Abstract

The study explored the 3D numerical solution of an unsteady Ag-MgO/water hybrid nanofluid flow with mass and energy transmission generated by a wavy rotating disc moving up and down. The nanofluid is generated in the context of Ag-MgO nanomaterials. Magnesium oxide and silver nanoparticles have been heavily reported to have broad-spectrum antibacterial operations among metal oxides and metals. Silver nanoparticles are without a doubt the most commonly used inorganic nanoparticles, with numerous innovations in biomaterial’s detection and antimicrobial operations. However, in current paper, the intention of the analysis is to boost thermal energy transmitting rates for a range of industrial implementations. When compared to a flat surface, energy transition is increased up to 15% due to the wavy swirling surface. The problem has been formulated as a system of PDEs, which included the Navier Stokes and Maxwell equations. Following that, the modeled equations are reduced to a dimensionless system of differential equations. The derived equations are then solved numerically using the Parametric Continuation Method (PCM). The findings are displayed graphically and debated. The geometry of a spinning disc is thought to have a positive impact on velocity and heat energy transfer. The insertion of nanostructured materials (silver and magnesium-oxide) increased the carrier fluid’s thermal properties considerably. It is more effective at dealing with low energy transmission.

1. Introduction

Fluid flow over the substrate of a rotating disc has garnered considerable attention because of its consequences in real phenomena. Flow over the rotating disc surface is commonly used in electric power generation systems, co rotating machines, aerodynamics engineering, rotating equipment, geothermal sector, chemical reaction, and computer processing [1]. Accurate analysis and precise measurements of reaction are the prerequisite for better understanding the factors that overcome kinetics of reaction. Electrode system of rotating disk is broadly used to examine the reactions kinetics and that are suffering from mass transmission deficiency [2]. Tassaddiq et al. [3] examined the MHD, an incompressible iron ferrite and carbon nanotubes CNTs hybrid nanoliquid over an impermeable spinning disk. They perceived that the fluid temperature and velocity are considerably increased by increasing disc rotating velocity. Mustafa et al. [4] used the Bingham fluid model to analyze the heat transmission and viscous dissipation for swirling viscoelastic fluid flow crossing over a permeable spinning disc. Using a greater suction velocity at the disc allows for a faster thermal efficiency. However, as the fluid yield stress increases, the heat transfer is expected to deteriorate. Hafeez and Khan [5] scrutinized the mass and heat flux theories in Oldroyd-B fluid flow over an extending disk. It should be noted that the solutal relaxation time coefficient has a negative impact on mass transmission rate. Gul et al. [6] modeled the hybrid nanofluid flow between disk and cone with several cases. Based on the analysis of the results, it was concluded that a rotating disc that a rotating disc with a fixed cone would attain the intended cooling of disk-cone tools if the surface temperature remains steady.

Fluid that is commonly used Ethanol, kerosene oil and water etc., which play a prominent role in energy transfer, heating and air conditioning processes, energy generation, and other small electronics mechanisms. However, since these liquids have a poor thermal energy transfer capacity, they are unable to accommodate the need for high heat exchange rates. Nanometer-sized particles (1-100nm), also recognized as nanomaterials, are applied to a natural fluid to substitute for this inadequacy and increase thermal conductivity. To quantify the thermophysical properties of various kinds of nanoparticles, the researcher used a variety of techniques [7]. Nanoparticles are used to clean surfaces in engineering because they have the ability to disperse and wet oil. It improves thermal efficiency, which is important in the fields of energy production, hypoxia, micro fabrication and metallurgy. Magnesium oxide MgO is a compound made up of Mg2+ and O2- ions that are bonded together through a powerful ionic bond. It is made by calcination of Mg (OH) 2 and MgCO3 at temperature range from 700°C-1500°C. Most of it is utilized in the hematologic and electrical industries. Similarly, Ag particles with antibacterial properties are used to control microorganism growth in wound, burns and surgical apparatus and infrastructure. Microorganisms are particularly toxic to compound based on silver and its ions. Hussanan et al. [8] investigated oxide nanomaterials in engine nanoliquids and water for energy up gradation. Using the finite element technique, Ghalambaz et al. [9] investigated convection flow of a hybrid nanofluid (Ag–MgO/water) within a cavity. Copper-Alumina micro materials were listed for the base fluid. Aluminum Oxide was used by Motlagh and Soltanpour [10] to elaborate the heat transition in a non-flat cavity. Acharya et al. [11] investigated the hybrid fluid flow over a spinning disc with the consequences of MHD and Hall current. They introduced the TiO2 and Cu nanomaterials to creative a class of nanoliquid. The magnetic interaction on flow with CNTs nano powders via a porous tube is studied by Akber et al. [12]. Shah et al. [13] reported that an angled magnetic field, performance of copper selenide and the efficacy of chemical catalytic reactors effects the energy and concentration distribution of nanofluids. Sowmya et al. [14] uncovered natural convective thermal transference in a rectangular chamber with two heated fins on the bottom wall for a hybrid nanofluid flow employing iron oxide and silver nanomaterials. Zhou et al. [15] Khan addressed Von Karman’s classic swirling flow for Maxwell fluid over a porous whirling disc with a constant suction/injection mechanism.

In the engineering sectors, complex nonlinear boundary value problems that cannot be addressed usually are often observed. Convergence is sensitive to the relaxation parameters and initial approach for many problems that are commonly solved by other numerical algorithms. The PCM’s goal is to explore the method’s generalizability as a feasible alternative to nonlinear problems [16]. Shuaib et al. [17] emphasized the 3D unsteady fluid and heat propagation across the substrate of a non-flat stretchable rotating disc. The fluid has investigated under the effects of a magnetic strength from the outside. The feature of an ionic transition boundary layer flow over a gyrating disc was discovered by Shuaib et al. [18]. The Poisson’s, Nernst-Planck equation and Navier Stokes equations, were used to solve for the ionic compounds. Wang et al. [19] presented stability analysis of nonlinear problems for engineering applications through parametric continuation algorithm. They also looked at the static bifurcation that happens when solving nonlinear initial value problems with different characteristic roots and provided an algorithm for instantly calculating the bifurcation points.

The aim of this study is to modify an idea of Ref. [20,21], by investigating the influence of two separate nanoparticles, Silver Ag/water and magnesium oxide MgO/water hybrid nanofluids, on a wavy spinning disc that moves upward and downward. This research is being considered in order to increase the thermal conductivity of the fluid flow. The modelled equations are solved numerically using the parametric continuation process (PCM), and the results have been validated and compared with Matlab’s package boundary value solver (bvp4c). All outcomes are in the closest possible agreement with one another.

2. Mathematical formulation

The physical analysis of the problem, physicochemical characteristics and the equation of motion has been discussed in this section.

2.1 Physical description of the problem

We have assumed a 3D flow of Ag-MgO/Water (Silver and magnesium-oxide) hybrid nanoliquid over a wavy up and down moving spinning disk. Initially the disk is at a(0) = h. At a vertical distance Z = a(t) the disk is moving with velocity ω = a(t). The consequences of buoyancy impacts are negligible. The disk is revolving about z-axis with angular velocity Ω(t), and it has been considered that the Ag-MgO nano-size particles are scattered consistent. The magnetic field of constant magnitude is uniformly applied with and respectively, where and are unit vectors.

2.2 Equation of motion

The modeled equations, based on above presumption are expressed as [20,21]:

| (1) |

| (2) |

| (3) |

| (4) |

| (5) |

| (6) |

| (7) |

Here Fr and Fθ along x and z direction are the body forces, respectively, which can be stated as [21]:

| (8) |

| (9) |

Here, Ha is , in which θ is the direction and B0 is the magnitude of magnetic field, where the velocity components are specified as u,v,w.

2.3 Boundary condition

The initial and boundary conditions for wavy gyrating disk are:

| (10) |

2.4 Thermophysical properties of nanoliquid

The density and specific heat capacity of the hybrid nanofluid can be revealed as [21]:

| (11) |

| (12) |

where (Cp)s1,(Cp)s2 are specific heat capacity, ρs1,ρs2 are the density and φ1,φ2 are the volume friction of the Ag-MgO hybrid nanoliquid respectively shown in Table 1.

Table 1. The numerical properties of water and hybrid nanofluid [20].

| ρ(kg/m3) | Cp(j/kgK) | k(W/mK) | β×105(K−1) | |

|---|---|---|---|---|

| Pure water | 997.1 | 4179 | 0.613 | 21 |

| Magnesium oxide | 3560 | 955 | 45 | 1.80 |

| Silver | 10,500 | 235 | 429 | 1.89 |

The hybrid nanofluid viscosity μhnf is expressed as [22]:

| (13) |

Here, the thermal conductivity and Prandtl number is expressed as [21]:

| (14) |

2.5 Karman’s approach

We use the following similarity framework, to reduce Eqs (1)–(7) and (10) to the system of ODEs [20]:

| (15) |

As a result of Eq (15), we get the following:

| (16) |

| (17) |

| (18) |

| (19) |

| (20) |

| (21) |

The transform conditions are:

| (22) |

Sign ω edify disk’s rotation, S controlled the up and down fluctuating of the disk and γ is the is the thermal energy parameter, which can be defined as [18]:

| (23) |

The dimensionless form of skin friction and Nusselt number is:

| (24) |

Where, τwr and τwϕ represent the radial and transverse stress respectively.

3. Numerical solution

The following steps have been used, while solving the system of ODE (16–21) and their boundary conditions (22):

Step 1: Reducing the system of modeled equations to the first order ODE we introduced the following similarity variables:

| (25) |

Using Eq (25) into the BVP (16–21) and (22), we get:

| (26) |

| (27) |

| (28) |

| (29) |

| (30) |

| (31) |

the boundary conditions are:

| (32) |

Step 2: By introducing the embedding parameter p

We introduced the parameter p in the above system of Eqs (26–31) as follow:

| (33) |

| (34) |

| (35) |

| (36) |

| (37) |

| (38) |

Step 3: Differentiating w.r.t parameter ‘p’

Eqs (33–38) after differentiating w.r.t parameter p reform to the following structure with respect to parameter p

| (39) |

where, R is the remainder and A is the coefficient matrix:

| (40) |

where i = 1, 2, ………11.

Step 4: Apply specify Cauchy problem and superposition principle for each component

| (41) |

where U, W are unknown vector functions and a is unknown blend coefficient. Solving the Cauchy problems for each component

| (42) |

| (43) |

by putting Eq (41) into the original Eq (39), we get

| (44) |

Step 5: Solving the Cauchy problems

The numerical implicit scheme is implemented in the proposed problem, presented as follow: From Eqs (42) and (43)

| (45) |

| (46) |

here, we obtained the iterative form of the problem.

| (47) |

| (48) |

4. Analysis and discussion of results

4.1 Analysis

The numerical outcomes of the system of DE (Differential Equations) are calculated via using PCM, and the bvp4c technique has been used to compare and validate the results. The results have been revealed through Figs (2–11). Fig 1 displays the mechanism of fluid flow over a curvy surface with up and down fluctuation under the consequences of magnetic field. In current paper, the intention of the analysis is to boost the thermal energy transmitting rates for a range of industrial implementations. When compared to a flat surface, energy transition is increased up to 15% due to the wavy swirling surface.

Fig 1.

4.2 Discussion of results

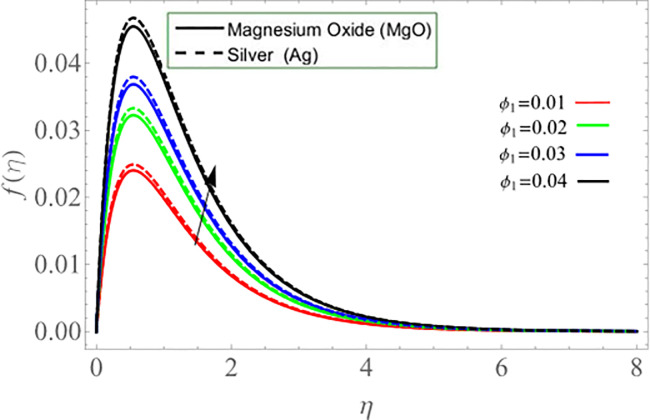

Figs (2–5) elaborate the upshot of volume friction parameters (ϕ1 or ϕAg and ϕ2 or ϕMgO) on axial velocity f(η) and energy profile θ(η) respectively. It can be perceived that the velocity and temperature transmission rate enhance with the rising values of ϕ1&ϕ2. Physically, the increasing number of nanoparticles (Ag-MgO) in base fluid reduces the specific heat capacity of water and improve the thermal diffusivity, because the specific heat capacity of silver and magnesium-oxide is less than water. Eventually, fluid losses its viscosity, which cause rises in temperature and velocity of fluid.

Fig 2.

Fig 5.

Fig 3.

Fig 4.

The unsteadiness parameter S upshot on axial f(η) and azimuthal velocity h(η) profiles is demonstrated through Figs 6 & 7, respectively. It has been concluded that the axial velocity enhances with the positive increment of unsteadiness parameter S, while azimuthal velocity reduces. Because the kinetic viscosity of fluid deceases with its effect, that’s why such scenario has been observed in Fig 6. The effects of disk rotation ω parameter on radial velocity g(η) is shown via Fig 8.

Fig 6.

Fig 7.

Fig 8.

It’s reasonable to assume that improvement rate of disk rotation significantly encourages the kinematic energy of the fluid ions, that leads to an increase in velocity g(η), which also generates heat. The disc surface eventually heats up and improves the fluid temperature θ(η). Fig 9 revealed that the effect of parameter γ reduces the temperature profile. Because the fluid particle releases thermal energy during upward/downward movement, which causes the declination of fluid temperature. The rotating disk’s upward and downward velocity is regulated by the parameter γ.

Fig 9.

Fig 10 explored the consequences of Prandtl number Pr on energy profile. It can be noticed that the temperature declines by the action of Prandtl number. Physically, the action of Prandtl number directly affect the dynamic viscosity and specific heat capacity of fluid, as result the fluid thermal capability declines. Figs 11 & 12 demonstrate the influence of Batchlor number Bt on magnetic strength profile along axial m’(η) and radial direction n(η), respectively. The magnetic strength profile show declination versus the influence of Batchlor number, because the increment in Bt negatively affect the molecular diffusion rate of fluid.

Fig 10.

Fig 11.

Fig 12.

Table 1 elaborate the thermophysical characteristics of silver, base fluid, and magnesium-oxide. Table 2 revealed the comparison between PCM and bvp4c method numerically for all velocities. It can be presumed that the parametric continuation method has strong convergence versus other numerical method. Tables 3 and 4 display the influence of nanoparticles quantity ϕ on velocity radial and azimuthal direction, skin fraction and Nusselt number.

Table 2. Comparative analysis between PCM and bvp4c method.

| PCM | bvp4c | |||||

|---|---|---|---|---|---|---|

| η | f(η) | g(η) | θ(η) | f(η) | g(η) | θ(η) |

| 0.0 | 0.0000 | 0.0000 | 1.0000 | 0.0000 | 0.0000 | 1.0000 |

| 0.5 | 0.0002 | 0.0020 | 0.2711 | 0.0002 | 0.0020 | 0.2721 |

| 1.0 | 0.0060 | 0.0157 | 0.0572 | 0.00061 | 0.01488 | 0.0572 |

| 1.5 | -0.0391 | -0.0771 | 0.0093 | -0.0393 | -0.0775 | 0.0097 |

| 2.0 | -0.1359 | -0.1913 | 0.0019 | -0.1360 | -0.1914 | 0.0008 |

Table 3. The comparative analysis of silver and magnesium-oxide nanoparticles on velocity profile.

| Silver (Ag) | Magnesium oxide MgO | |||

|---|---|---|---|---|

| η | f′(0) | g′(0) | f′(0) | g′(0) |

| 0.00 | 1.3725 | 1.5912 | 1.4323 | 1.6562 |

| 0.05 | 1.5134 | 1.6724 | 1.8735 | 1.7821 |

| 0.01 | 1.7642 | 1.8054 | 2.1012 | 1.8922 |

| 0.15 | 2.0400 | 2.1791 | 2.2700 | 1.2901 |

| 0.20 | 2.2531 | 2.3753 | 2.4531 | 2.5102 |

Table 4. Quantitively analysis for Nusselt number and Skin fraction.

| Silver (Ag) | Magnesium oxide MgO | |||

|---|---|---|---|---|

| η | h′(0) | θ′(0) | h′(0) | θ′(0) |

| 0.00 | 1.2724 | 1.6954 | 1.5513 | 1.6582 |

| 0.05 | 1.2921 | 1.4362 | 1.3835 | 1.7734 |

| 0.10 | 1.5139 | 1.2482 | 0.1012 | 1.7622 |

| 0.15 | 0.3612 | 1.7014 | 1.3910 | 2.3684 |

5. Conclusion

In the present study, we numerically scrutinized an unsteady 3D numerical model for Ag-MgO hybrid nanoliquid flow with mass and energy transition caused by the up and downward fluctuation of a wavy gyrating disc. Magnesium oxide and silver nanoparticles have been heavily reported to have broad-spectrum antibacterial operations among metal oxides and metals. However, in current paper, the study’s goal is to increase the rate of thermal energy propagation for a variety of industrial applications. For the purpose, the problem has been formulated as a system of partial differential equations (Navier Stokes and Maxwell). During the study, the following observation have been made:

Silver nanoparticles are without a doubt the most used inorganic nanoparticles, with numerous innovations in biomaterial’s detection and antimicrobial operations.

In comparison to a smooth substrate the wavy spinning surface raises the heat transfer rate by 15%.

Magnesium oxide (MgO) is made up of Mg2+ and O2- ions that are held together by a strong ionic bond. Which can be synthesized at temperatures ranging from 700 0C to 1500 0C degrees Celsius and is primarily used in refractory and electrical applications.

The up and downward fluctuation of the curly spinning disc affects fluid temperature and velocity in a constructive way.

Water’s thermophysical properties are improved by the close bonds between water atoms (H++OH-) and silver ions Ag+.

Hybrid nanoliquids are more effective at overcoming low energy transfer. For example, it improves carrier fluid thermal efficiency, which is essential in power generation, microfabrication, hyperthermia, metallurgical fields and air conditioning.

The parametric continuation method is a strong numerical technique for highly nonlinear system of PDE than others numerical algorithm.

Acknowledgments

The second and third authors would like to acknowledge the support provided by the University of Tabuk. Furthermore, the second author would like to acknowledge the support provided by the Nanotechnology Research Unit (NRU), University of Tabuk, Saudi Arabia.

Data Availability

All the data used are inside the paper.

Funding Statement

This study was funded by the Deanship of Scientific Research at King Khalid University, Abha, Saudi Arabia in the form of a grant to TM (GRP/342/42). Additionally, EA and MA received support from the University of Tabuk and EA received support from the Nanotechnology Research Unit (NRU), University of Tabuk, Saudi Arabia.

References

- 1.Ahmadian A., Bilal M., Khan M. A., & Asjad M. I. (2020). The non-Newtonian maxwell nanofluid flow between two parallel rotating disks under the effects of magnetic field. Scientific Reports, 10(1), 1–14. doi: 10.1038/s41598-019-56847-4 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Chen W., Xu M. L., Li M. F., Wei Z., Cai J., & Chen Y. X. (2020). Quantifying intrinsic kinetics of electrochemical reaction controlled by mass transfer of multiple species under rotating disk electrode configuration. Journal of Electroanalytical Chemistry, 872, 114042. [Google Scholar]

- 3.Tassaddiq A., Khan S., Bilal M., Gul T., Mukhtar S., Shah Z., et al. (2020). Heat and mass transfer together with hybrid nanofluid flow over a rotating disk. AIP Advances, 10(5), 055317. [Google Scholar]

- 4.Mustafa M., Tabassum M., & Rahi M. (2021). Second law analysis of heat transfer in swirling flow of Bingham fluid by a rotating disk subjected to suction effect. Thermal Science, 25(1 Part A), 13–24. [Google Scholar]

- 5.Hafeez A., & Khan M. (2021). Flow of Oldroyd-B fluid caused by a rotating disk featuring the Cattaneo-Christov theory with heat generation/absorption. International Communications in Heat and Mass Transfer, 123, 105179. [Google Scholar]

- 6.Gul T., Bilal M., Alghamdi W., Asjad M. I., & Abdeljawad T. (2021). Hybrid nanofluid flow within the conical gap between the cone and the surface of a rotating disk. Scientific Reports, 11(1), 1–19. doi: 10.1038/s41598-020-79139-8 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Jeon J., Park S., and Lee B. J., “Analysis on the performance of a flatplate volumetric solar collector using blended plasmonic nanofluid,” Solar Energy, vol. 132, pp. 247–256, 2016. [Google Scholar]

- 8.Hussanan A., Salleh M. Z., Khan I., and Shafie S., “Convection heat transfer in micropolar nanofluids with oxide nanoparticles in water, kerosene and engine oil,” Journal of Molecular Liquids, vol. 229, pp. 482–488, 2017. [Google Scholar]

- 9.Ghalambaz M., Doostani A., Izadpanahi E., & Chamkha A. J. (2020). Conjugate natural convection flow of Ag–MgO/water hybrid nanofluid in a square cavity. Journal of Thermal Analysis and Calorimetry, 139(3), 2321–2336. [Google Scholar]

- 10.Motlagh S. Y. and Soltanipour H., “Natural convection of al2o3-water nanofluid in an inclined cavity using buongiorno’s two-phase model,” International Journal of Thermal Sciences, vol. 111, pp. 310–320, 2017. [Google Scholar]

- 11.Acharya N., Bag R., & Kundu P. K. (2019). Influence of Hall current on radiative nanofluid flow over a spinning disk: a hybrid approach. Physica E: Low-dimensional Systems and Nanostructures, 111, 103–112. [Google Scholar]

- 12.Akbar N. S., Raza M. and Ellahi R. (2015). Influence of induced magnetic field and heat flux with the suspension of carbon nano-tubes for the peristaltic flow in a permeable channel. Journal of Magnetism and Magnetic Materials, 381, 405415. [Google Scholar]

- 13.Shah N. A., Animasaun I. L., Chung J. D., Wakif A., Alao F. I., & Raju C. S. K. (2021). Significance of nanoparticle’s radius, heat flux due to concentration gradient, and mass flux due to temperature gradient: The case of Water conveying copper nanoparticles. Scientific Reports, 11(1), 1–11. doi: 10.1038/s41598-020-79139-8 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Sowmya G., Gireesha B. J., Animasaun I. L., & Shah N. A. (2021). Significance of buoyancy and Lorentz forces on water-conveying iron (III) oxide and silver nanoparticles in a rectangular cavity mounted with two heated fins: heat transfer analysis. Journal of Thermal Analysis and Calorimetry, 1–16. [Google Scholar]

- 15.Zhou S. S., Bilal M., Khan M. A., & Muhammad T. (2021). Numerical Analysis of Thermal Radiative Maxwell Nanofluid Flow Over-Stretching Porous Rotating Disk. Micromachines, 12(5), 540. doi: 10.3390/mi12050540 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Patil A. (2016). A Modification and Application of Parametric Continuation Method to Variety of Nonlinear Boundary Value Problems in Applied Mechanics. [Google Scholar]

- 17.Shuaib M., Shah R. A., & Bilal M. (2020). Variable thickness flow over a rotating disk under the influence of variable magnetic field: An application to parametric continuation method. Advances in Mechanical Engineering, 12(6), 1687814020936385. [Google Scholar]

- 18.Shuaib M., Shah R. A., Durrani I., & Bilal M. (2020). Electrokinetic viscous rotating disk flow of Poisson-Nernst-Planck equation for ion transport. Journal of Molecular Liquids, 113412. [Google Scholar]

- 19.Wang Z., Liang S., Molnar C. A., Insperger T., & Stepan G. (2020). Parametric continuation algorithm for time-delay systems and bifurcation caused by multiple characteristic roots. Nonlinear Dynamics, 1–13. [Google Scholar]

- 20.Ahmadian A., Bilal M., Khan M. A., & Asjad M. I. (2020). Numerical analysis of thermal conductive hybrid nanofluid flow over the surface of a wavy spinning disk. Scientific reports, 10(1), 1–13. doi: 10.1038/s41598-019-56847-4 [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Ma Y., Mohebbi R., Rashidi M. M. & Yang Z. MHD convective heat transfer of Ag-MgO/water hybrid nanofluid in a channel with active heaters and coolers. Int. J. Heat Mass Transf. 137, 714–726 (2019). [Google Scholar]

- 22.Shah N. A., Animasaun I. L., Wakif A., Koriko O. K., Sivaraj R., Adegbie K. S., et al. (2020). Significance of suction and dual stretching on the dynamics of various hybrid nanofluids: Comparative analysis between type I and type II models. Physica Scripta, 95(9), 095205. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

All the data used are inside the paper.