Abstract

The surface of a tight reservoir appears to be oil-wet or mixed-type wet upon soaking in crude oil for a long time, and the yield decreases rapidly after fracturing under the influence of capillary force. The oil sweep efficiency affected by many factors such as formation water dilution, salinity, crude oil type, temperature, and pressure can be enhanced by adding nanosurfactants into the fracturing fluid, so it is necessary to study the influence of different factors on the spontaneous imbibition replacement efficiency of nanosurfactants. In this study, the basic properties of nanosurfactants such as particle size, oil–water interfacial tension (IFT), and the wetting modification effect were tested, and the influence of surfactant type, concentration, temperature, and pressure on imbibition replacement efficiency was studied. The main conclusions are as follows: (1) The particle size of the nanosurfactant that was synthesized by a microemulsion method is 12–21 nm, which indicated good injectability in tight cores. Moreover, the IFT values between the crude oil and five kinds of 0.30 wt % nanosurfactants were all lower than 0.15 mN/m, and nanosurfactant C had the best wetting modification effect with increasing the contact angle by 100.30°. (2) The type and concentration of surfactant have a certain influence on imbibition replacement efficiency, and appropriate concentration of anionic nanosurfactant is beneficial to enhancing the imbibition replacement efficiency. The imbibition replacement efficiency of 0.30 wt % anionic surfactant C solution is higher than that of nonionic and cationic surfactant solutions, and the imbibition replacement efficiency is as high as 33.386% under NTP. (3) The nanosurfactant in brine is prone to forming fine emulsified oil droplets with crude oil and activates the oil droplets in the small pores to enhance the imbibition replacement efficiency. The crude oil type, temperature, and pressure can influence imbibition replacement efficiency, and the influence of crude oil type and temperature is greater than that of pressure. This work further studies the influencing factors of imbibition replacement efficiency.

1. Introduction

With the development of science, technology, and economy, the demand for energy resources has been surging. At the same time, the proportion of unconventional oil and gas resources is increasing year by year.1 After decades of development, the exploitation technology of tight oil and gas resources has become more and more mature as tight oil and gas resources play a decisive role in the exploration and development of global oil and gas resources.2,3 Generally, the natural productivity of a single tight oil and gas well is low, and measures need to be taken to realize economic exploitation. The combination of horizontal well drilling and fracturing is one of the main methods of tight oil and gas reservoir exploitation. The complex fracture network formation after fracturing provides a large specific surface area for oil and gas seepage, which is conducive to spontaneous imbibition and to forming industrial oil and gas flow.4−6

Generally, it is difficult for the injected water to reach the deep layer under external force in tight reservoirs—capillary force is the main driving force for spontaneous imbibition in tight reservoirs.25,26 As one of the important displacement mechanisms of the enhanced oil recovery in the tight oil and gas field, spontaneous imbibition is a process where the non-wetting phase can be displaced by the wetting phase only depending on the capillary force in the tight reservoir, and sometimes there is also a need to consider gravity or external driving force, e.g., injection water pressure. Since the 1960s, many scholars have made many achievements using different methods to study the spontaneous imbibition process in tight reservoirs. In 2001, Babadagli used epoxy to treat the surface of the core and found that the imbibition displacement rate and efficiency of the untreated core were higher than those of the treated core, which means the contact area affects the imbibition.7 In 2004, Hatiboglu et al. tested the imbibition effect of cores with different diameters and lengths and found that the smaller the core length and size were, the higher the imbibition rate and efficiency were.8 In 2006, Li studied the influence of permeability on the imbibition effect and results showed that there are great differences in the imbibition phenomenon and imbibition mechanism between the high permeability core and low permeability core.9 From 2010 to 2013, Peng and Li studied the influence of salinity, temperature, viscosity, wettability, and interfacial tension on the imbibition effect and found that viscosity, wettability, and interfacial tension are the most important factors affecting the imbibition effect, while temperature indirectly affects the imbibition by changing the viscosity.10−18 In 2014, Akbarabadi et al. studied the microimbibition displacement mechanism of tight shale samples with nanoCT and found that the small pores could not be effectively wetted, leading to the imbibition fluid not being able to enter the small pores and replace the oil.19 The results showed that the more organic carbon content there was in the fillings, the lower the imbibition efficiency was, and the illite content had no effect on imbibition efficiency. From 2019 to 2020, Liu et al. studied the influence of different types of surfactants on the imbibition and emulsification effect with nuclear magnetic resonance technology.20−22 Also, Liang et al. studied the nanoemulsion microscopic imbibition mechanism with microfluidic chip technology.24−27,31

Based on the previous studies, conventional surfactants were synthesized into nanoparticles by the microemulsion method, which improved the ability of chemicals to enter the pore throat and reduce the adsorption of surfactants on the solid surface, to achieve a uniform long-term effect of wetting modification.6,23,25−27 The interaction mechanism between the nanosurfactant and solid surface was analyzed with the capillary force formula by testing the basic properties such as IFT and wetting reversal. Finally, the effects of surfactant type, concentration, crude oil type, temperature, and pressure on imbibition replacement efficiency were studied based on the practical application of the Shengli Oilfield of Sinopec, China, and the experimental conditions are included in Section 2.1, which were used in order to obtain a more economical and effective chemical formula. This study is a further improvement on the influencing factors of imbibition replacement efficiency with the nanosurfactant.

2. Results and Discussion

2.1. IFT and Contact Angle Measurement Result

Figure 1 shows the test results of IFT between the 0.30 wt % nanosurfactant solution and crude oil. According to the experimental results, all IFTs between the five nanosurfactant solutions and crude oil are small, which are all in the range of 0.06–0.14 mN/m (σA = 0.08 mN/m, σB = 0.14 mN/m, σC = 0.06 mN/m, σD = 0.11 mN/m, σE = 0.10 mN/m). A lower IFT will reduce the dynamic force of spontaneous oil displacement in the capillary, which will not help replace the crude oil in core pores, so a smaller oil–water IFT is not be conducive to high oil displacement efficiency. However, a lower IFT can reduce the size of removed oil droplets to enhance the deforming ability of oil droplets and make it easier for oil droplets to pass through small pore throats while the capillary pressure difference at both ends of pore throats caused by the Jarmin effect can be reduced to improve the oil sweep efficiency.

Figure 1.

Test results of interfacial tension between the 0.30 wt % nanosurfactant and crude oil.

Figure 2 shows the test results of the wetting angle of the core after soaking in 0.30 wt % nanosurfactant solution for 24 h. The CA of oil drops on the surface of cores soaked in salt water is 51.25° before chemical treatment and changes to θA = 136.30°, θB = 120.05°, θC = 152.45°, θD = 147.15°, and θE = 115.30° after 24 h of soaking. Results demonstrate that before chemical treatment, the core is oil-wet, and the capillary force acts as the imbibition resistance of the nanosurfactant solution; after chemical treatment, the oil drop angle on the core surface is more than 90° and the core is water-wet, and the capillary force acts as the imbibition force of the nanosurfactant solution. The wetting angle increment of nanosurfactant C is the largest, up to 100.30°, indicating that the oil displacement rate and efficiency of nanosurfactant C solution are both higher than the other nanosurfactants.

Figure 2.

CA after treatment with 0.30 wt % nanosurfactant for 24 h.

2.2. Spontaneous Imbibition Experimental Results

2.2.1. Rock Sample Parameters

In the experiment, the reservoir cores from the block in the Shengli Oilfield of Sinopec, China were selected as the samples. The effects of the type and concentration of nanosurfactant, distilled water-soaked or brine-soaked, temperature, and pressure on the spontaneous imbibition replacement efficiency were tested. Table 1 shows the core parameters.

Table 1. Core Parameters and Corresponding Experimental Parameters.

| core no. | length, mm | diameter, mm | porosity, % | gas permeability, 10–3 μm2 | nanosurfactant | water | T & P |

|---|---|---|---|---|---|---|---|

| 1 | 50.12 | 25.01 | 7.33 | 5.6 | 0.30 wt % A | brine | NPT |

| 2 | 50.24 | 25.02 | 6.77 | 4.5 | 0.30 wt % B | brine | NPT |

| 3 | 50.32 | 24.99 | 6.46 | 4.3 | 0.30 wt % C | brine | NPT |

| 4 | 50.21 | 24.97 | 6.76 | 5.2 | 0.30 wt % D | brine | NPT |

| 5 | 50.23 | 25.01 | 6.74 | 4.9 | 0.30 wt % E | brine | NPT |

| 6 | 50.77 | 25.01 | 6.22 | 5.6 | 0.00 wt % C | brine | NPT |

| 7 | 50.57 | 25.02 | 6.78 | 4.5 | 0.10 wt % C | brine | NPT |

| 9 | 50.86 | 25.01 | 5.95 | 4.3 | 0.50 wt % C | brine | NPT |

| 10 | 50.74 | 25.04 | 5.11 | 5.2 | 0.30 wt % C | distilled water | NPT |

| 11 | 50.26 | 25.02 | 6.52 | 4.8 | 0.30 wt % C | brine | 60 °C & NT |

| 12 | 50.75 | 25.04 | 6.13 | 4.7 | 0.30 wt % C | brine | 15 MPa & NP |

| 13 | 50.64 | 25.03 | 5.81 | 5.2 | 0.30 wt % C | brine | 15 MPa & 60 °C |

2.2.2. Type and Concentration of Nanosurfactant

According to Section 2.1, all nanosurfactant solutions can reduce the IFT between oil and water and change the surface wettability of the solid surface. To further verify the influence of the nanosurfactant on the oil sweep efficiency, different types and concentrations of nanosurfactants under normal temperature and pressure were tested, and the results are shown in Figures 8 and 9.

Figure 8.

Imbibition replacement efficiency when the temperature and pressure change.

Figure 9.

(a) Heavy oil gas chromatography test results. (b) Light crude oil gas chromatography test results.

According to Figure 3, the oil sweep efficiency is greatly influenced by the type of nanosurfactant. The oil sweep efficiencies of the five surfactants from high to low are C = 33.386% > D = 29.111% > A = 25.013% > E = 11.213% > B = 8.020%. The oil sweep efficiencies of anionic C and D are higher than those of the nonionic and cationic samples. The results show that there is strong adsorption of cations on the surface of the tight sandstone reservoir preventing the surfactant from seeping into the deep reservoir, while the low adsorption of non-cations on the surface of the rock cannot reach effective wetting modification.22,28 Therefore, the imbibition replacement efficiency of the anionic surfactant solution is higher than that of the nonionic and cationic surfactant solution.

Figure 3.

Imbibition replacement efficiency of different types of nanosurfactants, 0.30 wt % A, B, C, D, & E.

0.00, 0.10, 0.30, and 0.50 wt % nanosurfactant C solutions were prepared to test the influence of concentration on imbibition oil sweep efficiency. According to the results shown in Figure 4, when the concentration of surfactant is 0.00 wt %, the core has a relatively low imbibition replacement efficiency. At this time, crude oil is only displaced by the mixed wetting on the surface of the pore throat. When the concentration of surfactant is 0.30 wt %, the imbibition replacement efficiency is the highest, reaching 33.386%; while the concentration of surfactant is 0.50 wt %, the imbibition replacement efficiency drops to 27.582%, indicating that a higher concentration of surfactant is not better. When the adsorption of nanosurfactants on the solid surface reaches dynamic equilibrium, excess nanosurfactants cannot further change the wettability of the solid surface, and the lower oil–water IFT results in an adverse effect on the imbibition displacement.

Figure 4.

Imbibition replacement efficiency of nanosurfactants with different concentrations, 0.00 −0.50 wt % C.

In conclusion, the type and concentration of surfactant have a certain influence on the imbibition replacement efficiency and appropriate concentration of anionic nanosurfactant can improve imbibition replacement efficiency.

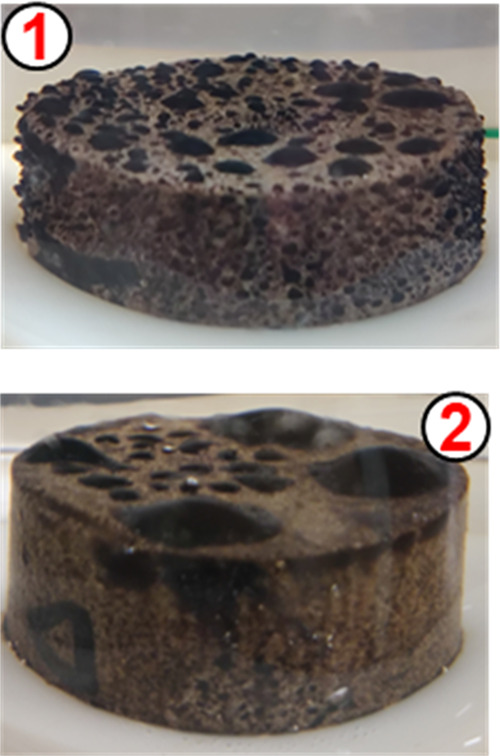

2.2.3. Distilled Water and Simulated Formation Water

Considering the certain degree of salinity in the formation, it is necessary to test the imbibition replacement efficiency of the nanosurfactant in 2.00 wt % KCl simulated formation water and distilled water. As shown in Figure 5, the imbibition replacement efficiency of the nanosurfactant C solution in brine is 33.386%, and the imbibition replacement efficiency of the nanosurfactant C solution in distilled water is 28.242%, indicating that the nanosurfactant in the brine solution has better imbibition replacement efficiency. By analyzing the morphology of emulsified oil droplets formed on the core surface in the two media (Figure 6), it is found that the nanosurfactant in brine is more likely to form small emulsified oil droplets with crude oil and to displace the oil droplets in the small channels to enhance the imbibition oil sweep efficiency. However, a larger oil drop on the rock surface in the distilled water solution causes a lower replacement efficiency.

Figure 5.

0.30 wt % nanosurfactant C spontaneous oil recovery with brine or distilled water, NPT. Notes: (1) brine surfactant solution core surface-emulsified oil drops and (2) distilled water surfactant solution core surface-emulsified oil drops.

Figure 6.

Emulsifying effect on the rock surface with brine or distilled water.

2.2.4. Temperature and Pressure

The nanosurfactant featuring strong adaptability of temperature and pressure has the capacity for better imbibition replacement efficiency in a reservoir. As shown in Figure 7, the core is placed in the intermediate container ② soaked in nanosurfactant solution, the equipment is pressurized and heated by the ISCO pump ③ and the heating device ①, and the imbibition replacement efficiency is calculated by the weighing method. According to the experimental results (Figure 8), when the temperature and pressure increase simultaneously, the 0.30 wt % nanosurfactant C solution has the highest imbibition replacement efficiency, reaching 59.810%; The corresponding imbibition oil sweep efficiency is 50.502% under 60 °C and normal pressure; the imbibition replacement efficiency is 43.983% under 15 MPa and normal temperature; the imbibition oil sweep efficiency is 33.386% under normal temperature and pressure. It shows that both temperature and pressure have effects on the imbibition replacement efficiency, and the temperature has a more obvious influence on the imbibition replacement efficiency than pressure. As temperature rises up, the nanosurfactant molecules in the solution becomes active, while the viscosity of the crude oil decreases, and the crude oil on the rock surface is more easily stripped and displaced.

Figure 7.

Equipment for spontaneous imbibition under heating and pressure.

2.2.5. Crude Oil Component

In order to further test the adaptability of surfactant C in different oil reservoirs, crude oil and an equal proportion of crude oil and kerosene mixed oil were selected for spontaneous imbibition experiments. Figures 9,b and 10a show the test results of the component and spontaneous imbibition of two types of crude oil, respectively. According to the results, the imbibition replacement efficiency of the saturated light crude oil core is far higher than that of the heavy oil, and the imbibition replacement efficiencies of the two crude oils are 38.39 and 15.24%, respectively. The content of heavy hydrocarbon above C16+ in heavy oil is as high as 61.49%, and the content of heavy hydrocarbon above C16+ in light crude oil is only 7.91%, which shows that this kind of anionic nanosurfactant finds it easier to emulsify light crude oil with a lower molecular weight to achieve a better imbibition displacement effect.

Figure 10.

Spontaneous imbibition replacement efficiency of different types of crude oils.

Table 2 is a summary of the effects of different factors on imbibition.

Table 2. Summary of the Effect of Different Factors on Imbibition.

| factors | types | effect | |||

|---|---|---|---|---|---|

| chemical types | anionic | cationic | nonionic | Anion works best. | |

| concentration, wt % | 0.00 | 0.10 | 0.30 | 0.50 | Best when the concentration is 0.30 wt %. |

| crude oil types | crude oil | mixture of reservoir crude oil and kerosene | The higher the crude oil viscosity, the lower the imbibition efficiency. | ||

| water type | distilled water | simulated formation water | The formation water is conducive to the emulsification of crude oil and improves imbibition replacement efficiency. | ||

| temperature | NT | 60 °C | Temperature is beneficial to enhancing imbibition replacement efficiency. | ||

| pressure | NP | 15 MPa | Pressure helps to enhance the imbibition effect, but the effect is weaker than that of temperature. | ||

3. Conclusions

The tight reservoir soaked with crude oil for a long time makes the surface of the reservoir oil-wet or mixed-type wet. The capillary force causes a rapid decline in the oil production after fracturing. By adding a nanosurfactant to the fracturing fluid, the imbibition replacement efficiency during the flowback process of the fracturing fluid can be enhanced. In this study, the basic properties of the nanosurfactant such as particle size, oil–water IFT, and wetting modification effect were tested, and their influence was studied. The main conclusions are as follows:

-

(1)

The nanosurfactant synthesized by the microemulsion method has a particle size between 12 and 21 nm, and it has a good injectability in tight cores. The IFT values between the crude oil and the five kinds of 0.30 wt % nanosurfactants are all lower than 0.15 mN/m, nanosurfactant C has the best wetting modification effect, and the CA increases by 100.30°.

-

(2)

The type and concentration of surfactant have a certain influence on the imbibition replacement efficiency in that an appropriate concentration of anionic nanosurfactant is beneficial to enhancing the imbibition replacement efficiency. The imbibition replacement efficiency of 0.30 wt % anionic surfactant C solution is higher than that of nonionic and cationic surfactant solutions, and the imbibition replacement efficiency is as high as 33.386% at NPT.

-

(3)

In brine, the nanosurfactant is more likely to form fine emulsified oil droplets with crude oil and activate the oil droplets in the small pore channels to enhance the imbibition replacement efficiency, while in distilled water solution, oil droplets on the rock surface are large and have an adverse effect on the imbibition replacement efficiency. The imbibition replacement efficiency of 0.30 wt % nanosurfactant C solution in brine is 5.144% higher than that in distilled water.

-

(4)

Temperature, pressure, and the type of crude oil all have an influence on the imbibition replacement efficiency. Also, temperature has a greater influence on the imbibition replacement efficiency than pressure. When increasing the temperature or lowering the molecular weight of the crude oil component, the nanosurfactant molecules in the solution become more active, the viscosity of the crude oil decreases, and the crude oil on the rock surface is more easily stripped and displaced out of the core.

4. Methodology

Due to the influence of formation water dilution, salinity, crude oil types, temperature, and pressure, it is necessary to study the influence of different factors on spontaneous imbibition replacement efficiency. This study analyzed the interaction mechanism between the nanosurfactant and tight reservoir by testing the properties of nanosurfactant, such as nanoparticle size, IFT, and wetting modification effect and investigated the influence of different factors on the replacement efficiency of the nanosurfactant by changing the spontaneous imbibition experimental conditions.

4.1. Rock and Fluid Properties

4.1.1. Rock Sample

The tight sandstone core is taken from a block in the Shengli Oilfield of Sinopec, China. The reservoir is 3330–3850 m deep and belongs to a medium-low porosity and ultralow permeability reservoir. The core’s effective porosity is between 5 and 8%, gas permeability is 4–7 mD, and XRD and basic parameters are shown in Table 3. The experimental object is shown in Figure 11.

Table 3. Rock Sample XRD Mineral Analysis Result.

| mineral type | quartz | anorthite | titanomagnetite | illite | chlorite |

|---|---|---|---|---|---|

| molar content, % | 57.61 | 15.12 | 5.24 | 10.65 | 11.38 |

Figure 11.

Rock sample after saturated oil.

4.1.2. Additives and Fluids

The nanosurfactants, including anionic, cationic, and nonionic mixtures, were produced in Dongying, Shandong, China. 2 wt % KCl brine was used; the crude oil viscosity is 100 mPa s; the ratio of the mixture of reservoir crude oil and kerosene is 1:1; and the viscosity is 2 mPa s at 25 °C. The sample is shown in Figure 12.

Figure 12.

Nanosurfactant and oil sample.

4.2. Surfactant Nanoparticle Size Test

The nanosurfactant was synthesized by microemulsion in the laboratory, mainly composed of a water phase, oil phase, and surfactant. A Zetasizer nanolaser nanoparticle size analyzer was used to test the particle size of five kinds of nanosurfactants. The main steps are as follows: 0.30 wt % nanosurfactant solution was prepared; the instrument was preheated; the cuvette was cleaned; the particle size of the sample was determined and the curve was plotted. The abscissa is the logarithm of the particle size, and the ordinate is the volume fraction. Table 4 and Figure 13 show the test results of the five kinds of nanosurfactants and the corresponding nanoparticle size. According to the results, the five kinds of surfactants have nanoparticle sizes, and the particle size is between 12 and 21 nm.

Table 4. Nanosurfactant Number and Type.

| no. | A | B | C | D | E |

|---|---|---|---|---|---|

| type | anionic | anionic | cationic | cationic | nonionic |

| concentration, % | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| nanoparticle size, nm | 21 | 18 | 16 | 19 | 12 |

Figure 13.

Nanosurfactant solution particle size test result.

4.3. IFT and CA Measurements

Capillary force is one of the important factors in determining the spontaneous imbibition replacement efficiency of the nanosurfactant solution. It can be seen from the capillary force formula (1)(23) that there are two influencing factors of capillary force so that it is necessary to test the oil–water IFT and the wetting effect of the nanosurfactant.

| 1 |

where Pcap is the capillary force, σ is the IFT between the well entry fluid and crude oil, θ is the rock/inflow fluid/crude oil three-phase CA, and r is the capillary radius.

4.3.1. IFT Evaluation Experiment

The ring method was applied. A BZY-1 type surface interface tension tester was used to measure the ″oil/water″ IFT. The experimental process is as follows: (1) 2 wt % KCl simulated formation water was prepared for a certain concentration of nanosurfactant solution; (2) the sample cylinder was filled with distilled water and alcohol to calibrate the instrument; (3) the nanosurfactant solution was dropped into a clean sample pool, the device was turned on, the IFT of ″crude oil - nanosurfactant solution″ was determined, and the test points of each nanosurfactant solution were averaged.

4.3.2. CA Test

The ″hanging drop method″ was applied. The C601 CA tester was used to measure the ″crude oil to rock″ CA on the surface of the core section simulating formation water immersion at room temperature. The specific experimental process is as follows: (1) untreated natural core slices were placed in simulated formation water, crude oil was dropped on the lower surface of core slices through a micropipette, and the CA of the oil droplets on the core surface was measured with a CA tester; (2) the untreated natural core slices were immersed in different types of nanosurfactant solutions for more than 24 h, then removed and wiped clean, and re-placed into simulated formation water after chemical agent treatment. Step 1 was performed again to measure the CA of the oil droplets on the core surface; (3) a comparison of the ″oil-rock″ CA on the surface of core slices in simulated formation water before and after chemical agent treatment was made to evaluate the wetting modification effect of the nanosurfactant.

4.4. Spontaneous Imbibition Experiments

The spontaneous imbibition oil replacement experiment comprehensively reflects the relationship among the nanosurfactant wetting modification, reducing IFT, and reservoir structure. Because spontaneous imbibition is affected by many factors such as nanosurfactant type, concentration, formation salinity, crude oil type, temperature, and pressure, these factors are required to be comprehensively considered in the experimental process. Usually, a volume method is used to test the spontaneous imbibition oil sweep efficiency with an Amott bottle. The specific experimental process and principle are as follows: (1) A nanosurfactant solution is prepared with simulated formation water. (2) The core is evacuated and saturated with simulated formation water to displace the saturated crude oil for increasing irreducible water saturation and the crude oil saturation is calculated. (3) The treated core and nanosurfactant solution are put into an Amott bottle for spontaneous imbibition displacement experiment. (4) The Amott bottle is used to record the volume of crude oil displaced by spontaneous imbibition of nanosurfactant solution in the core so as to obtain the replacement efficiency. (5) Using distilled water, the type and concentration of nanosurfactant, crude oil type, experimental temperature or pressure, and other experimental conditions are changed—steps (1) to (4) can be followed to test the spontaneous imbibition replacement efficiency under different conditions. Figure 14 shows the saturated fluid experimental device of the Amott bottle with the core, and Figure 15 shows the Amott bottle during the experiment. In addition, both gravity and capillary forces influence the spontaneous imbibition, and the bond number has been used to characterize the relative importance of gravity forces over capillary forces.

| 2 |

where Nb is the bond number, dimensionless; Δρ is the density difference between the displacing and displaced slugs, kg/m3; k is the permeability, m2; σ is the interfacial tension between the displacing and displaced slugs, mN/m; and θ is the contact angle. From eq 1, we can see that higher permeable will produce greater gravitational influence, and when the cores’ permeability is higher than 10 × 10–3 μm2, the gravitational forces need to be taken into consideration. In this article, the core length used in this article is relatively short (3–5 cm) and gas permeability is less than 6.0 × 10–3 μm2; thus, gravity is not considered. In actual oil reservoirs, gravity has a certain influence on spontaneous imbibition.29,30,32

Figure 14.

Experimental setup of Amott type spontaneous imbibition bottle with the core. Notes: (1) ISCO constant speed constant pressure pump, (2) Amott bottle, (3) intermediate container with nanosurfactant solution.

Figure 15.

Spontaneous imbibition in Amott bottles during the experiment.

Acknowledgments

This work is financially supported by the Cooperative Innovation Center of Unconventional Oil and Gas (Ministry of Education & Hubei Province), Yangtze University (NO. UOG2020-16).

Glossary

Nomenclature

- CA

contact angle

- IFT

interfacial tension

- P, T

pressure, temperature

- NP, NT

normal pressure, normal temperature

- NPT

normal pressure and temperature

- XRD

X-ray diffraction

The authors declare no competing financial interest.

References

- EIA . 2020Annual Energy Outlook 2019. U.S. Energy Information Administration. [Google Scholar]

- Clouser G.; Wagman D. East Texas Thrives: One of the world’s most heavily drilled regions thrives as unconventional gas plays take off. Oil Gas Investor, Tight Gas 2006, 8–10. [Google Scholar]

- Khlaifat A. L.; Qutob H.; Barakat N.. Tight gas sands development is critical to future world energy resources. SPE Middle East Unconventional Gas Conference and Exhibition, Muscat, Oman, 31 Jan-2 Feb, 2011.

- Peng S.; Xiao X. Investigation of multiphase fluid imbibition in shale through synchrotron-based dynamic micro-CT imaging: μCT on Multiphase Imbibition in Shale. JGR Solid Earth 2017, 122, 4475–4491. 10.1002/2017JB014253. [DOI] [Google Scholar]

- Meng M.; Ge H.; Ji W.; Shen Y.; Su S. Monitor the process of shale spontaneous imbibition in co-current and counter-current displacing gas by using low field nuclear magnetic resonance method. J. Nat. Gas Sci. Eng. 2015, 27, 336–345. 10.1016/j.jngse.2015.08.069. [DOI] [Google Scholar]

- Wang J.; Zhou F.; Zhang L.; et al. Study on reason analysis and removal solution on water locking damage in tight sandstone reservoirs. J. Dispersion Sci. Technol. 2019, 41, 1–10. 10.1080/01932691.2019.1637754. [DOI] [Google Scholar]

- Babadagli T. Scaling of Cocurrent and Countercurrent Capillary Imbibition for Surfactant and Polymer Injection in Naturally Fractured Reservoirs. Spe J. 2001, 6, 465–478. 10.2118/74702-PA. [DOI] [Google Scholar]

- Hatiboglu C U; Babadagli T.. Experimental Analysis of Primary and Secondary Oil Recovery from Matrix by Counter-Current Diffusion and Spontaneous Imbibition, SPR 90312, 2004.

- Li J S.Influence of Surfactant System on Imbibition Process. China: doctoral thesis, Graduate School of Chinese Academy of Sciences (Institute of Percolation Fluid Mechanics), 2006. [Google Scholar]

- Peng X. Q.; Guo S. P.; Han D. Imbibition behavior of brine with and without surfactant in neutral-wet sandstone. China: Pet. Geol. Recovery Effic. 2010, 17, 48–51. [Google Scholar]

- Li A. F.; Fan T. Y.; Zhao L. Experimental study of spontaneous imbibition in low permeability core, fractured reservoir. China: Pet. Geol. Recovery Effic. 2011, 18, 67–69. [Google Scholar]

- Kathel P.; Mohanty K. K.. EOR in tight oil reservoirs through wettability alteration. SPE 166281, SPE annual technical conference and exhibition; New Orleans, 2013. [Google Scholar]

- He K.; Xu L.; Gao Y.; Yin X.; Neeves K. B. Evaluation of surfactant performance in fracturing fluids for enhanced well productivity in unconventional reservoirs using Rock-on-a-Chip approach. J. Pet. Sci. Eng. 2015, 135, 531–541. 10.1016/j.Pet..2015.10.008. [DOI] [Google Scholar]

- Tagavifar M.; Balhoff M.; Mohanty K.; Pope G. A. Dynamics of low-interfacial-tension imbibition in oil-wet carbonates. SPE J. 2019, 24, 1092–1107. 10.2118/194194-PA. [DOI] [Google Scholar]

- Wang X.; Peng X.; Zhang S.; Du Z.; Zeng F. Characteristics of oil distributions in forced and spontaneous imbibition of tight oil reservoir. Fuel 2018, 224, 280–288. 10.1016/j.fuel.2018.03.104. [DOI] [Google Scholar]

- Standnes D. C.; Austad T. Wettability alteration in chalk: 2. Mechanism for wettability alteration from oil-wet to water-wet using surfactants. J. Pet. Sci. Eng. 2000, 28, 123. 10.1016/S0920-4105(00)00084-X. [DOI] [Google Scholar]

- Li Z.; Wu H.; Yang M.; Jiang J.; Xu D.; Feng H.; et al. Spontaneous emulsification via once bottom-up cycle for the crude oil in low-permeability reservoirs. Energy Fuels 2018, 32, 3119–3126. 10.1021/acs.energyfuels.7b03720. [DOI] [Google Scholar]

- Ning J.; Wei B.; Mao R.; Wang Y.; Shang J.; Sun L. Pore-level observations of an alkali induced mild O/W emulsion flooding for economic enhanced oil recovery. Energy Fuels 2018, 32, 10595–10604. 10.1021/acs.energyfuels.8b02493. [DOI] [Google Scholar]

- Akbarabadi M.; Piri M.. Nanotomography of the Spontaneous Imbibition in Shale. Unconventional Resources Technology Conference; 2014.; Liu J, Sheng JJ, Wang X, Ge H, Yao E. Experimental study of wettability alteration and spontaneous imbibition in Chinese shale oil reservoirs using anionic and nonionic surfactants. J Pet. Sci Eng 2019; 175: 624–33.

- Liu J.; Sheng J. J. Investigation of countercurrent imbibition in oil-wet tight cores using NMR technology. SPE J 2020, 25, 2601. 10.2118/201099-PA. [DOI] [Google Scholar]

- Liu J.; Sheng J. J.; Huang W. Experimental investigation of microscopic mechanisms of surfactant-enhanced spontaneous imbibition in shale cores. Energy Fuels 2019, 33, 7188–7199. 10.1021/acs.energyfuels.9b01324. [DOI] [Google Scholar]

- Liu J.; Sheng J. J.; Tu J. Effect of spontaneous emulsification on oil recovery in tight oil-wet reservoirs. Fuel 2020, 279, 118456. 10.1016/j.fuel.2020.118456. [DOI] [Google Scholar]

- Wang J.; Zhou F.; Xue Y.; et al. The adsorption properties of a novel ether nanofluid for gas wetting of tight sandstone reservoir. Pet. Sci. Technol. 2019, 1–19. [Google Scholar]

- Towler B. F.; Lehr H. L.; Austin S. W.; et al. Spontaneous Imbibition Experiments of Enhanced Oil Recovery with Surfactants and Complex Nano-Fluids. J. Surfactants Deterg. 2017, 20, 1–377. 10.1007/s11743-017-1924-1. [DOI] [Google Scholar]

- Liang X.; Liang T.; Zhou F.; Zhu J.; Wang R.; Li Y. Enhanced fossil hydrogen energy recovery through liquid nanofluid huff-n-puff in low permeability reservoirs. Int. J. Hydrogen Energy 2020, 45, 19067. 10.1016/j.ijhydene.2020.05.109. [DOI] [Google Scholar]

- Liang X.; Zhou F.; Liang T.; Wang C.; Wang J.; Yuan S. Impacts of low harm fracturing fluid on fossil hydrogen energy production in tight reservoirs. Int. J. Hydrogen Energy 2020, 45, 21195. 10.1016/j.ijhydene.2020.06.01. [DOI] [Google Scholar]

- Yuan S.; Liang T.; et al. A Microfluidic Study of Wettability Alteration Rate on Enhanced Oil Recovery in Oil-Wet Porous Media. Abu Dhabi International Petroleum Exhibition & Conference; OnePetro: Abu Dhabi, UAE, November 2019, SPE-197715-MS. [Google Scholar]

- Liu J.; Sheng J. J.; Wang X.; et al. Experimental study of wettability alteration and spontaneous imbibition in Chinese shale oil reservoirs using anionic and nonionic surfactants. J. Pet. Sci. Eng. 2019, 175, 624–633. 10.1016/j.Pet..2019.01.003. [DOI] [Google Scholar]

- Schechter D. S.; Zhou D.; Orr F. M. Jr. Capillary Imbibition and Gravity Segregation in Low IFT Systems. Presented at the SPE Annual Technical Conference and Exhibition; OnePetro: Dallas, Texas, U.S.A., 1991, 6–9 October, SPE-22594-MS. [Google Scholar]

- Morrow N. R.; Mason G. Recovery of oil by spontaneous imbibition. Current opinion in colloids and interface science. Curr. Opin. Colloid Interface Sci. 2001, 6, 321–337. 10.1016/S1359-0294(01)00100-5. [DOI] [Google Scholar]

- Al-Anssari S; Nwidee L. N.; Arif M.; et al. Wettability alteration of carbonate rocks via nanoparticle-anionic surfactant flooding at reservoirs conditions. Presented at the SPE Symposium: Production Enhancement and Cost Optimisation; OnePetro: Kuala Lumpur, Malaysia, November 2017. SPE-189203-MS. [Google Scholar]

- Azad M.IFT Role on Oil Recovery During Surfactant Based EOR Methods. Surfactants in Upstream E&P; Springer: 115–148. [Google Scholar]