Abstract

Can green chemistry be the right reading key to let organocatalyst design take a step forward towards sustainable catalysis? What if the intriguing chemistry promoted by more engineered organocatalysts was carried on by using renewable and naturally occurring molecular scaffolds, or at least synthetic catalysts more respectful towards the principles of green chemistry? Within the frame of these questions, this Review will tackle the most commonly occurring organic chiral catalysts from the perspective of their synthesis rather than their employment in chemical methodologies or processes. A classification of the catalyst scaffolds based on their E factor will be provided, and the global E factor (E G factor) will be proposed as a new green chemistry metric to consider, also, the synthetic route to the catalyst within a given organocatalytic process.

Keywords: catalyst synthesis, E factor, green chemistry, organocatalysis, sustainability

Efactor under scrutiny: Do you know which is the impact on the overall process of the organocatalyst synthesis? Within the framework of the green chemistry principles, this Review analyses the synthetic routes towards some of the most important organocatalyst scaffolds. The introduction of a new chemistry metric, the EG factor, will provide an idea of the actual impact of the catalyst synthesis within the overall organocatalytic process.

1. Introduction

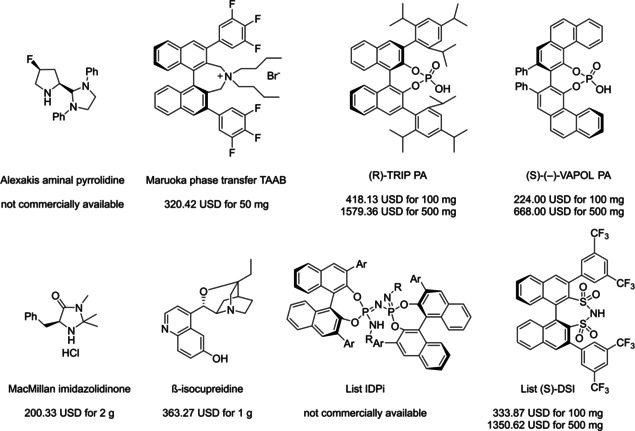

Among the three major branches of asymmetric catalysis, namely bio‐, organometallic and organo‐catalysis, the latest has exponentially gained attention and importance just starting from the end of 1999.[1] Despite the presence of isolated examples of asymmetric catalysis from small organic molecules in the early literature,[2] the well‐defined area of asymmetric organocatalysis has emerged thanks to the elucidation of general activation modes and to its broad applicability. Apart from the novelty, several key factors have given a significant contribution to the widespread success of chiral organic scaffolds as catalysts, such as: biodegradability, general insensitivity towards oxygen and moisture, availability from natural sources and generally lower cost with respect to enzymes or transition metals. All of these key factors give a nod to the twelve principles of green chemistry,[3] and it is worth noticing that both green chemistry and asymmetric organocatalysis were emerging and relatively unexplored research areas, growing side by side more or less simultaneously. Anyway, a mutual interconnection between the two areas, from a formal point of view, is still missing. While the constant demand for more eco‐sustainable protocols still makes green chemistry an attractive research field, nowadays asymmetric organocatalysis seems to have fully exploited its potential. In fact, if compared to the mole of catalysts and protocols provided by academia, industrial applications are relatively scarce.[4] This is not surprising if the cost and the synthetic efforts to prepare some classes of organocatalysts are taken into account (see Figure 1 for complex molecular scaffolds),[5] making inconvenient their employment on a large scale.

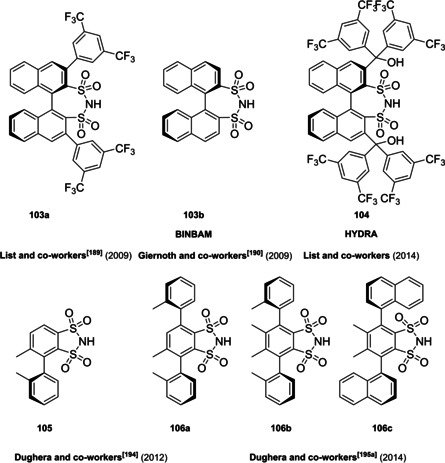

Figure 1.

Some complex molecular scaffolds employed in organocatalysis.[10]

If in the original definition an organocatalyst is a small organic molecule having no metal as part of the “active principle”,[6] no limitation is imposed to the employment of transition metals, toxic reagents, or difficult reaction conditions in the synthetic route towards the target organic compound. Moreover, in the last years to answer to the specific request for high reactive and enantioselective compounds, organocatalysis has moved more and more towards the development of catalysts with very complex structures without taking inspiration from sustainability. Curiously, the three pioneering papers of modern asymmetric organocatalysis present three complementary aspects with reference to the complexity of the catalyst scaffold.[7] Thus a discrepancy between organocatalysis and green chemistry may arise.

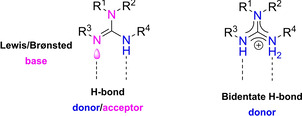

Within this background, our aim will be to critically analyze the synthetic routes followed to prepare organocatalyst scaffolds, providing the reader with the tools to evaluate these synthetic processes based on the twelve principles of green chemistry.[3] A classification of the catalyst scaffolds based on their E factor will be provided in order to give a trusted general idea of the impact of the synthetic process towards the catalyst.[8] Indeed, the E factor appears to be the most complete mass‐based parameter to evaluate the overall greenness in the context of an entire process, also in the perspective of industrial applications. On the contrary, other mass‐based metrics would neglect other important waste sources (e. g., reaction mass efficiency) or would lead to situations of ambiguity in the definition of non‐benign reagents (e. g., effective mass yield). On the contrary, impact‐based metrics like the EcoScale would likely lead to the calculation of meaningless negative scores. In fact, it must be stressed that most of the synthetic routes to organocatalyst scaffolds consist in multiple steps and have not been designed in the perspective of sustainability. As highlighted in Chapter 8, a global E factor (E G factor) will be proposed as a new green chemistry metric to consider, also, the synthetic route towards the catalyst within a given organocatalytic process. Organocatalyst scaffolds will be divided according to the general classification by List and Maruoka in: Lewis bases, Brønsted bases, Brønsted acids and Lewis acids.[6]

Additional insights will be dedicated, in separate chapters, to hydrogen bonds and phase‐transfer organocatalysts. Green chemistry related to the process analyzed will be discussed. Moreover, solvents employed will be evaluated according to the solvent sustainability guide, while hazard classification from European Union and ECHA will be reported for the most used reagents.[9] In any case, it must be stressed that this critical review does not intend to diminish the importance of organocatalysts with very complex structures. In our opinion a major inspiration of catalyst design to the twelve principles of green chemistry in the future may help to develop really sustainable processes.

2. Lewis Base Catalysts

2.1. Prolines, imidazolidinones, and other amino acid derivatives

The first chapter of this review is dedicated to those catalysts which, according to List and Maruoka, can be classified as Lewis bases. Between them, proline and derivatives boosted a rapid and extraordinary development of this field, making aminocatalysis the privileged method for the asymmetric functionalization of carbonyl compounds.[11]

From the infancy of aminocatalysis, the natural amino acid proline (1 a) has assumed a central role as to be considered both as the “simplest enzyme” in nature[12] and as “the universal catalyst”.[13] In fact, because of its versatility, efficiency and generality, 1 a has been extensively applied as the privileged catalyst in the nucleophilic addition or substitution of carbonyl compounds, imines, azodicarboxylates and nitrosobenzenes with a variety of electrophiles.[11a, 11b, 11c, 14] Moreover, being a natural and renewable compound, 1 a fully meets the principles of green chemistry.[15] Considering the catalytic power of natural product 1 a, chemists dedicated a lot of efforts to the development of its derivatives to improve the solubility, enhance the acidity or increase the steric hindrance of the directing group (Figure 2). The stereoinduction in the product can be controlled through hydrogen‐bond interactions or steric hindrance,[16] thus catalysts derived from 1 a can be divided into two main groups.[17] The first group is characterized by a hydrogen‐bond donor substituent, able to activate and position the electrophile, while the catalysts from the second group present a bulky moiety allowing the electrophile to approach the enamine only from one side (Figure 2).

Figure 2.

Classification of catalysts derived from 1 a.

Compounds 1 b–1 f preserve the central proline moiety, in which a tunable hydrogen‐bond donor is introduced to increase the solubility and enhance the acidity. In general, these catalysts revealed to be more reactive and more enantioselective in specific reactions, but the generality of 1 a was lost. Between all the structures developed, we decided to present the synthesis of the three derivatives depicted in Scheme 1. In accordance with the 2nd principle, the incorporation of the starting material is maximized, in fact catalysts 1 d, 1 e–1 f are obtained through lateral derivatization of a natural compound, thus preserving its original stereochemistry.

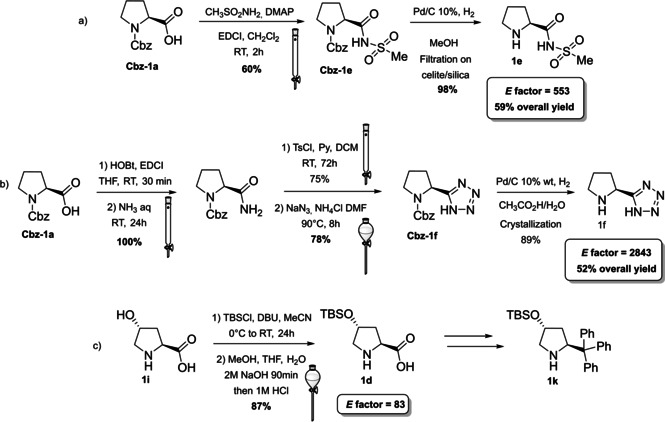

Scheme 1.

Synthesis of selected proline derivatives bearing hydrogen‐bond‐directing groups (DMAP= 4‐dimethylaminopyridine, DCM= dichloromethane, EDCl= 1‐(3‐dimethylaminopropyl)‐3‐ethylcarbodiimide, DBU= 1,8‐diazabicyclo[5.4.0]undec‐7‐ene, TBSO= tert‐butyldimethylsilyl ether).

The groups of Yamamoto and Ley, independently, contributed to this field introducing proline derivatives bearing a tetrazole and an acyl sulfonamide group (Scheme 1a, b, catalysts 1 e and 1 f).[18, 19] The tetrazole and the sulfonamide moieties are employed to replace proline carboxylic acid function in order to obtain a more soluble catalyst with preserved (1 f) or increased acidity (1 e). In both cases, protection of the secondary amine functionality with N‐carboxybenzyl group (Cbz) is applied to direct the reaction towards the carboxylic group of 1 a. The 8th principle of green chemistry is not taken into account, since protection/deprotection strategies were not minimized or excluded. The synthesis of compound 1 e is quite straightforward, and it is based on the coupling of protected‐proline Cbz‐1 a, in classic reaction conditions, with a sulfonamide (Scheme 1a). The Cbz removal is then realized through hydrogenolysis. Product 1 e is obtained in around 60 % yield and one column chromatography can be avoided employing crude Cbz‐1 e in the hydrogenation step. In order to remove palladium on carbon (Pd/C), the sulfonamide 1 e should be filtered through a short pad of silica and celite. An E factor of 533 is obtained. The introduction of the tetrazole moiety is lengthier and requires five synthetic steps, two column chromatographies, one extractive workup and one crystallization, affording catalyst 1 f in 52 % yield with an E factor of 2843 (Scheme 1b). The carboxylic group of Cbz‐proline is first converted in an amide and then to a cyano group, which allows the introduction of the tetrazole after reaction with sodium azide. Finally, Cbz protecting group is removed.[18] Both synthetic procedures go against the 3rd, 4th, and 5th principles of green chemistry employing volatile organic compounds (VOC) solvents and reagents, which are flammable (hydroxybenzotriazole (HOBt), DMF), from harmful to very toxic for aquatic life (HOBt, NaN3, Pd, NH3) and that can cause damage to fertility and to unborn child (DMF).

The last derivative of proline, that we present, is obtained from trans‐4‐hydroxy‐L‐proline (1 i), a natural non‐conventional amino acid that can be isolated by hydrolyzed gelatin in accordance with the 7th principle. The same 1 i can be used as catalyst after a simple protection of the hydroxyl group as silyl ether (Scheme 1c). The protected trans‐4‐hydroxy‐L‐proline derivative 1 d is obtained in 87 % yield after a two‐step reaction, one extractive workup, and precipitation, resulting in a low E factor of 83. Compound 1 d can be further derivatized and converted to catalyst 1 k belonging to the second group (steric bulk control).[20] Between catalysts that can exert enantiocontrol through steric bulk, diarylprolinol ethers and imidazolidones are the most exploited.[21] For this reason, we will analyze their synthesis and evolution. Jørgensen and Hayashi groups, independently, contributed to the development of diarylprolinol ethers 1 g.[22] These compounds originated from the need to find a catalyst combining both high reactivity and high selectivity (Figure 3). As the authors told, the inspiration came from two related compounds: methylpyrrolidine (1 l) and diarylprolinol (1 m) both bearing proline skeleton. Compound 1 l is characterized by high reactivity but low selectivity probably due to an insufficient steric shielding; on the contrary 1 m is highly selective but poorly reactive. The simple protection of the OH group as silyl ether prevents oxazolide formation delivering a catalyst, which is at the same time highly reactive and enantioselective.

Figure 3.

Comparison between methylpyrrolidine 1 l, diarylprolinol 1 m, and diarylprolinol ether 1 g.

Different synthetic routes have been proposed to access 1 m, from which the most active diarylprolinol ether (1 g) can be prepared in one step (Scheme 2). As summarized in Scheme 2, 1 m can be obtained from two different multi‐step approaches employing the natural compounds 1 a or racemic pyroglutamic acid (4) as starting materials. Bhaskar Kanth and Periasamy proposed a three‐step synthesis starting from 1 a in which the amine functionality is protected as carbamate with ethyl chloroformate; at the same time, the carboxylic group is esterified with methanol. In the next step, a Grignard reagent is exploited to introduce the diphenyl functionality on the carboxylic group. Deprotection and crystallization delivers product 1 m in 91 % yield. A low E factor of 177 can be calculated from this process considering that all the intermediates are purified by extractive workup avoiding production of waste due to chromatography.[23]

Scheme 2.

Synthesis of selected proline derivatives bearing sterically hindered directed groups.

Nevertheless, the usage of ethyl chloroformate and phenylmagnesium bromide may cause risks and concerns for large scale production, considering that these compounds are highly flammable, they can cause skin burns and eye damage. Moreover, ethyl chloroformate is fatal if inhaled and phenylmagnesium bromide may cause genetic defects and cancer (data from ECHA).[24]

The synthetic path developed by Corey et al. employs as starting material racemic pyroglutamic acid (rac‐4), a natural amino acid derivative. The synthesis of diarylprolinol ((S)‐1 m) is accomplished by a three‐step sequence (esterification, reaction with phenylmagnesium chloride, and reduction with borane) followed by resolution of rac‐1 m with (S)‐(+)‐O‐acetylmandelic acid and recrystallization (Scheme 2). Access to the catalyst enantiomer (R)‐1 m is possible employing as resolution reagent (R)‐(−)‐O‐acetylmandelic acid.[25] All reactions are run at room temperature observing the 6th principle and, despite the employment of a resolution reagent does not meet the 9th principle, the chosen one is a natural compound derivative. As concern the safety, acetyl chloride is less toxic than ethyl chloroformate but still highly flammable and borane cannot be considered a green reagent, being also harmful for aquatic life. This process is characterized by an E factor of 466, higher than the one obtained by Bhaskar Kanth and Periasamy,[23] but if one takes into account the cost of the process, Corey path is probably more appealing considering that both racemic and L‐pyroglutamic acid are less expensive than 1 a (100 g of racemic pyroglutamic acid 4 costs 66.84 USD; 100 g of L‐pyroglutamic acid costs 73.92 USD; 100 g of 1 a costs 208.94 USD from Sigma–Aldrich/Merck). For what concerns 1 g, its synthesis can be easily realized incorporating the TMS group in a single step starting from the corresponding prolinol 1 m (Scheme 2).[22a] Because of the need for a repeated extractive workup and a chromatographic purification the E factor rises to 476, starting from 1 a.

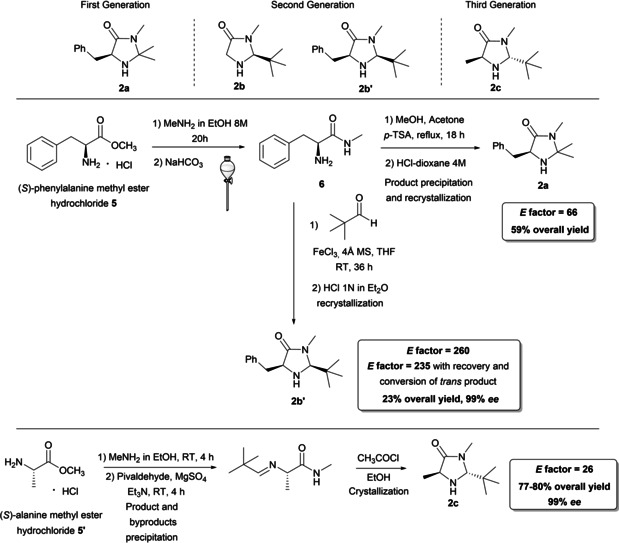

Together with enamine catalysis, iminium ion activation allows the asymmetric functionalization of a variety of unsaturated carbonyl compounds. In this case the primary role of catalyst is occupied by MacMillan's imidazolidinones 2, which are able to form a reversible and reactive iminium ion, ensuring stereocontrol from π‐facial discrimination. MacMillan's imidazolidinones 2 can be classified as 1st, 2nd and 3rd generation catalysts (Scheme 3), differing from the presence of a hydrogen or substituents in the α‐positions to the secondary amine group.[7b, 26b, 26c] Second‐generation compounds have been introduced by MacMillan and co‐workers to increase imidazolidinone reactivity in the presence of furan and indole substrates. In fact, the removal of one of the methyl group from the 1st generation compounds allows the catalyst to form the iminium ion more straightforwardly. At the same time, the substitution of the other methyl with a more hindered t‐butyl group increases the coverage of the blocked Si‐enantioface, thus obtaining stereocontrol. 1st and 2nd Generation imidazolidinone, according to MacMillan protocol, can be obtained from a common intermediate which is synthesized from (S)‐phenylalanine methyl ester 5, an amino acid derivative, through amide bond formation (Scheme 3). The amide 6 can be cyclized in the presence of acetone and an acidic catalyst to give imidazolidinone 2 a (first generation) in 59 % yield after acidification. The simple workup consisting of extraction, product precipitation, and recrystallization contributes to a very low E factor of 66.

Scheme 3.

Synthesis of MacMillan imidazolidinones belonging to the 1st, 2nd and 3rd generation.

On the contrary, for the 2nd‐generation compounds e. g. 2 b’, the E factor rises to 260. The approach pursued is the same, but the lower overall yield (23 % versus 59 %) contributes to the E factor increase. The value can be reduced to 235 if the trans product is recovered and converted to cis‐imidazolidinone (2 b’) through elimination reaction in the presence of NaHCO3 and FeCl3, in THF as the solvent. Attention should be paid in the employment of methylamine (can cause serious eye and skin damage and respiratory irritation, contains gas under pressure and may explode if heated) and FeCl3 which may be corrosive to metals, causes skin irritation and may cause an allergic skin reaction although being a fully abundant natural compound. Few and medium issue solvents (MeOH, EtOH, acetone) are applied in two out of four synthetic steps to 1st generation imidazolidinones. A step forward enamine catalysis and the merge between organo‐ and photoredox catalysis have been made possible through the development of 3rd generation imidazolidinones.[27] These compounds are characterized by a reduced steric hindrance because of the trans arrangement of substituents. Despite the similar synthetic approach, 2 c is obtained from alanine methyl ester hydrochloride in higher yield with respect to compounds 2 a and 2 b. The lack of intermediates purifications and chromatography results in a very low E factor of 26.[28] Recent developments towards recoverable MacMillan catalysts 2 have been summarized by Deepa and Singh.[29]

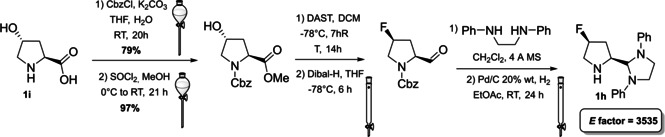

The last example we present is the modular aminal–pyrrolidine (1 h) designed by the group of Alexakis (Scheme 4).[30] This organocatalyst is characterized by a pyrrolidine moiety in which an aminal group is introduced to increase steric bulk. The aminal moiety can, in fact, accommodate different substituents making this structure modular. Moreover, the introduction of a group at the 4‐position of the pyrrolidine moiety, like a fluorine atom, is able to stabilize one catalyst conformation, allowing efficiency and enantioselectivity improvement. Alexakis and co‐workers proposed a multi‐step synthesis starting from natural product trans‐4‐hydroxy‐L‐proline (1 i) (Scheme 4). In the first two steps, the amine functionality is protected with CbzCl and the carboxylic acid is esterified with methanol. Then, a nucleophilic substitution at low temperature is exploited to introduce the fluorine atom and invert the configuration of the stereogenic center. The ester is reduced to aldehyde at −70 °C, allowing the introduction of aminal group after reaction with a diamine. According to the diamine employed, it is possible to modulate the catalyst structure. The application of two cryogenic steps is not in line with the 6th principle of green chemistry. In the last step the Cbz protecting group is removed and product 1 h is obtained in 61 % overall yield. Considering the presence of two column chromatography purifications and the absence of sequential reactions in one solvent, the E factor rises to 3535.

Scheme 4.

Synthesis of modular 1 h (DAST= diethylaminosulfur trifluoride, Dibal‐H= diisobutylaluminium hydride).

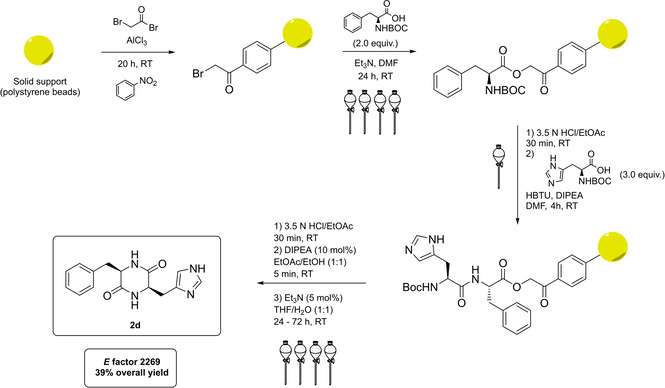

Although organocatalysis is strictly referred to small organic molecules, synthetic peptides represent a very interesting class of compounds for asymmetric synthesis, especially because of their easiness of preparation and availability of starting materials.[31] Between them, α,α‐ and α,β‐dipeptides are those finding a practical synthetic application. Among the very first examples of dipeptide organocatalysts,[32] Inoue and co‐workers proposed an interesting cyclo‐L‐phenylalanine‐L‐histidine (2 d) for the asymmetric Strecker reaction. A recent approach to 2 d includes polystyrene‐supported Merrifield‐type solid‐phase synthesis, followed by deprotection from support and cyclization in mild reaction conditions,[33] as depicted in Scheme 5.

Scheme 5.

Synthesis of 2 d (HBTU= 3‐[Bis(dimethylamino)methyliumyl]‐3H‐benzotriazol‐1‐oxide hexafluorophosphate, DIPEA= N,N‐diisopropylethylamine).

Throughout the synthesis of this catalyst, it is remarkable the lack of any chromatographic purification, an interesting point in the aim of reducing the total waste amount. Unfortunately, the need for several extractions and washing steps with classical VOCs contributes to a high final E factor value of 2269. Nevertheless, as a starting point for a green improvement of the procedure some important key features can be identified, such as the use of naturally occurring amino acids as the substrates and the recyclability of the solid support. Moreover, the volatile solvents employed are among the less environmentally hazardous (e. g., EtOAc, EtOH) or possess suitable green alternatives (e. g., 2‐MeTHF instead of CH2Cl2 or THF). Very recently, even DMF was shown to be dispensable for solid phase peptide synthesis, in favor of N‐octyl pyrrolidone.[34]

For what concerns classical dipeptides, the lowest molecular weight subclass of polypeptide catalysts, their design has been inspired by Type I aldolases. According to Reymond and co‐workers,[35] peptides catalysts can be classified in four main classes and divided in class I, if based on terminal primary amines, and class II peptides if based on secondary amines. A quaternary ammonium salt or a free carboxyl group can be present as displaced in Scheme 6.

Scheme 6.

Design of potential peptide catalysts and synthesis of Juaristi catalyst 1n for the neat aldol reaction under ball milling conditions (iBBCl= isobutyl chloroformate, NMM= 4‐methylmorpholine).

Being inspired by Type I aldolases, it is not surprising that the aldol reaction was the first transformation on which peptide organocatalysts were tested. With the development of this branch of catalysis, several different peptides turned out to be excellent chiral organocatalysts,[36] including green approaches.[37] However, proline‐based α,α‐ and α,β‐dipeptides undoubtedly preserved their privileged role.[38] Herein, we describe the route towards catalyst 1 n by Juaristi and co‐workers, an α,β‐proline‐based dipeptide applied to the neat aldol reaction under ball milling conditions (Scheme 6).[37d] Despite the design of catalyst 1 n has not been explicitly inspired by the twelve principles, naturally occurring L‐proline and L‐alanine are employed as the starting materials (7th principle), warming or extreme cooling are avoided (6th principle) and catalyst 1 n is employed to promote and accelerate heterogeneous reactions (9th principle). Room for improvement is offered by the possibility of replacing reaction solvents (namely, THF and methanol) with their greener counterparts 2‐MeTHF and ethanol, respectively. Unfortunately, two chromatographic purifications severely affect the overall waste amount, thus a final E factor value of 3080 is obtained.

2.2. Chiral 4‐(dimethylamino)pyridines

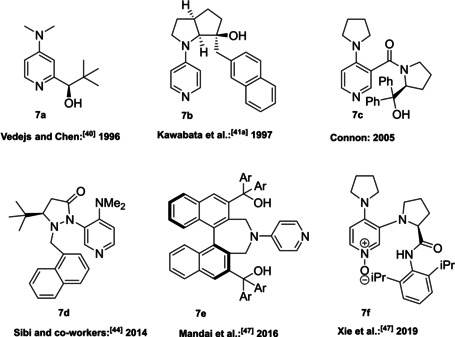

4‐(Dimethylamino)pyridine (DMAP) and its derivatives are generally employed as acyl transfer catalysts[39] and the pioneering paper of Vedejs and Chen paved the way to the organocatalyzed asymmetric version of these reactions.[40] Nowadays, different chiral DMAPs are available and, as it can be seen from Figure 4, the induction of stereocontrol is linked to the presence of an element of chirality in the DMAP backbone (central, axial, planar, and helical chirality).[41, 42] A limitation in the employment of these catalysts is their acute dermal toxicity which can be reduced through DMAP salt formation, the salt produces, in fact, only local irritation. Alternatively, DMAP can be immobilized, allowing also for its recyclability thus increasing process sustainability.[43]

Figure 4.

Selected examples of chiral DMAP 7 a–7 f.[46]

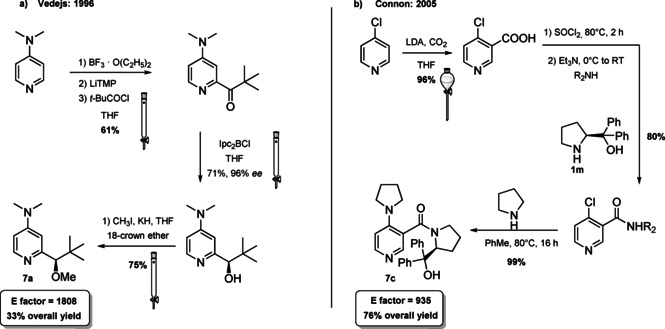

The chiral DMAP 7 a, developed by Vedejs and Chen, is a quite simple compound, in which a chiral center is present on a branched chain installed on the α‐position to the nitrogen in the pyridine ring (Figure 4 and Scheme 7a).[40] A similar approach was later applied by Connon et al., installing a chiral amine, such as (S)‐α,α‐diphenylprolinol (1 m), through amide bond formation on the β‐position of the pyridine ring (compound 7 c, Scheme 7b).[41g] In this case, to induce remote stereocontrol the hydroxyl group is not protected and exploited for hydrogen‐bond formation. The synthetic procedures reported are based on a classical chemistry. As it can be seen from Scheme 7a, compound 7 a can be obtained in four synthetic steps. Despite THF is employed as the solvent in all steps, sequential reactions are not telescoped in a one‐pot multistep reaction, but all intermediates are isolated through three column chromatographies. The employment of additional solvent contributes to an E factor of 1808. Connon et al. managed to reduce the number of purification steps, obtaining a lower E factor of 935; anyway, the employment of thionyl chloride and low temperature lithiation is not aligned with green chemistry principles (Scheme 7b).

Scheme 7.

a) Synthetic protocol reported by Vedjes and Chen to obtain the first chiral DMAP 7a; b) Synthetic protocol reported by Connon to obtain bifunctional chiral DMAP 7c. ee=enantiomeric excess (LiTMP= lithium 2,2,6,6‐tetramethylpiperidide, LDA= lithium diisopropylamide, Ipc2BCl= −‐B‐chlorodiisopinocampheylborane).

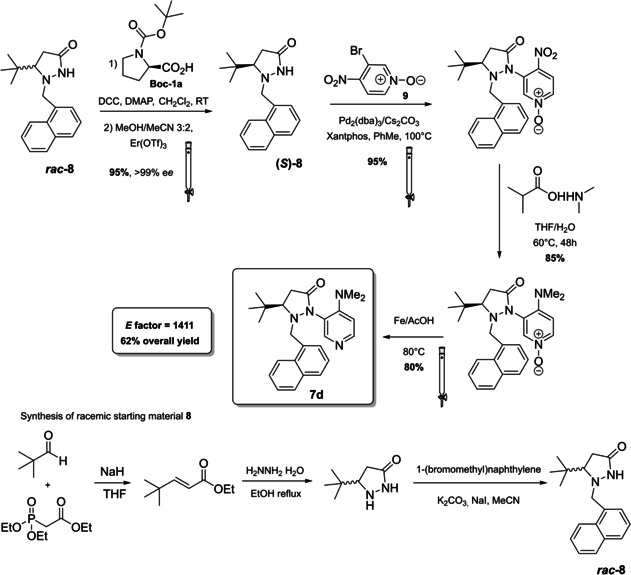

Applied to the kinetic resolution of axially chiral biaryl compounds (selectivity factor 51) and secondary alcohols, DMAP with fluxional chirality 7 d has been introduced by Sibi and co‐workers in 2014 (Figure 4 and Scheme 8).[44] A fluxional group attached to the nitrogen atom of a chiral pyrazolidinone, whose steric hindrance can be modulated, is the main distinguishing peculiarity of these catalysts. The second nitrogen of the pyrazolidinone moiety is directly link to the meta position of the catalytic site embodied by a DMAP derivative (Scheme 8). Eight synthetic steps are necessary to construct fluctional catalyst 7 d starting from a simple aldehyde. In order to build just the chiral pyrazolidinone 8, five out of eight steps are employed. In fact, 8 is prepared as racemic mixture and then the single enantiomer is resolved. Despite the natural compound 1 a is employed as the resolution agent, this strategy goes against the 8th principle. In fact, 1 a should be priorly protected with tert‐butyloxycarbonyl (Boc) group ; then, the resulting protected scaffold should be installed on the pyrazolidinone to obtain a diastereomeric pair, from which (S)‐enantiomer of 8 can be separated by chromatography. In order to introduce the DMAP structure, chiral 8 is subjected to a coupling reaction in the presence of 3‐bromo‐4‐nitro‐pyridine N‐oxide (9). The nitro group is then exploited to insert the 4‐dimethylamino functionality. Catalyst 7 d is finally obtained treating the N‐oxide with iron powder in acetic acid at 80 °C. Apart from CH2Cl2 and THF, all the solvents employed have been classified as medium issue solvents.[45] For a potential scale‐up of this reaction on industrial scale, one should take into account the presence of potential hazards derived from the employment of flammable liquids and solids and the toxicity against aquatic life of compounds like N,N’‐dicyclohexylcarbodiimide (DCC) and 7 d itself. This process is characterized by an E factor of 1411.

Scheme 8.

Synthetic procedure to obtain DMAP with fluxional chirality 7d (Pd2 (dba)3 = Tris(dibenzylideneacetone)dipalladium(0)).

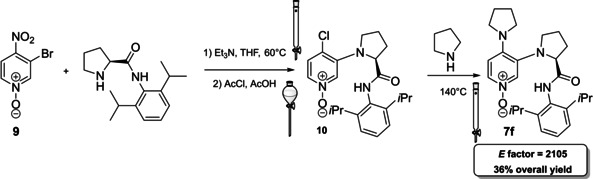

If Sibi et al.[44] employed N‐oxide as intermediates, recently Xie et al. applied chiral DMAP‐N‐oxides 7 f as acyl transfer catalysts for Steglich rearrangement (Figure 4 and Scheme 9).[46] The approach applied is very similar to the one of Connon, in fact the catalyst exploits an amide group as hydrogen‐bond donor and the simple pyridine is replaced by an N‐oxide (Scheme 9). Starting from the commercially available 9, the reaction can be performed on a gram scale. Although it accounts only for three steps, the E factor is quite high (2105), since each intermediate is purified. This could be, mainly, due to the authors intent to characterize all the intermediates. For what concerns N‐oxides, no information about safety has been reported. Hazards about the other reagents employed have been discussed in other sections.

Scheme 9.

Chiral DMAP−N‐oxide 7 f synthesis.

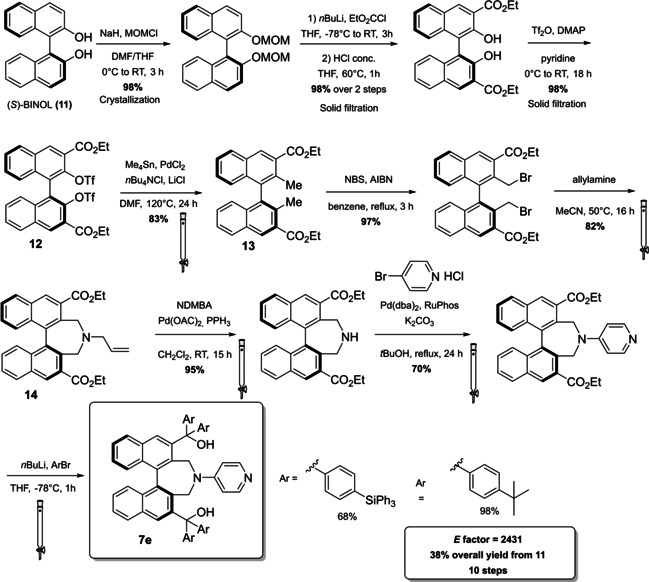

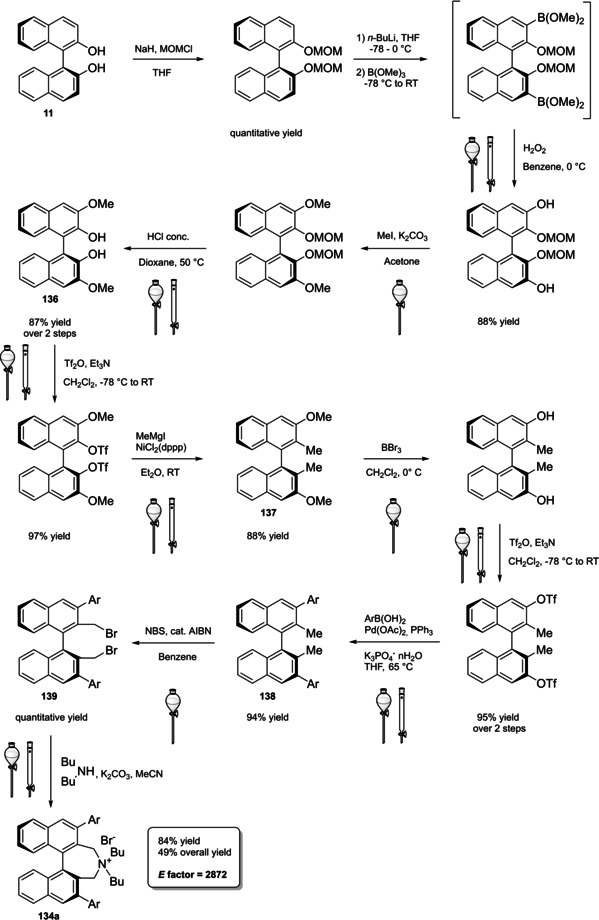

As last example for this section, we analyze the synthesis of the axially chiral DMAP 7 e derived from (S)‐BINOL (11) in 10 steps with an overall yield of 38 % (Scheme 10).[47] Employing well established protocols a binaphthyl unit, assuring chirality, is inserted at the C4 position of the pyridine ring. At the same time, the pyridine activity is enhanced by the lack of substituents at its C2 and C3. The catalyst backbone is constructed starting from (S)‐BINOL 11 (410 g) applying a series of lithiation and metal‐catalyzed cross couplings. As emphasized by the authors, the conversion of ditriflate 12 to compound 13 is realized through a Migita–Kosugi–Stille coupling. This reaction employs Pd nanoparticles as catalyst avoiding the use of Me2Zn, which being pyrophoric and costly could represent a problem for large scale production. The bromination is realized with N‐bromosuccinimide and the bromine atoms are then exploited to close a seven‐member ring including an amine group after deprotection (intermediate 14). Pyridine can be introduced applying the Buchwald–Hartwig amination. When possible, crystallization and solid filtrations are preferred to chromatography: in fact, only four column chromatography are realized along the ten synthetic steps. The catalyst obtained is very reactive and only 0.5 mol % are sufficient to realize the kinetic resolution and desymmetrization of diols in quantitative yield and high enantiomeric excess. All the reaction medium employed with the exception of t‐BuOH and MeCN are classified as major issues solvents.

Scheme 10.

Axially chiral DMAP 7 e derived from (S)‐BINOL 11 (MOMCl= Methoxymethyl chloride, NBS= N‐bromosuccinimide, AIBN= α,α,′‐azoisobutyronitrile, NDMBA=1,3‐dimethylbarbituric acid).

3. Brønsted Base Catalysts

3.1. Organosuperbases: Chiral Guanidines and Iminophosphoranes

Chiral guanidines and iminophosphoranes can be considered both as Brønsted bases, according to the classification of List and Maruoka, and as organosuperbases.[6] They are, in fact, characterized by a strong basicity which confers them the ability to deprotonate and activate weakly acidic pronucleophiles.[48] A very recent review analyzes the basicity of these compounds and their application as organocatalysts.[49] For this reason, this chapter will focus on organosuperbase structures and synthesis with an emphasis on the respect of the green chemistry principles.

3.1.1. Chiral Guanidines

The classification of chiral guanidines as organo‐superbases is linked to the combination of strong basicity with hydrogen‐bond donor ability (Figure 5) resulting from the formation, after protonation, of a high delocalized conjugated guanidinium system. In order to become widely exploited as organocatalysts, their development had to face different challenges. In fact, there was a general lack of methodologies giving access to guanidine moiety, it was very difficult to introduce chiral groups around the guanidine and these compounds resulted very difficult to isolate because of their intrinsic basicity and polarity.

Figure 5.

General structure of guanidines emphasizing the donor/acceptor ability of this moiety.

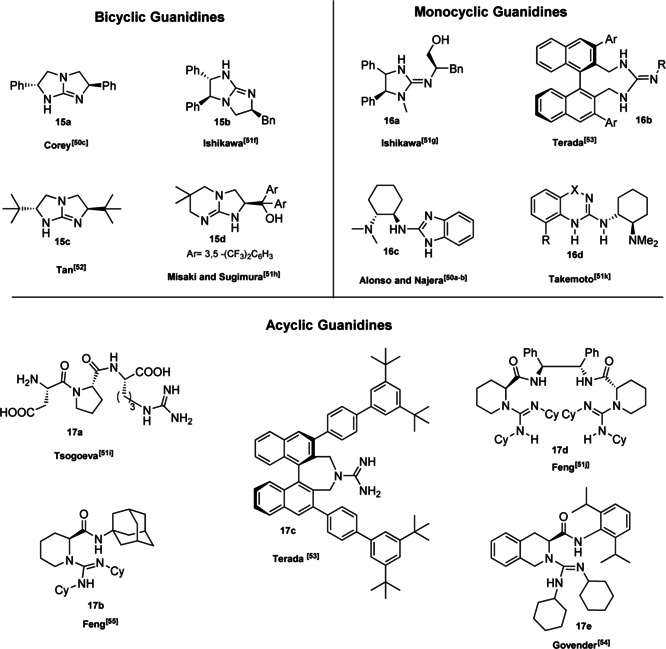

Pioneering studies were realized by the groups of Nájera[50a] and Davis[50b] in the 1990s, but we had to wait the end of the century to have a breakthrough. Corey and Grogan[50c] and the group of Lipton[32a] worked extensively in order to make the synthesis of chiral guanidines more accessible and thus exploiting these compounds as effective chiral organocatalysts. Figure 6 shows a selection of chiral guanidine organocatalysts which are classified as bicyclic, monocyclic and acyclic compounds, according to the inclusion or not of the guanidine moiety in a cyclic framework. In general, bicyclic guanidines 15 a–15 d are characterized by a rigid structure influencing their chemical, physical and electronic properties. Most of monocyclic guanidines 16 a–16 d have a pseudo‐C2‐symmetry, while the open chain compounds 17 a–17 e are sterically more easily accessible, more flexible and their conformational freedom can be reduced introducing hydrogen‐bond donor groups or sites for substrate–catalyst interactions.

Figure 6.

Selected examples of chiral guanidine superbases.

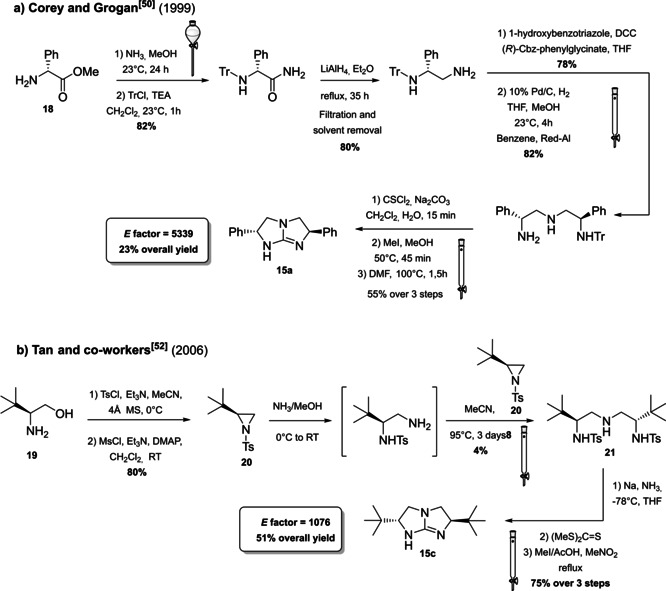

The development and the application of these compounds and their derivatives in asymmetric organocatalyzed reactions has already been critically addressed in several comprehensive reviews and will not be the subject of this section.[51] In contrast, we will focus on selected methodology to access chiral guanidine organocatalysts. The first general route to chiral C2‐symmetric bicyclic guanidines without the need for resolution was reported by Corey and Grogan employing the chiral (R)‐methylphenylglycinate (18) as starting material (Scheme 11a).[50] The reaction scheme proposed by Corey and Grogan is composed by eight steps in which each reaction can be realized on gram scale and the guanidine product 15 a is obtained in 23 % overall yield. The process is characterized by an E factor of 5339, a high value that takes into account several purifications by column chromatography and the employment of stoichiometric co‐reagents. Moreover, some toxic reagents such as iodomethane and thiophosgene are employed. A more performing and efficient approach was proposed by the Tan group in 2006 (Scheme 11b).[52] It is, in fact, composed only by four synthetic steps, an increased overall yield of 50 % and an E factor value of 1076 which is almost five times smaller than the one obtained by Corey and Grogan. The key feature of this synthetic methodology is the employment of aziridine intermediate 20, which can be easily obtained from commercially available amino alcohols such as L‐t‐leucinol (19). N‐tosyl aziridine (20) can participate in a regio‐ and stereospecific ring opening, giving access to a triamine 21, which, after removal of tosyl groups, can be cyclized in a one‐step one‐pot process to the corresponding guanidine 15 c. The cyclization is still realized in the presence of toxic thiophosgene and iodomethane, but more attention is given to the prevention of waste limiting intermediate purification. Contrary to Corey and Grogan, the procedure of Tan and co‐workers includes some cryogenic reactions that compromise the energy efficiency of the process.

Scheme 11.

Comparison between Corey and Tan methodologies to obtain bicyclic chiral guanidines 15a and 15c (Tr= triphenylmethyl chloride, TEA= triethylamine).

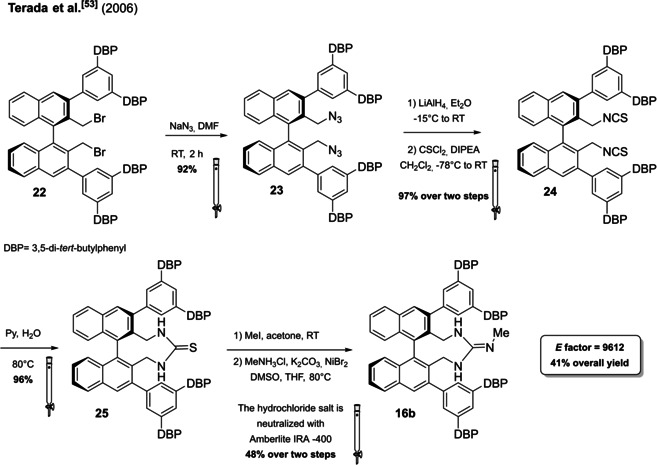

Monocyclic guanidines are frequently included in a C2‐symmetric framework in which the stereocontrol is obtained by the introduction of bulky groups around the guanidine moiety (Figure 6). This can be easily obtained including the guanidine inside a cycle which is constructed on an axially chiral BINOL skeleton (Figure 6 compound 16 b). In fact, the bulky aryl substituents at the 3,3’‐positions are able to break the symmetry, creating an effective chiral environment around the guanidine. Terada group worked extensively on these structures which can be obtained by lengthy synthetic protocols composed by multiple steps. The efforts needed to obtain these structures are balanced out by the fact that monocyclic guanidines are high active and selective catalysts in very low loading. Moreover, the guanidine catalyst can be recovered from the reaction mixture as hydrochloride salt applying a simple extractive workup. As a representative of this class of compounds the synthesis of one of Terada catalyst is presented.[53] Compound 16 b can be obtained from (R)‐BINOL 11 in around 20 % overall yield by a synthetic protocol composed by thirteen steps (Scheme 12). As it can be seen from Scheme 12 only the last six steps are analyzed in this section since the construction of BINOL skeleton will be addressed in Chapter 4. The introduction of the monocyclic guanidine moiety is realized by nucleophilic substitution of the dibromide BINOL‐derivative 22 with sodium azide in dimethylformamide as solvent. The reduction of the chiral diazide 23 with LiAlH4 allows the introduction of a diamine functionality, which is then converted to a diisothiocyanate 24. Once the diisothiocyanate has been installed, the monocycle can be closed exploiting thiourea formation. In the last two steps the thiourea 25 is converted into the monocyclic guanidine. The synthetic protocol is very robust: in fact, almost each step is characterized by a yield above 90 %, but almost all intermediates are purified by column chromatography.[53] The latter which is responsible for around 40 % of total waste mass, contributes to a very high E factor of 9612 only for the last six synthetic steps. Moreover, no specific attention is paid to the use of safer solvents and reagents (5th principle) and to energy efficiency (6th principle), in fact most of the reactions require low temperatures (from −78 °C to −15 °C). The principle of atom economy is respected.

Scheme 12.

Synthetic steps for the production of an axially chiral guanidine 16b.

The open‐chain guanidines 17 a–17 e are more easily accessible, but generally characterized by a lower enantioselectivity. Two examples from the Govender[54] and Feng[55] groups have been selected. In general, the acyclic guanidine is obtained through a multistep synthesis starting from β‐amino carboxylic acids 26 a or 26 b on which the amine functionality is exploited to install the guanidine unit, while the carboxylic acid is converted to an amide bringing a bulky substituent (Scheme 13). In order to introduce the amide functionality, the secondary amine group is protected through Cbz or Boc and the protected group is removed before guanidine introduction (against 8th principle). In both cases, two chromatographic purifications are required. The procedures reported by the groups of Feng and Govender are comparable and, in terms of E factor, the synthetic route of Feng and co‐workers (E factor 1061) should be preferable compared to the Govender protocol (E factor 1369). Anyway, less hazardous reagents were applied by the Govender group. In addition to protecting groups, Feng et al., in fact, employed trifluoroacetic acid (TFA), which is corrosive and n‐BuLi which is flammable and can ignite spontaneously in the presence of water. The employment of n‐BuLi not only implies to work in dry reaction conditions but it also needs for low reaction temperature. A solution to this issue would be to run this reaction in a flow chemistry fashion.

Scheme 13.

Feng and Govender synthetic procedures to obtain chiral open‐chain guanidines 17b and 17e.

3.1.2. Iminophosphoranes

Iminophosphoranes belong to the family of chiral organosuperbases and they can be classified in two main groups (Figure 7). Type 1 iminophosphoranes 27 and 28 are characterized by a chiral spirocyclic system containing a chiral phosphorous atom. Type 2 iminophosphoranes 29 and 30 bear an acyclic system in which a hydrogen‐bond donor group is included, making these compounds bifunctional catalysts.[56]

Figure 7.

Classification of chiral iminophosphoranes.

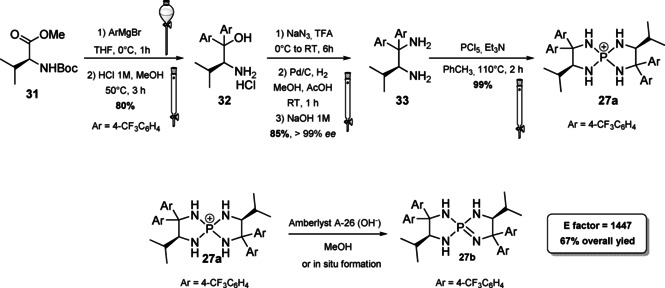

In this section, a brief overview on iminophosphoranes will be given analyzing the synthetic protocols of one compound for each type. For Type I iminophosphoranes, we report the synthesis of the [5,5]‐P‐spirocyclic scaffolds 27 a and 27 b, which were introduced by Ooi and co‐workers in 2007 (Scheme 14).[57] Modulating the structure of starting material and Grignard reagent it is possible to access a library of compounds. The synthesis of the salt requires the preparation of the corresponding 1,2‐diamine 33, which can be obtained from a sequence of five steps starting from Boc‐L‐Val‐OMe (31). This amino‐acid derivative (7th principle) is converted to a tertiary alcohol by reaction with a Grignard reagent followed by acidification. The amino alcohol 32 is then treated with NaN3, and the azide functionality introduced by nucleophilic substitution is reduced in the presence of Pd/C and H2 to the corresponding diamine 33. Iminophosphoranes 27 a are released upon treatment with phosphorus pentachloride in the presence of Et3N as HCl scavenger. Salts of 27 a are stable and can be isolated by column chromatography. In order to obtain free iminophosphorane 27 b, the salt has to be treated with Amberlyst A‐26 or activated in situ by addition of a base (t‐BuOK). The reaction can be run on gram scale starting from amino acid derivative 31. The yield is moderate (around 67 %) and the E factor is 1447.

Scheme 14.

Reaction scheme for the synthesis of [5,5]‐P‐spirocyclic iminophosphoranes of Type I.

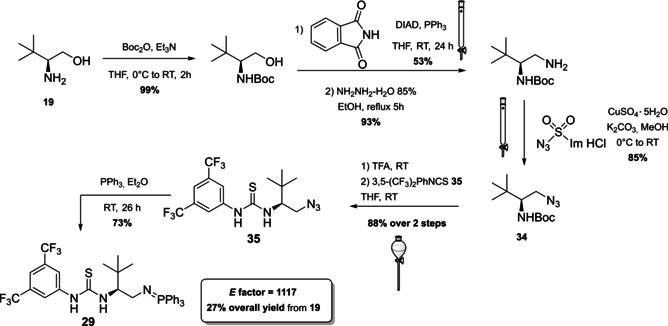

Safety concerns arise from the employment of hazardous chemicals such as sodium azide and phosphorus pentachloride (against 3rd and 4th principles).[57] Type 2 iminophosphorane catalysts have been introduced by the group of Dixon in 2013 and allow the dual activation of the substrate through hydrogen bonds (Scheme 15).[58] The authors idea was to insert the Brønsted basic moiety on a structure containing a hydrogen‐bond donor, such as a thiourea, in the last step of the synthetic protocol. This could be realized applying the Staudinger reaction on a preformed chiral organoazide 35. L‐tert‐leucine‐derived azide 34 can be obtained on gram scale starting from L‐t‐leucinol (19), the amino alcohol derived from t‐leucine (7th principle, Scheme 15). The strategy applied relies on primary amine protection (against 8th principle) followed by reaction with phthalimide, a known ammonia synthetic equivalent which, upon cleavage, allows the introduction of a second amine functionality. According to the 3rd and 4th principles ammonia, which is corrosive and toxic for aquatic life, is replaced by phthalimide, for which no hazards have been reported by ECHA.[59] Nevertheless, the cleavage needs the application of hydrazinium oxide, which is suspected to cause cancer and, if released in the environment, is very toxic to aquatic life with long lasting effects. Then, an azide group is introduced applying the diazotransfer reagent imidazole‐1‐sulfonyl azide hydrochloride, a bench stable and crystalline equivalent of trifyl azide (Scheme 15).[60] The amine group is then deprotected and the free primary amine is exploited to insert the thiourea moiety. In the late stage, the Staudinger reaction with triphenylphosphine allows the isolation by precipitation and filtration of the bench‐stable bifunctional iminophosphoranes 29. The calculated E factor starting from 19 is 1117. A particular attention is given to prevention of waste (1st principle) considering that a six steps protocol counts only two purifications by column chromatography. Moreover, in the point of view of green chemistry, some iminophosphorane catalysts have been immobilized on a solid support allowing catalysts recovery up to eleven times without affecting reactivity.[61]

Scheme 15.

Synthetic protocol to access bifunctional iminophosphorane 29 (DIAD= diisopropyl azodicarboxylate).

The last catalyst we present has been developed very recently by the group of Terada, and it represents the first example of “chiral cooperative binary based catalyst” 36, a compound able to activate less acidic pronucleophiles such as α‐phenylthioacetates (Scheme 16).[62] Catalyst 36 presents, in fact, two organosuperbase functionalities, with a different role in the catalytic process, one acting as organosuperbase, the other operating substrate recognition. A convergent synthesis is exploited to obtain compound 36 starting from a P 2‐phosphazene precursor 37 (it will act as organosuperbase site in the catalyst), a chiral cyclic thiourea 38 (it will act as substrate recognition site) and a chiral 1,2‐diaminoethane derivative 39 (linker between the two sites). If one considers the synthetic steps needed to obtain all the precursors and the one necessary to connect them (overall seventeen steps), the E factor obtained is very low (1701) in comparison with other protocols composed by a similar number of steps. A particular attention is, in fact, dedicated to the prevention of waste (1st principle) avoiding all the unnecessary intermediate purifications and preferring distillation or crystallization to column chromatography. On the other hand, standard reagents are employed and most of them pose severe concerns about safety (as examples: NaBF4, KOMe, CS2, Et3N), human health (as examples: POCl3, MsCl, NaN3, CS2, MeI, Et3N) and environmental health (as examples: NH3, NaN3, MeI, TFA).

Scheme 16.

Synthesis of chiral cooperative binary base catalyst 36.

3.2. Cinchona alkaloids, 9‐amino (9‐deoxy)epi Cinchona alkaloids, and their derivatives

Cinchona alkaloids are naturally occurring molecules (Figure 8), which can be considered as the roots of organocatalysis. In fact, at the beginning of the 20th century Bredig and Fiske were the first to describe the employment of the naturally occurring molecules quinine as catalyst.[63a] This innovative concept had to wait for the Wynberg studies in 1975[63b] to be recognized and further for the early 2000s to blossom.[7b, 7c] After that, the gold rush in organocatalysis started.[11b, 11c]

Figure 8.

Cinchona alkaloids pseudo‐enantiomers and a bit of history on the discovery of these compounds.[64]

Their success as organocatalysts is mainly linked to their conformational flexibility in solution, which can be tuned by different stimuli, affecting the catalytic behavior and allowing these compounds to have high tolerance towards substrates.[65] Moreover, the OH group at the C9 atom can be exploited to form hydrogen bonds, which, in synergy with the quinuclidine nitrogen, makes the alkaloid a bifunctional catalyst. Being natural compounds, Cinchona alkaloids are not only the ideal catalysts to meet the green chemistry principles, but they can also be considered a molecular platform on which to construct different families of catalysts including phase‐transfer catalysts (Scheme 17). Between them, 9‐amino (9‐deoxy)epi Cinchona alkaloids have a central role. These catalysts have been introduced in early 2007, by the groups of Chen[66] and Melchiorre[67] and McCooey and Connon,[68] who were working independently and almost at the same time on this topic. These compounds have allowed to expand the substrate scope of aminocatalysis to ketones, α,β‐unsaturated compounds, and α‐branched aldehydes, keeping high levels of stereocontrol and exploiting different activation modes (enamine, dienamine, trienamine, iminium ion).[65] The introduction of the primary amine functionality, in fact, gives to the Cinchona alkaloid an additional chemical handle for covalent interactions. The quinuclidine nitrogen maintains the role of base participating in nucleophile/electrophile activation.

Scheme 17.

Variety of catalysts that can be obtained from Cinchona alkaloids.

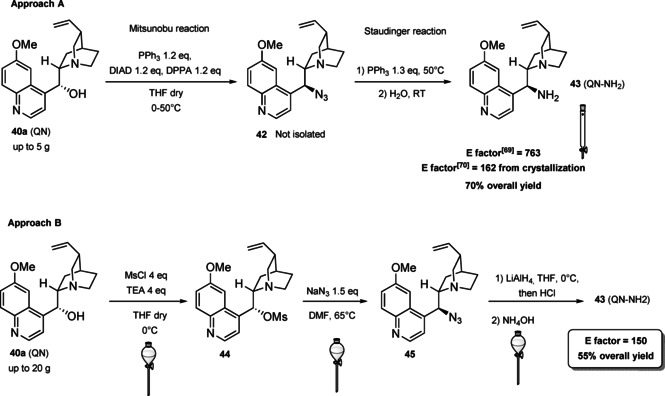

Now our discussion will focus on the synthesis of 9‐amino (9‐deoxy)epi Cinchona alkaloids such as compound 43 (Scheme 18). The general procedures described for quinine (40 a) can be applied to all the other members of the Cinchona alkaloids family. Two different approaches can be pursued:[69, 70]

Scheme 18.

Different approaches for the synthesis of 43.

the amination of alcohol at the C9 atom according to Mitsunobu protocol followed by in situ azide Staudinger reduction (Scheme 18, Approach A); and

mesylation at the C9 atom followed by nucleophilic displacement with sodium azide and reduction with lithium aluminium hydride (Scheme 18, Approach B).

In both cases, the reaction proceeds with inversion of configuration at the C9 atom. Approach A (Scheme 18) is based on a one‐pot two steps protocol characterized by mild reaction conditions and high stereoselectivity. The protocol is compatible with the presence of other functional groups on the starting material and can be scaled up to five grams of alkaloid. In the Mitsunobu reaction, the alcohol at the C9 atom is reacted with a nucleophile in the presence of triphenylphosphine (PPh3) and diisopropyl azodicarboxylate (DIAD). In order to introduce an amine functionality, the nucleophile employed is diphenylphosphoryl azide (DPPA), a safer alternative to hydrazoic acid. Azide 42 is not isolated but reduced in situ adding an excess of PPh3. A consecutive hydrolysis according to Staudinger reaction affords product 43. In accordance with green chemistry, all the sequence of reactions is telescoped into a single solvent in a one‐pot fashion. If 9‐amino (9‐deoxy)epi quinine (43) is isolated by column chromatography, the process E factor is 763.[69] With regard to waste prevention, column chromatography can be avoided treating the crude reaction mixture with aqueous HCl solution. The addition of an acid causes the precipitation of product hydro‐chloride salt. The free amine can be, later, obtained by neutralization with NH4OH aqueous solution.[70] Notably, the removal of chromatographic purification makes the protocol greener with an E factor which is 4.7 times smaller (162 vs 763) than the previous including column on silica gel.

Despite an E factor of 162, Melchiorre and co‐workers pointed out that approach A has some limitations for large‐scale production, the major concerns being the employment of expensive reagents (DIAD and DPPA) and of an excess of PPh3. Indeed, high amounts of triphenylphosphine oxide are yielded as waste causing difficulties during purification. The alternative protocol proposed by Melchiorre and co‐workers (Scheme 18 Approach B)[70] is composed by three steps, in which each product is purified by an extractive workup avoiding the production of silica gel waste in accordance with the 1st principle. The protocol appears more economic, in fact the expensive DIAD and DPPA are replaced by methanesulfonyl chloride (MsCl) and NaN3. On the other hand, approach B is not in line with the 3rd and the 4th principles (safer synthesis and safer chemicals). In fact, sodium azide is more toxic than DPPA, the equipment to make the nucleophilic displacement should be free of heavy metals, in order to avoid detonation in case of thermal or mechanical stress, and the waste should be handled with care, in order to avoid the formation of the poisonous and explosive HN3. Interestingly, the azides derived by Cinchona alkaloids are not a problem for safety since their exothermic degradation starts more than 60 °C above the reaction temperature. The last step is the reduction of 45 which can be realized with LiAlH4 or H2/Pd. The latter reduction methodology is applied to obtain the simultaneous reduction of either the azide and the double bond, to yield the dihydro derivative. Also in this case, the product is purified by hydro‐chloride salt formation. As emphasized by Melchiorre and co‐workers, the salt is an air stable solid that can be stored for weeks and when needed neutralized to release the free amine. A lower E factor of 150 was found for approach B, even though 43 is obtained in a lower yield (55 % yield vs 70 % yield for approach A).

4. Brønsted Acid Catalysts

4.1. Phosphoric acids

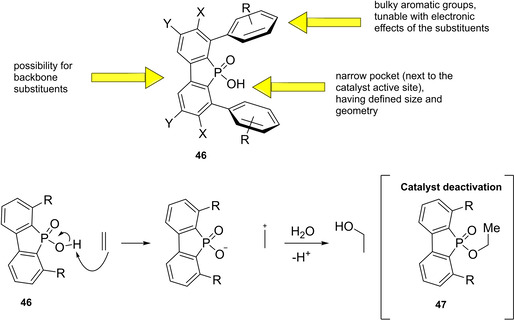

Almost the entire class of Brønsted acid organocatalysts consists of very complex scaffolds. The reason for this is due to the mutual interconnection, for historical reasons, of the concepts of Brønsted acid organocatalyst and confined catalyst. In fact, the first examples of Brønsted acid organocatalysts, namely axially chiral BINOL‐derived phosphoric acids, take the moves from the molecular scaffold of Sir John Cornforth's phosphinic acids, dating back to 1978.[71] Cornforth, winner of the Nobel Prize for Chemistry in 1975 for his contributions to the stereochemistry of enzyme catalyzed reactions, was the first to apply this know how in designing the structure of a catalyst for hydration of C−C double bonds. In particular, he guessed the potential of introducing bulky aromatic groups in appropriate positions of the phosphinic acid scaffold 46, in order to obtain a narrow pocket for substrates, mimicking the active site of an enzyme. Furthermore, electron‐donating or withdrawing substituents on these aryl groups have the function of tuning the acidity of the compound, apart from defining the pocket size and geometry (Figure 9).

Figure 9.

General structure of Cornforth phosphinic acids and proposed mechanism for phosphinic acid‐catalyzed hydration of alkenes.

The work of Cornforth deeply influenced the pioneering publications of Akiyama et al.[72] and Uraguchi and Terada[73] in the field of chiral phosphoric acids. For what concerns phosphoric acid organocatalysts themselves, regardless of their structure, according to List and Maruoka definition,[9] there is no unequivocal criterion to classify them as Brønsted acids rather than Lewis acids. This ambiguity is due to the strong dependence of their activation mechanism on the substrates, the reactants and the reaction conditions. Thus, it is possible to distinguish among protonation/ion pairing and coordination/hydrogen bond donation,[74] and even between mono‐ and bifunctional modes of activation.[75] This formal classification is not always easy to verify from an experimental point of view. However, mechanistic insights are not the subject of this review.[74, 75] For simplicity, all phosphoric acid organocatalysts, because of their chemical nature of phosphoric acid cyclic diesters (pK a between 12 and 14 in acetonitrile),[76] will be classified here as Brønsted acids. In the following sections phosphoric acids catalysts will be analyzed according to their backbone.

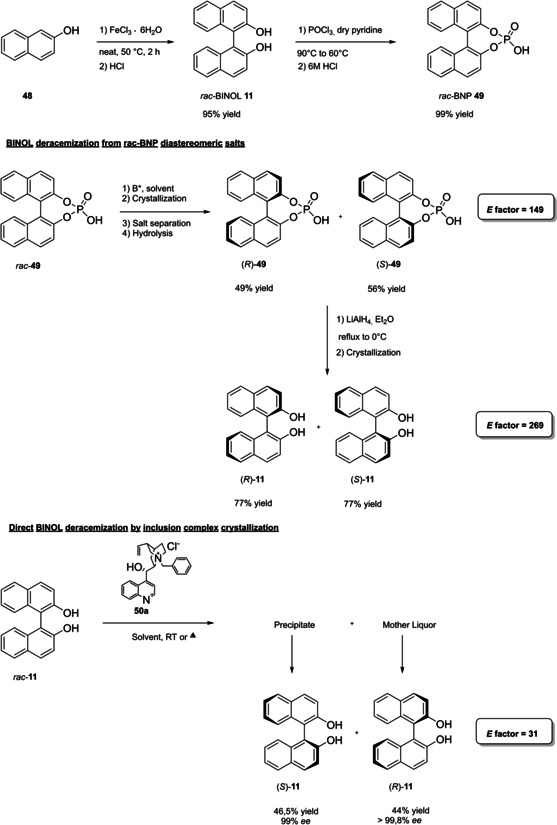

4.1.1. BINOL‐based phosphoric acids (BPAs)

In 2004, the first examples of BINOL‐PAs appeared in the literature by Akiyama et al.[72] and Uraguchi and Terada[73] as stereoselective catalysts for Mannich‐type reactions. From that moment, a wide variety of highly performing BINOL‐PAs started to appear in the literature. One of the most popular phosphoric acid organocatalysts[77] is 3,3′‐bis(2,4,6‐triisopropylphenyl)‐1,1′‐binaphthyl‐2,2′‐diyl PA, known as TRIP, developed by List and co‐workers.[78] The very first common structural feature of these catalysts is obviously (1,1′‐binaphthalene)‐2,2′‐diol (BINOL) backbone. BINOL 11 itself is a synthetic scaffold, whose large availability on the market in both enantiomers at reasonable price is justified by the full‐blown role of its derivatives as “privileged chiral catalysts”.[79] However, neither this molecule, nor its direct precursor are derived from natural sources. Indeed, historical synthetic route to 11 includes FeIII‐catalyzed radical coupling of 2 equivalents of β‐naphthol (48),[80] followed by an articulate racemate resolution (Scheme 19). The synthesis starts from 48, which although not derived from natural feedstocks, can be assumed on edge a low‐environmental impact synthetic molecule, being obtainable on industrial scale by air oxidation of naphthalene in steam current. In this case, no waste mass is assumed to derive from the process, since the oxygen in the air is a renewable source and steam plays a role in the water cycle. Historical preparation from naphthalene sulfonation/cleavage in molten alkali,[81] as well as other inconvenient chemical processes (including non‐regioselective procedures) will then be neglected. The homocoupling of 48 to rac‐11 requires over‐stoichiometric amount of the iron hydrate salt. Nevertheless, the product can be afforded in excellent yield by gentle heating in neat conditions. This feature makes the protocol preferable with respect to other available procedures based on catalytic copper,[82] vanadium,[83] ruthenium,[84] rhenium,[85] solid supports like alumina[82e, 82f, 82g, 82h] or acidic silica,[86] electrochemical methods[87] and even iron chloride hexahydrate under microwave irradiation.[88] Benefits of employing catalytic amounts of the metal species are compensated by the detrimental use of volatile organic compounds (VOCs) such as DCM or petroleum ether, scarce eco‐compatibility of the exhausted catalyst, low energy efficiency in terms of the 6th principle and difficulties in the scaleup. In fact, iron chloride is perfectly eco‐compatible (being a component of lava rocks), non‐volatile and cheap, and heating does not represent a problem on an industrial scale. At this point the resolution of the racemates has to be performed, and the general route proposed in Scheme 19, which is a common chemical resolution, is not the only valid alternative. If the above depicted strategy is followed, 1,1’‐bi‐2‐naphthyl‐phosphate (BNP) 49 has to be prepared, according to the general protocol of direct reaction with POCl3 by Jacques et al.[89] It is worth noticing that, although the reaction is critically performed in dry pyridine as the solvent, its amount is relatively limited, and no further chromatographic purification is required, but simple precipitation and washing with diluted HCl currently makes it the optimal strategy. The resolution of the two enantiomers can then be performed with cinchonine (50 a) (see Scheme 19 for yields). Other chiral amines or auxiliaries can be instead employed, this item affecting both the cost and the E factor of the process. In fact, inexpensive 2‐aminobutanol[90] and more complex amines lead to lower yields and enantioselectivities. At this point, the very first and simplest chiral BINOL‐derived phosphoric acid has been afforded in enantiopure form. To be fair, simple 49 was often employed as a chemical resolving agent[89] rather than as a chiral catalyst. The E factor for enantiopure 49, resulting from the first four steps proposed in Scheme 19 and considering the masses of both the isolated enantiomers as useful products, is 149 if cinchonidine (41 a) is employed as the chiral base.[91] This value could be subject to decrease, considering the recycling of solvents and resolving agent 41 a. Further dephosphorylation with lithium aluminum hydride finally affords the atropoisomers of 11, each one in 77 % yield. Because of this additional step, the E factor rises to 269 for 11, considering the masses of both the enantiomers as useful products also in this case. Different strategies to resolve the racemic mixture of the atropoisomers are described in various reviews specifically dedicated to the synthesis of BINOL 11.[92] However, since the aim of this review is to focus the attention on the greenness of organocatalysts synthesis, it is worth pointing out some important observations before proceeding with the discussion. In the above‐described historical route to access enantiopure BINOL, multiple derivatization steps affect the atom economy of the process and, consequently, the E factor. Similarly, the methods based on derivatization and protecting groups removal go against the 2nd and the 8th principle. Second, enzymatic resolution, even though it may appear a cheap alternative to chemical resolution when low‐cost enzymes (e. g., lipases from bacteria) are suitable for this purpose, it accounts for the biomass wasted in the enzyme isolation which affects the E factor and the atom economy of the overall process. Third, even if the product is afforded in high yield, the enantiopurity is not sufficiently high (ee<95 %), making necessary an additional crystallization which produces additional waste, while increasing the E factor at the same time. Therefore, only methods affording enntiopure 11 in yield and ee superior to 90 % will be analyzed.

Scheme 19.

The most common complete synthetic routes to enantiopure BINOL 11.

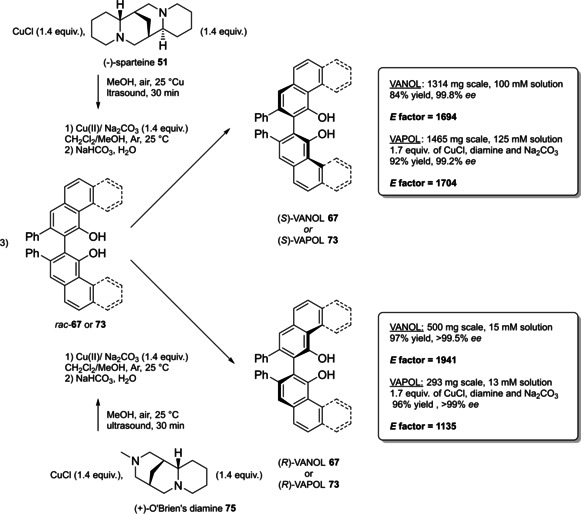

These include examples of chemical resolution having improved E factor with respect to the route depicted in Scheme 19, namely racemate desimmetrization and asymmetric synthesis. Established that derivatization should be avoided, the best way to resolve racemic BINOL is obviously to directly proceed on this substrate by using chiral auxiliaries. N‐benzylcinchonidinium chloride (50 a) guarantees high yield and ee for both the enantiomers of BINOL and,[93] despite its synthesis has to be taken into account (see Chapter 5), leads to a considerably lower E factor of 31, performing the process in refluxing acetonitrile as the crystallization solvent. The complementary approach with pseudoenantiomer 50 a [94] affords the association complex of the (R)‐enantiomer as a precipitate. Employment of trans‐1,2‐ciclohexyldiamine,[95] phenylethylamine,[96] proline and prolinamide,[97] 3‐alkyl‐4‐(1’‐phenylethylamino)butanoic acid,[98] and other chiral amines[99] or auxiliaries[100] results in overall worse results in terms of yield or ee. Nevertheless, resolution strategies are limited by a maximum yield of 50 % for each enantiomer, even if both of them can be considered useful products. Deracemization strategies rely instead on the possibility of converting one enantiomer into the other, starting from the racemate, affording a single enantiopure useful product. An interesting mild deracemization protocol based on room temperature treatment with chiral copper complexes has been proposed by Wulff and co‐workers.[101] The initial procedure was limited to the obtainment of (S)‐11 in 94 % yield and 92 % ee (97 % yield, 92 % ee at −20 °C) with CuCl complex and (−)‐sparteine (51) on a 200 mg scale, while less efficient performances in terms of ee were obtained on a 5 g scale (98 % yield, 87 % ee at −20 °C) or employing corresponding copper(II) complex (94 % yield, 80 % ee).[101a] Later in‐depth studies lead to the comprehension of the nature of deracemization process, which involves oxidation of the biaryl scaffold. The protocol was then improved by reducing the total amount of costly (−)‐sparteine, which was replaced by quenching with HCl (97 % yield, 92 % ee) or NaHCO3 (95 % yield, 93 % ee) and finally performed with O'Brien's diamine (synthetic analogue of non‐natural (+)‐sparteine) to obtain (R)‐11 (95 % yield, 98 % ee).[102] Taking into consideration the easiness of racemic synthesis, greener methods to easily access optically pure 11 may involve, in a future perspective, the use of Viedma ripening or temperature cycling,[103] which have been only recently applied to the deracemization of axially chiral compounds,[104] including a BINOL derivative.[105]

For what concerns successful protocols of asymmetric synthesis, these are limited to the access to (S)‐11 (Scheme 20).

Scheme 20.

Successful protocols for (S)‐BINOL asymmetric synthesis.

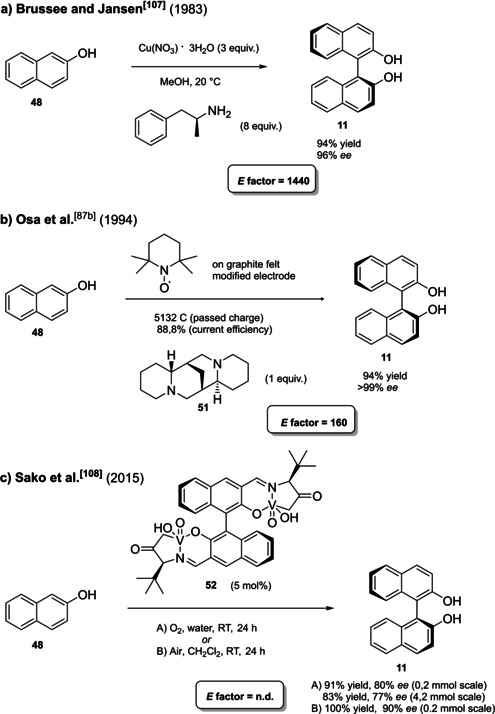

Asymmetric synthesis of BINOL relies on oxidative coupling of β‐naphthol, whose proof of concept, although in low yield and optical purity, was given by Feringa and Wynberg in 1978.[106] Five years later, Brussee and Jansen could afford (S)‐BINOL in 94 % yield and 96 % ee by oxidative coupling promoted by a chiral copper(II) complex with D‐amphetamine.[107] This was the first high‐performing protocol to selectively obtain a single atropoisomer as useful product. Moreover, the reaction is carried out in methanol and mild reaction conditions, generating the catalyst in situ, albeit high amounts of expensive D‐amphetamine and tri‐hydrate cupric nitrate are employed. The E factor for the process is 1440, without taking into account recovering and recycling of the 80 % of the amine, as well as chemical waste deriving from its synthesis (Scheme 20a). Another interesting procedure is based on cyclic voltammetry electrooxidation on a TEMPO‐immobilized based graphite felt electrode (Scheme 20b). In this case, the almost perfect optical purity derives from the employment of natural‐occurring (−)‐sparteine 51, which is recovered in 95 % yield and recycled.[87b] In this case, the calculated E factor is 160, which could potentially be improved avoiding column chromatography, responsible for around 80 % of the total mass waste.[108]

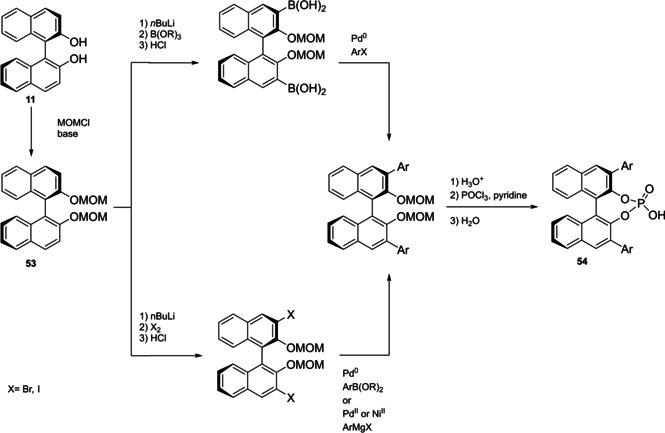

Differently from the BINOL backbone, the synthesis of cyclic phosphoric acid diester derivatives is a quite standard synthetic route, involving: hydroxyl‐groups protection (e. g., like MOM‐ether 53); lithiation followed by halogenation (bromination/iodination) or boronylation; Suzuki cross‐coupling with an aryl‐boronate or an aryl halide (bromide/iodide); ether hydrolysis; one‐pot phosphorylation and phosphoryl chloride hydrolysis (Scheme 21).[109]

Scheme 21.

Standard protocols for the synthesis of BINOL‐derived phosphoric acids 54.

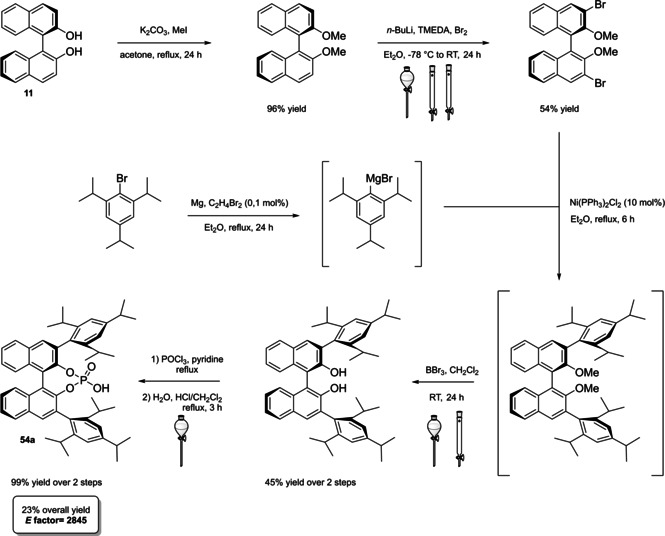

Calculation of the E factor in the case of BPAs is not possible in a general fashion, due to the strong dependence of the overall amount of waste on the selected protocol (via borylation or halogenation of 11 in 3,3’), the aryl group (preparation of the corresponding arylboronic ester or aryl halide), the source of Pd0 or NiII, the selected protecting group and, obviously, reaction yield in each step. However, some criticisms can be highlighted with respect to the twelve principles. First of all, BINOL is not a natural feedstock (7th principle), and the environmental impact of its synthesis has been evaluated by above mentioned E factor calculations. Second, no particular attention is devoted to the use of safer solvents and auxiliaries (5th principle), as well as to reduce derivatives (8th principle) and, thus, to atom economy (2nd principle). Finally, critical or difficult reaction conditions are applied, implying higher risk (1st and 12th principle) and lower energy efficiency (6th principle). To give a practical example, the E factor of TRIP‐PA (54 a),[78] one of the most occurring BPAs organocatalysts,[109] has been evaluated on the basis of a well‐established synthetic protocol (Scheme 22).[78b]

Scheme 22.

Standard protocol for the synthesis of 54 a.[78b]

Starting from enantiopure 11, introduction of methyl ether protecting groups on phenolic hydroxyl groups (against 2nd and 8th principle) occurs in nearly quantitative yield. In order to selectively brominate the 3,3′‐position, a classical ortho‐lithiation reaction, is performed under inert atmosphere at −78 °C, very far from energy efficiency conditions (6th principle). After an extraction and two chromatographic purifications, Negishi cross coupling with a suitably generated Grignard reagent is performed, followed by protecting group removal, after which further extractive and chromatographic purification are required. Phosphorylation in pyridine with POCl3 finally allows to isolate the desired phosphoric acid 54 a after a simple extraction, in 23 % overall yield with an E factor of 2845. The E factor of BINOL 11 is not taken into account in this calculation. Apart from the use of Grignard reagents and pyridine, whose safety issues have already been discussed above, it must be stressed the critical use of phosphorous oxychloride, which is a typical reagent for phosphorylation, but causes damage to organs upon prolonged exposure and is harmful if swallowed and fatal if inhaled.

Actually, it has been demonstrated that the use of protecting groups is dispensable, and that 3,3′‐substituted BPAs can be prepared either by the bromination–Suzuki cross‐coupling–phosphorylation or by the bromination–phosphorylation–Suzuki coupling sequence.[110] In this way, starting from 3,3′‐dibromo/diiodo BINOL 55, the number of steps could potentially be reduced to four. The procedure has however been applied just to a limited number of 3,3′‐hindered BPAs (Scheme 23).

Scheme 23.

Protecting group‐free 3,3’‐functionalization of BPAs with aryl groups (dppf=1,1′‐Bis(diphenylphosphino)ferrocene, DME=1,2‐Dimethoxyethane).

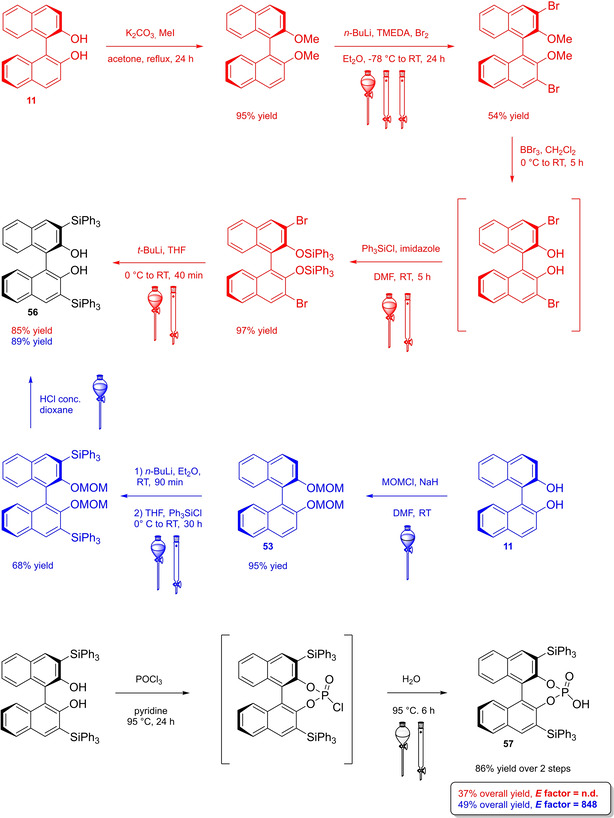

In 2018, Feringa and co‐workers proposed Pd‐promoted cross coupling to functionalize 11 with 3,3′‐substituents characterized by a lower E factor.[111] Nevertheless, the mandatory employment of highly pyrophoric t‐BuLi strongly limits its safeness (1st and 3rd principles) and scalability. Another notable example of efficient 3,3′‐hindering substituents for BINOL is represented by bulky silyl groups. The very first route to o‐silyl derivatives of BINOL has been developed by Yamamoto in 1988 and relies on rearrangement of o‐bromo phenolic silyl ether functions to o‐silyl phenols.[112] The resulting 3,3′‐bis‐silylated BINOLs, apart from being good chiral ligands, can be considered as well suitable backbones for new chiral BPAs, like 3,3′‐triphenylsilyl‐2,2′‐binaphthyl phosphoric acid (57) (TIPSY‐PA), reported for the first time by the MacMillan group.[113] A more convenient route to 3,3’‐silylated BINOL derivatives was however exploited by MacMillan and co‐workers, including direct lithiation of BINOL‐MOM ether 53.[114] Several silylated BPAs can be obtained. As reported in Scheme 24, two possible routes to silylated BPAs are proposed, TIPSY 57 was chosen as model compound.

Scheme 24.

Alternative synthetic routes to 57 are depicted, respectively, in red and in blue. Common steps are depicted in black (TMEDA=N,N,N′,N′‐Tetramethylethylenediamine).

Both the routes include critical operations, with respect to the principles of green chemistry, the blue one presenting a reduced number of synthetic steps (5 against 7) and chromatographic purifications (3 against 4) together with higher overall yield (49 % against 37 %). Moreover, the use of highly pyrophoric t‐butyllithium is avoided in favor of handier n‐butyllithium, which is nevertheless a non‐green reactant too (3rd and 4th principles). Consequently, Yamamoto's route to TIPSY diol 56 (in red) was not considered in the calculation of the E factor for compound 57, which is 848 according to MacMillan's route (in blue). To summarize, the access to 3,3’‐silylated BPAs can be slightly more atom‐economic and less waste‐producing than 3,3’‐aryl BPAs.

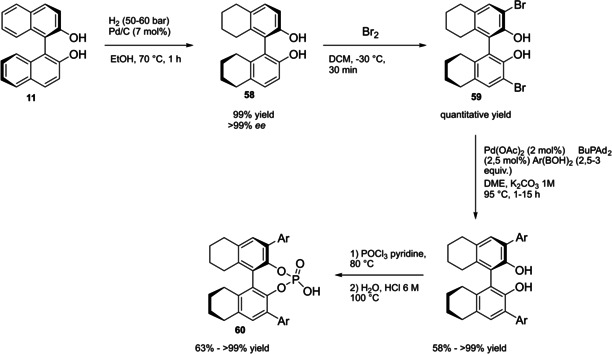

Finally, modified BINOL‐scaffolds have been synthesized in order to tune the electronic effects and increase the steric bulkiness of BPAs, one of the most important being H8‐BINOL 58, namely 5,5′,6,6′,7,7′,8,8′‐octahydro‐2,2′‐binaphthol. This scaffold can be directly prepared by hydrogenation of 11 over a heterogeneous catalyst like Pd/C (Scheme 25).[115] Finally, the phosphoric acid functionality is installed by treatment with POCl3. High‐yielding protocols for the bromination of this substrate give access to its 3,3’‐dibromo derivative 59 [116] and, also in this case, a protecting‐group free strategy for the Suzuki cross‐coupling on the unprotected diol 58, more compliant to the 8th principle, has been reported (Scheme 25).[117]

Scheme 25.

Access to H8‐BINOL‐phosphoric acids 60.

The E factor of the overall process strongly depends on the aryl boronic acid and the yield of the last two steps. However, it is worth noticing that, despite an additional reduction step is required, with respect to the synthesis of simple BPAs, H8‐BINOL dibromo derivative 58 can be recovered in almost quantitative yield without the necessity of any ortho‐lithiation. Direct reduction of BINOL‐phosphoric acids to the corresponding H8‐BINOL‐phosphoric acids in high yield is also possible, although the reaction has been performed just on a sub‐mmol scale with a limited substrate scope (Scheme 26).[118]

Scheme 26.

Direct reduction of BINOL‐PAs to H8‐BINOL‐Pas 60.

4.1.2. VANOL‐ and VAPOL‐based vaulted phosphoric acids (VPAs)

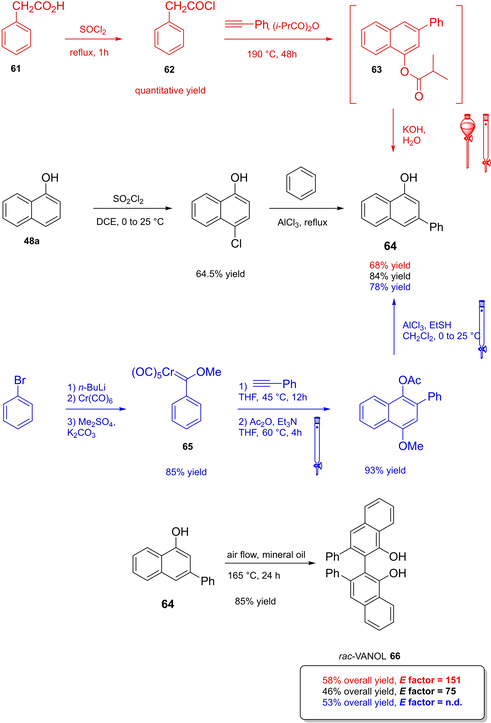

3,3′‐Diphenyl‐2,2′‐binaphthalene‐1,1′‐diol (VANOL) (66) and 2,2′‐diphenyl‐3,3′‐biphenanthrene‐4,4′‐diol (VAPOL), commonly identified as vaulted biaryls, due to their complex three dimensional molecular structure, have been designed and synthesized for the first time by Wulff in 1993 to be employed as chiral ligands in Al‐catalyzed Diels‐Alder reactions.[119] With the rise of asymmetric organocatalysis, VANOL and VAPOL have proven to be suitable scaffolds for hindered cyclic phosphates having narrow pockets for substrates, without the necessity of providing further functionalization by Suzuki, Negishi, or Kumada cross‐coupling. Currently, no asymmetric synthetic route exists to directly obtain optically pure vaulted biaryls, but several strategies have been proposed to access their racemate,[120] which can be further resolved in the two atropoisomers or deracemized in a single enantiomeric form. All of these protocols have been optimized, so to provide standard ways to prepare these compounds in enantiopure form.[121] Within the framework of VANOL and VAPOL synthetic routes, major issues concern the synthesis of the monomer building blocks. An open air, high temperature oxidative coupling of the monomer finally affords the corresponding racemic vaulted biaryl. Alternative routes to rac‐VANOL are outlined in Scheme 27. The first route, namely cycloaddiction/electrocyclization cascade (CAEC, depicted in red Scheme 27), starts from commercially available phenylacetyl chloride 62, which can be obtained in quantitative yield by reacting phenylacetic acid 61 with thionyl chloride in CH2Cl2,[122] with an optional catalytic amount of DMF.[123] The following step relies on a [2+2] cycloaddition of the phenylketene generated by thermal decomposition of the acyl chloride and phenylacetylene. The resulting cyclic adduct 63 undergoes electrocyclic ring opening/ring closure, to be then trapped as an O‐acyl‐3‐phenyl‐α‐naphthol, which is finally hydrolyzed to give 3‐phenyl‐α‐naphthol 64.[120a] In the optimized version of the procedure, 64 can be obtained in 68 % yield after two crystallizations and a chromatographic column.[121] The original alternative approach to compound 64 (depicted in blue in Scheme 27) includes synthesis and crystallization of a stable chromium carbene complex, which reacts with phenylacetylene in a benzannulation reaction, followed by acetylation to afford a stable naphthol derivative. Upon reaction with ethanethiol in the presence of AlCl3, methyl ether cleavage and reductive deacetylation give naphthol 64.[120] In terms of green chemistry, the latter alternative is even less preferable than the first one, since two chromatographic purifications are needed and critically toxic chromium‐based species are employed. However, the privileged protocol to naphthol 64 is the three‐step route via chlorination of cheap and commercially available α‐naphthol 48 a, followed by AlCl3 in situ generation of cyclohexa‐2,5‐dienone and its rearrangement to naphthol 64 (depicted in black in Scheme 27).[120] Employment of non‐green or even major issues VOCs (e. g., benzene) as the solvents is the only criticism; in return, despite a lower overall yield, the protocol is scalable on industrial scale, since no chromatographic purification is needed. Actually, chromatographic purification of residual mother liquor would increase the yield of the naphthol chlorination step from 64.5 % to 73 % and those of phenylation of 4‐chloro‐1‐naphthol from 84.1 % to 93.3 %, although increasing the total waste amount.[121] Open‐air homocoupling of 64 finally leads to rac‐VANOL 66 in 85 % yield.[120a]

Scheme 27.

Alternative multi‐step syntheses of rac‐VANOL 66.

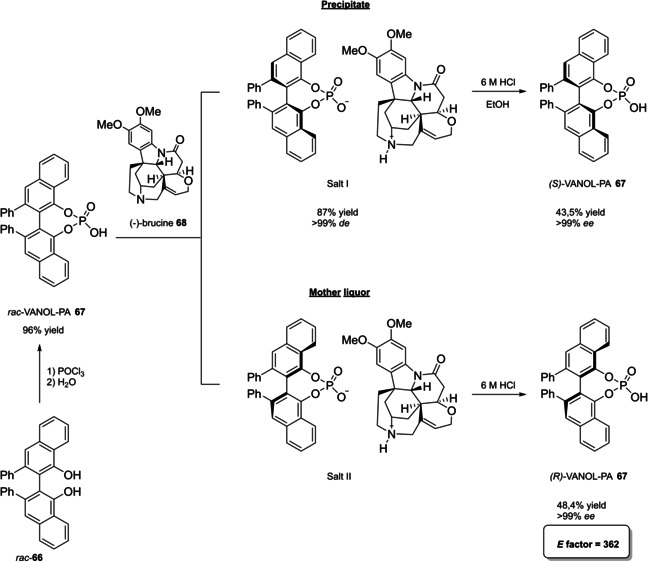

Classical phosphorylation into the corresponding atropoisomeric phosphoric acids and chemical resolution thereof is shown in Scheme 28.[120a, 121] Indeed, more waste would result from deprotection of VPAs to afford the two enantiopure VANOL atropoisomers, which formally represent the starting material for enantiopure VPAs.

Scheme 28.

Optimized classical chemical resolution of rac‐VANOL 66.

Derivatization of rac‐66 by phosphorylation and resolution of the atropoisomers with naturally occurring[124] (−)‐brucine 68 potentially gives access to either the enantiopure acids by simple acidification of the salts with HCl (Scheme 28), or to the enantiopure forms of VANOL 66, by treatment of the corresponding brucine phosphates with sodium bis(2‐methoxyethoxy)aluminum hydride (Red‐Al) in toluene at room temperature. Considering the route from α‐naphthol 48 a, the E factor for enantiopure VANOL phosphoric acid 67 is 362, if both the enantiomers are assumed to be useful products. A more recent resolution strategy of VANOL describes the replacement of brucine with inexpensive (1S,2S)‐(+)‐cyclohexyldiamine, giving however poorer results in terms of yield and ee.[124]

For what concerns the synthetic strategies towards 2‐phenyl‐4‐phenantrol 72, key substrate in the synthesis of VAPOL, a single substantial difference exists with respect to those towards naphthol 64. Indeed, while a low yielding chlorination of 4‐phenanthrol has been reported,[125] the rearrangement of 1‐chloro‐4‐phenanthrol to 72 by refluxing in benzene in the presence of AlCl3 has not been investigated yet.[121, 126] Synthetic routes relying on CAEC or benzannulation of a chromium carbene complex are instead viable alternatives (Scheme 29).

Scheme 29.

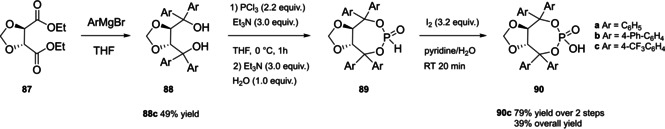

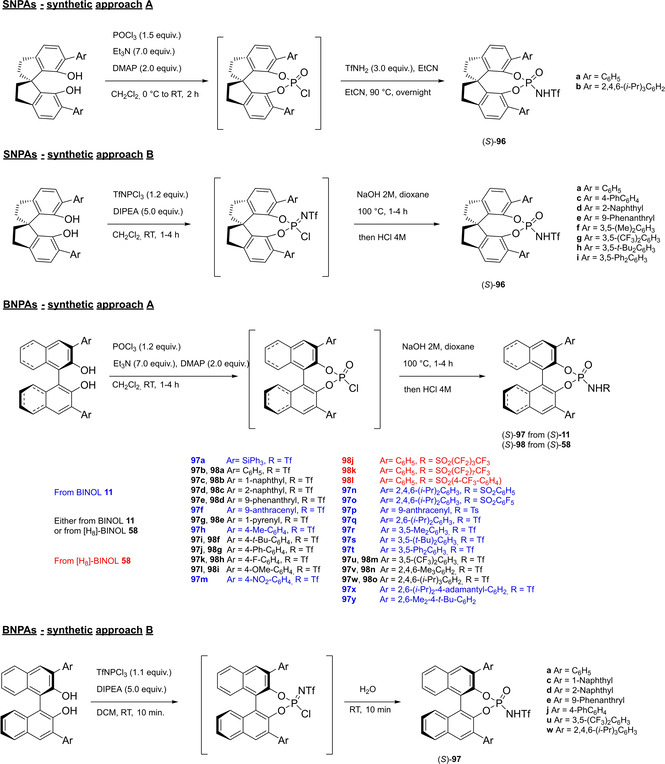

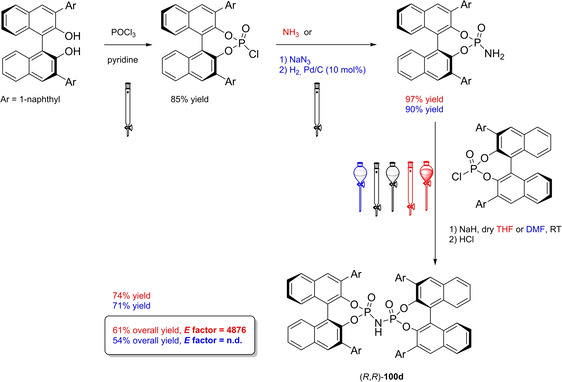

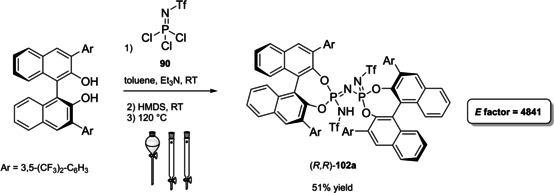

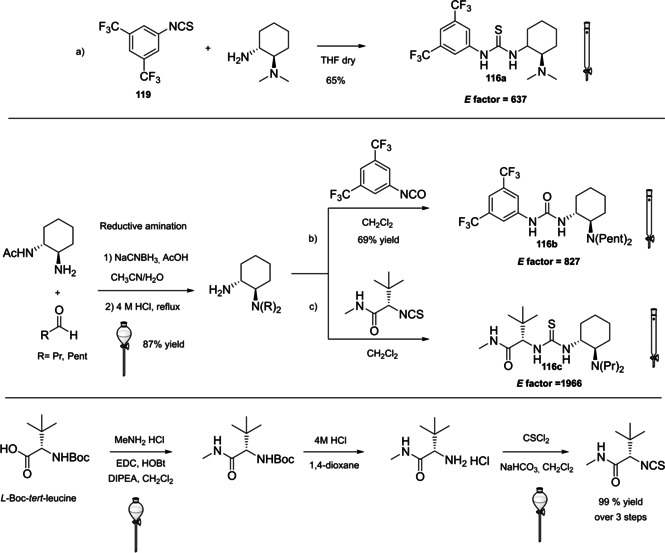

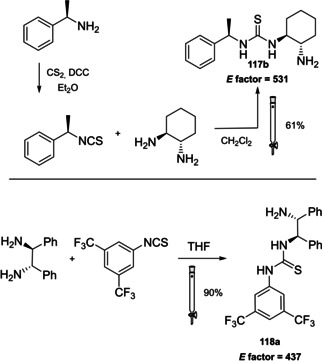

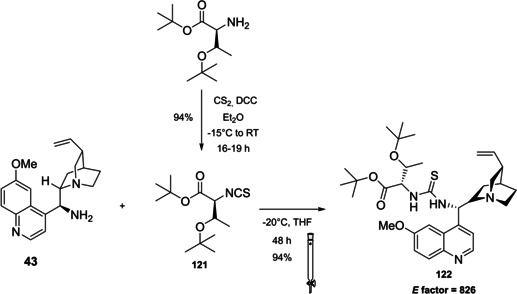

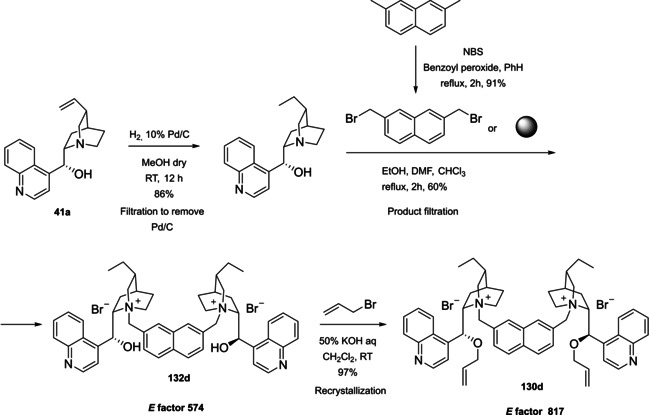

Alternative multi‐step syntheses of rac‐VAPOL 73.