Abstract

PURPOSE

This study aimed to assess the influence of various micromechanical surface conditioning (MSC) strategies with or without coupling agent (silane) application on the micro-shear bond strength (µSBS) of resin- matrix ceramics (RMCs).

MATERIALS AND METHODS

GC Cerasmart (GC), Lava Ultimate (LU), Vita Enamic (VE), Voco Grandio (VG), and Brilliant Crios (BC) were cut into 1.0-mm-thick slices (n = 32 per RMC) and separated into four groups according to the MSC strategy applied: control-no conditioning (C), air-borne particle abrasion with aluminum oxide particles (APA), 2W- and 3W-Er,Cr:YSGG group coding is missing. The specimens in each group were further separated into silane-applied and silane-free subgroups. Each specimen received two resin cement microtubules (n = 8 per subgroup). A shear force was applied to the adhesive interface through a universal test machine and µSBS values were measured. Data were statistically analyzed by using 3-way ANOVA and Tukey HSD test. Failure patterns were scrutinized under stereomicroscope.

RESULTS

RMC material type, MSC strategy, and silanization influenced the µSBS values (P<.05). In comparison to the control group, µSBS values increased after all other MSC strategies (P<.05) while the differences among these strategies were insignificant (P>.05). For control and APA, there were insignificant differences between RMCs (P>.05). The silanization decreased µSBS values of RMCs except for VE. Considerable declines were observed in GC and BC (P<.05).

CONCLUSION

MSC strategies can enhance bond strength values at the RMC - cement interface. However, the choice of MSC strategy is dependent on RMC material type and each RMC can require a dedicated way of conditioning.

Keywords: Air-borne particle abrasion; Er,Cr:YSGG laser; Micro-shear bond strength; Resin-matrix ceramic; Silane

INTRODUCTION

The procurement of a durable bond between machine-milled restorations and luting cement by the genesis of chemical bonds and mechanical interlocking is one of the major climacterics influencing the long-term viability of prosthetic treatment as poor bonding may lead to low fracture strength, low retention, inferior marginal fit, and micro-leakage.1,2,3,4,5,6 As attempts to achieve a durable bond, manifold micromechanical (mechanical, chemical, and laser irradiation) and chemical (silicon coatings, use of coupling agents) surface conditioning strategies are in use.1,2,3,4,7,8,9,10

Micromechanical surface conditioning (MSC) strategies function by removing the loose contaminated surface, forming micro-retentive grooves, increasing roughness, and enhancing wettability for the genesis of micromechanical interlock between substrate and adherent.11,12 Supportively, the Wenzel equation emphasized that micro-surface roughness is essential to enhance hydrophilicity.13 Previously, a number of MSC strategies have been proposed.14 Of these; air-borne particle abrasion (APA) and laser irradiation (LI) are common.5,15,16 In APA, the substrate surface is roughened by throwing abrasive particles.17,18 Although being a well-established strategy;6,9,18 it has a propensity for surface-damage1,9 and microcrack creation.11,17,18 Changes in particle type, particle size, propulsion pressure, distance from the nozzle to the substrate surface, and abrasion time may lead to differences in the indentation pattern of the substrate surface.14 In LI, the inorganic content of the very superficial layer is removed with the aid of micro-explosions and vaporization.2,11 Alterations in laser type, power output, distance from the nozzle to the substrate surface, irradiation time may differently influence the surface topography of the substrate.14 Although several types have emerged to roughen ceramics;4,11,14 the use of erbium, chromium-doped yttrium, scandium, gallium, and garnet (Er,Cr:YSGG) laser has recently been widespread.1,2,4,5,16 Due to its hydrokinetic nature, there is less risk of forming a heat-damaged layer.4,15

Chemical surface conditioning strategies function by chemically bonding inorganic and organic materials.10 With this regard, coupling agents have gained popularity and are recommended to promote luting cement hydrophilicity9 subsequent to the MSC strategies.6,12 However, their benefits are still controversial.19,20,21 These mediators are synthetic organic-inorganic silicon compounds that can be either monofunctional (non-functional), bifunctional, or bis-functional (cross-linking / dipodal). Monofunctional agents contain only one reactive (alkoxy) group that can react with inorganic materials and are used as primers in surface modification. Bifunctional agents contain two reactive groups and thereby, function as chemical adhesion promoters between dissimilar matrices through dual reactivity.8 Bis-functional silanes possess two silicon atoms with three hydrolysable alkoxy groups and are incorporated with bifunctional silanes to increase bonding and hydrolytic stability.22,23,24 The chemical formula for a bifunctional silane is Z-(CH2) n-Si-(OR)3; where Z is organo-functional end connecting with organic materials such as resin composites, (CH2) n is linker group, and (OR)3 is alkoxy end connecting with inorganic materials such as ceramics. Organo-functional end reacts with the methacrylate groups of the resins via a free radical polymerization process. After hydrolysis to silanol groups, the alkoxy groups react to the surface hydroxyl groups of inorganic substrates.6,9,11,17,22,23,24,25,26

Lately introduced resin-matrix ceramics (RMCs) amalgamate the advantageous characteristics of dental ceramics and composite resins,1,4,7,8,9,11,27,28,29,30 and thereby, provide the followings: enhanced and fast machinability, superior fatigue resistance, acceptable wear resistance, low abrasive effect to opposing teeth, promising bond strength, polishability, no requirement for firing and intraoral reparability.1,3,7,18,31,32,33,34,35,36 It is of clinical significance to have advanced knowledge about the restorative material from which the indirect restoration is produced, to promote a strong bonding since the surface conditioning strategy varies according to the chemical composition of the restorative material used.17,25 The RMCs consist of organic and inorganic portions in different proportions and are polymerized under high pressure and temperature leading to the increased monomer to polymer conversion rates (up to 96%).9,21,37 Few free monomers stay available for copolymerization with monomers of the luting cement. Therefore, prior to adhesive cementation, the use of a customized surface conditioning strategy is essential.21,38

The preference for luting cement can be considered as another critical factor in the establishment of a durable bond.9,17,26 Since self-adhesive luting cements do not have any preprocessing of the tooth surface, they have commonly been used.4,8,9 Moreover, the bonding workflow in self-adhesive cements was made very simple in contrast to that of total-etch cements.5,8 Thereby, ease of handling property overcame the technique sensitivity of luting cements. Although total-etch adhesive systems provide better service in terms of bond strength when compared to self-adhesive systems,1 a study by Bellan et al.8 demonstrated that the self-adhesive resin cement did not differ from the total-etch adhesive and self-etch adhesive resin cement. Additionally, despite conflicting results, the curing mode of luting cements can be influential on the durability of the bond. Dual-cured cements are found more reliable.4,9 From this perspective, it is plausible to combine the customized surface conditioning strategy with appropriate luting cement.39 For instance, Alp et al.7 recommended APA with dual-polymerizing resin cements that contain 10-metacryloxydecyl dihydrogen phosphate (MDP) monomer for nanohybrid-composite resin materials.

To the best knowledge of authors, data regarding the influence of APA, LI, and silane application on the micro-shear bond strength (µSBS) of RMCs are scarce. Therefore, this study aimed to investigate the micro-shear bond strength of dual-cured resin cement to 5 different RMCs surface-conditioned with 8 different strategies. The null hypothesis was that there would be no statistically significant effect of MSC protocols and silanization on the data of micro-shear bond strength of different RMCs.

MATERIALS AND METHODS

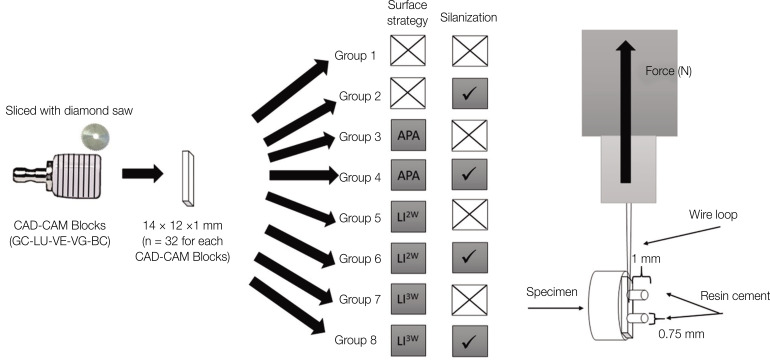

In the current study, 5 different RMCs (GC Cerasmart [GC], Lava Ultimate [LU], Vita Enamic [VE], Voco Grandio [VG], and Brilliant Crios [BC]) were used. The brands, manufacturers, chemical compositions, and batch numbers of the materials used are depicted in Table 1. The schematic setup of the study is shown in Fig. 1.

Table 1. Brands, manufacturers, chemical compositions, and batch numbers of the materials used in the present study.

| Material | Brand | Manufacturer | Chemical composition | Batch number |

|---|---|---|---|---|

| CAD-CAM resin-matrix ceramic block | GC Cerasmart | GC Dental Products, Leuven, Belgium | Organic part: Bis-MEPP, UDMA, DMA | 1509052 |

| Inorganic part: 71 wt% silica and barium glass nanoparticles | ||||

| Lava Ultimate | 3M ESPE, St. Paul, MN, USA | Organic part: Bis-GMA, Bis-EMA, UDMA, TEGDMA | N644403 | |

| Inorganic part: 80 wt% silica and zirconia nanoparticles and zirconia/silica nanoclusters | ||||

| VITA Enamic | VITA Zahnfabrik, Bad Säckingen, Germany | Organic part: UDMA, TEGDMA | 43230 | |

| norganic part: 86 wt% glass ceramic (SiO2, Al2O3, Na2O, K2O, and other oxides) | ||||

| Voco Grandio | VOCO GmbH, Cuxhaven, Germany | Organic part: methacrylates | 1925249 | |

| Inorganic part: 86 wt% filler | ||||

| Brilliant Crios | COLTENE, Altstätten, Switzerland | Organic part: cross-linked methacrylates | I24143 | |

| Inorganic part: 70.7 wt% barium glass and amorphous silica | ||||

| Dual-cured resin luting cement | Bifix SE | VOCO GmbH, Cuxhaven, Germany | Base: UDMA, GDMA, catalysts, initiators. | 1924379 |

| Catalyst: GDMA, acidic adhesive monomer, UDMA, Bis-GMA, Hydroxypropyl methacrylate, benzoyl peroxide | ||||

| Silane coupling agent | Ultradent Silane | Ultradent Products, South Jordan, UT, USA | Methacryloxypropyltrimethoxy silane < 10%, isopropyl alcohol < 95% | BJ5XL |

Al2O3, alumina; Bis-EMA, ethoxylated bisphenol dimethacrylate; bis-GMA, bisphenol-A-glycidyl methacrylate; Bis-MEPP, 2,2-Bis(4-methacryloxypolyethoxyphenyl) propane; DMA, dimethacrylate; GDMA, glycerol dimethacrylate; K2O, potassium oxide; Na2O, sodium oxide; SiO2, silica; TEGDMA, triethylene glycol dimethacrylate; UDMA, urethane dimethacrylate

Fig. 1. Schematic setup of the experiment.

From each RMC block, 32 specimens (in total 160) were cut into slices (12 × 14 × 1.0 mm) by using a low-speed (150 rpm) diamond saw (Microcut 201, Metkon Instruments Ltd, Bursa, Turkey) under water cooling. Subsequently, the specimens were fixed with a cyanoacrylate luting cement (Zapit, Dental Ventures of America, Corona, CA, USA) onto auto-polymerized acrylic resin cylinders (Ortho-jet, Lang Dental, Wheeling, IL, USA).

The bonding surfaces of the specimens were ground with 600-grit silicon carbide paper under constant water flow with a 100 rpm/min polishing device (Gripo 2V, Metkon Instruments Ltd, Bursa, Turkey) for 15 seconds. All specimens were ultrasonically-cleaned (Biosonic Ultrasonic Cleaner UC1-110, Coltene Whaledent, Cuyahoga Falls, OH, USA) in distilled water for 24 hours, and dried with oil-free air to remove surface-waste. The bonding surfaces of the specimens were then subjected to one of the following MSC strategies:

· Group 1 (Control - C): Neither silane nor MSC was applied.

· Group 2 (S): Silane was applied for 60 seconds by using a disposable micro-tipped applicator. The surface was then air-dried.

· Group 3 (APA): The surfaces were roughened with 50 µm aluminum-oxide (Al2O3) particles (Korox 50, Bego, Bremen, Germany) from a distance of 10 mm for 20 seconds under 2 bar propulsion pressure (Rotaks-Dent, Istanbul, Turkey) by positioning nozzle perpendicular to the surface. The specimens were then cleaned in distilled water and air-dried.

· Group 4 (APA + S): After abrading the surface with the same procedure performed in Group 3, silane was applied as described in Group 2.

· Group 5 (LI2W): The surfaces were irradiated with Er,Cr:YSGG laser (Waterlase MD, Biolase, Irvine, CA, USA) on hard tissue mode with an MG6 sapphire tip by using a non-contact mode at an energy level of 2W, a repetition rate of 10 Hz, and 140 ms pulse duration with 55% water and 65% air for 20 sec.

· Group 6 (LI2W + S): After irradiating the surface with the same procedure performed in Group 5, silane was applied as described in Group 2.

· Group 7 (LI3W): The surfaces were irradiated by using Er, Cr: YSGG laser with the same parameters that were used in Group 5. However, the output power was increased to 3.0 W.

· Group 8 (LI3W + S): After irradiating the surface with the same procedure performed in Group 7, silane was applied as described in Group 2.

Following the above-mentioned MSC strategies, two polyvinyl microtubules with an inner diameter of 0.75 mm and thickness of 1.0 mm were fixed on the bonding surfaces with the aid of flowable composite resin (Clearfil Majesty Flow, Kuraray Noritake Dental Inc., Okayama, Japan). A dual-cured self-adhesive resin cement (Bifix SE, VOCO, Cuxhaven, Germany) was syringed into these polyvinyl microtubules and subsequently light-cured according to the manufacturers' instructions for 20 seconds by using a quartz-tungsten halogen light-curing unit (Hilux UltraPlus, Benlioglu Dental, Ankara, Turkey) in standard mode with an intensity setting of 800 mW/cm2. Accordingly, two resin microtubules were generated on each specimen (n=8 per subgroup). Polymerized specimens were kept in distilled water at 37℃ for 24 hours and then the polyvinyl microtubules were carefully removed with a sharp scalpel.

The test was conducted by using a universal testing machine (EZtest-500 N Shimadzu; Kyoto, Japan). A metal wire with a diameter of 0.2 mm was wrapped around the resin microtubules and a tensile force of 0.5 mm/min was applied until breaking/rupture occurred. Failure load was recorded in Newtons (N) and µSBS values were calculated in megapascals (MPa) by using the following equation:

| (Load at failure (N)) / (Surface area (mm2)) |

The bonding interfaces were scrutinized under a stereomicroscope (Leica S8 APO; Leica Microsystems GmbH, Germany) at ×40 magnification in order to determine the failure patterns of the specimens and categorized as 3 types: (1) adhesive failure at the RMC surface with no residues of resin cement; (2) cohesive failure in the inner portion of resin cement or RMC; (3) mixed failure consisting of both cohesive and adhesive failures (Fig. 2).

Fig. 2. Different failure patterns. (A) adhesive, (B) mixed failure, (C) cohesive failure.

The data were statistically analyzed using a software program (IBM SPSS Statistics v23, IBM Corp., Chicago, IL, USA). Conformity to normal distribution was done by using the Shapiro-Wilk test. Three-way analysis of variance (3-Way ANOVA) was used to test the influence of 3 variables (RMC material type, MSC strategy, and silane application) on the µSBS values. Tukey HSD test was used for multiple comparisons. The significance level was taken as P < .05.

RESULTS

In accordance with the results of 3-way ANOVA, µSBS values were significantly affected by all variables and their interaction terms (P < .05), except RMC material type × MSC strategy × silane application (P = .172) (Table 2). The mean µSBS values and standard deviations with Tukey post hoc comparisons are presented in Table 3.

Table 2. Three-way ANOVA results of µSBS values.

| Source | Type III sum of squares | Df | Mean square | F | P |

|---|---|---|---|---|---|

| Resin-matrix ceramic material type (A) | 434.068 | 4 | 108.517 | 7.776 | < .001 |

| Surface conditioning strategy (B) | 862.929 | 3 | 287.643 | 20.612 | < .001 |

| Silane application (C) | 325.043 | 1 | 325.043 | 23.292 | < .001 |

| A * B | 445.442 | 12 | 37.120 | 2.660 | .002 |

| A * C | 632.906 | 4 | 158.227 | 11.338 | < .001 |

| B * C | 195.645 | 3 | 65.215 | 4.673 | .003 |

| A * B * C | 231.999 | 12 | 19.333 | 1.385 | .172 |

Df, degree of freedom; F, variance analysis test statistics. P < .05 indicates a significant difference.

Table 3. Mean ± standard deviation of µSBS values (MPa) of CAD-CAM RMC materials treated with different surface conditioning strategies to resin luting cement.

| MSC strategy | Silane application | RMC Type | Total | ||||

|---|---|---|---|---|---|---|---|

| GC | LU | VE | VG | BC | |||

| Control | No | 13.93 ± 4.37 | 13.31 ± 3.97 | 11.40 ± 3.09 | 14.47 ± 4.25 | 14.32 ± 2.06 | 13.48 ± 3.64D |

| Yes | 13.54 ± 4.37 | 13.35 ± 3.01 | 11.92 ± 2.74 | 14.32 ± 3.73 | 13.72 ± 3.84 | 13.37 ± 3.49D | |

| Total | 13.74 ± 4.23CD | 13.33 ± 3.40CD | 11.66 ± 2.83D | 14.40 ± 3.87CD | 14.02 ± 3.00CD | 13.43 ± 3.55a | |

| APA | No | 17.98 ± 4.83 | 17.89 ± 4.05 | 14.10 ± 2.46 | 19.86 ± 3.11 | 18.88 ± 1.35 | 17.74 ± 3.77AB |

| Yes | 13.69 ± 3.45 | 16.11 ± 3.48 | 20.44 ± 3.65 | 19.27 ± 3.39 | 12.91 ± 3.18 | 16.48 ± 4.43BC | |

| Total | 15.84 ± 4.62BCD | 17.00 ± 3.76ABC | 17.27 ± 4.44ABC | 19.57 ± 3.16AB | 15.89 ± 3.88BCD | 17.11 ± 4.14b | |

| LI2W | No | 18.96 ± 4.22 | 21.82 ± 4.30 | 15.76 ± 5.23 | 17.43 ± 3.74 | 18.61 ± 4.69 | 18.51 ± 4.69AB |

| Yes | 12.83 ± 3.52 | 19.81 ± 3.66 | 18.08 ± 4.29 | 18.03 ± 2.76 | 12.14 ± 2.60 | 16.18 ± 4.51BC | |

| Total | 15.89 ± 4.91BCD | 20.82 ± 3.99A | 16.92 ± 4.77ABC | 17.73 ± 3.19ABC | 15.37 ± 4.96BCD | 17.35 ± 4.72b | |

| LI3W | No | 19.10 ± 4.12 | 18.96 ± 3.24 | 16.63 ± 5.43 | 23.86 ± 6.05 | 18.29 ± 2.09 | 19.37 ± 4.85A |

| Yes | 12.73 ± 2.25 | 14.88 ± 2.37 | 19.03 ± 3.42 | 17.79 ± 4.09 | 10.60 ± 3.94 | 15.01 ± 4.45CD | |

| Total | 15.92 ± 4.59BCD | 16.92 ± 3.46ABC | 17.83 ± 4.56ABC | 20.83 ± 5.89A | 14.44 ± 5.00CD | 17.19 ± 5.12b | |

| Total | No | 17.49 ± 4.69A | 17.99 ± 4.85A | 14.47 ± 4.53BCD | 18.90 ± 5.47A | 17.52 ± 3.30A | 17.28 ± 4.80 |

| Yes | 13.20 ± 3.34CD | 16.04 ± 3.87ABC | 17.37 ± 4.74AB | 17.36 ± 3.84AB | 12.34 ± 3.47D | 15.26 ± 4.38 | |

| Total | 15.34 ± 4.58ab | 17.02 ± 4.46bc | 15.92 ± 4.82ab | 18.13 ± 4.75c | 14.93 ± 4.25a | 16.27 ± 4.70b | |

a–c: No difference between the same superscript lowercase letter, A–D: No difference between the same superscript uppercase letter

SC, surface conditioning; RMC, resin-matrix ceramic; GC, GC Cerasmart; LU, Lava Ultimate; VE, Vita Enamic; VG, Voco Grandio; BC, Brilliant Crios; APA, air-borne particle abrasion; LI2W, laser irradiation with 2.0 W power; LI3W, laser irradiation with 3.0 W power

The RMC material type had a statistically significant effect on µSBS values (P < .001). The highest and lowest mean µSBS values were obtained at VG (18.13 ± 4.75) and BC (14.93 ± 4.25). Except for the differences between the mean µSBS values of GC-VG, LU-BC, VE-VG, and VG-BC, the comparisons among restorative materials were detected as statistically insignificant (P > .05). The MSC strategy significantly influenced µSBS values (P < .001). The highest and lowest mean µSBS values were observed at LI2W (17.35 ± 4.72) and C (13.43 ± 3.55). The surface-conditioned groups showed significantly higher µSBS values than the C group (P < .05). No statistically significant differences among the SC groups were detected (P > .05). The silanization also significantly affected µSBS values (P < .001). The highest and lowest mean µSBS values were obtained at silane-free (17.28 ± 4.80) and silane-applied (15.26 ± 4.38) groups.

Considering RMC material type and MSC strategy interaction, the highest and lowest mean µSBS values were exhibited by VG conditioned with LI3W (20.83 ± 5.89) and by unconditioned VE (11.66 ± 2.83). While comparing control and conditioned groups of RMCs, all MSC strategies in VE, APA and LI3W in VG, and only LI2W in LU were found to be significantly higher than their control groups (P < .05). However, no significant differences were observed in all other groups (P > .05). The differences between the SC groups in all RMCs did not show significance (P > .05). The difference among RMCs in the C and APA groups was also statistically insignificant (P > .05). The differences only between GC-LU and LU-BC materials in the LI2W group and the differences only between GC-VG and VG-BC materials in the LI3W group were significant (P < .05).

Considering RMC material type and silanization interaction, the highest and lowest mean µSBS values were found at silane-free VG (18.90 ± 5.47) and silane-applied BC (12.34 ± 3.47). The µSBS values of silane-applied materials except VE were lower. However, the differences between silane-applied and silane-free groups showed statistical significance only for GC and BC (P < .05). Among the silane-free restorative materials, the VE group exhibited a significantly lower µSBS value compared to other RMCs (P < .05), and no significant difference was found among the other 4 RMCs (P > .05). While silane-applied restorative materials were compared, differences between GC-VE, GC-VG, LU-BC, VE-BC, and VG-BC groups were statistically significant (P < .05).

Considering MSC strategy and silanization interaction, the highest and lowest mean µSBS values were detected at silane-free LI3W (19.37 ± 4.85) and silane-applied C (13.37 ± 3.49) groups. The µSBS values of the surface-conditioned specimens were higher in both the silane-applied and silane-free groups compared to the C group. In silane-free groups; while a significant difference was observed among each MSC strategy and the control group (P < .05), there was no significant difference between the MSC strategies themselves (P > .05). In silane-applied groups, while APA and LI2W differed significantly from the C group (P < .05), there was no significant difference between LI3W and the C group (P > .05). Again, there was no significant difference between MSC strategies.

Considering RMC material type, MSC strategy, and silanization interaction, silane-free VG conditioned with LI3W (23.86 ± 6.05) and silane-applied BC conditioned with LI3W (10.60 ± 3.94) indicated the highest and lowest mean µSBS values, respectively.

The failure patterns of RMC specimens after SCM and silane application are presented in Table 4.

Table 4. Failure patterns of RMC bloks subjected to different MSC stratiegies and silane application.

| MSC strategy | Silane application | RMC type | Failure patterns | ||

|---|---|---|---|---|---|

| Adhesive | Cohesive | Mixed | |||

| Control | No | GC | 7 | - | 1 |

| LU | 8 | - | - | ||

| VE | 8 | - | - | ||

| VG | 6 | - | 2 | ||

| BG | 7 | - | 1 | ||

| Yes | GC | 8 | - | - | |

| LU | 8 | - | - | ||

| VE | 8 | - | - | ||

| VG | 7 | - | 1 | ||

| BG | 7 | - | 1 | ||

| APA | No | GC | 6 | - | 2 |

| LU | 6 | - | 2 | ||

| VE | 7 | - | 1 | ||

| VG | 5 | 1 | 2 | ||

| BG | 6 | - | 2 | ||

| Yes | GC | 7 | - | 1 | |

| LU | 7 | - | 1 | ||

| VE | 4 | 2 | 2 | ||

| VG | 6 | 1 | 1 | ||

| BG | 8 | - | - | ||

| LI 2W | No | GC | 5 | 1 | 2 |

| LU | 4 | 2 | 2 | ||

| VE | 7 | - | 1 | ||

| VG | 6 | - | 2 | ||

| BG | 6 | 1 | 1 | ||

| Yes | GC | 8 | - | - | |

| LU | 5 | 1 | 2 | ||

| VE | 6 | 1 | 1 | ||

| VG | 6 | 1 | 1 | ||

| BG | 8 | - | - | ||

| LI 3W | No | GC | 5 | 1 | 2 |

| LU | 5 | - | 3 | ||

| VE | 6 | - | 2 | ||

| VG | 4 | 2 | 2 | ||

| BG | 6 | - | 2 | ||

| Yes | GC | 8 | - | - | |

| LU | 7 | - | 1 | ||

| VE | 5 | 1 | 2 | ||

| VG | 6 | - | 2 | ||

| BG | 8 | - | - | ||

DISCUSSION

Since reliable bonding is essential for the long-term clinical success of indirect restorations,4,5,17 this comparative in-vitro study evaluated the influences of different MSC strategies and the coupling agent implementation on the adhesive features of dual-cured resin cement to recently introduced different RMCs. The results of 3-way ANOVA proved that RMC material type, MSC strategy, and silane implementation had significant effects on µSBS values. Therefore, the null hypothesis was rejected.

Various surface conditioning strategies are recommended to create micro-porosities (transformed zone) on the bonding surface of the ceramics for better infiltration of the luting cement.9,17 Supportively, Şişmanoğlu et al.39 and Çelik et al.40 reported favorable outcomes for the RMCs conditioned with different strategies. This is in accordance with the results of the current study as all surface-conditioned silane-free specimens demonstrated significantly higher µSBS values. Conversely, Barutcigil et al.1 reported that the SC-strategies (tribo-chemical silica coating, APA, 10% hydrofluoric acid etching, universal adhesive, and LI2W) had insignificantly increased the bond strength, except for universal adhesive group.

For GC and VE, the highest increase was observed in LI3W followed by LI2W, and APA. This finding may be related to the transformed zone formed on the bonding surface after conditioning. For these RMCs, the depth of this zone might be much greater in LI. Moreover, the increased power output creates a deeper transformed zone.2 Even so, it cannot be deduced that the relationship between power-output and bond strength is directly proportional as the irradiated material type is another dependent-variable.2,41 This also provides consistency with the current study: (i) while comparing LI2W and LI3W RMCs, a decline in µSBS values was detected only in LU and BC. Gökçe et al.42 associated inferior bond strength values with high power settings and mentioned from a heat-damaged layer. The bonding behavior of LU and BC can be attributed to this layer which might be poorly attached to the infra-layers; (ii) while comparing APA and LI2W conditioned VG groups, a decline in µSBS values was also detected. However, the µSBS values increased in VG conditioned with LI3W. From this perspective, it can be understood that LI2W is not strong enough to provide sufficient contribution for surface activation in VG.

LU in LI2W laser and VG in LI3W laser exhibited significantly higher µSBS values than other RMCs. This bonding behavior of LU can be attributed to a number of factors: First, it contains ZrO2 in high proportion.37 In accordance with Vickers Hardness Scale, Al2O3 presents superior hardness (2000) than that of ZrO2 (1200). Accordingly, during abrasion, harder Al2O3 micro-abrasive particles become more effective on the intaglio surface and successfully form an active surface (deeper transformed zone) for strong adhesion. Second, LU has manifold chemicals (Bis GMA, UDMA, Bis-EMA, and TEGDMA) in its organic part.31,37 Different chemicals offer different hardness and roughness at different levels. This may create a uniformly activated surface for adhesion. Third, LU has a lower micro-hardness than VE and VG.43,44 Thereby, it can be roughened easily with LI2W and this conditioning strategy can be strongly recommended to the clinicians. However, since LI3W detrimentally influences the inorganic structure, lower µSBS values than those of LI2W were found. Higher µSBS values of VG may be correlated with its micro-chemical structure as it contains high amount of nanohybrid fillers (86 wt%).43

In silane-applied groups, all MSC strategies caused less increase (APA > LI2W > LI3W) in µSBS values. In the LI process, inorganic content is removed from the surface of the ceramic.2,11 This situation may weaken the connection of silane with ceramic. The highest increase was seen in APA. In this process, Al2O3 particles with a diameter of 50 µm were sprayed towards the surface. Only chemicals with less hardness than the hardness of the abrasive agent were eliminated from the ceramic surface. As with the LI, the whole inorganic part was not affected.

The specimens in Group 4 exhibited lower µSBS values. This can be attributed to the nature of APA. During APA, some of the Al2O3 particles sprayed remain embedded in the ceramic surface. Also a layer coated with Al2O3 may form on the surface. Increasing abrasion pressure also increases the amount of Al2O3. After the silane application, unstable =AL-O-Si ≡ bonds are formed, which in turn negatively affects the µSBS values.22

Silane application only increased the values of the VE and can be linked to the robust microstructural geometry of polymer-infiltrated-ceramic network:33 First, this inorganic part (86 wt%) consists of feldspar glass-ceramic reinforced with Al2O3.37 It microstructurally differs from other RMCs including dispersed-fillers.28 Second, the silane content of this RMC system may account for increasing the bond strength.17 Third, 58 – 63% of the inorganic structure is SiO2. The amorphous ceramic structure allows selective dissolution when exposed to MSC strategies.17 It is thought that this may positively affect the silane-substrate connection.

Silane application mostly decreased the values of GC and BC groups because the ratio of the inorganic filler in these materials (GC: 71 wt% and BC: 70.7 wt%) is relatively lower than others (LU: 80 wt%, VE: 86 wt%, VU: 86 wt%).33 In other words, the polymeric structure is more. Also, both groups showed a similar pattern of decline. This situation was associated with the presence of similar inorganic content (silica and barium glass). The silane application generally lowered the µSBS. The organo-functional group of the silane normally links with the organic resin monomer as mentioned above.22,23 However, RMCs have both organic and inorganic parts. Thus, the organo-functional group of the silane has to be shared between the resin cement and RMC. Since it was previously occupied by RMC, the number of C-C connections between the resin cement is reduced. A much greater decline in GC and BC is associated with this. The polymeric phases present approximately similar proportions (30%) in both materials.

The results of this study confirm that the RMC material type had a significant influence on bond strength. However, this does not provide consistency with the results of a study by Çelik et al.40 reporting that RMC material type did not significantly cause alterations in bond strength values. They emphasized that only MSC strategy can become influential on bond strength.

For the assessment of bond strength, the micro-shear (µSBS), the micro-tensile (µTBS),1 and 4-point flexural29 tests are available. Although µTBS test permits a more homogeneous and uniform distribution of stress during loading; µSBS test is more common as: (i) it is easy and rapid; (ii) specimen preparation stage involving cutting sticks that have small bonded areas in µTBS test is very difficult.1 Therefore, the µSBS test was preferred in this study.

In a number of studies,45,46 cohesive and mixed failures at higher bond strength values and adhesive failures at lower bond strength values were reported. This provides consistency with the results of the current study.

The current study has several limitations. The longpulsed laser was used. However, ultra-short pulsed femtosecond lasers limit temperature distribution, reduce energy loss on the surface, and thereby minimize thermal destruction. Surface topographies of the conditioned-specimens were not examined. Only one size of Al2O3 particles for APA protocol was used. For investigating surface topographies after conditioning, a profilometer and scanning electron microscopy were not used. Further studies need to be performed with thermal aging for better understanding the hydrolytic stability.

CONCLUSION

Within the limitations of the present study, although MSC strategy is dependent on RMC material type and each RMC can require a dedicated way of conditioning, all micromechanical surface conditioning strategies enhanced the micro-shear bond strength values of all resin-matrix ceramics to dual-cured resin cement.

Silane application adversely affected the bond strength of dispersed filler resin-matrix ceramics. However, silane application can improve the bonding efficiency of resin-matrix ceramic with polymer infiltrated ceramic network.

Footnotes

The authors are very grateful to Voco GmbH Company for material support.

References

- 1.Barutcigil K, Barutcigil Ç, Kul E, Özarslan MM, Buyukkaplan US. Effect of Different Surface Treatments on Bond Strength of Resin Cement to a CAD/CAM Restorative Material. J Prosthodont. 2019;28:71–78. doi: 10.1111/jopr.12574. [DOI] [PubMed] [Google Scholar]

- 2.Cengiz-Yanardag E, Kurtulmus Yilmaz S, Karakaya I, Ongun S. effect of different surface treatment methods on micro-shear bond strength of CAD-CAM restorative materials to resin cement. J Adhes Sci Technol. 2019;33:110–123. [Google Scholar]

- 3.Conejo J, Ozer F, Mante F, Atria PJ, Blatz MB. Effect of surface treatment and cleaning on the bond strength to polymer-infiltrated ceramic network CAD-CAM material. J Prosthet Dent. 2020 doi: 10.1016/j.prosdent.2020.08.016. [DOI] [PubMed] [Google Scholar]

- 4.Ghallab O, Wahsh M, Kamel M. Assessment of Er, Cr: YSGG laser surface treatment and self-adhesive resin cements formulae on microtensile bond strength to various CAD/CAM ceramic esthetic. Egypt Dent J. 2018;64:1459–1472. [Google Scholar]

- 5.Harorli OT, Barutcugil C, Kirmali O, Kapdan A. Shear bond strength of a self-etched resin cement to an indirect composite: effect of different surface treatments. Niger J Clin Pract. 2015;18:405–410. doi: 10.4103/1119-3077.151783. [DOI] [PubMed] [Google Scholar]

- 6.Helbling F, Özcan M. Adhesion of resin cement to contemporary hybrid ceramic and polymeric CAD/CAM materials: effect of conditioning methods and ageing. J Adhes Sci Technol. 2019;33:886–902. [Google Scholar]

- 7.Alp G, Subaşı MG, Johnston WM, Yilmaz B. Effect of different resin cements and surface treatments on the shear bond strength of ceramic-glass polymer materials. J Prosthet Dent. 2018;120:454–461. doi: 10.1016/j.prosdent.2017.12.016. [DOI] [PubMed] [Google Scholar]

- 8.Bellan MC, Cunha PFJSD, Tavares JG, Spohr AM, Mota EG. Microtensile bond strength of CAD/CAM materials to dentin under different adhesive strategies. Braz Oral Res. 2017;31:e109. doi: 10.1590/1807-3107BOR-2017.vol31.0109. [DOI] [PubMed] [Google Scholar]

- 9.Ghorab S, Farahat D. Influence of sandblasting parameters and luting materials on microshear bond strength to a CAD/CAM hybrid ceramic material. Egypt Dent J. 2020;66:1637–1648. [Google Scholar]

- 10.Eldafrawy M, Greimers L, Bekaert S, Gailly P, Lenaerts C, Nguyen JF, Sadoun M, Mainjot A. an interfacial fracture toughness study. Dent Mater. 2019;35:1279–1290. doi: 10.1016/j.dental.2019.05.019. [DOI] [PubMed] [Google Scholar]

- 11.Demirtag Z, Culhaoglu AK. Surface roughness of ceramic-resin composites after femtosecond laser irradiation, sandblasting or acid etching and their bond strength with and without silanization to a resin cement. Oper Dent. 2019;44:156–167. doi: 10.2341/17-391-L. [DOI] [PubMed] [Google Scholar]

- 12.Lise DP, Van Ende A, De Munck J, Vieira L, Baratieri LN, Van Meerbeek B. Microtensile bond strength of composite cement to novel CAD/CAM materials as a function of surface treatment and aging. Oper Dent. 2017;42:73–81. doi: 10.2341/15-263-L. [DOI] [PubMed] [Google Scholar]

- 13.Marshall SJ, Bayne SC, Baier R, Tomsia AP, Marshall GW. A review of adhesion science. Dent Mater. 2010;26:e11–e16. doi: 10.1016/j.dental.2009.11.157. [DOI] [PubMed] [Google Scholar]

- 14.Tzanakakis EG, Tzoutzas IG, Koidis PT. Is there a potential for durable adhesion to zirconia restorations? a systematic review. J Prosthet Dent. 2016;115:9–19. doi: 10.1016/j.prosdent.2015.09.008. [DOI] [PubMed] [Google Scholar]

- 15.Kurtulmus-Yilmaz S, Cengiz E, Ongun S, Karakaya I. The effect of surface treatments on the mechanical and optical behaviors of CAD/CAM restorative materials. J Prosthodont. 2019;28:e496–e503. doi: 10.1111/jopr.12749. [DOI] [PubMed] [Google Scholar]

- 16.Oz FD, Canatan S, Bolay S. Effects of surface treatments on the bond strength of composite resin to hybrid computer-assisted design/manufacturing blocks. J Adhes Sci Technol. 2019;33:986–1000. [Google Scholar]

- 17.Campos F, Almeida CS, Rippe MP, de Melo RM, Valandro LF, Bottino MA. Resin bonding to a hybrid ceramic: effects of surface treatments and aging. Oper Dent. 2016;41:171–178. doi: 10.2341/15-057-L. [DOI] [PubMed] [Google Scholar]

- 18.Kim JE, Kim JH, Shim JS, Roh BD, Shin Y. Effect of air-particle pressures on the surface topography and bond strengths of resin cement to the hybrid ceramics. Dent Mater J. 2017;36:454–460. doi: 10.4012/dmj.2016-293. [DOI] [PubMed] [Google Scholar]

- 19.Sağirkaya E, Atay A. Effects of different surface treatments on the bond strength of CAD/CAM resin nano ceramic or ceromer to resin cement. Cumhur Dent J. 2019;22:226–234. [Google Scholar]

- 20.Şişmanoğlu S, Gürcan AT, Yıldırım-Bilmez Z, Turunç-Oğuzman R, Gümüştaş B. Effect of surface treatments and universal adhesive application on the microshear bond strength of CAD/CAM materials. J Adv Prosthodont. 2020;12:22–32. doi: 10.4047/jap.2020.12.1.22. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Emsermann I, Eggmann F, Krastl G, Weiger R, Amato J. Influence of pretreatment methods on the adhesion of composite and polymer infiltrated ceramic CAD-CAM blocks. J Adhes Dent. 2019;21:433–443. doi: 10.3290/j.jad.a43179. [DOI] [PubMed] [Google Scholar]

- 22.Lung CY, Matinlinna JP. Aspects of silane coupling agents and surface conditioning in dentistry: an overview. Dent Mater. 2012;28:467–477. doi: 10.1016/j.dental.2012.02.009. [DOI] [PubMed] [Google Scholar]

- 23.Zakir M, Ashraf U, Tian T, Han A, Qiao W, Jin X, Zhang M, Tsoi JKH, Matinlinna JP. The role of silane coupling agents and universal primers in durable adhesion to dental restorative materials-a review. Curr Oral Heal Reports. 2016;3:244–253. [Google Scholar]

- 24.Tekçe N, Tuncer S, Demirci M, Kara D, Baydemir C. Microtensile bond strength of CAD/CAM resin blocks to dual-cure adhesive cement: The effect of different sandblasting procedures. J Prosthodont. 2019;28:e485–e490. doi: 10.1111/jopr.12737. [DOI] [PubMed] [Google Scholar]

- 25.Awad MM, Albedaiwi L, Almahdy A, Khan R, Silikas N, Hatamleh MM, Alkhtani FM, Alrahlah A. Effect of universal adhesives on microtensile bond strength to hybrid ceramic. BMC Oral Health. 2019;19:178. doi: 10.1186/s12903-019-0865-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.Rodrigues C, Guilardi LF, Follak AC, Jacques LB, May LG. Effect of an MDP-containing ceramic primer application on adhesion to a ZLS ceramic with or without prior acid etching. J Adhes Sci Technol. 2020 doi: 10.1080/01694243.2020.1855917. [DOI] [Google Scholar]

- 27.Albero A, Pascual A, Camps I, Grau-Benitez M. Comparative characterization of a novel CAD-CAM polymer-infiltrated-ceramic-network. J Clin Exp Dent. 2015;7:e495–e500. doi: 10.4317/jced.52521. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 28.Coldea A, Swain MV, Thiel N. Mechanical properties of polymer-infiltrated-ceramic-network materials. Dent Mater. 2013;29:419–426. doi: 10.1016/j.dental.2013.01.002. [DOI] [PubMed] [Google Scholar]

- 29.Kömürcüoğlu MB, Sağrkaya E, Tulga A. Influence of different surface treatments on bond strength of novel CAD/CAM restorative materials to resin cement. J Adv Prosthodont. 2017;9:439–446. doi: 10.4047/jap.2017.9.6.439. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 30.Spitznagel FA, Boldt J, Gierthmuehlen PC. CAD/CAM ceramic restorative materials for natural teeth. J Dent Res. 2018;97:1082–1091. doi: 10.1177/0022034518779759. [DOI] [PubMed] [Google Scholar]

- 31.Bajraktarova-Valjakova E, Korunoska-Stevkovska V, Kapusevska B, Gigovski N, Bajraktarova-Misevska C, Grozdanov A. Contemporary dental ceramic materials, a review: chemical composition, physical and mechanical properties, indications for use. Open Access Maced J Med Sci. 2018;6:1742–1755. doi: 10.3889/oamjms.2018.378. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 32.Aboushelib MN, Elsafi MH. Survival of resin infiltrated ceramics under influence of fatigue. Dent Mater. 2016;32:529–534. doi: 10.1016/j.dental.2015.12.001. [DOI] [PubMed] [Google Scholar]

- 33.Alamoush RA, Silikas N, Salim NA, Al-Nasrawi S, Satterthwaite JD. Effect of the composition of CAD/CAM composite blocks on mechanical properties. Biomed Res Int. 2018:4893143. doi: 10.1155/2018/4893143. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 34.Kassem AS, Atta O, El-Mowafy O. Fatigue resistance and microleakage of CAD/CAM ceramic and composite molar crowns. J Prosthodont. 2012;21:28–32. doi: 10.1111/j.1532-849X.2011.00773.x. [DOI] [PubMed] [Google Scholar]

- 35.Zandparsa R. Digital imaging and fabrication. Dent Clin North Am. 2014;58:135–158. doi: 10.1016/j.cden.2013.09.012. [DOI] [PubMed] [Google Scholar]

- 36.Magne P, Schlichting LH, Paranhos MP. Risk of onlay fracture during pre-cementation functional occlusal tapping. Dent Mater. 2011;27:942–947. doi: 10.1016/j.dental.2011.05.011. [DOI] [PubMed] [Google Scholar]

- 37.Duarte S, Sartori N, Phark JH. Ceramic-reinforced polymers: CAD/CAM hybrid restorative materials. Curr Oral Health Rep. 2016;3:198–202. [Google Scholar]

- 38.Said AM, Zohdy MM, Morsy TS. The effect of aging and surface treatments on micro-shear bond strength of resin nano-ceramic material using two resin cements. J Dent Oral Sci. 2020;2:1–4. [Google Scholar]

- 39.Şişmanoğlu S, Turunç-Oğuzman R. Microshear bond strength of contemporary self-adhesive resin cements to CAD/CAM restorative materials: effect of surface treatment and aging. J Adhes Sci Technol. 2020;34:2484–2498. [Google Scholar]

- 40.Çelik E, Şahin SC, Dede DÖ. Effect of surface treatments on the bond strength of indirect resin composite to resin matrix ceramics. J Adv Prosthodont. 2019;11:223–231. doi: 10.4047/jap.2019.11.4.223. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 41.Harorli OT, Barutcugil C, Kirmali O, Kapdan A. Shear bond strength of a self-etched resin cement to an indirect composite: effect of different surface treatments. Niger J Clin Pract. 2015;18:405–410. doi: 10.4103/1119-3077.151783. [DOI] [PubMed] [Google Scholar]

- 42.Gökçe B, Ozpinar B, Dündar M, Cömlekoglu E, Sen BH, Güngör MA. Bond strengths of all-ceramics: acid vs laser etching. Oper Dent. 2007;32:173–178. doi: 10.2341/06-52. [DOI] [PubMed] [Google Scholar]

- 43.Colombo M, Poggio C, Lasagna A, Chiesa M, Scribante A. Vickers micro-hardness of new restorative CAD/CAM dental materials: evaluation and comparison after exposure to acidic drink. Materials (Basel) 2019;12:1246. doi: 10.3390/ma12081246. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 44.Lawson NC, Bansal R, Burgess JO. Wear, strength, modulus and hardness of CAD/CAM restorative materials. Dent Mater. 2016;32:e275–e283. doi: 10.1016/j.dental.2016.08.222. [DOI] [PubMed] [Google Scholar]

- 45.Peumans M, Valjakova EB, De Munck J, Mishevska CB, Van Meerbeek B. Bonding effectiveness of luting composites to different CAD/CAM materials. J Adhes Dent. 2016;18:289–302. doi: 10.3290/j.jad.a36155. [DOI] [PubMed] [Google Scholar]

- 46.Murillo-Gómez F, De Goes MF. Bonding effectiveness of tooth-colored materials to resin cement provided by self-etching silane primer after short-and longterm storage. J Prosthet Dent. 2019;121:713.e1–713.e8. doi: 10.1016/j.prosdent.2018.12.018. [DOI] [PubMed] [Google Scholar]