Abstract

Biopolymer-based flocculants have become a potential substitute for inorganic coagulants and synthetic organic flocculants due to their wide natural reserves, environmental friendliness, easy natural degradation, and high material safety. In recent years, with more and more attention to clean technologies, a lot of researches on the modification and application of biopolymer-based flocculants have been carried out. The present paper reviews the latest important information about the base materials of biopolymer-based flocculants, including chitosan, starch, cellulose, and lignin etc. This review also highlights the various modification methods of these base materials according to reaction types in detail. Via the recent researches, the flocculation mechanisms of biopolymer-based flocculants, such as adsorption, bridging, charge neutralization, net trapping, and sweeping, as well as, some other special mechanisms are comprehensively summarized. This paper also focuses on the water treatment conditions, the removal efficiency, and advantages of biopolymer-based flocculants in applications. Further, this review sheds light on the future perspectives of biopolymer-based flocculants, which may make progress in the sources of base materials, modification processes, multi-function, and deepening application researches. We believe that this review can guide the further researches and developments of biopolymer-based flocculants in the future, to develop them with a higher efficiency, a lower cost, more safety, and multi-function for more diversified applications.

Graphical abstract

Keywords: Biopolymer-based flocculants, Flocculation, Modification methods, Flocculation mechanisms, Water treatment

Introduction

With the progress of human development, the discharged sewage becomes diversified, which has an increasingly detrimental impact on the ecological environment. Besides, about one-fifth of the world’s population has no access to safe water, so pathogens in the water cause about 5500 deaths per day (Schwarzenbach et al. 2006). Therefore, the increasingly serious pollution of natural water has a long-term negative impact on the ecological environment and human health. To solve this problem, researches on water treatment methods have begun to increase. At present, water treatment technologies mainly include coagulation/flocculation (Rajala et al. 2020), adsorption (Zheng et al. 2019), ion exchange (Can et al. 2020), advanced oxidation (Wang et al. 2019a), biological treatment (Lin et al. 2019), and membrane filtration (Fu and Zhang 2018), etc.

As one of the water treatment technologies, flocculation is used to promote the solid-liquid separation of colloidal suspension (Dao et al. 2016). It has advantages of a low investment cost, high treatment efficiency and simple operation (Dao et al. 2016; Yang et al. 2016a). Flocculation can effectively deal with various types of water pollution, such as turbidity, dyes, heavy metal ions, other industrial/agricultural wastewater, algae, and sludge dewatering. Therefore, it can be called a very economical and effective water treatment method.

Flocculant is a kind of water treatment agent. It can aggregate the colloidal substances and particulate matters suspended in the liquid to form larger flocs, and then promote the settlement of these particles from the stable suspension (Salehizadeh et al. 2018). As the core of flocculation, flocculants’ characteristics directly determine the efficiency of water treatment (Liao et al. 2014). According to the chemical composition, the flocculant can be divided into inorganic coagulants and organic flocculants. The inorganic coagulants, such as iron salts and aluminum salts, have a low cost, but they are highly dependent on temperature, pH, and other conditions. Besides, for flocculation based on inorganic coagulants, the dosage is large and the suitable types of sewage are few (Sharma et al. 2006). In addition, it may cause the phenomenon of high metal concentration (Renault et al. 2009a) in the treated water body, and then threaten human health. Besides, organic flocculants can be divided into synthetic organic flocculants and biopolymer-based flocculants. The synthetic organic flocculants can reach good efficiency at low dosage, but have the risk of difficult biodegradability (Chen et al. 2018b) and toxicity (Lu et al. 2014). Biopolymer-based flocculants refer to the long-chain molecules produced by the cells of living organisms and the materials derived from these long-chain molecules or bio-based monomers (Song et al. 2009; Yates and Barlow 2013). Biopolymer-based flocculants have many excellent properties, such as wide sources, easy modification and processing, environmental friendliness (low toxicity/non-toxicity, easy biodegradation), low dosage requirements, a wide range of adaptable pH, good flocculation efficiency (Renault et al. 2009a; Jiang 2015; Filho et al. 2018; Liu et al. 2020), etc. As biopolymer-based flocculants are of great benefit to reduce the risk of water treatment, researches of new flocculants based on biopolymers are the focus of scholars in recent years.

Biopolymer-based flocculants have the potential to scale up practical applications. In terms of economic feasibility, a triangle evaluation model was established to evaluate the performance of biopolymer-based flocculants in wastewater treatment (Sun et al. 2020a, b). This triangular evaluation model includes three aspects: environmental impact, economic benefit, and energy consumption. The evaluation results showed that these three aspects are obviously influenced by the flocculant characteristics and flocculation conditions of biopolymer-based flocculants; by optimizing these two aspects of biopolymer-based flocculants, can biopolymer-based flocculants have a low environmental impact, low energy consumption, and high economic benefits. Another report shows that the cost of flocculation depends not only on the cost of flocculant itself, but also on the dosage; although the unit price of chitosan is three times higher than that of ferric chloride, the cost of chitosan (65 $/ton treated biomass) is lower than that of ferric chloride (87 $/ton treated biomass) when it is used in flocculation of Chlamydomonas (Lama et al. 2016). In terms of practical application, the materials based on Moringa oleifera have been widely used in developing countries (Beltrán-Heredia and Sánchez-Martín 2009; Baptista et al. 2015). In Egypt and Sudan, natural polypeptides produced from the seeds of Moringa oleifera have been used to produce drinking water. When Moringa oleifera is used in drinking water treatment, the consumption of it is 1 seed/L for slightly polluted water, and 2 seeds/L for water with poor quality (Foidl et al. 2001). Therefore, biopolymer-based flocculants have the economic feasibility potential to scale up, which makes them likely to be widely used in the future.

However, at present, there are few reviews on biopolymer-based flocculants, while most of these reviews are only focused on chitosan. For example, Renault et al. (2009b) reviewed the flocculation efficiency of chitosan-based flocculants, and discussed the influence of chitosan characteristics and sewage conditions. Bhalkaran and Wilson (2016) also summarized the influence of sewage conditions on the treatment efficiency of chitosan-based flocculants. More importantly, they began to pay attention to the relationship between the physicochemical properties of flocculants and the wastewater treatment efficiency, namely the structure-function relationship. Likewise, Yang et al. (2016a) reviewed the structural factors’ effects on flocculation efficiency, and believed that they should be the focus of flocculants selection and design. Nevertheless, in addition to chitosan, there are many other biopolymers, such as starch, cellulose, and lignin etc. that can be used as the base materials of biopolymer-based flocculants. Being similar to chitosan, they also have the advantages of non-toxicity, environmental friendliness, and biodegradability. Therefore, an overview of the various biopolymers is necessary.

The flocculation efficiency of biopolymer-based flocculants is affected by their physicochemical properties (Bhalkaran and Wilson 2016). These characteristics are produced by the modification of biopolymers. Tang et al. (2018) summarized the factors influencing the preparation of biopolymer-based flocculants by graft polymerization. However, with the recent development, there are many modification methods to prepare biopolymer-based flocculants from natural raw materials, not only by graft polymerization. Thus, it is essential to summarize the modification methods of biopolymer-based flocculants, according to the reaction types.

Some of the flocculation mechanisms for biopolymer-based flocculants are similar to those of inorganic coagulants and synthetic organic flocculants, but it has something unique. Lee et al. (2014) believed that the flocculation mechanisms of biopolymer-based flocculants are mainly charge attraction, charge neutralization, and bridging. From recent reports, some novel interactions between biopolymer-based flocculants and contaminants have been reported. In order to have a comprehensive understanding for the flocculation mechanisms of biopolymer-based flocculants, it is necessary to review the interaction between biopolymer-based flocculants and various contaminants from the latest researches.

Accordingly, in this paper, the commonly used base materials, modification methods (according to reaction types), flocculation mechanisms, and water treatment applications of biopolymer-based flocculants are reviewed. At the same time, the future perspectives of biopolymer-based flocculants are discussed. Firstly, according to the sources and extraction methods of the base materials, it is obviously known whether their natural reserves are rich and whether they are economical and easy to obtain. Therefore, the sources of the base materials and the new biopolymer-based flocculants researches based on these materials in recent years are summarized. Secondly, at present, there are few reports summarizing the modification methods of biopolymer-based flocculants according to reaction types. However, the modification methods of different reaction types affect the structural characteristics of flocculants, which may have an important impact on the flocculation effect (Yang et al. 2016a). Thus, according to the different reaction types, the modification methods of biopolymer-based flocculants are reviewed in detail. Thirdly, a deep understanding of flocculation mechanisms is conducive to the further design of biopolymer-based flocculants. Nevertheless, a comprehensive summary about this is lacking. Therefore, the flocculation mechanisms of the biopolymer-based flocculants are systematically studied in this paper. Fourthly, the water treatment conditions, the removal efficiency and advantages of biopolymer-based flocculants in applications are summarized. Finally, the future development of biopolymer-based flocculants is prospected. This review aims to provide a reference for the development of biopolymer-based flocculants with higher efficiency, a lower cost, more safety, and multi-function in the future.

Progress in the commonly used base materials

The base materials which are biopolymers extracted from natural raw materials are diversified and rich in reserves. They can be obtained from animals, plants, and fungi etc. At present, among the diverse base materials used in the researches of biopolymer-based flocculants, the commonly used are chitosan, starch, cellulose, and lignin.

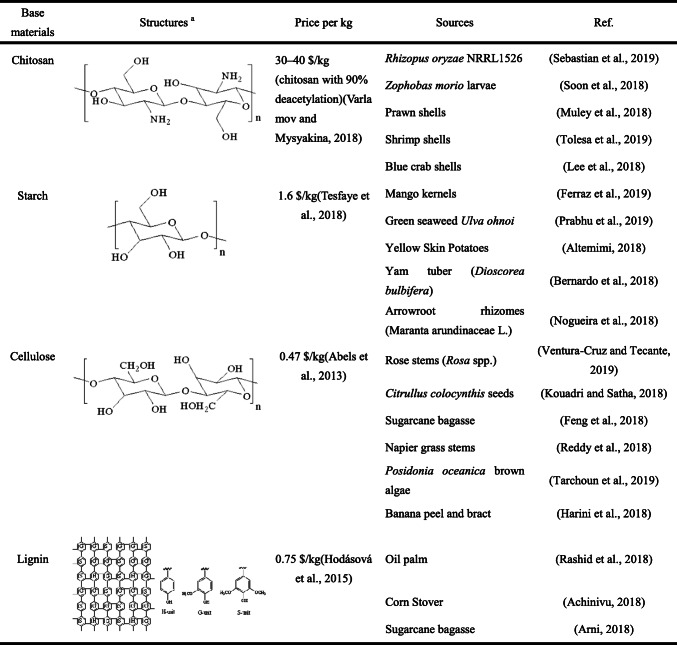

Chitosan

Chitosan is a kind of polycationic polysaccharide with a low cost and wide sources (Zheng et al. 2018). It has the properties of biodegradability, immunostimulatory, and antibacterial activity (Sanchez-Salvador et al. 2021). Chitosan can be obtained by partial deacetylation of chitin. This process of chitin requires high-temperature chemical hydrolysis in concentrated alkaline solution (Duan et al. 2019). In recent reports, the sources of chitosan were Rhizopus oryzae NRRL1526 (Sebastian et al. 2019), Zophobas morio larvae (Soon et al. 2018), prawn shells (Muley et al. 2018), shrimp shells (Tolesa et al. 2019), and blue crab shells (Lee et al. 2018), (Table 1) etc. The process of extracting chitosan from natural raw materials mainly includes three steps: demineralization, deproteinization, and deacetylation. At present, the most common commercial extraction method of chitosan is the chemical method using strong acids and bases. In order to reduce the reaction time and improve the purity and yield of the product, researchers have developed many new extraction methods of chitosan. Among them, the microwave radiation assistant extraction method has been widely used (El Knidri et al. 2018). After extraction, chitosan with 90% deacetylation for water treatment was about 30–40 $/kg (Varlamov and Mysyakina 2018). Besides, there are amino and hydroxyl groups in the chitosan molecular structure (Table 1), easy for modification that makes it possible for chitosan to obtain multi-function and more chemical properties (Filho et al. 2018). Some properties (mechanical and structural properties, solubility and gel formation ability) of chitosan can be changed by incorporating to the new copolymers (Sanchez-Salvador et al. 2021). Therefore, chitosan is a kind of good base material for biopolymer-based flocculants.

Table 1.

Sources of biopolymer-based flocculants

aThe structures of chitosan and starch are redrawn from Salehizadeh et al. (2018) Recent advances in polysaccharide bio-based flocculants. Biotechnol. Adv. 2018. The structures of cellulose and lignin are redrawn from Chio et al. (2019) Lignin utilization: A review of lignin depolymerization from various aspects. Renew. Sust. Energ. Rev. 2019

Starch

Starch, a polymer composed of α-D-glucose units (Bolto and Gregory 2007b), is a kind of water-soluble glycan with strong regeneration (Wei et al. 2018b). In recent reports, the natural sources of starch are as follows: Mango kernels (Ferraz et al. 2019), Green seaweed Ulva ohnoi (Prabhu et al. 2019), Yellow Skin Potatos (Altemimi 2018), Yam tuber (Dioscorea bulbifera) (Bernardo et al. 2018), Arrowroot rhizomes (Maranta arundinaceae L.) (Nogueira et al. 2018) (Table 1) etc. The common methods for extracting starch are the wet milling process and the alkali method from cereals as the largest source (El Halal et al. 2019). Starch has the advantages of low price and easy availability, due to its abundance. In 2016, the price of starch in the market was 1.6 $/kg (Tesfaye et al. 2018). Based on the above advantages, the development of starch as a biopolymer-based flocculant started very early (Fanta et al. 1972).

Cellulose

Cellulose is the most abundant biopolymer in the world. Its structure consists of repeated covalently linked β-D-anhydroglucopyranose units (Roy et al. 2009). In recent researches, the sources of cellulose are Rose stems (Rosa spp.) (Ventura-Cruz and Tecante 2019), Citrullus colocynthis seeds (Kouadri and Satha 2018), Sugarcane bagasse (Feng et al. 2018), Napier grass stems (Reddy et al. 2018), Posidonia oceanica brown algae (Tarchoun et al. 2019), Banana peel, and bract (Harini et al. 2018) (Table 1) etc. Because of its abundant sources, the price of cellulose is very low. Some researchers estimated that the price of cellulose was about 0.40 €/kg (Abels et al. 2013), that is, about 0.47 $/kg. Therefore, a lot of researches have been devoted to the chemical modification of cellulose to improve its water solubility and flocculation performance for better application in water treatment (Cai et al. 2015). In 2002, cellulose was successfully dissolved by some ionic liquids for the first time. Since then, many cellulose-based materials have been prepared by using ionic liquids as direct solvents and dissolution regeneration process (Xia et al. 2020).

Nanocellulose has attracted some researchers’ attention due to its high specific surface area, high tensile strength, high reactivity, and low density (Morantes et al. 2019; Negro et al. 2020). Therefore, some studies used nanocellulose as flocculants. For example, cationic hairy cellulose nanocrystals can flocculate clay suspension in a wide dosage range (7.5–75 mg/g) (Campano et al. 2019b). Morantes et al. (2019) used epoxy-propyltrimethylammonium chloride to react with cellulose nanocrystals. By this method, they prepared a cationic cellulose-based flocculant (CNC-EPTMAC), which was used to treat 0.25 wt.% SiO2 suspensions. The results showed that the reduction of the SiO2 concentration in suspension could be 99.7% when the concentration of CNC-EPTMAC was only 2 ppm. It seems that cellulose nanocrystals with a small size could be a good choice to synthesize cellulose-based flocculants.

Lignin

Lignin, a biopolymer with the second largest nature reserves in the world (Brenelli et al. 2016), has a variety of functional groups, such as carbonyl, carboxyl, phenolic hydroxyl, alcohol hydroxyl, aromatic, methoxy, and conjugated double bond (Guo et al. 2018b) etc. In recent reports, the sources of lignin are as follows: Oil palm (Rashid et al. 2018), Corn Stover (Achinivu 2018), Sugarcane bagasse (Arni 2018) (Table 1) etc. At present, the most commonly used method to extract cellulose from raw biomass is to decompose lignin into soluble segments, dissolve them in solvents, and then separate lignin from the filtrate (Jiang and Hu 2016). To dissolve lignin, many researchers try ionic liquids as solvents, which was inspired by the effectiveness of ionic liquids as strong solvents for cellulose. Dissolved in ionic liquids, lignin can be depolymerized to further produce lignin-derived materials. The depolymerization methods include acid depolymerization, alkali depolymerization, hydrogenation depolymerization, and oxidation depolymerization. In addition, lignin can also be transformed into a series of derivative materials with ionic liquids as solvents and additives (Xia et al. 2020). After it is extracted from the natural sources, the price of high purity lignin could be 0.75 $/kg (Hodásová et al. 2015). Besides, lignin is abundant in paper mill sludge, making it a potential source of lignin. Making use of paper mill sludge, a kind of waste, to prepare water purification materials, in turn to solve environmental problems, will be of great value (Guo et al. 2018b).

In the past, the preparation methods of lignin-based flocculants in many researches were based on free radical polymerization. However, lignin will inhibit the free radical reaction and reduce the grafting efficiency in free radical polymerization-based preparation methods. To solve this problem, Chen et al. (2020a) developed a new grafting method. In their study, linear cationic polyacrylamide was synthesized by free radical polymerization, using 4-chloromethyl styrene as a chain transfer agent, ammonium persulfate as an initiator, acrylamide, and methylacryloyloxyethyltrimethyl ammonium chloride as monomers. Then, the lignin-cationic polyacrylamide flocculant was prepared by the mixing reaction of cationic polyacrylamide, enzymatic hydrolysis lignin, and NaOH solution. The grafting efficiency was improved by the effective reaction of chlorine of cationic polyacrylamide with phenolic hydroxyl groups of lignin.

Some other base materials

In addition to the above four main materials, researchers also used a variety of other biopolymers for the synthesis of biopolymer-based flocculants. For example, Moringa oleifera-based flocculants are easily operated by unqualified persons, and the water treated by Moringa oleifera based flocculants has little impact on human health. Therefore, this kind of material is favored by developing countries (Beltrán-Heredia and Sánchez-Martín 2009). Furthermore, it has been reported that a coagulant was extracted from Moringa oleifera by the method of saline and aqueous extraction processes followed by ultrafiltration. This coagulant can reduce the pollutant concentration of surface water without increasing the organic matter in the treated water (Baptista et al. 2015).

Agricultural production will generate a large number of non-food biomass. Although the utilization rate of these agricultural wastes is very low, they have considerable potential values (Goodman 2020). Therefore, using agricultural wastes to produce flocculants might be an attractive alternative strategy. For example, Khiari et al. have prepared sodium carboxymethyl cellulose flocculants with date palm rachis, an agricultural waste, as raw materials, and investigated its turbidity removal efficiency. The results show that under the optimal conditions, the turbidity removal rate of the flocculant produced by date palm rachis was about 95% (Khiari et al. 2010). Besides, some researchers extracted mucilage from the peel of dragon fruit, and used it with polyaluminum chloride for turbidity removal. The results show that this kind of mucilage can reduce the dosage of polyaluminum chloride, and improve the removal rate of turbidity (Le et al. 2020).

Extracellular biopolymer flocculants (EBFs) are substances secreted by a variety of microorganisms in a culture medium. These substances are composed of proteins, polysaccharides, and lipids. EBFs are nontoxic and biodegradable (Salehizadeh and Yan 2014). For example, Paenibacillus elgii B69 can produce an exopolysaccharide compound of gluconic acid, glucose, mannose, and xylose. This kind of EBFs has good flocculation efficiency of dyes, kaolin, and heavy metal ions (Li et al. 2013). High polymer polysaccharide and protein, produced by Klebsiella sp., can remove 53.27% sulfamethoxazole from domestic water (Xing et al. 2013). In another research, Bacillus licheniformis cells and metabolites (protein and polysaccharide) were used to flocculate kaolin and quartz. The results showed that different metabolic components (protein and polysaccharide) had good efficiency on different target removal substances (kaolin and quartz), respectively (Ghashoghchi et al. 2017).

Besides, a kind of dextran-based flocculant was prepared and used in the wastewater treatment of a kaolin-Congo red binary contaminants system. The maximum removal rate of dextran-based flocculants for the Congo red could reach 88.2% (Zhao et al. 2018). A kind of β-cyclodextrin-based flocculant was synthesized by the ultrasound-assisted method. The turbidity removal rate of humic acid-kaolin sewage with the β-cyclodextrin-based flocculant could reach 97.5% (Liu et al. 2019). The residual turbidity of 3 mass% kaolin suspension treated with the poly (vinyl alcohol)-Acacia nilotica gum flocculant was as low as 15.3 NTU under the optimal conditions (Nasim et al. 2018). In addition, the xylan-based flocculant was used to treat pulp mill wastewater; the removal rates of turbidity and lignin were 94.5% and 45.0%, respectively (Chen et al. 2018b).

Development of the modification methods

In order to further improve the flocculation performance of biopolymer-based flocculants, or to achieve the multifunctionality of flocculants (e.g., sterilization(Liu et al. 2017a; El-Naggar et al. 2018; Li et al. 2017; Chen et al. 2020b; Tang et al. 2010), scale-inhibition (Du et al. 2018b)), researchers would like to modify various functional groups on biopolymers. Through the modification of different reaction types, biopolymers may get different structural characteristics (functional groups, molecular weight, charge density, etc.). As a result, the molecular structure of biopolymer-based flocculants seems to impact the flocculation efficiency (Yang et al. 2016a). Therefore, the selection of modification methods is the key to preparing biopolymer-based flocculants, but there are few reports summarizing the modification methods according to different reaction types. In this part, they are summarized according to reaction types, such as graft copolymerization, etherification, amination, esterification, acylation, oxidation, cross-linking, and Mannich reaction, as shown in Table 2.

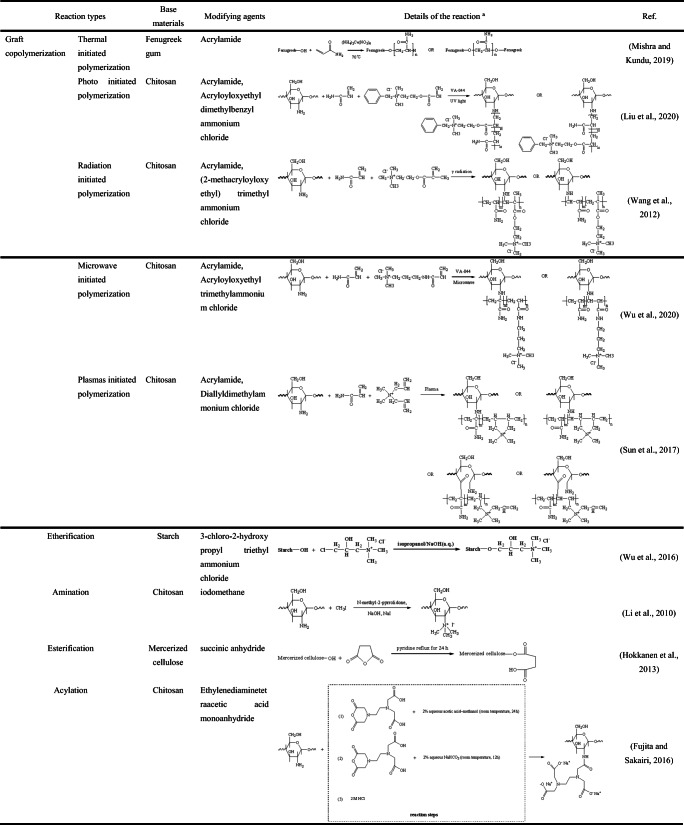

Table 2.

Reaction types of modification in biopolymer-based flocculants synthesis processes

aPartial steps from the synthesis processes

Graft copolymerization

Graft copolymerization of biopolymer-based flocculants can be initiated in many ways, including thermal initiation, photo initiation, radiation initiation, microwave initiation, and plasma initiation.

Thermal initiation

Heating monomers to produce free radicals can cause polymerization. However, the activity of monomers is usually low, so initiators are often added to solve this problem. The initiator decomposes to produce free radicals by heating, which can further initiate polymerization. Initiator VA-044 in the thermal initiation method was reported by Liu et al. (2018a). In their experiments, magnetic nanoparticles were firstly prepared by solvothermal method, and then modified by vinyl groups; finally, the VA-044 initiator was used to initiate graft copolymerization of itaconic acid, chitosan, and the modified magnetic nanoparticles at 50 °C to prepare the magnetic flocculant Mag@PIA-g-CS.

Among these initiation methods, the reaction efficiency of thermal initiation may be the lowest (Zhao et al. 2018). Mishra and Kundu (2019) compared the characteristics of the biopolymer-based flocculants prepared by microwave initiation with those by thermal initiation. In that study, polyacrylamide grafted-fenugreek gum was prepared by microwave initiation and thermal initiation (Table 2), respectively, using fenugreek gum as a base material, ceric ammonium nitrate as an initiator, and acrylamide as a graft monomer. The flocculation experiments demonstrated that the turbidity removal rate of the biopolymer-based flocculants prepared by microwave irradiation was about 96%, while that by the thermal initiation was 89%. Therefore, it could be concluded that thermal initiation may be not a good way to initiate graft copolymerization.

Photo initiation

The polymerization of monomers with biopolymers can be initiated under UV irradiation. It has been reported that the CS-g-pAO flocculant was prepared under 500 W and 11.7 × 102 μw/cm2 of UV irradiation by grafting acryloyloxyethyl dimethylbenzyl ammonium chloride and acrylamide onto chitosan with VA-044 as a photo initiator (Liu et al. 2020) (Table 2). Similarly, another study (Liu et al. 2018b) polymerized acrylamide, itaconic acid, and chitosan to obtain the CS-g-p (AM-IA) flocculant by UV initiation, namely photo initiation.

Radiation initiation

Radiation initiation refers to the polymerization of each reactant initiated under the irradiation of high-energy rays (e.g., α-ray, β-ray, γ-ray, X-ray, etc.). For example, under γ-ray initiated copolymerization, acrylamide and (2-methacryloyloxyethyl) trimethyl ammonium chloride were grafted onto chitosan (Wang et al. 2012) (Table 2).

Microwave initiation

The microwave frequency of 2450 ± 50 MHz is close to the rotational vibration frequency of the chemical groups, which can activate the groups and make the monomers polymerized. Under the microwave of 2450 MHz, Wu et al. (2020) synthesized the CS-g-pAD flocculant by grafting acryloyloxyethyl trimethylammonium chloride and acrylamide onto chitosan (Table 2).

Plasma initiation

When ionized gaseous substances, composed of electrons, ions and neutral particles, irradiate monomers, monomer polymerization occurs as a result. Through plasma initiation, Sun et al. (2017) synthesized acrylamide-diallyldimethylammonium chloride-grafted-chitosan under certain discharge power and reaction time (Table 2).

Etherification

As shown in Table 1, biopolymers contain abundant hydroxyl groups, making the materials easily etherified with etherifying agents under alkaline conditions. Wang et al. (2016b) etherified water-soluble starch with butyl glycidyl ether. Firstly, 2-hydroxy-3-butoxypropyl starch was formed. Then, in the dimethyl sulfoxide solvent, the cationic etherifying agent 2,4-bis(dimethylamino)-6-chloro-[1,3,5]-triazine was used to etherify 2-hydroxy-3-butoxypropyl starch to form temperature & pH responsive starch. Three starch-based flocculants were prepared by Wu et al. (2016), among which etherification was used in the modification of two flocculants (STC-CTA and CMS-g-PDMC). STC-CTA was prepared by the etherification of starch with (3-chloro-2-hydroxypropyl) trimethyl ammonium chloride (Table 2). In the preparation of CMS-g-PDMC, chloroacetic acid was used as an etherifying agent which reacted with starch to prepare carboxymethyl starch, and then poly[(2-methacryloyloxyethyl) trimethyl ammonium chloride] was grafted to carboxymethyl starch under the initiation of potassium persulfate.

Amination

Amination is a common and simple method for preparing biopolymer-based flocculants (Yang et al. 2016a). Li et al. (2010) synthesized N,N,N-trimethyl chitosan chloride through the reductive methylation of chitosan and iodomethane, which was called a special direct amination (Yang et al. 2016a) (Table 2). After that, an amphiphilic chitosan-based flocculant (O-carboxymethyl-N-trimethyl chitosan chloride) was synthesized by reductive carboxymethylation of N,N,N-trimethyl chitosan chloride with monochloroacetic acid in the presence of sodium hydroxide.

Esterification

The hydroxyl groups on biopolymers can be converted into ester groups after esterification with organic and inorganic acids and their derivatives (e.g., anhydride, chloride and oxychloride) (Lewicka et al. 2015). As can be seen in Table 2, Hokkanen et al. (2013) esterified mercerized cellulose with succinic anhydride to form a cellulose-based flocculant under pyridine reflux.

Acylation

Acylation introduces acyl groups into the nitrogen and oxygen etcetera atoms of biopolymers. Parviainen et al. (2014) directly acylated the hydroxyl groups of cellulose with 2-bromoisobutyryl bromide to obtain a cellulose macromolecular initiator. Then, N,N-dimethyl aminoethyl methacrylate was grafted with the macromolecular initiator to form cellulose-g-poly(N,N-dimethyl aminoethyl methacrylate). Finally, it was quaternized to form cellulose-g-poly(methacry-loxyethyl trimethylammonium chloride). In another research (Fujita and Sakairi 2016) (Table 2), ethylene diamine tetraacetic acid-linked chitosan was synthesized by N-acylation of chitosan and ethylene diamine tetraacetic acid monoanhydride. This flocculant is a linear non-crosslinking polymer.

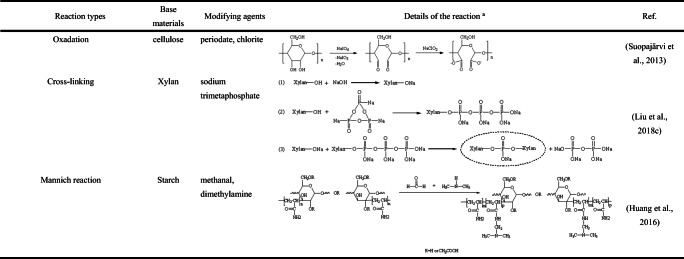

Oxidation

The hydroxyl groups on biopolymers can be oxidized to aldehyde groups. In addition, the aldehyde groups can be further transformed into other functional groups by modification. Suopajärvi et al. (2013) used sodium periodate to oxidize the two ortho hydroxyl groups in cellulose to form aldehyde groups, and then used sodium chlorite to oxidize aldehyde groups to carboxyl groups, thus introducing dicarboxyl groups into cellulose (Table 2).

Cross-linking

The molecular weight of biopolymers can be increased by cross-linking modification. The increase of molecular weight can improve the bridging flocculation efficiency of biopolymer-based flocculants (Runkana et al. 2006). Thus, cross-linking may be a good method to enhance the flocculation efficiency of biopolymer-based flocculants. As shown in Table 2, Liu et al. (2018c) applied a reported cross-linking method (Dulong et al. 2004) to prepare biopolymer-based flocculants. They used sodium trimetaphosphate as a cross-linking agent to make xylan cross-linked in an alkaline condition to form the phosphorylated xylan flocculant.

Mannich reaction

Mannich reaction was reported in 1912 (Mannich and Krösche 1912). This method was also used in the modification of biopolymer-based flocculants. Huang et al. (2016) carboxymethylated starch with monochloroacetic acid to form carboxymethyl starch. Then, acrylamide monomer was grafted onto carboxymethyl starch by the initiation of ammonium persulfate to obtain CMS-g-PAM. Finally, CMS-g-PAM was added into the aqueous solution of formaldehyde and dimethylamine for Mannich reaction to obtain carboxymethyl-starch-graft-aminomethylated-polyacrylamide (Table 2).

Flocculation mechanisms of biopolymer-based flocculants

Generally, the principle of flocculation lies in the solid-liquid separation of sewage or sludge. Like other kinds of flocculants, biopolymer-based flocculants can destabilize, aggregate, and separate (e.g., ordinary sedimentation (Li et al. 2018) and magnetic separation (Lü et al. 2018; Liu et al. 2018a)) aqueous contaminants by destroying the stability of the colloidal system in polluted water. However, according to the recent researches, there is something special about the flocculation mechanisms of biopolymer-based flocculants. In general, the flocculation process of biopolymer-based flocculants is usually the result of several mechanisms, including adsorption, bridging, charge neutralization, net trapping and sweeping, as well as, some other special mechanisms. In detail, some case studies are listed in Table 3.

Table 3.

Case studies about flocculation mechanisms of biopolymer-based flocculants

| Base materials | Flocculants | Targets | Flocculation mechanisms | Ref. |

|---|---|---|---|---|

| Chitosan | Dextran-chitosan | Kaolin suspension water | Charge attraction, hydrophobic interaction effect, bridging, charge neutralization, sweeping | (Zeng et al. 2019) |

| Chitosan-grafted poly(acrylamide-co-acryloyloxyethyl trimethylammonium chloride) | Sludge | Electrical neutralization, patching, adsorption, bridging | (Wu et al. 2020) | |

| 2,4-bis(dimethyl amino)-6-chloro-(1,3,5)-triazine modified chitosan | Tetracycline and Cu(II) | Charge attraction, coordination effect, π–π stacking | (Jia et al. 2016) | |

| Carboxymethyl chitosan-grafted-poly(acrylamide-ammonium dithiocarbamate) | Ni(II), COD, and turbidity | Chelation, net trapping, bridging | (Sun et al. 2020b) | |

| Poly(dimethyl acryloyloxyethyl benzyl ammonium chloride)-grafted-chitosan | Diesel-in-water emulsion | Patching mechanism, bridging action, charge neutralization | (Lü et al. 2019) | |

| Quaternized chitosan-grafted magnetic nanoparticles | Diesel-in-water emulsion | Patching mechanism | (Lü et al. 2018) | |

| Chitosan-grafted poly(N-n-propylacrylamide) | Tetracycline and Cu(II) | Coordination effect, H-bond, hydrophobic association | (Ren et al. 2017) | |

| Starch | Starch-graft-poly[(2-methacryloyloxyethyl) trimethyl ammonium chloride | Humic acid | Charge neutralization, bridging | (Wu et al. 2016) |

| Cellulose | Carboxymethylcellulose-grafting-(poly N-isopropyl acrylamide-co-poly diallyl dimethyl ammonium chloride) | Nonylphenol, humic acid and kaolin | Charge attraction, hydrophobic interaction | (Yang et al. 2016b) |

| Cellulose-grafting-poly(methyl acryloyl oxygen ethyl trimethyl ammonium chloride) | Kaolin suspension water | Charge attraction, bridging action | (Li et al. 2018) | |

| Lignin | Alkaline lignin-grafting-dimethyl diallyl ammonium chloride | Disperse yellow dye | Charge neutralization, bridging | (Guo et al. 2019) |

| Lignin-grafting-(acrylamide-dimethyl diallyl ammonium chloride) | Disperse yellow dye | Charge neutralization, bridging | (Guo et al. 2018b) | |

| Xylan | Cationic xylan-(2-methacryloyloxyethyl trimethyl ammonium chloride) | Pulping wastewater | Charge neutralization, bridging | (Chen et al. 2018b) |

Adsorption mechanism

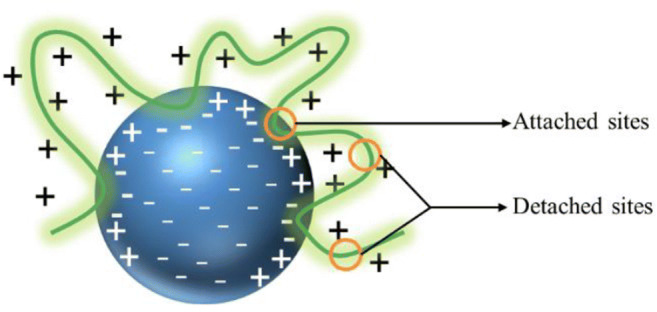

There are usually charge attraction (Zeng et al. 2019; Jia et al. 2016; Yang et al. 2016b; Li et al. 2018) and hydrogen bond (Ren et al. 2017) between the molecular chain of biopolymer-based flocculants and the surface of contaminants, which will result in the adsorption of contaminants onto the biopolymer-based flocculants molecules. When the charges carried by biopolymer-based flocculants molecules and contaminants are opposite, adsorption occurs between them, which is referred to as charge attraction; Hydrogen bond refers to the adsorption between contaminants and biopolymer-based flocculants by the attraction of hydrogen atoms and electronegative atoms. Thus, the adsorption occurs in effective attached sites, not in the whole molecular chain (Sharma et al. 2006). As shown in Figure 1, the detached sites of biopolymer-based flocculants would extend into the water.

Fig. 1.

Adsorption mechanism (Sharma et al. 2006) of biopolymer-based flocculants

Compared with unmodified biopolymers, the biopolymer-based flocculants usually gain longer molecular chains and higher molecular weight through modification. Thus, the probability of effective attached sites in biopolymer-based flocculants may be higher, allowing biopolymer-based flocculants to absorb more contaminants (Wu et al. 2020).

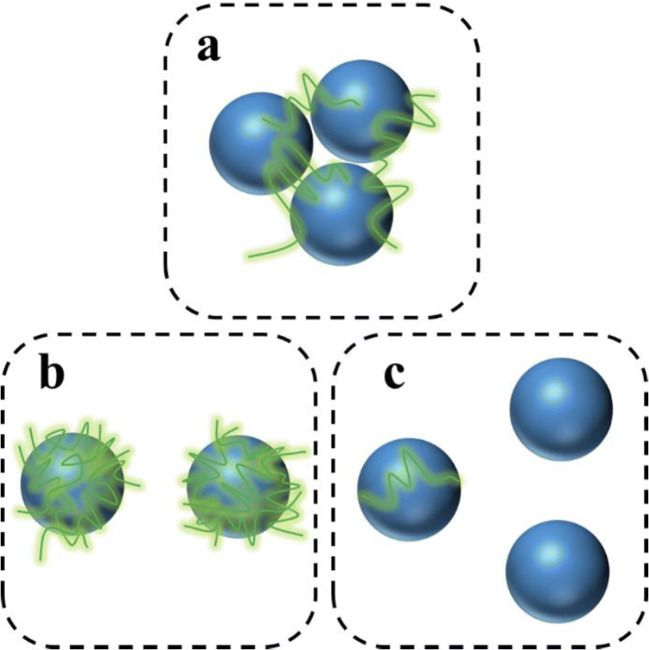

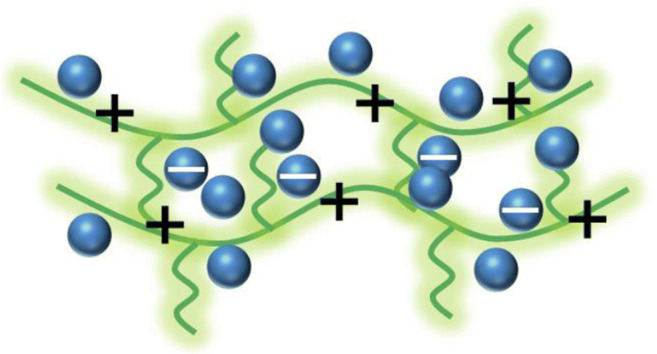

Bridging mechanism

After the effective attached sites on the biopolymer-based flocculants adsorb the contaminants, the non-adsorbed parts of the chain will extend to the outside, like “bridging,” adsorbing, and linking other more contaminants (Figure 2a). This phenomenon of bridging the long-distance contaminants into flocs is called the bridging mechanism. It is common in biopolymer-based flocculants (Zeng et al. 2019; Guo et al. 2018b, 2019; Li et al. 2018; Lü et al. 2019; Chen et al. 2018b; Sun et al. 2020b; Wu et al. 2020).

Fig. 2.

Bridging mechanism of biopolymer-based flocculants; a Appropriate flocculants dosage (Bolto and Gregory 2007a), b excessive flocculants dosage, and c inadequate flocculants dosage

In the case of bridging flocculation, the higher molecular weight of the biopolymer-based flocculants is, the higher flocculation efficiency will be (Runkana et al. 2006). However, the effects of dosage may be more varied. When the dosage of biopolymer-based flocculants is excessive (Figure 2b), the surface of contaminants is totally covered by biopolymer-based flocculants molecules, and there will be no site on the contaminants to bridge. Consequently, the aqueous system becomes stabilized, and the flocculation efficiency deteriorates (Sun et al. 2020b). Nonetheless, when the dosage of biopolymer-based flocculants is inadequate (Figure 2c), there may be no enough effective bridge contact (Bolto and Gregory 2007b).

Charge neutralization mechanism

The contaminants in sewage usually have the same charges. Therefore, the electrostatic repulsion between them makes them disperse uniformly and stably in the colloidal system, which is not easy to agglomerate. If the electrical property of the biopolymer-based flocculants is opposite to that of the contaminants, the electrostatic attraction makes the biopolymer-based flocculants molecules be adsorbed on the surface of contaminants, resulting in charge neutralization. It decreases the electric repulsion between contaminants. Then, contaminants will collide with each other under the Brownian motion, which leads to flocculation (Zeng et al. 2019; Guo et al. 2019; Guo et al. 2018b; Chen et al. 2018b; Wu et al. 2020). This phenomenon is called charge neutralization mechanism of biopolymer-based flocculants (Figure 3a). In addition, the mechanism of flocculation can be judged by measuring zeta potential. If the zeta potential of the system is close to 0 at the best flocculation efficiency point, the flocculation is mainly caused by charge neutralization (Lü et al. 2019).

Fig. 3.

Charge neutralization mechanism (Salehizadeh et al. 2018) of biopolymer-based flocculants: a Ordinary one; b Patching mechanism

However, there is another case. When the high charge density biopolymer-based flocculants are adsorbed on the surface of low charge density contaminants with opposite charges, sites on the surface of the contaminants may not be all neutralized by the molecular chain segments of biopolymer-based flocculants. The reason is that the sites may tend to be electrically neutral as a whole. Therefore, coating patches and uncoated regions with opposite electric charges are interspersed on the surface of contaminants. When contaminants are close to each other, electrostatic attraction exists between coating patches and uncoated regions with opposite charges, and thus flocculation will occur (Figure 3b). This mechanism, which is different from the ordinary charge neutralization mechanism, is called “patching mechanism.” It often occurs in the flocculation of biopolymer-based flocculants (Lü et al. 2018; Lü et al. 2019; Wu et al. 2020).

Net trapping and sweeping

Net trapping (Sun et al. 2020b) and sweeping (Zeng et al. 2019) were found in the flocculation of biopolymer-based flocculants. As shown in Figure 4, the sediment initially formed by biopolymer-based flocculants will move for a period before settling down. During this process, the sediment will capture more other contaminants and form larger flocs.

Fig. 4.

Net trapping and sweeping mechanism of biopolymer-based flocculants (Zeng et al. 2019)

Other special mechanisms

In addition to the above mechanisms, due to the abundant special functional groups of biopolymer-based flocculants, there are some other special mechanisms, such as hydrophobic interaction effect (Zeng et al. 2019; Yang et al. 2016b; Ren et al. 2017), coordination effect (Jia et al. 2016; Ren et al. 2017), chelation (Sun et al. 2020b; Tang et al. 2020), and π-π stacking (Jia et al. 2016).

As shown in Figure 5, there are some case studies for the special flocculation mechanisms of biopolymer-based flocculants. (i) Hydrophobic interaction effect: the hydrophobic chains on the biopolymer-based flocculants will interact with hydrophobic contaminants. Then, the hydrophobic contaminants may be wrapped in the polymer net of biopolymer-based flocculants through the hydrophobic interaction (Yang et al. 2016b) (Figure 5a). (ii) Coordination effect: if the biopolymer-based flocculants contain amino, amide, hydroxyl groups etc., there will be coordination effect on heavy metal ions (Ren et al. 2017) (Figure 5b). (iii) Chelation: functional groups of biopolymer-based flocculants, such as carboxyl, dithiocarboxy groups etc., will form chelation with heavy metal ions (Sun et al. 2020b) (Figure 5c). (iv) π-π stacking: if the aromatic rings are introduced into biopolymer-based flocculants through modification, the aromatic rings on biopolymer-based flocculants will react with the aromatic rings of contaminants by π-π stacking(Jia et al. 2016) (Figure 5d).

Fig. 5.

Case studies for other flocculation mechanisms of biopolymer-based flocculants; a Hydrophobic interaction effect (Yang et al. 2016b), b coordination effect (Ren et al. 2017), c chelation (Sun et al. 2020b), and d π-π stacking (Jia et al. 2016)

As mentioned above, biopolymer-based flocculants, with rich functional groups, have varied flocculation mechanisms for contaminants. Thus, in applications, biopolymer-based flocculants may get satisfying flocculation efficiency by combined mechanisms.

Recent applications of biopolymer-based flocculants

Compared with the traditional flocculants, biopolymer-based flocculants, as a kind of newly born flocculants, their applications become more diversified. In recent years, biopolymer-based flocculants are mainly applied in the treatment of turbidity, dyes, heavy metal ions, and other industrial/agricultural sewage, as well as algae capture and sludge dewatering. To reveal the parameter details, some case studies are listed in Table 4.

Table 4.

Applications of biopolymer-based flocculants

| Sewage types | Targets | Sewage characteristics | Flocculants | Operating conditions | Removal efficiency | Ref. |

|---|---|---|---|---|---|---|

| Turbidity | Kaolin particles | Kaolin: 2.5 g/L; Turbidity: 2000-3000 NTU | Microcrystalline cellulose-grafted-poly(methyl acryloyl oxygen ethyl trimethyl ammonium chloride) | Stirring rates and time: 200 rpm for 1 min, and 40 rpm for 5 min;Settling time: 30 min; Optimum dosage:0.6 mg/L; pH: 2–12 | Turbidity reduction: 96.90% | (Li et al. 2018) |

| Kaolin particles | Kaolin: 0.1%(w/v) | Konjac glucomannan-graft-poly-(2-methacryloyloxyethyl) trimethyl ammonium chloride | Stirring rates and time: 400 rpm for 30 s, and 250 rpm for 1–4 min;Settling time: 30 min; Dosage: 1 ppm; pH: 1–9 | Turbidity reduction: ≥ 90% | (Ren et al., 2016) | |

| Kaolin particles | Kaolin: 3 mass% | Polyvinyl alcohol-Acacia nilotica gum (70% PVA, 30% NG) | Homogenization | Residual turbidity: 15.3 NTU (pH = 2.6) | (Nasim et al. 2018) | |

| Kaolin particles | Kaolin: 5.0 g/L;Turbidity: 4200 NTU | Microcrystalline cellulose-grafted-poly(acrylic acid-co-methacryloxyethyltrimethyl ammonium chloride) | Stirring rates and time: 200 rpm for 3 min, and 30 rpm for 7 min; Settling time: 10 min;pH: 7 | Turbidity reduction: 99.82% | (Wang et al. 2019b) | |

| Kaolin particles, Orthophosphate | Kaolin: 400 mg/L; Orthophosphate: 25 mg/L | Carboxymethyl chitosan-grafted-(3-chloro-2-hydroxypropyl trimethylammonium chloride) | Stirring rates and time: 295 rpm for 3 min, and 25 rpm for 20 min; Coagulant: ferric chloride 12.5 mg/L; pH: 4 | Turbidity reduction: 99.2%;orthophosphate reduction: 97.8% | (Agbovi and Wilson 2018) | |

| Dye | Ethyl violet | Ethyl violet: 300 mg/L; | Sulfomethylated softwood kraft lignin | Stirring rates and time: 200 rpm for 3 min, and 50 rpm for 10 min; Settling time: 2 h; Dosage: 300 mg/L; pH: 9 | Dye reduction: 99.1%; COD reduction: 90.0% | (He et al. 2016) |

| Reactive black 5 (RB5), Reactive orange 16 (RO16) | Reactive black 5: 100 mg/L; Reactive orange 16: 100 mg/L | Lignin-[(2-(methacryloyloxy) ethyl) trimethyl ammonium chloride] | Stirring rates and time: 150 rpm for 10 min; Optimum dosage: 120 mg/L for RB5, 105 mg/L for RO16 | RB5 reduction: 98%; RO16 reduction: 94% | (Wang et al. 2018) | |

| Congo red (CR) with the impact of Kaolin particles | Congo red: 30 mg/L; Kaolin: 1 g/L | Dextran-graft-poly(acrylamide-benzyl(methacryloyloxyethyl)dimethylammonium chloride) | Stirring rates and time: 200 rpm for 6 min, and 40 rpm for 15 min; Settling time: 30 min; Dosage: 10–20 mg/L; | CR reduction: 80.4–88.2% | (Zhao et al. 2018) | |

| Heavy metal ions | Pb(II) with the impact of Kaolin particles | Pb(II): 25 mg/L; Turbidity: 20 NTU | Carboxymethyl chitosan-g-poly(acrylamide-ammonium dithiocarbamate) | Stirring rates and time: 300–400 rpm for 3–5 min, and 50–70 rpm for 10–15 min;Settling time: 15 min; Dosage: 50 mg/L; pH: 5; | Pb(II) reduction: 95.24% | (Sun et al. 2020b) |

| Cu(II) with the impact of Kaolin particles | Cu(II): 25 mg/L; Turbidity: 100 NTU | Xanthated chitosan | Stirring rates and time: 120 rpm for 2 min, and 40 rpm for 10 min; Settling time: 10 min; pH: 6 | Cu(II) reduction: 93.6% | (Yang et al. 2018) | |

| Ni(II) | Ni(II): 20 mg/L | Carboxylated chitosan-graft-poly(acrylamide-2-acrylamido-2-methylpropane sulfonic acid) | Stirring rate: 350 rpm; Reaction time: 2 h; Dosage: 2 mg/L; pH: 10 | Ni(II) reduction: 75.7% | (Sun et al. 2019b) | |

| Cr, Ni | Cr: 9.1 mg/L, Ni: 44.6 mg/L | Carboxylated chitosan-graft-poly [acrylamide-2-Acrylamido-2-methylpropane sulfonic acid | Stirring rates and time: 350 rpm for 3 min, and 60 rpm for 15 min; Settling time: 40 min; Dosage for Cr: 2.5 mg/L at first stage flocculation, 0.5 mg/L at second stage flocculation (pH = 5, reaction time 2 h);Dosage for Ni: 1.0 mg/L at first stage flocculation, 0.3 mg/L at second stage flocculation (pH=10, reaction time 2 h) | Cr reduction: 94.6%; Ni reduction: 99.4% | (Sun et al. 2019a) | |

| Pulp mill sewage | COD, BOD, Lignin, Sugar, Turbidity |

COD: 4470 mg/L, BOD: 873 mg/L, Lignin: 1.47 g/L, Sugar: 1.02 g/L, Turbidity: 957 NTU, pH: 6.6, Zeta potential: − 30.7 mv, Particle size: 423 nm, Suspend solid: 356 mg/L |

Xylan-poly(2-methacryloyloxyethyl) trimethyl ammonium chloride | Stirring rates and time: 100 rpm for 30 min;Dosage: 500 mg/L | COD reduction: 61.7%; BOD reduction: 73.5%; Lignin reduction: 45.0%; Sugar reduction: 65.7% ; Turbidity reduction: 94.5% | (Chen et al. 2018b) |

| Turbidity, Dissolved turbidity, Total solids, COD |

pH: 7.7, Total solids: 6.59 g/L, Total suspend solids: 3.35 g/L, Turbidity: 2400 NTU, COD: 2280 mg/L, Total dissolved solids: 3.24 g/L, Dissolved turbidity: 89 NTU, Dissolved COD: 1890 mg/L, Dissolved chlorides: 157 mg/L |

Chitosan, bentonite | Stirring rates and time: 180 rpm for 1.5 min (addition of chitosan), and 40 rpm for 5 min (addition of bentonite); Dissolved air floatation for 10 min; Dosage of chitosan: 50 mg/L; Dosage of bentonite: 100 mg/L | Turbidity reduction: 83–89%; Dissolved turbidity reduction: 68–71%; Total solids reduction: 18–22%; COD reduction: 19–23% | (Miranda et al. 2013) | |

| Oily sewage | Turbidity, oil concentration, COD, SS |

Turbidity: 2755 NTU, COD: 8400 mg/L, crude oil: 2954 mg/L, suspension solid: 2675 mg/L, pH: 7.3 |

Chitosan-grafting-poly(dimethyl acryloyloxyethyl benzyl ammonium chloride) | Stirring rates and time: 180 rpm for 0.5 min, and 80 rpm for 10 min; Settling time: 30 min; Dosage: 500 mg/L | Turbidity reduction: 98.5%; Oil reduction: 99.6%; COD reduction: 82.1%; SS reduction: 95.1% | (Lü et al. 2019) |

| Oil concentration | Oil: 2 g/L | Quaternized chitosan-grafted magnetic nanoparticles | Shaking for 5 min; Dosage: 15 mg/L (pH = 4), 17 mg/L (pH = 7), 19 mg/L (pH = 10) | Oil reduction: 105 g of diesel oil/g of flocculant | (Lü et al. 2018) | |

| Antibiotic sewage | Tetracycline (TC), Cu(II) | Mass ratio of Cu(II):TC=2:1 | [2,4-bis(dimethylamino)-6-chloro-(1,3,5)-triazine]-modified-chitosan | Stirring rates and time: 200 rpm for 2 min, and 50 rpm for 8 min; Settling time: 30 min; Dosage: 0.15 g/L; | TC reduction: 98.9% | (Jia et al. 2016) |

| Norfloxacin (NOR), Tylosin (TYL) |

Norfloxacin (NOR): 10 μg/L, or Tylosin (TYL): 10 μg/L |

Phenylalanine-modified-chitosan | Stirring rates and time: 200 rpm for 5 min, and 80 rpm for 10 min; Settling time: 30 min; Conditions for NOR: pH = 5.89, dosage = 29.8 mg/L, kaolin = 37.5 mg/L, and HA = 6.69 mg/LConditions for TYL: pH = 7.42, dosage = 29.7 mg/L, kaolin = 20.6 mg/L, and HA = 6.07 mg/L | NOR reduction: 76.19%;TYL reduction: 82.01% | (Du et al. 2018a) | |

| Algae polluted water | Chlorophyll-a |

Turbidity: 21-30 NTU, Chlorophyll-a: 0.15-0.16 mg/L, COD: 126.4-130.0 mg/L |

Chitosan-graft-poly(N-n-propylacrylamide) | Stirring rates and time: 300 rpm for 2 min, and 70 rpm for 5 min; Settling time: 10 min; pH: 9; Dosage:10 mg/L; G: 250 s-1 | Chlorophyll-a reduction: 92.20% | (Sun et al. 2017) |

| Chlorophyll-a, COD |

Turbidity: 10-30 NTU, Chlorophyll-a: 0.16-0.18 mg/L, COD: 43.0-60.0 mg/L |

Carboxylated chitosan graft-(3-chloro-2- hydroxypropyl) trimethylammonium chloride-dimethyl diallyl ammonium chloride | Stirring rates and time: 400 rpm for 3 min, and 60 rpm for 5 min;Settling time: 15 min; Dosage: 4 mg/L; pH: 7; G: 200 s-1 | Chlorophyll-a reduction: 98.8%; COD reduction: 96.5%; | (Chen et al. 2018a) | |

| Chlorophyll-a, Turbidity, COD |

Turbidity: 22-33 NTU, Chlorophyll-a: 0.15-0.16 mg/L, COD: 126.4–130.0 mg/L |

Maleoyl chitosan-graft-poly(acrylamide acryloxyethyl trimethyl ammonium chloride) | Stirring rates and time: 350 rpm for 1 min, and 70 rpm for 5 min;Settling time: 10 min;Dosage: 4-6 mg/L; pH: 6–9; G: 150–250 s-1 | Chlorophyll-a reduction: 96.6%; Turbidity reduction: 90.8%; COD reduction: 96.5%; | (Chen et al. 2019) | |

| Sludge dewatering | Sludge CST, SV30, SRF |

Moisture content: 95.0%, SRF: 98.3 × 1011 m/kg, CST:120 s, SV30: 85.0% |

Combined silicon-aluminum-iron-starch | Stirring rates and time: 250 rpm for 1 min, and 50 rpm for 5min; Dosage: 300 mg/L; pH: 7 | CST reduction: 78.5%; SV30 reduction: 27.1%; SRF reduction: 97.5% | (Lin et al. 2015) |

| Sludge CST, SV30, SRF, TTF, Dryness, DR(dewatering ratio) |

Moisture content: 95.0%, SRF: 98.3 × 1011 m/kg, CST:120 s, SV30: 85.0%, TTF: 162 s, Dryness: 15.25% |

Combined aluminum-ferrous-starch | Stirring rates and time: 250 rpm for 1 min, and 50 rpm for 5 min; Dosage: 8.8 g/kg dry sludge; pH: 5 | CST reduction: 65.3%; SV30 reduction: 23.5%; SRF reduction: 95.8%; TTF reduction: 91.9%; Dryness increasement: 76.3%; DR: 70% | (Peng et al. 2017) | |

| Sludge FCMC, SRF |

Moisture content: 97.2%, SRF: 1.83 × 1013 m/kg |

Chitosan-grafting-dimethy ldiallyl ammonium chloride | Stirring rates and time: 200 rpm for 30 s, and 50 rpm for 5 min; Settling time: 20 min; Dosage: 20 mg/L; pH: 6.9; | FCMC reduction: 29.9%; SRF reduction: 88.4% | (Wang et al. 2016a) | |

| Sludge CST, SRF |

Moisture content: 94.8%, VSS/TSS: 0.49, D0.5: 15.648μm, Zeta potential: − 24.6 mV, CST: 1523.7 s, SRF: 2.36 × 109 m/kg |

Chitosan-grafting-dimethy ldiallyl ammonium chloride | Stirring rates and time: 400 rpm for 1 min, and 40 rpm for 10 min; Reaction: 30 min at 200 rpm; Dosage: 35 mg/g TSS | CST reduction: 95.6%; SRF reduction: 88.8% | (Zhang et al. 2019) | |

| Sludge moisture content, SRF |

Moisture content: 97.9%, SRF: 3.74 × 1013 m/kg |

Carboxymethyl chitosan-graft-poly(acrylamide-methacryloxyethyltrimethyl ammonium chloride) | Stirring rates and time: 350 rpm for 1 min; Settling time: 30 min; Dosage: 20 mg/L; pH: 5–6 | Moisture content reduction: 22.1%; SRF reduction: 70.9% | (Shi et al. 2019) |

Turbidity

Most sewage usually contains a lot of fine suspended solids. If it is discharged into the environment, the turbidity of natural water will rise. As a result, it may cause adverse effects on the aquatic ecosystem (Wang et al. 2019b).

With the aid of biopolymer-based flocculants in the coagulation process for turbidity removal, the dosage of inorganic coagulants can be reduced. Thus, it can reduce the environmental risk and water treatment cost brought by inorganic coagulants. For example, a cellulose-based flocculant C-g-PDMC (Li et al. 2018), which was prepared by methyl acryloyl oxygen ethyl trimethyl ammonium chloride grafted to microcrystalline cellulose, was used to treat kaolin suspension with polyaluminum chloride (PAC). The dosage of PAC was reduced with the aid of C-g-PDMC (optimal PAC dosage was 2 mg/L for single treatment and 1.5 mg/L for synergistic treatment). The removal rate of turbidity could reach 98.32% by the synergistic treatment of PAC and C-g-PDMC. Thus, biopolymer-based flocculants can be a good aid in reducing the dosage of inorganic coagulants.

Furthermore, when biopolymer-based flocculants are used alone in the turbidity flocculation, they present a high turbidity removal efficiency, a broad adaptable pH range, and resistance of the metal salts interference. (i) The high turbidity removal efficiency: in recent years, researches of biopolymer-based flocculants have greatly improved the turbidity removal efficiency, even more than 99%. For example, the MCC(pAA-co-pDMC) flocculant was prepared by microcrystalline cellulose grafted with methacryloxyethyltrimethyl ammonium chloride and acrylic acid. The turbidity removal efficiency of it could reach 99.82% when pH was 7 and kaolin concentration was initially 5 g/L (Wang et al. 2019b). The CMC-CTA flocculant, prepared by carboxymethyl chitosan grafted with 3-chloro-2-hydroxypropyl trimethylammonium chloride, got the highest turbidity removal rate of 99.2%, at pH 4 (Agbovi and Wilson 2018). (ii) Wide adaptable pH range: It was reported that konjac glucomannan-graft-poly-(2-methacryloyloxyethyl)trimethyl ammonium chloride had good turbidity removal efficiency on kaolin suspension in the range of 1<pH<9 (Ren et al. 2016). (iii) Resistance of metal salts interference: some biopolymer-based flocculants even get the optimum removal efficiency for turbidity with metal salt interference and under acidic conditions. For example, the PVA-NG flocculant (Nasim et al. 2018) was prepared by mixing polyvinyl alcohol and acacia nilotica gum. It had the optimum efficiency of treating 3 mass% kaolin suspension at the ratio of 7:3 (polyvinyl alcohol: acacia nilotica gum), dosage of 25 ppm, and pH of 2.6. The optimum residual turbidity is only 15.3 NTU. In addition, with the interference of 0.03 M Ca2+ or Fe3+, the residual turbidity was even as low as 8.6 NTU and 10.52 NTU, respectively. Therefore, as an alternative to traditional flocculants, biopolymer-based flocculants can enhance turbidity removal efficiency with a wide adaptable pH range and good resistance of metal-salt interference.

It should be noted that some structural characteristics of biopolymer-based flocculants have a significant impact on turbidity removal. Liu et al. (2017b) prepared St-g-PAM-co-PDMC with different charge densities and average graft chain lengths, by graft copolymerization of starch with different dosages of acrylamide and (2-methacryloyloxyethyl) trimethyl ammonium chloride. Then, the starch-based flocculants were used for the turbidity removal of the kaolin suspension. This study showed that high charge density could enhance the turbidity removal efficiency when the flocculant dosage was not sufficient; when the flocculant was excessive, high average graft chain length was easy to cause colloidal stabilization for Kaolin. Therefore, the expected treatment efficiency of turbidity could be obtained by designing the structural characteristic parameters such as charge density and average graft chain length of biopolymer-based flocculants.

Dyes

Sewage with dyes has a great negative impact on the ecological environment and human health. The reason is that the dye molecules have biological toxicity, and the toxicity can be further enhanced when the molecules chelate metal ions. Besides, dye molecules absorb light in the water environment, inhibiting the photosynthesis of aquatic plants. Thus, the dissolved oxygen in water decreases, resulting in water quality deterioration (Jiang et al. 2017).

Dyes can be divided into cationic and anionic. For removing these two different forms of dye molecules, different functional groups of biopolymer-based flocculants are demanded. Hence, it is necessary to develop suitable biopolymer-based flocculants for removing cationic dyes and anionic dyes, respectively. For cationic dyes, sulfomethylated softwood kraft lignin could remove 99.1% of ethyl violet (cationic dye) from sewage, under the conditions of pH = 9 and initial dye concentration of 300 mg/L (He et al. 2016). For anionic dyes, the cationic lignin-based flocculant, prepared by the radical polymerization of (2-(methacryloyloxy) ethyl) trimethyl ammonium chloride and lignin, has good removal efficiency of two kinds of anionic dyes (reactive black 5, reactive orange 16). The optimal removal rates of reactive black 5 and reactive orange 16 could be higher than 98% and 94%, respectively (Wang et al. 2018).

In actual dye sewage, dyes may coexist with other contaminants. Thus, the effects of co-existing contaminants on dye removal by biopolymer-based flocculants were studied. However, for biopolymer-based flocculants, it was reported that dye removal efficiency of the suspended particle-dye binary polluted sewage might be better than that of the dye single polluted sewage (Zhao et al. 2018). The main reason is that, before biopolymer-based flocculants are added, some dye molecules in the binary polluted system have been adsorbed on the suspended particles. After that, it can be more easily removed by flocculation. For a reported graft dextran flocculant, the dye removal rates were 68.1% for congo red single polluted sewage, and 88.2% for kaolin-congo red binary system (Zhao et al. 2018). Besides, when biopolymer-based flocculants are used with inorganic coagulants to treat dyes, they can also enhance the resistance of coexisting contaminants (e.g., ions, kaolin particles, humic acid, etc.) (Guo et al. 2019), and improve the dye removal efficiency. A reported synergistic treatment using lignin-based flocculant and polyaluminum chloride was more effective in removing reactive blue than polyaluminum chloride alone. However, the dosing method of biopolymer-based flocculants in synergistic treatment with inorganic coagulants will impact the flocculation efficiency (Guo et al. 2018a). As mentioned above, biopolymer-based flocculants have strong anti-interference ability to eliminate the coexisting contaminants’ interference, and can help the inorganic coagulants enhance the dyes removal efficiency.

The dyes removal efficiency of biopolymer-based flocculants is easily affected by molecular factors, such as the structure characteristics (branched vs. linear) and charge density. The dyes removal efficiency of branched molecules is better than that of linear molecules, because the flocs generated by branched flocculants have stronger resistance, as well as larger and looser structures. Thus, they are easier to settle down. However, if the amount of grafted branches is too large, it is easy to produce steric hindrance effect and hamper the removal of dyes (Guo et al. 2020). In terms of the charge density, a higher charge density of biopolymer-based flocculants could result in better dye removal efficiency (He et al. 2016).

Heavy metal ions

Heavy metal ions pollution is one of the main sources of natural water pollution. For one thing, it will harm aquatic organisms and human health; for another thing, the water polluted by heavy metal ions cannot be recycled, thus reducing the available water resources and causing economic losses (Sun et al. 2020b).

The composition of actual heavy metal sewage is often complex, which may contain some other kinds of contaminants or a variety of heavy metal ions. For example, electroplating wastewater contains not only heavy metal ions, but also COD, suspended particles, etc. For biopolymer-based flocculants, sometimes the sewage with multiple pollutants did not have a negative impact on the flocculation efficiency of heavy metal ions, but even promoted it. The main reason is that the chelate formed by biopolymer-based flocculants and heavy metal ions could react with COD and suspended particles through net trapping and adsorption bridging, thus improving the removal capacity of heavy metals (Sun et al. 2020b). A xanthated chitosan flocculant was reported for treating Cu(II) sewage. The maximum removal efficiency of Cu(II) was less than 92.4% in the treatment of Cu(II) single polluted sewage. However, the removal efficiency of Cu(II) could reach 93.6% in the treatment of turbidity-Cu(II) binary polluted sewage (Yang et al. 2018). The presence of turbidity could enhance the removal efficiency of biopolymer-based flocculants on heavy metal ions, but this enhancement only existed within a certain turbidity range (Sun et al. 2020b). However, if varied heavy metal ions coexisted in the sewage, there was a competitive relationship between the heavy metal ions to react with biopolymer-based flocculants (Sun et al. 2019b).

In addition, the pH value of sewage has a great influence on removing heavy metal ions by biopolymer-based flocculants. The lower the pH is, the less favorable it is for biopolymer-based flocculants to remove heavy metal ions (Sun et al. 2019b; Yang et al. 2018; Wu et al. 2018). In the low pH condition, some functional groups on biopolymer-based flocculants were protonated, and positive charges were accumulated on the molecular chain. It reduced the chelating ability of functional groups (Sun et al. 2019b), and decreased the collision of biopolymer-based flocculants with heavy metal ions (Yang et al. 2018).

Up to now, flocculation technology based on biopolymer-based flocculants has been able to enhance the treatment of heavy metal ions sewage. Firstly, with the aid of biopolymer-based flocculants, the flocculation performance of inorganic coagulants on heavy metal ions could be improved. Compared to using polyaluminium ferric chloride alone, combining it with a sulfonated chitosan-based flocculant to remove heavy metal ions could form bigger flocs, thus gain a better flocculation efficiency (Tang et al. 2020). Secondly, the removal efficiency of heavy metals by only using biopolymer-based flocculants has met the emission standards. For example, the reported two-stage flocculation technology based on biopolymer-based flocculants could remove 94.7% of Cr ions and 99.4% of Ni ions (Sun et al. 2019a). In their research, the concentration of residual heavy metal ions could meet the requirement of Chinese emission standards (GB21900-2008).

Other industrial/agricultural processes

Pulp mill sewage

The pulp mill sewage usually contains dissolved, insoluble, organic and inorganic substances. The insoluble substances are often in the form of fine particles, so it is tough to remove (Chen et al. 2018b).

Biopolymer-based flocculants with high charge density can remove contaminants from pulp mill sewage by charge neutralization and the bridging mechanism. A xylan-polymerizing (2-methacryloyloxyethyl) trimethyl ammonium chloride flocculant could reach the COD removal efficiency of 61.7% and the turbidity removal efficiency of 94.5% in pulp mill sewage treatment (Chen et al. 2018b). Nevertheless, it is worth noting that although higher charge density probably tends to enhance the flocculation of biopolymer-based flocculants on pulp mill sewage, the effect of molecular weight may be opposite (it was reported that the removal efficiency of biopolymer-based flocculants with low molecular weight was higher) (Miranda et al. 2013).

Oily sewage

Oily sewage comes from various industrial fields, such as petroleum, steel smelting, food, leather, etc. (Ma et al. 2018; Lü et al. 2019). The oily sewage is usually in the form of emulsion, hence increasing the difficulty to remove oil.

The surfaces of the oil droplets are negatively charged, thus can be removed by the biopolymer-based flocculants with cationic groups via electrostatic attraction. In addition, the introduction of hydrophobic groups can enhance the adsorption and bridging effect of biopolymer-based flocculants on oil droplets. For example, a chitosan-grafting-poly(dimethyl acryloyloxyethyl benzyl ammonium chloride) flocculant, which was prepared by introducing cationic and hydrophobic groups into chitosan by graft reaction, could remove more than 98% oil from oily sewage (Lü et al. 2019). Similarly, quaternized chitosan magnetic flocculants had positive surface charges, and could remove oil droplets through electrostatic interactions. The oil removal efficiency of them could reach 105 g of diesel oil/g of flocculants. The higher the cationic charge intensity was, the better the flocculation of oil droplets was (Lü et al. 2018).

Antibiotic sewage

The sources of antibiotic contaminants are usually livestock sewage and industrial sewage. Antibiotics and heavy metal ions often coexist in such sewage (Hou et al. 2019), which increases the difficulty of water treatment. Nonetheless, antibiotics entering the environment will cause antibiotics resistance of bacteria (Ben et al. 2008), which will threaten human health. It was reported that the death rate of drug-resistant strains would double (Sandberg et al. 2018). However, the emergence of biopolymer-based flocculants provides a new opportunity for removing antibiotics from sewage.

After modification, biopolymer-based flocculants may remove antibiotics by π-π stacking, electrostatic attraction, hydrogen bond, hydrophobic association, etc. Aromatic rings, introduced into biopolymer-based flocculants, can interact with the aromatic rings on antibiotic molecules by π-π stacking, thus improving the removal efficiency of antibiotics by biopolymer-based flocculants. For example, BDAT-CTS, a chitosan-based flocculant with triazine rings, can react with negative charged aromatic rings on tetracycline antibiotics. The removal efficiency of tetracycline and Cu(II) in mixed sewage by BDAT-CTS was 98.8% and 94.0%, respectively (Jia et al. 2016). In another research, a phenylalanine-modified-chitosan flocculant with linear molecular architecture was reported. Owing to the introduction of aromatic rings, it could directly react with antibiotics by cation-π interaction. At the same time, there were electrostatic attraction and hydrogen bond between the phenylalanine-modified-chitosan and antibiotics. The theoretical removal efficiencies of Norfloxacin and Tylosin in mixed sewage by phenylalanine-modified-chitosan flocculants were 76.19% and 82.01%, respectively (Du et al. 2018a). Of course, biopolymer-based flocculants could also effectively remove antibiotics only through hydrogen bond and hydrophobic association. A thermoresponsive chitosan-based flocculant was used to treat tetracycline-Cu(II) binary polluted sewage. Under optimal conditions, the removal efficiencies of tetracycline and Cu(II) could be both higher than 90% (Ren et al. 2017).

As antibiotics and heavy metal ions often coexist in sewage, the actual binding interactions between antibiotics and heavy metal ions would also have important impacts on the flocculation efficiency of antibiotics by biopolymer-based flocculants. Studies showed that the stronger the binding energies between antibiotics and heavy metal ions were, the easier it was for the antibiotics to be removed by biopolymer-based flocculants (Hou et al. 2019; Ren et al. 2017).

Retention aids

Retention aids are usually used in papermaking process. They play an important role in the aggregation of fillers and fine fiber powders in pulp suspension, and can improve the retention performance in the paper-making process (You et al. 2019). For the aim of non-toxicity, some studies try to use biopolymer-based flocculants as retention aids. For example, hairy cationic nanocrystalline cellulose was used as a retention aid in papermaking process. The results showed that adding 20 mg/g hairy cationic nanocrystalline cellulose could shorten the pulp drainage time by 78% and improve the retention by 77% (Campano et al. 2019a). In another study, a kind of leather waste-based composite was prepared by using collagen wastes as starting materials. This flocculant has good retention performance, and the best retention rate was more than 85% at the dosage of 0.6 wt.% (You et al. 2019). A starch-based flocculant was synthesized by graft copolymerization of starch with acrylamide (AM) and diallyldimethylammonium chloride (DADMAC). The results showed that the fillers retention of this flocculant was higher than that of cationic polyacrylamide when the dosage was 0.05%, the intrinsic viscosity was 7.35, and the cationic degree was 22% (Lu et al. 2004).

Algae

In the process of human production, a large number of nutrient elements, such as nitrogen and phosphorus, are discharged into the natural water body, which makes the water eutrophic, thus leading to the outbreak of algae (Sun et al. 2017). However, some algae can release toxins, which pose a serious threat to human and animal health (Liu et al. 2013). Besides, algae usually form a stable suspension in the water body and are difficult to remove owing to its negatively charged surface (Banerjee et al. 2012) and small size (Choy et al. 2018).

Compared with traditional flocculants, biopolymer-based flocculants have a better flocculation efficiency of algae. Sometimes, the same algae removal efficiency can be achieved even if the amount of biopolymer-based flocculants is less than that of inorganic coagulants. A cationized starch-based flocculant, which was obtained by modifying maize starch with glycidyltrimethylammonium chloride, was used for flocculating algae suspension. This cationized starch-based flocculant (substitution degree of 0.13), with only one-tenth the dosage of aluminum sulfate, could achieve a similar algae removal efficiency (El-Naggar et al. 2018). In another research, a carboxylated chitosan-based flocculant (CC-g-PCD) was used to treat the actual lake water containing algae. The dosage of it to achieve the optimal flocculation efficiency was only one-tenth of that of polyferric sulfate and polyaluminum chloride (Sun et al. 2019c). The algae flocculation efficiency of acrylamide- and dimethyl diallyl ammonium chloride-grafted chitosan [CS-g-P(AM-DMDAAC)] was better than that of traditional polyacrylamide and polymeric aluminum ferric flocculants. For CS-g-P(AM-DMDAAC), the turbidity removal efficiency of low turbidity algae water could reach 99.02%(Sun et al. 2017). A carboxylated chitosan-based flocculant CPCTS-g-P (CTA-DMDAAC) had a better flocculation efficiency on microcystis aeruginosa polluted water than traditional flocculants (e.g., polyacrylamide, polyferric sulfate and polyaluminium chloride). Its removal efficiency of chlorophyll-a could reach 98.8% (Chen et al. 2018a). Similarly, a maleoyl chitosan-based flocculant [MHCS-g-P(AM-DAC)] had a better flocculation efficiency than the above mentioned three traditional flocculants in treating natural water containing algae. Its removal efficiency of chlorophyll-a could reach 96.6% (Chen et al. 2019). Therefore, flocculation based on biopolymer-based flocculants is a promising water treatment method for algae removal.

Sludge dewatering

Sludge, which contains harmful contaminants adsorbed from the sewage, is produced in the process of sewage treatment. Therefore, sludge disposal is an important part of the sewage treatment process (Anjum et al. 2016; Wei et al. 2018a). The efficiency of sludge dewatering affects the subsequent transportation and operation costs (Mowla et al. 2013), so it is very important to improve the sludge dewatering efficiency. Flocculation is widely used for sludge dewatering (Wang et al. 2016a), which belongs to the category of chemical conditioning pretreatment of sludge (Wei et al. 2018a). Recently, the application of biopolymer-based flocculants in the flocculation for sludge dewatering is a hot research direction.

Compared with traditional inorganic coagulants and synthetic organic flocculants, biopolymer-based flocculants have a higher sludge dewatering efficiency and wider pH adaptability. For example, the combined silicon-aluminum-ferric-starch flocculant had a very good dewatering efficiency in the pH range of 3.0–11.0, and its dewatering efficiency was better than that of polyaluminum chloride, polyacrylamide, and ferric chloride (Lin et al. 2015). In another research, the combined aluminum-ferrous-starch flocculant (CAFS) was used in sludge dewatering. After the flocculation for sludge dewatering, CST, SV30, and SRF of sludge were 41.7 s, 65%, and 4.1 × 1011 m/kg, respectively. The sludge cake formed by the CAFS had lower compressibility than that of the traditional flocculants. Namely, the CAFS flocculant had a better dewatering efficiency (Peng et al. 2017). Under the same conditions of pH and dosage as the traditional flocculants, the FCMC and SRF of sludge were 68.10% and 2.12 × 1012 m/kg, respectively, after sludge dewatering with chitosan-grafting-dimethy ldiallyl ammonium chloride (chitosan-g-DMDAAC). The treatment efficiency was better than polyacrylamide and cationic polyacrylamide (Wang et al. 2016a). In another study, the chitosan-g-DMDAAC was used in the dewatering of anaerobically digested sludge. Within the optimal dosage, the CMC was 81.7%, SRF was 2.64 × 108 m/kg, and CST was 1.31 s·L·g−1 (Zhang et al. 2019). In the pH range of 5–6, the carboxymethyl chitosan-graft-poly(acrylamide-methacryloxyethyltrimethyl ammonium chloride) flocculant could achieve the best efficiency on sludge dewatering. After flocculation for sludge dewatering, the moisture content was 76.26%, and the SRF was 1.09 × 1013 m/kg (Shi et al. 2019). The experimental results of various studies showed that biopolymer-based flocculants could be used as an excellent substitute for traditional flocculants in sludge dewatering.

When biopolymer-based flocculants are used with inorganic coagulants for sludge dewatering, the dosing method will affect sludge dewatering efficiency. It was reported that the sludge dewatering efficiency of the starch-3-chloro-2-hydroxypropyl trimethylammonium chloride (St-WH) used with the inorganic coagulant FeCl3 was better than that of St-WH used alone. However, only by adding St-WH after FeCl3 during dosing was the sludge dewatering efficiency optimal. Through this dosing method, SRF and FCMC could reach (0.25 ± 0.01) × 1012 m/kg, (81.2 ± 0.6)%, respectively (Wei et al. 2018b).

Pilot-scale test, full-scale test and practical application

At present, most of the researches about biopolymer-based flocculants are laboratory-scale, and rare reports have pilot-scale test, full-scale test, and practical application.

In terms of pilot-scale test and full-scale test, it is reported that raw water from the Zhenjiang section of the Yangtze River in China was used for pilot-scale test of chitosan-based flocculants. This process can reduce the turbidity of raw water from 33-50 NTU to 0.47 NTU; Even under shorter sedimentation time than the actual process, all the effluent parameters fully meet the Chinese drinking water quality standard GB 5749-2006 (Yang et al. 2011). Another study showed that the efficiency of a tannin-based flocculant was similar to or even better than that of batch trials (Sánchez-Martín et al. 2010). In the full-scale test, Moringa oleifera-derived coagulants were used to treat raw water with the turbidity of 270-380 NTU, and the effluent turbidity could be less than 4 NTU (Dorea 2006).

In terms of practical application, the materials based on Moringa oleifera have been widely used in developing countries (Beltrán-Heredia and Sánchez-Martín 2009; Baptista et al. 2015). In Egypt and Sudan, natural polypeptides produced from the seeds of Moringa oleifera have been used to produce drinking water. This simple water treatment technology has two methods. (i) Add Moringa oleifera seeds powder into raw water, stirring for about 5 minutes, standing for about 1 hour, and then purified water was obtained by filtration; (ii) Soak the cloth containing Moringa oleifera seeds powder in raw water overnight; Then, take out the cloth and use the supernatant. This simple technique can remove up to 99% of the colloidal matters (Foidl et al. 2001).

However, there are still three limitations in this practical technology that has been used in developing countries. (i) The consumption of Moringa oleifera seeds is large. If Moringa oleifera seeds powder is used to treat domestic wastewater, it needs 96 g seeds/(person·day); (ii) The pre-concentrated form has a bitter taste. The pre-concentration is used to reduce the volume and weight of Moringa oleifera seeds, which would make the treated water taste bitter; (iii) Flocculation performance is not stable, and it will be affected by seasons (Foidl et al. 2001).