdicios - Módulo 6. [Google Scholar]

- IPCC . IPCC; 2006. Directrices para los inventarios nacionales de gases de efecto invernadero - Elimimación de desechos sólidos - Capitulo 3. [Google Scholar]

- IPCC . Contribución de los Grupos de trabajo I,II y III al Quinto Informe de Evaluación del Grupo Intergubernamental de Expertos sobre el Cambio Climático. 2014. Cambio climático 2014: informe de Síntesis. [Google Scholar]

- Jóhannesson S.E., Davíðsdóttir B., Heinonen J.T. Standard ecological footprint method for small, highly specialized economies. Ecol. Econ. 2018;146(December 2016):370–380. [Google Scholar]

- Kafle G.K., Kim S.H., Sung K.I. Ensiling of fish industry waste for biogas production: a lab scale evaluation of biochemical methane potential (BMP) and kinetics. Bioresour. Technol. 2013;127:326–336. doi: 10.1016/j.biortech.2012.09.032. [DOI] [PubMed] [Google Scholar]

- Krotscheck C., Narodoslawsky M. The Sustainable Process Index. A new dimension in ecological evaluation. Ecol. Eng. 1996;6(4):241–258. [Google Scholar]

- Madage S.S.K., Medis W.U.D., Sultanbawa Y. Fish silage as replacement of fishmeal in red Tilapia feeds. J. Appl. Aquacult. 2015;27(2):95–106. [Google Scholar]

- Malakahmad A., Abualqumboz M.S., Kutty S.R.M., Abunama T.J. Assessment of carbon footprint emissions and environmental concerns of solid waste treatment and disposal techniques; case study of Malaysia. Waste Manag. 2017;70:282–292. doi: 10.1016/j.wasman.2017.08.044. [DOI] [PubMed] [Google Scholar]

- Mamouni Limnios E.A., Ghadouani A., Schilizzi S.G.M., Mazzarol T. Giving the consumer the choice: a methodology for Product Ecological Footprint calculation. Ecol. Econ. 2009;68(10):2525–2534. [Google Scholar]

- Martínez-Alvarez O., Chamorro S., Brenes A. Protein hydrolysates from animal processing by-products as a source of bioactive molecules with interest in animal feeding: a review. Food Res. Int. 2015;73(1069):204–212. [Google Scholar]

- Ministerio de Agricultura . 2018. Cadena de la acuicultura. [Google Scholar]

- Olsen R.L., Toppe J. Fish silage hydrolysates not only a feed nutrient, but also a useful feed additive. Trends Food Sci. Technol. 2017;66:93–97. [Google Scholar]

- Perez-Martinez M.M., Noguerol R., Casales B.I., Lois R., Soto B. Evaluation of environmental impact of two ready-to-eat canned meat products using Life Cycle Assessment. J. Food Eng. 2018;237(May):118–127. [Google Scholar]

- Pullin R.S.V., Froese R., Pauly D. 2007. Indicators for the Sustainability of Aquaculture. Ecological and Genetic Implications of Aquaculture Activities; pp. 53–72. [Google Scholar]

- Sharif A., Baris-Tuzemen O., Uzuner G., Ozturk I., Sinha A. Revisiting the role of renewable and non-renewable energy consumption on Turkey’s ecological footprint: evidence from Quantile ARDL approach. Sustain. Cities Soc. 2020;57(August 2019):102138. [Google Scholar]

- Spanopoulos-Hernandez M., Ponce-Palafox J.T., Barba-Quintero G., Ruelas-Inzunza J.R., Tiznado-Contreras M.R., Hernández-González C., Shirai K. Production of biological silage from fish waste, the smoked yellowfin tuna (Thunnus albacares) and fillet of tilapia (Oreochromis sp), for feeding aquaculture species. Revista Mexicana de Ingeniera Qumica. 2010;9(2):167–178. http://www.scopus.com/inward/record.url?eid=2-s2.0-79960206448&partnerID=40&md5=aebc679ffc5dee73f2cd9d052af5db5c [Google Scholar]

- Suarez L.M., Montes J.R., Zapata J.E. Optimización del Contenido de Ácidos en Ensilados de Vísceras de Tilapia Roja (Oreochromis spp.) con Análisis del Ciclo de Vida de los Alimentos Derivados. Inf. Tecnol. 2018;29(6):83–94. [Google Scholar]

- Syrovátka M. On sustainability interpretations of the Ecological Footprint. Ecol. Econ. 2020;169(December 2019):106543. [Google Scholar]

- Tian M., Gao J., Zheng Z., Yang Z. The study on the ecological footprint of rural solid waste disposal-example in Yuhong district of shenyang. Proc. Environ. Sci. 2012;16:95–101. [Google Scholar]

- Tiwari A. A review on solar drying of agricultural produce. J. Food Process. Technol. 2016;7(9) [Google Scholar]

- van’t Land M., Vanderperren E., Raes K. The effect of raw material combination on the nutritional composition and stability of four types of autolyzed fish silage. Anim. Feed Sci. Technol. 2017;234(October):284–294. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data will be made available on request.