Abstract

Materials exhibiting high energy/power density are currently needed to meet the growing demand of portable electronics, electric vehicles and large-scale energy storage devices. The highest energy densities are achieved for fuel cells, batteries, and supercapacitors, but conventional dielectric capacitors are receiving increased attention for pulsed power applications due to their high power density and their fast charge–discharge speed. The key to high energy density in dielectric capacitors is a large maximum but small remanent (zero in the case of linear dielectrics) polarization and a high electric breakdown strength. Polymer dielectric capacitors offer high power/energy density for applications at room temperature, but above 100 °C they are unreliable and suffer from dielectric breakdown. For high-temperature applications, therefore, dielectric ceramics are the only feasible alternative. Lead-based ceramics such as La-doped lead zirconate titanate exhibit good energy storage properties, but their toxicity raises concern over their use in consumer applications, where capacitors are exclusively lead free. Lead-free compositions with superior power density are thus required. In this paper, we introduce the fundamental principles of energy storage in dielectrics. We discuss key factors to improve energy storage properties such as the control of local structure, phase assemblage, dielectric layer thickness, microstructure, conductivity, and electrical homogeneity through the choice of base systems, dopants, and alloying additions, followed by a comprehensive review of the state-of-the-art. Finally, we comment on the future requirements for new materials in high power/energy density capacitor applications.

1. Introduction

To limit global warming to <1.50 °C, as set out in the Paris agreement, carbon dioxide emissions need to decrease ∼45% by 2030 and reach net-zero by 2050.1,2 Technologies based on renewable resources such as sun, wind, and tides will play a pivotal role to meet these targets. Although the increasing deployment of renewable energies is encouraging, there still are many barriers to the replacement of power generation from traditionally high CO2-emitting sectors based on coal and gas, which is still a critical and large portion of the energy generation, due to the intermittent nature of renewables. Hence, to simultaneously move away from fossil fuels and to circumvent the unpredictability inherent in clean energy resources, it is necessary to integrate energy-harvesting technologies with energy storage devices.

Energy storage, therefore, is emerging as a key enabler for sustainable renewable technologies, particularly for the electrification of transportation but also in more specialized applications such as heart defibrillators and active armor.3 Technologies already exist to store energy, such as batteries, electrochemical supercapacitors, and electrostatic capacitors.4−16 The latter are electrical energy-storage devices belonging to the category of passive components, which are ubiquitous in electronics. Indeed, every year more than 3 trillion multilayer ceramic capacitors (MLCCs) are manufactured from BaTiO3 (BT), the prototypical ferroelectric (FE) ceramic.17−22

In comparison with Li-ion batteries or fuel cells, the nonpolarized electrostatic or dielectric capacitors possess high power density (∼104–105 W/kg) resulting from their faster charging/discharging characteristics (∼μs), which are advantageous for power electronics in electrical vehicles (EVs) and pulse power applications (Figure 1a).4,23−27 Hence, electrostatic capacitors are emerging as promising candidates for energy storage devices, where high power density in combination with high energy density are important technological requirements, as illustrated by the exponential rise in publications devoted to energy storage involving electrostatic ceramic capacitors, Figure 1b. Apart from high energy density and fast charging–discharging rate, other properties such as temperature/frequency stability, fatigue resistance, lifetime reliability, equivalent series resistance, and manufacturing cost are equally important for dielectric capacitors used in practical applications. New electroceramics are, therefore, required to facilitate near-engine power electronics, exhibit ultrafast charging, and have more durable EV performance at high temperature and voltage. Thus, future electroceramics must (i) deliver high energy density (Wrec > 10 J cm–3) and conversion efficiencies (η > 90%); (ii) endure wider temperature ranges (−50–250 °C) and frequency ranges (1–1000 Hz); (iii) exhibit greater reliability (>105 cycles) and fatigue resistance (<5% change over capacitor lifetime); and (iv) be compatible with cost-effective internal electrodes and be easily integrated with other components.

Figure 1.

(a) Applications for energy storage capacitors. *EMP: electromagnetic pulse. (b) Number of annual publications on lead-based ceramics, lead-free ceramics, ceramic multilayers, and ceramic films for energy storage capacitors from 2010 to 2020. (Collected from Web of Science, search “energy storage/density lead-based ceramic, lead-free ceramic, multilayer ceramic, ceramic capacitor, ceramic films but NOT polymer”). Reproduced with permission from PixaBay, Creative Commons License.

Historically, many different dielectric materials, ranging from paper and plastic to ceramics, have been employed in the fabrication of electrostatic capacitors. Nowadays, capacitors are fabricated from either polymers or ceramics because they offer the best combination of properties in terms of capacitance, dielectric loss, breakdown strength (BDS), and for the latter, thermal stability.

The prospects of employing ceramic capacitors for energy storage can be traced back to the 1960s work by Jaffe28 from the Clevite Corp., USA. One decade later, Burn and Smyth29 from Sprague Electric Company evaluated the energy storage performance in SrTiO3 (ST) and BT with applied electric fields up to 400 kV cm–1. Until that point, quantitative data of energy storage on these materials were limited to fields generally smaller than 150 kV cm–1 due to the relatively low dielectric BDS of the fabricated ceramics. They emphasized that the maximum energy density for a ceramic should be obtained for thinner dielectric layers due to the lower probability for the occurrence of defects (such as pores, voids, or microcracks), which are well-known sources of dielectric breakdown. Later in 1990, Love,30 also from Sprague Electric Company, revisited energy storage in ceramic capacitors and highlighted empirical design principles to achieve enhanced energy storage in capacitors, as shown in Table 1. Commercial C0G-type capacitors are manufactured from low relative permittivity (εr) linear dielectrics but may achieve an energy storage of 1 J cm–3, by virtue of their intrinsically high BDS. The significance of the BDS, to achieve high energy storage becomes apparent in the case of X7R-type capacitors, fabricated from high εr BT. An important correlation between dielectric BDS and the thickness (t) can be extracted from Table 1. Indeed, by halving the t of the dielectric layers, the energy storage appears to increase >3 fold. This effect has been recently captured by Yang and co-workers,31 who compiled BDS data from literature for several dielectric materials of different t and observed decay inversely proportional to (t)a, where a was determined as 0.5. Finally, when comparing the energy storage of Z5U and X7R, it becomes apparent that high εr alone is not a sufficient parameter to achieve high energy storage. Interestingly, Love30 stressed that the capacitor industry was rather conservative in terms of perfecting the BDS of ceramics to reach values near those of single-crystals, which would significantly enhance the energy storage in ceramic capacitors.

Table 1. General Characteristics of Commercial Type Ceramic Materials Relevant for Energy Storage (Adapted from Love30) Using Electronic Industries Alliance (EIA) Classificationsa.

| dielectric type | dielectric BDS (V μm–1) | relative permittivity, εr | t (μm) | energy at 1 kV (J cm–3) |

|---|---|---|---|---|

| C0G (temperature coefficient 0 with tolerance ±30 × 10–6/K) | 65 | 75 | 18.5 | 0.88 |

| Z5U (+10/+85 °C, ΔC/C0 = +22/–56%) | 13.2 | 7500 | 95 | 0.02 |

| X7T (−55/+125 °C, ΔC/C0 = +22/–33%) | 16 | 2800 | 70 | 0.71 |

| X7R (−55/+125 °C, ΔC/C0 = ± 15%) | 30 | 2000 | 38 | 1.40 |

| X7R | 40 | 2000 | 30 | 1.34 |

| X7R | 90 | 1800 | 20 | 4.82 |

Class I ceramic capacitors are accurate, temperature-compensating capacitors, C0G will have 0 drift with a tolerance of ±30 × 10–6/K. Class II ceramic capacitors have a dielectric with a high permittivity. C and C0 are represented capacitance value and capacitance value at 25 °C.

Love30 proposed that maximum energy storage density can be achieved in intermediate rather than high εr materials since they exhibit larger BDS. Fletcher and co-workers32 convincingly postulated that greater energy storage densities can indeed be achieved in FE materials, whose Curie temperature (Tc) is adjusted to ensure that the material is operated in the paraelectric regime, where it shows a relatively small zero-field εr, an approach already mentioned by Jaffe in 1961.28

In 2009, Ogihara and co-workers33 proposed the use of so-called weakly coupled relaxors, such as 0.7BaTiO3–0.3BiScO3 (0.7BT–0.3BS), to fabricate energy storage devices. This new conceptual approach aimed at exploiting the extraordinary temperature stability of εr exhibit by this family of materials. When compared with commercial X7R capacitors, 0.7BT–0.3BS capacitors displayed superior performance, reaching a recoverable energy density (Wrec) of 6.1 J cm–3 at 730 kV cm–1. Again, the large dielectric BDS played a decisive role in this performance. More recently, in 2019 Wang, Reaney and co-workers34 unveiled a novel approach to enhance energy storage characteristics via the fabrication of chemically heterogeneous but electrically homogeneous ceramics, with Wrec reaching 10.5 J cm–3, as detailed later in this review.

Here, we present the principles of energy storage performance in ceramic capacitors, including an introduction to electrostatic capacitors, key parameters for evaluating energy storage properties, microstructural considerations, and critical electrical factors. Second, we will review the current state-of-the-art for lead and lead-free electroceramics for energy storage capacitors with bulk ceramics, ceramic multilayers (MLs), ceramic films and glass ceramics evaluated separately. Third, we will describe strategies for optimizing energy storage in electroceramics. Finally, we will demonstrate, with appropriate examples, a guide to the future development for electroceramics in energy storage capacitors.

2. Principles of Energy Storage in Electroceramics

2.1. Electrostatic Capacitors

The simplest dielectric capacitor consists of two parallel metallic plates separated by an insulator, which becomes polarized under the application of an electric field. This is the defining behavior of a dielectric material. The actual capacitance, C (i.e., ability to store charge), of an ideal capacitor is given by the ratio of the charge, Q, stored on each metallic plate and the applied voltage, V, as shown by eq 1.

| 1 |

Nevertheless, from a practical viewpoint, a more useful equation to compute the C of a real device, as illustrated in Figure 2, encompassing a dielectric material between two parallel plates of area, A, separated by a distance, d, subject to a V, can be obtained through the application of Gauss’s law

| 2 |

where ε is the permittivity of the dielectric, and a measure of its polarizability. Combination of eqs 1 and 2 provides the relationship:

| 3 |

From eq 3, it becomes immediately apparent that the ability of dielectric capacitor to charge and, therefore store energy, is ultimately associated with ε of the dielectric.

Figure 2.

Schematic representation of an electrostatic capacitor, where D, P, and ε0 are electric displacement, polarization, and electric permittivity of free space (electric constant), respectively.

2.2. Key Parameters for Evaluating Energy Storage Properties

During the application of a V, the electrostatic energy stored, W, in the dielectric can be estimated by

| 4 |

where Qmax is the maximum charge achieved at the end of the charging cycle and dq is the incremental charge increase during the charging cycle. The volumetric energy density, Wst (i.e., the energy stored per volume unit, A d), is a common key performance indicator, expressed by

| 5 |

where E is the electric field and Dmax is the electric displacement in the material under the maximum applied field, Emax. The electrical displacement (D) corresponds to the charge density (Q/A) on the metallic plates and is expressed by D = ε0E + P (Figure 2), where P is the polarization (surface charge density).

For high ε materials, D is approximately equal to P, and it follows that D = εE = ε0εrE, where ε0 is the permittivity of free space (= 8.854 × 10–12F m–1) and εr is the relative permittivity, which is the ε/ε0 ratio. This approximation allows stored energy density (Wst) to be defined in terms of P, as follows

| 6 |

where Pmax is the maximum polarization reached at the Emax. From a practical viewpoint, eq 6 is prevalent in the calculation of Wst because several experimental methods exist to determine P under an applied E. In 1961, Jaffe28 pointed out that the recoverable energy (Wrec) corresponds to the area above the discharging curve, whose upper limit is given by the Pmax. Essentially, the mathematical integration of the area above a polarization-electric (P–E) loop provides an estimate of Wrec, as schematically illustrated in Figure 3 for four distinct types of polarization response.

Figure 3.

Four distinctive P–E hysteresis loops and their energy storage behavior: (a) linear, (b) FE, (c) relaxor-ferroelectric (with the schematic of energy storage calculation), and (d) antiferroelectric materials. *Wloss is loss energy density.

For linear dielectrics such as Al2O3, where εr is independent of the applied E. The calculation of Wrec from the P–E response illustrated in Figure. 3a, is given by

| 7 |

which clearly shows that Wrec is dependent on εr and E. Parts b–d of Figure 3 show cases where polarization responses deviate from linearity, and consequently, the computation of Wrec needs to be carried out using eq 6. The response illustrated in Figure 3b is typical of a classical FE material, such as BT, where the hysteresis is linked to polarization switching of macroscopic FE domains, as explained in detail in the review by Damjanovic.35 Already in 1961, Jaffe28 stressed that in FEs, charging energy is mainly absorbed by domain switching and is retained as remanent polarization (Pr). The typically high remanence of classical FEs can be effectively minimized via chemical doping, giving rise to the response shown in Figure 3c, which is characteristic of relaxor-ferroelectrics (RFEs), such as doped-BT and Pb(Mg1/3Nb2/3)O3.36

It is now generally accepted that relaxor behavior originates from the response of polar nanoregions (PNRs) to an alternating E. RFEs remain unsaturated at high applied E, and therefore, any increment of the E will have a contribution to energy storage. Remanence-free materials are therefore, preferable for achieving high Wrec. Linear dielectric materials meet this requirement but due to their low εr, energy storage is limited. Antiferroelectrics (AFEs) display low-remanence under low E but at large E the P–E loop opens due to the stabilization of an FE with respect to AFE phase and they display a saturated polarization, as illustrated in Figure 3d. In principle, therefore, as suggested by Jaffe,28 AFEs should afford advantages for high energy storage, providing that dielectric breakdown issues are eliminated (i.e., the BDS should be high enough to induce the AFE-FE phase transition).

From the above, it becomes evident that nonlinear dielectric materials such as FEs, RFEs, and AFEs exhibit energy dissipation (Wloss); therefore, the Wrec is actually the most important parameter, as schematically illustrated in Figure 3c (red area). Hence, Wrec becomes

| 8 |

Energy conversion efficiency of a capacitor can then be calculated as

| 9 |

where Wloss is the energy loss during discharging, which correlates to the area enclosed by the P–E loop (Figure 3c green area).

Electric-field induced polarization can be determined via the measurement of charge, current, and voltage responses, typically achieved using either the Sawyer–tower, the virtual ground, the shunt or the current step methods. Each presents advantages and disadvantages as listed in Table 2. For details of each method, the reader is referred to Prume and co-workers.37 Prume, Schmitz, and Tiedke proposed that overall the virtual ground method offers the highest precision for the measurement of FEs.

Table 2. Comparison of Different Hysteresis Measurement Methods for FEs37.

| method | measured quantity | reference component | integration necessary | bandwidth requirement | influence of parasitics |

|---|---|---|---|---|---|

| Sawyer–tower | charge Q | capacitor | no | moderate | high |

| virtual ground | current I | no | yes | high | low |

| shunt | current I | resistor | yes | high | high |

| current step | voltage V | no | no | moderate | moderate |

2.3. Key Factors for Optimizing Energy Density

The microstructural features of electroceramics, such as density, grain size, secondary phases and core–shell structures, play an important role in energy storage properties. Simultaneously, the intrinsic electrical response, e.g., band gap, alongside the electrical microstructure, i.e., the distribution of conductive and resistive elements, are equally critical factors for the optimization of energy density. The following section reviews these factors, and gives examples of where and how they may be optimized.

2.3.1. Intrinsic Band Gap

The band gap (Eg) is the forbidden energy between the top of the valence band and bottom of the conduction band. Eg is commonly used to define insulator (Eg > 4.0 eV), semiconductor (0.0 eV < Eg < 4.0 eV), and metal (Eg = 0.0 eV). For semiconductor, the intrinsic BDS can be defined as

| 10 |

where BDS is direct proportional to Eg.38 Thus, semiconductors with wider Eg have higher intrinsic BDS. The electronic structure and band gaps of semiconductor can be studied theoretically using, e.g., linear discriminant analysis, or experimentally, e.g., absorbance spectroscopy and diffuse reflectance spectroscopy.39 A general rule of thumb is that the activation energy (Ea) for conduction is approximately half Eg. Both may be increased by doping or through the formation of solid solutions, often delivering higher BDS and Wrec.40,41

For example, the highest Eg ∼ 3.58 eV among all different kinds of lead-free electroceramics was found in NaNbO3 (NN), as shown in Figure 4a.42 Thus, NN was introduced into Na0.5Bi0.5TiO3 (NBT) and BiFeO3–BaTiO3 (BF–BT) to enhance Eg. The Eg for BF–BT–xNN ceramics increased from 2.5 eV up to 2.95 eV for x ≤ 0.15, as shown in Figure 4b accompanied by significant enhanced Wrec ∼ 8.12 J cm–3 under electric field ∼400 kV cm–1, along with greater thermal stability (±10%, −50 to +250 °C) and ultrafast discharge rate (t0.9 < 100 ns), Figure 4.43

Figure 4.

(a) Comparison of the Eg among dielectric perovskites and a schematic of electronic breakdown. (b) Variation of average grain size and Eg as a function of NN concentration. (c) P–E loops and dP/dE under different E, (d) Wrec and η values, and (e) pulsed overdamped discharging energy density (WD) of the BF–BT–0.10NN ceramic. (a) Reproduced with permission from ref (42). Copyright 2019 John Wiley and Sons. (b-e) Reproduced with permission from ref (43). 2020 John Wiley and Sons.

2.3.2. Electrical Microstructure

The distribution of regions with different conductivity and εr are important aspects of the so-called “electrical microstructure” of electroceramics.44 In many instances, such as the core–shell microstructure or grain boundary response of BT based ceramics, the distributions are markedly heterogeneous and lead to localization of the electrical field strength in lower εr regions or pathways for breakdown through interconnected conducting regions. In 2019, electrical homogeneity was for the first-time proposed by Wang, Reaney and co-workers in the BF–BT system as a key factor to optimize BDS and as a consequence Wrec. Electrical heterogeneity was effectively eliminated by alloying with a third end-member so that it became more difficult to form a conductive pathway at high field, resulting in higher BDS and Wrec.34

A homogeneous electrical microstructure may be obtained in many different ways such as heat-treatment in the appropriate atmosphere (N2, Air, O2) provided the type and magnitude of electrical conductivity is affected by oxygen stoichiometry. Practically, however, in production, a suitable dopant strategy is utilized once the conduction type is known (p vs n type). For example, the conductivity of BF-ST-based compositions is suppressed by doping with 3 mol % Nb on the B-site to compensate for Bi volatilization and the formation of oxygen vacancies (VO..), through variation of the Fe valence (Fe3+ to Fe4+).45

For materials with more than one bulk-like region, e.g., phase mixtures, core–shell microstructures, or surface layers, alternating current (AC) impedance spectroscopy (IS) is able to show multiple responses and the resistance (R) and C can be extracted.46−53 Both the volume fraction and difference in magnitude of R and C for multiple electrical responses are equally important in influencing energy storage performance. Given the importance of the electrical microstructure, a brief outline of the role of IS is described and its advantages with respect to direct current methods are emphasized.

Direct current (DC) electrical measurements are the most commonly employed technique to evaluate the electrical characteristics of materials. However, they merely give the overall response instead of the properties of specific regions (e.g., grains and grain boundaries) unless microprobe techniques are employed.54,55 Such techniques are useful but the sample volume is small, which casts doubt on their ability to represent global behavior and they are difficult to implement experimentally.

An alternative and much more convenient technique is IS. In IS measurements, an AC signal with small voltage over a wide range of frequency, typically 10–2 to 107 Hz, is applied on the sample.44,56 The small voltage prevents any permanent change to the sample as well as yielding a (near) linear relationship between input and output. The wide range of frequencies allows separation of the response of different electro-active regions according to their relaxation times. For energy storage capacitors, impedance is capable of: (i) establishing the contributions to the electrical microstructure (grains, grain boundaries, core–shell structure and electrode–sample interface) and determine their individual conductivity and εr which give an insight into the distribution of electrical components within the sample; (ii) verifying the origin of the dominant electrical behavior (i.e., grains, grain boundary or interfacial layer response);57,58 and (iii) determining the conduction mechanism and charge carrier type which helps further interpret the electrical response of the material.47

Impedance can be defined as a complex number which usually contains both resistive and reactive (capacitive and/or inductive) components:

| 11 |

Different electro-active regions of a material are characterized by a R and a C, usually in parallel. Then the electric relaxation time or time constant, τ, of each region can be expressed as its R and C

| 12 |

at the frequency of maximum loss, ωmax, it holds the relation:

| 13 |

Due to their different R and C values, electro-active regions can be separated in the frequency domain. Once the value of R and C are extracted, they can then be assigned to appropriate regions of the sample.

Normally the impedance measurement needs to be taken over a temperature and/or oxygen partial pressure (pO2) range to gain a better understanding of the conduction mechanism and the charge carrier. The associated activation energy, Ea, can be estimated using Arrhenius equation

| 14 |

where σ is the conductivity, σ0 is pre-exponential factor, k is the Boltzmann constant, and T is temperature. Ea may be related to predominant charge carrier and conduction mechanism. The type of charge carrier may also be determined to some extent by the pO2 dependence of conductivity, i.e., p-type: conductivity increases with increasing pO2; n-type: conductivity decreases with increasing pO2; ionic charge carrier: conductivity is independent with pO2.

2.3.3. Density and Porosity

The density of the ceramic materials plays an essential role on electrical performance, especially BDS. Ceramics with higher density tend to support higher E closer to the intrinsic/theoretical BDS. In contrast, low density ceramics exhibit conductive pathway composed of pores/voids which result in short circuit under modest field strengths. The relationship between the voltage across the pore and the external E based on a “slab” model is shown below

| 15 |

where Vc and Vext are the voltage applied cross the cavity pore and external applied voltage, εc and εd are the permittivity of the cavity and the dielectric, respectively,59,60 and td and tc are the thicknesses of the dielectric and cavity, respectively. Thus, the local E increases markedly for materials with larger pores and pore volumes, resulting in lower BDS.

High density electroceramic materials are commonly obtained by optimization of the sintering conditions, including sintering temperature/time and heating/cooling rate. For ceramics that are difficult to densify using a conventional approach, sintering aids are often added.61−64 Higher density ceramics may be obtained by the addition of ZnO,65 CuO,66 and MgO,62 which enhances BDS and Wrec. For K0.5Na0.5NbO3–Bi(Mg2/3Nb1/3)O3 (KNN–BMN), small amounts of CuO help densify ceramics through the formation of a transient liquid phase, as reported by Qu and co-workers (Figure 5).64 The sintering temperature was also reduced from 1150 to 930 °C, allowing compatibly with Cu or Ag/Pd internal electrode in MLs and giving rise to Wrec ∼ 4.02 J cm–3 at 400 kV cm–1 for 0.9KNN-0.1BMN with 1% mol CuO.66

Figure 5.

Scanning electron microscopy (SEM) images of the 0.9KNN-0.1BMN-x mol % CuO ceramics with (a) x = 0.25; (b) x = 0.5; (c) x = 1.0; (d) x = 1.5, as liquid phase is circled in red. (e) Unipolar P–E hysteresis loops and (f) Calculated W and Wrec under different E of 0.9KNN-0.1BMN-1 mol % CuO ceramics.66 Reproduced with permission from ref (66). Copyright 2017 John Wiley and Sons.

Different sintering technologies, such as spark plasma sintering (SPS), two-step sintering,67 and the formation of coatings using chemical methods,68−81 have also been shown to improve density and give rise to higher BDS and Wrec.

2.3.4. Grain Size

The effect of grain size (G) on energy storage properties has been discussed for several electroceramics because of the relationship between BDS and G, expressed in eq 16

| 16 |

where a is the exponent values being in the range of 0.2–0.4.31,82−84 Waser explained that leakage current in fine-G ceramics is lower than coarse-G ceramics due to the high grain boundary density which act as barriers for charge carriers.85 Thus, dielectric materials with high density and fine-G are required to optimize energy storage. G may be tailored by chemical doping and the formation of solid solution. It may also be modified by the application of an ultrathin coating on the primary particles prior to sintering via chemical coating methods, e.g., SiO2 on BT ceramics.67,77,86−89 The optimization on Emax and Wrec via grain size-engineering for several materials is illustrated in Figure 6.

Figure 6.

Relationship between energy storage properties of ceramics and G: (a) G vs Emax and (b) G vs Wrec. *AN: AgNbO3.

For example, an average G ∼ 10 μm was reported for BF–BT ceramics, which was reduced to <2 μm after A-site Nd doping, as shown in Figure 7. Meanwhile, improved Wrec ∼ 1.8 J cm–3 and η ∼ 88% were obtained for 15 mol % Nd–BF–BT and 40 mol % Nd–BF–BT, respectively.90 Similar optimization behavior has also been found in KNN–BMN and KNN–ST ceramics, resulting in BDS ∼ 400 kV cm–1 and Wrec > 3.5 J cm–3.91,92

Figure 7.

SEM images of x mol % Nd-doped BF–BT with different Nd concentrations: (a) BF–BT, (b) 2.5 mol % Nd–BF–BT, (c) 5 mol % Nd–BF–BT, (d) 7.5 mol % Nd–BF–BT, (e) 10 mol % Nd–BF–BT, (f) 15 mol % Nd–BF–BT, (g) 20 mol % Nd–BF–BT, (h) 30 mol % Nd–BF–BT, and (i) 40 mol % Nd–BF–BT; the G distributions of Nd-doped BF–BT are shown in the insets of the SEM images.90 (j) G, density and (k) energy storage performance at 170 kV cm–1, as a function of x(Nd) mol % in BF–BT ceramics. Reproduced with permission from ref (90). Copyright 2017 Royal Society of Chemistry.

2.3.5. Core–Shell Structure

Core–shell subgrain microstructures are observed in many lead-free ceramics, due to either kinetic limitations of the diffusion process (typical for BT based ceramics) or immiscibility on cooling from high temperature for perovskite end members with dissimilar ion size and bonding (BF based ceramics).22,34,45 The effect of core–shell microstructures on energy storage performance is still unclear. In BT-based ceramics, the cores are often more conducting than the doped shells and core to core conductive pathways lead to breakdown.93−96 For BF based ceramics, the defect chemistry of the cores and shells remains to be elucidated, but initial work suggests that further dopants are needed to create electrical homogeneity and thus eliminate the conducting pathways.34,45 The theoretical modeling has reported a positive influence of core–shell microstructure but none have been unambiguously validated experimentally.97

3. State-of-the-Art in Electroceramics for Energy Storage

3.1. Bulk Ceramics

3.1.1. Lead-Based Ceramics

Lead-based ceramics are used commercially as energy storage materials for high-power pulsed capacitors due to their excellent Wrec and η.98−101 The energy storage properties of RFE and AFE lead-based ceramics are summarized in Table 3.

Table 3. Summary of Energy Storage Properties for Lead-Based Ceramicsa.

| compositions | E (kV cm–1) | ΔP (μC cm–2) | Wrec (J cm–3) | η (%) | ref |

|---|---|---|---|---|---|

| (Pb0.89Ba0.08La0.02)(Zr0.7Sn0.27Ti0.03)O3 | 135 | 22.6 | 2.1 | 76.5 | (150) |

| (Pb1.067La0.02)(Zr0.95Ti0.05)O3 | 90 | 39.5 | 2.12 | 92.98 | (141) |

| 0.90(Pb0.97La0.02)(Zr0.65Sn0.30Ti0.05)O3–0.10Bi(Zn2/3Nb1/3)O3 | 115 | 29 | 2.19 | 95.6 | (162) |

| Pb0.97La0.02(Zr0.58Sn0.35Ti0.07)O3 | 118 | 29.0 | 2.35 | 86.1 | (158) |

| Pb0.91La0.02Ba0.06(Zr0.65Sn0.3Ti0.05)O3 | 150 | 29.5 | 2.4 | 82 | (159) |

| (Pb0.93Ba0.04La0.02)(Zr0.65Sn0.3Ti0.05)O3–0.005Mn2O3 | 308 | 31.5 | 2.64 | 73 | (161) |

| Pb0.97La0.02(Zr0.33Sn0.55Ti0.12)O3@0.05SiO2 | 238 | 34.6 | 2.68 | 83.5 | (87) |

| (Pb0.87Ba0.1La0.02)(Zr0.65Sn0.3Ti0.05)O3–0.75Y | 130 | 46.5 | 2.75 | 71.5 | (149) |

| (Pb0.88La0.08)(Zr0.91Ti0.09)O3 | 170 | 31.5 | 3.04 | 92 | (112) |

| 1.7 mol % Pr3+ doped 0.24Pb (In1/2Nb1/2)O3–0.42Pb(Mg1/3Nb2/3)O3-0.34PbTiO3 | 50 | 20 | 3.1 | 90 | (109) |

| 0.92Pb(Tm0.5Nb0.5)O3–0.08Pb(Mg1/3Nb2/3)O3 | 310 | 17.03 | 3.12 | (136) | |

| (Pb0.87Ba0.1La0.02)(Zr0.68Sn0.24Ti0.08)O3 | 180 | 58.2 | 3.2 | (151) | |

| Pb0.97La0.02(Zr0.50Sn0.46Ti0.04)O3 | 150 | 43 | 3.2 | 86.5 | (124) |

| 0.55(Pb0.97La0.02)(Zr0.93Sn0.05Ti0.02)O3–0.45(Pb0.93Ba0.04La0.02) (Zr0.65Sn0.3Ti0.05)O3 | 180 | 25 | 3.2 | 74.4 | (160) |

| Pb0.97La0.02(Zr0.56Sn0.35Ti0.09)O3 | 175 | 39.4 | 3.3 | 80 | (166) |

| (Pb0.895La0.07)(Zr0.9Ti0.1)O3 | 175 | 42.3 | 3.38 | 86.5 | (115) |

| 0.9PbHfO3–0.1Pb(Mg0.5W0.5)O3 | 155 | 43.5 | 3.7 | 72.5 | (134) |

| Pb0.94La0.04(Lu0.5Nb0.5)O3 | 681 | 3.85 | (137) | ||

| (Pb0.955La0.03)(Zr0.50Sn0.42Ti0.08)O3 | 180 | 41 | 3.99 | 79.2 | (127) |

| Pb0.97La0.02(Zr0.60Sn0.35Ti0.05)O3 | 200 | 34.48 | 4.1 | (121) | |

| (Pb0.97La0.02)(Zr0.5Sn0.44Ti0.06)O3 | 250 | 29.3 | 4.2 | 82 | (117) |

| (Pb0.97La0.02)(Zr0.5Sn0.44Ti0.06)O3 | 250 | 29.3 | 4.2 | 82 | (118) |

| Pb0.955La0.03(Zr0.5Sn0.43Ti0.07)O3 | 200 | 36 | 4.2 | 78 | (126) |

| (Pb0.97La0.02)(Zr0.8Sn0.145Ti0.055)O3 | 225 | 34 | 4.38 | 73 | (124) |

| (Pb0.858Ba0.1La0.02Y0.008)(Zr0.65Sn0.3Ti0.05)O3- (Pb0.97La0.02)(Zr0.9Sn0.05Ti0.05)O3 | 200 | 46.8 | 4.65 | 60 | (152) |

| La0.02Pb0.97[(Yb0.5Nb0.5)0.92Ti0.08]O3 | 240 | 34 | 5.18 | 65 | (135) |

| (Pb0.97La0.02Zr0.85Sn0.12Ti0.03O3)−0.5 wt % Al2O3 | 315 | 35.5 | 5.3 | 88.3 | (72) |

| (Pb0.955Sr0.015La0.02)(Zr0.75Sn0.195Ti0.055)O3 | 350 | 33.5 | 5.56 | 70 | (156) |

| Pb0.97La0.02(Zr0.5Sn0.45Ti0.05)O3 | 400 | 36.2 | 5.6 | 63 | (116) |

| (Pb0.858Ba0.1La0.02Y0.008)(Zr0.65Sn0.3Ti0.05)O3–(Pb0.97La0.02)(Zr0.9Sn0.05Ti0.05)O3 | 306 | 48.5 | 6.4 | 62.4 | (173) |

| Pb[(Lu0.5Nb0.5)–(Mg0.5W0.5)]O3 | 340 | 46 | 6.4 | 71 | (132) |

| Pb0.91La0.06(Zr0.552Sn0.368Ti0.08)O3@1 wt %PbO–B2O3–SiO2–Al2O3–ZnO–MnO2 | 380 | 43 | 7.4 | 91.6 | (77) |

| PbHfO3 | 270 | 44.5 | 7.6 | 80.8 | (133) |

| Pb0.98La0.02(Hf0.45Sn0.55)0.995O3 | 380 | 36 | 7.63 | 94 | (138) |

| (Pb0.91La0.06)(Zr0.96Ti0.04)O3–1.0 mol % MnCO3 | 300 | 43.5 | 7.65 | 87 | (145) |

| (Pb0.98La0.02)(Zr0.55Sn0.45)0.995O3 | 400 | 41.5 | 10.4 | 87 | (131) |

| (Pb0.94La0.02Sr0.04)(Zr0.9Sn0.1)0.995O3 | 400 | 44 | 11.18 | 82.2 | (130) |

t of the bulk ceramics is commonly >0.1 mm.

3.1.1.1. Lead-Based Relaxor-Ferroelectrics

Many lead-based RFEs, including Pb(Mg1/3Nb2/3)O3–PbTiO3 (PMN–PT), Pb(Zn1/3Nb2/3)O3–PbTiO3 (PZN–PT), and (Sr,Pb,Bi)TiO3 (SPBT)-based materials, have been reported as potential candidates for energy storage capacitors.102−110 Zhang and co-workers investigated the relaxation behavior and energy storage properties of (1–x)PMN–xPT ceramic, obtaining Wrec ∼ 0.47 J cm–3 at room temperature.102 Li and co-worker probed the effect of domain structure on Wrec and thermal stability of 0.2PMN–0.8Pb(SnxTi1–x)O3 (PMN–PSxT1–x) ceramics, as illustrated in Figure 8. 0.2PMN–0.8PST ceramics exhibited Wrec ∼ 0.85 J cm–3 with excellent thermal stability which was attributed to the coexistence of ferroelectric domains and PNRs.111

Figure 8.

Wrec of 0.2PMN–0.8PSxT1–x ceramics with different Sn (x) contents at 70 kV cm–1. The insets show the mechanism of enhanced energy storage due to coexistent-phase structure and the Wrec for PMN–PSxT1–x ceramics under different electric fields. Reproduced with permission from ref (111). Copyright 2018 Elsevier.

3.1.1.2. Lead-Based Antiferroelectrics

PbZrO3 (PZ) is the first known AFE and exhibits a double P–E hysteresis loop below TC. However, the high critical switching field required for an AFE–FE phase transition at room temperature limits applications for energy storage. Chemical substitution to reduce switching field is an effective strategy to overcome the problem and three well-known PbZrO3 based compositions are reviewed: (i) (Pb,La)(Zr,Ti)O3 (PLZT);112−115 (ii) (Pb,La)(Zr,Sn,Ti)O3 (PLZST);116−129 and (iii) (Pb,La)(Zr,Sn)O3 (PLZS).130,131 Additionally, some new AFEs have also been identified based on PbHfO3, Pb(Lu0.5Nb0.5)O3, Pb(Yb0.5Nb0.5)O3, and Pb(Tm0.5Nb0.5)O3.132−138

3.1.1.2.1. (Pb,La)(Zr,Ti)O3 (PLZT)

According to the phase diagram (Figure. 9), PLZT exists as homogeneous compositions over a wide range of mol % La in the PbZrO3–PbTiO3 solid solution.139,140

Figure 9.

Phase diagram of PLZT at room temperature.139 Reproduced with permission from ref (139). Copyright 2014 Elsevier.

When Pb ions are replaced by ≤30 mol % La on the A-site in accordance with a lead vacancy (Vpb..) ionic compensation model, an orthorhombic AFE phase similar to PbZrO3 occurs for Zr rich compositions. However, only PLZT with <10 mol % La is typically utilized for energy storage applications141−147 since higher concentrations have lower polarization and therefore lower Wrec. Li and co-workers prepared (Pb0.97La0.02)(Zr0.95Ti0.05)O3 ceramics via a solid-state reaction route, yielding Wrec ∼ 0.83 J cm–3 and η ∼ 70% under an electric field of 55 kV cm–1.114 Jo and co-workers found that AFE and RFE behavior can both be obtained by substitution of La and excess PbO in PLZT, resulting in the enhancement of Wrec by promoting a slim and slanted hysteresis loop. Both high Wrec ∼ 3.04 J cm–3 and η ∼ 92% were obtained along with no performance degradation after 105 cycles.112 Tuning the Zr/Ti ratio has also shown to be an effective way to improve Wrec of PLZT ceramics. Qiao and co-workers reported slimmer P–E loops giving a Wrec ∼ 3.38 J cm–3 in (Pb0.895La0.07)(ZrxTi1–x)O3 ceramics by changing the Zr/Ti ratio (Figure 10), which was attributed to the reduction of tolerance factor and “enhancement of antiferroelectricity”.115 Mn doping is also suggested to improve Wrec of PLZT by “enhancing antiferroelectricity”.143−145

Figure 10.

Effect of Zr/Ti ratio on P–E loops and energy storage properties of PLZT.115 Reproduced with permission from ref (115). Copyright 2019 Elsevier.

3.1.1.2.2. (Pb,La)(Zr,Sn,Ti)O3 (PLZST)

To further optimize the energy storage properties of PLZT ceramics, Sn may be substituted on the B-site of PLZT, which broadens the AFE compositional range,72,77,87,116,122,148−166 in accordance with phase diagram from 1989 (Figure 11).167 (Pb0.97La0.02)(Zr,Sn,Ti)O3 with 2 mol % La has been most commonly studied in which the Zr/Ti/Sn ratio is varied to give a complex phase diagram that contains FE tetragonal (FT), high-temperature nontilted FE rhombohedral (FR(HT)), low temperature FE rhombohedral (FR(LT)) AFE tetragonal (AT), and AFE orthorhombic (AO) phases.

Figure 11.

Phase diagram of (Pb0.97La0.02)(Zr,Sn,Ti)O3, where T, R, and O represent the tetragonal, rhombohedral, and orthorhombic structure, respectively, and HT and LT represent high and low temperature, respectively. Reproduced with permission from ref (167). Copyright 2005 John Wiley and Sons.

We note that the AT phase in both PLZT and PLZST has been shown to be incommensurate by a number of researchers and might be better described as a AO phase in which there is disorder of antipolar coupling.168−170 PLZST is AFE for concentrations with <15 mol % Ti. For compositions with AO structure, the critical phase switching fields are above BDS but ceramics with the AT phase undergo electric field-induced AFE-FE switching at room temperature, for which the switching field increases with increasing Sn concentration (Figure 12).118 Adjusting the Zr/Sn/Ti ratio leads to optimization of Wrec in PLZST ceramics116,118,148,157 with an increase in Sn concentration leading to a reduction in switching field (forward threshold electric field, EF, and backward threshold electric field, EB) and weakening ferroelectricity.171Wrec ∼ 5.6 J cm–3 and high thermal stability have been obtained in PLZST ceramics with a Zr/Sn/Ti ratio of 0.5:0.45:0.05116 while Wang and co-workers reported, in their study of the (Pb0.97La0.02)(Zr0.5Sn0.5-xTix)O3 solid solution, superior Wrec of 4.2 J cm–3 with η of 82% for (Pb0.97La0.02)(Zr0.5Sn0.44Ti0.06)O3 ceramics with good temperature stability.118 Recently, a ferrielectric (FIE) configuration was reported in PLZST which consists of ferroelectric ordering segments with either magnitude or angular modulation of dipoles.172 The net polarization of field-induced FE order can be tailored by adjusting the Sn/Ti ratio.

Figure 12.

AFE-type P–E hysteresis loops of Pb0.97La0.02(Zr0.5Sn0.5–xTix)O3 with x = (a) 0.10, (b) 0.08, (c) 0.06, and (d) 0.04.118 Reproduced with permission from ref (118). Copyright 2016 Elsevier.

The performance of PLZST ceramics is also influenced by the Pb/La ratio.117,122,126 The AFE phase becomes more stable with a commensurate increase in the AFE–FE switching field as La concentration increases. The energy storage properties of (Pb1–1.5xLax)(Zr0.5Sn0.43Ti0.07)O3 ceramics were optimized (Wrec of 4.2 J cm–1) by Dan and co-workers for compositions with x = 0.03 due to a large switching electric field and high BDS.3,126 Furthermore, doping with Ba and Sr (A-site) improves fatigue behavior and temperature stability, suppresses the stress sensitivity, and enhances energy storage.148,150−153,155,161,173

3.1.1.2.3. (Pb,La)(Zr,Sn)O3 (PLZS)

Wang and co-workers reported a unique E-induced multiphase transition in PLZS for which a conventional AFE–FE phase transition at low E, followed by a second FE-FE phase transition at a higher E, leads to an increase in polarization.131Wrec of 10.4 J cm–3 and η of 87% were achieved at 400 kV cm–1 for (Pb0.98La0.02)(Zr0.55Sn0.45)0.995O3 ceramics, along with superior discharge current density of 1640 A cm–2 and ultrafast discharge speed (75 ns discharge period) (Figure 13a,b).131 Subsequently, a record-high Wrec∼ 11.2 J cm–3 and a high η ∼ 82% were realized in (Pb0.98–xLa0.02Srx)(Zr0.9Sn0.1)0.995O3 ceramics, as illustrated in (Figure 13c,d). The substitution of Pb by Sr gave rise to an increase in BDS and AFE/FE switching fields, leading to further enhancement of energy storage performance.130

Figure 13.

(a) Bipolar P–E hysteresis loops and (b) energy storage properties of (Pb0.98La0.02)(Zr0.55Sn0.45)0.995O3 ceramics under different applied fields.131 (c) Unipolar P–E hysteresis loops of the (Pb0.94La0.02Sr0.04)(Zr0.9Sn0.1)0.995O3 ceramic under different applied fields. (d) Wrec of (Pb0.98-xLa0.02Srx)(Zr0.9Sn0.1)0.995O3 with Sr concentration (x = 0–0.06) as a function of the E.130 (a, b) Reproduced with permission from ref (131). Copyright 2019 John Wiley and Sons; (c, d) Reproduced with permission from ref (130). Copyright 2019 Royal Society of Chemistry.

3.1.2. Lead-Free Ceramics

In the last decades, extensive research has focused on lead-free electroceramics due to concerns over the toxicity of lead/lead oxide-based compounds.174−176 As a result, there has been a steady but continuous improvement in their energy storage performance,31,103,177−180 with a view to replacing existing lead-based materials. Several lead-free ceramic systems are considered as potential candidates to replace PLZT for energy storage applications, including those based on BT, ST, KNN, BF, NBT, AgNbO3 (AN), and NN.

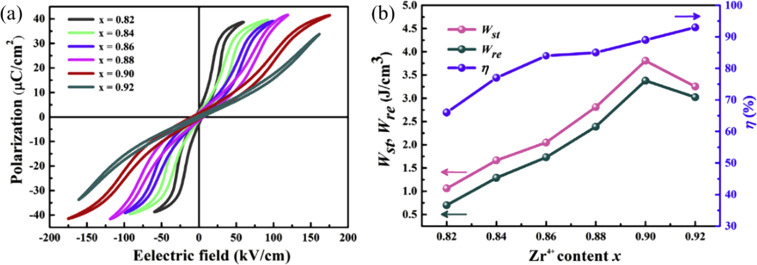

3.1.2.1. BaTiO3-Based Ceramics

BT-based dielectric ceramics have been studied for decades and dominate the commercial market of ceramic capacitors.81,181 Several studies have reported improvements in energy storage performance of BT-based ceramics through (i) substituting oxides to improve BDS, such as Al2O3, La2O3, MgO, SiO2;79,80,182−184 (ii) employing different sintering techniques, such as SPS, citrate precursor, and cold sintering (CS) to increase ceramic density or control grain growth;68,76,185 (iii) adding sintering aids such as ZnNb2O6 and NiNb2O6 to increase density;186,187 (iv) introducing further end-members in the solid solution, Bi(Mg1/2Ti1/2)O3,188,189 BiYbO3,190 BMN,191−193 NBT–Na0.73Bi0.09NbO3,194 Nd(Zn1/2Ti1/2)O3,195 Bi(Zn2/3Nb1/3)O3,196 Bi(Li1/2Nb1/2)O3,197,198 Bi(Zn1/2Zr1/2)O3,199 Bi(Zn1/2Ti1/2)O3,200 YNbO4,201 Bi0.9Na0.1In0.8Zr0.2O3,202 Bi(Li1/2Ta1/2)O3,203 Bi(Mg1/2Zr1/2)O3,204 Bi(Zn1/2Sn1/2)O3,205 K0.5Bi0.5TiO3–KNbO3,206 and K0.5Bi0.5TiO3–NN207 to promote RFE behavior. The energy storage properties of BT-based materials are summarized in Table 4.

Table 4. Energy Storage Properties of BT-Based Materialsa.

| compd | E (kV cm–1) | ΔP (μC cm–2) | Wrec (J cm–3) | η (%) | ref |

|---|---|---|---|---|---|

| 0.9BT–0.1BMN | 143.5 | ∼16 | 1.13 | 95 | (192) |

| Ba0.85Ca0.15Zr0.1Ti0.9O3 | 200 | ∼15 | 1.153 | (182) | |

| 0.9BT–0.1(Bi0.9Na0.1)(In0.8Zr0.2)O3 | 180 | ∼20 | 1.33 | 88 | (202) |

| 0.88(Ba0.8Sr0.2)TiO3–0.12 Bi(Zn2/3Nb1/3)O3 | 225 | 17 | 1.62 | 99.8 | (210) |

| 0.9BT–0.1BMN–0.3 wt % MnCO3 | 205 | 16.28 | 1.7 | 88.5 | (191) |

| 0.92(0.65BT–0.35NBT)–0.08(Na0.73Bi0.09NbO3) | 172 | ∼25 | 1.7 | 82 | (194) |

| 0.92(0.92BT–0.08K0.5Bi0.5TiO3)–0.08NN | 220 | ∼23 | 1.96 | 67.4 | (207) |

| 0.88BT–0.12Bi(Li0.5Nb0.5)O3 | 270 | ∼19 | 2.03 | 88 | (197) |

| 0.9BT–0.1Bi(Li0.5Ta0.5)O3 | 280 | ∼11.9 | 2.2 | 88 | (203) |

| 0.85BT–0.15Bi(Zn0.5Sn0.5)O3 | 280 | ∼23 | 2.41 | 91.6 | (205) |

| 0.9BT–0.1Bi(Zn0.5Zr0.5)O3 | 264 | ∼25 | 2.46 | (199) | |

| 0.85BT–0.15Bi(Mg0.5Zr0.5)O3 | 280 | ∼23 | 2.9 | 86.8 | (204) |

| 0.9Ba0.65Sr0.35TiO3–0.1BMN | 400 | 23 | 3.34 | 85.71 | (211) |

| 0.65(Ba0.98Li0.04)Ti0.98O3–0.35(Sr0.7Bi0.2)TiO3 | 410 | 35 | 3.54 | 77 | (212) |

| 0.6BT–0.4Bi(Mg0.5Ti0.5)O3 | 340 | ∼40 | 4.49 | 93 | (208) |

| BT–0.06Bi2/3(Mg1/3Nb2/3)O3 | 520 | 25 | 4.55 | 91 | (209) |

t of the bulk ceramics is commonly >0.1 mm.

The most effective approach, however, is the introduction of a Bi-based perovskite end member in which the B-site contains multiple cations. Doping with a Bi ion that has a lone pair electronic 6s2 configuration into the Ba-site increases Pmax. Pr is minimized by forming a so-called “weakly coupled relaxor” state in which long-range polar coupling is disrupted by the multiple B-site ions which have different valence and ionic radius to Ti. Using this principle, Hu and co-workers208 reported high Wrec of 4.49 J cm–3 with a η of 93% for 0.6BT–0.4 Bi(Mg0.5Ti0.5)O3 (BT–BMT) ceramics that were temperature stable to 170 °C (variation Wrec < 5% and η < 4%).

Of greater commercial potential, Yang and co-workers reported similar properties with BT–0.06 Bi2/3(Mg1/3Nb2/3)O3 (BT–0.06B2/3MN) but in compositions compatible with Ag/Pd electrodes due to the presence of only 4 mol % Bi on the A-site.209 Similar energy storage properties, Wrec ∼ 4.6 J cm–3 and η ∼ 92% (Figures 14a,b) to BT–BMT were obtained for BT–0.06B2/3MN ceramics which also benefited from the highest BDS, ∼520 kV cm–1, among all reported BT-based compositions.209 BT–0.06B2/3MN is not electrically homogeneous but BDS and Wrec were still optimized by reducing, though not completely eliminating, the difference between the bulk and grain boundary responses with respect to undoped BT, Figures 14c,d.209

Figure 14.

(a) Unipolar P–E loops under Emax and (b) calculated Wrec and η at different electric field for BT–0.06B2/3MN ceramics. (c) Z* plots of (c) BT at 400 °C and (d) BT–0.06B2/3MN at 550 °C.209 Reproduced from ref (209). Copyright 2020 American Chemical Society.

3.1.2.2. SrTiO3-Based Ceramics

ST, which is an incipient ferroelectric, is considered as a promising candidate for energy storage applications due to its relatively high permittivity (εr ∼ 300) and low dielectric loss (<1%) at room temperature. Extensive efforts have been made to improve the energy storage performance of ST-based ceramics, including (i) doping with Ba,213−216 Dy,217 Mg,218 Ce,64 and Bi219−222 on the A-site or Mn223 and Sn224,225 on the B-site; (ii) using sintering aids, such as ZnO,65 MgO,226−228 SiO2,63,229 SrO–B2O3–SiO2,230 ZnO–Li2O,231 Bi2O3–B2O3–SiO2,232 B2O3–SiO2–Bi2O3–CaO–BaO,233 Al2O3,234 BaO–TiO2–SiO2,75 BaCu(B2O5),235 and NiNb2O6;236 (iii) employing different sintering techniques such as microwave sintering73,75 and SPS;70 and (iv) introducing complex end-members, such as NBT,237,238 NBT–Ba(Al0.5Nb0.5)O3,239 NBT–BT,118,240,241 and Bi(Mg0.5Hf0.5)O3.242 The energy storage properties of ST-based materials are summarized in Table 5.

Table 5. Energy Storage Properties of ST-Based Materialsa.

| compounds | E (kV cm–1) | ΔP (μC cm–2) | Wrec(J cm–3) | η (%) | ref |

|---|---|---|---|---|---|

| 95 wt % Ba0.4Sr0.6TiO3–5 wt %MgO | 300 | 11.88 | 1.5 | 88.5 | (227) |

| Ba0.4Sr0.6TiO3–8 mol % SiO2 | 400 | 9.11 | 1.6 | 90.9 | (229) |

| 0.6ST–0.4NBT | 210 | ∼20 | 1.7 | 69.93 | (237) |

| 0.45ST–0.2NBT–0.35BT | 170 | ∼25 | 1.78 | 77.06 | (243) |

| (Sr0.99Mg0.01)TiO3 | 362 | ∼12 | 1.86 | 89.3 | (218) |

| 0.5ST–0.5(0.94 Bi0.54Na0.46TiO3–0.06BT) | 180 | ∼30 | 1.88 | 79 | (239) |

| 0.5ST–0.5(0.95NBT–0.05BaAl0.5Nb0.5O3) | 190 | ∼28 | 1.89 | 77 | (240) |

| Ba0.4Sr0.6TiO3–9 wt %(Bi2O3–B2O3–SiO2) | 279 | ∼17 | 1.98 | 90.57 | (232) |

| 0.95(Sr0.5Na0.25Bi0.25TiO3)–5 wt %MgO–0.05KNbO3 | 178.5 | ∼27 | 2 | 76.34 | (244) |

| Ba0.4Sr0.6(Ti0.996Mn0.004)O3–2 wt % MgO | 300 | ∼16 | 2.014 | 88.6 | (228) |

| Ba0.3Sr0.6Ca0.1TiO3–2 wt %MgO | 194.33 | ∼23 | 2.223 | (245) | |

| Sr0.985Ce0.01TiO3–3 wt % SiO2 | 290 | ∼10 | 2.23 | (64) | |

| SrTi0.985(Zn1/3Nb2/3)0.015O3–4.5 wt %ZnNb2O6 | 422 | 9.34 | 2.35 | 77 | (246) |

| 0.9ST–0.1(Bi0.48La0.02Na0.48Li0.02Ti0.98Zr0.02O3) | 323 | ∼20 | 2.59 | 85 | (247) |

| 0.8ST–0.2(NBT– Ba0.94La0.04Zr0.02Ti0.98O3) | 320 | ∼22 | 2.83 | 85 | (248) |

| 0.995(0.6ST−0.4NBT)−0.005ZrO2 | 285 | ∼25 | 2.84 | 71.54 | (74) |

| 0.9(Sr0.7Bi0.2)TiO3–0.1 Bi(Mg0.5Hf0.5)O3 | 360 | ∼22 | 3.1 | 93 | (242) |

| Ba0.3Sr0.7TiO3–1.6 wt % ZnO | 400 | 3.9 | (65) | ||

| 98.5 wt %Ba0.4Sr0.6TiO3–1.254 wt %Al2O3–0.246 wt %SiO2 | 493 | 5.09 | (234) |

The t of the bulk ceramics is commonly >0.1 mm.

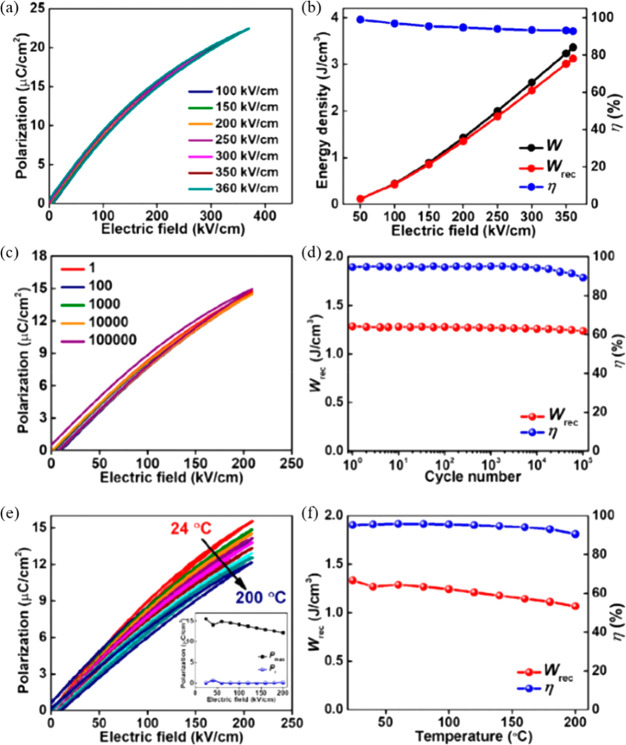

From a review of the literature, doping commonly increases both εr and Pmax but decreases the BDS, sintering aids increase BDS but lower the Pmax. The highest energy densities have therefore been achieved through either dopants and/or alloying with “relaxor end-members” which also act as sintering aids. Adopting these protocols, a Wrec of 3.1 J cm–3 with η ∼ 93% was obtained for 0.9(Sr0.7Bi0.2)TiO3–0.1 Bi(Mg0.5Hf0.5)O3 ceramic at 360 kV cm–1, Figures 15a,b,242 which was also fatigue-resistant up to 105 cycles and temperature stable from 25 to 200 °C, Figures 15c–f.242

Figure 15.

(a) Unipolar P–E loops and (b) W, Wrec, and η of 0.9(Sr0.7Bi0.2)TiO3–0.1Bi(Mg0.5Hf0.5)O3 ceramic as functions of E. (c) Unipolar P–E loops and (d) Wrec and η of 0.9(Sr0.7Bi0.2)TiO3–0.1Bi(Mg0.5Hf0.5)O3 ceramic as functions of cycle numbers up to 105. (e) Unipolar P–E loops, with the inset shows the Pmax and Pr as functions of temperature, and (f) Wrec and η of 0.9(Sr0.7Bi0.2)TiO3–0.1Bi(Mg0.5Hf0.5)O3 ceramics as a function of temperature. Reproduced with permission from ref (242). Copyright 2019 John Wiley and Sons.

3.1.2.3. K0.5Na0.5NbO3-Based Ceramics

In 2016, the energy storage properties of KNN–(Bi,Na)HfO3 solid solutions were first investigated, and Wrec ∼ 0.54 J cm–3 was achieved at 129 kV cm–1.249 ZnO and CuO were introduced as sintering aids improved Wrec in KNN-based ceramics66,250 by decreasing porosity and restricting grain growth. BDS of 400 kV cm–1 was obtained in 0.8KNN-0.2Sr(Sc0.5Nb0.5)O3 ceramic with 0.5 mol % ZnO250 and CuO reduced the sintering temperature and enhanced the density of 0.9KNN–0.1BMN ceramics.66 A third perovskite end-member, e.g., ST, BF, and BMN, has also been shown to optimize energy storage properties.91,92,251Wrec of 4.03 J cm–3 at 400 kV cm–1 was obtained in 0.85KNN–0.15ST bulk ceramics92 with similar energy storage performance realized in 0.90KNN–0.10BMN ceramic with a large Pmax (41 μC cm–2) obtained at 300 kV cm–1, Figure 16.91 The energy storage properties of KNN-based materials are summarized in Table 6.

Figure 16.

(a) Unipolar P–E hysteresis loops and (b) calculated W and Wrec and (c) Wloss and η for 0.90KNN–0.10BMN ceramics under different E. Reproduced with permission from ref (91). Copyright 2017 Royal Society of Chemistry.

Table 6. Energy Storage Properties of KNN-Based Materialsa.

| compounds | E (kV cm–1) | ΔP (μC cm–2) | Wrec (J cm–3) | η (%) | ref |

|---|---|---|---|---|---|

| (K0.48Na0.52)0.88Bi0.04NbO3 | 189 | ∼12.7 | 1.04 | (252) | |

| 0.93KNN–0.07BMN | 150 | ∼22.5 | 1.3 | 58.8 | (253) |

| 0.9KNN–0.1BF | 206 | 23.7 | 2 | 61 | (251) |

| 0.8KNN–0.2Sr(Sc0.5Nb0.5)O3–0.5%ZnO | 400 | ∼11.6 | 2.6 | 73.2 | (250) |

| K0.14Bi0.12Na0.5NbO3–1 mol % CuO | 300 | 29 | 2.89 | 80 | (254) |

| 0.85KNN-0.15 Bi(Zn0.5Zr0.5)O3 | 325 | 30 | 3.5 | 86.8 | (255) |

| 0.9KNN–0.1BMN–1.0 mol % CuO | 400 | ∼21 | 4.02 | 57.3 | (66) |

| 0.85KNN–0.15ST | 400 | ∼26 | 4.03 | ∼52 | (92) |

| 0.9KNN–0.1BMN | 300 | ∼34 | 4.08 | ∼62.7 | (91) |

t of the bulk ceramics is commonly >0.1 mm.

3.1.2.4. BiFeO3-Based Ceramics

BF-based ceramics are best known as multiferroics but have also been explored for high-temperature ferroelectric and piezoelectric applications due to their high TC and large spontaneous polarization.256−259 Compared with other lead-free ceramics, BF-based were not initially considered as good candidates for energy storage applications due to their high leakage current.260p-type electrical conductivity due to the volatilization of Bi and the variation of Fe valence states has been reported frequently in BF system, which limits the BDS and restricts energy density.261−263 However, the introduction of dopants and alloying with end-members suppresses the leakage current, reduces the electrical conductivity, increases intrinsic Eg and induces transitions from a FE to RFE state. The energy storage properties of BF-based materials are summarized in Table 7.

Table 7. Energy Storage Properties of BF-Based Materialsa.

| compounds | E (kV cm–1) | ΔP (μC cm–2) | Wrec (J cm–3) | η (%) | ref |

|---|---|---|---|---|---|

| 3 mol % Nb2O5–0.65BF–0.35BT | 90 | 19 | 0.71 | (265) | |

| 0.61BF–0.33BT–0.06Ba(Mg2/3Nb1/3)O3 | 125 | 32.3 | 1.56 | 75 | (269) |

| 0.61BF–0.33BT–0.06La(Mg0.5Ti0.5)O3 | 130 | 33.3 | 1.66 | 82 | (267) |

| 0.6BF–0.34BT–0.06Sr(Al0.5Nb0.5)O3 | 150 | 35 | 1.75 | 81 | (270) |

| 15%Nd–0.70BF–0.30BT | 170 | 30.7 | 1.82 | 41.3 | (90) |

| 0.65BF-0.30BT–0.05Ba(Zr0.5Zn0.5)O3 | 190 | 32 | 2.04 | 54 | (34) |

| 0.65BF–0.30BT–0.05Bi(Zn2/3Nb1/3)O3 | 180 | 32.8 | 2.06 | 53 | (266) |

| 0.56BF–0.30BT–0.14AN | 195 | 26 | 2.11 | 84 | (268) |

| 0.60BF–0.30BT–0.10Nd(Mg2/3Nb1/3)O3 | 220 | 24 | 2.4 | 77 | (34) |

| 0.7(0.67BF–0.34BT)–0.3(Sr0.7Bi0.2)TiO3 | 180 | 37 | 2.4 | 90.4 | (271) |

| 0.62BF–0.3BT–0.08Nd(Zr0.5Zn0.5)O3 | 240 | 26 | 2.45 | 72 | (34) |

| 0.6BF–0.34BT–0.06Ba(Zn0.5Ta0.5)O3 | 160 | 41 | 2.56 | 71 | (272) |

| 0.67Bi0.9Sm0.1FeO3–0.33BT | 200 | 48 | 2.8 | 55.8 | (273) |

| 0.25Bi0.83Sm0.17Fe0.95Sc0.05O3−0.75[0.85BT-0.15Bi(Mg0.5Zr0.5)O3] | 206 | 36 | 3.2 | 92 | (274) |

| 0.61BF–0.33BST–0.06La(Mg2/3Nb1/3)O3 | 230 | 36.5 | 3.38 | 59 | (275) |

| 0.57BF–0.30BT–0.13 Bi(Li0.5Nb0.5)O3 | 280 | 30 | 3.64 | 74 | (276) |

| 0.57BF–0.33BT–0.10NN | 360 | 51 | 8.12 | 90 | (42) |

| 0.5BF–0.4ST–0.1BMN-0.03Nb | 460 | 45 | 8.2 | 74.1 | (45) |

The t of the bulk ceramics is commonly >0.1 mm.

BF–BT-based materials are purported as potential energy storage compositions due to their excellent BDS and high Pmax.34,45,90 Undoped BF–xBT ceramics exhibit optimized ferroelectric and piezoelectric properties in a mixed-phase region of 0.25≤ x ≤ 0.35.264 The majority of studies have focused on this region and modified compositions either by (i) A and/or B-site chemical doping, including Nd, Nb, Zn0.5Zr0.5, Zn2/3Nb1/3, and Li0.5Nb0.5 or (ii) alloying with a third end-member, such as Nd(Zn0.5Zr0.5)O3, Nd(Mg2/3Nb1/3)O3, La(Mg0.5Ti0.5)O3, Ba(Mg1/3Nb2/3)O3, AN, and NN.34,43,90,265−269

The importance of electrical homogeneity was first postulated in 2019 by Wang, Reaney, and co-workers as a key factor to optimize BDS as well as Wrec.34 Two electrical components with similar capacitance value, C∼ 8 × 10–10 F cm–1 and 1.4 × 10–9 F cm–1, were found in 0.7BF–0.3BT ceramics, as illustrated Figure 17a,b. However, the associated resistances, R1 ∼ 3.8 kΩ cm and R2 ∼ 1.3 MΩ cm, were vastly different. The presence of a large volume fraction of conductive cores (R1) easily led to electrical breakdown at lower electrical field. In contrast, only one single electrical component with C ∼ 1.87 × 10–9 F cm–1 and resistivity of ∼2.3 MΩ cm was observed for 8% Nd(Zr0.5Zn0.5)O3 (NZZ)-doped BF–BT ceramics (Figures 17c,d). The conductive electrical component was effectively eliminated by forming a solid solution with NZZ, inhibiting the formation of conductive pathways at higher electric field (>500 kV cm–1). As a result, optimized Wrec ∼ 2.45 and 10.5 J cm–3 were realized at Emax ∼ 240 and 700 kV cm–1 for 0.08NZZ-BF–BT bulk ceramics and MLs, respectively.

Figure 17.

Combined Z′′ and M′′ spectroscopic plots at 275 °C for (a) BF–BT and (b) BF–BT–0.08NZZ. Unipolar P–E loops of BF–BT–0.08NZZ (c) bulk ceramics and (e) ceramic MLs, with cross-section SEM image as shown in inset figure. Calculated energy storage properties of BF–BT–0.08NZZ (d) bulk ceramic and (e) ceramic MLs. Reproduced from ref (34). Copyright 2019 Royal Society of Chemistry.

Recently, superior energy density through tailored dopant strategies was achieved in BF–ST–xNb–yBMN ceramics, by promoting electrical homogeneity, enhancing Ea and suppressing the p-type conduction, all of which resulted in significantly enhanced BDS. The ceramic without Nb (BF–ST–0.06BMN, x = 0) exhibits a broadened arc in Z* at room temperature (Figure 18a) with at least two electrical components observed in combined Z′′ and M′′ spectroscopic plots (Figure 18b). By donor doping Nb on the B-site, only one ideal semicircle in the Z* plots with a single Debye peak at the same frequency in both Z′′ and M′′ spectroscopic plots was observed for all doped samples (Figures 18c,d), suggesting electrical homogeneity. Nb doping suppresses the formation of Fe4+ associated with the loss of Bi2O3 or/and VO.. during ceramic processing, thus reducing electrical conductivity with respect to x = 0 by several orders of magnitude, coupled with enhanced Ea (Figure 18e). A reduction in Seebeck coefficient from ∼ 600 μV K–1 to zero indicates a commensurate decrease in charge carrier concentration as Nb concentration increases. At x = 0.03, the BDS increases to 360 kV cm–1 (Figures 18g) which is insufficient on its own to optimize Wrec but when combined with an increase in BMN (y) concentration to reduce polar coupling, results in Wrec ∼ 8.2 J cm–3 at Emax ∼ 460 kV cm–1 for BF–ST–0.03Nb–0.1BMN ceramics, Figure 18h.45

Figure 18.

(a) Z* plots and (b) Combined Z′′ and M′′ spectroscopic plots of 0.54BF–0.4ST–0.06BMN–xNb (x = 0); (c) Z* plots and (d) Combined Z′′ and M′′ spectroscopic plots of x = 0.01–0.05; (e) Arrhenius plots, (f) Seebeck coefficients, and (g) unipolar P–E loops under Emax of x = 0.01–0.05. (h) Wrec and η of (0.6–y)BF–0.4ST–0.03Nb–yBMN. Reproduced from ref (45). Copyright 2020 Royal Society of Chemistry.

3.1.2.5. Na0.5Bi0.5TiO3–Based Ceramics

NBT-based ceramics are promising candidates of lead-free dielectrics due to their high Pmax and Tc. However, their large hysteresis and low BDS are not ideal for high energy density capacitor applications.277−284 Attempts to improve their properties generally fall into the following approaches: (i) doping on the A-site (Ba, Sr, K, Li, La, Dy, Nd)222,239,243,285−296 and B-site (commonly Nb)297 and codoping (K,Sr/Nb; K,La/Zr; Li,K,Sr/Ta,Nb; K,Mg/Nb; Ba/Nb; Ba/Sn; Ba/Sn,Zr; Ba/Ta; Ba/Zr; Ba,Ca/Zr; Ba,K,Ca/Nb,Zr; Ba/Mg,Nb; Ba/Mg; Ba,La/Al,Nb; Ba,Sr/Yb,Nb; Ba/Hf; La/Al; La,Ba/Nb; Sr/Sn; Sr/Zr; Sr/Mg; Sr/Mg,Nb);194,298−321 (ii) forming solid solution with other end-members, such as AN, NN, and SBT;297,322−325 (iii) using additives such as MnO, Fe2O3, MgO, SnO2, ZnO, CaO, and ZrO262,74,238,326−334 and (iv) employing different processing methods such as hot-pressing59 and synthesis using sol–gel derived powders.69,71,74,335,336 The energy storage properties of NBT-based materials are summarized in Table 8.

Table 8. Energy Storage Properties of NBT-Based Materialsa.

| compounds | E (kV cm–1) | ΔP (μC cm–2) | Wrec (J cm–3) | η (%) | ref |

|---|---|---|---|---|---|

| 0.95(0.76NBT–0.24ST)-0.05AN | 120 | 43.5 | 2.03 | 61.8 | (324) |

| Bi0.41Na0.35Sr0.21TiO3 | 135 | ∼35.8 | 2.04 | 82.4 | (290) |

| 0.75Na0.25Sr0.5Bi0.25TiO3–0.25MgO | 200 | ∼35 | 2.06 | 84 | (317) |

| 0.8(0.775NBT–0.225BaSnO3)–0.2BaZrO3 | 245 | 20 | 2.08 | 88.8 | (315) |

| 0.85NBT–0.15BaHfO3 | 175 | 29 | 2.1 | 66.1 | (310) |

| 0.775NBT–0.225BaSnO3–5 wt %MgO | 215 | ∼28 | 2.13 | 67.8 | (326) |

| Sn–0.45ST–0.2NBT–0.35BT | 240 | ∼21 | 2.25 | 79.51 | (328) |

| 0.9NBT–0.1Li2TiO3 | 200 | ∼25 | 2.3 | 74.2 | (291) |

| (0.5NBT–0.5ST) −1%SnO2 | 180 | 37.37 | 2.35 | ∼80 | (238) |

| (Na0.5Bi0.5)0.8Ba0.2Ti0.8Sn0.8O3 | 195 | ∼34 | 2.35 | 71.04 | (338) |

| {Bi0.5[(Na0.8K0.2)0.9Li0.1]0.5}0.96Sr0.04(Ti0.975Ta0.025)O3 | 143 | ∼43 | 2.42 | ∼64 | (339) |

| 0.55NBT–0.45(Bi0.2Sr0.7TiO3) | 200 | 25 | 2.5 | 95 | (222) |

| 0.94(BNT–Bi0.2Sr0.7TiO3)–0.06KNN | 180 | 37 | 2.65 | 84.6 | (298) |

| 0.95(0.6ST–0.4NBT)–0.05Zr | 285 | ∼25 | 2.84 | 71.54 | (74) |

| 0.85(0.95NBT–0.05SrZrO3)–0.15NN | 210 | ∼30 | 2.93 | 72 | (325) |

| 0.96(0.65NBT–0.35Sr0.85Bi0.1TiO3)–0.04NN | 220 | 50.46 | 3.08 | 81.4 | (323) |

| 0.6(Bi0.51Na0.47)TiO3–0.4Ba(Zr0.3Ti0.7)O3 | 280 | ∼25 | 3.1 | 91 | (299) |

| 0.9(0.76NBT−0.24NN)−0.1SBT | 200 | 43 | 3.12 | 75 | (340) |

| 0.93NBT–0.07LaAlO3 | 210 | 43 | 3.18 | 60 | (320) |

| (Na0.25Bi0.25Sr0.5)(Ti0.8Sn0.2)O3 | 310 | 26.5 | 3.4 | 90 | (321) |

| 0.85(Na0.5Bi0.5)0.7Sr0.3TiO3−0.15BMN | 250 | 38 | 3.45 | 88.01 | (316) |

| 0.95(0.6 Bi0.5Na0.5TiO3–0.4Sr0.7Bi0.2TiO3)–0.05AN | 246 | 41 | 3.62 | 89 | (322) |

| 0.65(0.84NBT–0.16K0.5Bi0.5TiO3)–0.35(Bi0.2Sr0.7TiO3) | 350 | ∼33.99 | 4.06 | 87.3 | (288) |

| 0.55NBT–0.45SBT | 315 | 19.1 | 4.14 | 92.2 | (295) |

| 0.90(Na0.5Bi0.5)0.7Sr0.3TiO3–0.10 Bi(Ni0.5Sn0.5)O3 | 270 | 47 | 4.18 | 83.64 | (341) |

| 0.75Bi0.58Na0.42TiO3–0.25ST | 535 | 41 | 5.63 | 94 | (342) |

| 0.78NBT–0.22NN | 390 | 45 | 7.02 | 85 | (297) |

| 0.62NBT–0.30SBT–0.08BMN | 470 | 48 | 7.5 | 92 | (337) |

t of the bulk ceramics is commonly >0.1 mm.

Notably, Li and co-workers reported that 0.55NBT–0.45(Sr0.7Bi0.2)TiO3(SBT) achieved Wrec of 2.5 and 9.5 J cm–3 with η > 90% for bulk ceramic and MLs at 200 and 720 kV cm–1 (Figure 19a,b), respectively.222 Superior Wrec ∼ 7.02 J cm–3 and η ∼ 85%, were also reported for 0.78NBT–0.22NN ceramics at Emax ∼ 360 kV cm–1, Figures 19c,d, with <10% variation from 25–250 °C and from 0.1 to 100 Hz.297

Figure 19.

(a) Unipolar P–E loop and the current–E curve for NBT–0.45SBT bulk ceramics. (b) Wrec and η for NBT–0.45SBT ceramic MLs; inset SEM image of the ceramic MLs (c) Bipolar P–E loops and (c) calculated Wrec and η of 0.78NBT–0.22NN ceramic.222,297 (a, b) Reproduced with permission from ref (222). Copyright 2018 John Wiley and Sons; (c, d) Reproduced with permission from ref (297). Copyright 2019 Royal Society of Chemistry.

Recently, Ji and co-workers337 proposed that the key factors for designing an ideal RFE with high energy density were as follows: (i) utilization of a highly polar base system (e.g., NBT); (ii) disruption of long-range polar coupling through forming solid solutions with, e.g., SBT and BMN without sacrificing average ionic polarizability, Figure 20a, and (iii) simultaneously inducing or retaining electrical homogeneity with a highly resistive single component in IS (∼250 kΩ cm at 660 °C), Figure 20b. These factors combined to give Emax ∼ 470 kV cm–1, Wrec ∼ 7.5 J cm–3, and η ∼ 92% for 0.62NBT–0.30SBT–0.08BMN, Figure 20c,d.

Figure 20.

(a) Tolerance factor and average ionic polarizability per unit cell of NBT–SBT–xBMN as a function of BMN concentration. (b) Combined Z′′ and M′′ spectroscopic plots for NBT–SBT–0.08BMN ceramics at 660 °C. (c) P–E loops at the Emax, and (d) Wrec and η for NBT–SBT–xBMN ceramics. Reproduced with permission from ref (337). Copyright 2021 Elsevier.

3.1.2.6. AgNbO3–Based Ceramics

AFEs have long been considered as the prime candidate for energy storage capacitors due to their large Pmax and small Pr. There are only a handful of lead-free AFE systems, with AN showing particular promise because it possesses a large saturation polarization of 52 μC cm–2 under an Emax ∼ 220 kV cm–1.343 Recent research on AN ceramics has focused on stabilizing the AFE phase so that switching field is moved to higher fields while simultaneously optimizing Pmax.344,345

There have been a number of recent studies on AN focusing on (i) substitution of aliovalent B-site oxides such as MnO2 and WO3;346,347 (ii) doping Ba, Sr, Ca, Bi, La, Sm, and Gd on the A-site348−356 often with isovalent Ta doping on the B-site;357−359 and (iii) forming solid solutions with end-members, such as BiMnO3 and Bi(Zn2/3Nb1/3)O3.360,361 Most dopants reduce the G of AN which maximizes BDS but delay the onset of the AFE-FE transition to higher field while simultaneously narrowing hysteresis in the induced FE phase. Wrec of 4.4, 4.5, and 5.2 J cm–3 with η of 70, 63, and 69.2% has been obtained for La, Gd, and Sm A-site doped AN ceramics,348,351,355,359,362 respectively, and B-site Ta-doped AN was reported to exhibit Wrec of 4.2 J cm–3 with η of 69% (Figure 21a,b).357 A-site doping with ions smaller in radius than Ag is suggested to decrease tolerance factor and enhance AFE stability, while donor doping is compensated by A-site vacancies which reduce antipolar and polar coupling of the AFE and field induced FE phases, respectively. Some authors postulate that substituting B-site ions with a lower polarizability than Nb also stabilizes the AFE phase and moves the switching field higher.348,350,359,363 The underlying principles are schematically represented in Figure 21c. The energy storage properties of AN-based materials are summarized in Table 9.

Figure 21.

(a) Bipolar P–E loops of AN and Ag(Nb0.85Ta0.15)O3 ceramics. (b) Energy storage performance of Ag(Nb1–xTax)O3 ceramics prior to their breakdown. (c) Schematic of the underlying principles for enhancing energy storage property in AN-based materials. (a, b) Reproduced with permission from ref (357). Copyright 2017 John Wiley and Sons; (c) Reproduced with permission from ref (359). Copyright 2019 Royal Society of Chemistry.

Table 9. Energy Storage Properties of AN-Based Materialsa.

| compounds | E (kV cm–1) | ΔP (μC cm–2) | Wrec (J cm–3) | η (%) | ref |

|---|---|---|---|---|---|

| AN | 150 | ∼34 | 2.0 | 46 | (345) |

| AN | 175 | ∼33 | 2.1 | 40–50 | (343) |

| Ag0.96Ba0.02NbO3 | ∼180 | ∼34 | 2.3 | 46 | (356) |

| 0.6 mol % BiMnO3–AN | 175 | ∼36 | 2.4 | 54 | (360) |

| 0.1 wt % Mn–AN | 150 | ∼37.2 | 2.5 | 57 | (346) |

| Ag0.91Bi0.03NbO3 | 200 | ∼30 | 2.6 | 86 | (353) |

| Ag0.90Sr0.05NbO3 | 190 | ∼38 | 2.9 | 56 | (354) |

| Ag0.94La0.02NbO3 | 230 | ∼28 | 3.12 | 63 | (352) |

| 0.3 wt % Mn-doped Ag0.97La0.01NbO3 | 142 | 37.8 | 3.2 | 62 | (351) |

| 0.1 wt % W-AN | 200 | ∼42.5 | 3.3 | 50 | (347) |

| AN–0.03NBT | 220 | 33 | 3.4 | 62 | (364) |

| Ag0.90Ca0.05Nb0.95Ta0.05O3 | 210 | 37 | 3.36 | 58 | (363) |

| Ag0.92Ca0.04NbO3 | 220 | ∼37.6 | 3.55 | 63 | (349) |

| Ag(Nb0.8Ta0.2)O3 | 270 | ∼30 | 3.7 | ∼65 | (358) |

| AgNb0.85Ta0.15O3 | 233 | ∼35.1 | 4.2 | 69 | (357) |

| 2 mol % La-doped AN | 273 | ∼30 | 4.4 | 70 | (350) |

| Ag0.88Gd0.04NbO3 | 290 | ∼32.5 | 4.5 | ∼63 | (355) |

| Ag0.94Sm0.02NbO3 | 310 | 31 | 4.5 | 63 | (362) |

| 0.99AN–0.01 Bi(Zn2/3Nb1/3)O3 | 220 | 46.8 | 4.6 | 57.5 | (115) |

| (Sm0.02Ag0.94)(Nb0.9Ta0.1)O3 | 280 | ∼36 | 4.87 | 63.5 | (359) |

| Sm0.03Ag0.91NbO3 | 290 | ∼36 | 5.2 | 69.2 | (348) |

| AgNb0.45Ta0.55O3 | 460 | ∼29 | 6.3 | 90 | (365) |

| Ag0.97Nd0.01Nb0.80Ta0.20O3 | 370 | 38 | 6.5 | 71 | (366) |

| Ag0.76La0.08NbO3 | 476 | 33 | 7.01 | 77 | (367) |

t of the bulk ceramics is typically >0.1 mm.

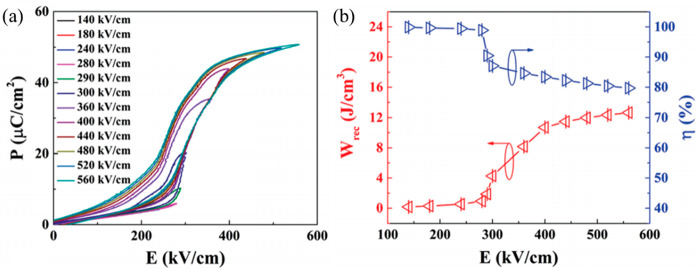

3.1.2.7. NaNbO3-Based Ceramics

Recently, AFE NN has received attention as a potential candidate for energy storage applications. An AFE double hysteresis loop is difficult to observe in NN because (i) the energy difference between the AFE phase and field-induced FE phase is very small and (ii) E-induced FE phase is metastable. Thus, AFE behavior in NN based materials is commonly stabilized by chemical substitution with end members such as BS and CaHfO3.344,368−370

Emax > 250 kV cm–1 and Wrec > 2.5 J cm–3 have been reported for NN in solid solution with BMN, ST, Bi(Mg2/3Ta1/3)O3, and Bi(Mg0.5Ti0.5)O3 by stabilizing the AFE phase or inducing relaxor behavior,371−374 as summarized in Table 10. Zuo and co-workers42 have also proposed the concept of an “AFE relaxor” to explain the energy storage properties of 0.78NN–0.22NBT ceramics. They argue that the local AFE phase transforms reversibly into an FE monoclinic phase at∼ 400 kV cm–1, giving a large ΔP (Pmax > 50 μC cm–2 and Prem < 5 μC cm–2). Wrec of ∼12.2 J cm–3 was reported with η ∼ 69%, at 680 kV cm–1, Figure 22.42 However, the term “AFE relaxor” has little physical significance since an antipolar phase cannot form short-range polar features characteristic of a relaxor. 0.78NN–0.22NBT may, therefore, be better described as either a relaxor or a short-range AFE phase that undergoes a field induced transition. This intriguing behavior is interesting, but it is the large Emax (680 kVcm–1) that is most likely responsible for the exceptional Wrec rather than the intrinsic crystal chemistry. The underpinning reasons for the large Emax most likely relate to the defect chemistry, band gap and electrical homogeneity, consistent with the key factors proposed by Ji and co-workers.337

Table 10. Energy Storage Properties of NN-Based Materialsa.

| compounds | E (kV cm–1) | ΔP (μC cm–2) | Wrec (J cm–3) | η (%) | ref |

|---|---|---|---|---|---|

| NN–0.09Bi(Zn0.5Ti0.5)O3 | 200 | 29 | 2.1 | 76 | (375) |

| 0.9NN–0.10BMN | 300 | ∼23 | 2.8 | 82 | (371) |

| 0.8NN–0.2ST | 323 | 34.5 | 3.02 | 80.7 | (372) |

| 0.78NN–0.22Ba(Mg2/3Nb1/3)O3 | 540 | 18.7 | 3.51 | 87 | (376) |

| Na0.7Bi0.1NbO3 | 250 | ∼30 | 4.03 | 85.4 | (377) |

| NN–MnO2 | 360 | 33 | 4.3 | 90 | (378) |

| Na0.84Bi0.08Nb0.92Zr0.08O3 | 430 | 30 | 4.9 | 88 | (67) |

| 0.9NN–0.1 Bi(Ni0.5Sn0.5)O3 | 550 | 25 | 5 | 68 | (379) |

| 0.78NN–0.22 Bi(Mg2/3Ta1/3)O3 | 620 | 17 | 5.01 | 86.8 | (373) |

| 0.92NN–0.08 Bi(Mg0.5Ti0.5)O3 | 480 | 38 | 5.57 | 71 | (374) |

| (Na0.91La0.09)(Nb0.82Ti0.18)O3 | 550 | 42 | 6.5 | 65.9 | (380) |

| 0.75[0.9NN–0.1 Bi(Mg0.5Ta0.5)O3]–0.25(Bi0.5Na0.5)0.7Sr0.3TiO3 | 800 | 22 | 8 | 90.4 | (381) |

| 0.76NN–0.24NBT | 680 | ∼55 | 12.2 | 69 | (42) |

t of the bulk ceramics is commonly >0.1 mm.

Figure 22.

(a) Bipolar P–E loops with corresponding current density-field (J–E) curves and (b) Wrec and η values of under different E for the 0.76NN–0.24BNT ceramic at 10 Hz (c) a comparison of Wrec, η, and Emax among the recently reported bulk ceramics; (d) temperature-dependent P–E hysteresis, (e) temperature- and frequency-dependent εr and (f) Wrec and η as a function of temperature for the 0.76NN-0.24NBT ceramic at 450 kV cm–1. Reproduced with permission from ref (42). Copyright 2019 John Wiley and Sons.

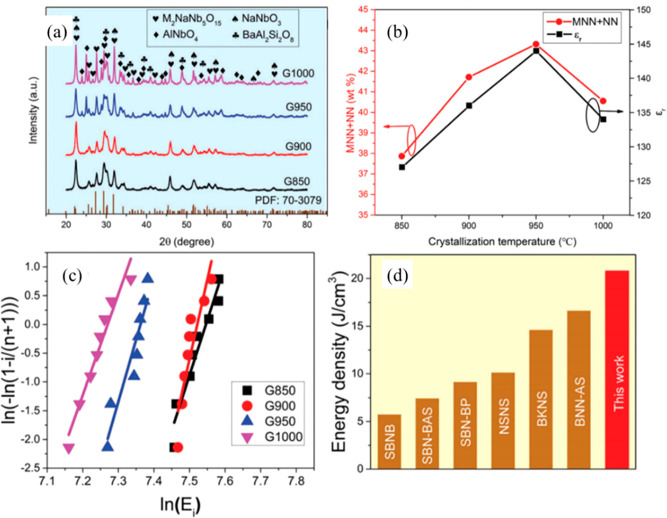

3.1.3. Glass Ceramics

Glass-ceramics are composed of one or more crystallized phases (ceramics) dispersed uniformly in amorphous phase (glass). They often exhibit the combined properties of ceramics and glass depending on the induced crystalline phases and their microstructures. Glass-ceramics are prepared by melting the requisite raw materials, cooling to room temperature to form a glass, followed by two step annealing to induce crystal nucleation (approximately at the glass transition temperature, Tg) and growth > TgFigure 23.179,382 The microstructure of a glass ceramic is typically dominated by a largely 2D and 3D defect-free (e.g., no grain boundaries) glass phase and a uniformly distributed (provided the system undergoes homogeneous rather than heterogeneous nucleation) ceramic phase. Wrec and η are both large due to the high BDS associated with the absence of 2D and 3D defects accompanied by a near zero value of Pr. The energy storage properties of glass-based glass ceramics are summarized in Table 11.

Figure 23.

Schematic of the processing step of glass-ceramics.

Table 11. Energy Storage Properties of Glass Ceramicsa.

| compounds | εr (1 kHz, 300 K) | E (kV cm–1) | Wrec (J cm–3) | ref |

|---|---|---|---|---|

| 14.4SrO–17.6BaO–32Nb2O5–36B2O3 | 117 | 1050 | 5.71 | (386) |

| 25.6BaO–6.4Na2O–32Nb2O5–36SiO2 | ∼90 | 1248 | ∼6.2 | (409) |

| 14.3SrO–17.5BaO–31.9Nb2O5–35.8B2O3–0.5ZnO + 0.5La2O3 | 131 | 1127 | 7.1 | (400) |

| 20BaO–20SrO–20Nb2O5-5Al2O3–1.5B2O3–33.5SiO2 + 0.2La2O3 | 92.4 | 1326 | 7.2 | (406) |

| 20SrO–20BaO–10Nb2O5–10TiO2–32SiO2–8Al2O3 | 52.9 | 1817 | 7.73 | (410) |

| 14.3SrO–17.5BaO– 31.9%Nb2O5–35.8%B2O3–0.5ZnO + 0.5Sm2O3 | 143.8 | 1132 | 8.15 | (402) |

| 14.4SrO–17.6BaO–32Nb2O5–36B2O3 + 1%Yb2O3 | 98.3 | 1398 | 8.5 | (403) |

| 15K2CO3–15SrCO3–30Nb2O5–32SiO2–4Al2O3–4B2O3 | 102 (10 kHz) | 1411 | 8.99 | (407) |

| 20BaO–20SrO–20Nb2O5–5Al2O3–1.5B2O3–33.5SiO2 + 0.05MnO2 | 95.8 | 1471 | 9.2 | (411) |

| 42[0.2Na2O–0.8SrO]–28Nb2O5–30SiO2 | 53 (100 kHz) | 2074 | 10.09 | (412) |

| 9.6K2O–22.4BaO–32Nb2O5–36SiO2 | 75 | 1937 | 12.06 | (393) |

| 25.6BaO–6.4K2O–32Nb2O5–36SiO2 + 1Gd2O3 | 83 | 1818 | 12.14 | (405) |

| 20BaO–12K2O–32Nb2O5–36SiO2 | 83 | 1859 | 12.7 | (413) |

| 15.16SrO–6.736BaO–10.104K2O–32Nb2O5–28B2O3–8P2O5 | 85.2 | 1844 | 12.83 | (395) |

| 6.4K2O–25.6SrO–32Nb2O5–36SiO2 + 3CaF2 | 114 | 1623 | 13.5 | (414) |

| 31.2SrO–7.8Na2O–26Nb2O5–35SiO2 | 91 | 1941 | 15.2 | (390) |

| 15 Bi2O3–15Nb2O5–40SiO2–30Al2O3 | 100 | 1861 | 15.3 | (391) |

| 65(48SrO–12Na2O–40Nb2O5)–35SiO2 | 124 | 1669 | 15.3 | (392) |

| 24BaO–6Na2O–30Nb2O5–10Al2O3–30SiO2 | ∼70 | 2322 | 16.6 | (388) |

| 15.4Na2O–15.4PbO–23.1Nb2O5–46.2SiO2 | 175 | 1486 | 17 | (385) |

| 25.6(0.4SrO–0.6BaO)–6.4K2O–32Nb2O5–36SiO2 | 118 | 1828 | 17.45 | (394) |

| 21.25BaO–1PbO–12.75Na2O–34Nb2O5–32SiO2 | 154 | 1638 | 18.29 | (389) |

| 25.6BaO–3.2Na2O–3.2K2O–32Nb2O5–36SiO2 | 22 | 4433 | 19 | (396) |

| 21.6BaO–2.4PbO–6Na2O–30Nb2O5–10Al2O3–30SiO2 | 137 | 1848 | 20.7 | (384) |

| 63SiO2–12BaO–16B2O3–9Al2O3 | 6 | 12,000 | 38.5 | (397) |

t of the bulk ceramics is commonly >0.1 mm.

As discussed above, the crystallization of glass ceramics is controlled by the annealing procedure, where the annealing temperature and time are critical for nucleation and growth of the ceramic phase, the microstructure and the properties. Generally, the volume fraction of crystalline phase increases with increasing annealing temperature and time, accompanied by an increase of εr and decrease of BDS. The optimized Wrec is a balance between εr and BDS. Chen and co-workers383 reported that tungsten bronze structured, Ba0.27Sr0.75Nb2O5.78 phase formed from the Na2O–BaO–SrO–Nb2O5–SiO2–B2O3 glass matrix at 800 °C and a secondary phase NaSr1.2Ba0.8Nb5O15 emerged when crystallization temperature exceeded 850 °C. Remarkably high BDS ∼ 1400 kV cm–1 with εr of ∼50 were obtained, leading to a Wrec = 4 J cm–3. Besides, Wang and co-workers reported ultrahigh Wrec of 20.7 J cm–3 in BaO–PbO–Na2O–Nb2O5–SiO2–Al2O3 (BPNN-AS) glass ceramics at the optimized crystallization temperature of 900 °C, as shown in Figure 24.384 With increasing crystallization temperature from 850 to 1000 °C, the BDS decreased from 1890 to 1440 kV cm–1 and the crystallinity increased from 64.5 to 97.3% (Figure 24b). Similar results were also reported in other glass ceramic systems, including Na2O–PbO–Nb2O5–SiO2,385 SrO–BaO–Nb2O5–B2O3,386 K2O–SrO–Nb2O5–SiO2–Al2O3–B2O3,387 BaO–Na2O–Nb2O5–SiO2–Al2O3,388 BaO–PbO–Na2O–Nb2O5–SiO2,389 SrO–Na2O–Nb2O5–SiO2,390 and Bi2O3–Nb2O5–SiO2–Al2O3.391

Figure 24.

(a) X-ray diffraction (XRD) patterns of BPNN-AS glass ceramics annealed from 850 to 1000 °C; (b) εr and M2NaNb5O15 + NN phase proportion with increasing annealing temperature; (c) BDS Weibull distribution plots; (d) Wrec of 900 °C annealed BPNN-AS glass ceramics, compared with other kinds of ferroelectric glass ceramics. Reproduced with permission from ref (384). Copyright 2018 Royal Society of Chemistry.

Each constituent oxide in the glass matrix has an important effect on the crystal phase, microstructure, BDS, and energy storage properties. For example, SiO2 is an important and active studied constituent oxide in glass matrix. With increasing SiO2 content, εr of SrO–Na2O–Nb2O5–SiO2 (SNN-Si) glass ceramics first increased and then decreased as shown in Figure 25a, which was attributed to the change of volume fraction Sr6Nb10O30 (Figure 25b). The optimal εr of 120 and BDS ∼ 1700 kV cm–1 were obtained with 35 mol % SiO2 (Figures 25a,c), resulting in the highest theoretical Wrec of 15.2 J cm–3.392 Wang and co-workers reported that, as K2O concentration increased in K2O–BaO–Nb2O5–SiO2 glass ceramics, grain boundary R and activation energy decreased, indicating the decrease of interfacial polarization, leading to the enhancement of BDS to ∼1900 kV cm–1 and Wrec ∼ 12 J cm–3.393 They also reported that substitution of Sr for Ba in SrO–BaO–K2O–Nb2O5–SiO2 led to the formation of solid phase Sr0.5Ba0.5Nb2O6 and improvement of dielectric properties.394 The highest BDS of ∼1800 kV cm–1 and Wrec of 17.5 J cm–3 were achieved with Sr = 0.4 due to a uniform and dense microstructure and lower interfacial polarization. Li and co-workers reported substitution of K with Ba in SrO–BaO–K2O–Nb2O5–B2O3–P2O5 glass ceramics transformed Ba0.5Sr0.5Nb2O6 to a solid solution of K2xyBa(1-x)ySr5–yNb10O30 and then KSr2Nb5O15 phase, leading to a decrease in εr.395 A maximum theoretical Wrec of 12.8 J cm–3 was obtained under BDS ∼ 1800 kV cm–1, along with dielectric loss <0.3%. Liu and co-workers studied the effect of R2O (R = Li, Na, K) on the phase structure, dielectric properties and BDS in BaO–R2O–Nb2O5–SiO2 glass ceramics, where the highest Wrec ∼ 19 J cm–3 was achieved with εr ∼ 22 and superior BDS of ∼4400 kV cm–1 in composition of BaO–Na2O–K2O–Nb2O5–SiO2.396

Figure 25.

(a) Dielectric properties, (b) XRD patterns, and (c) BDS of SNN-Si glass ceramics as a function of SiO2 concentration (β). Reproduced with permission from ref (392). Copyright 2017 Elsevier.