Abstract

Capsicums lose water very rapidly after harvest and the moisture loss causes severe shriveling making them unmarketable within 2–3 days. The moisture loss occurs even under low temperature conditions, though at lesser rates. Bell peppers packed in corrugated fiber board boxes (CFB) tend to lose moisture continuously as these boxes are permeable to both water vapour and respiratory gases even if they are non-ventilated. To reduce the moisture loss and maintain freshness, yellow colour capsicum (cv. Bachata) were packed in CFB boxes and over wrapped with different semi-permeable films using shrink wrapping technology. This box shrink wrapping significantly lowered the weight loss and maintained firmness of capsicum at ambient (25.7–33.2 °C and 25–63% RH) and low temperature (8 °C ± 0.5 and 80 ± 5% RH) conditions. Yellow colour capsicums packed in this way could be stored for 11 days at ambient temperature with a weight loss of < 6% as compared to about 20% weight loss in non-wrapped fruits. The storage life could be extended to 5 weeks by storing these shrink wrapped boxes at 8 °C without any shriveling and with a weight loss of < 5%. In addition to maintaining high humidity, the lower O2 and higher CO2 levels maintained surrounding the produce in the wrapped boxes helped to avoid shriveling and to retain the quality in terms of surface colour, firmness and other quality traits. The absorption of excessive relative humidity by CFB itself in the over wrapped boxes helped in avoiding condensation of water droplets. This in turn avoided the development of fungal growth and thus the risk of fruit decay.

Electronic supplementary material

The online version of this article (10.1007/s13197-020-04807-6) contains supplementary material, which is available to authorized users.

Keywords: Colour capsicum, Box wrapping, Storage life, Weight loss, Firmness, Quality

Introduction

Colour capsicum (Capsicum annuum L.) is widely grown commercially in poly-houses worldwide. It is being used widely as fresh-cut salad and in the fast food industry for its colour, flavor and nutritive value. Bell peppers contain high levels of vitamins (A, B, C, E) and abundant in numerous health promoting antioxidants such as flavonoids, phenols, carotenoids, etc. (Marin et al. 2004; Silvia et al. 2007). Bell peppers are highly perishable and the major physiological factor that affects the postharvest quality during transportation, storage and marketing is moisture loss (Lownds et al. 1994; Maalekuu et al. 2003; Smith et al. 2006) and chilling injury (Wang et al. 2019). The texture, in particular the crispness of the pepper is an important quality attribute to consumers. Capsicums are prone to moisture loss consequently shriveling due to their large surface to weight ratio. Severe shriveling and excessive softening result in the loss of crispness of pepper fruit that affects the consumer preference and market value (Rao et al. 2011).

The most effective method of maintaining pepper quality for extended periods is by storing at low temperature with higher relative humidity. The storage conditions recommended for bell pepper are 7.5 °C and 95% relative humidity (RH) while storing at higher temperatures will increase moisture loss and shriveling of the produce (Cantwell 2014). Modified atmosphere packaging (MAP) is another widely used technology that enhances the shelf life of fresh produce packed in semi-permeable polymeric films by creating congenial atmospheres and high humidity around the produce. Packaging of capsicum in semi-permeable films has been reported to reduce respiration, alleviate chilling injury, retard softening, maintain colour and prolong the shelf-life (Ben-Yehoshua et al. 1983; Manolopoulou et al. 2010). Packaging bell peppers with polyethylene bags at low temperature (7.5 °C) reduced the water loss by 40–50% and maintained the fruit quality (Meir et al. 1995). Capsicum packed in heat shrinkable film or cling film extended the shelf-life and maintained quality of fruits for 10 and 7 days under super market (18–20 °C; 90–95% RH) and ordinary market (28–30 °C; 60–65% RH) conditions, respectively compared to 5 and 2 days in case of non-packed capsicums (Mahajan et al. 2016). Xtend® film packaging was proved to be ideal for the storage of bell pepper at 7 °C by minimizing weight loss, maintaining firmness, and higher sensory scores compared to non-wrapped fruits (Sharma et al. 2018). Buendía-Moreno et al. (2020) studied the effect of an innovative active (antimicrobial) cardboard box (coated with encapsulated essential oils viz., carvacrol: oregano:cinnamon at 70:10:20 v/v including a βcyclodextrin) on the quality of yellow, red and green peppers during storage at 8 °C (90% RH). The spoilage of peppers was effectively controlled by the active packaging with lesser than 5% decay after 18 days compared to 10–15% decay in control fruits.

Minimization of water stress is the major factor enhancing postharvest life of bell pepper sealed in plastic film (Ben-Yehoshua et al. 1983; Lurie et al.1986). The storage life of capsicum reduces significantly if the moisture levels within the package are not controlled adequately. Although MA packaging reduces water loss, the excessive relative humidity (RH) created in the packages and subsequent water condensation can enhance the risk of fruit decay due to microbial proliferation (Scully and Horsham 2006). Peppers packed in LDPE films and stored at 8 ± 1 °C exhibited water condensation inside packs because of low water vapour permeability of the film, leading to saturation of air (dew point) and super-saturation, resulting in condensation that further affected the storage-life (Chitravathi et al. 2015). A possible solution recommended to control very high humidity levels is use of desiccants. Several researchers have studied the use of various desiccants such as silica gel, CaCl2, NaCl, KCl, sorbitol and xylitol to regulate in-package RH for various fresh fruits and vegetables (Ben-Yehoshua et al. 1998; Evelo and Horst 1996; Rodov et al. 1995; Song et al. 2001; Singh et al. 2014). Bell peppers packed in corrugated fiber board boxes (CFB) tend to lose moisture continuously as the boxes are permeable to both respiratory gases and water vapour even if they are non-ventilated unless otherwise packed in lacquered or laminated boxes. In the present investigation attempts were made to reduce the moisture loss and shriveling of colour capsicum (yellow) by increasing the in-box humidity levels and at the same time avoiding condensation of water over the produce. This is done by over wrapping the CFB boxes with different semi-permeable films using shrink wrapping technology, the results of which are reported in this paper.

Materials and methods

Yellow capsicum (cv. Bachata) were harvested with stalk at nearly 90% coloration from the experimental poly-houses of vegetable crop production. These were either pre-cooled (meant for low temperature storage) or not cooled (meant for ambient storage). About 1.5 kg capsicum were packed in each 30 × 25 × 10 cm size 5 ply non-ventilated CFB boxes of 180 GSM and sealed properly using gum tape. The compression strength of CFB boxes used was 350 KGF and bursting strenght of the board was 11 kg/cm2. These boxes were then loosely sealed with suitable size bags of three different polymeric films having different gas permeabilities: (i) PD-961 (an electronically cross-linked multi layered polyolefin film of 31 µ), (ii) BDF-2001 (a co-extruded multi-layered polyolefin film of 25 µ) both of them procured from Cryovac®, W. R. Grace and Co., Duncan, S.C and (iii) an ordinary LDPE film of 25 µ. The O2 transmission rates (cc/m2 day atm) of these films respectively were 7000, 4.8, 7800; CO2 transmission rates (cc/m2 day atm) were 21,000, 19.2, 42,000 and water vapour transmission rates (WVTR, g/m2 day) were 14, 8.3, and 23. The loosely film wrapped boxes were then passed through a hot air tunnel Weldotron model 7121A, Weldotron Corporation, New Jersey for 15–20 s at 150–165 °C to get the film shrunk tightly over the boxes. Capsicum packed and sealed in similar non ventilated CFB boxes without any film wrapping served as control. Both shrink wrapped boxes and non-wrapped boxes were then stored at ambient temperature (25.7–33.2 °C and 25–63% RH) and at 8 °C ± 0.5 (80 ± 5% RH) in a modular cold room. At ambient temperature each treatment had 6 replications and at 8 °C each treatment was replicated 9 times.

Measurement of in-box gas levels

Gas levels (% O2 and CO2) inside the shrink-wrapped and non-wrapped boxes was measured at specific intervals during the entire storage duration with the help of a gas analyzer (CheckMate 3 Headspace Analyser, Dansensor, Denmark). The gas needle of the instrument was pierced through a silicone septum glued to the boxes and inside gas levels were noted.

Physiological loss in weight (PLW %)

Eight individual capsicums per replication from each box were numbered and weights were noted at specific intervals over 11 days storage at ambient temperature and 5 weeks storage at 8 °C, and the cumulative weight loss were calculated as percentages of initial weights.

Quality attributes At ambient temperature three boxes per treatment were opened after 8 and 11 days storage and at 8 °C the boxes were opened after 3, 4 and 5 weeks of storage. At random three fruits per box per treatment were selected and evaluated for the below mentioned quality parameters.

Fruit surface colour

A color Reader, CR-10 (Minolta Co., Ltd, Osaka, Japan) having a measuring area of 8 mm diameter was used for measuring the surface colour. On the equatorial region of each individual fruit three measurements were taken at three equidistant points and colour values were expressed in terms of L* (lightness), a* (redness/greenness) and b* (yellowness) values. Total colour difference is calculated using the formula (Clarke et al.1984),

Firmness

Fruit was cut longitudinally along the lobes and firmness of each lobe was determined by an Instron-4201 texture analyzing instrument (Instron Corporation, Canton, MA, USA) using an 8 mm diameter cylindrical probe and a 500 kg load cell set at 25 kg moving at a cross-head speed of 100 mm/min.

Quality parameters The vitamin C and protein contents were estimated using standard methods of analysis (AOAC 1995). Total phenols, flavonoids, and antioxidant capacity (FRAP) were measured according to the methods described by Shivashankara et al. (2010). Total phenols were estimated using Folin-Ciocalteu colorimetric method. Acidic methanol extract was mixed with FCR reagent (Merck Co. Ltd, Germany), and 20% sodium carbonate reagent. The absorbance of developed color was read at 700 nm using a UV/Vis spectrophotometer (Model T80 + , PG instruments, Leicestershire, UK). Results were computed from the gallic acid standard curve and expressed as mg of gallic acid equivalents (GAE) per 100 g. Total flavonoids were determined by aluminum chloride colorimetric method. Methanol extract (1 ml) of the sample was mixed with 5% NaNO2 (0.3 ml) followed by 10% AlCl3 (0.3 ml). After 1 min, 2 ml of 1 M NaOH was added and diluted to 10 ml with double distilled water. The absorbance of the pink mixture was read at 510 nm using the above UV/Vis spectrometer and the results were computed from the standard curve and expressed as mg of catechin equivalents per 100 g. Antioxidant capacity were estimated using FRAP (Ferric Reducing Antioxidant Potential) method. The methanol extract (0.2 ml) of the sample was mixed with FRAP (1.8 ml) reagent and after 40 min, the absorbance of the intense blue colour mixture was measured at 593 nm. Results were computed from the standard curve of ascorbic acid and the antioxidant capacity was expressed as mg ascorbic acid equivalent antioxidant capacity (AEAC) per 100 g.

Statistical analysis

The values noted under each parameter were analyzed statistically using Factorial CRD. Data were analyzed by ANOVA and the significance among treatment means was determined by least significant difference (LSD) at the P ≥ 0.05 level.

Results and discussion

In-box gas composition

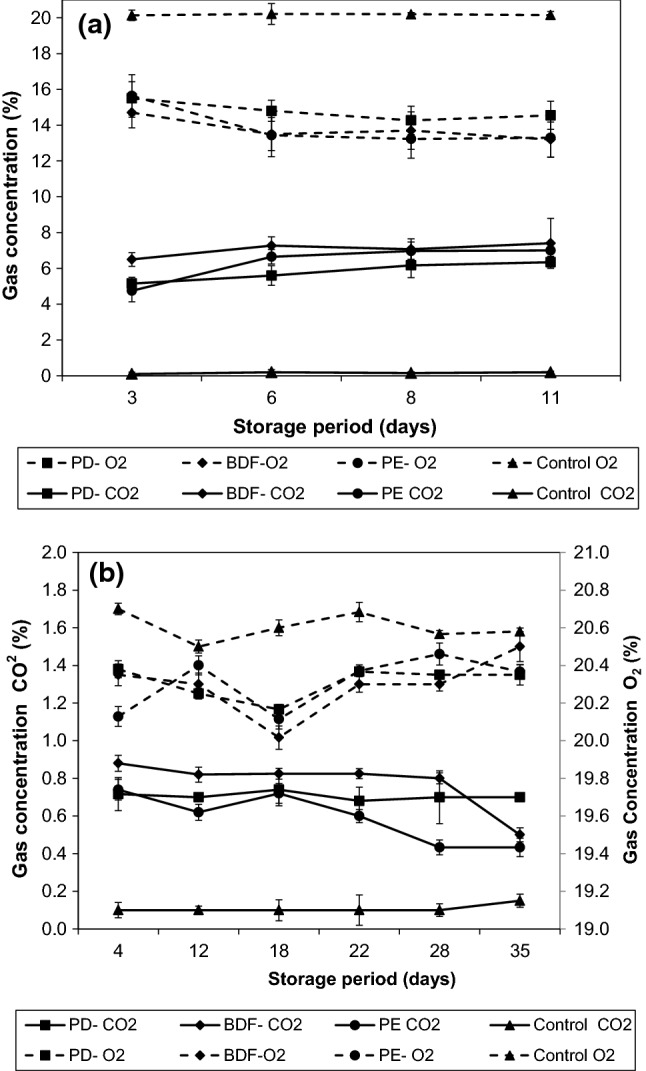

The non-wrapped CFB boxes stored at ambient temperature were found to be fully permeable to gases and the measured in-box O2 and CO2 levels were equal to atmospheric levels. The O2 and CO2 levels decreased significantly (due to passive modified atmospheres created by respiration of capsicum packed inside) when these boxes were shrink wrapped with different semi-permeable films. The O2 levels decreased to about 15–13% and the CO2 levels increased to about 5–7% (Fig. 1). Comparable trends of decrease in O2 and raise in CO2 levels in regular bulk modified atmosphere packs of non climacteric fruits like pomegranates with low respiration rates were reported earlier (Rao and Shivashankara 2018). In case of capsicum boxes stored at 8 °C, the in-box O2 and CO2 levels did not get modify much due to box shrink wrapping and decrease in O2 levels and increase in CO2 levels were very negligible (< 1% change). This could be due to reduced respiration rate of capsicum when stored at 8 °C compared to those stored at ambient temperature storage. The respiration rate of capsicum is generally low and which got further reduced due to low temperature storage. Sweet bell pepper had a low respiration rate at 12 °C which further decreased during storage (Cheema et al. 2018). The in-pack CO2 levels recorded in regular MA packed green capsicum stored at 5 °C were also reported to be very low (Manolopoulou et al. 2010). Though different films used for shrink wrapping had significantly different permeabilities, the in-box O2 and CO2 levels did not differ much in these films at both storage temperatures. This is in contrast to the results obtained by others in regular MAP who observed significant variations in in-pack O2 and CO2 levels when packed in differentially permeable films (Singh and Rao 2005; Selcuk and Erkan 2016; Rao and Shivashankara 2018). This could in addition to low respiration rate of capsicum, the more head space available within package (unlike regular MA packs) do not allow the buildup of CO2 concentration or reduction of O2 concentration.

Fig. 1.

Effect of capsicum box wrapping on in-box gas composition during storage at a ambient temperature (25.7–33.2 °C and 25–63% RH) and b LT (8 °C and 80 ± 5% RH). Error bars represent ± SE

Physiological loss in weight (PLW %)

Quick rate of moisture loss is an important physiological factor that adversely affects quality of peppers during transport, storage and marketing (Smith et al. 2006). Compared to most fruits, bell peppers have high postharvest water loss causing severe shriveling. This may be because it is a hollow fruit and has limited ability to store large volumes of water for long periods. Irrespective of the wrapping film used, box shrink wrapping significantly lowered the PLW (%) at both temperatures. At ambient temperature, box wrapped capsicums showed < 5% PLW after 8 days of storage compared to > 14% in case of non-wrapped fruits. At this stage the box shrink wrapped capsicums were fresh in appearance without any shriveling and softening whereas non-wrapped ones were shriveled and non-marketable in appearance. After 11 days of storage, the PLW (%) increased to > 19% in case of non-wrapped fruits compared to < 6% in case of box wrapped capsicum irrespective of the film used (Table 1). By this time the non wrapped capsicum exhibited severe shriveling symptoms and were highly un-acceptable. Shriveling of pepper was also reported to be due to water loss that was mainly because of lower storage RH, aggravated by the hollow centre of pepper fruit (Erin et al. 2013). The box-wrapped capsicums were still acceptable with very negligible level of shriveling symptoms that could be due to maintenance of high humidity levels inside the wrapped boxes. In box-wrapping, the water vapour released due to transpiration and respiration will be trapped inside the box because of overwrapping with films having low WVTR and the excess moisture will get absorbed by CFB box thus avoiding condensation of water droplets at the same time maintaining high humidity levels. Besides, packaging created a modified atmosphere with elevated concentration of CO2 and decreased O2 around the produce (Fig. 1), that slows down the metabolic processes and transpiration thereby reducing PLW.

Table 1.

Effect of box shrink wrapping on the weight loss, surface colour and firmness of capsicum during storage at

| Film type | PLW (%) |

Surface colour | Firmness (kg/cm2) |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| L* value | Total colour difference | ||||||||||

| 8 D | 11 D | 8 D | 11 D | Mean (F) | 8 D | 11 D | Mean (F) | 8 D | 11 D | Mean (F) | |

| (a) Ambient temperature (25.7–33.2 °C and 25–63% RH) | |||||||||||

| PD-961 | 4.52 | 5.58 | 58.00 | 57.38 | 57.69 | 1.15 | 2.21 | 1.68 | 8.07 | 7.02 | 7.55 |

| LDPE | 4.83 | 5.98 | 56.39 | 56.76 | 56.58 | 2.62 | 3.50 | 3.06 | 8.00 | 6.79 | 7.40 |

| BDF-2001 | 4.81 | 5.93 | 57.34 | 55.89 | 56.62 | 2.86 | 3.57 | 3.21 | 7.76 | 6.83 | 7.30 |

| Control | 14.41 | 19.72 | 55.62 | 52.54 | 54.08 | 3.89 | 7.78 | 5.83 | 6.59 | 5.61 | 6.10 |

| Mean (D) | 7.14 | 9.30 | 56.84 | 55.64 | 2.63 | 4.26 | 7.61 | 6.56 | |||

| Initial | 58.74 | 8.18 | |||||||||

| CD 5% | CD 5% | CD 5% | CD 5% | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Days (D) | 0.28 | 0.46 | 0.47 | 0.19 | |||||||

| Films (F) | 0.39 | 0.73 | 0.74 | 0.41 | |||||||

| D × F | 0.55 | 1.03 | 1.05 | 0.48 |

| Film type | PLW (%) |

Surface colour | Firmness (kg/cm2) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L* value | Total colour difference | ||||||||||||||

| 3 W | 4 W | 5 W | 3 W | 4 W | 5 W | Mean (F) | 3 W | 4 W | 5 W | Mean (F) | 3 W | 4 W | 5 W | Mean (F) | |

| (b) Low temperature (8 °C and 80 ± 5% RH) | |||||||||||||||

| PD-961 | 3.61 | 3.90 | 4.40 | 55.53 | 56.51 | 56.27 | 56.10 | 2.10 | 2.12 | 2.56 | 2.26 | 8.08 | 7.93 | 8.11 | 8.04 |

| LDPE | 3.68 | 3.89 | 4.65 | 56.76 | 56.61 | 56.26 | 56.54 | 2.93 | 3.34 | 3.97 | 3.41 | 8.18 | 8.10 | 7.95 | 8.08 |

| BDF-2001 | 3.32 | 3.61 | 4.34 | 55.98 | 56.69 | 56.90 | 56.52 | 2.58 | 3.40 | 3.29 | 3.09 | 8.01 | 8.00 | 7.89 | 7.97 |

| Control | 5.83 | 6.60 | 7.98 | 56.18 | 55.76 | 56.68 | 56.21 | 4.29 | 5.62 | 6.17 | 5.36 | 7.92 | 7.65 | 7.07 | 7.55 |

| Mean (D) | 4.11 | 4.50 | 5.34 | 56.11 | 56.39 | 56.53 | 2.98 | 3.62 | 4.00 | 8.05 | 7.92 | 7.75 | |||

| Initial | 58.74 | 8.18 | |||||||||||||

| CD 5% | CD 5% | CD 5% | CD 5% | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Weeks (W) | 0.08 | 0.48 | 0.73 | 0.16 | |||||||||||

| Films (F) | 0.11 | 0.62 | 0.94 | 0.26 | |||||||||||

| W × F | 0.18 | 1.08 | 1.62 | 0.37 |

D days, W weeks

At 8 °C storage, as expected the PLW was less compared to ambient temperature storage irrespective of the packaging method used. The lower

PLW at 8 °C can be ascribed to the slowdown of physiological processes viz., respiration and transpiration at low temperatures (Xing et al. 2011). Dependent on the type of film used, box wrapped capsicums had 4.3 to 4.7% PLW and showed no shriveling symptoms even after 5 weeks of storage compared to 8% weight loss in case of non-wrapped fruits with visible shriveling symptoms. Singh et al. (2014) also reported a significantly low PLW in active MA packed (38 µ PP film) green pepper with silica gel as moisture absorbent compared to control during 42 days storage at 8 ± 1 °C. In the present investigation, the non wrapped fruits were in marketable condition (with negligible shriveling) for only 3 weeks with 5.8% weight loss. Thus at both temperatures, the critical PLW was noticed as < 6% for yellow capsicum to be marketable in appearance. In the present investigation, box shrink wrapped capsicum could stay for 11 days at ambient temperature (25.7–33.2 °C and 25–63% RH) with 5.58% weight loss and 5 weeks at low temperature (8 °C and 80 ± 5% RH) with 4.4% weight loss which is less than the critical weight loss. Cheema et al. (2018) also reported that greenhouse grown sweet peppers treated with 0.01% hexanal vapor could maintain the visual appearance and shelf life attributes for 21 days at 12 °C with less than 6.0% weight loss.

Fruit surface colour

Irrespective of film used, box shrink wrapping significantly maintained the brightness (L* values) of yellow capsicum at ambient temperature compared to those packed in non-wrapped boxes that became slightly dull in appearance as indicated by lower L* values (Table 1). MA packaging and individual shrink wrapping was also found to be effective in the maintenance of peel brightness of pomegranate fruits (Rao and Shivashankara 2018 and Rao 2018). The more loss of peel brightness in non-wrapped fruits was attributed to the greater dehydration of the fruit and in the present investigation also the PLW was found to be 3 times higher in non-wrapped capsicum than the box wrapped ones. Among films, PD-961 film wrapped capsicum showed higher L* values compared to LDPE film at the end of 11 days of storage at ambient temperature. At low temperature storage, there was a slight decrease in the brightness of capsicum during 5 weeks of storage irrespective of the packaging method. At 8 °C, there was also no significant difference among different films with regard to surface L* values of capsicum packed in them. Singh et al. (2014) also observed minimal change in L* value of green capsicum at 8 ± 1 °C under active and passive MAP conditions during 6–7 weeks storage.

Irrespective of film used, box shrink wrapping significantly maintained the surface colour of yellow capsicum compared to those packed in non-wrapped boxes during storage at ambient temperature which is indicated by lower total colour difference (ΔE) values. The ΔE values of box wrapped capsicum were almost 50% of those packed in non-wrapped boxes (Table 1a). Among different films used for box shrink wrapping, PD-961 film showed the least total colour difference values even at the end of 11 days of storage at ambient temperature. Even at 8 °C storage, the ΔE values of box wrapped capsicum were significantly lower than that packed in non-wrapped boxes during entire 5 weeks of storage. Even after 5 weeks of storage at 8 °C, PD-961 film was found to be more effective in maintaining the surface colour with less ΔE values followed by BDF-2001 film when compared to LDPE film wrapping (Table 1b). The retention of yellow surface colour of capsicum due to box wrapping could be attributed to less moisture loss and low degradation of colour pigments responsible for the yellow color. High RH to a great extent and modified atmospheres to some extent (elevated CO2 and depleted O2 in-package concentrations) could have helped for this lower colour changes. A significant reduction in colour changes was also noted by MA packaging of green peppers, the colour values of which were comparable with the initial ones whereas non-packaged ones showed lower values i.e. higher colour change values (Manolopoulou et al. 2010; Singh et al. 2014). Significantly lesser changes in peel color (L*, C* and h°) values of pomegranates stored under MA packaging conditions compared to non-packed ones were also reported by Selcuk and Erkan (2014); Rao and Shivashankara (2018) which was mostly attributed to high relative humidity within the modified atmosphere packages and higher weight loss in control fruits.

Firmness

The firmness of capsicum decreased significantly with duration at both storage temperatures irrespective of the packaging method, but the loss was minimum at 8 °C compared to ambient storage (Table 1). Low temperature storage reduces tissue softening that could be due to decrease in respiration and transpiration rates, inhibition of cell-wall hydrolytic enzymes as well as reduced ethylene production (Smith et al. 2003). A gradual and continuous decrease in fruit firmness was also recorded in sweet bell pepper during storage at 12 °C (Cheema et al. 2018). Box shrink wrapping, irrespective of the film used, significantly maintained the firmness up to 8 days at ambient and 5 weeks at 8 °C compared to non-wrapped bell peppers (Table 1). At ambient temperature even after 11 days of storage, the firmness was significantly high in box wrapped capsicum compared to those packed in non-wrapped boxes; with 14–15% reduction in firmness in the former compared to 31.4% loss in firmness in the latter. At 8 °C, after 5 weeks of storage, box wrapped capsicum were significantly firmer than control fruits with only 0.9–3.5% reduction in firmness in the former compared to 13.6% loss in firmness in the latter. There is no significant difference in the firmness of capsicum wrapped in different films at both storage temperatures. A significant and steep decrease in firmness of green pepper was also noticed in non-packed fruits stored at RT and 8 °C whereas firmness was maintained by both active and passive MAP (Singh et al. 2014). Buendía-Moreno et al. (2020) also reported decreased firmness during storage of colour capsicum at 8 °C due to cell wall softening and capsicum packed in active CFB boxes maintained better firmness than control.

It is widely accepted that the increase in weight loss is related to the reduction of tissue turgor pressure and the cells begin to shrink and collapse which could lead to the loss of firmness (Lownds et al. 1994; Smith et al. 2003). In the present investigation also, the weight loss was significantly low (Table 1) in box wrapped yellow bell pepper thereby maintain higher firmness compared to non wrapped fruits. Low moisture loss coupled with less metabolic (enzyme activities) could have helped in better maintenance of firmness in box wrapped peppers at 8 °C compared to ambient stored counterparts. Further it was also reported that low oxygen and high carbon-dioxide levels in packed chillies decreased the activation of the tissue softening enzymes and thus helped in retaining firmness during storage (Smith et al. 2003).

Other quality parameters

The mean vitamin C value increased from the initial value with advancement of storage duration at both ambient temperature and 8 °C irrespective of the packaging method, the increase being more in 8 °C stored capsicum compared to ambient temperature stored produce (Table 2). As fruits were harvested at only 90% colouration, the ascorbic acid content might have increased till it reached the full ripe stage. The L-ascorbic acid content was also reported to increase in peppers as they ripen (Howard et al. 2000; Silvia et al. 2007; Lama et al. 2016). At ambient temperature, though vitamin C content decreased initially but increased latter significantly mainly attributed to its concentration because of more moisture loss with longer storage durations. The increase in vitamin C content was much higher in 8 °C stored capsicum than those stored at ambient temperature irrespective of the packaging method. In ambient temperature stored capsicum the degradation due to high temperature and concentration due to moisture loss might have happened simultaneously resulting in less increase in vitamin C content. However, at 8 °C the degradation might be much less (due to low metabolic activities) than the concentration in addition to its synthesis during slow ripening occurring at this temperature. This could be the reason for more increase in vitamin C content compared to ambient temperature stored capsicum. The vitamin C content of red bell pepper fruits was not decreased even after 21 days of storage at 7, 4 and 1.5 °C followed by 3 days shelf life at 20 °C (Lama et al. 2016). Further at 8 °C, the mean vitamin C content of non-wrapped values was slightly higher than box wrapped capsicum. Excessive moisture loss observed in non-wrapped fruits as reflected and reported under PLW might have resulted in an increase in ascorbic content per unit of fruit. Singh et al. (2014) also reported increase in ascorbic content per 100 g of fruit attributed to excessive moisture loss in green capsicum stored at both ambient and refrigerated conditions.

Table 2.

Effect of box shrink wrapping on the quality of capsicum during storage at

| Film type | Vitamin C (mg/100 g) |

Protein (%) |

Phenols (mg/100 g) |

Flavonoids (mg/100 g) |

FRAP (mg AEAC/100 g) |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 8 D | 11 D | Mean (F) | 8 D | 11 D | Mean (F) | 8 D | 11 D | Mean (F) | 8 D | 11 D | Mean (F) | 8 D | 11 D | Mean (F) | |

| (a) Ambient temperature (25.7–33.2 °C and 25–63% RH) | |||||||||||||||

| PD-961 | 133.3 | 158.3 | 145.8 | 0.82 | 1.17 | 1.00 | 78.06 | 85.95 | 82.01 | 11.95 | 9.15 | 10.55 | 32.83 | 30.83 | 31.83 |

| LDPE | 128.3 | 136.7 | 132.5 | 0.81 | 0.98 | 0.90 | 84.31 | 74.57 | 79.44 | 13.22 | 8.72 | 10.97 | 32.91 | 30.54 | 31.73 |

| BDF-2001 | 128.3 | 156.7 | 142.5 | 0.83 | 1.10 | 0.97 | 97.65 | 82.17 | 89.91 | 11.91 | 8.68 | 10.30 | 32.65 | 30.77 | 31.71 |

| Control | 125.0 | 158.3 | 141.7 | 0.76 | 1.26 | 1.01 | 79.22 | 90.81 | 85.02 | 7.72 | 9.49 | 8.61 | 32.62 | 30.86 | 31.74 |

| Mean (D) | 128.8 | 152.5 | 0.81 | 1.13 | 84.31 | 83.38 | 11.20 | 9.01 | 32.75 | 30.75 | |||||

| Initial | 136.7 | 0.89 | 94.64 | 8.30 | 33.46 | ||||||||||

| CD 5% | CD 5% | CD 5% | CD 5% | CD 5% | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Days (D) | 3.73 | 0.04 | 2.65 | 0.74 | 0.12 | ||||||||||

| Films (F) | 5.89 | 0.06 | 4.19 | 1.18 | 0.19 | ||||||||||

| D x F | 8.33 | 0.08 | 5.92 | 1.66 | 0.27 |

| Film type | Vitamin C (mg/100 g) |

Protein (%) |

Phenols (mg/100 g) |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3 W | 4 W | 5 W | Mean (F) | 3 W | 4 W | 5 W | Mean (F) | 3 W | 4 W | 5 W | Mean (F) | |

| (b) Low temperature (8 °C and 80 ± 5% RH) | ||||||||||||

| PD-961 | 172.7 | 161.7 | 190.0 | 174.8 | 1.13 | 1.14 | 1.11 | 1.13 | 100.3 | 125.9 | 141.6 | 122.6 |

| LDPE | 172.7 | 166.7 | 191.7 | 177.0 | 1.17 | 1.12 | 1.19 | 1.16 | 106.9 | 146.4 | 169.2 | 140.8 |

| BDF-2001 | 155.3 | 168.3 | 193.3 | 172.3 | 1.15 | 1.18 | 1.11 | 1.15 | 108.3 | 149.7 | 172.5 | 143.5 |

| Control | 168.0 | 196.7 | 198.3 | 187.7 | 1.22 | 1.31 | 1.24 | 1.26 | 117.1 | 126.2 | 202.1 | 148.5 |

| Mean (D) | 167.2 | 173.3 | 193.3 | 1.17 | 1.19 | 1.16 | 108.1 | 137.1 | 171.2 | |||

| Initial | 136.7 | 0.89 | 94.64 | |||||||||

| Film type | Flavonoids (mg/100 g) |

FRAP (mg AEAC/100 g) |

||||||

|---|---|---|---|---|---|---|---|---|

| 3 W | 4 W | 5 W | Mean (F) | 3 W | 4 W | 5 W | Mean (F) | |

| (b) Low temperature (8 °C and 80 ± 5% RH) | ||||||||

| PD-961 | 6.61 | 11.45 | 4.57 | 7.54 | 31.32 | 33.81 | 30.57 | 31.90 |

| LDPE | 6.92 | 9.84 | 11.99 | 9.58 | 29.67 | 33.77 | 31.62 | 31.69 |

| BDF-2001 | 5.88 | 11.84 | 8.61 | 8.77 | 31.70 | 33.74 | 31.65 | 32.36 |

| Control | 6.45 | 11.34 | 11.76 | 9.85 | 28.47 | 33.77 | 31.60 | 31.28 |

| Mean (D) | 6.47 | 11.12 | 9.23 | 30.29 | 33.77 | 31.36 | ||

| Initial | 8.30 | 33.46 | ||||||

| CD 5% | CD 5% | CD 5% | CD 5% | CD 5% | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Weeks (W) | 5.26 | 0.08 | 6.84 | 1.08 | 0.41 | |||||||||||||||

| Films (F) | 6.80 | 0.10 | 8.83 | 1.39 | 0.53 | |||||||||||||||

| W x F | 11.77 | 0.17 | 15.29 | 2.41 | 0.93 |

D days, W weeks

Irrespective of the packaging treatment and storage temperature, there was slight increase in the protein content of bell pepper during storage (Table 2). Slightly higher increase in protein content of non-wrapped peppers could be ascribed to the concentration of the same due to more water loss as reflected by higher PLW at both storage temperatures (Table 1). The mean phenol content decreased from the initial value during storage at ambient temperature irrespective of the packaging method whereas at 8 °C it increased gradually and significantly with increase in storage duration in all the packaging treatments (Table 2). An increase in total phenolic content was also observed in green chillies (Chitravathi et al. 2015), hot peppers (Monika et al. 2016) and pomegranate (Rao and Shivashankara 2018) during low temperature storage irrespective of packaging method that was attributed to the continued biosynthesis of phenolic compounds even after harvest. At low temperature storage, the mean phenol content was significantly low in the box wrapped capsicum (PD-961 film) compared to control. The phenol content in control fruits increased very high beyond 4 weeks of storage. The higher increase in phenolic compounds levels in control fruits could be due to low temperature stress especially with prolonged storage as also observed in red pepper (Ariel et al. 2005). A significant difference was also observed among different packaging films/treatments and interaction between packaging and storage duration. The mean phenol content of capsicum wrapped in BDF-2001, LDPE and control are significantly higher than those wrapped in PD-961 film. As compared to non-wrapped fruits, a significant increase in the total phenolic content of red bell pepper was also reported when packed in micro-perforated Xtend® bags and stored at different low temperatures (Lama et al. 2016). In case of flavonoids, there was slight increase during storage at both ambient temperature and 8 °C irrespective of the packaging method. At ambient temperature it increased during initial storage and then started declining whereas at 8 °C, flavonoids started increasing after 3 weeks of storage and then started declining beyond 4 weeks of storage (Table 2). Flavonoids content was also reported to increase after 10 days of storage at 8 °C and declined in the subsequent periods in greenhouse grown hot pepper (Monika et al. 2016). By the end of storage life, there was a very slight decrease in the total antioxidant activity of bell peppers in all the packaging treatments at both storage temperatures (Table 2). The total antioxidant activity decreased from the initial value of 33.46 (AEAC) to 30.75 after 11 days at ambient and to 31.36 after 5 weeks at 8 °C. This shows that there was no negative effect of box shrink wrapping on the retention/maintenance of total antioxidant activity of bell pepper at both storage temperatures. Ariel et al. (2005) also reported a slight decrease in antioxidant capacity of red bell pepper during storage at 10 °C irrespective of the treatment.

Stalks remained green and fresh in box wrapped capsicum whereas they started drying in case of non-wrapped capsicum. Spoilage was not observed in any of the packages at both storage temperatures except very slight fungal growth at the stalk ends in box wrapped capsicum stored at only ambient temperature which got dried up immediately once the boxes were opened (Plate).

Conclusion

The non ventilated CFB boxes used to pack bell peppers were found to be permeable to respiratory gases and water vapour. Shrink wrapping of these CFB boxes with semi permeable films helped in maintaining high RH without any moisture condensation as excessive relative humidity was absorbed by CFB itself. The box shrink wrapping significantly lowered the weight loss and maintained firmness of capsicum at ambient (25.7–33.2 °C and 25–63% RH) and low temperature (8 °C ± 0.5 and 80 ± 5% RH) conditions. Yellow colour capsicum (cv. Bachata) packed in this way could be stored for 11 days at ambient temperature and 5 weeks at low temperature without any visible shriveling (≈ 5% weight loss) and retained the quality in terms of surface colour, firmness, vitamin C, phenols and antioxidant contents.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- AOAC . Official methods of analysis. 16. Washington: Association of Official Analytical Chemists; 1995. [Google Scholar]

- Ariel RV, Carlos P, Laura L, Pedro MC, Gustavo AM, Alicia RC. UV-C treatments reduce decay, retain quality and alleviate chilling injury in pepper. Postharvest Biol Technol. 2005;35:69–78. doi: 10.1016/j.postharvbio.2004.06.001. [DOI] [Google Scholar]

- Ben-Yehoshua S, Rodov V, Fishman S, Peretz J (1998) Modified-atmosphere packaging of fruits and vegetables: reducing condensation of water in bell peppers and mangoes. In Bieleski R, Laing WA and Clark CJ (eds) Postharvest’96—proceedings of the international postharvest science conference, pp 387–392

- Ben-Yehoshua S, Shapiro B, Chen J, Lurie S. Mode of action of plastic film in extending life of lemon and bell pepper fruits by alleviation of water stress. Plant Physiol. 1983;73:87–93. doi: 10.1104/pp.73.1.87. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Buendía-Moreno L, Soto-Jover S, Ros-chumillas M, Antolinos-López V, Navarro-Segura L, Sánchez-Martínez MJ, Martínez-Hernández GB, López−Gómez A. An innovative active cardboard box for bulk packaging of fresh bell pepper. Postharvest Biol Technol. 2020;164:111171. doi: 10.1016/j.postharvbio.2020.111171. [DOI] [Google Scholar]

- Cantwell M (2014) Bell Pepper: recommendations for maintaining postharvest quality. [WWW Document]. https://postharvest.ucdavis.edu/Commodity_Resources/Fact_Sheets/Datastores/Vegetables_English/?uid=5&ds=799

- Cheema A, Priya P, Areeba A, Michael JP, Loong-Tak L, Jayasankar S, Gopinadhan P. Postharvest hexanal vapor treatment delays ripening and enhances shelf life of greenhouse grown sweet bell pepper (Capsicum annuum L.) Postharvest Biol Technol. 2018;136:80–89. doi: 10.1016/j.postharvbio.2017.10.006. [DOI] [Google Scholar]

- Chitravathi K, Chauhan OP, Raju PS. Influence of modified atmosphere packaging on shelf-life of green chillies (Capsicum annuum L.) Food Packag Shelf Life. 2015;4:1–9. doi: 10.1016/j.fpsl.2015.02.001. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Clarke FJJ, McDonald R, Rigg B. Modification to the JPC79 colour-difference formula. J Soc D Colour. 1984;100(4):128–132. doi: 10.1111/j.1478-4408.1984.tb00969.x. [DOI] [Google Scholar]

- Erin MO, Sheryl S, McLachlan A, Shane O, Allan W. High-pressure water washing and continuous high humidity during storage and shelf conditions prolongs quality of red capsicums (Capsicum annuum L.) Postharvest Biol Technol. 2013;81:73–80. doi: 10.1016/j.postharvbio.2013.02.012. [DOI] [Google Scholar]

- Evelo RG, Horst J. Modified atmosphere packaging of tomatoes: controlling gas and humidity. Packag Technol Sci. 1996;9(5):265–273. doi: 10.1002/pts.2770090504. [DOI] [Google Scholar]

- Howard LR, Talcott ST, Brenes CH, Villalon B. Changes in phytochemical and antioxidant activity of selected pepper cultivars (Capsicum species) as influenced by maturity. J Agric Food Chem. 2000;48:1713–1720. doi: 10.1021/jf990916t. [DOI] [PubMed] [Google Scholar]

- Lama K, Sharon AT, Yaacov P, Elazar F. Nutritional qualities and aroma volatiles of harvested red pepper fruits stored at suboptimal temperatures. Sci Hortic. 2016;213:42–48. doi: 10.1016/j.scienta.2016.10.015. [DOI] [Google Scholar]

- Laura BM, Sonia SJ, María RC, Vera AL, Laura NS, María José SM, Ginés Benito MH, Antonio LG. An innovative active cardboard box for bulk packaging of fresh bell pepper. Postharvest Biol Technol. 2020;164:111171. doi: 10.1016/j.postharvbio.2020.111171. [DOI] [Google Scholar]

- Lownds NK, Banaras M, Bosland PW. Post harvest water loss and storage quality of nine pepper (Capsium) cultivars. Hortic Sci. 1994;29:191–193. [Google Scholar]

- Lurie S, Shapiro B, Ben-Yehoshua S. Effects of water stress and degree of ripeness on rate of senescence of harvested bell pepper fruit. J Am Soc Hortic Sci. 1986;111:880–885. [Google Scholar]

- Maalekuu K, Elkind Y, Tuvia-Alkalai S. Quality evaluation of three sweet pepper cultivars after prolonged storage. Adv Hortic Sci. 2003;17(4):187–191. [Google Scholar]

- Mahajan BVC, Dhillon WS, Sidhu MK, Jindal SK, Mahesh Kumar MS, Dhaliwal SSP. Effect of packaging films on shelf-life and quality of bell pepper under super and ordinary market conditions. Indian J Hortic. 2016;73(1):114–119. doi: 10.5958/0974-0112.2016.00029.3. [DOI] [Google Scholar]

- Manolopoulou H, Xanthopoulos G, Douros N, Lambrinos G. Modified atmosphere packaging storage of green bell peppers: quality criteria. Biosyst Eng. 2010;106:535–543. doi: 10.1016/j.biosystemseng.2010.06.003. [DOI] [Google Scholar]

- Marin A, Ferreres F, Tomas-Barberan F, Gil M. Characterization and quantification of antioxidant constituents of sweet pepper (Capsicum annuum L.) J Agric Food Chem. 2004;52:3861–3869. doi: 10.1021/jf0497915. [DOI] [PubMed] [Google Scholar]

- Meir S, Rosenberger I, Aharon Z, Grinberg S, Fallik E. Improvement of the postharvest keeping quality and colour development of bell pepper (cv. ‘Maor’) by packaging with polyethylene bags at a reduced temperature. Postharvest Biol Technol. 1995;5:303–309. doi: 10.1016/0925-5214(94)00035-Q. [DOI] [Google Scholar]

- Monika SK, Małgorzata M, Barbara C, Monika K, Anna J, Irena P, Izabella J. Ozone-induced changes in the content of bioactive compounds and enzyme activity during storage of pepper fruits. Food Chem. 2016;211:59–67. doi: 10.1016/j.foodchem.2016.05.023. [DOI] [PubMed] [Google Scholar]

- Rao DVS. Individual shrink wrapping extends the storage life and maintains the quality of pomegranates (cvs.‘Mridula’and ‘Bhagwa’) at ambient and low temperature. J Food Sci Technol. 2018;55(1):351–365. doi: 10.1007/s13197-017-2945-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rao DVS, Shivashankara KS. Effect of modified atmosphere packaging on the extension of storage life and quality maintenance of pomegranate (cv.‘Bhagwa’) at ambient and low temperatures. J Food Sci Technol. 2018;55(6):2103–2113. doi: 10.1007/s13197-018-3125-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rao TVR, Gol NB, Shah KK. Effect of postharvest treatments and storage temperatures on the quality and shelf-life of sweet pepper. Sci Hortic. 2011;132:18–26. doi: 10.1016/j.scienta.2011.09.032. [DOI] [Google Scholar]

- Rodov V, Ben-Yehoshua S, Fierman T, Fang F. Modified-humidity packaging reduces decay of harvested red bell pepper fruit. Hortic Sci. 1995;30:299–302. [Google Scholar]

- Scully A, Horsham M. Emerging packaging technologies for enhanced food preservation. Food Sci Technol. 2006;20:16. [Google Scholar]

- Selcuk N, Erkan M. Changes in antioxidant activity and postharvest quality of sweet pomegranates cv. Hicrannar under modified atmosphere packaging. Postharvest Biol Technol. 2014;92:29–36. doi: 10.1016/j.postharvbio.2014.01.007. [DOI] [Google Scholar]

- Selcuk N, Erkan M. Impact of passive modified atmosphere packaging on physicochemical properties, bioactive compounds, and quality attributes of sweet pomegranates. Turk J Agric For. 2016 doi: 10.3906/tar-1509-57. [DOI] [Google Scholar]

- Sharma KD, Cardona JA, Sibomana MS, Herrera NGS, Nampeera E, Fallik E. Quality attributes of modified atmosphere packaged bell pepper (Capsicum annuum L.) during storage. J Nutr Food Technol. 2018;1(2):56–62. doi: 10.30881/jnfrt.00012. [DOI] [Google Scholar]

- Shivashankara KS, Jalikop SH, Roy TK. Species variability for fruit antioxidant and radical scavenging abilities in mulberry. Intl J Fruit Sci. 2010;10:1–12. doi: 10.1080/15538362.2010.530097. [DOI] [Google Scholar]

- Silvia A, Martins Leal PA, de Magalhães AM, Fuziki RT, Sanches J. Physico-chemical characterization of ‘Zarco HS’ yellow bell pepper for different ripeness stages. Sci Agric (Piracicaba, Brazil) 2007;64(1):19–22. doi: 10.1590/S0103-90162007000100003. [DOI] [Google Scholar]

- Singh R, Giri SK, Kotwaliwale N. Shelf-life enhancement of green bell pepper (Capsicum annuum L.) under active modified atmosphere storage. Food Packag Shelf Life. 2014;1:101–112. doi: 10.1016/j.fpsl.2014.03.001. [DOI] [Google Scholar]

- Singh SP, Rao DVS. Effect of modified atmosphere packaging (MAP) on the alleviation of chilling injury and dietary antioxidants levels in ‘Solo’ papaya during low temperature storage. Eur J Hortic Sci. 2005;70:246–252. [Google Scholar]

- Smith AC, Waldron KW, Maness N, Perkins-Veazie P. Vegetable texture: measurement and structural implications. In: Bartz JA, Brecht JK, editors. Postharvest physiology and pathology of vegetables. 2. New York: Marcel Dekker, Inc.; 2003. pp. 297–331. [Google Scholar]

- Smith DL, Stommel JR, Fung WM, Wang CY, Whitaker BD. Influence of cultivar and harvest method on postharvest storage quality of pepper (Capsicum annuum L.) fruit. Postharvest Biol Technol. 2006;42:243–247. doi: 10.1016/j.postharvbio.2006.06.013. [DOI] [Google Scholar]

- Song Y, Lee DS, Yam KL. Predicting relative humidity in modified atmosphere packaging system containing blueberry and moisture absorbent. J Food Process Preserv. 2001;25(1):49–70. doi: 10.1111/j.1745-4549.2001.tb00443.x. [DOI] [Google Scholar]

- Wang YX, Gao LP, Wang Q, Zuo J. Low temperature conditioning combined with methyl jasmonate can reduce chilling injury in bell pepper. Sci Hortic. 2019;243:434–439. doi: 10.1016/j.scienta.2018.08.031. [DOI] [Google Scholar]

- Xing Y, Xihong L, Qinglian X, Juan Y, Yaqing L, Yao T. Effects of chitosan coating enriched with cinnamon oil on qualitative properties of sweet pepper (Capsicum annuum L.) Food Chem. 2011;124:1443–1450. doi: 10.1016/j.foodchem.2010.07.105. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.