Abstract

The era of rapid industrialization succeeded by a shift in organizational focus on research and technology development which has fueled many industries along with the dairy industry to grow at an exponential rate. The dairy industry has achieved remarkable growth in the last decade in India. Waste produced by dairy industry consists of a high organic load thus cannot be discharged untreated. Even though treatment and management of waste are well documented, but the main problem is concerned with sludge produced after treatment. There is a gap in the application of various methods for effective treatment of the waste, hence there is a need for technology-oriented research in this area because of a paradigm shift in perspectives towards sustainable management of waste to recover value added products including energy as energy demand is also rising. Sludge which is generally land spread can also be used for energy generation. This paper discusses the environmental effects of waste generated due to dairy industrial activities; various methods used for the advanced treatment of dairy waste. This review article aims to present and discuss the state-of-art information for recovery of value-added products (single cell protein, biofertilizers, biopolymers and biosurfactants) from dairy waste with emphasis on integration of technologies for environmental sustainability. This paper also includes challenges and future perspectives in this field.

Keywords: Dairy waste, Sustainable environment, Single cell protein, Biofertilizer, Biosurfactant, Biopolymer

Introduction

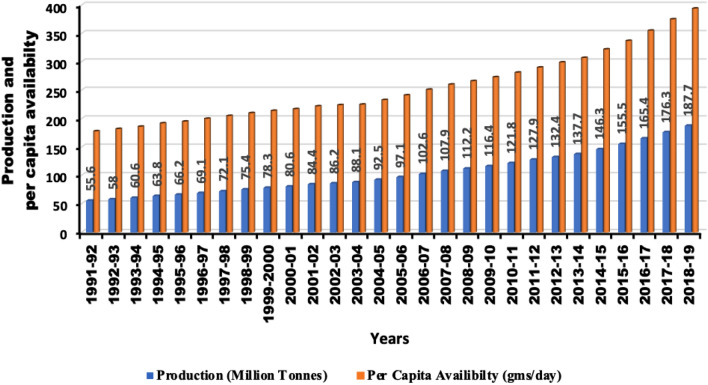

There is consistent and steep growth in India’s dairy sector in the last few decades and now India is one of the major milk-producing countries in the world. The report of the National Dairy Development Board (NDDB) shows that there is a consistent rise in production and demand for milk in the past decades (Fig. 1). This subsequently lead to the growth of dairy industry and there are large number of dairy plants spread in India [1].

Fig. 1.

Rise in production of milk.

Source: National Dairy Development Board (https://www.nddb.coop/information/stats/milkprodindia)

In India out of total 50% to 70% of milk processed is sold as plain or flavored milk and rest processed as cheese, butter, ice-cream, paneer, curd, ghee etc.

Due to increased growth of dairy industrial activities waste generation increases, which needs to be managed properly. Management of the waste is a burning issue globally which raises concept of waste management. With increased industrial growth and urbanization treatment and disposal poses more challenges due to huge money is required for this. However, considering ‘waste’ as a ‘resource”, resource recovery from wastes has been gaining interest of researchers because it offers social and environment sustainability. Present researches are mainly focused on recovery of resources such as single cell protein, biofertilizers, energy and bio-products from dairy industry waste/ waste water [2–10].

This review paper aims to summarize state-of-art information for the recovery of value-added products from dairy waste. The paper emphasizes the integration of technologies for valorization of dairy industry waste. This paper incorporates bottlenecks and future perspectives in research for dairy industry waste management and thus would be used for opportunities in technological innovation in this area.

Dairy Industry Waste: Sources and Types

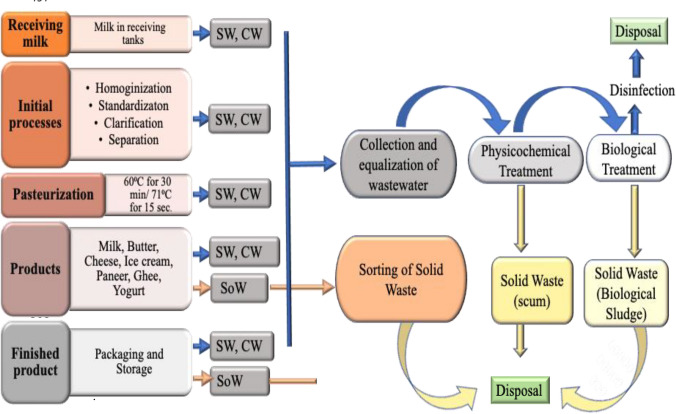

Various processes in dairy industry contribute to generation of wastewater i.e., from the place where the milk is received to process of production and packaging of products (Fig. 2). The necessity of cleanliness in milk processing units generates waste containing cleaning agents like detergents. The loss of excess products due to leakage, overflow, and careless control also add to waste production. Thus, sludge produced comprises the waste produced by processing, cleaning, and sanitary operations along with the waste generated by physicochemical and biological treatment processes.

Fig. 2.

Various processes generating dairy wastewater

Types of Dairy Waste

Dairy waste can be broadly classified into two types (a) wastewater i.e. effluent (b) solid waste [1].

Effluent

The dairy industry produces 1–3 L of wastewater for every liter of milk produced. The wastewater contains high organic load due to presence of carbohydrates, protein, and fats that come from milk [11]. The characteristics of the wastewater vary with the type of product being processed in the dairy plant [12]. The high organic load, of dairy wastewater requires attention for its treatment as it can lead to rapid depletion of oxygen wherever discharged. The government of India has defined strict regulations for the discharge of effluents to protect the environment (Biological Oxygen Demand5:100 mg/L, Total Suspended Solid 150 mg/Land oil grease 10 mg/L) [13].

Solid Waste

A full-fledged dairy that processes nearly 5 lakh liters of milk daily produces around 200–350 kg of sludge[1]. Generally, sludge is further classified into two broad categories a) chemical sludge, and b) biological sludge. The sludge contains degradable organic matter and non-biodegradable solid matter [14]. The amount of sludge produced increases with increase in wastewater. It becomes a challenge to handle and dispose of the sludge produced as it accounts for 60% of the total cost of treatment plant operation [15].

Characteristics of the Dairy Waste

The characteristics and quantity of wastewater produced by a dairy plant differ in volume, concentration, and composition. The variation is based on the type of product processed, operating methods, design of the plant, type of wastewater treatment applied, and the amount of water consumed [16]. The season also affects the composition of the wastewater [17]. Effluent is treated with ferric sulfate or aluminum chloride which adds up to the amount of sludge produced. Typical characteristics of sludge depend on the process used and vary with the type of treatment (aerobic or anaerobic) and chemical used in the physicochemical process [18]. The characteristic of wastewater reported by many researchers has been summarized in Table 1.

Table 1.

Characteristic of dairy industry wastewater

| S. no | pH | TDS (PPT) | SS (mg/L) | BOD (mg/L) | COD (mg/L) | References |

|---|---|---|---|---|---|---|

| 1 | 9.8 | 1.222 | – | 650 | 1448 | [18] |

| 2 | 6.8 ± 0.64 | 1.2 ± 0.25 | – | 320 ± 26.76 | 954 ± 86.18 | [16] |

| 3 | 6 ± 0.69 | 1.28 ± 0.25 | – | 355 ± 78.99 | 982 ± 67.57 | [16] |

| 4 | 4–12 | – | 250–2700 | 300–1400 | 650–3000 | [19] |

| 5 | 6.4 | 2.180 | 1260 + 60 | 1445 ± 30 | 4410 + 60 | [5] |

| 6 | 7–8 | 1.300 | 1200 | 1040 | 2100 | [20] |

| 7 | 7.4 | – | 1020 | 1710 | 2520 | [21] |

TDS Total dissolved solids, SS Suspended solids, BOD Biological oxygen demand, COD Chemical oxygen demand

Effects of Dairy Waste on the Environment and Lifeforms

The dairy industry waste adversely affects the quality of air, water, and soil [22]. When discharged in public sewers such wastewater causes complexity in secondary treatment like low settleability of sludge and other operations in the municipal sewage treatment. It can be because of sewage fungus, filamentous slime producing bacterial colonies [23].

The sludge produced by dairy industries is generally spread in the vicinity due to high transportation costs and thus leads to an accumulation of few substances in long term application. Therefore, there is a need to find alternative methods for its proper sludge utilization [24].

Current Treatment Technologies

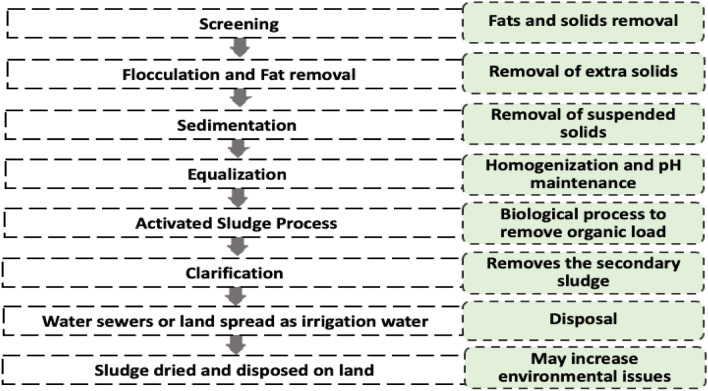

Treatment of dairy waste adopted in different countries differs according to the regulations and laws of the country. Various physical, chemical, and biological treatments have been reported. General treatment process adopted for dairy wastewater is shown in Fig. 3.

Fig. 3.

General treatment process for wastewater in dairy industry

Physicochemical Methods

Various treatments have been developed in different countries to treat dairy industry wastewater. The factors like capital cost, operating cost, need for treatment to make the wastewater in compliance with government regulations are considered while adopting a treatment process. The basic steps like screening, coagulation, dissolved air flotation, and adsorption have been reported [25, 26]. Various advanced processes have been adopted to treat wastewater which has been discussed and reported by researchers. The advanced methods are used to replace the energy-consuming conventional methods [27, 28]. The advantages and disadvantages of various physicochemical techniques are summarised in Table 2 [29].

Table 2.

Advantages and disadvantages of various physicochemical processes

| S. no | Physico-chemical method | Types | Advantage | Disadvantage |

|---|---|---|---|---|

| 1 | Membrane Filtration |

Nanofiltration (NF) Reverse osmosis Dialysis |

Non thermal Eco-friendly Easy recovery of water and other by-products |

Prone to membrane fouling Expensive cleaning and regeneration schemes may be necessary |

| 2 | Electrochemical |

Electrocoagulation Electro floatation |

Increases biodegradability Eliminates oil, grease and metals |

High capital cost and difficult to control |

| 3 | Adsorption |

Charcoal Clays Clay minerals, zeolites, and ores |

Ease of use | Lack of suitable adsorbent |

| 4 | Coagulation |

Ferrous sulfate Aluminium sulfate |

Hastens settling of the solid. Thus, detention of water is reduced | Produces large amount of sludge |

Biological Processes

Biological processes for the treatment of dairy waste are the most promising waste treatments [30]. Biological treatments are aerobic and anaerobic treatment technologies e.g. wetlands, trickling filters, Fluidized Bed Reactor (FBR), Up-flow Sludge Anaerobic Blanket (USAB), Completely Stirred Tank Reactor (CSTR), Moving Bed Biological Reactor (MBBR), Sequential Batch Reactors (SBR) and Activated sludge process (ASP) have been reported globally [11, 13, 31] and are discussed in this section.

Wetlands

Wetlands effectively uses vegetation and microbes of rhizosphere to remove organic load from wastewater. The main advantage of this technology is that it does not require full-time monitoring, low capital cost, less operative cost, and at the most it is ecofriendly [30]. The major drawback of this system is effluent cannot be discharged in sewer directly, instead can be used for irrigation. This system is considered as a zero discharge system [32].

Aerobic Treatments

Activated Sludge Process (ASP) The activated sludge process is one of the most preferred methods for reducing organic matter. The modified aerobic granular sludge is much more preferred than normal ASP as it possesses much more resistant to shocks, less toxicity and much more settleability of sludge. It is also highly efficient in recovery of biomass [33].

Sequencing Batch Reactor (SBR): Sequencing batch reactor is a series of tanks that operate to remove undesirable compounds. The tanks are filled at different times and function as a batch reactor. In such systems, process of aeration and sedimentation are performed instantaneously. The need for a clarifier is obviated in such a system as the process of equalization, aeration and sedimentation occurs in the same tank. Thus it becomes an economical choice as less investment is required and waste with higher solids can also be treated using it [27].

Rotating Biological Contactors (RBC) The RBCs are series of discs attached to a shaft. To achieve proper reduction a multiunit system of 3 to 6 sets of RBCs can be used. RBC has proved to be efficient as well as effective in three stage form. Aerobic filters cannot handle the high strength water as dairy wastewater. Due to high content of fat oil and grease (FOG) heavy biofilm can be formed, which leads to sloughing of biomass which eventually leads to less productivity [34].

Anaerobic Treatment

In comparison to the aerobic system, the anaerobic system does not require energy and thus is more economical. Production of methane from anaerobic digestion can be utilized as an energy source [35, 36]. Additionally, amount of sludge produced in such systems is less which is a beneficial aspect for disposal. It is efficient in destroying pathogens and sludge produced by this process is better in quality [37–39].The high biodegradability and moisture content are very useful in the process of anaerobic digestion to obtain sustainable bioenergy [40, 41].

Up-flow Anaerobic Sludge Blanket (UASB) It has been extensively used to treat dairy wastewater [11, 42]. The growth of microbial biomass is in suspended form. Flow of effluent in UASB is in an upward direction through sludge bed. Gas which is produced is separated by a separator and the leftover water without biomass is disposed of and sludge settles at the bottom [42].

Anaerobic Sequencing Batch Reactor (ASBR) ASBR operates in four stages: (i) feeding, (ii) reaction, (iii) settling and (iv) withdrawal after the accomplishment of treatment. Wastewaters can be treated using this reactor and it reduces the separate step of settling. The major limitation of this technique is that it does not work well when overloaded.

The aerobic and anaerobic treatments generate sludge. Sludge is generally uniform, practically having no odor, and contains a lot of organic matter and hence further processing of the sludge is required before disposal. Sludge is fed into the digester for further breakdown and stabilization. The dewatered sludge can be applied as a compost or landfill or it can be disposed of as land spread [27]. Land spreading can cause problems like accumulation of waste, eutrophication, and underground water contamination. Thus, it becomes important to find other options for treatment and disposal of dairy sludge [43].

Integration of Technologies

The conventional biological processes are not sufficient and suitable to treat wastewaters containing complex organic matter and inorganic matter due to limitations of microorganisms to metabolize it. The existing electrochemical process also posses’ drawbacks in terms of energy requirements. Bio-electrochemical systems (BES) are combination of biological and electrochemical process, treat the waste and simultaneously produces electricity, hydrogen, and other beneficial products and thus it plays a very important role in circular economy [44]. This is the system which can address two of the most important questions, i.e. “Power” and “Pollution”. Electrochemically active microbes, reduce organic matter at the anode resulting in transfer of electrons from anode to cathode. Output energy efficiency depends on number of electrons accumulated and transferred to the anode [45–48]. The types of BES are (i) Microbial Electrolysis Cell (MEC), (ii) Microbial Fuel Cells (MFC), (iii) Microbial Desalination Cell (MDC), (iv) Enzymatic Biofuel Cell (EBC), (v) Microbial Reverse-electrodialysis Cell (MRC), (vi) Microbial Solar Cells (MSC) and (vii) Microbial Electrosynthesis. The most advanced and widely studied BES are Microbial Fuel Cells [49].

Microbial Fuel cell (MFC) MFC is a type of BES in which microbes in the anode part of the cell produce electricity by oxidizing organic matter in the waste [47, 48, 50, 51]. In this process, microbes generate electrons and protons both. Electrons are transferred to the anode by bacteria. The protons produced should be removed from anode chamber through the proton exchange membrane to the cathode chamber where these protons combine with electrons and oxygen to produce water. Table 3 shows various integration of MFC with other waste treatment technologies.

Table 3.

Integration of MFC with other treatment processes

| S. no | Integrated systems | Benefits after system was integrated with MFC | References |

|---|---|---|---|

| 1 | Integrated modified Ludzack–Ettinger (MLE-MFC) | Sludge reduction (11%), Nitrate removal (31 ± 12%) | [52] |

| 2 | Membrane bioreactor (MBR-MFC) | Sludge reduction (6%), Nitrate removal (20 ± 12%) | [52] |

| 3 | Horizontal subsurface flow constructed wetland (HSSF-CW) | Overall efficiency was improved by 33% even in high organic loads | [53] |

Dairy Waste to Value-Added Products

Dairy waste is rich in organic matter and thus can be used as substrate for the production of various compounds. The products are summarized in Table 4. The compounds produced from the dairy waste described in Table 4, are very useful in the field of field of food, agriculture, petroleum, cosmetics, and pharmaceutical industries and for sustainable development [54–56].

Table 4.

Products produced from dairy waste

| S. no | Product | Microbe/biomolecules | Product yield using dairy waste | References |

|---|---|---|---|---|

| 1 | Biomass | Saccharomyces cereviesae | 0.32 g/L | [5] |

| 2 | Biopolymer | Xanthomonas spp | 35.3 g/L | [57] |

| 3 | Biosufactant (Sophorolipid) | Candida bombicana | 62 g/L | [58] |

| 4 | Bioplastic | Rhodopseudomonas rutilaI | 7.23 ± 0.08 g/L | [59] |

| 5 | Bioactive Peptide | Papain and pancreatic enzymes | 60 g BSA eq/L and to 1.7 g AA eq/L | [3] |

| 6 | Biohydrogen | landfill leachate sludge (LLS) | 113.2 ± 2.9 mmol H2/g COD | [60] |

BSA eq Bovine serum albumin equivalent, AA eq Amino acid equivalent, COD Chemical oxygen demand

Single Cell Protein (SCP) and Biofertilizer

Single-cell proteins (SCP) are dried bacteria, yeast, fungi, and algae. These are protein-rich and have advantages over the plant and animal proteins like the growth of these cells are not seasonal neither are affected by climate, thus they can be produced all-around the year [5]. Sludge generated from dairy industry was assessed for cultivation of Rhizobia in a study. Different concentrations of dairy sludge were used for cultivation of various Rhizobial strains [4].

Biopolymer and Biosurfactant

Biopolymer are natural polymers produced by living organisms. An exopolysaccharide Xanthan gum is synthesized by Xanthomonas spp. is a valuable industrial biopolymer. It has high viscosity in low concentration which is the attribute of its branched structure and elevated high molar mass and stability over a wide range of pH makes it a polymer of choice [57, 61, 62]

Biosurfactants are molecules having both hydrophilic and hydrophobic chemical groups in their structure and decrease the surface tension of liquids. Many microbes can be used to produce biosurfactants. Biosurfactants are used in field of food, agriculture, petroleum, cosmetics, and pharmaceutical industries [54–56].

Biofuel

Dairy industry waste, both wastewater and sludge like other wastes are a promising substrate for the production of Hydrogen (H2) [63–66] and Methane (CH4). In the search for alternate novel source for electric energy generation, dairy waste can be used efficiently in Microbial Fuel Cells (MFC) as substrate [13].

Bottlenecks and Perspectives

Sustainability is a big challenge for the developing countries like India. Thus, development of successful circular bioeconomy concept facilitates development of economic prosperity, environmental quality, and social equity for current and future generations [56]. Circular bioeconomy can be defined as summation of sustainable consumption of natural resources and their sustainable management. BES can be implemented in present waste treatment plants for solving problems of energy requirement and pollution. Still, there are many questions unanswered to implement it on large scale wastewater treatment plant related to cost of installation and operation, its low energy inputs, and efficiency in reducing COD. The operation of MFC is useful for short term analysis, but research should be directed towards long-term stability with waste generated from fields/plants [44, 67–71]. The recovery of value-added products from dairy waste, concerning techniques either independent or integrated, tailoring processes parameters is need of the hour and can be effectively used for production of bio-based products to reduce the hazards of the waste [72]. The use of consortia of microbes working in synergy is one of the broad and potential approaches. Thus, it can be very efficient in the treatment of dairy waste.

Opinion

Dairy waste poses high organic matter and a global concern as the amount of waste is increasing day by day and its proper disposal has become a pertinent issue due to strict rules of waste discharge and environmental protection. These wastes can be a substrate for large scale production of biomass, biopolymer and generating energy using integration of technologies. The integrated system like Bioelectric system (BES) and its further integration with other technologies can be beneficial to treat the waste and achieve “waste to resources” if dairy waste is appropriately utilised. In this context, concept of waste biorefinery employing recent developments in recovery of resources from dairy industry waste would be important aspect for sustainability.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- 1.Kavitha V, Geetha V, Jacqueline PJ. Production of biodiesel from dairy waste scum using eggshell waste. Int J Res Appl Sci Eng Technol. 2019;7:279–287. doi: 10.1016/j.psep.2019.03.021. [DOI] [Google Scholar]

- 2.Drisya CM, Manjunath NT. Dairy wastewater treatment and electricity generation using microbial fuel cell. Int Res J Eng Technol. 2017;4:1293–1296. [Google Scholar]

- 3.Monari S, Ferri M, Russo C, Prandi B, Tedeschi T, Bellucci P, Zambrini AV, Donati E, Tassoni A. Enzymatic production of bioactive peptides from scotta, an exhausted by-product of ricotta cheese processing. PLoS ONE. 2019;14:1–18. doi: 10.1371/journal.pone.0226834. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Singh AK, Singh G, Gautam D, Bedi MK. Optimization of dairy sludge for growth of Rhizobium cells. Biomed Res Int. 2013;2013:1–6. doi: 10.1155/2013/845264. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Suman G, Nupur M, Anuradha S, Pradeep B. Characterization of dairy waste and its utilisation as substrate for production of single cell protein. J Biotechnol Biochem. 2017;3:73–78. doi: 10.9790/264X-03047378. [DOI] [Google Scholar]

- 6.Raizada N, Sonakya V, Anand V, Kalia VC. Waste management and production of future fuels. J Sci Ind Res (India) 2002;6:184–207. [Google Scholar]

- 7.Kondaveeti S, Mohanakrishna G, Kumar A, Lai C, Lee JK, Kalia VC. Exploitation of citrus peel extract as a feedstock for power generation in microbial fuel cell (MFC) Indian J Microbiol. 2019;59:476–481. doi: 10.1007/s12088-019-00829-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Pugazhendhi A, Mathimani T, Varjani S, Rene ER, Kumar G, Kim SH, Ponnusamy V, Yoon JJ. Biobutanol: a promising liquid fuel for the future-recent updates and perspectives. Fuel. 2019;253:637–646. doi: 10.1016/j.fuel.2019.04.139. [DOI] [Google Scholar]

- 9.Khanal SK, Varjani S, Sze Ki Lin C, Awasthi MK. Waste-to-resources: opportunities and challenges. Bioresour Technol. 2020 doi: 10.1016/j.biortech.2020.123987. [DOI] [PubMed] [Google Scholar]

- 10.Rene ER, Ge J, Kumar G, Shingh RP, Varjani S. Resource recovery from wastewater, solid waste, and waste gas: engineering and management aspects. Environ Sci Pollut Res. 2020;27:17435–17437. doi: 10.1007/s11356-020-08802-4. [DOI] [PubMed] [Google Scholar]

- 11.Kushwaha JP, Srivastava VC, Mall ID. An overview of various technologies for the treatment of dairy wastewaters. Crit Rev Food Sci Nutr. 2011;51:442–452. doi: 10.1080/10408391003663879. [DOI] [PubMed] [Google Scholar]

- 12.Watkins M, Nash D. Dairy factory wastewaters, their use on land and possible environmental impacts—a mini review. Open Agric J. 2014;4:1–9. doi: 10.2174/1874331501004010001. [DOI] [Google Scholar]

- 13.Ahmad T, Aadil RM, Ahmed H, Rahman U, Soares BCV, Souza SLQ, Pimentel TC, Scudino H, Guimarães JT, Esmerino EA, Freitas MQ, Almada RB, Vendramel SMR, Silva MC, Cruz AG. Treatment and utilization of dairy industrial waste: a review. Trends Food Sci Technol. 2019;88:361–372. doi: 10.1016/j.tifs.2019.04.003. [DOI] [Google Scholar]

- 14.Kwapinska M, Horvat A, Liu Y, Leahy JJ. Pilot scale pyrolysis of activated sludge waste from milk processing factory. Waste Biomass Valor. 2019;11:2887–2903. doi: 10.1007/s12649-019-00596-y. [DOI] [Google Scholar]

- 15.Jayashree C, Janshi G, Yeom IT, Kumar SA, Banu JR. Effect of low temperature thermo-chemical pretreatment of dairy waste activated sludge on the performance of microbial fuel cell. Int J Electrochem Sci. 2014;9:5732–5742. [Google Scholar]

- 16.Lawrence W, Yung-Tse H, Nazih S. Physicochemical treatment processes. In: Wang LK, Hung YT, Shammas NK, editors. Handbook of environmental engineering. Humana Press; 2005. [Google Scholar]

- 17.Verma A, Singh A. Physico-chemical analysis of dairy industrial effluent. Int J Curr Microbiol Appl Sci. 2017;6:1769–1775. doi: 10.20546/ijcmas.2017.607.213. [DOI] [Google Scholar]

- 18.Ashekuzzaman SM, Forrestal P, Richards K, Fenton O. Dairy industry derived wastewater treatment sludge: generation, type and characterization of nutrients and metals for agricultural reuse. J Clean Prod. 2019;230:1266–1275. doi: 10.1016/j.jclepro.2019.05.025. [DOI] [Google Scholar]

- 19.Cecconet D, Molognoni D, Callegari A, Capodaglio AG. Agro-food industry wastewater treatment with microbial fuel cells: energetic recovery issues. Int J Hydrogen Energy. 2018;43(1):500–511. doi: 10.1016/j.ijhydene.2017.07.231. [DOI] [Google Scholar]

- 20.Khan MH, Hugar SC, Khatmode NP. Removal of dairy wastewater characteristic by using natural and chemical coagulant. Asian J Converg Technol. 2015;III:2–4. [Google Scholar]

- 21.Passeggi M, Lopez I, Borzaccani L. Integrated anaerobic treatment of dairy industrial wastewater and sludge. Water Sci Technol. 2009;59:501–507. doi: 10.2166/wst.2009.010. [DOI] [PubMed] [Google Scholar]

- 22.Chen GQ, Talebi S, Gras SL, Weeks M, Kentish SE. A review of salty waste stream management in the Australian dairy industry. J Environ Manag. 2018;224:406–413. doi: 10.1016/j.jenvman.2018.07.056. [DOI] [PubMed] [Google Scholar]

- 23.Shete B, Shinkar N (2013) Dairy industry wastewater sources, characteristics & its effects on environment. Int J Curr Eng Technol. http://inpressco.com/category/ijcet

- 24.Kwapinska M, Leahy JJ (2017) Pyrolysis—a way of recovering energy from wastewater sludge from milk processing factories. In: 5th International conference on sustainable solid waste management

- 25.Loloei M, Alidadi H, Nekonam G, Kor Y. Study of the coagulation process in wastewater treatment of dairy industries. Int J Env Health Eng. 2014;2:17–21. doi: 10.4103/2277-9183.132684. [DOI] [Google Scholar]

- 26.Sarkar B, Chakrabarti PP, Vijaykumar A, Kale V. Wastewater treatment in dairy industries—possibility of reuse. Desalination. 2006;195:141–152. doi: 10.1016/j.desal.2005.11.015. [DOI] [Google Scholar]

- 27.Birwal P, Desmukh G, Priyanka SPS. Advanced technologies for dairy effluent treatment. J Food Nutr Popul Health. 2017;1:1–5. [Google Scholar]

- 28.Shah AV, Varjani S, Srivastava VK, Bhatnagar A. Zero liquid discharge (ZLD) as sustainable technology—challenges and perspectives. Indian J Exp Biol. 2020;58:508–514. [Google Scholar]

- 29.Crini G, Lichtfouse E. Advantage an disadvantage of techniques used for wastewater treatment. Environ Chem Lett. 2019;17:145–155. doi: 10.1007/s10311-018-0785-9. [DOI] [Google Scholar]

- 30.Carvalho F, Prazeres AR, Rivas J. Cheese whey wastewater: characterization and treatment. Sci Total Environ. 2013;445–446:385–396. doi: 10.1016/j.scitotenv.2012.12.038. [DOI] [PubMed] [Google Scholar]

- 31.Jadeja NB, More RP, Purohit HJ, Kapley A (2014) Metagenomics analysis of oygenase from ativated sludge. Bioresour Technol 165:250–256. 10.1016/j.biortech.2014.02.045. Epub 2014 Feb 24. PMID: 24631150 [DOI] [PubMed]

- 32.Arvanitoyannis IS, Kassaveti A. Dairy waste management: treatment methods and potential uses of treated waste. In: Arvanitoyannis IS, editor. Waste management for the food industries. Elsevier Inc.; 2008. [Google Scholar]

- 33.Joshiba JG, Senthil Kumar P, Femina CC, Jayashree E, Racchana R, Sivanesan S. Critical review on biological treatment strategies of dairy wastewater. Desalin Water Treat. 2019;160:94–109. doi: 10.5004/dwt.2019.24194. [DOI] [Google Scholar]

- 34.Slavov AK. General characteristics and treatment possibilities of dairy wastewater—a review. Food Technol Biotechnol. 2017;55:14–28. doi: 10.17113/ftb.55.01.17.4520. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 35.Kalia VC. Joshi AP (1995) Conversion of waste biomass (pea-shells) into hydrogen and methane through anaerobic digestion. Bioresour Technol. 1995;53(2):165–168. doi: 10.1016/0960-8524(95)00077-R. [DOI] [Google Scholar]

- 36.Kalia VC, Purohit HJ. Microbial diversity and genomics in aid of bioenergy. J Ind Microbiol Biotechnol. 2008;35(5):403–419. doi: 10.1007/s10295-007-0300-y. [DOI] [PubMed] [Google Scholar]

- 37.Hung Y, Britz T, Van Schalkwyk C (2005) Treatment of dairy processing wastewaters. In: Wang LK, Hung YT, Lo HH, Yapijakis C (eds) Waste treatment in the food processing industry. CRC Press Taylor & Francis, Boca Raton, pp 1–28. 10.1201/9781420037128.ch1

- 38.Kalia VC, Sonakya V, Raizada N. Anaerobic digestion of banana stem waste. Bioresour Technol. 2000;73:191–193. doi: 10.1016/S0960-8524(99)00172-8. [DOI] [Google Scholar]

- 39.Kondaveeti S, Patel SKS, Pagolu R, Li J, Kalia VC, Choi MS, Lee J-K. Conversion of simulated biogas to electricity: sequential operation of methanotrophic reactor effluents in microbial fuel cell. Energy. 2019;189:116309. doi: 10.1016/j.energy.2019.116309. [DOI] [Google Scholar]

- 40.Gulhane M, Pandit P, Khardenavis A, Singh D, Purohit HJ. Biomethanation of vegetable market waste in an Anaerobic Baffled Reactor: effect of effluent recirculation and carbon mass balance analysis. Bioresour Technol. 2016;215:1–36. doi: 10.1016/j.biortech.2016.04.039. [DOI] [PubMed] [Google Scholar]

- 41.Patel SKS, Gupta RK, Kalia VC, Lee JK. Integrating anaerobic digestion of potato peels to methanol production by methanotrophs immobilized on banana leaves. Bioresour Technol. 2021;323:1–31. doi: 10.1016/j.biortech.2020.124550. [DOI] [PubMed] [Google Scholar]

- 42.Yirgu EAZ. Advanced technologies for the treatment of wastewaters from agro-processing industries and cogeneration of by-products: a case of slaughterhouse, dairy and beverage industries. Int J Environ Sci Technol. 2018;15(7):1581–1596. doi: 10.1007/s13762-017-1522-9. [DOI] [Google Scholar]

- 43.Ashekuzzaman SM, Leahy JJ, Kwapinska M, Richards K, Fenton O. Novel use of dairy processing sludge derived pyrogenic char (DPS-PC) to remove phosphorus in discharge effluents. Waste Biomass Valor. 2020;11:1453–1465. doi: 10.1007/s12649-019-00731-9. [DOI] [Google Scholar]

- 44.Jung S, Lee J, Park Y, Kwon EE. Bioelectrochemical systems for a circular bioeconomy. Bioresour Technol. 2020;300:122748. doi: 10.1016/j.biortech.2020.122748. [DOI] [PubMed] [Google Scholar]

- 45.Khan N, Danish KM, Khan Sultana, S, Khan MZ, Ahmad A (2017) Bioelectrochemical Systems for Transforming Waste to Energy Nishat. In: Oves DM, Khan MZ, Ismail IMI (eds) Modern age environmental problem and their remediation. Springer, Cham, pp 111–128. 10.1007/978-3-319-64501-8

- 46.Sambavi SM, Vishali S, Varjani S, Mullai P. Electricity generation in a microbial fuel cell using iron oxide nanoparticles. Indian J Exp Biol. 2020;58:571–577. [Google Scholar]

- 47.Mishra B, Varjani S, Kumar G, Awasthi MK, Awasthi SK, Sindhu R. Microbial approaches for remediation of pollutants: innovations, future outlook, and challenges. Energy Environ. 2020 doi: 10.1177/0958305X19896781. [DOI] [Google Scholar]

- 48.Do MH, Ngo HH, Guo W, Chang SW, Nguyen DD, Varjani S, Kumar M. Microbial fuel cell-based biosensor for online monitoring wastewater quality: a critical review. Sci Total Environ. 2020 doi: 10.1016/j.scitotenv.2019.135612. [DOI] [PubMed] [Google Scholar]

- 49.Ivase TJ, Nyakuma BB, Oladokun O, Abu PT, Hassan MN. Review of the principal mechanisms, prospects, and challenges of bioelectrochemical systems. Environ Prog Sustain Energy. 2020;39:1–9. doi: 10.1002/ep.13298. [DOI] [Google Scholar]

- 50.Kondaveeti S, Mohanakrishna G, Lee J-K, Kalia VC. Methane as a substrate for energy generation using microbial fuel cells. Indian J Microbiol. 2019;59:121–124. doi: 10.1007/s12088-018-0765-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 51.Yadav B, Pandey A, Kumar LR, Tyagi RD. Bioconversion of waste (water)/residues to bioplastics—a circular bioeconomy approach. Bioresour Technol. 2020;298:1–51. doi: 10.1016/j.biortech.2019.122584. [DOI] [PubMed] [Google Scholar]

- 52.Gajaraj S, Hu Z. Integration of microbial fuel cell techniques into activated sludge wastewater treatment processes to improve nitrogen removal and reduce sludge production. Chemosphere. 2014 doi: 10.1016/j.chemosphere.2014.06.013.117. [DOI] [PubMed] [Google Scholar]

- 53.Srivastava P, Abbassi R, Garaniya V, Lewis T, Kumar A. Performance of pilot-scale horizontal subsurface flow constructed wetland coupled with a microbial fuel cell for treating wastewater. J Water Process Eng. 2020;33:100994. doi: 10.1016/j.jwpe.2019.100994. [DOI] [Google Scholar]

- 54.Secato JFF, Diego F, Coelho DF, Rosa NGJ, Costa LDL, Tambourgi EB. Biosurfactant production using Bacillus subtilis and industrial waste as substrate. Chem Eng Trans. 2016;4:103–108. doi: 10.3303/CET1649018. [DOI] [Google Scholar]

- 55.Varjani S, Rakholiya P, Ng HY, Taherzadeh MJ. Bio-based rhamnolipids production and recovery from waste streams. Bioresour Technol. 2020 doi: 10.1016/j.biortech.2020.124213. [DOI] [PubMed] [Google Scholar]

- 56.Mohan SV, Varjani S, Pant D, Sauer M, Chang J. Circular bioeconomy approaches for sustainability. Bioresour Technol. 2020;318:124084. doi: 10.1016/j.biortech.2020.124084. [DOI] [PubMed] [Google Scholar]

- 57.Mesomo M, Silva F, Boni G, Padilha FF, Mazutti M, Mossi A, De D, Cansian L, Luccio D, Treichel H. Xanthan gum produced by Xanthomonas campestris from cheese whey: production optimisation and rheological characterisation. J Sci Food Agric. 2009;89:2440–2445. doi: 10.1002/jsfa.3743. [DOI] [Google Scholar]

- 58.Daverey A, Pakshirajan K. Pretreatment of synthetic dairy wastewater using the sophorolipid-producing yeast Candida bombicola. Appl Biochem Biotechnol. 2011;163:720–728. doi: 10.1007/s12010-010-9077-y. [DOI] [PubMed] [Google Scholar]

- 59.Dinesh GH. Simultaneous biohydrogen (H2) and bioplastic (poly-b-hydroxybutyrate-PHB) productions under dark, photo, and subsequent dark and photo fermentation utilizing various wastes. Int J Hydrogen Energy. 2020;45:5840–5853. doi: 10.1016/j.ijhydene.2019.09.036. [DOI] [Google Scholar]

- 60.Wong YM, Show PL, Wu TY, Leong HY, Ibrahim S, Juan JC. Production of bio-hydrogen from dairy wastewater using pretreated land fill leachate sludge as an inoculum. J Biosci Bioeng. 2019;127:150–159. doi: 10.1016/j.jbiosc.2018.07.012. [DOI] [PubMed] [Google Scholar]

- 61.Singh M, Kumar P, Ray S, Kalia VC. Challenges and opportunities for customizing polyhydroxyalkanoates. Indian J Microbiol. 2015;55:235–249. doi: 10.1007/s12088-015-0528-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 62.Patel SKS, Kumar P, Singh S, Lee JK, Kalia VC. Integrative approach to produce hydrogen and polyhydroxybutyrate from biowaste using defined bacterial cultures. Bioresour Technol. 2015;176:136–141. doi: 10.1016/j.biortech.2014.11.029. [DOI] [PubMed] [Google Scholar]

- 63.Prakash J, Sharma R, Patel SKS, Kim IW, Kalia VC. Bio-hydrogen production by co-digestion of domestic wastewater and biodiesel industry effluent. PLoS ONE. 2018;13:e0199059. doi: 10.1371/journal.pone.0199059. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 64.Kumar P, Sharma R, Ray S, Mehariya S, Patel SKS, Lee J-K, Kalia VC. Dark fermentative bioconversion of glycerol to hydrogen by Bacillus thuringiensis. Bioresour Technol. 2015;182:383–388. doi: 10.1016/j.biortech.2015.01.138. [DOI] [PubMed] [Google Scholar]

- 65.Patel SKS, Lee JK, Kalia VC. Nanoparticles in biological hydrogen production: an overview. Indian J Microbiol. 2018;58:8–18. doi: 10.1007/s12088-017-0678-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 66.Patel SKS, Lee JK, Kalia VC. Beyond the theoretical yields of dark-fermentative biohydrogen. Indian J Microbiol. 2018;58:529–530. doi: 10.1007/s12088-018-0759-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 67.Choudhury P, Shankar U, Uday P, Mahata N, Nath O. Performance improvement of microbial fuel cells for waste water treatment along with value addition: a review on past achievements and recent perspectives. Renew Sustain Energy Rev. 2017;79:372–389. doi: 10.1016/j.rser.2017.05.098. [DOI] [Google Scholar]

- 68.Faria A, Gonçalves L, Martins G. Resources recovery in the dairy industry: bioelectricity production using a continuous microbial fuel cell. J Clean Prod. 2017;140:971–976. doi: 10.1016/j.jclepro.2016.04.027. [DOI] [Google Scholar]

- 69.Pandey P, Shinde VN, Deopurkar RL, Kale SP, Patil SA, Pant D. Recent advances in the use of different substrates in microbial fuel cells toward wastewater treatment and simultaneous energy recovery. Appl Energy. 2016;168:706–723. doi: 10.1016/j.apenergy.2016.01.056. [DOI] [Google Scholar]

- 70.Rahimnejad M, Adhami A, Darvari S, Zirepour A, Oh SE. Microbial fuel cell as new technology for bioelectricity generation: a review. Alex Eng J. 2015;54(3):745–756. doi: 10.1016/j.aej.2015.03.031. [DOI] [Google Scholar]

- 71.Cheng D, Ngo HH, Guo W, Nghiem DL, Zhang S, Liang S, Varjani S, Wang J. Performance of microbial fuel cell for treating swine wastewater containing sulfonamide antibiotics. Bioresour Technol. 2020 doi: 10.1016/j.biortech.2020.123588. [DOI] [PubMed] [Google Scholar]

- 72.Varjani S, Joshi R, Srivastava V, Ngo HH, Gou W. Treatment of wastewater from petroleum industry: current practices and perspectives. Environ Sci Pollut Res. 2019 doi: 10.1007/s11356-019-04725-x. [DOI] [PubMed] [Google Scholar]