Abstract

Wooden breast (WB) condition is a chicken myopathy that causes quality losses and has been shown to negatively affect the sensory acceptance by consumers. In this work, we prepared emulsified chicken patties using WB meat and evaluated their texture profile and acceptability. Three formulations were processed: PN (100% normal breast), PW (100% WB meat) and PNW (50%:50% PN:PW). All the analyzed samples were in accordance with Brazilian legislation parameters for microbiological traits. A marked decrease (P < 0.001) of hardness was noted for PW and PNW samples compared with PN. The sensory ratings were not affected (P > 0.05) by the addition of WB meat in the different treatments. In fact, all samples presented a global sensory acceptance above 70%. The use of WB meat in the formulation of chicken patties is a useful practice to minimize the economic losses in the poultry industry, also helping to support decision-making and improve production performance.

Keywords: Myopathy, Wooden breast, Patties, Texture, Sensory acceptance

Introduction

The increasing demand for chicken meat because of its low cost, nutritional profile and sensory traits, has been driven the poultry sector to increase their productivity. To achieve this objective, it was necessary to enhance genetic selection in order to improve meat quality and growth rate of the birds (Petracci et al. 2017).

Despite the advances in the poultry industry, the high growth rate of the birds has been shown to negatively alter the muscular characteristics, such as diameter and length of the muscle fiber, besides also modifying the metabolism of the birds (Petracci et al. 2019). According Young and Rasmussen (2020), the time required to reach the commercial weight of the birds has been reduced with the genetic modification (from 43 to 35 days or less). Therefore, it is observed the presence of fibers of the type IIB in the Pectoralis major these broilers. In view of this observation, researchers hypothesized that accelerated bird growth may increase susceptibility to the development of myopathies such as wooden breast (WB) (Sihvo et al. 2014).

Wooden breast (WB) is the term attributed to a myopathy that affects the quality of chicken breast and which has already resulted, in combination with other myopathies, in economic losses of around US$ 200 millions for the poultry industry in the United States (Kuttappan et al. 2017).

The WB myopathy mainly affects the Pectoralis major in poultry breasts, causing tissue damage. This condition is described as a muscle of hard consistency, pale color, bleeding points, tail protrusion and viscous liquid on the surface, and may be present at different levels of severity and in combination with other myopathies already known as White Striping e Spaghetti Meat (Petracci et al. 2019).

The occurrence WB myopathy has generated negative impacts on the appearance of the chicken breast fillets, and may also affect the technological properties, nutritional value and, consequently, consumer acceptance, resulting in economic losses. Therefore, studies that enable a better understanding of how to use WB meat in the poultry industry are of paramount importance in the current scenario. Different researches have been demonstrated the potential of the WB in the production of meat products such as sausages (Madruga et al. 2019). Thus, the aim of this study was to investigate the effect of WB meat on the texture parameters and acceptability emulsified chicken patties.

Material and methods

Sample selection

Ten kilograms of boneless and skinless breast fillets (normal and WB) were obtained from Cobb® birds (males and females) after they were slaughtered at an age of 42–48 days in a slaughterhouse certified with Federal Inspection Seal (FIS). All other ingredients used in the processing of emulsified chicken patties were purchased in the local market of João Pessoa, Paraiba.

Broilers were slaughtered according to the Brazilian legislation (Brasil 1998), being submitted to electrical stunning, bleeding, scalding, evisceration, chilling and deboning. Breast selection (normal and WB) was manually performed through palpation of the muscle and verification of the appearance of chicken breast cuts according to procedures described by Bailey et al. (2015) and Kutappan et al. (2013).

After sample collection, the chicken breasts were stored at 4 °C for 24 h and frozen at −18 °C for 2 days until elaboration of emulsified chicken patties.

Processing of emulsified chicken patties

Three formulations of emulsified chicken patties were processed (Table 1): 100% normal breast (PN), 100% wooden breast (PW) and 50%: 50% normal: wooden breast (PNW). Regarding to the processing of emulsified chicken patties, the breast fillets were ground in an industrial grinder (Ibrasmak, MC 160, São Paulo, Brazil) and emulsified in a cutter (G. Paniz, 90,510, Caxias do Sul, Brazil) for 6 min with ingredients and additives (Table 1). Cold water was used to maintain meat emulsion temperature below 12 °C. The meat emulsion (100 g) was molded (10 cm diameter and 1 cm thickness) and wrapped in low-density polyethylene film. Finally, twenty samples per treatment (n = 20) of emulsified chicken patties were frozen at −18 °C and stored for further analysis.

Table 1.

Emulsified chicken patties formulations elaborated with N chicken breast, WB chicken and their mixture

| Raw material (%) | Formulations | ||

|---|---|---|---|

| PN | PW | PNW | |

| Normal meat | 70.0 | – | 35.0 |

| Wooden Breast meat | – | 70.0 | 35.0 |

| Chicken skin | 15.0 | 15.0 | 15.0 |

| Cold water | 15.0 | 15.0 | 15.0 |

| Ingredients (g/kg) | |||

| Onion dried | 40.0 | 40.0 | 40.0 |

| Garlic dried | 20.0 | 20.0 | 20.0 |

| Sodium Chloride | 20.0 | 20.0 | 20.0 |

| Cumin | 10.0 | 10.0 | 10.0 |

| Chili dried | 1.00 | 1.00 | 1.00 |

| Glutamate monosodium | 1.00 | 1.00 | 1.00 |

PN: only normal chicken breast meat; PW: only WB meat; PNW: mixture normal chicken breast meat and WB meat

Texture measurement

Texture assessment was performed in cooked samples. The samples of each treatment were cooked using an electrical grill (CKSTGR 3007, Oster, China) at 175 °C according to a standard protocol of 3 min, 2 min and then 15 s on each side until an internal end point temperature of 75 °C (El-Magoli et al. 1996). Six cylindrical samples (2.5 cm diameter × height of 1.0 cm) were taken from random locations in each treatment with a cylindrical cutter. Texture profile analysis (TPA) was carried out using a TA-XT2i Texture Analyzer (Stable Micro Systems, Surrey, United Kingdom) equipped with a cylindrical probe of 3.5 cm diameter (P/35) to compress each sample to 40% of its original height at a cross-head speed of 5 mm/s. Hardness (N), gumminess (N), chewiness (N), springiness (dimensionless), cohesiveness (dimensionless) and resilience (dimensionless) were determined according to Bourne (2002). Warner–Bratzler shear force (N) of cooked chicken patties was measured in eight rectangular blocks (2.5 cm × 1.0 cm × 1.0 cm) per treatment using a TA-XT2i Texture Analyzer (Stable Micro Systems, Surrey, United Kingdom) equipped with a Warner–Bratzler rectangular shear blade (10 mm/s test speed). Maximum force to cut the samples was recorded as the shear force.

Microbiological assessment

The microbiological analysis of emulsified chicken patties was carried out according to APHA (2015) in order to assure the sanitary conditions for consumption by the sensory assessors. The reference criteria used was established by Brazilian legislation (Resolution no 12; group 5, item (f), which states that Coliforms at 45 °C/g, Staphylococcus coagulase positive/g, reducing sulphite Clostridium and Salmonella spp./25 g must be analyzed for frozen and chilled meat products (Brasil 2001). Results were calculated as the means of three determinations.

Sensory evaluation

The evaluations were authorized by the Ethics and Research with Human Beings Committee (ERHBC 88553618.2.0000.5183), meeting the ethical and scientific requirements from Resolution number 466, National Health Council (Brasil 2012). Samples of each treatment were cooked using the same conditions described in “Texture measurement” section. Sensory characterization of emulsified chicken patties processed with normal and wooden breast chicken meat was conducted by 100 untrained between recruited among students and faculty members from the Federal University of Paraíba campus who reported regular chicken patties intake. Acceptance and purchase intent tests were carried out according to Meilgaard et al. (1999). Acceptance test assessed color, aroma, flavor, texture, appearance and global impression using a 9-point hedonic scale ranging from 1 (extremely disliked) to 9 (extremely liked). A 5-point hedonic scale was used for the test of intent to purchase. The sensory sessions occurred in individual booths under white fluorescent light and the samples were randomly served on plastic cups with a glass of water and a piece of unsalted cracker. Acceptability Index (AI) was calculated as follows: AI = (Ma/9) × 100, where Ma is the mean of the evaluated attribute.

Statistical analysis

A one-way ANOVA was applied to evaluate the results from emulsified chicken patties characterization. When significant differences were noted (P < 0.05), Tukey’s test were carried out. Data from sensory analysis was treated by a non-parametric Kruskal–Wallis test using SPSS®, version 23.

Results and discussion

All treatments had protein content higher than 15 g/100 g and lipid content lower than 23 g/100 g (data not shown), corroborating limits recommended by the Brazilian legislation for hamburger (Brasil 2000).

Regarding the texture profile of products (Table 2), there was difference among formulations (P < 0.05), except for cohesiveness. Hardness, gumminess, and chewiness showed similar behavior between the formulations. PNW treatment displayed a decrease in hardness, gumminess and chewiness variables (58.49%, 60.14% and 58.25%, respectively) compared to PW treatment, while PN sample presented higher values for hardness (32.16 N), gumminess (25.99 N) and chewiness (23.69 N). This result indicates that chicken patties prepared with normal breast need greater force to disintegrate during chewing until it reaches the point of being swallowed. Similar behavior was reported by Rigdon et al. (2020) in chicken sausages formulated with WB. These results suggest that the processing technique used to produce the emulsified chicken patty may be considered as a strategy that can alleviate inferior quality attributes of the raw material since the characteristic harder texture was not observed in the chicken patties formulated with wooden breast (Xing et al 2020). In addition, cooking process also seems to influence hardness and chewiness as noted by Geronimo et al. (2019) in cooked WB.

Table 2.

Texture profile of emulsified chicken patties elaborated with N chicken breast, WB chicken and their mixture

| Parameter | Formulations | |||

|---|---|---|---|---|

| PN | PW | PNW | P-value | |

| HardnessA | 32.16 ± 5.41a | 17.91 ± 1.80b | 13.35 ± 1.90c | *** |

| SpringinessB | 0.88 ± 0.03b | 0.91 ± 0.01a | 0.90 ± 0.01ab | *** |

| CohesivinessB | 0.81 ± 0.01 | 0.83 ± 0.02 | 0.83 ± 0.02 | ns |

| GumminessA | 25.99 ± 4.64a | 14.34 ± 1.25b | 10.36 ± 0.72c | *** |

| ChewinessA | 23.69 ± 4.12a | 13.06 ± 1.24b | 9.89 ± 1.22c | *** |

| ResilienceB | 0.38 ± 0.01b | 0.43 ± 0.03a | 0.43 ± 0.02a | ** |

| Shear forceA | 7.11 ± 0.74a | 7.56 ± 0.80a | 4.89 ± 0.38b | ** |

PN: only normal chicken breast meat; PW: only WB meat; PNW: mixture normal chicken breast meat and WB meat

A Data expressed as Newton (N)

B Dimensionless parameters

*: P ≤ 0.05, **: P ≤ 0.01, ***: P ≤ 0.001; ns: no significant difference. Different lowercase letters (a, b, c) indicate significant differences among formulations

Regarding elasticity and resilience, the lowest values were obtained for the PN treatment, which indicates that this sample presents lower recovery after removal of the compression force and lower capacity to return to its original state (Bourne 2002).

For all emulsified chicken patties samples, the counts of Salmonella sp. (absence) and the global means Coliforms 45 °C (1.25 × 102 ± 10.24 MPN/g), coagulase positive Staphylococcus (1.67 × 103 ± 0.57 × 103 CFU/g) and sulfite-reducing Clostridium (< 1.0 × 102 CFU/g) were below maximum levels allowed by Brazilian legislation (Brasil 2001). This result indicates that samples were safe for consumption, making possible the sensory evaluation of the product.

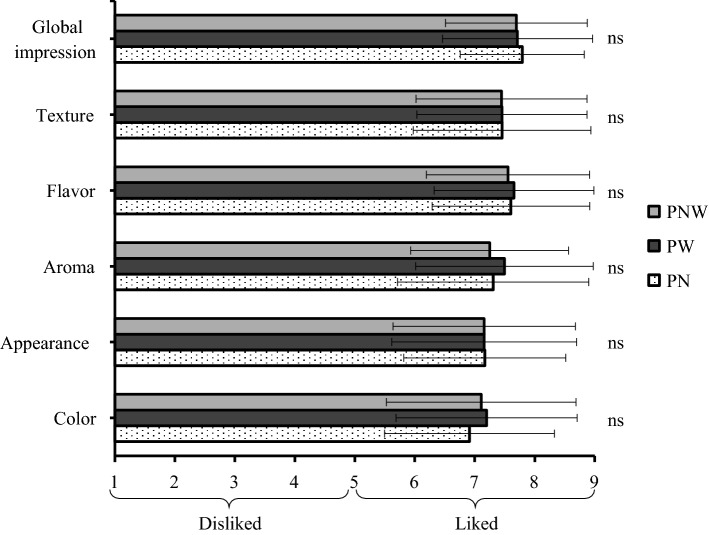

The sensory parameters evaluated by untrained judges in the acceptability test did not show significant difference (P > 0.05) among samples (Fig. 1), indicating that judges did not perceive any difference in emulsified products formulated with normal and wooden breast. The acceptance index was higher than 70% for all attributes evaluated in the three formulations, which is considered the limit of acceptance, that is, for all treatments, the attributes evaluated were well accepted among judges, which values were in the scale between "liked slightly" (6) and the "liked very much" (8). These results indicate that it is possible to incorporate meat from wooden breasts into the formulation of emulsified chicken patties without any noticeable sensory alteration. The absence of significant differences between samples processed with normal and wooden breast can be attributed to the technological processes used in the product elaboration such as grinding and emulsification, which alter the structure of the raw material and standardize the characteristics of the final product (Qin 2013).

Fig. 1.

Acceptability test of emulsified chicken patties elaborated with normal chicken breast, WB meat and their mixture. Footnote: PN: only normal chicken breast meat; PW: only WB meat; PNW: mixture normal chicken breast meat and WB meat. ns: no significant difference

The purchase intention of products also showed no difference (P > 0.05) among treatments. The global mean for PN, PW and PNW treatments was 4.02 ± 1.01, focusing on the "I would likely buy" scale (4) and suggesting that if processing industries use WB breasts for making hamburgers, potential consumers would buy the product as they would buy those made with normal breast. These results corroborate the data obtained by Qin (2013) when performing the acceptability test on nuggets made with WB and N breasts.

The results of sensorial analysis were compatible with those found in emulsion-type sausages elaborated with normal and wooden breast (Madruga et al 2019). The authors also obtained acceptability higher than 70% for all attributes evaluated and an average score of 3.9 for purchase intention indicating that the sausages elaborated with wooden breast were approved for untrained judges.

Conclusion

In our study, we demonstrated that the wooden breast meat can be effectively used in the emulsified chicken patties formulation without compromising the acceptance of the final product. These achievements may be useful to minimize economic losses and improve production performance in the poultry industry. Further studies may be performed to investigate the effect of different processing techniques on the quality of other meat products prepared with wooden breast meat.

Acknowledgements

This study was supported by grants from Guaraves Guarabira Aves Ltda Company, Conselho Nacional de Desenvolvimento Científico e Tecnológico (MCTI/CNPq) (Universal 01/2016; 430832/2016-8) and Coordenacão de Aperfeiçoamento de Pessoal de Nível Superior—Brasil (CAPES)—Finance Code 001.

Abbreviations

- WB

Wooden breast

- PN

Normal patty

- PW

Wooden breast patty

- PNW

Chicken patty prepared with a mixture of normal and wooden breast meat

- FIS

Federal inspection seal

- TPA

Texture profile analysis

- APHA

American Public Health Association

- ERHBC

Ethics and Research with Human Beings Committee

- AI

Acceptability index

- Ma

Mean of the evaluated sensory attribute

- ANOVA

Analysis of variance

- ns

No significant difference

Author contributions

Miriane Moreira Fernandes Santos: Data curation, Formal analysis, Writing - original draft. Darlinne Amanda Soares Lima: Data curation, Formal analysis, Validation. Íris Braz da Silva Araújo: Conceptualization, Writing - review & editing. Marta Suely Madruga: Funding acquisition, Supervision, Writing—review & editing. Fábio Anderson Pereira da Silva: Conceptualization, Methodology, Funding acquisition, Project administration, Resources, Supervision, Validation, Writing—review & editing.

Funding

The research was supported by Conselho Nacional de Desenvolvimento Científico e Tecnológico (MCTI/CNPq) (Universal 01/2016; 430832/2016-8).

Data Availability

None.

Declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Consent for publication

None.

Ethical Approval

This study was authorized by the Ethics and Research with Human Beings Committee (CAAE 88553618.2.0000.5183) of the Federal University of Paraiba, João Pessoa, Brazil.

Code Availability

None

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Miriane Moreira Fernandes Santos, Email: miriamemfs@gmail.com.

Darlinne Amanda Soares Lima, Email: darlinneamanda@yahoo.com.br.

Íris Braz da Silva Araújo, Email: iris.bsaraujo@gmail.com.

Marta Suely Madruga, Email: msmadruga@uol.com.br.

Fábio Anderson Pereira da Silva, Email: fabio.silva@academico.ufpb.br.

References

- APHA . Compendium of methods for the microbiological examination of foods. 5. Washington: American Public Health Association; 2015. [Google Scholar]

- Bailey RA, Watson KA, Bilgili SF, Avendano S. The genetic basis of pectoralis major myopathies in modern broiler chicken lines. Poult Sci. 2015;94:2870–2879. doi: 10.3382/ps/pev304. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bourne MC. Food texture and viscosity: concept and measurement. Geneva: Academic Press; 2002. [Google Scholar]

- Brasil (1998) Ministério da Agricultura, Pecuária e Abastecimento. Portaria no 210, de 10 de novembro de 1998. Aprova o regulamento técnico da inspeção tecnológico e higiênico sanitária de carne de aves. Diário Oficial da República Federativa do Brasil, Brasília, DF

- Brasil (2000) Regulamento Técnico de Identidade e Qualidade de Hambúrguer. Instrução Normativa Nº 20 de 31 de julho de 2000. Ministério da Agricultura, Pecuária e Abastecimento (MAPA), Brasília, DF

- Brasil . Regulamento Técnico sobre padrões microbiológicos para alimentos. Brasília: Agência Nacional de Vigilância Sanitária (ANVISA); 2001. [Google Scholar]

- Brasil . Conselho Nacional de Saúde. Resolução n 466. Diretrizes e Normas regulamentadoras de pesquisa envolvendo seres humanos. Brasil: Diário Oficial da República Federativa do Brasil; 2012. p. 59. [Google Scholar]

- El-Magoli SB, Laroia S, Hansen PMT. Flavor and texture characteristics of low fat ground beef patties formulated with whey protein concentrate. Meat Sci. 1996;42:179–193. doi: 10.1016/0309-1740(95)00032-1. [DOI] [PubMed] [Google Scholar]

- Geronimo BC, Mastelini SM, Carvalho RH, Barbon Júnior S, Barbin DF, Shimokomaki M, Ida EI. Computer vision system and near-infrared spectroscopy for identification and classification of chicken with wooden breast, and physicochemical and technological characterization. Infrared Phys Technol. 2019;96:303–310. doi: 10.1016/j.infrared.2018.11.036. [DOI] [Google Scholar]

- Kuttappan VA, Shivaprasad HI, Shaw DP, Valentine BA, Hargis BM, Clark FD, Mckee SR, Owens CM. Pathological changes associated with white striping in broiler breast muscles. Poult Sci. 2013;92:331–338. doi: 10.3382/ps.2012-02646. [DOI] [PubMed] [Google Scholar]

- Kuttappan VA, Bottje W, Ramnathan R, Hartson SD, Coon CN, Kong BW, Owens CM, V-AñonHargis MM. Proteomic analysis reveals changes in carbohydrate and protein metabolism associated with broiler breast myopathy. Poult Sci. 2017;96:2992–2999. doi: 10.3382/ps/pex069. [DOI] [PubMed] [Google Scholar]

- Madruga MS, Rocha TC, Carvalho LM, Sousa AMBL, Sousa Neto AC, Coutinho DG, Ferreira ASC, Soares AJ, Galvão MS, Ida EI, Estévez M. The impaired quality of chicken affected by the wooden breast myopathy is counteracted in emulsion-type sausages. J Food Sci Technol. 2019;56:1380–1388. doi: 10.1007/s13197-019-03612-0. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Meilgaard M, Civille GV, Carr BT. Sensory evaluation techniques. Boca Raton: CRC Press; 1999. [Google Scholar]

- Petracci M, Soglia F, Berri C. Poultry quality evaluation. Duxford: Woodhead Publishing; 2017. Muscle metabolism and meat quality abnormalities; pp. 51–75. [Google Scholar]

- Petracci M, Soglia F, Madruga M, Carvalho L, IdaEstévez EM. Wooden-breast, white striping, and spaghetti meat: causes, consequences and consumer perception of emerging broiler meat abnormalities. Compr Rev Food Sci Food Saf. 2019;18:565–583. doi: 10.1111/1541-4337.12431. [DOI] [PubMed] [Google Scholar]

- Qin N (2013) The utilization of poultry breast muscle of different quality classes. Master Thesis, University of Helsinki, Finland

- Rigdon M, Stelzleni AM, McKee RW, Pringle TD, Bowker B, Zhuang H, Thippareddiz H. Texture and quality of chicken sausage formulated with woody breast meat. Poult Sci. 2020;100:100915. doi: 10.1016/j.psj.2020.12.014. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sihvo HK, Immonen K, Puolanne E. Myodegeneration with fibrosis and regeneration in the pectoralis major muscle of broilers. Vet Pathol. 2014;51:619–623. doi: 10.1177/0300985813497488. [DOI] [PubMed] [Google Scholar]

- Xing T, Zhao X, Zhang L, Li JL, Zhou GH, Xu XL, Gao F. Characteristics and incidence of broiler chicken wooden breast meat under commercial conditions in China. Poult Sci. 2020;99:620–628. doi: 10.3382/ps/pez560. [DOI] [PMC free article] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

None.