Abstract

The last few decades have witnessed diversified in vitro models to recapitulate the architecture and function of living organs or tissues and contribute immensely to advances in life science. Two novel 3D cell culture models: 1) Organoid, promoted mainly by the developments of stem cell biology and 2) Organ-on-a-chip, enhanced primarily due to microfluidic technology, have emerged as two promising approaches to advance the understanding of basic biological principles and clinical treatments. This review describes the comparable distinct differences between these two models and provides more insights into their complementarity and integration to recognize their merits and limitations for applicable fields. The convergence of the two approaches to produce multi-organoid-on-a-chip or human organoid-on-a-chip is emerging as a new approach for building 3D models with higher physiological relevance. Furthermore, rapid advancements in 3D printing and numerical simulations, which facilitate the design, manufacture, and results-translation of 3D cell culture models, can also serve as novel tools to promote the development and propagation of organoid and organ-on-a-chip systems. Current technological challenges and limitations, as well as expert recommendations and future solutions to address the promising combinations by incorporating organoids, organ-on-a-chip, 3D printing, and numerical simulation, are also summarized.

Keywords: 3D printing, numerical simulations, organoids, organ-on-a-chip, synergistic engineering

1. Introduction

Drug discovery remains an unprecedented challenge and inadequate for treating many diseases that afflict humans because of enormous cost, time, and failure rates involved in clinical trials. Understanding disease mechanisms within sophisticated human organs needs more feasible models with lower costs, reduced time, and the greater simplicity of experiments.[1] Accurate human-representative models utilize many aspects of currently available technologies and hold promises for predicting the effectiveness and accuracy of drug responses to mimic key structural and functional properties of human organs from the subcellular to whole organ level.[2] Those developed systems have been committed to providing insights into basic biological principles, diseases, as well as potential treatments.[2] Animal models currently serve as gold standards for preclinical trials and exhibit comprehensive structural complexities and cell compositions like complex in vivo environments. They play a critical role in different application fields, such as experimental physiology and pathology, as well as drug screening).[3] Nevertheless, the complex physiology of animal models with specific signaling pathways and tissue-tissue or cell–cell interactions are difficult to be independent of other factors, and makes it challenging to distinguish and analyze the exact causal relationship, respectively. Moreover, animal models cannot precisely reflect human physiology, thus, have not been able to accurately predict in vivo toxicity responses upon drug treatment, may largely cause failure in drug development, particularly at the later stages.[3] For instance, animal model cannot assess toxicities of anticancer drug cisplatin because of its different species and impacts targeting to different membrane transporters that modulate drug accumulation between the human body and animals.[4] Furthermore, many animal models remain difficult to obtain and build for modeling numerous human immunological and neurological diseases (e.g., autoimmune diseases to cerebral cancer).[5] Besides, animal models always carry ethical issues that cannot be abused and discarded of the animals or employed for controversial experiments.[6] Therefore, in vitro models are urgently required to exhibit certain translation of their results to humans, and have attracted a lot of attention due to their lower costs, time saving, and the greater simplicity of experiments.

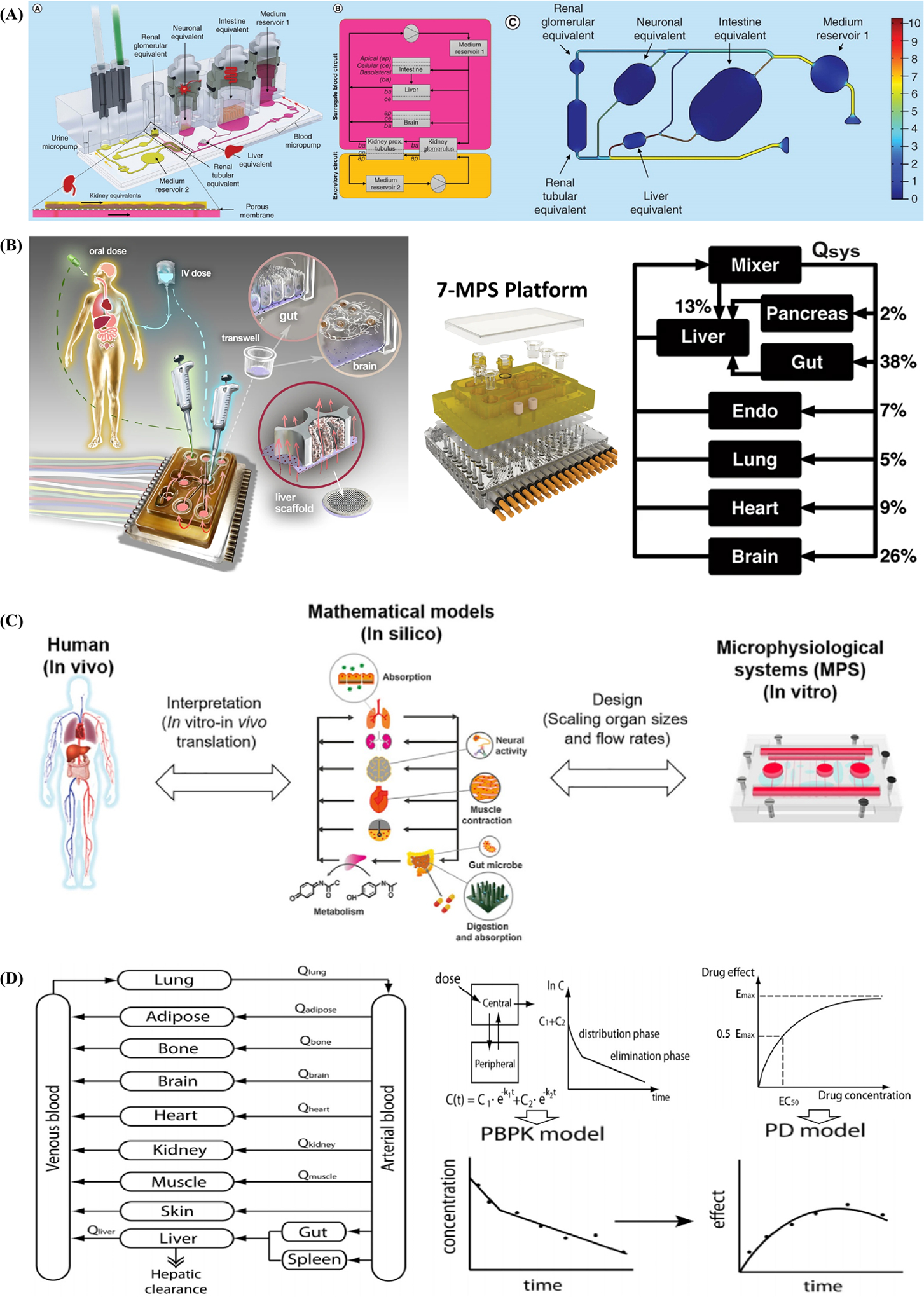

The survival and functionality of cells cultured in 2D and 3D models are noticeably dependent on the microenvironmental cues, such as spatiotemporal chemical treatments, physiological stimuli as well as cell–cell and cell–extracellular matrix (ECM) interactions.[7] 2D monolayer culture methods have been extensively and successfully adopted for their simplicity and cost-effectiveness. However, they usually exhibit insufficient physiological features for insufficient biophysical or biochemical stimuli as in vivo.[8] They are also inferior to the 3D culture that creates more defined and intricate microenvironment when recapitulating the living tissue or organ and modeling diseases.[9] The last decade witness the high-speed development of a novel microengineering device, also termed as organ-on-a-chip[10,11] or microphysiological system.[12] to recapitulate 3D tissue architectures, function, physiology, or pathology of living human organs in vitro. Existing organ-on-a-chip methods are primarily to combine proportional predifferentiated cells to imitate the composition of native tissues and perform their vital structural and functional features. Microengineering approaches are capable of precisely regulating the nutrient flow supply and shear stress stimulation, spatiotemporal chemical, and biological microenvironment, as well as the local electrical or mechanical behaviors of growing 3D tissues.[3] Furthermore, organ-on-a-chip technology can incorporate different 3D constructs into a dynamic circulation system that imitates the systematic interactions between a range of tissues and organs in the human body. They are also termed as human-on-a-chip[13] or body-on-a-chip,[14] being critical to drug discovery applications. Such multiorgans platform allows drugs and their metabolites to run through a range of organs before fulfilling its final action and subsequently allow them to perform in their final target sites in different parts of the organism.[15] Organ-on-a-chip acts as a promising model to ascertain the innermost human pathophysiology, as well as a suitable platform for disease modeling and drug discovery for its enhanced feasibility, productivity, and applicability.[16]

Unlike the rigorously controlled environments created by organs-on-chips, stem cell derived organoids developed from embryoid body cultures are largely self-organizing and similar to teratoma formation in vivo.[17,18] Organoids refer to 3D cell masses characterized by the presence of multiple organ-specific cell lineages, similar cellular organization to that of in vivo counterpart, as well as sophisticated 3D architecture and functional features.[19] Organoid models exhibiting higher physiological relevance than 2D models are more effectively benefit to introduce niche cues and narrow the gap between in vitro models and in vivo models. Pluripotent stem cells (PSCs) exhibit differentiation potential, which direct cell fate to specific tissue precursors and further down into organoids of targeted cell lineages through the supply of cues by activating or inhibiting signaling pathways.[20] Aggregates of PSCs process the processes of differentiation and morphogenesis after embedded in a hydrogel (often Matrigel) scaffolds, and imitate aspects of early embryonic development by improving appropriate exogenous factors.[21] Current organoids rely heavily on a high level of default robustness for the generation of a precisely organized tissue architecture of various shapes and sizes during spontaneous differentiation. Organoids are mostly superior in cellular heterogeneity, phenotype fidelity, and physiologically relevant complexity to organ-on-a-chip system which place predifferentiated cells at precise locations in an artificial manner. Accordingly, organoids can also address a gap in modeling pathology and diseases difficult or unlikely to study in animal models, and work as a promising personalized medicine approach.[22]

Due to recently evolving technological advancements in bioengineering and stem cell tissue engineering, organ-on-a-chip and organoid have emerged as two distinct approaches exhibiting their own merits and demerits for stem cell-derived 3D tissue preparation.[23,24] Accordingly, it is vital to identify the related pros and cons so as to enhance their applicability by correctly choosing cell sources according to research motivations and genetic backgrounds (e.g., cell lines or stem cells). Both of the two models uniquely summarize vital microstructures and functions concerning target tissues or organs and more effectively exploit structural fidelity in lineage specification, cell–cell interaction, and organ- or tissue-genesis.[25] This review systematically compares the physiological complexity, cellular diversity, and cellular genetic similarity, as well as microenvironmental control ability between self-renewing of organoids and well-defined manipulation of organ-on-a-chip to model disease etiology plus drug screening.

The overall goal of providing a path toward a superior, synergistic strategy of constructing tissues by integrating organ-on-a-chip to cultivate a range of organoids.[26] Each organoid covers different cell types requiring specific physiochemical cues and represents the structure and function of several organ systems.[27] Finding the right technological balance at the intersection of two promising approaches will be benefit to exploit an advanced integration strategy for high-fidelity stem cell-based human organ modeling, also known as collaborative engineering.[25] Strategic integration may address each approach’s limitations and figure out a large number of technical problems to some extent, and bring unprecedented bionic models suitable for various applications.[28] The strategy also increases structural and cellular fidelity varying from closed luminal cell spheroids to multilayers subtissue levels interfaces by recapitulating cell types and ratios of their counterpart in vivo.[29] The integration can enhance the spatial–temporal control of 3D tissue generation and microenvironment via biophysical stimuli, summarize various exogenous or endogenous cues as well as their concentration gradient, and further control the shape and size with built-in vascular system.[30] What is more exciting is achieving time-saving, labor-saving, and higher-throughput of drug screening and diversified applications by adding sensing systems and screenable readouts through biochemical and modular physical analysis as well as optical measurement in the integration models.[31–33]

Organoids or organs-on-chips have been more recently benefiting from the biocompatible BioMEMS (Biological Micro-Electro-Mechanical Systems)[34] and microfluidic chips.[35] The former enables precise control over cellular microenvironments under biological conditions, and the latter perfuses the system constructs by regulating fluid behavior and connections. Both of the mentioned systems have also been extensively adopted and utilized to develop 3D cell culture devices. However, the cumbersome user interfaces and time-consuming molding processes of lithography technology act as barriers to their clinical applications and commercial dissemination.[11] The novel 3D printing, also termed as rapid prototyping, is likely to bring unprecedented convenience and versatility and be adopted to produce microfluidic chips and 3D cell culture devices with precise shape, architecture, and structure of targeting tissues and organs.[36–38] The living systems on chips platform can also be reconstructed by the interaction of 3D printing-based biomimetic microfluidic chips and various microfluidics interface technologies and accessories (e.g., sensors, microvalves, and micropumps).[39] Researchers can acquire digital files of these molecules easily via the Internet, print them quickly by a 3D printer, and assemble the device manually, making it rapid and applicable to be employed in both clinics and research.[40,41] To be specific, 3D bioprinting can lay down biocompatible supporting materials and living cells simultaneously, and introduce the physiological relevant cues (e.g., well-defined cell arrangement) to more effectively simulate cellular diversity and microstructure exhibiting great consistency.[42–44] Various favorable merits are brought up and fully integrated, meanwhile, many drawbacks and difficulties in designing and optimizing culture devices are effectively avoided and complemented by integrating organoids/organs-on-chips and 3D printing.[45] In brief, 3D printing can simplify the fabrication of microfluidic devices and make 3D cell culture platforms cost-effective, time-saving, user-friendly, and less labor-intensive.

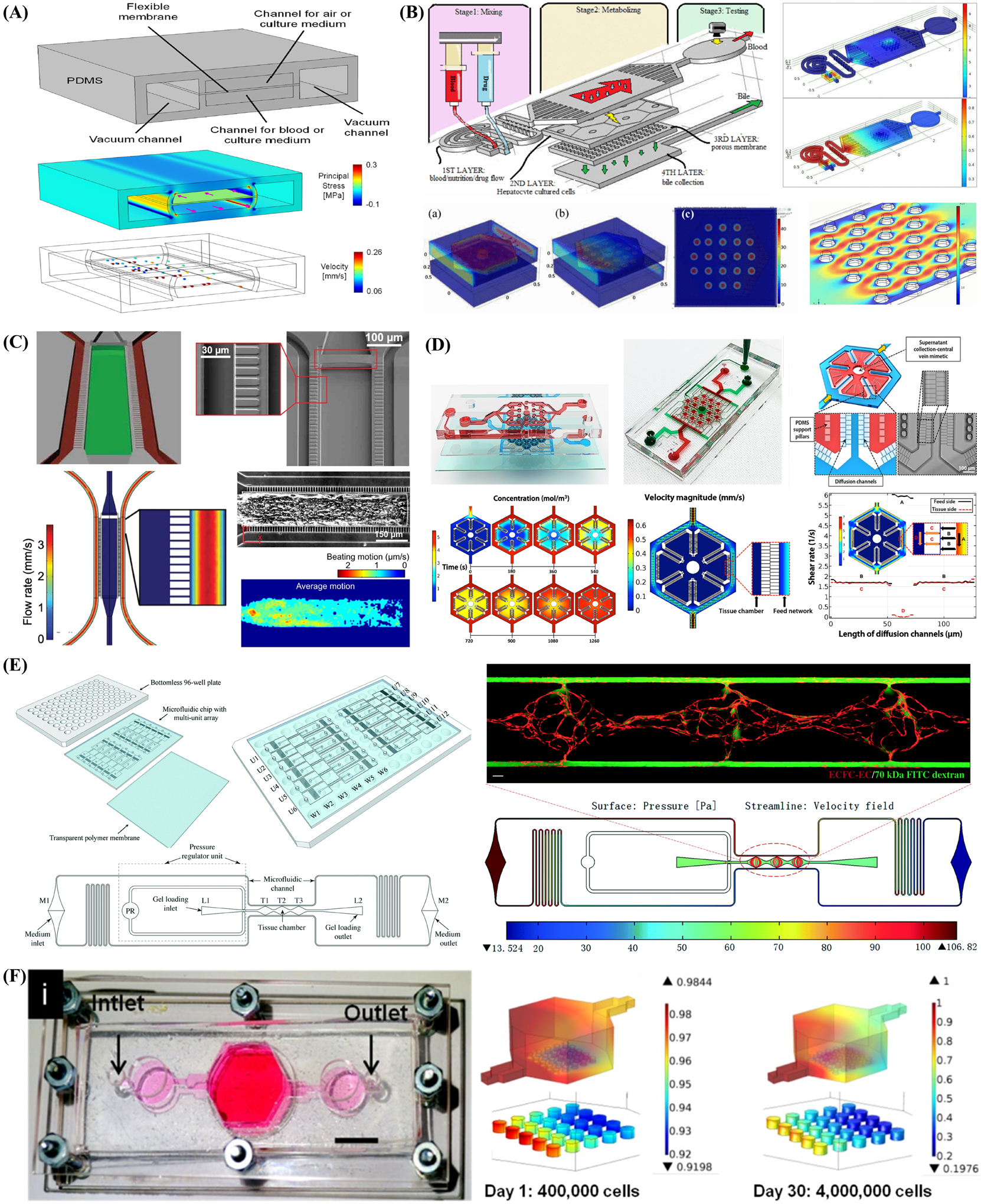

Numerical simulations using multiphysics software is a feasible tool that provides the necessary capabilities of modeling coupled fluid flow, mass transport, and biochemical, bioelectrical, and mechanical cues for designing and developing considerable proof-of-concept models.[46] Computational and mathematical modeling can contribute accurate and satisfactory results by simulating data gained from experiments, and avoid repetitive experimental measurements. This powerful tool can greatly reduce cost and time for analyzing, optimizing, and revising the design of 3D culture microfluidic chips, as well as shortening the design pipeline and boosting the development of elaborate 3D cell culture platforms.[47] For example, computational fluid dynamics (CFD) is more appropriate for analyzing flow patterns, pressure drops, wall shear stress profiles, and mechanical loads on microfluidic or membrane-based organ-on-a-chip devices. Multiphysics modeling can be employed as well to verify various speculations of cellular metabolic behaviors and activities (e.g., nutrient consumption, oxygen concentration, and distribution in microfluidic devices). Furthermore, it can imitate the effect of shear stress and flow field on cell migration, alignment, and phenotype, as well as the coupled effect between shear stress and submicrotopography.[48] Computational simulation of complex behavior arising in multicellular constructs, organoids, and multiorgan-on-a-chip or human-on-a-chip can provide critical insights for improving reproducibility or enhancing guidance. Nevertheless, incorporating numerical simulations into organoids or organ-on-a-chip models needs important advances in modeling and additional theoretical work in both simulation and experimental studies.

Organoid and organ-on-a-chip have been largely supported and increased funding from various funding agencies to build a flexible, reliable, affordable, and accessible in vitro microphysiological model to perform drug discovery, toxicity testing, and basic research.[49] In this review, we thoroughly compared their merits and differences between organoid and organ-on-a-chip models in cell sources, structural fidelity, cellular fidelity, and control ability from the application perspective, respectively. Then, we detailed the advantages and benefits by integrating organoid and organ-on-a-chip for enhancement in structural and cellular fidelity, increasing spatial–temporal control of 3D tissue generation and higher-throughput readouts. After-ward, the combinations of two 3D cell culture models with 3D printing or numerical simulation are separately illustrated for exploring their latest achievements, barriers, and future prospective. Furthermore, we provide the challenges and limitations facing organ-on-a-chip and organoids and 3D printing technologies and numerical simulation used for tissue models, and a conclusion with some personal insights to address the technologies which have their advantages, disadvantages, or scope of each model. The relatively elementary recommendations and future solutions are highly conducive to address the issue by integrating of organoid, organ-on-a-chip, 3D printing, and numerical simulation patient-specific disease-on-a-chip and human-on-a-chip.

2. Comparison Between Organ-on-a-Chip and Organoid Models

Organoid and organ-on-a-chip models are highly beneficial. Recognizing their merits and limitations of these approaches in terms of cell origin, structural fidelity, genetic stability, and environmental control capabilities and throughput will provide more insights into both approaches and their applicable environments. Moreover, such comparisons also reveal a future path to pursue in an integration approach integrating organoid, organ-on-a-chip, 3D printing, and numerical simulation toward patient-specific disease-on-a-chip and human-on-a-chip. In the present section, we first introduce the cell source of 3D cell culture which would be informative for comprehension, followed by comparing the above features and diversifications by presenting applications of both approaches in modeling biological processes of organ, cellular development, disease etiology plus drug screening. Subsequently, current technological challenges and future perspectives faced 3D cell culture models are also discussed.

2.1. Cell Source

Considerable cell sources from both human and animal origin are employed in existing organoids and organ-on-a-chip models. They fall into pre-existing well-differentiated cells (e.g., primary cells, immortalized cell lines, and tissue biopsies) and undifferentiated cells (e.g., embryonic stem cells (ESCs), induced pluripotent stem cells (iPSCs), and adult stem cells (ASCs)), each of which has distinct merits and demerits. Animal cell sources differ essentially from human physiological complexity and fail to summarize the inherent genetic mutations and variations of human cell sources for disease models and drug screening.[50] Pre-existing well-differentiated cells refer to well-established sources available extensively, as well as exhibiting genetically homogenous and slight phenotypic mismatches with actual tissues.[51] Undifferentiated cells are capable of differentiating successfully into specific lineages and genomes and encounter hurdles of arrested differentiation and inconclusive disease phenotypes, and potential mutagenesis and carcinogenicity by regulating mutations, chromosomal abnormalities, or epigenetic variations in DNA methylation patterns induced by viruses.[52] Thus, it is one of the critical procedures for both organoid models and organ-on-a-chip systems to correctly choose cell sources in line with research motivations and genetic background.[3] For instance, a liver-kidney-on-a-chip being seeded with Hep RG cells noticeably differs from that lined with HepaG2/C3A cells for drug screening duo to that only the former is capable of metabolizing ifosfamide into toxic chloroacetaldehyde.[53] Baudoin et al. clarified that tumor-derived hepatic cell lines exhibit inferiority to primary human hepatocytes in multiorgan-on-chips to summarize liver metabolism and functionality for predicting drug response application.[54] Furthermore, ESCs or iPSCs derived organoids also noticeably differ from primary tissue-based organoids and limit the presence of mesenchymal cell types and has no branding in the cultivating process when compared to the latter.[55,56]

Organ-on-a-chip systems are primarily dependent of the pre-existing well-differentiated cells.[16,57] The primary cell source refers to a type of mature cell covering a limited natural extracellular matrix and might vary from batch to batch. Given that primary cells derive from a specific patient, the primary cells based chips are capable of reestablishing disease models for individualized treatment and drug screening. Nevertheless, human primary cells are hard to acquire duo to the trauma of extraction and most primary cells adopted in the systems are of animal origin which significantly limit their translational ability and application areas.[58] Nevertheless, the primary cells based chips may also require the presence of cell lines in certain scenarios to regenerate the cell-or-organ level interactions.[59] Cell lines may be the most extensively used cell sources for organ-on-a-chip systems having been employed in research areas (e.g., kidney,[4] lung,[60] gut,[61] heart,[62] liver,[63] brain,[64] and as well as the integration of these organs on body-on-a-chip[65]). Consistent with primary cells, the inherent homogeneity of cell lines or mature cells within slightly natural extracellular matrix microenvironment leads to reproducible results and associated application in disease modeling. Nevertheless, this is at the expense of restricted patient specificity in contrast to other individual-specific cell sources.[3] Furthermore, immortalized cell lines would exhibit slight phenotypic diversifications from actual tissues in several cases (e.g., protein expression and metabolic pathways) and may not be the optimal choice.[66] Another common cell source for organ-on-a-chip is ex vivo tissue (e.g., intestinal and liver slices[67] or endocrine tissues).[68] ex vivo tissue biopsies originate from mature tissues and can more accurately reveal the biological information of living tissues consistent with primary cells.[69] Moreover, the biopsies may exhibit the additional benefit by incorporating some of the natural extracellular matrices and tissue structures and be capable of facilitating the recapitulation of organ tissues in the cultivating process. Nevertheless, current ex vivo tissues from human are not easily available except tumors for ethical issues and potentially cause rapid compromise of functions shortly after extraction, making them unsuitable for long-term culture and research.[70]

Organoid models are generally derived from primary tissue biopsies, or stem cells to summarize the structure and functionality of organ tissues.[71] Most common stem cell types consist of ASCs, ESCs, and iPSCs have the essential ability to be induced into one or clusters of specialized cells and be assembled into intricate structures resembling their counterparts in vivo.[72] ASCs can be derived from various sites of the human body of both juveniles and adults, thereby making them easy to access. ASC-derived organoids typically display a more mature phenotype and have been employed to model various organs. However, ASCs can only differentiate into certain types of cell lineages in accordance with derived-tissues and have various protocols that render heterogeneous phenotypes of organoid from batch to batch, making them less applicable to cell source of organoid in contrast to other stem cells.[73] ESCs originate from the inner cell mass (ICM) of an early-stage embryo named blastocyst. Both ESCs and ICM cells fall to totipotent or pluripotent cells.[74] Note that one type of the earliest entire organoid originates from mESCs (mouse embryonic stem cells) by culturing it under floating conditions within mixed culture media.[75] The most salient merit of the ESCs source is reflected by the unlimited differentiation potential and subsequent high phenotype fidelity. However, since researches associated with ESCs raise ethical difficulty and rigorous regulation, thus, it is extremely difficult nowadays to put this cell source into widespread practical research use.[76] In addition to ethical debates, there are still technical obstacles to guarantee creating various cell lines with genetic diversity, as well as exploring well-defined protocols to directional differentiation, and further hinder the application of ESCs.[77] iPSC (initially proposed in 2007 and awarded with Nobel Prize in 2012) represents the evident advancements in transfection protocols for stem cells and provide an ideal cell source for organoid models.[78] iPSCs can be conveniently generated from cells being harvested from specific tissues under defined factors by induced dedifferentiating process into the particular lineage and genomes.[78] Furthermore, iPSC can be easily harvested from donors with certain diseases and meanwhile without ethical concerns, making them overly applicable to studies on organ-level dysfunctions. The most advanced techniques (e.g., clustered regularly interspaced short palindromic repeats/CRISPR-associated nuclease9, CRISPR/Cas9 genome editing technology) may be employed to provide unique opportunities to scrupulously delve into more human diseases.[79] Few hurdles encountering the applications of iPSCs is also unavoidable to arrest their differentiation and vary indefinite disease’s phenotypes that be attributed to differences between the tissue of origin and genotype.[73] Therefore, future efforts are going forward to develop more reliable protocols for stem cell differentiation and to get rid of mutations, chromosomal abnormalities as well as epigenetic variations in DNA of stem cell sources.

2.2. Structural Fidelity

Self-organizing organoid and engineered organ-on-a-chip facilitate a thorough exploration of lineage specification, cell–cell interaction and organ-or tissue-genesis by adopting different strategies and possessing distinct merits. However, each model can also find its suitable applications concerning target tissues or organs because of their differences in structural fidelity. Organoid models can uniquely summarize important microstructures and functions of in vivo living tissues and provide ideal tools to explore human organs because of their high structural fidelity by rigorously applying timed chemical cues. Jo et al.[80] managed to induce self-organized multicellular 3D midbrain-like organoids by incorporating functional and electrically active midbrain dopaminergic (mDA), as well as specific layers of neuronal cells that could express characteristic human midbrain’s markers from human induced pluripotent stem cell (hiPSC) (Figure 1A). The midbrain organoids self-organized into neuro-melanin like granules whose structure was similar to the developing midbrain in vivo and performed function to produce cardinal midbrain dopaminergic neurons and dopamine after more than 2 months’ cultivation. For example, Vyas et al.[81] managed to employ hepatic organoid with high structural fidelity and self-organized ability to accurately imitate liver organogenesis and congenital diseases. The liver organoid originate from human fetal liver progenitor cells could re-establish parallel hepatobiliary organogenesis, high differentiated hepatocytes and biliary ductal structures after planted inside acellular ECM for cultivation. Moreover, they successfully extended their study and then developed a liver disease model resembling Alagille syndrome by inhibiting NOTCH signaling to interrupt duct morphogenesis. Furthermore, Zambrano et al.[82] induced human embryonic somatic cell (hESC) line AND-1 following formation protocol into typical finger-shaped structure of lung bud organoids for re-establishing a natural sequence of respiratory system differentiation from embryonic to alveolar stages (Figure 1B). They performed the trypsinization of the cells into small clumps covering 3–10 cells and subsequently seed and cultivate them on a low-attachment culture medium for around 25 days. The resultant organoids exhibited branching airway, early alveolar architecture as well as advanced paddle-racquet like structures, revealing that the organoids had reached the alveolar stage of lung differentiation and might become a versatile tool to model surfactant deficiency syndromes.

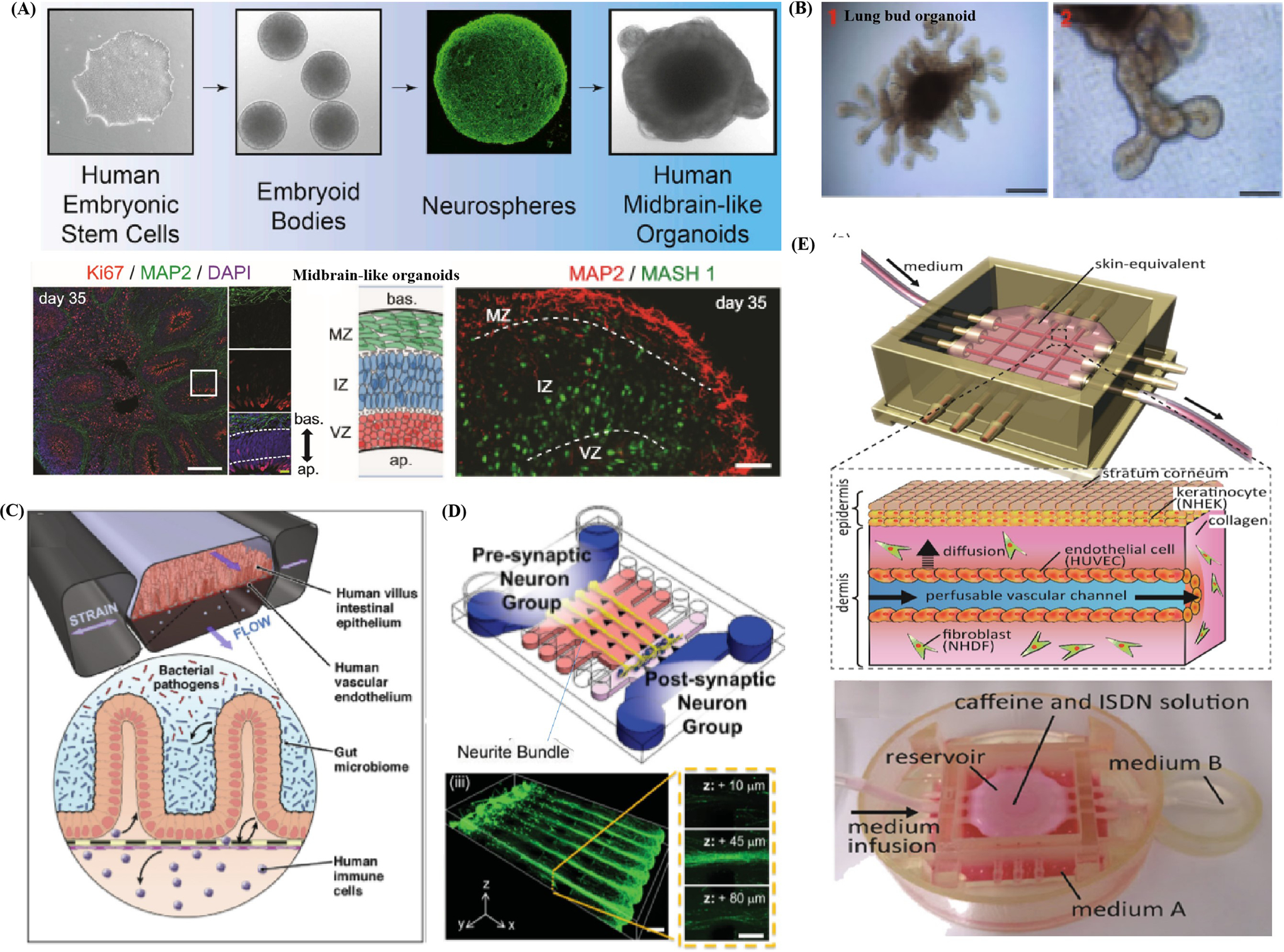

Figure 1.

Illustration of structure fidelity of organoid models and organ-on-a-chip systems. A) Schematic demonstrates the human midbrain-like organoids (hMLOs) from hPSCs in 3D culture which contain distinct layers of neuronal cells expressing human midbrain markers. Reproduced with permission.[80] Copyright 2016, Elsevier. B) Illustration of typical finger-shaped extensions of human lung bud organoid. Reproduced with permission.[82] Copyright 2018, Springer Nature. C) Schematic represents a novel gut-on-a-chip system comprised of artificial human villus intestinal epithelium and vacuum chamber for applying cyclic strains. The system is able to mimic complex interaction between Caco-2, vascular epithelial cells, microbiome, bacterial and immune cells. Reproduced with permission.[83] Copyright 2018, Elsevier. D) Schematic shows the neurons that are aligned on the Matrigel and cultivated to form the 3D neural circuit. Reproduced with permission.[84] Copyright 2015, John Wiley & Sons, Inc. E) Schematic exhibits the microstructure of the microfluidic vascular channels embedded in the vascular-skin-equivalent-on-a-chip, which could provide perfusion flow. Reproduced with permission.[91] Copyright 2017, Elsevier.

In contrast to organoid models that demonstrate high structural fidelity for their spontaneous organization ability, engineering-based models can largely contribute to exploit microfabrication methods to imitate the structures of in vivo tissue in a controllable microenvironment. Bein et al.[83] exhibited a novel human intestine organoids-on-a-chip which represents the typical design principle of organ-on-a-chip systems (Figure 1C). Human intestine model have been engineered with increasing complexity that also include neighboring channels lined by microvascular endothelium, immune cells, commensal microbes, pathogenic bacteria, and some permit application of cyclic mechanical forces that mimic peristalsis-like deformations experienced by living intestine in vivo. Bang et al.[84] developed a simplified neural-on-a-chip with aligned 3D neuronal circuit in Matrigel which covered new micropillar arrays (Figure 1D). The neural-on-a-chip imitated the multilayered structure of neuronal circuit, axon fasciculation, as well as neural bundle by culturing primary rat cortical neurons with align ECM components. These researchers also facilitated the patterning of Matrigel cross-linking density distribution during gelation process by controlling under hydrostatic pressure and delivering continuous flow via the chip. Subsequently, they reported the neurite growth rate (an average speed of 250 μm per day), formation of axon bundle with fasciculation, and the evolution of neural network from presynaptic to postsynaptic neurons after seeding on one side of the Matrigel., Ho et al.[63] developed a lobule-mimetic liver-on-a-chip to imitate the liver tissue by covering concentric-stellate-tip microelectrode arrays to pattern hepatic and endothelial cells. They managed to guide, snare, and align the massive cells simultaneously inside the well-defined chamber, resembling the basic morphology of hepatic lobule by dielectrophoresis manipulation that created a delicate spatial electric field. The successful field-induced orientation of randomly scattered cells to desired stellate patterns was identified as revealed from the results of fluorescent assay to faithfully recapitulate lobule microstructure.

Structural fidelity of organ-on-a-chip system is inferior to that of organoid model in most cases and are difficult to recreate the elucidate tissues’ structure duo to current limitations of microfabrication techniques and knowledge concerning microstructure of tissues. It still faced with the lack of some necessary functions even if reproducing several basic architectures of tissues or organs. For instance, one of the cases of liver-on-a-chip cannot summarize the directional biliary ductal clearance or reestablish the secretion of metabolic enzymes, which requires long cultivation time.[43] Organoid models typically lack tissue–tissue interface and vascular compartment, and form enclosed luminal structure,[86] the organ-on-a-chip system can be extremely suitable and informative when modeling basic tissue architecture as barrier,[87,88] thin-film interface[89] as well as tubular structure. For instance, Booth et al.[88] fabricated a microfluidic blood–brain barrier (BBB) restrictive membrane recapitulating the sophisticated biological architecture of its counterpart in vivo. It is capable of imitating shear stress of the dynamic vascular environment, and hinder various exogenous compounds (e.g., amino acids, selected sugar, and electrolytes) in the blood from entering the central nervous system. The artificial multilayer BBB covered two glass substrates for support, four polydimethylsiloxane (PDMS) layers with a porous polycarbonate membrane within them to achieve endothelial cells and astrocytes culture, two channels for flow penetration and embedded electrodes for trans-endothelial electrical resistance (TEER) test. Note that in the experimental process, the tight junctions and high viability of cells in BBB were revealed from the optical imaging results. Besides, the TEER test of BBB expressed a distinct higher level in selective permeability than conventional models, verifying that such system could act as a useful platform for imitating and exploring barrier function.

Tavana et al.[90] created a lung-on-a-chip, recapitulating a thin film structure within a small airway, to delve into the underlying mechanism of surface tension-induced lung diseases. They imposed pulmonary pressures via micropumps and thoroughly observed the metabolic activities of human alveolar epithelial cells with or without Survanta (a type of clinical surfactant). The high mechanical stresses could lead to substantial cellular injury, and adding the surfactant could protect epithelium and down-regulate the death rate of these cells. Ingber et al.[61] fabricated a gut-on-a-chip to reproduce the convoluted architecture and associated barrier function of the intestine in vivo. The chip displayed two microfluidic channels split by a porous flexible thin film being coated with ECM and lined by Caco-2 cells and cultivated under dynamic conditions performing shear stress and cyclic strain. This bio-microfluidic chips are convenient to imitate the thin film structure within a small airway by quickly polarizing cells into a columnar epithelium and developing into intestinal villi-like architecture. The blood circulatory system is critical to the exchange of nutrients and maintaining the homeostasis across the whole body by linking all types of organs. Mori et al.[91] devised a vascular-skin-equivalent-on-a-chip with artificial vascular channels and perfusion systems to imitate the architecture of its living counterpart (Figure 1E). Two ends of microfluidic channels were coated with endothelial cells to test the ability of molecules to penetrate the epidermal layer into vascular systems. Moreover, the researchers fixed peristaltic pumps and silicone tubes to the channels’ ends to simulate the perfusion conditions and supply nutrition to artificial skin. Furthermore, histological analysis suggested the similarity of epidermal and vascular morphology also further verified the suitability of organ-on-a-chip to model vascular systems.

2.3. Genomic Stability

Organoid models also should be highlighted for their genomic stability duo to consist of diversified, genomic stable, self-renewing cells that can differentiate into fully developed mini-organs harboring all main cell types at a similar ratio to its living in vivo counterpart. Lancaster et al.[92] described a recently established protocol for generating 3D brain tissue, i.e. cerebral organoids, which closely mimics the endogenous developmental program give rise to developing cerebral cortex, ventral telencephalon, hippocampus, choroid plexus, and retinal identities within 1–2 months (Figure 2A). This straightforward protocol can easily be implemented in a standard tissue culture room and be applied to developmental studies, as well as to the study of a variety of human brain diseases. Cerebral organoids can also be maintained in long-term culture and be potential to model later events, such as neuronal maturation and survival. Qian et al. illustrated that forebrain organoids covered various cell types induced by two rounds of patterning factors; these brain-region-specific organoids exhibit high reproducibility, display a well-developed six cortical layers for human cortical development, and lead to the remarkable reduction of both tissue and temporal development heterogeneity.[21] Primary information obtained are concerning signaling pathways of solid organs (e.g., liver) and regarding their role in organogenesis remains a pivotal unanswered problem. Alagille syndrome is primarily attributed to mutation of the JAG1 gene and refers to a genetic disorder impairing liver by causing abnormalities in bile ducts. Guan et al. created iPSC-derived liver organoid[93] harbored endothelial cells, hepato-blasts, and mesenchymal cells in similar proportion to living tissue to imitate the elaborate intrahepatic bile ducts. They identified that C829X mutation leads to profound alteration, rather than G274D mutation of JAG1 for the ascertainment of these genetic disease-induced abnormalities. Furthermore, they could acquire valuable information concerned with the role of these critical signaling pathways and ascertain the role of JAG1 in epithelial cells assisted by the high cellular similarity.[93]

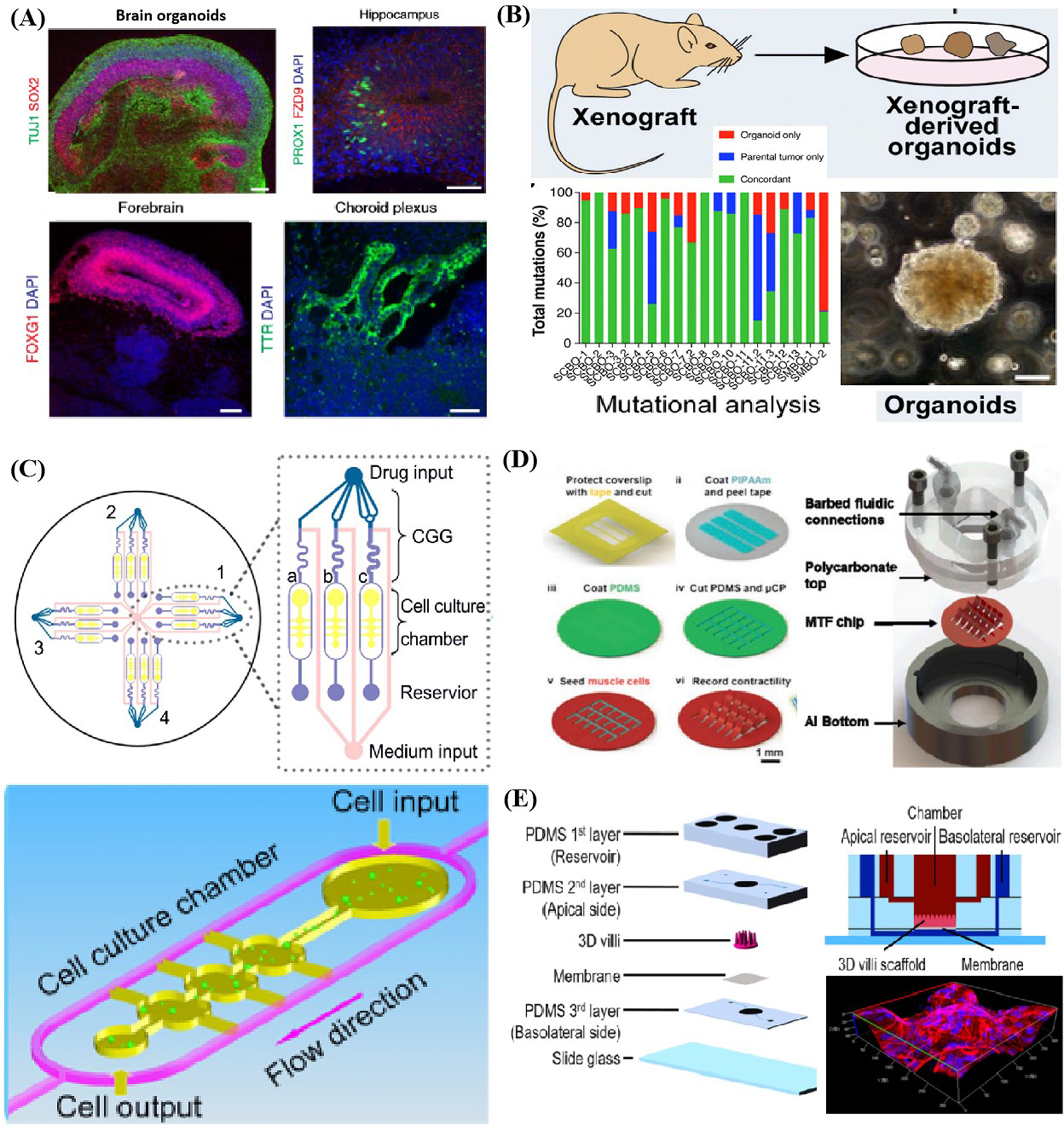

Figure 2.

Examples of the genomic stability of organoid models, and displays of the environmental control ability and throughput of organ-a-chip systems. A) Established protocol for generating cerebral organoids which closely mimics the endogenous developmental program and can give rise to developing cerebral cortex, ventral telencephalon, choroid plexus and retinal identities. Reproduced with permission.[92] Copyright 2018, Springer Nature. B) Schematic represents the gene mutation rates identified in organoids compared with parental tumor and demonstrates gene fidelity during organoid cultivation. Reproduced with permission.[97] Copyright 2018, Elsevier. C) Microfluidic cell culture device comprised of four uniform units to create a series of concentration gradient for drug test. Reproduced with permission.[110] Copyright 2013, Elsevier. D) Illustration of microfluidic devices integrated with MTF chip for cyclic stretch application, barbed fitting for perfusion control, aluminum bottom for temperature maintenance and stimulator for electrical field loading. Reproduced with permission.[112] Copyright 2013, Royal Society of Chemistry. E) Schematic exhibited a gut-on-a-chip which fabricated 3D villi scaffold for cell arrangement and culture in dynamic environment. Reproduced with permission.[115] Copyright 2017, Springer Nature.

Research work published in Nature series demonstrated that the extent of the resultant genetic and transcriptional heterogeneity and its functional consequences of genetic variation within cell lines, and provides a framework for researchers to measure such variation in efforts to support maximally reproducible cancer research. Current cell lines used in 2D cell culture and organ-on-a-chip systems might also face the same problems in long-term cultivation, which makes somewhat untrustworthy and limits their applications in disease modeling and drug screening.[94–96] In contrast, the high genomic stability of organoid models also reflects in a conserved genomic landscape resembling their parental cells, thereby making organoid a feasible and expandable material source in search of genotype–phenotype relationship, drug response as well as functionality of certain tissue (e.g., tumor).[53] Lee et al.[97] fabricated and exhibited mutation rates of derived bladder cancer organoids originating from 22 patients compared with parental tumors (Figure 2B). The organoids maintained the heterogeneity of corresponding parental tumors, and kept histopathological and molecular diversity, and patterned a range of genomic variations resembling tumor evolution during cultivation. They could also gain insights into the partial relationship between the mutational profiles and verified certain responses when applying xenografts in vivo by phylogenetic analysis based on this useful and efficient organoids platform. Sylvia et al. employed pancreatic organoids derived normal and neoplastic tissues, which recapitulated the ductal and disease state features, to dissect the role of gene Kras in pancreatic neoplasia.[98] They managed to simulate the physiological spectrum of carcinomas generation from early-stage neoplasms to lesions by orthotopically transplanting the organoids. Furthermore, they reminisced of pancreatic intraepithelial neoplasms to invasive, metastatic tumor. They have identified the genes that drive the adenocarcinoma pathogenesis and critical molecular signaling pathways through inducing mutation of certain cancer genes followed by thoroughly proteomic profiles and transcriptional analyzing.

Additionally, the organoid regenerative methods can serve as an innovative tool to rescue those affected by specific mono-genic diseases by homologous engraftment of organoid to the right site after mutation correction. The most representative case is cystic fibrosis caused primarily by mutations in cystic fibrosis (CF) transmembrane conductance regulator (CFTR) gene. CFTR gene has been ascertained the functionality of an anion channel and is critical to electrolyte and fluid homeostasis of epithelium. Despite that various assays have been developed to assess the functionality of CFTR and explore efficient new drugs, existing reagents have poor performance to all for the mutation variability in different patients.[99] Ogawa et al.[100] fabricated bile organoid covered epithelialized cystic as well as ductal structures which could exhibit mature biliary markers from iPSC. They cocultured the organoid with OP9 mouse bone marrow stromal cells at the hepatoblast stage to achieve NOTCH signaling by performing serum-free protocol. Note that after CFTR modulators were added to stabilize protein and hinder misfolding, cysts originating from CF patients’ iPSC were ascertained to be recovered by forskolin-swelling tests. This verified the ability of organoid in regenerative correction of certain diseases or being engrafted in the right site in clinical perspective and even verified using murine test.[101] Moreover, Schwank et al.[102] developed intestinal organoids originating and expanded from both primary large(LI) and small(SI) intestinal stem cells to cure the identical disease. The cells originated from two homozygous CF patients having undergone common mutation at F508. They employed a range of sgRNAs with the plasmid, which encodes wild-type CFTR, to correct CFTR sequence based on CRISPR/Cas9 technology. Moreover, they introduced a silent mutation downstream the correction for polymerase chain reaction (PCR) testing and proved the successful repair of F508 and site-specific knock-in events in most cases. Similar examples cover the rectification of Kras gene mutation by Sylvia et al.,[55] correction of dyskerin gene (DKC1) in congenital dyskeratosis by Cas9-mediated intestinal organoid by Woo et al.,[103] reversion of certain functional loss attributed to RPGR gene mutation in retinitis pigmentosa by Deng et al.[104] In brief, researchers can construct matched diseased and healthy organoids with high cellular fidelity compositionally and genetically, and make them a regenerative clinical therapy and a feasible tool to access the disease progression, assess drug resistance, and toxicity.[94,97,99]

Indeed, engineering-based organ-on-a-chip systems are essential inferior to organoid models in physiological complexity, cellular diversity, and cellular genetic similarity for their over-simplified cellular composition and limited cell types.[4,16] However, it does not indicate that organ-on-a-chip models remain inferior to organoid in terms of applications as underlying biological exploration for organs, disease generation, as well as drug screening. Since organoid models rely on poorly defined Matrigel and essential organization ability of stem cells, which could lead to great variability in size, shape, and viability and hard dissection in the analysis of certain factors or signaling pathways.[99] Furthermore, deficiency of stromal components (e.g., immune cells) also hinders the use of organoids in modeling diseases or drug toxicity characterized by inflammatory responses.[38]

In contrast, organ-on-a-chip models can draw upon well-defined biochemical and physical modulators to determine the cell fate in regulated cell niches, thereby rendering simplicity to model monocue or several factors influences. For the features of organ-on-a-chip mentioned above, Sung et al.[105] developed a simple breast cancer-on-a-chip to summarize the transition of carcinoma, being critical to the breast cancer progression. The proposed breast cancer-on-a-chip, covering a compartmentalized culture system, could simulate the transition from ductal carcinoma in situ to invasive ductal carcinoma. They could conduct cell–cell signaling studies of a single cell without interference (human mammary fibroblasts) by coculture of epithelial cells with fibroblasts and exertion of spatial–temporal control. Furthermore, they managed to cast light on the fact that soluble factors just begin the transition, whereas only direct contact could lead to the transition of carcinoma. Their subsequent study identified the effects of specific critical ECM components during breast cancer progression with seven different combinations of three ECM proteins and by characterizing the proliferation and morphology of T47D clusters.[106] Moreover, the capability of organ-on-chip models to decipher the complex factors in microenvironment have been identified by numerous correlations of biochemical or physiological factors with biological process, including estrogen receptor protein with the proliferation of breast cancer cells,[107] transforming growth factor-β inhibitor with lung adenocarcinoma cell,[108] endothelin-1 and rho-associated kinase (ROCK) inhibitors with cardiomyocytes thin film,[109] etc.

2.4. Environmental Control Ability and Throughput

Organ-on-a-chip systems can control the delivery of different biochemicals or compounds and provide delicate spatial–temporal control over cell culture through manipulating input and output flow conditions (e.g., flow rates and associated shear stress) with syringe or micropump. Moreover, these microfluidic systems can also introduce a range of stimuli (e.g., concentration gradient,[110,111] electromechanical force,[112] mechanical force,[113,114] and shear stress[115]) in a high-throughput manner to simply combined with monitoring systems.

Organ-on-a-chip systems can manipulate the fluid flow spatial–temporally to re-establish the microniches for cell culture, which is one of the most prominent differences between organoid models and organ-on-a-chip systems. For instance, one drawback of tumor organoid is typically lacking vasculature, perfusion system, and many invasive cell types. Sobrino et al.[116] developed a vascularized organ-on-a-chip system with its unique ability to supply perfusion flow and was employed to imitate human microvessels and cultivate tumor cells to develop vascularized microtumors. The enormous benefits of controlled perfusion brought by microfluidic devices have been verified by tracking protein expression and status, and identified through considerable metabolic heterogeneity and correlation between tumor and vasculature, as well as their response to anticancer drugs.

The simple manipulation of reagent dosage by organ-on-a-chip systems makes them trustworthy and feasible tools to take efficient drugs, identify combination schemes and ascertain appropriate dosage according to toxicities and side effects. Xu et al.[110] developed a lung cancer-on-a-chip covering four microfluidic chips, each of which covered three culture chamber and a concentration gradient generator (Figure 2C). By regulating the concentration at drug inlet, reagents types as well as channel width, they could also produce a range of combinations and concentrations of drugs. Based on this efficient and high-throughput chip, they could provide a clear individualized prescription for eight patients in the meantime with a single or multidrug combination of appropriate dosage. Sara et al.[111] created spatial gradients of cellular composition and matrix in the hydrogel with U87 cells seeded in it. They could recreate the heterogeneous microenvironment of glioma and explore how gradations of biochemical or biophysical cues impact the malignant phenotype and treatment via the platform. In this study, a range of injecting precursors with spatial-gradated and well-defined chemical composition were produced using microfluidic mixing methods first, followed by patterning them into optically translucent hydrogel with certain structures. They could explicitly trace the effects of gradations in microenvironment by simultaneously performing polymerase chain reaction, enzyme-linked immunosorbent assay and metabolic activity assay of glioblastoma multiforme, thereby illustrating the great spatial control ability of the organ-on-a-chip model.

Furthermore, organ-on-a-chip systems can easily incorporate many microenvironmental stimuli (e.g., electromechanical force, mechanical force, and shear stress) for the essential convenience of integration with various engineering methods when comparison with organoid models. For instance, Agarwal et al.[112] advanced a high throughput heart-on-a-chip with orientated rat cardiomyocytes attached on thin films embedded in it, which could be employed to clinically alleviate translational barriers in the analysis of inotropic effects of β-adrenergic (Figure 2D). To be specific, they fabricated a submillimeter scaled PDMS cantilever and cultured the anisotropic rat cardiomyocytes cells and tissues on the substrate to imitate the laminar structure of the heart ventricle. Moreover, a metallic base was covered to stabilize the temperature. They also regulated the wash-in and wash-out fluid flow of drug by syringe pumps and exerted electrical field to induce contractile stresses. Likewise, Wang et al.[113] employed the identical heart-on-a-chip with patient-derived iPSC lined on the thin elastomer films to elucidate the efficacy of TAZ modRNA on Barth syndrome. They also employed fibronectin micropatterns to replicate the contractile pathophysiology in vitro under biophysical cues (e.g., mechanical force) to cultivate and manipulate the iPSC self-developed into laminar myocardium with immature phenotypes (e.g., aligned sarcomeres and metabolic abnormalities like in vivo model). Furthermore, Parker et al.[114] devised a stretchable heart-on-a-chip which could reestablish mechanical overload and failing myocardium of diseased heart in vitro. They employed cyclic stretch on engineered laminar ventricular tissue on a stretchable chip and ascertained the differences among animal models, clinical records and data harvested on-chip in various aspects (e.g., gene expression, myocyte architecture, calcium handling, as well as contractile function). The quantitative results demonstrated that the cyclic stretch could exert great influence on the gene expression profiles, myocyte shape as well as sarcomere alignment. Organ-on-a-chip could faithfully imitate the diseased heart in vitro on the basis of inference by replicating structural and mechanical cues. Shim et al.[115] created a gut-on-a-chip that re-established two features of its counterpart in vivo, the 3D villi structure and shear stress, which are conducive to the differentiation and phenotype fidelity of cell culture (Figure 2E). Subsequently, they designed a delicate collagen scaffold capable of recapitulating the structure of human intestinal villi, and combined it into the microfluidic chip to introduce shear stress by fluid perfusion.[116] They compared the morphology, representative enzymes’ activity and epithelium absorptive permeability of Caco-2 cells in three culture conditions, such as 2D culture on transwells, 2D culture on microfluidic chip and 3D culture on microfluidic chip, respectively. The results enabled them to identify noticeable enhancement in the Caco-2 cells’ metabolic activity and demonstrated the collective influence of 3D architecture and perfusion condition.

Besides spatial control ability, engineering-based organ-on-a-chip systems can also exert temporally control over culture processes. For example, Gretchen et al.[117] developed a liver-on-a-chip to prove the ADMET (e.g., absorption, distribution, metabolism, excretion, and toxicity) properties of acetaminophen by combining intestinal cells’ chambers and monolayers lined with HepG2/C3A cells. The device helping ascertain the dose-dependent hepatotoxicity induced by metabolic processes and glutathione depletion attributed to acetaminophen could serve as a good example to certify the temporal control ability of organ-on-a-chip systems. Researchers could regulate the residence time of drugs in the chamber to approximate to the identical durations that the drugs particularly stay in vivo, and study the potential toxicity of oral drugs or other chemicals that aided by microfluidic technology.

High throughput is another characteristic of organ-on-a-chip systems and conducive to clinical application which needing strict time requirement compared with organoid models. Multiwells organ-on-a-chip is able to simultaneously perform numerous experiments on the same chip promoted by engineering-based principles. For instance, Grosberg et al.[109] designed a muscle-on-a-chip covering 24-well plate to analyze reactions of muscular thin films (MTF) with ROCK inhibitor and endothelin-1 at different concentrations in the meantime. The MTFs seeded with muscular cells are patterned with ECM by microcontact printing and then placed in each well of the same chip. Subsequently, they tracked the projection and calculated the stress of MTF after treatment with reagents. The results certified the high throughput trait of multiwells organs-on-chips by adding high concentration of endothelin-1 to enhance contractility of MTFs while ROCK inhibited it. Wevers et al.[118] designed a high throughput 3D microfluidic platform to culture neuronal-glial networks, which is termed as OrganoPlate covering 384-well plate microtiter for 3D cell culture and coverslip-thickness glass for optical evaluation. Each independent culture unit of OrganoPlate contained four nearby wells, with two for providing medium and the other for cell/ECM mixture and monitoring, could be applied in the recapitulation of a miniaturized organ or tissue. In subsequent tests, the researchers implanted neurons and astrocytes into the chip and then subjected to immunofluorescence staining to classify the cells that came from a large number of cell sources. The responses of cells at different stages to various compound treatments with a range of concentrations are simultaneously ascertained by electrophysiological analysis.

3. Integration with Emerging Technologies

As previously discussed, neither organ-on-a-chip systems nor organoid models are perfect in the face of diverse and sophisticated studies or clinical purposes. Organ-on-a-chip systems may be inferior to organoid models in structural or cellular fidelity as they are sometimes not capable of replicating solid tissues or organs with elaborate microstructures as they rely on microfabrication methods and predifferentiated cell sources.[3,66] While organoids can narrow the gap between existing in vivo models and in vitro models by cultivating and manipulating cell sources long enough to self-organize and imitate various critical traits of target tissues, they still lack critical cell types, stromal components, and can recapitulate only the early phase of organogenesis.[81,85] Organoid models also lack tissue–tissue interfaces and generally form closed luminal structures which might entrap cells and render difficulties in analyzing luminal contents. Moreover, organoid models show variability in size and shape from batch-to-batch due to the poor definition of Matrigel components and the absence of microenvironmental control, making high-throughput analysis difficult.[83] In contrast, organ-on-a-chip systems are capable of providing cells with a consistent microenvironment and exerting great spatial–temporal control over 3D cell culture by incorporating biophysical or biochemical cues, spatial organization, well-defined cellular components, specific physiological functions, and cell–cell and cell–matrix interactions. Therefore, a strategic integration between these two 3D cell culture models may overcome the limitations of each approach and establish unprecedented and amenable biomimetic models for various applications.[83] Nevertheless, these 3D cell culture models are subject to numerous technical problems that hinder their utilization, propagation, and combination. For instance, the current fabrication methods—derived from conventional microelectro-mechanical systems (MEMS) manufacturing—are labor-intensive and require specific knowledge concerning micro- or nanomanufacturing, making it expensive, time-consuming, and difficult for researchers to create their own devices.[43,77] In addition, most 3D culture devices cannot faithfully reproduce the real 3D structure, reducing the merit of such platforms in providing topological clues for cell development due to the limitations of conventional manufacturing methods. These barriers can be overcome by integrating 3D printing, an emerging tool with convenient manufacturing processes that allows for the building of complex 3D architecture.[76] The combination of 3D printing technology and 3D cell culture technology can also enhance the integrity of biological microfluidic platforms, making it more user-friendly and easier to operate. Moreover, numerical simulation can be incorporated into the 3D cell culture procedures (e.g., device design and read-out), potentially enhancing the practicability and translational ability of biomicrofluidic chips. In Sections 3.1–3.3, the advantages of integrating organoid models, organ-on-a-chip systems, 3D printing, and numerical simulation are discussed. Furthermore, current limitations and prospects are illustrated to better clarify the roles of these novel technologies in biological research and clinical applications.

3.1. Integration Between Organoids and Organ-on-a-Chip

Organoids rely heavily on spontaneous self-assembly for the generation of a precisely organized tissue structure.[119] The formation process varies for each tissue type but generally follows the pattern of proliferation, differentiation, cell sorting, lineage commitment, and morphogenesis.[120] As 3D organoids increase in size and volume, growing cells in the organoid core become distant from the surface in contact with fresh medium; subsequently, simple diffusion becomes insufficient for providing oxygen and nutrients and limits waste removal, ultimately resulting in internal cell necrosis, which hinders the maximum size and extent of tissue maturation of the organoids.[121] There is also limited control over the size, shape, and relative arrangement of different cell types within 3D organoids, limiting their applications in reproducible quantitative studies, which are required for robust drug screening and testing. On the other hand, microfluidic organ-on-a-chip is an artificial bioengineering system composed of arranged cells that recreate the structural and functional features of human tissue/organ physiology, it has the advantage of a controlled environment that provides controlled fluid flow, cell–cell interaction, matrix properties, and biochemical and biomechanical cues.[122] Exposure of cells to physiological shear flow, mechanical stress, and substrate stiffness can have profound effects on cell and tissue physiology.[123,124] Moreover, sensors and actuators can be integrated into the microfluidic devices to enable precise monitoring and control.[125,126] Organoids or organ-on-a-chip alone have limited capacity to meet the broad range of needs that arise in the drug discovery process. The similarities of organoids to actual organs make them more attractive for target identification and validation early in the pipeline, whereas organ-on-a-chip as more reproducible and controllable engineered constructs are better suited for efficacy and safety screening.

Advances in microfluidic organ-on-a-chip approaches have allowed us to engineer organoids with essential structural and physiological features in a controlled manner and obtain microscale structures and parameters that approximate conditions in vivo.[127] By combining the strength of the two technologies, microfluidic organoid-on-a-chip can facilitate better nutrient and gas exchange to prevent cell death in the organoid core and recapitulate 3D tissue architecture and physiology.[128] This combination may also provide more versatile and predictive preclinical models that are broadly applicable to conventional and emerging drug discovery processes.[129] Notably, recent studies have demonstrated the proof-of-concept of engineering a perfused organoid-on-a-chip system by combining a 3D matrix, mechanical fluid flow, and in situ self-organization of multiple organoid types (e.g., brain, intestines, liver, pancreas, and lung) at a millimeter scale.[130] Organoid-on-a-chip may also enable the development of personalized disease models using patient-derived tissue specimens or by reprogramming iPSCs from skin cells as organoids.[131] Indeed, microengineered tumor organoid systems grown directly from patient biopsies may resolve some of the issues that often occur with unpredictable growth patterns and substantial heterogeneity.[132] The convergence of the two approaches to produce multiorganoid-on-a-chip or human organoid-on-a-chip is emerging as a new approach for building 3D models with higher physiological relevance.[133] Furthermore, the integration of chemically defined hydrogels with human organoid-on-a-chip may lead to the next generation of 3D models that show precise spatiotemporal control of niche factors. Additional bioengineering approaches, such as single-cell genomics, live imaging, and genome editing, may also be incorporated into organoid-on-a-chip systems to study human physiology, diseases, and organogenesis and achieve personalized medicine.

3.1.1. Enhancing Structural and Cellular Fidelity

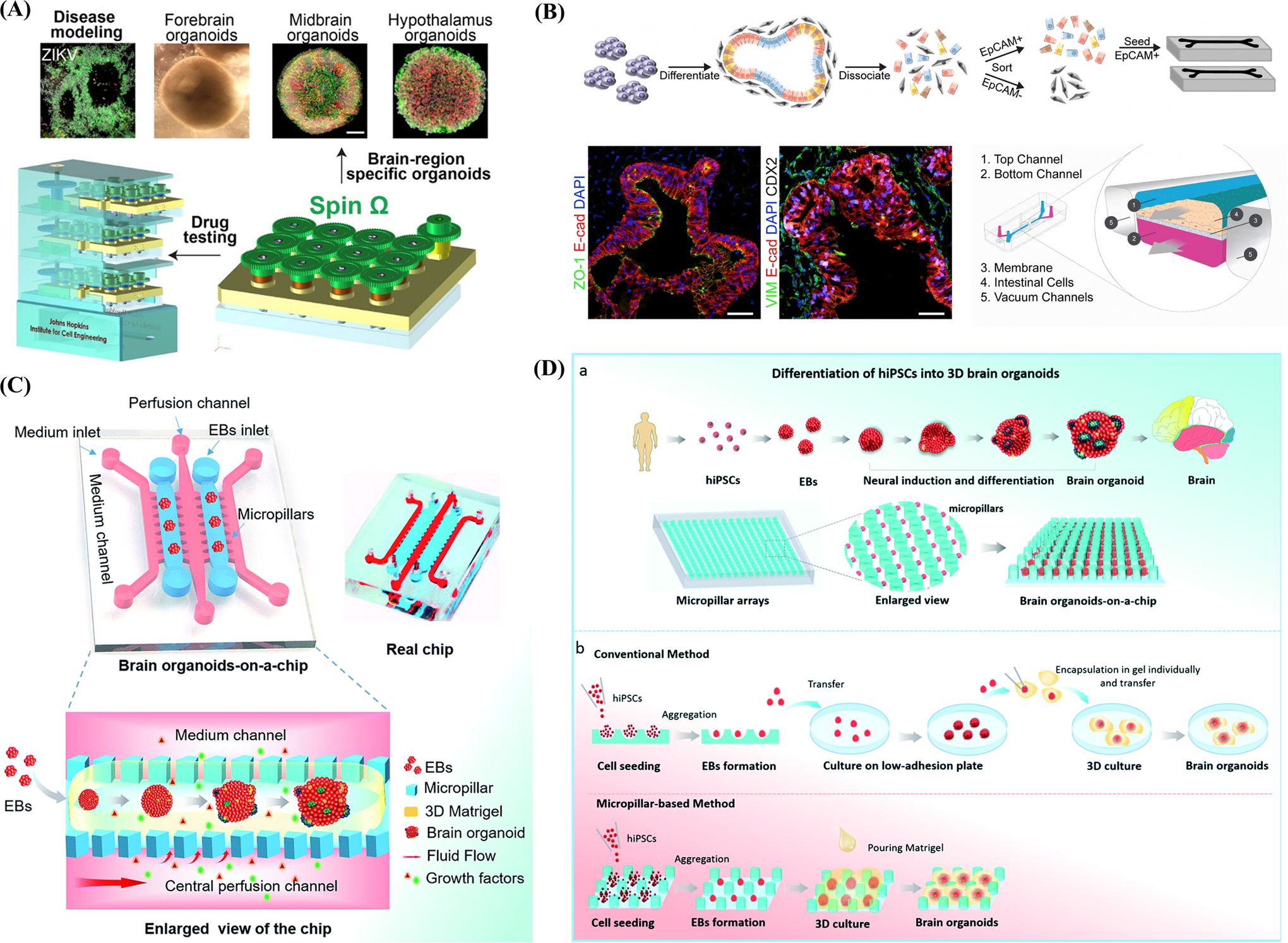

Epithelial organoid models typically form closed luminal cell spheroids and lack tissue-tissue interfaces while organ-on-a-chip systems usually exhibit inferior structural fidelity at subtissue levels.[31] One recent advance in cerebral organoid technology was the adoption of a miniaturized multiwell spinning bioreactor (Spin Ω) as a cost-effective, simple-to-use system to facilitate nutrient and oxygen absorption, which enables formation of longer neuroepithelium-like zones and supports growth of large, complex organoids (Figure 3A).[21] This Spin Ω is fitting a standard 12-well tissue culture plate that dramatically reducing the required media volume and allowing to optimize protocols to generate forebrain organoids from human iPSCs with minimized heterogeneity and variability that enables quantitative analyses and better recapitulation of the developing human cortex. Above the cover of Spin Ω, spinning shafts are attached to a set of 13 interconnecting gears and driven by a single electric motor. They used computer-aided design software to design and 3D print each component. They also developed protocols for midbrain and hypothalamic organoids and employed the forebrain organoid platform to model Zika virus (ZIKV) exposure. These organoids recapitulate key features of human cortical development, including progenitor zone organization, neurogenesis, gene expression, and, notably, a distinct human-specific outer radial glia cell layer. This brain-region-specific organoids and Spin Ω provide an accessible and versatile platform for modeling human brain development and disease and for compound or drugs testing.

Figure 3.

Schematic illustration of the benefits brought by the integration between organ-on-a-chip systems and organoid models and elucidates the concept of synergistic engineering among 3D cell culture, 3D printing and numerical simulation. A) Miniaturized spinning bioreactor (Spin Ω)-based brain-region-specific (forebrain, midbrain, and hypothalamic) organoids from human iPSCs culture system and modeling impact of Zika virus (ZIKV) exposure. Reproduced with permission.[21] Copyright 2016, Elsevier. B) The upper work-flow demonstrates the procedures of seeding epithelial cells derived from iPSC-based intestinal organoids into intestinal-on-a-chip. The lower immunofluorescence images represent the confluent monolayers of cells across the whole channel. Reproduced with permission.[135] Copyright 2018, Elsevier. C) Illustration of a biomimetic microfluidic chip comprised of micropillar arrays which allows direct formation from cell aggregates to brain organoids without much labor-intensive operation and reduces cultivation time. Reproduced with permission.[141] Copyright 2017, Royal Society of Chemistry. D) Schematic represents the brain organoid-on-a-chip devices which incorporated fluid flow in the EBs culture. Reproduced with permission.[147] Copyright 2017, Royal Society of Chemistry.

Furthermore, as each model has its suitable target organs or tissues, it is possible to combine organoid and organ-on-a-chip systems to overcome the disadvantages of each model. Kasendra et al.[85] combined intestine-on-a-chip and organoids to create a useful research tool that can emulate intestinal villus structure and functionality. The authors obtained epithelial cells from healthy intestinal biopsies and expanded them into intestinal organoids through culturing. Then, they dissociated and seeded these organoids on a porous membrane embedded in a microfluidic chip. In addition, the human intestinal microvascular endothelium was cultivated in another parallel microchannel within the same chip and exposed to perfusion flow and cyclic deformation. In this bio-microfluidic chip, the polarized epithelial cells differentiated into organoids and lined up to form villi-like projections. One side of intestinal organoids interacted with the endothelium, while the other side was exposed to an open lumen. Remarkably, transcriptomic analysis showed that the structural fidelity of this hybrid model in mimicking the human duodenum was greater than that of either organ-on-a-chip or organoid models alone. Another example that illustrates the utility of the hybrid model is the brain organoid-on-a-chip.

To test the early stage neurodevelopmental disorders caused by nicotine exposure, Wang et al.[134] integrated the organoid and organ-on-a-chip systems to fabricate a brain organoid-on-a-chip platform. Under controlled continuous perfusions, embryonic bodies could differentiate into brain organoids that re-established key brain-specific features, such as regional and cortical organization. Immunohistochemical and PCR analysis identified abnormal neuronal differentiation with enhanced TUJ1 expression and migration under nicotine exposure. Moreover, Lancaster et al.[92] successfully integrated organoid and organ-on-a-chip models to increase the surface area-to-volume ratio of artificial human forebrain tissue and maintain self-assembly during cultivation. Typically, organoid development requires nonadhesion cultivation conditions and cell–cell interactions, which are hard to attain in a microfluidic chip. By employing Poly(lactic-co-glycolic acid) fibers as floating scaffolds, the authors overcame the incompatibility between organ-on-a-chip systems and organoid protocols. Other than improved maturity of the neuroectoderm, this newly developed platform could also recapitulate characteristic cortical tissue, such as cortical plate and radial units, thanks to the basal membrane included in the chip. These studies prove that great advantages can be achieved by integrating different 3D culture models.

As far as genomic stability is concerned, organ-on-a-chip systems cannot fully recapitulate cell types and their ratios in vivo and may introduce unexpected mutations during cultivation. Organoid models also have a limited abundance of cell types, such as immune cells and stromal components, which may restrict their application. However, the combination of these models may, to some extent, overcome this drawback. Workman et al.[135] incorporated intestinal organoids derived from human iPSCs with a gut-on-a-chip to explore the normal and pathophysiologic reactions of the intestinal epithelium (Figure 3B). This platform can form polarized intestinal folds containing all intestinal epithelial subtypes and is biologically responsive to exogenous stimuli under a wide range of gastro-intestinal conditions. Flow cytometry was also employed for cell sorting to address the inhibition effect of mesenchymal cells on epithelial monolayer expansion, improving the efficiency of producing monolayers.

3.1.2. Increasing Spatial–Temporal Control of 3D Tissue Generation

Despite the fact that the organoid generation process (self-assembly, self-pattering, and self-morphogenesis[136]) depends heavily on the self-organizing ability and default robustness of stem cells, the recapitulation of various exogenous or endogenous cues, including the concentration gradient of biochemical cues,[137] growth factors,[138] and topological,[139] are extremely important in coaxing organized tissues in vitro. As mentioned in Section 3.1.1, engineering-based organ-on-a-chip systems can simultaneously incorporate a great number of temporal (resident time of specific factors or cultivation duration) and spatial controls.[137,140] Thus, the strategic integration of these two methods can compensate for the disadvantages of organoids, such as extremely long cultivation periods or undesirable scalability, and maximize the advantages of organ-on-a-chip by introducing biophysical stimuli as mechanical forces, electric or magnetic fields, and shear stress.[141]

Park et al.[140] incorporated a neuro-organoid induced from rat neural progenitor cells into a microfluidic chip that contains 50 cylindrical microwells to explore the effects of flow on neuro-organoids. Under slow cerebrospinal interstitial flow exerted by an osmotic micropump on the microwell arrays, the neuro-organoids exhibited more robust and elaborate neural architecture than those under a static culture environment. Furthermore, the authors extended their study to model Alzheimer’s disease (AD) by including amyloid-β, a major contributor to AD. They found that cell viability under dynamic conditions was lower than that of traditional devices, demonstrating the ability of the integrated chip to achieve more physiologically relevant results. Similarly, Wang et al.[141] employed an organ-on-a-chip comprised of 3D Matrigel to provide hiPSC-derived 3D brain organoids with multicellular tissue structure and fluid flow conditions (Figure 3C). The brain organoid under a perfused cultivation environment exhibited excellent recapitulation of key features of the development of human brain-like cortical architecture and neural circuit generation. Notably, organoids cultured in such a controlled manner displayed an improvement in expressing cortical layer makers. Taking these two cases into consideration, it is safe to conclude that controlled biophysical stimuli provided by organ-on-a-chip systems can pave the way for better recreation of living tissues by organoid models in vitro. Since organoid models rely heavily on spontaneous differentiation, it is difficult to envisage and control their shape and size in a favorable manner for experimental purposes or therapeutic applications. Moreover, without defined vascular systems to carry the blood and transport nutrients and waste, the mortality of cells inside the organoid models is extremely high, limiting the scale of the obtained organoid. To address this problem, Sakaguchi et al.[142] integrated thick tissues with built-in channels that function as surrogates of the vascular system. By seeding and lining endothelial cells within the channels as well as controlling the perfusion flow, cell-sustaining substances can reach the inner parts of the tissue. Similarly, Zhang et al.[143] proposed a hybrid strategy incorporating organ-on-a-chip, organoids, and 3D bioprinting to fabricate cardiovascular-organoid-on-a-chip with an endothelialized perfusion system. Through encapsulation and bioprinting directly into lattices, the endothelial cells can migrate to form the confluent endothelium. Furthermore, seeded cardiomyocytes can align to generate the myocardium with controlled anisotropy and are able to contract spontaneously and synchronously. Finally, the cardiovascular-organoid is embedded in a microfluidic bioreactor. Testing cardiovascular toxicity exhibited an impressive ability of this synthesized platform to recreate the human myocardium in vitro and screen pharmaceutical compounds.

3.1.3. Improving High-Throughput Readouts

Organoid models, which possess high structural and functional fidelity, usually lack a screenable readout, whereas organ-on-a-chip systems are convenient for integrating complicated sensing systems and are conducive for various analytical methods. Consequently, the integration of the two methods may improve high-throughput platforms for the exploration of basic biological principles or performing drug and toxicology measurements in the pharmaceutical industry.

Quadrato et al.[144] cultivated human whole-brain organoids over an extended period of time and then isolated cells from these organoids to investigate complicated cellular interactions. Notably, the authors stimulated photosensitive cells to control neuronal activity, and introduced a high-density microelectrode sensing system to analyze gene profiles of over 80 000 cells derived from 31 brain organoids. Facilitated by a high-throughput integrated platform, they managed to finish the largest-to-date molecular map of cell types and provided insights into the functions of neuronal circuits. Their study illustrates the high-throughput advantage achieved by integrating the two models. Zhang et al.[145] also integrated an automated, noninvasive, in situ, continual monitoring system with biomicrofluidic chips to assess various environmental parameters and biological responses over a long cultivation period. The platform enabled biochemical and modular physical analysis as well as optical measurement, and enhanced the throughput of drug screening. Furthermore, Devarasetty et al.[146] inserted a simple sensing system into a microfluidic chip. This integrated platform was used to capture the physiological activity of beating cardiac organoids and improve drug screening throughput. Additionally, the system was capable of translating captured files and creating beat kinetic plots for cardiac organoids. Using this system, the authors could distinguish differences in cardiac organoid beat rates under treatment with different agents, such as heart rate stimulating or decreasing agents, and at various concentrations. They were also able to verify the efficacy of certain drugs in a high-throughput manner.

Current protocols for inducing organoid generation are time-consuming, typically requiring several weeks or even months for stem cells and other cell sources to expand, differentiate, and form an assembly.[16,147] Research conducted in laboratories can bear long procedures; however it is not practical for clinical applications, such as elucidating personalized pathology or testing drug responses for specific patients. By exploiting the precise spatiotemporal control ability of organ-on-a-chip systems, we can shorten the generation time of organoids, leading to a more promising future of patient-specific organoid-on-a-chip technology.[16] Zhu et al.[147] combined organoids with an organ-on-a-chip system that contains micropillar arrays to form a novel platform for brain organoid production (Figure 3D). Under the control of well-designed micropillar microstructures in the microfluidic chip, embryoid bodies were able to differentiate into brain organoids directly and rapidly expand neuroepithelial cells. The authors were thus able to remarkably reduce labor-intensive procedures and form massive brain organoids within a relatively short period of time.

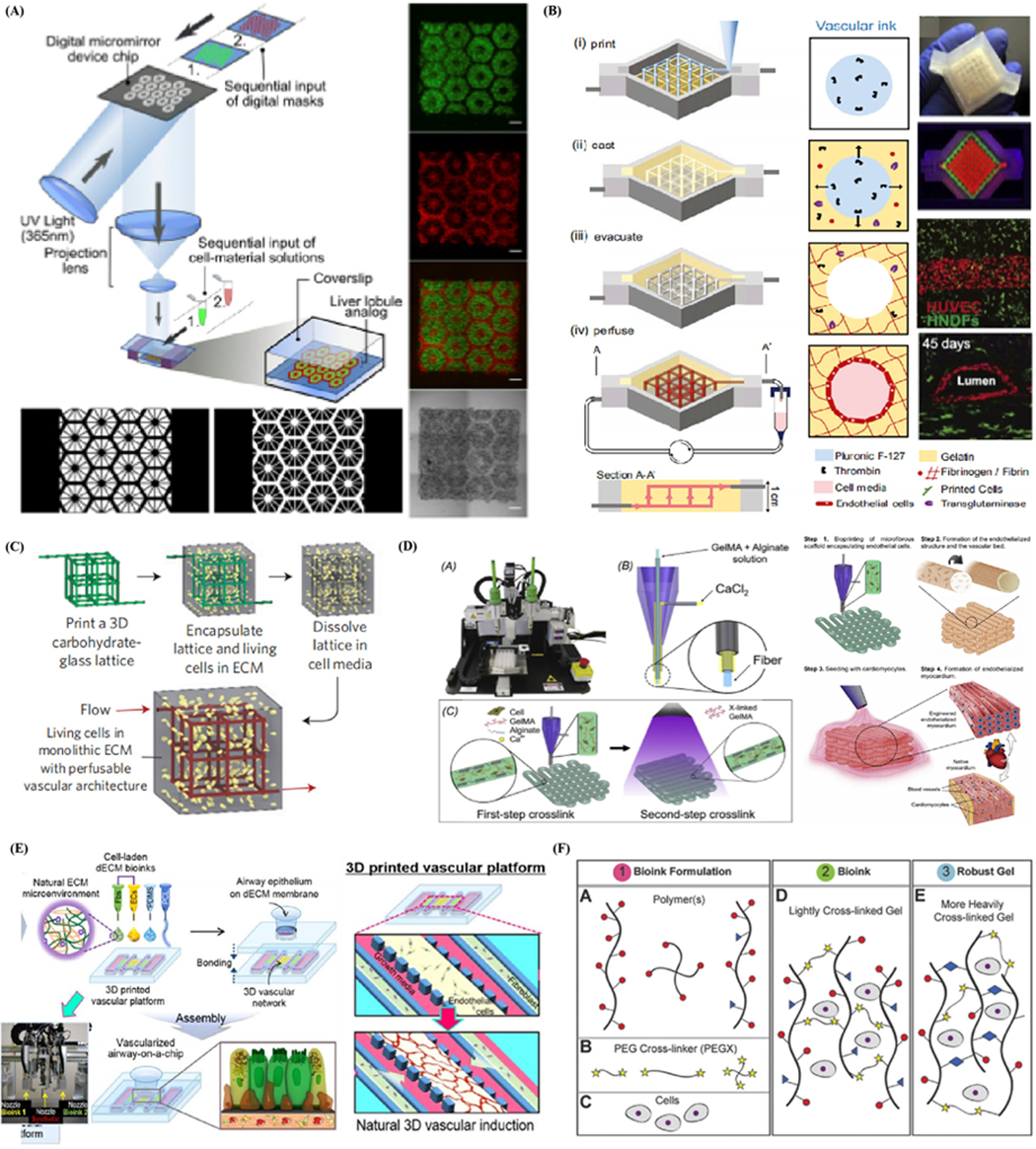

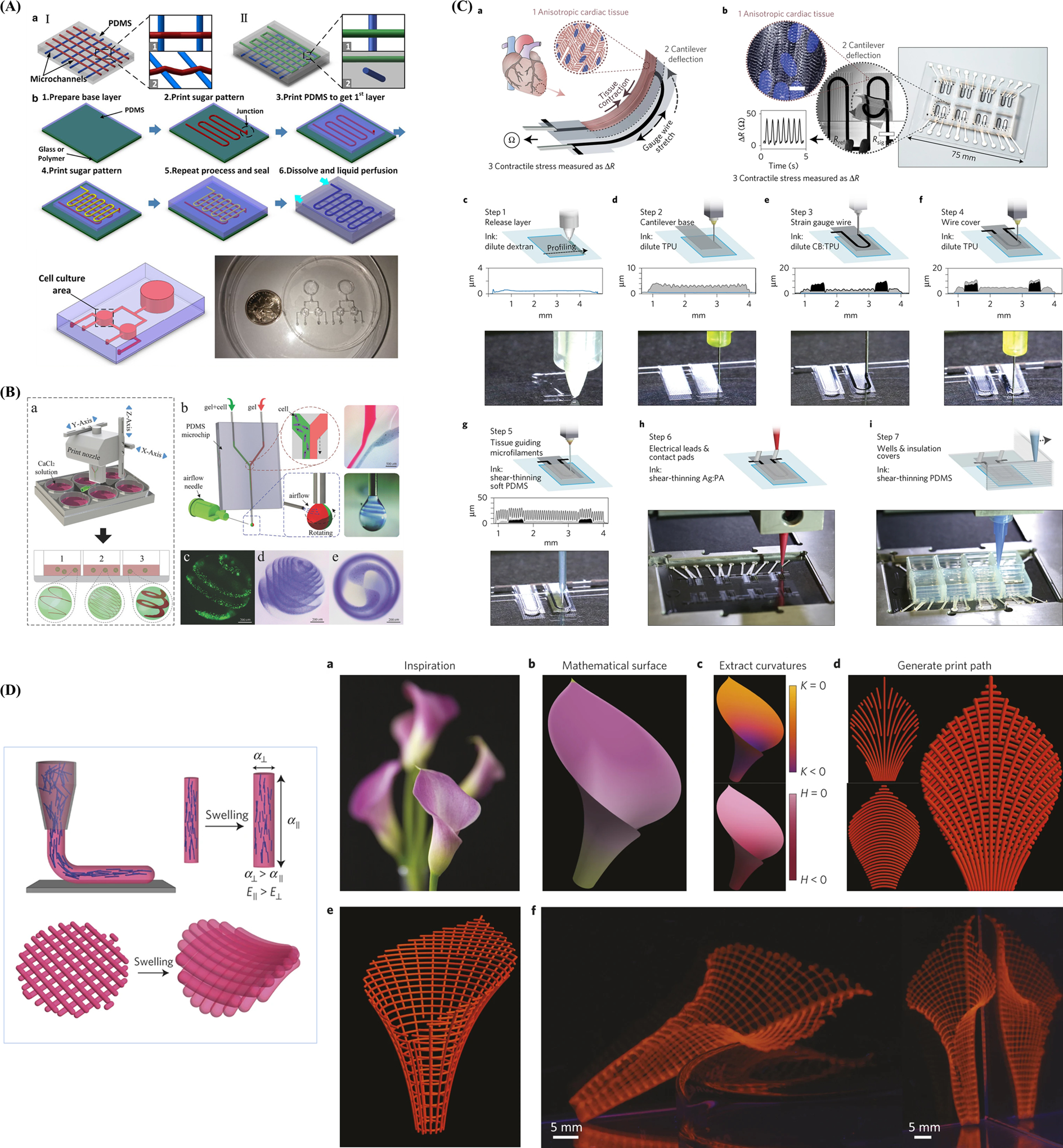

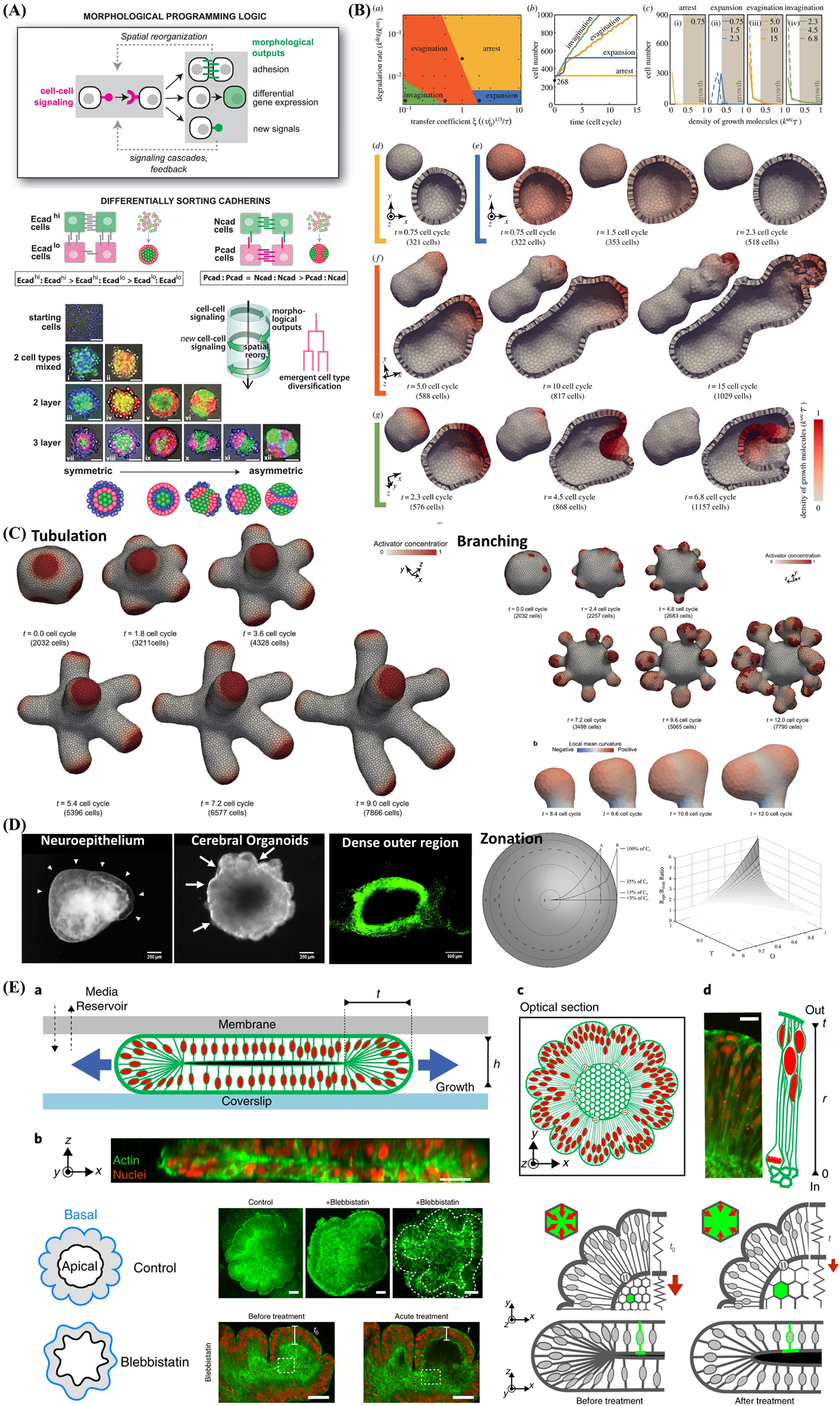

3.2. Integration with 3D Printing

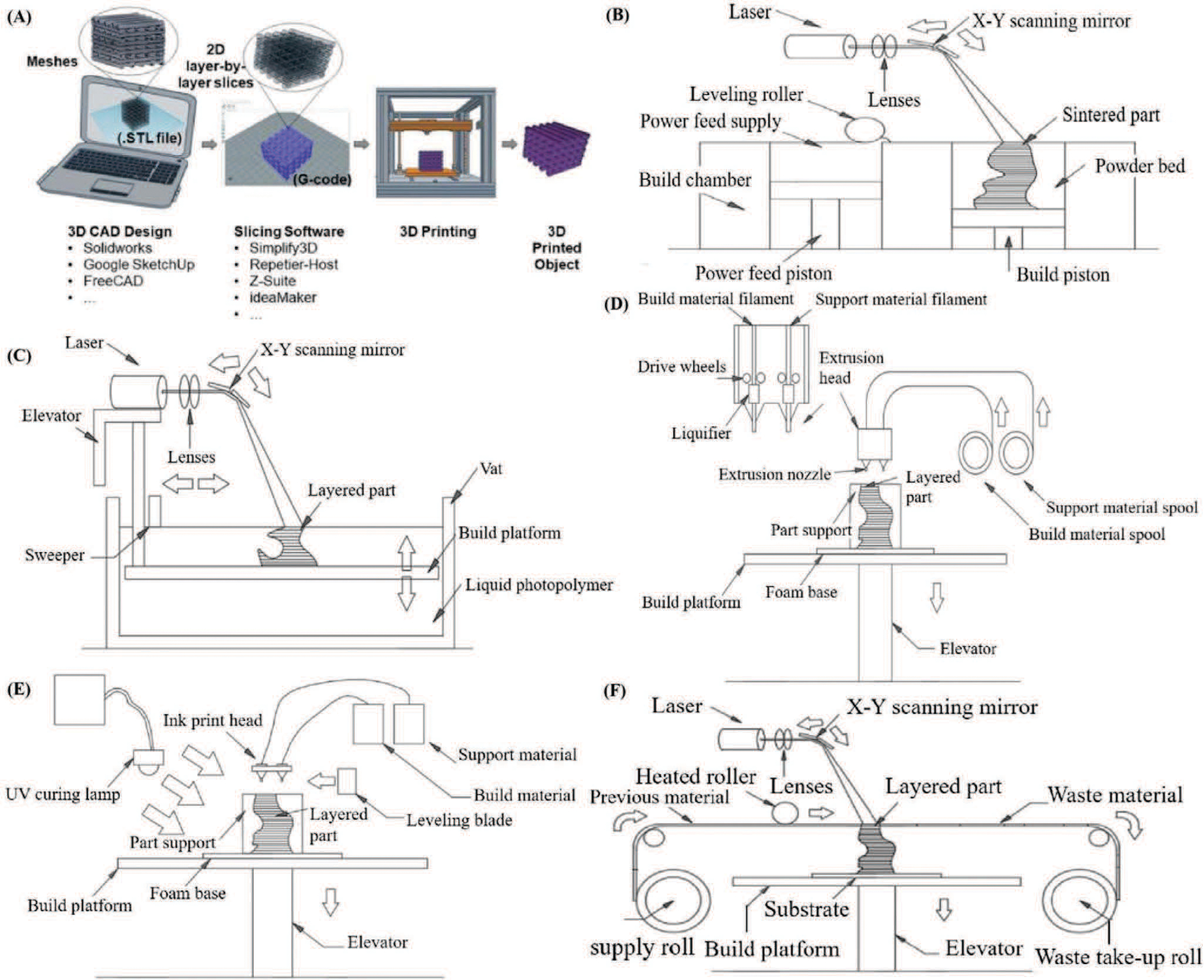

Additive manufacturing, also termed 3D printing or rapid prototyping, is a layer-by-layer manufacturing technique that is widely utilized for its ability to rapidly fabricate versatile, customized objects using various materials.[148,149] A commercial bioprinter should include three essential elements, such as a robotic motion system, bioink dispensers, and computer-based software-enabled operational control to print bioink with satisfactory resolution. The design of computer-aided design (CAD) software-enabled blueprint to control mechanical motion trajectory of a robotic system as the preprocessing step, the movement of the motion system in x-, y-, and z-axes, and the dispensing system controls the accurate deposition of the print ink as the processing step. Finally, bioink is deposited, solidified, and stacked layer-by-layer in the 3D bioprinter as the postprocessing step (Figure 4A).[150] There has been a recent advancement in materials and the accuracy of 3D bioprinting, attracting an increasing number of researchers that have employed this promising fabrication technology in 3D cell culture.[151] One of the most exciting benefits of 3D printing is that printed objects can be of almost any shape or geometry. Moreover, the objects can be produced using digital model data from CAD models or other electronic data sources, such as computerized tomography (CT) scans. 3D printing also allows for simplified fabrication processes of convoluted devices free from the labor-intensive and time-consuming manual manipulations, leading to easy design revisions, manufacturing, testing, and iterations. Additionally, 3D printing is cost-effective and environmentally friendly as there is no need for any agents used in the etching process.[152] Furthermore, as 3D printing is inherently amenable to CAD and other computer-aided software, integration between 3D printing, and 3D cell culture can potentially allow for cloud manufacturing and commercialization of organoid- or organ-on-a-chip models. To summarize, it is possible to reconstruct living systems on chips with precise shape, architecture, and structure of target tissues and organs anywhere within a short time period with the help of 3D printing, bringing unprecedented versatility and convenience to the modeling process.[153,154]

Figure 4.