Abstract

Anodised titanium has a long history as a coating structure for implants due to its bioactive and ossified surface, which promotes rapid bone integration. In response to the growing literature on anodised titanium, this article is the first to revisit the evolution of anodised titanium as an implant coating. The review reports the process and mechanisms for the engineering of distinctive anodised titanium structures, the significant factors influencing the mechanisms of its formation, bioactivity, as well as recent pre- and post-surface treatments proposed to improve the performance of anodised titanium. The review then broadens the discussion to include future functional trends of anodised titanium, ranging from the provision of higher surface energy interactions in the design of biocomposite coatings (template stencil interface for mechanical interlock) to techniques for measuring the bone-to-implant contact (BIC), each with their own challenges. Overall, this paper provides up-to-date information on the impacts of the structure and function of anodised titanium as an implant coating in vitro and in/ex vivo tests, as well as the four key future challenges that are important for its clinical translations, namely (i) techniques to enhance the mechanical stability and (ii) testing techniques to measure the mechanical stability of anodised titanium, (iii) real-time/in-situ detection methods for surface reactions, and (iv) cost-effectiveness for anodised titanium and its safety as a bone implant coating.

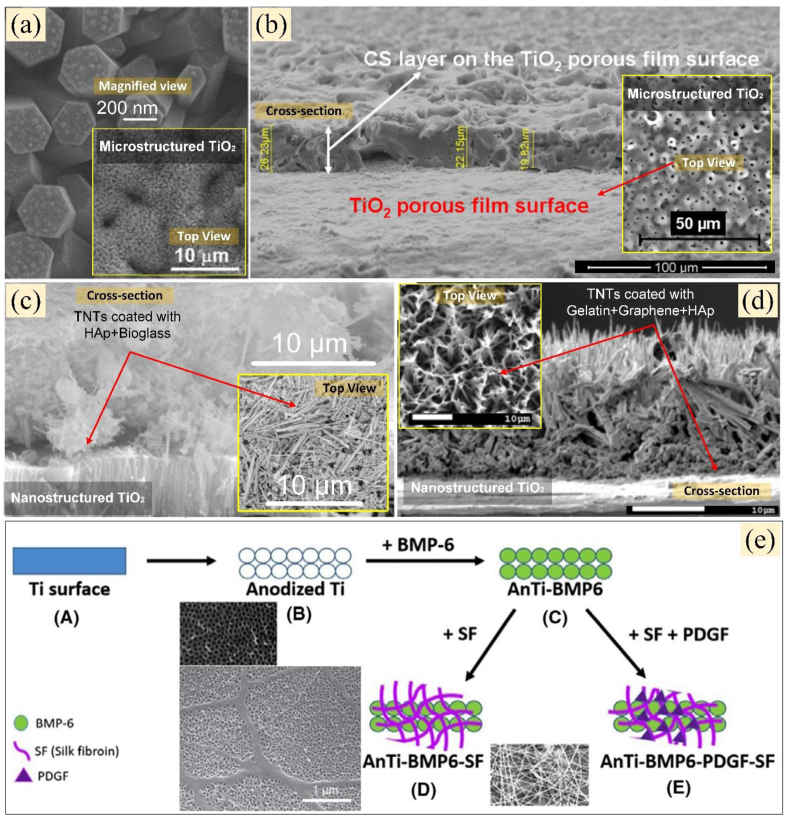

Keywords: Anodised titanium, Anodic oxidation, Anodic layer, Titanium nanotube, Implant coating, Surface modification, Anodization, TiO2, Coating template stencil

Anodised titanium, Anodic oxidation, Anodic layer, Titanium nanotube, Implant coating, Surface modification, Anodization, TiO2, Coating template stencil.

1. Introduction

In the 1950s, Brånemark discovered that titanium could permanently incorporate with bone and introduced the term “osseointegration”, which describes the stable fixation of titanium to bone tissues [1, 2]. Since then, numerous studies have been conducted to obtain a better understanding of the benefits of osseointegration in implants [3, 4]. In most of their reported findings, in order to guarantee that an implant is well integrated into the body's bone-like structures over a long period of time, it surface must be bioactive [5, 6]. Thus, the porous, rough and crystalline surface of anodised titanium with higher surface energy, hydrophilicity, and crystallinity has been recognised as possessing the ideal bioactive coating properties for osseointegration of implants [7, 8].

A passive thin film of titanium dioxide (TiO2) occurs naturally on the surface of a titanium, with a thickness of ~2–5 nm in atmospheric conditions. This passive layer naturally protects the bulk titanium metal from corrosion [9]. Titania (TiO2) exists as three crystallographic phases namely, anatase, brookite, and rutile. Among these phases, rutile is the most common and stable form, and in the industry, only rutile and anatase are manufactured on a large scale. Both anatase and brookite structure are based on cubic packing of oxygen atoms with octahedral coordination. On the other hand, rutile structure is based on a slightly distorted hexagonal close-packing of oxygen with the titanium atoms occupying half of the octahedral interstices [10]. Moreover, anatase and rutile exhibit negative surface charge in physiological solutions. These materials are biocompatible, corrosion-resistant and show good photocatalytic performance [11]. Owing to these properties, a combination of both structures has been widely used in biomedical applications [12, 13, 14, 15].

Commercially pure titanium (cp-Ti) and Ti-6Al-4V alloys are the most prominent titanium alloys used for biomedical applications [4, 16]. These materials are widely used due to their high Young's modulus (compared to human bone [15]), eminent biocompatibility, machinability, formability, compatibility, corrosion, and crack resistance, as well as their remarkable bending and fatigue strength [17, 18]. These properties make titanium and its alloys ideal for bone and joint or cochlear replacements, orthodontic surgery screw parts, tooth fixation dental implants, artificial heart valves, and surgical instruments [19, 20].

However, owing to its bio-inertness, insignificant bone apposition of titanium occurs after implantation [21, 22, 23]. This apposition response results in major clinical issues, such as high rate of implant failure [24, 25] and bacterial infections [26, 27, 28], which then requires some extra systemic treatments [29]. Titanium and its alloy also have low hardness, wear and abrasion resistance. These properties can cause a reduction in the implant service life [30]. Therefore, to overcome the drawbacks, different surface coating methods have been trialled including sol-gel [31], plasma spraying [32], biomimetic coating [18], gel oxidation [33], chemical vapour deposition [34], and anodic oxidation [35]. These methods have produced coatings with excellent physicochemical and mechanical properties and importantly created a bioactive surface on titanium substrates. Among these surface modification techniques, anodic oxidation (AO) has earned substantial attention due to its simplicity, cost-effectiveness, and high clinical success rates [4].

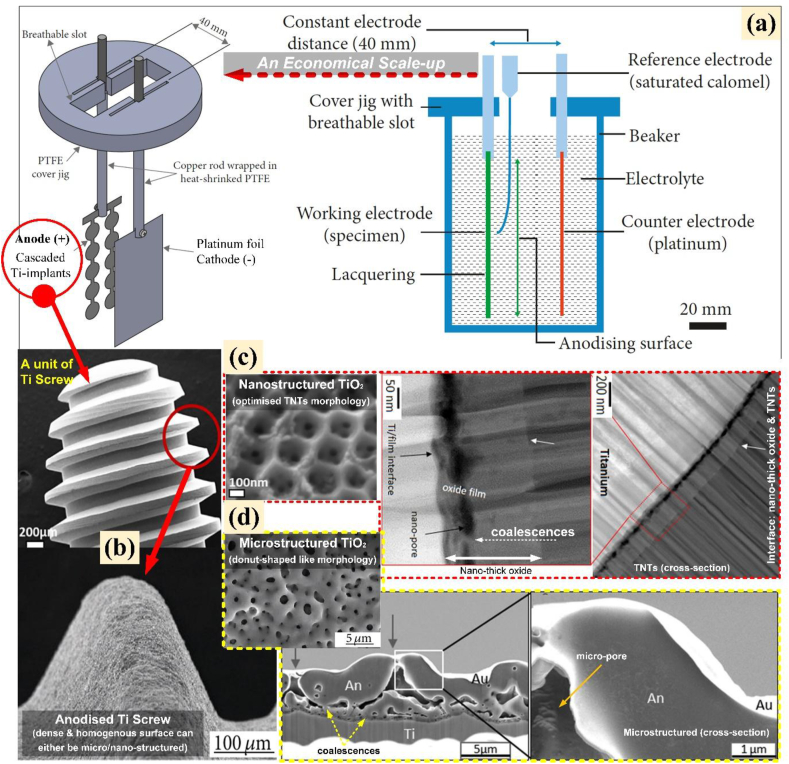

Work of anodic oxidation of titanium started in the 1950s [36]. Anodic oxidation is an electrochemical method used to oxidise the titanium substrates into forming ceramic TiO2 layers of thicknesses varying from hundreds of nanometres to hundreds of micrometres [37, 38]. In the electrolytic oxidation process, tailoring the electrochemical parameters such as applied voltage, electrolyte composition and concentration, and current density will drive the formation of the ceramic TiO2 layer (anodised titanium) with distinctive properties [39, 40]. In some cases, calcium phosphate (CaP) containing compounds and titanate compounds could be incorporated or doped on the titanium surface when the substrate is anodised in CaP containing electrolytes [40, 41, 42, 43, 44, 45]. At present, titanium-based devices doped with CaP compounds have been applied clinically for dental and orthopaedic implants [3, 4], for instance, in intramedullary nails and rods, bone plates and screws, spine cages, and spinal surgery [20].

In addition, recently the fabrication of anodised titanium topography has focussed on the growth of self-ordered nanotubes (TNTs) [46, 47, 48, 49, 50], which has allowed their use as a structure with good osseointegration capabilities [51, 52, 53] to drug nanocontainers for localised therapeutics [46, 47, 54, 55]. Such diverse possibilities for the use of anodised titanium as implant coating material has motivated this current review. The review focusses on the following key aspects: (i) emerging trends in the fabrication of anodised titanium, (ii) mechanism for the formation of anodic oxide layers (anodised TiO2), (iii) factors affecting the formation of the layers, (iv) recent surface treatments to enhance the coating performances, (v) current challenges of anodised titanium as bone implant coating as well as its applications. In relation to its applications, this review paper also emphasises that the anodised titanium has recently been used as a template stencil for other biomaterial elements to be incorporated such that it forms a biocomposite surface (based on mechanical interlock mechanism between material interfaces) either in micro- and/or nano-structured forms [56, 57, 58, 59, 60, 61].

2. Anodic oxidation

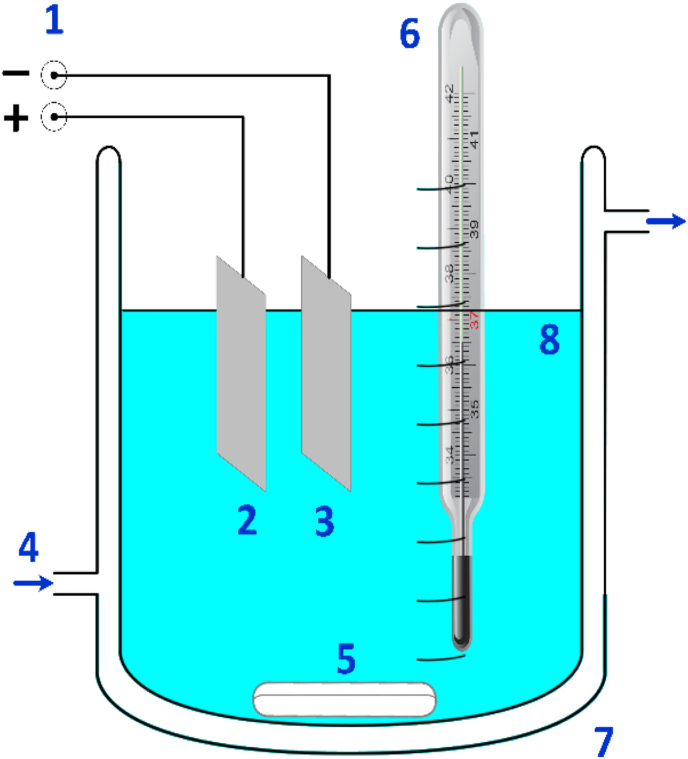

In general, anodised titanium is an oxide coating engineered on titanium surface using a surface modification technique (i.e., anodic oxidation). This surface modification technique is an in-situ electrochemical method for depositing an oxide layer on the anode surface of a metal substrate by using an electrical field to aid the ionisation of elements in the aqueous electrolyte and their diffusion to the metal [17]. The deposited oxide (anodic layer) has been produced by the oxidation of the metal base, and varies in thickness from tenth of nanometres to hundreds of micrometres depending on the parameters used in the anodic oxidation cell (AO cell) and the processing parameters. The common setup for an AO cell consists of anode, cathode, electrolyte bath, power supply, magnetic stirring bar, thermometer, and cooling system as shown in Figure 1 [62]. The anodisation is typically combined with essential pre-processing such as acid activation, polishing, alkaline cleaning, electrolyte formulation and sample drying. Generally, nitric acid, hydrofluoric acid, and acetone are all used for polishing, alkaline cleaning, and acid activation. One of the ultimate functions of these processes is to remove the native oxide layer and contaminants that are present on the titanium substrate when it was exposed to air at room temperature [63, 64, 65, 66, 67, 68].

Figure 1.

Schematic diagram of anodic oxidation, AO electrochemical cell: (1) power supply, (2) anode (3) cathode (4) cooling water (5) magnetic stirrer bar (6) thermometer, (7) jacketed beaker, (8) electrolyte (redrawn with permission from [62]).

Over the last decades, anodic oxidation has become popular in the surface modification of titanium for biomedical applications due to its significant advantages, i.e. (i) simple processing method and cost-effectiveness [2, 69, 70], (ii) capability to improve coating adhesion, interfacial bonding and corrosion resistance with easily tuneable properties [71, 72, 73, 74, 75, 76, 78, 79], (iii) as well as enhanced mechanical compatibility of the coating via the creation of porous structure with excellent potential for cell colonisation [17, 35, 80, 81]. The anodising variables that influence the characteristics of the oxide layer are: (i) process parameters i.e. applied voltage, current density, anodising time, ultrasonic and stirring effect, bath temperature, types and concentration of electrolytes; (ii) alloying elements of titanium substrate; (iii) pre- and/or post-treatment such as acid/alkaline treatment [45, 82], hydrothermal [83, 84, 85], heat [86, 87, 88], ultraviolet irradiation or photocatalytic [18, 87], ultrasonic [50, 89], microwave [44, 90] also two-step oxidation [91, 93].

2.1. Types of anodic oxidation

Anodic oxidation (AO) can be categorised into two types of processes: galvanostatic and potentiostatic [81]. The differences between the two processes are as follows:

-

•

Potentiostatic process [94]: The anodic oxidation is carried out at constant voltage while the current changes.

-

•

Galvanostatic process [95]: The anodic oxidation is carried out at constant current while the voltage changes.

At low applied voltage (lower than the dielectric breakdown limit), the current-voltage characteristics of the power supplied vary according to the Ohm's law. Hence, a thin and compact oxide layer is produced. At this stage, the anodic oxidation is carried out in a potentiostatic process [62]. Meanwhile, visible sparking, cracking noise, gas evolution, localised melting and voltage oscillations occur if the voltage is higher than the dielectric breakdown limit, and this stage of reactions is found in the galvanostatic process. As a result, oxide layers that are thick, less uniform, more porous, slightly cracked, and of complex are produced. This type of anodic oxidation can be labelled in different manners as micro-arc oxidation (MAO) [90], anodic spark deposition (ASD) [96], plasma electrolytic oxidation (PEO) [97] or plasma electrolytic saturation (PES) [95], microplasma oxidation (MPO) [98], micro-arc discharge oxidation (MDO) [99], or anodic plasma-chemical process (APC) [100].

Moreover, in galvanostatic AO, the applied voltage usually in the range of 150 V–1000 V, depending on several parameters, including electrolyte type and concentration, pH, and temperature. In the anodic and cathodic half circle, the voltage is usually in the range of 150–1000 V and 0–100 V, respectively [17]. Electrical arcing is commonly associated with galvanostatic AO; Arcing is a luminous discharge of electrical current crossing the gap between two electrodes. The arcing can only be achieved by the use of sufficiently high current, temperature, and pressure (from the applied electrical fields) during anodic oxidation. For instance, the local temperature and pressure in the discharge channel during MAO can increase up to 10,000 K and several hundred bars, respectively. Usually, the coating produced via MAO consists of three layers: (i) a porous and thick outer layer with numerous cavities and cracks, (ii) an inner layer which acts as a barrier, and (iii) a thin interlayer between the dense layer and titanium substrate [17]. The cracks are observed owing to the thermal stress gradients established during and after arcing [62]. Ultimately, high quality coatings with good adhesive strength and wear resistance of the oxide layer can be feasibly produced by MAO [101].

2.2. Formation of the TiO2 layer

As the redox process take place in an AO cell (Figure 1) in either acidic, alkaline, or CaP-based electrolytes, the oxidation occurs on the substrate functioning as the anode, whereas reduction takes place at the cathode. Eqs. (1), (2), (3), and (4) show the main reactions leading to the oxidation at the anode surface [17, 81];

At the Ti/TiO2 interface:

| Ti → Ti2+ + 2e− | (1) |

At the TiO2/electrolyte interface:

| 2H2O → 2O2- + 4H+(oxygen ions react with titanium to form TiO2) | (2) |

| 2H2O → O2 (gas) + 4H+ + 4e−(oxygen gas evolves and is generally lost to the atmosphere or adheres to the electrode-electrolyte interface) | (3) |

Thus, at both the interfaces:

| Ti2+ + 2O2− → TiO2 + 2e− | (4) |

On the other hand, at high voltage, the anodised TiO2 layer is formed due to the inward migration of O2− ions from the electrolyte to the metal/film interface and the outward migration of Ti4+ ions from metal substrate to film/electrolyte interface. Delplancke et al. [102] explained that the growth of an anodic film on titanium surface occurs through the following steps:

natural continuous formation of Ti-oxide film growth of the TiO2 crystals possible formation of a discontinuous film; thickening and coalescence of the TiO2 film oxygen evolution dissolutions of the film in electrolyte.

The growth of the final TiO2 coating by anodic oxidation shows a linear relationship with the applied voltage, and the correlation factor is known as the growth constant [103]. The relationship of final TiO2 thickness and applied voltage can be represented by Eq. (5) [17, 81].

| d = αU | (5) |

where,

d = Final oxide thickness

α = A constant within the range 1–3 nm/V, but most often around 2 nm/V

U = Applied voltage

The growth rate is strongly dependent on the process parameters of anodic oxidation. However, this relationship is invalid if the oxide layer formation increases to a thickness value that causes the dielectric breakdown limit of the TiO2, depending on the process conditions of the anodic oxidation (discussed in section 3). This is due to the fact that the TiO2 layers will no longer be resistive enough when the applied voltage reaches the dielectric breakdown limit [17].

On the other hand, the formation of TiO2 nanotubes (TNTs) is slightly different from the above anodic oxidation. In general, the formation of TNTs starts when Ti is oxidised to Ti4+ and forms a compact TiO2 layer through the reactions shown by Eqs. (6) and (7). Further, the fluoride ions chemically dissolve TiO2 or react with Ti4+ with at the oxide-electrolyte interface and lead to the formation of water-soluble [TiF6]2- (Eqs. (8) and (9)). As a result, the compact TiO2 layer transforms to TiO2 nanotubes [49, 104, 105].

| Ti → Ti4+ + 4e− | (6) |

| Ti + 2H2O → TiO2 + 4H+ + 4e− | (7) |

| TiO2 + 6HF → [TiF6]2− + 2H2O + 2H+ | (8) |

| Ti4+ + 6F− → [TiF6]2− | (9) |

Moreover, Allam and Grimes [105] described the possible formation mechanism of TNTs produced by anodising in chloride based electrolytes (Eqs. (10), (11), and (12)).

| TiO2 + H+ + Cl− → TiO(OH)Cl | (10) |

| TiO(OH)Cl + 3H+ + Cl− → TiCl22+ + 2H2O | (11) |

| TiCl22+ + 4Cl− → TiCl62− | (12) |

2.2.1. Micropore formation mechanism

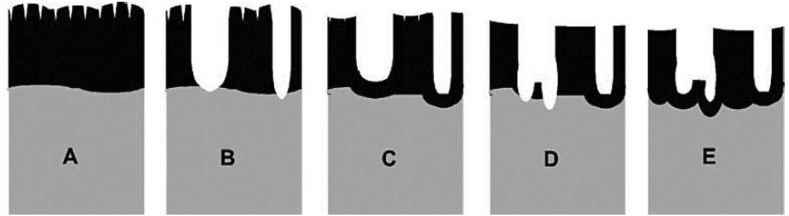

The formation of micropores in the anodised layers can be described using avalanche theory [38, 76]. Figure 2 illustrates the growth model of micropores produced by MAO. The newly-formed oxide layer on the anode keeps growing until the dielectric breakdown limit is reached during anodic oxidation (Figure 2A). At this stage, the local temperature is increased by over 1000°-3000 °C and this leads to localised melting on the anode surface. Compressive stress of oxide layer increases significantly during the transformation from amorphous oxide layer to crystalline oxide layer. Breakdown of the barrier oxide layer occurs and this results in the formation of pores on the oxide layer (Figure 2B). The potential drop at the weak points exceeds the dielectric limit and causes sparking to occur. However, a new oxide layer immediately covers the areas where electrical breakdown occurred and this process is called repassivation (Figure 2C). The process continues with the formation of small pores on the oxide layer due to the breakdown occurring again inside the repassivated regions (Figures 2D and 2E) [106]. The produced oxide layer is not uniform due to the existence of flaws, defects, local stress, and non-uniform oxide thickness [107].

Figure 2.

Formation mechanism of oxide layer under MAO: (A) oxide growth at maximum thickness, (B) crystallite (pore formation) revolution of oxide, (C) instant reassignment of the pores, (D) bursting of reassigning oxide, and (E) dissolution and second reconstitution of the formed oxide (taken with permission from [106]).

2.2.2. Nanotube formation mechanism

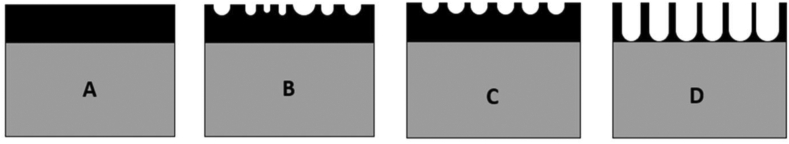

Unlike MAO, formation of TiO2 nanotubes (TNTs) usually occurs under potentiostatic mode (<30 V) [94]. Figure 3 shows the growth mechanism of TiO2 nanotubes; first, the TiO2 layer is formed on the anode (Figure 3A). Then, fluoride ions react with newly-formed TiO2 and form TiF62-. As a result, irregular pits are formed on the TiO2 layer (Figure 3B). With an increase in anodising time, the pores are uniformly distributed and orderly structured as the oxide layer (Figure 3C). The depth of the pores increases further due to the effect of electrochemical oxidation and electrochemical corrosion (Figure 3D). Lastly, the TiO2 nanotubes are formed and length of the nanotubes do not increase any further since both electrochemical oxidation and the electrochemical corrosion are in a dynamic balanced state [108, 109].

Figure 3.

Formation mechanism of TiO2 nanotubes. The reaction leading to the TNTs' synthesis in Ti (A) begins with the formation of the TiO2 layer on the metal (B), then this oxide is dissolved with fluoride ions leading to the appearance of nanopores (C) and deepened until the nanophores form an orderly and compact layer of TNTs (D) (redrawn and adapted from [109]).

Fabrication of TiO2 nanotubes using fluoride based electrolyte has resulted in many problems arising from its toxicity, time required, corrosion, and environmental pollution [110]. In order to overcome these problems, extensive research has used fluoride free electrolyte to produce nanotubes TiO2 [111, 112, 113, 114]. Rapid breakdown anodisation (RBA) has been introduced to shorten the anodising time for fabricating TiO2 nanotubes. In RBA, titanium is transformed into TiO2 nanotubes within few seconds after applying voltage in chloride, perchlorate, and bromide-based electrolytes. The thin layer of TiO2 is grown over the applied voltage, which is quickly attacked by halide ions. As a result, localised pits are formed on the TiO2 layer. Subsequently, water soluble halide ions such as [TiCl6]2− are formed resulting in the formation of TiO2 nanotubes [115]. The TiO2 nanotube formation mechanism for fluoride free electrolyte is almost similar to fluoride-based electrolyte (Figure 3). The only differences are processing time and types of water-soluble ions involved in the process.

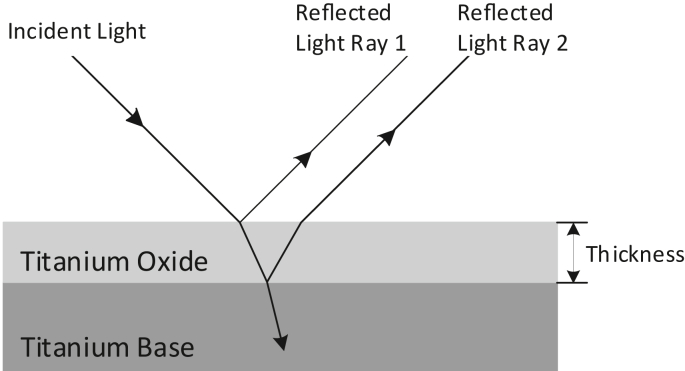

2.3. Colourisation in anodised titanium

Visually, anodised titanium may appear in different colours, and this phenomenon is called colourisation. The cause of different colours in anodised titanium depends on the thickness and the crystal structure of the anodic TiO2 layers. Various colour of coatings such as blue, black, orange, green, silver, grey, brown, yellow, and purple could be easily achieved by tailoring the parameters of anodic oxidation [116]. The colour of anodised titanium can be explained by the multi beam interference theory [102]. According to the theory, interference colours are affected by the non-uniformity of the oxide layer on the titanium substrate. As illustrated in Figure 4, the reflected beams from the oxide surface and surface oxide/titanium substrate interface can produce interference colours. The colour of oxide layer will change due to the increase of oxide thickness. According to Fresnel law, constructive and destructive interference of certain wavelengths results in various colours, depending on thickness of the oxide layer [102, 117]. Apart from that, another explanation of the colour difference of the oxide layer may be ascribed to the differences in crystal structures of the anodic layer. The colour formation can be due to the interference of waves in a crystalline or partly crystalline anodic layers [118]. In general, different colours namely, orange, yellow, blue, green, brown, grey, and purple are produced by anodisation of titanium [119].

Figure 4.

Multi beam interference responsible for colour of anodised titanium (redrawn with permission from [102].

2.4. Evolution of methods for anodic oxidation

In early work on coating development via anodic oxidation, dilute acids such as sulphuric acid, acetic acid, and hydrochloric acid, bases such as sodium hydroxide and salts such as sodium sulphate were used as electrolyte to form TiO2 coating [37]. Nanoporous or microporous compact oxide layer can be formed by using dilute acid or alkaline electrolytes [118]. Traditionally, this compact oxide surface morphology provides high energy interaction of bone-to-implant contact (BIC) [18, 120]. In 1995, Ishizawa and Ogino introduced the calcium-phosphorous (CaP) based electrolyte which is able to produce microporous TiO2 and incorporate Ca2+ and PO43- ions into the oxide layer [51]. The advantages of CaP based electrolyte lies in its ability to form a thick (1–10 μm), rough, and porous oxide layer integrated with calcium and phosphate ions, which have beneficial effects on the growth of bone tissue and enhanced anchorage of the implants to the bone [62]. The presence of CaP ions has been shown to support cell growth, nutrient circulation, and augmented BIC matrix [120].

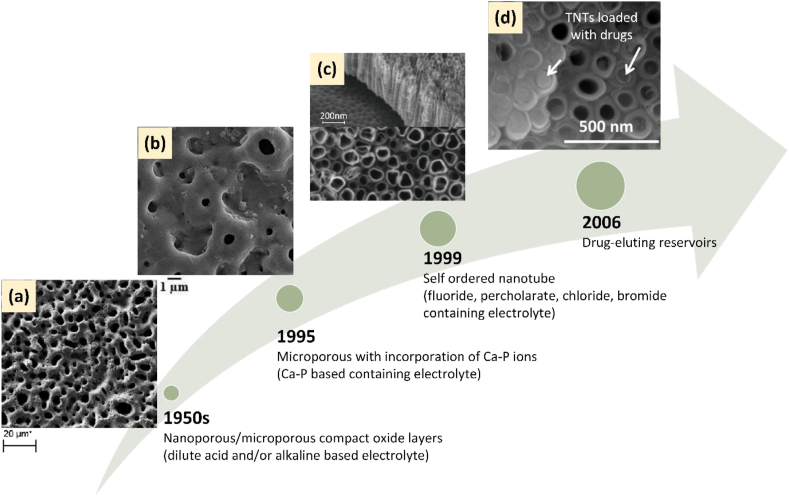

In 1999, Zwilling et al. fabricated self-ordered TiO2 nanotubes by anodising titanium substrates in a fluoride based electrolyte [121, 122]. In order to improve the processing time of anodic oxidation, many researchers focus on the fluoride-free electrolyte, such as perchlorate, chloride, and bromide-based electrolytes for fabricating TiO2 nanotubes [112, 113, 114, 123, 124, 125]. The TiO2 nanotubes (TNTs) have similar dimensions to the non-stoichiometric component of human bone nanocrystal [4, 15], thus promoting osseointegration, preventing the adhesion of bacteria on implant surface, and enabling local drug release [109]. The ability of TNTs as drug eluting reservoirs was first reported in 2006 by Ayon et al. [46]. Overall, the timeline of electrolyte evolution for anodic oxidation and the development of functionality for the oxide layer is shown schematically in Figure 5. Among other factors in brief, the type of electrolyte will significantly produce TiO2 layers with differing characteristics, as discussed in section 3. At present, the research is focussed on CaP-based and fluoride based electrolyte [15].

Figure 5.

The evolution of (i) electrolytes for anodic oxidation (a–c), (ii) functions of the anodised titanium (a) for high energy interaction of bone-to-implant contact (BIC), (b) to promote cell ingrowth, nutrient circulation, and augmented BIC matrix, (c) to interact with bone nanocrystals and (b & c) enhanced BIC matrix of bone anchorage, and (d) as a drug-eluting reservoir. (micrographs redrawn and adapted with permission from (a) [62], (b) [116], (c) [135] (d) [136]).

Eaninwene et al. [47] is believed to be the first to suggest the need for investigating the ability of the TNTs to deliver drugs, and Ayon et al. [46] was the first to conduct the required investigation. The core purpose was to fabricate the implant surface that can overcome infection [47] and reduce inflammation [46, 47] while promoting bone ingrowth (hard tissue secretion). Ayon et al. [46] was the first to design anticoagulants, analgesics and antibiotic drugs-eluting implants via TNTs loaded with dexamethasone, while Eaninwene et al. [47] prolonged the TNT drug delivery capacity in preventing infection by coating the TNTs with a combination of dexamethasone and penicillin/streptomycin.

However, until recently, there has been insufficient work on in vivo or post-implant studies to verify the feasibility of the proposed mechanism and the stability impact of TNTs as drug-eluting reservoirs on clinical trials. Therefore, there are gaps in the discussion with regard to the following aspects (i) the degradation state of drug-loaded TNTs post-implantation to ensure no toxicity [126], and (ii) the long-term mechanical stability of TNT for load-bearing implants allows for bone fixation [127], are challenges that need to be ascertained through clinical trials [128]. Current progress, challenges and perspectives of TNTs as drug-eluting implants has focussed on enhancing the total dosage of drugs in the TNTs [129, 130], release kinetics during initial burst release (IBR) or the total release (TR) [126, 131] and implementation of different payloads of therapeutics for single load or co/multiple delivery [54, 126, 132, 133]. This physicochemical modification work focused on enhancing the current TNT implant properties to promoting better cell integration and antibacterial capacity to treat patients suffering from a broad range of bone diseases [127, 128, 134].

3. Factor affecting characteristics of TiO2 layer

Anodisation parameters greatly influence the characteristics of the TiO2 anodised layer. It is evident that variations in the surface morphologies, mineralogies, topographies, and biocompatibilities of TiO2 anodic layer can result by tailoring the anodisation parameters. The following section will discuss the effects of the major anodisation parameters on the characteristics of anodised layer.

3.1. Critical parameters in anodisation

3.1.1. Applied voltage

The effect of applied voltage on the characteristics of TiO2 anodic layer have been investigated. Most studies show that the surface porosity, thickness, roughness, wettability, and crystallinity increased with increase in the applied voltage. This is due to increased electrochemical reactions at higher applied voltage which caused an increase in the thickness and resistance of the oxide layer. Therefore, higher potential energy is required to break down the dielectric layer, leading to the formation of porous surface, increased surface roughness, and improved wettability of the oxide layer [137]. The crystallinity of TiO2 anodic layer was enhanced at higher voltages owing to the localised heating on the surface of titanium during anodisation [17] leading to melting of the surface and recrystallisation. As a result, higher crystallinity of TiO2 (anatase and rutile), titanate compounds, and CaP compounds are generally obtained at higher applied voltages. Teng et al. [138] studied the effect of applied voltage on surface characteristics of the oxide layer. High purity titanium foils were anodised in mixtures of H2SO4 and H3PO4 at varying voltages (100 V, 140 V, 180 V, and 200 V). They found that a more porous, rougher, and higher crystallinity oxide layer was obtained at the applied voltage of 200 V and these results match observations in other studies [19, 28, 64, 66, 67, 68, 69, 70, 71, 72, 73]. In the case of fabrication of TiO2 nanotubes, low voltages (5–60 V) were applied during anodic oxidation. Hsu et al. [147] performed anodic oxidation at 5 V and 10 V in NH4F/NaCl electrolyte to produce TiO2 nanotubes. The diameters of nanotubes increased from 24-30 nm for 5 V to 35–53 nm for 10 V which matches trends in other studies with similar electrolytes [75, 76, 77, 78, 79, 80, 81, 82, 83, 84, 85, 86, 87, 88, 89, 90, 91, 92, 93, 94, 95, 96]. Michalska-Domańska et al. [169] reported that the diameter of nanotubes did not grow linearly with applied voltage when fabrication was done at 30–60 V in ethanol-based electrolyte containing NH4F and deionised water. The diameters increased linearly from 30 V (88 nm) to 50 V (124 nm) but decreased at 60 V (105 nm). Su and Zhou [170] also observed that the diameter of nanotubes decreased when the applied voltage exceeds a critical value. The diameter of pores and the thickness of the layer grow linearly in an organic electrolyte up to a potential of less than 60 V. When the potential exceeds ~60 V, the pore diameter decreases due to the restriction on the dissociation of water, and this has a detrimental effect on the morphology of the resulting pores [169].

3.1.2. Current density

The current density is defined as amount of current flow through a unit cross-sectional area. In anodic oxidation, the current density also plays a crucial role in tailoring the surface characteristics. Similar to applied voltage, higher current density leads to higher intensity of the spark discharge and results in highly crystalline, porous oxide layers. Quintero et al. [171] used prepared TiO2 layer on titanium in a mixture of H2SO4 and H3PO4, employing current densities of 10 mA/cm2 to 50 mA/cm2. They found that the porosity and crystallinity increased with current density and less time was required for morphological transition when a higher current density was applied. Other researchers [41, 66, 171, 172, 173] also noticed the same trend. Laurindo et al. [174] investigated the effect of high current density (400, 700, 1000 and 1200 mA/cm2 for a period of 15 s) on the surface characteristics of oxide layer in CaP-based electrolyte. They noticed that the porosity and rutile content were decreased significantly and cracks were observed at current density values exceeding a threshold of 1000 mA/cm2. Abdullah et al. [175] explained that the existence of cracks was due to the thermal gradients established during and after arcing. Feschet-Chassot et al. [77] also reported that higher current density of AO in hydrofluoric acid results in greater diameter and higher hydrophilicity of TNTs. Feschet-Chassot et al. discovered that during the initial 70 s of AO, the current density decayed to a local minimum of 10 mA/cm2 and created local TiO2 oxide pits with a diameter of 30 nm. After the current density was increased to 12.7 mA/cm2 at 1000 s, the diameter of the formed TNTs was 85 nm. 20 minutes after that, TNTs arrays with diameters of 100 nm and 105 nm grew to full size. This indicates that the dissolution rate of TNT is greater than its rate of development. As a result, in a steady state, the pore diameter varies regardless of the anodisation time.

3.1.3. Anodisation time

Another important key factor in modifying the surface characteristics of TiO2 anodic layer is anodisation time. Most of studies reported that prolonged anodisation time results in higher spark discharge intensity which leads to the formation of high-surface area and high crystallinity anodic layer. However, there is also exception to this rule if the anodisation time exceeds the limit which results in unstable discharge sparks [176]. Durdu et al. [177] fabricated the TiO2 layer in Ca-P based electrolyte at current density of 0.123 A/cm2 for 5, 10, 20, 40, 60 and 90 min. The coating thickness and density were enhanced with increasing anodisation time. Moreover, Li et al. [178] studied the effect of anodisation time on the formation of TiO2 nanotubes at 10 V for 10 min, 30 min, 1 h, and 4 h in 1 M NaF. The pore diameters and surface roughness increased with anodisation time. The array of nanotubes clumped together as the anodisation time increased, lowering the surface free energy due to the increased tubular length. As the oxide film thickens near the wall over time, the field intensity increases, causing the tube to widen [78, 178]. Overall, the effect of anodisation time on surface characteristics of TiO2 anodic layer also has been intensively reported in other works [78, 144, 145, 179, 180, 181, 182, 183, 184, 185, 186, 187, 188, 189]. These studies showed when the anodising time was increased from hundreds of seconds to hundreds of minutes, which increased the thickness of the TiO2 anodic layer as well as pore diameter, surface roughness, and hydrophilicity.

3.1.4. Ultrasonic agitation and stirring effects

Ultrasonic and magnetic stirring have been employed by researchers to facilitate the formation of highly crystalline porous oxide layer during anodisation. Neupane et al. [65] investigated the effects of ultrasonic intensity on the fabrication of TiO2 on titanium substrate anodised in CaP-based electrolyte. Different ultrasonic intensities (180, 250 and 350 W) were applied during anodic oxidation. They found than the porosity, surface roughness and crystallinity of the oxide layer increased with ultrasonic intensity. They explained that ultrasonic waves increase the anodisation reaction rates. Moreover, these results indicated that ultrasonic condition resulted in uniform mass transfer and higher homogeneity in electrolyte compositions. As a result, more nucleation sites are produced during the anodic oxidation for the pore formation on the oxide layer. Under different intensities of UV illumination (0.8–4.7 mW/cm2), Liu et al. [157] demonstrated that with the assistance of ultrasonic wave irradiation, highly order TiO2 nanotubes can be produced. However, tube length of the wall thickness of TiO2 nanotubes decreased due to the ultrasonic irradiation. To investigate the effect of stirring speed on surface characteristics of anodic layer, Lee et al. [190] prepared TiO2 layer by anodising in Ca-P based electrolyte at different agitation speeds (300–1500 rpm). They observed the same trend as Neupane et al. [65] after applying higher agitation speeds. They explained that gas bubbles attached on the anode surface during anodic oxidation will decrease the surface area of the anode for electrochemical reactions. By applying higher agitation speeds during anodic oxidation, the attached gas bubbles could be removed which enhanced the electron transfer from the film/electrolyte interface to the metal substrate. Consequently, the surface of the anodised titanium became more porous and highly crystalline. Furthermore, Syrek et al. [191] and Liu et al. [192] concluded that when the stirring speed exceeded the critical value (300 rpm), it will result in the reduction of TiO2 nanotube pores size and breakage of nanotubes structure. This is owing to the occurrence of turbulent flow at stirring speed more than 300 rpm which inhibits the efficient equilibration of electrochemical reaction rates.

3.1.5. Bath temperature

The bath temperature is an essential factor in determining the surface characteristics of TiO2 anodic layer. Huang & Liu [193] prepared TiO2 layer on pure titanium foils in 2 M NaOH in different bath temperatures and found worm-like nanostructures after anodising at 20 °C, while short nanowire-like nanostructures were formed at 40 °C and 60 °C. Increased temperature increased the photoelectrochemical property of titanium oxide and this was attributed to the presence of sub-oxide species from the heated alkaline electrolyte causing nanotube growth to slow and thus structure on the surface became more compact, and this resulted in higher photocurrent. Lee et al. [42] revealed that higher bath temperature will inhibit the formation of porous oxide layer since it favours the reactants during the anodic oxidation. Thereby, porous oxide layer will not be formed on the titanium anodised at higher bath temperature. Yetim [194] and Traid et al [195] also found that higher bath temperature leads to the reduction of porosity and thickness of TiO2 anodic layer. Similarly, lower bath temperature also induces the formation of TiO2 nanotubes with ideal packed hexagonal prisms. Lazarouk et al. [196] demonstrated that highly self-ordered TiO2 nanotubes with a structure close to packed hexagonal prisms and smooth tubular morphology were formed at the bath temperature <0 °C. They explained that lower bath temperature results in higher gas solubility and reduces the gas bubbles which periodically block the continuity of the electrochemical process. Furthermore, Peighambardoust et al. [79] reported that higher tube wall thickness to tube diameter ratio could be achieved by anodising in low bath temperature (0 °C). This behaviour is consistent with that found by other researchers [162, 163, 197], who also noted that the decrease in bath temperature leads to formation of TiO2 nanotubes with packed hexagonal prism structure.

3.1.6. Type of electrolytes

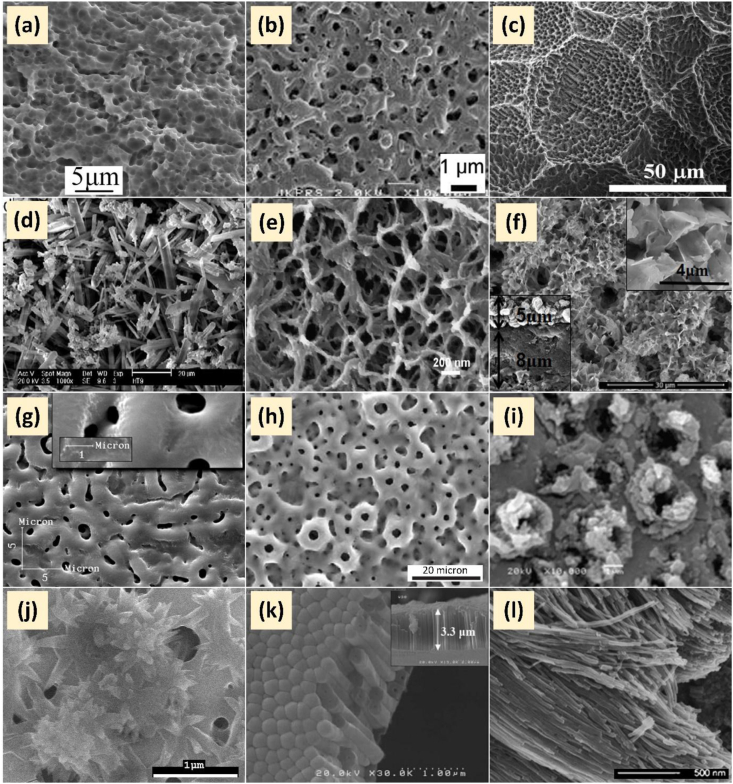

As listed in Table 1, the choice of electrolyte had an impact on the properties of the oxide layer produced, whereas Figure 6 depicts the more common AO morphologies from different electrolytes. The electrolyte could change the properties of the final coating, leading to surface structures, morphology, and mineralogy being tailored to fit different biomedical applications.

Table 1.

Summary of surface morphology and mineralogy of anodised titanium produced from different electrolytes.

| Electrolyte composition | Surface morphology (pore diameter) | XRD detected phase(s) | Ref. |

|---|---|---|---|

| Sulphuric acid | Open pores (0.1–0.5 μm) | Ti, anatase, rutile | [143, 173, 198] |

| Acetic acid | Pores with small white substrates (1 μm) | Ti, anatase | [199] |

| Phosphoric acid | Open pores (0.3–1 μm) and flowery pattern | Ti, anatase | [200, 201, 202, 203] |

| Hydrochloric acid | Open pores (10 μm) | Ti, anatase, rutile | [204] |

| Sodium sulphate | Gel-like pore structure | Ti, anatase, rutile | [72, 143, 205] |

| Sodium hydroxide | Nanorod, nanowire, nanoleaf, and nanoflower porous structure | Ti | [193, 206, 207] |

| Potassium hydroxide | Open pores (150 nm) | Ti | [207, 208] |

| Sulphuric acid + Phosphoric acid | Open pores (0.5–1.6 μm) | Ti, anatase, rutile | [138, 171, 209] |

| Potassium hydroxide + Potassium silicate | Large open pores (5–6 μm) | Ti, anatase | [210] |

| Chromic acid + hydrogen fluorine | Rose-like irregular pore |

Ti, anatase | [142] |

| Sodium hydroxide + Na-tartrate + EDTA + Sodium silicate | Open pores (1 μm) | Ti, anatase, rutile | [211] |

| Tetraborate electrolytes; lithium, sodium and potassium tetraborate |

Cortex-like structure |

Ti, anatase, rutile, amorphous B2O3 |

[91] |

|

Ca-P based electrolyte | |||

|

Donut-shape pore (1 μm) | Ti, anatase, rutile, Ca2Ti5O12, β-Ca2P2O7, α-Ca3(PO4)2, CaTiO3 | [66, 139, 142, 174, 177, 182, 192, 212, 213, 214, 215] |

|

Nanoflower-like structure | Ti, anatase, rutile, Na2Ti3O7 | [43] |

|

Need-like structure | Ti, anatase, rutile, HAp | [216] |

|

Petaling-like structure |

Ti, anatase, rutile, HAp |

[40] |

|

Fluorine based electrolyte | |||

|

[148] | ||

|

[14, 217, 218, 219, 220, 221, 222] | ||

|

[223, 224] | ||

|

[160] | ||

|

[158] | ||

|

[180] | ||

|

[225] | ||

|

[226] | ||

|

Nanotubes, TNTs |

Ti |

[162] |

|

Non-fluorine based electrolyte | |||

|

[123] | ||

|

[124] | ||

|

[112] | ||

|

[112] | ||

Figure 6.

FESEM micrographs of different morphologies of anodised titanium produced in different type of electrolytes; (a) Ti alloy anodised in NaTESi electrolyte, containing 300 g/L sodium hydroxide, 65 g/L Na-tartrate, 30 g/L Ethylenediaminetetraacetic acid (EDTA) and 6 g/L Na2SiO3 [211]; (b) Ti alloy anodised in 1 M Sulphuric Acid, H2SO4 [173]; (c) Micro/nano-textured Ti surface anodised in electrolyte consisting of 0.95 mol dm−3 NaCl and 1.2 mol dm−3 HF [206]; (d) Needle-like structure of HAp on Ti anodised in 0.0105 mol/L Ca(NO3)2, 0.0063 mol/L NH4H2PO4 co-deposited with TiO2 under an influence of 200 °C hydrothermal bath [227]; (e) Network of nanowire on Ti substrate anodised in 80 °C of 4 M NaOH [193]; (f) MAO Petaling-like structure anodised in 0.2 mol/L calcium acetate ((CH3COO)2Ca•H2O) and 0.1 mol/L monosodiumorthophosphate (NaH2PO4•2H2O) [40]; (g) Cortex-like structure on cp-Ti surface anodised in 1.4 M H3PO4 electrolyte [200]; (h) Donut-shape like on Ti substrate anodised in 0.04 mol/l β-glycerophosphate disodium salt pentahydrate (C3H7Na2O6P•5H2O) and 0.4 mol/l calcium acetate monohydrate ((CH3COO)2Ca•H2O) [41]; (i) Rose-like irregular pore on Ti substrate anodised in 0.5 M chromic acid solution with 1.7 wt% HF electrolyte [142]; (j) Nanoflower-like structure on cp-Ti anodised in 0.04 M β-glycerophosphate, 0.4 M calcium acetate (CA), and 1.0 M sodium hydroxide (NaOH) [43]; (k) TNT anodised in ethylene glycol + 4wt% H3PO4 + 0.25wt% HF [162]; (l) TNT anodised in nonfluorine based electrolyte, 50/50 water–ethylene glycol mixture containing 0.3M NaCl or 0.3 M KBr [124]. All micrographs redrawn and adapted with permission form the cited literatures.

Throughout Table 1 and Figure 6, it clearly can be seen that various patterns of microporous and highly crystalline TiO2 anodic layer could be obtained by anodising in acidic electrolyte (sulphuric acid, acetic acid, phosphoric acid, and hydrochloric acid) and neutral electrolyte (sodium sulphate). In contrast to acidic and neutral electrolyte, nanoporous amorphous TiO2 anodic layer is formed by anodising in alkaline electrolyte (potassium hydroxide and sodium hydroxide). These contradictory surface characteristics are due to the acidic and neutral electrolyte having higher electrical conductivity compared to alkaline electrolytes. As a results, the driver force for arcing and dielectric breakdown is enhanced by the higher electrical conductivity of electrolyte, consequently increasing the oxidation rate [62].

An interesting application could result from anodising a metal in CaP-based electrolyte. For example, Ca2Ti5O12, β-Ca2P2O7, α-Ca3(PO4)2, CaTiO3, and HAp can possibly be formed by anodising titanium in Ca-P based electrolyte. The formation of Ca and CaP compounds is owing to the calcium ions and phosphate ions which are ionically contained on the oxides surface of titanium during anodic oxidation. It is believed that the Ti-OH groups which are produced during anodic oxidation induced the precipitation of Ca and Ca-P compounds by reacting with calcium and phosphate ions [41, 216]. The nanoflower sodium titanate on titanium substrate was firstly reported by Lee et al. [43] by anodising cp-Ti in mixture of calcium acetate, β-glycerophosphate, and sodium hydroxide. They claimed that NaOH promotes the dissolution of titanate precursor and results in anisotropic growth of sodium titanate. Meanwhile, TiO2 nanotubes could be obtained through anodising in fluorine based or non-fluorine-based electrolyte. Fluorine based electrolytes are commonly used to achieve self-organised highly ordered TiO2 nanotubes, however, it is time consuming and non-environmental compliance. Hence, non-fluorine-based electrolytes are introduced to overcome these drawbacks. Yet to date, uniformity in sizes and lengths of TiO2 nanotubes remains a major challenge.

3.1.7. Electrolyte concentration

The electrolyte concentration is one of the important parameters that influence the surface characteristics of the TiO2 layer formed by anodisation. Previous research has shown that there is a positive correlation between the electrolyte concentration and surface characteristics. The increase in electrolyte concentration increases the surface porosity, thickness, roughness, and crystallinity. This is owing to the higher concentration of O2 bubbles evolved from the reactions enhancing the arcing intensity and crystallisation of the coating [228, 229]. Alves et al. [230] investigated the effect of calcium acetate concentration on surface characteristics of anodised titanium. The concentration of calcium acetate was varied from 0.15 mol/L to 0.35 mol/L. The results showed that an increase in electrolyte concentration resulted in higher pore diameters. The pores size for 0.15 mol/L to 0.35 mol/L were 0.5–1 μm and 1.5–2 μm, respectively. Moreover, rutile TiO2 was formed when 0.35 mol/L of calcium acetate was employed. A similar trend of results was also observed by using higher concentration of tricalcium phosphate [213], acetic acid [199], and sulphuric acid [231]. Table 2 summarises the variations in the pore sizes as seen present this study.

Table 2.

Pore size variations of micropores in relation to electrolyte concentrations.

| Electrolyte | Low Concentrations | Pore Sizes | High Concentration | Pore Size | Ref. |

|---|---|---|---|---|---|

| Ca3(PO4)2 | |||||

|

2 and 4 g/L |

~1 μm2 |

6–10 g/L |

some nm2 up to 9 μm2 |

[213] |

| CH₃COOH | |||||

|

0.01 and 0.1 M |

order of 1 μm Ø |

0.5 M |

10 μm Ø, but some were small ~1 μm Ø |

[199] |

| H2SO4 | |||||

|

0.1 M | tens of nano to micrometres | 1.2 M | ~50 μm | [231] |

On the other hand, the surface characteristics of TNTs are strongly link to the concentration of the following species:

-

•

Fluorine: The optimal concentration of fluorine ions required to produce highly homogeneous TiO2 nanotubes is in the range of 0.5–1 wt % owing to the sufficiently slow etching rate. Higher concentration of fluorine ions (>1 wt%) results in fast chemical etching which will prevent the formation of nanotubes.

-

•

Aqueous solvent: The pore sizes, lengths, and diameters of TiO2 nanotubes increase with increasing amount of water owing to the lower diffusivity of the electrolyte [232]. Lei et al. [166] suggested that the optimal water content for formation of uniform circular TiO2 nanotubes was 0.75 wt%. The nanotubes possess regular circular pores when the water content is low (<0.75 wt%). Lei et al. discovered that the top view of nanotube morphology is not circular but an irregular polygon at higher water concentrations (2–10 wt%). These findings suggest that adding different amounts of water to the electrolyte can influence the diffusivity and relative concentrations of the ions. As the water content in the solution increases, the ionic strength of the solution decreases, potentially resulting in lower diffusivity. As a result, an irregular hollow polygonal morphology is observed at higher water contents owing to the slow diffusion of F−- anions to the Ti metal from the electrolyte.

-

•

Non aqueous solvent: Song et al. [233] reported that the pore sizes and diameters of TiO2 nanotubes increase with increasing concentrations of ethylene glycol. Similar to effect of aqueous solvent, higher concentration of ethylene glycol leads to a reduction of diffusivity of electrolyte and promote the formation of tube-like structure. Moreover, they suggested that the optimal concentration of ethylene glycol in mixtures of 0.15 mol/L NH4F and 0.11 mol/L citric acid to form uniform TiO2 nanotubes was 60%.

-

•

Acidic electrolyte: Due to its ability to form barrier type TiO2 films, H3PO4 is most commonly used in conjunction with fluorine-based electrolytes. As the oxide film thickens and its resistance increases, acidic elements from the phosphoric acid film act as a barrier to the flow of ions and electrons, slowing and eventually ceasing the oxidation process. The presence of a poreless barrier layer limits the final thickness of the oxide to a few hundred nanometres, resulting in compact nanotubular structures [234]. Chen et al. [226] and Zhang et al. [76] concluded that the addition of H3PO4 significantly decreased the pore sizes and length while increasing the diameter of TiO2 nanotubes. Both of them reported that the structure of nanotubes was not formed if the concentration of H3PO4 was ≥10 wt%. This is owing to the inhibiting effect of PO43- anions on the migration of F− anions, O2- ions, and Ti4+ ions for the formation of nanotubes.

3.2. Alloying elements of titanium

Among the Ti-alloys commonly used for biomedical applications, Cp-Ti, Ti-6Al-4V, Ti-6Al-7Nb, Ti-13Nb-13Zr, and Ti-12Mo-6Zr have been widely used for implants and hard tissue replacement [235]. The effect of alloying elements of titanium substrates on the surface characteristics of oxide layer is well known. Ou et al. [236] compared the surface characteristics of anodised cp-Ti and Ti-30Nb-1Fe-1Hf. The crystallinity of anodic oxidation film on cp-Ti was higher although identical anodising conditions were used. The authors claimed that Nb in Ti-Nb suppresses the transition from amorphous to crystalline state during the anodic oxidation. Similar results were obtained by Roman et al. [161] who found that highly crystalline TiO2 nanotubes were successfully coated on the cp-Ti and Ti-6Al-4V, but not on Ti-6Al-7Nb which formed an amorphous inhomogeneous nanotube structure. Furthermore, Yu et al. [211] investigated the surface characteristics and adhesive strength to epoxy of three different types of titanium alloys anodised in NaTESi electrolyte, namely TA15 (Ti–6Al–2Zr–1Mo–1V), TB8 (Ti–15Mo–3Al–2.7Nb–0.2Si), and TC4 (Ti–6Al–4V). After anodising at 20 V, on the TA15 samples, a uniform, dense oxide film formed, while on the TB8 samples, micro-protrusions were seen on a porous oxide film, and on the TC4 samples, an easily dissolved oxide film with large-scale pits were formed. At 20 V, 15 V, and 10 V, the maximal shear strengths were 15.5 MPa (TA15), 19.2 MPa (TB8), and 17.6 MPa (TC4). These differences are attributed to the variations in potential responses under constant current anodisation. Overall, Yu et al. [211] concluded that after anodisation, TiO2 roughness increased noticeably, and this was owing to the changes in the surface features and phase composition of the films, which are alloying element dependent. The cohesive failure of TB8, a near-beta titanium alloy, confirms that it can achieve a better surface topography for adhesion.

4. Surface treatments to enhance the anodised titanium coating performances

It has been a typical practice that, prior to AO, most samples are ultrasonically cleaned with acetone to remove foreign substances from its polished surface. In conjunction, pre- or post-treatment is performed to improve the bioactivity and mechanical compatibility of the AO coating in the biological environment by providing actives sites for radical nucleation species inside the film [18], subsequently increasing or maintaining the coating integrity [237, 238, 239, 240]. The treatments are either two-step AO [93, 241] or a combination of AO with other methods such as chemical, or thermal; these approaches are implemented before and/or after the process to enhance the ability to form a biomimetic structure on the coating [69, 242]. The pros and cons of pre-/post-treatment of anodised titanium have been addressed several times [4, 15, 81, 239, 243, 244], and this current review study highlights recent pre- or post-treatment advances that enhance the anodised titanium coating performances.

In order to design a hierarchical micro and nanoporous anodised titanium substrate, Lin et al. [45] initiated pre-treatment on titanium substrate using hydrogen fluoride (HF) polarisation to enrich nano-γ-TiH dissolution on the coating layer during NaOH anodisation. As a result, in just 1 day, the MG-63 cells were able to be cultured on this coating structure resulting in enhanced cell adhesion and the presence of multiple filopodias proliferating on the hierarchical micro/nanoporous surface. This pre-treatment verified that hydrogen fluoride reacts as a catalyst to increase hydrogen reaction and/or diffusion during AO, which triggers the formation of dense nanostructures on the micro-phase of Ti hydrides on the final coating structure. Thus, this latest pre-treatment appears to be a necessary and promising procedure for further investigation [45].

Other post-treatment methods on the other hand provided final anodised coating morphologies with a mixture of nanostructured and micron-sized features resulting in an extremely rough, porous and hydrophilic surface [18, 44, 45, 50, 83, 90, 93, 245]. Meanwhile, ultraviolet-assisted post-treatments developed by Lee at al [18] are intended to resolve concerns that the Ca-P micro-arc anodised coatings does not enable rapid nucleation to precipitate bone-like apatite on the surface. This particular post procedure successfully promotes the intensive deposition of Ti-OH on the anodised surface, resulting in a continuous biomimetic layer of thicker, denser and crystalline deposition of bone-like apatites on the anodised Ca-P titania in just 7 days. These Ca-P biomimetic structures showed similar stoichiometry to hydroxyapatite (HAp) found by Song et al. [41] and have recently been engineered by He et al. [83] on top of needle-like Hap structures. He et al. conducted hydrothermal-electrochemical deposition treatment on acid-based anodised titanium for 120 min at 120 °C in an autoclave (the solvent was a mixture of 0.138 mol/L NaCl, 0.016 mol/L K2HPO4·3H2O and 0.02 mol/L CaCl2) [83]. The researchers created a bilayer HAp structure with hexagonal edges, which grew in a perpendicular direction to the microporous substrate. As the underlying needle-like HAp layer expanded to a certain level, a large extent of nucleation was seen to develop further into another layer at the top of the needle-like HAp, and this was identified as cotton-like HAp. Owing to the high crystal density of the needle-like HAp precipitated during the first stage of the hydrothermal process, cotton-like HAp was formed after the second process in an AO hybrid with the hydrothermal process.

More complex post-treatment procedures have been carried out by Lin et al. [44, 90]. This is intended to create a highly biocompatible heterogeneous nano-micro Ca/P coating structure. Three Ca/P-based micro-arc anodised titanium samples were prepared in XP-1500 vessels, all of which were immersed in a solution containing 50 mL double-distilled water +0.05 mM calcium hydroxide and 0.03 mM ammonium dihydrogen phosphate. The sample immersed at pH of 6.7 was labelled as MWCP, with the one immersed in pH of 9 was MWCP9 and in pH 11 was MWCP11. The samples were then irradiated with a MARS-5 8 microwave reaction system at 2.45 GHz and 400 W. The maximal temperature was set at 200 °C with a heating rate of 10 °C/min and the temperature was kept at 200 °C for 1 min. In just 7 days, the cell viabilities in the proposed samples were substantially higher than that of anodised titanium treated with hydrothermal alone. The highest alkaline phosphatase activity was expressed on the surface of MWCP11 (highest Ca and P content) after 7 days and 14 days of cultured MG63 cells compared to the other groups. This experiment showed that the rapid microwaved nano-scale surface modification on micro-arc anodised titanium was advantageous in; (i) promoting early cell differentiation via its nanostructured anatase containing calcium and phosphorus on the surface; and (ii) producing heterogenic surfaces that adsorb more proteins by positively charged divalent ion-mediated or terminal OH radical-mediated mechanisms. Such functional surfaces have shown that the microwave process can be a useful method for altering both the nanoscale topography roughness and the micropore surface potential of the anodised surface, thereby improving the differentiation of the attached osteoprogenitor stem cell.

Another complex yet worth noting is Zang et al.'s hybrid post-treatment [246] which tested in vivo by Li et al. [245]. The novel Fe-doped hydroxyapatite nanotubes which showed magnetic characteristics on micro-arc oxidised titanium were successfully developed for drug loading application as shown in Figure 7. The micro-arc Ca-P-based anodised titanium (Figure 7(a)) was treated hydrothermally at 110 °C for 24 h to form the top layers of hydroxyapatite (HAp) nanotubes (Figure 7(b)), which were then electrochemically treated with 0.01 M NaCl-adjusted to pH 1.9 by 1.0 M HCl, resulting a local dissolution on basal planes of HAp nanorods that transformed to nanotubes (Figure 7(c)). This hybrid post treatment produced ferromagnetic HA/TiO2-matrix coatings in the form of tubular nanotubes on top of micropores. As the acidic electrochemical processing time lasted from 2 to 4 min, the premature nanotube would undergo corrosion from the outside to the base plane leading to collapse into nanoslices at 6 min. This magnetic HAp/TiO2-matrix coating surface is super hydrophilic with a high adhesion strength to the substrate and improved osteoblast response in terms of adhesion, proliferation, differentiation and extracellular matrix mineralisation in vitro [245, 246] and new bone formation in vivo [245].

Figure 7.

Magnetic HAp formed on top of micro-arc CaP-based anodised titanium (a), whereas its hydrothermal treated nanorods surface (b), transformed into magnetic nanotubes (c), using electrochemical post treatment (taken with permission from [245, 246]).

Anodised HAp nanotubes have demonstrated the ability to bind tightly to the Ti substrate, while being extremely hydrophilic and capable of improving the osteoblast response [246, 247, 248]. Previous studies have shown that nanorods TiO2 could be transformed into nanotubes via hydrothermal process [245, 246]. Generally, hexagonal nanorods have positively charged Ca-rich prism-faceted planes and negatively charged OH¯ and P-rich basal-faceted planes. Due to different charges of the crystallographic planes of nanorods, it is believed that selective dissolution on the basal planes of nanorods may form magnetic nanotubes on Ti substrate [245, 246, 249]. Based on studies performed by Peng et al. [250] and Park et al. [251], the recent study by Zhang et al. hypothesised that the Fe-doped HAp nanotubes can exhibit reasonable drug loading and release kinetic properties due to its magnetic nanotopography compared to HAp nanotubes or nanopores [246]. Li et al. [245] proves that micromagnetism provided by Fe-HAp nanotubes further enhances cell response, but up to this date their potential as drug-eluting reservoirs has never been investigated.

As for TNTs, Mansoorianfar et al. [50] have recently engineered tuneable TNTs using sonoelectrochemical process. The composition of the anodising solution is NH4F (0.3 M), water (2 vol%) in ethylene glycol. They performed anodisation for 2 h such that after 45 min, the substrates were treated with ultrasonication for 15 min. This step is critical to be taken before the next hour of AO, as it allows TNTs to form uniformly on the final coating. Then the final coating is again treated with light ultrasonic for 30 s in ethanol to remove the damaged nanotubes and clean the surface. The first hour of AO created a low-order nanotube on the surface, where all preformed nanotubes were removed by sonication at the next hour, and the fresh surface acts as a template to promote the construction of a clean, open-hole nanostructure.

The goal of this post procedure is to design scalable TNTs that can improve the ability of the structure to elude dopant drugs. Throughout this experiment, it was found that the drug release mechanism of the constructed tuneable TNTs demonstrated four synchronised drug eluding steps: (i) lower initial burst release, (ii) controlled semi-steady release, (iii) specific release, and (iv) sustained steady release [50]. Li et al. [49] addressed the stability of TNTs in detail based on comprehensive work done by others and clogging contaminants, lower crystallisation, uneven tube density, structural degradation, and inadequate sterilisation were identified as key challenges in in vivo and clinical implementation of TNTs [49].

For the Ca-P doped microporous anodised titanium, current trends suggest a design of hybrid morphology such as cortex-like [91, 92], petaling-like [40], or nanoflower-like [43] structures to enhance the bioactivity and biocompatibility of the formed micro-arc anodised titanium (MAT) coatings. However, the in vivo or clinical complexities of these structures have not yet been identified and their mechanical stability as implant materials is still unknown. Although most Ti-based implants have a MAT biomimetic surface, the concept is still constrained by technology or clinical studies to determine whether the mechanical stability of the proposed surface is adequate for implant coating [136, 252, 253].

5. Current challenges in using TiO2 anodic layer

The fundamental research on titanium implants has garnered many reviews, addressing the challenges to the proposed implant and its modified surfaces [3, 4, 254, 255, 257, 258]. As far as the biological response is concerned, recent findings state that the anodised titanium has an ability to reduce the risk of haemolysis [259, 260]. The anodised titanium, even in its amorphous phase [259] is capable of regulating the distance and contact osteogenesis of cells for bone healing [261]. As for its physical structure, the microporous surface of anodised titanium had the ability to retain red blood cells. The cells were observed to be attached to micropores and have the correct shape and form of acanthocytes, which were well distributed on the top of the anodised structure and within the micropores [259]. This observation shows that the anodised titanium has an effective topography for cell attachments, and consequently could provide synergetic effects to the bone reconstruction [261, 262].

Despite the promising biological response, concerns remain over its mechanical stability [240, 257, 263]. In a wide range of perspectives, several studies have alluded to the mechanical stability of anodised titanium as bone implant coatings. Thus, in addition to the existing literature [39, 257, 263, 264], this review covers the following relevant discussion gaps; (i) techniques to enhance mechanical stability and (ii) testing methods to measure the mechanical stability of anodised titanium, (iii) real-time/in-situ detection methods for the surface reactions, and (iv) cost-effectiveness for anodised titanium and safety for use as a bone implant coating.

Previous studies have intensively reviewed the mechanical stability of anodised titanium as a bone implant coating [240, 263, 264] particularly the manner in which the mechanical properties of an implant differ from its surface coating. Implants, as bulk or as porous as scaffolds were structurally subjected to aseptic loosening, fatigue structure, fracture toughness, fretting fatigue strength and stress shielding effects once in contact with the implanted environment [16, 240, 257, 265]. In the case of titanium, incorporation of aluminium-vanadium, nickel, and zirconium have been traditionally the most promising alloying elements to enhance the mechanical stability of Ti-implant [257]. The consensus is that the majority of the current Ti alloy surfaces have inadequate comparative studies of their mechanical surface properties along with tissue responses. Typically, surface properties are studied only when they bear relevance to surface treatment. Therefore, there should be a wider scope of testing in order to find out how alloying constituents affect the surface mechanical stability of Ti alloys side-by-side, which could influence the material's cellular response in vitro or in vivo.

Nitinol [266, 267] is an example of a Ti alloy with advanced functionality. These nickel titanium alloys (TiNi, NiTi, or Nitinol) exhibit distinct characteristics such as increased pseudoelasticity and memory effect (superelasticity) [266]. The Young's modulus of the NiTi porous alloy, in particular, ranges from 1.8 to 14.7 GPa. These values are closest to those of human bone (17.6–31.2 GPa), and they are also the lowest among other Ti alloys [268]. NiTi's mechanical properties may reduce implant stress shielding and, as a result, postoperative complications [269]. Wong et al. [270], on the other hand, discovered a potential risk to the safety application of NiTi in vivo that requires further investigation. A higher surface nickel concentration may disrupt the implant-bone osseointegration process [270].

An analogous to this alloying technique, the doping and/or infusing of different types of materials in a coating structure are common practises used to induce the mechanical stability of a coating. This process is known as surface functionalisation [74, 252, 253, 254, 255, 271] or modification [4, 6, 240, 263, 264, 272]. Often in the applications, the implant surface is functionalised to enhance mechanical properties and biocompatibility. In that sense, the major advantage of Ti-based implant is that it can easily form an in-situ highly adherent TiO2 film on the surface by only applying a simple anodisation treatment such as AO.

5.1. Techniques to enhance mechanical stability of anodic TiO2 layer

One of the most important properties of a coating that defines its mechanical stability is wear and corrosion resistance. The present trend in metallic biomaterial coatings is the formation of TiO2 nanoparticles as a surface structure to protect the implant from corrosion. For instance, to protect an easily degraded biocompatible implant from corrosion, a magnesium based implant has been coated with TiO2 particles [273, 274, 275].

A slightly different but in line with this current challenge is a recent study reported by Chitsaz-Khoyi et al. [95] on the development of titanium-carbon-nitride (TiC/N) coatings on NiTi surface using a hybrid PEO method with electrophoretic deposition (EPD) in single step AO. The study reported that the anodised Nitinol increased the surface hardness (H) and elastic modulus (E) to values that were almost double the amount of unmodified surface, which were from ca. E = 75 GPa and ca. H = 4 GPA to ca. E = 157 GPa and ca. H = 11 GPas, respectively. A lower porosity and dense structure of the anodised titanium can be achieved by suspending the hydroxyapatite (HAp) nanoparticles in their altered electrolyte [95], which significantly reduces the hardness of the coating (to ca. H = 9 GPa) and the elastic modulus (to ca. E = 131 GPa). Moreover, Chitsaz-Khoyi et al. found that their anodised titanium structurally acts as a barrier layer on NiTi surface and hinder the diffusion of corrosive ions into the surface and subsequently improves the corrosion resistance of NiTi [95]. Therefore, this study shows how easy it is to modify the AO cell and its parameters such as electrolyte formulations (aqueous Hap suspension) and the AO setup (hybrid with EPD) to significantly alter the hardness and elasticity of the coatings and of the materials corrosion resistivity as a whole.

Another study reported by Yang et al. [276] provided further interesting evidence that the alteration of the AO electrolyte has a significant effect on the mechanical stability of anodised titanium. According to this work, there are a multitude of possibilities for altering the PEO electrolytes used in previous studies [276], thereby improving the final mechanical stability of the anodised titanium. The presence of organic molecules to base electrolytes significantly affected the formation of the pore morphology and anti-abrasion films on Ti6Al4V [277, 278]. Silicate-based electrolytes are one of the more common electrolytes in AO used to produce anodised titanium incorporated with inorganic polymer functional groups [211, 276, 277, 278, 279]. The anti-abrasive and anticorrosive ability of the anodised titanium improved with addition of silanes to the mixture [276]. Recently, the oxidation of cp-Ti in sodium silicate (Na2SiO3) altered with aminopropyl trimethoxy silane (APS) electrolyte by Yang et al. showed an improvement in the mechanical stability of the anodised titanium and subsequently promoted the crystallisation of TiO2 while maintaining a smoother and thicker surface morphology of the film [276].

Yang et al. suggested that the improved resistance to corrosive media is attributed to the formation of a finer inner and outer layer of the anodised titanium, which was compact and thus resistant to corrosion [276]. The APS is confirmed to exist on the anodised surfaces and in between film defects due to the adsorption, self-condensation and/or chemical bonding of the oxidised Ti-O-Si group from the altered electrolytes, resulting in increased abrasive and corrosive resistance of the final anodised film [276]. Moreover, Yang et al. showed that the addition of APS to the silicate-based electrolyte is able to reduce the energy-intensive nature of traditional PEO, without compromising the desirable structures and performance of the final anodised titanium, while at the same time improving the mechanical stability of the coating [276].

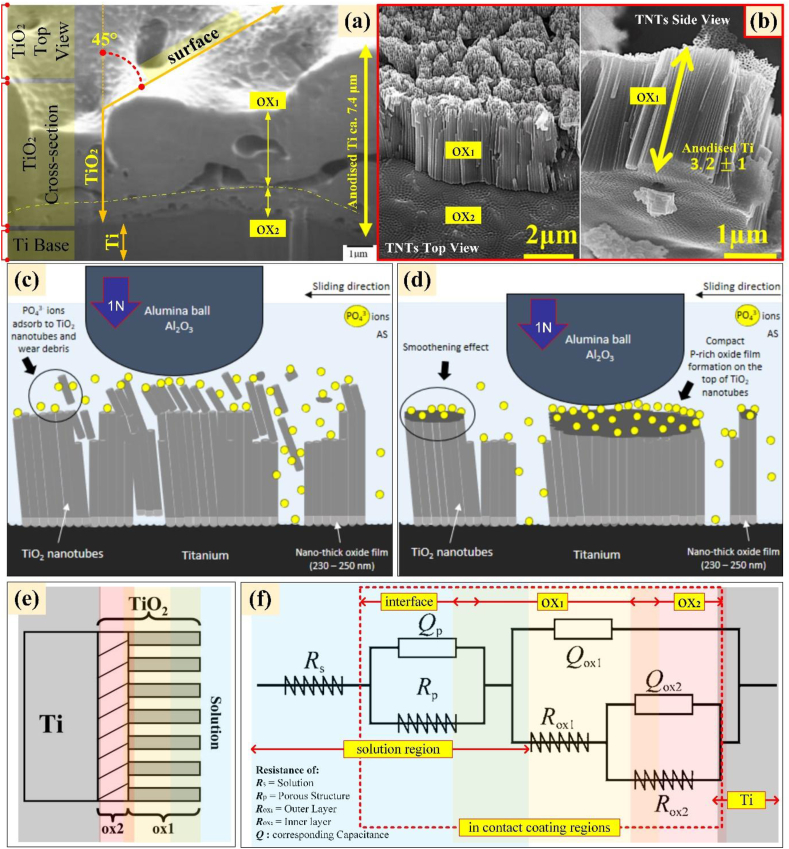

Figure 8(a) depicts a cross-section of the common microporous structure of anodised titanium. As can be seen throughout the coating layers, the in-situ deposited TiO2 protruded from the Ti substrate and causes the coalescence of small pores into large, discontinuous but interconnected and elongated ones, creating subsurface layers (Figure 8, ox1 and ox2) and pores from the base to the outer surface. The presence of subsurface porosity formation was due to the fact that the only segment in which pore formation can occur is when a consistent microstructure has been established [62]. These coalescing microstructures of anodised titanium make the coating strongly adherent to the oxidised structure in terms of layer-by-layer, which results in excellent corrosion resistance and wear protection against friction [189, 280, 281, 282, 283], subsequently reduced the fretting fatigue of the coated surface [39, 284]. There is no significant evidence to date that the microporous anodically deposited TiO2 (microstructured anodised titanium) on the titanium-based implant generates a modulus elasticity mismatch between its gradually constructed microporous structure from the base to the surface of the host substrate. At this stage, the structural assumption that the stress shielding effects between anodised titanium and Ti-based implants may not occur. Despite its brittleness, most of the literature on microstructured anodised titanium found that the coating is highly adherent to the substrate with excellent corrosion and wear protection capability [138, 141, 144, 189, 209, 280, 281, 282, 283].

Figure 8.

Cross-section of microstructured anodised titanium (a), and titanium nanotubes, TNTs (b), upon tribo-mechanical test (c), with increased mechanical stability (d), and these coating structures could schematically be represented in two-layer model (e), via electrochemical analysis (f) (reillustrated with permission from [50, 62, 286, 287]).

In terms of wear behaviour of anodised titanium in body fluids, Cheraghali et al. confirms that the anodised samples wear more and have a higher tribocorrosion rate than thermally oxidised titanium, but have the highest cell viability [285]. Their study found that the corrosion rate of the anodised samples was significantly lower than that of thermally oxidised titanium, which explains why the mechanical biocompatibility was lower. To overcome this specific issue, a duplex coating has been proposed [285] where before anodisation, the cp-Ti substrate was thermally oxidised. Cheraghali et al. reported that a low capacity for plastic deformation of the oxide phases formed on the surface prevented plastic deformation, and consequently no plastic deformation and no grooves were observed on the surfaces of thermally oxidised/anodised samples. The oxygen's diffusion from thermal oxidation caused a lowering of the active slip systems in titanium, which caused the ‘c to a’ ratio for hexagonal closed packed (HCP) of the anodised titanium substrate to increase by over 1.588 [285]. The cp-Ti has a lower tribocorrosion rate at different sliding distances of 16–76% when thermally oxidised [285]. Thus, it is possible that passivation of anodised TiO2 layers on thermally oxidised cp-Ti improved wear resistance of the anodised titanium.

On the contrary, it is well known that the nanotube formed by anodisation of titanium (TNTs) exhibit poor mechanical stability [49, 263, 288] owing to their tubular structures [48, 50, 289] as depicted in Figure 8(b). The granulation, structural degradation, uneven density, and contamination all impede the clinical implementation of TNTs [49, 290, 291]. The apparent presence of discontinuous layers between the metal base to oxide layer (ox1 to ox2) and the inhomogeneous lateral attachment between the nanotubes (ox1) are depicted in Figure 8(b) and these reveal the fragility of the TNTs. These structures relative could be easily detached from Ti-base [48] or suffer fracture between the tubes [292] when its subjected to external force during implantation [291] or by incorrect handling in transport, storage or use [242]. Structurally, these layers of TNTs suffer from weak delamination strength [48, 127]. Prior to the implantation procedures, the coating structure should be able to withstand the premature delamination that potentially yields wear debris on the surface. Debris or loose oxide from the coating could activate the immune system and osteoclasts, causing bone resorption and aseptic implant failure [7, 293, 294].

To resolve these issues of TNTs, Zhao et al. [295] attempted to increase the adhesion strength of the nanostructured anodic layer by using non-protonated polar substances, such as ether/cyclohexane for the AO base electrolyte. The anodising process was conducted in an ethylene glycol/NH4F system containing 3 vol% H2O, 0.5 vol% H3PO4 and 0.3 wt% NH4F as electrolyte. It was discovered in their study that the hydrogen-assisted cracking mechanism is the main pathway for oxide layer detachment from the substrate. The cohesion of the nanotubes layer (Figure 8(b): ox1) and the underlying metal (Figure 8(b): ox2) was controlled by the protonation at the metal to oxide interface. This proposed mechanism claims that high H2 solubility in solvents containing ethyl functional groups can eliminate the hydrogen-assisted cracking during AO, subsequently increasing the mechanical stability of TNTs.

In Ti alloys, Renjie et al. [294] proposed that the compaction/reduction of the α-phase and/or increase in the amount of the β-phase was the most important factor in promoting the mechanical biocompatibility of the surface. Recently, Chernozem et al. [296] reported the anodic deposition of TNTs on β-alloy Ti-xNb hybrid composites (x = 5, 25 or 50) and it was observed that there was a significant increase in β-phase elements in the alloy leading to an increase in the surface's elastic modulus after anodisation. The surface load-deformation behaviour of TNTs on Ti-50Nb was reduced by approximately 17% when compared to TNTs structure on Ti-Nb composites with lower wt% Nb and by approximately 23% when compared to cp-T [296]. Regarding Young's modulus, the value obtained for the β-alloy Ti-xNb hybrid composites coated with TNTs was approximately the same as that of bone (ca. 20–30 GPa [265, 292]), suggesting that the nanostructured anodic surface has a beneficial effect and could represent a possible solution to the mechanical mismatch between bone and implant materials [296]. Since anodically grown TNTs on the proposed hybrid composite have reduced length, Chernozem et al. confirmed that the pronounced double-wall nanostructural arrays are enhanced. The brittle nature of TNTs wall recovery was controlled by changing the substrate composition. Based on Chernozem et al. study, it can be concluded that the voltage applied during the controlled anodisation process and the alloying element content affect the total performance of the resulting anodised TNT layers. Owing to the different morphologies and crystal structures of the TNTs, the resulting mechanical properties varied. Other previous studies reached similar conclusions on the mechanical stability of TNTs [180, 292, 297, 298].

Regarding the surface of the implant, recent developments have included materials that imitate natural materials and are often cited as "biomimetic" [162, 299, 300, 301, 302] or "bioinspiring" [252, 253] interfaces. However, few details have been provided on the mechanical stability of these biomimetic structures. Future research needs to discuss their tribo-mechanical (dry/wet-contact performance [303, 304]) behaviour that complements the surface integrity of the engineered implants [22, 257, 305]. The bone crystal nanostructure, for instance, was an inspiration for the design of TNTs [4]. To mitigate the material plastic deformation owing to its amorphous structure, Bartmanski et al. [292] coated the nanoparticle of Hap and Cu on top of the TNT surface. The findings show that when TNT is altered to incorporate bioactive nanoparticles, this results in improved nanomechanical coating properties, which is significant as they decrease from 0.42 to only 0.007 H2/E3 ×103 GPa. In comparison to the uncoated TNTs or unmodified Ti surfaces, the procedure upgrades the nano-hardness (ca. 0.21 GPa) and Young's modulus (ca. 28.49 GPa) of the coated structure, having mechanical property at dry-contact close to human bone [265, 292]. Unfortunately, they did not perform any tests on wet-contact performances (fluid contacting/corrosion) to simulate design issues in body fluids, and these tests can not be generalised to design issues in body fluids or corrosion in fluids. To guarantee the mechanical integrity of the engineered surface, additional research is required on the mechanical stability of these promising materials.