Abstract

With a wide variety of techniques and compatible materials, three-dimensional (3D) printing is becoming increasingly useful in environmental applications in air, water, and energy. Through the advantages of quick production, cost-effectiveness, customizable design, the ability to produce complex geometries, and more, 3D printing has supported improvements to air quality monitors, filters, membranes, separation devices for water treatment, microbial fuel cells, solar cells, and wind turbines. It also supports sustainable manufacturing through reduced material waste, energy use, and carbon emissions. Applications of 3D printing within four environmental disciplines are described in this article: sustainable manufacturing, air quality, water and wastewater, and alternative energy sources.

Introduction

Three-dimensional (3D) printing is a method of producing three-dimensional objects by joining materials layer-by-layer under the direction of a computer. The development of computer-aided 3D modeling technology supported the emergence of 3D printing in the 1980s [1]. This technology allows for more customizable products, complex structures, and lightweight design. It also offers the advantages of speed, flexibility, sustainability, risk reduction, and accessibility. Cost is cited as both an advantage and disadvantage of 3D printing as it depends on the printing technique, material, and quantity. Small quantities can be printed at a relatively low cost using simple methods such as fused deposition modeling. Still, mass-production, especially with more complex printing methods, has not been widely implemented due to high costs [2]. Some additional challenges to the widespread use of 3D printing include the limited ability to produce large structures, print defects, and low selection of compatible materials [2]. Addressing these challenges can help to increase the potential applications of 3D printing.

As new fabrication methods and printable materials continue to be developed, 3D printing is becoming progressively useful in a diversity of applications, including the automotive, aircraft, medical, food, and robotics industries. Some environmental uses of this technology have been developed for air, water, and energy. Although most of these are small, individual devices for sampling, sensing, or separating [3], these early applications demonstrate that 3D printing has the potential to make significant impacts within environmental applications in the future. As the challenges within 3D printing are further researched and addressed, the technology is likely to bring improvements to separation devices, sensors, alternative energy technologies, and more. Additionally, 3D printing supports sustainable manufacturing by reducing waste, energy demand, and carbon emissions. This article describes four broad areas of environmental applications that are benefitting from advancements in 3D printing: sustainable manufacturing, air quality, water and wastewater, and alternative energy sources. These areas are outlined in Figure 1.

Figure 1.

Summary of environmental applications of 3D printing.

Sustainable manufacturing

3D printing offers a new approach to manufacturing that changes environmental implications throughout the entire product life cycle and increases the potential for sustainability. Resource demands and manufacturing waste can be significantly reduced because additive manufacturing builds products layer-by-layer rather than cutting away from a larger volume. Conventional production requires raw material to be altered and formed into a product through subtractive processes, which inherently create waste [4•]. Because 3D printing is an additive process, scraps are not produced. The only material losses are generally support structures printed with the product which are cut out following production, and these materials can be reused in most 3D printing methods [5]. 3D printing also reduces waste from defects [4•]. This resource efficiency reduces material-related energy demands. Ghobadian et al. [4•] suggest that 3D printing has the potential to reduce or eliminate waste from manufacturing significantly, but the technology needs to first be legitimized so that it can be more widely adopted.

3D printing also lowers the energy demands of manufacturing by shortening the process and making production more direct [5]. These efficient manufacturing processes also reduce CO2 emissions [5]. Additionally, 3D printing can lower the carbon emissions associated with shipping. With the ability to print items on-site, firms and consumers could produce their materials from digital files rather than rely on shipping [6]. For example, John Deere has developed a distributed manufacturing system so that locations can download digital designs and print products in place of ordering them form warehouses [4•]. This can reduce both material waste [4•] and shipping distances, lowering the associated carbon footprint [6]. Gebler et al. [5] suggest that 3D printing technologies could have the potential to eventually cut net CO2 emissions and energy use from industry provided that they can be implemented in mass production, production speed can be improved, and printable materials become more available. They also caution that the sustainability benefits of 3D printing could be offset by a ‘rebound effect’ if the overall activity is increased as a result of improved efficiency.

Material choice drives part of the environmental impact of 3D printing. In the laser metal deposition technique, a stream of metal powder is introduced to a pool of melted metal formed by a laser to absorb and deposit the metal from the powder stream. The materials involved are much more easily reused than those in fused deposition modeling techniques [7], where a thermoplastic polymer filament is heated and extruded onto a surface [2]. More material waste is associated with this method because support structures must often be printed with the product to hold disconnected or overhanging elements in place. These support structures were previously thought to be unsuitable for reuse [5]. However, DePalma et al. [8] outlined a process to mill the supports and extrude them into new filament along with virgin material. The acrylonitrile butadiene styrene (ABS) plastic used, however, undergoes thermal degradation during FDM printing. The development of different plastics could enhance the capability for reuse [8]. Although ABS is currently one of the most common materials in 3D printing, it is viewed as unsustainable because it is petroleum-based. Polylactic acid (PLA), also suitable for FDM, can be made from corn, which has the advantage of being renewable but requires high water inputs. Researchers are analyzing different methods to procure natural materials such as cellulose-chitin material, coffee grounds, and algae as 3D printing materials for more sustainable production [6]. While material choice can affect the sustainability of 3D printing, the ecological impacts of most printers are dominated by the energy demand of the machine, which is also an area for improvement [9].

While methods involving the melting of metal powder, including laser metal deposition, have the environmental advantage of material reuse, they are energy-intensive. FDM methods have a much lower energy demand in comparison but have a unique disadvantage of emissions [10]. Kim et al. [11] found that FDM using ABS plastic released high concentrations of nanoparticles and volatile organic compounds (VOCs), including toluene, ethylbenzene, and formaldehyde, a known carcinogen. These emissions were reduced when PLA was used in place of ABS, producing significantly less particulate matter and no VOCs, though Chan et al. [12] showed that VOCs were emitted during 3D printing processes with PLA. The concentrations of VOCs following printing at a typical and worst-case scenario were below occupational exposure limits and presented a low risk of adverse health effects. The study by Kim et al. further supports the environmental advantages of PLA over ABS.

Mohammed et al. [13••] proposed a technology called EcoPrinting, a 3D printing process that uses waste polymers as source material and has a near-zero carbon footprint. The EcoPrinting system is equipped with a solar charging battery system and several low power devices to reduce energy demand [13••]. This system was used for humanitarian aid in the Solomon Islands to repair water transmission infrastructure by printing pipe couplers and plumbing seals [13••]. The EcoPrinting process was optimized for ABS plastics and was used with plastic from car parts and electronic waste sourced from a landfill and local businesses in the Solomon Islands [13••]. The resulting filaments from recycled material showed the same tolerances as commercial-grade filaments [13••]. The EcoPrinting system worked effectively, demonstrating promising developments in 3D printing by both operating without electrical connection and by using collected ABS plastic waste as the printing material.

Air quality

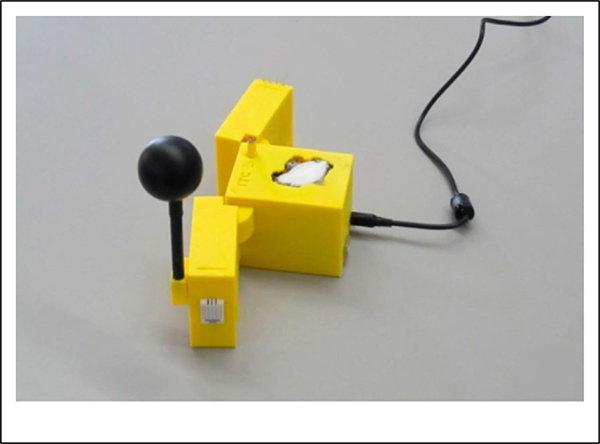

3D printing can be used to develop instrumentation for air quality monitoring. Salamone et al. [14] used 3D printing to produce a nano environmental monitoring system, nEMoS, to quantify indoor air quality. nEMoS, shown in Figure 2, was designed using low-cost sensors and an Arduino board housed in a 3D printed case to be inexpensive and give consistent data [14]. It reports CO2 concentration in addition to lighting levels, airspeed, radiant temperature, air temperature, and relative humidity [14]. Under controlled conditions, nEMoS gave readings within 5% of those by commercial tools [14]. Casings for other monitors, including iAir for indoor air quality [15] and the HOPE sensor for outdoor air quality [16] have also benefitted from the customization capabilities of 3D printing. Wang et al. [17] developed another personal monitor using 3D printing, but for particulate matter. This was intended to be small, portable, and wearable for work and health-related environments [17]. Their system was printed using a digital light projection method and features microchannels that separate the incoming aerosol particles by mass and size [17]. Once separated, the mass concentration of the aerosol particles is measured by capacitance sensors [17]. The system developed by Wang et al. demonstrates progress toward more accurate miniaturized sensors [17]. 3D printing technologies facilitated the smaller design of their system.

Figure 2.

nEMos system for indoor air quality monitoring (taken from Ref. [14]).

In addition to producing instruments to detect air pollution, 3D printing can be used to create devices such as filters and scrubbers for the removal of pollutants. Xu et al. [18•] developed a flexible air filter from a 3D printed grid that acts as a photocatalyst to remove NO from the air. 3D printing facilitated the sophisticated interior of the filter and allowed the product to be scalable for other applications [18•]. The filter was optimized experimentally and through simulation, and the final product obtained 52.6% NO conversion [18•]. Scrubber components can also be produced via 3D printing, such as the circular channel of the Vortecone scrubber used by Kumar et al. [19]. In this application, 3D printing offered the advantage of producing the unique geometry of a curved surface.

Water and wastewater

Advancements have supported a variety of techniques for water and wastewater treatment in 3D printing, including developments to membranes. Membrane technology is replacing many conventional methods for treatment because it is cost-effective and highly efficient [20]. Because 3D printing supports designs with multiple levels of hierarchy, it has the potential for use in membrane production [20] and can offer a lower-cost alternative to traditional membranes [21]. 3D printing works well with ceramic membrane-based treatment materials [22] but is limited because printers cannot efficiently print below submicron resolution [20]. Another limitation is that only certain materials are compatible with specific 3D printing techniques [22], and not all will provide desired membrane characteristics such as wettability [20]. The development of new materials for 3D printed membranes and increased strength are topics for future research to support their improved performance [21]. Akowanou et al. [23] demonstrated the viability of 3D printed ceramic water filters.

Similarly, the ceramic meshes developed by Chen et al. [24] to separate oil and water were 3D printed and combined with aluminum borate whiskers that grew in situ. 3D printing allowed the team to develop different, complex internal structures optimized for three specific situations. Another device for oil/water separation, a superhydrophilic membrane, was developed by Li et al. [25] and printed using direct inkjet writing. The ceramic mesh and superhydrophilic membrane both performed with high separation efficiency, demonstrating the potential for future 3D printed separation devices.

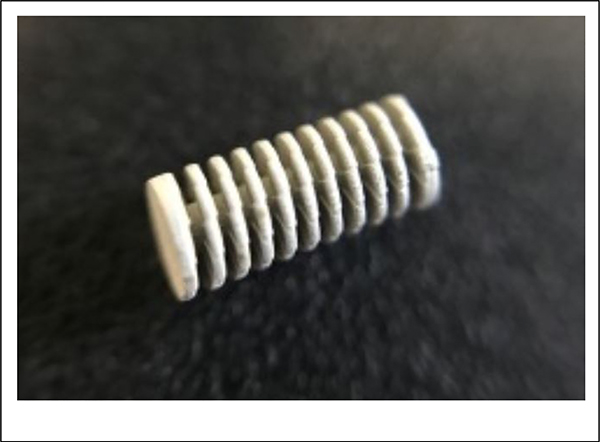

Beyond membranes and other ceramic separation structures, additional applications of 3D printing in water treatment involve photocatalysts and microdevices. Martín de Vidales et al. [26••] mixed photocatalyst TiO2 with printable LDPE and demonstrated its use in the removal of ofloxacin, a modal organic pollutant, from synthetic wastewater. TiO2 requires UV radiation to activate, so by combining with low-density-polyethylene (LDPE), the device floats on water and uses sunlight as an activator [26••]. The catalytic activity of this system was improved with increases to the active surface, which is made possible by 3D printing [26••]. Bernasconi et al. [27] also used 3D printing to develop a device with photocatalytic properties in addition to antimicrobial activity. This team’s microrobots, shown in Figure 3, were produced using a stereolithography 3D printing method combined with wet metallization [27]. This method allows for the possibility of mass production because many devices can be metalized at a time [27]. Both the microrobots and the floating photocatalysts are effective, low-cost treatment solutions.

Figure 3.

The final appearance of microrobot following deposition and plating (taken from Ref. [27]).

Alternative energy sources

A fourth environmental application of 3D printing is renewable energy, where microbial fuel cells, wind turbines, and solar cells have all been tested with printed components. Microbial fuel cells (MFCs) can harvest electrons to produce power while simultaneously oxidizing organic pollutants in wastewater [28]. Improvements to the anode of these systems, where bacteria are carried, can significantly improve the overall performance of the MFC [29]. Bian et al. [29] developed a porous carbon anode using 3D printing and carbonization. The porous structure supports microbial growth, which further increases the area available for adhesion. Because of the 3D anode’s greater surface area and stronger microbial adhesion, it performed significantly better than the typical 2D anode [29].

3D printing has also been incorporated into more popular renewable energy technologies such as photovoltaic (PV) cells. An area of interest for applying 3D printing in the solar industry is the production of solar cells on flexible surfaces, which may include metal foils and translucent plastics [30]. Alternatively, 3D printing can be used to create ultra-thin arrays of microcells with flexible front electrodes that perform nearly as well as traditional solar cells [30]. In a third application, three-dimensional photovoltaic cells produced by 3D printing have been demonstrated to obtain higher energy densities than conventional flat, stationary panels [30]. Because these structures are printed, their geometries can be optimized, and the complex structures are easily manufactured.

As solar cells grow in demand, alternatives to the traditional p–n junction devices are being evaluated, such as dye-sensitized solar cells (DSSCs). DSSCs collect sunlight using dye molecules that are adsorbed to the surface of oxide semiconductors [31•]. These thin films are generally produced using random assembly sintering processes, but Knott et al. [31•] used a two-photon polymerization 3D printing method. This gave a higher level of control and allowed them to implement light scattering designs, which enhanced the cell’s photocurrent up to 25% [31•].

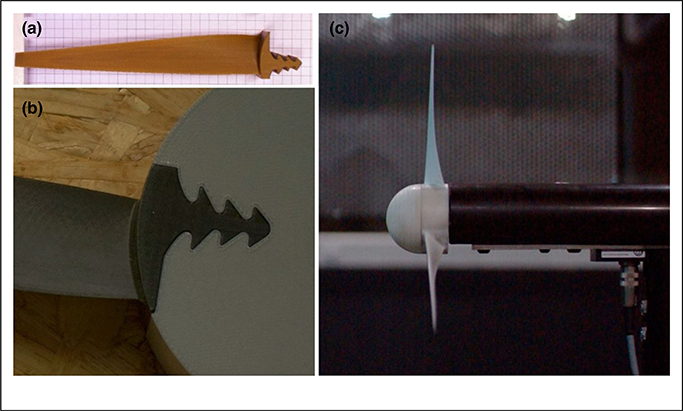

Additionally, 3D printing is being used to produce parts for wind energy applications. Momeni et al. [32] printed turbine blades to mimic plant leaves. The unique geometry was made possible by the printing process and reduced strain within the blades. A self-heating mesh for blade de-icing was developed by Ming et al. [33] and produced using 3D printing to enhance turbine performance. Functional small-scale wind turbines have even been built for residential use using 3D printing. A turbine designed by Davis et al. [34] was printed from ABS plastic and equipped with a generator and bearings for a total cost of 21.63 USD. It could generate 0.2 kW, useful for charging 12 to 24-volt batteries, or as part of an array for residential electricity generation. Lipian et al. [35] also produced a small-scale wind turbine rotor using 3D printing for its quick production abilities. The components of the turbine are shown in Figure 4. The ‘fast track’ method presented in the study may help to simplify and expedite experimental aerodynamics in the future, as 3D printing can produce a prototype within a day. 3D printing offers the advantages of speed, low cost, and the ability to form complex shapes to support improvements to wind turbines and their parts.

Figure 4.

A printed turbine blade (a), blade connection to the hub (b), and printed rotor in operation (c) (taken from Ref. [35]).

Conclusion and perspectives

As 3D printing becomes more prominent, it has presented new opportunities for sustainable manufacturing, air pollution monitoring and filtering, water treatment, and renewable energy. While there are trade-offs between different printing techniques and materials, the technology generally reduces waste compared to traditional manufacturing methods. It also brings the benefit of more customized design, enabling innovations like light-scattering designs in solar cells and the optimization of oil–water separation devices for a variety of situations. Increases in surface area, and therefore performance, of microbial fuel cells and floating photocatalysts were possible because of high-resolution printing techniques. Other intricate designs facilitated by 3D printing include the flexible air filter and microchannels within the personal particulate matter sensor.

Additionally, printed products can be designed to be lightweight and portable, which are essential design considerations for floating photocatalysts and personal air quality monitoring systems. The cost was kept low in some systems but is an area for improvement in others. Improvements in production speed, the scaling-up of printing processes, and the development of materials compatible with a variety of 3D printing techniques will provide even more opportunities for environmental applications.

Disclaimer

The U.S. Environmental Protection Agency funded and collaborated in the work described here. It has been subjected to the Agency’s review and has been approved for publication. Note that approval does not signify that the contents necessarily reflect the views of the Agency. Mention of trade names, products, or services does not convey official EPA approval, endorsement, or recommendation.

Footnotes

Conflict of interest statement

Nothing declared.

References and recommended reading

Papers of particular interest, published within the period of review, have been highlighted as:

• of special interest

•• of outstanding interest

- 1.Savini A, Savini GG: A short history of 3D printing, a technological revolution just started. 2015 ICOHTEC/IEEE International History of High-technologies and their Socio-cultural Contexts Conference (HISTELCON); IEEE: 2015:1–8. [Google Scholar]

- 2.Ngo TD, Kashani A, Imbalzano G, Nguyen KTQ, Hui D: Additive manufacturing (3D printing): a review of materials, methods, applications and challenges. Compos Part B Eng 2018,143:172–196. [Google Scholar]

- 3.Hu L, Jiang G: 3D printing techniques in environmental science and engineering will bring new innovation. Environ Sci Technol 2017, 51:3597–3599. [DOI] [PubMed] [Google Scholar]

- 4.Ghobadian A, Talavera I, Bhattacharya A, Kumar V, Garza-Reyes JA, Regan N: Examining legitimatisation of additive manufacturing in the interplay between innovation, lean manufacturing and sustainability. Int J Prod Econ 2020, 219:457–468.• If more widely adopted, additive manufacturing may help to significantly reduce or eliminate waste. The authors pose five propositions to advance legitimation of the technology.

- 5.Gebler M, Uiterkamp A, Visser C: A global sustainability perspective on 3D printing technologies. Energy Policy 2014, 74:158–167. [Google Scholar]

- 6.Folk E: How Sustainable is 3D Printing? 2019.

- 7.Abdulrahman KO, Akinlabi ET, Mahamood RM: Laser metal deposition technique: sustainability and environmental impact. Procedia Manuf 2018, 21:109–116. [Google Scholar]

- 8.DePalma K, Walluk MR, Murtaugh A, Hilton J, McConky S, Hilton B: Assessment of 3D printing using fused deposition modeling and selective laser sintering for a circular economy. J Clean Prod 2020, 264:12. [Google Scholar]

- 9.Faludi J, Hu Z, Alrashed S, Braunholz C, Kaul S, Kassaye L: Does material choice drive sustainability of 3D printing? Int J Mech Mechatron Eng 2015, 9:216–223. [Google Scholar]

- 10.Suarez L, Dominguez M: Sustainability and environmental impact of fused deposition modelling (FDM) technologies. Int J Adv Manuf Technol 2020, 106:1267–1279. [Google Scholar]

- 11.Kim Y, Yoon C, Ham S, Park J, Kim S, Kwon O, Tsai PJ: Emissions of nanoparticles and gaseous material from 3D printer operation. Environ Sci Technol 2015, 49:12044–12053. [DOI] [PubMed] [Google Scholar]

- 12.Chan FL, Hon CY, Tarlo SM, Rajaram N, House R: Emissions and health risks from the use of 3D printers in an occupational setting. J Toxicol Environ Health Part A 2020, 83:279–287. [DOI] [PubMed] [Google Scholar]

- 13.Mohammed MI, Wilson D, Gomez-Kervin E, Rosson L, Long J, IEEE: EcoPrinting: Investigation of Solar Powered Plastic Recycling and Additive Manufacturing for Enhanced Waste Management and Sustainable Manufacturing. 6th IEEE Conference on Technologies for Sustainability Technologies (SusTech) Nov 11–13; Long Beach, CA: IEEE: 2018:249–254.•• EcoPrinting technology uses waste plastic as source material and is powered by a solar charging battery system, giving it a near-zero carbon footprint. This system was used for humanitarian aid in the Solomon Islands.

- 14.Salamone F, Belussi L, Danza L, Ghellere M, Meroni I: Design and development of nEMoS, an all-in-one, low-cost, web-connected and 3d-printed device for environmental analysis. Sensors 2015, 15:13012–13027. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Marques G, Pitarma R: A cost-effective air quality supervision solution for enhanced living environments through the internet of things. Electronics 2019, 8. [Google Scholar]

- 16.Rebeiro-Hargrave A, Motlagh NH, Varjonen S, Lagerspetz E, Nurmi P, Tarkoma S: MegaSense: cyber-physical system for real-time urban air quality monitoring. 2020 15th IEEE Conference on Industrial Electronics and Applications (ICIEA) 2020. [Google Scholar]

- 17.Wang Y, Valega Mackenzie F, Ingenhut B, Boersma A: Miniaturized 3D printed particulate matter sensor for personal monitoring. 17th International Meeting on Chemical Sensors; Vienna, Austria: 2018:402–403. [Google Scholar]

- 18.Xu X, Xiao SN, Willy HJ, Xiong T, Borayek R, Chen W, Zhang DQ, Ding J: 3D-printed grids with polymeric photocatalytic system as flexible air filter. Appl Catal B Environ 2020, 262:9.• 3Dprinting was used to produce a flexible photocatalytic air filter for NO removal from the air. Because the filter was printed, it was designed with a complex interior structure and is scalable for other applications.

- 19.Kumar AR, Levy A, Kumar A, Schafrik S, Novak T: Computational fluid dynamics modeling and laboratory analysis of aerosol particles’ capture on thin swirling water film in a Vortecone. Powder Technol 2020, 361:499–506. [Google Scholar]

- 20.Tijing LD, Dizon JRC, Ibrahim I, Nisay ARN, Shon HK, Advincula RC: 3D printing for membrane separation, desalination and water treatment. Appl Mater Today 2020, 18:22. [Google Scholar]

- 21.Issac MN, Kandasubramanian B: Review of manufacturing three-dimensional-printed membranes for water treatment. Environ Sci Pollut Res 2020, 27:36091–36108. [DOI] [PubMed] [Google Scholar]

- 22.Dommati H, Ray SS, Wang JC, Chen SS: A comprehensive review of recent developments in 3D printing technique for ceramic membrane fabrication for water purification. RSC Adv 2019, 9:16869–16883. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 23.Akowanou AVO, Deguenon HEJ, Groendijk L, Aina MP, Yao BK, Drogui P: 3D-printed clay-based ceramic water filters for point-of-use water treatment applications. Prog Addit Manuf 2019, 4:315–321. [Google Scholar]

- 24.Chen Z, Zhang DW, Peng E, Ding J: 3D-printed ceramic structures with in situ grown whiskers for effective oil/water separation. Chem Eng J 2019, 373:1223–1232. [Google Scholar]

- 25.Li X, Shan H, Zhang W, Li B: 3D printed robust superhydrophilic and underwater superoleophobic composite membrane for high efficient oil/water separation. Sep Purif Technol 2020, 237:116324. [Google Scholar]

- 26.de Vidales MJM, Nieto-Marquez A, Morcuende D, Atanes E, Blaya F, Soriano E, Fernandez-Martinez F: 3D printed floating photocatalysts for wastewater treatment. Catal Today 2019, 328:157–163.•• A floating photocatalyst was developed using 3D printing technology by combining LDPE with photocatalyst TiO2. The resulting product was lightweight and able to float on water to use UV radiation as an activator.

- 27.Bernasconi R, Carrara E, Hoop M, Mushtaq F, Chen XZ, Nelson BJ, Pane S, Credi C, Levi M, Magagnin L: Magnetically navigable 3D printed multifunctional microdevices for environmental applications. Addit Manuf 2019, 28:127–135. [Google Scholar]

- 28.Calignano F, Tommasi T, Manfredi D, Chiolerio A: Additive manufacturing of a microbial fuel cell-A detailed study. Sci Rep 2015, 5:10. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 29.Bian B, Shi D, Cai XB, Hu MJ, Guo QQ, Zhang CH, Wang Q, Sun AX, Yang J: 3D printed porous carbon anode for enhanced power generation in microbial fuel cell. Nano Energy 2018, 44:174–180. [Google Scholar]

- 30.Ruiz-Morales JC, Tarancon A, Canales-Vazquez J, Mendez-Ramos J, Hernandez-Afonso L, Acosta-Mora P, Rueda JRM, Fernandez-Gonzalez R: Three dimensional printing of components and functional devices for energy and environmental applications. Energy Environ Sci 2017, 10:846–859. [Google Scholar]

- 31.Knott A, Makarovskiy O, O’Shea J, Wu YP, Tuck C: Scanning photocurrent microscopy of 3D printed light trapping structures in dye-sensitized solar cells. Sol Energy Mater Sol Cells 2018, 180:103–109.• 3D printing supports a high level of control in the production of thin films for dye-sensitized solar cells, allowing for the implementation of light-scattering designs to improve performance.

- 32.Momeni F, Sabzpoushan S, Valizadeh R, Morad MR, Liu X, Ni J: Plant leaf-mimetic smart wind turbine blades by 4D printing. Renew Energy 2019, 130:329–351. [Google Scholar]

- 33.Ming Y, Duan Y, Zhang S, Zhu Y, Wang B: Self-heating 3D printed continuous carbon fiber/epoxy mesh and its application in wind turbine deicing. Polym Test 2020, 82:106309. [Google Scholar]

- 34.Davis MS, Madani MR: 3D-printing of a functional small-scale wind turbine. 6th International Renewable and Sustainable Energy Conference (IRSEC) Dec 05–08; Rabat, MOROCCO: IEEE: 2018:410–415. [Google Scholar]

- 35.Lipian M, Kulak M, Stepien M: Fast track integration of computational methods with experiments in small wind turbine development. Energies 2019, 12. [Google Scholar]