Abstract

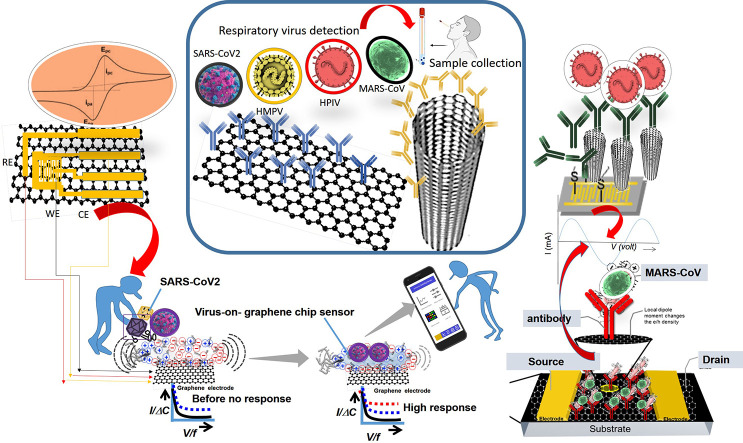

Recent COVID-19 pandemic has claimed millions of lives due to lack of a rapid diagnostic tool. Global scientific community is now making joint efforts on developing rapid and accurate diagnostic tools for early detection of viral infections to preventing future outbreaks. Conventional diagnostic methods for virus detection are expensive and time consuming. There is an immediate requirement for a sensitive, reliable, rapid and easy-to-use Point-of-Care (PoC) diagnostic technology. Electrochemical biosensors have the potential to fulfill these requirements, but they are less sensitive for sensing viruses/viral infections. However, sensitivity and performance of these electrochemical platforms can be improved by integrating carbon nanostructure, such as graphene and carbon nanotubes (CNTs). These nanostructures offer excellent electrical property, biocompatibility, chemical stability, mechanical strength and, large surface area that are most desired in developing PoC diagnostic tools for detecting viral infections with speed, sensitivity, and cost-effectiveness. This review summarizes recent advancements made toward integrating graphene/CNTs nanostructures and their surface modifications useful for developing new generation of electrochemical nanobiosensors for detecting viral infections. The review also provides prospects and considerations for extending the graphene/CNTs based electrochemical transducers into portable and wearable PoC tools that can be useful in preventing future outbreaks and pandemics.

Keywords: Electrochemical nanobiosensor, Graphene, Carbon nanotubes, Respiratory viruses, Diagnosis

Graphical abstract

1. Introduction

The latest World Health Organization (WHO) report revealed over hundreds of million positive cases with millions of deaths occurred worldwide due to lower respiratory tract infections (LRTI). The ongoing virus infection of new severe acute respiratory syndrome (SARS) coronavirus-2 (CoV-2) cases reported above 177 million and claimed ~3.84 million deaths as of this review submission. Other common among the respiratory viruses are Influenza A and B viruses (FluA and FluB), Human adenovirus (HAdV), and Respiratory syncytial viruses (RSV) tend to exhibit more frequent mutations and potentially cause future pandemics that may surface with the signs and symptoms similar or more severe to that of COVID-19. Infants, children, elderly, and those with pre-existing chronic disease conditions or with compromised immune system are more vulnerable to LRTI. These new emerging viral variants may cause future morbidity and mortality and pose serious threat to public health and the global economy. Rapid and early diagnosis of viral LRTI is the only option to prevent future outbreak and spread of viruses.

Conventional diagnostic approaches for detecting viral infections are limited to only detecting viral nucleic acids using PCR or RT-qPCR, which limits in its accessibility, assay speed and cost. Therefore, it is imperative to explore the existing diagnostic approaches, tools and techniques to improving or re-purposing for early monitoring and disease prevention. In the last decade, nanotechnology has opened several avenues to improving current diagnostic assays and developing point-of-care devices by interfacing with new nanomaterials to improve sensitivity and detection speed. Nanomaterials can attach to living cells, viruses, proteins or other molecules allowing their early detection in a sample, and they simultaneously exhibit unique physico-chemical or electrical properties that make them suitable to address the needs of current challenges in rapid diagnosis of infections derived from viruses.

In this review, we explored the uses and application of functional nanomaterials in biosensing with special emphasis to carbon-based nanostructures, including lightweight two-dimensional (2D) graphene and one-dimensional carbon nanotubes (CNTs) that are electrically conductive, chemically stable with large surface-to-volume ratios. These nanomaterials in conjunction with specific bio−/chemical-receptors provide them with improved properties in developing future electrochemical nanobiosensors for PoC detection ability with cost-effectiveness, sensitivity, and fast detection of various respiratory viruses. Further, enhanced sensitivity and specificity for virus detection can be achieved through graphene and CNTs' surface modification via suitable functional groups and/or combination with other materials in hybrid nanostructures. This review covers all the above elements highlighting; (a) key advancement made in functional surface modification of graphene and CNTs toward the development of electrochemical nanobiosensors that can be potentially applied for respiratory virus electrochemical detection platforms, (b) current understanding on classical detection methods for respiratory viruses and fabrication processes of graphene, and (c) CNTs interfaced electrochemical biosensors for sensitive detection. Finally, the advantages and future challenges of graphene and CNTs based electrochemical sensor devices.

2. Respiratory viruses and epidemiology

Biosensing of any viral infections requires a thorough understanding of viruses, their mode of transmission or port of entry, and associated diseases caused in humans or other living beings. There are a variety of different portals through which viruses gain entry into the body, such as respiratory tract, gastrointestinal and genital tracts, subcutaneous (skin), placenta and eyes [1]. Most common viral transmission and infection occurs via the respiratory tract in humans, which is the main portal entry focused in this review. Respiratory viruses are small microorganisms and leading causative agents of diseases in humans with severe impact on morbidity and mortality worldwide. There have been diverse pathogenic respiratory viruses taking part in both lower and upper Respiratory Tract Infections (LRTI, URTI) that include RSV, influenza viruses, Human Adenovirus (HAdV), Human Rhinovirus (HRV), Human Metapneumovirus (HMPV), Human Parainfluenza Virus (HPIV), Human Bocavirus (HBoV), Severe Acute Respiratory Syndrome (SARS) Coronavirus-1 (SARS-CoV-1), Middle East Respiratory Syndrome Coronavirus (MERS-CoV), and SARS-CoV-2 (Table 1 ) [2,3].

Table 1.

A summary of distinct respiratory viral features, such as size, genome, morphology, disease symptoms and related outbreaks in the past decades.

| Virus | Size | Genome | Morphology | Disease Symptoms | Outbreak Examples | Ref. |

|---|---|---|---|---|---|---|

| Respiratory syncytial (RSV) | 120–300 nm | -ssRNA | Enveloped, spherical or filamentous, F, G and SH proteins protruding from the envelope |

Cold like symptoms, wheezing, bronchiolitis |

Most of outbreaks reported in NICUs [6,7] | [2,16] |

| Influenza | 80–120 nm | Segmented -ssRNA | Enveloped, Elliptical, (H) and (N) proteins protruding from the envelope | Mild fever, myalgia, sore throat, cough, and headache severe: pneumonia, ARDS |

In 1918, “Spanish Flu” pandemic. In 2009, “Swine Flu” pandemic |

[8,17,18] |

| Human adenovirus (HAdV) |

90 nm | dsDNA | Non-enveloped Icosahedral |

Mild fever, sore throat, cough, chest pain, headache, or severe pneumonia or bronchitis | In 2007, United States [2] | [2] |

| Human rhinovirus (HRV) | 30 nm | +ssRNA | Nonenveloped, Icosahedral | Sore throat, cough, sneezing, congestion, fatigue, body aches and loss of appetite | In 2009, Canada, in long-term care facilities [19] | [2] |

| Human parainfluenza virus (HPIV) | 150-200 nm | -ssRNA | Enveloped, Elliptical, HN, F glycoproteins protruding from the surface |

Mild common cold with fever, croup, bronchiolitis, pneumonia. |

In 2018, residential care facility for the disable (HPIV-3) Croatia [20] | [2] |

| Human meta-pneumovirus (HMPV) | 150–200 nm | -ssRNA | Enveloped, Elliptical,F, G, SH glycoproteins protruding from the envelope |

Fever, cough, tachypnoea, dyspnoea, hypoxia, rhinitis and sore throat |

In 2006, Canada in long term care facility [21] In 2005, Taiwan [22] |

[2] |

| Human bocavirus (HBoV) |

18–26 nm | -ssDNA or + ssDNA | Non-enveloped, icosahedral |

Cough, fever, rhinorrhoea, asthma exacerbation, bronchiolitis, acute wheezing and pneumonia. |

In 2014, Japan [23] | [2] |

| SARS-CoV-1 | 100-160 nm | +ssRNA | Enveloped, spherical, or pleiomorphic | Mild flu-like, fever, cough, sore throat, lethargy, severe pneumonia, ARDS also vomiting, diarrhea |

SARS-CoV-1 Outbreak between 2002 and 2004 (China) [11] | [2] |

| MERS CoV | 120 nm | +ssRNA | Enveloped, spherical, or pleomorphic | Fever, diarrhea, and abdominal pain, severe pneumonia | MERS-CoV Outbreak in in middle east (Saudi Arabia) 2012 [10] | [2] |

| SARS-CoV-2(Covid19) | 120–160 nm | +ssRNA | Enveloped Helical “crown like” appearance “Spike” proteins (S) protruding from the envelope |

+Loss of smell or taste asymptomatic cases |

In 2019- present SARS-CoV-2 pandemic (China and worldwide) | [2,3] |

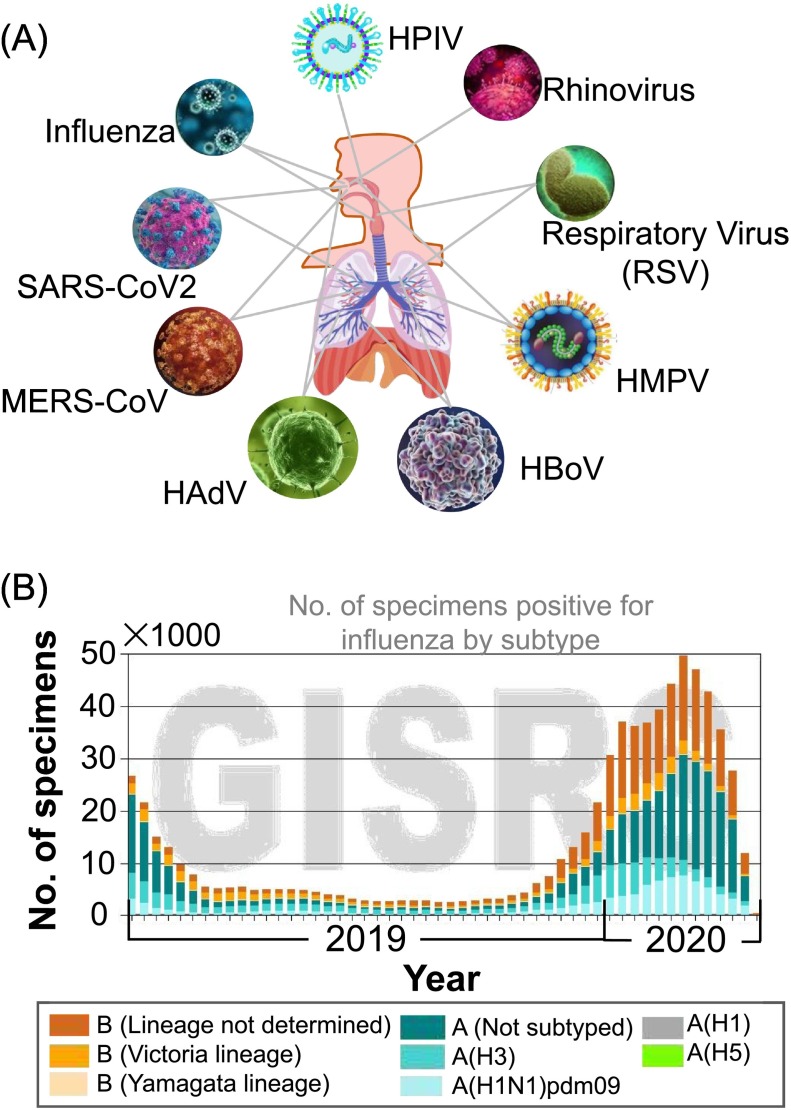

Respiratory viruses mostly cause URTIs, such as common cold, sinusitis, pharyngitis, epiglottitis and laryngotracheitis. However, they may progress and lead to LRTIs, such as pneumonia or bronchitis [2]. Viral transmission occurs through several routes, for e.g., aerosol (long range) or airborne (short range, caused by sneezing, coughing etc.) respiratory droplets, contact directly or indirectly [2]. URTIs caused by viruses presents general flu-like symptoms including cough, runny nose, sneezing, fever, chest pain, difficulty breathing (especially with epiglottitis). Symptoms of LRTIs include cough, fever, chest pain, sputum production, tachypnoea and more. Pneumonia may cause other symptoms such as headache, myalgia, nausea, vomiting and diarrhea. The primary cause of bronchiolitis in infants related outbreak is associated with RSV according to reports from neonatal intensive care units (NICUs) [4]. RSV causes annually, ~33.8-million new cases of acute LRTIs in children worldwide with <5 years of age with hospital admissions of 3.2 million and 59,600 in-hospital children's deaths in 2015 [5,6]. It has been reported that about 60–70% of children aged just a year and all of the children aged ~2 years have been infected by RSV [6,7]. Geographically, it is observed that the RSV travels south to north showing within March–June period in the countries located in southern hemisphere region and September–December in the northern hemisphere region [6]. RSV wave occurs during the rainy season in humid countries. A summary of distinct respiratory viral features such as size, genome, morphology, disease symptoms and related outbreaks in the past decades is presented in Table 1 (Fig.1 ).

Fig. 1.

(A) Schematic images showing different portal entry of viruses through nose, throat and lungs. Respiratory viruses are commonly spread through inhaling the virus particles containing droplets (B) Influenza subtype profile in global influenza types in circulation in the order high to low number of incidence occurred with influenza A and B followed by subtypes, H1N1, H3 and B-Yamagata that are derived from influenza A [9].

In 20th century, three influenza pandemic outbreaks occurred in 1918, 1957 and 1968 termed Spanish, Asian, and Hong Kong influenza, respectively based on their presumed sites of origins [8]. They represent three distinct antigenic influenza A virus subtypes, such as H1N1, H2N2, and H3N2, respectively. The recent global influenza surveillance and response system (GIRS) WHO recorded during 2019–2020 showed that influenza A(H1N1) strain subtype found to be more frequent type of viral infections caused that reached to a highest peak in 2020 (Fig. 1B) [9]. Most viral pneumonia cases are reported to be caused by influenza viruses and in some cases, secondary bacterial infections after influenza may lead to serious outcomes [8].

Other large family of viruses that constitute over 50 distinct serotypes are double stranded DNA based adenoviruses [2]. These virions are non-enveloped that bear size of ~90 nm with icosahedral symmetry. Most adenoviruses infections occur in children aged less than 5-year or adults with compromised immune system. In 2007, HAdV viruses caused severe outbreaks, while in 2014, initially new HAdV-14 variant emerged with military staff (US) and then spread in the populations and led to pneumonia and acute respiratory distress syndrome (ARDS) [2]. Human Rhinoviruses (HRVs) are ~30 nm in diameter are other non-enveloped viruses made of single stranded +ve sense RNA (Table 1). These HRVs are identified with over 150 different strains that causes a higher frequency of colds affecting mostly children approx. 12 infections per year. Among other RNA viruses, single stranded –ve sense and non-segmented RNA viruses called Human parainfluenza virus (HPIV). These are larger viruses that measure 150– 200 nm in diameter and pleomorphic enveloped virions that infects young children and causes mild to severe pneumonia and bronchitis worldwide. Major risk factors for HPIV infections are associated with malnutrition, vitamin deficiency, and respiratory irritants. There are four classes of HPIVs (1–4), while the HPIV-4 is again having subtypes a and b that infects about 5 million young children every year in the United States. Similar ~200 nm diameter size of another –ve sense, ssRNA enveloped virus that has been for over 50 years in the human population is called Human Metapneumovirus (HMPV). Globally, it causes respiratory tract infections about 20% among children.

Among DNA based viruses, Human Bocavirus (HBoV) is a small 18– 26 nm ssDNA virus is found to be active and causes infections especially during the winter and spring months (Table 1). According to an epidemiological report, HBoV is generally found to co-exist about 50% cases with other respiratory viruses [2]. HBoV mostly found to be associated with pneumonia in young children.

The human corona virus was discovered in the beginning of 1960 and it has been mostly circulating in the human population for a longtime [10,11]. The word “corona” was derived for these viruses because of its crown-like morphology viewed under a scanning under electron microscope. Genetic studies classified these viruses into alpha-, beta-, gamma-, and delta-CoV. There are five different human coronaviruses namely, alpha- (including 229E and NL63) and beta- (OC43, HKU1, and SARS-CoV) coronaviruses [10,11]. Interest in this group of viruses has drawn attention after 2003 global pneumonia outbreak (SARS-CoV-1), which resulted in ~800 deaths and affected people in ~30 countries. The second outbreak took place in 2012 caused by MERS-CoV virus and MERS-CoV with new flu-like respiratory illness that was reported in over 21 countries [10,11]. Further, a new virus was identified that caused recent corona virus disease 19 (COVID-19) that transmitted across global boundaries and caused respiratory tract infections. According to WHO, as of June 2021, there have been over 178 million COVID-19 confirmed cases and over 3.8 million deaths worldwide [12]. The fatality ratio was reported to be higher in male to female (2.4:1) [13]. The studies suggested that SARS-CoV-2 infections occur in all age groups. However, old age people (70 year) are at higher risk and vulnerable due to potential pre-existing health conditions. The median time from symptoms to death and incubation time is reported to be 14 and 5.2 days, respectively. The individuals with chronic pre-existing condition, especially cardiovascular disease, diabetes and hypertension and other compromised immune systems are major associated risk factors for COVID-19 [3]. SARS-CoV-2 particles are approximately 120–160 nm in diameter decorated with ~20 nm petal-shaped spike protein extending on viral peripheral surface and this virus belong to sub-genus Sarbecovirus and genus Betacoronavirus whose morphology varies from oval to spherical or pleomorphic [14]. A summary of distinct respiratory virus features such as size, genome, morphology, disease symptoms and related outbreaks in the past decades are presented in Table 1.

Despite of major advancement in science and medicine, the potential for spread of viral diseases is ever increasing and these outbreaks risks escalate into epidemics or pandemics. Delayed detection of infectious diseases presents risks in controlling the spread of disease or pandemics. There are many preventable non-medical reasons, of which are urbanization, global travel, climate change and human-animal contact that are the likely causes for future pandemics to occur. However, most importantly, medical intervention, such as by early disease diagnosis, treatment and prevention offers effective controlling of disease, allow rapid isolation of diseased individuals, reporting and surveillance of episodes for infection control measures [15]. Current practices in contagious disease diagnosis approaches are inadequate and therefore fail in very first step of early disease diagnosis and prevention, and therefore required re-evaluation of current diagnostic practices to develop new diagnostic tools. In this review, we first began assessing the most common traditional diagnostic methods employed for viral disease diagnosis. Later, explored on possible means by which these approaches can potentially be further improved with respect to sensitivity, speed of detection, and cost-effectiveness with special emphasis to interfacing carbon-based nanostructured materials.

3. Conventional/laboratory-based methods for diagnosis viral diseases

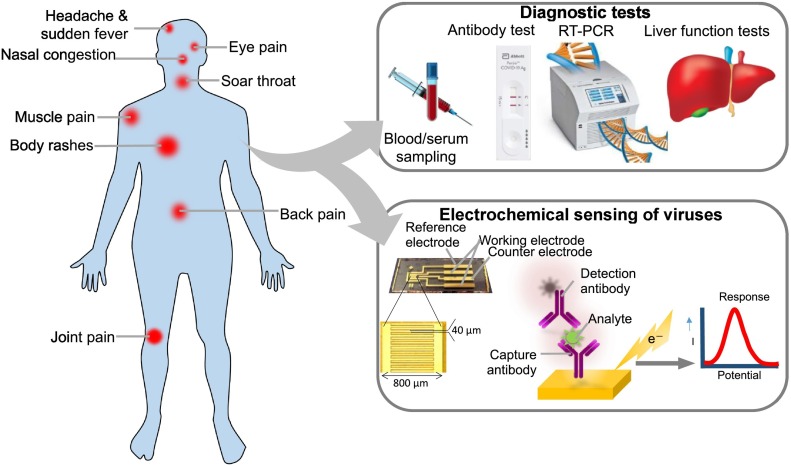

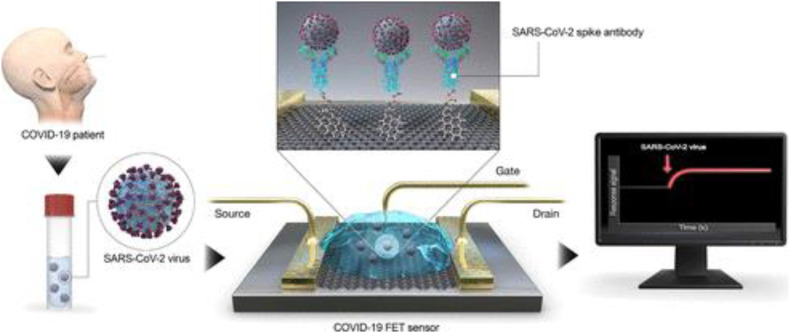

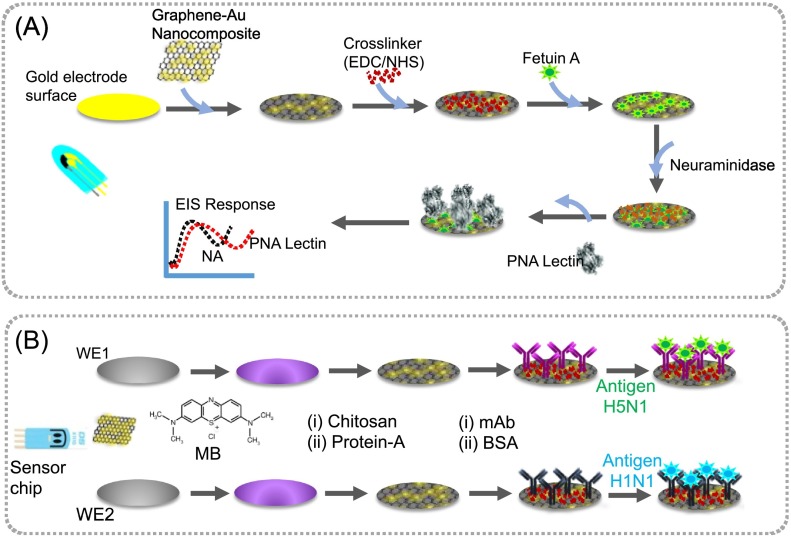

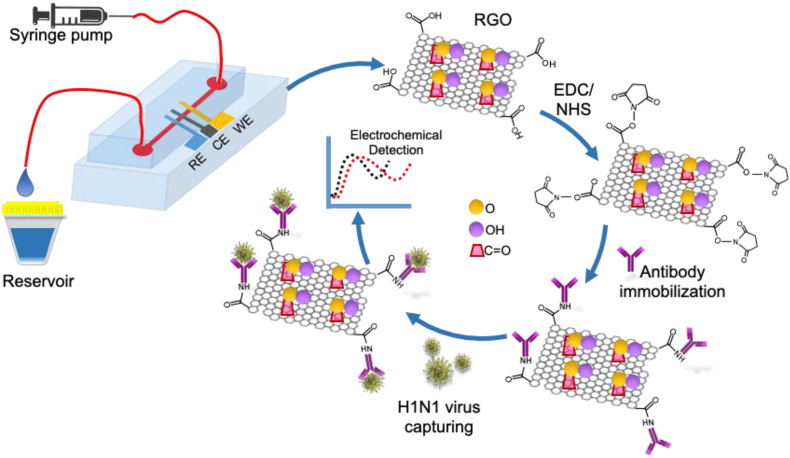

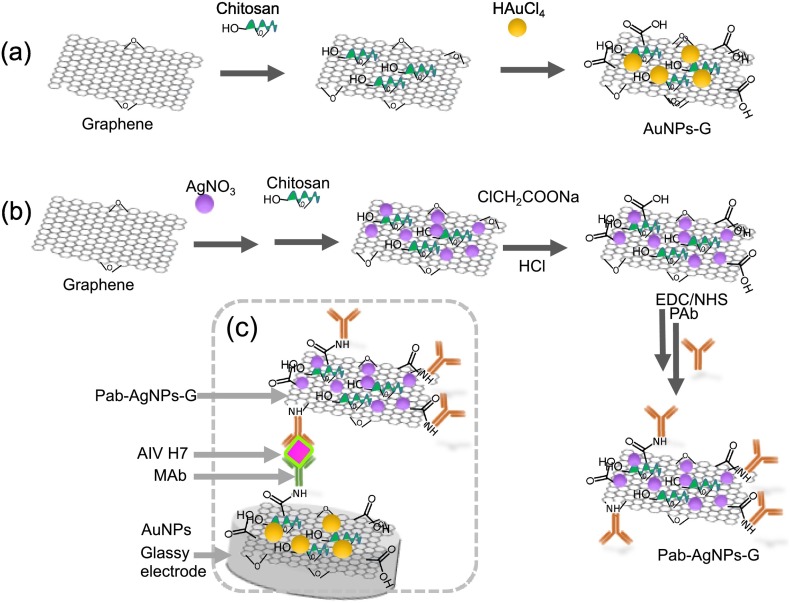

Currently, there are various methods employed for viral diagnosis (Fig. 2 ). All those existing methods can be classified into five categories, such as virus detection via viral isolation from cell cultures, detecting viral-antigens and their viral nucleic acids, electron microscopy or detection of antibodies (serology) [24].

Fig. 2.

Schematic illustration of conventional clinical laboratory based diagnostic methods for viral diagnosis.

3.1. Virus isolation from cell cultures

Viruses are cultured in disaggregated cells derived from tissue samples and isolated following chemical, mechanical and enzymatic treatments as gold standard approach for isolating virus. It is used to compare new methods and the only method that provides a supply of isolated viruses for further study through other methods [24]. There are many different cell lines used for virus isolation, for example, primary monkey kidney cell line, which is used for respiratory viruses and human epithelial cell line such as HEp-2 used for RSV isolation. Proliferation of viruses in cell culture can be monitored by cytopathic effect (CPE), which involves the visualization of morphological changes (such as swelling, shrinking etc.) in the cell culture. This method allows detection of multiple viruses however requires trained laboratory staff and it is difficult to accurately interpret CPE. The time required for cell cultures varies from long incubation periods of 1–4 weeks for classical methods to 1–2 days for rapid culture (e.g., shell vial assay) methods.

3.2. Direct detection via viral antigens

In our recent review, [25] we have comprehensively described different approaches to detecting viral or bacterial infections using host-biomarker proteins or antibodies that are not covered in this review. However, some of the approaches described for host biomarker proteins are also applicable to detection of viral antigens. Antigen detection methods, such as immunofluorescence (IF), immunochromatography, immunohistochemistry and enzyme-immunoassays (EIA or ELISA), provide direct evidence of viral infection in clinical samples. In immunofluorescence assays, viruses are detected by the interaction of fluorochrome tagged antibodies binding to target antigens, which then absorbs and emits light at a specific wavelength that is detected optically. IF is widely used for detection of respiratory virus infections, especially with parainfluenza viruses and adenoviruses; rapid diagnosis (less than 2 h) is possible [24]. Immunohistochemistry works on a similar principle as that of IF; here antibodies are tagged instead of fluorochrome with colored complex formed by an enzyme and substrate reaction. Generally, a horseradish peroxidase enzyme is used as a secondary probe for this method. One advantage of immunohistochemistry over IF is that immunohistochemistry stained slides can be kept for longer time than IF stained ones, making it possible to carry out several observations and a disadvantage is that immunohistochemistry method requires more time than IF, usually more than 24 h. One property of both IF and immunochromatography (IC) methods is that viral antigens are detected in-situ [24].

EIAs, or ELISAs can be used to detect viral antigens or antibodies and are very commonly used methods. There are different types of ELISA tests with various properties, detection and amplification systems, and sensitivities [25]. For example, with direct ELISA method, the antigen is detected through enzyme-labelled antibody directly; therefore, it is faster than indirect ELISA, although it is also less sensitive due to no signal amplification step. Indirect ELISA tests require an unlabeled primary antibody and a secondary, labelled antibody, which increases the sensitivity of the test through signal amplification, but it also leads to less diagnostic specificity. IC assays are widely used for virus detection, such as influenza A, B and RSV. The technique is based on the lateral movement of antigen or antigen-antibody complexes through the test strip by capillary action. Unlike ELISA, there are no reagent additions or washing steps required for IC assays. They require moderate expertise, equipment, and takes relatively short time (~30 min) to see the results, and some are approved as “point-of-care (PoC)” tests. However, IC is less sensitive compared to other antigen-based methods [26]. These isolation/separation methods are less sensitive as compared to viral culture or DNA/RNA (nucleic acids)-based polymerase chain reaction (PCR). Another downside is that some viruses, specifically Influenza A, have antigenic variations from year to year making the antigenic test kits unreliable or limited when a novel subtype of virus emerges.

3.3. Detection by electron microscopy

Electron microscopy (EM) is a rapid method used for virus diagnosis and it is the only method that can be used for direct visualization of viruses. EM is also important in detection of novel and non-culturable viruses, such as SARS-CoV, which was first identified in 2003 [24,26,27]. One advantage of EM over serologic and molecular methods is that there is no need for organism-specific reagents for viral detection. Thin sectioning and negative staining are two sample preparation methods that are used for examining viruses. Thin section EM takes around 3 days, whereas negative stain EM takes around 1 h. However, EM has the limitations of low sensitivity compared to other methods and requires expensive equipment and high expertise for operation of electron microscopy equipment [24,26].

3.4. Viral nucleic acids detection

Another method to viral antigen or antibody detection is by RNA/DNA from viruses that can be isolated from infected-cells and analyzed by classical methods such as Southern Blotting (DNA), Northern Blotting (RNA), dot blot, in situ hybridization or nucleic acid amplification methods (e.g. PCR, RT-PCR) [24,27]. Classical hybridization techniques are sensitive however, they are not very suitable for routine testing. Nucleic acid detection is especially useful for the cases where the viruses cannot be cultured easily or with latent viral infections. It is also more rapid and safer than viral culture methods. Development of PCR testing has evolved as a most sensitive molecular technique for detecting virus. Conventional PCR tests take 5–9 h and are more suitable for multiplex testing (detection of multiple viruses at once). However, it is prone to cross contamination because PCR tubes must be opened before the detection step, and toxic substances like ethidium bromide are used for amplicon (PCR product) detection. Real-time PCR has a shorter assay time of 1–5 h, less prone to cross contamination as it combines the amplification and detection steps in one-step and thus the test tube is not required to be open for detection. It is more sensitive than conventional PCR [24,26,27]. For RNA virus detection, reverse transcriptase PCR (RT-PCR) is applied, where reverse transcriptase enzyme is used to convert RNA to DNA first. An advantage of PCR technique is that it can be quickly adapted for novel viruses through a specifically designed primer/probes. Most commonly, RT-PCR method is utilized to demonstrate the detection of SARS-CoV-2 SARS virus [27].

3.5. Detection of antibodies in blood (serological assays)

Serological tests are widely used for detecting immunoglobulins (Ig), such as IgM and IgG antibodies. There are several methods used to detect viral antibodies described in previous section and most common methods include EIA-ELISA, immunoblotting (Western Blotting), serum neutralization assay, indirect immunofluorescence, hemagglutination-inhibition. Serological tests can detect both recent and past infections, providing information of the cause or origin of the disease (etiology). Time required for serologic tests depends on the type of method and it can range from 30 min to 24 h [26]. Antibody based ELISA tests are commonly used for viral detection, as they are rapid and relatively cheaper alternatives to other methods. Hemagglutination inhibition test is based on inhibition of hemagglutinin molecules by antiviral antibodies and therefore, highly useful for influenza virus detection as it shows enhanced sensitivity [28]. There are limitations to serological assays such as in some infection cases, antibody response is not strong enough to detect viral antigens or with immunocompromised patients sample the assay response was found to be weaker and cross reactivity between similar viruses was also reported [24,26].

So far, various methods have been reported for detecting causative viral infections by means of probing viral antigens, their nucleic acids, host antibodies or by physically examining the whole virus itself. However, the main problem in detecting viral causative agents at the early onset of infection is extremely challenging because of their low titer values. Another challenge is viruses such as SARS-2 are likely to mutate and with signs and symptoms that severely affects elderly people, infants, pregnant women, children and individuals with chronic pre-existing disease conditions or compromised immune system. Until now, only nucleic acid-based detection such as PCR/RT-PCR are the reliable methods used for accurately detecting viral infections at the early onset of disease. These nucleic acids-based methods require prior knowledge of viral genome sequence or run parallel tests for a range of known pathogenic viral nucleic acid probes for diagnosis of viral infections. There is always a need and demand to develop new, simple, rapid and accurate PoC detection device for pathogenic viruses, or by adding new functionality to existing sensing regimes. Elaboration of biosensor with nanomaterials-assisted biosensing can potentially address the future PoC diagnostic devices that can function remotely and in resource-limited settings without relying on centralized clinical laboratories, including those described in former sections of this review. Development of biosensor incorporating carbon nanomaterials (NMs) such as graphene and CNTs provides an exceptional advantage with their biological compatibility as well as, superior chemical properties. Graphene and CNTs nanostructures long been used for bio−/chemical sensing of a variety of targets, such as biomolecules, chemicals, and gases. There are several transduction methods for designing of carbon NMs integrated biosensors and a majority of these rely on electrical and fluorescence transduction schemes. Electrical (electrochemical) biosensing is another potentially most suitable type of transduction scheme that can be employed for infectious viral disease diagnosis. Integrating carbon nanomaterials provides unique physico-chemical properties and surface chemical modifications on electrochemical biosensors, making carbon nanomaterials most suitable nano-candidates for biosensing viral pathogens with greater speed, and sensitivity.

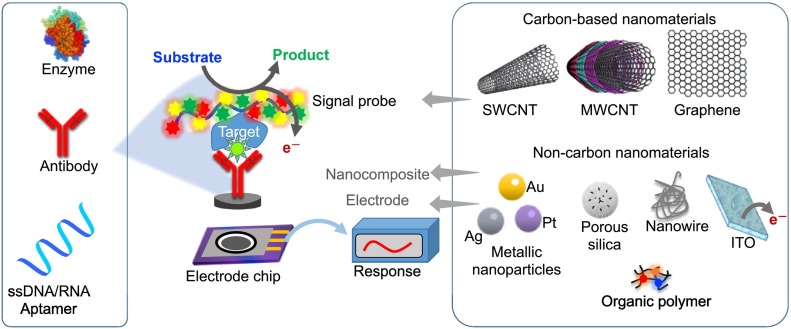

4. Electrochemical biosensors

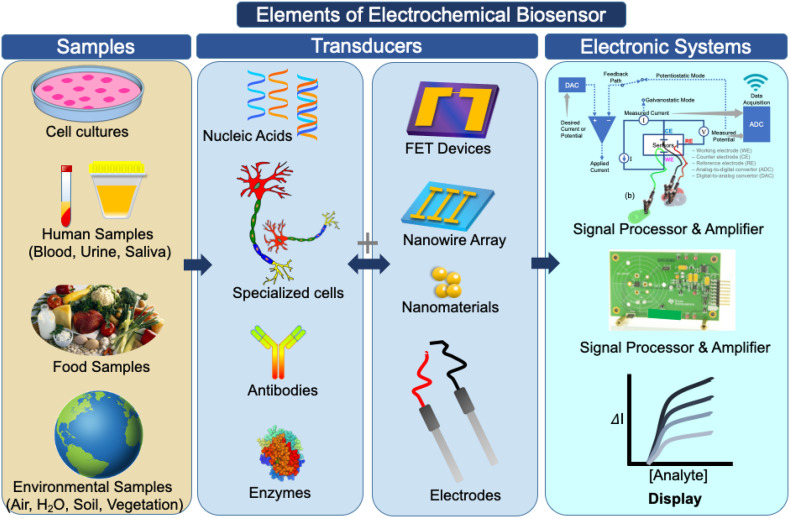

Biosensors play an essential role in disease diagnosis and health care monitoring applications and there has been a continuous effort made toward the improvement of health care technologies. A biosensor is an analytical device that detect and quantify biomolecular interaction that takes place between an immobilized probe with target/analyte molecules on a transducer platform (Fig. 3 ). Biosensors are powerful analytical tools in point-of-care diagnostics that facilitates personalized medicine therapeutics and cost-effective medical treatments. Biosensor devices are also widely used for detecting nucleic acids, various proteins, or for monitoring target (antigen) – probe (antibody) interactions. A biosensor is constructed by interfacing its transducer surface with a bio-receptor element, mainly antibodies, receptor, DNA/RNA that translate biochemical signal into a quantifiable electronic/electronic, electrochemical, optical, acoustic, or magnetic signal.

Fig. 3.

Scheme showing biosensor design components employed for sensing of target analyte samples, with special emphasis to utilizing an electrochemical biosensing platform that transforms biochemical information into current or voltages signals on an electrochemical transducer surface.

Electrochemical biosensors so far are the most widely used and highly preferred type of sensing platforms. As per the IUPAC definition, electrochemical biosensor is a self-contained integrated device that is capable of providing specific quantitative or semi-quantitative analytical information [29]. In other words, an electrochemical biosensor, which transforms a biochemical reaction into a measurable analytical signal, which is usually in terms of changes in current or voltages, whereby an interfaced bio-electrochemical element serves as transduction element (Fig. 6b). Electrochemical biosensing devices are designed by using different recognition elements, such as living whole-cells, micro-organisms, nucleic acids, antibodies, or enzymes [30]. Enzyme based electrochemical biosensing detection techniques are most widely used techniques, whereas immunosensors were developed by using antibodies, fragments of antibodies or antigens to monitor molecular binding in bio-electrochemical reactions [31]. The electrochemical biosensing research development in fact began after Clark first published papers on the development of oxygen electrode and modified oxygen electrode system in 1955–1956 and 1962, respectively [[32], [33], [34]]. These works sparked the development of different electrochemical transduction signal modes such as polarographic, potentiometric and conductometric based on enzyme reaction based biosensing platforms. These developments lead to the evolution of a first electrochemical biosensing technology, now commercially marketed as glucose biosensor device first produced by Clark's group Yellow Spring Instrument Company in 1975 [33]. The performance of electrochemical biosensor and analyte detection ability is heavily dependent on electrode material, electrode design, dimension, geometry and surface because electrochemical reaction signal are generally measured in close proximity of electrode surface area. Electrochemical sensor system development conventionally requires a working electrode (redox electrode), a counter or auxiliary and a reference electrode. Ag/AgCl is commonly used as reference electrode in the electrochemical sensor because it maintains a known and steady potential. Typically, in the electrochemical sensor, working electrode is used as transducing element and a counter electrode serves to establish a contact to the electrolyte solution in order to apply a current on the working electrode. In the electrochemical biosensor development, conductive and chemically stable materials such as, carbon based nanostructures (graphene, GO, CNTs, and graphite), gold, platinum and silicon-based materials were generally used to fabricate working and counter electrodes. The electronic transducing working electrode surface is chemically modified with nanostructures and referred to as chemically modified electrode (CME). The CME surface modified/immobilized with nanostructure provides excellent electronic, ionic or semiconducting properties with a biochemical-film on transducer surface [29] as shown in scheme Fig. 4 .

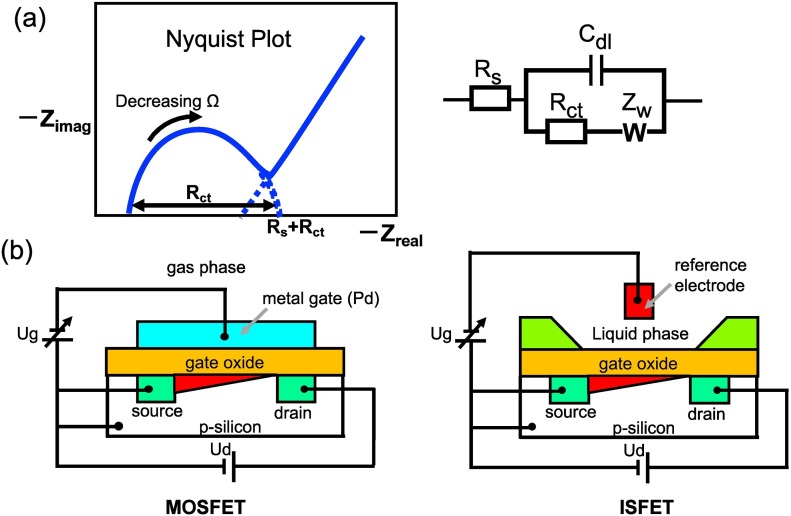

Fig. 6.

Schematic illustration of (a) EIS Nyquist plot (Zimag/Zreal) and Randles circuit consist of W, which is Warburg element that corresponds to diffusion processes. (b) Structures of MOSFET and an ISFET, where Ugand, Ud are gate voltage the source-drain voltage, respectively.

Fig. 4.

Scheme showing the typical components of a electrochemical biosensor including probe, target and interfacing of nanostructure electrode for biosensing of target molecules [29].

Electrochemical biosensors are popularly used for detecting a variety of biomolecules because they can be easily integrated with multiple modules such as; (i) miniaturized lab-on-a-chip, (i) low-cost microelectronic circuits, (iii) interfacing with electronic read-out, and (iv) a signal processing unit. Electrochemical biosensors being sensitive, easy to miniaturize, require small analyte volumes, excellent limit of analyte detection and display on-site results are most desired in medical diagnostics and in many other research areas including food safety and environmental monitoring.

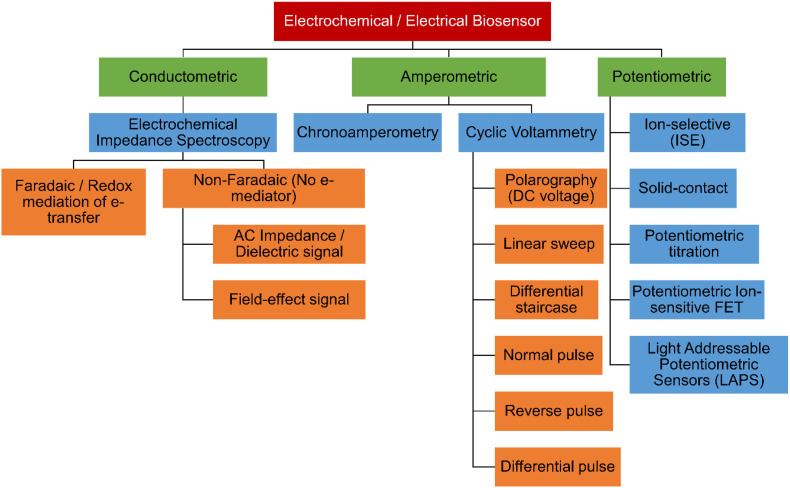

Electrochemical biosensor can be classified based on type of transducer modes used for signal measurements. These includes conductometry and surface charge, amperometry and potentiometry transduction platforms (Fig. 5 ) [29,30]. General principle of electrochemical biosensing (bio-electrochemistry) is based on electrochemical reaction taking place on or at the proximity of electrode and or between the electrodes that lead to; (i) a measurable current signal (amperometric), (ii) cumulate charge or potential(potentiometric), or (iii) changes in the conductivity of the medium (conductometric) [30].

Fig. 5.

Classification of electrochemical biosensors based on type of transducer and signal modes.

4.1. Conductometric biosensor

In the conductometric electrochemical biosensor, analyte induced signal is measured through electrolyte solution on transducing electrode that conduct an electric current between electrodes. These conductometric electrochemical biosensors with electrochemical transducer formats have been conventionally employed for sensing various biomolecules, disease biomarkers, proteins or antibodies. Most of designed conductometry-sensors are based on electrochemical impedance spectroscopy (EIS) or conductometric measurement technique. In the following section, basic principle and mechanism of EIS are discussed.

4.2. Electrochemical impedance spectroscopy basic principle and mechanism

EIS method measures the multiple microscopic electrochemical reaction processes between electrode and electrolyte system with an applied electrical stimulus. The transfer of electrons takes place due electrical perturbation, and it initiates oxidation and reduction reactions between electrode to electrolyte or vice-versa. The EIS sensor signal transduction is originating as a result of charges flow-rate and electrons as a function of electrode resistance, electrolyte as well as electrochemical reaction rates at the interface of sensor electrode [35,36]. In principle, AC current or potential is measured as function of frequency by applying AC current (galvanostatic) or potential (potentiostatic) to the electrochemical sensor. The electrochemical impedance parameter Z(ω,t) is a ratio of applied potential E(ω,t) or DC constant potential and current I(ω,t), which is described by following Eqs. (1a), (1b);

| (1a) |

| (1b) |

where, ωis an angular frequency (ω = 2πf, f is AC frquency) and t is time. The magnitude of impedance is |Z|, while the real and imaginary impedance are represented by Z′ and Zʺ respectively. Here, j represents an imaginary number √-1, and φ shows the phase angle between V and I.

A Nyquist plot generally represents the impedance data, where real impedance (Z') profile is plotted as a function of imaginary impedance (Z"). Another representation is shown by Bode plot where |Z| and/or φ is represented as a function of applied AC frequency. These data representation allow defining the electrochemical sensor signal transduction mechanism and characteristics such as interfacial and conductive properties of electrode and electrolyte. In EIS, representation of complex impedance data values is generally molded using an equivalent electrical circuit to analyze sensor performance parameters such as inductive, capacitive and resistive components. EIS method is generally classified in to two EIS sensor categories: (a) Faradaic electrochemical sensor and (b) non-Faradaic electrochemical sensor (Fig. 5). Faradaic sensor refers to electrical charge transfer across a sensor electrode and electrolyte in the presence redox species, whereas non-Faradaic sensor system does not require redox mediator to initiate the charge transfer between the electrodes. Conductometric sensors design can function in both Faradaic and non-faradaic types of EIS detection regimes.

4.2.1. Faradaic electrochemical sensor

In Faradaic electrochemical sensor, electrochemical transducer measures the impedance (resistance and reactance) signal through charge transfer capability of an analyte between the electrode and redox electrolyte solution, or redox medium between the electrodes or reference nodes over a wide range of applied alternating current frequency (Hz to MHz). In Faradaic EIS technique, an electroactive species (redox reagent) reduces and oxidizes at the electrochemical sensor electrode surface to induce the electrical signal (current, impedance). Developing Faradaic electrochemical sensor or Faradaic impedimetric sensor requires a redox reagent/probe and a constant applied DC in order to generate signal from electrochemical reactions. Therefore, difference between the applied potential and cell-equilibrium potential is generated (called an over-potential) through an applied constant or variable potential over the electrode cell/sensor. The over-potential generation results in promoting electron transfer in electrochemical redox reaction known as Faradaic process [37]. Faradaic sensor signal response is defined by Faraday's law (Eq. (2)), where the Faradaic current is directly proportional to; (i) number of electrons transferred in electrochemical redox reaction (n), (ii) Faraday constant(F), (iii) surface area of electrode (A) and, (iv) analyte/electroactive species flux (j) at the interfacial boundary.

| (2) |

The Faradaic sensors exhibits greater sensitivity than the non-Faradaic sensors because it measures current generated from the redox reactions. However, detection and biosensing of certain specific biomolecules using the Faradaic sensor can be difficult due to potential interactions of the target molecule with electrolyte. The Faradaic sensor signal response modeled through appropriate equivalent circuit with signal parameters such as impedance, which is a complex number, and often, real part is associated with resistive behavior (Z real), whereas the imaginary part (Z imag) is associated with capacitive process. Other parameters include (i) R s, resistance of electrolyte solution (ii) C dl , double layer capacitance and is also accompanied with a constant phase element (CPE), (iii) R ct, charge transfer resistance and (iv) Z w is Warburg impedance.

The R ct generates through potential due to oxidative and reductive process at the sensor electrode surface including the stearic effect or repulsion of charges species on conductive electrode surface. Warburg impedance (Z w) originates due to diffusion of electroactive charges through electrolyte solution to surface of sensor electrodes. Here, Nyquist plot provides the charge transfer resistance values (R ct), in which the R ct is the diameter of semicircle and Warburg impedance (Z w), which can be eliminated through an inclined 45° straight line at low AC signal frequencies (Fig. 6a) [35,36]. In the Faradaic electrochemical sensor, oxidation and reduction reactions are performed with a mediating redox chemical present in the medium. The most commonly employed redox mediator electrolyte is Fe(CN)6 3−/4- in the literature. A few Faradaic electrochemical sensors designs also utilized conductive polymer structure such as polyaniline, ploypirrole and polythiophene that facilitate the redox process through conducting charges along their chain structure due to doping mechanism.

4.2.2. Non-faradaic electrochemical sensor

Non-Faradaic based electrochemical sensor does not require redox intermediary chemicals/agents and it measures the change in dielectric parameters (capacitance, impedance, permittivity, current) in between the electrode and the medium (electrolyte) as well as at the sensor electrode interface. Non-Faradaic EIS method has exceptional advantage owing to its feasibility to miniaturization of sensor design, real-time monitoring and most importantly, it does not require additional electrodes and accessories. The impedance signal transduction in non-Faradaic type of sensor originates from change in dielectric properties between the electrodes which is ascribed from the formation of double-layer capacitance and its charging and discharging process. Here, sensing principle of non-Faradaic type of EIS sensors is therefore relied on changes in charge distribution or conductivity or dielectric properties as a result of formation of analyte–target complex on the surfaces of conductive electrodes [38]. The impedance signal directly depends on different parameters that mainly include double layer capacitance formation, nature of charge carries and their concentration in between the electrodes, the electrode design and geometry, as well as the type of conductive electrode material employed. The equivalent circuit for such sensor system consists of a combination of capacitors and resistors. The transducing sensor signal response can be described by an equivalent circuit that is comprised of elements such as capacitors and resistors. Here, the |Z| and φ components are adequate transducer parameters. As per the Helmholtz model, the double layer capacitance (C) is given by the following Eq. (3).

| (3) |

C depends on the relative permittivity (ε r) of the solution, permittivity of free space (ε 0), electrode surface area (A) and Helmholtz layer. For providing larger sensor surface, non-Faradaic conductor electrodes can also be made capacitive sensor that consist of interdigitated fingers pattern. Here, capacitance signal changes due to dielectric properties change in between the electrodes. This change in capacitance is correlated to the binding of analyte/target molecules and the concentration of captured target by chem−/bio-receptors tethered on sensor electrodes.

Recently, immunoassays utilizing capacitive array sensors have been employed for detection of multi-analytes through both Faradaic and non-Faradaic electrochemical regimes. These arrays of sensors offers complex multi-analytes or multiplexed detection option with simple analytical procedure, short analysis time, require low sample volume, high test efficiency, and less expensive as compared with that of single-analyte assays. Several immunoassays have been successfully designed that utilize capacitive label-free biosensors platforms without/with involving a redox mediator (non-Faradaic or Faradaic, respectively) [[39], [40], [41]]. However, there are major challenges in the development of capacitive label-free biosensors mainly because of their poor reproducibility which is associated with non-uniformity in fabricated electrode designs that provides a large standard deviation and non-specific signal.

Further, other types of electrochemical sensor systems include field-effect transistors (FETs), which utilizes source-drain electrode terminals to fabricating ion-sensitive FETs (ISFETs) and metal-oxide FETs (MOSFETs) transistors. These FET sensors are designed to measure the current signal generated as a potentiometric effect at a gate electrode (Fig. 6b). In surface charge-based electrochemical transduction system, ISFETs are used to detect the ion concentrations [29,30]. Here FET gate electrode surface is modified with an ion-selective membrane (ISM) to measure the analyte signal. If these sensors are used for biological sensing purposes, they are called for instance, enzyme-FETs (ENFETS) or immunological FETs (IMFETs) for integrating FETs with enzyme or antibody, respectively. To understand ISE-based biosensors, ENFETs and IMFETs can be understood by further reading on biologically sensitive FETs reported by Schöning et al. [42]. Interested readers can find more information on FET sensors in a recent review by Sadighbayan et al. [43].

4.3. Amperometric sensors

Amperometric electrochemical sensing usually requires a three electrodes system made of a reference (Ag/AgCl), working electrode (Au, carbon), and a counter or auxiliary electrode (Pt). Here, the current signal is continuously measured by an amperometric transducer following redox reaction of an electroactive species (redox/electron mediator) in a bio−/chemical reaction taking place on the electrochemical transducer surface. In other words, the concentration of bulk electroactive species in the electrochemical sensor system is directly proportional to the generated current from oxidation and reduction of charge species produced/consumed at the bio-electrode-electrolyte interface [29,30]. This electrochemical biosensing method rely on use of redox reagents to mediate oxidation and reduction of the analyte at the working sensor electrode because not all biomolecules (protein, DNA, microorganisms) have ability to serve as redox mediator themselves. These sensors are known as amperometric sensors because the transducing signal is measured as changes in current signal at a certain value of applied potential. If the transducing current signal measurement is performed by applying different values of potential, such method is known as voltammetry sensing method, which is reviewed in the following section. The concentration of analyte/target molecule is directly proportional to the value of peak current with respect to selected potential range. According to literature reports, the amperometric devices exhibit superior sensitivity compared with the potentiometric devices [29,30,44].

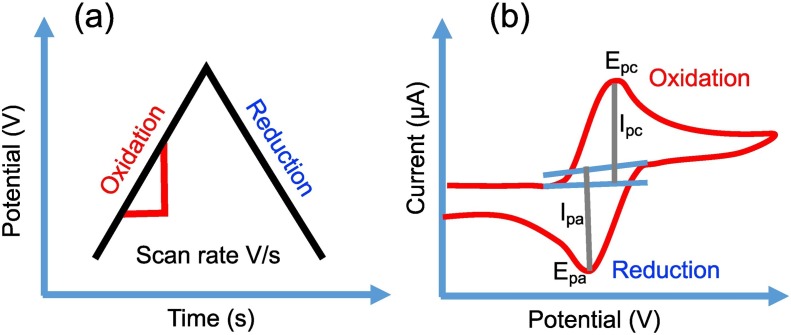

4.3.1. Cyclic voltammetry (CV)

In the voltammetry electrochemical/bio sensing method, the analytical measurement of analyte concentrations is obtained by measuring transducing current against varying applied potential. Therefore, voltammetry is classified as an amperometric electrochemical technique. Further, voltammetry can be categorized based on the condition of applied potential that includes linear seep, differential staircase, pulse voltammetry (normal, reverse and differential pulse), and polarography (DC Voltage) voltammetry [29,30,44]. Cyclic voltammetry is a most commonly utilized amperometry technique that provide important chemical/biosensing parameters such as kinetics of rate of electrochemical reaction and redox potential. Typically, CV is operated by sweeping the voltage between two values (V 1 and V 2) at a fixed electrochemical reaction rate (voltage/s). In the electrochemical reaction sweep, initial voltage (V 1) is swept to final voltage (V 2) and then the voltage sweep is returned to V 1 as shown in Fig. 7 (a-b). The electrochemical scan rate is defined by a ratio (V 2 -V 1 )/(t 2 -t 1) to generate an electrochemical signal in a given time of interval. In CV, potential (voltage) and current (I) parameters are measured between the working-reference and working-counter electrodes, respectively. A voltammogram is generated by plotting the measured current signal as a function of applied voltage. The current signal increases when the potential voltage (V 1) increases toward the oxidation potential of the target analyte molecule. After the potential voltage V2 reaches to reduction potential, the current begins to decrease which is displayed as a peak shaped curve at which the analyte concentration diminishes on the surface of electrode (Fig. 7b). In a reverse voltage sweep, the voltage scan turns back to voltage (V 1) through reduction reaction as the current decreases, which is seen as a second, reduction peak with opposite polarity in comparison with forward scan until finally voltage scan reaches to V 1. The information related to the reversibility of electrochemical reactions can be obtained in the reverse voltage scan sweep at a specific scant rate. The nature of voltammogram shape provides information about analyte concentration on the working electrode. Performance of voltammogram depends on several factors such as scan rate, electrode material, adsorption, and concentration of analyte.

Fig. 7.

(a) An illustration of scan rate activity with potential over time and (b) cyclic voltammetry curve for detailed oxidation and reduction reaction illustrated with potential over current.

4.3.2. Chrono-amperometry

Chrono-amperometry is based on amperometric principle in which a square wave potential is applied at working electrode to measure the steady-current signal [29,30,44]. The change in sensor electrode current signal response originates due to change in thickness of diffusion layer on the working electrode surface. The chrono-amperometry technique is introduced by Nernst and its principle is based on the formation of a static thin film which is in contact with electrode surface. This arrangement allows controlled diffusion process through which transfer of analyte occur from electrolyte solution to the electrode. In this case, the transfer of analyte concentration (c 0) in the bulk-solution while balancing a gradient concentration in the electrochemical reaction between electrolyte solution and electrode surface. In the chrono-amperometry, the current response can be defined by Cottrell equation, where linear electrochemical diffusion process on planar electrode is monitored by measuring the current as a function of time. Cottrell equation exhibits that the current I is dependent on Faraday's constant (F), the number of electrons transferred per molecule (n), electrode area (A), the concentration of analyte (c 0), diffusion coefficient (D), time (t) were all expressed in the following Eq. (4).

| (4) |

Chrono-amperometry electrochemical technique does not relay on reactants labelling and it is a sensitive and supportive technique utilized for time dependent CV measurements.

4.4. Potentiometric sensors

In potentiometric sensors, the transducers measure potential due to the accumulation of charges on the working electrode where bio−/chem-receptors interact with analytes. The potential measurement is performed between the reference and working electrodes when negligible current flows through them. Typically, potentiometric devices transduce the ion activity signal in the electrochemical reactions [29,30]. The detection of analyte is usually determined by Nernst equation, which shows the correlation of potential with concentration of analyte and known as direct potentiometry method. In this technique, cell potential (E cell) or electromotive force (EMF) is measured at working electrode at zero current and define by Eq. (5)

| (5) |

where, parameters in Eq. (5) represents absolute temperature (°K) (T), universal gas constant (R), ratio of ion concentration (Q) between electrode, number of charges (n) and Faraday constant (F).

Potentiometric transducers can be designed for different transducing platforms that includes ion-selective electrode with polymer or membrane, wire electrodes based solid electrodes, potentiometric titration, ISEFTs and light addressable potentiometric sensors (LAPS). Most of the potentiometric electrochemical sensors utilize ion-selective electrodes (ISE) to achieve lower analyte detection limit. Potentiometric sensor offers advantages of measuring small concentrations in small sample volumes, minimized or no chemical cross talk during measurement of a sample. In the potentiometric titration method biochemical reaction point is measured in which equal quantities of opposing solutions, such as 0.1 M HCl and 0.1 M NaOH gain equilibrium state. Here, end point is determined by measuring changes in electrode potential at steady or negligible current which is brought through variation in solution concentration. ISFETs are another potentiometric sensor formats to measure changes in pH values, selective ion-concentrations and the enzyme involved biocatalytical reaction kinetics. Further, LAPS is another example of novel optical/electrochemical hybrid potentiometric technique. LAPS combines a focused light source scanning that allows determining the potential distribution at the sample and substrate interface. Potential distribution along the interface of the sample and substrate surfaces. Bratov et al. provided detailed information about potentiometric sensor arrays, their design, and development of different approaches for further reading [45].

In recent years, the conventional electrochemical transducers provided opportunity to integrate them with carbon-based nanomaterials to enhance the sensitivity, surface-to-volume ratio, charge-carrier density that constitute new generation of powerful electrochemical sensing platforms that find application in sensitive detection of analytes, such as SARS-CoV-2 which otherwise, not possible by conventional electrochemical sensors. The major issues in the development of electrochemical nanobiosensors include designing of transducer biosensing interface, high selectivity and sensitivity of biosensor, response time, compatibility with complex biological samples, confined operating environmental conditions, multiplexing biosensor with multi-analyte detection capability within one biosensor device. Recently, nanomaterial interfaced electrical biosensors with new design and strategies have been attracted much attention to apply them for respiratory virus detection. Advancement in structure and functional properties of nanomaterials, especially carbon-based nanostructures with the nanofabrication approaches include electron beam lithography, photolithography, nano-printing lithography played a crucial role in designing and specification of new generation of electrochemical biosensors [46,47]. Nanomaterials, specifically carbon based nanomaterials such as graphene, CNTs and its derivatives offer significant advantages in electronic biosensing of infectious viruses and other biomolecules that include label free, real-time, high sensitivity, interfacing with wafer-scale semiconductor chip fabrication, increase spatial resolution of sensor signal and ease of scale-up production.

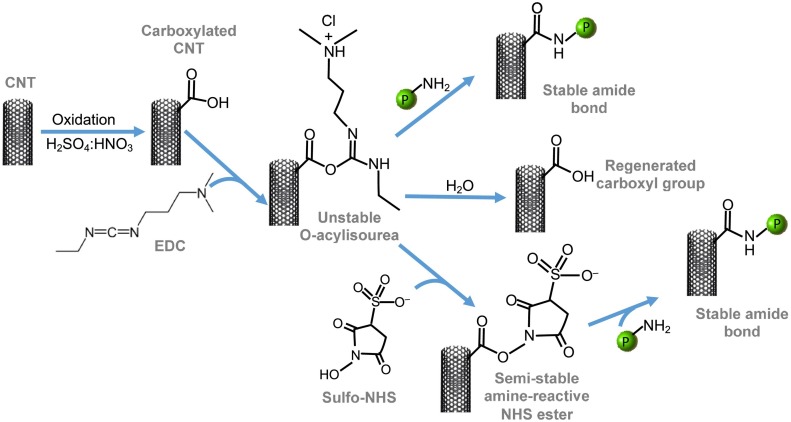

The following sections describe on the advantages of 2D graphene and CNT nanostructures and their unique physicochemical properties, various approaches employed for their surface modification/chemistry and linker molecule characteristics that facilitate in the development of electrochemical nanobiosensors. Further, advantages of sensors interfaced with these carbon-based nanostructures and their unique physicochemical properties in designing new nanobiosensors with special emphasis to detecting viral or other disease causative agents are presented.

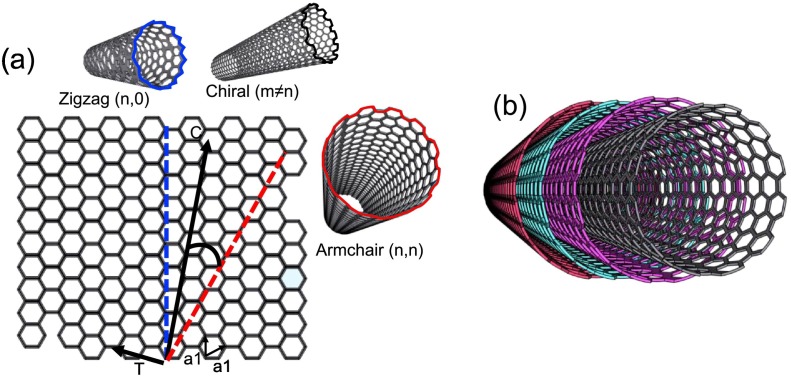

5. Carbon nanomaterials: properties and surface modification

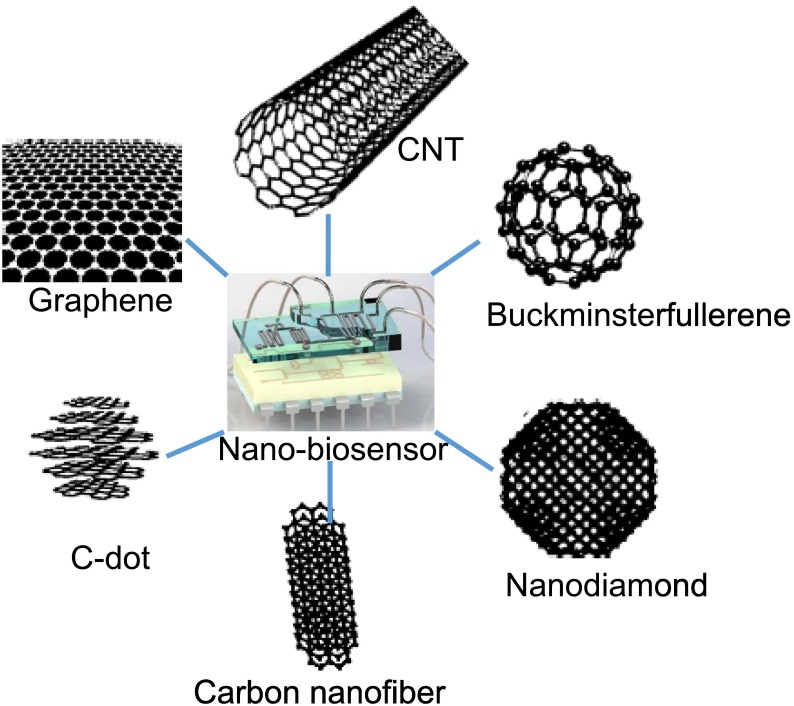

Carbon materials are applicable in every aspect of our daily life because they are abundant and lightweight materials that can be used for a variety of applications [48]. These carbon-based nanomaterials can be classified based on their dimensionalities (D) as zero-D (0D) such as carbon dots, one-D (1D) as in CNTs, and two-D (2D) in graphene nanostructures (Fig. 8 ). These nanomaterials bear wider operating temperature, sensitivity and wider dynamic transducing signal range even in harsh environmental conditions. The emerging applications of CNTs and graphene in sensor and energy storage fields has led to their large-scale industrial productions. Both graphene and CNTs are important polymorphic forms of carbon and possess excellent electronic (electron transfer), mechanical properties and excellent biocompatibility. These useful features of graphene and CNTs make them excellent carbon-based materials for the fabrication of sensor electrode.

Fig. 8.

Schematic illustration of certain allotropes of carbon nanomaterials for nanobiosensor development.

Interfacing graphene and CNTs nanostructures in electrochemical sensors enhances sensitivities by several orders of magnitude, enabling fabrication of an entirely new generation of biosensor devices. Graphene and CNTs nanostructures carry extraordinary structural, electrical, physical, and optical properties and following section highlight their unique characteristics that make them superior nanomaterials for the development of electrochemical biosensing transducing platforms. The following sections also describe individual nanostructure properties, their surface functionality and important case studies successfully employed for biological sensing.

5.1. Graphene nanostructure properties

Graphene is identified as a new class of 2D material with an atom-thick honeycomb sheet made of carbon atoms. Novoselov's group (University of Manchester) received a Nobel Prize (physics) (2010) for their outstanding work on synthesis of graphene and isolation, identification, and characterization. Graphene being a 2D material has unique properties most desired in the development of electrical sensor and other future applications. The diameter of a carbon atom is 0.33 nm, which implies that there are approximately 3 million graphene layers in a one-mm of graphite material [49]. Graphene is one atom thin transparent conductor and suitable nanostructure especially for sensor technologies today because, it has high electron mobility that is four-times larger than Group III-V semiconductors and ~ 200-times higher than Si, much higher electrical conductivity than copper, and has a large 2630 m2/g surface area [50]. In graphene, thin layer sp2 carbon atoms are connected covalently forming a honeycomb lattice structure, which makes graphene zero-gap or semimetal semiconductor arising from valance and conductive bands touch Dirac points in its electronic structure [50]. This allows graphene to be a very attractive nanomaterial for sensitive biosensors and high-speed transistors platforms.

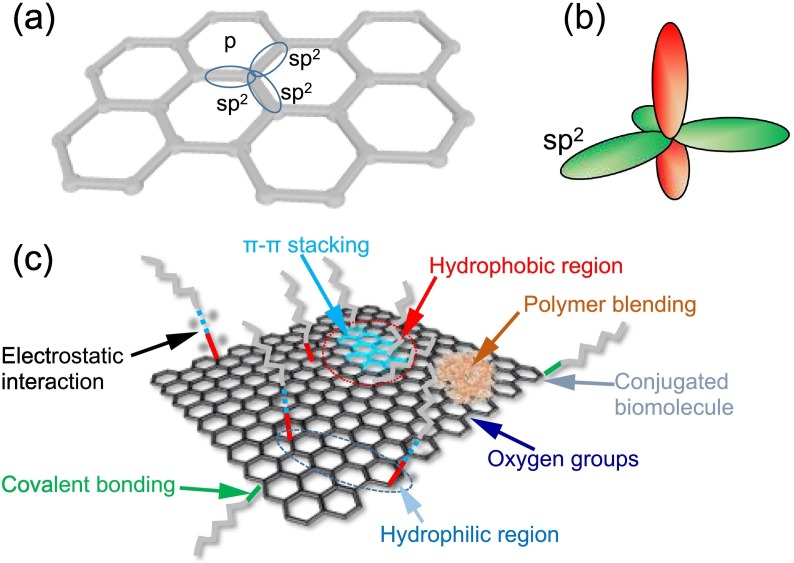

The unique electronic feature of graphene makes the incident light to constantly transmit through its nanostructure in the range of visible-IR. The optical opacity of graphene is about 2.3% and its transmittance is proportional to the number of graphene layers [50]. Graphene has the ability to quench photoluminescence, which enables its usefulness in designing optical sensor devices. In the graphene structure, carbon atoms are connected with strong σ-bonds of sp2 hybridized orbitals, which gives rise to a 2D- hexagonal networks of carbon (Fig. 9a-b). Graphene exhibits outstanding electronic and photonic properties due to the presence of π-orbitals orthogonal in the hexagonal plane [50,51].

Fig. 9.

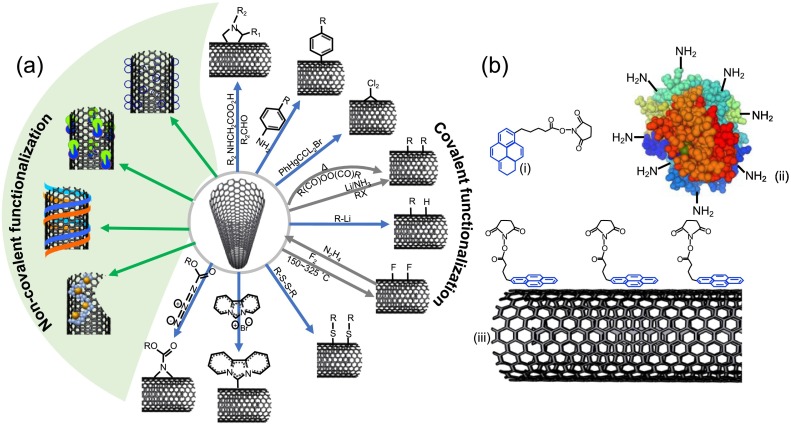

Schematic illustration of graphene structure with; (a) sp2 hybrid carbon-atoms, (b) π and σ bonds formation and (c) Schematic illustration of different chemical surface modifications on graphene by non-covalent and covalent functionalization [51].

The superior thermal transport properties of graphene is attributed to its out of plane quadratic dispersion of phonon in its 2D crystal structure. Graphene's thermal conductivity is one order higher compared to Cu and measured to be 5000 W mK−1. Similarly, graphene found to be applicable for heat management in electronics due to its excellent heat conductivity. Interfacial thermal resistance can be minimized by strongly coupling graphene and polymer. Graphene is used to fabricate highly conductive transparent films because of its unique carrier mobility and electrical conductivity [52]. Further, graphene structure composed of sp2 carbon hybrids, which establishes σ bonds with the neighboring atoms and the length each carbon bond is 0.142 nm. This σ bond property in graphene influences on the strength or Young's modulus (1 TPa with a thickness of ~0.33 nm) that makes mechanical strength of graphene ~100-times greater than for steel. Graphene is also stretchable flexible conductor [50], graphene can also exhibit magnetic properties such as paramagnetic, and exhibits magnetic switching (ferromagnetic or antiferromagnetic) phenomena [[52], [53], [54]]. Recent studies show externally induced magnetic property of graphene through its modification by coupling with magnetic nanoparticles either by in-situ chemical reduction of metal precursors such as iron, cobalt, or nickel-salt precursors, or coupling graphene with magnetic nanoparticles synthesized [52]. These hybrid features enable tuning the graphene surfaces to adsorb guest molecules and segregation that is most desired properties for fabricating high sensitivity graphene-based sensors.

Graphene has been utilized as electrochemical nanomaterial for the fabrication of sensors such as gas, chemical, and bio- sensors because of its superior physico-chemical and biological properties. Graphene can be used to design electrical sensor as a silicon analog because of its advantages of flexibility, miniaturization, and cost-effectiveness. However, the major challenges to fabricating sensor devices using graphene are poor chemical functionality and lack of energy band gap in its electronic energy structure. Therefore, development of further approaches/methods are required to engineer electronic and surface functionality of graphene structure. The following sections describe various approaches employed for surface modification of graphene, their surface chemistry and linker molecule characteristics and ways to utilize them as superior nanomaterials for fabricating electrochemical biosensing transducing platforms.

5.2. Graphene surface modification

Understanding the process/methods of graphene synthesis is important to appropriately modify the graphene nanostructure surface. There are different approaches to synthesize graphene and the most simplest method being first reported by Novoselov and Geim in 2004 is by exfoliation of graphene layers from graphite using a scotch-tape [55]. Among other methods, chemical vapor deposition (CVD) method that utilizes carbon precursors, such as methane (CH4) or ethanol (C2H6O) for their thermal decomposition on a transition metal foil as a catalyst such as Cu, Ni or Fe at high temperatures (~1000 °C) [56]. Then, transfer polymer method is used to separate or peel off the synthesized graphene from the surface of catalyst metal foil, where polymethylmethacrylate (PMMA) or polydimethylsiloxane (PDMS) served as suitable polymers for graphene transfer process [50]. Further, considerable research effort has been made for the preparation of graphene oxide (GO) [57]. GO differs from graphene because of the presence of additional oxygen atoms bound with the carbon networks making GO hydrophilic in nature and easy to prepare its dispersion in water, unlike graphene which is hydrophobic in nature. GO can be chemically reversed to reduced graphene oxide (rGO) by reducing by means of different chemical or thermal reduction processes in high yields. However, the major challenge is to control the structural defects by reduction process that limit the electrical performance of rGO. Despite, it is most preferred approach for surface modification of graphene nanomaterial and synthesis in large- scale of graphene and its nanocomposites.

Unlike GO, it is difficult to handle graphene's hydrophobicity or preparation of its dispersions in water or polar media, which is essential for biosensor surface modifications, and thus making it a challenging task for fabrication of graphene biosensor. The reactive chemical functional groups on pure graphene are essential for the covalent or non-covalent coupling of specific molecules, however pure graphene does not possess any additional chemical functionally on its surface. Therefore, different approaches have been introduced for surface modification of graphene with tunable surface chemistry. This includes covalent and non-covalent functionalization of graphene nanostructures as shown in schematic Fig. 9c. Additionally, surface properties of graphene nanostructures are chemically modified by various approaches, such as doping graphene with other elements, changing the number of graphene layers, inducing defects, and forming different sizes, such as in the form of nanoplatelets, nanoflakes and nanoribbons. The chemically modified graphene forms a strong interface for the biological systems to be tethered without geometric restrictions or compromising the integrity of the attached biomolecule/chemical, which is most desired feature for electrochemical biosensing of analytes, especially for example, respiratory viruses or the disease diagnosis.

There have been numerous studies reporting surface modifications of GO and graphene based on covalent and non-covalent interactions. In covalent modifications, the sp2 structure of graphene honeycomb lattices forms covalent adducts with reactive species and induce defects that causes loss of the electronic properties [58]. The degree of functionalization in graphene lattices can be identified by the ratio of sp2 and sp3 hybridized carbon atoms, which can be observed in its Raman spectra. Noncovalent immobilization of graphene/GO is highly preferred because of reactive surface, dispersibility, biocompatibility, coupling capacity to capture the desired analyte for sensing properties. The most common strategies for non-covalent immobilization/functionalization utilize Van der Waals, π-π interactions, hydrogen bonding and ionic interactions facilitates non-covalently modifying graphene and GO [59]. The graphene surface can be non-covalently functionalized without altering the graphene's electronic and structural properties, and it is easy to surface-modify simultaneously to introduce new desired surface chemical groups.

Graphene and GO surfaces can be non-covalently modified with desired organic molecules or polymers via Van der Waals or π-π interactions. These interactions can induce high hydrophobic character of graphene/GO. The most common interactions between graphene/GO with organic molecules are π–π interactions that varies from small to most expanded π network. Presence of uniform oxygen functional groups on the surface of and edges of GO promotes the hydrogen bonding and ionic interactions. Georgakilas et al. [59] has provided a comprehensive review on non-covalent interactions in graphene and GO in relation to the Van der Waals, π-π interactions, hydrogen bonding and ionic interactions.

For non-covalent functionalization, mostly aromatic derivatives such as pyrene and perylenediimide derivatives are utilized as electron acceptor molecules and or electron donor on graphene/rGO sheets through π–π interactions that leads to induced repulsive forces between the layers and provide highly dispersible nanostructures in aqueous phase with remarkable charge transfer capability. The most suitable and common aromatic compounds used for functionalization of graphene/rGo through noncovalent π–π interactions is listed in Table 2 . These include porphyrin derivatives [[60], [61], [62]], pyrene [[63], [64], [65], [66], [67], [68]], pyridine and fluorinated benzene derivatives [69], ionic liquids [[70], [71], [72], [73], [74]] and polymer ionic liquid [75], quinolone [76], anthracene [77], coronene derivative [78] and triphenylene [79]. These aromatic molecules have ability of donating or withdrawing electron, stacking capability (planarity) and electrostatic repulsion with graphitic materials (graphite/graphene/rGO) which can result in the stabilized and highly dispersed exfoliated graphene sheets (EGS) from graphite/GO/rGO/graphene materials. Further attempts have been made for enhancing dispersion stability of hydrophobic G or rGO in water by utilizing amphiphilic organic molecules (surfactants) and macromolecules such as sodium dodecyl benzenesulfonate, [80,81] zwitterionic (quaternary ammonium salts) [82,83] and non-ionic [84], polar functional groups [85], sodium cholate [86], cellulose [87,88] (Table 2). The hydrophobic interaction graphene/rGO surfaces with hydrophilic/ionic/polar/non-ionic functional groups of surfactants and macromolecules allow exfoliate/charge transfer and stability of surface modified graphitic nanomaterials.

Table 2.

The list of most suitable aromatic/surfactants/amphiphilic compounds for functionalization of graphene/rGo through noncovalent π–π interactions reported in the literature.

| Surface functional molecule for non-covalent functionalization | Carbon nanomaterial | Interaction | Reference |

|---|---|---|---|

| Pyridinium-functionalized porphyrin | Graphene | Size and planarity with graphene by π stacking | [60] |

| Protoporphyrins of iron (FePP) and zinc (ZnPP) | Graphene | Large bandgap (0.45 eV) yielded bv FePP π–π stacking in graphene, while ZnPP physi-sorbed (0.23 eV). | [61] |

| Porphyrin derivatives with sulfonate (negatively charged TPP-SO3Na) and ammonium groups (positively charges TPP-ammonium) | rGO | Non-covalent functionalization induced repulsive forces between the negative charges. | [62] |

| 3.4.9.10-perylenetetracarboxylic diimidebisbenzenesulfonicacid (PDI) -acceptor and Pyrene-1–sulfonic acid (Pys)-donor | rGO | Electron donor or acceptor π-π interactions for remarkable charge-transfer ability | [65] |

| Different polar molecules: naphthalene, 1-napthylamine, and 1-naphthol | GO/FeO.Fe2O3 and multi-walled carbon nanotubes (MWCNTs)/ FeO.Fe2O3 | Polar nature of molecules with the adsorption ability | [89] |

| Four pyrene units and a laterally-grafted oligo ether dendron | Graphite exfoliation | Tetrapyrene aromatic rings interacted with basal plane of graphene, hydrophilicity due to oligo ether chains | [63] |

| Sulfonated pyrene derivatives:PS1(1-pyrenesulfonic acid sodium), PS2 (6,8-dihdroxy-1,3-pyrenedisulfonic acid disodium), PS3 (8-hydroxypyrene-1,3,6-trisulfonic acid trisodium) and PS4 (pyrene-1,3,6,8-tetrasulfonic acid tetrasodium) | Graphite exfoliation | PS2 is the most asymmetric functionalization with highest dipole moment for graphite exfoliation | [64] |

| PS1: 1-pyrenesulfonic acid sodium salt | In-situ exfoliation of graphite, graphene nanosheets (GNS) | GNS surface decorated with functional molecules via with π–π stacking force | [66] |

| 1-pyrenecarboxylic acid (PCA) | Graphite exfoliation into single-, few-, and multilayered graphene flakes | PCA induces separation of graphitic layers with the help of its carboxylic groups and prevent π-stacking reform reversing. PCA also exhibits a hydrophobic pyrene group which mimics graphene with π-π interaction | [67] |

| Lamination of PCA-functionalized graphene onto flexible-transparentpolydimethylsiloxane (PDMS) | Multifunctional hybrid structure for electronic device | [90] | |

| Pyrene butanoic acid succidymidyl ester (PBSA) | Few layers of CVD graphene | Interactions (π − π) between PBSA and graphene | [91] |

| Pyrenebutanoic acid-succinimidyl ester | Noncovalent functionalization of Epitaxial graphene | Graphene non-covalently binds with pyrene and succinimide ester reactive group | [92] |

| 1,3,6,8-pyrenetetrasulfonic acid (Py-SO3) tetrasodium hydrate,1-pyrenemethylamine (Py-NH2) hydrochloride | Exfoliation of graphite | Strong anchoring of planar aromatic structures of pyrene moles on hydrophobic graphene surface via π–π interactions yielding a stable graphene/pyrene hybrid | [68] |

| Sulfonated aluminum phthalocyanine (aromatic planar component) | GO, rGO, single wall carbon nanotubes (SWNTs) | π–π interactions of aromatic planar component | [93] |

| Pynidinium tribromide (aromatic with hydrophilic groups) | highly oriented pyrolytic graphite (HOPG) | Hydrophilic or lipophilic chains electrostatic repulsions | [69] |

Imidazolium ionic liquids (IL) with phyneyle:

|

Graphene | IL-4 exhibited most effective graphene stabilizer via π–π stacking with its two phenyl groups was | [70] |

| 1-allyl-methylimidazolium chloride ionic liquid | rGO | Prevented aggregation between graphene nanosheets with cation–π stacking/π–π interaction and electrostatic repulsion | [71] |

Hydrophilic ILs:

|

rGO | Dispersion and stabilization are the driving forces caused by the cation-π and/or π–π interactions | [72] |

Imidazolium salt (functional amphiphilic ionic liquid):

|

GO | Interaction with imidazolium moieties and graphitic structure occur by π-cation stacking electrostatic interactions and post-reduction | [73] |

| Two vinyl-benzyl groups containing imidazolium ionic liquids (Imi-ILs). | GO | Exchange of ions between -vely charged GO and + ve imidazolium of Imi-ILs. Imi-ILs attachment via non-covalent π-stacking on graphene | [74] |

Polymer IL-

|

Exfoliation of graphite into graphene | Interaction of GO sheet edges with -COO of imidazolium cations in PIL via electrostatic attractions and also cation−π and/or π − π interactions | [75] |

| Quinoline | Non oxidized graphene flakes (NOGFs) from exfoliation of graphite | Binding of benzoic portion of quinoline to basal plane of NOGFs via strong via π–π interaction. | [76] |

| 9-anthracene carboxylic acid (ACA) | Surface modification of rGO for enhanced electrochemical properties | Stacking (π-π interaction) of the benzene ring in ACA anion on surface of rGO, while -COO− assisted their dispersion and water-solubility promoted by hydrogen bonding. | [77] |

Derivative of coronene (Anionic):

|

Stabilization and functionalization of graphene sheet | π-π stacking and non-covalent charge transfer between CS and graphene sheet | [78] |

Stabilizer C10:

|

Expanded graphite into few-layer graphene (FLG) dispersion | C10, an amphiphilic aromatic molecule with core triphenylene six-acid groups. Strong affinity interaction between π-electron rich aromatic core and graphene via π–π interaction. | [79] |

| Sodium dodecyl benzenesulfonate (SDBS) | Exfoliation of graphite to graphene | Anionic SDBS surfactant induce uniform dispersion in water preventing π-π stacking | [81] |

Ionic surfactants:

|

Exfoliation, stable dispersion, surface modification GO, rGO | SDBS modified rGO showed excellent dispersibility and electrical conductivity | [80] |

| Exfoliation and surface modification of GO | SO3− groups provided electrostatic repulsion, Sulfonated graphene forms a stable suspension followed by replacement of SO3− with a cationic nonylphenyl-PEG-quaternary ammonium salt (NPEQ) to form a stable suspension. | [82] | |

Ionic surfactants:

Zwitterionic:

|

rGO stabilization | Interaction of rGO with hydrophobic tail (alkyl vs. aromatic); or polar heads (sulfonic vs. carboxylic groups) of different surfactants. PSS and Tween 80 modified rGO exhibited significant increase in capacitance | [85] |

| Sodium cholate | Exfoliation of graphene | Graphene interaction with carboxylic polar head groups | [86] |

| Polyvinylpyrrolidone (non-ionic macromolecule) | Exfoliation of graphite | hydrophilic polymer confers exfoliation and colloidal stability graphene in water | [84] |

| Anionic polysaccharide: Carboxymethyl cellulose (CMC) | Porous rGO | Active functional groups of CMC such as carbonyl and hydroxyl groups which show a strong affinity toward metal ions as well as stable dispersion | [87] |

Another most frequently employed approach for surface modification of graphene is based on covalent chemistry to immobilize specific functional molecules, which is most essential feature in biological/chemical sensor applications. Covalent surface modification of graphene induces interaction with sp2 carbon-atoms, re-hybridization occurs from sp2 to sp3 carbon-atoms hybridization that facilitate graphene edges be easily functionalized covalently. Graphene's surface modification via covalent functionalization enhances graphene's properties, such as tuning electrical conductivity, controlled surface chemical functionality, opening its band gap, stability and dispersibility. A summary of various chemical linkers/molecules required for covalent functionalization of graphene/GO/derivatives including the chemical functionality characteristics is listed in Table 3 . A detailed mechanism of covalent binding of graphene/GO/derivatives is previously reported that are notable, [[94], [95], [96]] and a comprehensive review provides various routes for covalent functionalization of graphene on solid substrates [97]. Generally, surface functionalization approaches for graphene/GO/derivatives were classified in five groups that include; (a) functionalization of organic molecules, such as free radicals, (b) oxidation, (c) cycloadditions, (d) hydrogenations and (e) halogenations. The most suitable common chemical compounds for functionalization of graphene/rGO via covalent approach are summarized in Table 3.

Table 3.

The list of most suitable covalent coupling linkers for functionalization of graphene/rGo through covalent interactions reported in the literature.

| Surface functional molecule for covalent functionalization | Carbon nanomaterial functionalization feature | Interaction | Reference |

|---|---|---|---|

| Free radical addition | |||

| Aryl diazonium salt | GO reduction in presence of a surfactant (SDBS) with hydrazine followed by treatment with aryl diazonium salts | Aryl radical formation from aryl diazonium ion by elimination of nitrogen and the radical aryl moiety interact/bind to graphene sp2 surface which donates an electron | [108] |

| 4-nitrophenyl diazonium (NPD) tetrafluoroborate | Aryl groups grafting to epitaxial graphene via reduction of 4-nitrophenyl diazonium (NPD) tetrafluoroborate | Transfer of electron to the diazonium salt from the graphene layer and its substrate | [109] |