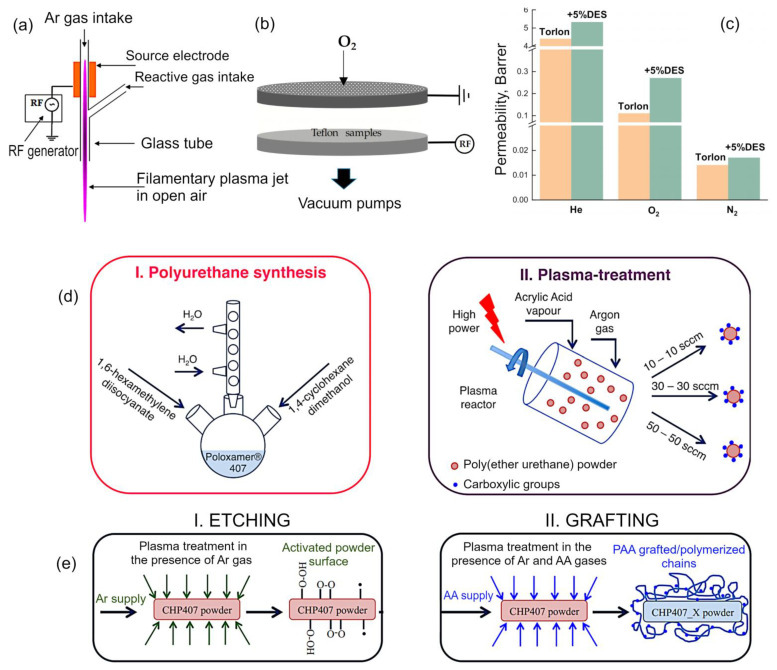

Figure 7.

(a) Configuration of the dielectric barrier discharge Y-shaped source. Reproduced from Panaitescu et al. (2020) [73] under conditions of the CC BY license. (b) Scheme of the electrode system of the plasma reactor setup used for plasma nano/microtexturing of Teflon samples. The upper electrode is a shower-head type to allow homogeneous feed of the process gas (O2 in this case). Samples are placed on the bottom electrode, which is radio-frequency (RF) powered. Reproduced from Mundo et al. (2017) [74] under conditions of the CC BY license. (c) Permeability of Torlon and Torlon/DES-5 composites for He, N2, and O2 at 30 °C. Reproduced from Pulyalina et al. (2021) [75] under conditions of the CC BY license. (d) Schematic representation of the two main steps needed for the design of an amphiphilic poly(ether urethane) exposing a tunable amount of carboxylic groups: (I) polyurethane synthesis; (II) powder plasma treatment. (e) Schematic representation of the plasma treatment process: (I) etching phase in the presence of Ar gas to create free radicals on powder surface and (II) grafting step in the presence of Ar gas and acrylic acid vapors to expose carboxylic groups. Reproduced from Laurano et al. (2019) [80] under conditions of the CC BY license.