Abstract

The two-tank water system is common practice for the storage and distribution of water in many homes. Water is transported via a pipeline network from the storage tank (lower tank) to the distribution tank (overhead tank) using an electric pumping machine. Due to limited control in the existing pumping system, water wastage becomes inevitable. Determining the quality of water in the overhead tank before supply in the home is still unaddressed. In this work, an integrated Android mobile App and a control system were developed to assess the water quality, perform level check in the overhead tank, and activate intelligent pumping control. An ultrasonic pulse-echo technique was used for water level checks, while the water turbidity and pH signals were used for water quality checks. Three-level control conditions (LC_1, LC_2, LC_3) and two water quality check conditions (QC_1 and QC_2) were devised and used in the intelligent control algorithm of the system. Control valve1 regulates the flushable poor water quality while valve2 regulates the house's supply of good water quality. The absolute relative error between the expected time and the system time of filling the tank level was observed to be less than 10% when the water volume is less than 81%. Hence, distortion in the sensory signals increases and worsen as the water level approaches the ultrasonic sensor position. The poor internet signal network was observed to affect the real-time monitoring and automation of the system control through delay in system responses to commands. However, the average recorded response time of the system is 3 s, and it could be less in the situation of good internet network services.

Keywords: Firebase, Pitch-catch, Pulse-echo, Time-of-flight, Turbidity, pH scale, Ultrasonic

Firebase, Pitch-catch, Pulse-echo, Time-of-flight, Turbidity, pH scale.

1. Introduction

Recently, IoT has gained tremendous attention in the IT industry ranging from simple automation based applications to sophisticated applications [1]. The standard setting of water storage and circulation system in homes and industries consists of overhead storage, pipeline network, and underground storage tanks [2]. In monitoring an overhead tank set-up, remote monitoring and data collection systems are necessary to collect information from the tank based on the pre-set values and communicate processed information to the user when necessary or make decisions in a dire situation. IoT trend has opened up research areas, including investigating the systematic evaluation of water features by articulating its based sensor networks. Classifying water quality for human use promotes human health and the ecosystem [3, 4]. It helps to determine the usefulness of the collected water and how to manage it adequately. Determining water quality involves measuring different factors that are a function of water usage [5, 6, 7]. Fundamental factors in most water quality design systems are pH, salinity level and amount of particle suspense [8]. The primary water supply system in residential homes consists of four (4) key components, which follows a particular sequence: Water sources, Primary storage/water treatment, water supply mechanism (electric pump and pipe networks), Secondary storage/water distribution stage. However, efficient water management, water quality, and water level monitoring are still constraints for residential homes and industries.

During water pumping from underground storage tank to overhead storage tank, there is always water overflow that leads to water wastage. Secondly, as water circulates from the overhead storage tank to indoor utility points, there is a challenge of determining the remaining volume of water in the tank, and this could result in an unscheduled stoppage of economic or domestic activities. Also, ascertaining the water quality to be supplied to the indoor facility for delicate use is of concern, especially when the overhead water storage tank is not easily accessible. This work seeks to address these specific problems.

Various scholarly works have sought to address water quality and water level indication through different techniques. In [9], K. Saravanan et al. proposed a new Supervisory Control and Data Acquisition (SCADA) system that integrates the Internet of Things (IoT) technology for real-time water quality monitoring. This work assessed the contamination of water, leakage in the pipeline through automatic measurement of some system parameters such as temperature sensor, flow sensor, a colour sensor in real-time. The measured parameters are processed through the Arduino coordinations and used to make an informed quality state of the water and its volume in the tank. The quality state of the water is communicated as a short message service (SMS) to the user.

Similarly, in [10], the authors designed a real-time wireless monitoring system for tank water levels based on GSM and supported an alarming subsystem. In [11], an IoT system for monitoring several water pollutant parameters was implemented. The monitored parameters were temperature, conductivity, pH, and turbidity. The parametric sensors and wireless network sensors were configured for accessible signal data collection and assessment.

A real-time water level monitoring system was designed and implemented in [12]. A water level sensor was used to detect the desired parameter. If the water level reaches the pre-set parametric value, the signal will be feed in real-time to social networks like Twitter. In [13], a system for detecting water level, water quality, and leakage in the water flow network was set up. The drop in water pressure was detected using a Force Sensitive Resistor (FSR), signifying water leakage contrary to a pre-set value. Sensor HC-SR04 was configured as a water level detector on the soft water tank, and ATMega 328 microcontroller functioned as a data processor. A pre-set percentage range of the sensors was used to manipulate the pump's operation through the regulating valves. In this work [14], a configured monitoring system was discussed based on ATMega 328 microcontroller to replace the level stick sensor used in beverage industries to monitor the water level in water tanks. Non-contact water level monitoring system was implemented using LabVIEW and Arduino in [15]. Depending on the sensor reading, the LabVIEW program sends the data to Arduino, and through the Arduino board, the pump is switched ON if only the water level in the upper tank is low. Also, the pump is switched OFF if the water level is filled in the upper tank.

None of the works reviewed considered a method of detecting and flushing poor quality water or having a handy mobile application for real-time update and monitoring. A low cost and efficient water quality and water level monitoring/control system that integrates with the IoT technology for real-time system monitoring was duly designed and implemented in this work. An Android mobile App was also developed to offer a user-friendly interface and handy control over the system. An innovative poor quality water outlet valve was introduced to take care of poor quality water when detected. This system can serve suitably well for effective water management at homes or industries and other utility applications of water.

2. System principles

2.1. Water level detection via sound-echo reflection

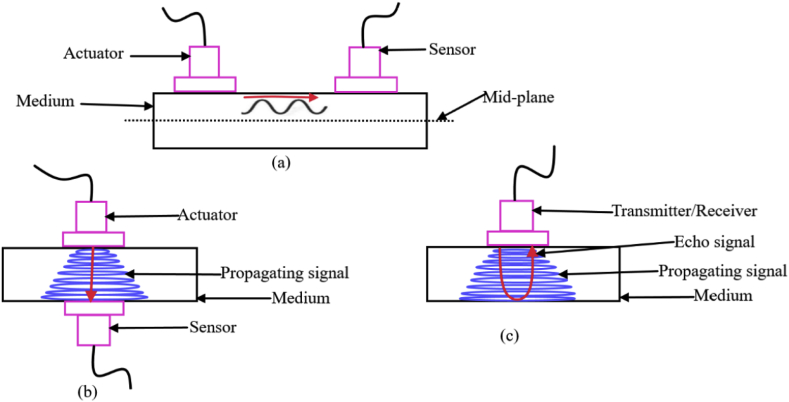

An ultrasonic transducer is an electronic device that can emit ultrasound waves through an actuator and receive the transmitted scattered wave or reflected echo wave through a sensor after interaction with an object (damage, cracks, discontinuity, corrosion, void, etc.) [16, 17, 18]. Ultrasonic transducers used for inspection are straight beam, angle beam, dual element, delay line, and immersion [19]. However, an inspection of a structure can either be active sensing or passive sensing [20, 21]. The standard configurations of transducers used in ultrasonic inspection analysis are Pitch–Catch, Pulse-Echo, and Through-Transmission [22, 23], as shown in Figure 1. In the pitch-catch configuration mode, the actuator and sensor distance apart and use two probes for sending and receiving burst waves.

Figure 1.

The three commonly transducer configurations for structure inspection: (a) Pitch-Catch (b) Through transmission (c) Pulse-Echo.

In contrast, Pulse-Echo mode uses one transducer that serves both emitting functions and receiving a tone burst wave with a probe [22, 23, 24, 25]. The operating frequency range of ultrasound is 20KHz -200MHz [26], as in Figure 2. Pulse-Echo configuration is majorly used for liquid level sensing [27]. The fluid level measuring transducer is installed at the top of the storage tank. The transducer is set into vibration with a series of amplified burst signals at a centre frequency range of KHz –MHz to generate a propagation wave that the transducer would detect as an echo after hitting the surface of a structure. This is shown in Figure 3. The depth of the empty tank is H, the depth of the tank from transducer level to water level surface is , and the depth of the water level is L. Time-of-Flight (ToF) is the total time taken for the transmitted Pulse (PE) signal to return to the transducer as Echo (EO) after interaction with the water surface. This is measured as given in Eq. (1)

| (1) |

| (2) |

| (3) |

| (4) |

| (5) |

Figure 2.

The frequency range of different sounds.

Figure 3.

Water level determination using Pulse-Echo configuration.

Hence, Water depth in the storage tank is,

| (6) |

where

= Time of flight of sensor signal.

= velocity of light in air.

= distance from the sensor to the water level surface.

= Pulse transmission time.

= Echo transmission time.

The percentage of water in the overhead tank is,

| (7) |

Therefore the volume of water remaining in the overhead tank is given in (2)

| (8) |

where

= Overhead Storage Tank Capacity.

To determine the overhead water tank capacity, the useful volume required to meet the total water demand of the residential home must be known. Further details are in [28]. Hence, overhead storage capacity is determined using (9)

| (9) |

where

= maximum necessary quantity of water stored in the tank (m3) in an hour.

= the difference between the daily flow into the overhead tank from the reservoir and the daily consumption from the overhead tank.

2.2. Water quality detection techniques

Water quality is determined through the combinational effects of turbidity and the pH level scale of the water. The water particle suspensions are assessed using an optical turbidity sensor. Turbidity is the loss of clarity in water due to particles that may lead to light absorption, reflection, or dispersion [5, 17]. This parametric effect is quantified using Beer-Lambart law by relating the transmitted light to the source intensity , absorption coefficient per unit length , turbidity , and the length of the passing light [29, 30]. This is given in Eq. (10).

| (10) |

The value of the transmitting light is express as a function of the scattering angle , the particle size , the wavelength of the light , and the optical properties of the medium and particles . This is then represented in Eq. (11).

| (11) |

The pH scale is the range of acidic and alkalinity of a substance that determines hydrogen's potential [7]. According to the US Environmental Protection Agency, pH is classified as a secondary contaminant of drinking water and should range from 6.5 – 8.5 [31]. Although WHO recommended a pH of 6.5 for public drinking water, pH values above 8.5 are considered a high degree of alkalinity though not a health risk but could cause some effects like lowering the efficiency of electric water heater, thereby resulting in increased energy consumption and could as well cause coffee water to taste bitter [32]. Figure 4 shows the pH scale range.

| (12) |

Figure 4.

The pH scale.

In this study, the output reading values of the turbidity sensor and the pH sensor reading values were used to decide the quality of water in the overhead distribution tank for specific domestic use.

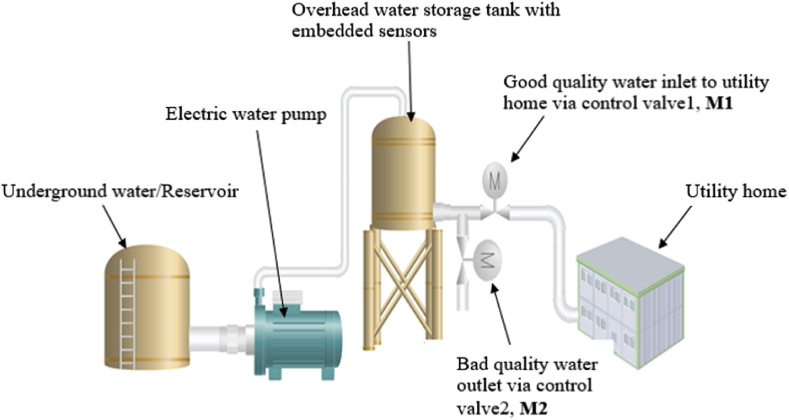

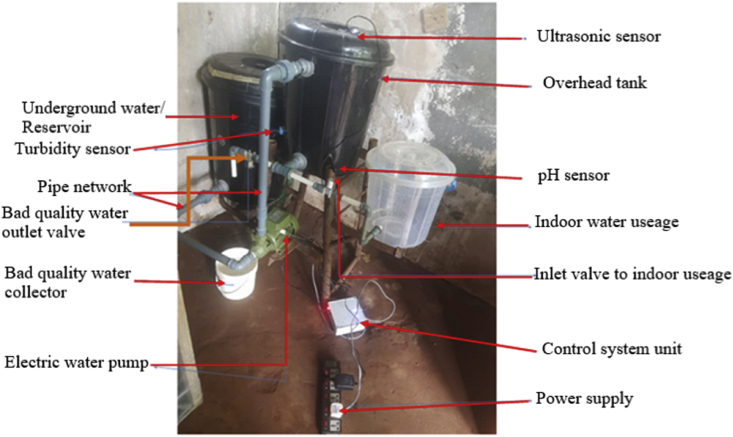

3. Conceptual system architecture and block diagram

A typical home water storage system consists of a reservoir, Overhead tank, Electric water pump, flow pipelines and one manually control valve that regulates water flow into the house through the inlet pipeline. Figure 5 shows the conceptual architecture of the redesigned home water storage system with two electronically control valves and an overhead water storage tank with an embedded Ultrasonic sensor and pH sensor. The valve1 regulates water inlet of good quality to the residential house while the valve2 regulates the flush out of poor quality water. Figure 6 is the block diagram of the water storage system control.

Figure 5.

Conceptual Architecture of the system.

Figure 6.

The system block diagram.

The proposed system consists of five distinct units with different functions as detailed below:

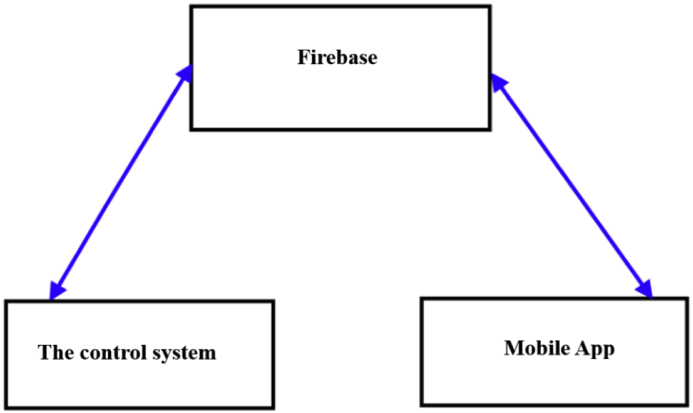

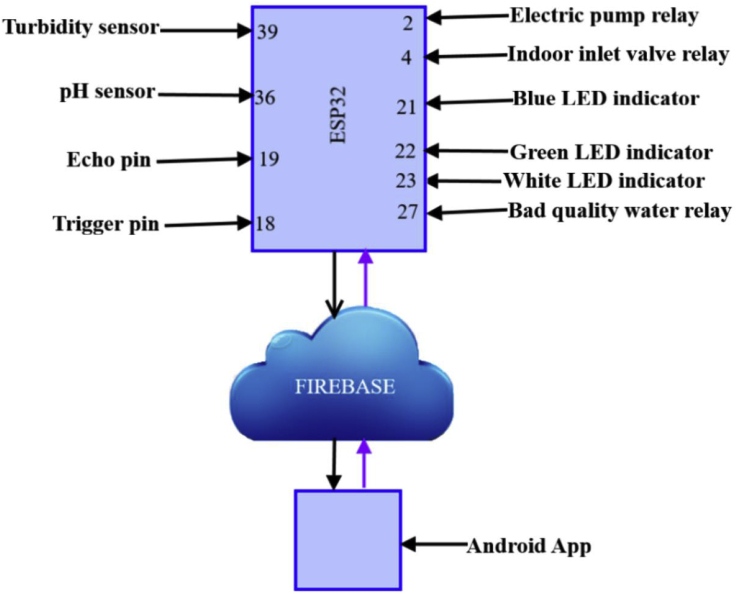

-

•

The connectivity unit. This unit involves three components. The control system receives requests and returns responses in real-time to the Android Mobile Application through the central component, firebase, as shown in Figure 7. Firebase is a Google-backed open-access application development platform that allows developers to build high-class mobile Apps for IOS, Android, and Web App. Its real-time database is cloud-hosted with no SQL and promotes data storage, retrieval, and synchronization between users and client devices [33, 34].

-

•

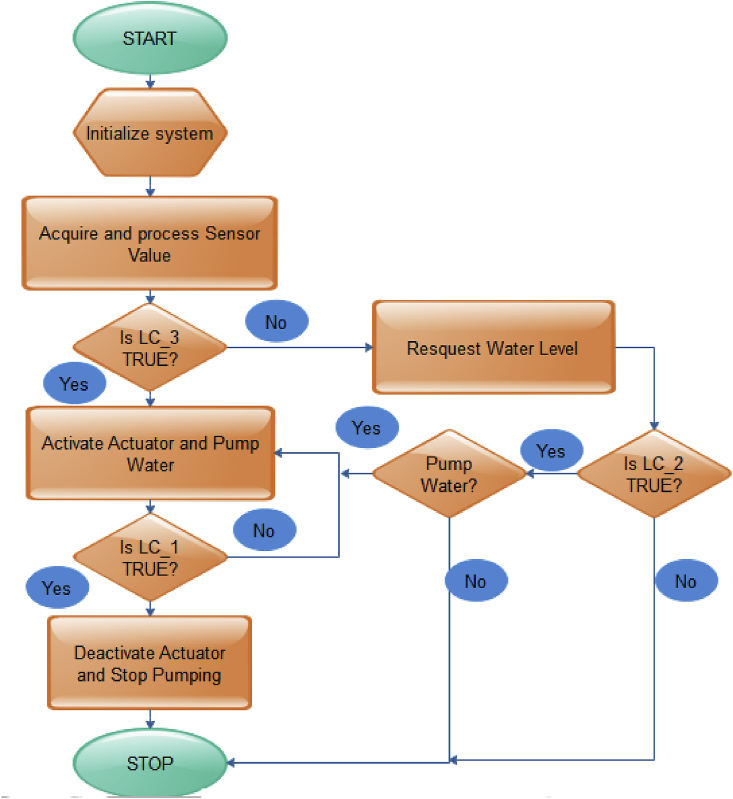

The water level sensing unit. This unit determines the percentage volume of water in the overhead water storage tank through pulse-echo inspection techniques of structures. The flowchart of this unit is shown in Figure 8. The ultrasonic sensor used in the design is HCSR04. It has a ranging accuracy of about 3mm and can measure 0.02m–4m none contact distance and 40KHz resonant frequency.

-

•

The Water quality sensing unit. This unit determines water quality in the overhead tank through the combined conditions of the pH value and Turbidity value. The flow chart of this unit is shown in Figure 10. The pH sensor used in the design is analogous pH sensor V2 with an accuracy of at 25 °C [35], and the turbidity sensor used in the design is SEN0189 with a wavelength of 910nm and response time of less than 500 ms [36].

-

•

The actuating and pumping unit. This unit ensures the appropriate switching ‘ON’ of the Electric water pump at a low water level in the overhead tank. It switches the electric water pump OFF at detection of full tank status.

-

•

The Microcontroller Unit. This unit controls, manages, and coordinates the activities of the other four units that interfaced with it. The core component of this unit is the ESP32 that has an integrated Wifi module and Bluetooth module for wireless communication with peripheral devices via internet connection.

Figure 7.

The connectivity path between the system control and the Mobile App.

Figure 8.

Overhead Tank water level control.

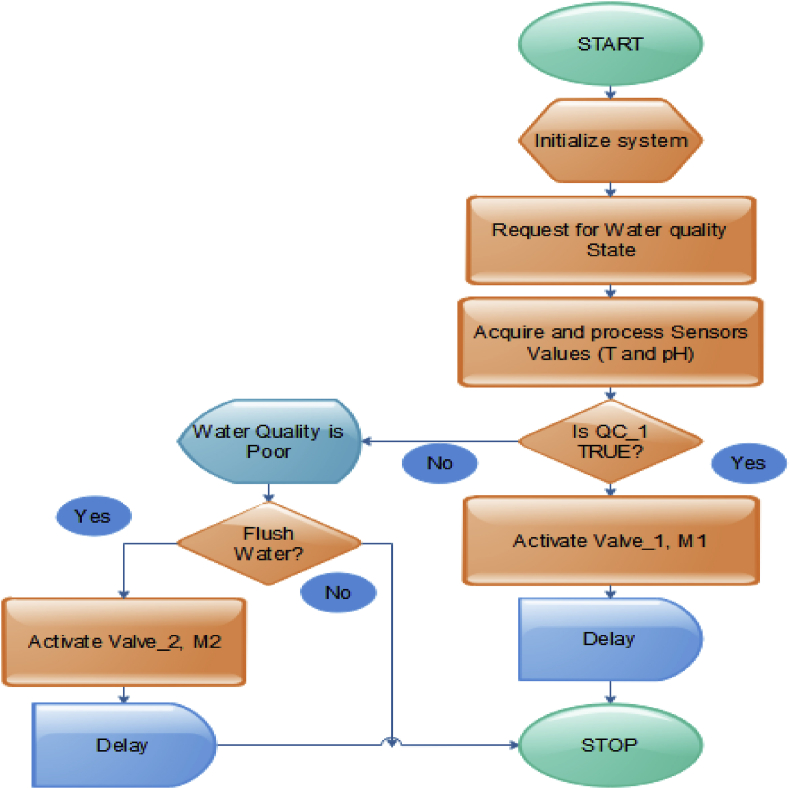

Figure 10.

Water quality control flowchart.

4. System implementation

4.1. Water level control

There are three conditions considered when designing the water level control. The first condition is when the overhead water tank is filled up to overflow level. This condition is tagged LC_1, and the action to take is to switch OFF the electric water pump through the actuator automatically. The second condition, LC_2, is when the water level in the overhead tank is between 30% and 50%. In this situation, the user can either refill the overhead tank to the overflow level or not. However, when the water level percentage is between 30% and 10%, the control system automatically issues a switching ON command to the actuator, transforming into water pumping. This is the condition LC_3 considered to be critical and requires overriding priority over every other activity. These conditions are shown in Table 1.

Table 1.

Water level control conditions.

| Water Level Conditions | Water Level Percentage | Actuator State | Remarks |

|---|---|---|---|

| LC_1 | Auto-OFF | Overhead Tank filled | |

| LC_2 | Optional | A reasonable volume of water in the overhead tank | |

| LC_3 | Auto-ON | The volume of water at a critical level |

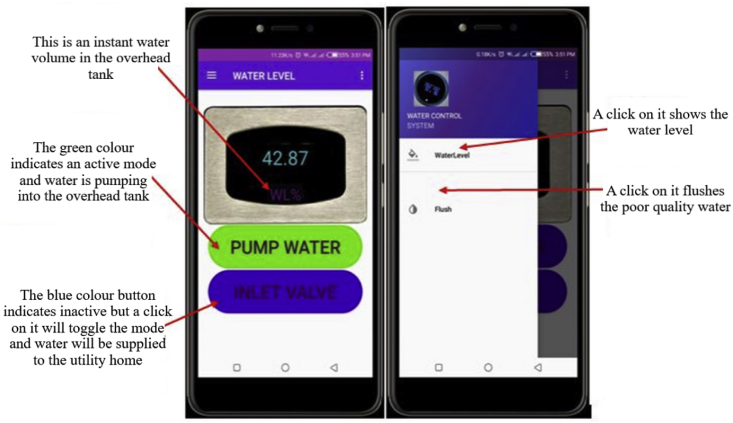

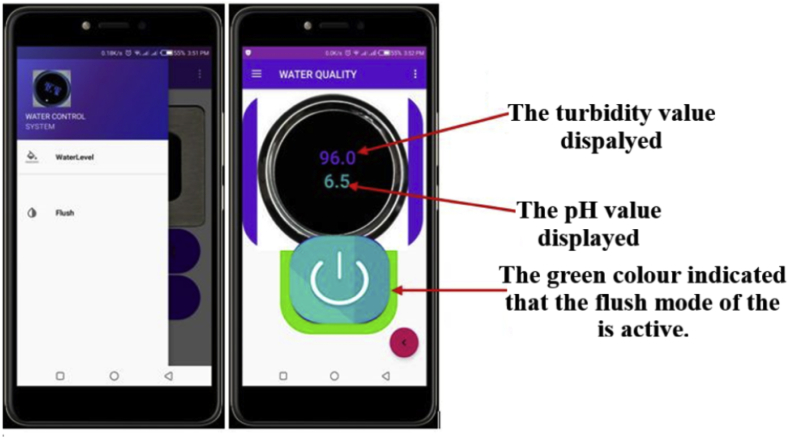

Figure 8 below is the flowchart of the water level condition control. When the system is installed and switched ON, the ultrasonic sensor performs empty tank depth determination, H(m). This is when there is no water in the tank. Subsequently, the sensor acquires the depth (m) of the tank above the water level surface for computation of the remaining water percentage. LC_3 is repeatedly checked every hour of the day. The homepage of the designed Android App displays the percentage of the remaining water in the overhead tank. This is captured and shown in Figure 9.

Figure 9.

The screenshot of the detected water level and pumping request.

When the Android App is opened, it sends water level requests to the microcontroller and displays the responses in a few seconds, depending on the strength of internet connectivity. Figure 9 is the screenshot of the display result obtained on 23/04/2020 at 3:51 PM. The percentage of water in the overhead tank was 42.87%. This means that the volume of water in the overhead tank is 21.435 L, as the filled volume is 50 L. The colour of the buttons indicates whether the command is sent or not. The green colour defines an active mode (command sent), while the blue colour indicates an inactive mode (command not sent). The pump water button controls the electric pump's operation by switching it ON and OFFthrough the actuator. The Inlet valve button controls the operation of the Valve1 that supplies water into the residential building.

4.2. Water quality control

Table 2 depicts two conditions created and used to programme the system decision's control structure for water quality, as given in Figure 10. The two conditions are QC_1 and QC_2. In QC_1, the pH scale value should be in the range of 7.0–8.5 and the turbidity value to be less than 22. Hence, the water quality is suitable for indoor use and control of valve1, M1 activated while that of valve2, M2 deactivated. The second condition is representing a QC_2 as in Table 2. The pH scale and turbidity value values in this condition suggest that the water quality is only suitable for outdoor use or could be flush out. In this condition, control valve1, M1 is deactivated, and control valve2, M2 is activated.

Table 2.

Water quality control and remark for use.

| Conditions | pH scale | Turbidity scale | Control Valve1,M1 | Control valve2,M2 | Remark |

|---|---|---|---|---|---|

| QC_1 | T < 22 | ON | OFF | For indoor use | |

| QC_2 | otherwise | T > 22 | OFF | ON | For outdoor use |

4.3. Control system design component and the complete system setup

The control system is the brain of the water level and water quality monitoring system. It makes use of the algorithm programmed to the central controller component. Flow charts depicted in Figures 8 and 10 are the basis of the algorithm used for the system decision making. The system Pinout configuration of the ESP32 module interfaced with the firebase and the designed android application is shown in Figure 11. The implemented complete system prototype is shown in Figure 12.

Figure 11.

The system components wiring network with the ESP32.

Figure 12.

The implemented system prototype.

5. Test result and discussion

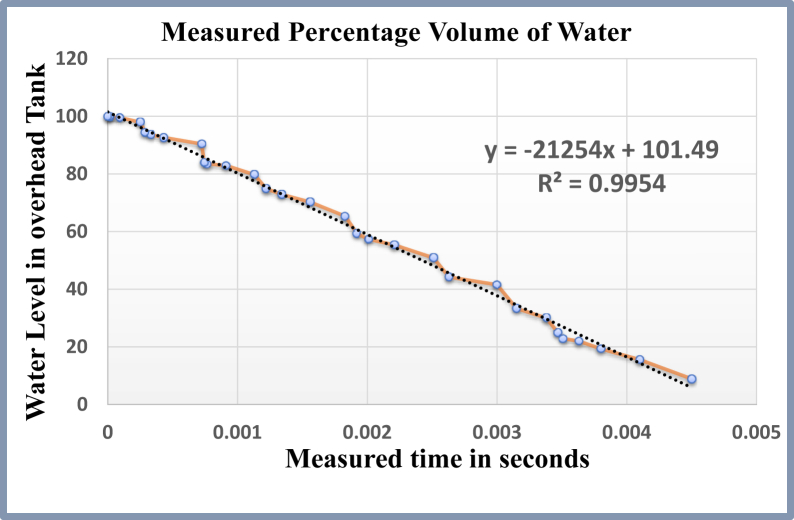

The depth of the overhead storage tank was measured at an empty state, and 31 inches (0.7874m) was recorded. However, at 20 °C, sound travels 1m in 2.9154 ms. This was used to estimate the water volume percentage in the overhead storage tank and compared it with the experimental measurements. The graphs based on estimation and experimental measurements were plotted, as shown in Figures 13 and 14, respectively. It was observed that as the volume of water in the overhead tank increases, the time of echo reflection decreases. However, the experimental graph has some degree of distortions, which could be attributed to the water turbulence and temperature increase during the measurement.

Figure 13.

Water percentage in the overhead tank based on estimated time.

Figure 14.

Water percentage in the overhead tank based on the measured time.

The time of flight, TOF, for incremental water height was calculated using the linearity equations of estimated and measured values. The absolute relative errors of TOF were calculated, and incremental water volume was plotted against it, as shown in Figure 15. It was observed that the absolute relative error was less than 10% when the water volume in the tank is less than 81%. Hence, distortion in the sensory signals increases and worsen as the water level approaches the ultrasonic sensor position. The poor internet signal network was observed to affect the real-time monitoring and automation of the system control through delay in system responses to commands. However, the average recorded response time is 3 s, and it could be less in good quality internetwork services.

Figure 15.

Relative error of the estimated and measured values.

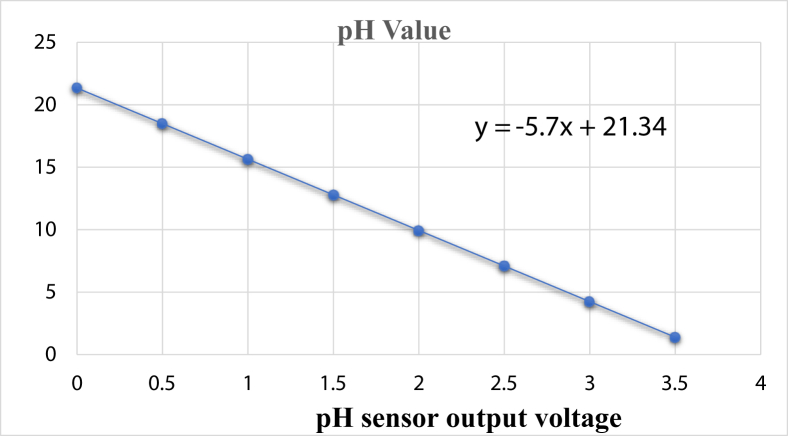

After calibration of the pH sensor using the standard solutions provided by the manufacturer in [35], its linearity graph and equation were obtained, as revealed in Figure 16. The same procedure was performed for the turbidity sensor [36], and its polynomial graph is shown in Figure 17.

Figure 16.

The pH scale value graph of the sensor.

Figure 17.

The Turbidity sensor value graph.

Figure 18 shows the screenshot display of results obtained when the particle constituents of the water were increased. In this condition, the water quality was poor and could only be used in outdoor functions such as washing cars and other laundry activities. The Flush water function was activated using the button shown in Figure 18, which shows the poor water control pane and valve 2, M2 was activated while valve 1, M1, was deactivated.

Figure 18.

The screenshot of poor water control Pane and sample of captured poor water quality values.

6. Conclusion

This paper presents a water level and water quality monitoring system that integrates with the IoT technology for real-time monitoring of a two-tank system. The essence of the system's design and its implementation is to provide a cheap, convenient solution to water wastage and water quality determination. Most of the designed system has shortcomings in real applications and does not provide convenience in using them. The designed system was implemented using hardware components like a microcontroller, actuator, electronic control valves, water pump, ultrasonic sensor, turbidity sensor, pH sensor. These hardware components were networked and programmed in line with the algorithm and flow chart operation developed for the system. Unlike most solutions, an Android mobile App with a user-friendly interface was developed and integrated into the system. Through the Android mobile App, the user could monitor the level and quality of water in the overhead tank to be supplied in the utility home. An innovative poor quality water outlet valve and control algorithm was integrated into the system. This allows for easy flushing of poor quality water from the overhead tank when detected. The flush poor quality water could be used for other external purposes or recycled through a treatment process. The decrease in the reliability of the ultrasonic sensory signal as water approaches the total capacity of the overhead tank is attributed to water turbulence and would be considered in further study. The application scope of this system is versatile. It could be effectively integrated into an existing water system management as it doesn't require additional calibration after installing it and downloading the mobile App.

Declarations

Author contribution statement

Samuel C. Olisa & Juliet E. Olisa: Conceived and designed the experiments; Performed the experiments.

Christopher N. Asiegbu & Bonaventure O. Ekengwu: Contributed reagents, materials, analysis tools or data; Wrote the paper.

Abdulhakim A. Shittu & Martin C. Eze: Analyzed and interpreted the data.

Funding statement

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Data availability statement

Data will be made available on request.

Declaration of interests statement

The authors declare no conflict of interest.

Additional information

No additional information is available for this paper.

References

- 1.Pasika S., Gandla S.T. Smart water quality monitoring system with cost-effective using IoT. Heliyon. 2020;6 doi: 10.1016/j.heliyon.2020.e04096. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Maharashtra P. 2012. Sanitation and Liquid Waste Management, Gujarat, India.https://pas.org.in/Portal/document/ResourcesFiles/pdfs/Module_1/Basics/of/water/supply/system.pdf [Google Scholar]

- 3.Schweitzer R.W., Harvey B., Burt M. Using innovative smart water management technologies to monitor water provision to refugees. Water Int. 2020;45:651–659. [Google Scholar]

- 4.Goda T. Monitoring and measurement of water quality parameters. Int. J. Water Resour. Dev. 1988;4:270–275. [Google Scholar]

- 5.Dube T., Mutanga O., Seutloali K., Adelabu S., Shoko C. Water quality monitoring in sub-Saharan African lakes: a review of remote sensing applications. Afr. J. Aquat. Sci. 2015;40:1–7. [Google Scholar]

- 6.Tortajada C. Water management in Mexico city metropolitan area. Int. J. Water Resour. Dev. 2006;22:353–376. [Google Scholar]

- 7.Al-Omari A., Fayyad M., Jamrah A. Drinking water quality in roof storage tanks in the city of Amman, Jordan. Water Int. 2008;33:189–201. [Google Scholar]

- 8.Abdel-Dayem S. Water quality management in Egypt. Int. J. Water Resour. Dev. 2011;27:181–202. [Google Scholar]

- 9.Saravanan K., Anusuya E., Kumar R., Son L.H. Real-time water quality monitoring using Internet of Things in SCADA. Environ. Monit. Assess. 2018;190 doi: 10.1007/s10661-018-6914-x. [DOI] [PubMed] [Google Scholar]

- 10.Ramadhan A.J., Mahdi A. 2017. Remote Monitoring and Automatic Controlling of Water Tank Level Based on GSM. [Google Scholar]

- 11.Parameswari M., Moses M.B. Online measurement of water quality and reporting system using prominent rule controller based on aqua care-IOT. Des. Autom. Embed. Syst. 2018;22:25–44. [Google Scholar]

- 12.Perumal T., Sulaiman M.N., Leong C.Y. IEEE 4th Global Conference on Consumer Electronics. GCCE; 2015. Internet of Things (IoT) enabled water monitoring system; pp. 1–3. [Google Scholar]

- 13.Arjun K., Latha C.A. Detection of water level , quality and leakage using raspberry PI with internet of Things. Int. Res. J. Eng. Technol. (IRJET) 2017;4:2875–2880. https://irjet.net/archives/V4/i6/IRJET-V4I6709.pdf [Google Scholar]

- 14.Hidayat M.R., Sambasri S., Fitriansyah F., Charisma A., Iskandar H.R. IEEE 5th International Conference on Wireless and Telematics (ICWT) 2019. Soft water tank level monitoring system using ultrasonic HC-SR04 sensor based on ATMega 328 microcontroller; pp. 1–4. [Google Scholar]

- 15.Shrenika R.M., Chikmath S.S., Ravi Kumar A.V., Divyashree Y.V., Swamy R.K. Vol. 2017. ICRAECT; 2017. Non-contact water level monitoring system implemented using LabVIEW and Arduino; pp. 306–309. (Proceedings - 2017 International Conference on Recent Advances in Electronics and Communication Technology). [Google Scholar]

- 16.Fisher D.K., Sui R. An inexpensive open-source ultrasonic sensing system for monitoring liquid levels. Agricul. Eng. Int.: CIGR J. 2013;15:328–334. [Google Scholar]

- 17.Jeswin C., Marimuthu B., Chithra K. 2017 International Conference on Information Communication and Embedded Systems. Vol. 2017. ICICES; 2017. Ultrasonic water level indicator and controller using AVR microcontroller. [Google Scholar]

- 18.Shah P.P., Patil A.A., Ingleshwar S.S. Proceedings of the International Conference on IoT in Social, Mobile, Analytics and Cloud, I-SMAC 2017. 2017. IoT based smart water tank with Android application; pp. 600–603. [Google Scholar]

- 19.Alobaidi W.M., Alkuam E.A., Al-Rizzo H.M., Sandgren E. Applications of ultrasonic techniques in oil and gas pipeline industries: a review. Am. J. Oper. Res. 2015;5:274–287. [Google Scholar]

- 20.Olisa S.C., Khan M.A., Starr A. Review of current guided wave ultrasonic testing (GWUT) limitations and future directions. Sensors (Switzerland) 2021:21. doi: 10.3390/s21030811. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Ihn J.B., Chang F.K. Pitch-catch active sensing methods in structural health monitoring for aircraft structures. Struct. Health Monit. 2008;7:5–19. [Google Scholar]

- 22.Jata K.V., Kundu T., Parthasarathy T.A. Advanced Ultrasonic Methods for Material and Structure Inspection. Wiley-ISTE; 2010. An introduction to failure mechanisms and ultrasonic inspection; pp. 1–42. [Google Scholar]

- 23.Kundu T., Placko D. Wiley-ISTE; 2010. Advanced Ultrasonic Methods for Material and Structure Inspection. [Google Scholar]

- 24.Barski M., Kedziora P., Muc A., Romanowicz P. Structural Health Monitoring (SHM) methods in machine design and operation. Arch. Mech. Eng. 2014;61:653–677. [Google Scholar]

- 25.Awad T.S., Moharram H.A., Shaltout O.E., Asker D., Youssef M.M. Applications of ultrasound in analysis, processing and quality control of food: a review. Food Res. Int. 2012;48:410–427. [Google Scholar]

- 26.ANSI/ASA S1.1-2013 - acoustical terminology. https://webstore.ansi.org/standards/asa/ansiasas12013 (n.d.)

- 27.Le A. Ultrasonic sensing basics for liquid level sensing , flow sensing , and fluid identification applications, Texas instruments application report. SNAA220A. 2015:1–10. [Google Scholar]

- 28.Biblio Design, sizing, construction and maintenance of gravity-fed system in rural areas - module 2 : principles and sizing of a gravity fed system. https://www.pseau.org/outils/biblio/resume.php?d=1670 (n.d.)

- 29.Postolache O., Girzo P., Pereim M., Ramos H. IEEE Instrumentation and Measurement Technology Conference. 2002. IR turbidity sensor: design and application; pp. 21–23. [Google Scholar]

- 30.Parra L., Rocher J., Escrivá J., Lloret J. Design and development of low cost smart turbidity sensor for water quality monitoring in fish farms. Aquacult. Eng. 2018;81:10–18. [Google Scholar]

- 31.United States Environmental Protection Agency pH. https://www.epa.gov/caddis-vol2/caddis-volume-2-sources-stressors-responses-ph (n.d.)

- 32.McClanahan M.A., Mancy K.H. Effect of pH on quality of calcium carbonate film deposited from moderately hard and hard water. J. Am. Water Works Assoc. 1974;66:49–53. [Google Scholar]

- 33.Firebase. https://firebase.google.com/ (n.d.)

- 34.What is firebase? https://www.educative.io/edpresso/what-is-firebase (n.d.)

- 35.Gravity: analog pH sensor/Meter Kit V2 – DFRobot. https://www.dfrobot.com/product-1782.html (n.d.)

- 36.Gravity: analog turbidity sensor for Arduino - DFRobot. https://www.dfrobot.com/product-1394.html (n.d.)

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data will be made available on request.