Abstract

Although more than 3 million head of dairy cows enter the food supply chain in the U.S. every year, research on this topic remains limited and scarce. Meat production from dairy cows is a significant component of beef production, accounting for almost 10% of U.S. commercial beef production. Thus, the purpose of this review is to demonstrate the importance of dairy cows as a beef source, and to provide an overview on topics from farm to meat product—culling, marketing, transportation, welfare, body composition and its relationship with lactation particularities, carcass characteristics, meat quality, and traceability. Current scientific evidence has shown that culling a dairy cow at an appropriate time has beneficial effects on cow welfare and, consequently, cow value. During marketing the dairy cow is visually evaluated for health and factors associated with its expected carcass value; thus, marketing a well-conditioned cow will ensure that the animal is fit for transportation and provides high carcass yield. However, limitations such as low body condition score, lameness or mobility problems, and visual defects remain persistent. Even though beef harvest plants accommodate cows in all body composition states, the current carcass grade system does not reflect the mature cow industry needs. Therefore, improvement of the grading system could maximize carcass utilization and increase cow carcass value by recognizing subprimal cuts that could be merchandised as whole muscle cuts. Lastly, implementation of a traceability system would unify information from the farm to harvest assisting the industry in making further advancements.

Keywords: carcass category, cow carcass, dairy beef, mature cow, slaughter cow

Introduction

Dairy “cull cow” and “slaughter cow” are terms generally used to refer to cows sold to meat packing plants and not held for additional or future milk or beef production. “Cull dairy cow” is a term that refers to the dairy cow, lactating or dry, removed from the herd due to single or multiple reasons, destined to be harvested for meat production. This term is not intended to include dead or euthanized dairy cows. Although “cull cow” or “slaughter cow” are terms often used for both dairy and beef cows, in this review the focus will be solely on dairy cows because the knowledge for beef cows is far more developed than that for dairy cows. In fact, genetic selection and management of dairy cows have been focused on milk production, with relatively little attention to their contribution to beef production.

More than 3 million head of dairy cows were slaughtered in 2019 to enter the beef supply chain in the United States. While these animals make an essential contribution to the beef industry, little research has been dedicated to study the cull dairy cow as a beef source and the stages involved in this process, from the culling decision to the resulting meat quality. Therefore, the goal of this review is to highlight the importance of cull dairy cows as a beef source in the United States, and to discuss several topics involved in beef products derived from cull dairy cows, from the farm to the harvest plant, concluding with beneficial recommendations for the future of this production system. Main topics include culling, marketing procedures and cow categories, transportation, body composition and its association with lactation particularities, carcass characteristics, meat quality, welfare and traceability.

Importance of Dairy Beef

About 21% of the beef produced in 2019 in the United States came from the dairy sector, which shows the vital importance of this sector for national beef production. The 12.4 billion kg of commercial beef produced in the U.S. comprises 51.2% steers, 28.2% heifers, 19% cull cows, and 1.7% bulls, and in that total beef production 13.4%, 9.7%, and 0.1% were derived from dairy steers, dairy cows, and dairy heifers, respectively (Geiser and Boetel, 2017; Schaefer et al., 2017; ERS, 2019). In fact, the dairy sector has a relatively consistent production of animals throughout the year compared with the beef industry (Boetel, 2017). For the purpose of this review, the focus will be exclusively on cull dairy cows, since an extensive review on dairy steers has already been provided by Schaefer et al. (2017).

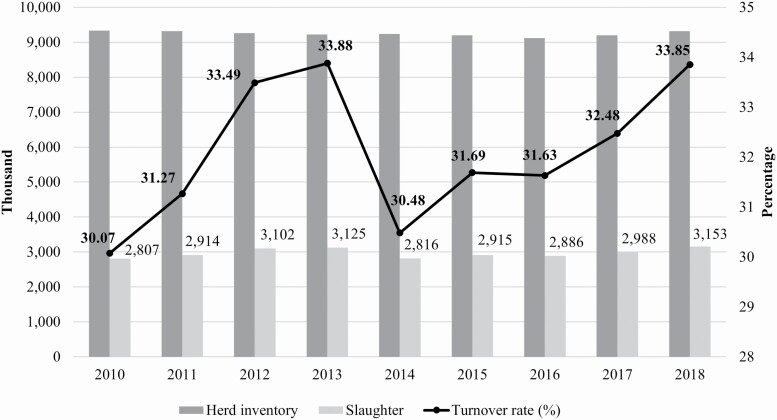

The annual cow herd culling rate in dairy farms varies from 30% to 35% (Figure 1), which is essential to maintain high milk production, maximize profitability, and allow accelerated genetic improvement. On the other hand, although the number of beef cows harvested each year is similar to dairy cows harvested, the beef cow herd inventory is considerably larger (about 31 million cows), so that annual beef cow harvest represents only a 9.6% culling rate (ERS, 2019). Culling rate of the dairy herd has been increasing since 2014, though cyclicity is evident (Figure 1). Most dairy cows are sent to slaughter around 4 to 5 yr of age, while beef cows remain in the herd much longer, being slaughtered from 7 to 12 yr of age. Moreover, besides being harvested on average much younger, dairy cows receive a high-quality diet throughout their entire life, which may contribute to some quality advantages when compared with beef cows. Every year around three million dairy cows are slaughtered, supplying the food industry with primal cuts as loin, round, rib, and chuck, and manufactured ground beef (Davis and Lin, 2005).

Figure 1.

Dairy cow herd inventory, slaughter under federal inspection, and culling rate from 2010 to 2018. Dark gray bars reflect total number of dairy cows in annual inventory (left axis). Light gray bars represent number of dairy cows slaughtered (left axis; Source: USDA Market News). The turnover percentage is shown by the solid line (right axis).

Although the cull dairy cow is an essential contributor to the meat industry and, therefore, influences consumer eating experiences, there is still not enough research and attention dedicated to this topic. Moreover, there is a strong, however, misleading belief that dairy cow carcasses are solely used for manufacturing of ground beef and, therefore, research aiming to improve carcass and meat quality may seem irrelevant. But in fact, dairy cow carcasses are also fabricated into primal and sub-primal cuts (AMS, 2021a). Thus, there remains a paucity of knowledge regarding carcass and meat quality of cull dairy cows. In other words, dairy cows must be acknowledged also as a valuable beef source and handled as such.

The majority of the studies on cull dairy cows have been undertaken to investigate feeding strategies in the months just prior to harvest (Vestergaard et al., 2007; Allen et al., 2009; Lee et al., 2009; Minchin et al., 2010; Therkildsen et al., 2011; Couvreur et al., 2019), while other production practices are often overlooked, such as culling management and marketing methods. Consequently, the value of carcasses from dairy cows has been seldom taken into account and such studies are scarce (Stelzleni et al., 2007; Bazzoli et al., 2014; Gallo et al., 2017; Moreira et al., 2021). In the next topics, we review the stages in the process of marketing cull dairy cows, from farm to the harvest plant, beginning with the farmer’s culling decision.

Culling Decision

Culling is the identification and removal of a cow from the herd, which leads to sale and harvest, resulting in a financial salvage value that contributes to offsetting the cost with heifer replacement. Culling is an important component of overall herd management, and therefore it should be considered in the context of its connection with management practices, farm goals, cow health, economic parameters, and milk production (Monti et al., 1999).

The percentage of cows removed from the herd is often described as culling rate, which is calculated as the number of cows culled over a specific time period divided by the inventory of cows for the same period, multiplied by 100 (Fetrow et al., 2006). Terms like “turnover rate” (Fetrow et al., 2006), “proportion removed from herd” (Smith et al., 2000), among others are also used interchangeably in the literature, but “culling rate” seems to be the most common term. Care must be taken when interpreting or comparing culling rates because the methods used to calculate this index may vary, as researchers sometimes use additional factors in these calculations, such as “dead” or “sold for dairy” (Fetrow et al., 2006; Hadley et al., 2006). In this review we do not include death or euthanasia in the definition of culling.

According to the literature, culling rates in the United States vary from less than 25% to over 35%, with an average of about 30%. In terms of farm profitability, the optimum culling rate should not exceed 30% (Smith et al., 2000); however, in the United States and Canada, culling rates higher than 30% are common (Haine et al., 2017). Studies by Smith et al. (2000) reported culling rates in the United States of 36.3% for what they labeled the “Midsouth region” and 34.5% for the “South region.” More recent studies found annual culling rates in the United States of approximately 32% (De Vries et al., 2010) and 30.3% in Québec, Canada (Haine et al., 2017). In contrast, Pinedo et al. (2010) reported annualized rates of live culling and death to be 25.1% and 6.6%, respectively. Regardless of the variability in culling rate, excessively low or high removal rates can be seen as a sign of management problems. However, most importantly, the management goals and dynamic of each individual herd must be considered to determine its optimal culling rate (Haine et al., 2017).

Culling is a multifactor and complex decision for dairy farmers, which can be influenced by cow-level, herd-level, and market economic factors. In terms of cow-level, farmers consider factors such as milk production, health, stage of lactation, age, and reproductive performance in determining whether a cow should be culled (Hadley et al., 2006). The cow’s physiological changes can also affect its culling risk. A greater number of parities increases the risk of culling, as does the stage of lactation, for which culling rate is higher at the beginning and at the end (Hadley et al., 2006). Reproductive problems, which are defined as failure to conceive or abortion, are one of the major cow-level reasons for culling, especially in high-production cows (Bascom and Young, 1998; Hadley et al., 2006).

In addition to cow-level factors, herd-level factors may also influence culling decisions. According to Weigel et al. (2003), management practices, labor situations, animal handling, and milking facilities had a significant effect on risk of culling among low- and high-producing cows. At the individual farm level, herd-level factors include reproductive policy, type of facility, level of production, herd size, and other factors (Pinedo et al., 2014). Therefore, it is important to incorporate the information of population context into culling analysis at the individual herd level to understand the interaction between variables at different levels (Haine et al., 2017). Just as the management style and behavior of the farmer significantly contribute to the variability in herd productivity, they also play a key role in culling decisions (Beaudeau et al., 1996).

Additionally, market factors contribute to culling decisions. The prices of milk, feed, and cull cows, in addition to availability and cost of replacement heifers, also influence the farmer decision of which cows should be culled (Bascom and Young, 1998). Further, Hadley et al. (2006) reported that milk-to-feed price ratio can indicate milk production profitability, which positively correlates with many other parameters, and also has an effect on culling decisions.

Culling Reasons

Culling reasons reported by the Dairy Herd Information (DHI) program are feet and legs, dairy purposes, low production, reproduction, injury/other, mastitis, disease, udder problems, and death (DRMS, 2014). Furthermore, there are three significant perspectives regarding culling reasons that must be carefully understood: whether the culling was voluntary or involuntary; a cow is highly unlikely to be culled because of only one reason; finally, producers vary in the culling reason recorded even when a cow has similar individual characteristics (Bascom and Young, 1998; Eicker and Fetrow, 2003).

Type of culling decision is associated with the value of the culled cow (Langford and Stott, 2012). Culling can be classified as either voluntary (economic) or involuntary (biological). Voluntary culling is when a healthy and fertile cow is removed from the herd due to not attaining the farm standards for milk production. Such cows can be sold for dairy purposes to another dairy farm with different standards, or for meat value. Involuntary culling is when the producer is forced to remove the cow from the herd due to illness, injury, or infertility (Smith et al., 2000; Weigel et al., 2003; Fetrow et al., 2006), in which case the cow is sold for meat value or euthanized. Euthanasia is reluctantly practiced because it constitutes a complete loss of revenue from the cull cow.

Previous studies have investigated the predominant reasons for culling, which Pinedo et al. (2010) reported to be reproduction and injury/other. Similarly, Bascom and Young (1998) reported reproduction, mastitis, and low production. Hadley et al. (2006) listed injury/other, reproduction, and low production as the most common reasons for culling across all 10 states evaluated. Boujenane (2017) found that for Holstein dairy cows in Morocco the most common culling reasons were diseases, reproduction, and udder problems. Evaluating data from the Polish National Milk Recording System, Adamczyk et al. (2017) reported infertility, reproduction, and udder problems as the most common reasons of involuntary culling.

The DHI system allows the farmer to report only one reason for culling, however, quite likely cows are culled because of multiple reasons. Different farmers can rank culling reasons in different orders and, consequently, report a different final culling reason, which can lead to many biases and errors in surveys (Bascom and Young, 1998). In fact, demographic characteristics, attitudes, education, degree of involvement in dairy groups, economic factors, or biological variables can change the farmer’s culling criteria and decision making (Beaudeau et al., 1996). Bascom and Young (1998) demonstrated that for 35% of the cows, at least two reasons were cited for their removal, and 11% of the culled cows had three or more reasons. This emphasizes the importance of having a reporting system that accommodates more than one reason for culling. These authors also observed that reproduction was the most frequent primary reason reported, and udder conformation and low milk production were the most common secondary reasons. Surprisingly, Pinedo et al. (2010) found that 43% of herds evaluated did not use all disposal codes, which requires caution when comparing the frequency of reasons between farms.

Culling decision and culling reasons are also influenced by stage of lactation (Pinedo et al., 2010; Dechow and Goodling, 2008). Shortly after calving, cows experienced highest risk of culling, which drops during mid-lactation and rises again toward the end of lactation (Fetrow et al., 2006). Culling reasons such as death and injury are more frequently observed during early lactation, thus salvage value is likely reduced due to poor health status, or no salvage value would be obtained in the event of death (Hadley et al., 2006; Dechow and Goodling, 2008; Pinedo et al., 2010). On the other hand, cows reported with codes such as low milk production, reproduction, mastitis, and udder problems are often removed from the herd at the end of lactation (Hadley et al., 2006; Dechow and Goodling, 2008; Pinedo et al., 2010), when they are well-conditioned with potential to yield higher carcass weight (Seegers et al., 1998). Thus, ideally culling would happen later in the lactation stage for better health status and body composition, higher carcass weight, consequently, higher marketing prices (Seegers et al., 1998; Stojkov et al., 2020).

Above all, choosing when to cull the dairy cow has extremely important cow welfare and revenue implications (Ahola et al., 2011a; Langford and Stott, 2012). Culling at an appropriate time ensures that the cow is healthy when entering the food system and is able to endure travel to the sale barn and packing plant, given that transportation is stressful and physically demanding.

Marketing Cull Dairy Cows

Once a dairy cow is no longer economically or biologically able to produce milk, dairy producers should recognize the value of the cow as a beef source and their role as beef producers. Thus, producers should evaluate marketing options and their advantages. Marketing cull cows through live auctions or directly to packing plants are the two major marketing options for dairy producers. Dairy farmers apparently understand the benefits of marketing their cows through live auctions because this option is often preferred by producers. Glaze and Chahine (2009) reported that 64% of dairy farmers marketed their cull cows through auction markets, 17% marketed directly to packers, and the other 19% through private orders and contracts. Similarly, Rogers et al. (2004) found that 50% of the surveyed producers preferred to sell their cows using both market channels, but 40% preferred only live auctions and 10% sold cows exclusively to packers. According to the National Animal Health Monitoring System (NAHMS), 92% of the dairy operations sold their cull cows through a market, auction, or stockyard (USDA, 2018), and nearly 60% were sold to a market or auction while 36% of the cows were sent directly to a packer or slaughter plant (USDA, 2018).The fact that these percentages exceed 100% indicates that some operations use both avenues to sell their cows. There was a trend for a larger percentage of large dairy operations to sell cows directly to slaughter plants (USDA, 2018).

Culling dairy cows in a timely manner is one of the best approaches to preserve welfare and to maintain the salvage value of the cow (Ahola et al., 2011b). Dairy producers should understand the factors which determine cull cow value during marketing to improve their income from these animals (Gill, 1998). The practice of feeding high-concentrate diets before harvest is not common for cull dairy cows; instead, these cows are sold for harvest immediately after the culling decision has been made. Cull dairy cows receive a relatively high plane of nutrition during their entire life compared with cull beef cows, thus offering the potential to market these cows in the higher-quality cull cow categories without extra feeding time (Woerner, 2010).

Factors Determining Cow Price During Marketing

When the cow is marketed at an auction market, ownership of the cow transitions from the farmer to the packer-buyer at the time of sale. In this situation, the visual evaluation is done by the buyer to assess cow category and the risk of potential losses. The price offered for cull cows is also influenced by the meat business niche of each harvest plant and its internally generated carcass grading system. On the other hand, when cull cows are marketed directly to a packing plant, the cow owner is paid on the basis of carcass value factors; thus, the factors determining cow price are a subset of those applied when marketing at an auction market.

The focus of this review now turns to the factors evaluated in the dairy cow as a beef source at pre-harvest marketplaces (livestock market and auctions). Health status, age, visual defects, estimated body composition, body weight, and estimated dressing percent are the main factors determining the market value of live dairy cows (Gill, 1998; Smith, 2012; Moreira et al., 2020).

Health status

Health evaluation is the first and most important factor evaluated by the buyer during live cow assessment, as the health status of cull dairy cows is heterogeneous (Vogel et al., 2011). This evaluation is done in two steps as follows: first, assessment of the risk that the cow will pass USDA inspection to enter the food system, and second, assessment of the physical ability of the cow to endure transportation to and handling at the packing plant. The health evaluation enables the buyer to determine the risk that the cow will become a humane handling issue, and secondly, the risk for a financial loss due to euthanasia or condemnation (Moorman et al., 2018). Willingness to accept the risk on cows having questionable health varies among packing plants.

Dairy cow health condition is extremely important because it determines whether or not the cow can enter the food chain. Dairy cows are culled voluntarily or involuntarily due to health problems, which can be aggravated at the farm of origin, during transport, or while in the marketing system (Stojkov et al., 2018). As mentioned previously, among the most common culling reasons reported in the literature are the ones related to health problems (Hadley et al., 2006), thus cow health status becomes a determinant factor during marketing.

The practice of “pro-active culling” can prevent dairy cows from developing health issues that drastically reduce their commercial value and also result in welfare concerns (Stojkov et al., 2018). Although there is no regulation regarding cow body condition that is suitable for transport and marketing (Edwards-Callaway et al., 2019), training and promoting such recognition among dairy producers can help them to understand that culling dairy cows in a timely manner is one of the best practices to enable humane handling of the cow and maintain its salvage value (Mintert et al., 1990; Ahola et al., 2011b; Stojkov et al., 2018).

Age

Assessment of cow maturity has an important role in determination of market value for beef production, as it affects carcass yield and meat quality (Aberle et al., 2001). During auction marketing, which is only a few minutes in duration, a visual assessment of cow age is performed. This visual assessment is performed by assessing the length of tail, width of hips, broadness of the muzzle, and length of the head. The age of dairy cows is evaluated, especially, when the individual cow displays good fat cover and sufficient youthfulness to be a candidate for higher-quality carcass grades, such as “Select” or “Choice”. Thus, age assessment is a necessary consideration in estimating potential carcass value.

More than 70% of dairy cows are culled in their first three lactations, which means these animals are leaving the herd around 3 to 5 yr old (NAHMS; USDA, 2018). According to the literature, the average age of a cull dairy cow is around 4 yr old and, in terms of carcass maturity it would qualify for D maturity (AMS, 2017), which ranges from 72 to 96 mo. Cows culled at a younger age and well-conditioned have the potential to be graded higher and have greater carcass value.

Visual defects

Most dairy producers market their cull cows immediately or within a few days after the culling decision has occurred. In reality, however, many dairy farmers do not fully recognize the value of the cull dairy cow as a beef source (Ahola et al., 2011a), and the important association between (the absence of) visual defects and the cull cow price. Visual defects are normally responsible for a large number of value discounts on cull cow price at live auction. A visual defect is any physical abnormality visible in the cow body that can affect its health, mobility, or carcass yield. The most common and severe visual defects observed in dairy cows during marketing are low body condition score (BCS), lameness, and leg problems. Other defects but with low incidence are abscesses, prolapses, ocular neoplasia, and wounds. Harris et al. (2017) reported that 31% of cattle evaluated in holding pens at packing plants had at least one visible quality defect during the 2016 National Market Cow and Bull Beef Quality Audit, and cull dairy cows had the greatest incidence of defects, 37%.

Dairy cows with BCS below 2 are considered too thin, which can result in a higher incidence of injuries leading to carcass trimmed weight loss and possibly a non-ambulatory state or death (Ahola et al., 2011a; Harris et al., 2017). Recently, Stojkov et al. (2020) reported that price was primarily affected by BCS and quality defects. During a survey in 2008, Ahola et al. (2011b) found that market dairy cows had an average BCS of 2.6 ± 0.8 (on a 5-point scale). The authors also emphasized that 23% of dairy cows in the study were very light muscled. In a broader study, Harris et al. (2018) determined that 67% of dairy cows had an average BCS of 2.6. and were given the lowest muscle score.

Lameness is one of the leading cow health problems in the dairy industry with a prevalence ranging from 13% to 55% in the United States (Adams et al., 2017). Besides being a painful condition for dairy cows, lameness can reduce BCS, increase incidence of hock and knee injury, and increase involuntary culling (Cook et al., 2016; Adams et al., 2017). Often, cull dairy cows are marketed with lameness or leg problems which can drastically decrease the market value of the cow (Stojkov et al., 2020). Ahola et al. (2011b) reported that among dairy cows sold through livestock auction markets in the western United States, 55.3% were considered normal for locomotion score, 40.5% had some lameness, and 4.2% had severe lameness. In contrast, Harris et al. (2018) reported in the National Beef Quality Audit that 76% of dairy cows had normal locomotion score, 18.2% exhibited minor stiffness or shortness of stride, and 5% had severe lameness. These authors also found 2.2% of dairy cows had foot abnormalities and 2.4% had swollen joints. Locomotion scores range from 1: cow walks normal with no apparent lameness, to 4: cow is extremely reluctant to move even when encouraged (Harris et al., 2017). Measuring gait score as acceptable or not, Moorman et al. (2018) found 72.7% of culled cows were scored as having an unacceptable gait, and thus were sold for a lower price at Ontario auction markets. Drastically lower prices have been paid for lame cows. Stojkov et al. (2020) reported that non-lame cows were sold for an average price of Can$1.35/kg while cows with a locomotion score of 4 or higher (1 sound and 5 severely lame) were sold for Can$0.35/kg in livestock markets in British Columbia, Canada.

Besides the most common and severe visual defects, there are other important visual defects that have been reported to have low incidences. Nicholson et al. (2013) listed incidences for hide damage by insects (0.5%), latent hide damage (2.6%), jaw abscess (0.2%), knee/hock abscess (2.3%), hook/pin abscess (0.7%), and lumpy jaw (0.2%). Ahola et al. (2011b) reported 3.0% of dairy cows with evidence of mastitis. In contrast, Harris et al. (2018) reported a 10.3% incidence for mastitis and 3.8% for multiple udder defects. Investigating the prevalence of 10 advanced, severe cattle health and welfare conditions in mature cows in three areas of the world, Vogel et al. (2018) have reported prevalence of 0.13%, 0.42%, 1.64%, and 0.02% for ocular neoplasia, wounds, poor udder condition, and uterine prolapse, respectively, for dairy cows in North America. Although these quality defects have low prevalence, they draw attention to animal welfare concerns and adversely affect cow value.

Estimated body composition—muscling and fatness

Body composition of the cull dairy cow, in terms of the proportions of muscle, fat and bone, is another very important factor defining the live cow and its carcass value. In order to evaluate the body composition of the cull dairy cow during marketing, the buyer uses two scoring systems, BCS and muscling score (MS). BCS is a visual evaluation of body fat reserves using a 5-point scale; score 1 indicates a very thin cow, while score 5 indicates an excessively fat cow (Jones and Heinrichs, 2016). Muscle score is a visual evaluation of the amount of muscling and the potential carcass meat yield using a 5-point scale; muscle score 1 indicates a lightly muscled cow, while score 5 indicates a heavily muscled cow (Glaze et al., 2016; Duggin and Stewart, 2017). BCS is an inexpensive and simple live animal assessment, which is associated with carcass weight and dressing percent (Apple, 1999; Peel and Doye, 2012), often overlooked by the producer while culling (Moorman et al., 2018). Thus, BCS and MS are useful tools for buyers to estimate carcass composition and, consequently, cow value.

Body composition of dairy cows oscillates according to stage of lactation, as BCS decreases during early lactation and then increases after the peak of lactation (Wildman et al., 1982). A NAHMS (USDA, 2018) study reported that 20.1% of dairy cows were culled during the first 50 d in milk, 24% between 51 and 199 d in milk, 49.3% at 200 or more days in milk, and only 6.7% during the dry period. Culling dairy cows during early lactation may help explain the frequently undesirable BCS of cows sent to market. Moorman et al. (2018) reported that 40.5% of cull dairy cows sold through Ontario livestock auction markets had an unacceptable BCS (2.0 or less) and were consequently valued at lower prices. Additionally, Ahola et al. (2011b) reported that dairy cows were discounted -$20.47 per 45.4 kg for BCS of 1.0, -$12.19 for BCS of 1.5, -$5.82 for BCS of 2.0 and -$2.81 for BCS of 2.5 compared with the base cow BCS of 3.0; cows with BCS of 3.5 or 4.0 received premiums of $1.27 per 45.5 kg or $1.35 per 45.5 kg, respectively, and cows with BCS of 4.5 or 5.0 did not receive discount or premium. The 2016 National Market Cows and Bulls survey demonstrated that the discounts for inadequate muscling can be up to $31.59 per 45.4 kg (NBQA, 2016). These findings indicate that BCS and MS together characterize cow body composition, predict carcass meat yield, and significantly affect cow value. Therefore, dairy producers could include these two measures in their culling decision to strategically market their cull cows in a good body composition to maximize price per kg.

Body weight

According to the USDA national weekly direct cow and bull report, the body weight ranges of live cow categories overlap, indicating that body weight alone does not determine price (Table 1). The USDA Market News Service reported that live weight of slaughter cows in the categories of Premium White, Breaker and Boner ranged from 528 kg to 868 kg (Table 1). Cutter cows had a much wider range, from 347 kg to 941 kg (Table 1; AMS, 2019b). Cow body weight is the only quantitative information available at the marketplace. Body weight along with BCS and MS are used to determine carcass yield, and consequently, cow price per unit of weight. The buyer also estimates the processing costs for that specific carcass vs. its yield, thus approximating net revenue. Although red meat is the most valuable part of the carcass, heavier cows are worth less if that body weight includes excessive amounts of trimmable fat. In the same sense, light weight dairy cows (usually high in lean and low in fat) can be more valuable, but their carcasses are economically inefficient to process because of lower lean:bone ratio compared with a heavier carcass. Therefore, the body weight of a dairy cow provides an estimate of carcass weight in addition to the carcass processing costs for that specific animal, both of which are extremely important in the estimation of net revenue by packing plants.

Table 1.

USDA Agricultural Marketing Service national weekly direct bull and cow report of 8 January 20211

| Classes | Weight (kg) |

Average weight (kg) | Price range ($/cwt)2 |

Average price ($/cwt)2 |

|---|---|---|---|---|

| Premium White | 610–868 | 739 | 55.82–71.00 | 59.04 |

| Breaker (75% lean) | 622–748 | 685 | 55.82–62.97 | 58.63 |

| Boner (85% lean) | 528–741 | 635 | 56.06–61.00 | 59.54 |

| Cutter (90% lean) | 347–941 | 644 | 35.00–68.00 | 54.40 |

1Adapted from AMS (2021c).

2Price paid in dollars per 100 lb. (45.34 kg) of live weight ($/cwt).

Estimated dressing percent

Dressing percent (DP) is also a measure of the value of saleable product compared with the cow and harvesting costs (Coyne et al., 2019), and so it is an important factor in determining cow price during marketing (Table 1 and 2). After the body weight and body composition evaluation, the buyer visually estimates the DP, which is defined as the carcass weight divided by the live weight and expressed as a percentage. Dressing percent for dairy cows can range from 35% to 48% (AMS, 2019a; Moreira et al., 2020) depending on gut fill, pregnancy status, weight of udder, trimmable defects, BCS, and degree of muscling. According to the averages reported in the literature, DP can range from 40.4% to 55.2% (Table 3, see section Carcass characteristics). Smith (2012) described that mature cows are categorized according to estimated DP because it is an indicator of red meat yield. In fact, the visually estimated DP is a major contributor to the price variation within live cow categories which can be greater than between categories. The DP is categorized as low, average, or high, and this may be a function of biological type as well as the compositional conditions of the cow (AMS, 2019a; Moreira et al., 2020). Therefore, the value of the cow is based on the combination of body weight, estimated dressing percentage, and expected lean meat yield and fat proportion from the carcass (Peel and Doye, 2012).

Table 2.

Approximate associations between cull cow marketing classification, carcass quality grade, and cow body condition score1

| Marketing class | Lean yield (%) | Dressing percentage | Carcass quality grade | Body condition score |

|---|---|---|---|---|

| Breaker | 75–80 | High | Commercial | 4.5–5 |

| Average | Commercial | 4.5 | ||

| Low | Commercial/ Utility | 4–4.5 | ||

| Boner | 80–85 | High | Utility | 3.5–4 |

| Average | Utility | 3.5 | ||

| Low | Utility | 3–3.5 | ||

| Lean | 85–90 | High | Utility/ Cutter | 2.5–3.5 |

| Average | Cutter | 2.5 | ||

| Low | Cutter | 2–2.5 | ||

| Light | 75–90 | High | Cutter | 1.5–2 |

| Average | Cutter/ Canner | 1.5 | ||

| Low | Canner | 1–1.5 |

1Adapted from Peel and Doye (2017).

Table 3.

Live and carcass characteristics of cull dairy cows from various references

| Reference | Live | Carcass | Meat | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TR1 | LW | BCS | CW | DP | Matu2 | REA | Yield3 | Marb4 | L* | a* | b* | pH | WBSF | |

| Allen et al. (2009) | CT | 644 | 2.8 | 326 | 50.5 | 421 | 2.6 | 369 | 4.9 | |||||

| Arp et al. (2011) | CT-Exp1 | 655 | 314 | 53.0 | 437 | 67.9 | 2.8 | 408 | 33 | 18.4 | 15.1 | 5.9 | ||

| Bunmee et al. (2014) | CT | 36.5 | 18.5 | 14.2 | 8.2 | |||||||||

| Franco et al. (2009) | CT | 769 | 305 | 35.3 | 14.6 | 7.2 | 5.5 | 7.9 | ||||||

| Gallo et al. (2017) | HO | 618 | 2.7 | 251 | 40.4 | |||||||||

| Harris et al. (2018) | Dairy | 303 | 413 | 64.6 | 2.8 | 367 | ||||||||

| Jurie et al. (2007) | HO | 666 | 356 | |||||||||||

| Lowe et al. (2012) | CT | 614 | 3.1 | 340 | 55.2 | 471 | 69.2 | 3 | 473 | 27.2 | 26.1 | 22.3 | 5.5 | |

| Minchin et al. (2009) | GS | 699 | 3.5 | 324 | 32.2 | 11.5 | 11.4 | |||||||

| Minchin et al. (2010) | CT | 599 | 2.8 | 251 | 36.4 | 11.7 | 14.4 | |||||||

| Pateiro et al. (2012) | 314 | 35.6 | 20.6 | 11.8 | 5.7 | 5.1 | ||||||||

| Patten et al. (2008) | D-NF | 369 | 433 | 72.8 | 3.4 | 481 | 35 | 32.4 | 24.8 | 5.6 | ||||

| Stelzleni et al. (2007) | D-NF | 354 | 433 | 68.1 | 2.6 | 450 | 5.3 | |||||||

| Stelzleni et al. (2007) | D-F | 407 | 472 | 79.3 | 2.7 | 608 | 5.2 | |||||||

| Therkildsen et al. (2011) | CT | 631 | 272 | 42.7 | 36.4 | 23.1 | 11.2 | 5.6 | 7.4 | |||||

| Vestergaard et al. (2007) | CT | 552 | 2.7 | 248 | 45.1 | 32.6 | 20.6 | 9.5 | 5.6 | 5.9 | ||||

| Vogel et al. (2011) | Not sick | 50.4 | 35.5 | 19.5 | 7.7 | 5.9 |

1 TR: treatment defined by the author (CT, Control; HO, Holstein; GS, Grass silage; D-NF, Dairy non-fed; D-F, Dairy fed; NS, Not sick); LW, live weight, kg; BCS, body condition score, 1 = least fatness, 5 = most fatness; CW, carcass weight, kg; DP, carcass dressing percentage; Matu, skeletal maturity; REA, ribeye area, cm2; Yield, yield grade; Marb, marbling score; CIE L*, measurement of lightness; CIE a*, measurement of redness; CIE b*, measurement of yellowness; pH, ultimate muscle pH; WBSF, Warner-Bratzler shear force, kg.

2 Maturity score, 100 = A maturity; 200 = B maturity; 300 = C maturity; 400 = D maturity; and 500 = E maturity.

3 USDA yield grade, except for Harris et al. (2018) and Stelzleni et al. (2007) who provided preliminary yield grade.

4 Marbling score, 100 = practically devoid; 200 = traces; 300 = slight; 400 = small; 500 = modest; 600 = moderate; 700 = slightly abundant; and 800 = moderately abundant.

Utilization of Carcasses

Dairy cows comprise a heterogenous group of animals and consequently there is a large variability in their meat quality characteristics when compared with finished steers and heifers (Woerner, 2010). Despite the misleading concept that beef originated from cows is destined exclusively to be trimmings for manufacturing ground beef, these carcasses are also fabricated into primal cuts. Those cows that have sufficient youthfulness or fatness are processed into primal cuts, such as round, loin, rib, and chuck (Woerner, 2010). These merchandisable cuts are a valuable product for foodservice establishments such as restaurants, buffets, and cafeterias that market them as steaks and roasts (Gill, 1998; Woerner, 2010). Carcasses from relatively old or thin cows are de-boned, resulting in trimmings that have high lean and low fat concentrations. Such trimmings are readily marketed for blending with the relatively high fat trimmings from finished steers and heifers to manufacture beef products having intermediate fat content. In the United States, the market for meat from mature cows has been growing slowly, but steadily (Baldinger, 2019; Vaughn, 2019; Kronsberg, 2020). Meat from dairy cows is influencing consumer beef-eating experiences and, therefore, improving the quality of meat from these animals would have widespread impact on consumer satisfaction (Woerner, 2010).

Marketing Categories

The market category of cull cows influences their financial value. Marketed cull cows are first evaluated based on their health and mobility. Then, they are categorized based on expected lean meat yield. Subjective visual estimations of dressing percent and red meat percentage in the carcass are the two main criteria used to determine the market category of a cull cow.

According to the USDA Agricultural Marketing Service (AMS) the live cow (dairy and beef) classes reported are Premium White, Breaker, Boner, and Cutter. However, the Cutter category can be separated into Lean and Light cows. The grades reported by the AMS (AMS, 2021b) are described below (summarized in Table 2):

Premium White cows are fat, as a result of being fed a grain ration for 2 to 3 mo prior to harvest which causes their fat color to change from yellow to white if they had previously consumed a high level of beta-carotene (e.g., fed fresh grass). Merchandisable whole-muscle cuts are removed, and meat trimmings are obtained from the remainder of the carcass. These trimmings will consist of 50% to 65 % meat (lean) and 35% to 50 % fat.

Breaker cows are relatively fat cows with BCS between 4 and 5. External fat covers the carcass, typically more than 8.9 mm (0.35 inch) of backfat exists at the 12th rib, and considerable muscling is evident. Whole-muscle cuts are removed from these carcasses with the remainder of the carcass becoming beef trimmings composed of 75% to 80% lean.

Boner, also referred to as Boning Utility, is the most frequently observed cow category, with BCS from 3 to 4. Typically, this category of cow has between 3.8 to 8.9 mm (0.15 to 0.35 inch) of backfat at the 12th rib. The Boner carcass is normally boned after the removal of merchandisable cuts and the beef trimmings are composed of 80% to 85% lean.

Lean cows are thin cows, BCS between 2 to 3, with less than 3.8 mm (0.15 inch) of backfat at the 12th rib. Most of the carcass is harvested as boneless beef after yielding relatively few merchandisable cuts. The beef trimmings are 85% to 90% lean.

Light cows are small in overall size and weight, lightly muscled or extremely thin with a very low dressing percent. Carcasses are fabricated to yield mostly beef trimmings.

There is much overlap across all categories in live weight price ranges (Table 1). For the cow buyer, the aim is to estimate red meat yield as merchandisable cuts and trimmings and that respective weight times the value of cuts and value of beef trimmings becomes the value of the cow, which in the US is generally expressed in dollars per hundred pounds live weight. Thus, prices reported for cull cows may include all combinations of the yield and dressing percentage categories, as shown in a recent national weekly direct bull and cow report (Table 1). Across the cow categories, red meat yield can range from approximately 67% to 74 % of carcass weight.

Mature Cow Carcass Grades

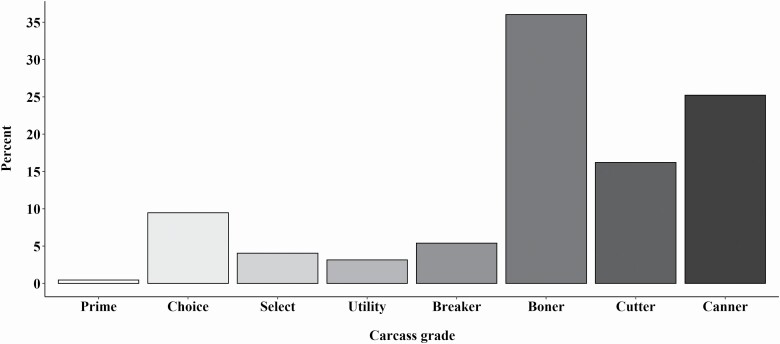

Although the USDA carcass quality grades of Commercial, Utility, Cutter, and Canner are suitable for mature cows, these grades are rarely used by the meat industry for two reasons. First, the market value of non-fed cow carcasses is determined by the amount and composition of boneless meat derived from the carcass, which do not correspond well with the criteria employed by the grading standards; and second, the cost of grading is not economically effective (Hodgson et al., 1992; Johnson and Rogers, 1997; Hilton et al., 1998). Instead, cow processing plants use their own classification systems, most of which are modifications of the USDA grading system and AMS classes (Table 2; Figure 2; Moreira et al., 2020, 2021). These in-house grading systems segregate cow carcasses based on various combinations of market classes, carcass maturity, merchandisable cut and beef trimming yields, and meat quality (e.g., lean and fat color; Figure 2; Hodgson et al., 1992; Hilton et al., 1998). Most importantly, these in-house grading systems are created to fulfill the packer market and business needs. As shown in Figure 2, nearly 10% of carcasses from 222 Holstein dairy cows that passed through a harvest plant in Wisconsin qualified for the USDA Choice quality grade (Moreira et al., 2021). Also, because of the use of in-house grading systems and, consequently, inconsistent classification nomenclature and procedures across processors, the information on market cow carcass yield and quality is extremely limited.

Figure 2.

Percent of Prime, Choice, Select, Utility, Breaker, Boner, Cutter, and Canner carcass grades of 222 Holstein dairy cows reported by Moreira et al. (2021).

Primal cuts (round, loin, rib, and chuck) from selected cow carcasses are fabricated into sub-primal cuts and merchandised as fresh, intact muscle cuts (AMS, 2021a) which are more valuable than beef trimmings. Therefore, the yield of these primal cuts is an important determinant of the value of a carcass. There have been efforts to develop a quantitative quality grading system for mature cow carcasses. Hodgson et al. (1992) advocated that the yield and quality grading system for mature cows should be redefined to accurately categorize cow carcasses according to cow beef marketing practices (percentage of lean, muscle to bone ratio, and percentage of primal and denuded subprimal cuts) and palatability attributes (tenderness, juiciness, flavor). Hodgson et al. (1992) suggested that cow carcasses could be assigned to one of three quality grades based on overall maturity, marbling score, and fat color. The authors also described three carcass quality grades (High, Medium, Low) based on palatability groups and utilization of end products. Hilton et al. (1998) created two alternative systems for quality grading carcasses of mature slaughter cows, one based on maturity and marbling, and another based on maturity, marbling and fat color. The authors suggested that the carcasses could be stratified into three palatability/end-use groups labeled as Premium, Breaking, and Boning. Johnson and Rogers (1997) reported regression equations that could be used to define and reflect current industry processing practices more accurately than previously available equations. Therefore, research aiming to study carcass utilization of cull dairy cows is crucial for improvement of standards and grading systems to reflect the industry marketing needs and the consumer palatability expectations.

Lactation and Body Composition of Dairy Cows

The primary purpose of a dairy cow is to produce milk; thus, the physiology of the dairy cow is designed to support every biological function needed for milk production. The dairy cow is removed from the herd once she is not economically or biologically able to produce milk, which means that the cow can be culled at any stage of lactation. However, the body composition of dairy cows oscillates considerably according to the stage of lactation (Vestergaard et al., 2007). Thus, the carcass weight and meat quality originating from dairy cows is expected to be highly variable (Shemeis et al., 1994b).

Cow body weight decreases sharply during early lactation, slowly starts to increase from approximately the peak of lactation through the end of lactation, and slightly increases during the dry period. Since body weight is gained more efficiently during late lactation than during the dry period (Wildman et al., 1982), the aim is to restore body condition during late lactation. During early lactation, when the energy demand increases drastically, body reserves are mobilized to supply fatty acids and amino acids to the mammary gland for milk production (Schäff et al., 2013; Ruda et al., 2019), and this can result in live weight loss as much as 1.1 kg/d during the first eight weeks of lactation (Yan et al., 2009). This rate of tissue mobilization may vary depending on factors such as milk yield, age, parity, diet, and hormones (Komaragiri and Erdman, 1997).

Tissue mobilization that occurs during lactation relies primarily on fat depots and secondarily on lean tissue. In the context of beef production, the focus is on the proportions of lean and fat that influence carcass value and carcass yield. Most of the body weight loss dairy cows experience during early lactation is primarily as adipose tissue loss. As indicated by Phillips et al. (2003), dairy cows lost 8 kg of body protein from -14 to 60 d in milk, and 56 kg of body fat between parturition and 60 d in milk. Komaragiri and Erdman (1997) reported that by week 5 post-partum, cows mobilized 42 kg of body fat per unit of decrease in BCS. Additionally, Andrew et al. (1994) reported that cows in early lactation contained 6.85% units less fat per unit of empty body weight than the average for cows in the prepartum and late lactation groups. Therefore, dairy cows sent to harvest during early lactation have used primarily their adipose tissue, and then muscle tissue, resulting in lower body weight, lower carcass yield, and a carcass composition that is relatively low in fat.

There is little information in the literature on carcass composition of dairy cows destined for beef production, especially on factors drastically influencing carcass yield (e.g., age, parity, stage of lactation, and health status) of animals transitioning from milk production to beef production. Butler-Hogg et al. (1985) studied body composition of British Friesian dairy cows in five different physiological states. Dairy cows that were non-pregnant and dry had the highest weights of empty body, total lean, and total fat. On the other hand, dairy cows in peak milk and mid-lactation groups had the lowest values for the respective parameters. Using BCS to classify the degree of fatness of dairy cows sent to harvest, Shemeis et al. (1994a) found that the proportion of cold carcass weight was improved markedly with improving body condition class from thin (BCS < 3) to fat (BCS > 4) due to increased fat proportion; in addition to increase in muscle to bone ratio and decrease in lean to fat ratio.

Although stage of lactation influences the saleable carcass value by the proportions of lean and fat, the non-carcass components such as gastrointestinal tract size, gut fill, udder weight, uterine weight, and organ weight are equally important because their weights vary drastically according to stage of lactation and affect dressing percent. During early lactation, the mammary glands are fully functional for high milk production, thus resulting in heavier udder weight (Butler-Hogg et al., 1985; Andrew et al., 1994) and udders are sent to rendering for low value. Udder weight at peak milk is heavier by 9.5 kg (Andrew et al., 1994) to 12 kg (Butler-Hogg et al., 1985) compared with a dairy cow at the end of lactation. During mid-lactation, the gastrointestinal tract tends to be slightly heavier with higher gut fill, which corresponds to cows with low BCS having a higher percentage of offal components (Shemeis et al., 1994a). In summary, cull dairy cows marketed during early lactation, besides having lower body weight, would receive a price discount due to lower saleable carcass yield and higher non-edible components.

Carcass Characteristics

In dairy cows most of the absorbed nutrients support a high metabolic capacity for milk production, whereas muscle growth is expected to have much lower priority (Therkildsen et al., 2011). In addition, dairy cows sent to harvest represent a highly variable harvest animal category and, consequently, a large amount of variability is often observed in the carcass characteristics of these animals (Vestergaard et al., 2007). In this section we review the data available in the literature on carcass characteristics of dairy cows. Table 3 presents an overview of the live animal, carcass and meat quality characteristics of these animals.

As shown in Table 3, the live weight of dairy cows sent to harvest is around 650 kg, depending on a variety of factors. Allen et al. (2009) reported dairy cow average live weights of 644 kg, 662 kg, and 669 kg for control, fed 90-d, and fed 90-d with ractopamine supplementation groups, respectively. Gallo et al. (2017) found lower average live weight for Holstein cows, 618 kg.

As previously mentioned, dressing percent of dairy cow carcasses can be affected by many factors such as feeding, management, and health status. Investigating the effect of preslaughter feeding and ractopamine hydrochloride supplementation, Allen et al. (2009) reported DP for market dairy cow carcasses to be 50.5%, 54.8%, and 54.6% for control, 90-d fed, and 90-d fed with ractopamine supplementation, respectively (Table 3). Gallo et al. (2017) reported that farm type, breed, calving to cull interval, and month of slaughter had a significant effect on DP, which the authors reported to be an average of 40.4% for Holstein cows. Vestergaard et al. (2007) reported slightly higher DP values, 45.1%, for non-fed group. Vogel et al. (2011) reported that sick dairy cows yielded 2% less than healthy cows (48.4 vs. 50.4), which emphasizes the welfare and economic importance of health status of cows sent to harvest. Carcass weight of dairy cows ranged from 248 kg to 407 kg (Table 3).

Most of the dairy cows are removed from the herd when they are around 3 to 5 yr old (USDA, 2018). Stelzleni et al. (2007) and Patten et al. (2008) reported skeletal maturity scores of 433 for non-fed dairy cows and 472 for fed dairy cows (Stelzleni et al., 2007). Harris et al. (2018) found slightly lower skeletal maturity scores, 413, and reported an overall carcass maturity score, a composite of skeletal and lean maturity scores, of 387 (C maturity). The maturity and nutritional regimen of dairy cows sent to harvest demonstrate the potential of these animals to produce beef with similar palatability attributes to beef products from fed or white-fat, beef-type cows (Stelzleni et al., 2007; Woerner, 2010).

Carcass yield grade indicates the weight of boneless, closely trimmed retail cuts from the high-value parts of the carcass (Hale et al., 2013). Harris et al. (2018) reported that preliminary yield grade, which is based solely on 12th rib fat thickness, for dairy cows was 2.8 compared with 3.1 for beef cows. Stelzleni et al. (2007) reported preliminary yield grades for non-fed and fed dairy cows of 2.6 and 2.7, respectively, compared with 3.0 for the USDA Select steer group. These results indicate the relatively low subcutaneous fat thickness of dairy cows. Allen et al. (2009) found yield grade value of 2.6 for non-fed dairy cows and 3.0 for dairy cows fed for 90 d. In contrast, Patten et al. (2008) reported higher yield grades, 3.4 for non-fed dairy cow and 4.1 for fed dairy cow carcasses. An indicator of muscling and an important yield grade factor is ribeye area (REA). As REA increases, meat yield increases. The REA for dairy cows varies from 64.6 cm2 to 79.3 cm2 (Table 3). Comparing mature cows and fed A-maturity USDA Select steer carcasses, Stelzleni et al. (2007) found REA of 68.1 cm2, 79.3 cm2, and 91.2 cm2 for non-fed dairy cow, fed dairy cow, and USDA Select carcasses (Table 3). The degree of muscling is lower in dairy cow carcasses than in finished beef steers, which is expected, but the meat yielded by dairy cows typically has less fat content.

Dairy cows have the advantage of higher marbling scores (McKenna et al., 2002). Stelzleni et al. (2007) showed that non-fed and fed dairy cows had higher marbling scores (450 and 608) compared with non-fed beef cows, fed beef cows, and USDA Select steers (377, 509, and 356), respectively. These authors also emphasized that the higher marbling score of dairy cow carcasses resulted in a more desirable final quality grade for dairy cows. Evaluating feeding strategies for market dairy cows, Allen et al. (2009) described that the control group had a marbling score of 369, the group fed for 90 d had marbling score of 539, and the group fed for 90 d with addition of ractopamine supplementation had marbling scores of 522. Harris et al. (2017) also reported that dairy cows had higher marbling scores compared with beef cows and to dairy and beef bulls (Table 3).

Meat Quality

The appearance of meat can be influenced by a variety of factors and strongly impact consumer decisions at the time of purchase, but the ultimate assessment of meat quality by consumers occurs during consumption (Joo et al., 2013). Meat quality encompasses appearance traits such as color, and palatability traits such as tenderness and flavor. Meat quality data for beef from cull dairy cows is sparsely available in the literature.

Color is an important quality attribute in consumer perception of meat freshness. Most dairy cows are slaughtered between 4 and 5 yr of age, and it is well known that the concentrations of myoglobin increase with age (Faustman and Suman, 2017). Therefore, it is expected that dairy cows would have darker meat color compared with younger, finished steers and heifers. The Hunter color solid coordinates (Hunt et al., 1991) are used to quantify meat color based on the CIE coordinates represented as lightness (L*), redness (a*), and yellowness (b*). The average CIE L*a*b* color parameters for non-fed longissimus muscle of dairy cows is 35.0, 32.4, and 24.8, respectively, compared with that from A-maturity Select-grade animals of 38.9, 30.7, and 23.8, respectively (Patten et al., 2008). These values indicate that the longissimus meat from dairy cows is darker, slightly more red, and slightly more yellow than younger animals. The majority of studies have quantified the effect of feeding a high-concentrate diet on meat quality of dairy cows. Vestergaard et al. (2007) found that the CIE L*a*b* color parameters increased with feeding time (values of L*: 32.6, 33.9, 34.3; a*: 20.6, 21.3, 21.9; b*: 9.5, 10.1, 10.4 for groups that received 0, 2, and 4 mo of feeding prior to harvest, respectively). Therkildsen et al. (2011) found similar values, but with no significant difference between feeding treatments. Vogel et al. (2011) reported no statistical differences for sick and non-sick groups, but a* and b* values decreased as the water and feed withdrawal hours increased (Table 3).

Color and ultimate pH indicate the occurrence of dark cutting, a quality defect often observed in animals exposed to stress prior to harvest (Aberle et al., 2001). The carcass is most likely to be classified as dark cutting when ultimate pH is 5.87 or greater (Page et al., 2001). The causes of dark cutting are usually associated with the depletion of glycogen from muscle stores prior to slaughter due to stress (Ponnampalam et al., 2017). However, Apaoblaza et al. (2020) found that cattle raised in an extensive system have darker lean as a result of more oxidative metabolism rather than a stress-related event antemortem. Nevertheless, dark cutting is an issue that has an important economic impact in the beef industry. Vogel et al. (2011) reported pH and color values that indicated a borderline dark-cutter state in meat from Holstein cows, regardless of water and feed access treatments. Typically, pH gradually declines from around 7.2 to an ultimate pH of about 5.6 achieved at 24 h (Matarneh et al. 2017).

Tenderness is one of the most important eating quality elements according to consumer research, and it can affect the consumer decision to repurchase the product (Maltin et al., 2003; O’Quinn et al., 2018). The benchmark for acceptable shear force (a common measurement of meat tenderness) for beef longissimus muscle is 4.6 kgf (Shackelford et al., 1991). The relative youthfulness of cull dairy cows is one of the factors thought to explain the similar palatability attributes of beef products from cull dairy cows when compared with fed or white-fat, beef-type cows (Stelzleni et al., 2007; Woerner, 2010; Table 3) Shear force for non-fed dairy cows was 5.8 kgf, and for fed dairy cows was 6 kgf; compared with 5.3 kgf, 5.7 kgf, and 7.6 kgf for USDA Select A-maturity steers, fed beef cows, and non-fed beef cows, respectively (Stelzleni et al., 2007). In fact, all groups evaluated by Stelzleni et al.(2007) had shear force values above the acceptable threshold desired by consumers according to Shackelford et al. (1991). Vestergaard et al. (2007) found shear force values of 5.9 kgf, 5.7 kgf, and 5.1 kgf for 0, 2, and 4 mo of pre-harvest feeding, respectively. Therkildsen et al. (2011) reported a drastic decrease in shear force values for dairy cows fed a compensatory feeding strategy for 9 wk, 4.9 kgf, compared with 7.4 kgf for control group (Table 3). It is important to emphasize that shear force values may vary according to a variety of factors, such as breed, feeding time, age at slaughter, freezing/thawing, cooking temperature, coring, and shearing procedures, etc. As dairy cows sent to harvest have a large variability in terms of age, parity, stage of lactation, and body condition score, the literature findings regarding meat tenderness need to be interpreted with caution. Undoubtedly, additional research in this topic would aid the development of better cow carcass grading standards.

The perception of meat palatability is strongly associated with flavor which is a general term to define taste or aroma (Stelzleni and Johnson, 2008; Stelzleni and Johnson, 2010). In fact, studies have shown that flavor is the most important trait to overall eating quality of beef, followed by tenderness (O’Quinn et al., 2018). Meat from mature animals is often perceived as having undesirable flavors compared with meat from young cattle (under 42 mo). Stelzleni and Johnson (2010) benchmarked off-flavors (1 is extreme off-flavor and 6 is no off-flavor) on meat from fed and non-fed beef and dairy cows and A-maturity USDA Select steers (fed and non-fed cows were identified by trained plant buyers). The authors reported that the Select steers had the lowest incidence of off-flavors (5.5), followed by non-fed dairy cows (5.3), fed dairy and beef cows (5.2), and non-fed beef cows (4.8). Equally important, the authors broke down the off-flavor descriptions, and found that grassy, gamey, and other (commonly attributed to fishy or tallowy) flavors were the most frequently reported off-flavors for non-fed dairy cows; and livery, gamey, or other (fishy) flavors were the most reported off-flavors for fed dairy cows. Jurie et al. (2007) reported that meat from Holstein dairy cows did not differ in flavor compared with Salers cows, a beef breed. Vestergaard et al. (2007) reported that meat flavor was improved with duration of finishing time. Similarly, pre-harvest finish feeding was reported to positively impact flavor development in meat from dairy cows (Therkildsen et al., 2011).

Although meat from mature cows is perceived to have “off-flavor,” it is important to emphasize that the average American consumer is used to mild-flavored beef originated from grain-fed cattle, thus any deviation from that standard may challenge the consumer palate. In fact, most of the beef produced in the US comes from young cattle, Prime, Choice, and Select quality grades (“A” and “B” maturity; ERS, 2019, 2021), resulting in a beef flavor that is not fully developed (Vaughn, 2019). Additionally, consumers have the mentality that beef from older animals is not as good (Feldmar, 2019). However, the consumption of meat from old dairy cows is a normal practice in European countries (Vestergaard et al., 2007; Therkildsen et al., 2011; Bazzoli et al., 2014), and can be extremely valuable in some regions (Wilkes, 2016; Vaughn, 2019). The maturity of these animals is the reason for the more intensely meaty flavor, with a deeper beef taste, more flavorful fat, and complex textures (Feldmar, 2019), making this meat a high-value product in many high-end restaurants across the United States (Baldinger, 2019; Feldmar, 2019). However, the little research that has been conducted on meat quality of cull dairy cows aimed to eliminate this flavor, changing it to a milder beef flavor, and to modify the fat color from yellow to white.

The perceived disadvantages of the meat from cull dairy cows may actually offer advantages for future markets. Non-fed dairy cows have the potential to produce beef with good quality and acceptable sensory attributes (Stelzleni et al., 2007; Patten et al., 2008; Stelzleni and Johnson, 2010; Woerner, 2010). Thus, future research will be essential to characterize and guide improvements needed to merchandise dairy cow carcasses in accordance with market opportunities. Above all, culling healthy and well-conditioned dairy cows is essential to maximize the yield and quality of intact-muscle cuts and the commercial value of these cows.

Drug Residue

The United States National Residue Program (NRP) was designed to identify, prioritize, and analyze chemical residues and contaminants in meat, poultry, and egg products (Food Safety and Inspection Service; FSIS, 2020a). Under the Federal Meat Inspection Act, FSIS acts to ensure that USDA-inspected meat, poultry and egg products do not contain illegal levels of chemical residues (FSIS, 2020a). Thus, carcass and non-carcass components (offal) reported as “Detected–violative” is the basis for condemnation by FSIS. Additionally, the NRP maintains the “Residue Repeat Violators List”, which is intended for inspection program personnel, establishments, and livestock markets to identify producers with more than one residue violation in the last 12 mo in one or more establishments (FSIS, 2020a).

Although dairy cows are sampled at much higher rates than any other cattle category, there has been considerable improvement made over the years (FSIS, 2020a). Usually, the drug residue violation occurs due to failure to observe withdrawal times, treatments with doses greater than labeled, and improper maintenance of medication records (Dowling, 2013). Drug residue violations can lead to condemnation of carcasses, non-carcass components, financial loss, and adverse effects on consumers’ health (Reig and Toldrá, 2008).

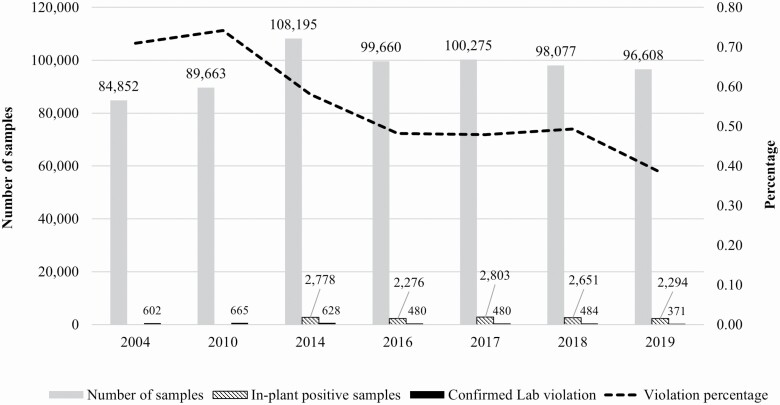

In 2000 the in-plant sampling revealed lab-confirmed violations for dairy cows of 1.1%. In 2004 the drug residue violations for dairy cows decreased to 0.71%, followed by a slight increase in 2010 to 0.74% (Figure 3). But since 2014, the violations decreased from 0.58% to 0.38% in 2019 (FSIS, 2020a; Figure 3). Notably, these data demonstrate the improvement made over the years to decrease drug residue violation in dairy cows (FSIS, 2020a).

Figure 3.

Number of total samples, in-plant positive samples, lab-confirmed sample violations, and drug residue violation percentage in dairy cow carcasses (FSIS, 2020a).

Transportation

Transportation of farm animals, especially dairy cows, has drawn public and scientific attention recently due to its connection with welfare, food safety, biosecurity, and product traceability (González et al., 2012a; Passafaro et al., 2019). The majority of cull dairy cows are sold through livestock markets, which might require multiple loadings and unloadings, and perhaps significant travel time before harvest (USDA, 2018). Transportation does require mobilization of body reserves to supply energy during this period of food deprivation. Additional consequences could be dehydration, worsened lameness, mortality for cattle with pre-existing conditions, and meat quality defects such as dark-cutting (González et al., 2012b).

Every dairy cow should be examined individually at the time of culling to determine its fitness for transport considering the effects of transportation on animal welfare and cow value. The clinical condition of the cow before transport is highly relevant information which has not received much scientific attention (Dahl-Pedersen et al., 2018a). The industry shares similar knowledge and applications regarding transportation; however, there is no definition for “fitness for transport” nor regulation of this topic with regard to cattle transport in the United States (Edwards-Callaway et al., 2019). Several associations provide training programs, guidelines, manuals and material for animal care and handling; however, there is no verification for adherence to these guidelines (Edwards-Callaway et al., 2019). According to the Twenty-Eight Hour Law, animals may not be confined in a vehicle or vessel for more than 28 consecutive hours without unloading the animals for feeding, water, and rest (USDA, 2021).

There are some policies and guidelines that exist outside the United States for cull dairy cow transport. According to the EU regulation on protection of animals during transport (Council Regulation, EC 1/2005), a cow can only be transported if she is fit for transport, which means the cow is not sick or injured, except slightly ill or injured, and if the transport will not cause additional suffering and the journey does not exceed 8 h. However, there is no elaboration on “slightly ill or injured” and “additional suffering”, which limits the impact of the regulations and instead relies on farmer and hauler judgment to ship and transport the cow (González et al., 2012b). According to the policies and guidelines of the Canadian Food Inspection Agency (CFIA, 2013) and National Farm Animal Care Council (NFACC, 2009), Stojkov et al. (2020) described fitness for transport for dairy cows as follows: poor fitness for transport (score 1) if they had one or more of the following conditions, BCS ≤ 2, locomotion score ≥4, udder condition ≥2 (1 normal milked (loose) udder to 3 for swollen/inflamed udder), or had one or more quality defects; all others scored as 0 being classified as good fitness for transport.

Recent evaluations of cull dairy cows during transport to packing plants have reported results that suggest greater attention and enforcement are needed. Stojkov et al. (2020) reported that about 30% of dairy cows sold at livestock markets in British Columbia, Canada, had poor fitness for transport. Dahl-Pedersen et al. (2018a) evaluated the clinical condition of cull dairy cows before transport and reported that 16% of the cows had BCS lower than 2.75, 31% of the cows were considered lame (locomotion scores of 3 and 4) and wounds were found in 22% of the animals but classified as superficial. Complementing the previous findings, Dahl-Pedersen et al. (2018b) also evaluated the changes in cow condition due to transport. The authors reported that 19% of the cows were lame or more lame after transport, with more wounds (34% after vs. 22% before) and more milk leakage (17% after vs. 1% before). In particular, the authors also found that the risk factors for becoming lame or more lame included low BCS, which means that the risk of lameness increased with decreasing BCS. Vogel et al. (2011) simulated feed and water deprivation during marketing and transportation by imposing 36 h of concurrent feed and water withdrawal on cull Holstein cows. Their recommendation was that feed and water deprivation should not exceed 18 h. The resilience of these cows in terms of meat quality might be because ruminants do not enter a metabolically fasted state within this time period.

Over 35% of dairy operations send their cows direct to slaughter, which could drastically minimize transport time and exposure to stressors (Edwards-Callaway et al., 2019). However, according to the NAHMS (USDA, 2018), this has not been the case. Seventy-seven percent of shipments sent to a market, auction, or stockyard traveled short distances (1.6 to 78.8 km) and 22% traveled long distances (80 km to >402 km). In contrast, 49% of shipments sent direct to slaughter traveled short distances, and 49.3% traveled long distances. Independently of the route, cull dairy cows are exposed to various stress factors during transportation, such as mixing with unfamiliar animals, handling by different people in multiple facilities, feed and water deprivation, engorged udders, and climate factors (Edwards-Callaway et al., 2019). The most recent NBQA (2016) showed that market cows and bulls traveled for an average of 6.7 h, and an average distance of 456 km (Harris et al. 2017). Following evaluation of the risk factors for deterioration during transport to slaughter in Denmark, Dahl-Pedersen et al. (2018b) found an average transport distance of 129 km and an average time of 3.1 h. Most of the cows (42%) were transported for a distance between 101 and 200 km, and 40% were transported for <2 h. In contrast, González et al. (2012a) reported an average of 12.9 h of time on truck and an average of 866 km traveled for cull cattle transported during long hauls (>400 km) from and to Alberta, Canada.

Besides deterioration of the physical and clinical condition of cull dairy cows, transportation can also cause body weight shrinkage, increased frequency of non-ambulatory conditions, damage to the carcass through bruising, and stress-induced meat quality problems such as dark-cutting, which all can result in economic losses (Dahl-Pedersen et al., 2018b). González et al. (2012a) investigated the effect of commercial long haul transport and observed that cull cattle had a body weight loss of 7.6% when coming from the auction and 13.5% when coming from the farm. This difference is reasonable since cattle departing from the market would have incurred prior shrink during transport from the farm to the market. The authors also emphasized that fill shrink is the loss of contents from the gastrointestinal tract and lack of water access, while carcass shrink is the loss that results from cellular losses of fluids and body reserves of energy such as glycogen and other nutrients; thus, carcass shrink could result in financial losses.

During transport, dairy cows may be exposed to incidents that potentially lead to bruises, a problem often observed in dairy cow carcasses due to their low body condition. According to the most recent NBQA (2016), more than half of the cows were bruised, but 67% possessed a bruise of minimal severity, meaning less than 0.45 kg of surface trim would be removed due to bruise damage. Nevertheless, 41% of dairy cows had multiple bruises, and 38% had major bruising (0.45–4.5 kg carcass trim; Harris et al., 2017). Of the bruising in cows, the greatest percentages were located on the round and sirloin. In Chilean commercial slaughter plants, Strappini et al. (2012) reported that 71% of the cow carcasses were bruised, and the majority of them happened within 1 h after arrival at the packing plant. In fact, the authors found that the anatomical site (back, pin, hip, butt, rib, round-loin, and forequarter) of the bruises was significantly associated with the stage at which the animal was at the moment of infliction (loading, transport, unloading, lairage, or stunning box).

Welfare

The welfare of cull dairy cows entering the food chain begins with daily welfare practices and care at the farm and ends at the stunning box in the harvest plant. Discussion of cull dairy cow welfare can be divided into on-farm and post-farm sections. On-farm animal welfare concerns are lameness, injury, health, and BCS, which impair animal performance and thereby result in the culling decision. The post-farm animal welfare concerns are unloading, handling, animal mixing, re-loading, and human–animal and animal–facility interactions (Losada-Espinosa et al., 2018). When animal welfare infractions occur, they can affect carcass yield and meat quality (e.g., dark cutting).

Cow housing design and management are factors associated with body injuries at the farm level (Zaffino Heyerhoff et al., 2014; Cook et al., 2016; Adams et al., 2017). Lameness, injury to the neck, hock, and knee, and debilitating diseases are the leading welfare concerns affecting subsequent cow value at auction markets. Lameness is one of the most important welfare problems for dairy cows because it decreases milk production and disrupts walking and standing/lying behavior (Rushen, 2001). Besides the symptoms of distress and severe pain, lameness also leads to a higher incidence of non-ambulatory cows and to other less acute consequences such as reduced time spent feeding and ruminating and decreased BCS (Sadiq et al., 2017). Stall surface and alley flooring type are also highly associated with knee and hock injuries. Adams et al. (2017) reported that operation size, bedding material, and housing type were associated with both lameness and hock lesions. Zurbrigg et al. (2005) showed that neck injury was associated with tie-rail height and that the prevalence of hock wounds increased by 36% for cows housed in stalls having electric trainers. Cook et al. (2016) observed the prevalence of lameness, hock and knee injury, neck injury, and back injury to be 13%, 50%, 9%, and 4%, respectively. Use of deep, loose bedding yielded significant improvements to incidence of lameness and hock and knee injury. Dairy producers should constantly re-evaluate their facilities and management practices for adjustments aiming to decrease the prevalence of lameness and injury.

Animal handling is another major on-farm cow welfare concern. According to the latest NAHMS report, only 56% of dairy operations surveyed provide personnel training for animal handling and cattle movement. In addition, training for handling of non-ambulatory animals was provided by only 33% of the operations (USDA, 2018). Improper animal handling is one of the causes for poor animal well-being and, more importantly, consumer distrust of the industry (Romero et al., 2013; Losada-Espinosa et al., 2018). Therefore, dairy farms should provide personnel training to ensure proper implementation and application of welfare practices. On-farm cow welfare has implications for the post-farm process in terms of transportation, live animal inspection, and carcass yield. Therefore, dairy producers should be aware that their animal welfare practices have both on-farm and post-farm consequences.

In the post-farm component, cull dairy cows are exposed to various stressors such as unfamiliar facility, unfamiliar cow handling personnel, mixing with unfamiliar animals, and unloading/loading. The travel time and prolonged fasting period in addition to these stressors constantly challenge cull dairy cows. Even though dairy cows stay in marketing stations for a short period, these animals cannot adapt to these environmental or physical challenges. Then, as a natural physiological response, the animal redirects energy from production to adaptation in order to cope with stressors (Losada-Espinosa et al., 2018). Moreover, animals culled due to health issues or injuries are even more susceptible to these stress factors (Vogel et al., 2011).