Abstract

Objective:

To evaluate the effect of material thickness and width of the gingival edge on the forces and moments delivered by aligners prepared from Duran foil (PET-G) to a maxillary incisor during tipping and intrusion.

Materials and Methods:

Aligners prepared from PET-G of three material thicknesses (0.5, 0.625, and 0.75 mm) and three widths of gingival edges (0–1, 3–4, and 6–7 mm) were investigated during incisor palatal tipping and intrusion of 0.5 mm each. Forces and moments were measured with a six-component measuring device. The influence of aligner thickness and aligner extend on the force and moment development were tested for statistical significance (P < .05).

Results:

The Fx and Fz forces produced during palatal tipping and intrusion by the 0.75-mm aligner material was significantly higher than those produced by the 0.5-mm-thick material (P = .005 and P = .047, respectively). There was no statistical difference between aligner thickness of 0.5 and 0.625 mm and between 0.625 and 0.75 mm. The same behavior was observed for the palatal moment (My). The Fx and Fz forces produced during palatal tipping and intrusion by the aligner with an extension of 0–1 mm edge was significantly lower than that of the aligner with a larger extension (3–4 mm edge: P = .003; 6–7 mm: P = .001). However, there was no statistical difference between aligners with a 3–4-mm and a 6-mm edge. The same behavior was observed for the palatal moment (My).

Conclusions:

The forces and moments exerted by the PET-G aligner on teeth vary, depending on the material thickness, width of the aligner edge, and direction of tooth movement.

Keywords: PET-G aligner, Biomechanics, Forces, Moments, Gingival edge width, Material thickness, Stiffness

INTRODUCTION

With the increasing esthetic demands and rapid development of techniques, transparent thermoplastic appliances are becoming more widely used in orthodontics. Aligner systems are based mainly on the same functional principle: they achieve minor tooth movement by a thin splint appliance. These systems vary in materials, design, and fabrication methods (Table 1).1–10 Most thermoplastic aligners are made chiefly from polyethylene terephthalate glycol (PET-G) and polyurethanes. The material thickness varies between 0.5 mm and 1 mm, and the gingival edge (width) ranges between 0 mm and 4 mm (Table 1). Based on the various manufacturers' suggestions, the maximum tooth movement should not exceed 1.0 mm in each staging (Table 1).1,3,4,9

Table 1.

Data on Four Different Thermoplastic Aligner Systems

| Name |

CA Clear Alignera |

Invisalignb |

Essix d |

ClearSmile e |

| Material | Duran | EX30/SmartTrack | Essix plastic | Erkudor |

| Major component | Polyethylene terephthalate glycol copolyester (PET-G) | Polyurethane | Polypropylene copolyester | Polyurethane |

| Thickness | 0.5, 0.625, 0.75 mm | 0.75 mm, 1.0 mm | 0.75, 1.0 mm | 0.8 mm |

| Edge | 2–3 mm | 0–1 mmc | 3-4 mm | 0–1 mm |

| Maximum tooth movement | 0.5, 1 mm | 0.25 mm | 1 mm | 0.5 mm |

| Fabrication | Laboratory | CAD/CAM | Laboratory | Laboratory |

| Company | Scheu-Dental | Align Technology | Dentsply | ClearSmile Aligners |

Information obtained from manufacturer's material product sheet with additional information from Tuncay.9

Trimmed short to the gingival margin at the cementoenamel junction (CEJ) or halfway between the CEJ and gingival margin.

Information obtained from manufacturer's material product sheet with additional information from Sheridan et al.1

Information obtained from Barbagallo et al.4

Only a few studies have shown that aligners' material properties affect forces delivered to the teeth.8,11–14 Hahn et al.11 found that aligners (Erkodur 1.0 and 0.8 mm, Biolon 1.0 and 0.75 mm) produced from thick materials delivered overall significantly higher forces than those made from thin materials. Kohda et al.12 supported this conclusion based on their investigations of different aligner materials (Duran, Erkudor and Hardcast). Kwon et al.13 used a three-point bending recovery test on flat specimens of three different materials from the Essix brand with different thicknesses. They showed that thin foils deliver lower forces than thicker materials of the same brand.13 Cowley et al.14 compared the retention of aligners with three margin designs (scalloped, straight cut at the gingival zenith, and straight cut 2 mm above the gingival zenith) using pull-off tests. The pull-off forces were measured perpendicular to the occlusal plane. Their results indicated that aligners with a 2-mm gingival border showed the greatest retention.14

Although some investigations have been concerned with the material thickness of various aligner materials and the retention capacity of aligner extensions, these investigations are of limited clinical usefulness. Biomechanically, the direction and amount of tooth movement should be combined with material composition as material thickness and aligner extension in one aligner system. For this reason, the present study focused on the force delivery system of Duran foils (PET-G, Scheu-Dental GmbH, Iserlohn, Germany). These foils are often used in orthodontic offices with three different thicknesses (0.5, 0.625, and 0.75 mm) and constructed with a 2–3 mm gingival edge (CA Clear Aligner, Scheu-Dental). The present study investigated the biomechanical effects of orovestibular and vertical tooth movement depending on the various PET-G foil thicknesses and their extension, the gingival edge width.

MATERIALS AND METHODS

Eighteen groups of PET-G-based aligners, consisting of edge widths of 0–1, 3–4, and 6–7 mm, with foils of three different material thicknesses (0.5, 0.625, and 0.75 mm), were investigated during 0.5 mm tipping and 0.5 mm intrusion.13 Each group consisted of three samples. Aligners were produced from a randomly chosen maxillary model with a standard dentition that was duplicated into two identical working plaster casts. The left maxillary incisor (tooth to be measured) on each model was either 0.5 mm palatally tipped or 0.5 mm intruded, microscopically controlled at 200x magnification using a digital microscope (Conrad Electronics, Hirschau, Germany). The aligners (Duran foils, Scheu-Dental) were vacuum-thermoformed by using the Biostar VI apparatus (Scheu-Dental) and the two prepared plaster models with identical heights. This makes the effective material thicknesses of the aligners reproducible. After separation from the working model, the gingival margins of the aligners were cut to the respective widths (0–1, 3–4, and 6–7 mm) and then trimmed and smoothed (Figure 1). Altogether, 27 aligners from each of the two models were prepared and used for the following measurements.

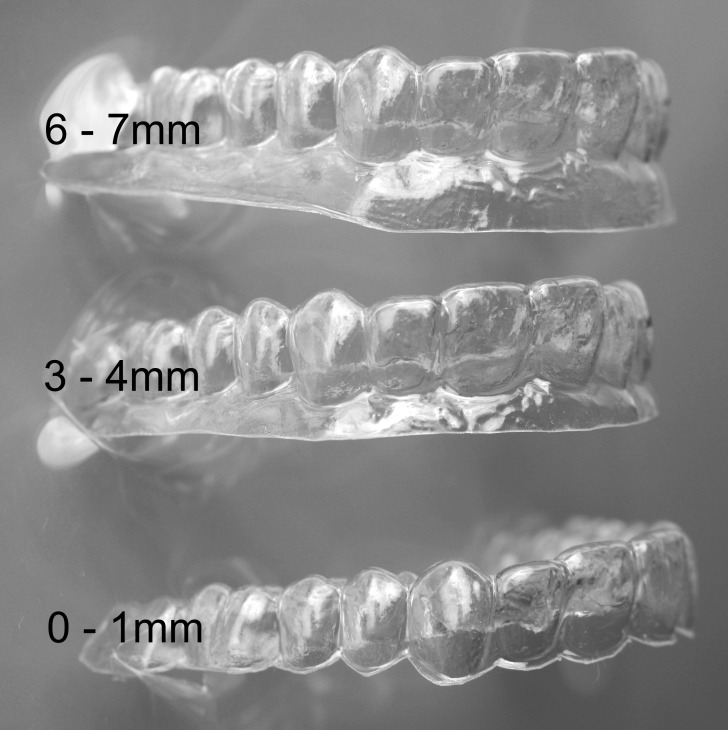

Figure 1.

PET-G aligner sample investigated in this study, with three different gingival edge widths (from top to bottom): PET-G aligner trimmed to a gingival edge width of 6–7 mm, 3–4 mm, and 0–1 mm, respectively.

To measure the force three-dimensionally, a measuring device11,15,16 was constructed taking into consideration the periodontal ligament17 (Figure 2). A six-component sensor (Nano17F/T Sensor, ATI Industrial Automation, Apex, NC) was connected to the tooth to be measured. The z-axis of the sensor was orientated along the incisor axis, through the imaginary center of resistance of the incisor. All other axes and planes were set to 5° mesiodistal crown angulation and 7° labiolingual crown inclination.18 The mobility of the tooth was adjusted by adding plaster onto the connection of sensor and cantilever arm, until a 1-N force on the incisor resulted in a relative displacement of 0.04 mm.19 This was performed to ensure that the stiffness of the measuring system was close to that of the elastic property of the periodontal ligament (PDL) within the linear region.17,20 Thirty seconds after mounting the aligner on the measuring setup, 50 values for each moment and force component were collected (ATI DAQ F/T Software, Version 2.0.2054.5.11, ATI) at a frequency of 7200 Hz. The resulting forces (Fx, Fy, Fz) and moments (Mx, My, Mz) were recorded in the x, y, and z directions (Figure 2). Fx represents the vestibular-palatal force (+Fx, −Fx), Fy represents the mesiodistal force (+Fy, −Fy), and Fz represents the intrusive-extrusive force (−Fz, +Fz). The measured moments were calculated and presented at the center of resistance of the measured tooth. In preexperiments with 10 identical aligners, the standard deviation of the forces was ±0.16 N—less than the data presented.

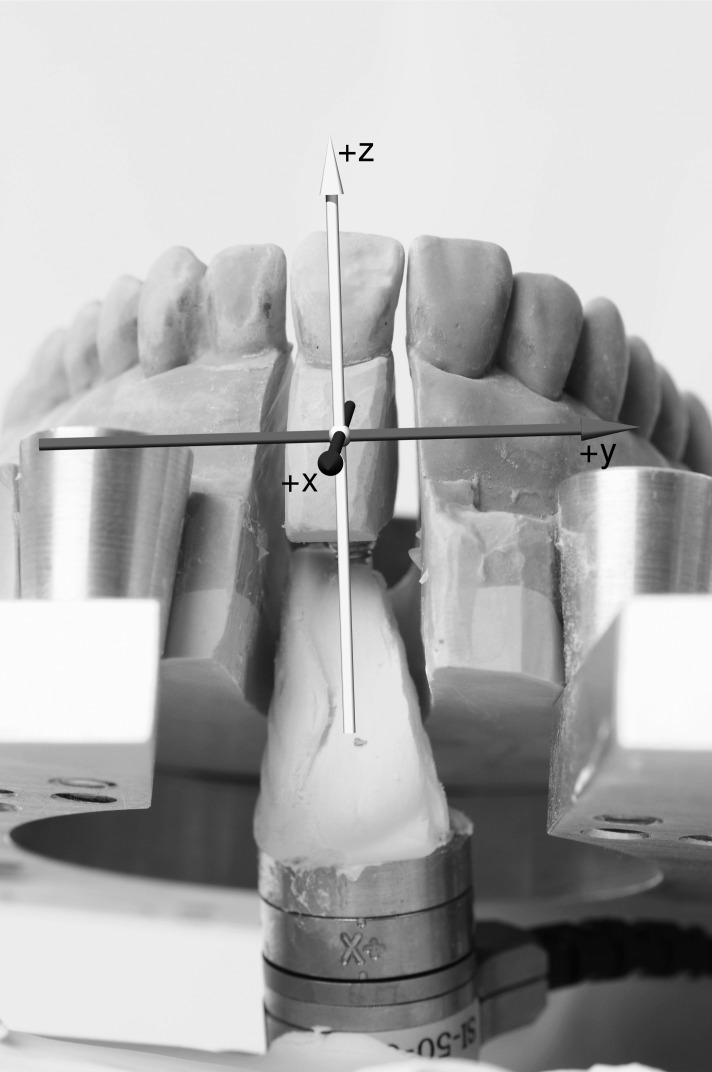

Figure 2.

Measuring device of the maxillary incisor mounted on a six-component force/moment sensor with the relevant coordinate system. The resulting forces and moments were recorded in the x, y, and z-axis, defined as Fx, Fy, Fz and Mx, My, Mz, respectively. Fx represented the vestibular-palatal force (+Fx, −Fx), Fy represented the mesiodistal force (+Fy, −Fy), and Fz represented the intrusive-extrusive force (−Fz, +Fz).

Statistical analyses were performed with IBM SPSS 23 (Armonk, NY). The Kruskal-Wallis test was applied to evaluate the overall impact of different material thicknesses and edge widths on the delivered forces. IBM SPSS ModelViewer pairwise comparison was applied as a post-hoc test to determine the statistical significance between groups. All statistical tests were performed with a significance level of P < .05.

RESULTS

Forces and Moments

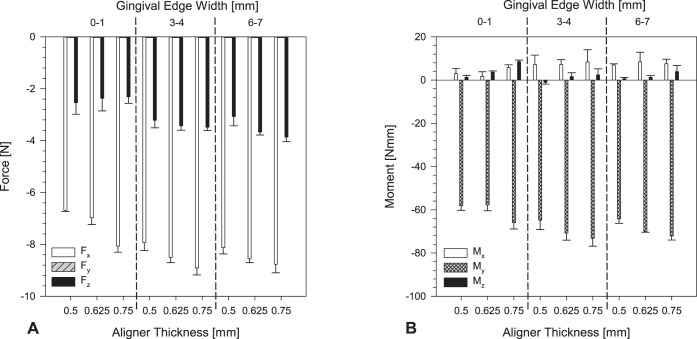

The average force in the vestibular-palatal (x) and intrusive-extrusive (z) direction during 0.5-mm palatal tipping varied between −6.7 N and −8.9 N, and between −2.3 N and −3.9 N, respectively (Figure 3). In the mesiodistal (y) direction, the force was close to 0 (Table 2). The mean palatal moment (My) lay between −58 Nmm and −73 Nmm. The average moment-to-force (M/F) ratio was 8–9 mm (Table 2).

Figure 3.

Resultant forces and moments of PET-G aligner of 0.5-, 0.625-, and 0.75-mm thickness with gingival edge widths of 0–1, 3–4, and 6–7 mm during 0.5-mm tipping. (A) Forces. (B) Moments. Fx, Fy, and Fz are the forces acting along the x-, y-, and z-axis, respectively, and Mx, My, and Mz are the moments acting in the x, y, and z-axis, respectively. For axis definitions, see Figure 2.

Table 2.

Results of the Forces and Moments (N = 54) During 0.5-mm Tipping and Intrusion of the Nine Groups of Aligners of Three Thicknesses and Three Edge Widths

| Movement |

Edge Width (mm) |

Thickness (mm) |

Fx (N) |

Fy (N) |

Fz (N) |

Mx (Nmm) |

My (Nmm) |

Mz (Nmm) |

MY/FX (mm) |

||||||

| Mean |

SD |

Mean |

SD |

Mean |

SD |

Mean |

SD |

Mean |

SD |

Mean |

SD |

||||

| Tipping | 0–1 | 0.5 | −6.68 | 0.05 | −0.02 | 0.00 | −2.54 | 0.45 | 2.99 | 2.42 | −58.17 | 2.10 | 1.28 | −2.85 | 8.70 |

| 0.625 | −6.98 | 0.26 | −0.02 | 0.00 | −2.37 | 0.49 | 1.74 | 2.11 | −57.74 | 2.70 | 3.65 | −2.53 | 8.28 | ||

| 0.75 | −8.06 | 0.24 | −0.02 | 0.00 | −2.31 | 0.25 | 5.80 | 1.28 | −65.98 | 2.93 | 8.58 | −0.92 | 8.18 | ||

| 3–4 | 0.5 | −7.94 | 0.30 | −0.02 | 0.00 | −3.21 | 0.29 | 7.17 | 4.38 | −64.80 | 4.35 | −1.08 | −1.62 | 8.17 | |

| 0.625 | −8.50 | 0.21 | −0.02 | 0.00 | −3.43 | 0.17 | 7.19 | 2.28 | −70.76 | 3.30 | 1.62 | −1.22 | 8.33 | ||

| 0.75 | −8.91 | 0.27 | −0.02 | 0.00 | −3.49 | 0.12 | 8.39 | 5.63 | −73.15 | 3.70 | 2.40 | −2.14 | 8.21 | ||

| 6–7 | 0.5 | −8.13 | 0.24 | −0.02 | 0.00 | −3.07 | 0.36 | 6.99 | 0.52 | −64.23 | 2.04 | 0.64 | −4.35 | 7.90 | |

| 0.625 | −8.56 | 0.15 | −0.02 | 0.00 | −3.67 | 0.11 | 8.44 | 4.42 | −70.02 | 0.39 | 1.30 | −1.75 | 8.18 | ||

| 0.75 | −8.77 | 0.33 | −0.02 | 0.00 | −3.86 | 0.18 | 7.57 | 2.07 | −72.14 | 1.86 | 3.90 | −2.91 | 8.23 | ||

| Intrusion | 0–1 | 0.5 | −0.52 | 0.26 | −0.01 | 0.00 | −1.23 | 0.09 | −1.31 | 1.49 | −6.72 | 1.52 | 1.55 | 0.46 | NAa |

| 0.625 | −0.52 | 0.01 | −0.01 | 0.00 | −1.70 | 0.05 | 3.13 | 0.16 | −9.47 | 1.23 | 2.97 | 0.64 | |||

| 0.75 | −0.64 | 0.05 | −0.01 | 0.00 | −2.52 | 0.29 | −2.68 | 1.55 | −10.74 | 0.32 | 2.59 | 0.81 | |||

| 3–4 | 0.5 | −0.68 | 0.24 | −0.02 | 0.01 | −8.51 | 0.46 | −0.57 | 3.12 | −12.01 | 0.34 | 4.77 | 1.41 | ||

| 0.625 | −0.79 | 0.35 | −0.03 | 0.01 | −9.02 | 0.89 | 3.77 | 1.80 | −13.34 | 2.30 | 3.14 | 4.05 | |||

| 0.75 | −1.57 | 0.21 | −0.01 | 0.00 | −12.29 | 0.73 | −0.72 | 3.63 | −12.22 | 1.32 | 3.38 | 1.11 | |||

| 6–7 | 0.5 | −0.88 | 0.13 | −0.02 | 0.00 | −8.84 | 0.65 | −2.27 | 4.97 | −11.05 | 1.53 | 4.96 | 1.12 | ||

| 0.625 | −0.65 | 0.30 | −0.03 | 0.00 | −10.71 | 0.77 | −1.51 | 0.94 | −13.39 | 0.90 | 6.47 | 3.02 | |||

| 0.75 | −1.44 | 0.62 | −0.02 | 0.00 | −12.02 | 0.54 | −0.31 | 1.34 | −10.76 | 3.71 | 6.97 | 1.73 | |||

NA indicates not applicable.

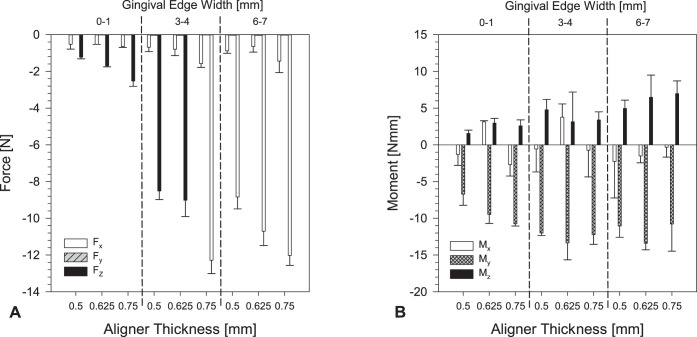

An intrusion of 0.5 mm led to forces varying from −1.2 to −12.3 N, depending on material thickness and edge width (Figure 4).

Figure 4.

Resultant forces and moments of PET-G aligner of 0.5-, 0.625-, and 0.75-mm thickness with gingival edge widths of 0–1, 3–4, and 6–7 mm during 0.5-mm intrusion. (A) Forces. (B) Moments. Fx, Fy, and Fz are the forces acting along the x-, y-, and z-axis, respectively, and Mx, My, and Mz are the moments acting in the x-, y-, and z-axis, respectively. For axis definitions, see Figure 2.

Material Thickness

Measurements show that material thickness significantly influenced the force that the aligner delivered to the tooth by palatal tipping (P = .011), but not as significant during intrusive movement (P = .054; Table 3).

Table 3.

Significance Levels Calculated for Forces and Moments of PET-G Aligner With Different Material Thicknesses Using SPSS 23a

| Edge Width, mm |

Thickness Comparison |

Palatal Tipping |

Intrusion |

|||

| Fx |

Fz |

My |

Fz |

My |

||

| Overallb | 0.011* | 0.361 | 0.020* | 0.054 | 0.263 | |

| 0.5 mm vs 0.625 mmc | 0.307 | 0.413 | ||||

| 0.625 mm vs 0.75 mmc | 0.516 | 0.574 | ||||

| 0.5 mm vs 0.75 mmc | 0.008* | 0.016* | ||||

| 0–1 | Overallb | 0.039* | 0.587 | 0.066 | 0.027* | 0.051 |

| 0.5 mm vs 0.625 mmc | 0.890 | 0.539 | ||||

| 0.625 mm vs 0.75 mmc | 0.408 | 0.539 | ||||

| 0.5 mm vs 0.75 mmc | 0.034* | 0.022* | ||||

| 3–4 | Overallb | 0.039* | 0.288 | 0.148 | 0.061 | 0.561 |

| 0.5 mm vs 0.625 mmc | 0.408 | |||||

| 0.625 mm vs 0.75 mmc | 0.890 | |||||

| 0.5 mm vs 0.75 mmc | 0.034* | |||||

| 6–7 | Overallb | 0.051 | 0.039* | 0.039* | 0.039* | 0.430 |

| 0.5 mm vs 0.625 mmc | 0.408 | 0.408 | 0.408 | |||

| 0.625 mm vs 0.75 mmc | 0.890 | 0.890 | 0.890 | |||

| 0.5 mm vs 0.75 mmc | 0.034* | 0.034* | 0.034* | |||

Significant values are labeled as follows: * P ≤ .05; ** P ≤ .01; *** P ≤ .001 (N = 9).

Kruskal-Wallis statistical test.

Post-hoc pairwise comparison after Kruskal-Wallis as implemented in the IBM SPSS ModelViewer. IBM SPSS 23 ModelViewer performed post-hoc pairwise comparisons only if the Kruskal-Wallis test showed a significant result for that variable.

During 0.5-mm palatal tipping, the Fx of the 0.5-mm-thick (-thick) aligners ranged from 6.7 to 8.1 N, forces of the 0.625-mm aligners ranged from 7.0 to 8.6 N, and forces of the 0.75-mm aligners ranged from 8.1 to 8.9 N (Figure 3A). Forces produced by the 0.75-mm aligners were 1.0 N higher during 0.5-mm palatal tipping than those produced by the 0.5-mm material (P = .005). The same significant results were found with the palatal moments (My).

During the 0.5-mm intrusion of the 0.5-mm aligners, the force (Fx) ranged from 1.2 to 8.8 N, forces of the 0.625-mm aligners ranged from 1.7 to 10.7 N, and forces of the 0.75 aligners ranged from 2.5 to 12.3 N (Figure 4). Forces produced by aligners of 0.75-mm-thick material were 2.8 N (P = .047) higher during 0.5-mm intrusion than those produced by the 0.5-mm material. No significant difference was observed between the 0.5- vs 0.625-mm aligner material groups or the 0.625- vs 0.75-mm groups (Table 3). In contrast to the intrusion forces, the intrusion moments showed no significant differences between the different thicknesses of the aligner materials (Table 3).

Aligner Edge

The width of the aligner edge showed a significant difference in the force delivered to the tooth during both palatal tipping (P = .001) and intrusion (P < .001; Table 4).

Table 4.

Significance Levels Calculated for Forces and Moments of PET-G Aligner With Various Edge Widths Using SPSS 23a

| Aligner Thickness |

Edge Width Comparison |

Palatal Tipping |

Intrusion |

|||

| Fx |

Fz |

My |

Fz |

My |

||

| Overallb | 0.001** | 0.000*** | 0.002** | 0.000*** | 0.004** | |

| 0–1 mm vs 3–4 mmc | 0.007** | 0.007** | 0.004** | 0.003** | 0.006** | |

| 3–4 mm vs 6–7 mmc | 1.000 | 0.981 | 1.000 | 1.000 | 1.000 | |

| 0–1 mm vs 6–7 mmc | 0.003** | 0.000** | 0.007** | 0.000** | 0.035* | |

| 0.5 mm | Overallb | 0.051 | 0.099 | 0.066 | 0.061 | 0.061 |

| 0–1 mm vs 3–4 mmc | ||||||

| 3–4 mm vs 6–7 mmc | ||||||

| 0–1 mm vs 6–7 mmc | ||||||

| 0.625 mm | Overallb | 0.066 | 0.039* | 0.061 | 0.027* | 0.061 |

| 0–1 mm vs 3–4 mmc | 0.408 | 0.539 | ||||

| 3–4 mm vs 6–7 mmc | 0.890 | 0.539 | ||||

| 0–1 mm vs 6–7 mmc | 0.034* | 0.022* | ||||

| 0.75 mm | Overallb | 0.066 | 0.027* | 0.061 | 0.061 | 0.561 |

| 0–1 mm vs 3–4 mmc | 0.539 | |||||

| 3–4 mm vs 6–7 mmc | 0.539 | |||||

| 0–1 mm vs 6–7 mmc | 0.022* | |||||

Significant values are labeled as follows: * P ≤ .05; ** P ≤ .01; *** P ≤ .001 (N = 9).

Kruskal-Wallis statistical test.

Post-hoc pairwise comparison after Kruskal-Wallis as implemented in the IBM SPSS ModelViewer. IBM SPSS 23 ModelViewer performed post-hoc pairwise comparisons only if the Kruskal-Wallis test showed a significant result for that variable.

During 0.5-mm palatal tipping, the Fx of the aligners with a 0–1-mm edge ranged from 6.7 to 8.1 N, forces of aligners with a 3–4-mm edge ranged from 7.9 to 8.9 N, and forces of aligners with a 6–7-mm edge ranged from 8.1 to 8.8 N (Figure 3). During 0.5-mm palatal tipping, the forces of aligners with a 3–4- and 6–7-mm edge were 1.2 N (P = .003) and 1.2 N (P = .001), respectively, higher than those with a 0–1-mm edge. There was no statistical difference between the 3–4-mm edge and the 6–7-mm edge. The same behavior was found for the palatal moment (My; Table 4).

During an intrusion of 0.5 mm, the Fz of the aligners with a 0–1-mm edge ranged from 1.2 to 2.5 N, forces of aligners with a 3–4-mm edge ranged from 8.5 to 12.3 N, and forces of aligners with a 6–7 mm edge ranged from 8.8 to 12.0 N (Figure 4). The forces of aligners with a 3–4 mm- (8.1 N; P < .001) and 6–7-mm edge (8.7 N; P < .001) were significantly higher than those with a 0–1 mm edge during an intrusion of 0.5 mm. No substantial difference was observed in the forces of aligners with a 3–4-mm edge vs those with a 6–7-mm edge. The same behavior was found for the palatal moment (My; Table 4).

DISCUSSION

The experimental setup used in this study showed only initial forces and moments. The simulation was done using plaster models. The elastic behavior of adjacent teeth in the clinical situation was not evaluated in this study. In contrast to previous studies,11,21 the special integration of the single incisor in the dental arch made it possible to take the initial restoring force of this tooth of 1 N with a tooth mobility of 0.04 mm19 into account. Biological variations of the PDL and individual differences in crown and root geometry were not considered in the experimental setup.

In this study, the forces exerted by the aligner on the tooth reached more than 6 N during tipping movement and more than 1 N during intrusion, which was much higher than the force suggested for minor tooth movement (approximately 0.5–0.75 N for tipping, approximately 0.10–0.25 N for intrusion) in the literature.22–24 The characteristics of aligner material are different from those of conventional orthodontic material (eg, NiTi archwire). These maintain almost a constant force level over a certain distance of tooth movement, whereas aligner materials do not.25

On the other hand, we measured only the initial forces applied to the tooth. Once fitted to the tooth, aligners exert long-term forces that decrease over time.4,8,26 A 5× force reduction within 2 weeks can be assumed.4

Only a few studies provide information about the moments delivered by aligners to the tooth.15,21 The differences in magnitude of the moments are attributed to the difference in aligner materials, aligner thickness, degree of tooth activation, measuring setups, and especially, type of tooth movement, which are not comparable.10,27

The M/F ratio applied to a tooth is relevant to clinical applications.15,28 Therefore, it is neither the magnitude of force nor the moment alone that determines the type of tooth movement. From previous studies it is known that the M/F ratio for controlled tipping should be ideally in the range of 8.28 In the present study, the calculated M/F ratio confirms this very well (M/F = 8.2).

Clinically, orthodontic treatment with the CA Clear Aligner is a three-step procedure with each staging. For each staging step, three aligners in three thicknesses (0.5, 0.625, and 0.75 mm) are produced from the same-setup model.2 Other aligner systems are produced from one (ClearSmile: 0.8 mm) or two different material thicknesses (Invisalign, Essix: 0.75 or 1.0 mm) with the thicker one being used for difficult cases.1,6 In this study, material thickness is shown to have an influence on force magnitude. Thicker material reduces aligner flexibility, enhances its rigidity, and leads to an increase in the force generated. This is in agreement with various studies found in literature.11,12 However, only the forces produced by aligners made from the 0.75-mm thick material were significantly higher than those made from 0.5mm-thick material. However, the difference in force magnitude for the 0.65-mm thick foil was not significant compared with 0.5- and 0.75-mm foils. Thus, the clinical benefit of the intermediate foil thickness is questionable.

Apart from material thickness, aligner systems have different gingival edge designs, for example, scalloped gingival border (Invisalign and ClearSmile) or straight border with different widths (Essix: 3–4 mm; CA Clear Aligner: 2–3 mm).1,3,8 Our results showed that edgeless aligners generated significantly lower forces than those with a wider edge. The influence of the gingival edge width on the force was more significant during intrusion than during tipping movement. The increased force might be due to the enhanced stiffness caused by the material shape. Therefore, the influence of the aligner edge width is clinically—especially during intrusion movements—less relevant with palatal tipping. Although the measurements were significant, the differences were less during palatal tipping. This might be due to a higher retention force of the aligner and a decrease of flexibility of the aligner material in combination with larger gingival edge width.14 In addition to the biomechanical aspects of aligner edge width, biological aspects (eg, body temperature, saliva, occlusal forces) must be considered clinically. A possible side effect of gingival edge width on periodontal and gingival health issues should be investigated in a further clinical study.

CONCLUSIONS

-

•

The material thickness and width of the aligner edge influence the force and moment generated by PET-G aligners. In general, aligners produced from thick material with a gingival edge generate higher forces than those produced from thin material without an edge.

-

•

Biomechanically, an aligner edge width of 0–1 mm or 3–4 mm can be recommended, depending on the direction of tooth movement. Longer aligner edges show no significant change in forces and moments.

-

•

The influence of material thickness and width of aligner edge on the force differs between tipping and intrusion. With palatal tipping, aligners prepared with a foil thickness of 0.5 mm and 0.75 mm and an aligner edge of 0–1 mm and 3–4 mm show significant differences. In contrast, a significant difference can be noticed during intrusion between foils with a thickness of 0.5 mm and 0.75 mm and an aligner edge.

-

•

For the PET-G aligner, we recommend the substitution of the three-step procedure (0.5, 0.625, and 0.75 mm) with a two-step procedure (0.5 and 0.75 mm).

-

•

Forces and moments occurring during aligner therapy can depend on the material itself, its thickness, and design. Therefore, using a PET-G of 0.5-, 0.625-, and 0.75-mm thickness, movements of more than 0.5 mm should not be carried out in a clinical set-up.

-

•

Further studies are necessary to compare different aligner materials. Increasing the sample size will improve the power of the results.

ACKNOWLEDGMENTS

The authors would like to thank Scheu-Dental GmbH for supplying the aligner material used in this study and Dr. Boryor for his assistance during the experimental setup. The aid of the Institute for Medical Informatics, Biometry and Epidemiology, and Dr. Baumert for help with statistical analysis is gratefully acknowledged.

REFERENCES

- 1.Sheridan JJ, Ledoux W, McMinn R. Essix appliance: minor tooth movement with divots and windows. J Clin Orthod. 1994;28:659–663. [Google Scholar]

- 2.Kim TW, Echarri P. Clear aligner: an efficient, esthetic, and comfortable option for an adult patient. World J Orthod. 2007;8:13–18. [PubMed] [Google Scholar]

- 3.Echarri P. Clear-Aligner. Madrid: Editorial Ripano SA; 2013. [Google Scholar]

- 4.Barbagallo LJ, Shen G, Jones AS, Swain MV, Petocz P, Darendeliler MA. A novel pressure film approach for determining the force imparted by clear removable thermoplastic appliances. Ann Biomed Eng. 2008;36:335–341. doi: 10.1007/s10439-007-9424-5. [DOI] [PubMed] [Google Scholar]

- 5.Duong T. History and overview of the Invisalign system. In: Tuncay OC, editor. The Invisalign System. London: Quintessence; 2006. pp. 25–34. [Google Scholar]

- 6.Tricca R, Li C. Properties of aligner material EX30. In: Tuncay OC, editor. The Invisalign System. London: Quintessence; 2006. pp. 177–186. [Google Scholar]

- 7.Sterental R. Staging. In: Tuncay OC, editor. The Invisalign System. London: Quintessence; 2006. pp. 105–114. [Google Scholar]

- 8.Cao H, Duong T. Application of mechanics with Invisalign. In: Tuncay OC, editor. The Invisalign System. London: Quintessence; 2006. pp. 153–162. [Google Scholar]

- 9.Tuncay OC. The Invisalign System. London: Quintessence; 2006. [Google Scholar]

- 10.Lombardo L, Martines E, Mazzanti V, Arreghini A, Mollica F, Siciliani G. Stress relaxation properties of four orthodontic aligner materials: a 24-hour in vitro study. Angle Orthod. In press. [DOI] [PMC free article] [PubMed]

- 11.Hahn W, Dathe H, Fialka-Fricke J, et al. Influence of thermoplastic appliance thickness on the magnitude of force delivered to a maxillary central incisor during tipping. Am J Orthod Dentofacial Orthop. 2009. 136:12 e11–e17; discussion 12–13. [DOI] [PubMed]

- 12.Kohda N, Iijima M, Muguruma T, Brantley WA, Ahluwalia KS, Mizoguchi I. Effects of mechanical properties of thermoplastic materials on the initial force of thermoplastic appliances. Angle Orthod. 2013;83:476–483. doi: 10.2319/052512-432.1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.Kwon JS, Lee YK, Lim BS, Lim YK. Force delivery properties of thermoplastic orthodontic materials. Am J Orthod Dentofacial Orthop. 2008;133:228–234. doi: 10.1016/j.ajodo.2006.03.034. quiz 328. e221. [DOI] [PubMed] [Google Scholar]

- 14.Cowley DP, Mah J, O'Toole B. The effect of gingival-margin design on the retention of thermoformed aligners. J Clin Orthod. 2012;46:697–702. quiz 705. [PubMed] [Google Scholar]

- 15.Hahn W, Engelke B, Jung K, et al. Initial forces and moments delivered by removable thermoplastic appliances during rotation of an upper central incisor. Angle Orthod. 2010;80:239–246. doi: 10.2319/033009-181.1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Hahn W, Fialka-Fricke J, Dathe H, et al. Initial forces generated by three types of thermoplastic appliances on an upper central incisor during tipping. Eur J Orthod. 2009;31:625–631. doi: 10.1093/ejo/cjp047. [DOI] [PubMed] [Google Scholar]

- 17.Dorow C, Krstin N, Sander FG. Determination of the mechanical properties of the periodontal ligament in a uniaxial tensional experiment. J Orofac Orthop. 2003;64:100–107. doi: 10.1007/s00056-003-0225-7. [DOI] [PubMed] [Google Scholar]

- 18.Andrews LF. The six keys to normal occlusion. Am J Orthod. 1972;62(3):296–309. doi: 10.1016/s0002-9416(72)90268-0. [DOI] [PubMed] [Google Scholar]

- 19.Dorow C, Krstin N, Sander FG. In vivo experimental investigation of tooth mobility in the human. Biomedizinische Technik. 2002;47(1–2):20–25. doi: 10.1515/bmte.2002.47.1-2.20. [DOI] [PubMed] [Google Scholar]

- 20.Toms SR, Eberhardt AW. A nonlinear finite element analysis of the periodontal ligament under orthodontic tooth loading. Am J Orthod Dentofacial Orthop. 2003;123:657–665. doi: 10.1016/s0889-5406(03)00164-1. [DOI] [PubMed] [Google Scholar]

- 21.Simon M, Keilig L, Schwarze J, Jung BA, Bourauel C. Forces and moments generated by removable thermoplastic aligners: incisor torque, premolar derotation, and molar distalization. Am J Orthod Dentofacial Orthop. 2014;145:728–736. doi: 10.1016/j.ajodo.2014.03.015. [DOI] [PubMed] [Google Scholar]

- 22.Proffit WR. Contemporary Orthodontics 3rd ed. St. Louis: Mosby; 2000. [Google Scholar]

- 23.Reitan K. Some factors determining the evaluation of forces in orthodontics. Am J Orthod. 1957;43:32–45. [Google Scholar]

- 24.Reitan K. Initial tissue behavior during apical root resorption. Angle Orthod. 1974;44:68–82. doi: 10.1043/0003-3219(1974)044<0068:ITBDAR>2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 25.Bartzela TN, Senn C, Wichelhaus A. Load-deflection characteristics of superelastic nickel-titanium wires. Angle Orthod. 2007;77:991–998. doi: 10.2319/101206-423.1. [DOI] [PubMed] [Google Scholar]

- 26.Vardimon AD, Robbins D, Brosh T. In-vivo von Mises strains during Invisalign treatment. Am J Orthod Dentofacial Orthop. 2010;138:399–409. doi: 10.1016/j.ajodo.2008.11.027. [DOI] [PubMed] [Google Scholar]

- 27.Elkholy F, Schmidt F, Jäger R, Lapatki BG. Forces and moments delivered by novel, thinner PET-G aligners during labiopalatal bodily movement of a maxillary central incisor: an in vitro study. Angle Orthod. 2016;86:883–890. doi: 10.2319/011316-37R.1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 28.Smith RJ, Burstone CJ. Mechanics of tooth movement. Am J Orthod. 1984;85:294–307. doi: 10.1016/0002-9416(84)90187-8. [DOI] [PubMed] [Google Scholar]