Abstract

The energy demand of the world is skyrocketing due to the exponential economic growth and population expansion. To meet the energy requirement, the use of fossil fuels is not a good decision, causing environmental pollution such as CO2 emissions. Therefore, the use of renewable energy sources like biofuels can meet the energy crisis especially for countries facing oil shortages such as Pakistan. This review describes the comparative study of biodiesel synthesis for various edible oils, non-edible oils, and wastes such as waste plastic oil, biomass pyrolysis oil, and tyre pyrolysis oil in terms of their oil content and extraction, cetane number, and energy content. The present study also described the importance of biodiesel synthesis via catalytic transesterification and its implementation in Pakistan. Pakistan is importing an extensive quantity of cooking oil that is used in the food processing industries, and as a result, a huge quantity of waste cooking oil (WCO) is generated. The potential waste oils for biodiesel synthesis are chicken fat, dairy scum, WCO, and tallow oil that can be used as potential substrates of biodiesel. The implementation of a biodiesel program as a replacement of conventional diesel will help to minimize the oil imports and uplift the country’s economy. Biodiesel production via homogeneous and heterogeneous catalyzed transesterification is more feasible among all transesterification processes due to a lesser energy requirement and low cost. Therefore, biodiesel synthesis and implementation could minimize the imports of diesel by significantly contributing to the overall Gross Domestic Product (GDP). Although, waste oil can meet the energy needs, more available cultivation land should be used for substrate cultivation. In addition, research is still needed to explore innovative solvents and catalysts so that overall biodiesel production cost can be minimized. This would result in successful biodiesel implementation in Pakistan.

1. Introduction

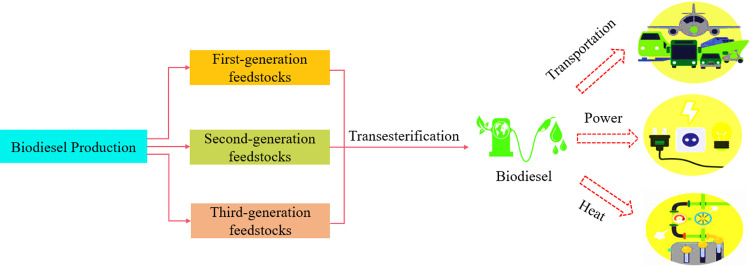

The energy demand of the world is skyrocketing due to its exponential population and economic growth. The use of fossil fuel-diesel to meet the energy needs is a question on its usage. Therefore, the world is more concerned about green energy sources like biofuels. Biodiesel is one of the biofuels that can minimize the use of fossil fuel-diesel. It is a viable energy replacement for petroleum-derived diesel and a prominent source of green energy.1,2 In comparison with petroleum diesel, it has low sulfur content, high cetane number, and flash point of higher than 130 °C. The production and utilization of biodiesel as an alternative fuel to diesel oil are becoming more popular because of the world’s energy crisis and depletion of natural resources of oils.3 The compatibility of biodiesel with internal oil, regeneration, and current fuel-based engines has led us to take the decision of replacing fossil fuel-diesel with biodiesel especially for diesel engine applications.4 Furthermore, hydrocarbon, carbon monoxide, and smoke emissions are 20, 30, and 50% lesser than petro-diesel, respectively.2,5 Biodiesel is synthesized by reacting the vegetable oils or animal fats with a solvent, i.e., mostly a short-chain alcohol (methanol or ethanol) using a catalyst (acidic or basic). Chemically, biodiesel is known as fatty acid methyl esters (FAMEs).6,7 It can be synthesized from all types of feedstocks including edible oils, non-edible oils, and oils extracted from wastes.8 The composition of FAMEs contains palmitic acid, stearic acid, oleic acid, linoleic acid, linolenic acid, palmitoleic acid, arachidic acid, and behenic acid. These acids are found in the composition of biodiesel when produced from all types of substrates such as edible oils, non-edible oils, and waste oils. The composition of biodiesel reflects the constituents of the substrate used to synthesize biodiesel. It plays a significant role in the characteristics of biodiesel such as viscosity, density, pour point, and oxidation stability. However, some other properties like the content of triglycerides, metal, and water depend upon the type of process used for its production and refining as well as the postproduction parameters. It is highly degradable and minimizes the impact on the global climate system. The use of biodiesel as a replacement of diesel causes less emissions of carbon monoxide (CO), particulate matter, hydrocarbons, oxides of sulfur and nitrogen, and aldehydes. It does not cause health problems due to effective burning since it does not produce carcinogenic compounds. For use in vehicles, it can be blended with conventional diesel in any proportion. It is the only fuel that can be directly used in an engine without any physical modifications required in the engine.9 Biodiesel has better combustion characteristics than biomass pyrolysis oil, waste plastic oil, and tyre pyrolysis oil.10 The comparison of characteristics of biodiesel with biomass pyrolysis oil, waste plastic oil, and tyre pyrolysis oil is described in detail in the next section of the manuscript. The use of various feedstocks as a substrate for biodiesel has been critically reviewed in this study. The availability of feedstocks and cost estimation for biodiesel production are also discussed in detail. Biodiesel production processes such as catalytic transesterification are also discussed along with their advantages and disadvantages. The feasibility of feedstocks is critically reviewed to come up with the most appropriate substrates to make the biodiesel implementation program possible in Pakistan on the national level. The main issues of biodiesel implementation are also highlighted. Previous studies focused on the implementation and production of biodiesel using one feedstock. To the best of our knowledge, no attention has been given to the comparative study of potential feedstocks. However, the comparative study is focused on identifying the most appropriate feedstocks along with their published literature. Moreover, the initiatives that must be taken by the government of Pakistan to implement the biodiesel program are also discussed. It is concluded that biodiesel implementation can significantly contribute to the overall Gross Domestic Product (GDP) of Pakistan.

2. Biodiesel Comparison with Other Potential Waste Oils

2.1. Biomass Pyrolysis Oil

Biomass pyrolysis oil is obtained as a liquid product from the pyrolysis of biomass, which is also called bio-oil. It is not produced as a result of thermodynamic equilibrium. It is usually synthesized as a result of rapid cooling in small reactors at pyrolysis temperatures. The physical and chemical compositions of biomass pyrolysis oil quickly change during storage.11 The characteristics of biomass pyrolysis oil are listed in Table 1.

Table 1. Characteristics of Biomass Pyrolysis Oila.

| physical property | parameter range |

|---|---|

| moisture content (wt. %) | 15–30 |

| pH | 2.5 |

| specific gravity | 1.2 |

| C | 54–58 |

| H | 5.5–7.0 |

| O | 35–40 |

| N | 0–0.2 |

| ash | 16–19 |

| viscosity (cP) | 40–100 |

| distillation residue | up to 50 |

Reproduced with permission from ref (12). Copyright 1999 ACS.

2.2. Tyre Pyrolysis Oil

Tyre pyrolysis is an important way to convert solid wastes into sustainable energy sources. In addition, tyre pyrolysis has a lot of advantages, and it can help to reduce the energy crisis. Several researchers have done the laboratory and pilot scale studies on the pyrolysis of tyres. The pyrolysis of tyres results in the production of char, gases, and higher density oils.13,14 The storage time of tyre pyrolysis oil is higher than those of other available oils, and it can be transported to anywhere having its appropriate use. Waste tyres have high volatilities, low ash content, and high heating values as compared to biomass pyrolysis oil and coal. Therefore, waste tyres can be an efficient and cheaper source of energy, and their thermal decomposition can make it possible to recover the useful compounds.15 The production of waste oil from the tyres is most commonly done using pyrolysis. This technology has gained interest over the past few years.16 However, not much attention has been given to the use of tyre pyrolysis oil as a substitute of diesel. Table 2 shows the comparison of physicochemical characteristics of tyre pyrolysis oil with diesel.

Table 2. Characteristics of Tyre Pyrolysis Oil and Diesela.

| physical property | tyre pyrolysis oil | diesel |

|---|---|---|

| moisture content (wt %) | 0.1793 | 0.0161 |

| specific gravity | 0.9313 | 0.8406 |

| C | 85.71 | 86.23 |

| H | 10.01 | 13.00 |

| N | 0.32 | 0.10 |

| H/C ratio | 0.12 | 0.15 |

| viscosity (m cP) | 5.54 | 3.42 |

| flash point (°C) | 43 | 50 |

| fire point (°C) | 50 | 56 |

Reproduced with permission from ref (17). Copyright 2021 Elsevier.

Table 2 describes the physical properties of tyre pyrolysis oil in comparison with diesel oil. It can be observed that the moisture content and viscosity of tyre pyrolysis oil are higher than those of diesel. Moreover, it has also high carbon and nitrogen contents that increase the chance of NOx, carbon monoxide (CO), and carbon dioxide (CO2) emissions.

2.3. Waste Plastic Oil

Due to the continuous growth of automobiles, oil consumption of the world is rising steeply. Therefore, the use of waste oils is gaining significant attention as a substitute of diesel. The use of waste plastic oil as a mixture with heavy oil has been studied in the past for marine purposes. The results indicated that the use of waste plastic oil as a mixture with heavy oil decreases the viscosity and significantly increases the performance of engine. Plastic materials such as polyethylene, polypropylene, Teflon, and Nylon can be used to produce waste plastic oil. Plastic bags, empty bottles, ropes, and other waste plastics thrown in the sea and rivers cause damage to marine lives.18 Therefore, the use of waste plastics to produce oil helps to overcome the energy crisis as well as contributes to the decrease of environmental pollution.19Table 3 shows the physicochemical characteristics of biodiesel and waste plastic oil.

Table 3. Physical Properties Comparison of Waste Plastic Oil with Biodiesela.

| physical property | waste plastic oil | biodiesel |

|---|---|---|

| specific gravity | 0.836 | 0.842 |

| C | 45 | 76.31 |

| H | 2.5 | 12.15 |

| O | 11.54 | |

| kinematic viscosity (cSt) | 2.52 | 4.82 |

| flash point (°C) | 42 | ≤130 |

| fire point (°C) | 45 | |

| gross calorific value (MJ/kg) | 44 | 39.9 |

| cetane number | 51 | 58.60 |

Reproduced with permission from ref (20). Copyright 2021 Elsevier.

From Table 4, it can be observed that biodiesel exhibits better flow and combustion properties than other oils. It can prove to be an excellent source of energy production and utilization and can meet the energy demand especially in underdeveloped countries such as Pakistan. The potential feedstocks, their availability, literature work, and the influence of biodiesel implementation in Pakistan are discussed in detail.

Table 4. Advantages and Disadvantages of Biodiesel and Other Waste Oils.

| advantages | disadvantages | |

|---|---|---|

| biodiesel | It is a renewable source of energy having a high cetane number. | NOx emissions are higher for biodiesel combustion than for other waste oils. |

| It causes less CO, CO2, and hydrocarbon emissions than other sources of energy. | The storage time of biodiesel is shorter (100 days) than those of other waste oils. | |

| It has higher lubricity and can be directly used in the diesel engine without any modifications. | The gross calorific value for biodiesel is a bit lesser than those of other waste oils, which makes the use of biodiesel higher to produce the same amount of energy. | |

| It has a high flash point as compared to other waste oils including biomass pyrolysis oil, waste plastic oil, and tyre pyrolysis oil. | ||

| diesel | It has high energy content and low viscosity, which make it suitable for proper burning in diesel engines. | It has high carbon content, which causes CO, CO2, and hydrocarbon emissions. |

| The higher gross calorific value of diesel causes its lesser consumption for the same amount of energy production. | The higher amount of sulfur present in diesel causes the release of carcinogenic compounds and atmospheric pollution. | |

| biomass pyrolysis oil | It is a decent way of energy utilization as well as of using biomass for energy recovery purposes. | It has high moisture content, which causes the loss of energy produced. |

| It helps to decrease the solid and liquid biomass since it is utilized for biomass pyrolysis oil. | ||

| It has low carbon and sulfur contents, which cause the decrease of emissions of carcinogenic compounds. | The consumption of biomass pyrolysis oil is higher than those of other oils to produce the same amount of energy. | |

| tyre pyrolysis oil | It is an alternative oil that can be used as a substitute of energy in diesel engines and an excellent way of using waste tyres for energy production. | It has a low gross calorific value (42 MJ/kg) as compared to diesel, which causes its higher consumption. |

| It has low emissions of SOx, CO, and CO2 as compared to diesel. | The viscosity of tyre pyrolysis oil is higher, which causes difficulty in the flow of oils. | |

| waste plastic oil | It can be produced from almost all types of plastics, which makes its availability easier and vast. | It has higher cost due to sophisticated unit operations involved during the oil extraction from the burning of waste plastic materials. |

| It causes less environmental pollution than tyre pyrolysis and biomass pyrolysis oil. |

3. Results and Discussion

3.1. Feasibility of Potential Feedstocks for Biodiesel Synthesis

The selection of feedstock is one of the key factors to choose the process that should be used for biodiesel synthesis. The feedstock covers 75% of the total cost of the biodiesel synthesis process.8 The oil content depends on the nature of the feedstock itself. Figure 1 shows the overall cost breakdown of the biodiesel production process.

Figure 1.

Overall cost breakdown of biodiesel synthesis.

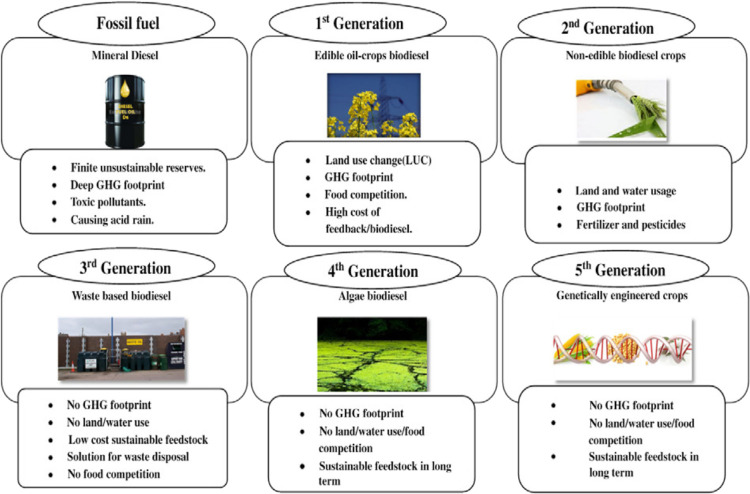

Therefore, cheaper feedstocks can effectively decrease the overall cost of biodiesel synthesis.21 The potential feedstocks to produce biodiesel are classified into six categories, i.e., fossil fuel, first-generation (edible oil crops), second-generation (non-edible crops), third-generation (waste materials), fourth-generation (algae-based), and fifth-generation (genetically engineered crops) as described in Figure 2.

Figure 2.

Classification of feedstocks for biodiesel synthesis. Reproduced with permission from ref (22). Copyright 2019 Elsevier.

At present, more than 95% of biodiesel is produced by using first-generation feedstocks around the globe.23 The production of biodiesel from first-generation feedstocks is more suitable and viable in those regions where agricultural land and water resources are abundantly available. However, the production of biodiesel from edible oil crops is not always favorable24 as it increases land usage and can cause a shortage of food supply in the future.25,26 The production of biodiesel from non-edible oil crops does not affect the food chain supply, but land and water resources can be affected.27 Past research depicted that the synthesis cost of biodiesel from non-edible oils is very high as compared to that of petro-diesel. Microalgae are the only feedstock available in nature that can solely meet the renewable energy-based fuel demand. The waste resources, i.e., third-generation feedstocks (waste cooking/frying oil, animal/plant fats, and palm oil mill effluent (POME)), are considered as the most feasible feedstocks to synthesize biodiesel as they are abundantly available as a waste. A large quantity of vegetable oil (≤80%) is utilized by the food processing industries.28,29 Waste oil-based biodiesel is more feasible, environmentally safer, and cost-effective among all the available resources because it does not affect land usage, food chain supply, and water resources. Moreover, its use as a substrate proves to be the cheapest source of biodiesel synthesis. The production of biodiesel has been increased up to 10.3% (29.7 billion liters) to fulfill the world’s fuel demand during the year of 2018.30Figure 3 shows the production of biodiesel (billion liters) in different countries. From Figure 3, it can be seen that the United States is producing maximum biodiesel as compared to other countries, producing 6 billion liters of biodiesel per year.

Figure 3.

Capacity of biodiesel production in billion liters. Reproduced with permission from ref (22). Copyright 2019 Elsevier.

It can be observed from Figure 3 that developed countries are already focusing on synthesizing biodiesel to meet their energy needs. To meet the energy demand in the cheapest way, the United States is producing the highest amount of biodiesel with a production of 6 billion liters in 2014. Therefore, underdeveloped countries such as Pakistan should also consider the use of biodiesel as an excellent way to meet the energy demand.31 The export of biodiesel will also contribute to the Gross Domestic Product (GDP) in the country’s overall economy.

3.1.1. Biodiesel Synthesis Using Non-Edible Oils

The production of biofuels from edible oils would negatively impact the balance of food supply to the market. The trend in the global end stock of vegetable oil indicated a continuous increase in the production of edible oil until it represents a decreasing rate of end stock; its use for biodiesel production is increasing every year.32 When both fuel and food markets compete for the same origin, such as the supply of arable land and the available land was initially used to grow food that would become depleted. Based on these circumstances, the use of edible oil-derived biodiesel as a substitute for existing diesel-fuel clearly poses a high risk to the world’s edible oil supply.33 Therefore, the aim of today’s research is to draw the focus away from edible resources to low-cost potential feedstocks for biodiesel synthesis. Non-edible derived fuel has good combustion characteristics with good engine efficiency and reasonable emission properties for its ASTM fuel content.34 Such resources would prove to be more useful and eco-friendly alternatives in enhancing the biofuel characteristics through the advent of new and advanced technologies.35 Edible oils are not extracted in adequate quantities in many countries to satisfy the human requirements and must be imported to meet the energy needs.36 The price of biodiesel derived from edible oils is considerably greater than that of petroleum-diesel.37 Different oils derived from non-edible crop seeds or kernels are alternative feedstocks for producing biodiesel. Relevant non-edible oil plants include Jatropha,38,39 tobacco,40 neem,41 cotton,42,43 mahua,44 karanja,45 marine mango,46 castor,47 and rubber seed oil.48 Among all these feedstocks, the most widely used for biodiesel synthesis are Jatropha, mahua, castor, and karanja oil.49Table 5 presents a description based on a broad literature survey of the oil-based plants and their oil contents. To extend the discussion, the most appropriate and commonly used non-edible oils have been presented.

Table 5. Oil Contents in Kernels and Seeds of Non-Edible Plant Sources.

| oil

content, % |

|||||

|---|---|---|---|---|---|

| sr. no. | botanical name | local name | kernel, wt % | seed, wt % | ref |

| 1 | Datura stramonium | 10.3–23.2 | (50) | ||

| 2 | Pistacia chinensis | 30 | (51) | ||

| 3 | Sapium sebiferum | 12–29 | (52) | ||

| 4 | Euphorbia lathyris | 48 | (52) | ||

| 5 | Thlaspi arvense | field pennycress | 20–36 | (53) | |

| 6 | Moringa oleifera | moringa | 2.9 | 33–41 | (53) |

| 7 | Thevetia peruviana | yellow oleander | 67 | 8.41 | (54) |

| 8 | Simmondsia chinensis | jojoba | 45–55 | (53) | |

| 9 | Melia azedarach | Persian lilac | 10 | (54) | |

| 10 | Hevea brasiliensis | rubber tree | 40–50 | 40–60 | (53,54) |

| 11 | Argemone mexicana | Mexican prickly poppy | 22–36 | (55) | |

| 12 | Nicotiana tabaccum | tobacco | 17 | 36–41 | (56) |

| 13 | Gossypium sp. | cotton | 17–25 | (57) | |

| 14 | Cerbera odollam (Cerbera manghas) | sea mango | 6.4 | 54 | (54) |

| 15 | Linum usitatissimum | linseed | 35–45 | (54) | |

| 16 | Ricinus communis | castor | 45–50 | (54) | |

| 17 | Schleichera trijuga | kusum | 10–65 | (58) | |

| 18 | Madhuca indica | mahua | 50 | 35–50 | (53) |

| 19 | Azadirachta indica | neem | 25–45 | 20–30 | (26) |

| 20 | Pongamia pinnata | karanja, pungam | 30–50 | 25–50 | (59) |

| 21 | Jatropha curcas | Jatropha, ratanjyot | 40–60 | 20–60 | (56) |

3.1.1.1. Jatropha Plant

The Jatropha plant is one of the highly promising sources of oil in South and Central America, India, Southeast Asia, and Africa. Today, it is the main feedstock for biodiesel synthesis in emerging countries such as India, where the annual production is approximately 15,000 tons.49 It can be cultivated everywhere under variant atmospheric conditions on dry, sandy, and saline soils and under low and high rainfall. It is easy to cultivate with no intensive care and with little effort. It has a 30 to 50 years balanced life cycle, which prevents annual replantation. Jatropha oil content changes based on species type but is about 46–58% in kernels and 40–60% in seeds. Jatropha has similar properties to diesel such as the cetane number and calorific value.60 As an alternative fuel, it has great potential because it does not need any engine modifications.49 Based on the discussed characteristics of the Jatropha plant, it can prove to be the best non-edible feedstock for biodiesel synthesis.61 The higher oil content present in the seeds makes it a cheaper source to synthesize biodiesel in underdeveloped countries such as Pakistan.

3.1.1.2. Castor Plant

The castor plant has excellent environmental properties as Jatropha and can be easily cultivated as weed. It is indigenous to India, Thailand, Brazil, and China. India produces approximately 0.73 metric tons annually, which represents 60% of the global castor production.53 Castor oil is fully soluble in alcohols and has up to 7 times higher viscosity than other vegetable oils.62 An issue for its direct application as a fuel is the high viscosity of crude castor oil.63 The proportion of other fatty acids present in castor oil is 0.2% linolenic acid, 2.8% oleic, 0.7% palmitic, and 4.4% linoleic acid. The industrial value and use of castor oil can be due to its various chemical properties such as very low freezing point (−12 °C to −18 °C),64 high molecular weight (298 g/mol), low melting point (5 °C), and unsaturated bonds.65 Although the viscosity of unpurified castor oil is considerably higher than those of the other vegetable oils used as feedstock, after its transesterification, the kinematic viscosity of castor oil is reduced to a lower value, making it comparable to other oils and suitable for biodiesel blends.

This results in lower energy consumption during castor oil transesterification. Biodiesel derived from castor oil has a flash point of 260 °C, an iodine value of 80, a heating value of 39.5 GJ/ton, minimum potassium and sulfur contents, and ash contents of 0.04 and 0.02%, respectively.66 The castor tree consumes 34.6 tons of CO2/ha and has strong potential for carbon trading. Extracting castor oil from a natural castor bean mutant that has a comparatively lower content of ricin oleic acid and a higher content of oleic acid has permitted its diversifying uses.67 In addition, genetically silencing the fatty hydroxylase gene responsible for this conversion prevents the conversion of oleic acid into ricinoleic acid.68 Thus, castor oil is an attractive choice for biodiesel production to be considered in Pakistan.

3.1.1.3. Neem and Mahua Plants

Neem and mahua trees grow in several parts of the world from an average to a large scale. These are considered as essential oil sources. Most of the parts of a neem tree such as leaves and wood can be used as pesticides, in medicine, and as organic fertilizers.69 The neem and mahua oil annual productions in Pakistan and India are 100,000 and 180,000 tons, respectively.70 Mahua kernels have 50% oil,53 which comprises around 20% of FFAs making the production of biodiesel process from such oils to be very important and feasible.71 At present, only 25–30% of this vegetable oil supply has been used. The light to dark brown non-edible vegetable oil derived from the tree seeds has the potential to be used as a substrate for biodiesel synthesis.72 Higher free fatty acid content of neem oil makes it necessary to convert it into the biodiesel. A few researchers have proposed a pretreatment of crude neem oil with an acid catalyst to decrease the free fatty acid content (from 21.6% to less than 1%).73 To achieve such results, researchers have developed a two-stage mechanism and optimized the reaction parameters. This method procured 89% of biodiesel yield, and fuel quality parameters were found within the constraints offered by American biodiesel standards.74

3.2. Implementation of Biodiesel in Pakistan

As renewable energy sources such as biodiesel are attaining worldwide attention, Pakistan might face energy challenges in the near future because of the depletion of fossil fuel based energy sources.75 Moreover, fossil fuel usage has led to many problems including water and land pollution. The country is currently facing serious issues in terms of economic aspects because of the ever-widening shortfall between the demand and supply of energy.76,77 Along with many other developed countries, it is facing a huge shortage of energy and imports of oil from various countries like Indonesia and Malaysia. The use of biodiesel will provide the best potential renewable fuel by decreasing the need to import fossil fuel-based oil from countries like Iran. There are two solutions to meet the energy demand, including process optimization78 and the use of waste oils for biodiesel synthesis using short-chain alcohols. Studies indicate that an abundant amount of ethanol is produced in Pakistan due to the vast cultivation of sugarcane. The sugarcane residue is utilized to produce ethanol, which is used for various purposes. The excess amount of ethanol after meeting the demand in terms of its use in industries can be used as a renewable solvent for biodiesel synthesis. Moreover, in some cases, ethanol is also used as a gasoline blend in specified proportion, which extends its applications to a wider range.79 Therefore, biodiesel has become a relatively inexpensive biofuel for Pakistan and has started to be extensively used in many other areas.80 The Ministry of Energy says that there are few biodiesel plants that are producing biodiesel from chicken fats. The use of chicken fats alone cannot meet the energy demand in terms of biodiesel. So, the other available waste oils should be considered as a potential feedstock for the biodiesel.

3.2.1. Potential Waste Oils for Biodiesel Production in Pakistan

In the view of the formal discussion, the possible cost-effective feedstocks for biodiesel synthesis in Pakistan can be plants and animal wastes, i.e., chicken fat, dairy scum, waste cooking oil (WCO),81 and tallow oil.82 Oil-importing countries like Pakistan must take into consideration the recycling of used oils to get the benefit from the investment spent on vegetable oil imports. The waste oils can be collected from commercial or domestic areas where various types of waste oils are produced and can be used in biodiesel synthesis. In 2014–2015, the productions of cottonseed oil, rapeseed oil, sunflower oil, and canola oil were 500,000, 85,000, 91,000, and 10,000, respectively, in Pakistan, which were observed to be 350,000, 83,000, 88,000, and 10,000, respectively, in 2015–2016.83 Waste cooking oil is obtained from the food processing industries e.g., snack industries, catering services, eateries, fast food cafes, and a large number of houses using vegetable oil for cooking and frying purposes. Although manpower is needed to collect the waste oils of the industrial sector as well as restaurants in different areas, it can be an excellent feedstock on smaller-scale biodiesel synthesis. Algae can also be used for biodiesel synthesis as it is abundantly present in Pakistan. Microalgae have very good characteristics such as higher oil content, lesser cultivation land requirement, and environmentally safer nature. In addition, microalgae are able to simultaneously perform oxygenic photosynthesis and hydrogen production. They only require light, carbon dioxide, and organic nutrients to work efficiently, resulting in the production of hydrogen. 1.8 kg of CO2 is required to produce 1 kg of algal biomass, which considerably minimizes environmental pollution. They have the ability to produce 0.1 million liters of algal oil, which is highest among all other edible and non-edible oil plants. Apart from these benefits, biodiesel production using algal oil is expensive due to the complex oil extraction process. The growth of algae is also difficult in some cases. The vegetable oil typically reacts with a short-chain alcohol resulting in the production of biodiesel.84 Coal is used to manufacture methanol, and Pakistan’s coal reserves are 180 billion tons, which is the fifth largest coal reserve in the world.85 Although methanol is the most commonly used solvent in biodiesel synthesis, it is not present in abundant amounts. So, the use of ethanol can prove to be a cheaper and suitable solvent for biodiesel production in Pakistan. Table 6 compares methanol and ethanol characteristics as a solvent for biodiesel production.

Table 6. Advantages and Disadvantages of Methanol and Ethanol.

| methanol | ethanol |

|---|---|

| advantages | |

| It has high reactivity as compared to ethanol. | It is a renewable source of energy and can be easily produced from molasses. |

| It is cheaper in nature than ethanol. | The huge quantity of ethanol can be produced, which makes its availability easier. |

| disadvantages | |

| It has higher flammability as compared to ethanol. | It is less reactive than methanol. |

| It is non-renewable in nature. | It is a bit expensive in nature as compared to methanol. |

Ethanol is renewable, less toxic, and less reactive, which is also closer to methanol. Therefore, it has more importance as a solvent for biodiesel synthesis. At present, ethanol is synthesized on a large scale from bagasse, and there are 76 industries producing sugar in Pakistan, with a shattering potential of 300,000 tons every day.86 The primary by-product of the sugar industry is sugarcane molasses, which is used for the synthesis of ethanol. The sugar industries with a 300,000 ton capacity export 80,200 tons of sugar that can be used to synthesize ethanol instead of exporting.87 Base catalysts such as sodium hydroxide (NaOH) are used for the synthesis of biodiesel. Caustic soda production is enough to fulfill the country’s needs, and its processing can be enhanced because of the availability of significant resources of sodium chloride to use it as a catalyst for biodiesel synthesis. Jatropha oil can also prove to be a prominent feedstock for biodiesel production for Pakistan.88 Pakistan’s agricultural economy is vast because more than 70% of its population is associated with the agriculture profession directly and indirectly. Based on a map formulated by the Pakistan Soil Survey (reported in 1988), the classification of land is done into nine primary groups. Cultivated farmlands are spread across Pakistan, described in yellow on the map shown in Figure 4.89 The free available land for cultivation is approximately 28 million hectares. This large area of land is not readying the Jatropha trees due to deficiency of water, hot weather, and dry soil.90

Figure 4.

Land distribution survey map for Pakistan. Reproduced with permission from ref (85). Copyright 2009 Elsevier.

In short, Pakistan is growing well in the agricultural sector. Despite being a fertile land, it is sad to see the imports of oil products, grains, and dairy products. The neighboring country of Pakistan, India is also synthesizing biodiesel using Jatropha oil.91 The plant seeds of Jatropha in Pakistan can be cultivated especially in low humid and salty lands and can sustain during hot weathers. Moreover, Jatropha plant seeds can produce 2 tons of biodiesel per hectare.

3.2.2. Demand and Import of Oils in Pakistan

Figure 5 shows the total production and imports of cooking oil in Pakistan. The local production of cooking oil is not enough to meet the country’s requirement. Therefore, Pakistan is importing a huge quantity of cooking oil from countries like Indonesia and Malaysia. It needs approximately 1.55 million tons of edible oil at the moment, while the local industries only produce 0.52 million tons of oil, annually.

Figure 5.

Import and production of cooking oil in Pakistan (2005–2017). Reproduced with permission from ref (22). Copyright 2019 Elsevier.

According to Zubair Tufail, President of the Federation of Pakistan Chambers of Commerce and Industry, Pakistan has become one of the world’s highest vegetable oil consuming countries. He also added that Indonesia and Malaysia will remain the two primary oil suppliers to Pakistan. The only way of decreasing the oil imports is to convince the oil supplier countries to invest in the oil sector of Pakistan. Therefore, the Ministry of Energy of Pakistan has requested Malaysia and Indonesia to enhance investment in Pakistan so that they could earn from trade activities to Afghanistan along with the Central Asian states through Pakistan.92 Similarly, Pakistan is importing a huge amount of petroleum diesel annually, and even though local diesel production reduced the import of diesel in 2012–2013, it rose to 14 million tons in 2018 as shown in Figure 6.

Figure 6.

Import and production of petroleum products in Pakistan. Reproduced with permission from ref (93). Copyright 2021 MDPI.

The production of petroleum products remained constant as shown in Figure 6. However, imports of petroleum products showed a continuous rising trend. The rising imports of petroleum products are not beneficial for the country’s progress. Therefore, the use of diesel can be minimized by promoting the biodiesel program and implementing it on the national level. Therefore, waste oils available in Pakistan must be used by installing new biodiesel plants. This step would significantly decrease the energy crisis, minimizing the imports of diesel oil.

3.3. National Biodiesel Program

To implement the biodiesel as an alternative energy source of petroleum diesel, the Alternative Energy Development Board (AEDB) has recommended some policies aiming to minimize the cost of imported diesel. On 14 Feb 2014, the Economic Coordination Committee (ECC) of the National Cabinet has permitted the implementation of biodiesel in the country in a conference. The important points presented in the conference in this regard are presented below.

-

1.

Gradual implementation of a biodiesel blend with petroleum diesel is required to achieve the target of 14% minimum volume of total fuel consumption by 2022.

-

2.

The Ministry of Petroleum & Natural Resources (MPNR) must develop a plan to set the quality standards of the biodiesel blend (B-100) and blends up to B-20.

-

3.

It is necessary for Oil Marketing Companies (OMC) to purchase the biodiesel (B-100) from oil manufacturer companies and sell the biodiesel blend (starting from B-5) to customers at their own selling rates.94

3.4. Impact of Biodiesel Implementation on Various Sectors in Pakistan

3.4.1. Bioenergy Impact on the Industrial Sector

Petroleum products are the major sources of energy to run the industries in Pakistan. It is due to the fact that a major proportion of energy and electricity is produced by petroleum products in Pakistan apart from their use as direct fuel. However, the introduction of bioenergy such as biodiesel from various substrates as the cheapest source of energy is highly considered to be an energy alternative for Pakistan. 23% of the total energy generation is used in the industrial sector in Pakistan. The extensive use of energy in industries causes environmental problems due to the emission of oxides of carbon, nitrogen, and sulfur. Therefore, the use of biodiesel can decrease the overall cost of the energy required to run the industry. This will also help to use the waste oils in a useful way, minimizing the pollution and overall running cost of industries.

3.4.2. Bioenergy Impact on Pakistan’s Economy

The development in the industrial sector and urbanization has led to many environmental problems such as pollution, smog, water pollution, and ozone depletion. Various petroleum products are currently used for energy generation as well as a fuel in the transportation sector. Petroleum products containing volatile organic compounds such as gasoline and sulfur dioxide release an extensive quantity of greenhouse gases, causing ozone depletion. A long term solution to solve such problems is needed for the successful implementation of the biodiesel program. Biodiesel is an environmentally feasible energy source that can also be applied as a petroleum diesel blend. The blending of biodiesel with petroleum diesel would minimize the import of diesel ensuring the saving of trillions of Pakistani rupees every year.95 At present, B10 Jatropha-biodiesel is used as a blend with petroleum-diesel. In the future, more Jatropha seeds would be required, increasing the land requirements as well as making a huge impact on the country’s economy. The B10 and B20 biodiesel blend can be implemented for the local transportation sector in Pakistan. The annual consumption of diesel in Pakistan is 8 million tons. At the moment, the B10 biodiesel blend requirement in Pakistan is 0.8 million tons. By implementing jatropha-biodiesel, annual reduction cost in diesel imports can be obtained as high as USD 0.4 billion.59 The influence of relying on petroleum fuels can be significantly decreased by steadily moving to biodiesel blends by favorable economic programs, practices, and establishing new targets. Directives, policies, and procedures are deemed necessary for the successful implementation of biodiesel for applications in transport and power generation. Licensing and performance measurement procedures for biodiesel synthesis should be established. The capital investment of biofuel synthesis by early support from the government, commercial bank credits, and tax concessions can also facilitate the implementation of the national energy program. The arrangement of farming land for the cultivation of feedstocks by the government of Pakistan as well as the declaration of the National Energy Policy on renewable energy will decrease the imports of fossil-derived fuels and provide stability to petroleum reserves.

3.4.3. Current Energy Policy of Pakistan

Economic contemplation is a prominent part of the energy policy and the efficient supply in the system. Investment costs for new biodiesel plants include construction costs, expense of the facility, infrastructure, integration systems, transmission, grid interface, and the system of collection. The government of Pakistan has been pondering all sorts of capital expenditure including growth, net metering, interoperability costs, and energy policy benefits.96 The national biodiesel and power project did not comment on service and maintenance concerns for the energy sector. The power group policy of 2015 discussed the operation and maintenance as a tariff-based part of the energy purchase price (EPP) and the power purchase price (CPP). The EPP includes variable cost of service, maintenance, fuel, and utilities. The CPP covers equity return, debt servicing, working expenses, insurance, fixed operational, and maintenance costs. The government is determined to implement a protection package between Independent Power Producers (IPP) and AEDB (Alternative Energy Development Board) in the form of a mutual energy purchase agreement.

The policy of the country has invoked energy prices, tariff concepts, feeding tariffs, US dollar fixed rates, and premiums to ensure the fastest growth. In addition, the NPP was considering the cost of petrol.97 The energy policy has partially considered the net available value and the corresponding annual cost of up-front tariffs. The up-front tariff covers rates, charges, equity returns, debt servicing, penalties, and benefits on a quarterly basis under the NEPRA Tariff Standards and Procedure Rules, 1998 and Section 7(3) of the Act.98 Traditionally, the government has implemented tax laws to boost up the economy. The NPP, 2013 and PGP, 2015 had given NEPRA and the authorities of other provinces to agree with the tax rules and regulations. The biodiesel implementation policy introduced a tax discount on renewable technologies. Except for a few gaps, the energy policies have considered the economic criteria extensively.99 All policies need to reduce the cost of generating power because around 10 Pakistani rupees per unit is still unaffordable for many people. The policies authorized the tax to be set by the NEPRA and the other provinces of the country. Tax implementation and collection is the most contentious issue in the energy sector of Pakistan.100 In different provinces, the consumer pays double tax with different ratios. Furthermore, due to higher losses in distribution and transmission, the consumer pays an additional 2.5% tax as said by NEPRA in 2018. Therefore, it is necessary to negotiate with state entities to overcome the gaps and provide affordable, accessible, and cleaner fuels such as biodiesel blends up to B15.

3.5. Impact of Jatropha Oil on the Biodiesel Implementation Program

The steps are taken by the government of Pakistan in cultivating the Jatropha plant for biodiesel synthesis. Research and progress reports are continuously prepared, and findings are monitored and evaluated.101

3.5.1. Current Jatropha Cultivation Status

Jatropha has been cultivated and reported for a long time in the Province of Sindh. The Jatropha oil in Pakistan was used to treat a lot of diseases in the villages and towns in the past. As Jatropha seeds are imported from other countries, they are cultivated at a smaller scale by private tycoons. In 2005, the plantation of Jatropha was 2 acres only and it was increased to 400 acres due to aggressive campaigns by the AEDB. As a result, several private organizations are interested in the cultivation of Jatropha, and its plantation is increased in each province including Punjab, Baluchistan, and Sindh. In these locations, the normal life of Jatropha trees may range from several weeks to 18 months. Due to the developed interest of private organizations, Pakistan State Oil (PSO) bought seeds and cultivated about 20,000 Jatropha plants. Similarly, more than 200,000 Jatropha trees were cultivated near Karachi to meet the Jatropha oil required on request in 2009. The Jatropha cultivation in 2014 by PSO is shown in Figure 7.

Figure 7.

Jatropha cultivation by PSO. Reproduced with permission from ref (102). Copyright 2015 Intech.

Figure 7 describes the total cultivation of Jatropha by PSO every year. Several other private organizations are also interested in installing oil extraction plants like Engro that will help to produce biodiesel in further treatment processes. Pakistan State Oil has further increased the area to its various farmhouses for biodiesel production and implementation on the commercial scale. Six million more plants can be cultivated for Jatropha oil-based biodiesel production. These trees will not only produce Jatropha oil but consume carbon dioxide contributing to a green environment. 24 million kilograms of Jatropha seeds will be produced in order to meet the Jatropha oil demand.

A total of 9.2 million liters of biodiesel (cost of around PKR 400 million @ PKR 48/liter of fossil diesel) will be produced per year. Similarly, some other departments of Pakistan including Karachi’s Forest department along with the Pakistan Army have also shown interest and cultivated the Jatropha trees in the various areas of Sindh. So far, they have cultivated around 5000 trees for the first trial. Similarly, the Pakistan Agricultural Research Council (PARC) and a Canadian company, Kijani Energy, are also interested in investing in the Jatropha cultivation sector by large-scale development for biodiesel synthesis on marginal areas.103 In 2009, Kijani Energy invested around US$ 150 million, resulting in the cultivation of Jatropha on 200,000 acres of land in Cholistan, Umerkot, Tharparker, Khairpur, and Sanghar for the purpose of Jatropha cultivation.104 In short, there are various benefits of cultivating such trees contributing to the biodiesel implementation program in Pakistan. There are various factors that can affect the production of biodiesel from Jatropha including the increase in the cost of seeds, cost of synthesis, tax policies implemented by the government, oil cake, and Jatropha surplus. By the implantation of the biodiesel program and cultivation of Jatropha, several job opportunities will be created from plantation, seed gathering, oil extraction, and synthesis of the biodiesel.105 The job opportunities created from the plant cultivation and seed extraction will be approximately 40 men/(ha yr).106

3.6. Exploitation of Biofuels in Pakistan

The production of biofuels from various waste oils will prove to be a significant source of alternative energy in the future. To develop significant progress in bioenergy, there are many challenges needed to be sorted out listed in Table 7 before successful implementation of the bioenergy program. The issues with the biodiesel implementation and feedstock cultivation are discussed in detail.

Table 7. Challenges for Biodiesel Production from the Cultivated Feedstocks and Suggested Solutionsa.

| no. | challenging issues | measures | feasible facts |

|---|---|---|---|

| 1 | difficulties in cultivation, harvesting, and collection | well planned crop cultivation and rotation that can help to minimize deforestation | extensive quantity of feedstocks available |

| 2 | constraints of the equipment | the installation of biorefining plants by the development of new and more energy efficient equipment | feasible technologies available to develop energy efficient equipment |

| 3 | low energy densities feedstocks | sustainability standards of the forest for the cultivation of first- and second-generation feedstocks | energy can be delivered in all ways such as solid, liquid, and gaseous fuels for combustion engines, heating, and electricity production |

| 4 | expensive transportation, handling, and storage | regulations development plan for proper use of labor and land | significant development in rural areas |

| 5 | food security | measures to protect the biodiversity | the steps taken to create job opportunities for local people |

Reproduced with permission from ref (107). Copyright 2018 Elsevier.

3.6.1. Awareness on Different Forums

To make the biodiesel implementation program successful on the national level in Pakistan, there is a dire need to share the stories related to the success of big cities of Pakistan as well as other developing countries. This is specifically for rural areas, which can be replicated.108 This is the most important and crucial step to make the sustainable biodiesel program successful. The role of media and public organizations is very important to provide information and awareness to the people regarding the impact of biodiesel synthesis through various specialized agencies and training facilities. This will help to encourage the farmers to adopt the cultivation of substrates for biodiesel production as well as sustainable agriculture.

3.6.2. Development of Science and Technology

The centers of science and technology for bioenergy and clubs should also be launched for the promotion of science and technology in all academic institutes as well as the establishment of museums. Mirza et al.109 highlighted the flaws and suggested that the participation of the community is only limited to a few projects related to renewable energy, which resulted in the lack of coordination of the respective departments responsible for the development of renewable energy, implementation, and its commercialization. Moreover, there is a need to effectively utilize the infrastructures of the technical education to promote the production and implementation of renewable energy programs by launching short courses dealing with renewable energy technologies. Well trained policy making professionals are required to be involved to set new policies and ways to implement them on all levels.110

3.6.3. Research and Development

This is very important to promote research and development to play its significant contribution regarding sustainable biodiesel synthesis so that its production cost can be minimized, making the technology easier to implement on small-scale levels. For this purpose, the universities are required to promote research on renewable energy production and to introduce the subjects of renewable energy in different degree programs. Several universities in Pakistan have started working on transesterification of Jatropha oil including the University of Agriculture, Quaid-e-Azam University, UET Lahore, and NED University Karachi.111 On the other hand, PSO has also started the collaboration with Pakistani universities for this purpose. NED University Karachi researchers successfully implanted PSO’s biodiesel in a single four-stroke engine. The testing of Jatropha-biodiesel showed that it is the cheapest energy source due to its extensive availability and showed better combustion characteristics than diesel, canola oil-biodiesel, and castor oil biodiesel. The researchers also concluded that biodiesel produced for Jatropha oil was inexpensive as compared to the other sources. The obtained results indicated that biodiesel from jatropha oil is considerably environmentally sustainable with minimal environmental pollution related to diesel fuel as well as biodiesel from another natural feedstock available.

3.7. Sustainable Biodiesel Production Processes in Pakistan

The yield of biodiesel synthesis is dependent on the process itself along with the feedstock characteristics. It is synthesized by reacting a short-chain alcohol and triglyceride. Figure 8 shows the classification of transesterification based on the use of different catalysts.

Figure 8.

Classification of transesterification for biodiesel synthesis. Reproduced with permission from ref (112). Copyright 2017 Elsevier.

As indicated in Figure 8, transesterification can be mainly classified as homogeneous, heterogeneous, and enzymatic-catalyzed transesterification. The catalysts used in the transesterification reaction can be acidic or basic in nature. The advantages and disadvantages of each process are described in the section of the manuscript.

3.7.1. Homogeneous Catalytic Transesterification

Homogeneous catalysts are defined as “the catalysts that have the same phase as that of oil and alcohol in transesterification reaction”. These catalysts are most commonly used because of their higher reaction rate. There are two major types of catalysts that can be used in homogeneous catalyzed transesterification, including homogeneous acid and homogeneous alkali catalysts.112

3.7.1.1. Homogeneous Alkali-Catalyzed Transesterification

Biodiesel is most commonly synthesized by homogeneous alkali-catalyzed transesterification because of its several advantages including a higher reaction rate and shorter reaction time than acid-catalyzed transesterification. The most commonly used alkali catalysts are sodium hydroxide (NaOH) and potassium hydroxide (KOH). Homogeneous alkali-catalyzed transesterification can be applied to various types of feedstocks at low temperature and atmospheric pressure. The reaction rate is 4000 times higher than acid catalysts.113 The disadvantages of alkali-catalyzed transesterification include the effect of FFA content on the purity of biodiesel. When the feedstock contains higher FFA content, the reaction occurs between FFA and the catalyst resulting in the formation of soap.114 The presence of soap causes product contamination resulting in the decrease of biodiesel yield. The presence of water also causes the hydrolysis of triglycerides to diglycerides. Therefore, alkali-catalyzed transesterification can be applied to feedstocks containing FFA content (≤5%) and water-free triglyceride substrates.

3.7.1.2. Homogeneous Acid-Catalyzed Transesterification

Homogeneous acid-catalyzed transesterification is commonly applied to low-cost feedstocks like waste cooking oil and waste palm oil. Hydrochloric acid (HCl) and sulfuric acid (H2SO4) are the most commonly used acid catalysts. There are two processes taking place in acid catalytic transesterification, including esterification and transesterification.115 Acid catalysts have the ability to catalyze both types of catalysts. These are insensitive to the presence of FFA content. The disadvantages of these catalysts include severe reaction condition requirement, low reaction rate, high oil to alcohol ratio needed, and severe environmental issues due to corrosion.116 These drawbacks of acid catalysts make the process unfeasible for industrial operations. Table 8 shows the previous work done using homogeneous catalysts for various feedstocks such as edible oil, non-edible oil, and algal oil.

Table 8. Literature Summary of Homogeneous-Catalyzed Transesterification.

| feedstock | catalyst | reaction time (h) | T (°C) | molar ratio | biodiesel yield (%) | ref |

|---|---|---|---|---|---|---|

| jojoba oil-wax | sodium methoxide | 4 | 60 | 7.5:1 | 55 | (117) |

| canola oil | KOH | 0.33 | 25 | 6:1 | 86.1 | (118) |

| waste cooking oil | KOH | 0.33–2 | 30–50 | 7:1–8:1 | 88–90 | (119) |

| cottonseed oils | NaOH | 1 | 55 | 77 | (120) | |

| tobacco seed oil | NaOH | 1.5 | 55 | 3:1 | 100 | (121) |

| soybean oil | potassium methoxide | 0.25 | 80 | 6:1 | 99 | (122) |

| sunflower oil | KOH | 0.5 | 25 | 6:1 | 100 | (123) |

| karanja oil | KOH | 1.5 | 60 | 10:1 | 92 | (124) |

| palm kernel oil | KOH | 1 | 60 | 6:1 | 96 | (125) |

| soybean oil | HCl | 45 | 70 | 20:1 | 70 | (126) |

| waste cooking oil | H2SO4 | 10 | 95 | 20:1 | >90 | (113) |

| canola oil | AlCl3 | 18 | 100 | 24:1 | 98 | (127) |

| soybean oil | trifluoroacetic acid | 5 | 120 | 20:1 | 98.4 | (128) |

| algal oil | KOH | 0.7–0.1 | 60 | 20:1 | 92.4 | (129) |

| algal oil | H2SO4 | 1.5 | 60 | 12:1 | 86.1 | (130) |

| algal oil | NaOH | 1.1 | 50 | 8:1 | 87 | (131) |

| algal oil | H2SO4 | 1.05 | 50 | 8:1 | 89 | (131) |

| waste cooking oil | H2SO4 | 2 | 70 | 2:1 | 98 | (132) |

| cooking oil | H2SO4 | 1.05 | 69.79 | 4.62:1 | 97.2 | (133) |

It can be seen from the literature summary presented in Table 8 that NaOH and KOH gave maximum yields of biodiesel. The production of biodiesel is also dependent upon the composition of triglycerides. Therefore, biodiesel yield is strongly influenced by the oil type itself. It can be noted that non-edible oils produce lesser yield than edible oils due to the presence of impurities. However, the use of non-edible oils can help to avoid the shortage of edible oils.

3.7.2. Heterogeneous Catalytic Transesterification

Heterogeneous catalytic transesterification is advantageous over homogeneous catalytic transesterification. It is easy to separate the product from the catalyst, and no soap formation takes place. Heterogeneous catalysts are more environmentally safer and can be used in continuous industrial transesterification processes.134

3.7.2.1. Heterogeneous Acid-Catalyzed Transesterification

Heterogeneous acid catalysts have low activity as compared to homogeneous catalysts. However, these catalysts are used for industrial synthesis of biodiesel due to their less toxic nature, less corrosiveness, insensitivity toward FFA content, easy separation of the product, and no product contamination. The regeneration and recycling of such catalysts are also easier. The disadvantages of heterogeneous acid-catalyzed transesterification are slower reaction rate and the formation of undesirable products during side reactions. The commonly used acid catalysts include zirconium dioxide (ZrO2),135 tin dioxide (SnO2),136 titanium dioxide (TiO2),137 and zeolites.138 These catalysts have high selectivity to produce biodiesel due to high acidic strength. The process of their production is not easy like tin dioxide. Zeolites can also be used to synthesize biodiesel. The advantages of zeolites are as follows: these catalysts can be obtained from natural sources, they are inexpensive, and their acidic strength is controlled by modifying the aluminosilicate framework.139

3.7.2.2. Heterogeneous Alkali-Catalyzed Transesterification

Heterogeneous alkali-catalyzed transesterification is considered as the best technique to produce biodiesel. The use of heterogeneous alkali-catalyzed transesterification has several advantages: the catalyst is reusable, and it is more environmentally safer than heterogeneous acid catalysts, it can be synthesized easily from cheaper sources like limestone and calcium hydroxide, the amount of wastewater production is less, and catalyst activity is the same as that of the alkali catalyst under the same operating conditions.140 However, heterogeneous alkali-catalyzed transesterification reaction is facing challenges; the catalyst is needed to activate on high temperatures, and the reaction rate is much slower than homogeneous alkali catalysts.140Table 9 presents the summary of heterogeneous catalyzed transesterification by using various substrates.

Table 9. Summary of Biodiesel Production Using Heterogeneous-Catalyzed Transesterification.

| feedstock | catalyst | reaction time (h) | T (°C) | molar ratio | biodiesel yield (%) | ref |

|---|---|---|---|---|---|---|

| soybean oil | CaO | 1 | 93 | (141) | ||

| sunflower oil | CaO/SBA-14 | 5 | 160 | 1:12 | 95 | (142) |

| palm oil | CaO/Al2O3 | 5 | 65 | 1:12 | 98.64 | (143) |

| crude palm kernel oil | SO42–/ZrO2 | 1 | 200 | 6:1 | 90.3 | (144) |

| canola oil | nano-g-Al2O3 | 8 | 65 | 15:1 | 97.7 | (145) |

| sunflower oil | WO3/ZrO2 | 5 | 200 | 20:1 | 97 | (146) |

| waste cooking oil | Zn/CaO | 1.4 | 65 | 12:1 | 98.5 | (147) |

| waste cooking oil | CaO | 3 | 65 | 12:1 | 95 | (147) |

| canola oil | KF/Al2O3 | 8 | 65 | 15:1 | 97.7 | (148) |

| canola oil | K2CO3/Al2O3 | 8 | 60 | 15:1 | 97 | (148) |

| RBD palm oil | brick bar ash | 3 | 60 | 12:1 | 88.06 | (149,150) |

| algal oil | CaO | 3 | 70 | 10:1 | 92.03 | (151) |

| algal oil | CaO/Al2O3 | 2 | 50 | 10:3 | 88 | (152) |

| WCO | biochar CaO/Al2O3 | 3.25 | 65 | 18:1 | 98.3 | (153) |

| algal oil | CaO/dolomite catalyst | 3 | 65 | 6:1 | 90 | (154) |

| waste cooking oil | CaO/MgO | 2 | 90 | 15:1 | 96.47 | (155) |

| algal oil | Ca(OH3)2 | 3 | 80 | 30:1 | 99 | (156) |

| waste cooking oil | CaO/MgO | 7.8 | 69.37 | 16.7:1 | 98.37 | (36) |

| sunflower oil | MgO/MgAl2O4 | 3 | 110 | 12:1 | 95 | (157) |

The above-described transesterification processes are the most commonly used for the production of biodiesel. Although higher yield in the case of microalgae was observed, however, microalgae-transesterification requires a comparably higher reaction time, making it an expensive process. Therefore, use of waste oils can prove to be more feasible and sustainable as a substrate in the long run. However, the higher reaction rate of homogeneous alkali-catalyzed transesterification makes it a cost-effective industrial process.158 Therefore, alkali-catalyzed transesterification for industrial biodiesel production in Pakistan. The use of alkali-catalyzed transesterification will increase the overall yield of biodiesel. Table 10 summarizes the comparison of advantages and disadvantages of acid and alkali-catalysts.

Table 10. Comparison of Acid and Alkali-Catalysts for Biodiesel Synthesis.

| alkali-catalysts | acid-catalysts |

|---|---|

| advantages | |

| cheaper and easily available | can be produced from waste resources |

| higher reaction rate | insensitive to FFA content of feedstock |

| higher product yield | reusable and environment-friendly |

| highly effective at low temperatures and atmospheric pressure | can be used for biodiesel synthesis using waste feedstocks |

| disadvantages | |

| not reusable | lower reaction rate than alkali-catalysts |

| highly affect the environment sustainability | lesser yield of the product |

| sensitive to FFA and water present in the feedstock | cause product contamination if not separated |

4. Recommendations

Based on the findings of this study, the government of Pakistan must take the following steps to meet the country’s overall biodiesel demand.

-

1.

Create public awareness by conducting seminars and empower environmental groups to seek support in favor of biodiesel implementation in the country

-

2.

Work in-line with the other Provinces to equally distribute the biodiesel feedstock production in each province

-

3.

Take steps to promote research and collaboration between industries and research institutes to successfully implement the biodiesel program

-

4.

To cultivate the feedstock trees along the roadsides to produce the substrates for biodiesel synthesis and maintain a green environment

-

5.

A need for biodiesel project extension to pilot scales to commercialize biodiesel and set the supply chain

5. Conclusions

This review presented the comparative study of feedstocks and implementation of biodiesel in Pakistan. The key findings of this study are presented below.

-

1.

Biodiesel can be synthesized from various feedstocks such as edible, non-edible, and waste oils. Due to the disadvantages of edible and non-edible oils, waste oils offer a lot of advantages and can be efficiently used for biodiesel synthesis. Waste oils have various advantages such as no effect on food sources and availability and GHG footprint, no land, and water use. Biodiesel is usually synthesized from waste oils via catalytic transesterification in which oil reacts with a short-chain alcohol such as methanol and ethanol in the presence of a catalyst. Overall, acid catalysts, although have a lower reaction rate, are preferred over alkali catalysts for industrial synthesis of biodiesel because of greater friendliness and tolerance toward %FFA of feedstocks. The present study also highlighted the importance of biodiesel for developing Asian countries, such as Pakistan, facing an energy crisis due to exponential growth in population. Based on literature survey, feedstocks present in abundant amounts in Pakistan include chicken fat, dairy scum, WCO, and tallow oil. The commonly used solvent in transesterification reaction is methanol having high reactivity and cost. However, cultivation of sugarcane is abundant in Pakistan. The sugar industry is well-grown in Pakistan exporting 80,200 tons of sugar. Therefore, the residue of sugar such as molasses can be used to produce ethanol, which is an excellent solvent for biodiesel synthesis.

-

2.

Biodiesel implementation in Pakistan is crucial and needed to be implemented to minimize the imports of oil from Indonesia and Malaysia. Pakistan is importing 0.93 million tons of edible oil at present. Edible oil is majorly used in the food processing industry, and waste cooking oil is generated from such industries. Moreover, two important feedstocks including Jatropha and algae can be grown in the free available land present in Pakistan (28 million hectares). The plantation of Jatropha trees will help to install new plants to extract Jatropha oil as well as to produce biodiesel. The implementation of 10% Jatropha-biodiesel can reduce $0.4 billion from the total annual imports of Pakistan. Therefore, attention should be given to biodiesel synthesis and implementation so that it can help to meet the energy demand as well as increase the export of Jatropha oil. Based on this review, it is concluded that the use of waste oils can meet the energy needs. More available cultivation land should be used for substrate cultivation. In addition, research is still needed to explore innovative solvents and catalysts so that overall biodiesel production cost can be minimized. For this purpose, the government of Pakistan must promote collaboration between industries and research institutes for successful implementation of biodiesel program in the country.

Acknowledgments

The authors thank the Universiti Teknologi Petronas Research Grant (YUTP 015LC0-208) under the project “Biodiesel production from wastes using Supercritical Technology” for providing the opportunity of working and writing the review paper in Universiti Teknologi Petronas, Malaysia. Support from the Ministry of Education Malaysia through HICoE award to CBBR is duly acknowledged.

The authors declare no competing financial interest.

References

- Atabani A.; Mofijur M.; Masjuki H.; Badruddin I. A.; Chong W.; Cheng S.; Gouk S. A study of production and characterization of Manketti (Ricinodendron rautonemii) methyl ester and its blends as a potential biodiesel feedstock. Biofuel Research Journal 2014, 1, 139. [Google Scholar]

- Aghbashlo M.; Tabatabaei M.; Mohammadi P.; Mirzajanzadeh M.; Ardjmand M.; Rashidi A. Effect of an emission-reducing soluble hybrid nanocatalyst in diesel/biodiesel blends on exergetic performance of a DI diesel engine. Renewable Energy 2016, 93, 353–368. 10.1016/j.renene.2016.02.077. [DOI] [Google Scholar]

- Fukuda H.; Kondo A.; Noda H. Biodiesel fuel production by transesterification of oils. J. Biosci. Bioeng. 2001, 92, 405–416. 10.1016/S1389-1723(01)80288-7. [DOI] [PubMed] [Google Scholar]

- Hajjari M.; Ardjmand M.; Tabatabaei M. Experimental investigation of the effect of cerium oxide nanoparticles as a combustion-improving additive on biodiesel oxidative stability: mechanism. RSC Adv. 2014, 4, 14352–14356. 10.1039/c3ra47033d. [DOI] [Google Scholar]

- Datta A.; Mandal B. K. A comprehensive review of biodiesel as an alternative fuel for compression ignition engine. Renewable and Sustainable Energy Reviews 2016, 57, 799–821. 10.1016/j.rser.2015.12.170. [DOI] [Google Scholar]

- Granjo J. F. O.; Duarte B. P. M.; Oliveira N. M. C. Integrated production of biodiesel in a soybean biorefinery: Modeling, simulation and economical assessment. Energy 2017, 129, 273–291. 10.1016/j.energy.2017.03.167. [DOI] [Google Scholar]

- Yusoff M. H. M.; Ayoub M.; Jusoh N.; Abdullah A. Z. The Challenges of a Biodiesel Implementation Program in Malaysia. Processes 2020, 8, 1244. 10.3390/pr8101244. [DOI] [Google Scholar]

- Škrbić B.; Cvejanov J.; Đurišić-Mladenović N. Chemometric characterization of vegetable oils based on the fatty acid profiles for selection of potential feedstocks for biodiesel production. J. Biobased Mater. Bioenergy 2015, 9, 358–371. 10.1166/jbmb.2015.1527. [DOI] [Google Scholar]

- Zahid I.; Ayoub M.; Abdullah B. B.; Nazir M. H.; Ameen M.; Zulqarnain; Mohd Yusoff M. H.; Inayat A.; Danish M. Production of Fuel Additive Solketal via Catalytic Conversion of Biodiesel-Derived Glycerol. Ind. Eng. Chem. Res. 2020, 59, 20961–20978. 10.1021/acs.iecr.0c04123. [DOI] [Google Scholar]

- Krishania N.; Rajak U.; Verma T. N.; Birru A. K.; Pugazhendhi A. Effect of microalgae, tyre pyrolysis oil and Jatropha biodiesel enriched with diesel fuel on performance and emission characteristics of CI engine. Fuel 2020, 278, 118252. 10.1016/j.fuel.2020.118252. [DOI] [Google Scholar]

- Zhang Q.; Chang J.; Wang T.; Xu Y. Review of biomass pyrolysis oil properties and upgrading research. Energy Convers. Manage. 2007, 48, 87–92. 10.1016/j.enconman.2006.05.010. [DOI] [Google Scholar]

- Oasmaa A.; Czernik S. Fuel oil quality of biomass pyrolysis oils state of the art for the end users. Energy Fuels 1999, 13, 914–921. 10.1021/ef980272b. [DOI] [Google Scholar]

- Antoniou N.; Zabaniotou A. Features of an efficient and environmentally attractive used tyres pyrolysis with energy and material recovery. Renewable and sustainable energy reviews 2013, 20, 539–558. 10.1016/j.rser.2012.12.005. [DOI] [Google Scholar]

- Škrbić B. D.; Đurišić-Mladenović N.; Cvejanov J. Differentiation of syngases produced by steam gasification of mono-and mixed sources feedstock: A chemometric approach. Energy Convers. Manage. 2018, 171, 1193–1201. 10.1016/j.enconman.2018.06.060. [DOI] [Google Scholar]

- Ayoub M.; Yusoff M. H. M.; Nazir M. H.; Zahid I.; Ameen M.; Sher F.; Floresyona D.; Budi Nursanto E. A Comprehensive Review on Oil Extraction and Biodiesel Production Technologies. Sustainability 2021, 13, 788. 10.3390/su13020788. [DOI] [Google Scholar]

- Jeng-Chung C.; Wei-Hsin C.; Ni-Bin C.; Davila E.; Tsai C.-H. Interactive Analysis of Waste Recycling and Energy Recovery Program in a Small-Scale Incinerator. J. Air Waste Manage. Assoc. 2005, 55, 1356. 10.1080/10473289.2005.10464723. [DOI] [PubMed] [Google Scholar]

- Umeki E. R.; de Oliveira C. F.; Torres R. B.; Santos R. G. D. Physico-chemistry properties of fuel blends composed of diesel and tire pyrolysis oil. Fuel 2016, 185, 236–242. 10.1016/j.fuel.2016.07.092. [DOI] [Google Scholar]

- Zahid I.; Ayoub M.; Abdullah B. B.; Nazir M. H.; Kaimkhani M. A.; Sher F. Activation of Nano Kaolin Clay for Bio-Glycerol Conversion to a Valuable Fuel Additive. Sustainability 2021, 13, 2631. 10.3390/su13052631. [DOI] [Google Scholar]

- S., Moriya, Yaginuma H. W. R., Matsumoto T., Nakajima M., Tsukada M., Isshiki N., , Studied of recycled fuel oil for diesel engine extracted from waste plastics disposals, in: Energy Conversion Engineering Conference and Exhibit, (IECEC), 35th Intersociety 2000,1, 510–515.

- Wang Z.; Burra K. G.; Lei T.; Gupta A. K. Co-pyrolysis of waste plastic and solid biomass for synergistic production of biofuels and chemicals-A review. Prog. Energy Combust. Sci. 2021, 84, 100899. 10.1016/j.pecs.2020.100899. [DOI] [Google Scholar]

- Nazir M. H.; Ayoub M.; Zahid I.; Shamsuddin R. B.; Yusup S.; Ameen M.; Qadeer M. U. Development of lignin based heterogeneous solid acid catalyst derived from sugarcane bagasse for microwave assisted-transesterification of waste cooking oil. Biomass Bioenergy 2021, 146, 105978. 10.1016/j.biombioe.2021.105978. [DOI] [Google Scholar]

- Khan H. M.; Ali C. H.; Iqbal T.; Yasin S.; Sulaiman M.; Mahmood H.; Raashid M.; Pasha M.; Mu B. Current scenario and potential of biodiesel production from waste cooking oil in Pakistan: An overview. Chin. J. Chem. Eng. 2019, 27, 2238–2250. 10.1016/j.cjche.2018.12.010. [DOI] [Google Scholar]

- Panichelli L.; Dauriat A.; Gnansounou E. Life cycle assessment of soybean-based biodiesel in Argentina for export. The International Journal of Life Cycle Assessment 2009, 14, 144–159. 10.1007/s11367-008-0050-8. [DOI] [Google Scholar]

- Predojević Z. J.; Škrbić B. D. Alkali-catalyzed production of biodiesel from waste frying oils. J. Serb. Chem. Soc. 2009, 74, 993–1007. 10.2298/JSC0909993P. [DOI] [Google Scholar]

- Ajjadi B.; Raman A. A. A.; Arandiyan H. A comprehensive review on properties of edible and non-edible vegetable oil-based biodiesel: composition, specifications and prediction models. Renewable and Sustainable Energy Reviews 2016, 63, 62–92. 10.1016/j.rser.2016.05.035. [DOI] [Google Scholar]

- Harvey M. A. S. P.; Pilgrim S. The new competition for land: Food, energy, and climate change. Food policy 2011, 36, S40–S51. 10.1016/j.foodpol.2010.11.009. [DOI] [Google Scholar]

- Gebremariam S. N.; Marchetti J. M. Process simulation and techno-economic performance evaluation of alternative technologies for biodiesel production from low value non-edible oil. Biomass Bioenergy 2021, 149, 106102. 10.1016/j.biombioe.2021.106102. [DOI] [Google Scholar]

- Nikkhah A.; Assad M. E. H.; Rosentrater K. A.; Ghnimi S.; Van Haute S. Comparative review of three approaches to biofuel production from energy crops as feedstock in a developing country. Bioresource Technology Reports 2020, 10, 100412. 10.1016/j.biteb.2020.100412. [DOI] [Google Scholar]

- Arshadi M.; Attard T. M.; Lukasik R. M.; Brncic M.; da Costa Lopes A. M.; Finell M.; Geladi P.; Gerschenson L. N.; Gogus F.; Herrero M.; Hunt A. J.; Ibáñez E.; Kamm B.; Mateos-Aparicio I.; Matias A.; Mavroudis N. E.; Montoneri E.; Morais A. R. C.; Nilsson C.; Papaioannou E. H.; Richel A.; Rupérez P.; Škrbić B.; Bodroža Solarov M.; Švarc-Gajić J.; Waldron K. W.; Yuste-Córdoba F. J. Pre-treatment and extraction techniques for recovery of added value compounds from wastes throughout the agri-food chain. Green Chem. 2016, 18, 6160–6204. 10.1039/C6GC01389A. [DOI] [Google Scholar]

- Ma Y.; Liu Y., Biodiesel production: status and perspectives. In Biofuels: alternative feedstocks and conversion processes for the production of liquid and gaseous biofuels, Elsevier, 2019; pp. 503–522, 10.1016/B978-0-12-816856-1.00021-X. [DOI] [Google Scholar]

- Biodiesel annual report, g.s., http://www.ren21.net/wp-content/uploads/2018/06/17-. 2018.

- Pilorgé E. Sunflower in the global vegetable oil system: situation, specificities and perspectives. OCL 2020, 27, 34. 10.1051/ocl/2020028. [DOI] [Google Scholar]

- Banković-Ilić I. B.; Stamenković O. S.; Veljković V. B. Biodiesel production from non-edible plant oils. Renewable and Sustainable Energy Reviews 2012, 16, 3621–3647. 10.1016/j.rser.2012.03.002. [DOI] [Google Scholar]

- Hamza M.; Ayoub M.; Shamsuddin R. B.; Mukhtar A.; Saqib S.; Zahid I.; Ameen M.; Ullah S.; Al-Sehemi A. G.; Ibrahim M. A review on the waste biomass derived catalysts for biodiesel production. Environmental Technology & Innovation 2021, 101200. 10.1016/j.eti.2020.101200. [DOI] [Google Scholar]

- Atabani A. E.; Silitonga A. S.; Ong H. C.; Mahlia T. M. I.; Masjuki H. H.; Badruddin I. A.; Fayaz H. Non-edible vegetable oils: a critical evaluation of oil extraction, fatty acid compositions, biodiesel production, characteristics, engine performance and emissions production. Renewable and sustainable energy reviews 2013, 18, 211–245. 10.1016/j.rser.2012.10.013. [DOI] [Google Scholar]

- Foroutan R.; Mohammadi R.; Esmaeili H.; Bektashi F. M.; Tamjidi S. Transesterification of waste edible oils to biodiesel using calcium oxide@ magnesium oxide nanocatalyst. Waste Manage. 2020, 105, 373–383. 10.1016/j.wasman.2020.02.032. [DOI] [PubMed] [Google Scholar]

- Carraretto C.; Macor A.; Mirandola A.; Stoppato A.; Tonon S. Biodiesel as alternative fuel: Experimental analysis and energetic evaluations. Energy 2004, 29, 2195–2211. 10.1016/j.energy.2004.03.042. [DOI] [Google Scholar]

- Patil P. D.; Gude V. G.; Deng S. Biodiesel production from Jatropha curcas, waste cooking, and Camelina sativa oils. Ind. Eng. Chem. Res. 2009, 48, 10850–10856. 10.1021/ie901146c. [DOI] [Google Scholar]

- Tiwari A. K.; Kumar A.; Raheman H. Biodiesel production from jatropha oil (Jatropha curcas) with high free fatty acids: an optimized process. Biomass Bioenergy 2007, 31, 569–575. 10.1016/j.biombioe.2007.03.003. [DOI] [Google Scholar]

- Veljković V.; Lakićević S.; Stamenković O.; Todorović Z.; Lazić M. Biodiesel production from tobacco (Nicotiana tabacum L.) seed oil with a high content of free fatty acids. Fuel 2006, 85, 2671–2675. 10.1016/j.fuel.2006.04.015. [DOI] [Google Scholar]

- Nabi M. N.; Hustad J. E.; Kannan D. In First generation biodiesel production from non-edible vegetable oil and its effect on diesel emissions, Proceeding Of The 4th BSME, ASME International Conference On Thermal Engineering, 2008; 2008; pp. 748–750. [Google Scholar]

- Azcan N.; Danisman A. Alkali catalyzed transesterification of cottonseed oil by microwave irradiation. Fuel 2007, 86, 2639–2644. 10.1016/j.fuel.2007.05.021. [DOI] [Google Scholar]

- Georgogianni K. G.; Kontominas M. G.; Pomonis P. J.; Avlonitis D. A.; Gergis V. Alkaline conventional and in situ transesterification of cottonseed oil for the production of biodiesel. Energy Fuels 2008, 22, 2110–2115. 10.1021/ef700784j. [DOI] [Google Scholar]

- Indumathi M.; Rajarajeswari G. Mahua oil-based polyurethane/chitosan/nano ZnO composite films for biodegradable food packaging applications. Int. J. Biol. Macromol. 2019, 124, 163–174. 10.1016/j.ijbiomac.2018.11.195. [DOI] [PubMed] [Google Scholar]

- Naik M.; Meher L.; Naik S.; Das L. Production of biodiesel from high free fatty acid Karanja (Pongamia pinnata) oil. Biomass Bioenergy 2008, 32, 354–357. 10.1016/j.biombioe.2007.10.006. [DOI] [Google Scholar]

- Kansedo J.; Lee K. T.; Bhatia S. Cerbera odollam (sea mango) oil as a promising non-edible feedstock for biodiesel production. Fuel 2009, 88, 1148–1150. 10.1016/j.fuel.2008.12.004. [DOI] [Google Scholar]

- Krist S., Castor Oil. In Vegetable Fats and Oils, Springer: 2020; pp. 197–203. [Google Scholar]

- Jin J.; Tan Y.; Liu R.; Zheng J.; Zhang J. Synergy effect of attapulgite, rubber, and diatomite on organic montmorillonite-modified asphalt. J. Mater. Civ. Eng. 2019, 31, 04018388. 10.1061/(ASCE)MT.1943-5533.0002601. [DOI] [Google Scholar]

- Jain S.; Sharma M. P. Prospects of biodiesel from Jatropha in India: a review. Renewable and Sustainable Energy Reviews 2010, 14, 763–771. 10.1016/j.rser.2009.10.005. [DOI] [Google Scholar]

- Wang R.; Zhou W.-W.; Hanna M. A.; Zhang Y.-P.; Bhadury P. S.; Wang Y.; Song B.-A.; Yang S. Biodiesel preparation, optimization, and fuel properties from non-edible feedstock, Datura stramonium L. Fuel 2012, 91, 182–186. 10.1016/j.fuel.2011.07.001. [DOI] [Google Scholar]

- Li X.; He X.-Y.; Li Z.-L.; Wang Y.-D.; Wang C.-Y.; Shi H.; Wang F. Enzymatic production of biodiesel from Pistacia chinensis bge seed oil using immobilized lipase. Fuel 2012, 92, 89–93. 10.1016/j.fuel.2011.06.048. [DOI] [Google Scholar]