Abstract

Bearing is one of the most fundamental components of rotary machinery, and its fatigue life is a crucial factor in designing. The design optimization of tapered roller bearing (TRB) is a complex design problem because various arrays of designing parameters and functional requirements should be fulfilled. Since there are many design variables and nonlinear constraints, presenting an optimal design of TRBs poses some challenges for metaheuristic algorithms. The Harris hawks optimization (HHO) algorithm is a robust nature-inspired method with unique exploitation and exploration phases due to its time-varying structure. However, this metaheuristic algorithm may still converge to local optima for more challenging problems such as the design of TRBs. Therefore, this study aims to improve the accuracy and efficiency of the shortcomings of this algorithm. The performance of the proposed algorithm is first evaluated for the TRB optimization problem. The TRB optimization design has nine design variables and 26 constraints because of geometrical dimensions and strength conditions. The productivity of the proposed method is compared with diverse metaheuristic algorithms in the literature. The results demonstrate the significant development of dynamic load capacity in comparison to the standard value. Furthermore, the enhanced version of the HHO algorithm presented in this study is benchmarked with various well-known engineering problems. For supplementary materials regarding algorithms in this research, readers can refer to https://aliasgharheidari.com.

Keywords: Optimization, Swarm-intelligence algorithms, Harris hawks optimization, Constrained optimization, Tapered roller bearing, Fatigue life

Introduction

The tapered roller bearing (TRB) has been utilized for various applications since it can be employed to convey motions, such as rotation, oscillation, and linear motion of systems [1]. Since the tapered roller bearing has conical rollers capable of running on conical races, it can resist a huge amount of radial and thrust loads [2].

To evaluate the life of roller bearing, several factors should be taken into consideration, the most dominant factors of which are the heat treatment of the bearing, surface coating, and lubrication system [3, 4]. Consequently, to boost the performance of TRB, enhance the fatigue life [5], and decrease the amount of maintenance/replacement costs, it is significant to present the optimal design of TRB. Therefore, the optimal design of TRB has been studied in a vast body of literature (Table 1 shows some of the previous works related to the roller bearing design). In the optimal design of TRBs proposed by Tiwari et al. [2] using a genetic algorithm, the objective function was fatigue life which must be maximized, and the constraints contained the geometrical parameters and strength. Furthermore, sensitivity analysis was conducted by the authors to investigate the influence of various parameters on the design parameters. Tiwari et al. [6] analyzed the thermal behaviour of TRBs. In another study, design optimization was presented for the cylindrical roller bearing with the logarithmic profile by Kumar et al. [7]. A robust optimization study was presented by Verma and Tiwari [8] for minimizing the variation and maximizing the performance of tapered roller bearing. Similarly, Kaylan et al. [9] used a multi-objective optimization methodology to maximize the dynamic capacity, minimize the film thickness, and maximize the bearing temperature. In this regard, an NSGA-II was used, and sensitivity analysis was performed to evaluate the sensitivity of objectives with the design variables. Genetic algorithm (GA) was used by Choi and Yoon [10] to present and optimize a design that enhanced the system life of a double row angular contact ball bearings used in an automobile wheel. Chakraborty et al. [11] proposed the optimal design of a deep groove ball bearing using GA and showed that the optimized design variables led to superior performance to the parameters presented in the standard catalog. Dandagwhal et al. [12] optimized the design of cylindrical roller bearings and deep groove ball bearings. In this study, the modified version of the optimization algorithm based on teaching–learning was used to achieve the best design for bearings. Related to the design on deep groove ball bearings, the performance of particle swarm optimization (PSO) and GA was evaluated by Panda et al. [13] to find the best design. Kang et al. [14] optimized the geometric parameters of an angular contact ball bearing to enhance its performance using a robust optimization analysis. Tiwari and Vaghole [15] hybridized the artificial bee colony and the grid search method to improve the performance of spherical roller bearing. Moreover, a sensitivity analysis was performed to evaluate the influence of design parameters on the objective function.

Table 1.

Previous work-related to optimum design of roller bearing

| Type of bearing | Description |

|---|---|

| Spherical roller [1] | Multi-objective optimization related to maximization of dynamic capacity and wear life of bearing and minimization of the elasto-hydrodynamic film thickness using non-dominated sorting genetic algorithm (NSGA-II) |

| Tapered roller [2] | The maximization of the fatigue life using a genetic algorithm (GA) |

| Tapered roller [4] | Quasi-static analysis of tapered roller bearings for different roller surface profiles |

| Tapered roller [6] | Optimum design based on the thermal behaviour of tapered roller bearing using an evolutionary algorithm |

| Crowned cylindrical roller [7] | Obtained optimum design to increase the life of cylindrical roller bearings using genetic algorithm (GA) |

| Tapered roller [8] | Robust optimum design of tapered roller bearings using evolutionary algorithm |

| Tapered roller [9] | Multi-objective optimization of tapered roller bearing design based on fatigue, wear, and thermal considerations through genetic algorithm (GA) |

| Contact ball bearing [10] | Maximize system life though filling geometrical and operational restrictions devoid of expanding mounting space |

| Ball bearing [11] | Maximization of fatigue life through genetic algorithm (GA) |

| Deep groove ball bearing [12] | Optimization of fatigue life using teaching–learning-based algorithm |

| Angular contact ball bearing [14] | Robust design optimization under manufacturing tolerance |

| Spherical roller [15] | Optimum design using artificial bee colony algorithm and grid search method |

The optimization process in engineering cases is obligated to satisfy the decision-maker’s requests [16–19]. This target should be done within the decision-making procedure reasonably and efficiently [20–24]. Such complex problems can be within any engineering domain [25–27]. Some examples are parameters identification, prediction scenarios, electro-mechanical systems [28, 29], expert systems [30–35], and clustering problems [36]. Nowadays, the use of optimization algorithms such as PSO [37] and variants of differential evolution (DE) [38, 39] and ant colony optimizer (ACO) [40] has an undeniable role in engineering problems to address the challenging requirements of engineering systems [41, 42]. There are recently a good set of swarm-based optimizers, including slime mould algorithm (SMA)1 [43], hunger games search (HGS)2 [44], gradient-based optimizer (GBO) [45], and Runge–Kutta optimizer (RUN)3 [46]. The swarm-based approaches [47–49] can sort out exploration and exploitation segments using stochastic-enabled processes.

Harris hawks optimization (HHO)4 is one of the most recent meta-heuristic algorithms showing superiority in many engineering problems [50, 51]. For instance, in one study, the HHO algorithm was used by Abbasi et al. [52] to minimize the entropy generation of microchannel heat sinks. In this work, the performance of the HHO algorithm was compared with various algorithms in the literature, and the results proved the superiority of the HHO algorithm. A hybrid version of the Harris hawk optimization algorithm (HHO) and grasshopper optimization algorithm (GOA) was presented [53] to investigate the optimal placement of multiple optical network units in fibre-wireless networks. Izci et al. [54] employed the HHO algorithm to adjust the parameters of the PID controller to control the aircraft pitch. The performance of the HHO algorithm was compared with that of the salp swarm algorithm (SSA) and atom search optimization (ASO). The results revealed the superiority of the HHO algorithm to other metaheuristic algorithms. In another study, the HHO algorithm was used to tune the PID controller parameters to control the speed of a DC motor [55].

Improving the optimization algorithms via hybridization with other algorithms is a common approach for improving their accuracy and efficiency [41, 42, 51, 56–58]. Song et al. [59] proposed an improved version of the HHO algorithm, in which by adding Gaussian mutation and dimension decision strategies, the exploitation and exploration phases of the HHO algorithm were improved. In another study, Ridha et al. [60] presented a boosted version of the HHO (BHHO) algorithm for parameter identification of photovoltaic modules. Comparing results with other metaheuristic algorithms available in the literature showed that BHHO outperformed other algorithms in identifying the parameters of single-diode solar cell models. Barshendeh et al. [61] introduced a novel hybrid multi-population algorithm with artificial ecosystem-based optimization and Harris hawks optimization to achieve the best result related to engineering problems. A modified version of the HHO algorithm was proposed by Gupta et al. [62]. In this study, four strategies were combined with the main HHO algorithm to enhance the efficiency of the HHO algorithm. A hybridize version of the HHO algorithm for SAR target recognition and stock market index prediction was proposed by Hu et al. [63]. In this investigation, the velocity of the PSO algorithm and the crossover vector of the AT algorithm was combined with the HHO algorithm to improve its performance. Zhang et al. [25] applied adaptive cooperative and dispersed foraging strategies to improve the position update. These changes improved diversity and avoided local optima. Abdol-Basset et al. [64] hybridized the HHO algorithm with simulated annealing to improve HHO performance for the feature selection.

Survival exploration strategies applied successfully to the structure of the HHO, which resulted in efficient results compared to other competitors [65]. Authors developed a Gaussian bare bone HHO in [66] for predicting entrepreneurial intentions. A multi-population DE-based version was also proposed that can show excellent exploratory patterns [67]. HHO and its progressive variants also applied to parameters identification of photovoltaic cells [60, 68], image segmentation [69, 70], web service composition [71], diagnosing coronavirus disease [72], predicting di-2-ethylhexyl phthalate toxicity [65], parameter estimation of photovoltaic models [73, 74], real-world engineering optimization problem [75], and feature selection [76, 77]. For a review of recent works on HHO, please refer to work in [78].

According to the reviewed papers, the optimization-based designs available in the literature are mainly based on classical algorithms like genetic algorithm (GA). While the classical algorithms can be efficient for some of the problems, there is still room for novel algorithms to present an optimal roller bearing design. This paper proposes an improved version of the HHO algorithm that shows superiority in roller bearing design. A multi-strategy algorithm based on the Harris hawk optimization algorithm is designed with some advantages compared to the standard HHO. At the beginning of standard HHO, a chaotic technique is performed to distribute agents equally in the search space. In the exploration phase, new strategies are added to increase the power of the exploration phase. Finally, a chaotic local search is added to avoid local optima. The optimization of TRBs demonstrates the efficiency of the proposed algorithm. Furthermore, to evaluate the accuracy and efficiency of the proposed algorithm, it is benchmarked on several famous engineering problems. The rest of this paper is organized as follows: In Sect. 2, the geometry of TRBs is given, and stress analysis is conducted on the roller bearing. An optimization methodology for TRB maximization, including the objective function, design variables, and the associated constraints, is elaborated on comprehensively in Sect. 3. An overview of the proposed EHHO algorithm is given in Sect. 4. The results are addressed in Sect. 5. Finally, Sect. 6 is reserved for conclusions.

Tapered roller bearing

Geometrical structure of TRB

There are four critical elements in this type of bearing, which are shown in Fig. 1: (1) shortened cones with the number of rollers inside this, (2) a cage to carry rollers, (3) cone (internal ring), and (4) cap or external ring. The TRB has a larger lip at the cone’s back to reinforce the axial force from the set of rollers and a smaller lip near the cone, the function of which is to provide the consistency of the rollers.

Fig. 1.

Structure of TRB

The measurement parameters of TRB, based on standard catalog [79], consists of (d) as a bore diameter, (T) as the width of the bearing, (D) appears for outer diameter, (C) stands for the width of the cup, () and (B) represent the contact angle and the cone’s width, respectively, as demonstrated in Fig. 1.

The semi-taper angle () is formulated according to two other separate parameters, named pitch diameter () and mean diameter (), as follows:

| 1 |

The constraints of the design optimization problem are related to the internal dimension of the TRB, which is explained below.

The minimum thickness of the front-face of the cup, shown in Fig. 2, is calculated using Eq. (2), and the one related to the cone is determined from Eq. (3):

| 2 |

| 3 |

Fig. 2.

Internal dimensions of tapered roller bearing

The minimum width of the back-face and the front-face of the cup, and , respectively, can be expressed as [2]:

| 4 |

| 5 |

Moreover, the total width is calculated as follows:

| 6 |

Similar to the cup, there is a back-face related to the cone, the minimum of which can be derived from Fig. 2 as follows:

| 7 |

is related to internal dimensions and is given as

| 8 |

Moreover, the thickness of the back-face of the cup is determined using Eq. (9):

| 9 |

One of the internal dimensions () relates to the surface of the cone, which is shown in Fig. 2 can be calculated as

| 10 |

Stress analysis of TRB

Every equipment during its operation experiences loads and stresses in terms of normal and shear types. For TRB, these loads act on the bearing’s flange. To determine such forces, the free body diagram shown in Fig. 3 is taken into consideration. The forces which act on the bearing components are obtained according to the static equilibrium formula of bearing. () and () are loads on the cup and spherical face of TRB roller, respectively, which are written in Eq. (11) as follows:

| 11 |

where force is determined based on stribeck’s equation [80], is roller contact angle, is named as cone contact angle and calculated as , and Flange angle () is given as Eq. (12)[8]:

| 12 |

where the value of R is 95% of the length AB and =0.125.

Fig. 3.

Schematic view of roller’s force

Load () causes bending stress () and shear stress (). Also, tensile stress () happens due to flange loads and is formulated in Eq. (13).

| 13 |

The maximum shear stress occurring in TRB’s flange shape is written by

| 14 |

Similarly, the other components of stresses which are created by bending moment are given by

| 15 |

where ,, and indicate the number of rollers, area moment of inertia, and Young’s modulus, respectively. As the result of determining all the components of stresses, the maximum principal stress is achieved in the flange shape part of the roller using Eq. (16):

| 16 |

The computation of the above parameters exploited as the constraints for the optimization process is explained below.

Formulation of the optimization problem

In this part of the paper, the formula to achieving the best performance of TRB is explained in detail. Design parameters and structural constraints are set to maximize the objective function (fitness function) as shown below:

| 17 |

In Sects. 3.1 to 3.3, the method of obtaining three parts of an optimization problem, including variables, objective functions, constraints, is defined.

Fitness function

Fatigue, corrosion, and creep are among the main factors for fracture in roller bearings. These kinds of failures can be diminished or removed by a proper design [2, 80]. The fatigue life in the bearing is distinguished as one of the crucial design considerations and can be calculated as follows:

| 18 |

where is known as dynamic load, is defined as the life of bearing with 90% reliability, n is defined as an exponent of load life, and P is specified as radial load [80]. The fatigue life of bearing and dynamic load is related to each other. Thus, maximizing dynamic capability is formulated as a fitness function to improve the bearing’s performance. The fitness function is written as shown below:

| 19 |

The dynamic load capacity for roller bearing is formulated as [14]:

where

| 20 |

where , , are the number of rollers, adequate length, and mean diameter of rollers, respectively. Also, is equal to 0.65 and is taken as a reduction factor into account. is related to edge loading, which is 1.2 for TRB [80]. Finally, is taken as 1.1 [81].

Optimization variables

Nine variables are used for optimizing the design of TRB. The internal geometry of bearing, including sufficient length (), mean and peach diameter (,), and the number of rollers () influences the dynamic load of bearing. Also, there are other types of variables that are used as constraints. and are minimum and maximum roller diameter, respectively. The remaining three variables, i.e., , and , are described as mobility parameters, the outer ring strength, and semi-taper angle in the bearing, respectively. The nine design variables are defined as follows:

| 21 |

All the design variables are positive integers for this problem.

Constraints

In this subsection, design constraints of the optimization problem are present. To decrease the stress concentration of the cup and cone of rollers, the lower and upper limits of the pitch diameter should be set as the following equation, which is defined as Constraints 1 and 2:

| 22 |

Hence, these constraints are written in the following form:

| 23 |

For restricting the contact stress, the mean diameter should be arranged as follows:

| 24 |

where is the largest value of the contact load and and are minimum and maximum ranges obtained for mean diameter. According to the above explanation, Constraints 3 and 4 are derived as shown below:

| 25 |

According to the internal geometry of TRB, the length of the roller () should have the range in Eq.(26) to project from both faces of the cup.

| 26 |

Therefore, Constraints 5 and 6 can be expressed as follows:

| 27 |

The limit area for the number of roller is specified according to Eq. (28), which contains lower and upper limits of pitch diameter.

| 28 |

Thus, Constraints 7 and 8 take the following form:

| 29 |

The following design criteria are chosen for the roller diameter:

| 30 |

The ranges for and are selected from a survey on TRBs [82]. d and D taken as bore and outsider diameter, respectively. As a result, Constraints 9 and 10 are expressed as follows:

| 31 |

Constraints 11 and 12 related to mobility factor are represented in the following form:

| 32 |

The criteria for value are obtained from the study on TRBs [82].

Constraint 13 is associated with the width of the bearing cup, which is expressed as

| 33 |

Constraint 14 comes from the periphery of bearing. Width of the cup,, should have the following condition in the internal geometry of the bearing:

| 34 |

The higher stress level should be avoided in the cone of TRB. Thus, Constraint 15 is designed according to the cone of TRB, which is represented as

| 35 |

where and are minimum thickness of cup and cone of TRB, respectively.

The difference between , as the lowest thickness of the front-face of the cup, and value should be positive. Therefore, Constraint 16 can be formulated as Eq. (36):

| 36 |

For secure operation of the bearing, there should be a clearance between back-face of the cup and angle of the roller’s short end. Constraint 17 is given as

| 37 |

The contact between the chamfer of the back-face of the cone and the roller’s corner of the big end should be avoided. Hence, adequate space between them is considered. Therefore, Constraint 18 is given as

| 38 |

An appropriate distance must be considered among the chamfer of the front-face of the cone’s and edge of the tiny end of the roller. This gap can be reflected as Constraint 19, which is written as:

| 39 |

Constraints 20 and 21 are associated with resistance of the cone’s lips and thickness of the cup’s front-face. For Constraint 20, because the larger lip in comparison to the smaller one is subjected to superior load, Eq. (40) is proposed as the constraint; for Constraint 21, the thickness of the front-face of the cup should have conditions based on Eq. (41).

| 40 |

| 41 |

Constraint 22 related to the sufficient length, , is expressed as Eq. (42):

| 42 |

| 43 |

Constraint 24 is in corelation with stress at the flange of the cone, which is given by Eq. (44):

| 44 |

where is the largest stress at the flange and is yield stress.

A restriction for contact stress is taken into account because the stress should not exceed 4000 MPa. Therefore, Constraint 25 is given as follows:

| 45 |

where is the allowable contact stress and is the actual contact stress between the cone and the roller when the roller is loaded with over the cone.

There should be sufficient spacing between the rollers to have the secure operation of the bearing. The relevant Constraint (26) is written as follows:

| 46 |

Optimization methodologies

In this section, the optimization process of TRB’s design is described in great detail. From bearing catalog [83] and bearing standard [79], different TRB cases are introduced, the fatigue life of which is improved by the proposed methods. To perform the optimization process, some constant inputs reported in Table 2 are needed. These inputs show some characteristics related to different case bearings. Dynamic capacity () of every bearing is mentioned in Table 2, and radial force used in the calculation is based on 60% of dynamic capacity. Also, some material properties of bearings are reported in Table 3. The experiment tests for optimizing the fatigue life of TRBs are performed by boosted Harris hawk optimization algorithm. The Harris Hawk optimization algorithm is explained briefly in Sect. 4.1 as it forms the basis for the proposed algorithm; the proposed algorithm is presented in detail in Sect. 4.2.

Table 2.

Input parameters for tapered roller bearings [79]

| Bearing number | Standard boundary dimensions | Standard internal dimensions | Standard chamfering dimensions | Dynamic load rating | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

mm |

mm |

mm |

mm |

mm |

mm |

mm |

degree |

mm |

mm |

mm |

mm |

mm |

kN |

|

| 30,204 | 47 | 20 | 12 | 14 | 15.25 | 33.20 | 37.304 | 12.9527 | 1.0 | 1.0 | 1.0 | 1.0 | 0.5 | 27.5 |

| 30,205 | 52 | 25 | 13 | 15 | 16.25 | 37.40 | 41.135 | 14.0361 | 1.0 | 1.0 | 1.0 | 1.0 | 0.5 | 30.80 |

| 32,205 | 52 | 25 | 15 | 18 | 19.25 | 40.20 | 37.555 | 21.2500 | 1.0 | 1.0 | 1.0 | 1.0 | 0.5 | 35.80 |

| 322/28 | 58 | 28 | 16 | 19 | 20.25 | 43.90 | 42.436 | 20.5666 | 1.0 | 1.0 | 1.0 | 1.0 | 0.5 | 41.80 |

| 32,206 | 62 | 30 | 17 | 20 | 21.25 | 45.20 | 48.982 | 14.0361 | 1.0 | 1.0 | 1.0 | 1.0 | 0.5 | 50.10 |

| 30,207 | 72 | 35 | 15 | 17 | 18.25 | 51.80 | 58.844 | 14.0361 | 1.5 | 1.5 | 1.5 | 1.5 | 0.5 | 51.20 |

| 30,306 | 72 | 30 | 16 | 19 | 20.75 | 48.40 | 58.287 | 11.8597 | 1.5 | 1.5 | 1.5 | 1.5 | 0.4 | 56.10 |

| 32,207 | 72 | 35 | 19 | 23 | 24.25 | 52.40 | 57.087 | 14.0361 | 1.5 | 1.5 | 1.5 | 1.5 | 0.5 | 66.00 |

| 30,307 | 80 | 35 | 18 | 21 | 22.75 | 54.50 | 65.769 | 11.8597 | 2.0 | 2.0 | 1.5 | 1.5 | 0.8 | 72.10 |

| 32,208 | 80 | 40 | 19 | 23 | 24.75 | 58.40 | 64.715 | 14.0361 | 1.5 | 1.5 | 1.5 | 1.5 | 0.5 | 74.80 |

Table 3.

Material properties of the bearing (steel)

| Description | Value |

|---|---|

| Safe contact stress | 4000 MPa |

| Young’s modulus | 210 GPA |

| Yield strength | 600 MPa |

| Poisson’s ratio | 0.3 |

The optimization algorithms are so sensitive to their parameters, and choosing proper parameters can guarantee good convergence toward the optimal solution. Thus, to calibrate the parameters of the optimization algorithm, several different cases are considered and performed on bearing number 30204. The best performance of the parameters is reported in Table 4. Also, 10,000 iterations are chosen for executing the optimization process.

Table 4.

The optimization parameters

| Optimization method | Parameters | Value |

|---|---|---|

| EHHO and HHO | Population | 80 |

| 1.5 | ||

| Number of iterations | 10,000 | |

| WOA | Population | 80 |

| b | 1 | |

| Number of iterations | 10,000 | |

| SCA | Population | 80 |

| a | 2 | |

| Number of iterations | 10,000 |

For having the fair comparison of results [84–87], two other effective algorithms (whale optimization algorithm [88, 89], and sine cosine algorithm (SCA) [90–93] are added to execute the simulated experiments. The coding of each algorithm is written in Matlab software, and the final results are based on ten separate runs. The best result of dynamic capacity for each algorithm is reported for the final comparison.

Harris hawks optimization algorithm (HHO)

Heidari et al. [50] have recently developed a novel and robust optimization algorithm that mimics Harris hawks birds’ cooperative behavior. These birds can capture the prey using several strategies. These strategies can be simulated as the main structure of the Harris hawk optimization algorithm (HHO). Like every other optimizer, the Harris hawk optimizer has exploration and exploitation phases to find the final optimum solution of the objective function. All details related to the mechanism of the Harris hawk optimizer are explained in the following subsections.

Exploration (observation) stage

In this stage, the birds search and track the variables’ space for detecting the prey’s position as the optimum solution. Two equations are represented in this stage based on the strike tactics of Harris hawks: perching strategy and crouching strategy. These two strategies are expressed in the following form:

| 47 |

where is the position of the prey, is the place of search agents for the next round of algorithm, is the position of the search agents in the current iteration, and is selected arbitrarily based on the present search agents. through produce a random number in the interval of 0 and 1. is formulated as follows:

| 48 |

where is the location of each search agent, and is the number of search agents.

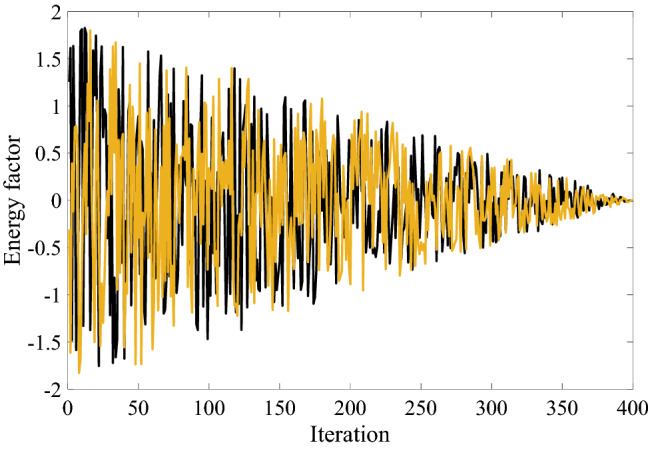

Energy factor (transition factor)

The energy factor controls the changing phases between exploration and exploitation behaviours. The factor is described in Eq. (49). When the factor is > 1, the exploration stage is performed, and when is < 1, the exploitation phase is carried out.

| 49 |

where is the initial energy which is randomly chosen between ( − 1,1), is the maximum iteration number, and is the current iteration. The energy factor is plotted against the iteration number in Fig. 4.

Fig. 4.

Energy factor

Exploitation (intensification) stage

In this stage, the Harris hawks birds utilize diverse hunting strategies. These exploitation strategies contain 4 main attacking movements: soft besiege, hard besiege, soft besiege with progressive rapid dives, and hard besiege with progressive rapid dives. These four exploitation techniques are defined as follows:

Exploitation’s technique 1(Soft besiege)

In this situation, the prey is confused and looks for a way to escape. This strategy is performed when , , which means that the prey is very exhausted. This tactic is modelled as

| 50 |

where denotes the location of the tired prey, J is a factor to show the prey’s behaviour, and is randomly chosen from [0,1].

Exploitation’s technique 2 (hard besiege)

This tactic happens when , . A killer method as a surprise pounce is executed in this part and can be mathematically presented as Eq. (51):

| 51 |

Exploitation’s technique 3 (Soft besiege with progressive rapid dives)

When , and , the Harris hawk birds perform their next action based on the following expression:

| 52 |

| 53 |

where is known as the levy flight function, is the random vector, is the number of search agents. and are chosen from [0,1] and is equal to 1.5. To update the positions of search agents, the following expression proposed:

| 54 |

Exploitation’s technique 4 (hard besiege with progressive rapid dives)

In the last tactic of the exploitation phase, the Harris Hawks, as search agents for the optimizer, are very close to the prey and kill it. This strategy is explained according to Eq. (55) and Eq. (56):

| 55 |

| 56 |

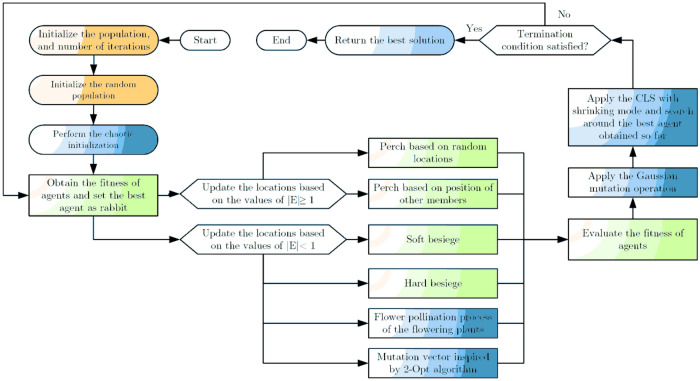

The flowchart of the HHO process is given in Fig. 5.

Fig. 5.

The flowchart of the HHO algorithm

Proposed enhanced Harris hawks (EHHO)

The mathematical formulation and procedure of the enhanced version of the Harris hawk optimization algorithm are elaborated in this part. Based on the no free lunch (NFL) theory, not every algorithm applies to all problems. For instance, initialization in the HHO algorithm is based on arbitrary numbers, generating a mature population. Furthermore, the proposed strategies used in HHO for updating the population are limited for several applications. Plus, this algorithm is trapped in the local optimum. To enhance the performance of the HHO algorithm and improve the exploitation and exploration phases of the main algorithm, the following methods are added to the HHO algorithm: (1) chaotic method, (2) update besiege strategy 3, (3) update besiege strategy 4, (4) Gaussian mutation, and (5) CLS with a shrinking mode. The first two techniques are presented to assistant the HHO algorithm in generating a different mature population; the third technique is added to the HHO algorithm to enhance its performance for updating the population, and the last two techniques are added to the main HHO algorithm to prevent it from being trapped in the local optimum.

Chaotic method

The initialization in the optimization algorithms is responsible for spreading the design variables in the design space, which can lead to the convergence of the algorithm to the global optimum. The chaotic initialization approach is a powerful procedure that helps the algorithm to generate a more diverse population. The chaotic method has been employed in a wide range of engineering problems, such as feature selection and chaos control [94, 95]. A large number of chaotic maps [96], such as the Chebyshev map, circle map, and intermittency map, are available in the literature. Herein, a prominent logistic map is used, which is described as follows:

| 57 |

where is a controlling factor is an arbitrary number between 0 and 1, and is the number of search agents. To achieve a population with better quality, after the first arbitrary initialization in the main HHO algorithm, chaotic mapping is performed. This modification improves the convergence of the algorithm [97]. This disturbance can then be obtained using the following formulation:

| 58 |

where is the position of the ith Harris hawk with chaotic disturbance, and is the ith value in the chaotic sequence.

Update besiege strategy 3

To effectively update the location in Strategy 3 of the standard HHO algorithm, instead of utilizing a soft besiege with rapid progressive dives, a formulation from the flower pollination optimization algorithm is utilized [20]. This approach can be developed as follows [98]:

| 59 |

where denotes an arbitrary number between 0 and 1, and and represent pollens from the jth and kth flowers of the identical population, respectively. This technique can enhance the performance of the HHO algorithm to present a more diverse solution in the next iteration.

Update besiege strategy 4

In this section, to improve the performance of the HHO algorithm, a mutation vector extracted from the 2-Opt algorithm and differential evolution algorithm (DE) [99, 100] is replaced by hard besiege with a rapid progressive diving technique. This approach can be expressed as follows:

| 60 |

where is a parameter that strikes an equilibrium between the local and the global capacity of the enhanced version of the HHO algorithm. , , and are selected from the population. is an arbitrary number between 0 and 1. This method aims to restrict the rising exploitation and prevents being trapped in local optima [60].

Gaussian mutation

Another approach employed in this study to enhance the diversity of the solution is the Gaussian mutation. This strategy has been adopted in a wide range of metaheuristic algorithms to create diversity in solutions [97, 101]. The main purpose of the Gaussian mutation is to boost the global search. Gaussian mutation makes a slight arbitrary change in the group of search agents to prevent trapping in the local optima, leading to more exploitation ability and better convergence. Considering the average of 0 and the standard deviation of 1, a random variable is formed. The Gaussian density function can be formulated as follows [97]:

| 61 |

where indicates the variance, and represents an arbitrary Gaussian value between [0,1]. The standard deviation is considered to be equal to 1. The Gaussian function with various standard deviation rates is demonstrated in Fig. 6. In the proposed algorithm, firstly, the population is updated according to the energy escaping factor and besiege methods; then, a new population of Harris hawks is created based on Eq. (62):

| 62 |

where denotes the location of the new population in each iteration. represents the Gaussian step vector according to the Gaussian density presented in Eq. (61).

Fig. 6.

Gaussian function for different values of standard deviation

CLS with shrinking mode

Local search (LS) is one of the most efficient strategies for preventing algorithms from being trapped in local optima. It is essential to scour the final solution’s vicinity since, most of the time, the solution is in the neighbourhood of local optima, and the algorithm cannot detect it. Consequently, adding LS to the main HHO algorithm can significantly enhance the performance of the algorithm. Note that, sometimes, LS is not sufficient and would not lead to desirable results. Thus, a chaotic local search (CLS) can be utilized. Since there is randomicity in chaos, CLS can lead to immature convergence [97]. The CLS strategy is added in the last step of the algorithm to detect the best solution. The CLS approach can be formulated as follows:

| 63 |

where is the kth new location created by CLS, shows the best rabbit found so far, is the signal generated in the kth chaos, and LB and UB represent the lower and upper limits of the search space, respectively. denotes the shrinking scale factor, and t is the current iteration. is used to handle the shrinking rate and is equal to 1500. Figure 7 depicts the flowchart of the enhanced version of the Harris hawk algorithm (EHHO).

Fig. 7.

The flowchart of the EHHO algorithm

Results and discussions

In this section of the study, first, the simulated experiment’s outcome is presented, and the manner every element of the proposed algorithm can affect the promotion of the final result is examined in detail. Also, the results are compared with the value from the existing catalog. For checking the proposed algorithm's capability, some of the famous engineering problems are chosen to be examined under the proposed algorithm.

Optimum design of TRB

For performing the optimization process, every variable’s limit should be identified in the first calculation stage not to exceed the reasonable number. Maximum and minimum values of each variable used in the design of TRB are computed based on Constraints 1–8 (Table 5). The reported limitation of variables in Table 5 is used as the boundaries of the design variables in optimization algorithms, which include enhanced Harris hawk (EHHO), standard Harris hawk (HHO), whale algorithm (WOA, and sine cosine algorithm (SCA). Different algorithms, including the best solution with their optimum variables, are summarised in Tables 6, 7 for ten different tapered roller bearings. In Tables 6, 7, results are ranked based on the value of dynamic load capacity. It is seen from the results that the introduced enhanced Harris hawk optimization algorithm has superior capability in finding the maximum dynamic load capacity as the optimum outcome and ranks first among the other algorithms. After the enhanced Harris hawk algorithm, the standard Harris hawk has better convergence toward the maximum solution among the rest of the algorithms. It is noteworthy that all values of dynamic load capacity are significantly improved, among which bearing number 30205 has higher improvement (29.4%), and bearing number 32208 has the lowest improvement (16.6%).

Table 5.

Lower and upper limits for optimization design variables

| Bearing number | Design variables | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (mm) | (mm) | |||||||||||||||||

| L.L | U.L | L.L | U.L | L.L | U.L | L.L | U.L | L.L | U.L | L.L | U.L | L.L | U.L | L.L | U.L | L.L | UL | |

| 30204 | 22 | 45 | 1.5452 | 11.8003 | 1.5452 | 10.7741 | 5 | 91 | 0.3 | 0.4 | 0.5 | 0.6 | 0.4 | 0.5 | 0.01 | 0.07 | 0.80 | 0.95 |

| 30205 | 27 | 50 | 1.6390 | 11.5 | 1.6390 | 11.8539 | 7 | 95 | 0.3 | 0.4 | 0.5 | 0.6 | 0.4 | 0.5 | 0.01 | 0.07 | 0.80 | 0.95 |

| 32205 | 27 | 50 | 1.8028 | 11.5 | 1.8028 | 14.4848 | 7 | 87 | 0.3 | 0.4 | 0.5 | 0.6 | 0.4 | 0.5 | 0.01 | 0.07 | 0.80 | 0.95 |

| 322/28 | 30 | 56 | 1.9435 | 13 | 1.9435 | 15.4870 | 7 | 90 | 0.3 | 0.4 | 0.5 | 0.6 | 0.4 | 0.5 | 0.01 | 0.07 | 0.80 | 0.95 |

| 32206 | 32 | 60 | 2.0903 | 14 | 2.0903 | 15.9770 | 7 | 90 | 0.3 | 0.4 | 0.5 | 0.6 | 0.4 | 0.5 | 0.01 | 0.07 | 0.80 | 0.95 |

| 30207 | 38 | 69 | 2.1132 | 15.5 | 2.1132 | 13.4001 | 7 | 102 | 0.3 | 0.4 | 0.5 | 0.6 | 0.4 | 0.5 | 0.01 | 0.07 | 0.80 | 0.95 |

| 30306 | 33 | 69 | 2.2023 | 18 | 2.2023 | 14.4075 | 5 | 98 | 0.3 | 0.4 | 0.5 | 0.6 | 0.4 | 0.5 | 0.01 | 0.07 | 0.80 | 0.95 |

| 32207 | 38 | 69 | 2.3992 | 15.5 | 2.3992 | 17.5231 | 7 | 90 | 0.3 | 0.4 | 0.5 | 0.6 | 0.4 | 0.5 | 0.01 | 0.07 | 0.80 | 0.95 |

| 30307 | 39 | 77 | 2.4967 | 19 | 2.4967 | 16.0424 | 6 | 96 | 0.3 | 0.4 | 0.5 | 0.6 | 0.4 | 0.5 | 0.01 | 0.07 | 0.80 | 0.95 |

| 32208 | 43 | 77 | 2.5541 | 17 | 2.5541 | 17.5231 | 7 | 94 | 0.3 | 0.4 | 0.5 | 0.6 | 0.4 | 0.5 | 0.01 | 0.07 | 0.80 | 0.95 |

Table 6.

Optimization parameters for TRB design

| Bearing number | Rank | Optimization method | Optimum parameters | Cost | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

(mm) |

(mm) |

(N) |

||||||||||

| 30204 | 1 | EHHO | 33.0749 | 7.2313 | 10.7305 | 14 | 0.3940 | 0.5933 | 0.4656 | 0.07 | 0.95 | 34,538.3 |

| 2 | HHO | 33.9860 | 6.3966 | 10.3566 | 16 | 0.4 | 0.6 | 0.5 | 0.07 | 0.9403 | 32,557.6 | |

| 3 | WOA | 34.3789 | 5.9630 | 10.5196 | 17 | 0.4 | 0.6 | 0.5 | 0.0521 | 0.95 | 31,982.2 | |

| 4 | SCA | 33.6178 | 6.6400 | 10.0329 | 15 | 0.4 | 0.5352 | 0.4814 | 0.07 | 0.95 | 31,500.8 | |

| 5 | GA [2] | 34.999 | 5.29 | 10.0 | 20 | 0.3306 | 0.5847 | 0.4507 | 0.0623 | 0.9465 | 31,220 | |

| 30205 | 1 | EHHO | 38.1566 | 6.4914 | 11.8460 | 18 | 0.4 | 0.5980 | 0.4507 | 0.0699 | 0.9440 | 39,864.3 |

| 4 | HHO | 39.4099 | 5.4227 | 11.0261 | 22 | 0.3126 | 0.5792 | 0.4827 | 0.0679 | 0.9059 | 36,069.5 | |

| 2 | WOA | 38.3892 | 6.2773 | 11.7593 | 18 | 0.3649 | 0.5978 | 0.4982 | 0.07 | 0.9466 | 38,224.3 | |

| 3 | SCA | 38.1955 | 6.6053 | 10.8431 | 17 | 0.3 | 0.6 | 0.4 | 0.0103 | 0.8549 | 36,322.9 | |

| 5 | GA [2] | 39.366 | 5.38 | 11.0 | 21 | 0.3011 | 0.5479 | 0.4658 | 0.0575 | 0.9447 | 34,810 | |

| 32205 | 1 | EHHO | 37.8752 | 6.0067 | 14.4667 | 20 | 0.4 | 0.6 | 0.5 | 0.0660 | 0.95 | 44,818.5 |

| 2 | HHO | 38.6718 | 5.2887 | 14.1878 | 23 | 0.3759 | 0.5602 | 0.4522 | 0.0103 | 0.8888 | 42,703.4 | |

| 4 | WOA | 38.5210 | 5.7723 | 13.2257 | 22 | 0.3847 | 0.6 | 0.5 | 0.07 | 0.95 | 41,498.6 | |

| 3 | SCA | 38.0050 | 5.8745 | 13.9157 | 20 | 0.3268 | 0.5129 | 0.4054 | 0.0104 | 0.95 | 42,449.7 | |

| 5 | GA [2] | 38.646 | 5.38 | 13.0 | 22 | 0.3278 | 0.5978 | 0.4464 | 0.0517 | 0.9494 | 40,600 | |

| 322/28 | 1 | EHHO | 42.2922 | 6.6763 | 15.3855 | 20 | 0.3999 | 0.5920 | 0.5 | 0.0106 | 0.9470 | 52,898.5 |

| 3 | HHO | 42.6596 | 6.3735 | 15.0591 | 22 | 0.3314 | 0.5824 | 0.4865 | 0.0679 | 0.9145 | 51,313.4 | |

| 2 | WOA | 42.6949 | 6.3743 | 15.0751 | 21 | 0.3697 | 0.5724 | 0.4731 | 0.0697 | 0.9310 | 51,360.6 | |

| 4 | SCA | 42.6438 | 6.5608 | 14.6048 | 20 | 0.3258 | 0.5 | 0.4 | 0.0604 | 0.95 | 49,833.0 | |

| 5 | GA [2] | 42.839 | 6.14 | 14.0 | 21 | 0.3260 | 0.5987 | 0.4683 | 0.0699 | 0.9499 | 485,400 | |

| 32206 | 1 | EHHO | 45.4239 | 8.1034 | 15.9621 | 17 | 0.3999 | 0.5998 | 0.4976 | 0.0699 | 0.9493 | 61,182.7 |

| 3 | HHO | 46.1074 | 7.8389 | 14.2253 | 18 | 0.4 | 0.6 | 0.4157 | 0.0245 | 0.95 | 56,315.1 | |

| 4 | WOA | 45.9059 | 7.8566 | 14.9822 | 17 | 0.4 | 0.6 | 0.5 | 0.0390 | 0.95 | 56,317.9 | |

| 2 | SCA | 46.0303 | 7.7433 | 14.8871 | 18 | 0.3946 | 0.6 | 0.4523 | 0.0109 | 0.95 | 57,582.7 | |

| 5 | GA [2] | 47.329 | 6.37 | 15.0 | 21 | 0.3647 | 0.5993 | 0.4983 | 0.0666 | 0.9495 | 52,250 | |

Bold values indicate the best results

Table 7.

Optimization results for TRB design

| Bearing number | Rank | Optimization method | Optimum parameters | Cost | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

(mm) |

(mm) |

(N) |

||||||||||

| 30207 | 1 | EHHO | 53.8069 | 9.1539 | 13.0691 | 18 | 0.356722 | 0.5213 | 0.4974 | 0.0514 | 0.9142 | 62,084.4 |

| 2 | HHO | 53.3063 | 9.6201 | 12.5616 | 17 | 0.361756 | 0.5476 | 0.4572 | 0.0101 | 0.8666 | 60,868.1 | |

| 4 | WOA | 56.1596 | 6.9678 | 11.9946 | 24 | 0.300363 | 0.5006 | 0.4860 | 0.0339 | 0.8010 | 53,606.8 | |

| 3 | SCA | 53.3906 | 9.5264 | 12.2235 | 17 | 0.36438 | 0.5359 | 0.4689 | 0.0188 | 0.8322 | 58,961.8 | |

| 5 | GA [2] | 56.117 | 6.89 | 13.0 | 23 | 0.3305 | 0.5027 | 0.4666 | 0.0699 | 0.9417 | 54,510 | |

| 30306 | 1 | EHHO | 51.5299 | 10.4971 | 14.3968 | 15 | 0.371458 | 0.5983 | 0.4822 | 0.0393 | 0.9432 | 68,439.6 |

| 2 | HHO | 52.2482 | 9.8508 | 14.0246 | 16 | 0.325396 | 0.6 | 0.5 | 0.0697 | 0.9076 | 65,748 | |

| 4 | WOA | 52.1721 | 10.0208 | 13.2669 | 15 | 0.378517 | 0.6 | 0.5 | 0.0256 | 0.95 | 61,105.3 | |

| 3 | SCA | 51.8496 | 10.3815 | 13.2908 | 15 | 0.330331 | 0.5463 | 0.4084 | 0.0605 | 0.9085 | 63,557.4 | |

| 5 | GA [2] | 54.221 | 7.74 | 14.0 | 20 | 0.3451 | 0.5597 | 0.4999 | 0.0699 | 0.9498 | 59,350 | |

| 32207 | 1 | EHHO | 53.2245 | 9.0549 | 17.5122 | 18 | 0.397334 | 0.5969 | 0.4998 | 0.0556 | 0.9463 | 77,162.2 |

| 4 | HHO | 55.4309 | 6.9632 | 16.9182 | 24 | 0.300001 | 0.5000 | 0.4630 | 0.0687 | 0.8663 | 70,135.9 | |

| 2 | WOA | 53.0241 | 9.5731 | 16.2293 | 17 | 0.315465 | 0.5536 | 0.4555 | 0.0548 | 0.8974 | 73,982.6 | |

| 3 | SCA | 53.2925 | 9.1628 | 16.7300 | 17 | 0.311826 | 0.5757 | 0.4844 | 0.0666 | 0.95 | 72,252 | |

| 5 | GA [2] | 54.381 | 7.99 | 16.0 | 20 | 0.3516 | 0.5968 | 0.4678 | 0.678 | 0.9204 | 69,810 | |

| 30307 | 1 | EHHO | 58.0431 | 11.8241 | 16.0144 | 15 | 0.309913 | 0.5864 | 0.4378 | 0.07 | 0.95 | 84,483.3 |

| 5 | HHO | 60.1575 | 10.1419 | 13.8516 | 18 | 0.367968 | 0.5022 | 0.4115 | 0.0574 | 0.9387 | 73,329.2 | |

| 3 | WOA | 60.4662 | 9.6153 | 14.6739 | 20 | 0.371041 | 0.5549 | 0.4623 | 0.0438 | 0.8433 | 75,411.3 | |

| 2 | SCA | 56.9436 | 12.8484 | 15.2605 | 13 | 0.3776 | 0.6 | 0.4 | 0.0688 | 0.95 | 79,927.4 | |

| 4 | GA [2] | 60.875 | 8.77 | 15.0 | 20 | 0.3545 | 0.5823 | 0.4853 | 0.0643 | 0.9043 | 74,940 | |

| 32208 | 1 | EHHO | 59.7637 | 10.1674 | 17.5122 | 18 | 0.399854 | 0.5965 | 0.4987 | 0.0303 | 0.95 | 87,259.1 |

| 4 | HHO | 60.2563 | 9.6762 | 15.6860 | 20 | 0.30076 | 0.5012 | 0.4891 | 0.0693 | 0.8020 | 79,052.7 | |

| 2 | WOA | 60.4622 | 9.7165 | 16.4699 | 19 | 0.4 | 0.6 | 0.5 | 0.0607 | 0.9498 | 82,458.4 | |

| 3 | SCA | 59.5876 | 10.4600 | 16.1836 | 17 | 0.308451 | 0.6 | 0.4 | 0.0479 | 0.9116 | 81,068.9 | |

| 5 | GA [2] | 60.800 | 9.06 | 15.0 | 20 | 0.3847 | 0.5988 | 0.4517 | 0.0390 | 0.8626 | 75,420 | |

Bold values indicate the best results

Moreover, in the results obtained by the enhanced Harris hawk optimization algorithm, it can be seen that although some bearing cases have lower roller numbers, they show better efficiency in terms of fatigue life. Therefore, having a higher number of rollers does not guarantee better fatigue life. Some parameters related to internal geometry which are obtained during the optimization process are summarized in Tables 8, 9.

Table 8.

Optimum internal geometry obtained by different optimization algorithms

| Bearing number | Optimization method | Optimum parameters of internal geometry | |||||||

|---|---|---|---|---|---|---|---|---|---|

|

(mm) |

(mm) |

(mm) |

(mm) |

(mm) |

(mm) |

degree |

degree |

||

| 30204 | EHHO | 2.2030 | 2.2030 | 1.0400 | 2.3337 | 1.0339 | 0.5 | 8.7777 | 2.3134 |

| HHO | 2.2030 | 3.0515 | 1.2920 | 2.4685 | 1.4004 | 0.5 | 9.2694 | 2.0416 | |

| WOA | 2.2030 | 3.4253 | 1.0686 | 2.5396 | 1.2424 | 0.5 | 9.5160 | 1.9047 | |

| SCA | 2.3026 | 2.7863 | 1.2104 | 2.8651 | 1.2823 | 0.9332 | 9.1177 | 2.1261 | |

| GA [2] | 2.437 | 3.665 | 1.509 | 3.603 | 1.703 | 1.520 | 9.757 | 1.693 | |

| 30205 | EHHO | 2.3075 | 2.3745 | 1.0144 | 2.3113 | 1.0004 | 0.5 | 10.3736 | 2.0283 |

| HHO | 2.3075 | 3.5346 | 1.6393 | 2.5202 | 1.7984 | 0.5 | 10.9930 | 1.6864 | |

| WOA | 2.3075 | 2.5903 | 1.0648 | 2.3517 | 1.0850 | 0.5 | 10.4966 | 1.9603 | |

| SCA | 2.3536 | 2.4301 | 1.8304 | 2.4816 | 1.7893 | 0.6843 | 10.3245 | 2.0569 | |

| GA [2] | 2.352 | 3.534 | 1.475 | 2.710 | 1.642 | 0.681 | 10.79 | 1.676 | |

| 32205 | EHHO | 1.5837 | 1.6465 | 1.4182 | 2.6248 | 1.0000 | 0.5 | 16.0377 | 2.8668 |

| HHO | 1.5837 | 2.3463 | 1.5138 | 2.8495 | 1.2640 | 0.5 | 16.6748 | 2.5172 | |

| WOA | 1.6002 | 2.2189 | 2.5027 | 2.7563 | 2.1172 | 0.5423 | 16.2961 | 2.7283 | |

| SCA | 1.6829 | 1.8344 | 1.6553 | 2.9283 | 1.2598 | 0.7550 | 16.1557 | 2.8034 | |

| GA [2] | 1.766 | 2.463 | 2.192 | 3.307 | 1.901 | 0.969 | 16.71 | 2.558 | |

| 322/28 | EHHO | 1.9662 | 1.9662 | 1.6443 | 2.4794 | 1.0782 | 0.5 | 15.5429 | 2.7660 |

| HHO | 1.9870 | 2.3064 | 1.8310 | 2.6277 | 1.3302 | 0.5554 | 15.7802 | 2.6362 | |

| WOA | 1.9662 | 2.3211 | 1.8718 | 2.5717 | 1.3707 | 0.5 | 15.7831 | 2.6346 | |

| SCA | 1.9841 | 2.2846 | 2.3161 | 2.5713 | 1.7631 | 0.5476 | 15.6578 | 2.7048 | |

| GA [2] | 2.197 | 2.627 | 2.222 | 3.272 | 1.763 | 1.116 | 16.00 | 2.541 | |

| 32206 | EHHO | 2.3840 | 2.3840 | 1.3077 | 2.952969 | 1.0039 | 0.5 | 10.2180 | 2.1123 |

| HHO | 2.3840 | 2.9840 | 2.9680 | 3.013218 | 2.6907 | 0.5 | 10.3759 | 2.0271 | |

| WOA | 2.3840 | 2.8116 | 2.2291 | 3.004961 | 1.9558 | 0.5 | 10.3532 | 2.0387 | |

| SCA | 2.3893 | 2.9304 | 2.2828 | 3.047944 | 2.0271 | 0.5212 | 10.4075 | 2.0088 | |

| GA [2] | 2.401 | 4.154 | 1.897 | 3.358 | 1.873 | 0.568 | 10.80 | 1.654 | |

Table 9.

Optimum internal geometry obtained by different optimization algorithms

| Bearing number | Optimization method | Optimum parameters of internal geometry | |||||||

|---|---|---|---|---|---|---|---|---|---|

|

(mm) |

(mm) |

(mm) |

(mm) |

(mm) |

(mm) |

degree |

degree |

||

| 30207 | EHHO | 3.0310 | 3.7907 | 2.0602 | 2.0602 | 1.5009 | 0.8121 | 10.3803 | 2.0283 |

| HHO | 3.1125 | 3.3767 | 2.3059 | 2.3059 | 1.6669 | 1.1380 | 10.1922 | 2.1331 | |

| WOA | 3.0625 | 6.0366 | 2.6099 | 2.6099 | 2.4212 | 0.9380 | 11.2649 | 1.5385 | |

| SCA | 3.1576 | 3.4895 | 2.4410 | 2.5059 | 1.8146 | 1.3186 | 10.2299 | 2.1126 | |

| GA [2] | 3.000 | 5.955 | 1.863 | 2.370 | 1.695 | 0.688 | 10.90 | 1.524 | |

| 30306 | EHHO | 3.5805 | 4.6056 | 1.4645 | 3.2652 | 1.5018 | 0.4 | 8.2577 | 1.9991 |

| HHO | 3.5805 | 5.2806 | 1.7469 | 3.3612 | 1.8673 | 0.4 | 8.4846 | 1.8735 | |

| WOA | 3.6121 | 5.2185 | 2.3656 | 3.4910 | 2.4582 | 0.5508 | 8.4326 | 1.9031 | |

| SCA | 3.5919 | 4.8920 | 2.4862 | 3.3418 | 2.5307 | 0.4543 | 8.3110 | 1.9706 | |

| GA [2] | 3.643 | 7.219 | 1.175 | 3.988 | 1.595 | 0.698 | 8.797 | 1.474 | |

| 32207 | EHHO | 2.8315 | 3.1627 | 2.0059 | 3.7359 | 1.5000 | 0.5 | 10.3718 | 2.0283 |

| HHO | 2.8315 | 5.2111 | 2.2368 | 4.1453 | 2.0808 | 0.5 | 11.2268 | 1.5556 | |

| WOA | 2.8315 | 2.9474 | 3.3453 | 3.6495 | 2.7443 | 0.5 | 10.1836 | 2.1339 | |

| SCA | 2.8392 | 3.2167 | 2.7584 | 3.7521 | 2.2280 | 0.5309 | 10.3400 | 2.0467 | |

| GA [2] | 2.962 | 4.331 | 2.787 | 4.471 | 2.447 | 1.023 | 10.69 | 1.786 | |

| 30307 | EHHO | 3.5035 | 4.5974 | 1.6982 | 3.4281 | 1.5178 | 0.8 | 8.2579 | 1.9992 |

| HHO | 3.5035 | 6.5665 | 3.6045 | 3.6882 | 3.6380 | 0.8 | 8.7935 | 1.7035 | |

| WOA | 3.5254 | 6.9000 | 2.6154 | 3.8705 | 2.7292 | 0.9043 | 8.9430 | 1.6198 | |

| SCA | 3.6216 | 3.6367 | 2.0072 | 3.8521 | 1.6918 | 1.3625 | 7.9418 | 2.1752 | |

| GA [2] | 3.556 | 7.325 | 2.069 | 4.101 | 2.264 | 1.050 | 8.739 | 1.531 | |

| 32208 | EHHO | 3.0175 | 3.3879 | 1.7375 | 4.0043 | 1.5 | 0.5 | 10.3753 | 2.0283 |

| HHO | 3.2353 | 4.0084 | 2.5722 | 4.9797 | 2.4025 | 1.3710 | 10.5557 | 1.9299 | |

| WOA | 3.0175 | 4.0227 | 2.6850 | 4.0948 | 2.5127 | 0.5 | 10.5523 | 1.9312 | |

| SCA | 3.1223 | 3.2859 | 2.6658 | 4.3794 | 2.3700 | 0.9190 | 10.2781 | 2.0834 | |

| GA [2] | 3.348 | 4.611 | 2.685 | 5.554 | 2.615 | 1.825 | 10.70 | 1.809 | |

The convergence curve of the optimization algorithms shows how to obtain the final result (Fig. 8). Better performance of EHHO than other algorithms is seen obviously. One of the main reasons for this high-quality result is to have a mature population at the beginning of the optimization process, which is attributed to the chaotic initialization. Another reason for the improved efficiency is due to using the flower pollination and 2-Opt algorithms. Using two other techniques, Gaussian mutation and chaotic local search, can facilitate the optimization process for finding the optimum solution at the end of the algorithm. Local optimum is a significant obstacle experienced by most algorithms; having an efficient structure for avoiding local optima is one of the advantages of suitable algorithms. Using a chaotic local search technique can assist the algorithm in preventing falls in the local optima. It is noteworthy that the structure of SCA is not appropriate for this TRB problem and has minimum convergence result compared to the other algorithms.

Fig. 8.

The convergence curve for different bearing numbers a 30204, b 30205, c 32205, and d 322/28

To see the proficiency of the algorithms in more detail, a statistical analysis is performed for some cases of tapered roller bearings. Table 10 shows the result of this analysis in terms of standard deviation (STD), worst solution, and best mean. The result of statistical analysis demonstrates that the EHHO has the lowest STD among the other algorithms. The lowest STD demonstrates that EHHO can easily find the maximum solution in every run of the optimization process and proves the robustness of this algorithm. Also, the best, mean, and worst solutions belong to the EHHO algorithm. After the EHHO algorithm, the SCA ranks second in terms of the lowest STD; however, SCA obtains the lowest best result.

Table 10.

Statistical results for four optimization algorithms

| Bearing number | Optimization method | Best | Mean | Worst | STD |

|---|---|---|---|---|---|

| 30204 | EHHO | 34,538.27 | 34,113.06 | 32,818.62 | 530.10 |

| HHO | 32,557.60 | 25,667.99 | 17,659.57 | 5590.53 | |

| WOA | 31,982.23 | 27,132.90 | 20,411.60 | 3410.19 | |

| SCA | 31,500.79 | 30,394.68 | 28,808.47 | 852.50 | |

| 30205 | EHHO | 39,864.26 | 39,616.49 | 38,925.36 | 326.06 |

| HHO | 36,069.50 | 24,354.68 | 17,916.79 | 6067.16 | |

| WOA | 38,224.26 | 32,832.10 | 27,058.17 | 3565.19 | |

| SCA | 36,641.31 | 35,693.81 | 34,614.29 | 746.37 | |

| 32205 | EHHO | 44,818.52 | 44,619.33 | 43,782.81 | 413.32 |

| HHO | 42,703.37 | 34,546.78 | 19,051.47 | 8463.81 | |

| WOA | 41,498.62 | 36,313.34 | 20,771.22 | 7514.12 | |

| SCA | 42,449.72 | 40,926.80 | 39,385.14 | 1092.16 | |

| 322/28 | EHHO | 52,898.87 | 52,747.44 | 51,864.48 | 338.20 |

| HHO | 51,313.38 | 38,916.64 | 26,217.00 | 9552.93 | |

| WOA | 51,360.63 | 40,454.10 | 27,595.49 | 8753.15 | |

| SCA | 49,833.04 | 47,829.98 | 46,190.28 | 1294.12 |

Bold values indicate the best results

LL lower limit, UL upper limit

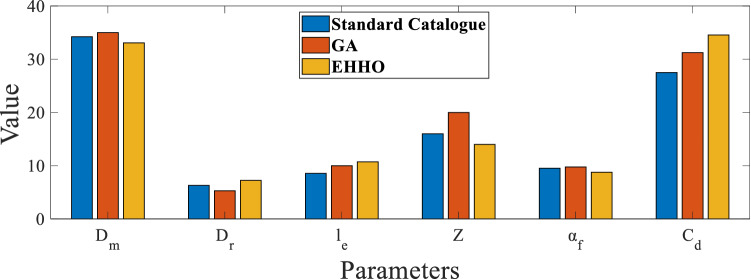

Figure 9 compares the design variables from the enhanced Harris hawk algorithm (EHHO), genetic algorithm (GA), and the standard catalogue. The graph in Fig. 9 shows that the EHHO algorithm successfully maximizes the fatigue life of bearing with a lower number of rollers. Also, Fig. 9 shows that the EHHO algorithm uses a higher mean diameter value and has sufficient length compared to GA and bearing standard.

Fig. 9.

Comparison of design variables: standard catalog, GA, and EHHO

Stability evaluation is one of the vital steps of performance verification [102, 103]. For quality evaluation metrics [104], we considered the average of solutions as the primary metric to judge the accuracy of the performance. We fixed fair judgments as per references [24, 85, 105, 106]. For having an exhaustive vision of the proposed algorithm, different algorithms are created with separate techniques used in EHHO. These algorithms are created based on techniques including chaotic initialization, Gaussian mutation, deferential evaluation, pollination algorithm, and chaotic local search mentioned in the optimization methodology section. The optimization process is performed for these algorithms in 500 iterations, and the results are summarized in Table 11. The convergence curves are shown in Fig. 10, in which using strategies of chaotic local search, chaotic initialization, and Gaussian mutation with standard HHO does not affect the accuracy significantly. By replacing the pollination algorithm and deferential evolution formulation with the hunting strategies of the Harris hawk algorithm, the results improve significantly. The EHHO, which is a combination of all the mentioned techniques, has the best results compared to the other ten algorithms in terms of precision, and its performance is not trapped to local optima. The STD result of EHHO also illustrates the performance of every element of this algorithm.

Table 11.

Statistical result for tapered roller bearing

| Bearing number | Optimization method | Best | Mean | Worst | STD |

|---|---|---|---|---|---|

| 32207 | HHO | 68,199.43 | 50,422.74 | 42,447.67 | 8681.153 |

| Cha-HHO | 66,916.79 | 48,827.31 | 44,035.26 | 7836.42 | |

| Gau-HHO | 62,472.2 | 55,858.61 | 52,381.36 | 3833.961 | |

| CLS-HHO | 58,549.38 | 51,582.96 | 34,497.03 | 9443.249 | |

| Cha-Gau-CLS-HHO | 63,363.86 | 54,171.72 | 45,688.48 | 5623.82 | |

| DE-Pol-HHO | 72,777.02 | 69,517.8 | 65,042.16 | 2953.21 | |

| Cha-DE-Pol-HHO | 74,132.74 | 69,715.49 | 65,524.29 | 2753.776 | |

| Gau-DE-Pol-HHO | 76,651.93 | 73,863.27 | 65,384.35 | 3386.548 | |

| CLS-DE-Pol-HHO | 73,378.96 | 68,353.78 | 62,805.36 | 3852.129 | |

| EHHO | 77,091.46 | 75,709.29 | 73,063.19 | 1264.924 | |

| 30307 | HHO | 62,170.57 | 45,428.87 | 39,287.2 | 8619.527 |

| Cha-HHO | 74,761.57 | 53,460.88 | 49,441.91 | 8823.459 | |

| Gau-HHO | 65,172.04 | 57,959.72 | 50,047.24 | 3569.721 | |

| CLS-HHO | 66,477.57 | 57,054.35 | 56,007.32 | 3310.984 | |

| Cha-Gau-CLS-HHO | 77,002.43 | 59,512.23 | 53,099.14 | 9651.839 | |

| DE-Pol-HHO | 79,627.92 | 71,732.16 | 46,078.51 | 10,340.03 | |

| Cha-DE-Pol-HHO | 81,008.2 | 76,080.66 | 68,414.83 | 4466.655 | |

| Gau-DE-Pol-HHO | 81,417.25 | 76,767.38 | 59,460.96 | 6366.401 | |

| CLS-DE-Pol-HHO | 81,663.6 | 74,097.82 | 70,330.55 | 3768.046 | |

| EHHO | 83,036.86 | 78,970.02 | 75,167.9 | 2782.379 | |

| 32208 | HHO | 73,873.29 | 56,993.26 | 42,935.66 | 8777.11 |

| Cha-HHO | 74,331.65 | 57,761.36 | 54,570.15 | 6962.738 | |

| Gau-HHO | 70,593.91 | 60,848.55 | 55,732.52 | 6369.845 | |

| CLS-HHO | 68,139.23 | 59,715.36 | 46,030.73 | 7312.302 | |

| Cha-Gau-CLS-HHO | 71,781.09 | 67,488.67 | 65,621.82 | 1777.807 | |

| DE-Pol-HHO | 83,381.08 | 77,385.17 | 70,067.29 | 4811.884 | |

| Cha-DE-Pol-HHO | 85,393.4 | 78,315.92 | 68,618.12 | 6102.392 | |

| Gau-DE-Pol-HHO | 85,506.08 | 83,351.81 | 78,067.71 | 2574.536 | |

| CLS-DE-Pol-HHO | 84,901.93 | 76,804.31 | 66,011.37 | 5429.324 | |

| EHHO | 86,603.7 | 84,233.2 | 80,135.14 | 2476.326 |

Bold values indicate the best results

Fig. 10.

Convergence curve for ten algorithms. a 32207, b 30307 c 32208

Engineering problems

There are many problems that their feature space is more complex than the assessed benchmark spaces [107–111]. Despite benchmark cases, engineering problems always involve some variables that are constrained [28, 112–115]. For testing and benchmarking the proposed algorithm, some popular and perplexing engineering functions are common in the literature. These engineering functions can challenge every optimization algorithm with their complexity in their structure. Most of these problems have more than three variables and constraints with many local optima. In this part of the paper, five well-known and challenging engineering problems are evaluated by the EHHO algorithm to examine the effectiveness and capability of this algorithm. The aspects of the engineering problems are described in the next subsections.

Cantilever beam

Figure 11 shows the structure of this benchmarked problem. This beam is exposed to the load at the right end. Five variables of beam design contain the vertical length of the connected boxes. The range of the variables is from 0 to 100. The target is to minimize the weight of the entire design. The optimization scheme of this problem is given in Eq. (64) below:

| 64 |

Fig. 11.

Cantilever beam design

The optimum solution of beam design is reported in Table 12. Moreover, Table 12 contains the optimum design results of other algorithms such as the modified firefly algorithm [116], crow search (CS) [117], and symbiotic organisms search (SOS) [118], and the standard Harris Hawk on the beam structure. The EHHO found 1.33995825 as the optimal solution of weight for the cantilever beam design, indicating the efficiency of this algorithm compared to the modified firefly algorithm, crow search algorithm, and symbiotic organisms algorithm. This case may be handy for building structures and how engineers can deal with a component [119].

Table 12.

Comparison results for cantilever beam design

| Optimization method | Optimum variables | Optimum cost | ||||

|---|---|---|---|---|---|---|

| Weight | ||||||

| EHHO | 6.0143 | 5.3029 | 4.4964 | 3.5053 | 2.1548 | 1.33995825 |

| HHO | 6.1016 | 5.343 | 4.4237 | 3.4533 | 2.1582 | 1.3403595 |

| MFA [116] | 5.98487 | 5.3167269 | 4.49733 | 3.5136165 | 2.161620 | 1.3399881 |

| CS [117] | 6.0089 | 5.3049 | 4.5023 | 3.5077 | 2.1504 | 1.33999 |

| SOS [118] | 6.01878 | 5.30344 | 4.49587 | 3.49896 | 2.15564 | 1.33996 |

Bold value indicates the best results

Pressure vessel

The cost of construction of every piece of equipment is substantial for manufacturers, and the minimization of expenses can be formulated as an interesting problem. The variables' vector of the pressure vessel problem contains some critical parameters such as the thickness of the head and shell ( and , respectively) and cylindrical curvature radius () and distance (). The limitation of the first and second variables is between 0 and 99, and the criteria for the third and fourth variables are between 10 and 200. The layout for this structure is as follows:

| 65 |

The result for this problem is presented in Table 13. It is obvious that the fabrication cost of the pressure vessel design related to EHHO is better than that of other algorithms mentioned in Table 13. Note that EHHO has improved the optimal solution by 2% compared to the standard HHO.

Table 13.

Comparison results for pressure vessel design

| Optimization method | Optimum variables | Optimum cost | |||

|---|---|---|---|---|---|

| Fabrication cost | |||||

| EHHO | 0.77817 | 0.38465 | 40.3196 | 200 | 5885.36355 |

| HHO [50] | 0.81758 | 0.40729 | 42.09174 | 176.75873 | 6000.46259 |

| CMVHHO [120] | 0.849756 | 0.421472 | 43.900722 | 155.517156 | 6039.6918 |

| ADHHO [121] | 0.87015 | 0.43114 | 45.01254 | 143.5317 | 6072.56 |

| CCMWOA [97] | 0.77966 | 0.38561 | 40.34738 | 199.6141 | 5895.2039 |

| WOA [88] | 0.81250 | 0.43750 | 42.09820 | 176.6389 | 6059.7410 |

| VPLSCA [122] | 0.8152 | 0.4265 | 42.0851 | 176.73154 | 6042.711935 |

| UBSCIW [123] | 0.7798 | 0.3866 | 40.3884 | 199.0685 | 5889.2305 |

| ESSA [124] | 0.781463 | 0.386278 | 40.4903 | 197.63744 | 5890.9885 |

Bold value indicates the best results

Spring geometry

The objective function of this design problem is to minimize the weight of a tension/compression spring. Shear stress and deflection influence the design of the spring, which can be related to constraints of spring. Three variables of coil number (), cord diameter (), and mean diameter () are chosen in the design vector to provide the lowest weight for the spring. The range for () is 0.05–2, for () is 0.25–1.3, and for the last variable () is 2–15. The spring formulation is derived as below:

| 66 |

Table 14 summarizes the value obtained from the optimization process. The EHHO diminishes the weight to an accuracy of 0.01266 kg compared to the other algorithms such as modified whale algorithm (CCMWOA) [97], enhanced salp swarm (ESSA) [124], whale algorithm (WOA) [88], and modified HHO (GCHHO) [59].

Table 14.

Results for tension/compression spring design

| Optimization method | Optimum variables | Optimum cost | ||

|---|---|---|---|---|

| Weight | ||||

| EHHO | 0.0516751748 | 0.356383766 | 11.30857249 | 0.012665236 |

| HHO | 0.05179 | 0.3593 | 11.13885 | 0.012665443 |

| MHHO [125] | 0.051654 | 0.355881 | 11.33883 | 0.01266619 |

| CCMWOA [97] | 0.051843 | 0.360444 | 11.07410 | 0.0126660 |

| WOA [88] | 0.051207 | 0.345215 | 12.0043032 | 0.0126763 |

| ESSA [124] | 0.051719 | 0.357434 | 11.247123 | 0.0126653 |

| GCHHO [59] | 0.0516479 | 0.355729 | 11.3471231 | 0.012665264 |

Bold value indicates the best results

Welded beam

There are 4 design variables for the welded beam design optimization problem (thickness, , height, , length of the bar,, with weld). There are 7 constraints, and most of them relate to load, stresses on the bar, and end deflection on the spring. The structural formulation, range of variables, and some constant parameters are provided by Eq. (67):

where

| 67 |

The results in Table 15 show the excellence of the proposed algorithm.

Table 15.

Results for welded beam design

| Optimization method | Optimum variables | Optimum cost | |||

|---|---|---|---|---|---|

| Fabrication cost | |||||

| EHHO | 0.2057003 | 3.4711372 | 9.03668181 | 0.20572935 | 1.72490231 |

| HHO | 0.204039 | 3.531061 | 9.027463 | 0.206147 | 1.73199057 |

| CMVHHO [120] | 0.205331 | 3.4787 | 9.039544 | 0.205723 | 1.726023 |

| WOA [88] | 0.205396 | 3.484293 | 9.037426 | 0.206276 | 1.730499 |

Bold value indicates the best results

Speed reducer

The scheme of the speed reducer is depicted in Fig. 12. The speed reducer shaft is exposed to stress and transverse deflection, and the gear teeth tolerate stresses such as bending stress, which can be considered constraints. The optimization problem for the speed reducer problem has seven variables and 11 nonlinear constraints. The variables are explained in Fig. 12. The formulation for the optimization design of the speed reducer can be expressed in Eq. (68):

| 68 |

Fig. 12.

Speed reducer design problem

The speed reducer’s optimum weight is reported in Table 16 for the algorithms. The EHHO reduces the optimum cost to 2994.4710 kg, which is a competitive result compared to other algorithms.

Table 16.

Results for speed reducer design

| Optimization method | Optimum variables | Optimum cost | ||||||

|---|---|---|---|---|---|---|---|---|

| Weight | ||||||||

| EHHO | 3.5 | 0.7 | 17 | 7.3 | 7.7153 | 3.3502 | 5.2866 | 2994.4710 |

| HHO | 3.50253 | 0.7 | 17 | 7.3 | 7.9206 | 3.3538 | 5.2867 | 3000.9479 |

| m-HHO [62] | 3.5 | 0.7 | 17 | 7.3 | 7.8 | 3.35127 | 5.28668 | 2996.6162 |

| GLF-GWO [126] | 3.5000091 | 0.7 | 17 | 7.3 | 7.8 | 3.3502335 | 5.2866856 | 2996.3680 |

Bold value indicates the best results

Conclusions and future works

In this paper, a novel algorithm is proposed to enhance the performance of the Harris hawk optimization algorithm (HHO) based on new features, which improve the exploration and exploitation phases of the original HHO algorithm. At first, chaotic initialization is used to explore the search area extensively to cover and generate all possible solutions equally. In this way, a mature population is created. After that, two of the Harris hawk pouncing strategies are changed to generate more appropriate agents for updating the population. Also, the Gaussian strategy makes the update of the population boosted. At the end of the proposed algorithm, a chaotic local search with the shrinking mode is exploited to avoid possible local optima. The proposed algorithm is tested on tapered roller bearings successfully. The objective function is related to the maximization of the fatigue life of TRB. It contains nine variables and 26 constraints. The results show that the best result can be obtained by the application of the enhanced Harris hawk algorithm (EHHO) on the design optimization of the fatigue life of TRB. In addition, the mentioned algorithm is tested on some common engineering problems in the literature. Similarly, the optimization results are improved using the EHHO algorithm compared to the algorithms from the literature. Therefore, the proposed algorithm can be used in complex engineering problems where there are many design variables.

Acknowledgements

This paper results from the MSc thesis of the first name that defended his thesis successfully within the revision of this research. We acknowledge the supports of Ozyegin University. We also acknowledge reviewers’ comments and the editor’s efforts, which significantly enhanced this research’s excellence.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Ahmad Abbasi, Email: ahmad.abbasi@ozu.edu.tr.

Behnam Firouzi, Email: behnam.firoozi@ozu.edu.tr.

Polat Sendur, Email: polat.sendur@ozyegin.edu.tr.

Ali Asghar Heidari, Email: as_heidari@ut.ac.ir, Email: aliasghar68@gmail.com.

Huiling Chen, Email: chenhuiling.jlu@gmail.com.

Rajiv Tiwari, Email: rtiwari@iitg.ac.in.

References

- 1.Jat A, Tiwari R. Multi-objective optimization of spherical roller bearings based on fatigue and wear using evolutionary algorithm. J King Saud Univ-Eng Sci. 2020;32(1):58–68. [Google Scholar]

- 2.Tiwari R, Sunil KK, Reddy R. An optimal design methodology of tapered roller bearings using genetic algorithms. Int J Comput Methods Eng Sci Mech. 2012;13(2):108–127. doi: 10.1080/15502287.2011.654375. [DOI] [Google Scholar]

- 3.Senthil Kumaran S, Srinivasan K. A review on life increment of tapered roller bearings. J Crit Rev. 2020;7(6):764–775. [Google Scholar]

- 4.Bhowmick H, Choudhary RTG (2006) Quasi-static analysis of tapered roller bearings and comparison of bearing lives for different roller surface profiles. In: 2nd international congress on computational mechanics and simulation, 2006

- 5.Hu Y, et al. Corrosion fatigue lifetime assessment of high-speed railway axle EA4T steel with artificial scratch. Eng Fract Mech. 2021;245:107588. doi: 10.1016/j.engfracmech.2021.107588. [DOI] [Google Scholar]

- 6.Tiwari R, Chandran R (2013) Thermal based optimum design of tapered roller bearing through evolutionary Algorithm. In: Gas turbine India conference, vol 35161. American Society of Mechanical Engineers, p V001T05A021

- 7.Kumar KS, Tiwari R, Prasad P. An optimum design of crowned cylindrical roller bearings using genetic algorithms. J Mech Des. 2009 doi: 10.1115/1.3116344. [DOI] [Google Scholar]

- 8.Verma SK, Tiwari R. Robust optimum design of tapered roller bearings based on maximization of fatigue life using evolutionary algorithm. Mech Mach Theory. 2020;152:103894. doi: 10.1016/j.mechmachtheory.2020.103894. [DOI] [Google Scholar]

- 9.Kalyan M, Tiwari R, Ahmad MS. Multi-objective optimization in geometric design of tapered roller bearings based on fatigue, wear and thermal considerations through genetic algorithms. Sadhana. 2020 doi: 10.1007/s12046-020-01385-3. [DOI] [Google Scholar]

- 10.Choi D-H, Yoon K-C. A design method of an automotive wheel-bearing unit with discrete design variables using genetic algorithms. J Trib. 2001;123(1):181–187. doi: 10.1115/1.1329878. [DOI] [Google Scholar]

- 11.Chakraborty I, et al. Rolling element bearing design through genetic algorithms. Eng Optimiz. 2003;35(6):649–659. doi: 10.1080/03052150310001624403. [DOI] [Google Scholar]

- 12.Dandagwhal R, Kalyankar V. Design optimization of rolling element bearings using advanced optimization technique. Arab J Sci Eng. 2019;44(9):7407–7422. doi: 10.1007/s13369-019-03767-0. [DOI] [Google Scholar]

- 13.Panda S, et al. Re-examination for effect of ball race conformity on life of rolling element bearing using Metaheuristic. Int J Adv Mech Eng. 2018;8(1):285–294. [Google Scholar]

- 14.Kang K, et al. Robust design optimization of an angular contact ball bearing under manufacturing tolerance. Struct Multidiscip Optim. 2019;60(4):1645–1665. doi: 10.1007/s00158-019-02335-2. [DOI] [Google Scholar]

- 15.Tiwari R, Waghole V. Optimization of spherical roller bearing design using artificial bee colony algorithm and grid search method. Int J Comput Methods Eng Sci Mech. 2015;16(4):221–233. doi: 10.1080/15502287.2015.1045998. [DOI] [Google Scholar]

- 16.Zhou Y, et al. Video coding optimization for virtual reality 360-degree source. IEEE J Select Topics Signal Process. 2019;14(1):118–129. doi: 10.1109/JSTSP.2019.2957952. [DOI] [Google Scholar]

- 17.Wu C, et al. Differential received signal strength based RFID positioning for construction equipment tracking. Adv Eng Inf. 2019;42:100960. doi: 10.1016/j.aei.2019.100960. [DOI] [Google Scholar]

- 18.Xue X, et al. Affine transformation-enhanced multifactorial optimization for heterogeneous problems. IEEE Trans Cybernet. 2020 doi: 10.1109/TCYB.2020.3036393. [DOI] [PubMed] [Google Scholar]

- 19.Ding L, et al. Definition and application of variable resistance coefficient for wheeled mobile robots on deformable terrain. IEEE Trans Rob. 2020;36(3):894–909. doi: 10.1109/TRO.2020.2981822. [DOI] [Google Scholar]

- 20.Wu C, et al. Critical review of data-driven decision-making in bridge operation and maintenance. Struct Infrastruct Eng. 2020 doi: 10.1080/15732479.2020.1833946. [DOI] [Google Scholar]

- 21.Jiang Q, et al. Optimizing multistage discriminative dictionaries for blind image quality assessment. IEEE Trans Multimedia. 2017;20(8):2035–2048. doi: 10.1109/TMM.2017.2763321. [DOI] [Google Scholar]

- 22.Wang B, et al. A kind of improved quantum key distribution scheme. Optik. 2021;235:166628. doi: 10.1016/j.ijleo.2021.166628. [DOI] [Google Scholar]

- 23.Yang Y, et al. New pore space characterization method of shale matrix formation by considering organic and inorganic pores. J Nat Gas Sci Eng. 2015;27:496–503. doi: 10.1016/j.jngse.2015.08.017. [DOI] [Google Scholar]

- 24.Bo W, et al. Malicious URLs detection based on a novel optimization algorithm. IEICE Trans Inf Syst. 2021;104(4):513–516. doi: 10.1587/transinf.2020EDL8147. [DOI] [Google Scholar]

- 25.Alam Z, et al. Experimental and numerical investigation on the complex behaviour of the localised seismic response in a multi-storey plan-asymmetric structure. Struct Infrastruct Eng. 2021;17(1):86–102. doi: 10.1080/15732479.2020.1730914. [DOI] [Google Scholar]

- 26.Zuo X, et al. The modeling of the electric heating and cooling system of the integrated energy system in the coastal area. J Coast Res. 2020;103(SI):1022–1029. doi: 10.2112/SI103-213.1. [DOI] [Google Scholar]

- 27.Zhu D, et al. Evaluating the vulnerability of integrated electricity-heat-gas systems based on the high-dimensional random matrix theory. CSEE J Power Energy Syst. 2019;6(4):878–889. [Google Scholar]

- 28.Zhang Y, et al. Analysis of grinding mechanics and improved predictive force model based on material-removal and plastic-stacking mechanisms. Int J Mach Tools Manuf. 2017;122:81–97. doi: 10.1016/j.ijmachtools.2017.06.002. [DOI] [Google Scholar]

- 29.Yin F, et al. Multifidelity genetic transfer: an efficient framework for production optimization. SPE J. 2021 doi: 10.2118/205013-PA. [DOI] [Google Scholar]

- 30.Eshtay M, Faris H, Heidari AA, Ala’M AZ, Aljarah I. AutoRWN: automatic construction and training of random weight networks using competitive swarm of agents. Neural Comput Appl. 2021;33(11):5507–5524. doi: 10.1007/s00521-020-05329-0. [DOI] [Google Scholar]

- 31.Faris H, et al. An intelligent system for spam detection and identification of the most relevant features based on evolutionary Random Weight Networks. Inf Fus. 2019;48:67–83. doi: 10.1016/j.inffus.2018.08.002. [DOI] [Google Scholar]

- 32.Faris H, et al. Time-varying hierarchical chains of salps with random weight networks for feature selection. Expert Syst Appl. 2019;140:112898. doi: 10.1016/j.eswa.2019.112898. [DOI] [Google Scholar]

- 33.Lin A, et al. Predicting intentions of students for master programs using a chaos-induced sine cosine-based fuzzy k-Nearest neighbor classifier. Ieee Access. 2019;7:67235–67248. doi: 10.1109/ACCESS.2019.2918026. [DOI] [Google Scholar]

- 34.Liu G, et al. Prediction optimization of cervical hyperextension injury: kernel extreme learning machines with orthogonal learning butterfly optimizer and broyden—Fletcher-Goldfarb-Shanno Algorithms. IEEE Access. 2020;8:119911–119930. doi: 10.1109/ACCESS.2020.3003366. [DOI] [Google Scholar]

- 35.Liu G, et al. Predicting cervical hyperextension injury: a covariance guided sine cosine support vector machine. IEEE access. 2020;8:46895–46908. doi: 10.1109/ACCESS.2020.2978102. [DOI] [Google Scholar]

- 36.Aljarah I, et al. Multi-verse optimizer: theory, literature review, and application in data clustering. In: Mirjalili S, Song-Dong J, Lewis A, et al., editors. Nature-inspired optimizers: theories, literature reviews and applications. Cham: Springer International Publishing; 2020. pp. 123–141. [Google Scholar]

- 37.Bai B, et al. Application of adaptive reliability importance sampling-based extended domain PSO on single mode failure in reliability engineering. Inf Sci. 2021;546:42–59. doi: 10.1016/j.ins.2020.07.069. [DOI] [Google Scholar]

- 38.Ma X, Zhang K, Zhang L, Yao C, Yao J, Wang H, et al. Data-driven niching differential evolution with adaptive parameters control for history matching and uncertainty quantification. SPE J. 2021;26(02):993–1010. doi: 10.2118/205014-PA. [DOI] [Google Scholar]

- 39.Sun G, Li C, Deng L. An adaptive regeneration framework based on search space adjustment for differential evolution. Neural Comput Appl. 2021 doi: 10.1007/s00521-021-05708-1. [DOI] [Google Scholar]

- 40.Zhao D, et al. Chaotic random spare ant colony optimization for multi-threshold image segmentation of 2D Kapur entropy. Knowl-Based Syst. 2020 doi: 10.1016/j.knosys.2020.106510. [DOI] [Google Scholar]

- 41.Hu J, et al. Orthogonal learning covariance matrix for defects of grey wolf optimizer: insights, balance, diversity, and feature selection. Knowl-Based Syst. 2021;213:106684. doi: 10.1016/j.knosys.2020.106684. [DOI] [Google Scholar]

- 42.Shan W, et al. Double adaptive weights for stabilization of moth flame optimizer: balance analysis, engineering cases, and medical diagnosis. Know-Based Syst. 2020;214:106728. doi: 10.1016/j.knosys.2020.106728. [DOI] [Google Scholar]