Abstract

Through advances in molecular design, understanding of processing parameters, and development of non‐traditional device fabrication techniques, the field of wearable and implantable skin‐inspired devices is rapidly growing interest in the consumer market. Like previous technological advances, economic growth and efficiency is anticipated, as these devices will enable an augmented level of interaction between humans and the environment. However, the parallel growing electronic waste that is yet to be addressed has already left an adverse impact on the environment and human health. Looking forward, it is imperative to develop both human‐ and environmentally‐friendly electronics, which are contingent on emerging recyclable, biodegradable, and biocompatible polymer technologies. This review provides definitions for recyclable, biodegradable, and biocompatible polymers based on reported literature, an overview of the analytical techniques used to characterize mechanical and chemical property changes, and standard policies for real‐life applications. Then, various strategies in designing the next‐generation of polymers to be recyclable, biodegradable, or biocompatible with enhanced functionalities relative to traditional or commercial polymers are discussed. Finally, electronics that exhibit an element of recyclability, biodegradability, or biocompatibility with new molecular design are highlighted with the anticipation of integrating emerging polymer chemistries into future electronic devices.

Keywords: biocompatible polymers, biodegradable polymers, molecular design, recyclable polymers, sustainable electronics

With the rapid growth of consumer electronics, their harmonious integration into modern society and the environment is contingent on new eco‐ and human‐friendly polymer technologies. This review explores emerging recyclable, biodegradable, and biocompatible polymer chemistries with a focus on molecular design for incorporation into the next‐generation of sustainable electronics with unrealized capabilities.

1. Introduction

As we become increasingly dependent on consumer plastics and electronics, it is highly desirable for these materials to be seamlessly integrated with the environment and human health. Their harmonious integration into our ecosystem relies on the design of materials to be recyclable, degradable in environmentally relevant conditions, and interfaced with living systems without an adverse impact. Worldwide, plastics approximately account for 150 million tons of solid waste annually, and discarded electronic gadgets additionally constitute 50 million tons of electronic waste (“e‐waste”).[ 1 , 2 ] Only 10–20% of these waste products are recycled, with the majority going directly into landfills and incinerators, much of which leach hazardous chemicals and toxic metals into the environment and ecology. While these low percentages for recycling can be partially attributed to consumer habits as well as the difficulty and cost associated with materials separation, they also leave great room for improvement for plastic and electronic industries to design materials that can be recycled or degraded using efficient, cost‐effective techniques or in a wider variety of environments. Electronics that can be recycled or degraded without leaving a negative footprint on the environment would reduce the amount of e‐waste by mitigating the negative effects of improper disposal. Recycling electronic components would conserve scarce natural elements (e.g., gallium, indium) and other valuable resources. Moreover, implantable devices that can degrade under physiological conditions into non‐toxic byproducts or that can function without an adverse immunological response will expand their impact on various biomedical applications. These temporary implants would be adsorbed by the body after a designated time of use, reducing the risk of infection and complications caused by secondary removal procedures. Notably, the integration of wearable and implantable electronics into human life and health is heavily dependent on the biocompatibility of these devices. The advancement of new technologies while promoting environmental and human health and a sustainable future relies on the rapidly growing progress of these recyclable, biodegradable, and biocompatible chemistries and their integration into electronics.

Although most commercial electronics are composed of and reliant on inorganic materials, organic materials possess a wide array of desirable properties for the realization of eco‐ and human‐friendly electronics. Polymers are attractive due to their scalability, solution processability, ability to be rationally tuned by synthetic design, and diverse material properties (e.g., stretchability, toughness, conformability, conductivity). Polymer‐based electronics typically use insulating polymers for various device components (i.e., encapsulants, substrates, dielectrics) and conjugated or doped polymers as the electronically‐active component (i.e., semiconductor, conductor). Much work has been done in designing polymers to be eco‐ and human‐friendly as well as to impart desirable properties (e.g., self‐healing, stimuli‐responsivity, adhesivity) for electronic applications. For example, our group demonstrated fully biodegradable and biocompatible thin film transistors (TFTs) based on a ultrathin cellulose substrate and acid‐labile polymer semiconductors that completely decomposed under mildly acidic (pH = 4.6) conditions within thirty days.[ 3 ] Furthermore, stretchability was realized when these polymer semiconductors were blended with a biodegradable elastomer.[ 4 ] These technologies yield broader applications in low‐cost, eco‐friendly, and bio‐integrated organic electronics.

In this review, we discuss how polymers are designed to impart properties that allow them to be recyclable, biodegradable, or biocompatible as well as how these polymers are used in various devices for electronic applications. We recognize that there have been several detailed reviews on recyclable polymers, biodegradable and biocompatible electronics, and bioresorbable electronics.[ 1 , 2 , 5 , 6 , 7 , 8 , 9 , 10 , 11 , 12 ] Those written on recyclable polymers focus on commercial plastics and do not discuss their potential use in electronics, while the biodegradable and biocompatible electronics reviews mainly examine inorganic electronics or do not cover recent discoveries in biodegradable and biocompatible chemistries. This review aims to focus on the underlying chemistries of sustainable polymers as well as provide prospective into how these new polymer chemistries can be used in electronics.

First, we give an overview on recyclable, biodegradable, and biocompatible terminology. Subsequently, we examine the current standards and regulations implemented by governing organizations as well as the characterization methods and tools used in studies for each of these polymer categories. For molecular design, we discuss established chemistries for sustainable polymers and then examine emerging polymers in the field and their advantages over existing chemistries. Finally, we review how polymers have been used in recyclable, biodegradable, or biocompatible electronic applications. It is important to note that the components (e.g., substrates, dielectrics, semiconductors, conductors) that make up electronic devices are composed of vastly different polymeric materials. Each component plays a crucial role in the functionality of the device. Currently, there is a gap between the polymeric materials commonly used in electronics and emerging polymer chemistries reported in literature over the past few years. We hope to provide readers with a fundamental understanding of the molecular design required to achieve these eco‐ and human‐friendly emergent properties as well as encourage the synergistic effort to bridge the gap between molecular design and device fabrication. The next‐generation of sustainable electronics with advanced, unrealized capabilities are contingent on the development and integration of emerging polymer chemistries (Figure 1 ).

Figure 1.

Schematic illustration of this review. The next generation of eco‐ and human‐friendly electronics rely on emerging molecular design and characterization techniques for recyclable, biodegradable, and biocompatible polymers.

2. Overview and Classifications

For this review, the terms “recyclable,” “biodegradable,” and “biocompatible” and the associated subcategories are defined based on reported literature.[ 1 , 5 , 8 , 10 , 13 , 14 ] Recyclable, biodegradable, and biocompatible polymers have been widely studied from both a chemistry and engineering perspective for applications in sustainable plastics and electronics. Discrepancies between the various definitions of these terms have evolved from the numerous studies from different disciplines that have emerged over the years. To clarify these discrepancies, classifications and definitions of each class of material are described based on terms that are generally used and accepted by researchers in both fields.

2.1. Recyclable

Recyclable polymers have been well classified in terms of recyclable, commercial plastics, whose terms we will translate to their use in electronics. About a decade ago, recycling methods for plastics have been classified into four main techniques: 1) primary, 2) secondary, 3) tertiary, and 4) energy recovery.[ 5 , 13 ] García and coworkers, in particular, defined primary recycling as reprocessing to produce a material with the same purpose, while secondary recycling yields a material with different uses than the original plastic.[ 1 ] The production of plastic bottles made from blends of polyethylene terephthalate (PET) recycled from plastic bottles and virgin PET is an example of primary recycling. Tire recycling is an example of secondary recycling as the vast majority of recycled tires are turned into other rubber products. Both primary and secondary recycling involve mechanical or physical processes, such as grinding, extrusion, and dissolution. However, these processes limit the recyclable materials to mainly thermoplastics, or polymers that can be moldable or reprocessable at elevated temperatures. While primary recycling is referred to as “closed‐loop recycling,” secondary recycling often results in plastics that are lower in quality—that is, polymers with lower molecular weight—and is commonly called “downcycling.” Currently, secondary recycling is the widespread method for large‐scale plastic recycling because achieving identical mechanical properties to those of the original state is limited due to degradation (i.e., chain scissions) or impurities.[ 15 ] When secondary recycling is not cost‐effective or complicated separations are required, the plastic waste is typically converted into fuel or incinerated.

Tertiary or chemical recycling involves using chemical processes to recover the individual components or monomers. Examples of such processes include hydrolysis, pyrolysis, hydrocracking, and gasification.[ 5 , 13 , 16 ] To expand industrial recycling beyond thermoplastics (primarily PET and polyethylene), ongoing research has focused on catalyst development to improve chemical recycling efficiency and reduce required energy inputs.[ 5 , 6 ] While typical tertiary conversion products are liquids and gases, which can be used for feedstock in fuel production, this method has potential for “upcycling” in which case pure monomers are recovered for repolymerization into higher grade products. Whereas downcycling results in polymers with decreased mechanical properties, upcycling can yield polymers with identical or better physical properties. Incineration, also known as quaternary recycling, is a method of energy recovery in the form of heat. While the energy generated from incineration is substantially less compared to the energy conserved from other recycling processes, incineration remains a popular method for waste volume reduction when dealing with mixed and heavily contaminated materials for recycling. Additionally, due to the inevitable release of toxins and greenhouse gases associated with quaternary recycling, it is crucial to develop primary, secondary, and tertiary recycling methods in the advancement of sustainability and energy conservation. To focus on the chemistries involved in furthering recycling efficiency, quaternary recycling will not be covered in this review.

2.2. Biodegradable

Biodegradable is a widely used term to classify a range of polymers and polymer composites that can be broken down into smaller constituent pieces under biologically benign or physiological conditions, whether the processes are chemical or biological. At the molecular level, these materials contain chemical linkages that are cleavable in biologically friendly conditions. Biologically friendly conditions include both in vivo degradation and degradation by the natural environment. Chemistries associated with tertiary recycling can also be classified as biodegradable if the conditions are physiologically relevant. Unlike recycling methods, the monomers do not necessarily have to be isolated and collected for further use. At the macroscopic level, biodegradable materials may partially degrade or fully degrade to monomeric units, as defined by Bao and coworkers as type I and type II, respectively.[ 8 ] Partially degradable (type I) materials are composed of polymers that can disintegrate without full chemical breakdown. In electronics, these materials are typically composed of degradable insulating mediums that hold together nondegradable active materials (i.e., carbon nanotubes, conjugated polymers). For many applications (e.g., implantable electronics, drug delivery), complete degradation into monomeric building blocks may be unnecessary if the polymers break down into substituents that can be either metabolized or excreted. On the other hand, in fully degradable (type II) materials, the polymer backbone can be degraded into oligomers and monomers, enabling potential upcycling or breakdown by microorganisms in the environment. Both the insulating matrix and active materials are degradable in type II electronics. Type II electronics open avenues for reducing electronic waste, recyclability, and improved biocompatibility, as small molecules are less likely to elicit adverse immune response.

Due to the wide appeal of biodegradable polymers for wearable and implantable biomedical applications, biodegradable materials are often studied along with their biocompatibility.[ 2 , 7 ] “Bioresorbable” electronics are a specific class of biodegradable materials that can dissolve away in aqueous environments and generate biologically non‐toxic degradation byproducts. Bioresorbable materials can either be type I or type II biodegradable materials, with studies primarily focusing on their dissolution mechanisms.[ 10 , 11 ] Thus, biodegradable electronics that directly contact the skin or living tissue require examination of the biocompatibility of the device, degradation intermediates, and polymer byproducts.

2.3. Biocompatible

The biocompatibility of electronics must be defined in the context of its location, time of use, and intended application. A material may be biocompatible in one circumstance but not in another. By the IUPAC definition, biocompatibility is the “ability to be in contact with a living system without producing an adverse effect.”[ 14 ] Generally, a material may be considered biocompatible if it produces an acceptable host response when exposed to the body or bodily fluids. Note that this is distinct from not causing any side effects or immune response. Frequently, biocompatible materials will result in varying degrees of inflammatory and immune responses; however, they are either not harmful or part of the body's normal responses. Signs of adverse response include chronic inflammation, production of cytotoxic substances, cell disruption, skin irritation, restenosis, thrombosis, and corrosion of the implanted material, particularly in the time frame of use and interference with the device function.[ 17 ] These responses are triggered by chemical or physical reactions to the material. Not only does the material have to be chemically compatible (i.e., hydrophilic, non‐fouling, non‐toxic) with its surrounding environment but also mechanically compatible (i.e., flexible, stretchable, conformal) when considering wearable and implantable electronics. Vigorous assessment by in vitro culture experiments or in vivo implantation is crucial before classifying a material as biocompatible.

3. Characterization and Evaluation Methods

The methods of characterization for sustainable polymers encompass a wide variety of techniques and are not standardized partly because there are different targeted environments for each polymer application. For example, standards for biodegradation in marine environments are expected to be different from those in the human body. While systematic metrics are yet to be established, instrumentation are key tools to establish degradation kinetics and identify byproducts. This section first reviews current standards and regulations established by international organizations and federal agencies for commercial plastics and electronic devices. Building off of these policies, we describe relevant experimental characterization methods for new and emerging recyclable, biodegradable, and biocompatible polymers. Table 1 summarizes key techniques and instrumentation commonly used to characterize polymeric materials and electronics with elements of recyclability, biodegradability, or biocompatibility.

Table 1.

Summary of key characterization techniques commonly used to determine recyclability, biodegradability, and biocompatibility

| Characterization technique | Information obtained | Recyclability | Biodegradability | Biocompatibility |

|---|---|---|---|---|

| Dynamic mechanical (thermal) analysis (DMA/DMTA) | Determination of the complex modulus through application of a sinusoidal stress and measurement of strain | ✓ | — | — |

| Gel permeation chromatography (GPC) | Determination of molecular weight and dispersity of polymers | ✓ | ✓ | — |

| Nuclear magnetic resonance (NMR) | Identification of small organic compounds through magnetic fields | ✓ | ✓ | — |

| Fourier‐transform infrared spectroscopy (FT‐IR) | Detection of vibration characteristics of chemical functional groups | ✓ | ✓ | — |

| Mass loss profile | Analysis of mass loss via an analytical balance over a specified period | — | ✓ | — |

| UV–vis spectroscopy | Analysis of the absorption or reflectance in the UV and visible ranges in which molecules undergo electronic transitions | — | ✓ | — |

| Scanning electron microscope (SEM) | Observation of surface topographical changes and composition by scanning with a focused beam of electrons | ✓ | ✓ | ✓ |

| Light/confocal/difference interference contrast (DIC) microscopy | Imaging of samples through the use of visible light, with increased optical resolution or contrast | — | — | ✓ |

| LIVE/DEAD cell viability assay | Determination of cell viability through fluorescent dyes to yield two‐color discrimination of live and dead cells | — | — | ✓ |

| Enzyme‐linked immunosorbent assay (ELISA) | Detection of the presence of a protein in a liquid sample using antibodies directed against the protein | — | — | ✓ |

| 3‐(4,5‐dimethylthiazol‐2‐yl)‐2,5‐diphenyltetrazolium bromide (MTT) assay | Colorimetric assessment of cell metabolic activity via enzymatic reduction of MTT dye to reflect the number of viable cells present | — | — | ✓ |

3.1. Characterization and Evaluation for Recyclable Polymers

3.1.1. Current Standards and Regulations

International Organization for Standardization (ISO) 15270 has been established to assist in the development of a sustainable global infrastructure for plastics recovery and recycling.[ 18 ] The ISO prioritizes the general reduction and optimization of material and energy resource use. The criteria for acceptance of a recycled material, although dependent on the application, may include proper identification, nature and concentrate of contaminants, as well as mechanical and chemical properties and packaging requirements. The recyclate can be used as long as it “meets or exceeds the specified minimum material and end‐use performance criteria.” The Association of Plastic Recyclers (APR) represents companies who acquire, reprocess, and sell more than 90% of the post‐consumer plastic processing capacity in North America. Their Design Guide for Plastics Recyclability considers an item recyclable when at least 60% of consumers have access to a collection system and an item can be further processed cost‐effectively into a post‐consumer plastic feedstock suitable for use in new products.[ 19 ] Although general guidelines for plastics recycling exist, current policies limit the polymers used to those that are commercially available, such as the well‐known Resin Identification Coding (RIC) system that categorizes plastics into seven groups. The Federal Resource Conservation and Recovery Act of 1976 is the principal federal law in the United States governing the disposal of solid waste and hazardous waste; however, it is difficult to say where polymer‐based electronics fit in as it only covers cathode ray tubes. The majority of states in the United States use the Producer Responsibility approach to hold manufacturers accountable for recycling of their products; however, state electronics recycling policies vary. As the next generation of recyclable plastics and electronics become commercially viable and widespread such that they are a significant waste stream, there must be guidelines for their disposal. We begin to address guidelines for these emerging recyclable materials through the experimental techniques used to characterize them.

3.1.2. Experimental Characterization Methods

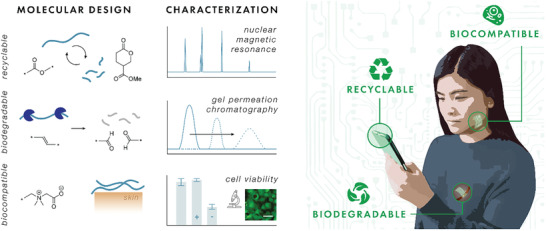

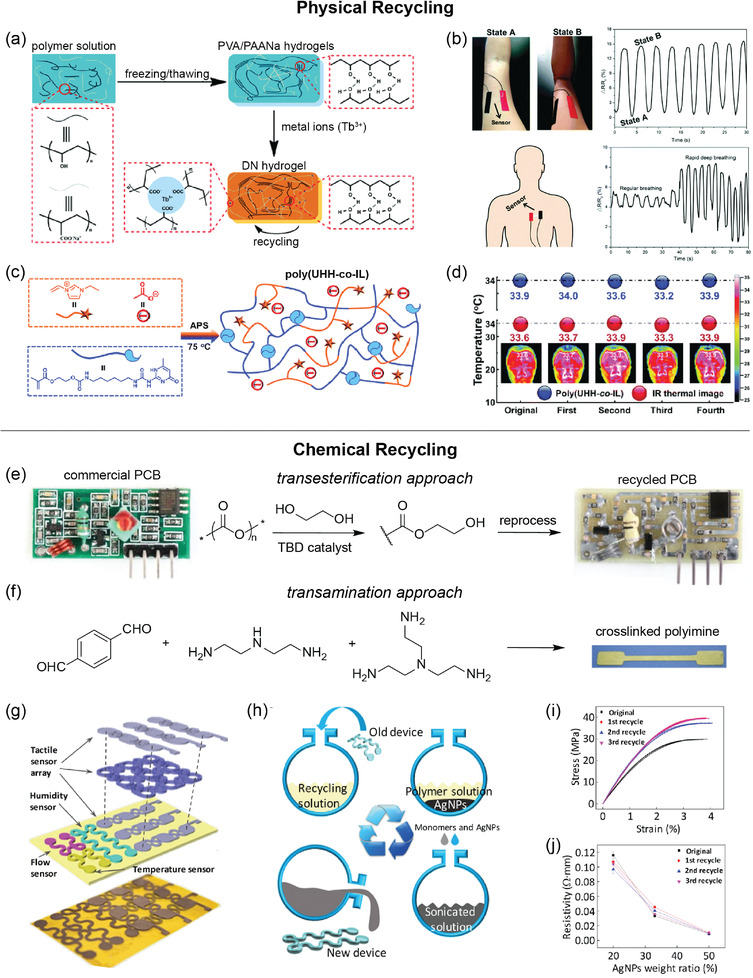

The specific characterization methods used to determine whether a polymer is recyclable depends heavily on the recycling process used. Common characterization tools for most types of recycling (mechanical and chemical) include gel permeation chromatography (GPC) to compare the initial and recycled polymer molecular weight distributions and polydispersities,[ 20 ] dynamic mechanical analysis (DMA) for studying the modulus of the material,[ 21 , 22 ] and scanning electron microscopy (SEM) to visually observe surface topographical changes.[ 22 ] When mechanical recycling techniques are employed, mechanical properties and applications of the recycled polymer are compared to the virgin material. For example, a thermally reprocessable rubber crosslinked by dynamic covalent Diels‐Alder bonds was proved dynamically recyclable through their reversible crosslinks which break at 150 °C and re‐form at 50–70 °C. Fourier‐transform infrared (FT‐IR) spectroscopy as well as its mechanical behavior (i.e., tensile testing, hardness and compression set, temperature response) after recycling confirmed reversibility of the network without a reduction in mechanical properties.[ 21 ] While the un‐crosslinked polymer was soluble in decalin at room temperature, the crosslinked material was not. By dynamic mechanical thermal analysis (DMTA), temperature cycles from 20 to 150 °C of the thermoreversible polymers were performed, showing recovery of the modulus to their original value (93 ± 10%). A study by Moore and coworkers demonstrated the thermal depolymerization and recyclability of self‐immolative, cyclic poly(phthalaldehyde) (cPPA) and its carbon nanofiber‐reinforced composites.[ 22 ] The depolymerization was monitored by Raman spectroscopy as well as thermal gravimetric analysis (TGA) along with real‐time mass spectroscopy corresponding to the mass loss observed in TGA. The mechanical properties of virgin and recycled materials were evaluated by DMA and quasi‐static tension, which displayed indistinguishable stress‐strain curves over three generations of recycling (Figure 2a). Qualitative morphology evaluation of the carbon fibers after matrix depolymerization was conducted by SEM, in which the fibers were reclaimed and nearly free of residue matrix. For recyclable electronics, such as an electronic skin composed of a dynamic covalent polyimine thermoset,[ 23 ] characterization of both mechanical properties and functionality (e.g., stress‐strain curves, uniaxial tension tests, electrical resistivity measurements, sensing functionality) were conducted. After recycling three times, stress–strain curves and electrical resistivity of the conductive films did not show noticeable change. The recycled tactile sensor indicated similar sensing performance compared with the original tactile sensor, with a slight reduction in sensitivity likely due to the slight increase in Young's modulus associated with additional crosslinking (Figure 2b). Additionally, a physically crosslinked double network hydrogel used to develop flexible strain sensors was recycled by dissolving in water and subsequent freeze/thaw cycles.[ 24 ] Comparison of the conductivity, tensile strength and strain, and dynamic rheological properties to those of the original hydrogel showed a recovery of >95% of its mechanical properties.

Figure 2.

Typical characterization methods used for recyclable, biodegradable, and biocompatible polymers. a) Indistinguishable stress–strain curves of cyclic poly(phthalaldehyde) (cPPA) under quasi‐static tensile loading over three generations of recycling. Adapted with permission.[ 22 ] Copyright 2019, American Chemical Society. b) Similar sensing performance of the polyimine‐based tactile sensor before and after recycling. Adapted with permission.[ 23 ] Copyright 2018, AAAS. c) Overlays of 1H NMR spectra of starting (blue) and recycled (green) lactone‐based monomers and polymer (red), which display identical chemical shifts (ppm) for the starting and recycled monomers. Adapted with permission.[ 25 ] Copyright 2018, AAAS. d) Weight loss profiles of polyesters PSG and PSG show significant degradation compared to controls PLA and PETg at 50 °C in phosphate‐buffed saline (pH = 7.4). Adapted with permission.[ 38 ] Copyright 2020, American Chemical Society. e) GPC traces of the original and degraded SPNs show a reduction of molecular weight based on retention time after treatment with both H2O2 and myeloperoxidase. Adapted with permission.[ 20 ] Copyright 2017, Springer Nature. f) UV–vis absorption spectra of a semiconducting imine‐based polymer solution under acidic conditions decreased over 40 d, demonstrating a loss of conjugation. Adapted with permission.[ 4 ] Copyright 2019, American Chemical Society. g) DIC microscopy images of nerve cross sections with shape memory polymer‐based MSC showed normal nerve fibers (green), while that with a silicone cuff showed nerve compression by fibrotic tissue ingrowth (arrowheads). Dotted lines indicate the relative positions of the MSC and silicone devices. Adapted with permission.[ 49 ] Copyright 2018, Springer Nature. h) LIVE/DEAD images of cells cultured on PAA‐rGO hydrogel show flourishing cell growth (green) and the absence of cell death (red). Adapted with permission.[ 51 ] Copyright 2018, Elsevier. i) The titer of PEG‐ and PTMAO‐specific immunoglobin M (IgM) in mice sera was detected with ELISA tests, demonstrating minimal immunogenicity of PTMAO. Adapted with permission.[ 52 ] Copyright 2019, AAAS.

When chemical recycling processes that produce monomers are used, characterization of the resulting monomer is often included to demonstrate purity for use in repolymerization in addition to examination of the recycled polymer's mechanical properties. For example, gravimetric and NMR analyses showed quantitative monomer recovery without impurities after catalytic chemolysis of lactone‐based polymers (Figure 2c).[ 25 ] In Helms and coworkers’ recycling of plastics by dynamic covalent diketoenamine bonds, polymers were depolymerized with acid, and components were separated to obtain yields for recovered monomers.[ 26 ] 1H NMR of the monomer showed no detectable side products, residual reagents, or additives. DMA of the recycled material displayed nearly identical properties to the original material. Similarly, García and coworkers compared 1H NMR spectra as well as DMA values of their starting and recovered materials to quantitate recyclability.[ 27 ] 1H NMR spectra of the recovered monomer were identical to that of the starting material, while the extracted complex modulus values from stress relaxation after recycling offered comparable performance to the original organogel. Although there is not a standardized method for characterizing recyclable polymers and polymer‐based electronics, these works show that the comparison of mechanical properties and applications of the recycled material after cycling to those of the virgin material constitute enough evidence for recycling. Studies also demonstrate monomer purity if depolymerized monomers can be recovered and separated.

3.2. Characterization and Evaluation of Biodegradable Polymers

3.2.1. Current Standards and Regulations

Regulations on the term “biodegradable” have been established to ensure the reliability of products used in the environment. The current American Society for Testing and Materials (ASTM) International policies are defined as standard specifications and test methods. These specifications create a pass or fail situation, while the test methods identify the specific testing parameters such as time frames and toxicity. Under anaerobic conditions, ASTM D5511‐18 and ASTM D5526‐18 indicate that a minimum of 70% of the material should be biodegraded by 30 days (digestion conditions) or the duration of the testing procedure (accelerated landfill conditions).[ 28 , 29 ] It is important to note that while the time scales are well defined for in vivo degradation of implantable or digestible materials, the time scales of environmental degradation procedures are more complex. For aerobic environments, ASTM D6400‐19 and ASTM D6868‐19 outline procedures for testing in composting conditions and classify plastics as biodegradable when 90% of the material is fully mineralized into CO2 within 180 days.[ 30 , 31 ] European and international standards EN 13432:2000 and ISO 14855, respectively, are similar to the described US standards and also determine biodegradability of plastics by analysis of evolved CO2.[ 32 , 33 ] These standards apply to the more restrictive definition of biodegradability in that the decomposition products are H2O, CO2, and biomass. Additionally, the standards focus on the resulting products after degradation and not the conditions for testing degradation. As the field of biodegradable polymers for human health applications has only recently emerged, there is a lack of clear procedures to follow for determining if materials are promising for use as implantable or bioresorbable electronics. Potentially, a synergistic fusion of current biodegradable and biocompatible regulations will be a good starting point for this rapidly growing field.

3.2.2. Experimental Characterization Methods

The methods used to characterize biodegradable polymers are similar to those used for chemically recyclable polymers that depolymerize to produce monomers and oligomers, such as TGA and NMR spectroscopy. Biodegradable polymers that are reported without analysis of degradation products are commonly evaluated by mass loss profiles, GPC, UV–vis spectroscopy, SEM, and FT‐IR spectroscopy.[ 3 , 4 , 34 , 35 , 36 , 37 ] Unlike recyclable polymers, characterization for biodegradable polymers does not often include comparison of mechanical properties and functionalities to that of the original material. As biodegradation typically produces monomers or oligomer products, these are commonly analyzed by NMR spectroscopy. However, since the classification of polymers as biodegradable does not require the isolation of the degradation byproducts, separation or extraction processes must also be considered in this case. Instead, biodegradable polymers are often characterized by monitoring the properties of the starting material over time after exposure to a stimulus. Hillmyer, Ellison, and coworkers showed characterization by mass loss of their biorenewable aromatic polyesters poly(salicylic glycolide) (PSG) and poly(salicylic methyl glycolide) (PSMG) after hydrolytic degradation at 50 °C in phosphate‐buffered saline (PBS) solution, artificial seawater, and DI water.[ 38 ] PSG and PSMG showed significant weight loss at faster time scales compared to polylactic acid (PLA), a representative degradable polyester, and poly(ethylene terephthalate‐co‐isophthalate) (PETg), which has similar chemical and physical characteristics to PSG and PSMG (Figure 2d). The supernatants of the degradation solutions were also analyzed by 1H NMR to determine that the products were the starting monomers (salicylic acid, glycolic acid, and lactic acid).

Another example of biodegradable characterization was demonstrated by GPC of semiconducting polymer nanoparticles (SPNs), which were used for ultrasensitive in vivo imaging as they eliminate tissue autofluorescence.[ 20 ] After enzymatic degradation using H2O2 and myeloperoxidase, GPC traces of the nanoparticles showed a reduction of molecular weight from M n ≈ 27–3 kDa (Figure 2e). UV–vis spectroscopy also displayed a decrease in absorption peaks, corresponding to a loss of conjugation associated with depolymerization; however, it is important to note that typically only conjugated polymers have a significant difference between polymeric and monomeric/oligomeric absorption to be analyzed effectively by UV–vis. UV–vis spectroscopy was also used to monitor the degradation of a semiconducting polymer consisting of acid‐labile imine bonds.[ 4 ] A solution of polymer in 1% 1 m trifluoroacetic acid (TFA) in chlorobenzene showed absorbance reduction and a visual solution color change from blue‐green to purple to clear, corresponding to degradation into monomeric units and eventually ring‐opening of the monomers (Figure 2f).[ 3 , 4 ] Additionally, Wallace and coworkers used FT‐IR and SEM to investigate the structural changes after enzymatic degradation of batteries composed of silk fibroin‐polypyrrole films.[ 37 ] FT‐IR displayed a reduction in the characteristic absorbance band (amide C—N stretching at 1236 cm–1) for the amorphous structure of silk, and SEM showed surface erosion of the surface morphology of the film, confirming that the enzyme could penetrate and diffuse inside the swollen film matrix.

Some polymers also allow for characterization techniques that are unique to the polymers’ chemical and physical properties. To probe the enzymatic hydrolysis of polyester elastomers, Sander, Coates, Hillmyer, and coworkers used pH‐stat titration to quantify the number of carboxylic acids formed during polyester hydrolysis and batch reaction vessels coupled to solution total organic carbon (TOC) analysis to quantify soluble hydrolysis products.[ 39 ] The plateaus of the hydrolysis curves as measured by pH‐stat titration suggested approximately 100% of esters hydrolyzed, at which analysis of the hydrolysis products by 1H and 13C NMR spectroscopy was consistent with the products expected from full hydrolysis. For solution TOC analysis, the lack of any appreciable dissolved organic carbon after one week of incubation without the enzyme indicated that both abiotic hydrolysis and leaching of organic compounds from the elastomers were negligible. As polymer macroscopic properties are dependent on the molecular and microscopic structure, a loss of functionality also indicates a structural change has occurred. For example, since the SPN‐based afterglow agents previously mentioned exhibit fluorescence and afterglow luminescence, quantification of the radiance intensities showed a decrease after enzymatic degradation via treatment with H2O2 and myeloperoxidase.[ 20 ] When characterizing biodegradable electronics, device failure is often additionally noted through manifestation of extreme loss in electronic performance or major substrate damage. For example, degradable cyclic poly(phthalaldehyde) (cPPA) substrates deformed after exposure to UV, causing the resistor to degrade and then fail, which was observed as a sharp increase in resistance.[ 40 ] In a similar manner, our group designed TFTs based on a biodegradable polymeric substrate and dielectric that irreversibly lost device functionality within two days as the semiconductor delaminated from the dielectric.[ 34 ] The substrate and dielectric components, however, did not fully degrade until after 30 days. As demonstrated, electronics typically fail before full degradation of the material. Consequently, a loss of functionality alone is not enough to constitute biodegradation of device components.

Due to experimental ease and challenges with isolation and analysis of degradation products, several reported biodegradable polymers only employ mass loss profiles along with some description of change in physical appearance to indicate decomposition.[ 41 , 42 , 43 ] Isolation procedures of the resulting material after degradation treatments alone could produce a mass loss. Batch‐to‐batch variability and the lack of reproducibility associated with simply reporting weight loss necessitate more required standards and methods for the characterization of biodegradable materials. A combination of molecular (i.e., NMR, FT‐IR, GPC), microstructural (i.e., SEM, AFM), and macroscopic (i.e., UV–vis, loss of electronic performance) characterization tools should be employed. Furthermore, for implantable electronics, the toxicity of the degradation products must be examined, much like those used in biocompatibility characterization. Although the biocompatibility of biodegradable electronics is commonly explored in relation to the bulk device before degradation, byproduct toxicity and in vivo studies are crucial in translating these technologies to real‐life applications.

3.3. Characterization for Biocompatible Polymers

3.3.1. Current Standards and Regulations

The commercial use of any material in the medical field must meet stringent safety requirements. In terms of regulation of polymeric materials and electronics, the ISO presents widely adopted medical device standards which are addressed in a guidance document called ISO 10993: Biological Evaluation of Medical Devices.[ 17 , 44 ] As devices are typically composed of more than one material, it is not sufficient to address the biocompatibility of a single material in relation to a specific location. However, if the material has a proven safe history of medical use, the material characterization phase of evaluation can be omitted.[ 17 ] These guidelines are currently divided into twenty parts, from animal welfare requirements to principles and methods for immunotoxicology testing of medical devices. The selected test program depends heavily on the material used, contact regime, and time duration of contact with the device. For example, the contact time is broken into short durations (<24 h), prolonged contact (24 h to 30 days), and permanent contact (>30 days). Additionally, biocompatibility protocols must account for potential misuse of the device or material. ISO 10993 is intended to assist developers and manufacturers in designing appropriate testing programs for their engineered device. Other country‐specific guidelines largely overlap with ISO 10993; however, only a couple political regions will be addressed here.

The United States Food and Drug Administration (FDA) uses the United States Pharmacopoeia (USP) 88 Biological Reactivity Tests for in vivo testing.[ 45 ] Similarly, these tests are directly related to the intended use and location of the plastic component, with different tests for intravenous injection, subcutaneous injection, and implantation. Biocompatibility assessment is conducted through chemical, mechanical, and thermal testing but also includes the effect of (repeated) sterilization procedures on the device. USP 88 categorizes plastics as Class I to VI as well as measures the biological response of animals using standardized temperatures and time regimes. It is important to note that although Class VI plastics must pass the most rigorous testing, it does not fully meet any category of ISO 10993 testing guidelines. European Union device manufacturers are currently governed by Regulations (EU) 2017/745 and 2017/746 for general medical devices and in vitro diagnostic medical devices, respectively.[ 46 , 47 ] These regulations provide clearer requirements for clinical data on medical devices and their assessment as well as enhanced provisions for post‐market surveillance. Collectively, these organizations address nearly all conceivable medical device testing concerns.

3.3.2. Experimental Characterization Methods

Since the immunological responses of the human body are complex, biocompatibility must be considered in relation to many different cell types and sites of application. Although the biocompatibility of electronics used in the biomedical field is highly dependent on the application of the device, biocompatible electronics developed in research mainly use a combination of microscopy/imaging techniques (e.g., brightfield/light, fluorescence, SEM, confocal) as well as various cell assays to test for viability. Examples of imaging techniques used for polymeric materials are described herein. In a study of rat hippocampal neurons cultured on flexible 3D pillar electrodes made of polydimethylsiloxane (PDMS), brightfield and confocal fluorescent microscopy images were taken.[ 48 ] Visual assessment confirmed healthy neuron growth with typical morphology, including formation of a confluent monolayer of cells and extensive branching neurites. Through a different imaging technique, thin shape memory polymer‐based multi‐electrode softening cuffs (MSCs) were compared to silicone analogues for fibrotic growth after implantation on somatic nerves.[ 49 ] Staining of adjacent tissue and comparison of differential interference contrast (DIC) microscopy images showed a reduction in inflammatory cells evoked by the MSC device (Figure 2g). These MSCs were not only chemically biocompatible but also mechanically biocompatible through their conformability. Traeger, Schubert, and coworkers employed high resolution microscopy to examine the gene transfection mechanism of a modified poly(ethylene imine) (PEI) copolymer.[ 50 ] Confocal microscopy, structured illumination microscopy with fluorescence imaging, and high‐angular annular dark‐field scanning transmission electron microscopy (HAADF‐STEM) of embedded cell samples revealed a co‐localization of DNA‐bound polymers within lysosomes, showing efficient release of DNA into the cytoplasm. In addition to cytotoxicity studies by cell incubation and viability, the blood compatibility of the PEI copolymer was assessed by a hemolysis assay, which determined low hemolytic activity as well as minimal aggregation of erythrocytes.

The in vitro and in vivo tests for biocompatible polymers and electronics vary greatly, especially due to the location in the body the material or device is intended to be used. A polyacrylic acid (PAA)/reduced graphene oxide (rGO) nanocomposite hydrogel used for wearable strain sensors was evaluated for biocompatibility through in vitro HEF1 fibroblast cell cultures.[ 51 ] Cell viability was investigated using a commercial LIVE/DEAD Viability/Cytotoxicity Kit, which simultaneously displays both live (green) and dead (red) cells by the targeting of different fluorescent dyes. In this kit, the green fluorescent calcein‐AM dye targets esterase activity in the cytoplasm of living cells, while the red fluorescent ethidium homodimer (EthD‐1) dye demonstrates cell death by penetrating damaged cell membranes. After staining, the cells were observed using confocal microscopy, demonstrating over 95% cell viability and flourishing cell growth after 14 days (Figure 2h). Poly(trimethylamine N‐oxide) (PTMAO), an ultralow fouling polymer reported by Jiang, was tested for in vitro fouling through incubation with plasma proteins and measurement by enzyme‐linked immunosorbent assay (ELISA).[ 52 ] Comparison of the developed polymer's protein and cell adsorption to that of commercial polymers displayed PTMAO's exceptional nonfouling capability. The nonfouling property was further tested in undiluted human blood serum, which is known as the most challenging in vitro system as it closely mimics humans’ complex biological environment. Surface plasmon resonance (SPR) binding analysis was used to detect low protein adsorption levels. Subcutaneous and intravenous injections in mice also indicated minimal immunogenicity by antibody tests by ELISA (Figure 2i). For a different PEI copolymer, a 3‐[4,5‐dimenthylthiazol‐2‐yl]‐2,5‐diphenyltetrazolium bromide (MTT) assay using human embryonic kidney (HEK) 293 cells was conducted to investigate in vitro cytocompatibility.[ 53 ] The interactions of this polymer with serum proteins were assessed by dynamic light scattering (DLS) measurements for particle size instead of SPR analysis, indicating serum stability and the absence of harmful serum coagulation. Although these methods vary widely, many studies similarly use a mix of imaging techniques and cell viability assays to compare the developed biocompatible polymeric material to its non‐biocompatible counterparts. The actual methods picked are specific to the material's intended application either on the skin, in bodily fluids, or elsewhere in the body.

4. Molecular Design of Polymers

From the molecular level, the chemical structures of polymers intrinsically determine their microscopic and macroscopic properties. The structure–property relationships of these polymers highlight the molecular design of polymers that exhibit recyclability, biodegradability, or biocompatibility. Typically, molecular design focuses on a bottom–up strategy, where the polymer repeating units are designed, tailored, and further polymerized into either linear or network structures. Understanding the molecular design of polymer structures allows for tuning of the polymer architecture as well as the development of materials with emergent, desired functionalities not already available in commercial polymers. In this section, we introduce basic established chemistries for each of these eco‐ and human‐friendly categories and then examine emerging polymers in each field and their advantages over existing chemistries. These basic chemistries cover commonly used functional groups as well as traditional polymers (i.e., commercial, naturally derived, or discovered over a decade ago), while emerging polymers are synthetically designed as recent, sustainable advances over the past few years.

4.1. Recyclable

4.1.1. Chemistries for Traditional Recyclables

Traditional recyclables are classified as plastics that are in widespread and commercial use, such as those in the RIC system. Most conventional recyclable linear polymers/thermoplastics (e.g., polyethylene, polyurethane, PET) are often subjected to physical downcycling processes, which unfortunately lead to the deterioration of mechanical properties through discoloration or decreases in molecular weight (Figure 3a). Additionally, thermal and catalytic pyrolysis at high temperatures (>400 °C) for polymers such as polyethylene suffer from low energy efficiency and lack of product control, resulting in complex product compositions that are difficult to separate for future use.[ 54 ] The high cost and energy consumption associated with downcycling and more common tertiary recycling methods have led to the recent exploration in improving catalytic recycling design. For example, Guan, Huang, and coworkers developed an iridium catalytic system based on alkane cross‐metathesis for the facile recycling of commercial polyethylene into useful liquid fuels and waxes under mild conditions.[ 54 ] This method also showed excellent degradation product distribution (liquid fuels versus waxes) through control of the catalyst structure and reaction time. Although the above secondary and tertiary recycling strategies have been advanced to improve recycling efficiency, they still typically lead to some unrecyclable impurities or only convert polymers into small‐molecule derivatives that require additional modification to be converted into polymerizable monomers.[ 55 , 56 ] One category of chemical recycling that has been gaining attention is the upcycling of polymers through the reclamation of pure monomers. As a specific example, Hedrick and coworkers investigated the organocatalyzed aminolysis of PET, one of the most recycled commercial thermoplastics, to produce a broad range of terephthalamide monomers.[ 57 ] On the other hand, the recycling of thermosets is challenging as they are typically permanently crosslinked and unlikely to be reprocessable via conventional methods. Hence, the expansion of recyclable thermosets as well as polymers that can be fully recycled into polymerizable monomers are desirable in terms of procedure simplification, energy cost, and the realization of sustainable materials with a broad range of mechanical properties.

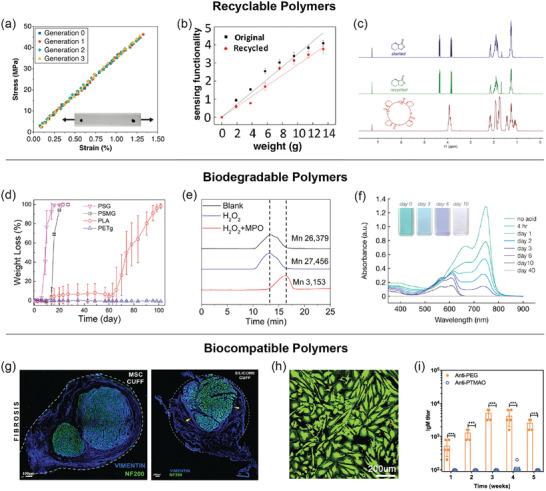

Figure 3.

Molecular design for traditional recyclables as well as emerging thermoplastic and thermosetting recyclable polymers. a) Traditional recyclable polymers include poly(ethylene terephthalate), polyethylene, and polyurethane. b) Thermally‐mediated polymerization and depolymerization of self‐immolative cPPA. c) Mechanical properties of the virgin and recycled cPPA thin films. Adapted with permission.[ 22 ] Copyright 2019, American Chemical Society. d) Divergent chemical recycling of a polyvalerolactone to CMVL monomer or new polymethacrylate. Adapted with permission.[ 64 ] Copyright 2018, American Chemical Society. e) Scheme of recyclable network PDKs synthesized from polyamines and ditopic triketones. f) Photographs showing orthogonal depolymerization of PDKs and triketone monomer recovery from mixed plastic waste. Adapted with permission.[ 26 ] Copyright 2019, Springer Nature. g) Scheme of reversible hemiaminal network synthesized from a PEG‐based monomer. Adapted with permission.[ 27 ] Copyright 2019, Wiley‐VCH.

4.1.2. Molecular Design of Recyclable Polymers

In discussing the molecular design of recyclable polymers in recent years, we will address various types of recyclable polymers (e.g., self‐immolative, linear, thermosetting) and include one or more examples in each category.

Self‐Immolative Polymers

With the goal of a circular plastics economy, the upcycling of polymers into reusable monomers or starting materials has been emerging as an attractive topic. In the last decade, vast attention has been paid to the development of self‐immolative polymers, which are a class of metastable polymers that self‐depolymerize into monomers upon external stimuli (e.g., backbone cleavage or removal of chain‐end capping functionality).[ 58 ] Moore and coworkers employed phthalide monomers for the preparation of self‐immolative cyclic poly(phthalaldehyde) (cPPA), of which the facile depolymerization and repolymerization was demonstrated for the recycling of carbon fiber‐reinforced cPPA composites.[ 22 ] cPPA depolymerized through cleavage of the acetal backbone at 120 °C in only 14 min, with simultaneous quantitative monomer recovery (Figure 3b). Both cPPA thin films and the reinforced composites retained >99% of their moduli and tensile strength after multiple recycling steps (Figure 3c). Interestingly, although thermal recycling methods are conventionally considered secondary recycling, self‐immolative polymers form a special class of recyclable polymers that allow for upcycling under broader recycling conditions. Additionally, changing the initiator during polymerization has been demonstrated to produce linear phthalide‐based polymers installed with various end‐caps that allow for triggered self‐degradation in response to different stimuli.[ 59 , 60 ] These phthalide‐based polymers possess a low ceiling temperature, owing to the metastable characteristic of their polymer backbone, and thus the working temperature range of the polymer needs to be considered in the design of thermally recyclable materials.

Thermoplastics

As the intrinsic instability of self‐immolative polymers limits their practical applications, recyclable polymers with a higher thermal stability are more desirable. To address this issue, Chen and coworkers introduced polylactone‐family polymers based on γ‐butyrolactone and its derivatives, in which the catalyst or monomer design allows for facile ring‐opening polymerization (ROP) to yield depolymerizable polylactones.[ 25 , 61 , 62 ] Both linear and cyclic polymers were synthesized, depending on the type of applied catalyst, and the resulting polymers showed enhanced thermostability and repeatable and quantitative recyclability by thermolysis or chemolysis.[ 25 ] In the presence of a catalytic amount of ZnCl2, the temperature required for recycling for both linear and cyclic polymers decreased from ≥300 to 120 °C. Consecutive polymerization‐depolymerization showed quantitative monomer recovery (97%) and reproducible, subsequent monomer conversion (85%) over three cycles. This work contributes to the efforts in achieving circular monomer–polymer–monomer cycles, a challenge in the development of chemically recyclable polymers.

While the synthetic design of new recyclable polymers can often be expensive, the modification of renewable or biobased polymerizable monomers offers further sustainability in addition to upcycling. Notably, commercial polyurethanes are commonly used in coatings, adhesives, sealants, elastomers, and foams; however, their resistance to degradation results in significant environmental challenges with millions of tons produced annually. Hillmyer and coworkers developed chemically recyclable thermoplastic polyurethanes (TPUs) and flexible foams from a depolymerizable polyester poly(β‐methyl‐δ‐valerolactone) (PMVL).[ 63 ] PMVL monomers were easily synthesized from sugar and estimated to be low in cost (≈$2 kg−1). The formed TPUs were linear with urethane‐rich segments, with high toughness and elasticity, mimicking commercial TPUs. In contrast, the PMVL foams were composed of branched networks with hard and soft segments. Due to the reversibility of urethane bonds, thermodynamic depolymerization of these foams occurred by heating at 200–250 °C at ≈100 mTorr, and the presence of catalytic Sn(Oct)2 facilitated depolymerization rates. This recycling method does not require the addition of any solvents, and pure monomers can be regenerated by distillation without a loss in purity. More recently, Hoye and coworkers prepared another substituted polyvalerolactone made from 4‐carbomethoxyvalerolactone (CMVL), a renewable monomer synthesized from malic acid in two steps.[ 64 ] This CMVL polymer goes through divergent chemical recycling through two independent pathways (Figure 3d). The first similarly uses Sn(Oct)2 with heating (150 °C) for a backbiting depolymerization to form the original monomer, while the second uses base to cleave the polyester through a retro‐oxa‐Michael reaction, producing a methacrylate analogue that could readily undergo radical polymerization to give a new polymethacrylate. The demonstrated catalytic strategies and divergent recycling realizes sustainable, high‐performance polymers designed to fit a circular economy and can be further extended to other polyols to create a wide range of recyclable materials.

Thermosets

The recycling of thermosets/polymer networks is usually more challenging as these polymer networks are typically permanently crosslinked, and therefore, more stable and resistant compared with thermoplastics. The introduction of dynamic covalent chemistries into polymer networks allows these thermosetting materials to be thermally processed and recycled like thermoplastics. At ambient temperatures, these reversibly crosslinked polymers behave as typical strong thermosets due to the favored association under equilibrium or slow exchanging dynamics. In contrast, with fast exchanging or enhanced dissociation at elevated temperatures, these dynamic networks can flow quickly and thus be reprocessed. The Diels–Alder reaction, a well‐documented dynamic chemistry, has been widely applied as a thermoreversible crosslinking tool owing to its easy chemistry, fast kinetics, and mild reaction conditions.[ 21 , 65 ] Wudl's seminal work on fully reversible, self‐healable Diels–Alder crosslinked networks,[ 66 ] together with Liebler's later work using dynamic transesterification,[ 67 ] paved the way toward new crosslinking strategies for a variety of recyclable rubber products. Picchioni and coworkers functionalized a commercial ethylene‐propylene rubber with furan groups, which were then crosslinked with bismaleimide through Diels–Alder cycloaddition.[ 21 ] The resulting crosslinkers dissociated at elevated temperatures (>150 °C) after one hour, and the subsequent thermal annealing allowed for re‐formation of networks. This dissociation‐reformation feature of the polymer network allows the material to be recycled using hot‐press, a secondary recycling method. Specifically, the material was cut into pieces and subjected to subsequent compression molding to yield new samples with comparable mechanical properties—a feat impossible with conventional synthetic rubbers. Other reversible chemistries, including transamination,[ 68 ] disulfide exchange,[ 69 ] siloxane exchange,[ 70 ] and dioxaboralane metathesis[ 71 ] have also been explored in producing self‐healing or recyclable polymer networks.

While existing strategies to create reprocessable thermosets have focused on dynamic covalent bond exchange and thermomechanical degradation, Johnson and coworkers provided a complementary approach using mild, chemically triggered network degradation, and the degradation products were recycled as valuable starting materials.[ 72 ] The authors selectively installed a small quantity of cleavable bonds within the backbone of an industrial thermoset polydicyclopentadiene (pDCPD) to yield recyclable products of controlled molecular weight and functionality. Altering the loading of cleavable silyl ether monomers for copolymerization with norbornene derivatives by ring‐opening metathesis polymerization (ROMP) produced degradable statistical copolymers. Excess tetrabutylammonium fluoride selectively cleaved these copolymers in 4 h at a low 10% cleavable monomer loading. For comparison, the authors explored introducing silyl ethers as crosslinkers between polynorbornene strands, which did not degrade even at 80% cleavable crosslinker loading. They recycled and copolymerized the degradation products with fresh DCPD monomers to yield new materials with comparable stress–strain behavior and elastic moduli relative to those of the virgin material. Thermoset composite recycling through the introduction of cleavable bonds within the polymer backbone can impart degradability and recyclability at low co‐monomer loadings, whereas the analogous addition of cleavable crosslinks cannot.

Additionally, while most reported dynamic covalent networks addressed their reprocessability, less attention has been paid to the recovery of the network into reusable building blocks or monomers. Another example of chemical degradation of thermosetting polymers by Helms and coworkers described recyclable networks based on dynamic covalent diketoenamine bonds, which undergo reversible depolymerization to give high‐value monomers in the recycling process.[ 26 ] In detail, β‐triketones and aromatic/aliphatic amines underwent a facile “click” reaction through ball‐milling to form poly(diketoenamine)s (PDKs), producing water as the only byproduct (Figure 3e). These PDKs were hydrolyzed in strong aqueous acid (0.5–5.0 m H2SO4) at ambient temperature and further treated to regenerate triketone and amine monomers. To demonstrate the facile recycling of these PDKs, they physically mixed these PDKs with commercial plastics, which do not depolymerize under the same recycling conditions, and treated the mixture with recycling procedures (Figure 3f). Desirably, PDKs were selectively dissembled from the mixed plastic waste streams, and monomers were cleanly retrieved. This selectivity in recycling highlights the simplicity of raw‐material recovery from plastic waste mixtures, of which the purification or recovery procedures are typically tedious, complex, and highly energy demanding. The facile, clean, and selective recycling features “closed‐loop recycling” of thermosetting materials and renders these plastics as promising polymers with minimal environmental impact. While the authors refer to this process as closed‐loop recycling, this term was previously only used to refer to primary recycling, which involves physical or mechanical processes. Perhaps with the rapid advancement of chemical recycling, the term is evolving to encapsulate all polymers capable of regenerating the original material without a loss in quality regardless of the process used.

Recyclable thermosets that are also conductive are even rarer. Building from previous work on recyclable thermosetting polymers,[ 73 ] García and coworkers further demonstrated organogel composites that are both conductive and fully recyclable.[ 27 ] They found that polymer composites comprised of a hemiaminal dynamic covalent network (HDCN) and fillers could exhibit high conductivities up to 9.95 mS cm–1, which are suitable for sensing applications. Various conductive fillers (e.g., carbon nanotubes, carbon black, graphite) and solvents were screened for in the synthesis of HDCNs based on polyethylene glycol (PEG) monomers (Figure 3g). The resulting conductivity, modulus, and relaxation time can be effectively tuned based on filler selection, which highly impacts the interaction strength with the polymer matrix. While HDCNs synthesized in N‐methyl‐2‐pyrrolidone (NMP), N‐cyclohexyl‐2‐pyrrolidone, dimethylformamide, and dimethyl sulfoxide were recyclable in pH‐neutral water with 95% monomer recovery, conductive filler‐matrix networks could be recycled using dilute acid (pH = 3) via hydrolysis within 20 min. These organogel composites enable desirable conductive functionalities and potential applications for recyclable thermosets to be used in electronics.

4.2. Biodegradable

4.2.1. Basic Chemistries for Biodegradables

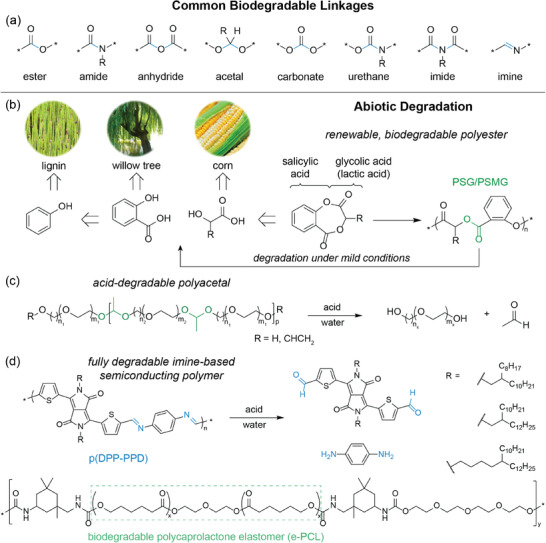

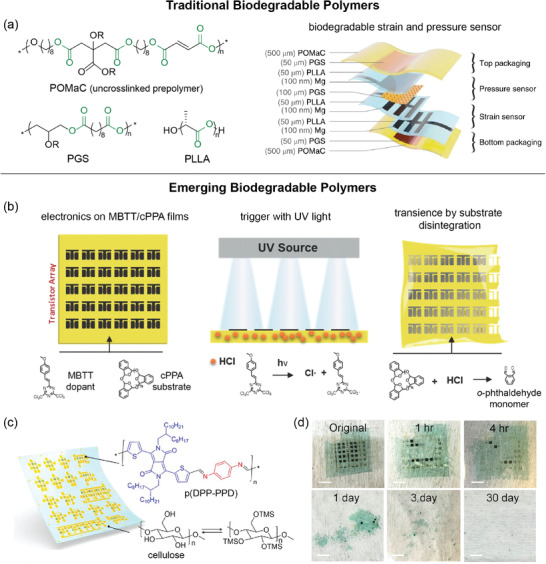

Common biodegradable polymers are derived from naturally occurring materials, such as plant‐based cellulose and dextran as well as animal‐derived collagen and silk fibroin. On the other hand, biodegradable synthetic polymers offer more control of the polymer architecture, and thus, degradation kinetics and mechanical properties. Most explored biodegradable polymers are based on hydrolytically cleavable linkages, including ester, amide, anhydride, acetal, carbonate, urethane, imide, and imine bonds (Figure 4a). Polylactic acid (PLA, PDLA, PLLA), poly(lactic‐co‐glycolic acid) (PLGA), and poly(caprolactone) (PCL) are well‐established degradable polymers that take advantage of their cleavable ester bonds.[ 6 , 12 ] However, the degradation of these polymers in landfills is highly dependent on the molecular weight, temperature, humidity, and oxygen availability and does not occur under common environmental conditions.[ 74 ] In addition to common polyesters, biodegradable elastomers with flexible and stretchable mechanical properties have also been explored. A widely used biodegradable elastomer in biomedical applications, poly(glycerol sebacate) (PGS), was first introduced by Langer and coworkers in 2002.[ 41 ] Compared with biodegradable elastomers at the time, the covalent crosslinks in PGS provided both toughness and flexibility, which are ideal for implantable devices that undergo large deformations in the body's dynamic environment. The degradation of PGS occurred through surface decomposition instead of bulk degradation, in which mechanical properties decrease abruptly.[ 75 ] In vivo degradation of PGS samples in rats were fully absorbed in 60 days. In contrast, agitation for the same amount of time in a PBS (pH = 7.4) solution only resulted in ≈17% degradation by mass loss. There is much room for improvement in the molecular design of biodegradable polymers with more robust and controlled degradation as well as uniformity to ensure a reproducible biological response for implantable applications. While there are also moieties susceptible to oxidative and reductive cleavage,[ 76 , 77 , 78 , 79 ] redox‐responsive polymers for biodegradation have been less studied. Additionally, emerging synthetic polymers have been designed to degrade when stimulated by light as well as to be enzymatically degradable, some of which will be explored in the next section.

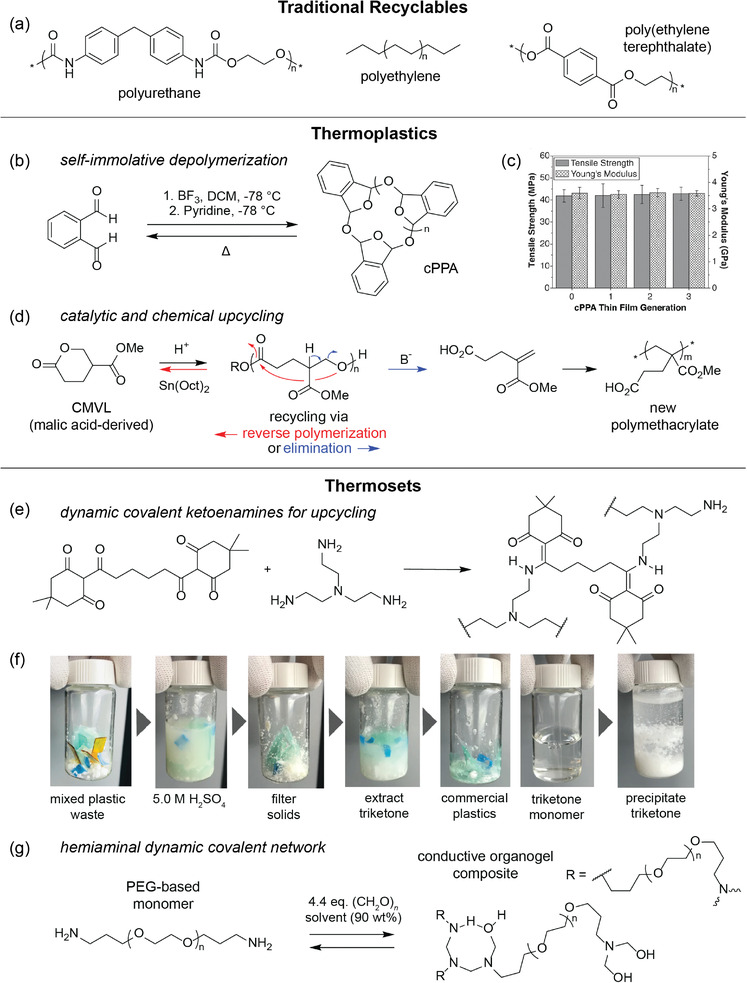

Figure 4.

Chemistries of common biodegradable linkages and molecular design for emerging abiotically biodegradable polymers. a) Chemical structures of moieties susceptible to hydrolytic cleavage, which are commonly used in biodegradable polymers. Blue shows the bond(s) being broken. b) Scheme of renewable, biodegradable aromatic polyesters synthesized through ROP of a biobased lactone monomer. Adapted with permission.[ 38 ] Copyright 2020, American Chemical Society. c) Scheme of water‐soluble, temperature‐responsive polyacetals and their degradation via acid hydrolysis. Adapted with permission.[ 36 ] Copyright 2016, American Chemical Society. d) Chemical structures of the fully degradable semiconducting polymer p(DPP‐PPD) and its monomeric byproducts after cleavage as well as biodegradable elastomer e‐PCL. Adapted with permission.[ 4 ] Copyright 2019, American Chemical Society.

4.2.2. Molecular Design of Biodegradable Polymers

Abiotic Degradation

Synthetic biodegradable polymers are typically abiotically degraded, in which chemical and physical conditions not derived from living organisms are used. Among the different classes of synthetic polymers, polyesters are the most studied for biomedical applications. Traditional aromatic polyesters, such as PET, make up close to 10% of the global plastic market, are not readily degradable, and are derived from non‐renewable resources. Over the past few years, tremendous effort has been directed at designing these polyesters to be renewable and biodegradable. Miller and coworkers copolymerized camphoric acid, an inexpensive and biorenewable diacid from camphor laurel trees, with various diols to afford copolymers with a large range of glass transition temperatures (T g).[ 80 ] Polyethylene camphorate was degraded by agitation in aqueous solutions of pH = 1 and pH = 2 and deionized (DI) water at pH = 7 for 14 days at room temperature. GPC analysis after DI water treatment showed a reduction in M n from 20,200 to <600 Da. In a further attempt to address the feasibility of using camphoric acid to replace the phthalic acid in PET, copolymers comprised of both acid blocks were successfully prepared. However, the increase in biobased camphorate incorporation decreased the T g from that of PET from 71 to 41 °C, requiring further tuning of the polymer architecture to serve as an alternative to PET in terms of its physical properties. Recently, Hillmyer, Ellison, and coworkers also synthesized biodegradable polyesters from sustainable feedstocks that rapidly degrade under mild conditions (Figure 4b).[ 38 ] Aromatic polyesters derived from salicylic acid, poly(salicylic glycolide) (PSG) and poly(salicylic methyl glycolide) (PSMG), were found to have comparable glass transition temperatures and Young's moduli to those of PET. PSG and PSMG were immersed in PBS solution (pH 7.4), artificial seawater (pH = 8.0), DI water (pH = 7.1) and 0.1 m NaOH at 50 °C. Both samples showed significant weight loss within 30 days compared to PLA, which took twice as long to degrade. These biorenewable polyesters have facile degradation properties that could substitute for nondegradable PET derivatives. While it is not necessary for biodegradable polymers to be also biobased, we highlight these select efforts in achieving fully sustainable polyesters.

Polyacetals are another class of polymers that have been synthetically designed to exhibit biodegradability as the ketal functionalities are typically degradable under mildly acidic conditions. Koberstein and coworkers demonstrated a new family of acid‐degradable polyacetals with lower critical solution temperature (LCST) behavior owing to the presence of both hydrophobic and hydrophilic blocks along the polymer chain, and the polyacetals were found to possess predictable temperature response (Figure 4c).[ 36 ] These water‐soluble, temperature‐responsive polymers have potential applications in tissue scaffolds, actuators/artificial muscles, and drug delivery vehicles. The synthesized polyacetals were relatively stable under neutral conditions, with a molecular weight decrease of ≈10% after 3 days at pH = 7.4. In contrast, the molecular weight decreased by ≈70% after 3 days at pH = 6.5, and the polymer completely degraded after 3 days at pH = 5.5. These mildly acidic conditions are analogous to areas in the human body, such as the upper stomach (pH = 4.0–6.5), endosomes and lysosomes (pH = 4.5–5.5), and tumor tissues (pH = 4.2–6.7).[ 81 ] Polyesters and polyacetals are typically synthesized through ROMP or step‐growth polymerizations, which often give fairly broad polydispersities of ≈1.5–2. For better control of polydispersities and design of the polymer architecture (e.g., block copolymer, star/branch structure), living chain polymerizations have been applied for the preparation of biodegradable materials. As the biodegradability of polymers has been shown to be dependent on their molecular weight,[ 82 , 83 ] polymers with narrow polydispersities can be anticipated to give more controlled biodegradation. Gutekunst and coworkers achieved rapid and living polymerizations of polyacetal materials using modular enyne monomers.[ 35 ] The obtained degradable polymers possess narrow polydispersities of ≈1.1–1.5 and exhibit optimal degradation in the presence of acetic acid (AcOH) or trifluoroacetic acid (TFA). The polyacetal showed gradual hydrolysis in neutral conditions, with a 63% reduction in molecular weight after 48 h by GPC. The addition of AcOH resulted in a higher 80% mass reduction after 48 h, while TFA caused rapid degradation into small molecules after 24 h. Although a large amount of organic solvent was needed for the polymers to dissolve due to their hydrophobic nature, the enyne monomers can be designed to be more hydrophilic.

The integration of fully biodegradable electronics calls for polymer semiconductors and conductors that are also biodegradable. However, most reported biodegradable polymers are insulating polymers. Designing biodegradable electronically‐active conjugated polymers involve the incorporation of degradable bonds that maintain conjugation into the polymer backbone. Our group incorporated hydrolyzable imine linkages, which preserve conjugation, into the backbone of conjugated donor–acceptor polymers to achieve transient semiconductors. These acid‐labile semiconducting polymers were further blended with a biodegradable elastomer to achieve semiconductors that are both stretchable and fully degradable.[ 4 ] The molecular design involved a dialdehyde‐functionalized diketopyrrolopyrrole (DPP) and p‐phenyldiamine, which were polymerized by imine condensation to form p(DPP‐PPD). Upon spin‐coating a solution of p(DPP‐PPD) and urethane‐based elastomer (e‐PCL), the thin film exhibited self‐assembled nanoconfined fibril aggregates of p(DPP‐PPD) embedded within the e‐PCL matrix (Figure 4d). A solution of neat p(DPP‐PPD) in 1% 1 m TFA in chlorobenzene showed peak maxima in UV–vis absorption spectra diminishing completely after 10 days, with all absorption peaks becoming negligible after 40 days. Thin films of both neat and nanoconfined p(DPP‐PPD) in water with 0.1 m TFA displayed similar trends of peak maxima decreasing after 10 days. This biodegradable active material further advances the development of new multifunctional technologies for human health and environmental sustainability.

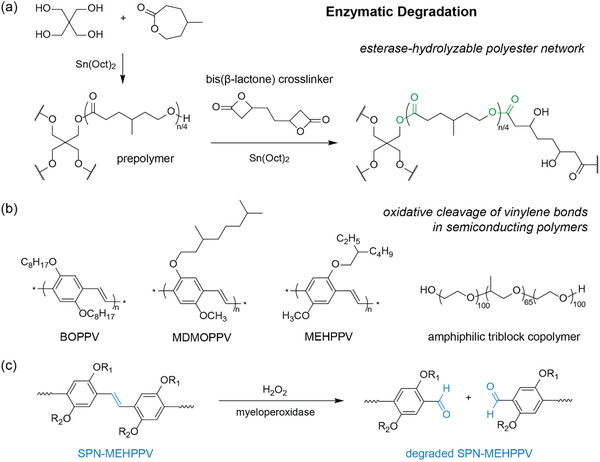

Biodegradation

Unlike the previously discussed abiotic degradation studies, biodegradation in natural systems is inherently biologically benign as it is achieved through microorganisms and their enzymes. Sander, Coates, Hillmyer, and coworkers designed chemically crosslinked polyester elastomers that are renewable and enzymatically hydrolyzable.[ 39 ] ROP of γ‐methyl‐ε‐caprolactone generated prepolymers, which were then crosslinked using a novel bis(β‐lactone) crosslinker (Figure 5a). The obtained polyester networks were subjected to degradation experiments using Fusarium solani cutinase (FsC), an esterase (hydrolase enzyme) from filamentous fungi, and were found to readily hydrolyze at neutral pH and environmentally relevant temperatures (2−40 °C). In contrast, abiotic degradation of traditional polyester networks typically requires much harsher conditions (e.g., strong acid or base, temperatures >200 °C). The extracellular esterases cleaved the polyesters into smaller, water‐soluble monomeric units of hexanoic acids and oligomers that can be taken up and used by microorganisms, producing CO2 and microbial biomass.[ 84 ] Complete degradation was achieved at temperature‐dependent rates, with higher temperatures giving faster hydrolysis rates.

Figure 5.

Molecular design for emerging enzymatically biodegradable polymers. a) Synthesis of a renewable polyester network obtained through ROP of derived caprolactone and subsequent crosslinking with a bis(β‐lactone) monomer. Adapted with permission.[ 39 ] Copyright 2018, American Chemical Society. b) Chemical structures of the semiconducting polymer nanoparticles and triblock copolymer. c) Scheme of the degradation of SPNs, which contain vinylene bonds that are cleavable in the presence of oxidative species and myeloperoxidase. Adapted with permission.[ 20 ] Copyright 2017, Springer Nature.

Enzymes are also capable of chemical reactions at physiological conditions that would otherwise require harsh or non‐biocompatible conditions abiotically. Pu and coworkers took advantage of enzymatically biodegradable vinylene bonds that undergo oxidative cleavage by H2O2 and myeloperoxidase.[ 20 ] The authors designed semiconducting polymer nanoparticles (SPNs) that store photon energy and emit long‐NIR afterglow luminescence for applications in ultrasensitive in vivo optical imaging. These phenylenevinylene‐based SPNs (BOPPV, MDMOPPV, MEHPPV) were transformed into water‐soluble nanoparticles in the presence of an amphiphilic triblock copolymer (Figure 5b). They treated the SPN solutions to H2O2 and myeloperoxidase at 37 °C for 8 h in PBS solution (Figure 5c). GPC, UV–vis spectroscopy, and quantification of the fluorescence and afterglow luminescence intensities of the original SPNs, SPNs treated with H2O2, and SPNs treated with both H2O2 and myeloperoxidase were used to analyze successful degradation of the polymer. As H2O2 is produced naturally in the lungs, gut, and thyroid gland of humans, these semiconducting polymers have potential to be used for implantable electronics in certain locations in the body.

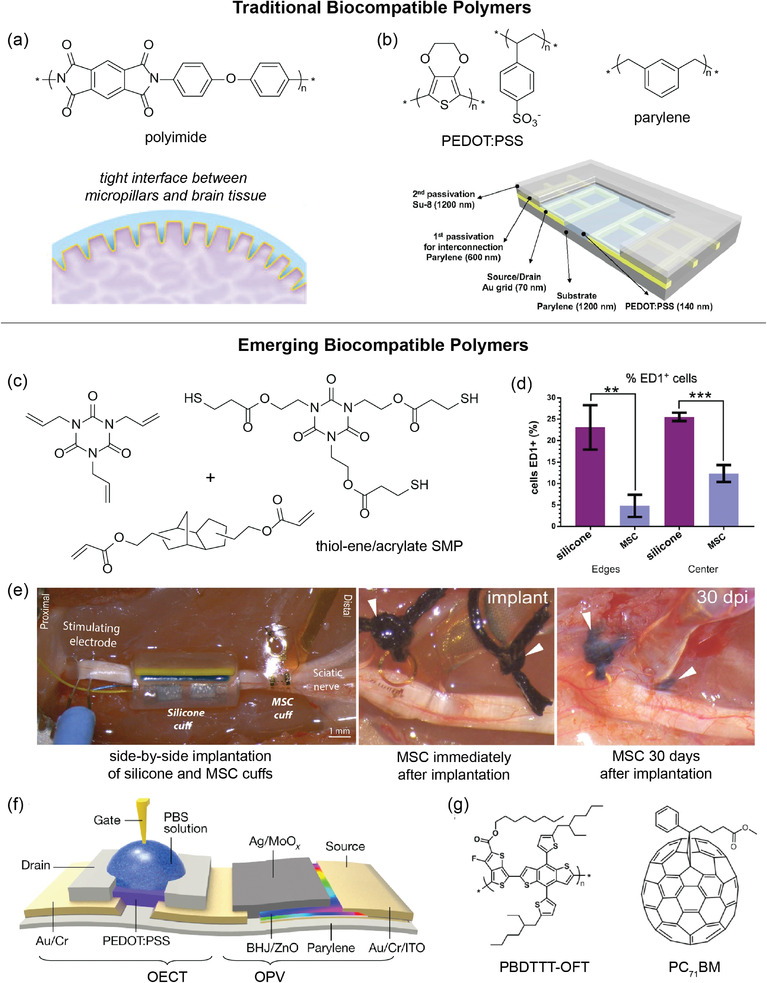

4.3. Biocompatible Polymers

4.3.1. Basic Chemistries for Biocompatible Materials

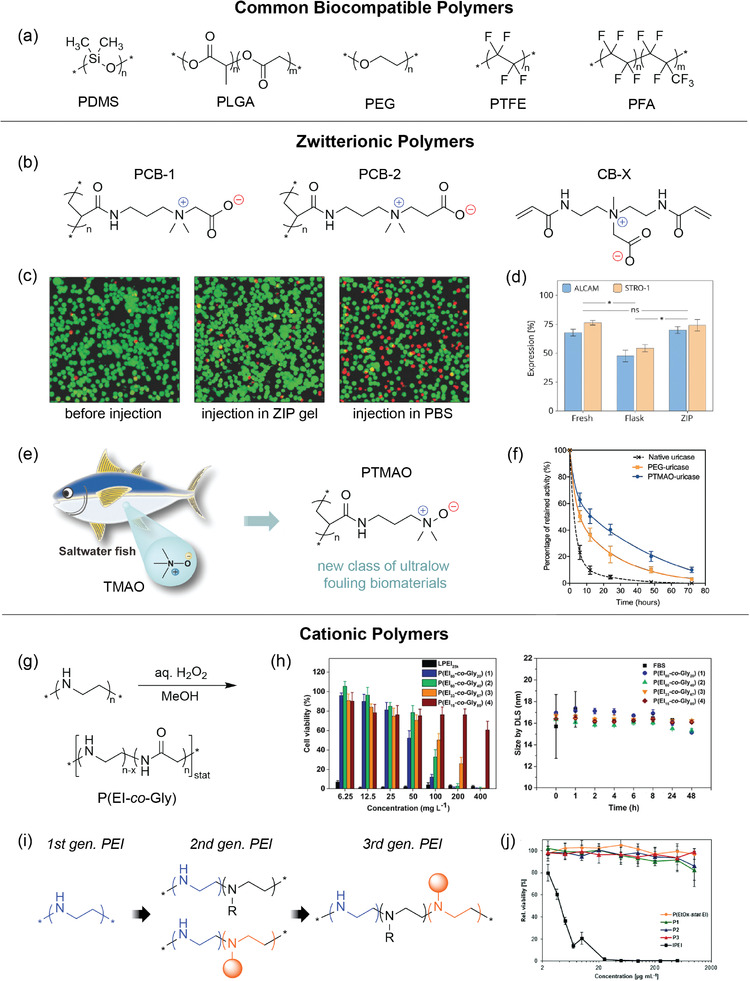

Retrieved from biological systems, natural polymers, including protein‐ and polysaccharide‐originated polymers (e.g., silk fibroin,[ 85 , 86 ] collagen,[ 87 ] gelatin,[ 88 ] elastin[ 89 ]) are readily available, inexpensive, and typically biocompatible (i.e., non‐toxic and noninflammatory).[ 90 , 91 , 92 ] More detailed descriptions of various traditional biocompatible and bioresorbable natural polymers and their uses can be found in recent reviews.[ 2 , 10 ] However, these naturally‐derived polymers can uncontrollably elicit undesired immunogenic response due to batch‐to‐batch variability or inherent bioactivity.[ 8 , 93 ] Synthetic polymers designed to be biocompatible have been widely used in drug delivery,[ 94 , 95 , 96 ] tissue engineering,[ 97 , 98 ] and gene transfection.[ 50 , 99 ] For example, due to their inertness, low density polyethylene (LDPE) and polydimethylsiloxane (PDMS) have been accepted by the US National Heart, Lung, and Blood Institute as discriminatory tools for validation of both in vitro and in vivo tests in the evaluation of biomaterials.[ 7 ] Parylene, PLA, PLGA, and PEG are examples of polymers frequently used in implantable electronics and have been approved by the US FDA for clinical use.[ 10 ] Notably, fluoropolymers have among the best biocompatibility of all plastics due to their typical lubricity, ability to be sterilized, broad temperature tolerance, and minimal chemical reactivity in the body.[ 100 ] Class VI USP approved fluoropolymers include ethylene tetrafluoroethylene (ETFE), fluorinated ethylene propylene (FEP), perfluoroalkoxy alkane (PFA), polytetrafluoroethylene (PTFE), and polyvinylidene fluoride (PVDF).[ 101 ] The chemical structures of several common biocompatible polymers are shown in Figure 6a. While there are a number of established and commercial biocompatible polymers, new molecular design allows for synthetic tuning of specific functionalities, enabling a broader range of wearable and implantable electronic applications in different locations of the body and bodily fluids.

Figure 6.

Molecular design for common and emerging biocompatible polymers. a) Chemical structures of biocompatible polymers commonly used in medical applications. b) Chemical structures of the injectable zwitterionic hydrogel platform based on carboxybetaine (CB) polymers and crosslinker. c) LIVE/DEAD stained HEK‐293T cells before and after injection in ZIP gel and PBS control as well as d) expression of multipotency biomarkers ALCAM and STRO‐1 after culture in control flasks and ZIP gels demonstrate improved biocompatibility of the hydrogel. Adapted with permission.[ 109 ] Copyright 2018, Wiley‐VCH. e) The design of PTMAO is derived from TMAO, a zwitterionic osmolyte in saltwater fishes. f) Pharmacokinetics profile of each uricase protein sample after the third intravenous (IV) injection were determined by measuring the retained activity in mice sera. Adapted with permission.[ 52 ] Copyright 2019, AAAS. g) Scheme of the oxidation of commercial linear PEI to P(EI‐co‐Gly) by H2O2. h) Cell viability and serum stability of linear PEI as well as P(EI‐co‐Gly) copolymers. Adapted with permission.[ 53 ] Copyright 2015, American Chemical Society. i) Different generations of linear PEI. The multifunctional third generation PEI outperforms first (PEI) and second (single PEI modifications) generations in terms of biocompatibility and biodegradability. j) Relative viability of L929 cells after 24 h incubation with PEI and PEI copolymers at different concentrations. Adapted with permission.[ 50 ] Copyright 2017, Royal Society of Chemistry.

4.3.2. Molecular Design of Biocompatible Polymers