Abstract

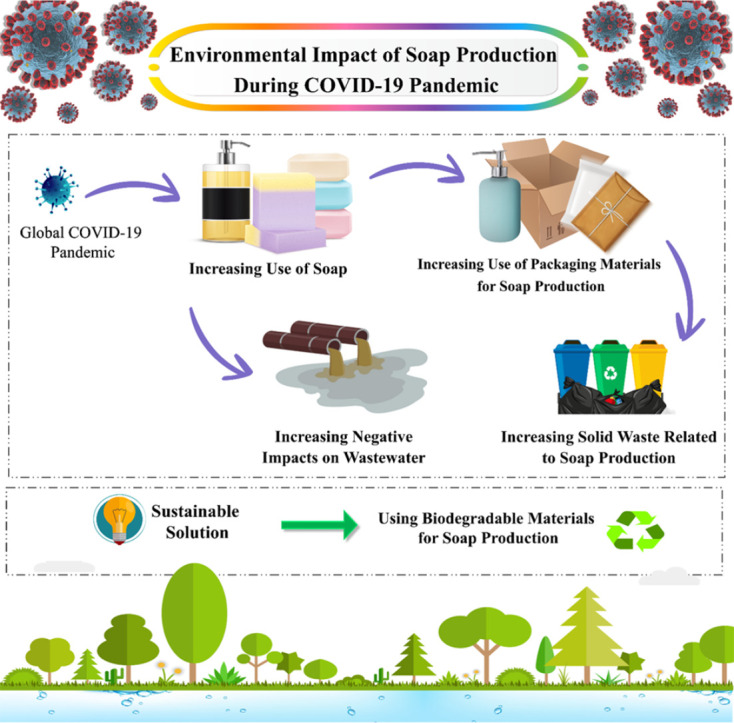

A year into the coronavirus disease 2019 pandemic, the role of washing hands with soap and hand disinfectants is unavoidable as a primary way to control the infection spread in communities and healthcare facilities. The extraordinary surge in demand for handwashing products has led to environmental concerns. Since soaps are complex mixtures of toxic and persistent active ingredients, the prudent option is to promote eco-friendly replacements for the current products. On the other hand, with the increase in soap packaging waste production, soap packaging waste management and recycling become essential to reduce environmental impact. This systematic review aimed to collect some recent methods for identifying biodegradable and sustainable raw materials to produce and package cleaning agents, especially soap.

Keywords: Coronavirus disease 2019, Biodegradable soap, Environmental pollution, Packaging waste, Water pollution, Sustainable solution

Graphical abstract

1. Introduction

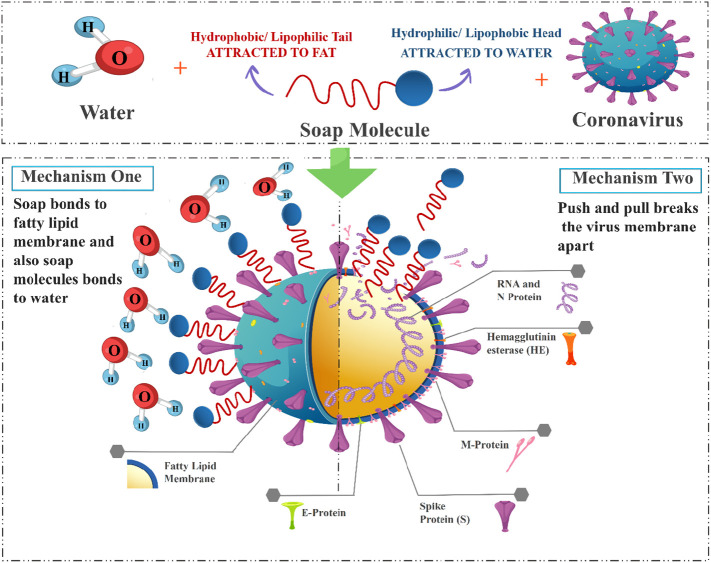

The coronavirus disease 2019 (COVID-19), as a zoonotic disease, is a strain of severe acute respiratory syndrome that has posed severe global health challenges and affected human life quality. This pandemic has already resulted in extreme societal, economic, and political disruption worldwide (Zambrano-Monserrate et al., 2020; Liu et al., 2021; Akrofi and Antwi, 2020; Teymourian et al., 2021). In a systematic review of physical measures to reduce respiratory virus transmission, handwashing was demonstrated to reduce transmission by 45–55% (Jefferson et al., 2009; Brauer et al., 2020). Frequent and correct handwashing with soap as a sustainable factor has been one of the primary recommendations to prevent the coronavirus transmission (Anon, 2021e; Antwi et al., 2020; Wiktorczyk-Kapischke et al., 2021). The mechanical process of handwashing with water and soap has been the “gold standard” for removing most transient and resident microorganisms from hands (Foddai et al., 2016). Soap molecules have two different ends: a hydrophilic polar head and a nonpolar hydrophobic tail that bonds with the coronavirus's lipid envelope and breaks down the virus lipid membrane deactivating it (Schmidt, 2020; Usman et al., 2020). Therefore, the virus's fragmented components are completely dissolved, and running water flushes them away.

During the pandemic, detergents and soaps as a high-volume cleaning agent product, after use, are released directly into the sewage system and, eventually, into the environment. Every person uses 0.4 to 9 ml amounts of soap in each hand wash (Larson et al., 1987). With frequent handwashing and the significant increase of soap cleaners, all these detergents' chemical ingredients are transferred to the ecosystem (Kalbusch et al., 2020). Soaps and detergents' vital ingredients are derived from petrochemicals. Therefore, there is a need for eco-friendly cleaning agents for human and environmental safety.

Various nature-based compounds, such as vegetable oils and plant and fruit extracts, have been reported to have antimicrobial, antifungal, and antioxidants properties (Masdar et al., 2020; Thirunavukkarasu et al., 2020; Ameh et al., 2013). These natural compounds are readily biodegradable and do not produce any additional dangerous waste. Since soap consumption patterns change in the COVID-19 pandemic and there are many different varieties of soap cleaning products, it is not easy to establish the overall environmental impact of a given product. One great way to assess soap's actual environmental influence is to review its life cycle: production ingredient, packaging, use, disposal, and recycling. Therefore, this short review highlighted the environmental concerns of using soaps, such as packaging waste, and considered sustainable, eco-friendly material substitutes to petrochemical-based soaps.

2. Chemistry of soaps and detergents

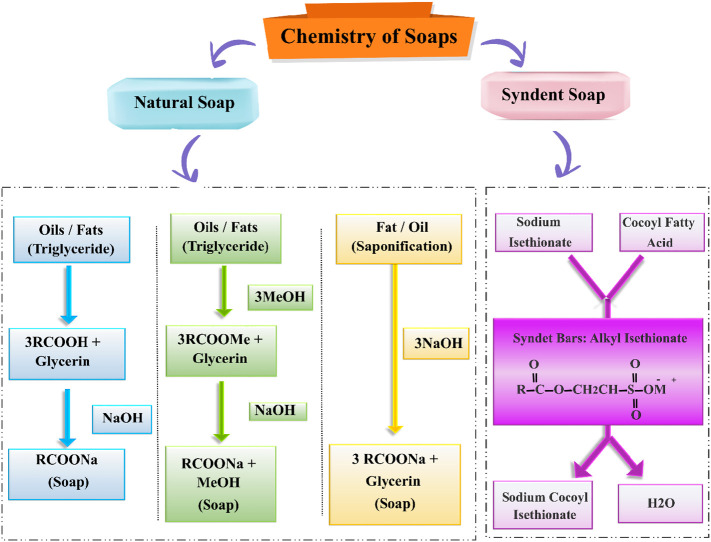

Soap, as the oldest skin cleaner, is a pioneer detergent. Evidence has shown that the first production of soap-like materials dates back to around the third millennium BCE in ancient Babylon (Levey, 1954). The Greek physician Galenus first introduced soaps for therapeutic purposes and cleaning the body in 200 CE (Partington, 1999). The Sumerian pharmacological tablet, one of the oldest preserved medical documents from about 2200 BCE, combined animal and vegetable oils with soda and other alkalies and used it to form a soap-like material for medical purposes (Konkol and Rasmussen, 2015). Technological advances over time until the 19th century revealed different structures of fatty acids in neutral fats and oils, leading to a more comprehensive understanding of soap-making chemistry (Willcox, 2000). From a strictly chemical perspective, soap is a combination of fat or oil (fatty acids), water, and an alkali or even an organic base. In a saponification reaction, neutral fat and an alkali react to create glycerol and soap molecules. Fig. 1 highlights soap-making reactions.

Fig. 1.

Natural and syndet soap-making reactions.

The application of soap in regular handwashing is accessible and essential because it removes contaminants that cannot be wholly eliminated by water. Soaps and detergents solubilize insoluble contaminants, trap dirt and carry it away with water, dissolve the lipid bilayer membrane enveloping microorganisms, inactivate them, and eliminate viruses and bacteria. Handwashing and hand hygiene are now regarded as one of the most effective actions to reduce the spread of respiratory and diarrheal infections from one person to the next and prevent infections, including COVID-19 (Anon, 2021f). Hand sanitizers effectively kill 99.9% of microbes by disrupting most viruses' and bacteria's protective membranes, making them fall apart. However, they do not work for some types of infections and organisms, such as norovirus infection (Vogel, 2011), Clostridium difficile, Gram-positive species of spore-forming bacteria, which can infect the bowel and cause diarrhea (Gerding et al., 2008), or Cryptosporidium, a parasite that can cause a respiratory and gastrointestinal illness (Gormley et al., 2011). Hand sanitizers may not remove and inactivate harmful chemicals, like pesticides or heavy metals, or perform effectively on extremely dirty or greasy skin. Addition of surfactant agents while sanitizing liquids can significantly improve the virucidal efficiency of sanitization and increase virus inactivation feature (Jahromi et al., 2020). Although hand sanitizers do not function well on dirty hands, they can be effective when soap and water are not available (Hadaway, 2020).

3. Common ingredients of soap

Soaps as cleaning agents are a class of chemical-based formulated products designed to meet agreed performance standards and answer consumers' expectations and needs. In addition to its cleaning properties, a good soap should deliver other features, such as good lathering performance, low skin irritation, physical and chemical stability, easy rinsability from skin and bathtub, homogenous and uniform structure with a reasonable erosion rate, and good resistance to cracking (Friedman and Wolf, 1996). The primarily used triglycerides (oils and fats) for soap production are derived from tallow fat, palm kernel oil, olive oil, and coconut oil (Hollstein and Spitz, 1982). Toiletry soaps are prepared by adding particular components, e.g., dyestuffs, fragrances, and other additives (Biermann et al., 1987).

A wide range of ingredients may be used to design personal cleaning products with different characteristics of quality, odor, color, shape, and packaging design. Based on the ingredients' chemical composition, soaps are categorized into two broad groupings: natural and synthetic. In natural soaps, the chemistry is similar to the formulation of ancient soaps. Oils and fats originating from plants or animals are the primary components in most of this type of soaps, without any additional components, such as plasticizers, binders, preservatives, and parabens (Friedman, 2016). Most natural soaps create no toxic waste and byproducts and require a minimal amount of energy in the production process; thus, they are more compatible with nature (Maotsela et al., 2019). Small manufacturers and households can easily produce natural soaps with simple and accessible ingredients (Antonić et al., 2020).

In synthetic soaps, also known as syndet, cleaning agents are usually made from blends of synthetic surfactants, plasticizers, binders, and other additives (Hollstein and Spitz, 1982; Abbas et al., 2004). Synthetic soaps are formulated from fats, petroleum, and oil-based products using a mixture of sulfonation, ethoxylation, and esterification processes (Abbas et al., 2004). Formulated soap products contain multiple components. The most commonly and widely used ingredients and typical range in the soap are listed in Table 1 .

Table 1.

The most commonly used ingredients in the soap along with their function and typical range.

| Ingredient functions | Ingredient | Typical range (%) |

|---|---|---|

| Saponified oils | Tallow, stearic acid, palm kernel oil, olive oil, palm oil | 15–80% |

| Emollienting agent | Glycerol stearate, glycerine, castor oil, silicone fluids | 1.0–3.0% |

| Colorant | Dyestuff, beta-carotene, chromium hydroxide green, carbazole violet | 0.001–0.1% |

| Chelating agent | EDTA, hydroxyethane diphosphonic acid | 0.005–0.2% |

| Bleaching agent | Titanium dioxide | 0.1–2.0% |

| Water | Water | 5–30% |

| Antioxidants | Butyl hydroxy toluene, 2-t-butylbenzene-1, 4-diol | 0.005–0.01% |

| Crack resistance agent | Coconut fatty acids | 1.0–3.0% |

| Antibacterial agents | Tricloson, trichlorocarbon | 0.3–1.5% |

| Anti-acne compounds | Sulfur, salicylic acid, benzoyl peroxide | 0.5–10% |

| Secondary surfactants | Sodium lauryl ether sulphate, lauramine oxide, cocoamidopropyl betaine, disodium cocoyl glutamate, TEA oleate | 0.5–5.0% |

| Moisturizing agent | Lactose, propylene glycol, urea, Aloe barbadensis leaf extract | 0.1–10.0% |

| Thickening agent | PEG-40 hydrated castor oil, benzoic acid | 0.5–0.6% |

| pH-buffer | Citric acid monohydrated, polycarboxylates | 0.5% |

| Fragrance | Perfume, vanillin | 0.5–1% |

Every person uses about 0.4 to 9 ml of soap per hand wash (Larson et al., 1987). With frequent handwashing during the COVID-19 pandemic and thus the significant increase in hand hygiene products, chemical ingredients are transferred to the sewage system and eventually to the ecosystem (Kalbusch et al., 2020). Due to the growing use of soaps, studies should focus on recognizing and developing products with an ecological recycling approach and lower environmental impacts to reduce the environmental effect of these residues and improve public health.

4. Soap mechanism of action against coronaviruses

As an amphiphilic pin-shaped molecule, the soap acts like a double agent. One end of soap molecules with hydrophilic nonfatty head is attracted to water, and their other with hydrophobic fatty tail is attracted to the dirt or oil. The efficiency of soap in eliminating coronaviruses is attributed to the low surface tension of soap solution, as well as its slightly alkaline nature, amphiphilic mobility, and ability to form a micelle (Chaudhary et al., 2020). In the case of coronavirus, the cleaning mechanism of soap is based on the same principle that acts to dissociate the viral aggregate from the skin, break viruses to individual viral particles, and eliminate viruses. A mechanism for destroying/dissolving the virus's outer lipid membrane, which is arranged as a continuous double-layer of about 5 nm thick, is to use soap (Marwah and Marwah, 2020).

4.1. Solubilization of virus lipid membranes

The process of virus membrane solubilization by soap linear fatty acid can be summarized in three basic steps. In most of the enveloped viruses, the lipid membrane includes phospholipids and membrane proteins insoluble in water. (a) When detergent monomers are added, hydrophobic-hydrophobic interactions occur between phospholipid tails in the biological membrane and the detergent monomers' tails. (b) As the concentration of a surfactant increases due to structural changes in the lipid bilayer, perturbation of the membrane occurs. At a surfactant concentration in a bulk phase above a critical micelle concentration (CMC), surfactant molecules tend to aggregate, forming thermodynamically stable micelles. (c) The increasing concentration of surfactants equal to or higher than CMC causes the fatty lipid outer layer to become saturated with detergent molecules and detergent-saturated bilayers to form lipid-protein-detergent mixed micelles (Lichtenberg et al., 2013). Protective lipid bilayers are entirely solubilized by uptake into detergent micelles; the virus breaks down into fragments and thus is no longer infectious (Fig. 2 ). The virus's fragmented components are also entirely dissolved by surfactant molecules in the form of micelles and then are quickly washed away with water.

Fig. 2.

The schematic of the soap mechanism of action for coronavirus elimination.

4.2. Entrapment of viruses

Entrapment of viruses by surfactant micelles could also happen as a probable mechanism of the viral particle's inactivation (Pramod et al., 2020). Handwashing with soap and warm water for at least 20 s is one of the World Health Organization (WHO)’s guidelines to protect against coronavirus. The solubilization mechanism of virus lipid membranes cannot explain the complete inactivation of viruses in this short period. There must also be a way to explain the elimination of the virus without actually disabling it. Soap surfactant molecules approach the target lipid membrane, which encloses coronavirus proteins and RNA, and make a micelle (Ke et al., 2020). Micellization is possible when the surfactant concentration exceeds the critical value. In micelle structure formation, fatty acids, as essential components of the soap, are significant as hydrophobic segments entrap the virus via hydrophobic-hydrophobic interactions. While nonpolar hydrophobic tails are latched into the coronavirus cell, the hydrophilic polar “head” of the soap makes a hydrogen bond crosslink with the surrounding water (Hanafy et al., 2018). The interaction between the micelles' hydrophilic heads and the surrounding water causes severe disruption, which may dissociate the entrapped coronavirus cell from the hands' dead cells and wash it away along with water flow (Fig. 2). In this way, the virus fragments are removed from the surface with water without being wholly inactivated.

The effectiveness of handwashing with soap for the correct duration of time plays a vital role in controlling and preventing the spread of coronavirus and other viruses. Probably, all the above mechanisms act simultaneously in coronavirus elimination. Although the antimicrobial activity of plain soaps has little or no effect on bacteria and viruses, their surfactant function combined with good rubbing and scrubbing the hands while rinsing under water can effectively remove coronavirus from the hands' dead cells (Larson, and Committee, A.G, 1995; Organization, W.H, 2009).

5. Impacts of COVID-19 pandemic on global soap production and usage

The coronavirus outbreak has led to an unprecedented impact on hand soap markets across every region globally. The pandemic has also spurred people to stockpile and panic buy hand soaps, escalating the demand for drugstore products, like soap or sanitizers (Brandtner et al., 2021). Additionally, the use of hand hygiene products, such as soap and alcohol-based hand sanitizers, significantly increased before and after patient contact in hospitals and for washing linens in hospitals (Israel et al., 2020; Al-Tawfiq et al., 2019). According to a study by O'Connell et al., soap purchase among 138 product categories increased more than doubled during the four weeks ending March 22 in 2020 compared with the same period in 2019 (O'Connell et al., 2020). Only in the United Kingdom, the sales of hand soaps have risen 102% since the pandemic was declared (Anon, 2021). One of the main findings of the current research is that the soap market had a significant rise in demand. It can be attributed to the increased awareness and focus on the significance of frequent handwashing as an effective method to prevent the transmission and spread of COVID-19 and other diseases. The world production of soap is expected to grow from $180.99 billion in 2020 to $188.09 billion by the end of 2021 at a compound annual growth rate of 3.9%, forecasted to reach 6.7% from 2020 to 2030 (Anon, 2021c, Anon, 2021d). This phenomenon occurs not only on a national and global scale but also in small regions, such as administrative areas. Arifin and Miazunati reported that the increase in using soap for washing hands led to the huge generation of soap liquid waste in Magelang City. Accordingly, in Magelang City, the amount of soap liquid waste under normal conditions and during the COVID-19 pandemic increased by an average of almost 50.71%. Some gray water samples, including handwashing waste gathered from offices in Magelang City, were examined. The results showed that some parameters were established above the quality standard, which can adversely affect the environment and contaminate water and soil (Usman et al., 2020).

However, it appears that most of these sales are related to the home and personal care segment, and with the pandemic, sales in other segments, such as coatings, oil, and gas, have decreased (Edser, 2020). Soaps and detergents used in a wide range of hospitals and for home cleaning applications are released into the wastewater flow and can have far-reaching environmental impacts. The fast growth of the soap and detergent market during the COVID-19 pandemic has led to the discharge of high surfactant concentrations in the aquatic and terrestrial environment (Jardak et al., 2016). The toxic compounds of surfactants can affect living organisms from bacteria to mammals and abiotic parts of the environment (Olkowska et al., 2014; Pironti et al., 2020). Surfactants and their degradation products accumulate in wastewater treatment plants and change physicochemical properties of surface waters, sediments, and soils (Pironti et al., 2020). The introduction of these residual compounds in the aqueous environment will decrease oxygen diffusion by 40% and increase concentrations of hydrocarbons and pesticides into aqueous systems (Kruszelnicka et al., 2019; Daverey and Dutta, 2020; Kumar et al., 2021). They are also obstructing the aqueous system's auto-remediation processes and affect the growth and nitrification capacity of microorganisms in the soil (Jardak et al., 2016). The severe increase in soap consumption over a short period may increase environmental pollution and change the quality of the greywater (Kumar et al., 2021). Before the COVID-19 pandemic, these emerging pollutants were already harming the environment, and the increase in soap consumption has made their adverse effects more apparent since this discharge is over and above the everyday discharge. The long-term impacts of these effects that may continue for long periods have yet to be quantified.

6. Environmental effects of handwashing wastewater

According to WHO, handwashing with soap can be considered a vital and necessary public health action for preventing coronavirus spread. Each person should wash hands at least five times per day, each time for almost 20–30 s. If the tap is closed, a single handwashing with rubbing soap consumes almost 2 l of water, and this amount can reach 4 l when the tap is kept open. This considerable water consumption can lead to an increase in wastewater generation by 15–18%, which reduces water quality because such wastewater is contaminated with soap surfactants. This situation creates problems and challenges during wastewater treatment, and if water is directly discharged into freshwater bodies without any treatment, it might bring harmful effects on the environment and health (Juela Quintuña, 2020; Lechuga et al., 2016; Pattusamy and Nandini, 2013).

The high concentration of detergents in freshwater bodies can cause massive foam to be created on water's surface, leading to the reduced rate of oxygen penetration into water. This situation prevents dissolved oxygen to be effectively absorbed by aquatic organisms. These substances in the aquatic ecosystem are responsible for altering chemical and physical parameters of water like pH, turbidity, salinity, and temperature (Chen et al., 2021). The reduction in water quality causes biochemical and physiological impairments in fish and can also affect the value of dissolved oxygen used by fish, bringing significant damage to fish's gill (Hafizah et al., 2021; Ge et al., 2018).

Moreover, these different substances in water can be harmful to aquatic plants. Discharging of detergents into freshwater bodies can cause the eutrophication process. This process can be considered a major threat to marine life, especially corals and seaweed. Reduction in the population of sea plants threatens sea species dependent on them for spawn, protection, home, and food (Bandala et al., 2021). Detergents in the aquatic environment can finally enter the soil and bring adverse effects on flora in the area, especially on the germination of plants (Issayeva et al., 2015). A high concentration of surfactants leads to the destruction of the soil structure, threatening the plant's health (Shafran et al., 2005; Wiel-Shafran et al., 2006; Sawadogo et al., 2014). After detergents enter into the soil, the soil's pH increases, leading to the separation of the soil components. The proper pH for plants is almost 5–9, and any changes, including pH increase and decrease, will threaten the soil's biological activity levels (Anwar, 2011a; Anwar, 2011b).

Demand for soaps with antibacterial additives, such as TCC and TCS, has increased during the pandemic. However, in multiple studies, the FDA has found that antibacterial soap is no more effective than regular soap (Usman et al., 2020). These chemicals could contribute to antibiotic resistance and give rise to antibiotic-resistant strains of bacteria (Kumar et al., 2021). The removal efficiency for TCS in current wastewater treatment techniques cannot offer complete elimination. The residual TCS concentration may pose severe threats to the ecosystem and adversely affect aquatic organisms. These antibacterial additives can sabotage wastewater treatment processes that depend on microbial activity (Usman et al., 2020). Moreover, TCS under sunlight produces chloroform in water classified as a probable human carcinogen (Wandosell et al., 2021).

Such substances in the natural ecosystem cause adverse effects on flora and fauna because of high absorbance capacity to particles, toxicity, foam, and low biodegradability, leading to a decrease in water quality, such as reducing light transmission, eutrophication, and pH changes in soil and water (Mousavi and Khodadoost, 2019).

7. A sustainable solution: Biodegradable hand soap

Soap is the most widely used surfactant in most developed countries' household and personal care sector. As mentioned, surfactants can be subdivided into two classes: natural and synthetic. The difference between them is not in their washing ability but in their feedstock origin, which can be oleochemical or petrochemical (Tesser et al., 2020). Natural soap is considered to have a natural origin if its formulas comprise vegetable oils and animal fats. Synthetic soap is mainly petroleum-based (e.g., sodium lauryl sulfate (SLS)), hardly biodegradable, and has a high aquatic toxicity potential (Deleu and Paquot, 2004; Bilal and Iqbal, 2019).

Some of the additional ingredients used in personal care products might result in severe health concerns for humans and the ecosystem. For example, some antibacterial and antifungal agents, such as triclosan (TCS), triclocarban (TCC), fragrances, and preservatives, have been long used in handwashing products (Allmyr et al., 2006). Incorporating such chemical elements into hand hygiene products can substantially increase the extent of human exposure to them and can cause unexpected health risks. Moreover, the intentional or unintentional disposal release of these chemical elements contaminates the environment (Catalano et al., 2021). As a cross-sectional study, Alhazmi et al. reported that 34.8% of the participants used antibacterial soap against the coronavirus (Alhazmi et al., 2019). However, the Food and Drug Administration (FDA) has not confirmed that antimicrobial ingredients in hand hygiene products are more effective than other ingredients in different types of soap; they may even cause antibiotic resistance and allergic development.

Increased handwashing has led to the release and accumulation of potentially toxic components into the environment. Accordingly, the industry and research organizations need to find alternative solutions for producing more sustainable and safer soaps that entail a minimum environmental impact and can be formulated with biodegradable materials. Since biodegradable soaps are made of natural materials, they will naturally decompose over time. Therefore, these soaps are an optimal alternative to synthetic soaps for their selectivity, structural diversity, good performance in extreme conditions, mass production potential via fermentation, environmentally-friendly nature (Sajna et al., 2015). With the green chemistry principle, herbal soaps made of plant-based renewable resources can serve the 17 sustainable development goals proposed by the UN for protection of the planet, since these soaps involve clean energy development, good health, sustainable community development, providing a safe life and high quality water. The skin and hair can be freshened and protected against different skin and hair problems due to the availability of phytochemicals, including vitamins, proteins, terpenoids, tannins, and other bioactive ingredients (Atolani et al., 2016). Moreover, biosurfactants are safe and have a variety of biological functions, making them a good option in pharmaceutical and biomedical domains. Since information on the probable toxicity of synthetic antioxidants is emerging, it has been attempted to replace synthetic antioxidants with natural additives, particularly those obtained from plant resources, spices, vegetables, culinary herbs, and agro-industry by-products of oilseeds and fruits, containing high levels of phenolics and other active ingredients (Adigun et al., 2019; Villalobos-Delgado et al., 2019). Adigun et al. evaluated the effects of antioxidants from Newfoundland wild berries on natural herbal soap's shelf life to preserve against lipid oxidation and microbial growth. According to their research findings, considerable amounts of phenolics, unsaponified neutral lipids, and antioxidants were retained in soaps made of natural additives and wild berry extracts with cold saponification. Furthermore, there was a higher level of total phenolic content and antioxidant activities in natural herbal soaps compared to commercial types, which potentially improves their shelf life (Adigun et al., 2019). Table 2 shows recent studies on the production of biodegradable and natural soaps and the replacement of synthetic ingredients with sustainable materials.

Table 2.

Recent studies on soap production with biodegradable and natural ingredients.

| Biodegradable or natural compound | Advantages | Instead of | Reference |

|---|---|---|---|

| Cysteine-octanoyl | - Excellent metal-binding and foaming features over a wide pH range - Acceptable biodegradability and biological degradation - Without additional hazardous waste - Easily breakable into octanoic acid and cysteine in the environment |

Sodium dodecyl sulfate and SLS | (Taseidifar, 2020) |

| Olive and rapeseed–palm fried/used oils | - Producing ecologically and economically sustainable soaps - Soaps waste treatment being more manageable than fried/used oil waste treatment - Having green perspective |

Synthetic fatty acids | (Antonić et al., 2020; Li et al., 2020; Mustakim et al., 2020) |

| Beef tallow and waste cooking oils | - Reducing environmental pollution - Producing economically sustainable toilet soaps |

Synthetic fatty acids | (Maotsela et al., 2019) |

| Almond shells and orange peels | - Producing functional, inexpensive, and good quality green soap - Utilizing waste products as primary raw materials - Promoting recycling with an eco-friendly approach |

Synthetic fatty acids | (Félix et al., 2017) |

| Wild berry | - Growing the shelf life of natural herbal soaps - Functioning as antioxidants |

Butylated hydroxytoluene (BHT) and butylated hydroxyanisole (BHA) | (Adigun et al., 2019) |

| Dioscorea hispida or ubi gadong | - Acting as antioxidants - Being neutral in pH |

BHT and BHA | (Masdar et al., 2020) |

| Golden apple and cranberry fruit flakes | - Having antioxidant activity with free radical scavenger characteristics | Industrial antioxidants | (Cho et al., 2006) |

| Daniellia oliveri seed, Ocimum basilicum, Vitellaria paradoxa, Moringa oleifera leaves and seeds, and ocimum basilicum leaves | - Producing biodegradable antiseptic herbal soaps - Being originated from natural renewable sources - Being highly economical compared to commercial soaps |

Sodium hydroxide, sodium silicate, sodium sulphate and artificial perfumes, colourants, preservatives, and synthetic antimicrobial agents | (Atolani et al., 2016) |

| Palm kernel oil and shea butter | - Acting as an antimicrobial agent against some pathogenic microorganisms | Triclosan, trichlorocarbanilide, and chloroxylenol | (Aliyu et al., 2012) |

| Neem oil and shea butter oil | - Acting as an antimicrobial agent against S. aureus and B. subtilis microorganisms | Triclorocarbanilide | (Ameh et al., 2013) |

| Aloe vera, basil, and guava leaf | - Producing economical and practical toilet soaps - Being suitable to various skin types - Having great antioxidant values |

Synthetic fatty acids | (Ezeonu et al., n.d.) |

| Coconut oil, evening primrose oil, palm oil, jojoba oil, olive oil or corn oil | - Inducing a natural fragrance - Being eco-friendly - Being harmless and safe to the human body - Having excellent economic efficiency |

Artificial fragrance | (Hunsang, 2020) |

| Sapogenin (Saponaria officinalis) | - Having antifungal and antibacterial activities - Being biodegradable - Having low carbon and ecotoxicity footprints |

Chemical surfactants | (Sajna et al., 2015) |

| Neem oil | - Having an antimicrobial agent - Being suitable for allergic skin diseases, such as acne, psoriasis, and eczema - Being an inexpensive source of fatty materials for toilet soap formation |

Diethanolamine, isopropyl synthetic fatty acids, and butylated hydroxyl toluene and triclosan additives | (Mak-Mensah and Firempong, 2011) |

| Acalypha indica | - Having antimicrobial and antifungal activities | Synthetic antimicrobial agents | (Thirunavukkarasu et al., 2020) |

| Fat and flesh extracted in the leather industry | - Being a new source of fatty materials for soap formation by utilizing the leather industry solid waste - Reducing the environmental impact of leather waste |

Synthetic fatty acids | (Pathan et al., 2019) |

| Green and red betel plant | - Having an antibacterial action with Staphylococcus aureus - Having moisture content for glycerin soap bar |

Synthetic antimicrobial agents | (Hafizah et al., 2021) |

| Avocado (Persea americana) | - Having excellent biochemical properties - Having sunscreen performance |

Synthetic fatty acids, chemical emulsifier | (Ge et al., 2018) |

8. Soap packaging waste management

The packaging function assumes a pivotal role in safely distributing products throughout supply chains. According to various formulas applied to manufacture products, soap packaging materials have been engineered to adequately protect soap during distribution, storage, sale, shipping, and use. Paper, waxed papers, aluminum, and, to some extent, a film such as biaxially oriented polypropylene, polyethylene glycol coated paper, low-density polyethylene, cellophane, and other materials have been used as packaging materials (Drobac et al., 2020; Malik et al., 2017). The analysis of the municipal solid waste demonstrated that containers and packaging waste accounted for 82.2 million tons of the total waste produced in 2018 (Anon, 2021b). A study on the environmental impacts of soaps and their associated packaging found that solid and liquid soaps have 0.1% and 2% of the total environmental impact, respectively (Ferre et al., 2012). As the COVID-19 pandemic has disrupted waste recycling activities, eco-friendly management and handling of packaging waste can help address the challenge faced by the waste management industry (Ragazzi et al., 2020; Rowan and Laffey, 2020). The trouble with soap packaging begins during soap manufacture. Various resources are used in the production and distribution of packaging materials, including water, energy, petroleum, minerals, and chemicals. In the production process of packaging materials, hydrocarbon pollution, heavy metals (e.g., cadmium and lead), and air emissions are generated from pigments. Moreover, this process causes the generation of wastewater and sludge with toxic materials (Kutz, 2007). Many wastes may be generated as a result of packaging and consuming resources in large amounts. A high amount of financial, material, and human resources should be spent to deal with solid wastes. Moreover, packages cause considerable environmental pollution and endangers the human survival environment (Zhang and Zhao, 2012; Bigdeloo et al., 2021). After their use, packages are mostly thrown away, buried in landfills, or broken into small pieces and carried by water currents or wind into the environment. Packages transferred to landfills, particularly plastic ones, are not quickly, or sometimes never, degraded (EPA, 2015). Thus, the chemical constituents of packaging materials, such as dyes and inks in labels, can leak into soil and groundwater. In the United States, some local jurisdictions and states have implemented regulations and laws that influence packaging production, usage, and discarding. These regulations include standards for producing packaging with environmentally-friendly materials with the least need for recycled content, limitations on usages of some specific materials in packaging, and even absolute prohibitions on certain plastic types of packaging (Anon, n.d.). There are major implications for attitudes toward packaging for both environmental and detergent policies (Kitz et al., 2021; Teymoorian et al., 2021; Rowan and Moral, 2021; Rowan and Casey, 2021).

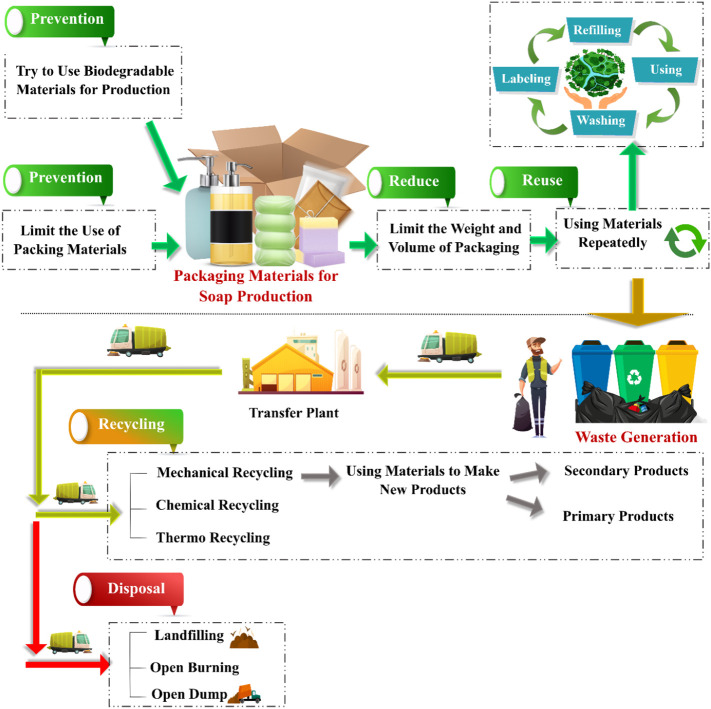

Due to the growing soap demand and since packages are produced and discarded on a large scale during the pandemic, soap manufacturers should use recycling and eco-friendly packaging to conserve and prevent the environment from destruction (Hahladakis and Iacovidou, 2018). According to the European Union's Packaging and Packaging Waste Directive, the packaging industry should improve packaging's sustainability by reducing material weight and using recycled materials (Saadat et al., 2020; Anon, 2021a). Reusable packaging is another waste treatment method that represents a significant opportunity to maintain the functionality of the material. In reusable forms of packaging, customers return empty packaging, which will be recovered and refilled for future use (Coelho et al., 2020; Babader et al., 2016). Reusable packaging is usually made of long-lasting materials and is mainly produced for multiple cycles and extended life. In reusable packaging systems, glass bottles can withstand at least 30 cycles, and 20 cycles is expected for returnable plastic bottles (Rowan and Moral, 2021; Scharpenberg et al., 2021). Strategies to reduce waste packaging are shown in Fig. 3 .

Fig. 3.

Reduce, reuse, and recycle strategies for cleaning agents' packaging waste.

Biodegradable packaging is progressively promoted as a solution to some of these challenges. Biodegradable polymers, such as polyhydroxyalkanoates and polylactic acid, can be degraded by microorganisms and used to substitute conventional plastics (Zhong et al., 2020). Table 3 shows recent studies on recycling and reusing materials or on biodegradable materials in the cleaning agent packaging industry.

Table 3.

List of recent publications on the reusing and recycling process related to cleaning agents' product packaging.

| Article title | Strategies | Assessment | Year | Reference |

|---|---|---|---|---|

| Minimization of household hazardous solid waste (HHSW) with 4R concepts (reduce, reuse, recycle, and recover) in Padang City, Indonesia | Returning plastic and bottle packaging for reusing | - Soap waste components are reused by reuse packaging. - Packaging production is reduced by returning plastic and bottle packaging to the manufacturer or factory. - Recollecting plastic waste packaging is more complex than recycling plastic; thus, 9% of the total product is in the environmental producer responsibility program. |

2019 | (Ruslinda et al., 2019) |

| Systematic packaging design tools integrating functional and environmental consequences on product life cycle: Case studies on laundry detergent and milk | Refill packaging production as an eco-friendly solution | - The emission factor in the life cycle assessment for liquid detergent bottle packaging production is 284 g CO2eq/unit, while the emission factor for refill packaging production as environmentally conscious behavior is 62.6 g CO2eq/unit. | 2020 | (Yokokawa et al., 2020) |

| Comparative Life Cycle Assessment of Multiple Liquid Laundry Detergent Packaging Formats | Use of high-density polyethylene pourable bottle | - Packaging systems containing conventional pourable bottles made of high-density polyethylene have lower environmental burdens than packaging systems containing water-soluble polyvinyl alcohol pods. | 2020 | (Kim and Park, 2020) |

| Analyzing the packaging strategy of packaging-free supermarkets | Packaging-free supermarkets (the larger the container, the lower the material consumption) |

- The use of reusable buckets as detergents and shower gels reduces ecosystems' damage by reducing the negative impact on agricultural occupation, climate change, and water depletion and improving overall environmental performance. | 2021 | (Scharpenberg et al., 2021) |

| Sustainability of reusable packaging–Current situation and trends | Refillable by the bulk dispenser and returnable packaging | - The detergent producer provides refilling systems in stores, and dispensers for personal care and cleaning products. - 70% of packaging is returned, cleaned, and refilled by the company. |

2020 | (Coelho et al., 2020) |

| Laminated film for packaging US10046395B2 |

Paper-free packaging | - Sustainable plastic laminated films are produced by polyester, polyethylene, and metallized polyester. | 2018 | (Janardhana and Tewari, 2018) |

| Product packaging US20200239211A1 |

Blister packs easily collected after use | - Biodegradable materials or a recyclable material are used. | 2018 | (Boulton and Iyer, 2020) |

| Drivers, opportunities, and barriers for a retailer in the pursuit of more sustainable packaging redesign | Reducing the environmental impact by redesigning packaging | - The bigger detergent powder packaging saves materials, energies, transportation, and water per kilo of product sold. | 2020 | (Gustavo et al., 2018) |

| The Consumer Acceptance Of Primary Packaging Alternatives | Sustainable packaging | - the sustainability of products and their packaging increase | 2020 | (Habermann, 2020) |

9. Conclusion

During the COVID-19 pandemic, the frequent and increased use of handwashing products result in environmental pollution. Using non-biodegradable chemical and antimicrobial components in soap and detergent products, such as TCS and SLS, has caused severe health concerns for humans and the ecosystem. Industry and research organizations need to find ecologically and economically sustainable materials for producing soaps and soaps packaging that significantly reduce the environmental impacts and decrease the risk of hazardous materials in wastewater and sludge. The soaps made from natural sources and waste material such as almond shells, orange peels, different oils extracted from the seeds, plant-based additives, and waste cooking oils and fat extracted in the leather industry avoided the inclusion of auxiliary raw materials such as sodium silicate, sodium dodecyl sulfate, sodium silicate, and synthetic fatty acids, artificial fragrance, preservatives, and synthetic antimicrobial agents. Since biodegradable soaps are formulated with environmentally friendly natural materials, they will naturally decompose over time. Improving biodegradable and herbal soaps and detergents and producing more sustainable and eco-friendly hygiene products are attractive solutions to overcome environmental impacts of these products. Industries should gradually move toward developing sustainable hygiene products with the focus on natural and non-synthetic chemicals, biodegradable and non-toxic ingredients, natural compounds for antimicrobial purposes, and reusable and recyclable packaging materials.

Formatting of funding sources

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

The authors would like to gratefully thank Amirkabir University of Technology (AUT), Tehran, Iran for their financial support.

Editor: Damià Barceló

References

- Abbas S., Goldberg J.W., Massaro M. Personal cleanser technology and clinical performance. Dermatol. Ther. 2004;17:35–42. doi: 10.1111/j.1396-0296.2004.04s1004.x. [DOI] [PubMed] [Google Scholar]

- Adigun O., Manful C., Prieto Vidal N., Mumtaz A., Pham T.H., Stewart P., Nadeem M., Keough D., Thomas R. Use of natural antioxidants from newfoundland wild berries to improve the shelf life of natural herbal soaps. Antioxidants. 2019;8(11):536. doi: 10.3390/antiox8110536. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Akrofi M.M., Antwi S.H. COVID-19 energy sector responses in Africa: a review of preliminary government interventions. Energy Res. Soc. Sci. 2020;68:101681. doi: 10.1016/j.erss.2020.101681. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Alhazmi A.M., Alshammari S.A., Alenazi H.A., Shaik S.A., AlZaid H.M., Almahmoud N.S., Alshammari H.S. Community’s compliance with measures for the prevention of respiratory infections in Riyadh, Saudi Arabia. J. Fam. Community Med. 2019;26(3):173. doi: 10.4103/jfcm.JFCM_4_19. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Aliyu M., Tijjani M., Doko M., Garba I., Ibrahim M., Abdulkadir S., Abba D., Zango U. Antimicrobial activity of Sabulun Salo a local traditional medicated soap. Niger. J. Basic Appl. Sci. 2012;20(1):35–38. [Google Scholar]

- Allmyr M., Adolfsson-Erici M., McLachlan M.S., Sandborgh-Englund G. Triclosan in plasma and milk from Swedish nursing mothers and their exposure via personal care products. Sci. Total Environ. 2006;372(1):87–93. doi: 10.1016/j.scitotenv.2006.08.007. [DOI] [PubMed] [Google Scholar]

- Al-Tawfiq J.A., Abdrabalnabi R., Taher A., Mathew S., Rahman K.A. Infection control influence of Middle East respiratory syndrome coronavirus: a hospital-based analysis. Am. J. Infect. Control. 2019;47(4):431–434. doi: 10.1016/j.ajic.2018.09.015. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ameh A., Muhammad J., Audu H. Synthesis and characterization of antiseptic soap from neem oil and shea butter oil. Afr. J. Biotechnol. 2013;12(29) [Google Scholar]

- Anon Soap and body wash: COVID-19. 2021 Mar. 26. https://www.researchandmarkets.com/issues/soap-and-body-wash-rising-by-194pct cited. Available from:

- Anon EU rules on packaging and packaging waste, including design and waste management. 2021 Mar. 20. https://ec.europa.eu/environment/topics/waste-and-recycling/packaging-waste_en cited. Available from:

- Anon Containers and packaging: product-specific data. 2021 Mar. 20. https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/containers-and-packaging-product-specific-data#C&POverview cited. Available from:

- Anon Hand soap market forecast, trend analysis & competition tracking. 2021 Mar. 26. https://www.factmr.com/report/4718/hand-soap-market cited. Available from:

- Anon Soap and cleaning compounds global market report 2021. 2021 Mar. 28. https://www.globenewswire.com/news-release/2021/02/03/2168901/0/en/Soap-And-Cleaning-Compounds-Global-Market-Report-2021-COVID-19-Impact-and-Recovery-to-2030.html cited. Available from:

- Anon. How to Protect Yourself & Others. [cited 2021e Mar. 8]; Available from: https://www.cdc.gov/coronavirus/2019-ncov/prevent-getting-sick/prevention.html.

- Anon. Handwashing an effective tool to prevent COVID-19, other diseases. [cited 2021f Mar. 28]; Available from: https://www.who.int/southeastasia/news/detail/15-10-2020-handwashing-an-effective-tool-to-prevent-covid-19-other-diseases.

- Anon Packaging and environmental legislation in the United States: an overview. https://www.packaginglaw.com/special-focus/packaging-and-environmental-legislation-united-states-overview Available from:

- Antonić B., Dordević D., Jančíková S., Tremlova B., Kushkevych I. Physicochemical characterization of home-made soap from waste-used frying oils. Processes. 2020;8(10):1219. [Google Scholar]

- Antwi S.H., Getty D., Linnane S., Rolston A. COVID-19 water sector responses in Europe: a scoping review of preliminary governmental interventions. Sci. Total Environ. 2020:143068. doi: 10.1016/j.scitotenv.2020.143068. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Anwar F. Effect of laundry greywater irrigation on soil properties. J. Environ. Res. Dev. 2011;5(4):863–870. [Google Scholar]

- Anwar A. 2nd International Conference on Environmental Science and Development. 2011. Effect of greywater irrigation on soil characteristics. [Google Scholar]

- Atolani O., Olabiyi E.T., Issa A.A., Azeez H.T., Onoja E.G., Ibrahim S.O., Zubair M.F., Oguntoye O.S., Olatunji G.A. Green synthesis and characterisation of natural antiseptic soaps from the oils of underutilised tropical seed. Sustain. Chem. Pharm. 2016;4:32–39. [Google Scholar]

- Babader A., Ren J., Jones K.O., Wang J. A system dynamics approach for enhancing social behaviours regarding the reuse of packaging. Expert Syst. Appl. 2016;46:417–425. [Google Scholar]

- Bandala E.R., Kruger B.R., Cesarino I., Leao A.L., Wijesiri B., Goonetilleke A. Impacts of COVID-19 pandemic on the wastewater pathway into surface water: a review. Sci. Total Environ. 2021:145586. doi: 10.1016/j.scitotenv.2021.145586. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Biermann M., Lange F., Piorr R., Ploog U., Rutzen H., Schindler J., Schmid R. Surfactants in Consumer Products. Springer; 1987. Synthesis of surfactants; pp. 23–132. [Google Scholar]

- Bigdeloo M., Teymourian T., Kowsari E., Ramakrishna S., Ehsani A. Sustainability and circular economy of food wastes: waste reduction strategies, higher recycling methods, and improved valorization. Mater. Circ. Econ. 2021;3(1):1–9. [Google Scholar]

- Bilal M., Iqbal H.M. An insight into toxicity and human-health-related adverse consequences of cosmeceuticals—a review. Sci. Total Environ. 2019;670:555–568. doi: 10.1016/j.scitotenv.2019.03.261. [DOI] [PubMed] [Google Scholar]

- Boulton O.J., Iyer N.D.K. 2020. Product Packaging. (Google Patents) [Google Scholar]

- Brandtner P., Darbanian F., Falatouri T., Udokwu C. Impact of COVID-19 on the customer end of retail supply chains: a big data analysis of consumer satisfaction. Sustainability. 2021;13(3):1464. [Google Scholar]

- Brauer M., Zhao J.T., Bennitt F.B., Stanaway J.D. Global access to handwashing: implications for COVID-19 control in low-income countries. Environ. Health Perspect. 2020;128(5):057005. doi: 10.1289/EHP7200. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Catalano A., Iacopetta D., Rosato A., Salvagno L., Ceramella J., Longo F., Sinicropi M., Franchini C. Searching for small molecules as Antibacterials: non-cytotoxic diarylureas analogues of triclocarban. Antibiotics. 2021;10(204):2021. doi: 10.3390/antibiotics10020204. (s Note: MDPI stays neutral with regard to jurisdictional claims in published …) [DOI] [PMC free article] [PubMed] [Google Scholar]

- Chaudhary N.K., Chaudhary N., Dahal M., Guragain B., Rai S., Chaudhary R., Sachin K., Lamichhane-Khadka R., Bhattarai A. 2020. Fighting the SARS CoV-2 (COVID-19) Pandemic with Soap. [Google Scholar]

- Chen Z., Rao Y., Usman M., Chen H., Białowiec A., Zhang S., Luo G. Anaerobic fermentation of hydrothermal liquefaction wastewater of dewatered sewage sludge for volatile fatty acids production with focuses on the degradation of organic components and microbial community compositions. Sci. Total Environ. 2021:146077. doi: 10.1016/j.scitotenv.2021.146077. [DOI] [PubMed] [Google Scholar]

- Cho, S.H., Zehntner, B., and Tuck, A.M., Skin Care Compositions. 2006, Google Patents.

- Coelho, P.M., Corona, B., ten Klooster, R., and Worrell, E., Sustainability of reusable packaging-current situation and trends. Resource. Conserv. Recycl. X, 2020: p. 100037.

- Daverey A., Dutta K. COVID-19: eco-friendly hand hygiene for human and environmental safety. J. Environ. Chem. Eng. 2020:104754. doi: 10.1016/j.jece.2020.104754. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Deleu M., Paquot M. From renewable vegetables resources to microorganisms: new trends in surfactants. Comptes Rendus Chimie. 2004;7(6–7):641–646. [Google Scholar]

- Drobac J., Alivojvodic V., Maksic P., Stamenovic M. MATEC Web of Conferences. EDP Sciences; 2020. Green face of packaging–sustainability issues of the cosmetic industry packaging. [Google Scholar]

- Edser C. Surfactants versus COVID-19. Focus Surfact. 2020;2020(7):1. [Google Scholar]

- EPA Getting up to speed: ground water contamination. 2015. https://www.epa.gov/sites/production/files/2015-08/documents/mgwc-gwc1.pdf Retrieved March 7, 2019]; Available from:

- Ezeonu, C.S., Ugwu, M.I., and Otitoju, O., Evaluating the Dermal Properties of Toilet Soaps Incorporated with Different Herbal Extracts.

- Félix S., Araújo J., Pires A.M., Sousa A.C. Soap production: a green prospective. Waste Manag. 2017;66:190–195. doi: 10.1016/j.wasman.2017.04.036. [DOI] [PubMed] [Google Scholar]

- Escamilla, M., Ferre, A., Hidalgo, C., Fuentes, N., and Kaps, R., Revision of European Ecolabel Criteria for Soaps, Shampoos and Hair Conditioners. European Commission, 2012.

- Foddai A.C., Grant I.R., Dean M. Efficacy of instant hand sanitizers against foodborne pathogens compared with hand washing with soap and water in food preparation settings: a systematic review. J. Food Prot. 2016;79(6):1040–1054. doi: 10.4315/0362-028X.JFP-15-492. [DOI] [PubMed] [Google Scholar]

- Friedman M. Soap Manufacturing Technology. Elsevier; 2016. Chemistry, formulation, and performance of Syndet and combo bars; pp. 73–106. [Google Scholar]

- Friedman M., Wolf R. Chemistry of soaps and detergents: various types of commercial products and their ingredients. Clin. Dermatol. 1996;14(1):7–13. doi: 10.1016/0738-081x(95)00102-l. [DOI] [PubMed] [Google Scholar]

- Ge Y., Si X., Wu B., Dong X., Xu Z., Ma W. Oil content and fatty acid composition of the seeds of 16 avocado (Persea americana) accessions collected from southern China and their application in a soap bar. J. Agric. Sci. 2018;10:69–78. [Google Scholar]

- Gerding D.N., Muto C.A., Owens R.C., Jr. Measures to control and prevent Clostridium difficile infection. Clin. Infect. Dis. 2008;46(Supplement_1):S43–S49. doi: 10.1086/521861. [DOI] [PubMed] [Google Scholar]

- Gormley F.J., Little C.L., Chalmers R.M., Rawal N., Adak G.K. Zoonotic cryptosporidiosis from petting farms, England and Wales, 1992–2009. Emerg. Infect. Dis. 2011;17(1):151. doi: 10.3201/eid1701.100902. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Gustavo J.U., Jr., Pereira G.M., Bond A.J., Viegas C.V., Borchardt M. Drivers, opportunities and barriers for a retailer in the pursuit of more sustainable packaging redesign. J. Clean. Prod. 2018;187:18–28. [Google Scholar]

- Habermann J. University of Twente; 2020. The Consumer Acceptance of Primary Packaging Alternatives. [Google Scholar]

- Hadaway A. Handwashing: clean hands save lives. J. Consume. Health Internet. 2020;24(1):43–49. [Google Scholar]

- Hafizah I., Aisyah Y., Hasni D. IOP Conference Series: Earth and Environmental Science. IOP Publishing; 2021. Effect of betel type (Piper sp) and concentration of betel leaf extract on quality and antibacterial activities of glycerine bar soap. [Google Scholar]

- Hahladakis J.N., Iacovidou E. Closing the loop on plastic packaging materials: what is quality and how does it affect their circularity? Sci. Total Environ. 2018;630:1394–1400. doi: 10.1016/j.scitotenv.2018.02.330. [DOI] [PubMed] [Google Scholar]

- Hanafy N.A., El-Kemary M., Leporatti S. Micelles structure development as a strategy to improve smart cancer therapy. Cancers. 2018;10(7):238. doi: 10.3390/cancers10070238. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Hollstein M., Spitz L. Manufacture and properties of synthetic toilet soaps. J. Am. Oil Chem. Soc. 1982;59(10):442–448. [Google Scholar]

- Hunsang, K., Natural fragrance soap. 2020, Google Patents.

- Israel S., Harpaz K., Radvogin E., Schwartz C., Gross I., Mazeh H., Cohen M.J., Benenson S. Dramatically improved hand hygiene performance rates at time of coronavirus pandemic. Clin. Microbiol. Infect. 2020;26(11):1566. doi: 10.1016/j.cmi.2020.06.002. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Issayeva A., Zh S.E., Zhymadullayeva A., Balgabekova A. The effect of detergents on the anatomical changes in the roots of beans. J. Educ. Policy Entrep. Res. 2015;2(2):18–22. [Google Scholar]

- Jahromi R., Mogharab V., Jahromi H., Avazpour A. Synergistic effects of anionic surfactants on coronavirus (SARS-CoV-2) virucidal efficiency of sanitizing fluids to fight COVID-19. Food Chem. Toxicol. 2020;145 doi: 10.1016/j.fct.2020.111702. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Janardhana S., Tewari A. 2018. Laminated Film for Packaging. (Google Patents) [Google Scholar]

- Jardak K., Drogui P., Daghrir R. Surfactants in aquatic and terrestrial environment: occurrence, behavior, and treatment processes. Environ. Sci. Pollut. Res. 2016;23(4):3195–3216. doi: 10.1007/s11356-015-5803-x. [DOI] [PubMed] [Google Scholar]

- Jefferson T., Del Mar C., Dooley L., Ferroni E., Al-Ansary L.A., Bawazeer G.A., Van Driel M.L., Foxlee R., Rivetti A. Physical interventions to interrupt or reduce the spread of respiratory viruses: systematic review. Bmj. 2009;339 doi: 10.1136/bmj.b3675. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Juela Quintuña D.M. 2020. Estimated Impact of COVID-19 on Water Needs and Volume and Quality of Wastewater. Available at SSRN 3651551. [Google Scholar]

- Kalbusch A., Henning E., Brikalski M.P., de Luca F.V., Konrath A.C. Impact of coronavirus (COVID-19) spread-prevention actions on urban water consumption. Resour. Conserv. Recycl. 2020;163:105098. doi: 10.1016/j.resconrec.2020.105098. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ke Z., Oton J., Qu K., Cortese M., Zila V., McKeane L., Nakane T., Zivanov J., Neufeldt C.J., Cerikan B. Structures and distributions of SARS-CoV-2 spike proteins on intact virions. Nature. 2020;588(7838):498–502. doi: 10.1038/s41586-020-2665-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kim S., Park J. Comparative life cycle assessment of multiple liquid laundry detergent packaging formats. Sustainability. 2020;12(11):4669. [Google Scholar]

- Kitz R., Walker T., Charlebois S., Music J. Food packaging during the COVID-19 pandemic: consumer perceptions. Int. J. Consum. Stud. 2021;00:1–15. doi: 10.1111/ijcs.12691. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Konkol K.L., Rasmussen S.C. Chemical Technology in Antiquity. ACS Publications; 2015. An ancient cleanser: soap production and use in antiquity; pp. 245–266. [Google Scholar]

- Kruszelnicka I., Ginter-Kramarczyk D., Wyrwas B., Idkowiak J. Evaluation of surfactant removal efficiency in selected domestic wastewater treatment plants in Poland. J. Environ. Health Sci. Eng. 2019;17(2):1257–1264. doi: 10.1007/s40201-019-00387-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kumar A., Jain V., Deovanshi A., Lepcha A., Das C., Bauddh K., Srivastava S. Environmental impact of COVID-19 pandemic: more negatives than positives. Environ. Sustain. 2021:1–8. doi: 10.1007/s42398-021-00159-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kutz M. vol. 2. Wiley Online Library; 2007. Environmentally Conscious Materials and Chemicals Processing. [Google Scholar]

- Larson E.L., Committee, A.G APIC guidelines for handwashing and hand antisepsis in health care settings. Am. J. Infect. Control. 1995;23(4):251–269. doi: 10.1016/0196-6553(95)90070-5. [DOI] [PubMed] [Google Scholar]

- Larson E.L., Eke P.I., Wilder M.P., Laughon B.E. Quantity of soap as a variable in handwashing. Infect. Control Hosp. Epidemiol. 1987;8(9):371–375. doi: 10.1017/s0195941700067436. [DOI] [PubMed] [Google Scholar]

- Lechuga M., Fernández-Serrano M., Jurado E., Núñez-Olea J., Ríos F. Acute toxicity of anionic and non-ionic surfactants to aquatic organisms. Ecotoxicol. Environ. Saf. 2016;125:1–8. doi: 10.1016/j.ecoenv.2015.11.027. [DOI] [PubMed] [Google Scholar]

- Levey M. The early history of detergent substances: a chapter in Babylonian chemistry. J. Chem. Educ. 1954;31(10):521. [Google Scholar]

- Li W., Guan R., Yuan X., Wang H., Zheng S., Liu L., Chen X. IOP Conference Series: Earth and Environmental Science. IOP Publishing; 2020. Product soap from waste cooking oil. [Google Scholar]

- Lichtenberg D., Ahyayauch H., Goñi F.M. The mechanism of detergent solubilization of lipid bilayers. Biophys. J. 2013;105(2):289–299. doi: 10.1016/j.bpj.2013.06.007. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Liu M., Liu M., Li Z., Zhu Y., Liu Y., Wang X., Tao L., Guo X. The spatial clustering analysis of COVID-19 and its associated factors in mainland China at the prefecture level. Sci. Total Environ. 2021;777 [Google Scholar]

- Mak-Mensah E., Firempong C. Chemical characteristics of toilet soap prepared from neem (Azadirachta indica A. Juss) seed oil. Asian J. Plant Sci. Res. 2011;1(4):1–7. [Google Scholar]

- Malik N., Kumar P., Shrivastava S., Ghosh S.B. An overview on PET waste recycling for application in packaging. Int. J. Plast. Technol. 2017;21(1):1–24. [Google Scholar]

- Maotsela T., Danha G., Muzenda E. Utilization of waste cooking oil and tallow for production of toilet “Bath” soap. Procedia Manufact. 2019;35:541–545. [Google Scholar]

- Marwah A., Marwah P. Coronavirus (COVID-19): a protocol for prevention, treatment and control. J. Appl. Natural Sci. 2020;12(2):119–123. [Google Scholar]

- Masdar N.D., Roslan R.A.B., Hasan S.B., Kamal M.L. Charting the Sustainable Future of ASEAN in Science and Technology. Springer; 2020. Determination of antioxidant from Ubi Gadong tubers for facial soap Bar; pp. 193–201. [Google Scholar]

- Mousavi S.A., Khodadoost F. Effects of detergents on natural ecosystems and wastewater treatment processes: a review. Environ. Sci. Pollut. Res. 2019;26(26):26439–26448. doi: 10.1007/s11356-019-05802-x. [DOI] [PubMed] [Google Scholar]

- Mustakim M., Taufik R., Trismawati T. The utilization of waste cooking oil as a material of soap. J. Dev. Res. 2020;4(2):86–91. [Google Scholar]

- O’Connell M., De Paula Á., Smith K. 2020. Preparing for a Pandemic: Spending Dynamics and Panic Buying during the COVID-19 First Wave. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Olkowska E., Ruman M., Polkowska Ż. Occurrence of surface active agents in the environment. J. Anal. Method. Chem. 2014;2014 doi: 10.1155/2014/769708. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Organization, W.H . World Health Organization; 2009. WHO Guidelines on Hand Hygiene in Health Care: First Global Patient Safety Challenge Clean Care Is Safer Care. [PubMed] [Google Scholar]

- Partington J.R. JHU Press; 1999. A History of Greek Fire and Gunpowder. [Google Scholar]

- Pathan E., Ahmed S., Shakil S.R. Utilization of limed flesh through fat extraction and soap preparation. Europ. J. Eng. Technol. Res. 2019;4(10):198–202. [Google Scholar]

- Pattusamy V., Nandini N. Detergent and sewage phosphates entering into lake ecosystem and its impact on aquatic environment. Int. J. Adv. Res. 2013;1(3) [Google Scholar]

- Pironti C., Motta O., Ricciardi M., Camin F., Cucciniello R., Proto A. Characterization and authentication of commercial cleaning products formulated with biobased surfactants by stable carbon isotope ratio. Talanta. 2020;219 doi: 10.1016/j.talanta.2020.121256. [DOI] [PubMed] [Google Scholar]

- Pramod K., Kotta S., Jijith U., Aravind A., Tahir M.A., Manju C., Gangadharappa H. Surfactant-based prophylaxis and therapy against COVID-19: a possibility. Med. Hypotheses. 2020;143:110081. doi: 10.1016/j.mehy.2020.110081. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ragazzi M., Rada E.C., Schiavon M. Municipal solid waste management during the SARS-COV-2 outbreak and lockdown ease: lessons from Italy. Sci. Total Environ. 2020;745 doi: 10.1016/j.scitotenv.2020.141159. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rowan N.J., Casey O. Empower eco multi-actor HUB: a triple helix “academia-industry-authority” approach to creating and sharing potentially disruptive tools for addressing novel and emerging new green Deal opportunities under a United Nations’ sustainable development goals framework. Curr. Opin. Environ. Sci. Health. 2021:100254. [Google Scholar]

- Rowan N.J., Laffey J.G. Unlocking the surge in demand for personal and protective equipment (PPE) and improvised face coverings arising from coronavirus disease (COVID-19) pandemic–implications for efficacy, re-use and sustainable waste management. Sci. Total Environ. 2020:142259. doi: 10.1016/j.scitotenv.2020.142259. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rowan N.J., Moral R.A. Disposable face masks and reusable face coverings as non-pharmaceutical interventions (NPIs) to prevent transmission of SARS-CoV-2 variants that cause coronavirus disease (COVID-19): role of new sustainable NPI design innovations and predictive mathematical modelling. Sci. Total Environ. 2021:145530. doi: 10.1016/j.scitotenv.2021.145530. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ruslinda Y., Raharjo S., Dewilda Y., Aziz R. IOP Conference Series: Materials Science and Engineering. IOP Publishing; 2019. Minimization of household hazardous solid waste (HHSW) with 4R concepts (reduce, reuse, recycle and recovery) in Padang City, Indonesia. [Google Scholar]

- Saadat S., Rawtani D., Hussain C.M. Environmental perspective of COVID-19. Sci. Total Environ. 2020:138870. doi: 10.1016/j.scitotenv.2020.138870. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sajna K.V., Höfer R., Sukumaran R.K., Gottumukkala L.D., Pandey A. Industrial Biorefineries & White Biotechnology. Elsevier; 2015. White biotechnology in biosurfactants; pp. 499–521. [Google Scholar]

- Sawadogo B., Sou M., Hijikata N., Sangare D., Maiga A.H., Funamizu N. Effect of detergents from grey water on irrigated plants: case of okra (Abelmoschus esculentus) and lettuce (Lactuca sativa) J. Arid Land Stud. 2014;24(1):117–120. [Google Scholar]

- Scharpenberg C., Schmehl M., Glimbovski M., Geldermann J. Analyzing the packaging strategy of packaging-free supermarkets. J. Clean. Prod. 2021;292 [Google Scholar]

- Schmidt C.W. Lack of Handwashing access: a widespread deficiency in the age of COVID-19. Environ. Health Perspect. 2020;128(6) doi: 10.1289/EHP7493. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Shafran A., Gross A., Ronen Z., Weisbrod N., Adar E. Effects of surfactants originating from reuse of greywater on capillary rise in the soil. Water Sci. Technol. 2005;52(10−11):157–166. [PubMed] [Google Scholar]

- Taseidifar M. Environmental applications of a biodegradable cysteine-based surfactant. Ecotoxicol. Environ. Saf. 2020;206 doi: 10.1016/j.ecoenv.2020.111389. [DOI] [PubMed] [Google Scholar]

- Tesser R., Vitiello R., Russo V., Turco R., Di Serio M., Lin L., Li C. Industrial Oil Plant. Springer; 2020. Oleochemistry products; pp. 201–268. [Google Scholar]

- Teymoorian T., Teymourian T., Kowsari E., Ramakrishna S. Direct and indirect effects of SARS-CoV-2 on wastewater treatment. J. Water Proc. Eng. 2021;42 doi: 10.1016/j.jwpe.2021.102193. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Teymourian T., Teymoorian T., Kowsari E., Ramakrishna S. Challenges, strategies, and recommendations for the huge surge in plastic and medical waste during the global COVID-19 pandemic with circular economy approach. Mater. Circ. Econ. 2021;3(1):1–14. [Google Scholar]

- Thirunavukkarasu A., Nithya R., Sivashankar R., Sathya A.B., Rangabhashiyam S., Pasupathi S.A., Prakash M., Nishanth M. Green soap formulation: an insight into the optimization of preparations and antifungal action. Biomass Convers. Biorefine. 2020:1–12. [Google Scholar]

- Usman M., Farooq M., Hanna K. Environmental side effects of the injudicious use of antimicrobials in the era of COVID-19. Sci. Total Environ. 2020;745 doi: 10.1016/j.scitotenv.2020.141053. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Villalobos-Delgado L.H., Mateo J., Caro I., Ramos M.-Y.L., Mendez N.G., Cansino R.G., Mondragón E.G.G. Sustainable Meat Production and Processing. Elsevier; 2019. Natural antioxidants in fresh and processed meat; pp. 207–236. [Google Scholar]

- Vogel L. Hand sanitizers may increase norovirus risk. Can. Med. Assoc. 2011;183:E799–E800. doi: 10.1503/cmaj.109-3922. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Wandosell G., Parra-Meroño M.C., Alcayde A., Baños R. Green packaging from consumer and Business Perspectives. Sustainability. 2021;13(3):1356. [Google Scholar]

- Wiel-Shafran A., Ronen Z., Weisbrod N., Adar E., Gross A. Potential changes in soil properties following irrigation with surfactant-rich greywater. Ecol. Eng. 2006;26(4):348–354. [Google Scholar]

- Wiktorczyk-Kapischke N., Grudlewska-Buda K., Wałecka-Zacharska E., Kwiecińska-Piróg J., Radtke L., Gospodarek-Komkowska E., Skowron K. SARS-CoV-2 in the environment–non-droplet spreading routes. Sci. Total Environ. 2021;770 doi: 10.1016/j.scitotenv.2021.145260. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Willcox M. Poucher’s Perfumes, Cosmetics and Soaps. Springer; 2000. Soap; pp. 453–465. [Google Scholar]

- Yokokawa N., Masuda Y., Amasawa E., Sugiyama H., Hirao M. Systematic packaging design tools integrating functional and environmental consequences on product life cycle: case studies on laundry detergent and milk. Packag. Technol. Sci. 2020;33(11):445–459. [Google Scholar]

- Zambrano-Monserrate M.A., Ruano M.A., Sanchez-Alcalde L. Indirect effects of COVID-19 on the environment. Sci. Total Environ. 2020;728 doi: 10.1016/j.scitotenv.2020.138813. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zhang G., Zhao Z. Green packaging management of logistics enterprises. Phys. Procedia. 2012;24:900–905. [Google Scholar]

- Zhong Y., Godwin P., Jin Y., Xiao H. Biodegradable polymers and green-based antimicrobial packaging materials: a mini-review. Adv. Indus. Eng. Polym. Res. 2020;3(1):27–35. [Google Scholar]