Abstract

The study was performed on water spinach (Ipomea aquatica), a hidden gem with lots of nutritional attributes and medicinal properties. To check its feasibility as an ingredient in other food products and to know its nutritional attributes, powders were made by drying the leaves and stems of the plant using different drying techniques such as sun drying, freeze-drying, and tray drying. The physicochemical analysis of powder was done to get a comparative result, in which the freeze-dried powder showed the most significant result. The physicochemical analysis revealed that lyophilized water spinach powder has a good amount of carbohydrates (58.15%), ash (12.39%), protein (4.01%), and fat (4.46%) content. The powder also possessed a high antioxidant property of 77.25% and a total phenolic content of 32 µg/ ml. SEM and XRD results showed that the water spinach powder was amorphous in nature.

Keywords: Drying technique, Freeze drying, Total phenolic content, SEM, XRD

Introduction

Ipomoea aquatic Forsk, commonly called Water spinach, belongs to the family Convolvulaceae. It is a tender, trailing, or floating perennial plant that grows on moist soil along the margins of freshwater in ditches, marshes, and wet rice fields (Prasad et al. 2008).

It is a vascular aquatic and marshy plant native to tropics and subtropics that grow wild and sometimes cultivated in south-east Asia, India, and southern China (Gothberg et al. 2002). Although it grows as a weed in India and the USA, in south-east Asian countries like Malaysia, China. It is grown commercially and one of the popular green leafy vegetables (Prasad et al. 2008). All parts of the young plant are edible, but the shoot tips and younger leaves are comparatively used more. Stems take relatively more time than leaves to cook (Top and Ashcroft 2002). Ipomea aquatic has been seen to be a good source of plant fibers, vitamins. It has natural antioxidants and can be used as a food supplement or pharmaceutical and medical industries (Huang et al. 2005).

Drying is the most ancient method of preserving foods. Even today, hundreds of variants are being used to dry particulate solids, pastes, continuous sheets, slurries, or solutions; thus, drying provides the most diversity among food process engineering unit operations (Patil et al. 2014).

Drying means the “removal of water” and is considered the most common and economical preservation method for many fruits and vegetables in many countries. Despite there being so many drying methods, which are traditional and primitive, there is a constant need to apply advanced techniques in drying with the objectives of increasing productivity and obtaining closer control of the process to achieve a product quality (Patil et al. 2014).

There are three types of drying processes used to dry different kinds of food products. They are (a) Sun drying or solar drying, (b) Atmospheric drying (kiln, cabinet, tunnel, spray, microwave), and (c) Sub-Atmospheric drying (vacuum & freeze drying).

However, freeze-drying is the most advanced method as well as the best method used for the dehydration of the food (Srivastava and Kumar 2003).

Scanning electron microscopy (SEM) is a widely utilized electron beam instrument used for imaging surface topography. It can easily interpret and generate the nature of the micrograph for the characterization of food materials. Similarly, X-Ray diffraction methods (XRD) is a very useful and quick characterization tool that is used to identify and characterize the crystallinity, which is an important aspect to check the stability of the powder and also provide data to unit cell measurements that came about as finely ground, homogenized and average bulk composition. The basis for all the diffraction analysis is creating of X-ray in the X-ray tube. The aim of this study was to study the microstructure of water spinach powder produced by different drying methods (Alsebaeai et al. 2018).

Exploring the technologies in the processing of this underutilized & cheap vegetable “water spinach” may help to know its potential to make the value-added product and a low-cost food product that will help the malnourished population in providing them all type of nutrition for a better lifestyle.

Material and methods

Fresh leaves of Water spinach along with the whole vine was procured from the local market of Varanasi, India. The experiments were conducted out at Center of Food Science and Technology (Institute of Agricultural Sciences); Department of Physics (Institute of Science); Department of Microbiology (Institute of Medical Science); Banaras Hindu University, Varanasi (UP)India.

Processing of water spinach powder

The method of processing of water spinach powder is shown in Fig. 1a. Three drying techniques made three different samples. The control sample (C) was unblanched while the other three samples were blanched at 85◦C for 3 min after that, grounded as powder and named as blanched sundried sample (S), blanched tray dried sample (T), and blanched lyophilized sample (L).

Fig. 1.

a Flow diagram for development of water spinach powder

Physical analysis of water spinach powder

Surface color measurement was determined using the (L, a, b)* system by Color Flex, Hunter Lab. Bulk density was determined according to the protocol (Sahin et al. 2013). Where L* represents lightness, a*represents greenness, and b*represents yellowness.

Proximate analysis of water spinach powder

Proximate water spinach powder analysis, including moisture content, acidity, ash, crude fat, crude protein, and crude fiber, was analyzed (AOAC 2000). Carbohydrate content was determined using the difference method (FAO 2003).

Analysis of bioactive compounds in water spinach powder

Antioxidant activity of water spinach was evaluated by 2, 2 Diphenyl-1-picrylhydrazyl (DPPH) method according to Benzie and Strain (1996).

The total polyphenol content (TPC) of each water spinach dried sample was evaluated using the Folin-Ciocalteu phenol reagent by the method of Huang et al. (2005). Gallic acid was used to prepare a standard curve (5–60 μg /mL; y = 0.00128x + 0.3079; r2 = 0.989; y is the absorbance; x is the solution concentration).

Microscopy of water spinach powder

Microstructure analysis by scanning electron microscopy

The powdered samples' appearance and shape were observed by scanning electron microscope (Quanta 200 camera, Thermo Fisher Scientific, USA). In SEM analysis, the powdered sample was placed on aluminum stubs using a double-sided adhesive tape with an acceleration of 20 kV voltage (Alsebaeai et al. 2018).

X-ray diffraction

X-Ray Diffraction (XRD) characteristics of water spinach powder were examined by Empyrean multipurpose diffractometer (Malvern P analytical, UK). A small number of samples were pressed in an aluminum holder, and the diffractometer was operated with input energy of 40 mA and 45 kV. The diffract grams were taken between the angle of 10◦ and 79◦ (2θ) with a step angle of 0.013◦ for 6 min.

Results and discussion

As the leaves of water spinach wilts rapidly, drying techniques were used to make its powder and study its attributes and its feasibility to add it in other products to make a value-added product. The results show the lyophilized sample is more acceptable in most of the aspects. However, the results also showed various attributes of water spinach by which water spinach powder can be used to make value-added products and also be added in the regular diet as a green leafy vegetable.

Determination of the Physical & Chemical properties of the Water spinach powder

Physical analysis

Color

The effect of the drying method on the color of water spinach powder is presented in Table 1. The color was measured by spectrophotometer in which values of L*, a*, b* were determined. The values for L* ranges from 33.41 to 44.28, greenness indicated by a negative value for a* ranges from − 1.73 to − 2.83, while b* value ranges from 14.87 to 22.52. Shin et al. (2015) confronted similar results in case of sundried sample (L* = 45.68, a* = − 2.63, b* = 22.57). The green color was more retained in lyophilize dried powder as processing at low temperature and vacuum.

Table 1.

Effect of drying on the color, bulk density, pH, acidity, and proximateanalysis of all the powdered samples of water spinach

| Control (C) | Sample S | Sample T | Sample L | |

|---|---|---|---|---|

| L* | 44.28 ± 0.1 | 36.72 ± 0.1 | 37.67 ± 0.2 | 33.41 ± 0.2 |

| a* | − 2.27 ± 0.001 | − 0.19 ± 0.001 | − 1.73 ± 0.002 | − 2.83 ± 0.005 |

| b* | 22.526 ± 0.005 | 14.87 ± 0.025 | 16.27 ± 0.015 | 20.8 ± 0.01 |

| Bulk density | 0.378 ± 0.001 | 0.575 ± 0.005 | 0.576 ± 0.005 | 0.248 ± 0.001 |

| pH | 6.74 ± 0.01 | 6.92 ± 0.01 | 7.05 ± 0.01 | 7.05 ± 0.01 |

| Acidity | 0.0032 ± 0.0001 | 0.0059 ± 0.0001 | 0.0063 ± 0.0002 | 0.0068 ± 0.0001 |

| Constituents | Amount in % of the sample | |||

| Ash | 11.0 ± 0.03 | 11.7 ± 0.03 | 10.03 ± 0.03 | 9.98 ± 0.04 |

| Crude fibre | 12.9 ± 0.02 | 12.46 ± 0.01 | 12.77 ± 0.04 | 12.39 ± 0.01 |

| Protein | 3.98 ± 0.03 | 3.86 ± 0.03 | 3.89 ± 0.03 | 4.01 ± 0.02 |

| Fat | 4.05 ± 0.05 | 4.09 ± 0.04 | 4.65 ± 0.01 | 4.46 ± 0.01 |

| Carbohydrate (by difference) | 57.35 ± 0.05 | 57.77 ± 0.02 | 59.18 ± 0.03 | 58.15 ± 0.01 |

Bulk density

Untapped density is a significant parameter for the powder because it indicates the area covered by the powder, which is vital for the packing industry. Untapped density is expressed in grams per milliliter, and the results are presented in Table 1. The untapped density known as bulk density was found in the range from0.248 to 0.576 g/ml, of which the blanched tray dried (T) sample had the highest bulk density (0.576 g/ml).

pH and acidity

pH and acidity of the water spinach powder are presented in Table 1. The pH ranged from 6.74 to 7.50, while the acidity was to be found to be from 0.0032 to 0.0068. The lyophilized sample has a higher pH with low acidity. Shin et al. (2014) confront more or less similar results in the case of lyophilized (5.96) and sundried (5.57) water spinach powder. Powders being in the neutral pH range show the better shelf life and its use in value-added products as the proliferation and growth of microorganisms would be less.

Proximate analysis of water spinach powder

Moisture content, ash, protein, fat, and carbohydrate content of the powder made from different drying techniques is given in Table 1. The table clearly shows that there are no major significant differences among the entire four samples. More or less similar results for protein, fat, fiber, ash, and carbohydrate were reported by Umar et al. (2007) in oven-dried water spinach powder at 60 °C.

The Proximate analysis of the samples revealed a diversified result; however lyophilized sample seemed to be nutritionally richer than other samples. The higher carbohydrate content can make a significant contribution to dietary intake, especially in diets for malnourished. The high ash content can result in a good sign to find some nutritionally essential minerals.

Analysis of bioactive compound in water spinach powder

Antioxidant activity of water spinach powder

The inhibitor color of the free radical compound (DPPH) determined the antioxidant activity of the powder. The results range from 68 to 77.25% and are presented in Fig. 2a. According to the results, the powder obtained from the lyophilize drying has the highest inhibition activity. A similar trend of results for lyophilized (77.93%) and sundried water spinach sample (77.24%) has been reported by Shin et al. (2014).

Fig. 2.

a Antioxidant activity of water spinach powder. b Total phenolic content of water spinach powder

Total phenol content of water spinach powder

The total phenol content of the powder ranges from 21 to 50 (µg/ml) and is shown in Fig. 2b. The control sample has the highest phenolic content of 50(µg/ml). Phenols are a vital plant constituent. There is a definite connection between total phenols and antioxidant activity because phenolic compounds are active hydrogen donors, making them excellent antioxidants (Tyagi et al. 2020). Prasad et al. (2005) also found that water spinach powder is good source of phenolic content; therefore it is good source of natural antioxidants.

Study of characterization of water spinach powder

Morphological characterization of water spinach powder by SEM

The three-dimensional characteristics of the surfaces of powder particles obtained from water spinach by different drying were analyzed using SEM (Scanning Electron Microscopy).

The micrographics are shown in Fig. 3a, b, c, and d. According to the images, continuous, intact, amorphous and porous regions were destroyed during the shift from freeze to sun drying technique. Dried water spinach samples showed collapsed inter-cell connections and damaged tissue structures with the broken cell wall. The comparative study between all four samples shows that the morphology of the control sample, lyophilized, sundried, and tray dried sample, is almost similar. The amorphous nature of the powder significantly increases its solubility with the solvents, thus making it more bioavailable.

Fig. 3.

a Scanning electron microscope of control sample. b Scanning electron microscope of sundried sample. c Scanning electron microscope of Tray dried sample. d Scanning electron microscope of lyophilized sample

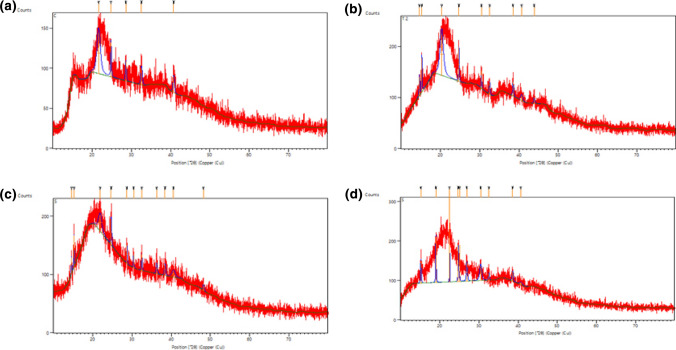

X-Ray diffraction analysis of the water spinach powder

The crystalline or amorphous nature of the powder can be determined by X-ray diffraction analysis. The results are shown in Fig. 4a, b, c, and d. X-ray spectra were recorded with 2θ angles over the scanning range of 10◦ to 79◦. The diffused curve shows that the sample is amorphous in nature as the molecules are disorderly placed, producing dispersed bands. The parameter of main diffraction peaks from water spinach powder is given in Table 2. It was observed the curve for all four samples were almost similar.

Fig. 4.

a XRD of the water spinach powder (Control sample). b XRD of the water spinach powder (Sample S). c XRD of the water spinach power (Sample T). d XRD of the water spinach power (Sample L)

Table 2.

XRD parameter of water spinach powder

| Sample | Position(°2θ) | Height (cts) | FWHM left (°2θ) | d-spacing (ang) | Rel.int.I (a.u) |

|---|---|---|---|---|---|

| C | 21.6819 | 51.35 | 1.0234 | 4.0989 | 100 |

| S | 15.2478 | 54.86 | 0.1023 | 5.8109 | 100 |

| T | 20.3320 | 82.22 | 1.0234 | 4.3679 | 100 |

| L | 22.4973 | 216.53 | 0.0384 | 3.9522 | 100 |

Conclusion

This study has explored more research possibilities for this “hidden gem” green leafy vegetable. Results of this study showed drying treatments to be effective in preserving water spinach for future and more extensive use. Comparatively, freeze-dried samples showed better nutritional content and color retention. The plant water spinach grows more or is cultivated generally in unsuitable areas for crop production because of the presence of pollutants and heavy metal content. The study can be used to give a proper reputation and cultivation practices to this vegetable despite calling it only weed or noxious. The low and affordable price of this vegetable will provide the low-income group and malnourished people with the option of nutritionally rich food. It is expected that the results of this study might be useful to promote the commercial application of dried water spinach as a raw ingredient/additive while developing novel value-added food products.

Acknowledgements

The work described has not been published before, it is not under consideration for publication elsewhere, its submission to JFST publication has been approved by all authors as well as the responsible authorities—tacitly or explicitly—at the institute where the work has been carried out, if accepted, it will not be published elsewhere in the same form, in English or in any other language, including electronically without the written consent of the copyright holder, and JFST will not be held legally responsible should there be any claims for compensation or dispute on authorship. The author is grateful to Department of Physics, Banaras Hindu University, Varanasi for providing the SEM and XRD facilities required for the study.

Abbreviations

- C

Control sample

- S

Blanched sundried sample

- T

Blanched tray dried sample

- L

Blanched lyophilized sample

- DPPH

2, 2-Diphenyl-1-picrylhydrazyl

- SEM

Scanning electron microscope

- XRD

X-ray diffraction

Authors contributions

This work was designed by PJ, AK, AKC, MS; the experiments were carried out by PJ and AK under the supervision of AKC and MS. All authors contributed to the results and discussion. The first draft of the manuscript was prepared by PJ and AK, and all authors contributed to the final version. All authors have read and agreed to the published version of the manuscript.

Funding

Not Applicable.

Data availability

The authors confirm that the data supporting the findings of this study are available within the article.

Declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human or animal subjects.

Consent to participate

Not Applicable.

Consent for publication

All authors agree to publish.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Pallawi Joshi, Email: pallawijoshi1916@gmail.com.

Aparna Kumari, Email: arpita1.1997@gmail.com.

Anil Kumar Chauhan, Email: anilchauhancfst@gmail.com.

Meenakshi Singh, Email: drmeenakshisingh15@gmail.com.

References

- AOAC . Official methods of analysis of the association of official analytical chemists. seventeenth. Gaithersburg, MD: Association of Official Analytical Chemists; 2000. [Google Scholar]

- Alsebaeai M, Chauhan AK, Arvind YP. Microscopic characterizations of green chilli powder. Int J CurrMicrobiolAppSci. 2018;7:2488–2497. [Google Scholar]

- Benzie IF, Strain JJ. The ferric reducing ability of plasma (FRAP) as a measure of “antioxidant power”: the FRAP assay. Anal Biochem. 1996;239(1):70–76. doi: 10.1006/abio.1996.0292. [DOI] [PubMed] [Google Scholar]

- FAO (2003) Food energy- methods of analysis and conversion factors. FAO Food and Paper Nutrition Paper 77

- Gothberg A, Gerger M, Bengstan B. Accumulation of Heavy metal in water spinach (Ipomea aquatica) cultivated in the Bangkok region, Thailand. Environ Toxicol Chem. 2002;21:1934–1939. [PubMed] [Google Scholar]

- Huang DJ, Chen HJ, Lin CD, Lin YH. Antioxidant and antiproliferative activities of water spinach (Ipomoea aquatica Forsk) constituents. Bot Bull Acad Sin. 2005;46:99–106. [Google Scholar]

- Patil V, Chauhan AK, Singh RP. Optimization of the spray-drying process for developing guava powder using response surface methodology. Powder Technol. 2014;253:230–236. [Google Scholar]

- Prasad KN, Divakar S, Shivamurthy GR, Aradhya SM. Isolation of a free radical-scavenging antioxidant from water spinach (Ipomoea aquatic Forsk) J Sci Food Agric. 2005;85:1461–1468. [Google Scholar]

- Prasad KN, Shivamurthy GR, Aradhya SM. Ipomoea aquatica, an underutilized green leafy vegetable: a review. Int J Bot. 2008;4:123–129. [Google Scholar]

- Şahin-Nadeem H, Dinçer C, Torun M, Topuz A, Özdemir F. Influence of inlet air temperature and carrier material on the production of instant soluble sage (Salvia fruticosa Miller) by spray drying. LWT. 2013;52:31–38. [Google Scholar]

- Shin LE, Zzaman W, Kuang YT, Bhat R. Influence of dehydration techniques on physicochemical, antioxidant and microbial qualities of I pomoea aquatica F orsk.: an underutilized green leafy vegetable. J Food Process Preserv. 2015;39(6):1118–1124. [Google Scholar]

- Srivastava RP and Kumar S (2003) Fruits and vegetable preservation–principles and practices. International Book Distributing Co., India. Pages 360

- Top M, Ashcroft B. Water Spinach (KangKong) Melbourne, Victoria: Department of Environment and Primary Industries; 2002. [Google Scholar]

- Tyagi P, Chauhan AK, Aparna, Optimization and characterization of functional cookies with addition of Tinospora cordifolia as a source of bioactive phenolic antioxidants. LWT Food SciTechnol. 2020;130:109639. [Google Scholar]

- Umar KJ, Hassan LG, Dangoggo SM, Ladan MJ. Nutritional composition of water spinach (Ipomoea aquaticaForsk.) leaves. J ApplSci. 2007;7(6):803–809. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

The authors confirm that the data supporting the findings of this study are available within the article.