Abstract

PURPOSE

This in-vitro study evaluated and compared the color stability of 3D-printed and conventional heat-polymerized acrylic resins following aging, mechanical brushing, and immersion in staining medium.

MATERIALS AND METHODS

Forty disc-shaped specimens (10 mm in diameter and 3 mm thick) were prepared from two 3D-printed [DentaBASE (DB) and Denture 3D+ (D3D)] and one conventional polymethylmethacrylate (PMMA) denture materials. The specimens were thermo-cycled, subjected to mechanical brushing, and were immersed in either coffee, lemon juice, coke, or artificial saliva (AS) to simulate one and two years of oral use. Color measurements of the specimens were recorded by a spectrophotometer at baseline (T0), and after one (T1) and two years (T2) of simulation. The color changes (∆E) were determined and also quantified according to the National Bureau of Standards (NBS) units. Descriptive statistics, followed by factorial ANOVA and Bonferroni post-hoc test (α=.05), were applied for data analysis.

RESULTS

The independent factors, namely material, staining medium, and immersion time, and interaction among these factors significantly influenced ∆E (P<.009). Irrespective of the materials, treatments, and time, the highest and the lowest mean ∆Es were observed for PMMA in lemon juice (4.58 ± 1.30) and DB in AS (0.41 ± 0.18), respectively. Regarding the material type, PMMA demonstrated the highest mean ∆E (2.31 ± 1.37), followed by D3D (1.67 ± 0.66), and DB (0.85 ± 0.52), and the difference in ∆E between the materials were statistically significant (P<.001). All the specimens demonstrated a decreased color changes at T2 compared to T1, and this difference in mean ∆E was statistically significant (P<.001).

CONCLUSION

The color changes of 3D-printed denture resins were low compared to conventional heat polymerized PMMA. All the tested materials, irrespective of the staining medium used, demonstrated a significant decrease in ∆E values over time.

Keywords: 3D-printing, CAD/CAM technologies, Stereolithography, Polymethylmethacrylate, Colour change, Colour change

INTRODUCTION

Edentulism or complete tooth loss is an incapacitating condition that has been shown to affect an individual's Oral Health Related Quality of Life.1,2 Although edentulism has decreased in the current generation cohort, an increased life expectancy has contributed to an increase in the overall number of edentulous patients.3 Edentulism is mainly the result of dental caries and periodontitis, and rehabilitation of patients with complete edentulism has been accomplished with complete dentures (CD).1,3

Complete dentures are considered a primary option to treat complete edentulism in many patients.4,5,6 The ‘gold standard’ material for fabricating traditional CD has been the polymethylmethacrylate (PMMA) resin material due to its low cost, ease of handling and manipulation, acceptable physical and mechanical properties and satisfactory esthetic appearance.7,8 However, dimensional changes, susceptibility to fracture, color instability, abrasion, tissue irritations, and increased risk of denture-associated infections are considered the main drawbacks of this material.8,9 Furthermore, the denture's surface and subsurface voids can jeopardize the mechanical properties and compromise the dentures' esthetic and hygienic outcomes.10

In recent years, the use of digital technology is gaining tremendous recognition in various specialties of dentistry. This said, the designing and manufacturing of dental prostheses/appliances using digital materials, devices, computer-aided design, and computer-assisted manufacturing (CAD/CAM) have aided in limiting the burden of dentists and dental technicians.11,12 The advantages of 3D-printed dentures are less manufacturing time with high precision, cost-effectiveness, reduced number of patients' visits, and increased patient comfort.11,13 3D-printed dentures are usually produced by the stereolithography (SLA) method, which involves layer by layer laser beam scanning and polymerization of the methacrylate-based photocurable resin.14,15

Poor oral hygiene among denture wearers is well documented. As a result, these patients suffer from denture-related stomatitis, which occurs mainly due to dental plaque accumulation over prolonged period.16,17 Thus, the denture wearers must follow a strict denture cleansing method to prevent biofilm formation on the denture surface.18 Denture cleansing with tooth brush and dentifrice or soap is the most commonly practiced method due to its simple technique, low cost, and proved efficacy in removing organic deposits.19 On the contrary, brushing with dentifrices significantly impacts the form of wear and roughness of restorative and prosthetic materials.20 The wear and roughness of acrylic dentures favor biofilm formation and staining, in addition to the loss of surface details and diminished gloss.20,21

The other concern with poor oral hygiene is the staining of the denture resins, which could intensify with an individual's dietary habits. There is considerable evidence that beverages such as tea, coffee, and wine significantly increase stains on acrylic resin.22 Furthermore, it has been demonstrated that stains from carbonated drinks and juices have less staining effect on denture resin material compared to natural colorants found in coffee, tea, and tobacco.22,23

3D-printed dentures are still a newer concept in dentistry, and they should be thoroughly investigated in terms of mechanical, physical and aesthetic properties before considering it as a viable alternative to conventional PMMA dentures. Therefore, the present in-vitro study aimed to evaluate and compare the color stability of newly introduced 3D-printed and conventional heat-polymerized complete denture resins following aging and mechanical brushing. The null hypothesis is that there are no differences in color stability between the 3D-printed and conventional denture resins used for fabricating removable CD.

MATERIALS AND METHODS

Two 3D-printed [DB (DentaBase, LOT # MO/07875, Asiga, Alexandria, NSW, Australia) and D3D (Denture 3D+, LOT # WY032N01, NextDent, AV, Soesterberg, The Netherlands)] and one conventional (QC-20 heat-polymerize, LOT # D64015111, DeguDent GmbH, Hanau, Germany) denture base acrylic resin were evaluated.

The sample size was calculated using G*Power v. 3.1.9.3 freeware (Heinrich-Heine-Universität Düsseldorf, Germany). The effect size of 0.6, power of 0.8, α = .05 and estimated SD of 0.32 required a minimum of eight samples in each group. However, the samples were increased to 10 to accommodate any specimen loss during the experiment.

Forty disk shaped specimens (10 mm diameter and 3 mm thickness) were fabricated from each material. For DB and D3D materials, the digital specimen file (.STL)(Fig. 1A) was imported into a operational standard slicing software (Chitubox All-in-one SLA/DLP/LCD Slicer, Guangdong, China) equipped with the 3D-printer (ST-1600 3D-Printer, Satori Ltd., London, UK). The 3D-printing resin was poured into the printer, and the specimen was printed layer by layer at a thickness of 50 µm at 0° in a pre-determined dimension by Mask Stereolithography (MSLA) technique.24 The obtained specimens were cleaned with isopropanol and post-print cured by immersion in glycerin for an additional 40 min using a post-curing oven (Zirlux, Zahn Dental Labs, Henry Schein, Waltham, MA, USA) to ensure the reaction of remaining monomers.14 For the conventional heat polymerized acrylic resin specimens, the lost wax technique was followed. The prepared wax pattern was processed to PMMA using the flask-press-pack method.7 Following deflasking, the redundant resin from all the specimen surface was trimmed using a tungsten carbide bur.

Fig. 1. Representative specimen image. (A) Digital file image used for fabrication of 3D-printed specimens, (B) Final specimen after polishing and identification.

For the purpose of standardization, the specimens were handled by a single investigator for finishing and polishing. The specimens were finished with sequential use of silicon carbide paper (Dentaurum, Ispringen, Germany) at 300 rpm under water cooling. Polishing was accomplished using water and pumice slurry in a polishing unit (Derotor, London, England) for 90 s. The specimens' dimensions to the nearest ± 0.05 mm were confirmed using a digital caliper (Digimatic Micrometer, Mitutoyo, Kanagawa, Japan). The specimens were cleaned ultrasonically in distilled water for 5 min and dried with tissue paper before baseline color measurements (T0).

Following T0, the specimens were thermocycled (TC), subjected to mechanical brushing and later immersed in staining medium corresponding to one year of oral use. The specimens were TC for 10,000 cycles at 5℃ – 55℃, with 30 s dwell time and 10 s transfer time in a thermocycler (Huber 1100, SD Mechatronik GmbH, Feldkirchen-Westerham, Germany) to represent one year of oral use.25 After TC, the specimens were cleaned under running water and stored in distilled water before mechanical brushing simulation.

A simulator device (ZM 3, SD Mechatronik GMBH, Feldkirchen Westerham, Germany) was used to simulate brushing. The specimens were fixed onto the customized plexiglass inside the brushing device's containers using a drop of acrylic monomer. The device was equipped with 12 separate slots to which 12 soft toothbrushes (Colgate® 360®, Colgate-Palmolive Company, Riyadh, Saudi Arabia) were attached. A slurry was then prepared using commercially available dentifrice (Colgate® Regular, Colgate-Palmolive Company, Riyadh, Saudi Arabia) and deionized water at a ratio of 1:1 (by weight) and mixed in a plaster vacuum mixer. All 12 containers were filled with the slurry to cover the specimens (approx. 12 ml/container). Mechanical brushing was accomplished at 356 rpm, under a vertical load of 200 g and a stroke path of 3.8 cm, brushing 12 specimens simultaneously. The total brushing time was 50 min (17,800 cycles) that equalled to one year of tooth brushing.26 The slurry was refilled, and toothbrushes were replaced every 4,500 cycles. The toothbrushes were replaced in accordance with the American Dental Association (ADA) recommendations, which states that brushes be replaced 3 – 4 months or earlier if the toothbrush bristles wear away.27 The specimens were then stored in distilled water for 24 hours before immersion procedure according to the ISO/TR 11405:1994 recommendation.7

After identification with a bur (Fig. 1B), the specimens were randomly allocated into four groups (n = 10) according to the staining medium used (coffee, lemon juice, coke, and artificial saliva). Coffee (Nescafe Classic, Nestle, Riyadh, Saudi Arabia) and artificial saliva (AS) was prepared fresh. In contrast, lemon juice (Florid's natural lemonade juice, Lake Wales, FL, USA) and coke (The Coca-Cola Company, Riyadh, Saudi Arabia) were used as received from the manufacturer. The coffee beverage was prepared by adding 15 g of coffee powder into 250 mL of boiling water and continuously stirred for 10 min. Once the prepared solution was cooled down to room temperature, it was filtered using a filter paper to remove the residue.28 The AS was prepared by a pharmacist per the description from a previous study.29 The pH of beverages and AS was determined using a benchtop pH meter (pH 2700, OAKTON Instruments, Vernon Hills, IL, USA).

The specimens were then individually immersed in vials containing 20 mL of either of the beverages. Each specimen was suspended inside the vial using dental floss to ensure equal exposure of both surfaces to the beverages. The specimens were immersed in their respective beverages for 288 hours, and the beverages were changed every 24 hours. The immersion time used in this study was equal to one year of oral exposure.30

The specimens were later removed from the vials, cleaned under running water, and further stored in distilled water for 24 hours. The second color measurements (T1) were recorded, and the specimens were again subjected to the whole procedure (TC + mechanical brushing + immersion) as detailed above to simulate another year of oral use, followed by final color measurements (T2).

Before each color measurement, the specimens were dried well with a disposable paper towel. The color of the specimens were recorded in the 3-dimensional Commission Internationale de l'Eclairege L*a*b* (CIELab) color space using an UV light visible spectrophotometer (LabScan® XE, Hunter Associates Laboratory Inc., Reston, VA, USA). The CIE L*a*b* system is a chromatic value color space measuring both value and chroma on L*a*b* coordinates: L* measures the lightness of the color (a value of 100 corresponds to perfect white and 0 to black); a* measures color in the red (a* > 0) and green (a* < 0) dimension; and b* measures color in the yellow (b* > 0) and blue (b* < 0) dimension.31 The CIE L*a*b* mean reading was repeated three times and the average was calculated for each specimen. The total color alteration (ΔE*) for each specimen at T1 and T2 was calculated using the equation (1) and (2), respectively:

| ΔE*(T1) = [(ΔL1 − L0*)2 + (Δa1 − a0*)2 + (Δb1 − b0*)2]1/2 | (1) |

| ΔE*(T2) = [(ΔL2 − L0*)2 + (Δa2 − a0*)2 + (Δb2 − b0*)2]1/2 | (2) |

According to the ISO/TR-28642:2016 norm, the CIELAB 50:50% perceptibility threshold (PT) ΔE values is ≤ 1.2, whereas 50:50% acceptability threshold (AT) ΔE value is between 1.2 and 2.7. Any ΔE values above the AT limit is not clinically acceptable.32 Furthermore, in relating the color difference to a clinical situation, the ΔE values were converted to National Bureau of Standards (NBS) units using the equation 3.33

| NBS unit = ΔE × 0.92 | (3) |

Data analyses were performed using Statistical Package for Social Sciences v.20.0 (SPSS) (IBM SPSS Inc., Chicago, IL, USA). Shapiro-Wilk test revealed the presence of a normal distribution. Descriptive statistics (mean and SD) were used to describe the quantitative color difference (ΔE). Factorial ANOVA was used to quantify the effect of material type, staining medium, and immersion time on ΔE values. Bonferroni post-hoc test was used for multiple comparisons between independent factors (Materials/staining medium/Time) (α = .05).

RESULTS

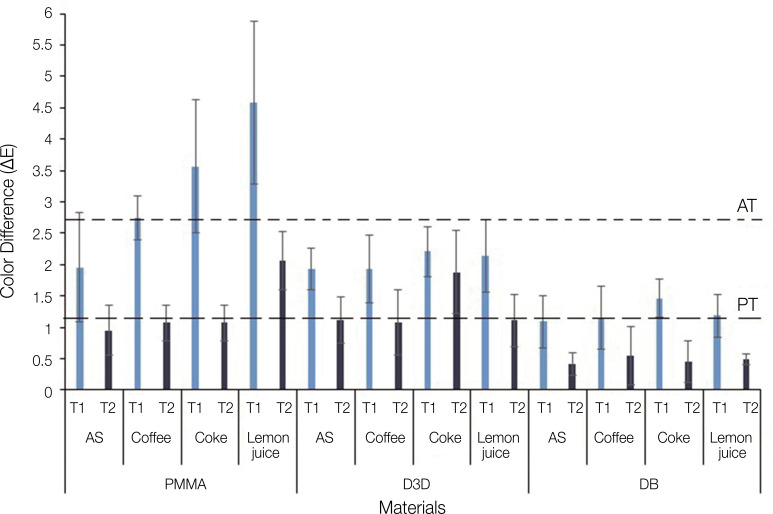

The reported pHs of coffee, lemon juice, coke, and AS were 5.1, 2, 2.5, and 7.2, respectively. The results (Mean ΔE values) are presented in Fig. 2. Irrespective of the materials, TC and immersion in staining medium, the highest and lowest mean ΔE values were observed for PMMA in lemon juice (4.58 ± 1.30) and DB in AS (0.41 ± 0.18), respectively. The mean ΔE values from all materials at T1 were below the AT except for coffee (2.74 ± 0.35), coke (3.56 ± 1.06), and lemon juice (4.58 ± 1.30) groups of PMMA. However, at T2, the mean ΔE values significantly decreased below the PT except for lemon juice (2.06 ± 0.47-PMMA) and coke (1.88 ± 0.66-D3D).

Fig. 2. Mean ΔE values after thermal-cycling, mechanical brushing and immersion procedure. PT-perceptibility threshold (ΔE ≤ 1.2); AT-acceptability threshold (ΔE >1.2 and ≤ 2.7); AS-artificial saliva.

Factorial ANOVA demonstrated that independent factors namely material, staining medium, immersion time significantly influenced ΔE (P < .009) (Table 1).

Table 1. Two-way ANOVA for ΔE.

| Source of variation | df | Sum of squares (SS) | Mean SS | F | P value |

|---|---|---|---|---|---|

| Material | 2 | 85.546 | 42.773 | 144.163 | < .001* |

| Treatment | 3 | 20.172 | 6.724 | 22.663 | < .001* |

| Time | 1 | 72.897 | 72.897 | 245.693 | < .001* |

| Material * staining medium | 6 | 23.901 | 3.984 | 13.426 | < .001* |

| Material * time | 2 | 14.461 | 7.230 | 24.370 | < .001* |

| Staining medium * time | 3 | 2.609 | 0.870 | 2.931 | .035* |

| Material * staining medium * time | 6 | 5.257 | 0.876 | 2.953 | .009* |

df: Degrees of Freedom (N-1), F: variation between sample means / variation within the samples

*denotes significance

Regarding the material type, PMMA demonstrated the highest mean ΔE (2.31 ± 1.37), followed by D3D (1.67 ± 0.66), and the lowest mean ΔE was observed with DB (0.85 ± 0.52) (Table 2). The difference in mean ΔE between the materials was found to be statistically significant (P < .001) (Table 3). Amongst the different staining media used, the highest ΔE was observed in lemon juice (1.93 ± 1.46) followed by coke (1.86 ± 1.09) and coffee (1.42 ± 0.84). The lowest ΔE value was observed in AS (1.24 ± 0.72) (Table 2). The difference in mean ΔE was found to be statistically significant between lemon juice and AS (P < .001), lemon juice and coffee (P < .001), AS and coke (P < .001), as well as between coke and coffee (P < .001). However, the difference in mean ΔE was not statistically significant between lemon juice and coke (P > .05) as well as between AS and coffee (P > .05) (Table 3). The mean ΔE at different measurement intervals showed higher ΔE values at T1 (2.16 ± 1.18) compared to T2 (1.06 ± 0.65) (Table 2). The difference in mean ΔE between T1 and T2 was statistically significant (P < .001) (Table 3).

Table 2. Mean total color changes for the measured variables.

| Variables | Mean | SD | Min | Max | |

|---|---|---|---|---|---|

| Materials | |||||

| PMMA | 2.31a | 1.37 | 0.24 | 6.69 | |

| D3D | 1.67b | 0.66 | 0.00 | 2.96 | |

| DB | 0.85c | 0.52 | 0.15 | 2.22 | |

| Staining medium | |||||

| Lemon juice | 1.93a | 1.46 | 0.38 | 6.69 | |

| Artificial saliva | 1.24b | 0.72 | 0.15 | 3.88 | |

| Coke | 1.86a | 1.09 | 0.23 | 5.43 | |

| Coffee | 1.42b | 0.84 | 0.00 | 3.31 | |

| Measurement time | |||||

| One year | 2.16a | 1.18 | 0.40 | 6.69 | |

| Two years | 1.06b | 0.65 | 0.00 | 2.96 | |

Different lower case in a row indicates statistically significant difference within the measured variables

Table 3. Multiple comparisons between independent factors (materials/staining medium/time) to test pair-wise significant difference.

| Materials/Staining medium/Time (i) | Materials/Staining medium/Time (j) | Mean difference (i−j) | P value | |

|---|---|---|---|---|

| Materials | ||||

| PMMA | D3D | 0.637 | < .001* | |

| DB | 1.459 | < .001* | ||

| D3D | DB | 0.822 | < .001* | |

| Staining medium | ||||

| Lemon juice | AS | 0.691 | < .001* | |

| Coke | 0.072 | 1.000 | ||

| Coffee | 0.508 | < .001* | ||

| AS | Coke | −0.618 | < .001* | |

| Coffee | −0.183 | .404 | ||

| Coke | Coffee | 0.435 | < .001* | |

| Time | ||||

| T1 | T2 | −1.10 | < .001* | |

*denotes significance

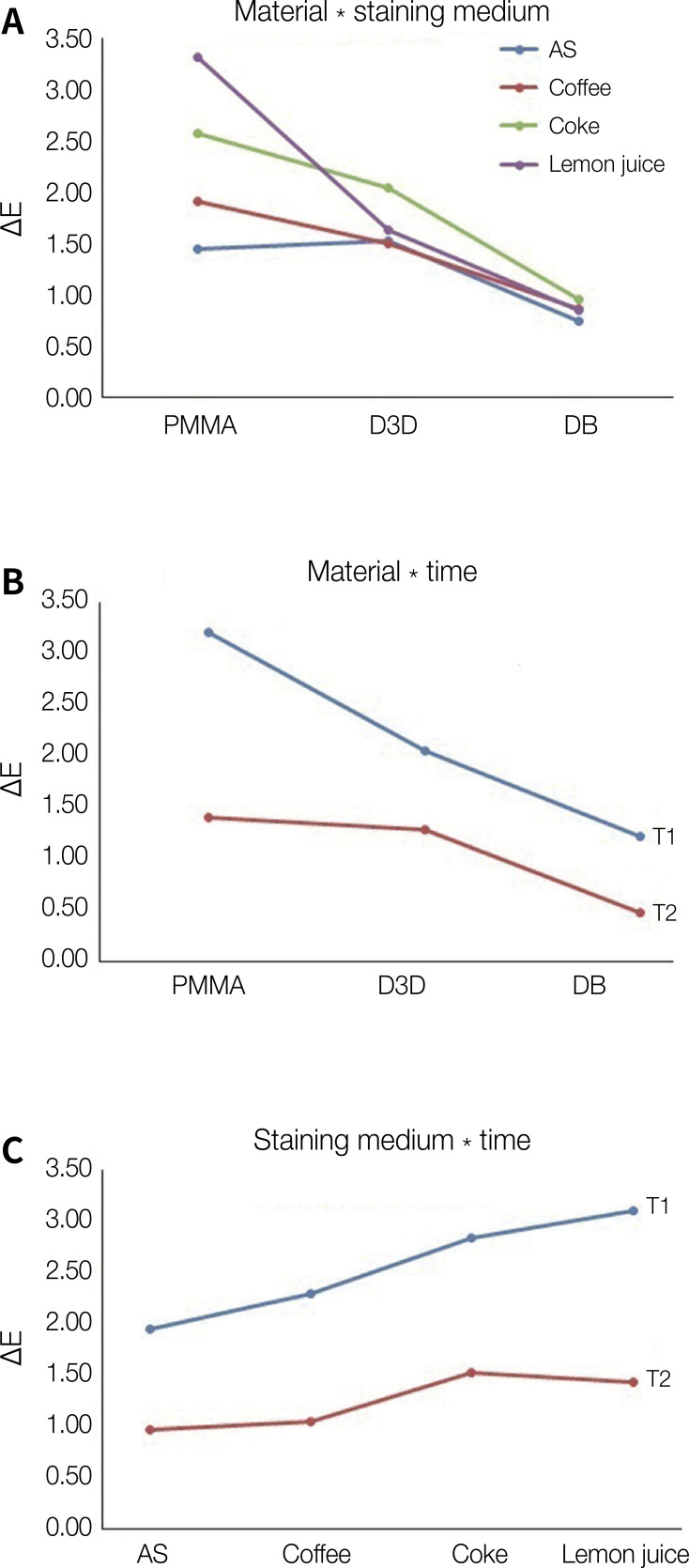

Fig. 3 presents the interactive plots for mean color difference. The interaction of materials and staining medium showed the highest mean and the lowest mean ΔE values for PMMA in lemon juice and DB in AS, respectively (Fig. 3A). Similarly, the interaction between materials and time showed the highest mean ΔE for PMMA material at T1 while the lowest mean ΔE was recorded for DB at T2 (Fig. 3B). The interaction between staining medium and time demonstrated the highest mean ΔE for lemon juice at T1 and the lowest mean ΔE for AS at T2 (Fig. 3C). Irrespective of material type, treatment, and time, the lowest ΔE was recorded with DB in AS at T2. Based on the total mean color changes, material type was the most important factor followed by time and treatment influencing the ΔE.

Fig. 3. Interactive plot for total color change. (A) The interaction of materials and staining medium showed highest mean ΔE for PMMA in lemon juice and lowest mean ΔE for DB in AS, (B) The interaction of materials and time showed highest mean ΔE for PMMA at T1 and the lowest mean ΔE for DB at T2, (C) The interaction of staining medium and time showed highest mean ΔE for lemon juice at T1 and the lowest mean ΔE for AS at T2.

Table 4 presents the NBS and ΔE values. Among the tested materials, DB showed extremely slight color change at T1 and slight color change at T2. D3D materials showed perceivable color change at T1 and slight color change at T2. PMMA material at T1 showed marked and perceivable color changes, but at T2, there was a slight color changes and perceivable color change (lemon juice).

Table 4. ΔE and NBS values.

| Materials | Staining medium | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| AS | Coffee | Coke | Lemon juice | ||||||

| ∆E | NBS | ∆E | NBS | ∆E | NBS | ∆E | NBS | ||

| PMMA | |||||||||

| T1 | 1.95 | 1.79† | 2.74 | 2.52† | 3.56 | 3.27†* | 4.58 | 4.21†* | |

| T2 | 0.95 | 0.87‡ | 1.07 | 0.98‡ | 1.57 | 1.44‡ | 2.06 | 1.89† | |

| D3D | |||||||||

| T1 | 1.93 | 1.77† | 1.93 | 1.77† | 2.21 | 2.03† | 2.14 | 1.96† | |

| T2 | 1.11 | 1.02‡ | 1.07 | 0.98‡ | 1.88 | 1.72† | 1.11 | 1.02‡ | |

| DB | |||||||||

| T1 | 1.09 | 1.00‡ | 1.16 | 1.06‡ | 1.46 | 1.34‡ | 1.19 | 1.09‡ | |

| T2 | 0.41 | 0.37* | 0.55 | 0.50* | 0.45 | 0.41* | 0.49 | 0.45* | |

NBS: National Bureau of Standards, AS: Artificial saliva

NBS classification *- extremely slight change; ‡- slight change; †- perceivable; †*- marked change

DISCUSSION

In the current study, the color stability of two 3D-printed and one conventional heat-polymerized denture resins were evaluated and compared. The materials were subjected to aging by thermal cycling and mechanical brushing and exposed to staining medium to simulate one and two years of oral use. The statistical analysis outcome recommends rejecting the null hypotheses as significant differences in color stability were observed among the resin materials.

The denture resin materials' color in this study was recorded in 3D-CIE L*a*b* color space using a UV light visible spectrophotometer. The spectrophotometry is the most recommended and accurate method as they provide a quantitative assessment of a materials' color change besides allowing objective evaluation of the color.34 The ΔE (ΔEab), representing the color difference after different treatments, is obtained by calculating the L*a*and b*values.34 There are two critical thresholds for assessing color differences: the perceptibility threshold (PT) and the acceptability threshold (AT). Under standard controlled environment, the ΔE value ≤ 1 is visually imperceptible. It is noteworthy, however, to stress that the perceptibility limit followed by each author differ. Goldstein and Schmitt35 report that having ΔE values ≥ 3.7 is not clinically acceptable, and the color difference between the two observed objects can be easily detected.31

Thermal cycling (TC) is regarded as a valid method to simulate in-vitro aging of dental materials. Although, there is no standardized TC protocol applied for laboratory testing of dental materials,36 the specimens in the current study were subjected to 10,000 thermal cycles that represented one year of oral simulation.25 The specimens were held alternatively first in 5℃ cold water and then in 55℃ hot water bath in accordance with ISO TS 11405 Technical Specification.36 This repeated exposure to cold and hot bath mimics the thermal stresses occurring in the oral cavity to which the denture resin materials would be exposed due to the consumption of cold and hot beverages.37 This TC process in wet conditions may cause denture polymer degradation, and heat stress may increase water sorption, causing the absorbed water to behave as a plasticizer and soften the denture, thus affecting the denture resin properties.38

The AT and PT ΔE values in the present study were evaluated according to the ISO/TR-28642:2016 norms; ΔE values for PT were ≤ 1.2, and between 1.2 and 2.7 for AT. Any ΔE values above the AT limit was considered clinically unacceptable.32 It has been reported that ΔE values increase with an increased immersion time in staining medium.8,39 However, in this study, we observed a significant decrease (P < .05) in ΔE values over time irrespective of the group and materials tested. This could be attributed to the specimens' mechanical brushing, which could have inhibited the adsorption of colorants onto the resin surfaces.40 Another possible explanation is the change in surface properties of the resins following aging.41 These findings are consistent with those reported by others.42,43 Keskin42 examined PMMA denture resins' color stability following immersion in coffee and tea solutions for one week and reported an initial increase and then a decrease, in the materials' ΔE values. Similarly, Imirzalioglu et al.43 studied the effect of four solutions (saliva, saliva-tea, saliva-coffee, and saliva-nicotine) on various denture base resins at 7 and 30 days. The authors demonstrated increased ΔE values at one week followed by a decreased ΔE values at 30 days.

The comparison among the denture material types showed that conventional PMMA had the highest total mean color changes (ΔE = 2.31), followed by D3D (ΔE = 1.66) and DB (ΔE = 0.85) materials. The difference in ΔE between the materials was statistically significant (P < .001). The study revealed a significant difference among the resin materials, suggesting that color stability is material-dependent. The difference in the color changes between the 3D-printing resins could be related with the composition of the materials. Denture 3D+ (D3D) resin consist of more than 90% methacrylic oligomers, methacrylate monomer, phosphine oxides, and pigment. On the contrary, DentaBase (DB) resin consists of functional methacrylic resins, initiators, dyes, and stabilisers. Furthermore, the different values of ΔE could be related to the alteration in the optical characteristics of the resin materials due to water absorption.44 Resin materials that can absorb water can also be able to absorb other liquids that may contribute to discoloration.45

The present findings are in disagreement with previous studies.7,46 Gruber et al.7 evaluated the color stability of CAD/CAM subtractively and additively manufactured (3D-printed) and conventional heat-cured PMMA resin. The authors demonstrated maximum discoloration and inferior color stability with 3D-printed resin groups compared to CAD/CAM subtractively manufactured and conventional PMMA resins. The authors speculated that increased water sorption of 3D-printed resin groups could be the possible reason for the low color stability. Furthermore, the authors stressed that surface deterioration of the 3D-printed resins is another aspect that may have influenced the color stability. Filler content has an inverse relation with surface deterioration, and most 3D-printed resins have less inorganic fillers.7

Similarly, Shin et al.46 evaluated the color stability of CAD/CAM blocks and 3D-printing resins for their degree of discoloration based on material type, colorants types, and immersion duration in the colorants. The authors concluded that 3D-printing resins demonstrated color differences above the AT (ΔE > 2.25) following immersion for 7 days or longer in all test groups. The authors also revealed that after thermal cycling, the water sorption of 3D-printed resin was high compared to prefabricated PMMA. However, in the same study, the authors showed that each study material showed distinct properties, even when using the same 3D-printing method. Thus, it was evident that other factors, such as material properties and other output parameters, could affect the water sorption rate of 3D-printing resin.46 While water sorption alone does not justify low color stability; it could be considered a contributing factor.47

In contrast, the present findings are consistent with the outcome of a study by Koh et al.14 The authors evaluated and compared the color stability of Dentca 3D-printed denture teeth and four conventional types of denture teeth. It was observed that Dentca denture teeth, when immersed in some colorants, showed color changes, but the maximum ΔE of 3D-printed denture teeth was within the AT limit. However, the comparison of the findings between studies should be made with extreme care due to the variation in the material type used, the experimental protocol followed, measurement techniques and the immersion process, which can impede the comparison results.

The highest mean color difference among the beverages was observed in lemon juice (ΔE = 1.93) followed by coke (ΔE = 1.86) and coffee (ΔE = 1.42). The least difference was observed in AS (ΔE = 1.24). An unusual finding in this study was that specimens immersed in AS (pH = 7.2) also produced color differences above the PT at T1. This suggests that the material properties such as the composition, surface characteristics, amount of residual monomer and porosities, polarity of the beverages, and the immersion period in the beverages can interfere with other parameters besides the solutions' pH. These parameters can change the polymer's solubility and promote surface degradation, thereby accelerating the discoloration process.48

The difference in mean ΔE was insignificant between AS and coffee (P > .05). It was assumed that coffee, being the most chromogenic beverage relative to others, would produce more discoloration. The coffee constituents (tannin and chlorogenic acids) and pH (4.9 to 5.2) are found to induce and accelerate the discoloration process.28 However, the assumption was wrong as coffee's discoloration potential was below lemon juice and coke. The low discoloration of specimens in coffee solution is possibly explained by the dislodging of the coffee layers from the specimen surface into the solution as they reach a certain thickness.39,42

Compared to AS and coffee, specimens immersed in lemon juice and coke exhibited increased discoloration. However, no significant difference was observed between them (P > .05). The NBS units are essential for color comparison to a clinical situation and quality control.49 The results can be interpreted as trace to appreciable.

The current laboratory study's strength is the substantial methodological approach, including thermal cycling, mechanical brushing, specimen exposure to staining medium, and color measurements to reproduce the clinical environment. Despite the strength, this study had few limitations. Firstly, the standard methodological approach may not be logical in in vivo environments. The brushing cycles adopted in this study is based on the fact that patients brush their dentures twice a day. Nevertheless, the exact brushing cycles vary for some patients who practice cleaning their dentures repeatedly.50 Secondly, it is impractical to simulate the period that the beverage is in contact with artificial dentures inside the mouth before swallowing.51 Finally, there was no substantial comparison of the present findings with previous data due to the limited number of studies concerning the properties of 3D-printed resins, such as watersorption, surface roughness, hardness before their inclusion in routine clinical practice.

CONCLUSION

Based on the experimental conditions of the present study and according to the methodology used, it was possible to conclude that the color changes of 3D-printed denture resins were low compared to conventional heat polymerized PMMA. All the tested materials, irrespective of the staining medium used, demonstrated significant decrease in color changes over time.

References

- 1.Cunha-Cruz J, Hujoel PP, Nadanovsky P. Secular trends in socio-economic disparities in edentulism: USA, 1972-2001. J Dent Res. 2007;86:131–136. doi: 10.1177/154405910708600205. [DOI] [PubMed] [Google Scholar]

- 2.Emami E, de Souza RF, Kabawat M, Feine JS. The impact of edentulism on oral and general health. Int J Dent. 2013;2013:498305. doi: 10.1155/2013/498305. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Anadioti E, Musharbash L, Blatz MB, Papavasiliou G, Kamposiora P. 3D printed complete removable dental prostheses: a narrative review. BMC Oral Health. 2020;20:343. doi: 10.1186/s12903-020-01328-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Al-Dwairi ZN, Tahboub KY, Baba NZ, Goodacre CJ, Özcan M. A comparison of the surface properties of CAD/CAM and conventional polymethylmethacrylate (PMMA) J Prosthodont. 2019;28:452–457. doi: 10.1111/jopr.13033. [DOI] [PubMed] [Google Scholar]

- 5.Paulino MR, Alves LR, Gurgel BC, Calderon PS. Simplified versus traditional techniques for complete denture fabrication: a systematic review. J Prosthet Dent. 2015;113:12–16. doi: 10.1016/j.prosdent.2014.08.004. [DOI] [PubMed] [Google Scholar]

- 6.Saponaro PC, Yilmaz B, Heshmati RH, McGlumphy EA. Clinical performance of CAD-CAM-fabricated complete dentures: a cross-sectional study. J Prosthet Dent. 2016;116:431–435. doi: 10.1016/j.prosdent.2016.03.017. [DOI] [PubMed] [Google Scholar]

- 7.Gruber S, Kamnoedboon P, Özcan M, Srinivasan M. CAD/CAM complete denture resins: an in vitro evaluation of color stability. J Prosthodont. 2021;30:430–439. doi: 10.1111/jopr.13246. [DOI] [PubMed] [Google Scholar]

- 8.Dayan C, Guven MC, Gencel B, Bural C. A comparison of the color stability of conventional and CAD/CAM polymethyl methacrylate denture base materials. Acta Stomatol Croat. 2019;53:158–167. doi: 10.15644/asc53/2/8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Singh S, Palaskar JN, Mittal S. Comparative evaluation of surface porosities in conventional heat polymerized acrylic resin cured by water bath and microwave energy with microwavable acrylic resin cured by microwave energy. Contemp Clin Dent. 2013;4:147–151. doi: 10.4103/0976-237X.114844. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Anusavice K, Chiayi S, Ralph Rawls H. Phillips' Science of Dental Materials. 12th ed. Philadelphia, USA: Saunders; 2012. [Google Scholar]

- 11.Hada T, Kanazawa M, Iwaki M, Arakida T, Soeda Y, Katheng A, Otake R, Minakuchi S. Effect of printing direction on the accuracy of 3D-printed dentures using stereolithography technology. Materials. 2020;13:e3405. doi: 10.3390/ma13153405. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Kattadiyil MT, Goodacre CJ, Baba NZ. CAD/CAM complete dentures: a review of two commercial fabrication systems. J Calif Dent Assoc. 2013;41:407–416. [PubMed] [Google Scholar]

- 13.Chen J, Ahmad R, Suenaga H, Li W, Sasaki K, Swain M, Li Q. Shape optimization for additive manufacturing of removable partial dentures-A new paradigm for prosthetic CAD/CAM. PLoS One. 2015;10:e0132552. doi: 10.1371/journal.pone.0132552. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Koh ES, Cha HS, Kim TH, Ahn JS, Lee JH. Color stability of three dimensional-printed denture teeth exposed to various colorants. J Korean Acad Prosthodont. 2020;58:1–6. [Google Scholar]

- 15.Revilla-León M, Özcan M. Additive manufacturing technologies used for processing polymers: Current status and potential application in prosthetic dentistry. J Prosthodont. 2019;28:146–158. doi: 10.1111/jopr.12801. [DOI] [PubMed] [Google Scholar]

- 16.Shinawi LA. Effect of denture cleaning on abrasion resistance and surface topography of polymerized CAD CAM acrylic resin denture base. Electron Physician. 2017;9:4281–4288. doi: 10.19082/4281. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 17.Sorgini DB, Silva-Lovato CH, de Souza RF, Davi LR, Paranhos Hde F. Abrasiveness of conventional and specific denture-cleansing dentifrices. Braz Dent J. 2012;23:154–159. doi: 10.1590/s0103-64402012000200011. [DOI] [PubMed] [Google Scholar]

- 18.Pellizzaro D, Polyzois G, Machado AL, Giampaolo ET, Sanitá PV, Vergani CE. Effectiveness of mechanical brushing with different denture cleansing agents in reducing in vitro Candida albicans biofilm viability. Braz Dent J. 2012;23:547–554. doi: 10.1590/s0103-64402012000500013. [DOI] [PubMed] [Google Scholar]

- 19.de Andrade IM, Silva-Lovato CH, de Souza RF, Pisani MX, de Andrade KM, Paranhos Hde F. Trial of experimental toothpastes regarding quality for cleaning dentures. Int J Prosthodont. 2012;25:157–159. [PubMed] [Google Scholar]

- 20.de Freitas Pontes KM, de Holanda JC, Fonteles CS, Pontes Cde B, Lovato da Silva CH, Paranhos Hde F. Effect of toothbrushes and denture brushes on heat-polymerized acrylic resins. Gen Dent. 2016;64:49–53. [PubMed] [Google Scholar]

- 21.Dyer D, MacDonald E, Newcombe RG, Scratcher C, Ley F, Addy M. Abrasion and stain removal by different manual toothbrushes and brush actions: studies in vitro. J Clin Periodontol. 2001;28:121–127. doi: 10.1034/j.1600-051x.2001.028002121.x. [DOI] [PubMed] [Google Scholar]

- 22.Hersek N, Canay S, Uzun G, Yildiz F. Color stability of denture base acrylic resins in three food colorants. J Prosthet Dent. 1999;81:375–379. doi: 10.1016/s0022-3913(99)80001-8. [DOI] [PubMed] [Google Scholar]

- 23.Erdemir U, Yildiz E, Saygi G, Altay NI, Eren MM, Yucel T. Effects of energy and sports drinks on tooth structures and restorative materials. World J Stomatol. 2016;5:1–7. [Google Scholar]

- 24.Chung YJ, Park JM, Kim TH, Ahn JS, Cha HS, Lee JH. 3D printing of resin material for denture artificial teeth: chipping and indirect tensile fracture resistance. Materials (Basel) 2018;11:1798. doi: 10.3390/ma11101798. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 25.Gale MS, Darvell BW. Thermal cycling procedures for laboratory testing of dental restorations. J Dent. 1999;27:89–99. doi: 10.1016/s0300-5712(98)00037-2. [DOI] [PubMed] [Google Scholar]

- 26.Sorgini DB, da Silva-Lovato CH, Muglia VA, de Souza RF, de Arruda CN, Paranhos Hde F. Adverse effects on PMMA caused by mechanical and combined methods of denture cleansing. Braz Dent J. 2015;26:292–296. doi: 10.1590/0103-6440201300028. [DOI] [PubMed] [Google Scholar]

- 27.Van Leeuwen MPC, Van der Weijden FA, Slot DE, Rosema MAM. Toothbrush wear in relation to toothbrushing effectiveness. Int J Dent Hyg. 2019;17:77–84. doi: 10.1111/idh.12370. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 28.Al Amri MD, Labban N, Alhijji S, Alamri H, Iskandar M, Platt JA. In vitro evaluation of translucency and color stability of CAD/CAM polymer-infiltrated ceramic materials after accelerated aging. J Prosthodont. 2021;30:318–328. doi: 10.1111/jopr.13239. [DOI] [PubMed] [Google Scholar]

- 29.Klimek J, Hellwig E, Ahrens G. Fluoride taken up by plaque, by the underlying enamel and by clean enamel from three fluoride compounds in vitro. Caries Res. 1982;16:156–161. doi: 10.1159/000260592. [DOI] [PubMed] [Google Scholar]

- 30.Guler AU, Yilmaz F, Kulunk T, Guler E, Kurt S. Effects of different drinks on stainability of resin composite provisional restorative materials. J Prosthet Dent. 2005;94:118–124. doi: 10.1016/j.prosdent.2005.05.004. [DOI] [PubMed] [Google Scholar]

- 31.Chang JY, Chen WC, Huang TK, Wang JC, Fu PS, Chen JH, Hung CC. Evaluating the accuracy of tooth color measurement by combining the Munsell color system and dental colorimeter. Kaohsiung J Med Sci. 2012;28:490–494. doi: 10.1016/j.kjms.2012.04.006. [DOI] [PubMed] [Google Scholar]

- 32.ISO/TR-28642. Dentistry-guidance on colour measurments. Geneva; Switzerland: International Standards Organization (ISO); 2016. Available at: https://www.iso.org/obp/ui/#iso:std:iso:tr:28642:ed-2:v1:en. [Google Scholar]

- 33.Judd DB. Physiological optics at the national bureau of standards. Appl Opt. 1967;6:13–26. doi: 10.1364/AO.6.000013. [DOI] [PubMed] [Google Scholar]

- 34.Song SY, Kim KS, Lee JY, Shin SW. Physical properties and color stability of injection-molded thermoplastic denture base resins. J Adv Prosthodont. 2019;11:32–40. doi: 10.4047/jap.2019.11.1.32. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 35.Goldstein GR, Schmitt GW. Repeatability of a specially designed intraoral colorimeter. J Prosthet Dent. 1993;69:616–619. doi: 10.1016/0022-3913(93)90292-v. [DOI] [PubMed] [Google Scholar]

- 36.Morresi AL, D'Amario M, Capogreco M, Gatto R, Marzo G, D'Arcangelo C, Monaco A. Thermal cycling for restorative materials: does a standardized protocol exist in laboratory testing? a literature review. J Mech Behav Biomed Mater. 2014;29:295–308. doi: 10.1016/j.jmbbm.2013.09.013. [DOI] [PubMed] [Google Scholar]

- 37.Eliasson ST, Dahl JE. Effect of thermal cycling on temperature changes and bond strength in different test specimens. Biomater Investig Dent. 2020;7:16–24. doi: 10.1080/26415275.2019.1709470. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 38.Silva Cde S, Machado AL, Chaves Cde A, Pavarina AC, Vergani CE. Effect of thermal cycling on denture base and autopolymerizing reline resins. J Appl Oral Sci. 2013;21:219–224. doi: 10.1590/1679-775720130061. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 39.Hollis S, Eisenbeisz E, Versluis A. Color stability of denture resins after staining and exposure to cleansing agents. J Prosthet Dent. 2015;114:709–714. doi: 10.1016/j.prosdent.2015.06.001. [DOI] [PubMed] [Google Scholar]

- 40.Bezgin T, Özer L, Tulga Öz F, Özkan P. Effect of toothbrushing on color changes of esthetic restorative materials. J Esthet Restor Dent. 2015;27:S65–S73. doi: 10.1111/jerd.12136. [DOI] [PubMed] [Google Scholar]

- 41.Buyukyilmaz S, Ruyter IE. Color stability of denture base polymers. Int J Prosthodont. 1994;7:372–382. [PubMed] [Google Scholar]

- 42.Keskin S. The treatment of prosthetic dental materials withhypchlorite. Ankara, Turkey: Middle East Technical University; 2002. [Google Scholar]

- 43.Imirzalioglu P, Karacaer O, Yilmaz B, Ozmen Msc I. Color stability of denture acrylic resins and a soft lining material against tea, coffee, and nicotine. J Prosthodont. 2010;19:118–124. doi: 10.1111/j.1532-849X.2009.00535.x. [DOI] [PubMed] [Google Scholar]

- 44.Buchalla W, Attin T, Hilgers RD, Hellwig E. The effect of water storage and light exposure on the color and translucency of a hybrid and a microfilled composite. J Prosthet Dent. 2002;87:264–270. doi: 10.1067/mpr.2002.121743. [DOI] [PubMed] [Google Scholar]

- 45.Bagheri R, Burrow MF, Tyas M. Influence of food-simulating solutions and surface finish on susceptibility to staining of aesthetic restorative materials. J Dent. 2005;33:389–398. doi: 10.1016/j.jdent.2004.10.018. [DOI] [PubMed] [Google Scholar]

- 46.Shin JW, Kim JE, Choi YJ, Shin SH, Nam NE, Shim JS, Lee KW. Evaluation of the color stability of 3D-printed crown and bridge materials against various sources of discoloration: an in vitro study. Materials (Basel) 2020;13:5359. doi: 10.3390/ma13235359. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 47.Berli C, Thieringer FM, Sharma N, Müller JA, Dedem P, Fischer J, Rohr N. Comparing the mechanical properties of pressed, milled, and 3D-printed resins for occlusal devices. J Prosthet Dent. 2020;124:780–786. doi: 10.1016/j.prosdent.2019.10.024. [DOI] [PubMed] [Google Scholar]

- 48.Omata Y, Uno S, Nakaoki Y, Tanaka T, Sano H, Yoshida S, Sidhu SK. Staining of hybrid composites with coffee, oolong tea, or red wine. Dent Mater J. 2006;25:125–131. doi: 10.4012/dmj.25.125. [DOI] [PubMed] [Google Scholar]

- 49.Nimeroff I, Judd D. Colorimetry. National Bureau of Standards Monograph 104. Washington: U.S. Dept. of Commerce, National Bureau of Standards; 1968. [Google Scholar]

- 50.Chang YH, Lee CY, Hsu MS, DU JK, Chen KK, Wu JH. Effect of toothbrush/dentifrice abrasion on weight variation, surface roughness, surface morphology and hardness of conventional and CAD/CAM denture base materials. Dent Mater J. 2021;40:220–227. doi: 10.4012/dmj.2019-226. [DOI] [PubMed] [Google Scholar]

- 51.Bitencourt SB, Catanoze IA, da Silva EVF, Dos Santos PH, Dos Santos DM, Turcio KHL, Guiotti AM. Effect of acidic beverages on surface roughness and color stability of artificial teeth and acrylic resin. J Adv Prosthodont. 2020;12:55–60. doi: 10.4047/jap.2020.12.2.55. [DOI] [PMC free article] [PubMed] [Google Scholar]