Abstract

Following a mandate from the European Commission, EFSA has developed a Guidance on Technical Requirements (Guidance on Particle‐TR), defining the criteria for assessing the presence of a fraction of small particles, and setting out information requirements for applications in the regulated food and feed product areas (e.g. novel food, food/feed additives, food contact materials and pesticides). These requirements apply to particles requiring specific assessment at the nanoscale in conventional materials that do not meet the definition of engineered nanomaterial as set out in the Novel Food Regulation (EU) 2015/2283. The guidance outlines appraisal criteria grouped in three sections, to confirm whether or not the conventional risk assessment should be complemented with nanospecific considerations. The first group addresses solubility and dissolution rate as key physicochemical properties to assess whether consumers will be exposed to particles. The second group establishes the information requirements for assessing whether the conventional material contains a fraction or consists of small particles, and its characterisation. The third group describes the information to be presented for existing safety studies to demonstrate that the fraction of small particles, including particles at the nanoscale, has been properly evaluated. In addition, in order to guide the appraisal of existing safety studies, recommendations for closing the data gaps while minimising the need for conducting new animal studies are provided. This Guidance on Particle‐TR complements the Guidance on risk assessment of nanomaterials to be applied in the food and feed chain, human and animal health updated by the EFSA Scientific Committee as co‐published with this Guidance. Applicants are advised to consult both guidance documents before conducting new studies.

Keywords: nanomaterial, nanofraction, solubility, dissolution/degradation rate, sample dispersion protocol, electron microscopy, particle size distribution

Short abstract

This publication is linked to the following EFSA Journal article: http://onlinelibrary.wiley.com/doi/10.2903/j.efsa.2021.6768/full

This publication is linked to the following EFSA Supporting Publications article: http://onlinelibrary.wiley.com/doi/10.2903/sp.efsa.2021.EN-6804/full

Summary

In the context of regulated food and feed products, when an application concerns a material that meets the definition of engineered nanomaterial set out in Regulation (EU) 2015/2283, the application must follow the EFSA Scientific Committee Guidance on risk assessment of nanomaterials to be applied in the food and feed chain, human and animal health, published in 2018 and updated in 2021, which is also used by EFSA when conducting its assessment. Nanospecific considerations for risk assessment may be required for conventional materials that contain a fraction of small particles, but do not meet the definition of engineered nanomaterial. Such particles may be formed naturally or as by‐products in the production process, or during handling and processing of foods.

Following a mandate from the European Commission, the European Food Safety Authority (EFSA) has developed this Guidance on Technical Requirements (Guidance on Particle‐TR), setting out the information requirements for applications in the regulated food and feed product areas, and establishing criteria for assessing the presence of a fraction of small particles, including particles requiring specific assessment at the nanoscale, in conventional materials which do not meet the definition of engineered nanomaterial set out in the Novel Food Regulation (EU) 2015/2283.

This document complements the EFSA Scientific Committee Guidance on risk assessment of nanomaterials to be applied in the food and feed chain, human and animal health mentioned above and should be considered by the applicant when preparing the application and dossier, and then by the EFSA Panels and units when considering the information submitted. Applicants are advised to consult both guidance documents before conducting new studies.

The present Guidance on Particle‐TR provides mandatory information requirements for novel food applications submitted in accordance to Regulation (EU) 2015/2283, and for those regulated food products to which the engineered nanomaterial definition is also directly or indirectly applicable: food flavourings, food additives, feed additives, vitamins and minerals used in food in accordance with Regulation (EC) No 1925/2006 and/or in food supplements in accordance with Directive 2002/46/EC as well as vitamins, minerals or other substances used in food for specific groups in accordance with Regulation (EU) No 609/2013. In order to maintain the coherence of the EFSA assessments on nanoparticles, this Guidance on Particle‐TR is also relevant for conventional materials in areas not covered by the engineered nanomaterial definition in food and feed (e.g. substances used in food contact materials and active substances in plant protection products), complementing the applicable specific guidance, e.g. the note for guidance on food contact materials (EFSA CEP Panel, 2008), and the Guidance documents on the risk assessment of pesticides.

The document guides the applicant on different ways for confirming when a conventional risk assessment is sufficient. The applicants may select, according to their knowledge and available information, the best appraisal route or combination of appraisal routes to justify: (a) the absence of a fraction of small particles, or (b) that the material contains a fraction of small particles but it is covered by the conventional risk assessment and does not require a separate assessment regarding nanoscale properties. The guidance also provides information related to best practices for reporting and assessing existing safety studies, and recommendations for generating additional information.

This Guidance on Particle‐TR is applicable to all chemical materials, marketed or to be marketed as substances or mixtures, to be assessed by EFSA, including mixtures and products marketed as liquid formulations unless the information confirms that they are true liquids and do not contain small particles in suspension. The characterisation of the fraction of small particles, including the particle size distribution, is needed in all cases unless the applicant demonstrates that the material will be fully dissolved under the intended use conditions and consumers will not be exposed to particles. For multi‐constituent substances and mixtures, the information to be submitted should cover each single constituent or each component in the mixture, as well as the multi‐component material. In the case of (a) botanicals and other chemically complex materials of biological origin with unknown or variable composition, (b) macromolecules of biological origin (e.g. enzymes and other proteins) or (c) other similar cases, the applicant should provide a rationale demonstrating that an assessment of the fraction of small particles including nanoparticles is not needed, or that is already covered in the safety assessment process.

The general principles and the summary of appraisal routes that applicants may follow to confirm that a fraction of small particles is either not present or covered by the conventional risk assessment are presented in Section 2. Solubility and dissolution rate can be used to demonstrate that under the anticipated use conditions the material will be fully dissolved in the marketed product, in food or, following ingestion, during the gastrointestinal tract processes, and that consumers will not be exposed to particles after food consumption. Under these circumstances, the conventional safety assessment is appropriate and no further characterisation of the fraction of small particles is required.

Section 3 describes the information requirements and methods that should be used when characterisation of the particle size distribution is needed. Screening methods are sufficient when the applicant is able to demonstrate that the particle size is equal to or larger than 500 nm and that the material contains less than 10% of particles (number‐based) with at least one dimension smaller than 500 nm; the detection capability of the method(s) used for this assessment should provide convincing evidence that particles smaller than 500 nm are adequately counted. As a proper sample dispersion is essential for the characterisation of the size distribution, a dispersion protocol to be followed by the applicants is included in Section 3.2.

Quantitative methods for characterising the particle size distribution are required for materials containing a fraction of small particles (particles < 500 nm). Electron microscopy is the preferred method and Appendix A provides information on how this characterisation should be reported in the application. A pragmatic trigger for materials consisting of or containing a fraction of small particles is applied when the large majority of the material is not at the nanoscale, but a tiny tail within the particle size distribution at the nanoscale may be present due to the manufacturing process. The trigger is that the material should have less than 10% of the particles (number‐based) of the sub‐500 nm fraction with at least one external dimension smaller than 250 nm. For conventional materials, this situation implies that the total mass of particles at the nanoscale is very low; in these cases, a conventional risk assessment is sufficient and no further assessment for properties at the nanoscale is needed. In addition to the numerical criteria, a description of the fraction of small particles (i.e. particles smaller than 500 nm) should confirm that the particles at the nanoscale are just part of the size distribution tail resulting from the same manufacturing process of the powder, and that all particles have similar characteristics except those directly related to size.

Section 4 presents the information to be provided on existing safety studies on conventional materials, not originally designed to specifically consider the presence of a fraction of small particles. There are two essential conditions to address that the possible adverse effects linked to the fraction of small particles, including nanoparticles, are covered by the study: (a) the available information should demonstrate that the test material included the fraction of small particles, and (b) the suitability of the study selection, study design and the level of dispersion/degree of agglomeration of the test material for assessing the hazard of small particles including nanoparticles.

Regarding the first condition, the applicant should provide at least the characterisation of the fraction of small particles of the marketed material and the variability between production processes and batches. Ideally, a comparison of the characterisation of the fraction of particles in the material as marketed and in the material used for the safety study should be provided. In other cases, the comparison should focus on the manufacturing process in order to demonstrate that the test material was produced by the same manufacturing process and current production conditions, and that the test material was in compliance with the current material specifications. If the manufacturing process has been modified, information addressing the changes regarding the fraction of small particles, should be provided. In case of broad‐range technical specifications of the bulk material that is placed on the market, the full range of small particles or at least the conditions representing the worst case, have to be covered by the test materials used in the existing studies.

Regarding the second condition, the criteria for checking the adequacy of the study selection, study design, and level of dispersion/degree of agglomeration are presented in Section 4.2. Information on the design and execution, in addition to a detailed characterisation of the test material, of any existing toxicity study is required to ensure that the study had addressed specific aspects related to particles in the nanoscale; including information on preparation of the test material to understand whether or not it would have minimised aggregation/agglomeration of the particles, the matrix/vehicle used, and the mode of administration. Specific recommendations are provided for the appraisal of in vivo and in vitro studies, and Appendix B describes best practices for reporting the information. Additional considerations are required for genotoxicity and toxicokinetic studies.

A decision process for assessing data gaps, determining if new additional studies are needed, and establishing the testing strategy are presented in Section 4.3; recommendations for conducting new studies are provided in Section 5. Applicants should consult these sections before conducting new studies, and follow the recommendations in order to avoid unnecessary duplication of animal studies.

1. Introduction

1.1. Background and Terms of Reference as provided by the European Commission

The engineered nanomaterial definition set out in Regulation (EU) 2015/22831 (the Novel Food Regulation) is also directly or indirectly applicable to other EU legislation concerning regulated food products (food flavourings, food additives, feed additives, vitamins and minerals used in food in accordance with Regulation (EC) No 1925/20062 and/or in food supplements in accordance with Directive 2002/46/EC3 as well as vitamins, minerals or other substances used in food for specific groups in accordance with Regulation (EU) No 609/20134), and in food information to consumers, and implies significant requirements in terms of the premarket safety assessment and the post market labelling requirements for foods containing engineered nanomaterials.

In the context of regulated food and feed products that are subject to the engineered nanomaterial definition set out in Regulation (EU) 2015/2283,1 we are currently facing two situations on nanomaterials that link their regulatory status with their safety assessment:

When an application concerns a material that meets the definition of engineered nanomaterial set out in the Novel Food Regulation (EU) 2015/2283, the application must contain all the information needed, e. g. description of physical and chemical properties, technical, biological and toxicological data on the material as required by the specific legislation, in order to allow for its safety assessment by EFSA, leading to its eventual authorisation. In terms of the safety assessment, EFSA is conducting its assessment in line with its recently updated guidance on risk assessment of the application of nanoscience and nanotechnologies in the food and feed chain.

A potentially more complex situation arises when an application concerns a conventional material which does not meet the definition of engineered nanomaterial but may contain small particles including particles at the nanoscale (< 100 nm in one or more dimensions). Particles at the nanoscale can be formed naturally or as by‐products in the production process or during handling and processing of the foods.

To proactively ensure that materials that fall in case (2) above, are properly assessed for safety by the applicants themselves when they conduct the safety tests required by the applicable legislation and by EFSA when the application is evaluated, technical guidance for applicants is necessary. It is therefore appropriate to request that EFSA develops technical guidance setting out the technical information that will need to be part of a new regulated food or feed application, to demonstrate whether a conventional material, which is not covered by the definition of engineered nanomaterial set out in the Novel Food Regulation (EU) 2015/2283, consists of or contains a fraction of small particles, including particles at the nanoscale.

TERMS OF REFERENCE

In accordance with Art 29 (1) of Regulation (EC) No 178/20025, the European Commission asks the European Food Safety Authority to develop technical guidance setting out the information requirements for applications in the regulated food and feed product areas of conventional materials which do not meet the definition of engineered nanomaterial set out in the Novel Food Regulation (EU) 2015/22831, in order to demonstrate whether a portion or the whole of the material is in the nanoscale.

Furthermore, for those materials which have been determined to contain a fraction of small particles, including particles at the nanoscale, the European Commission asks the European Food Safety Authority to include in the guidance the information requirements demonstrating that the nanoscale fraction of the material was properly evaluated in the safety studies of the material.

The guidance should in particular address the following parameters and include any other technical or scientific elements considered appropriate to be included:

-

a)

The physicochemical criteria that will help identify/signal materials that are likely to consist of small particles, including nanoparticles, or contain a fraction of small particles, including nanoparticles, in a given regulated food or feed product.

-

b)

The technical and scientific information (e.g. particle size distribution including necessary meta‐information) that the applicant will need to include in the application if a material meets the above criteria that will document the presence or absence of small particles, or a fraction of small particles, including nanoparticles, in the material and/or in the final regulated food and feed products.

-

c)

When applicable, the evidence requirements, in line with the EFSA guidance on risk assessment of the application of nanosciences and nanotechnologies in the food and feed chain that will demonstrate that the safety studies conducted included the fraction of small particles, including nanoparticles, so that EFSA can carry out the proper safety assessment of the material.

1.2. Interpretation of the Terms of Reference

In line with the Terms of Reference, EFSA has produced this Guidance on Technical Requirements addressing the presence of small particles (hereafter ‘Guidance on Particle‐TR’) describing the information to be submitted by applicants in the food and feed areas to allow the safety assessment of the materials with a fraction of small particles, including particles at the nanoscale.

In order to maintain the coherence of the EFSA assessments on nanoparticles, this Guidance on Particle‐TR is also relevant for conventional materials in areas not covered by the engineered nanomaterial definition in food and feed (e.g. substances used in food contact materials (FCMs) and active substances in plant protection products), complementing the applicable specific guidance, e.g. the note for guidance on food contact materials (EFSA CEP Panel, 2008), and the Guidance documents on the risk assessment of pesticides.

It should be noted that the definition of engineered nanomaterials also includes structures with size above the order of 100 nm that retain properties that are characteristic of the nanoscale.

1.3. Implementation of this Guidance on Technical Requirements in EFSA regulatory assessments

This Guidance on Particle‐TR provides mandatory information requirements for novel food applications submitted in accordance to Regulation (EU) 2015/2283 (the Novel Food Regulation), and for those regulated food products for which the engineered nanomaterial definition is also directly or indirectly applicable: food flavourings, food additives, feed additives, vitamins and minerals used in food in accordance with Regulation (EC) No 1925/2006 and/or in food supplements in accordance with Directive 2002/46/EC as well as vitamins, minerals or other substances used in food for specific groups in accordance with Regulation (EU) No 609/2013.

This Guidance on Particle‐TR should be considered by the applicants when preparing the application/dossier, and then by the EFSA Panels and Units when assessing the information submitted. The document guides the process to decide whether or not the material, or a fraction of it, does require specific assessment of properties at the nanoscale. This Guidance on Particle‐TR provides ways for confirming that a conventional risk assessment is sufficient. The applicants may select, according to their knowledge and available information, the best appraisal route or combination of appraisal routes to justify (a) the absence of a fraction of small particles, or (b) that the material contains a fraction of small particles but that this fraction is covered by the conventional risk assessment and relevant sectoral guidance documents, and does not require a separate assessment for the nanoscale. When preparing the application/dossier, if a particular appraisal route does not provide adequate justification regarding points (a) and (b) above, the applicant may consider other appraisal routes (see Figure 1 for details on the possible appraisal routes and links to the different sections of this document), nevertheless all information should be presented in the application/dossier. Some pieces of information, such as verifiable quantitative assessment of solubility or dissolution rates, may be essential. The Guidance also provides information related to best practices for reporting and assessing existing studies, and recommendations for generating additional information.

Figure 1.

Decision process for selecting the applicable guidance document(s) to be used for the risk assessment of the material regarding the assessment of small particles

In order to implement the Terms of Reference, this Guidance includes a set of working definitions and criteria with numerical thresholds, triggering information requirements applicable to conventional materials. The thresholds have been selected considering the need for achieving a high level of protection for consumers, and are based on scientific knowledge and technical reasons related to analytical limitations to the techniques available at present. The details for the selection are presented in the relevant sections and summarised in the Glossary. These thresholds have been specifically selected for the purpose of this Guidance, and are not necessarily relevant or applicable outside the context of setting information requirements for the risk assessment of conventional materials, and should in no way be seen as interpretation or implementation of existing regulatory thresholds, if any such thresholds are in place.

This Guidance on Particle‐TR complements the EFSA Scientific Committee Guidance on risk assessment of nanomaterials to be applied in the food and feed chain, human and animal health (EFSA Scientific Committee, 2021; hereafter ‘Guidance on Nano‐RA’). Applicants and other readers are referred to that guidance regarding the specific scientific elements to be considered when assessing the risk of particles at the nanoscale. It should be considered that the Guidance on Nano‐RA is currently being updated. Figure 1 presents the connectivity between this Guidance on Particle‐TR, the Guidance on Nano‐RA and the sectoral guidance documents; clarifying under which conditions the material requires assessment at the nanoscale following the Guidance on Nano‐RA.

According to this decision process, applicants, interested parties and risk assessors should apply this Guidance on Particle‐TR when assessing whether the material contains small particles. A full assessment addressing the properties at the nanoscale, in line with the Guidance on Nano‐RA, is required if the applicant or the risk assessor concludes that the material:

fulfils the definition of engineered nanomaterial according to the Novel Food Regulation (Regulation (EU) 2015/2283),

is a substance to be used to manufacture FCMs, which is in nanoform in accordance with Article 9(2) of Commission Regulation (EU) 10/2011, or deliberately engineered to particle size which exhibit functional physical and chemical properties that significantly differ from those at a larger scale in accordance to Article 5(2)(c)(ii) of Commission Regulation (EC) No 450/2009;

is an active substance in Plant Protection Products (PPP), consisting of or containing nanoforms according to the provisions of Commission Regulations (EU) 2018/1881, and (EU) 2020/878, amending the Annexes I, II, III, VI, VII, VIII, IX, X, XI and XII of the REACH Regulation to introduce nanospecific clarifications, or is a PPP with co‐formulants in nanoform;

is a nanostructured material according to the ISO definition, that may be composed of large particles but keeps nanoscale characteristics, or

consists of, or contains a fraction of small particles as outlined in this Guidance on Particles‐TR, unless according to the principles in this Guidance on Particle‐TR, the information confirms that the conventional assessment is sufficient to address the risk for consumers.

This Guidance on Particle‐TR intends to highlight that safety assessment of food/feed ingredients and additives consists of or contains a fraction of small particles may not be complete if only chemical aspects are considered without taking into account certain particle‐size related physical aspects as well. It should be noted that this Guidance on Particle‐TR only addresses the risk for consumers exposed via food. Other assessments to be performed by applicants, in particular human occupational exposure and environmental risk assessments are not addressed. However, some general principles may be relevant.

This Guidance on Particle‐TR is intended to assist applicants and interested parties intending to submit application dossiers or other comparable forms of submissions.

2. Materials requiring assessment according to this Guidance on Technical Requirements and general principles

2.1. Introduction

This Guidance on Particle‐TR is applicable to chemical materials either as substances or mixtures to be assessed by EFSA. This Guidance on Particle‐TR is also applicable to mixtures and products marketed as liquid formulations (e.g. suspensions) unless the methods described below confirm that they do not contain small particles in suspension, and therefore can be considered as ‘true liquids’ or ‘fully solubilised solids’. Substances that are true liquids or fully solubilised at normal conditions of oral ingestion (37°C and 1 atmospheric pressure, see Section 2.3.3) are sufficiently covered by the sectoral guidance.

The characterisation of the fraction of small particles, including the particle size distribution, is needed in all cases unless the applicant demonstrates that the material will be fully dissolved and consumers will not be exposed to particles. This Guidance on Particle‐TR focusses on the implications for the safety assessment. The decision whether or not a material is an engineered nanomaterial according to the definition in the Novel Food Regulation is outside EFSA's remit and is not addressed in this Guidance on Particle‐TR.

For multi‐constituent substances and mixtures (defined in the glossary), the information to be submitted according to this Guidance on Particle‐TR should cover each single constituent or each component in the mixture, as well as the full material. In the case of (a) botanicals and other complex materials of biological origin with unknown or variable composition, (b) macromolecules of biological origin (e.g. enzymes and other proteins), or (c) other similar cases, the applicant should provide a rationale demonstrating that an assessment of the fraction of small particles including nanoparticles is not needed, or that is already covered in the safety assessment process.

2.2. General principles and list of appraisal routes for confirming that a fraction of small particles is either not present or covered by the conventional risk assessment

This Guidance on Particle‐TR presents several appraisal routes for confirming that (a) the material does not contain a fraction of small particles, or (b) a fraction of small particles is present but properly covered by the conventional risk assessment. In both cases, an additional assessment related to the presence of particles at the nanoscale is not needed. The appraisal routes are listed according to the level of complexity for generating the information, but they should not be considered as a tiered approach.

The applicant may select one or several appraisal routes appropriate for each material to demonstrate the absence of a fraction of small particles, or that a fraction is present but well‐covered by the studies submitted by the applicant for the conventional risk assessment.

If the applicant confirms that a fraction of small particles is present but cannot demonstrate that the hazard assessment of the material also covers this fraction (see Section 4 for details), the applicant should present information to complement the risk assessment. Section 4.3 provides the information requirements to be considered by the applicants in order to cover the safety assessment of the fraction of small particles with nanoscale properties in line with the Guidance on Nano‐RA.

Table 1 complements Figure 1 summarising the different appraisal routes, describing the parameters or options to be considered for each appraisal route, and the associated decision criteria for confirming that the conventional risk assessment is sufficient, and methodology for obtaining the information.

Table 1.

List of appraisal routes and corresponding decision criteria for demonstrating that the material does not require specific assessment at the nanoscale (i.e. assessment according to Guidance on Nano‐RA)

| Parameters/Options | Decision criteria1 | Methodology | Comments |

|---|---|---|---|

| Appraisal routes using solubility and dissolution rate to demonstrate that consumers will not be exposed to small particles (Section 2.3 ) | |||

| Solubility in water (Section 2.3.1) | Equal to or higher than 33.3 g/L | According to OECD TG 105 (OECD, 1995) with specific considerations for small particles | For multi‐constituent substances and mixtures, the decision criterion has to be fulfilled for each constituent/component |

| Dissolution/degradation rate in water (Section 2.3.2) | Half‐life of 10 min or less corresponding to dissolved fraction equal to or higher than 88% in 30 min | Single concentration corresponding to exposure at the maximum use level in water | For multi‐constituent substances and mixtures, the decision criterion has to be fulfilled for each constituent/component. If solubility is pH dependent, the criteria should be confirmed at pH = 3 and/or pH = 7 |

| Solubility/dissolution in the marketed product or in food (Section 2.3.4) | At the expected maximum levels: the substance is fully dissolved in an aqueous or a non‐aqueous matrix; or residues in food are below the relevant solubility limit. | Solubility/dissolution tests of the substance in water, lipids or relevant simulants. | Results should confirm that under the intended use conditions (e.g. marketed product or food) the material or its residues in food will be solubilised in the products ingested by consumers |

| Appraisal routes related to the particle size distribution (Section 3 ), proper dispersion of the material is essential in each case | |||

| Particle size distribution of the material (Section 3.3) | Particles equal to or larger than 500 nm The detection capability of the method(s) used for this assessment should provide convincing evidence that the material contains less than 10% of particles (number‐based) with at least one dimension smaller than 500 nm | The method selection should be justified, and detection capability should be reported, examples of possible methods are:

|

Proper dispersion of the material should be ensured (Section 3.2) |

| For liquid formulations/products (Sections 2.3.3 and 3.3) | Results should confirm the absence of particles in suspension | Ultrafiltration, or other appropriate method if justified, of the liquid product The detection capability should be reported | To be tested for the full formulation as marketed |

| Particle size distribution of fraction of small particles (Section 3.4) | Less than 10% of the particles (number‐based) of the sub‐500 nm fraction with at least one external dimension smaller than 250 nm | Quantitative EM or a different method with justification | Applies to the fraction of small particles of the full material (also for multi‐constituent substances and mixtures) When the criterion is not met, this information is also required for assessing if the fraction of small particles is covered by the existing safety studies following the criteria described in Section 4 |

| Appraisal routes demonstrating that the fraction of small particles is properly covered by the existing safety studies (Section 4 ) | |||

| The studies address properly the potential hazards of the fraction of small particles (Sections 4.1 and 4.2) | The test material included the fraction of small particles, and The test design, and the level of dispersion/degree of agglomeration was sufficient for addressing the fraction of small particles | Characterisation of the test material (particle characteristics and particle size distribution), comparison with the marketed material, Specific consideration for genotoxicity and toxicokinetic assessments, and Demonstration of a sufficient level of dispersion/degree of agglomeration based on extraction of information from study protocol or additional information (See Appendix B) | For existing studies see details in Section 4. Before conducting new safety studies for materials containing a fraction of small particles, see the recommendations of the Guidance on Nano‐RA. |

| The submitted risk assessment covers the fraction of small particles (Section 4.3) | The gaps observed in the safety studies are covered (or are of overall low relevance) and do not trigger additional concerns | The lines of evidence are combined in a weight of evidence approach | See examples under Table 4, Section 4.3 |

OECD: Organisation for Economic Co‐operation and Development; EM: electron microscopy.

Fulfilling the decision criteria for one of the parameters/options is sufficient for demonstrating that the assessment according to the sectoral guidance is sufficient.

The technical feasibility for applying the criteria above may be problematic for complex materials of biological origin that are not fully characterised or are of variable composition, such as some novel foods, botanicals, enzymes and other proteins or extracts. These materials may have a fraction of small particles of natural origin similar to that of foods considered safe for consumption. In these cases, the applicant may justify that the fraction of small particles has similar fate in the gastrointestinal tract (GIT) and similar hazard properties to those naturally present in comparable foods, and covered by the available studies and does not require additional assessment. A scientifically sound case‐by‐case justification supported by the available evidence should be presented.

2.3. Confirmatory appraisal routes related to solubility and dissolution rate

The assessment of particles at the nanoscale refers to entities in solid form, including particles in suspension/dispersion (Rauscher et al., 2019b). From the risk assessment perspective, as indicated in the Guidance on Nano‐RA, if the material is expected to be fully solubilised in the food or in the GIT, an assessment at the nanoscale may not be needed.

The terms relating to solubility, dispersibility and dissolution rate have been explained in the Guidance on Nano‐RA. Briefly, solubility is a property of the substance defined as the proportion of a solute in a solvent under equilibrium conditions (i.e. in a saturated state), whereas dissolution is a process and the dissolution rate refers to the kinetics of dissolution. For nanomaterials, dissolution means that the material is solubilised into individual ionic or molecular species, and this needs to be differentiated from dispersion, which is a colloidal suspension of the particles. In addition, it is also important to consider the form in which a material may be solubilised. For example, some materials may not be solubilised as such, but they may do so as a result of a chemical transformation – such as hydrolysis or oxidation – if permitted by the conditions in a solvent.

A Guidance on safety assessment of nanomaterials in cosmetics has been published by the Scientific Committee on Consumer Safety (SCCS, 2019). Alike the Guidance on Nano‐RA, it emphasises the need to distinguish between solubility and dispersion of nanomaterials, and describes solubility as disintegration of a nanomaterial in an aqueous medium or biological environment into molecular components with the loss of nano features. It also highlights the consideration of the time required for dissolution, because that will determine the consideration for risk assessment to be based on either particle risk or solubilised substance risk (SCCS, 2019).

Following the ingestion of small particles, the material may dissolve in the GIT. As detailed in the Guidance on Nano‐RA, the dissolution/degradation of the material can be investigated under simulated GIT conditions. If the results confirm that the dissolution kinetics is rapid enough to achieve full solubilisation in the stomach or in the intestine before gastrointestinal uptake of the particles, a conventional risk assessment is sufficient. The principles of the Guidance on Nano‐RA have been adapted in this Guidance to offer a simplified dissolution rate assay in water (described in Section 2.3.2.3). If solubility is pH‐dependent and the criterion is not achieved at pH = 7, it would be sufficient to demonstrate that the dissolution rate at pH = 3, representing the stomach conditions, is sufficiently rapid to ensure full dissolution in the stomach.

Currently, there are no standardised methods for measuring the dissolution kinetics under conditions relevant for oral ingestion; consequently, a dissolution rate protocol is included in Section 2.3.2. Highly water soluble substances dissolve quickly, and are expected to be solubilised during food processing or quickly after ingestion. In order to avoid unnecessary testing, a threshold for substances with very high solubility in water has been included in Section 2.3.1, if water solubility is above this threshold, there is no need for conducting a dissolution rate study; in other cases, the dissolution rate protocol is needed for accounting that, after ingestion, dissolution will occur before reaching the intestine.

2.3.1. Solubility in water

2.3.1.1. Decision criteria

If the solubility of the substance in water is equal to or higher than 33.3 g/L, no additional assessment for the fraction of small particles is needed.

This criterion can also be applied to multi‐constituent substances and mixtures. For mixtures, each substance in the mixture should be tested separately and achieve the solubility criterion of equal to or higher than 33.3 g/L. For complex multi‐constituent substances where the solubility of each single component cannot be assessed, the applicant should consider the dissolution rate in water, focusing on the components with the slowest dissolution rate. Alternatively, other appraisal routes described in Sections 3 and 4 of this Guidance should be considered. If some components in the multi‐constituent substance or in the mixture do not achieve the solubility criterion the other appraisal routes should focus on those components.

2.3.1.2. Information required and methodology

A solubility test according to OECD TG 105 (OECD, 1995) or equivalent is required. It is important to remove any suspended particles from the suspension. Ultrafiltration is the recommended method for removing small particles (including nanoparticles) from the solubilised fraction. Other methods have also been mentioned in literature for this purpose. These include ultracentrifugation and dialysis. However, the separation process in these methods may be too slow compared to the dissolution process, and for this and other reasons, the use of ultracentrifugation and dialysis is not recommended (OECD, 2020).

2.3.1.3. Principles

The criterion on solubility in water is based on the SCCS Guidance (2019) and specifically on the criteria for measuring the solubility of nanoparticles. According to the SCCS (2019), nanospecific risk assessment may be waived for a material composed/comprised of small particles that has a high solubility (i.e. solubility of 33.3 g/L or more).

As a guide, the solubility of a substance should be seen in the context of the categories for degrees of solubility proposed by JECFA and the European and US Pharmacopoeias (Table 2).

Table 2.

Solubility Terms as defined by JECFA (2006) and European and US Pharmacopeias (Council of Europe (2019); USP38 and USP38 NF33**)

| Term | Parts of solvent required for 1 part of solute | Solubility defined in g/L |

|---|---|---|

| Very soluble | Less than 1 part | > 1,000 |

| Freely soluble | 1–10 parts | 1,000–100 |

| Soluble | 10–30 parts | 100 to 33.3 |

| Sparingly soluble | 30–100 parts | 33.3 to 10 |

| Slightly soluble | 100–1,000 parts | 10 to 1 |

| Very slightly soluble | 1,000–10,000 parts | 1 to 0.1 |

| Insoluble* | > 10,000 parts | < 0.1 |

The European Pharmacopeia terms it as ‘practically insoluble.

The United States Pharmacopeia–National Formulary (United States Pharmacopeial Convention, 2016).

The value of 33.3 g/L selected as threshold for this appraisal route is based on internationally agreed standard testing for chemicals in general. At this solubility level and above, the material is expected to be fully solubilised either in the food matrix or in the GIT, regardless the use levels. Therefore, consumers will not be significantly exposed to the material in particle form and a conventional risk assessment is sufficient.

Even if the criterion is not met, a proper measurement of solubility is essential for applying other appraisal routes. When testing insoluble or partially solubilised substances, it must be kept in view that they will be present in a test medium as a nano‐dispersion rather than a solution. Special attention should be paid to the agglomeration/aggregation behaviour, and the insoluble/partially soluble nature of small particles in the nanoscale (OECD, 2009; SCENIHR, 2009; Chaudhry et al., 2010; Gottardo et al., 2017).

2.3.2. Dissolution rate in water

2.3.2.1. Decision criteria

If, at a concentration corresponding to exposure at maximum use level (as detailed in Section 2.3.2.3), the (mass‐based) dissolution rate of the material in water (or the dissolution rate of each constituent in case of a multi‐constituent substance) shows a half‐life of 10 min or less, no additional assessment for the fraction of small particles is needed. This dissolution rate corresponds to 12% or less of the material (mass‐based) remaining present as particles after 30 min, a percentage and time point adequate for minimising measurement uncertainty. Multiple time points should be determined to establish the dissolution rate. No indication for incomplete dissolution should be observed within the time‐frame of the study.

This criterion is also applicable to mixtures. Each substance in the mixture should be tested separately and achieve the dissolution rate mentioned here. If some components in the mixture do not achieve this dissolution rate, the other appraisal routes should focus on those components.

2.3.2.2. Information required and methodology

A dissolution rate test as described below is required. The dissolution rate test should measure the dissolution of the test item at a single concentration, representing the maximum level of consumer exposure, at different time‐points. Background information on dissolution rate tests for particulate materials can be found in OECD (2020).

2.3.2.3. Principles

Size‐specific properties or effects of a material composed of small particles, including nanoparticles, are intrinsically linked to the stability of its small particle/nanoscale features. When the material loses these properties, e.g. due to dissolution, it will not be expected to behave differently from its corresponding conventional chemical form (i.e. the soluble substance having the same chemical composition).

The dissolution rate test is aimed to investigate whether a particulate material that is not completely soluble in water (i.e. with solubility < 33.3 g/L6) shows a dissolution rate7 in water indicating that, at the exposure levels expected for consumers, the particles will dissolve, and therefore consumers will not be exposed to small particles even if present in the material as marketed. It is a screening test in water, at room temperature, meant to address point 3 (‘Dissolution/Degradation rate [g/(L×h)]’) in Table 1C of the Guidance on Nano‐RA. If the test criterion is met, conventional risk assessment is sufficient, whereas if the criterion is not met, other appraisal routes should be considered.

In the case of sparingly and (very) slightly soluble materials, the threshold is based on the dissolution process instead of the solubility. Dissolution is a rate, whereas solubility represents an equilibrium situation. This dissolution approach takes explicitly into account the time needed for particles to cross the mucus layer lining the intestinal epithelium and subsequent cellular uptake. If the particles dissolve within this time frame, it can be assumed that uptake does not occur in the form of particles, and thus that there is no systemic exposure to particles. The time required for particles to cross the mucus layer and uptake by intestinal cells is short, i.e. within minutes.8 With this in mind, a cut‐off value for a dissolution/degradation rate based on a half‐life of 10 min is proposed to differentiate the quickly dissolving nanomaterials that can follow a conventional safety assessment according to relevant sectoral guidance, from those requiring further assessment according to this Guidance. This cut‐off value is considered analytically feasible. It is imperative that different time‐points are used to determine the dissolution rate, and that a clear decrease is observed (no plateau).9 The concentration(s) tested should be based on the intended maximum use levels, see below for further details.

For pragmatic reasons the dissolution rate in water is considered; however, key elements of the gastrointestinal conditions – pH and ionic strength – are taken into account.

The general outline of the test strategy is as follows.

The starting point is the identification of the intended maximum use level and the concentration at which the dissolution rate is to be tested. This process includes two steps. The first step is the estimation of the maximum daily amount to be ingested by the consumers. This should be estimated according to the intended use patterns and the exposure assessment methods described in the relevant guidance documents covering the risk assessment of regulated products in the different areas. It should be based on estimations of the maximum concentration in foods and maximum expected consumption of the food conducted according to the relevant sectoral guidance; when the material may be present in several food commodities, the estimation should include the maximum levels per day for the relevant population groups. This step is a standard part of the exposure assessment. The second step is to estimate the concentration at which the dissolution rate is to be tested. This estimation is done by assuming that the amount ingested per day is diluted in the GIT up to a volume of 2 L (Guidance on Nano‐RA). The volume should be adapted to 1 L when the dissolution/degradation is expected to occur only, or mostly, at the acidic conditions of the stomach, as well as in case of assessments for infants and children. In case of doubts on the exposure assessment, applicants may test somewhat higher worst‐case exposure levels for the dissolution rate than those included in the application.

Following the estimation of the concentration to be tested, for solid powdered materials the applicants should use the protocol proposed below (deviations should be justified):

Disperse the test item at room temperature in water containing 85 mmol/L NaHCO3 and 40 mmol/L NaCl,10 at the concentration selected as described above. Allow the soluble components to dissolve under stirring conditions (in general 300 rpm should be sufficient). If there are insoluble particles, these will exist in the medium forming a dispersion. An appropriate dispersion method (see Section 3.2) has to be applied to deagglomerate potential agglomerates. Attention should be paid to employing sonication techniques delivering sufficient energy (i.e. probe sonication11 instead of bath sonication). The analytical report should indicate the equipment used and the operating conditions (time, power output12) and the measured pH.

Analyse this dispersion (t = 0)13 for the chemical substances constituting the particles, e.g. for inorganic materials measure the associated characteristic elements (by techniques such as inductively coupled plasma optical emission spectroscopy (ICP‐OES) or inductively coupled plasma mass spectrometry (ICP‐MS)) after microwave‐assisted digestion.14

Then perform an ultrafiltration of a small aliquot of the dispersion (t = 0) using a membrane filter with pore size in the range 3–10 kDa. The membrane will retain the particles and the filtrate will contain only solubilised components.15 In some cases, filtration through a 0.22‐μm filter may be needed beforehand to remove larger particles (including potential agglomerates and aggregates) and prevent obstruction of the 10‐kDa membranes in the subsequent ultrafiltration step. The time between sampling and ultrafiltration has to be kept to a minimum.

Submit small aliquots of the dispersion at multiple, appropriate time points to the same separation treatment and the filtrate to the same chemical analysis as described above.16 The filtrate should be free of small particles/nanoparticles, which are retained on the membrane surface (if present). At each sampling occasion, care has to be taken to keep the time between sampling and ultrafiltration to a minimum.

The material is considered to degrade/dissolve quickly (i.e. to have a high degradation/dissolution rate with a half‐life of 10 min or less) if the degradation rate profile shows a clear decrease in the presence of particles17 over time (no plateau) and 12% or less of the material (mass‐based) – compared with the concentration at the beginning of the test18 – remains as particles after 30 min. A half‐life of 10 min or less is indicative that no (or a very limited number of) particles will remain to be taken up as such by consumers.19

At least four time points should be tested for the determination of the degradation/dissolution rate. For instance, the ultrafiltration and subsequent analysis should be repeated; in addition to t = 0, also at for example t = 5 min, t = 10 min, t = 30 min and t = 60 min. The degradation/dissolution curve has to be documented and the degradation/dissolution rate at t = 30 min calculated.

If degradation/dissolution is pH‐dependent, the dissolution test should be carried out at different points covering the pH range of physiological relevance (pH = 320 to pH = 7). If 88% dissolution or more is achieved in 30 min at pH = 7 and/or pH = 321 the confirmatory criterion is achieved (see previous bullet point). For the studies conducted at pH = 3, the concentration of test item should be multiplied by two, in order to account for the difference between the volume of the gastric compartment (1 L) and the volume of the gastro‐intestinal track (2 L).

The applicant may also consider the recommendations for degradation/dissolution rate of nanomaterials in the GIT described in the Guidance on Nano‐RA, including the characterisation of the degradation products.

2.3.3. Confirmation of absence of particles for liquid materials

For materials marketed in liquid form, it should be sufficient to demonstrate the absence of particles following ultrafiltration22 that the material is a true liquid and not a dispersion containing small particles.

Applicants should provide mass balance estimations or verification of the absence of small particles including nanoparticles by electron microscopy (EM). Other alternative methods for verifying the absence of the particles in suspension (e.g. see Mech et al., 2020a) may be used if properly justified.

2.3.4. Solubility/dissolution in the marketed product or in food

This appraisal route covers situations when according to the substance properties and the intended uses, consumers will only be exposed to the solubilised material. This happens when the substance will be fully dissolved or degraded into non‐nano forms in the marketed products or in the food of any nature – aqueous, non‐aqueous, semi‐solid, lipophilic, etc. – before ingestion by consumers. In those instances, a conventional risk assessment will therefore be sufficient.

A first situation covers substances marketed in liquid (either aqueous or non‐aqueous) matrices or when all intended uses require a dissolution of the substance in a liquid matrix before consumption. The applicant should provide information on the solubility of the substance in water, in the non‐aqueous matrix,23 or in a relevant solvent, as appropriate, and compare the solubility with the intended/resulting concentration of the substance in that matrix. The submitted information should provide convincing evidence for concluding that the substance will be fully dissolved in the solvent/matrix, and not just dispersed as small particles.

A second situation covers substances that are not intentionally added to food, but their use may lead to transfer or carry‐over of residues in food items.

The first case for this second situation is represented by substances used in FCMs that have solubility less than 33.3 g/L but may transfer from a FCM into food only at such low levels that are solubilised. Depending on the toxicological data, migration limits for non‐genotoxic substances are currently set at between 0.05 and 60 mg/kg food or food simulant (EFSA CEP Panel, 2008 and updates of the Note of Guidance), making 60 mg/L24 a generic upper migration limit for FCM substances (EU Reg. 10/2011). Putting this upper limit in perspective, it can be anticipated that if an FCM substance has solubility greater than 60 mg/L, then its transfer from the FCM to food will be in fully solubilised form and not as particles. In a case where migration of a FCM substance may exceed the prescribed generic limit of 60 mg/L, then from the risk assessment perspective, it will be irrelevant whether it is in solubilised or in particle form because it will not comply with legislation. Therefore, a conventional risk assessment may be sufficient for an FCM substance if its levels migrating into food can be considered to be in solubilised form on the basis of solubility/dissolution rate, or can be demonstrated to be solubilised under worse‐case time‐temperature conditions for the packaging (e.g. under the shortest time and lowest temperature conditions foreseeable for the packed food), before ingestion of the packed food.

The cases associated to carry‐over of residues in food are related to the use of feed additives and pesticides. The sectoral risk assessment processes provide guidance for estimating the nature of the residues (which may differ from the marketed substance) and its magnitude. In these cases, even if the marketed or ‘pristine’ material has a fraction of small particles, the solubility of the substance (or of the substances that constitute the residue) in water, lipids or relevant food simulants may be sufficient for confirming that, at the maximum residue levels of the substance, the residues in the treated animals/plants will be fully dissolved.

When addressing the characteristics and magnitude of expected or permitted levels of materials or their residues in food according to the sectoral guidances, applicants may consider this appraisal route as an alternative to the characterisation of the particle size distribution of the residues in food. Technically, the preferred experimental approach to test for solubility involves (ultra)filtration. However, such measurements in most foods are difficult or even impossible to implement given the capabilities of current methods and the compositional complexity of many foods. Therefore, appropriate food simulants such as those specified for migration testing (e.g. ethanol, acetic acid, olive oil, etc.) of FCM substances (EU Regulation 10/2011) could be used in such situations to provide conclusive evidence on the solubility in the foods that these simulants are representing.

3. Characterisation of the size distribution of the material including the fraction of small particles

3.1. Introduction

This Section includes the information on the particle size distribution that should be included in the application/dossier when the criteria on solubility and dissolution rate dealt with in Section 2 are not met.

For practical reasons and in line with current methods for measuring particle size distribution, the information requirements are divided in two steps: the characterisation of the particle size distribution of the full material and the characterisation of the fraction of small particles (< 500 nm). This characterisation is also needed for applying the appraisal routes described in Section 4.

Particle size is a distribution and should be described accordingly (e.g. see Section 3.4.2.3 for describing the particle size distribution for materials contains a fraction of small particles).

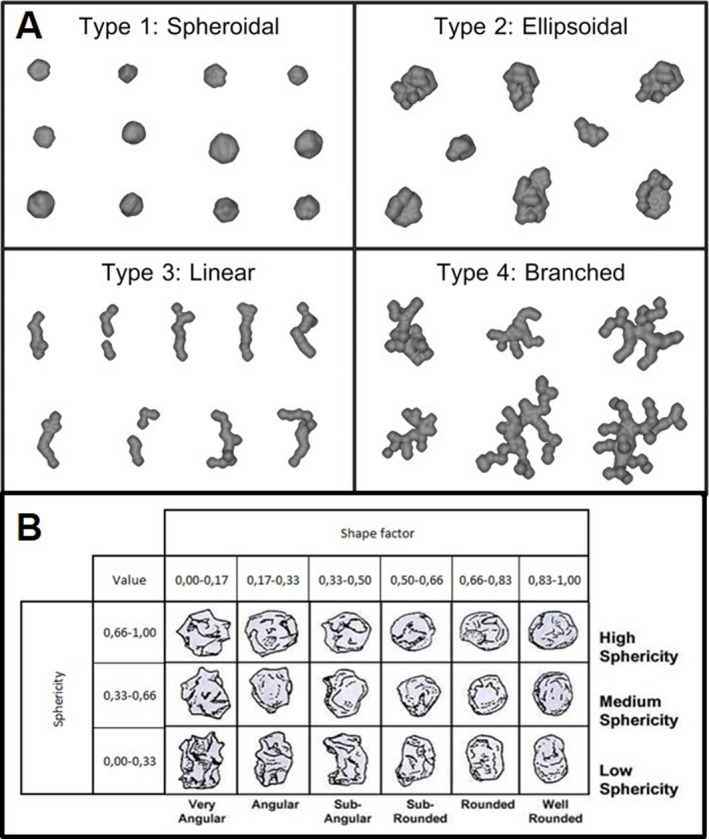

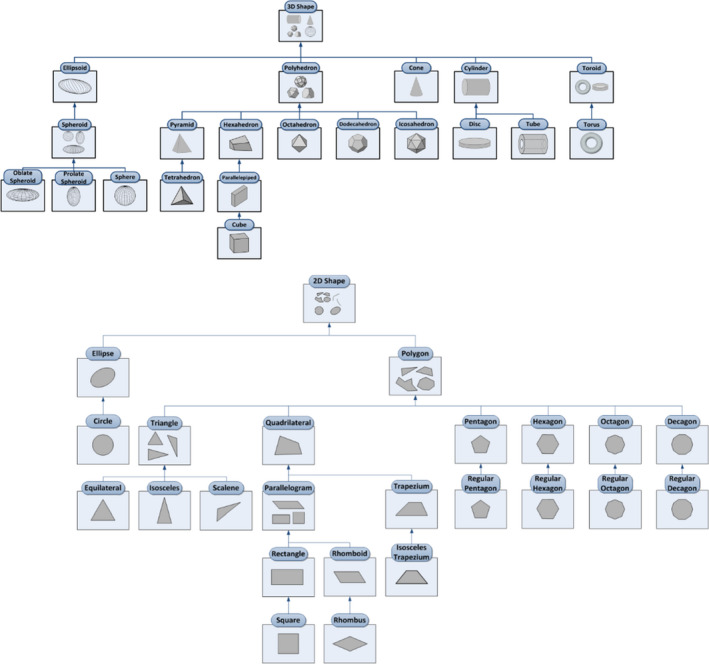

The physical property ‘particle size’ can only be defined unambiguously, i.e. with a single descriptor for particles with a regular shape (e.g. spheres, cubes). More precise in this context is the term ‘external dimension’. Industrial materials often consist of irregularly shaped particles with many possible external dimensions. The size reported for such particles thus strongly depends on the external dimension measured and reported. Many particle size analysis techniques produce equivalent spherical particle diameters and tend to overestimate the minimum external dimensions. The minimum external dimensions of particles with irregular shape can be better assessed by the minimum Feret diameter and/or the maximum inscribed circle diameter. For a detailed discussion of the measurement principles, measurands and how to interpret the results of different sizing techniques, users should consult the NanoDefine Methods Manual (Mech et al., 2020a,b,c. In all cases, users should report and justify the measurand used to estimate the minimum external dimension. It should also be noted that the fraction of small particles, including nanoparticles, require specific attention with regard to the representativeness of sampling and proper dispersion state. All measurements of particle size distribution should ensure a proper dispersion of the sample in line with the recommendations presented in Section 3.2. These recommendations should be also considered for preparing the samples for conducting safety studies and when interpreting results of the studies. Also, possibilities for deagglomeration of the small particles under different testing and physiological conditions should be considered in risk assessment (OECD, 2012; Peters et al., 2012 (ACS NANO, 2012)).

3.2. Dispersion protocol for sample preparation

Dispersion of materials composed of small particles (usually powders) in liquids is an important step in the sample preparation for most common particle size measurement methods. The dispersion procedure used may influence the particle size distribution measurements. For material characterisation, the final liquid dispersion of the material should result in a particle size distribution that consists of the smallest dispersible particles.25 The dispersion also needs to be sufficiently stable, i.e. show a constant size distribution pattern or minimal re‐agglomeration, avoiding particle sedimentation over the time necessary to carry out particle size measurements or for application in in vitro or in vivo toxicological tests.

Due to the likelihood of high physical and chemical variability amongst materials, a generally applicable standard operating procedure (SOP) is currently not available for dispersion of a dry powder in liquids. The following general steps should be considered when developing a dispersion procedure (Mech et al., 2020c):

Choice of media, pre‐dispersion and wetting can be the main limitations for an instrumental method used later.

Choice of the method for deagglomeration/disaggregation of the material; the input energy used – i.e. is it sufficient to deagglomerate/disaggregate without changing the particle morphology. A general choice for most materials with a fraction of small particles is ultrasonic treatment using either a probe or vial sonicator.

Stabilisation is the final and complex step in the process, therefore consideration of the choice of stabiliser is needed, along with other possible variables such as compatibility of the stabilisation method with the measurement method. Effectiveness of the stabilisation including the timescale for which stability must be ensured.

Concerning step (ii), it has to be noted that sonication may introduce a significant variability in the dispersion process due to the differences amongst the variety of sonication instruments that are available on the market. In order to reduce this variability, a ‘Generic SOP for calorimetric calibration of an ultrasonic probe sonication’ has been developed (Mech et al., 2020c). This SOP allows harmonisation in the use of different sonication instruments and methods (probe versus vial) by determination of the actual energy effectively transferred to the test sample.

For the purposes of this Guidance on Particle‐TR, a dispersion protocol can be considered effective if it yields samples which consist as much as possible of non‐agglomerated/non‐aggregated particles. To monitor the effectiveness of a protocol, analytical methods, which can reliably distinguish constituent particles from agglomerates and aggregates, are required. Suitable methods are those based on EM techniques, such as SEM or TEM. As EM methods require dry samples, care must be taken to optimise the specimen preparation to minimise re‐agglomeration of particulates during specimen drying. If it is not possible to verify agglomeration and aggregation state with EM, efforts should be made to empirically verify that the protocol has been optimised to produce the minimum mean particle size possible with the facilities available for dispersion. To do this, the dispersion steps should be applied systematically using different sonication times and fixed power settings with the mean particle size being measured by methods such as centrifugal liquid sedimentation (CLS), dynamic light scattering (DLS), Asymmetric Flow Field Flow Fractionation (AF4) (associated to suitable detection methods) or single particle ICP‐MS, as appropriate based on the concentration of the dispersion and the nature of the material. The most suitable sonication time and power should be chosen as the time when further incremental increases in sonication time and/or power do not result in significant further changes in mean size (Rauscher et al., 2019a).

As mentioned above, there is no universally applicable test protocol for preparing stable dispersions of materials with a fraction of small particles. On the other hand, in the scientific literature numerous specific methods for certain types of particles are reported. A more systematic approach has been proposed in the NanoDefine EU‐project, where a specific optimised dispersion protocol was developed for a number of priority nanomaterials and laid down in the form of SOPs (Mech et al., 2020c). Examples of these substances are CaCO3 (fine grade), BaSO4 (fine and ultrafine grade), kaolin, coated TiO2 (pigment grade), zeolite powder or MWCNT (highly tangled fibrous carbonaceous material). For each of these materials, specific dispersion requirements need to be met, along with corresponding types of dispersants, stabilisers and sonication conditions. Typical probe sonication dispersion conditions involve applying energies between 600 J/mL and 2,500 J/mL sample volume. These SOPs can serve as a starting point or guide templates for developing protocols for other materials on the basis of physicochemical similarities with one of the standard nanomaterials used in developing the SOPs.

As elaborated in a JRC report (Rauscher et al., 2019a) the effective stability (resistance to re‐agglomeration and/or selective sedimentation) of a prepared sample for the time between sample preparation and the end of the measurement should be verified.

In order to check the stability of dispersions, periodic verifications should be made of the apparent particle size distribution from stock dispersions using at least one technique which is sensitive to changes in particle size and quantity. CLS can be used to very sensitively reveal any change in size distribution, and therefore CLS can be regarded as well suitable for such verification – assuming the expected particle size range and density are compatible with the lower size limit of the CLS instrument being used. Re‐agglomeration changes the particle size distribution and often leads to sedimentation. However, certain dispersions may change over time due to gravitational sedimentation only (without re‐agglomeration); this can be easily reversed and therefore would not be regarded as instability of the dispersion. Before verifying size distributions with CLS or other appropriate alternative the sample dispersion should be re‐homogenised by a short period (few minutes) of bath sonication.

After dispersion, particles may re‐agglomerate. Therefore, it is important to ensure that suspensions are prepared with the intention of achieving sufficient dispersion stability to allow appropriate measurement of the needed parameters. Hence, further to optimising the dispersion energy mentioned above, additional steps should be taken to avoid re‐agglomeration of dispersed particles for the applied measurement techniques. In the case of aqueous dispersions this may be achieved by natural electrostatic stabilisation and appropriate modification of the pH value. In many cases, it may be necessary to add a dispersing agent or a surfactant. The choice of, e.g. surfactants depends on the intrinsic properties such as hydrophobicity, surface charge and chemical functionality of the specific material under consideration. Commercially available chemical surfactants e.g. phosphate, sulfonate or polyethylene glycol and others have been successfully applied for the above‐mentioned priority nanomaterials. Where applicable, measurements of the zeta potential can be useful to check whether a dispersion is expected to be stable for a sufficiently long period of time. An absolute value higher than 25 mV would be indicative for sufficient stability (Dukhin and Xu, 2020). As a guide, a minimum required stability time of 30 min has been suggested for these priority nanomaterials for the various applied measurement techniques as described by Mech et al., 2020c.

Other protocols for the preparation of nanomaterial dispersions by sonification and guidance for optimisation of the tests conditions and process parameters have also been published elsewhere (Taurozzi et al., 2012a,b).

Concerning characterisation of the dispersion stability, ISO Guidelines (ISO, 2013) and an OECD test approach for nanomaterials in simulated environmental media (OECD, 2017) have addressed the key aspects and described a method based on dispersion and re‐agglomeration characteristics of nanomaterials.

It is recommended that applicants follow the ISO and OECD guidelines mentioned above to adopt appropriate methods for preparing stable dispersions of their materials. In case of a broad particle size distribution with a high content of large particles, it may be necessary to remove the larger sized particle fraction by means of filtration or centrifugation, and then apply the guidelines to the remaining smaller particle fraction.

3.3. Characterisation of the particle size distribution

The characterisation of the particle size distribution is needed for all materials for which the solubility or dissolution rate cannot exclude the likelihood of exposure of consumers to undissolved particles. Considering currently available methods, a practical threshold of 500 nm as the upper limit for the range of ‘small particles’ is proposed. When a fraction of small particles is detected, the information provided in this section on the characteristics of this fraction is also needed for the appraisal routes described in Section 4, and consequently should be provided by the applicant even when the appraisal criteria are not met.

3.3.1. Particle size distribution of the material

3.3.1.1. Decision criteria

When the material is not expected to have a fraction at the nanoscale, the applicant should demonstrate that the particles are equal to or larger than 500 nm after a proper dispersion of the test material. The method(s) used for this assessment should provide convincing evidence that the material contains less than 10% particles (number‐based) with at least one dimension smaller than 500 nm.

3.3.1.2. Information required and methods

Different methods can be used for characterising the particle size distribution of the material. For the assessment of the fraction of small particles, these methods should be suitable for detecting particles with at least one dimension smaller than 500 nm.

Methods allowing the detection of small particles include:

Centrifugal liquid sedimentation

Particle tracking analysis

Descriptive electron microscopy

Filtration complemented with chemical analysis

The applicant should select the method(s) according to the characteristics of the material and justify the selection. The applicant may select a method other than those listed above. However, the applicant must justify the selection of a different method from those listed above. For each method, a description of the test conditions, including the sample preparation and dispersion protocols, the range of particle sizes covered by the method, and the detection accuracy within the relevant range of particle sizes should be reported. The selected method or methods should provide convincing evidence that the material contains less than 10% of particles (number‐based) with at least one dimension smaller than 500 nm. A combination of different methods may be needed in some cases.

3.3.1.3. Principles

This appraisal route offers an applicant the possibility to confirm using the screening methods that the particles are equal to, or larger than 500 nm, and as such contain only a very small proportion of the particles in the nanoscale.

The rationale behind this appraisal route is that particle uptake from the GIT has been generally found to be possible for sizes up to 250 nm. As described in more detail in the Guidance on Nano‐RA, the optimum size for particle uptake from GIT has been generally found to be smaller than this value, but there is some evidence that particles sized up to 250 nm can be absorbed with certain surface modifications/coatings (e.g. see the review by Chaudhry et al., 2008). Materials that only contain a negligible fraction of particles smaller than 250 nm would not have to undergo a nanospecific assessment. An uncertainty factor of 2 is applied to account for the limitations of available screening techniques for size measurements resulting in a limit of 500 nm. Limitations include the particle size range that can be detected, limits of quantification, conversion into number‐based distributions.

Assuming a normal size distribution of the full material (which represents a worst‐case scenario for conventional materials), 10% or less of the particles being smaller than 500 nm implies that the fraction of nanosized particles (1–100 nm) will be minimal and that the likelihood of a risk from their uptake is negligible. Important is that the applicant assures that the selected method for determining the size distribution covers this 10% threshold.

The proposed value of 10% number‐based particle size smaller than 500 nm is therefore considered sufficient to cover that the uptake of particles through the gastrointestinal epithelium would be only negligible, and a conventional risk assessment should be sufficient, with no need for further assessment of the material properties at the nanoscale.

3.3.1.4. Centrifugal liquid sedimentation

A relatively quick and economic method of ascertaining the presence of small particles in a dispersion of particulate material is through analysis by CLS. CLS is a scaled‐down version of analytical centrifugation that is designed in the form of a rotating disc, which contains a thin layer of liquid sucrose gradient. When a sample of particle dispersion is applied at the centre of the disc, which is rotating at around 24,000 rpm (30,000 G‐force), the centrifugal force leads the particles to sediment and travel outwards at velocities dependent on their particle size and morphology. Using X‐ray diffraction or optical detection, a typical equipment can measure the velocity of particle sedimentation to calculate particle size distribution against standards of known particle density and size. The method is regarded as quick, highly reproducible, and with a good sensitivity that can range from 3 nm to several μm (e.g. see validation study by Braun et al., 2011). Analysis of low‐density materials can require much longer times, but special discs are also available that can reduce the run time. The equipment is generally also accompanied with proprietary software that can convert mass‐based particle size distribution into number‐based values on the basis of particle morphology and density. Such a conversion may however be prone to errors, especially when the concentration of a nanofraction is very low as the instrumental ‘noise’ may also be counted as a particle signal.

There is ISO standard 13318 series for the method, which is also mentioned in the REACH guidance R7.1 for the characterisation of nanomaterials (ISO, 2001a, 2007a,b). Standard operating procedures for CLS have been developed by the NanoReg project for particle size determination.26

3.3.1.5. Particle tracking analysis

The evaluation of the number‐based particle size distribution in liquid dispersions can be effectively carried out using the particle tracking analysis (PTA) method for diffusion velocity measurements. PTA, also known as nanoparticle tracking analysis in some instrumental versions, is a single particle technique where scattered laser light is recorded with a microscope and a digital camera. The Brownian motion of the particles, as recorded in a video, is processed by the software to determine the diffusion coefficient for each constituent particle and from it calculate the hydrodynamic diameter.27

By means of PTA the sizing and number concentration measurement of particles in the size range of one or few tens of nm (depending on the chemical nature of the material) up to 1 μm approximately can be performed in aqueous suspensions. PTA measures the hydrodynamic diameter using the spherical model as DLS does but suffers less perturbation from large particles in polydisperse samples compared to DLS. However, the measured hydrodynamic diameter can be affected by the salt concentration of the suspending medium, pH and concentration of the dispersant. Therefore, the effects of these parameters should be investigated or controlled. For instance, when performing sample dilutions to obtain the optimal concentration for PTA measurement – which is in the range 106–109 particles/mL – it is important to ensure that the ionic strength, stabilizer concentration and pH are kept constant. All these parameters should be documented and reported. Reduction of dispersant concentration and changes in pH can lead to particle agglomeration and increase in polydispersity of the sample.

There is an ISO standard for the PTA method (ISO 19430:2016 (ISO, 2016)), whereas other sources are available which describe method validations (Kestens et al., 2017), interlaboratory comparisons (Hole et al., 2013; Maguire et al., 2017), and provide SOPs (EUNCL, 2018).

3.3.1.6. Descriptive electron microscopy

To assess the presence of nanoparticles, and before more advanced quantitative analyses are initiated, a detailed description of the material is a first and essential step to determine the basic properties of the examined nanoparticles and to assess the quality of the sample and specimen preparation.

This method may be used to confirm that the fraction of small particles is just a tail resulting from a manufacturing process of a powder and that all particles have similar characteristics except for size.

Based on a series of electron micrographs recorded at magnifications typically ranging from 100 to 100,000 times, and representative for the entire specimen, an overview of the specimen, and the properties of the nanoparticles of interest such as size, shape, surface and inner morphology, and crystallographic structure, can be visualised by the electron microscope. A descriptive EM analysis includes, at least, representative and calibrated micrographs, and a description of the following parameters: (i) the roughly estimated size (distribution) of the constituent and aggregated/agglomerated particles; (ii) the agglomeration and aggregation status; (iii) the general morphology; (iv) the surface topology; (v) the structure (crystalline, amorphous, etc.); and (vi) the presence of contaminants and aberrant particles. If contaminants are observed, such as salt crystals, organic matter, protein agglomerates, lipids, other type of particles (e.g. catalysts), they should be described and reported; in addition, selected micrographs can highlight unusual or rare features, such as impurities and crystal defects.