Abstract

Electrochemistry has recently gained increased attention as a versatile strategy for achieving challenging transformations at the forefront of synthetic organic chemistry. Electrochemistry’s unique ability to generate highly reactive radical and radical ion intermediates in a controlled fashion under mild conditions has inspired the development of a number of new electrochemical methodologies for the preparation of valuable chemical motifs. Particularly, recent developments in electrosynthesis have featured an increased use of redox-active electrocatalysts to further enhance control over the selective formation and downstream reactivity of these reactive intermediates. Furthermore, electrocatalytic mediators enable synthetic transformations to proceed in a manner that is mechanistically distinct from purely chemical methods, allowing for the subversion of kinetic and thermodynamic obstacles encountered in conventional organic synthesis. This review highlights key innovations within the past decade in the area of synthetic electrocatalysis, with emphasis on the mechanisms and catalyst design principles underpinning these advancements. A host of oxidative and reductive electrocatalytic methodologies are discussed and are grouped according to the classification of the synthetic transformation and the nature of the electrocatalyst.

1. Introduction

Since its inception in the 19th century, electrochemistry has matured to serve a variety of applications ranging from energy storage to metallurgy to chemical synthesis.1 The success of electrochemistry in these diverse contexts can be credited to the unique capabilities afforded by electrochemical systems. Principally, the use of an external applied potential provides a means to drive reactions far from thermodynamic equilibria, enabling access to reaction pathways and chemical intermediates that would otherwise be difficult to employ. Additionally, electrochemical systems often afford mild conditions and the potential for scalability, supporting their use in the industrial synthesis of bulk and fine chemicals. The use of electricity in place of environmentally deleterious chemical reagents such as stoichiometric oxidants and reductants also renders electrochemistry an attractive approach for improving the efficiency and sustainability of synthetic chemistry.

In recent years, electrochemistry has experienced an exciting and ongoing renaissance in the context of organic synthesis. Driven in part by the characteristic advantages of electrochemistry described above, this surge of interest has led to the development of an increasing number of electrochemical synthetic methodologies, including reactivities not directly attainable through traditional chemical methods alone.2,3 Specifically, single-electron oxidation and reduction events facilitated by electrochemistry are well-suited4 towards the creative use of radical intermediates in achieving synthetic transformations. When the formation and downstream reactivity of these intermediates are placed under the control of catalytic redox mediators, electrochemistry emerges as a powerful strategy for addressing prevailing trends in organic synthesis.

A conceptual analysis of an electrochemical reaction quickly reveals the enhanced capabilities offered by redox mediators in electrosynthesis. While electrochemistry can enable activation of substrates at the electrode surface (i.e., direct electrolysis), this mode of activation often requires substrate engineering to regulate reactivity and can forgo control over the selectivity of chemical steps following electron transfer.5 When electrochemistry is applied towards the construction and modification of complex organic molecules, the limitations of direct electrolysis can become more pronounced. However, such constraints can be addressed through the implementation of redox-active catalysts which facilitate efficient electron transfer events and offer increased selectivity relative to non-mediated processes.6

Electrocatalysis can either utilize molecular mediators as catalytic species (such as transition metal complexes or redox-active organic compounds; commonly referred to as homogenous or molecular electrocatalysis)7 or an electrode surface itself (referred to as heterogenous electrocatalysis8 herein). Traditionally, the term “electrocatalysis” is used to define the latter case involving an catalytic electrode, whereas systems featuring molecular mediators have been referred to as “molecular catalysis for electrochemical reactions.”9 In this review, electrocatalysis is described to encompass both homogeneous and heterogeneous cases, given that the defining feature of an electrocatalytic system is the use of a redox-active species which can facilitate a catalytic cycle and accelerate a specific reaction pathway.10,11 In many of the examples presented herein, electrocatalysis gives rise to new reactivities that are not accessible through non-electrocatalytic means.

The scope of electrocatalysis in chemical literature is extensive, with major areas of growth including the development of electrocatalytic systems for energy-related applications (such as water splitting12,13 and CO2 reduction14) and, more recently, synthetic chemistry.15,16 In the area of organic synthesis, continuing pressure to develop efficient and sustainable synthetic strategies has driven a tremendous surge of interest in electrocatalytic methodologies from within the broader organic chemistry community (Fig. 1).

Fig. 1.

Number of publications per year (indexed in SciFinder since 2000) in the research areas of organic electrochemistry and organic electrocatalysis.

This review highlights key innovations in the past decade (since ca. 2010) within the growing discipline of synthetic electrocatalysis. We aim to showcase the versatility of these electrocatalytic systems as well as illustrate the design principles used to develop the electrocatalytic mediators needed to power these systems. The electrocatalysts discussed herein can be subdivided into two general classes base on their role in mediating electrochemical transformations.13 The first category of electrocatalysts encompasses redox mediators which serve the sole purpose of facilitating electron transfer events between electrodes and substrates, accelerating redox reactions relative to a non-mediated system. The second category of electrocatalysts we discuss are electrocatalysts that shuttle both electrons and chemical information to substrates, placing reactivity and selectivity directly under the control of the catalyst itself. Consistent with the general definition of a catalyst, we primarily focus on reactions that utilize electrocatalysts in sub-stoichiometric amounts. However, to fully describe the reactivities enabled by electrochemical systems, we include some examples where an electrochemical mediator is used in higher loadings.

Emphasis is placed on the mechanistic details of a host of oxidative and reductive electrocatalytic transformations at the cutting edge of the discipline. We first discuss advancements occurring within the well-established realm of oxidative electrocatalysis, and then proceed to discuss emerging discoveries in the less explored areas of electroreductive transformations, paired electrolysis, and heterogenous electrocatalysis. Finally, we explore bioelectrocatalysis electrophotocatalysis to demonstrate the extension of electrocatalytic strategies into interdisciplinary applications. These recent developments illustrate many of the design principles used to realize a range of electrocatalytic methodologies and showcase the capabilities of electrochemistry in facilitating increasingly complex transformations.

Electrochemical glossary

Readers who are unfamiliar with electrochemical reactions can find valuable information on the basics of electrochemistry, including how to set up electrochemical reactions, in recent reviews by Hilt,17 Schotten and Willans,18 and in a recent account by Baran.19

In the present review, the following notation is used: a (+) sign denotes the anode; a (−) sign denotes the cathode; “|” denotes an undivided cell setup; “∥” denotes a divided cell setup. For example, “C(+)|Pt(−)” indicates that the electrolysis uses an C anode and a Pt cathode in an undivided cell. Current (i) or current density (j), electrode potential (Ec or Ea), cell voltage (Ucell) values are given when the electrolysis is conducted under constant current, constant potential, or constant cell voltage conditions, respectively. Potential values are listed with respect to a reference electrode such as ferrocene/ferrocenium (Fc/Fc+) or saturated calomel electrode (SCE). The conversion between Fc/Fc+ and SCE is E1/2(Fc/Fc+) = 0.40 V vs. SCE.

Additionally, throughout the text, mechanistic schemes are color-coded by the nature of the electrochemical transformation discussed: oxidative reactions are identified by a beige background, reductive reactions are shown with a blue background, and paired electrolysis reactions are presented with a grey background.

2. Anodic oxidation

Oxidative reactions are important tools for the synthesis of complex molecules, enabling the efficient construction of C–C bonds and the incorporation of heteroatoms into molecular architectures. Common chemical methods for oxidative reactions typically rely on the use of stoichiometric amounts of oxidizing agents, such as high-valent chromium and manganese complexes as well as hypervalent iodine species, which can often be hazardous and generate substantial amounts of waste. Recent methodological advances have led to milder reaction systems using more desirable oxidants such as O2 and H2O2.20,21 Nevertheless, finding “alternatives for oxidations” remains one of the key green chemistry research areas identified by the ACS Green Chemistry Institute Pharmaceutical Roundtable in their 2018 report.22 In this regard, the adoption of a catalyst that can be regenerated upon anodic oxidation is highly desirable from a green chemistry perspective, since waste generation is considerably reduced. Indeed, electrochemical oxidations are usually coupled with hydrogen evolution reaction to generate H2 gas as the major by-product.

Beyond its utility in recycling traditional chemical oxidants, anodic oxidation has been exploited towards the design of electrocatalytic systems to accomplish a wide range of chemical transformations. The scope of chemical mediators for these oxidative systems is extensive. For instance, the radical cations of triarylamines and ferrocenium ion (Fc+) have been employed for electron transfer. The phthalimide N-oxyl (PINO) radical, the radical cation from quinuclidine, chlorine radicals, and nitrate radicals have been used as hydrogen atom transfer (HAT) agents. Oxoammonium cations derived from nitroxyl radicals have been employed for formal hydride transfer. Further, anodic oxidation of metallic species to high valent states is often used to promote reductive elimination, which is commonly seen in C–H activation reactions. Recently, Earth-abundant 3d metals have been explored in a myriad of radical transformations. This diversity of electrooxidative reactions is discussed in the following subsections and is grouped based on the nature of the redox mediator.

Main group compounds as mediators

2.1. Halogen-based mediators (halides, hypervalent iodine)

Halide salts are among the simplest and most commonly used halogen-based mediators, which are non-toxic and inexpensive. Other less explored halogen-based mediators include iodate/periodate and hypervalent iodine compounds. Upon anodic oxidation, halides generate reactive halogen compounds (e.g., Cl2, Br2, I2), and when electrolysis is carried out in water, hypohalites can also form.

Well-established reactivities have been explored with oxidized halides, such as nucleophilic substitution and base-promoted elimination.23,24 Generation of radicals from the homolytic cleavage of weak heteroatom–halogen bonds is a less explored yet powerful approach for forging carbon–heteroatom bonds. Although halogen-based mediators can in theory be regenerated in electrochemical systems, in some cases they are used in stoichiometric amounts to ensure high reaction yields.

2.1.1. Activation of alkenes with halogens.

In 2016, Zeng, Sun, and co-workers generated 3-methoxyindolines via an electrochemical aminooxygenation reaction, mediated by iodide (Fig. 2).25 This reaction uses anodically generated iodine to produce an iodonium ion 2–3, which is subjected to an intramolecular SN2 reaction, followed by a second substitution with cathodically generated methoxide. LiClO4 can be removed from the system without affecting the yield, since the iodide source also functions as an electrolyte.

Fig. 2.

(A and B) Iodide-mediated aminooxygenation of alkenes.

In 2020, the formation of iodonium intermediates was explored by Lennox and co-workers for vicinal difluorination of alkenes (Fig. 3).26 The fluorine source arises from a mixture of commercially available Et3N·3HF and pyridine·9HF, to generate a ratio of 5.6 equivalents of HF per amine. The mechanism is proposed to start with formation of iodonium ion 3–3, followed by ring opening with fluoride and displacement of aryl iodide with a second fluoride ion. For alkenes that are more easily oxidized than the iodoarene, the authors first generated a pool of hypervalent iodine reagent and later added the alkene, demonstrating a broad functional group compatibility for this methodology.

Fig. 3.

(A and B) Hypervalent Iodine-mediated difluorination of alkenes.

2.1.2. α-Functionalization of nitriles and carbonyls.

Recently, the use of halides as electrochemical mediators for the α-functionalization of nitriles and carbonyls has been extensively explored. This reactivity relies on the α-deprotonation of these functional groups, generating stabilized anions, which can react with Br2 or I2 (see intermediate 4–3, Fig. 4). This newly installed halogen group can be easily displaced by a wide range of nucleophiles in an SN2 fashion. Appending a nucleophile in the same molecule has been employed to generate cyclic motifs intramolecularly (Fig. 4), such as cyclopropanes,27–30 cyclobutanes,31 cyclopentanes,32 β-lactams,33 and dihydrofurans.34 In the intermolecular realm, carbon, nitrogen, and sulfur nucleophiles have been explored, including nitrile anions,35 enolates,36 amines,37 sulfinates38 and carbamodithioates.39 Although several of these methods use high loadings or even stoichiometric amounts (see example 4–6, Fig. 4) of halide mediators, halide salts are fairly inexpensive. In 2021, the scalability of these methods was explored by Baran and Sabatini,25 where compound 4–5 was synthesized on a hundred-gram scale.

Fig. 4.

(A and B) Iodide-mediated cyclization.

During the 2010s, a different approach towards the electrocatalytic α-functionalization of ketones was reported by Zha, Wang, and co-workers, where the electrolysis of arylmethylketones and iodide is carried out under aerobic conditions (Fig. 5). The authors propose the intermediacy of a peroxyl radical (5–4), which could be later converted to different functionalities, such as α-keto-esters,40 α-keto-amides,41 enaminones,42 and isatins.43 Although the role of the iodide mediator is not fully understood for these reactions, we hypothesize that in situ generated iodine could react with an enolate, and the resultant C–I bond could undergo homolytic cleavage followed by O2 trapping to give the peroxyl radical intermediate.

Fig. 5.

(A and B) Iodide-mediated oxidation of methylketones.

Elinson and co-workers reported the electrochemical conversion of ketones to α-carbonyl-acetals.44–46 In this reaction, an enolate reacts with anodically generated iodine to form a C−I bond. Addition of cathodically generated methoxide to the carbonyl of 6–1 gives intermediate 6–3, which undergoes epoxide formation followed by methanolysis, releasing a phenol leaving group to generate 6–2. In 2017, a similar reactivity was explored by Zeng, Sun, and co-workers during the selective oxidation of lignin-type model compounds (Fig. 6).47

Fig. 6.

(A and B) Iodide-mediated oxidation of lignin model compounds.

2.1.3. Periodate as mediator.

The periodate anion is a versatile oxidant and is typically employed in the oxidative cleavage of diols or the in situ regeneration of catalysts such as osmium tetroxide or ruthenium tetroxide. Oxidative cleavage of vicinal diols, vicinal aminoalcohols, and α-hydroxyketones was studied by Pillai and co-workers using anodically generated periodate.48 The production of this hypervalent iodine reagent requires the use of a divided cell to prevent its unproductive cathodic reduction. This mediator was also employed by Schäfer and co-workers to promote regeneration of ruthenium tetroxide, which was used in the electrochemical oxidative cleavage of alkenes49 (Fig. 7). In 2020, Waldvogel and co-workers reported an efficient method for generating periodate electrochemically from iodide for ex situ applications.50

Fig. 7.

(A and B) Oxidative cleavage of alkenes using electrochemical generated periodate.

2.1.4. Oxidation of sulfur functional groups.

The use of halides and hypervalent iodine compounds as electrochemical mediators has been useful for the selective oxidation of different sulfur functional groups, including sulfinate salts, thiols, dithianes, and dithiolanes.51,52 For example, upon anodic oxidation of halides, sulfinate salts can form adducts with a labile heteroatom-halogen bond (O–I or S–I), which can be homolytically cleaved by light or heat. The newly generated sulfur-centered radicals (8–4) can then add to the π systems of alkynes53 or alkenes54 (Fig. 8), and this protocol can also be used for the construction of sulfonamides.55

Fig. 8.

(A and B) Radical cyclization triggered by electrochemical generated sulfur centered radicals.

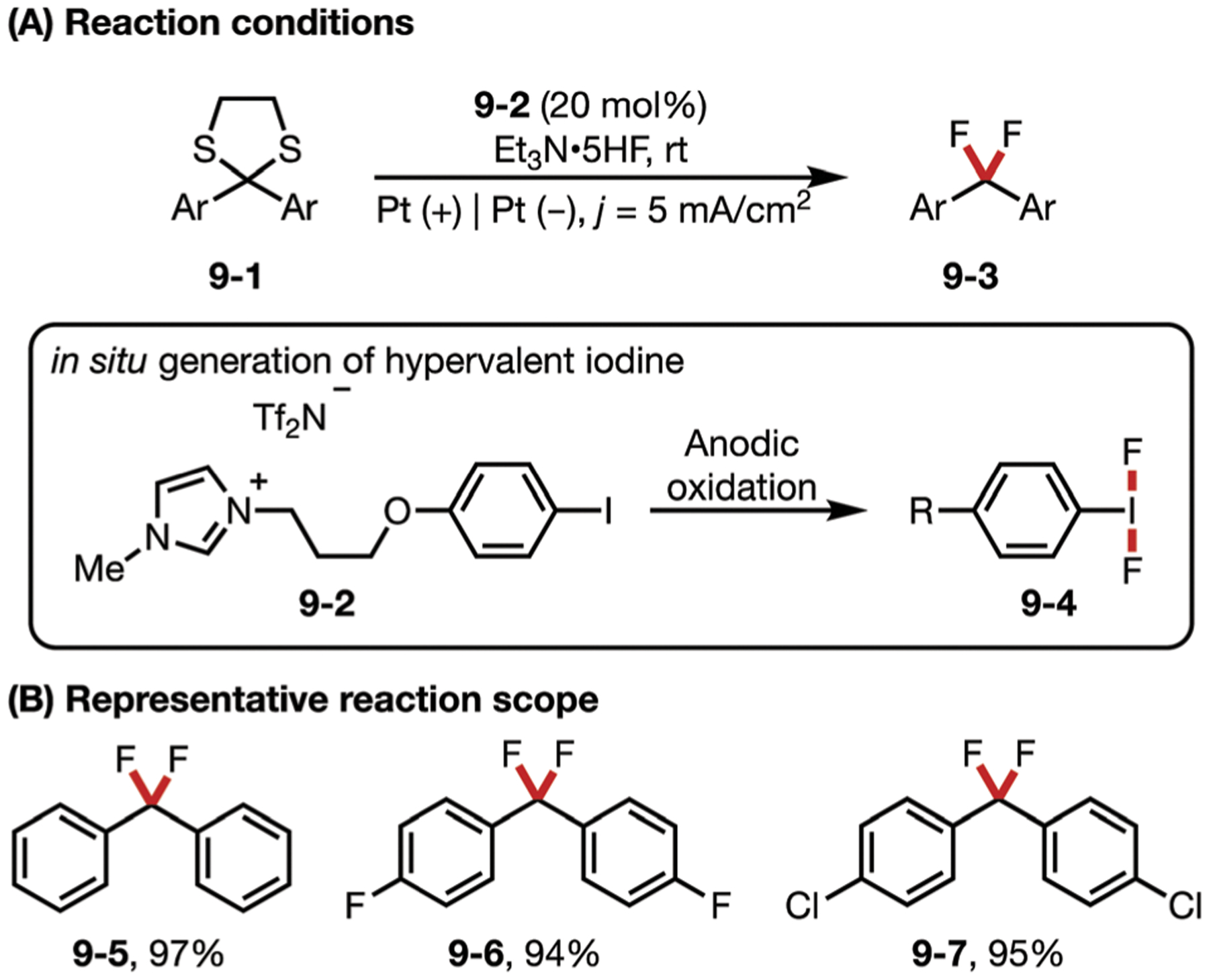

In 2010, Fuchigami and co-workers reported an electrochemical approach to convert dithiolanes to geminal difluoride groups (Fig. 9). This transformation is mediated by 9–2, which can undergo anodic oxidation in the presence of Et3N-5HF electrolyte to generate hypervalent iodine species 9–4 with a tethered imidazolium ion. 9–4 then reacts with substrate 9–1 to give the gem-difluorinated product 9–3. At the end of the reaction, the aryl iodide mediator can be recovered with a simple extraction and reused.56 Fuchigami has also developed a fluorodesulfurization employing chloride as an electrochemical mediator, which can aid in the generation of hypervalent iodine species from polystyrene-supported iodobenzene.57

Fig. 9.

(A and B) Hypervalent iodine-mediated fluorodesulfurization of dithiolanes.

2.1.5. Oxidation of nitrogenated functional groups.

The cleavage of weak nitrogen–halogen bonds is the basis for the development of a wide range of reactions. Two possible mechanisms for this reactivity have been proposed. In an ionic mechanism, upon formation of the iodinated amine intermediate, a simple beta-H+ elimination step promoted by base will generate a C=N group to complete the mediated dehydrogenation.58–60 In radical mechanisms, an N-centered radical is generated from the halogenated amine by modes of single-electron activation such as photoirradiation (see Section 7: Electrophotocatalysis).61,62 As an example of the ionic scenario, in 2014, Little and co-workers demonstrated the use of anodically generated electrophilic iodine species to promote the formation of benzoxazoles from 2-aminobenzoxazolines via key intermediate 10–452 (Fig. 10).

Fig. 10.

(A and B) Iodide-mediated synthesis of 2-aminobenzoxazoles.

2.2. Nitrate mediators

The nitrate radical was first identified in the atmosphere during the late 1800s and has been shown to play an important role in atmospheric chemistry. It can be formed by reaction of NO2 with ozone or through the decomposition of N2O5.63 Nitrate radicals can react with aldehydes via an HAT process, resulting in acyl radicals and nitric acid. Nitrate radicals can also add to alkenes, to furnish organic nitrate functional groups.

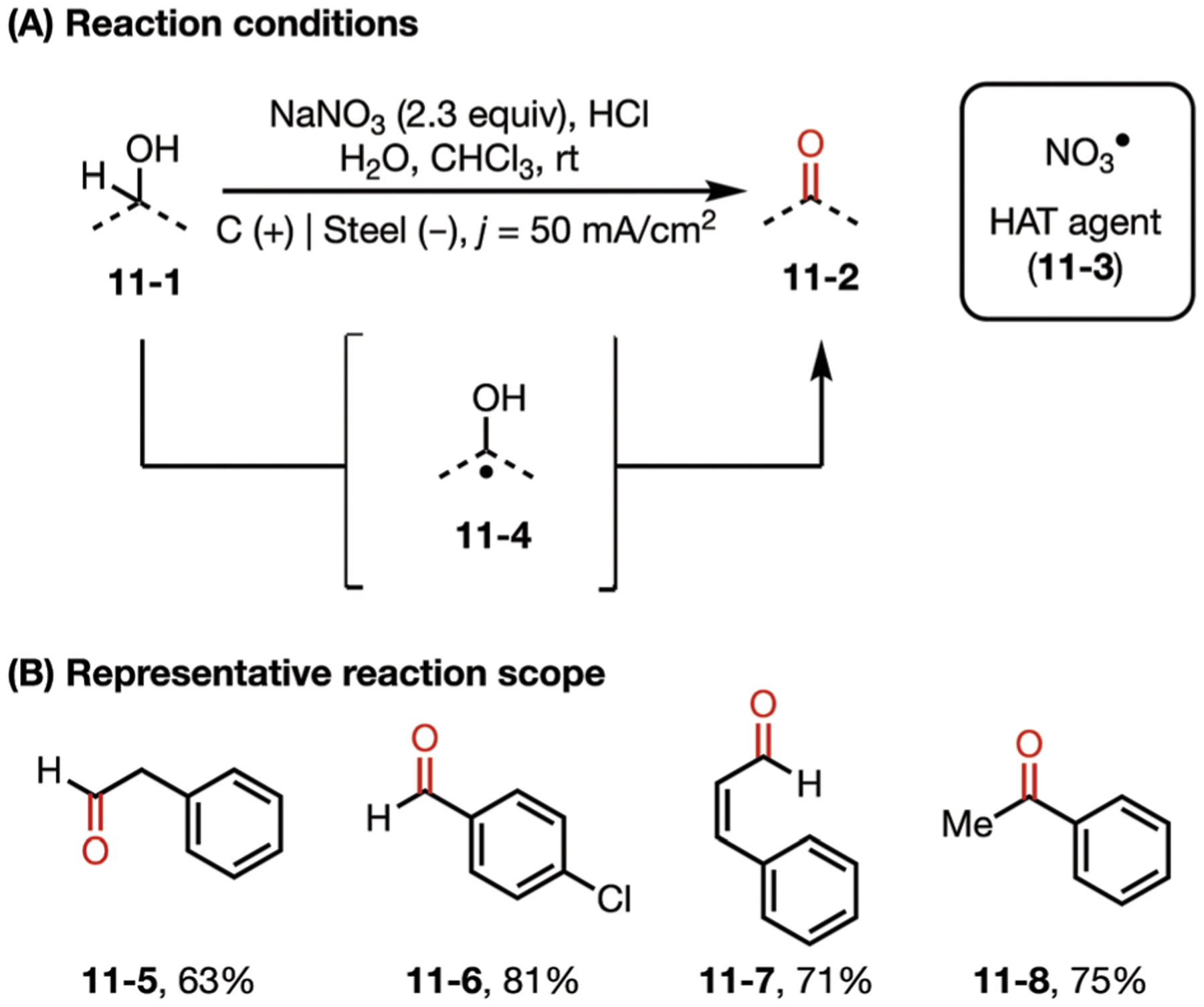

2.2.1. Alcohol oxidation.

Nitrate radicals can also be generated electrochemically via anodic oxidation of nitrate anions. Despite this interesting reactivities, this species has been rarely used in synthetic electrochemistry. One of these examples was reported in 2012 by Raja and co-workers, where an electrochemical oxidation of alcohols to aldehydes or ketones was mediated by nitrate radical64,65 (Fig. 11). This reaction is thought to proceed by an HAT event, whereby a nitrate radical removes a hydrogen from the carbinolic position, followed by a second oxidation proceeding through direct anodic oxidation of the carbon centered radical or a second oxidation mediated by nitrate radical.

Fig. 11.

(A and B) Nitrate-mediated oxidation of alcohols.

2.2.2. Fluorination of unactivated C(sp3)–H bonds.

In 2019, Baran and co-workers employed nitrate radicals to achieve fluorination of unactivated C(sp3)–H bonds66 (Fig. 12). The proposed mechanism starts with a HAT process mediated by a nitrate radical, which leads to a radical chain process that is sustained by the nitrogen-centered radical cation 12–4 derived from Selectfluor (12–3), the fluorinating agent. This methodology provided good yields for substrates containing ketones, esters, carboxylic acids, and imides.

Fig. 12.

(A–C) Nitrate-mediated C(sp3)–H fluorination.

2.3. Nitroxyl mediators

Stable nitroxyl radicals have been reported since the 1960s67–71 and have since attracted the attention of synthetic chemists. These radicals can be oxidized electrochemically to oxoammonium cations, which have been extensively studied for the oxidation of alcohols and amines. In 2015, Minteer, Sigman, and co-workers combined experimental and computational techniques to group nitroxyl mediators into four distinct classes, matching high or low oxidation potentials of the mediator with high or low catalytic activity for alcohol oxidation (Fig. 13).72 The top left quadrant of the graph originated from this study contains nitroxyls with high activity that can be generated at low potential, which is desirable for energy applications. On the other extreme, the bottom right corner contains poorly active mediators that require high oxidation potentials, which are useful as EPR labels. Curiously, TEMPO (labeled as number 1 in Fig. 13), the most frequently employed nitroxyl catalyst and EPR label, is not the best option for either applications, and its common use can be understood due to its relative ease of access. In 2018, Stahl, Rafiee, and co-workers extensively reviewed the use of nitroxyl radicals in electrocatalytic reactions.73

Fig. 13.

Minteer and Sigman’s model for nitroxyl mediators. This figure has been reproduced from ref. 72 with permission from American Chemical Society, copyright 2015.

2.3.1. Alcohol oxidation.

During the 2000’s, the research groups of Tanaka,74–76 Onomura,77 and Frontana-Uribe78 reported cooperative electrochemical systems involving bromide and nitroxyl radicals, which could generate oxoammonium cations capable of oxidizing primary and secondary alcohols to the corresponding carbonyl compounds. Tanaka79 and Brown80 also reported direct oxidation of TEMPO to induce oxidation of alcohols to carboxylic acids, or aldehydes, and ketones.

During the last decade, Stahl and co-workers have explored the oxidation of alcohols mediated by anodically generated oxoammonium cations.81–84 Stahl observed that ACT (4-acetamido-TEMPO) (E = 0.65 V vs. Ag/AgCl) is more electrocatalytic active than AZADO (2-azaadamantane-N-oxyl) and ABNO (9-azabicyclo[3.3.1]nonane N-oxyl) (EAZADO = 0.45 V, EABNO = 0.48 V, vs. Ag/AgCl) which are less sterically hindered.81 The higher activity of ACT is attributed to the fact that its corresponding oxoammonium cation is generated at a higher potential. A higher pH environment further contributes to the increase of turnover frequency of the electrocatalyst. This finding was explored for oxidation of alcohols and aldehydes into the corresponding carboxylic acids82,83 (Fig. 14).

Fig. 14.

(A and B) Nitroxyl-mediated oxidation of alcohols and aldehydes to carboxylic acids.

Identification of electrocatalytic systems that operate at low potentials and exhibit high turnover frequencies is highly relevant to the energy-conversion field. In 2016, Stahl and co-workers demonstrated an elegant example with a cooperative electrochemical system, composed of CuII(bpy) and TEMPO, for oxidation of alcohols85 (Fig. 15). This system combines CuII’s ability to promote single-electron oxidations with the electron-proton acceptor property of nitroxyl radicals. Since high energy intermediates are avoided in this catalytic cycle, this reaction can be realized with an anodic potential 500 mV lower than a system using only TEMPO, which would involve oxoammonium cations (−0.14 V and +0.36 V, vs. Fc0/Fc+). This cooperative system also proved to be advantageous in terms of kinetics, with a kobs (11.6 s−1) nearly 5 times higher than the corresponding kobs (2.3 s−1) for the TEMPO-only system.

Fig. 15.

Cooperative copper-nitroxyl system for oxidation of alcohols to aldehydes.

2.3.2. Oxidation of amines and carbamates.

The electrochemical generation of oxoammonium cations has been applied to oxidation of amines and carbamates, yielding amides and imides, respectively. While Little86 used a cooperative system formed by bromide/TEMPO, Kashiwagi87 and Stahl88 employed modified versions of TEMPO to accomplish this type of transformation (Fig. 16). The proposed mechanism first involves a two-electron-one-proton transfer to generate a stabilized iminium species 16–3 which is subsequently trapped by water to form a hemiaminal 16–4. In a second step, the hemiaminal 16–4 is subjected to a two-electron-one-proton transfer, forming the carbonyl group.

Fig. 16.

(A–C) Nitroxyl-mediated oxidation of carbamates.

2.3.3. Generation of nitrogen-centered radicals.

New reactivities of nitroxyl radicals and the corresponding oxoammonium cations have emerged recently. In 2014, Xu and co-workers reported the formation of nitrogen-centered radicals via the oxidation of amides by TEMPO+ under basic conditions89 (Fig. 17). Mechanistic investigation suggests that this process might involve a single-electron transfer from a nitrogen-centered anion to an oxoammonium cation. The nitrogenated radical was employed in a subsequent intramolecular reaction with an olefin to produce bicyclic products. In this reaction, TEMPO is used in stoichiometric amounts, since it is also employed as a radical trap.

Fig. 17.

(A and B) Radical cyclization triggered by electrochemical generated nitrogen centered radicals.

The formation of nitroxyl radicals was also explored by Lin and co-workers. During the investigation of an electrochemical alkene azidooxygenation,90 Lin postulated the anodically generation of a metastable charge-transfer complex (CTC) arising from the combination of azide anion with TEMPO+. This structure was confirmed by X-ray crystallography in 2021.91 When CTC is in solution, an equilibrium is established with formation of small amounts of azidyl radical, which can add to an alkene, generating a carbon centered radical that can be trapped by TEMPO.

During the development of this azidooxygenation of alkenes, minor amounts of vicinal diazides were frequently identified as side-products. In order to favor the formation of the diazides, Lin designed a new sterically hindered nitroxyl catalyst (CHAMPO, Fig. 18).92 Once the carbon-centered radical is generated, CHAMPO would be too sterically hindered to form a C–O bond, and a second azidyl group could be transferred, possibly via an inner-sphere mechanism.

Fig. 18.

(A–C) Nitroxyl-mediated diazidation of alkenes.

2.4. Phthalimide N-oxyl radical (PINO) and quinuclidine radical cation as HAT agents

The phthalimide N-oxyl radical (PINO) has been used in radical reactions since 1977, beginning with a seminal report by Grochowski and co-workers.93,94 The majority of reactions employing PINO take advantage of the high BDE of N-hydroxyphthalimide’s O–H bond (NHPI). Pedulli and co-workers95 measured a BDE equal to 88.1 kcal mol−1, which is similar to the C–H bonds of allylic (88.8 kcal mol−1) and benzylic (89.7 kcal mol−1) positions.96

During the 1980s, Masui and co-workers pioneered the electrochemical generation of PINO from catalytic amounts of NHPI, and employed this radical for a wide range of oxidative reactions, including the oxidation of alcohols to carbonyl compounds,97,98 conversion of acetals and ethers to esters,96,99,100 generation of imides from amides,101 and early examples of allylic and benzylic oxidations.96,102 Kinetic studies of the oxidation of benzhydrol to benzophenone mediated by electrochemically-generated PINO revealed a large primary KIE (kH/kD = 10.6 at 25 °C), indicating that a HAT process should be the rate-determining step.103

2.4.1. Allylic oxidation.

Oxidation of allylic C–H bonds offers a convenient and often selective approach for the functionalization of complex molecules104 and thus has been widely employed in total synthesis of natural products. In 2016, Baran and co-workers studied this transformation taking Masui’s pioneering work as a foundation to develop an optimized protocol. Baran incorporated two major modifications in their system105 (Fig. 19). Firstly, tBuOOH replaced O2 as terminal oxidant, which contributed to a substantial improvement in reaction conversion and reproducibility. Secondly, after the evaluation of different redox mediators, tetrachloro-N-hydroxyphthalimide (Cl4NHPI) was identified as an optimal choice. Cyclic voltammetry analysis showed that the N-oxyl radical derived from Cl4NHPI should be higher in energy and more reactive than the PINO radical, which facilitates the HAT step. Following the formation of an allylic peroxide intermediate, this peroxide was subsequently converted into the enone product. Control experiments showed that this final step can proceed without electrochemical assistance. This method was also employed in the oxidation of a wide range of terpenes and olefins.

Fig. 19.

(A–C) N-hydroxy phthalimide-mediated allylic oxidation.

2.4.2. Benzylic oxidations.

In 2017, Stahl and co-workers studied a cooperative catalytic system employing cobalt(II) acetate and NHPI under aerobic conditions to promote benzylic oxidation.106 During the development of this chemical method, a few substrates showed poor reactivity, and the authors hypothesized that the oxidation product would chelate cobalt, inhibiting the catalytic cycle. To overcome this limitation, the authors explored an electrochemical route for the generation of the PINO radical without cobalt, leading to improved yields.

In a subsequent work, Stahl and co-workers utilized anodically generated PINO to produce benzyl radicals, which were trapped by iodine, yielding benzylic iodides107 (Fig. 20). The choice of base was shown to be decisive in regulating the outcome of this reaction; when the sterically hindered 2,6-lutidine is used as base, the benzylic iodides can be generated efficiently. However, the use of pyridine as base leads to the unproductive formation of benzyl-pyridinium salts. Competition between hydrogen evolution and the reduction of iodine to iodide at the cathode required the use of a divided cell for these experiments, keeping all iodine in the anodic chamber.

Fig. 20.

(A and B) N-hydroxy phthalimide-mediated benzylic iodination.

2.4.3. Oxidation of unactivated C(sp3)–H bonds.

The oxygenation of unactivated C(sp3)–H bonds is a challenging transformation in organic synthesis and is typically approached through the use of highly reactive species. Curci and co-workers have studied the utilization of dioxiranes to promote these challenging oxidations,108 the most common members of this class of compounds, DMDO (dimethyldioxirane) and TFDO (methyltrifluoromethyldioxirane), are not commercially available due to their tendency to easily decompose. In 2007, White and co-workers reported the use of a new iron-oxo complex to achieve selective oxidation in complex architectures.109 These developments are transformative in the selective oxidation of complex molecules, especially in medicinal chemistry. Nevertheless, the application of many existing chemical methods in large-scale synthesis can still be challenging considering the cost of the required oxidants (e.g., trifluoroacetone) and catalysts.

In 2017, Baran and co-workers used PINO radicals and N-oxyl radicals derived from Cl4NHPI to promote a HAT process on unactivated C(sp3)–H bonds.110 However, this approach was unsuccessful, likely due to the inert nature of such C–H bonds. During an evaluation of different mediators, a stoichiometric amount of quinuclidine was identified as a promising option. Quinuclidine can be anodically oxidized to the corresponding radical cation (21–5), which is reactive enough to abstract hydrogen from electron-rich C(sp3)–H bonds, forming alkyl radicals that can be later trapped by O2. Use of this methodology culminated in the total synthesis of (+)-2-oxo-yahazunone (21–13; Fig. 21) by employing sclareolide (21–11) as a substrate. In 2019, Magauer and co-workers explored the electrochemical generation of the radical cation of quinuclidine to synthesize the natural product mitrephorone A (21–15).111

Fig. 21.

(A–C) Quinuclidine-mediated C(sp3)–H oxidation.

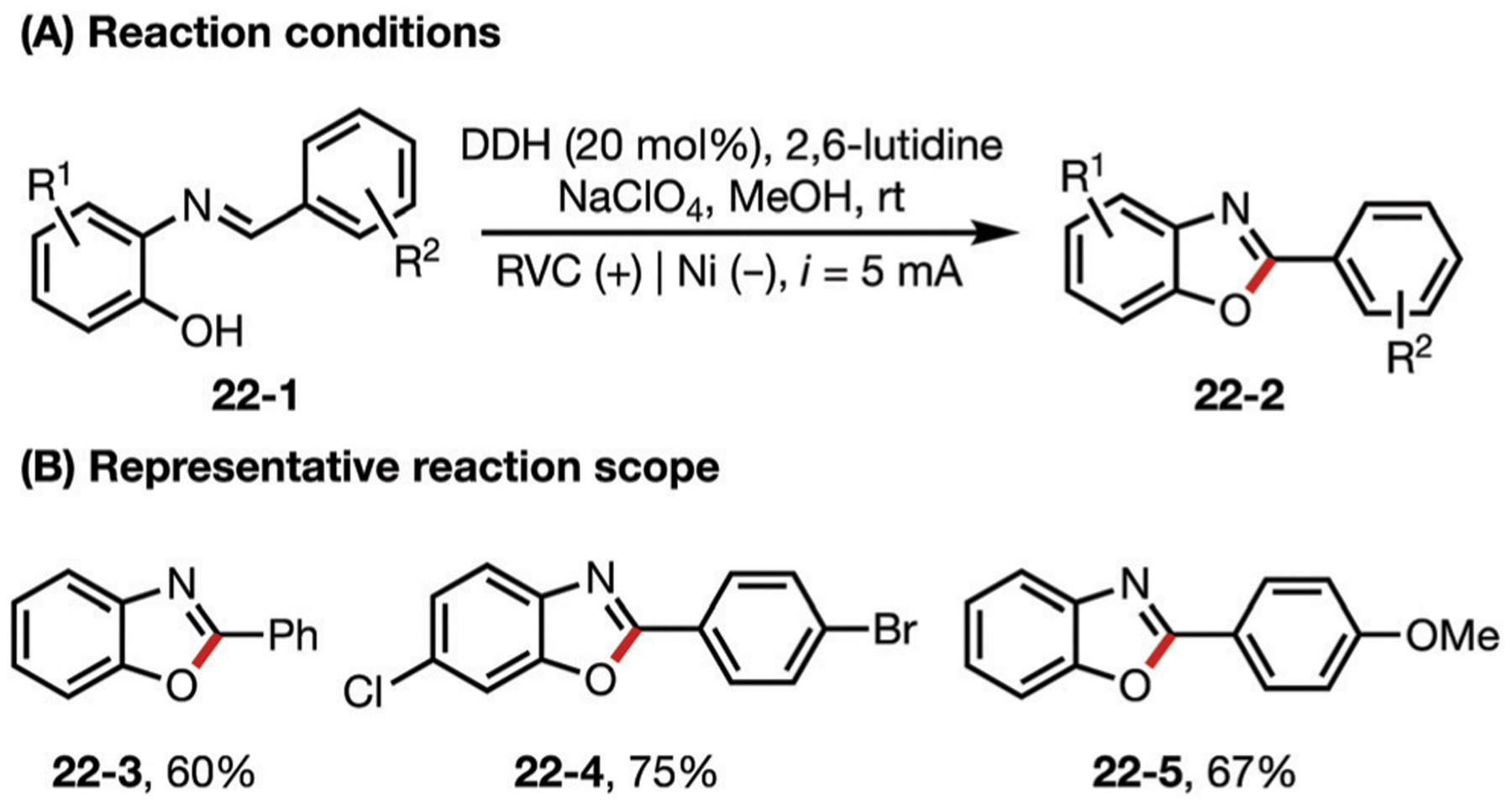

2.5. Dehydrogenation mediated by DDQ

DDQ (2,3-dichloro-5,6-dicyano-1,4-benzoquinone) is a useful oxidant used to mediate the dehydrogenation of different functional groups. DDQ produces a hydroquinone (DDHQ) as a by-product, which can be anodically oxidized back to DDQ, allowing for a catalytic process (Fig. 22). This approach has been explored for the oxidation of alcohols to aldehydes,112 secondary amines to imines,113 and for the synthesis of benzoxazoles.114

Fig. 22.

(A and B) DDQ-mediated generation of benzoxazoles.

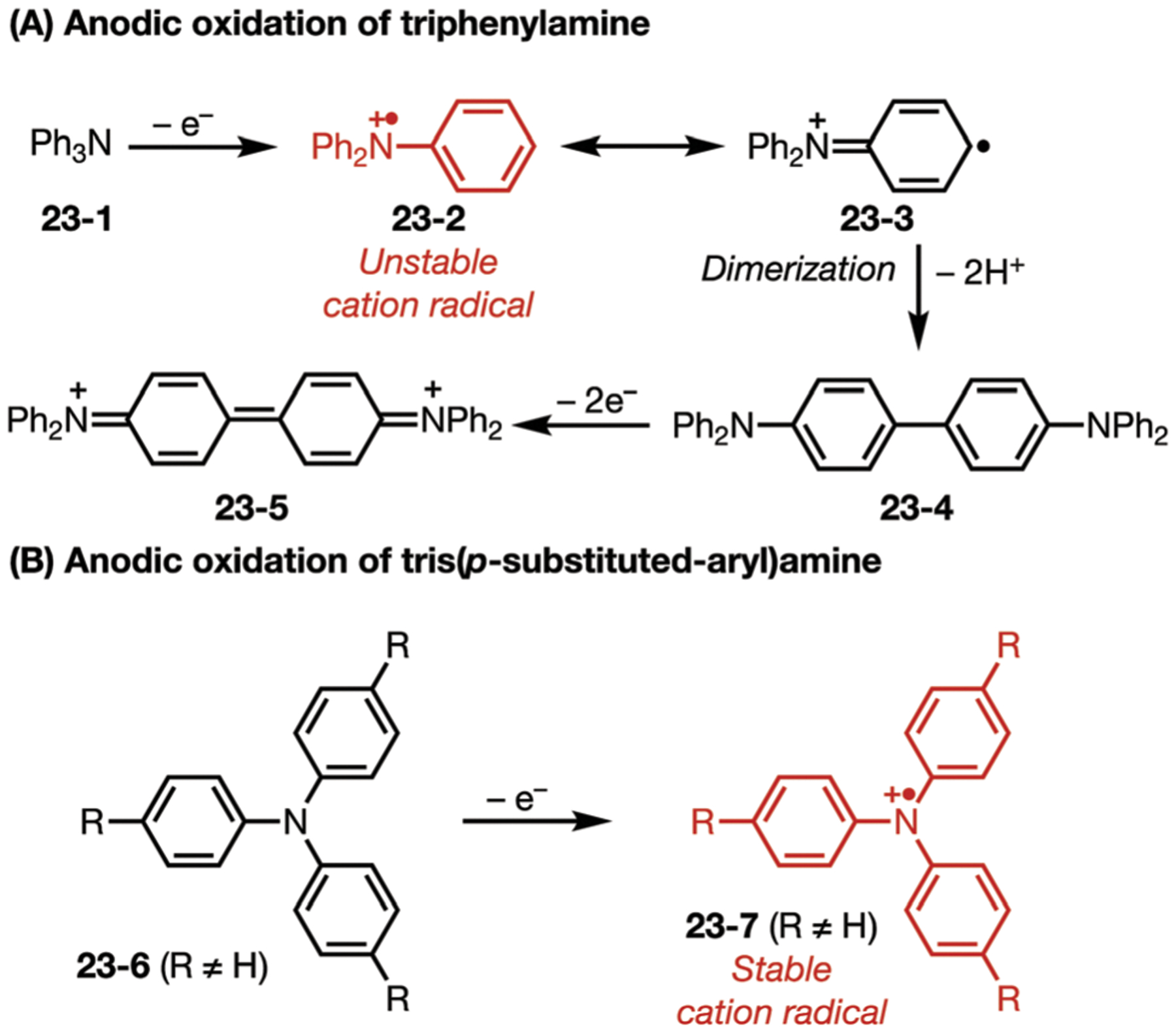

2.6. Nitrogen centered radical cation as electron transfer agents

In the 1960s, Nelson and co-workers demonstrated that anodic oxidation of triphenylamine (23–1) led to a rapid coupling to form tetraphenylbenzidine (23–4), which would undergo subsequent oxidation to form radical cation and dication species (Fig. 23). Notably, the addition of a para-substituent on the three aromatic rings (23–6) would alter the reactivity and allow the formation of a very stable nitrogen centered radical cation (23–7), which was observed by a reversible profile on cyclic voltammetry analysis.115,116 Introduction of electron-donating or electron-withdrawing groups on the para position of the aryl rings allows easy modulation of the oxidation potential. These mediators have been employed in a wide range of transformations to promote electron transfer events, such as the oxidation of sulfides,117,118 stilbenes,119 and strained bicycles.120,121

Fig. 23.

(A and B) Different stability profiles of triarylamine cation-radicals.

2.6.1. Oxidation of electron-rich aromatics.

In 2015, Little and co-workers explored the use of the cation-radical of tris-(p-bromophenyl)amine to oxidize benzylic alcohols to aldehydes and benzylic ethers to benzoate esters, among other transformations (Fig. 24).122 The use of a triarylamine allowed the authors to perform the oxidation at a much lower potential than the oxidation potential of the substrate, which enables higher yields and broader functional group compatibility. In this work, a polymeric ionic liquid was employed as electrolyte, which could be recovered and reused, simplifying product isolation and minimizing waste generation.

Fig. 24.

(A and B) Triarylamine-mediated oxidation of alcohols and ethers.

Inspired by the useful properties of radical cations derived from triarylamines, Zeng, Little, and co-workers developed analogue redox mediators using a triarylimidazole (TAI) scaf-fold that can be easily synthesized.123,124 The radical cation derived from TAI was able to oxidize benzylic alcohols and p-methoxytoluene to the corresponding benzaldehydes, benzylic ethers to benzoate esters, and chalcone epoxides (25–1) to radical cations (25–4) that can further engage in a Friedel–Crafts mechanism (Fig. 25).125

Fig. 25.

(A and B) Triarylimidazole-mediated oxidation of chalcone epoxides mediated by TAI cation-radical.

Little and co-workers also explored a fused-ring form of TAI mediator (2-aryl-1-methylphenanthro[9,10-d]imidazole, see 26–2), which yields a more stable radical cation than original TAIs. The higher stability of this radical cation was observed by cyclic voltammetry analysis: when the scan rate was decreased from 100 mV s−1 to 10 mV s−1 (a longer analysis time), the fused mediator 26–2 still presented a quasi-reversible profile, indicating a longer lifetime of the corresponding radical cation as compared to the radical cation derived from mediator 26–1126 (Fig. 26). Another analogue redox mediator, N-aryl-carbazole, was studied by Ma and co-workers, and the corresponding N-centered radical cation was also suggested as the key reactive species in oxidative transformations.127

Fig. 26.

Cyclic voltammogram of TAI 26–1 and its cyclized analogue 26–2. This figure has been adapted from ref. 126 with permission from American Chemical Society, copyright 2014.

2.6.2. Oxidation of anions into radicals.

In 2018, Xu and co-workers developed a radical cascade to produce imidazo-fused N-heterocycles128 (Fig. 27). Their approach relies on the generation of a nitrogen-centered radical by oxidation of the corresponding anion, which has an oxidation potential (Ep/2 = 0.66 V vs. SCE) significantly lower than common triarylamines (TBPA, Ep/2 = 1.08 V vs. SCE). This difference in potentials indicates that the substrate would likely undergo a direct oxidation, and that the triarylamine radical cation would play a minor role in the mechanism. Since triarylamines gave low yields (11–39%) of the desired product, the authors turned to tetraarylhydrazine mediators which proved more efficient. Tetra-(4-tert-butylphenyl)hydrazine showed an oxidation potential (Ep/2 = 0.68 V vs. SCE) lower than that of triarylamines, and could generate the desired bicyclic product in 89% yield. This was the first application of this mediator in synthetic electrochemistry.

Fig. 27.

(A and B) Tetraarylhydrazine-mediated synthesis of imidazo-fused N-heterocycles.

Xu and co-workers also explored mediated oxidation of enolates derived from dimethyl malonate and methyl acetoacetate (Fig. 28), which have low oxidation potential (enolate of dimethylmalonate, Ep/2 = 0.31 V vs. SCE).129 In order to achieve a mediated process, a phenothiazine (28–4; Ep/2 = 0.52 V vs. SCE) was employed, which has a lower oxidation potential than triarylamines, despite architectural similarities. The concentration of enolate 28–5 was kept small, as it was generated continuously by deprotonation of the dicarbonyl compound with cathodically generated hydroxide, which is an important feature to guarantee a mediated process. The resultant carbon-centered radical 28–6 was employed on the construction of substituted pyrrolidines and tetrahydropyridines.

Fig. 28.

(A–C) Phenothiazine-mediated synthesis of substituted pyrrolidines.

Transition metal complex as mediators

The combination of transition metal catalysis and electrochemistry offers the advantages of higher atom efficiency, milder reaction conditions, and safer protocols in place of using stoichiometric chemical oxidants to induce catalyst turnover. Furthermore, using electrochemistry to activate metal catalysts or key reactive intermediates derived from these catalysts has been shown to promote new reactivities that were previously challenging or unknown.

Metalla-electrochemical reactions fall into two broad categories. First, transition-metal complexes can serve as direct mediators to transfer electrons between electrodes and target substrates. Specifically, transition metal-bound substrate adducts exhibit lower oxidation potentials, and the oxidized open-shell species possess characteristics of persistent radicals, thus rendering the group transfer process to the substrates more selective and efficient. This type of metalla-electrochemical methods has given rise to numerous new transformations that were impossible or challenging to accomplish otherwise. A more detailed review on these methods can be found in a recent account.130

Second, electrochemistry supports traditional transition-metal catalyzed C–H activations, leading to a variety of transformations forging carbon–carbon and carbon–halogen bonds. In a transition-metal-catalyzed C–H activation, anodic oxidation can typically play two roles: to enable regeneration of the active transition metal catalyst (Fig. 29A) and to oxidize the transition metal catalyst intermediate to a high-valent species to induce subsequent reductive elimination (Fig. 29B). Detailed discussion on transition-metal catalyzed C–activation reactions can be found in recent reviews.131 An important advantage of metalla-electrochemistry is that C–H activation reactions employ electricity as the oxidizing equivalent, thus avoiding the use of external chemical oxidants and generation of wasteful by-products.

Fig. 29.

(A and B) Modes of electrochemical transition metal-catalyzed C–H functionalization.

Traditionally, anodic C–H activation has been dominated by precious transition metal catalysts based on palladium, ruthenium, iridium, and rhodium; more recently, however, 3d earth-abundant metals such as nickel and cobalt have seen increasing use in electrochemical C–H activation. In the following section we will discuss recent advances in metalla-electrochemical reactions grouped by different metal mediators.

2.7. Manganese

Manganese is a particularly attractive mediator in electrocatalytic systems due to its abundance, low toxicity, and low cost. Traditionally, manganese complexes have been employed in alkene and C–H functionalizations to form C–N, C–O, and C–halogen bonds via radical pathways.132 However, it was not until recently that redox-active manganese complexes matured as competent mediators for electrochemically-driven transformations. Mechanistic investigation of these catalytic cycles suggest that a MnII/MnIII redox pair is operating in many of these transformations.

2.7.1. Olefin functionalization.

In 1998, Snider reported the diazidation of alkenes and glycals using 3 equivalents of Mn(OAc)3·H2O.133 Snider proposed that the diazidation of alkene occurs via rapid azide transfer from MnIII-azide to the alkene and subsequently to the incipient alkyl radical intermediate. This pioneering discovery has provided inspiration for several recent developments in electrocatalysis.

In 2017, the Lin lab developed an electrochemical diazidation of alkenes using MnII salts as efficient and selective electrocatalysts.134 The resulting vicinal diazides can be easily reduced to form diamines, which are prevalent motifs in a variety of bioactive natural products, pharmaceuticals, and molecular catalysts. Unlike Snider’s reaction system, the MnII salt was added as precatalyst, and was then oxidized under electrochemical conditions to generate a MnIII–N3 intermediate (Fig. 30B). This oxidized intermediate serves as a latent azidyl radical source that delivers a first azide equivalent to the alkene (30–1), followed by addition of a second azide equivalent to the resultant alkyl radical (30–3) to furnish the diazide product 30–2. This work also features significantly milder reaction conditions than those reported by Snider. The Lin group later applied this strategy to the dichlorination of alkenes (Fig. 30D).135

Fig. 30.

(A–D) Manganese-catalyzed electrocatalytic diazidation and dichlorination of alkenes.

To extend the utility of the strategy used for this electrochemical diazidation protocol, the Lin group developed an additional electrochemical method for the heterodifunctionalization of alkenes based on anodically coupled electrolysis (ACE) strategy.136 The implementation of ACE strategy relies on the appropriate pairing of radical precursors (X1)− and (X2)− with a suitable metal catalyst. Two parallel anodic oxidations will take place: one radical precursor would undergo single-electron oxidation to generate a transient free radical (X1)• while the other precursor (X2)− would undergo catalyst-assisted anodic oxidation to form a (X2)• equivalent in the form of a metal-bound adduct. This adduct could then transfer the functional group of interest to the alkene substrate. The persistent radical effect would dictate the order in which radicals (X1)• and (X2)• add to the substrate, thereby inducing a highly chemo- and regioselective strategy for the heterodifunctionalization of alkenes. In the reaction reported by Lin, two different radical intermediates including a transient CF3 radical and a MnIII–Cl adduct were generated simultaneously via ACE from Langlois’s reagent and MgCl2 in the presence of MnII precatalyst. As shown in Fig. 31, the anodically generated CF3 radical adds to the alkene, which is followed by transfer of chlorine from MnIII–Cl to deliver the chlorotrifluoromethylated product 31–2. The use of ACE as a mechanistic design principle has also been utilized for the chlorophosphinoylation (Fig. 31C),137 and haloalkylation of alkenes (Fig. 31D).138

Fig. 31.

(A–D) Manganese-catalyzed electrocatalytic heterofunctionalization of alkenes.

The Lin group applied their strategy for the electrochemical heterodifunctionalization of alkenes to the radical cyclization of 1,6-enynes.139 In this reaction, the Langlois reagent (CF3SO2Na) and MgCl2 served as functional group donors and MnII served as the electrocatalyst. As depicted in Fig. 32, the 1,6-enyne substrate undergoes consecutive trifluoromethylation, radical ene–yne cyclization, and chlorination to furnish the substituted cyclized product (Fig. 32). The E/Z selectivity observed in the product was proposed to be sterically controlled. To explore the validity of this proposal, addition of bulky ligand (e.g. 2,2,-bipyridine) yielded near-complete selectivity for a single product isomer.

Fig. 32.

(A–C) Synthesis of chlorotrifluoromethylated pyrrolidines via electrocatalytic radical ene–yne cyclization.

The Mo group developed an electrochemical method to make trifluoromethylated oxindoles and related heterocycles.140 Langlois’ reagent is used as the CF3 source. Upon anodic oxidation, this reagent releases a CF3 radical which adds to the substrate to generate a tertiary alkyl radical and triggers cyclization onto the aromatic ring (Fig. 33). This protocol has been employed to forge complex ring systems through cascade cyclization (Fig. 33C).

Fig. 33.

(A–C) Manganese-mediated electrochemical trifluoromethylation for the synthesis of azaheterocycles.

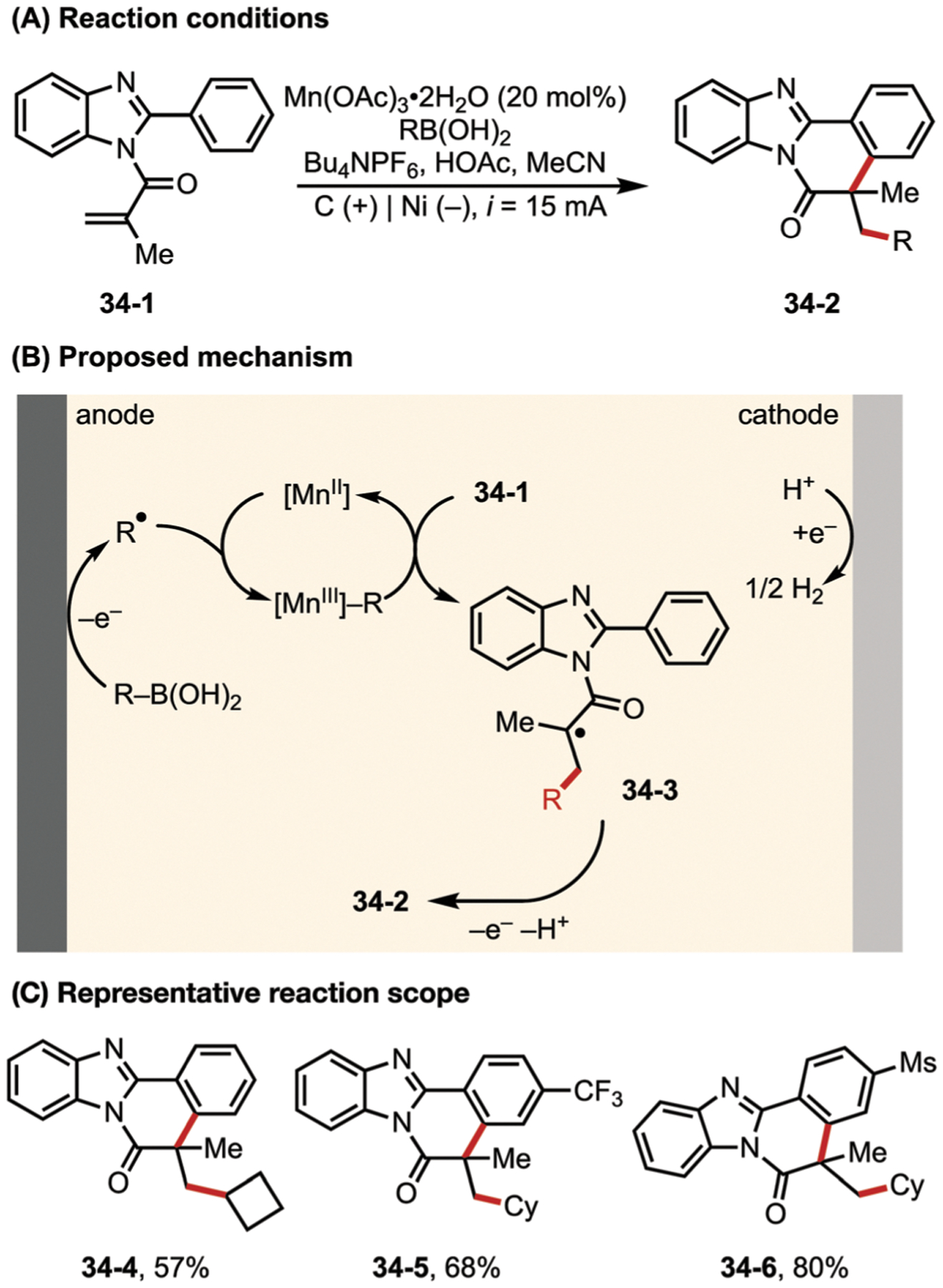

The Lei group has also used the MnII/MnIII redox pair to enable electrochemically driven radical cyclization reactions.141 In this work, the authors reported an electrochemically-driven, Mn-catalyzed coupling reaction between N-substituted 2-arylbenzoimidazoles (34–1) and alkylboronic acids (Fig. 34). EPR and CV data led them to propose a mechanism including the direct anodic oxidation of alkylboronic acids to alkyl radicals. Subsequent addition of these alkyl radicals to substrate 34–1 was proposed to be facilitated by a MnIII species, ultimately leading to the formation of cyclized product 34–2.

Fig. 34.

(A–C) Manganese-catalyzed electrochemical cyclization reaction of N-substituted 2-arylbenzoimidazoles with alkylboronic acids.

2.7.2. C(sp3)–H functionalization.

In addition to alkene functionalization, manganese electrochemical mediators have been utilized in C(sp3)–H functionalization. An interesting example from the Lei group described an electrochemical azidation of C(sp3)–H bonds facilitated by visible light catalysis (Fig. 35).142 In this work, DDQ was utilized as a HAT reagent to activate inert tertiary C–H bonds, which is then trapped by the azide-transfer complex MnIII–N3 formed in situ on the anode. Mechanistic studies suggested that both excited photocatalyst DDQ and the anodically generated azidyl radicals are capable of HAT to form alkyl or benzyl radicals. This reaction technically belongs to the electrophotocatalysis section (see Section 7) but is discussed here owing to its similarity in catalytic mechanism to other examples in this section.

Fig. 35.

(A–C) Manganese-catalyzed oxidative azidation of C(sp3)–H bonds under electrophotocatalytic conditions.

In 2021, the Ackermann group reported an electrochemical manganese porphyrin/salen complex-catalyzed azidation of unactivated secondary, tertiary, and benzylic C–H bonds.143 In this work, mechanistic studies suggest that a MnIII/MnIV redox pair is in operation.

A similar mechanism was proposed in another example by Morrill and co-workers that used a MnII catalyst to mediate an electrochemical synthesis of β- and γ-chlorinated ketones (Fig. 36).144 In this system, anodically generated MnIII–Cl is responsible for the activation of a cyclopropanol or cyclobutanol substrate (36–1) to afford alkoxy radical 36–3, which undergoes C–C bond homolysis to generate a primary alkyl radical 36–4. The release of ring strain is thought to be the driving force for cleavage of the C–C bond. In an alternative pathway, a MnIII-alkoxide resulting from ligand exchange between MnIII–Cl and 36–1 may undergo reversible β-scission to form 36–4. Trapping of this transient primary carbon-centered radical with the persistent MnIII–Cl species forms a new C−Cl bond.

Fig. 36.

(A and B) Manganese-catalyzed electrochemical deconstructive chlorination of cycloalkanols via alkoxy radicals.

2.7.3. Manganese-catalyzed alcohol oxidation.

Mn-Based mediators have also been shown to mediate alcohol oxidation reactions. Huang and co-workers developed an electrochemical Mn-catalyzed cyclization reaction to construct quinazolinones from aminobenzamides and alcohols in an undivided cell (Fig. 37).145 The authors proposed that the MnIII species generated on the anode can oxidize the alcohol to benzaldehyde, which then condenses with aminobenzamides to be further transformed into the cyclized product 37–3.

Fig. 37.

(A–C) Manganese-catalyzed electrochemical synthesis of quinazolinones.

2.8. Iron

The relatively low oxidation potential of ferrocene (E1/2(Cp2Fe) = 0.34 V vs. SCE in 9 : 1 MeCN : H2O) makes it a selective redox catalyst that bears a broad functional group tolerance.146 Ferrocene has been utilized in numerous transformations to activate N–H bonds to generate highly reactive amidyl radicals. Additionally, other iron complexes have found applications in electrochemical C–H activation reactions.

2.8.1. Radical cyclization.

In 2018, the Xu group reported a ferrocene-mediated electrochemical alkyne functionalization to access fluorinated dibenzazepines147 using CF2HSO2NHNHBoc as a CF2H radical precursor (Fig. 38). The electrolytic process commences with the anodic oxidation of Cp2Fe to Cp2Fe+. At the same time, methanol is reduced on the cathode to generate H2 and MeO−. The deprotonation and subsequent oxidation of CF2HSO2NHNHBoc (38–2) generates intermediate 38–5, which further loses an electron and a proton to afford diazene 38–6. The following decomposition of 38–6 releases a CF2H radical which can react with an alkyne group to furnish vinyl radical 38–8. This vinyl radical then cyclizes onto phenyl rings to afford a 7-member ring structure 38–9. Lastly, oxidative rearomatization of the cyclized intermediate affords the dibenzazepine product 38–3.

Fig. 38.

(A–C) Electrochemical difluoromethylarylation of alkynes.

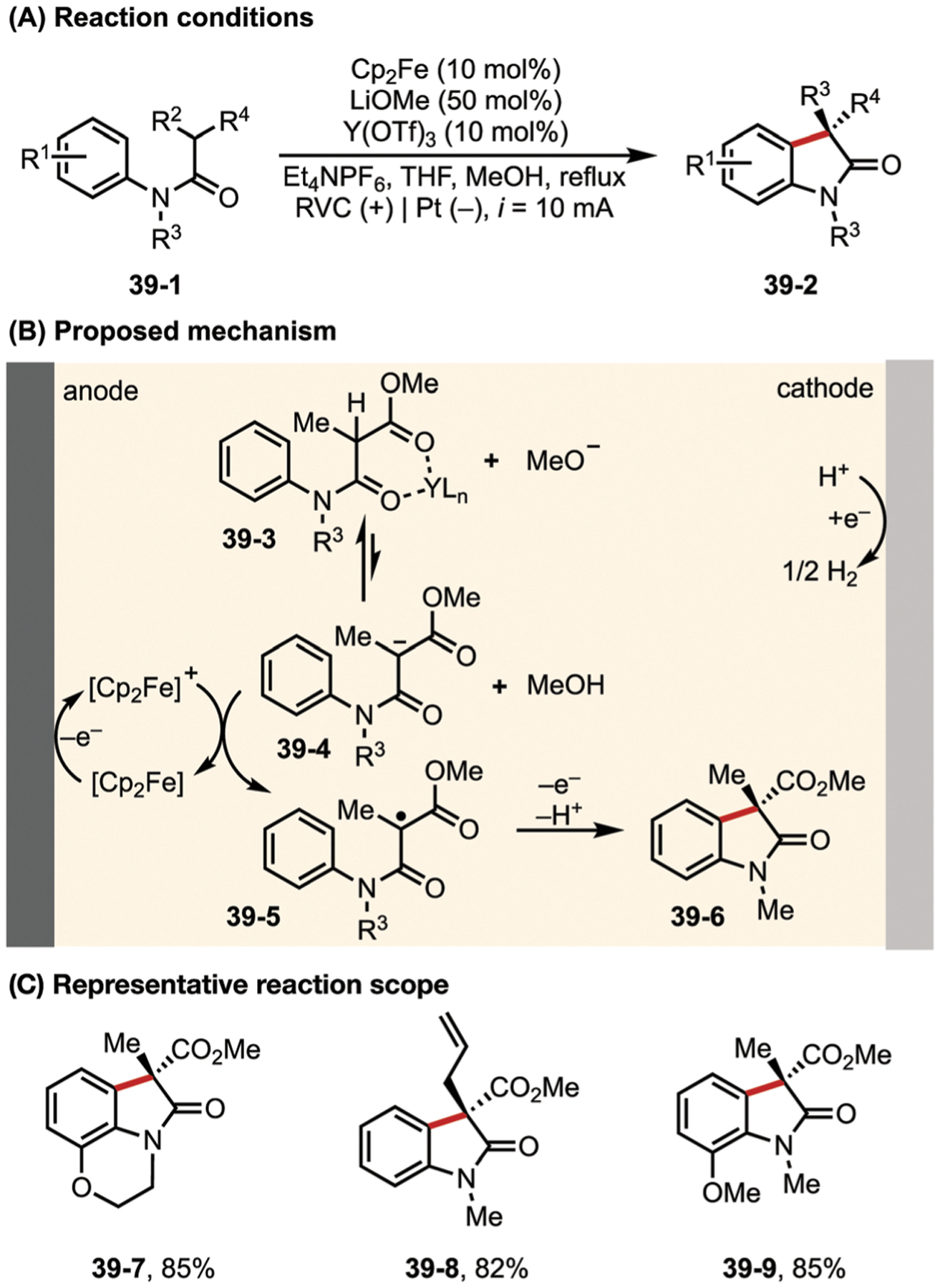

In another work by the Xu group, Lewis acids were used to acidify the tertiary C–H bond on malonate amides, which was then deprotonated by electrochemically generated methoxide (Fig. 39). Oxidation of the resulting anion 39–4 by a Fc/Fc+ couple then generates the alkyl radical intermediate 39–5, which subsequently undergoes cyclization to deliver product 39–6.148

Fig. 39.

(A–C) Electrochemical dehydrogenative cyclization of 1,3-di-carbonyls.

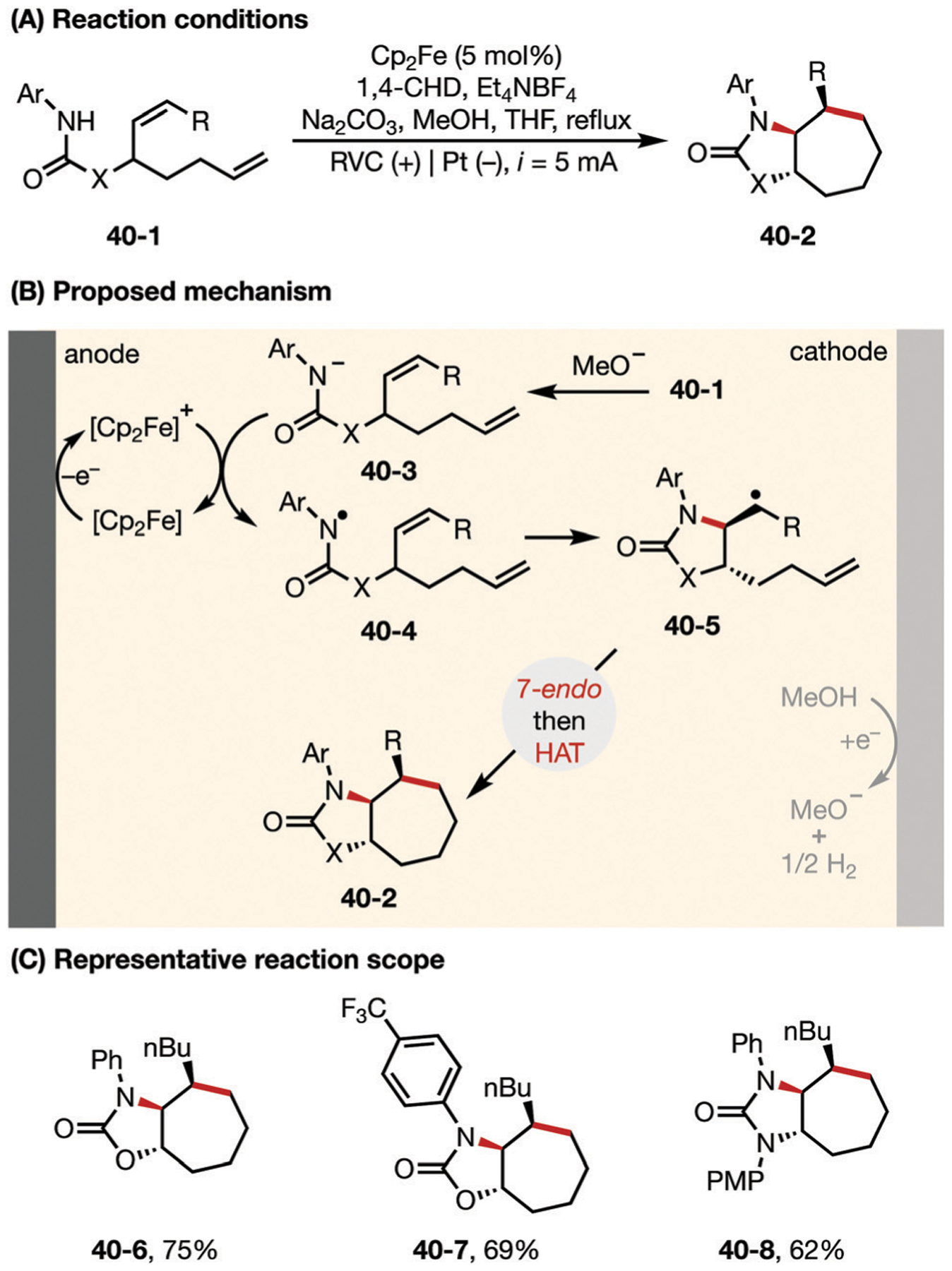

The Xu group employed a similar strategy for radical cascade cyclization reaction to access functionalized 7-member carbo-cyclic compounds (Fig. 40).149 The anodically generated amidyl radical by means of Cp2Fe+ catalysis undergoes stepwise 5-exo-trig and 7-endo-trig cyclization followed by HAT from 1,4-cyclo-hexadiene (1,4-CHD) to deliver product 40–2. It was concluded that the trans disposition of the alkyl radical and the alkene in the intermediate 40–4 is critical to inducing an 7-endo-trig cyclization pathway instead of the 6-exo-trig cyclization pathway in the second radical addition event.150 The typically favored 6-exo-trig cyclization is likely inhibited by the ring strain from the resultant trans-fused bicyclic ring system.

Fig. 40.

(A–C) Electrochemical synthesis of 7-membered carbocycles through cascade 7-endo-trig radical cyclization.

2.8.2. Aromatic C–H functionalization.

Fe(acac)3 has also been used as a catalyst in electrochemical C–H activation. The Ackermann group described a ferraelectrocatalytic C–H arylation in 2019.151 As shown in Fig. 41, this transformation is thought to proceed through a C–H cleavage (via a sigma bond metathesis pathway or through a base-assisted internal electrophilic substitution). After this initial event, the resultant FeII intermediate goes through an anodic single-electron-transfer (SET) and transmetallation to generate five-membered FeIII intermediate 41–4, which then reductively eliminates to release the arylated product. The iron catalyst is then regenerated on the anode.

Fig. 41.

(A and B) Electrochemistry-driven iron-catalyzed C–H arylation.

2.8.3. Various amination reactions.

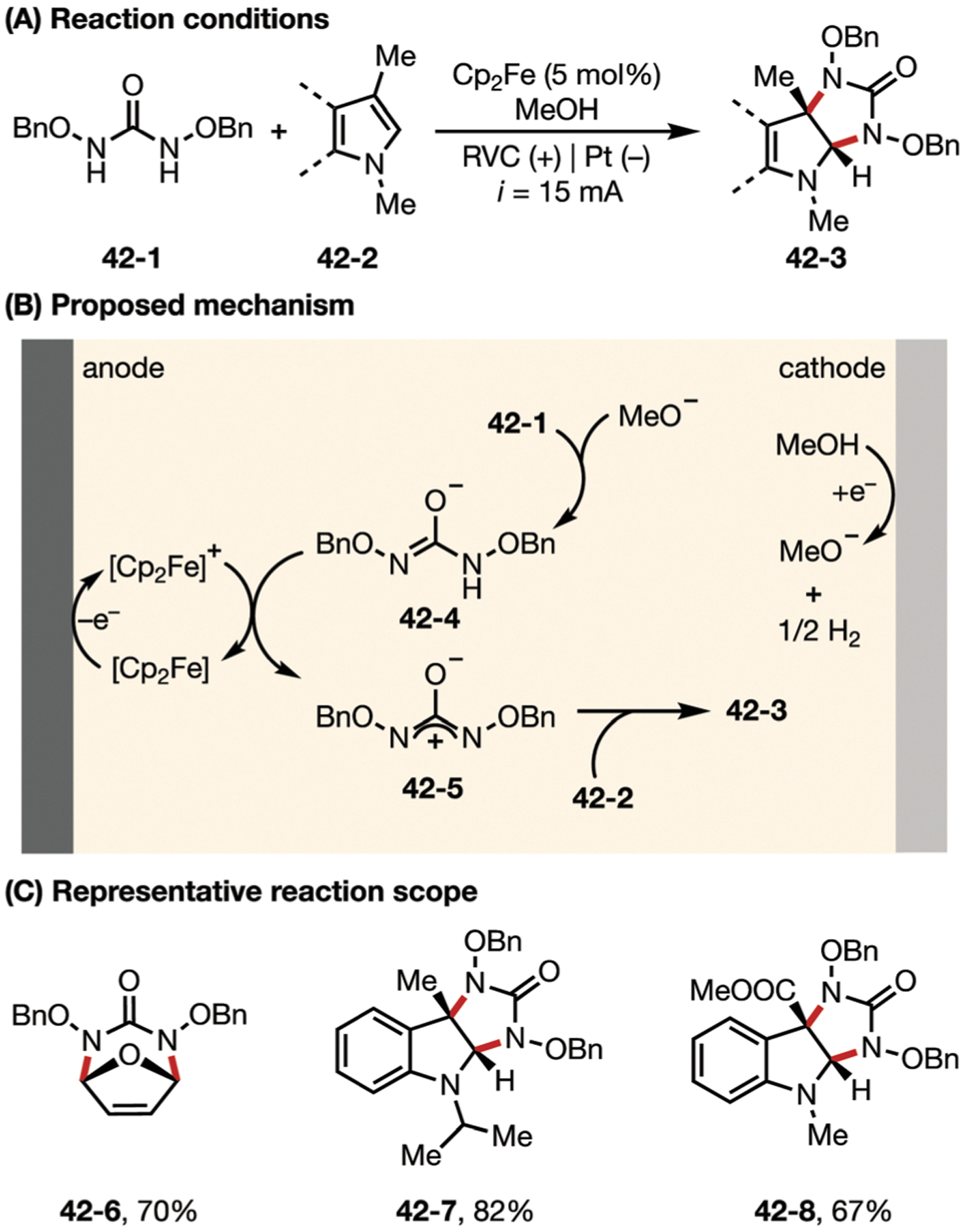

In a similar report in 2018, Luo and co-workers demonstrated an Fe-catalyzed electrochemical cycloaddition of diaza-oxyallyl cations to synthesize diamines.152 Like some previous examples in this section, this reaction also featured cathodic reduction of methanol paired with the anodic oxidation of ferrocene (Fig. 42). On the anodic side, the oxidized ferrocenium serves as a mediator to oxidize the deprotonated N,N-dibenzyloxyurea (42–4). As such, diaza-oxyallyl cation 42–5 is generated in an efficient fashion and reacts with a variety of heteroarenes to form value-added diamine products.

Fig. 42.

(A–C) Electro-oxidative generation of diaza-oxy-allyl cation toward the synthesis of diamine.

Furthermore, Banerjee and co-workers reported a synthesis of benzimidazolone and oxazinones from aryl benzyloxyureas using a ferrocene catalyst and paired electrolysis.153 Here, water was reduced cathodically and the resultant hydroxide ion acts as the active base to remove the proton on urea 43–1 (Fig. 43). The resultant species then undergoes Fc+-mediated oxidation to form zwitterionic nitrenium intermediate 43–3. Loss of a nitrene leaving group gives rise to an isocyanate intermediate 43–4, which undergoes 5-exo cyclization to give the desired product.

Fig. 43.

(A and B) Electrochemical access to benzimidazolone and quinazolinone via in situ generation of isocyanates.

2.9. Copper

2.9.1. Cyanation of alkenes.

In 2019, the Lin group reported a Cu-catalyzed enantioselective electrocatalytic cyanophosphinoylation of vinylarenes that made use of ACE strategy (Fig. 44). A secondary phosphine is oxidized in a Cu-mediated process to form a P-centered transient radical 44–4 and meanwhile CuII–CN is oxidized to CuIII–CN. This pair of open-shell intermediates will then react with the alkene sequentially following the persistent radical effect to give product 44–2. The bisoxazoline (BOX) ligands along with CN− play a key role in preventing the cathodic reduction of copper ions, which will result in Cu metal plating out.149 The high enantioselectivity of this transformation was found to be related to the structure of the ester groups on the sBOX ligand.

Fig. 44.

(A–C) Enantioselective electrocatalytic cyanophosphorylation of vinylarenes.

In 2020, the Lin group reported a dual electrocatalytic approach for the asymmetric hydrocyanation of conjugated alkenes (Fig. 45).154 Anodic oxidation generates a CoIII–H complex and a CuIII–CN complex in a concerted fashion. The CoIII–H species enables hydrogen-atom transfer to the alkene substrate, and CuIII–CN delivers a cyanide radical equivalent to the resultant alkyl radical. The enantioselectivity of the hydrocyanation reaction was again induced by the use of chiral Cu(sBOX) catalysts. Electrochemistry turns over both catalysts so that an external oxidant is not necessary. Notably, performing the same hydrocyanation reaction using traditional chemical oxidants without electrical input has not proven successful to give comparable efficiencies or enantioselectivities to the electrocatalytic protocol. This reaction is broadly applicable to the functionalization of conjugated alkenes, including alkenylarenes, dienes, enynes, and allenes. Computational studies using DFT unravelled the mechanism of enantioinduction facilitated by the Cu(sBOX) catalyst: the pendant ester group played a key part in enhancing the enantioselectivity of this reaction via a C–H⋯π interaction with the aryl group of the alkene substrate as illustrated in transition state 45–7.

Fig. 45.

(A–C) Dual electrocatalysis enables enantioselective hydrocyanation of conjugated alkenes.

2.9.2. C–H functionalization.

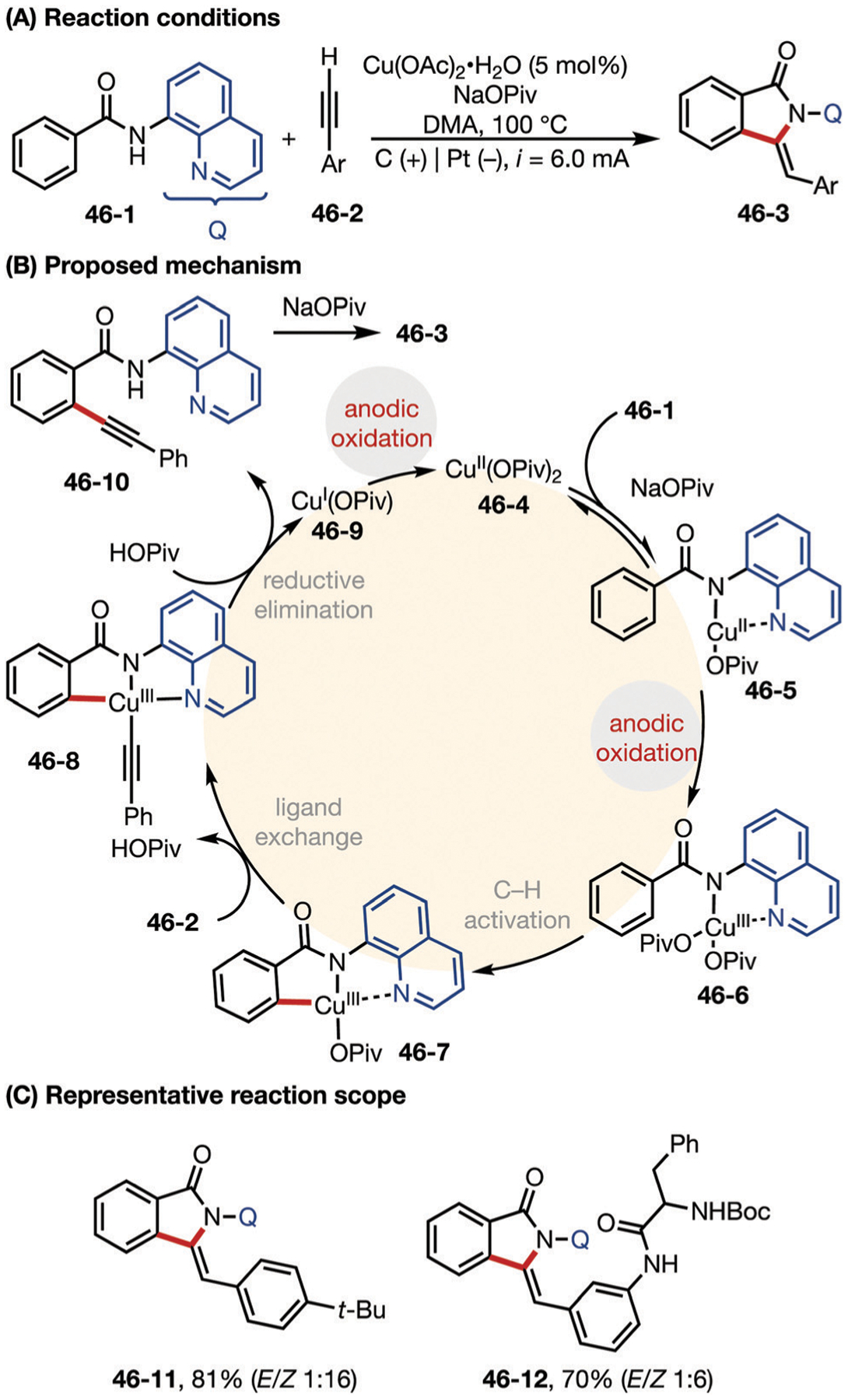

Ackermann and co-workers developed a Cu catalyzed C–H functionalization of benzamides to access isoindolones (Fig. 46).155 The CuI catalyst was oxidized on the anode the first time to CuII, which complexes with substrate 46–1, and a second oxidation occurs to generate a CuIII species (46–6) which is responsible for C–H activation. Thereafter, metalation of the terminal alkyne via ligand exchange and subsequent reductive elimination delivers the C–H alkynylated arene 46–10, which readily undergoes base-promoted cyclization to form isoindolone 46–3.

Fig. 46.

(A–C) Copper-catalyzed alkyne annulation.

In 2020, the Mei group reported a Cu/TEMPO co-catalyzed asymmetric Shono-type electrooxidation reaction. TEMPO acts as the redox mediator while copper with bisoxazoline ligands induce high enantioselectivities to afford C1-alkynylated tetra-hydroisoquinolines (Fig. 47).156

Fig. 47.

Cu(II)/TEMPO-coatalyzed enantioselective C(sp3)–H alkynylation of tertiary cyclic amines.

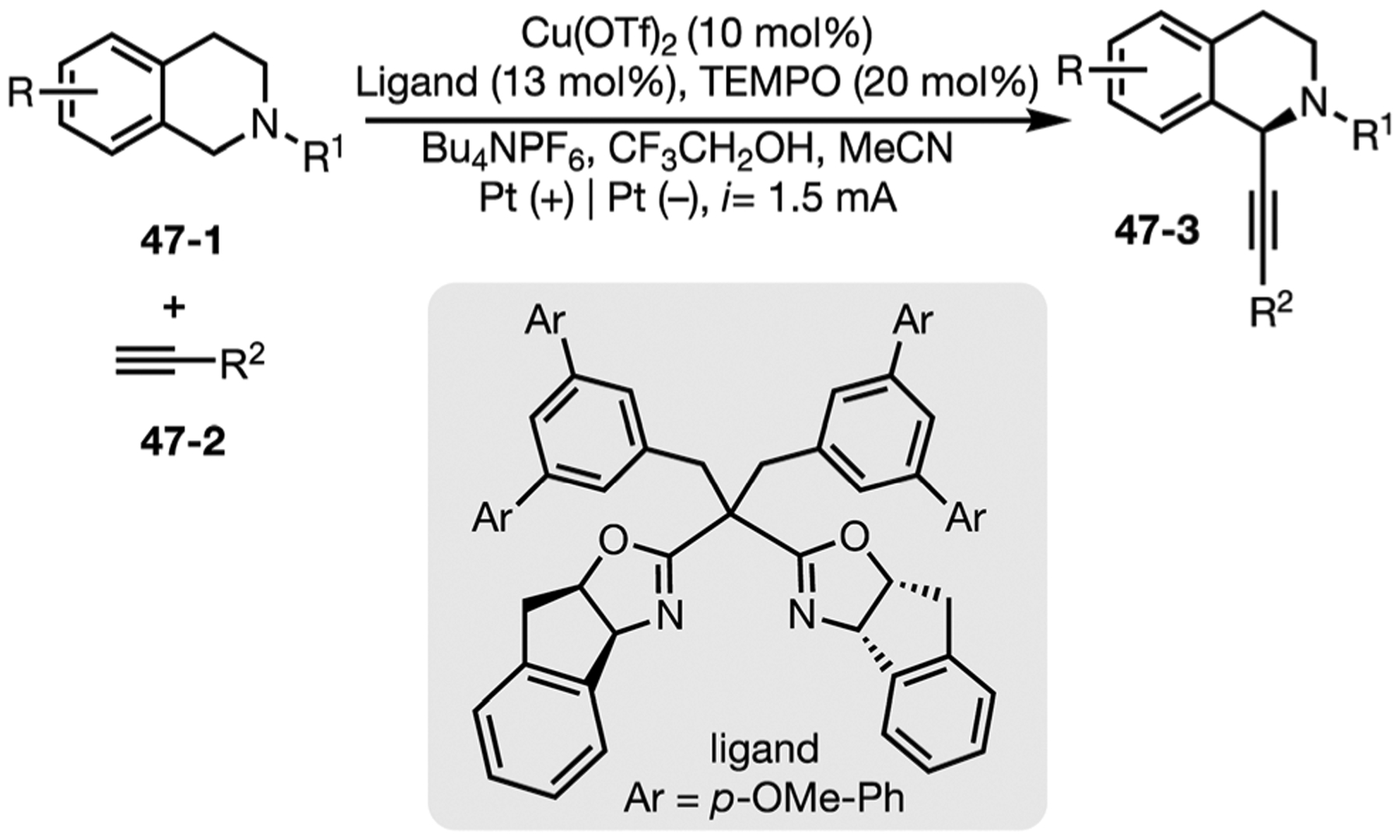

Mei’s group also demonstrated a Cu-catalyzed electrochemical C–H amination of arenes (Fig. 48).157 Another redox mediator used in this system is n-Bu4NI, which is directly recycled on the anode. Kinetic studies indicated that the electron transfer event between the iodine radical and copper complex is the rate-determining step. The authors proposed that the catalytic cycle starts with the coordination of substrates 48–1 and 48–2 to CuII catalyst to generate intermediate 48–5, and this complex is then oxidized by an iodine radical to form a CuIII species 48–6. Complex 48–6 then undergoes metal-to-ligand electron transfer to form radical cation 48–7. Subsequent intramolecular amine transfer to the radical cation and ligand exchange affords product 48–3 and generate a CuI species, which is oxidized on the anode to restore the catalyst to its active form. In a related report, Nicholls and co-workers disclosed a Cu(OAc)2 catalyzed directed C–H amination of benzamides with morpholine.158

Fig. 48.

(A–C) Copper-catalyzed electrochemical C–H amination of arenes with secondary amines.

2.9.3. Allylic amination.

The Hu group described an electrochemical method to accomplish a formal aza-Wacker cyclization of internal alkenes.159 In this protocol, as shown in Fig. 49, electrochemical oxidation generates amidyl radical 49–4 which subsequently cyclizes to generate alkyl radical 49–5. This radical intermediate is then trapped by the Cu catalytic cycle, and an elimination assisted by base yields the alkene product. After releasing the product, the resultant CuI catalyst is oxidized at the electrode to CuII to re-enter the catalytic cycle. A wide range of 5-membered N-heterocycles including oxazolidinone and pyrrolidinone-containing functionalizable alkenes can be prepared under mild conditions.

Fig. 49.

(A–C) Formal aza-Wacker cyclization by tandem electrochemical oxidation and copper catalysis.

2.10. Palladium

In 2007, Amatore, Jutand, and co-workers reported an electrochemical PdII-catalyzed C–H bond olefination reaction of N-acetyl-anilines.160 In this reaction, benzoquinone acts as a sub-stoichiometric redox mediator, which is electrochemically recycled.

Pd-Catalyzed electrocatalytic reactions have also enabled the strategic formation of C–O bonds. In 2013, the Budnikova group reported the electrochemical Pd-catalyzed C–H oxygenation of 2-phenylpyridine using perfluoroalkyl carboxylic acids (Fig. 50A).161 Cyclic voltammograms and NMR data suggested that this C–H functionalization reaction proceed through monometallic PdIII intermediates in acetonitrile or through bimetallic fluorinated PdII intermediates in dichloromethane.

Fig. 50.

(A) Electrochemical palladium-catalyzed ortho-oxygenation of 2-phenylpyridines with perfluorocarboxylic acids. (B) Electrochemical palladium-catalyzed phosphonation of pyridines.

The same group later developed an electrooxidative Pd-catalyzed phosphonation reaction of 2-phenylpyridine (Fig. 50B).162 The authors postulated and subsequently isolated a key intermediate, binuclear phosphonate bipalladium [(PhPy)Pd(EtO)2P(O)]2, whose structure was confirmed by X-ray analysis. This species could be electrochemically oxidized to a PdIII or PdIV reactive intermediate that undergoes reductive elimination to afford the phosphonated product.

Electrochemical Pd-catalyzed transformations have also been applied in carbon–halogen bond formation. In 2017, the Kakiuchi group reported a palladium-catalyzed ortho-selective chlorination of N-quinolinylbenzamide derivatives under anodic oxidation conditions (Fig. 51).163

Fig. 51.

Electrochemical palladium-catalyzed chlorination of N-quinolinylbenzamide derivatives.

The breadth of Pd electrocatalysis is further showcased in C–C bond formation. In 2017, the Mei group reported Pd-catalyzed C(sp2)–H functionalization of oximes using organoboron reagents or benzoyl acetic acids, providing ortho-methylated or ortho-acylated products, respectively.164 The proposed reaction mechanism starts with C–H activation to generate palladacycle 52–5. It is proposed that MeBF3K can be directly oxidized to afford a methyl radical, which is then trapped by palladacycle 52–5. Alternatively, 52–5 can undergo direct transmetallation with MeBF3K followed by anodic oxidation to form a PdIII or PdIV intermediate 52–6. This high-valent intermediate readily undergoes reductive elimination to deliver the methylated product and regenerate the PdII catalyst (Fig. 52).

Fig. 52.

(A and B) Palladium-catalyzed electrooxidative C–C bond formation of oximes.

In 2017, Surendranath and co-workers developed an electrochemical strategy to oxidize methane with PdSO4 as the mediator.165 Mechanistic studies support an electrochemical oxidation of PdII catalyst to a putative bimetallic PdIII,III2 intermediate, which rapidly functionalizes methane to generate CH3OSO3H and CH3SO3H via concurrent faradaic and non-faradaic pathways, respectively. Both CH3OSO3H and CH3SO3H can be thermally and hydrolytically converted to methanol (Fig. 53).

Fig. 53.

Electrochemical palladium-catalyzed methane monofunctionalization.

The Lei group reported a Pd-catalyzed electrochemical aminocarbonylation of alkynes under atmospheric pressure of CO in an undivided cell (Fig. 54).166 Based on cyclic voltammetry, kinetic analysis, and XAFS spectroscopy data, the authors proposed that the catalytic cycle proceeds through a Pd0/PdII redox pair. The reaction starts with amine substrate 54–2 binding to PdII catalyst 54–4, followed by CO insertion to generate intermediate 54–6, which reacts with alkyne 54–1 to give the palladium acetylide 54–7. This species then undergoes reductive elimination to release 2-ynamide 54–3. The resultant Pd0 subsequently gets oxidized on the anode to regenerate the catalytic cycle. Diverse primary and secondary amines with various functional groups are viable substrates for this reactivity.

Fig. 54.

(A–C) Electrochemical oxidative aminocarbonylation of terminal alkynes.

In 2017, the Mei group reported a PdII-catalyzed C(sp3)–H oxygenation via anodic oxidation. According to the proposed mechanism, electrochemical oxidation of divalent palladacycle 55–4 to a PdIII or PdIV intermediate (55–5) occurs to induce the subsequent reductive elimination (Fig. 55).167 Kinetic isotope effect (KIE) experiments suggested that the C–H activation of the substrate is the rate-limiting step (kH/kD = 3.7). The acylated product can re-enter the catalytic cycle to undergo an additional C–H activation, eventually resulting in di- or tri-acetoxylation products. The Sanford group has also applied electrochemistry in Pd-catalyzed electrochemical acetoxylations of C(sp2)–H and C(sp3)–H bonds.168

Fig. 55.

(A–C) Electrochemical palladium-catalyzed C(sp3)–H bond acetoxylation.

2.11. Ruthenium

A common practice for inducing C–H activation is to utilize nitrogen-based directing groups. In 2018, the Ackermann group reported a Ru-catalyzed electrocatalytic C–H activation with aromatic carbamates and phenols (Fig. 56).169 Based on mechanistic studies, the authors proposed that the catalytic cycle starts with the coordination of aromatic carbamates accompanied by C–H activation to generate ruthena(II)cycle intermediate 56–5. Subsequent coordination of an alkyne followed by migratory insertion affords the seven-membered ruthena(II)cycle 56–7. This species then undergoes reductive elimination to deliver the product and Ru0 intermediate 56–8. The anodic oxidation of intermediate 56–8 back to the active RuII species 56–4 completes the catalytic cycle.

Fig. 56.

(A–C) Electrochemical ruthenium-catalyzed alkyne annulations of arylcarbamates.

The Ackermann group later reported a Ru-catalyzed C–H activation to enable annulations between alkynes and benzoic acids.170 The proposed mechanism is similar to that of the previous example. In 2021, the group published an electrochemical three-component assembly of isoquinolines catalyzed by a RuII catalyst, shown in Fig. 57.171

Fig. 57.

(A and B) Ruthenaelectro-catalyzed three-component alkyne annulation.

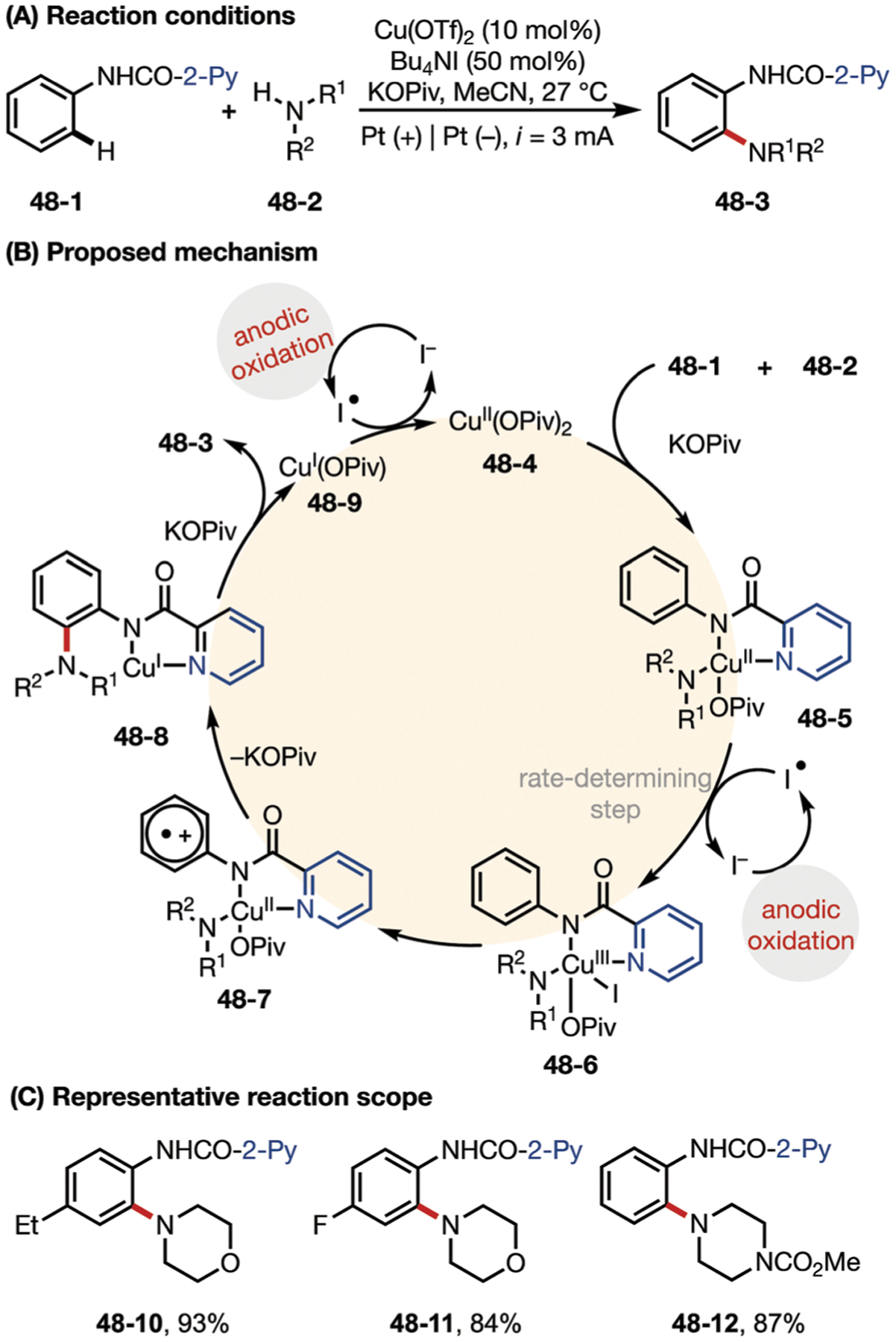

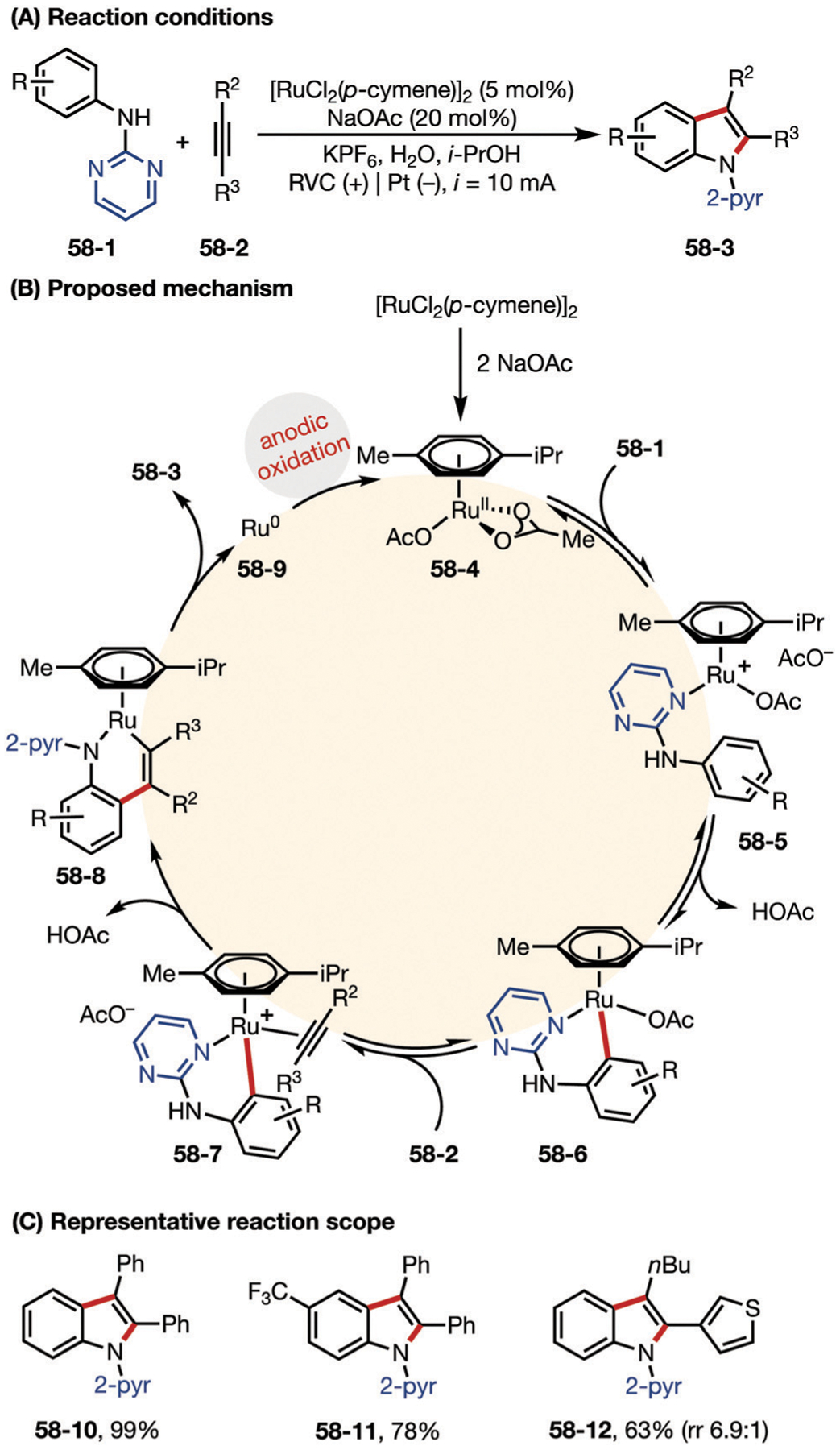

In 2018, the Xu group described a Ru-catalyzed electrochemical dehydrogenative annulation reaction of aniline derivatives and alkynes for the synthesis of indoles (Fig. 58).172 Similar to Ackermann’s work, an electric current is used to oxidize Ru0 precatalyst 58–9 to its active form. Xu proposed that NaOAc converts precatalyst [RuCl2(p-cymene)]2 into ruthenium diacetate complex 58–4. Coordination with the pyrimidine directing group promotes reversible C–H activation to form the six-membered ruthenacycle 58–6. Subsequently, intermediate 58–6 goes through ligand exchange, and migratory insertion of the bound alkyne into the Ru–C bond triggers the metal center to dissociate from the pyrimidyl nitrogen and instead complex with the amino group of the aniline moiety to obtain the six-membered ruthenacycle in the resultant intermediate 58–8. Eventually, reductive elimination delivers the product.

Fig. 58.

(A–C) Ruthenium-catalyzed Electrochemical dehydrogenative alkyne annulation.

2.12. Iridium

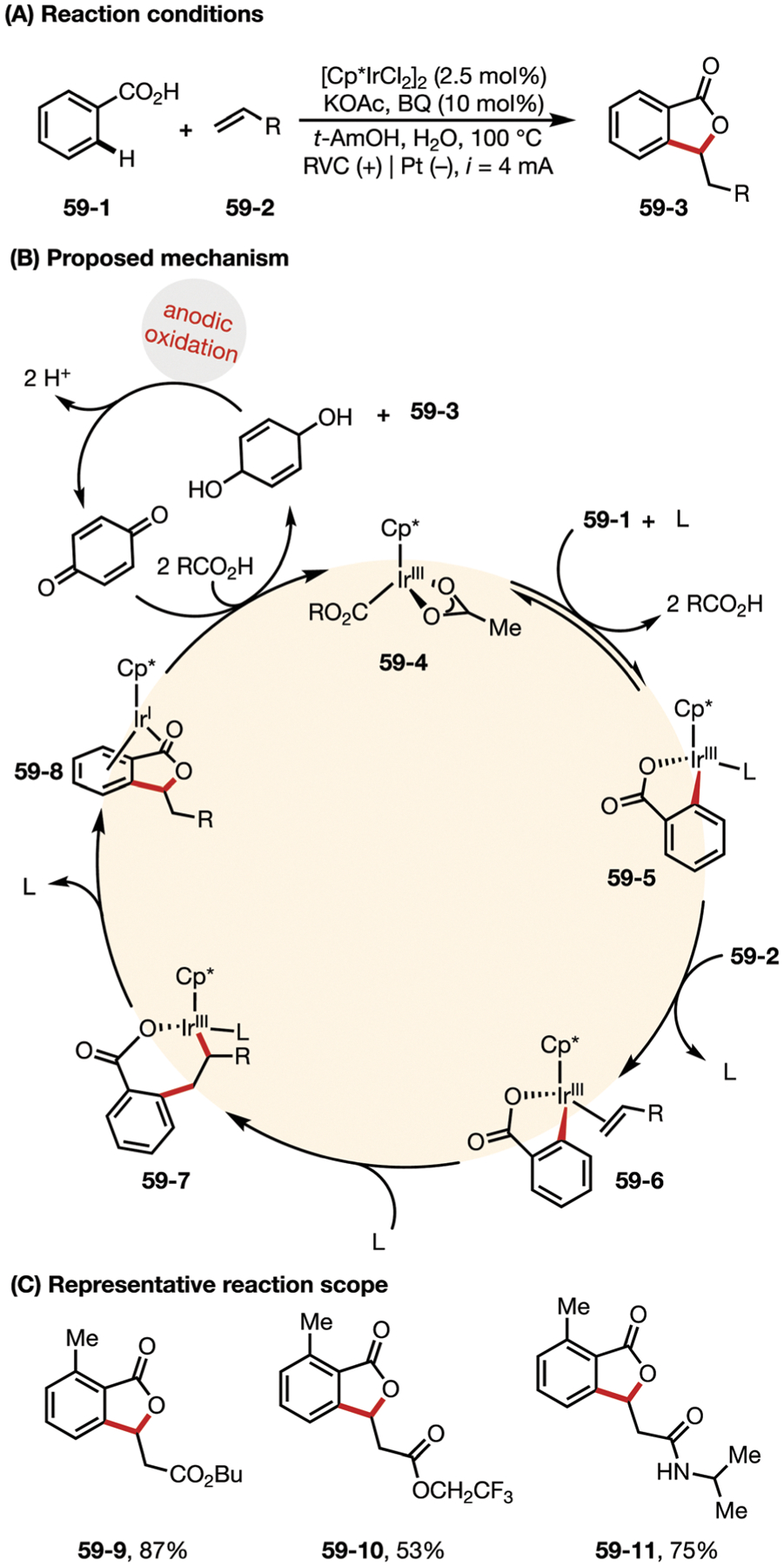

In 2018, the Ackermann group developed an Ir/benzoquinone co-catalyzed electrochemical C–H alkenylation of benzoic acids via ortho-coordination.173 Mechanistic studies in Fig. 59 suggested a facile C–H cleavage and the subsequent formation of IrIII cycle 59–7, which undergoes β-H elimination and reductive elimination to form IrI intermediate 59–8. Benzoquinone-mediated anodic oxidation then restores the IrI species to the active catalyst 59–4.

Fig. 59.

(A–C) Cooperative iridium-catalyzed electrooxidative C–H alkenylations.

In 2019, Mei and co-workers demonstrated that the synergistic combination of iridium catalysis and electrochemistry enables vinylic C–H activation of acrylic acids for alkyne annulation, producing α-pyrones in an undivided cell (Fig. 60).174 Without electricity, traditional chemical oxidants such as Ag0 or CuII did not give significant amounts of the desired product.

Fig. 60.

(A–C) Electrochemistry-enabled Ir-Catalyzed vinylic C–H Functionalization for alkyne annulation.

2.13. Cobalt

Cobalt electrocatalysis is a particularly powerful platform for a variety of C–H transformations and has been applied for the construction of C−O, C−N, and C–C bonds.

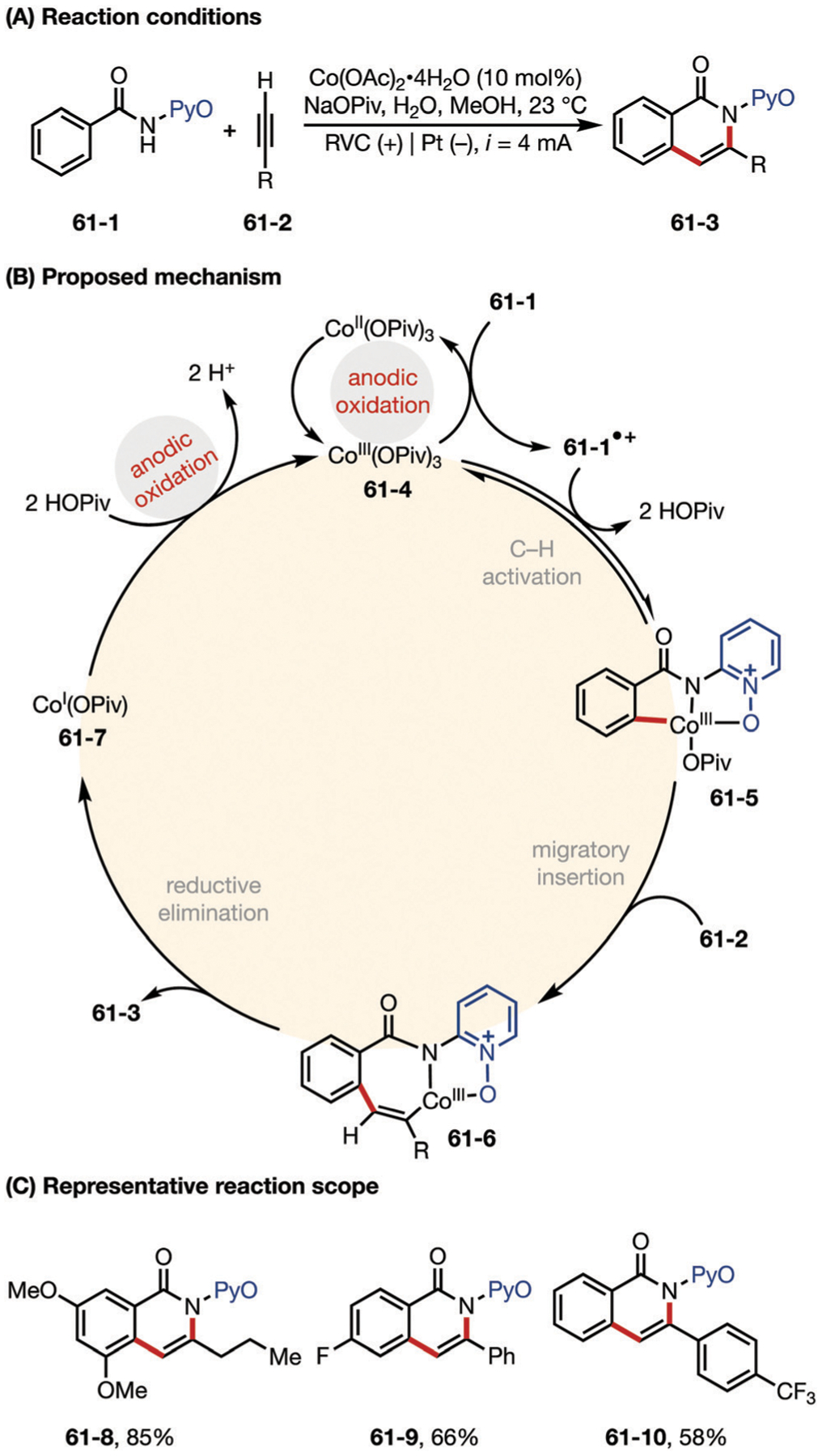

The Ackermann group has pioneered the development of cobalt-catalyzed metalla-electrochemical C–H activations.175 In 2018, the group reported a Co-catalyzed electrochemical C–H/N–H annulation of alkynes at room temperature.176 The proposed mechanism is shown in Fig. 61, the catalytic cycle starts with the anodic oxidation of CoI or CoII to an active CoIII carboxylate species 61–4. Thereafter, this species engages in carboxylate-assisted C–H activation of benzamides to generate intermediate 61–5, which then binds to phenyl alkyne to provide CoIII intermediate 61–6. Lastly, reductive elimination affords the desired product and form the putative CoI species 61–7. The catalytically active CoIII carboxylate complex is regenerated by anodic oxidation, thereby avoiding the use of sacrificial stoichiometric oxidants.

Fig. 61.

(A–C) Electrochemistry-enabled cobalt-catalyzed C–H/N–H Activation. PyO = 2-pyridyl N-oxide.

In 2020, the same group reported a cobalt-catalyzed electrochemical C–H allylation of benzamides with electronically unactivated alkenes.177 A similar mechanism involving CoII/III intermediates is proposed.

The Lei group has described several Co-catalyzed electrochemical C–H activation protocols.178 In 2018, Lei published a cobalt-catalyzed C–H amination of arenes to access synthetically useful arylamines (Fig. 62).179 Later, the authors reported a Co-catalyzed electrochemical [4+2] annulation of sulfonamides with alkynes to make a variety of sultams (Fig. 63).180 In this work, it was proposed that the [4+2] annulation reaction possibly proceeds through the following pathway: CoII species first coordinates with substrate 63–1 to generate CoII complex 63–4 and then undergoes single electron oxidation to access the CoIII complex 63–5. It is noteworthy that oxygen is critical for the reaction to proceed, and the authors hypothesize that H2O2 generated from O2 reduction could also oxidize CoII complex 63–4 to CoIII complex 63–5. Next, C–H activation followed by phenylacetylene insertion to generate intermediate 63–7, which undergoes reductive elimination to form the annulation product and CoI species. The generated CoI species is oxidized at anode to regenerate CoII. At the same time, O2 is reduced at the cathode to generate the superoxide radical anion, which then reacts with the solvent mixture to produce H2O2.

Fig. 62.

Cobalt-catalyzed electrooxidative C–H amination of arenes with alkylamines.

Fig. 63.

(A–C) Electrochemistry-enabled cobalt-catalyzed [4+2] annulation for the synthesis of sultams.

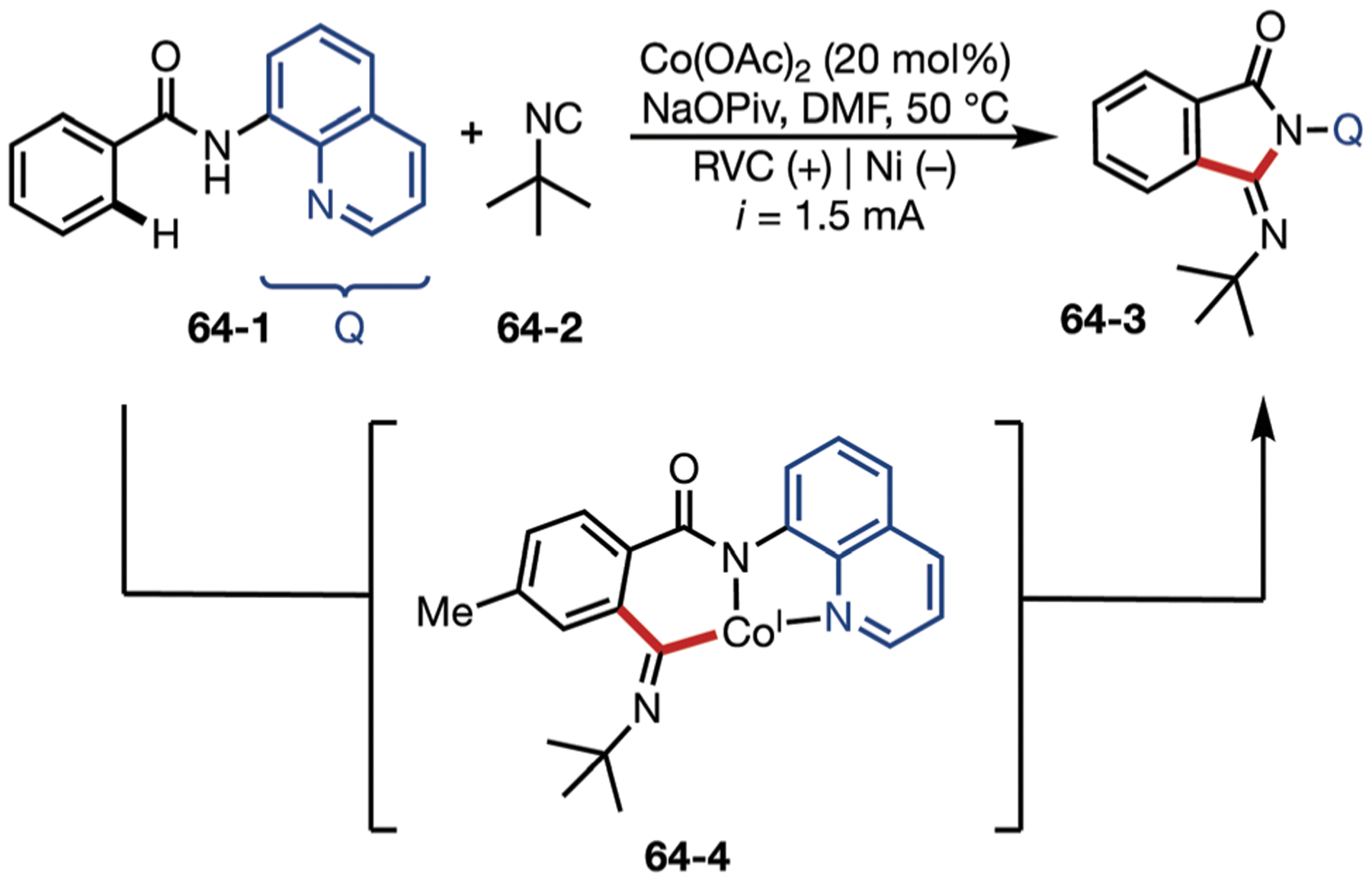

In 2019, the Yu group described a Co-catalyzed electrochemical oxidative C–H/N–H intramolecular annulation with isocyanides to synthesize iminoisoindolinone derivatives (Fig. 64).181 Anodic oxidation serves a similar role as in the previous examples.

Fig. 64.

Electrochemical oxidative C–H/N–H intramolecular annulation with isocyanides for iminoisoindolinone synthesis.

2.14. Nickel

In an early work, the Budnikova group developed a Ni- or Pd-catalyzed electrochemical ortho-fluoroalkylation of 2-phenylpyridine.182 Based on the cyclic voltammogram of [Ni(bpy)3]2+ catalyst, the authors proposed that the C–H functionalization process goes through a NiII/NiIII redox pair.

In 2019, the Ackermann group reported Ni-catalyzed electrochemical alkoxylations of benzamides and secondary alcohols.183 Notably, this reaction has not been shown possible with other transition metal catalysts prior to this work. Anodic oxidation is used to induce reductive elimination of a high valent NiIII or NiIV complex. In order to rationalize the C–O bond formation process, the well-defined NiIII complex 65–4 was synthesized and fully characterized, including X-ray diffraction analysis. Cyclic voltam-metric studies of 65–4 revealed an oxidation feature at a potential of 0.50 V vs. Fc0/+, suggesting the formation of a higher valent complex 65–5 (Fig. 65). DFT calculations indicate the redox non-innocence of the ligand during oxidation; thus the oxidation is best described as a ligand-centered process. Reductive elimination of this species gave the final product.

Fig. 65.

Nickellaelectro-catalyzed C–H alkoxylation with secondary alcohols.

2.15. Rhodium

In 2018, the Ackermann group reported a Rh-catalyzed electrochemical C–H alkenylation of benzoic acids mediated by a rhodium catalyst.184 As shown in Fig. 66, the authors proposed a catalytic cycle that proceeds via an ortho C–H activation of benzoic acid 66–1 followed by migratory insertion of alkene 66–2. Intermediate 66–7 subsequently undergoes β-hydride elimination and reductive elimination. Finally, anodic oxidation of RhI intermediate 66–8 regenerates the catalytically active complex 66–4 while generating the desired product 66–3. Based on competition experiments with CF3-substituted and CH3-substituted benzoic acids and isotope labelling experiments, it is believed that the C–H activation proceeds through a base-assisted internal electrophilic substitution mechanism.

Fig. 66.

(A–C) Electrooxidative rhodium-catalyzed C–H/C–H activation for dehydrogenative alkenylation.

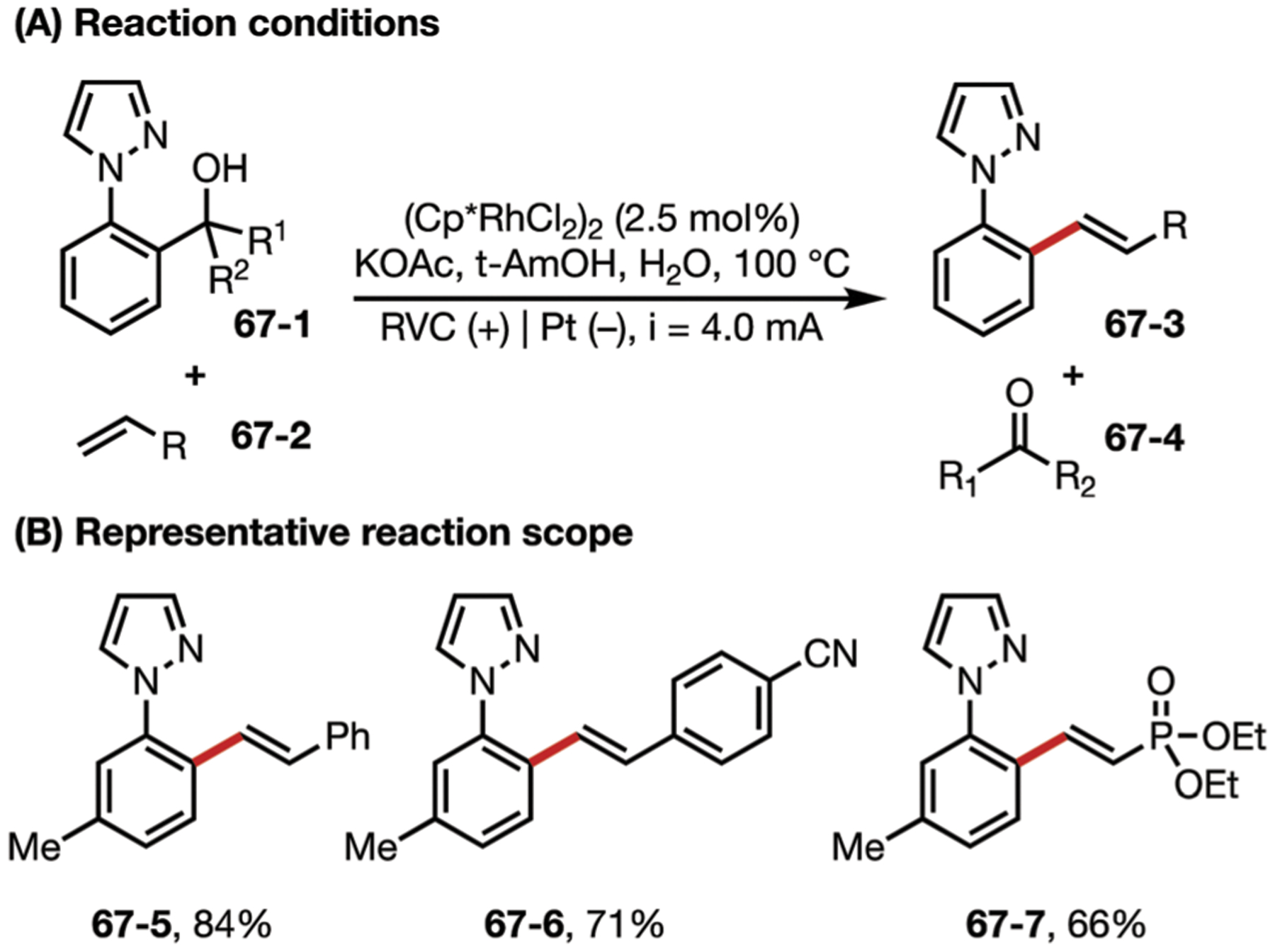

The Ackermann group also published an electrochemical arene alkenylation reaction catalyzed by a Rh complex. Like the previous example, this catalytic cycle also involves a RhI/RhIII redox pair. The proposed mechanism includes a key C–C bond activation step that leads to the formation of ketone by-product 67–4 (Fig. 67).185

Fig. 67.

(A and B) Electrochemical C–C bond activation C–C bond alkenylation by rhodium(III) catalysis.

The Xu group reported a Rh-catalyzed electrocatalytic C–H phosphorylation reaction in 2019.186 This method enabled the synthesis of triarylphosphine oxides from diarylphosphine oxides. In this work, electricity is used to oxidize RhIII intermediate 68–6 to facilitate reductive elimination towards C–P bond formation (Fig. 68). However, the authors stated that the exact oxidation state of intermediate 68–7 prior to reductive elimination remains unknown. Pyrazole, pyridazine, purines, and pyrrolo-pyrimidine directing groups were shown to be compatible with the C–H activation step.

Fig. 68.

(A–C) Rhodium(III)-catalyzed aryl C–H phosphorylation enabled by anodic oxidation induced reductive elimination.

3. Cathodic reduction

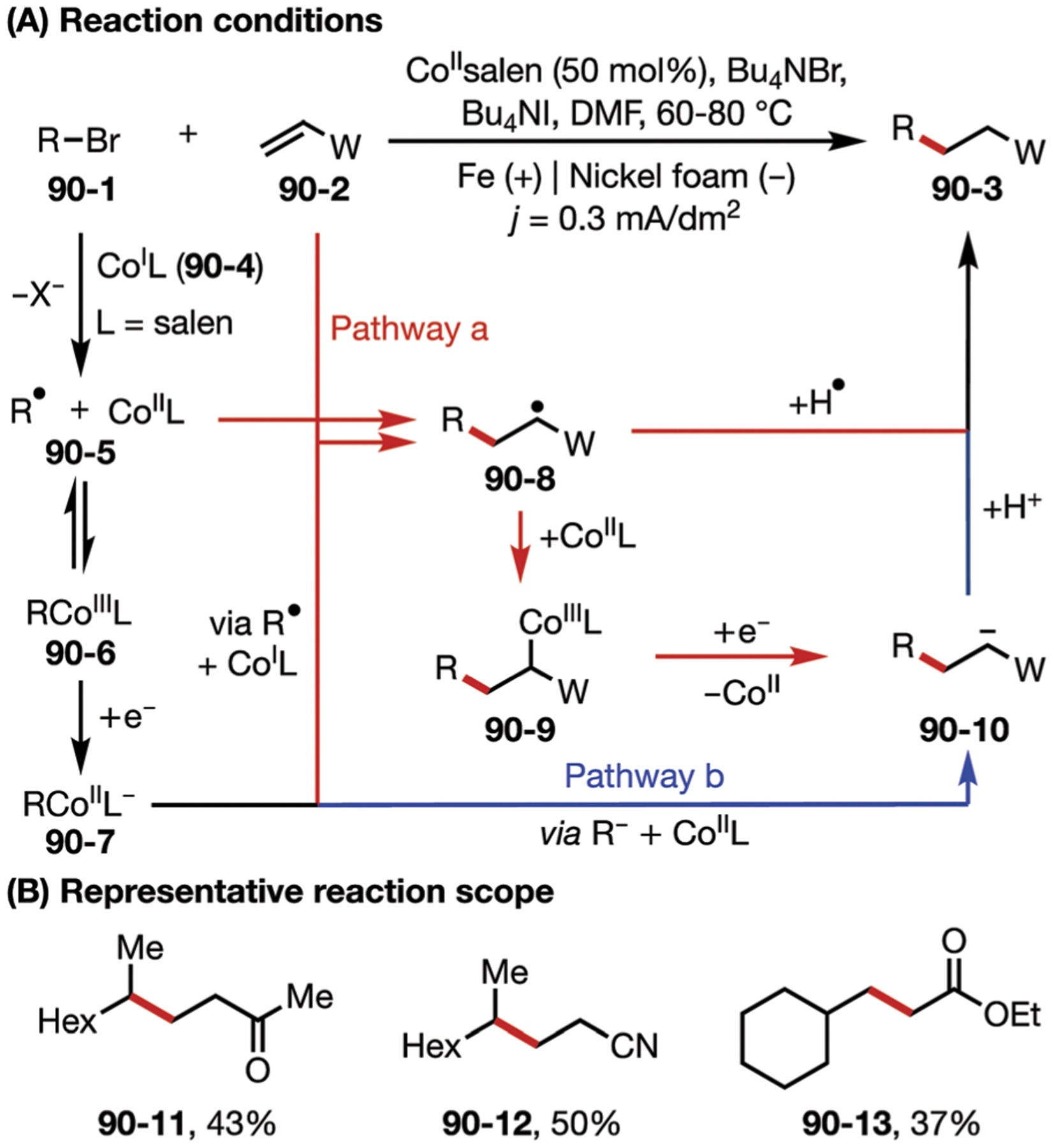

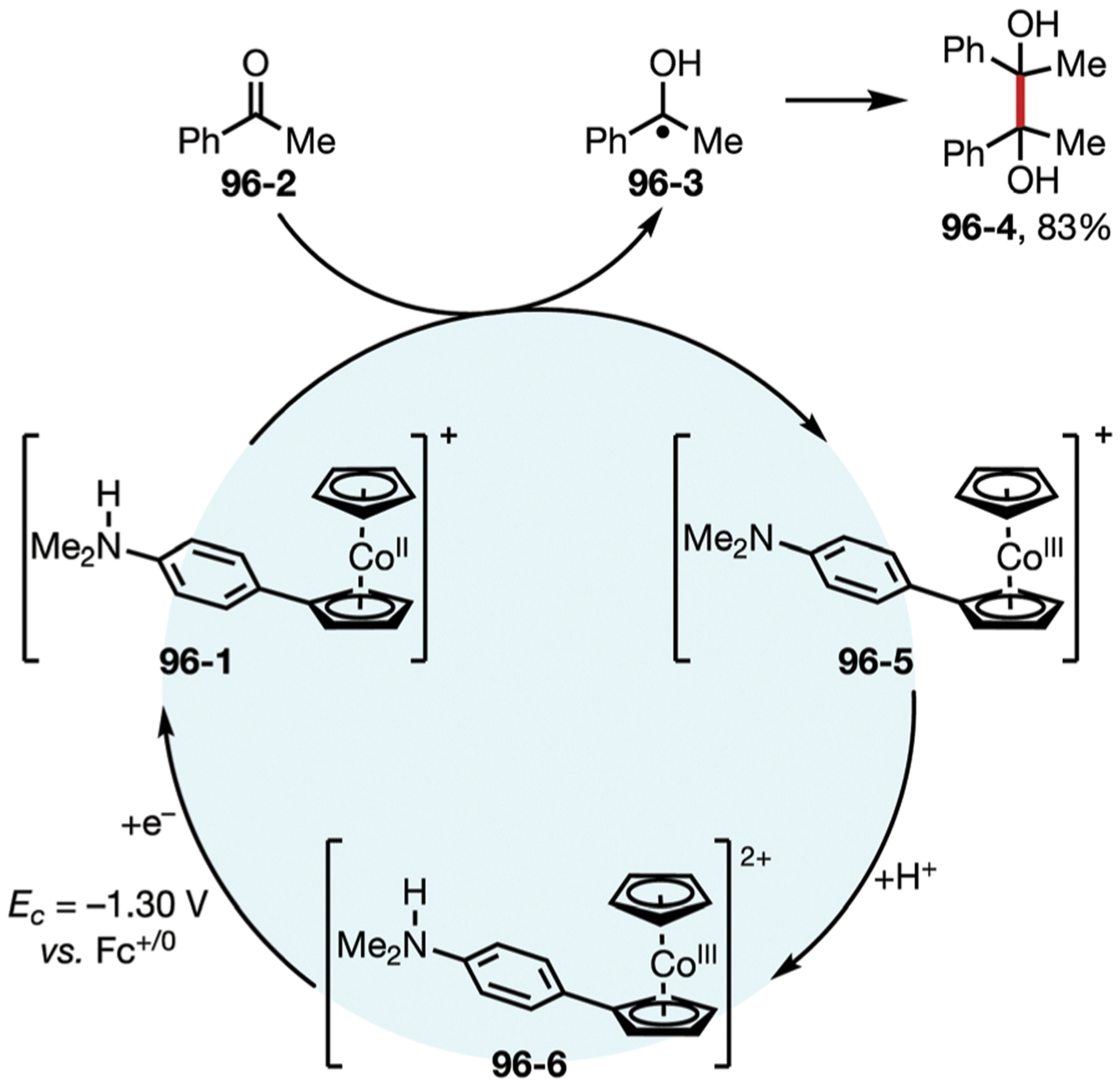

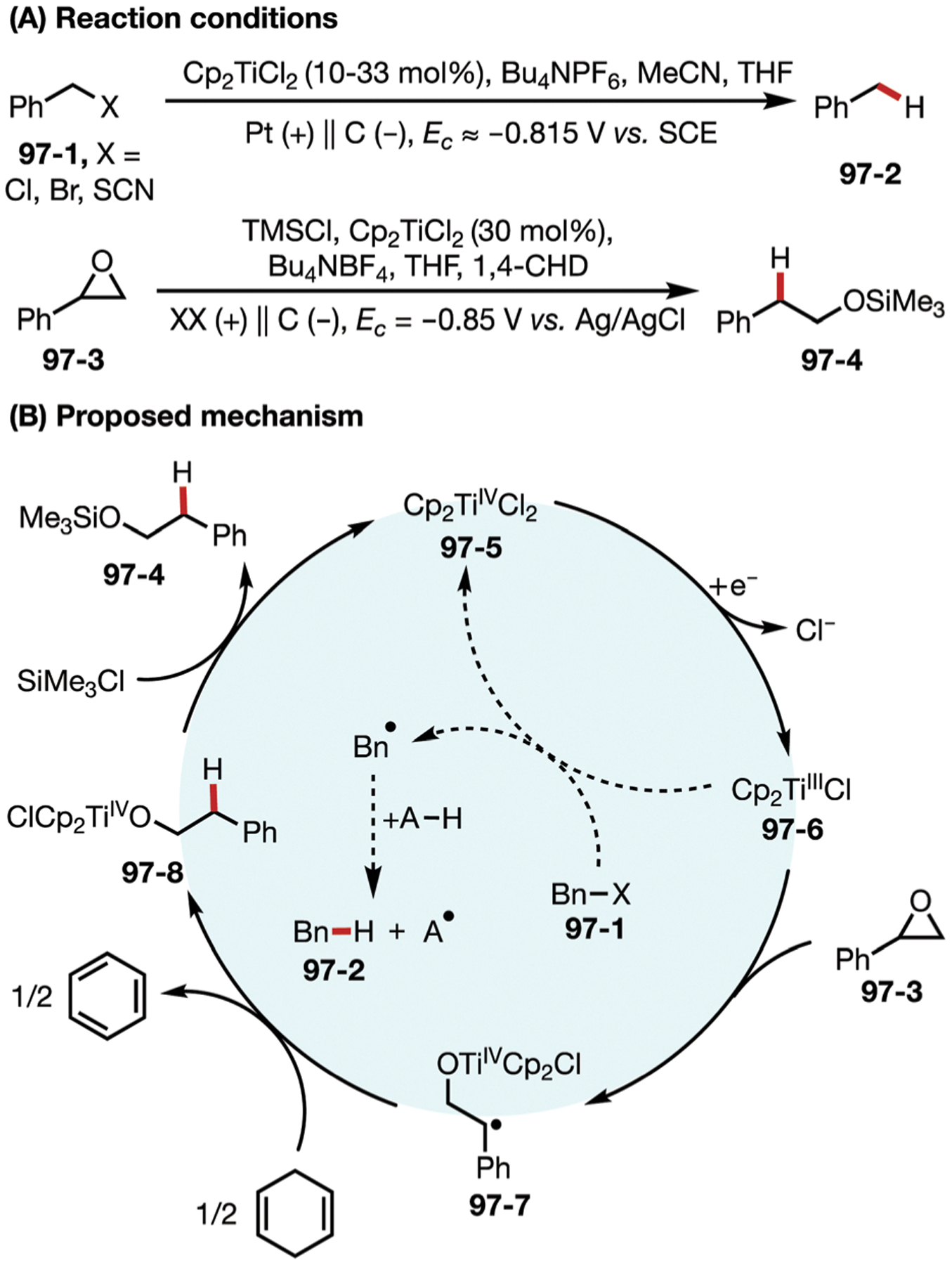

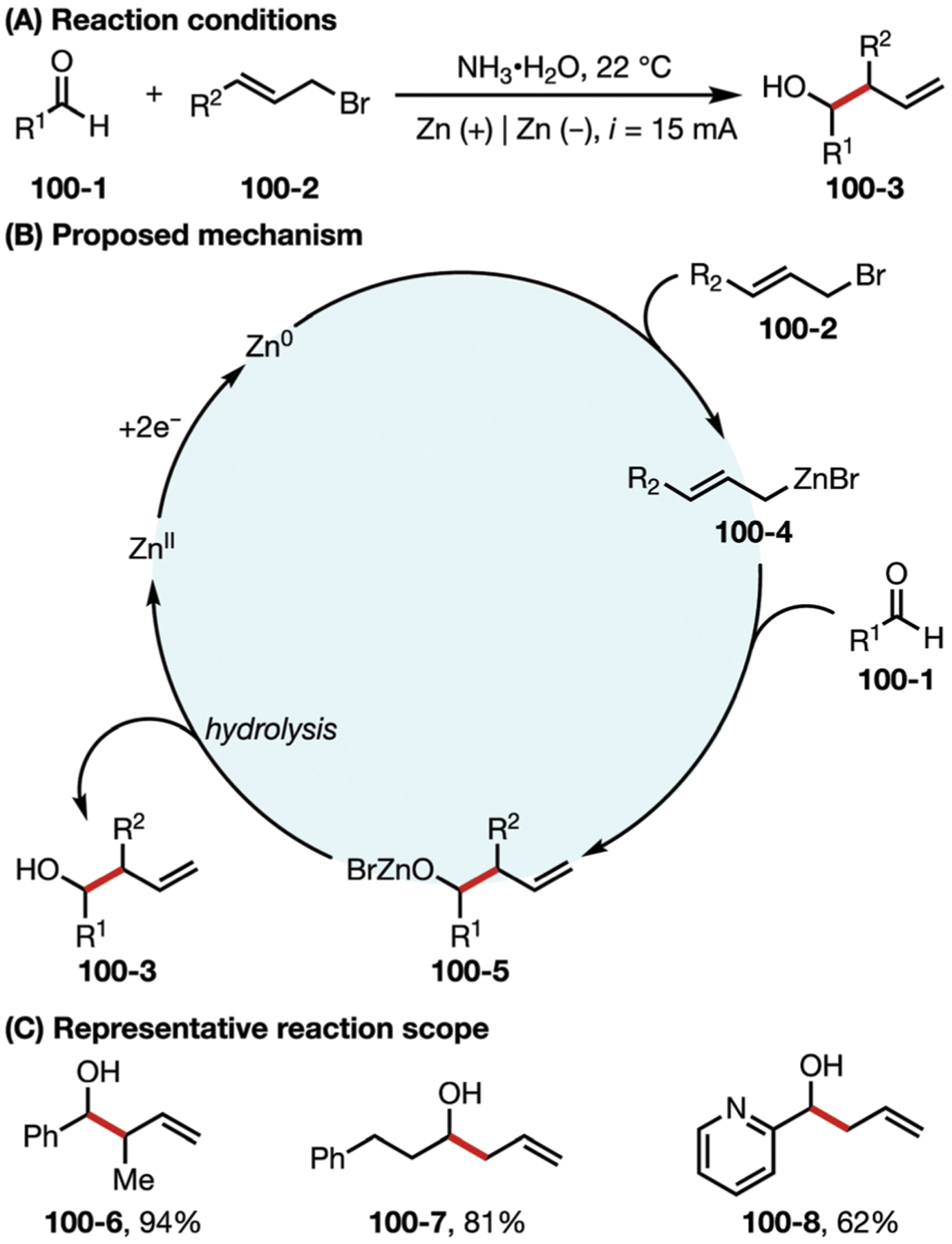

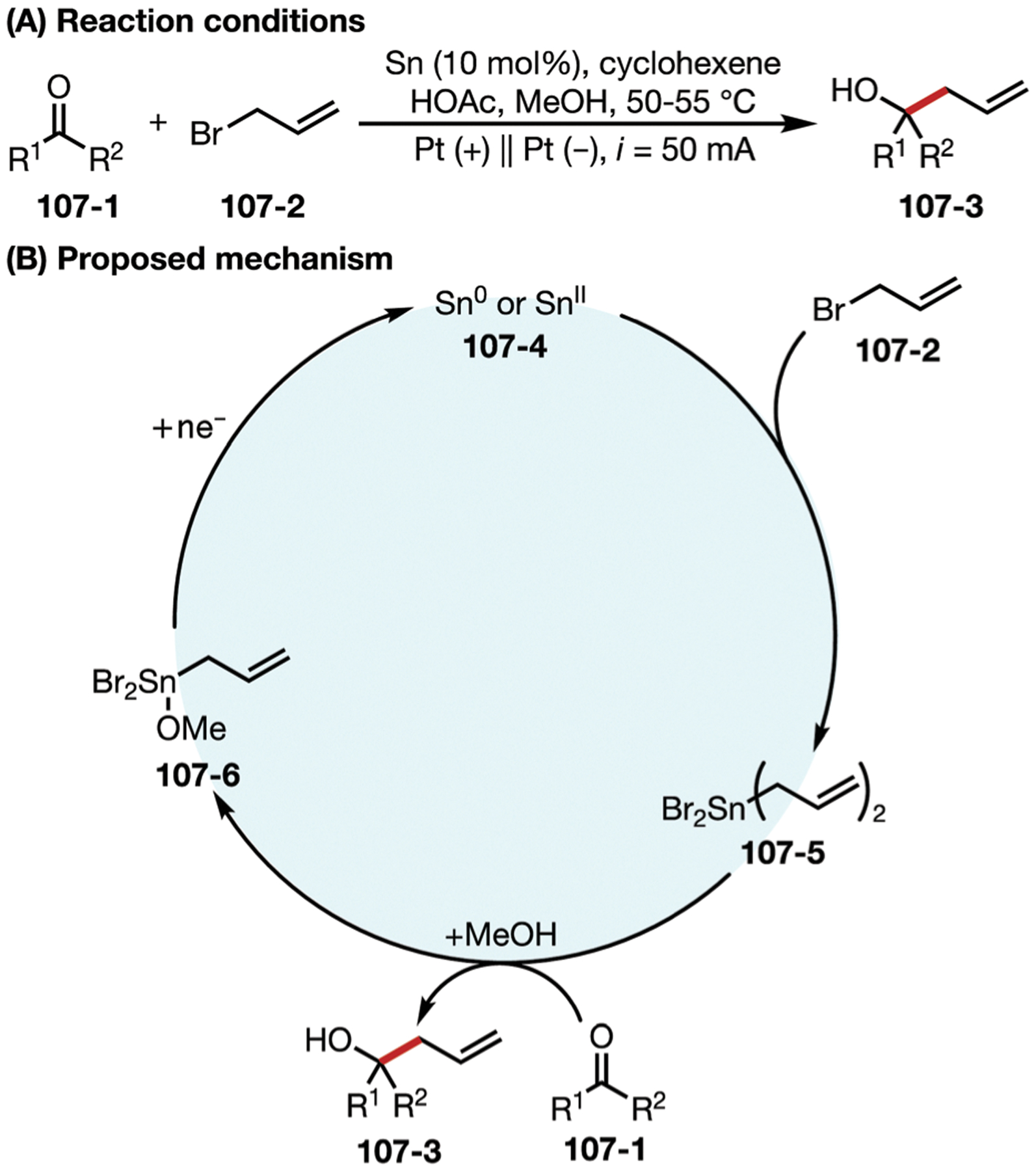

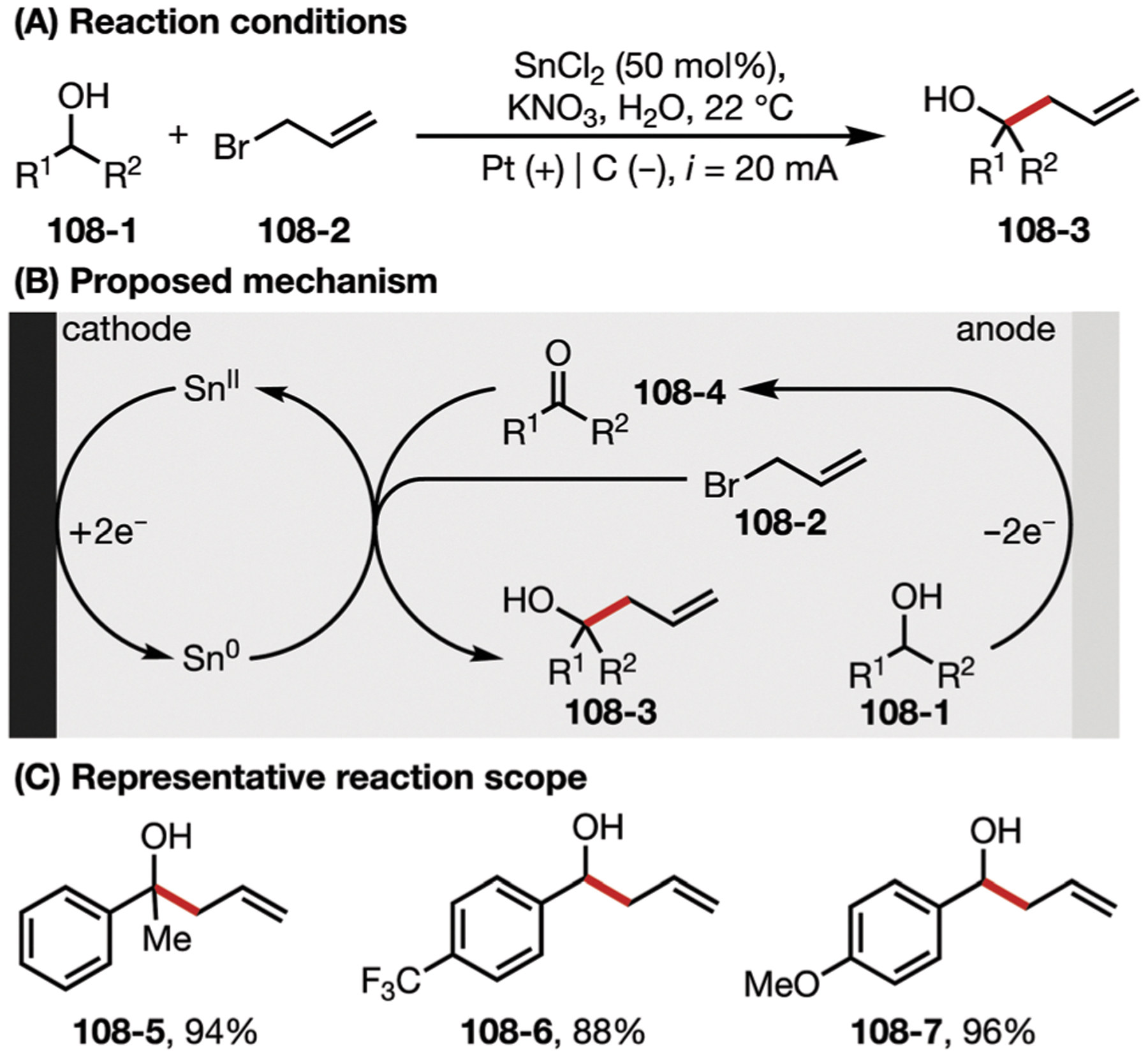

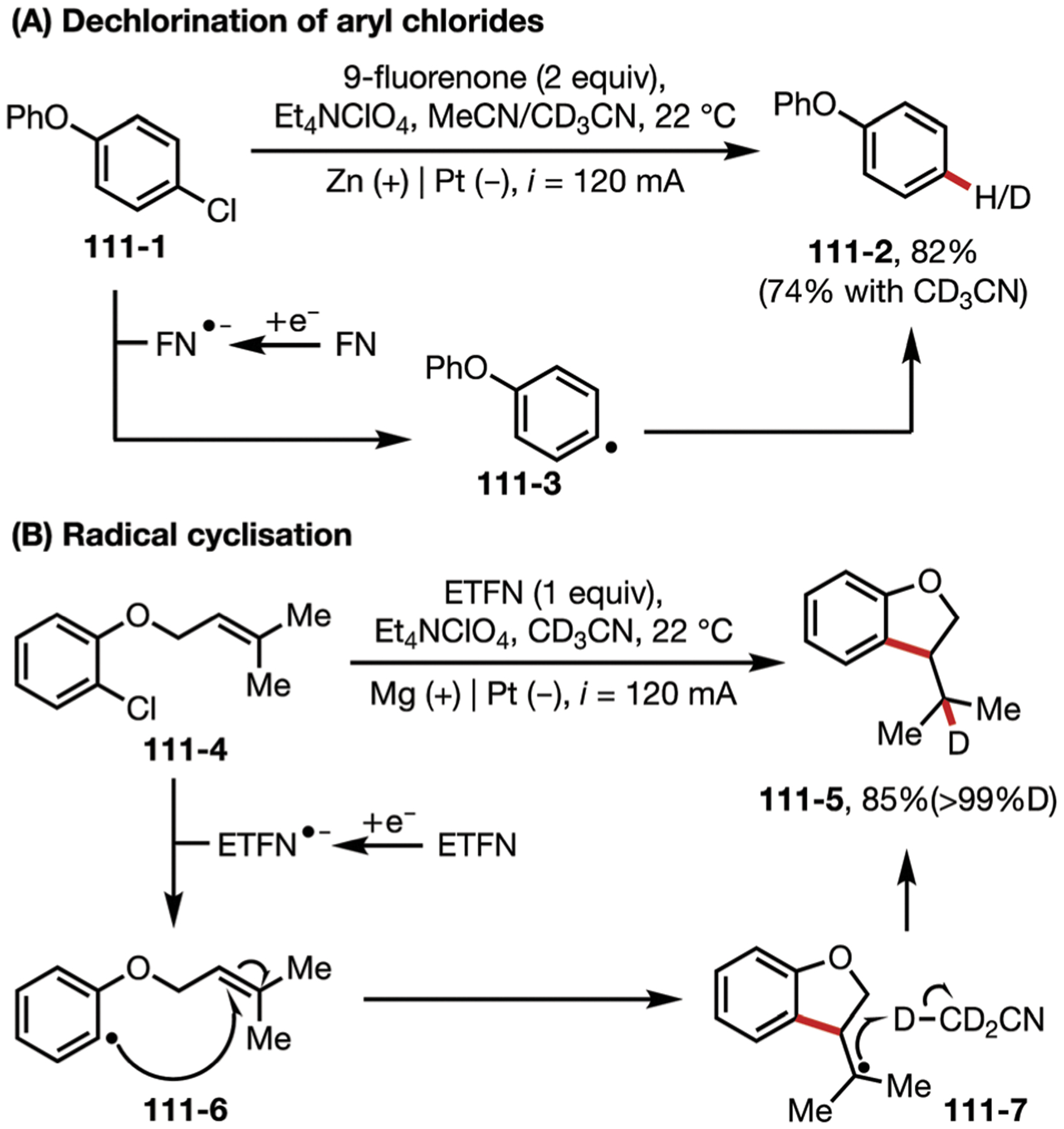

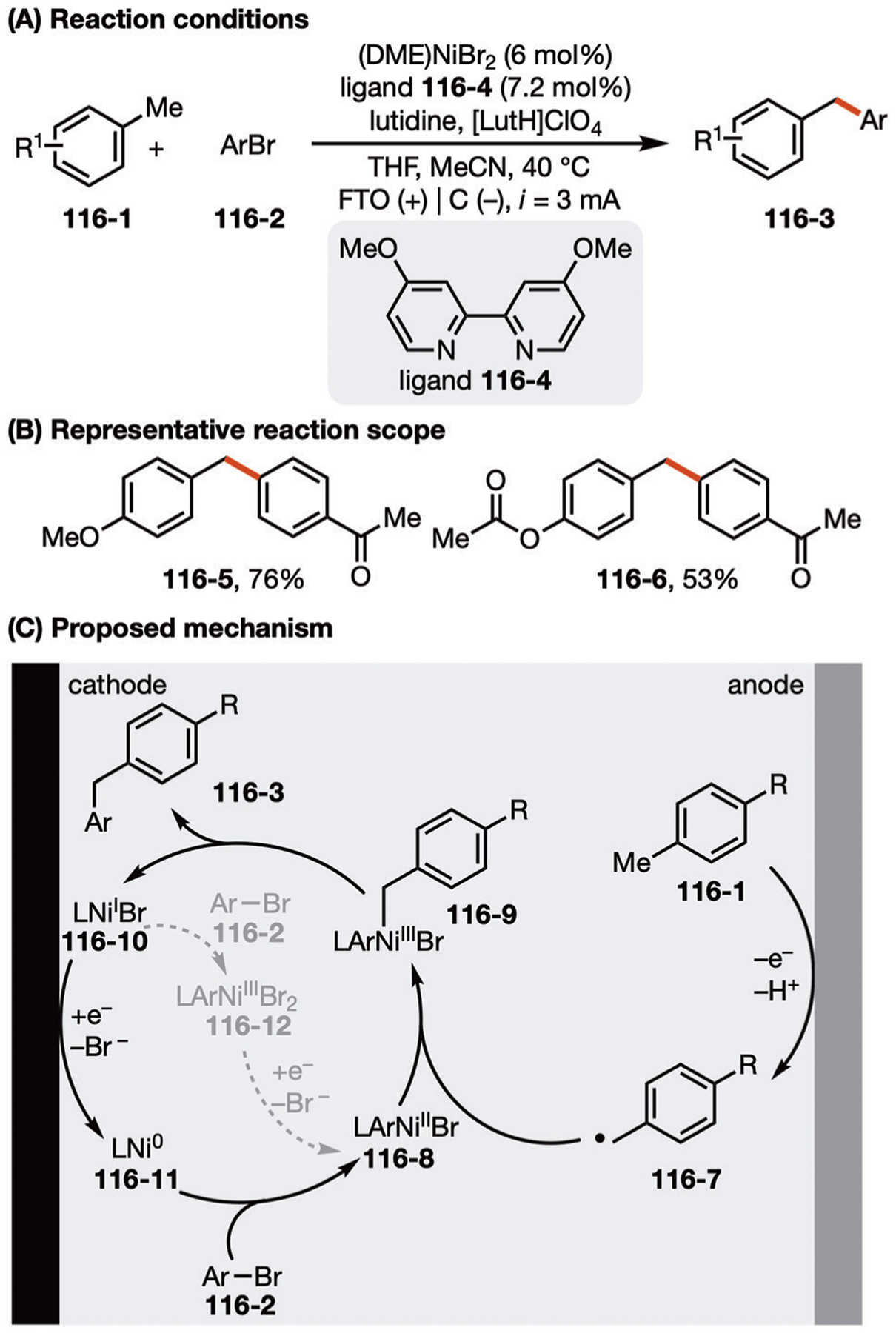

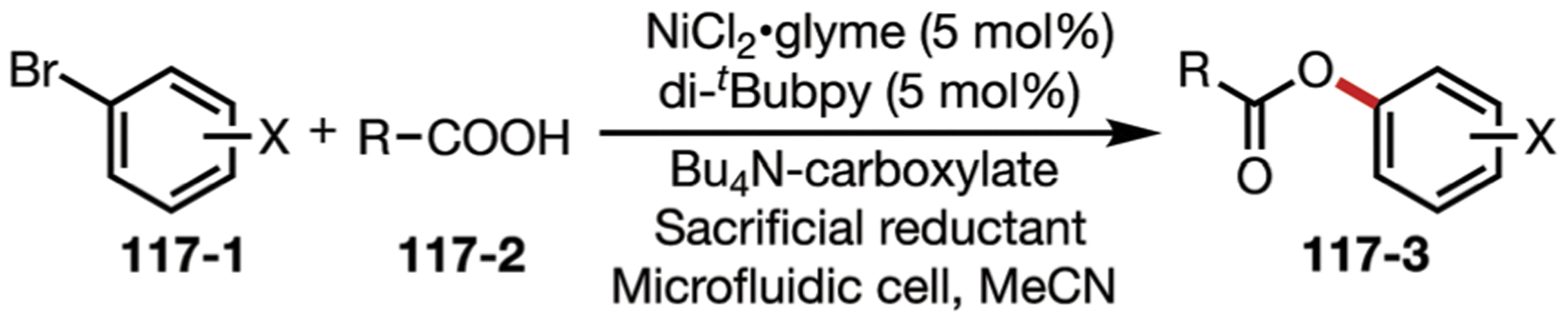

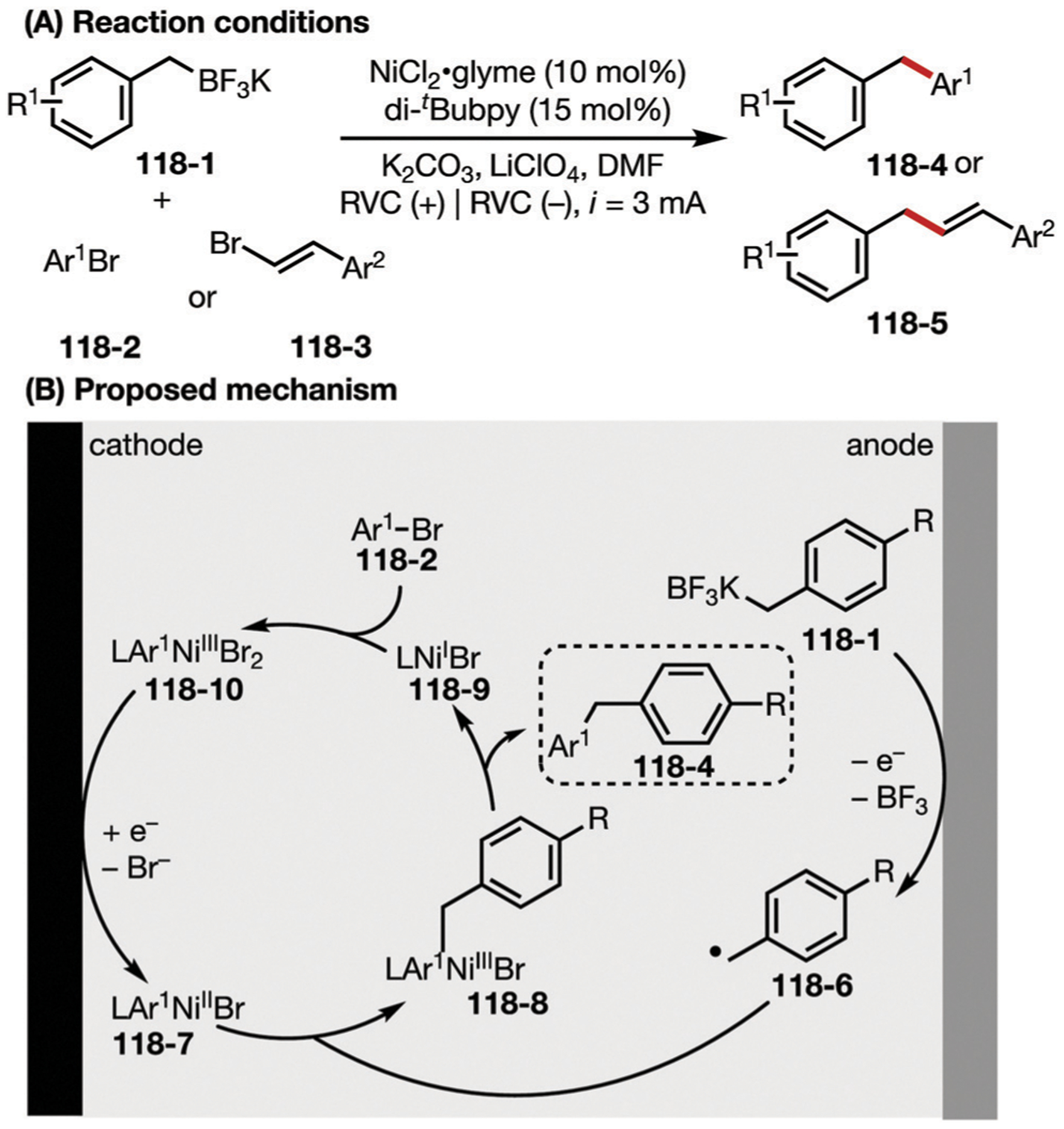

Compared to electrooxidative methodologies, the utility of electroreductive chemistry remains relatively underexplored. In recent years, electrochemistry has emerged as a powerful and efficient method for achieving challenging transformations at deeply reducing potentials.187–190 In contrast to traditional reductive reactions which use heterogeneous reducing metals or homogenous organic compounds as stoichiometric reductants, electroreductive chemistry provides several advantages including highly efficient electron transfer, tunable reducing potential, and good scalability. Nevertheless, these approaches rely on the direct reduction of reactants on the cathode surface, which may result in electrode passivation leading to lower selectivity. As such, reductive electrocatalysis has attracted increasing attention in synthetic chemistry for its ability to decrease reaction overpotential and regulate downstream chemical pathways. Currently, nickel complexes are the most predominant catalysts used in electroreductive chemistry. However, a variety of 3d block metals such as cobalt and zinc as well as organic compounds have also been demonstrated as efficient reductive mediators. Electroreductive transformations are usually coupled with the oxidation of sacrificial anodes, such as Mg, Zn or Fe, or readily oxidizable additives such as triethyl amine (Et3N). During electrolysis, the anodic oxidation of these sacrificial reductants generates metal salts or amine radical cations, which are typically innocuous. In addition, sacrificial reductants may also prevent the undesired oxidation of substrates or reactive intermediates when the electrolysis is carried out in an undivided cell.

3.1. Nickel

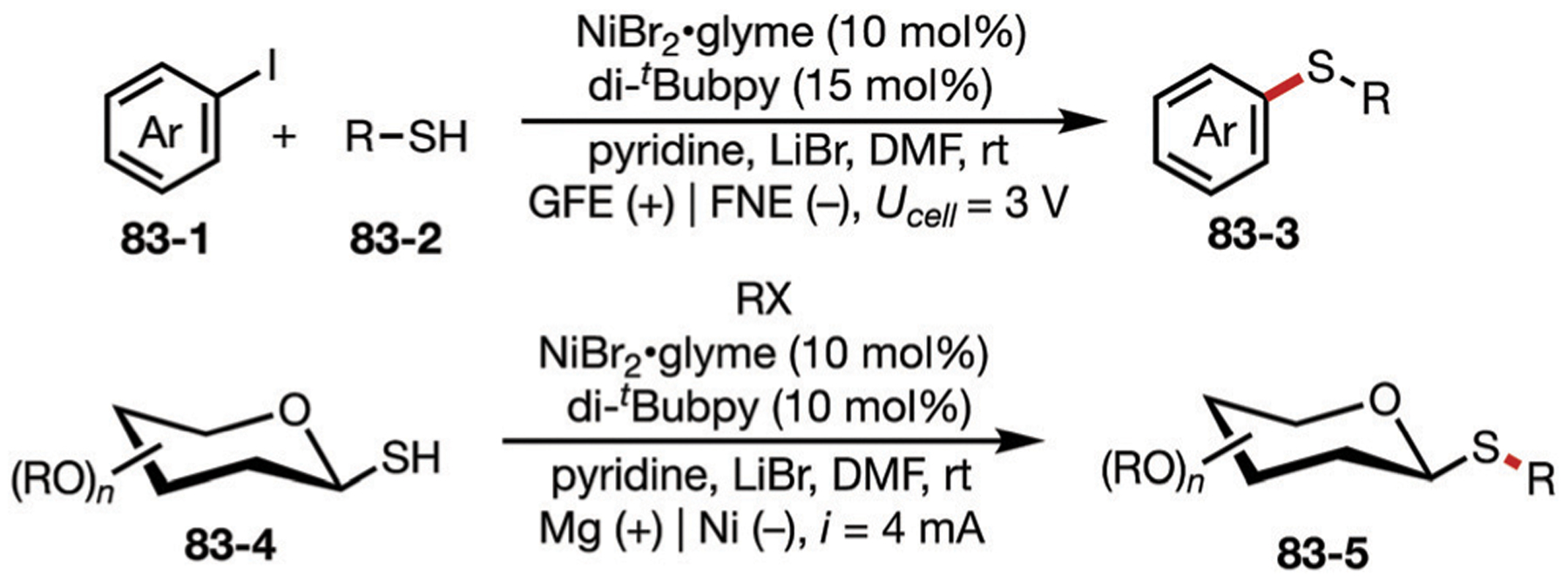

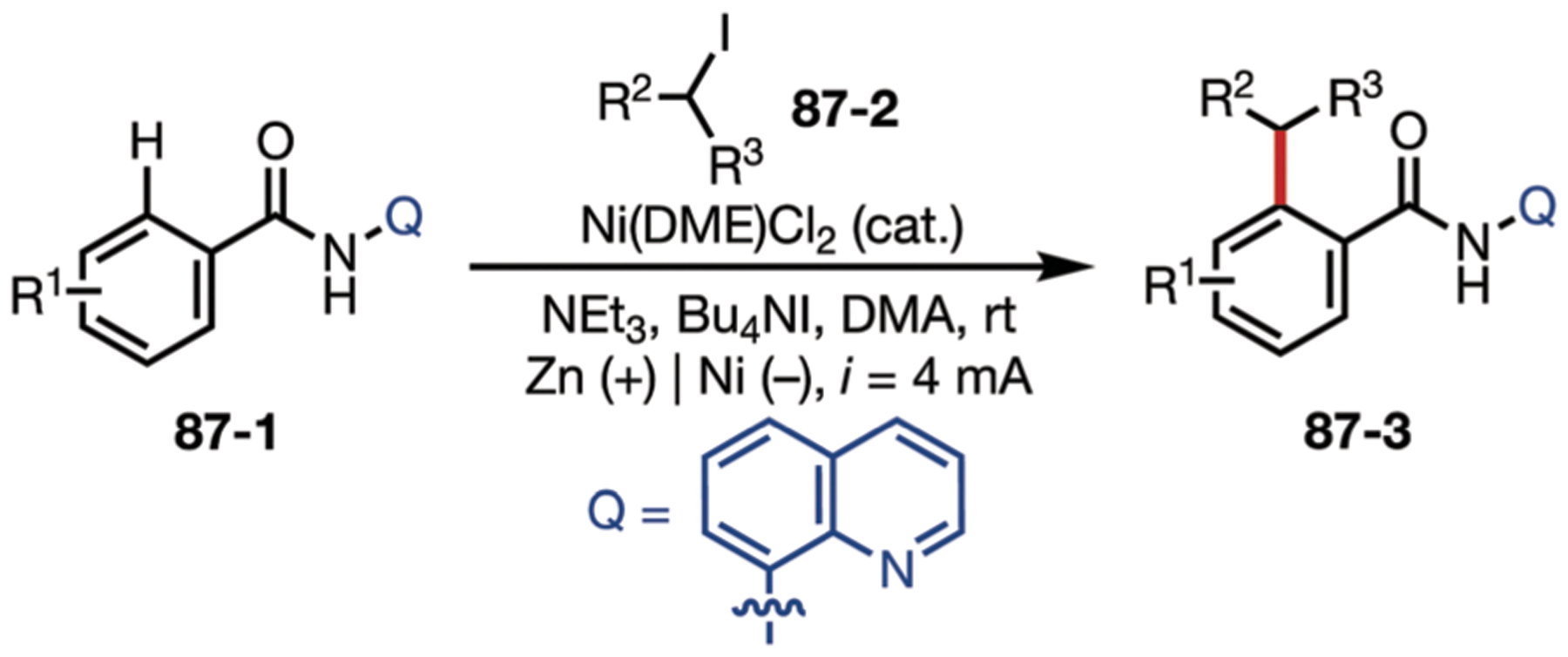

In this section, cathodic reduction utilizing nickel complexes is discussed. Electrochemistry advantageously supports the in situ generation of often sensitive Ni species, resulting in more practical conditions for Ni-catalyzed transformations compared to traditional methods. Consequently, a wide variety of protocols have been reported in this direction including cross-electrophile coupling (XEC), alkene difunctionalization, C–H activation, as well as C–N, C–S, and C–P bond formation.

3.1.1. Homocoupling of aryl halides.

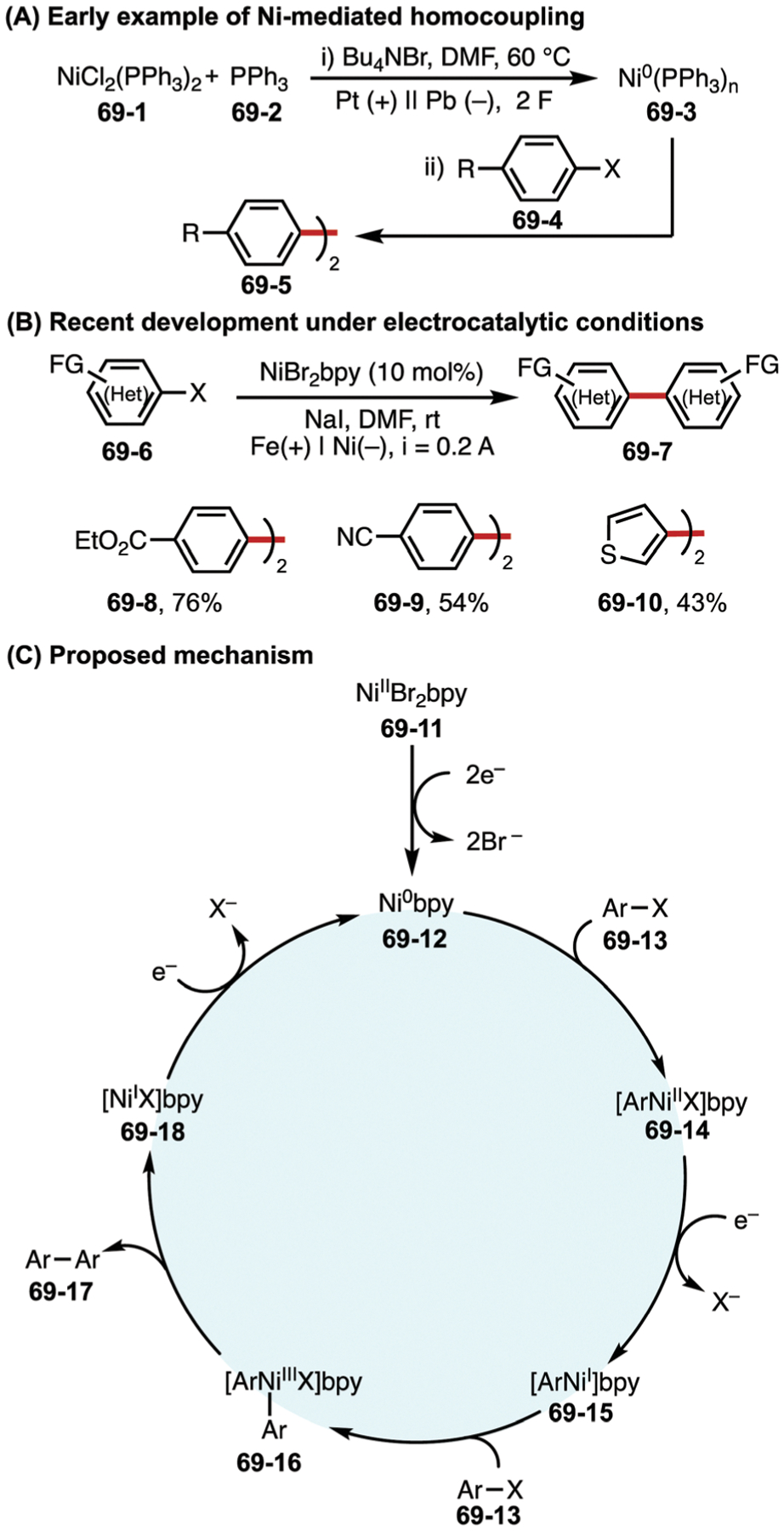

Among the earliest examples of electrochemically promoted homocoupling of electrophiles was Ban’s work using cathodically generated Ni0 species 69–3 (Fig. 69A).191 When used stoichiometrically, this nickel species was shown to facilitate the homocoupling of bromobenzene, which had previously been accomplished via chemical reductants such as Zn or AlEt3. This seminal work led to a number of further developments in Ni-catalyzed electrochemical coupling reactions.192–200

Fig. 69.

(A–C) Nickel-catalyzed electrochemical homocoupling reaction.