Abstract

Chapatti is a flattened circular flatbread also known as roti, poli, safari, and phulka, usually baked on a hot iron griddle. It is a staple diet of India and hence the quality of chapatti plays a major role in its acceptance. The overall quality of chapatti is dependent on various attributes such as pliability, handfeel, chapatti eating quality, and taste. These attributes are influenced by numerous factors, including wheat genotypes, wheat varieties, the molecular weight distribution of proteins, and processing techniques. This staple food has been extensively studied for various aspects, including processing, mechanism, fractionation, and reconstitution, quality improver, shelf life extension and also the mechanization of processing. This review focus on all the above-mentioned aspects and innovations carried out in this area.

Keywords: Chapatti, Baking, Heat transfer, Hydrocolloids, Enzymes

Introduction

Chapatti is an integral part of the diet of India since the ancient ages. It is also known as roti, poli, safari, phulka. It prepared with whole wheat flour, which develops into a dough by addition of water. This dough is then divided and rolled into a circular flat shape and baked on a hot iron griddle (Ghodke et al. 2009). Some modified versions of chapatti include thepla prepared with incorporation of spices and vegetables, paratha prepared with the application of ghee and oil. Puri is modified version wherein baking is replaced by frying.

The quality of chapatti has been influenced by various factors, including wheat genotypes, wheat varieties, molecular weight distribution of proteins, processing techniques, and many other things. In India, numerous varieties of wheat are available and it is difficult to generalize about their applications in suitable products. Hence, there is a need for the development of wheat varieties based on product requirements (Kundu et al. 2017).

In the majority of the portion of India, conventional methods are widely used in the preparation of chapatti. The chapattis thus prepared have a lower shelf life, and the main challenge associated with the shelf life of chapatti is staling. The retrogradation tendency of amylopectin is due to the presence of starches. Chapatti soon loses its texture and becomes unacceptable to the consumers (Hemalatha et al. 2014). Antistaling techniques like hydrocolloids, emulsifiers, and enzymes utilized to overcome the problem (Hemalatha et al. 2014).

Many authors have also reported improvements in the quality of chapatti with the addition of different flours (Gujral et al. 2013), fibers (Mehfooz et al. 2018), hydrocolloids (Ghodke 2009), modified hydrocolloids (Giri et al. 2017), enzymes (Hemalatha et al. 2014). Along with the advancements in the technologies, the treatments are getting modified and introduced newer techniques. Hence, these review focus on recent innovations that have been carried in traditional staple food of India.

Chapatti characteristics and recent developments

Wheat genotypes

It shows that with varying wheat genotypes, the bread-making properties and the properties of final products produced thereof are also changing. In a study conducted by Survase et al. (2017), nine wheat cultivars compared for their chapatti as well as bread- making properties and the final product characteristics. They have reported a high positive correlation for the resistance to extension of a chapatti strip compared to overall quality, pliability, handfeel, chapatti eating quality, and taste. They didn’t find any correlation between the high‐molecular‐weight glutenin subunit protein composition and the overall chapatti score. Also, chapatti characteristics negatively correlated with that of bread. Survase et al. (2017) have mentioned complications on the breeding of new wheat varieties and the germplasm exchange between various wheat producers cultivating wheat for chapatti and bread due to their different requirements for preparation.

Kundu et al. (2017) assessed fifty wheat varieties for their chapatti making characteristics based on various properties, including those of grains, dough, and pasting profiles. The author collected 50 wheat varieties like HS-240, VL-832, HD2687, WH-147, PBW-343, PDW-233(d), VL-804, WH-542, HS-365, WH-896(d), UP-2338, PBW-502, HW-741, HW-2044, HW-1085, NP-200(di), Shresth (HD 2687), and Aditya (HD 2781) from the different region of India, in which only 46% of varieties are good in chapatti preparation based on quality assessment (Kundu et al. 2017). The majority of the wheat cultivars studied were medium-hard to hard. There were two categories of characteristics; where one type having a positive impact on chapatti quality like water absorption, and damaged starch. The other group was posing a negative impact on chapatti quality, including protein content, SDS sedimentation volume, dough stability, and gluten content. They characterized these wheat cultivars into four classes such as good, acceptable, fair, and poor for their chapatti making characteristics.

Further, Kundu et al. (2017) have suggested the necessity for a generation of authenticated development of product-specific varieties of wheat. The range of characteristics of a variety of Indian wheat for its quality related to chapatti summarized in Table 1. Kundu et al. (2019) prepared whole wheat flours by using 20 diverse wheat cultivars and shows the highest diversity varied from 38 to 81 based on overall acceptability. That helps to understand the acceptability and quality traits of chapatti. The author observed that chapatti color was negatively impacted by protein, ash, damaged starch, and copper content, with showing significant improvement in pliability. These help to characterize wheat varieties as poor, satisfactory, and suitable for chapatti preparation.

Table 1.

Characteristics of variety of Indian wheat.

Source: Kundu et al. 2017

| Whole wheat flour characteristics | Range | Mineral (mg/100) | Range | Grain characteristics | Range | Rheological characteristics | Range | Pasting characteristics | Range |

|---|---|---|---|---|---|---|---|---|---|

| Flour moisture (%) | 5.85–12.84 | Iron (Fe) | 1.62–7.87 | Grain moisture (%) | 6.84–15.30 | Water absorption (%) | 58.8–79.0 | Peak viscosity (cP) | 1,319–3356 |

| Total ash (%) | 1.08–1.99 | Copper (Cu) | 0.15–0.64 | Hectolitre weight (kg/hL) | 70.50–89.78 | Arrival time (min.) | 1.1–8.0 | Trough (cP) | 426–1867 |

| Fat (%) | 1.16–3.17 | Zinc (Zn) | 1.88–7.74 | Length (mm) | 6.25–7.94 | Departure time (min.) | 3–20 | Breakdown (cP) | 335–1511 |

| Damaged starch (%) | 9.20–16.89 | Manganese (Mn) | 1.29–3.14 | Thousand kernel weight (g) | 27.01–50.25 | Stability (min.) | 1.2–15.2 | ||

| Protein (%) | 9.52–15.14 | Magnesium (Mg) | 50.9–464.8 | Hardness (N) | 40.72–91.56 | Softening (FU) | 9–100 | ||

| Wet gluten (%) | 14.49–43.70 | Grain diameter (mm) | 2.62–3.38 | ||||||

| Dry gluten (%) | 5.12–12.82 | Phenol (scale of colour) | 4–10 | ||||||

| Gluten index (%) | 33.28–99.52 | ||||||||

| SDS sedimentation value (mL) | 28.00–61.50 | ||||||||

| Falling number (s) | 243–765 |

Kumar et al. (2018a, b) also assessed different wheat cultivars for their impact on chapatti preparation quality. They evaluated 40 genotypes, including tall wheat varieties and commercial varieties like C273, C 306, WG 357, PBW varieties, DI 105, DI 9, WH 423, WH 595, WH 712, KO 123, HD 2793, etc. for their quality attributes. Amongst all the studied variety, they found C 306 has the highest chapatti score above all. They mentioned traditional tall varieties of wheat still possess outstanding wheat grain in terms of quality attributes over other commercially grown varieties, and the conventional C 306 has qualities that can’t be surpassed by other varieties of wheat. Bansal et al. (2000) have also stated C 306 to be the best chapatti wheat.

Molecular weight distribution of wheat gluten proteins

Wheat gluten proteins are usually mentioned as prolamins since they characterized by the presence of residues of proline and glutamine. These prolamins have subtypes, namely gliadin and glutenin (Francin Allami et al. 2011), which are the main functional protein fractions. Further, glutenin fragmented into high molecular weight glutenin subunits (HMW-GS with molecular weight 90–140 kDa) and low molecular weight glutenin subunits (LMW-GS with molecular weight 30–75 kDa) (Anjum et al. 2007). These HMW-GS are known for their ability to impart elasticity to the dough as well as a final product. LMW-GS fragmented into B, C, and D types depending on varying isoelectric point. Gliadin fractions (molecular weight 30,000–75,000 Da) are responsible for imparting viscosity to the dough via non-covalent binding. Further, it divided into γ, β, γ and ω subfractions (Zilic et al. 2011).

In a study conducted by Chaudhary et al. (2016), it was observed that, flour physicochemical, dough rheological and chapatti quality characteristics are influenced by the gluten proteins and the pattern of their molecular weight distribution in Indian commercial wheat varieties. They classified these proteins into five categories viz; glutenins, gliadins, low molecular weight gliadins, albumins, and globulins. Their distribution was found to be in a significant correlation between the properties of the flour, dough and chapatti.

Hemicellulose A

Hemicelluloses are cell wall polysaccharides. These show a capacity of binding with the cellulose microfibrils strongly with the help of hydrogen bonds. Revanappa and Salimath (2010) have reported a significant correlation between the structure of these hemicelluloses and the chapatti making the quality of wheat varieties. They described these hemicellulose A as xylans in nature, having few portions of arabinoxylan polysaccharides. They mentioned the presence of monosubstituted and di-substituted xylosyl residues. They further referred the association of these hemicelluloses with ferulic acid, uronic acid and other polysaccharides to be responsible for the variation in the physicochemical properties of the flour as well as the dough and chapatti making quality (Revanappa and Salimath 2010). In another study conducted by Revanappa et al. (2010), structural variations in pentosans have proposed to be the factor affecting the wheat chapatti making qualities.

High molecular weight glutenin subunits (HMW-GS)

High molecular weight glutenin subunits are known to be a contributing factor to the chapatti making the quality of wheat types. Glutenins impart extensibility to the dough. Sreeramulu et al. (2004) have remarked the presence of HMW-GS ‘20′ at Glu B1 locus as the main factor responsible for the betterment of the chapatti making qualities of various wheat cultivars. This HMW-GS ‘20′ is associated with the high-water absorption capacity of wheat flours and hence is having a high potential to impart chapatti better textural and organoleptic properties (Misra., 2000). It is mainly associated with the wheat varieties yielding best chapattis such as Lok 1 and PBX 175 and other traditional tall wheat varieties and derivatives thereof. Kumar et al. (2018a, b) suggested that not only this presence but also the frequency of occurrence of these subunits have an impact on the chapatti yielding quality of wheat cultivars. However, a complex inheritance of this trait can be observed in the recombinant wheat populations.

Fractionated and reconstituted wheat flour

Fractionation and reconstitution studies help to determine the impact of each flour constituent on the quality of the chapatti. It involves a set of experiments like lipid extraction followed by isolation of proteins and starches without loss of functional properties. Further, the reconstitution of these fractions carried out at desired levels.

Arya et al. (2016), utilized these fractionation and reconstitution techniques to examine the effects of flour fractions in dough rheological parameters and chapatti baking performance of Indian wheat varieties. They reported a loss in the spreadability of the reconstituted dough as compared to the primary dough. Gluten protein was the altering factor for this decrease in spreadability, which brought about an increase in the dough resistance in the reconstituted dough. While these, reconstituted flour chapattis were poor in terms of baking, addition of extra gluten during reconstitution resulted in good quality chapatti (Arya et al. 2016). They further mentioned that portion if gluten during reconstitution has a dominating effect over the chapatti quality.

Tao et al. (2016) carried out fractionation of wheat flour dough, which was subjected to multiple numbers of freeze/thaw cycles and fractionated into non-gluten proteins and starch. Variation in the rheological parameters of reconstituted dough was observed. They reported altered pasting behavior of reconstituted dough along with an increase in storage and loss modulus. They attributed this increase to the multiple’s freeze/thaw cycles, which enhanced the water absorption capacity of the reconstituted dough.

Incorporation of enzymes

Incorporation of enzymes during chapatti making has an impact on the quality of chapatti. Hemalatha et al. (2010) have studied the effect of enzymes over the chapatti quality. They treated dough for enzymatic activity using various enzymes including fungal α-amylase, bacterial α-amylase, xylanase and combination of bacterial α-amylase and xylanase. They found that the shear force in case of chapattis those were treated with any of these enzymes was lowered substantial as compared to the non-treated chapattis. Further, dough treated with amylase has altered soluble starch and soluble amylose content. Treatment with bacterial α-amylase also increased the soluble amylose content in chapattis. They also reported a significant decrease in the peak viscosity of the dough samples when treated with bacterial α-amylase, combinations of bacterial α-amylase, and xylanse. They further mentioned the residual enzyme activity to be responsible for this decrease. The treatment with these enzymes also elicited some modifications in the microstructure of chapattis. The combination of enzymes (bacterial a-amylase; 10.49 U and xylanase; 25.12 U) treated chapattis exhibited more uniform with distorted starch granules surrounded by protein matrix where non-treated chapattis have aggregated and overlapping. Enzyme treated chapattis were softer, more pliable, and better acceptability.

Incorporation of different flours

The substitution of wheat flour with one or more flour has gained much attention in the last decade. Various flours are being incorporated into wheat flour to serve many purposes, including enhancement of nutritional composition as well as physicochemical properties, inhibition of staling, shelf life, etc.

Gujral et al. (2013) substituted wheat flour to some levels with defatted, hydrothermally cooked, kilned oats flour and observed the alterations in chapatti making behavior and bioactive constituents. They reported an increase in the total phenolic content of chapattis but a reduction in the antioxidant activity and flavonoid content of the chapattis. The addition of oats flour brought about an increase in reducing power as well as metal chelating activity of the chapattis. They further mentioned a rise in non-enzymatic browning index of chapattis.

In another study, germinated brown rice has used for the substitution of whole wheat flour during chapatti preparation at 10% level (Gujral et al. 2012). An increase in total phenolic content, total flavonoid content, metal chelating activity, and antioxidant activity was reported with this substitution by germinated brown rice. Germination has previously reported enhancing characteristics of seeds owing to biochemical changes occurring during the process of germination (Hsu et al. 1980).

Defatted rice bran has also been substituted in place of wheat (Yadav et al. 2012) and found to improvise mechanical as well as the nutritional quality of chapattis. A decrease in dough extensibility observed with the addition of defatted rice bran. They also mentioned the varying effect of defatted rice bran addition with variation in their particle size on the chapatti characteristics.

Utilization of barley husk has also carried out to substitute wheat flour in the preparation of chapatti (Mehfooz et al. 2018). A reduction in the gluten index observed with this addition giving rise to a weakened gluten network as well as increased mixing tolerance index. They reported a significant positive correlation between a portion of barley husk and mixing tolerance index. Dough extensibility impacted by the addition in barley husk with reduction of elasticity and harder texture, which ultimately affects chapattis quality. However, the addition of barley husk didn’t affect the difference between viscoelastic moduli viz; storage modulus was higher than loss modulus in both the cases. The addition of barley husk (5–30%) was unable to achieve any significant difference from wheat flour chapattis due to the dilution of gluten. Both the chapattis were equally acceptable by the panelists.

In a recent study carried out by Gujral et al. (2018), refined wheat flour blended with hull-less barley bran. Nine different cultivars of barley used for the purpose and their effect on the functional characteristics were studied. This addition of hull-less barley bran brought out many beneficial changes in the dough and chapatti characteristics viz, increase in dough water absorption, increase consistency, and decrease in starch retrogradation tendency. The resultant blend of flours had more amount of beta-glucan accompanied by higher portions of total phenolics as well as flavonoids. They also mentioned more slow digestibility and resistant starch content in the chapattis prepared from blended flour. Due to the presence of more soluble starch and amylose, chapattis made from these blends also had lowered starch retrogradation. Significant correlations of these components were obtained with starch retrogradation viz; positive correlation with decrease in soluble starch and soluble amylose, negative correlation with total beta-glucan.

Banerji et al. (2018) described amaranth incorporation in wheat flour to improvise chapatti characteristics for rolling properties as well as nutrition. They recommended the inclusion of 40% amaranth to get chapattis with acceptable textural and sensory attributes. They observed a decrease in percent water absorption (84.80–77.55%) and dough stability (1.6–0.6 min) with the addition of 50% amaranth flour. Addition of amaranth flour also led to an increase in dough stickiness and overall improvements in softness, rollability and dough spreadability. Chapattis thus prepared were sounder for iron, calcium, magnesium, fats, proteins, and lysine as well as in vitro protein digestibility.

A blend of wheat: finger millet (3:1) was studied by Sharma et al. (2017) for its chapatti making characteristics. They portrayed a higher percentage of total phenolic content (30.7%), flavonoid content (38.2%), and antioxidant activity (75.4%) in this blend than wheat flour. Also, chapattis prepared from this blend showed lower tendency of retrogradation and higher portions of soluble starch and soluble amylose. Sharma et al. (2017) revealed the correlations amongst these properties like positive correlation between slowly digestible starch and total phenolic content, positive correlation between water absorption, and damaged starch content. They further stated amaranth to be a potential ingredient to be incorporated in chapattis with functional characteristics.

Pulse flour

Pulses are always portrayed as a good source of proteins, minerals, and fibers. Various authors have studied the addition of pulse flour during chapatti preparation, and its effect on nutritional as well as quality parameters of chapatti (Kadam et al. 2012; Cheng and Bhat 2015) Wani et al. (2016) prepared chapatti from wheat-pulse composite flours. They utilized 5 to 20% kidney bean and black gram flour to replace wheat flour in the preparation of composite flour. An increase in water absorption for dough making observed due to varying composition of these pulses. However, sensory acceptability scores for this composite flour chapatti reduced due to the typical beany flavor profile of these pulses. They also observed retention of the freshness of the chapatti prepared from this composite flour. The mechanism behind this retention was suggested as the considerable gelatinization of the starch in the system with lowered setback viscosity bringing out the proper baking process of chapatti (Wani et al. 2016).

Banana peel powder

In a recent study conducted by Kurhade et al. (2016), banana peel powder (5–20%) has utilized to substitute a portion of wheat flour. They reported improvements in the kneading and rollability characteristics of chapatti. Also, an increase in dough stickiness and strength observed with an increased proportion of banana peel powder. Total phenolic content and flavonoid content, along with antioxidant properties, were also enhanced with the addition. Chapattis thus prepared were softer in texture and had better pliability. They further added the reason behind this enhancement to be the starch granules arrangement present in chapattis made with banana peel powder, which was uniform, unlike the whole wheat chapatti (Kurhade et al. 2016).

Hydrocolloids

The addition of hydrocolloids during dough preparation is a common practice. Various authors have reported about the addition of hydrocolloids to impart chapatti better texture as well as reduce the extent of staling. Ghodke et al. (2009) incorporated several hydrocolloids (guar gum, carboxymethyl cellulose, carrageenan and hydroxypropyl methylcellulose) and examined their effect on chapatti quality during storage. They reported a decrease in tear force values of chapatti due to hydrocolloids. Also, the extensibility decreased during the storage of chapattis owing to this addition of hydrocolloids. Other characteristics of chapattis also altered, including moisture, water-soluble starch, in vitro starch digestibility with an increase in their values with respect to increasing proportions of hydrocolloids. They found no effect on the color of chapattis. Amongst all the hydrocolloids employed, guar gum found to be having an excellent impact compared to others due to its highest water absorption capacity, as explained by them.

Khan et al. (2011) also added carboxymethyl cellulose along with other additives during chapatti preparation. They studied their effect on the quality of dough and chapatti and even on the staling parameters of chapatti. They reported improvements in the pasting properties, water absorption properties, dough development time as well as stability of chapatti and dough due to the addition of carboxymethyl cellulose. They also mentioned about the augmented sensory characteristics as well as the reduced extent of mould growth onto chapattis.

Enzymatically modified guar gum

A recent study (Giri et al. 2017) utilizes enzymatically modified guar gum incorporated into a chapatti. Modification carried out using an enzyme, mannase in the concentration of 40 µl mannase/g guar gum at pH 5 and 50 °C for 48 h. It was found that the stickiness of the chapatti dough made with added modified guar gum was lower as compared to chapattis prepared with added guar gum. The main objective behind the modification was to lower the glycemic index of chapatti. The 5% of modified guar gum in chapatti preparation acceptable based on sensory and texture characteristics in which it reduces dough stickiness. The incorporation of these modified gum decreases tear force with increasing extensibility, which results in softer chapatti (Giri et al. 2017). Hydrocolloids have reported possessing the ability to reduce glycemic index (GI) of the food product (Cavallero et al. 2002), and such modification enables a reduction in their chain length as well as molecular weight which results in reduced viscosity. It enabled augmented levels of guar gum to be incorporated in the product and hence resulted in reduced GI of chapattis (Giri et al. 2017).

Fiber mixture

The trend of health-oriented products has led to many developments in bakery products, including sugar-free, low calorie, and high fiber products in the market. Chapatti also is not an exception. Since chapatti is a staple diet of India, it has considered a perfect vehicle for fortification practices. In a study conducted by Arya and Sonawane (2016), fibers from natural sources (wheat, soy) and type III resistant starch incorporated into wheat flour dough during the preparation of chapatti. It found that these incorporations lowered dough stickiness, whereas dough strength improved. They further optimized the levels of wheat fiber (2.5%), soy fiber (5.0%), and type III resistant starch (2.5%) to yield chapattis with highest acceptability as well as having softest texture and high extensibility (Arya and Sonawane 2016).

Milling conditions

Not only the composition and additives but milling conditions also affect the dough and chapatti quality. Ghodke et al. (2009) studied the effect of milling conditions on the properties of wheat flour dough as well as chapattis. The impact of these conditions on damaged starch has also studied. They have reported the significant effect of aperture, moisture and feed rate on the damaged starch content of wheat flour varied from 6.1 to 26.9%. Williams and Fegol (1969) have elucidated alignment of the rolls, and any alterations in the feed rate to the milling machine lead to alterations in the level of the starch damage. Milling causes mechanical damage to granules of starch and hence increases damaged starch content (Hoseney 1994). They also observed a decrease in the aperture to be responsible for increased dough stickiness, increased softness of chapatti (Ghodke et al. 2009). Ghodke et al. (2009) described an improvement in the quality of chapatti with damaged starch content.

The quality of ready to bake frozen chapatti

Frozen chapattis come under the category of convenience food since it minimizes the labor required for dough and chapatti preparation. Repetitive freeze–thaw cycles pose damage to the structure of proteins and hence inferior quality chapattis produced thereof. These losses can be reduced by the incorporation of certain additives like locust bean gum, guar gum, gum Arabic (Scwharzlaff et al. 1996). Consumer acceptance for ready to bake frozen chapatti is the primary criteria established by Yadav et al. (2009) based on sensory and textural characteristics of chapatti. These chapattis get affected with quality where it shows higher hardness, chewiness, cohesiveness, and springiness due to increase in the maximum load of resistance during frozen storage as compared to normal chapatti (Yadav et al. 2009). In a study conducted by Yadav et al. (2008a, b), the effect of glycerol monostearate and glycerol, along with repetitive freeze–thaw cycles on chapatti quality was studied. They found glycerol to retain the properties of the dough, working as a cryoprotectant. They further mentioned, glycerol absorbs free water, which leads to the condition wherein no water is available for the recrystallization and hence less damage to the protein structures. Also, retention of rheological quality of chapatti was also observed due to the addition of glycerol owing to the same reason. Ahmed et al. (2013) employed hydrocolloids like hydroxyl propyl methylcellulose (HPMC), carboxy methylcellulose (CMC) and guar gum to extend shelf life with improvement in quality of frozen and baked chapatti. The HPMC and CMC of 0.5% show that increase in dough stability, and dough development time in baked and fully baked chapattis (Ahmed et al. 2013) with enhancement in water absorption capacity due to a high number of hydroxyl groups which helps in holding of water, due to hydrogen bonding.

Heat transfer during baking

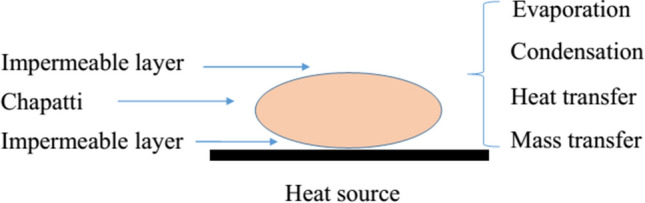

Apart from wheat genotype selection, dough making, the principal process during chapatti preparation is baking, which gives texture to the chapatti as well as is responsible for the development of aroma and taste (Sadeghi et al. 2016). Chapatti flour dough post rolling transferred on a hot iron griddle for baking; contact baking as shown in Fig. 1. Gupta (2001) studied the heat transfer modes during the contact baking of chapatti. They reported the modes for transfer of heat during the baking of chapatti to be conduction, convection, and radiation. Conduction being the major contributor for heat transfer (66.73%) is vital to get the impermeable layer of chapatti on both the surfaces. These layers entailed for an acceleration of cooking and puffing without affecting the surfaces, which in turn is responsible for structuring the quality of chapatti. The Yadav et al. (2008a, b) proposed optimized processing conditions like the baking temperature at 216ºC for a baking time of 2.1 min with thickness 3.2 mm to retain vitamin losses of B1 and B2.

Fig. 1.

Mechanism of contact baking of chapatti baking

Sadeghi et al. (2016) mentioned the inclusion of evaporation and condensation processes i.e., water transformation phases during baking. These phases accompanied by a number of heat and mass transfer processes in a porous medium and many physiological changes in the structure, aroma, and taste of chapatti. During baking of chapatti, its shows puff characteristics due to the generation of steam within the product with moisture retention (Kundu et al. 2019). Effect of heating (processing) generated during baking which alters on nutritional quality shown in Table 2.

Table 2.

Effect of processing on nutritional quality characteristics of chapatti.

Source: Ranga Rao et al. 1986

| Characteristics(%) | Control | Cooled immediately | Slowly cooled |

|---|---|---|---|

| Moisture | 10.2 | 6.8 | 7.2 |

| Free lipids | 1.40 | 1.74 | 1.74 |

| Bound lipids | 0.99 | 0.73 | 0.72 |

| Salt soluble proteins | 2.5 | 2.8 | 2.7 |

| Gliadin | 4.2 | 4.5 | 4.5 |

| Glutenin | 4.9 | 4.2 | 4.2 |

Chapatti press

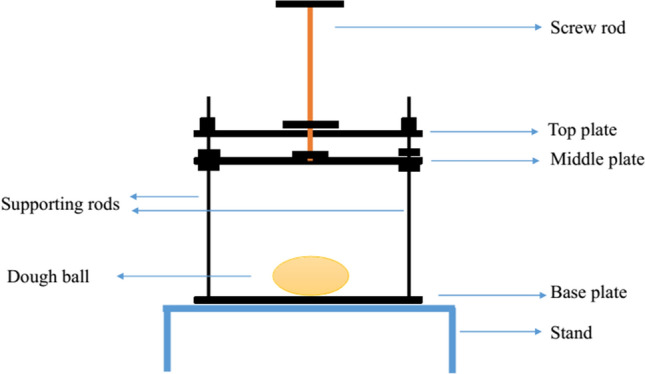

As has been discussed earlier, the preparation of chapatti is a tiresome and time-consuming process. Also, the process requires skill. Changing lifestyle and consumer demands based on this lifestyle have brought about the mechanization of the chapatti preparation process. Gurushree et al. (2011) designed and developed a chapatti press for the faster, mechanized rolling/sheeting of dough during the chapatti production process. Figure 2 elaborates on the design of the press. It consisted of three plates, a single screw rod rotating along the vertical axis, supporting rods, and metal strips. The dough ball placed between middle and base plate and grease and pressure applied by rotating the screw rod. Chapattis produced thereof had no significant difference as those with manually sheeted.

Fig. 2.

Design of chapatti press (modified Gurushree et al. 2011)

Conclusion

Various factors are responsible for determining the quality of the chapatti, such as wheat genotypes, wheat varieties, the molecular weight distribution of proteins, and processing techniques. Nutritional, as well as quality, make up of chapattis can be enhanced by altering these factors. Chapatti preparation has become comparatively easier with the mechanization of the process and development of baking techniques. More research needs to be carried out in order to study the impact of advanced baking techniques on the quality of chapatti as well as prevention of staling.

Acknowledgement

We are thankful to D Y Patil University for supporting.

Compliance with ethical standards

Conflict of interest

There is no conflict of interest by all authors.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- Ahmed A, Anjum M, Ahmad A, Khalid N, Randhawa MA, Ahmad Z, Farid W. Effects of Hydrocolloids on Partial Baking and Frozen Storage of Wheat Flour Chapatti. Food Sci Technol Res. 2013;19(1):97–103. [Google Scholar]

- Anjum FM, Khan MR, Din A, Saeed M, Pasha I, Arshad MU. Wheat Gluten: High Molecular Weight Glutenin Subunits—Structure, Genetics, and Relation to Dough Elasticity. J Food Sci. 2007;72(3):56–62. doi: 10.1111/j.1750-3841.2007.00292.x. [DOI] [PubMed] [Google Scholar]

- Arya S, Ananthanarayan L, Rodrigues L, Waghmare A. Fractionation and reconstitution of whole wheat flour and its effect on dough and chapatti quality. Food Measure. 2016;10(3):614–624. [Google Scholar]

- Arya SS, Sonawane SK. Impact of fiber mixture on dough and chapatti quality using D-optimal response surface methodology. J Microbiol Biotechnol Food Sci. 2016;5(5):424–433. [Google Scholar]

- Banerji A, Ananthanarayan L, Lele S. Rheological and nutritional studies of amaranth enriched wheat chapatti (Indian flat bread) J Food Process Preser. 2018;42(1):e13361. [Google Scholar]

- Bansal G, Singh RP, Nanda GS. Suitability of advanced wheat genotypes for bread, biscuit and chapaties. J Res Punjab Agric Univ. 2000;47:63–70. [Google Scholar]

- Cavallero A, Empilli S, Brighenti F, Stanca AM. High (1 - > 3,1 - > 4)- beta-glucan barley fractions in bread making and their effects on human glycemic response. J Cereal Sci. 2002;36(1):59–66. [Google Scholar]

- Chaudhary N, Dangi P, Khatkar BS. Assessment of molecular weight distribution of wheat gluten proteins for chapatti quality. Food Chem. 2016;199:28–35. doi: 10.1016/j.foodchem.2015.11.106. [DOI] [PubMed] [Google Scholar]

- Cheng YF, Bhat R. Physicochemical and sensory quality evaluation of chapati (Indian flat bread) produced by utilizing underutilized jering (Pithecellobium jiringa Jack.) legume and wheat composite flours. Int Food Res J. 2015;22(6):2244–2252. [Google Scholar]

- Francin-Allami M, Saumonneau A, Lavenant L, Bouder A, Sparkes I, Hawes C, Popineau Y. Dynamic trafficking of wheat γ-gliadin and of its structural domains in tobacco cells, studied with fluorescent protein fusions. J Experimental Botany. 2011;62(13):4507–4520. doi: 10.1093/jxb/err159. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ghodke SK. Effect of Guar Gum on Dough Stickiness and Staling in Chapatti-An Indian Unleavened Flat Bread. Int J Food Eng. 2009 [Google Scholar]

- Ghodke SK, Ananthanarayan L, Rodrigues L. Use of response surface methodology to investigate the effects of milling conditions on damaged starch dough stickiness and chapatti quality. Food Chem. 2009;112(4):1010–1015. [Google Scholar]

- Giri S, Banerji A, Lele SS, Ananthanarayan L. Effect of addition of enzymatically modified guar gum on glycemic index of selected Indian traditional foods (idli, chapatti) Bioactive Carbohydrates and Dietary Fibre. 2017;11:1–8. [Google Scholar]

- Gujral HS, Sharma P, Bajaj R, Solah V. Effects of incorporating germinated brown rice on the antioxidant properties of wheat flour chapatti. Food Sci Technol Int. 2012;18(1):47–54. doi: 10.1177/1082013211414173. [DOI] [PubMed] [Google Scholar]

- Gujral HS, Sharma P, Gill BS, Kaur S. Effect of incorporating hydrothermal, kilned and defatted oats on antioxidant and chapatti making properties of wheat flour. Food Chem. 2013;138:1400–1406. doi: 10.1016/j.foodchem.2012.09.115. [DOI] [PubMed] [Google Scholar]

- Gujral HS, Sharma B, Khatri M. Influence of replacing wheat bran with barley bran on dough rheology, digestibility and retrogradation behavior of chapatti. Food Chem. 2018;240:1154–1160. doi: 10.1016/j.foodchem.2017.08.042. [DOI] [PubMed] [Google Scholar]

- Gupta TR. Individual heat transfer modes during contact baking of Indian unleavened flat bread (chapati) in a continuous oven. J Food Eng. 2001;47(4):313–319. [Google Scholar]

- Gurushree MN, Nandini CR, Pratheeksha K, Prabhasankar P, Hosamane GG. Design, development and performance evaluation of chapati press cum vermicelli extruder. J Food Sci Technol. 2011;48(2):218–224. doi: 10.1007/s13197-010-0163-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Han T, Wang P, Ali B, Wu F, Jin Z, Xu X. Fractionation and reconstitution experiments provide insight into the role of wheat starch in frozen dough. Food Chem. 2016;190:588–593. doi: 10.1016/j.foodchem.2015.05.123. [DOI] [PubMed] [Google Scholar]

- Hemalatha MS, Leelavathi K, Salimath PV, Prasada Rao UJS. Control of chapati staling upon treatment of dough with amylases and xylanase. Food Biosci. 2014;5:73–84. [Google Scholar]

- Hemalatha MS, Prasada Rao UJS, Leelavathi K, Salimath PV. Influence of amylases and xylanase on chemical, sensory, amylograph properties and microstructure of chapati. LWT-Food Sci Technol. 2010;430(9):1394–1402. [Google Scholar]

- Hoseney RC (1994) In Principles of cereal science and technology 2nd edn. Amer Assoc Cereal Chemists (AACC), St Paul, USA, pp. 125–145

- Hsu D, Leung HK, Finney PL, Morad MM. Effect of germination on nutritive value and baking properties of dry peas, lentils, and faba beans. J Food Sci. 1980;45(1):87–92. [Google Scholar]

- Irshad MS, Ghodke SK, Ananthanarayan L. Inhibition of staling in chapati (Indian unleavened flat bread) J Food Process Preserv. 2008;32(3):378–403. [Google Scholar]

- Janne R, Blanshard JMV, Mitchell JR, Derbyshire W, Autio K. Properties of frozen wheat doughs at subzero temperatures. J Cereal Sci. 1998;28(1):1–14. [Google Scholar]

- Kadam ML, Salve RV, Mehrajfatema ZM, More SG. Development and evaluation of composite flour for missi roti/chapatti. Food Process Technol. 2012;3(1):7. [Google Scholar]

- Khan AN, Ahmed A, Bhatti MS, Randhawa MA, Ahmad A, Yousaf AA. Effect of additives on the shelf life extension of chapatti. Food Sci Technol Res. 2011;17(3):203–208. [Google Scholar]

- Kumar, S., Sohu, V.S., Singh, R.P., Gupta, S.K., Srivastava, P. and Bains, N.S. (2018). Investigating the role of high molecular weight glutenin subunits (HMW-GS) protein in end use quality of Indian flat breads. Indian J Biotechnol 17, 65–73. http://nopr.niscair.res.in/handle/123456789/44824

- Kumar S, Sohu VS, Bains NS. Agronomic performance of Indian wheat varieties and genetic stocks known for outstanding chapati quality characteristics. J Applied Natural Sci. 2018;10(1):149–157. [Google Scholar]

- Kundu M, Khatkar BS, Gulia N. Assessment of chapatti quality of wheat varieties based on physicochemical, rheological and sensory traits. Food Chem. 2017;226:95–101. doi: 10.1016/j.foodchem.2016.12.046. [DOI] [PubMed] [Google Scholar]

- Kundu M, Khatkar BS, Gulia N, Kumar R. Functional characterization of whole wheat flours for chapatti quality and acceptability. J Food Sci Technol. 2019;56:2296–2304. doi: 10.1007/s13197-019-03721-w. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kurhade A, Patil S, Sonawane SK, Waghmare JS, Arya SS. Effect of banana peel powder on bioactive constituents and microstructural quality of chapatti: unleavened Indian flat bread. Food Meas. 2016;10(1):32–41. [Google Scholar]

- Mehfooz T, Ali TM, Arif S, Hasnain A. Effect of barley husk addition on rheological, textural, thermal and sensory characteristics of traditional flat bread (chapatti) J Cereal Sci. 2018;79:376–382. [Google Scholar]

- Mishra BK. Quality needs for Indian traditional products. Wheat research needs beyond. 2000;2000:314–319. [Google Scholar]

- Ranga Rao GCP, Haridas Rao P, Leelavati K, Shurpalekar SR. Effect of grinding wheat in a disc mill on some chemical, rheological and Chapati making characteristics of flour. J Food Sci Technol. 1986;23:29–32. [Google Scholar]

- Revanappa SB, Salimath PV. Structural characterization of hemicellulose A from wheat (Triticum aestivum) varieties differing in their chapati-making quality. Carbohydr Polym. 2010;79(3):655–659. [Google Scholar]

- Revanappa SB, Nandini CD, Salimath PV. Structural characterization of pentosans from hemicellulose B of wheat varieties with varying chapati-making quality. Food Chem. 2010;119(1):27–33. [Google Scholar]

- Sadeghi F, Hamdami N, Shahedi M, Rafe A. Numerical modeling of heat and mass transfer during contact baking of flat bread. J Food Process Eng. 2016;39(4):345–356. [Google Scholar]

- Schwarzlaff SS, Johnson JM, Barbeau WE, Duncan S. Guar and locust bean gums as partial replacers of all-purpose flour in bread: an objective and sensory evaluation. J Food Quality. 1996;19(3):217–229. [Google Scholar]

- Sharma B, Gujral HS, Solah V. Effect of incorporating finger millet in wheat flour on mixolab behavior, chapatti quality and starch digestibility. Food Chem. 2017;231:156–164. doi: 10.1016/j.foodchem.2017.03.118. [DOI] [PubMed] [Google Scholar]

- Singh GH, Sharma P, Gill BS, Kaur S. Effect of incorporating hydrothermal, kilned and defatted oats on antioxidant and chapatti making properties of wheat flour. Food Chem. 2013;138:1400–1406. doi: 10.1016/j.foodchem.2012.09.115. [DOI] [PubMed] [Google Scholar]

- Singh GH, Sharma P, Bajaj R, Solah V. Effects of incorporating germinated brown rice on the antioxidant properties of wheat flour chapatti. Food Sci Technol Int. 2012;18:47–54. doi: 10.1177/1082013211414173. [DOI] [PubMed] [Google Scholar]

- Sreeramulu G, Banerjee R, Bharadwaj A, Vaishnav PP. Weight glutenin subunits (hmw-gs) in chapati making quality. The gluten proteins. 2004;295:162. [Google Scholar]

- Survase A, Furtado A, Thengane R, Fox G, Taylor T, Henry R. Comparison of chapatti and breadmaking quality of wheat genotypes. Cereal Chem. 2017;94(3):409–416. [Google Scholar]

- Tao H, Wang P, Ali B, Wu F, Jin Z, Xu X. Fractionation and reconstitution experiments provide insight into the role of wheat starch in frozen dough. Food Chem. 2016;190:588–593. doi: 10.1016/j.foodchem.2015.05.123. [DOI] [PubMed] [Google Scholar]

- Wani IA, Sogi DS, Sharma P, Gill BS. Physicochemical and pasting properties of unleavened wheat flat bread (Chapatti) as affected by addition of pulse flour. Cogent Food Agriculture. 2016;2(1):1124486. [Google Scholar]

- Williams P, Fegol K. Colorimetric determination of damaged starch in flour. Cereal Chem. 1969;46:56–62. [Google Scholar]

- Yadav DN, Patki PE, Khan MA, Sharma GK, Bawa AS. Effect of freeze–thaw cycles and additives on rheological and sensory properties of ready to bake frozen chapaties. Int J Food Sci Technol. 2008;43(9):1714–1720. [Google Scholar]

- Yadav DN, Singh KK, Rehal J. Studies on fortification of wheat flour with defatted rice bran for chapati making. J Food Sci Technol. 2012;49:96–102. doi: 10.1007/s13197-011-0264-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Yadav DN, Petki PE, Sharma GK, Srihari KA, Harilal PT, Bawa AS. Rheological and sensory quality of ready-to-bake chapatti during frozen storage. J Food Quality. 2009;32(4):436–451. [Google Scholar]

- Yadav DN, Patki PE, Mahesh C, Sharma GK, Bawa AS. Optimisation of baking parameters of chapati with respect to vitamin B1 and B2 retention and quality. Int J Food Sci Technol. 2008;43:1474–1483. [Google Scholar]

- Žilić S, Barać M, Pešić M, Dodig D, Ignjatović-Micić D. Characterization of Proteins from Grain of Different Bread and Durum Wheat Genotypes. Int J Mol Sci. 2011;12(9):5878–5894. doi: 10.3390/ijms12095878. [DOI] [PMC free article] [PubMed] [Google Scholar]