Abstract

The rivers in Mumbai are highly polluted with plastic waste and these rivers end up in the Arabian Sea, which brings all this waste back to the land during high tides. This garbage keeps piling up on land and it is difficult to manage this waste. Plastic waste causes harm to wildlife, environment, and human beings. Therefore. it is decided to design a rectangular suspended sea bin with the non-return flaps, facing the waves. The floating garbage that is flowing along the waves will enter the cage through the flaps and thus get trapped. The waves will thus progress without any hinderance due to the cage openings on the rear side. A comprehensive study is done with the weight, center of gravity and metacentric height of a rectangular coastal sea bin (CSB) for different materials. Aluminum is considered as an ideal material for the case study as it is durable, light- weight and non-corrosive. A simulated 3D CSB model with the scale ratio of 1:12.5 is also prepared.

-

•

Plastic waste causes harm to wildlife, environment, and human beings

-

•

A rectangular cage type rectangular coastal see bin (CSB) is designed with the non-return flaps, facing the waves for plastic collection

-

•

A simulated 3D CSB model with the scale ratio of 1:12.5 is also prepared.

Keywords: Aquatic debris, Floating cage, Sea bin, 3D model

Graphical abstract

Specifications table

| Subject Area: | Engineering |

| More specific subject area: | Water Resource Engineering |

| Method name: | Design of rectangular suspended coastal sea bin with the non-return flaps, facing the waves |

| Name and reference of original method: | Sheavly, S. B.; Register, K. M., 2007. Marine Debris & Plastics: Environmental Concerns, Sources, Impacts and Solutions. Journal of Polymers and the Environment. 15 (4), 301–305. Weiss, K.R., 2017.The pileup of plastic debris is more than ugly ocean litter. Knowable Magazine Moore, C.J; Moore, S.L; Leicester, M.K; Weisberg, S.B ,2001. A Comparison of Plastic and Plankton in the North Pacific Central Gyre. Marine Pollution Bulletin. 42 (12), 1297–1300 Jenna R. Jambeck; Roland Geyer; Theodore R. Sieger; Mirium Perryman; Anthony Andrady; Ramani Narayan; Kara Lavender Law, 2015. Plastic waste inputs from land into the ocean. Science. 347(6223),768-771 Simon, Matt. 2019. Ocean Cleanup's New Plastic-Catcher … Kinda Already Exists?. Wired. ISSN 1059-1028 J. Fang and K.V. Wong. 2006. An Advanced VOF Algorithm for Oil Boom Design, Int. J. Model. and Simulation, 26 (1), 36-44 Rafaela, G. Godoy, Marta Angela Marcondes, Rodrigo Pessoa, Andrezza Nascimento, Jefferson Russo victor, Alberto Jose da Silva Duarte, Patricia Bianca Clissa, Sabri Saeed Sanabani. 2020. Bacterial community composition and potential pathogens along the Pinheiros River in the southeast of Brazil. Scientific Reports. 10(9331). |

| Resource availability: | Auto CADD software for simulation, material selected for bin like aluminum, cast iron etc. |

Introduction

In recent times we often hear about plastic waste from all sorts of sources being disposed in the water bodies like rivers, creeks, lakes, which in turn reach the seas and oceans. This is estimated to account for 80% of the marine debris in the oceans. The remaining 20% is attributed to at-sea losses from ocean going vessels, from lost or abandoned fishing gear and from accidental or intentional dumping [1]. Plastic trash can be found floating at the surface, suspended throughout the water column, and residing on the floor of almost all water bodies. It is transported by rivers to the ocean, where it moves with the ocean currents, and persists in that environment for years, breaking down into smaller and smaller pimmeces [2].

Plastic waste has reached all the world's oceans. It is often eaten by birds and fish, concentrating toxic chemicals in their tissues, and filling their stomachs, causing them to starve. Plastic aquatic debris is much more than a mere aesthetic problem [3].

In addition to degrading the habitats and ecosystem services that humans use, plastic aquatic debris can directly interfere with navigation, impede commercial and recreational fishing, threaten health and safety, and reduce tourism. Large debris, such as derelict fishing nets and lines that float at or just below the surface, pose the greatest threat to vessel navigation. Lines and nets can become wrapped around propellers and entrained in intakes of motors, and vessels may strike large items, damaging hulls, and propellers [4].

To address this issue, lot of projects are undertaken worldwide by many countries. Most of these projects are based on fuel and engine mechanism which required constant human effort. These projects have mostly been used in open waters or where the water is deep however less efforts are made to focus on the coastal waters.

The first one is the interceptor [5]. The Interceptor is an autonomous solar powered device that uses a barrier stretching across a river to collect plastic. The trash is passed up a conveyor belt and deposited into bins, which signal to the system when they are full so that a boat can come and pick them up for recycling. The Interceptor can extract 50,000 kilograms of plastic per day. In optimal conditions, up to double this amount can be achieved. The Interceptor can work autonomously until it is full and can continue extracting debris even when the dumpsters are being emptied. Its large storage capacity allows for efficient emptying cycles, filling entire garbage trucks at once. The very first Interceptor, our prototype, is currently deployed in the Cengkareng Drain in Jakarta.

The second one is Mr. Trash Wheel. Mr. Trash Wheel is a sustainably powered trash interceptor invented in Baltimore, Maryland by Clearwater Mills, LLC. The project is run by the Waterfront Partnership of Baltimore's Healthy Harbour Initiative. The fleet of trash-collecting vessels has collected a total 907 tons of rubbish. The vessels are powered by waterwheels and the river's current, with solar panels for backup on slower days. Debris is collected by floating barriers and the wheels power a conveyor belt that transfers the rubbish out of the water and into a bin[5].

The third one is the Floating Boom [6]. The floating boom is called the Tactical Recovery System Hellas, or TRASH, and was manufactured by New Naval. Using technology New Naval developed for responding to oil spills, the mesh barriers collect river plastic and channels it towards a floating cage. This is used to lift the plastic up to the level of the wall so it can be removed.

The fourth one is the Eco boat. The government of the state of Sao Paulo, began the tests with two boats collecting floating waste, known as Eco boats, to assist in the cleaning of the Pinheiro's River [7]. Remediation projects have achieved good results in, but the river waters are still suffering from pollution. Bad smell, garbage accumulation and large numbers of insects are the main consequences of the pollution of the Pinheiro's River, which is in the south and west zones of the city.

From above examples it is clear that various measures are been taken for the removal of marine debris. It is also revealed from the studies that plastic debris need more attention because they cause long life effects on the aquatic life. It is also found that waste on the coasts was more of a secondary problem as compared to the recurring accumulation of waste on the coasts. This issue needs to be addressed by reduction of wastes at source, which is nothing but reduction in waste generation, however this issue is not the one which can be solved in a day it is a cumulative effort of the people as well as the government bodies. It is also necessary to come up with a temporary/permanent solution which can help in curbing this issue.

In this study, methods and equipment designs for cleaning rivers, lakes, creeks, seas, are explored for floating and suspended plastic waste because it does not necessarily need large treatment units thus saving excess land utilization, and this equipment can be transported and put to use at different locations according to the necessity. One 3D floating cage model called as Coastal Sea Bin (CSB) is prepared and its design, utility and implementation are also discussed in this study.

Model development

The plastic waste in the rivers end up in the sea, the sea thus brings back all this waste back to land during high tides. This garbage keeps piling up on land and it keeps getting difficult to manage this waste. The aim of this study is to develop a low energy consuming mechanism which will help in collecting the floating sea garbage in the coastal waters itself. From the previous study, it is observed that all similar projects have electrical equipment and work on battery/ fuel which consumed a considerable amount of energy. Therefore, it is decided that the structure would be a like a cage which would trap the sea waste. Initially it was supposed to be a floating cage which was anchored to the seabed which will help it in maintaining its position in water. It turned out that anchoring the cage to the seabed would not be feasible with waste collection and installation point of view.

This ideology was followed and the concept of a CSB is introduced which would remain suspended in water to collect the waste, this would need a design such that the cage is stable and does not topple due to the wave formations.

Material selection

For this CSB, the density and specific gravity of the material will play an important role to decide the metacentric height of the cage. Materials considered for calculations are Bakelite, PVC (Poly-Vinyl Chloride), Aluminum, High-Density Polyethylene, Cast Iron, Steel and Nylon. A sample material aluminum is considered as the reference material and calculated and designed rectangular cage. Since, aluminum is a very light metal. Its strength can be adapted to the application required by modifying the composition of its alloys.

Rectangular CSB

Based on the information gathered and theory developed, rectangular and semi-circular cross-section of the cage have considered. The metacentric heights for both these cross-sections are calculated and the results are discussed and compared. The only difference in these cross-sections is the shape of the sides.

The rectangular cross-section will be the safest cross-section when it comes to designing a stable and ergonomically structure due to its symmetry in all directions and planes. In this study, rectangular CSB is considered for the simplistic shape and easy installation. It is divided into five simple shapes or objects for ease of calculations, the simple shapes will be as follows. Centroids and center of gravities for each section is calculated. The rectangular CSB is provided with the net only on the rear-side. The sections of rectangular CSB are shown in the Fig. 1.

Fig. 1.

Sections of rectangular CSB.

Working principle

The installation of the rectangular CSB will be just where the waves begin to swell. The principle on which the CSB will work is that the waves will carry along with them the floating sea waste, due to the forces exerted by the wave, there will be pressure created on the flaps which will in turn open in the inward direction. This will lead the entry of the floating sea garbage into the hollow cage, as the wave progresses, so will the garbage, once it comes in contact with the net it will get obstructed and only the water will pass through it.

The size of the rectangular CSB is considered as 5000 mm x 1800 mm x 900 mm. It will be partly submerged in water to allow the aquatic life and the receding wave, if any, to have a safe passage below it. If at all aquatic life is trapped, they have ample of space between the net spacings to escape, but this should not be a problem as the fish in coastal waters are present at greater depths rather than the surface. The volume of the rectangular CSB is given in the Table 1.

Table 1.

Volume of individual portions and the total volume.

| Cross Section | Volume in cubic meter | Total (in cubic meter) | |

|---|---|---|---|

| Rectangle | Front | 0.138 | 0.6382 |

| Side | 0.0556 | ||

| Bottom | 0.174 | ||

| Top | 0.174 | ||

| Back | 0.0966 |

Different types of materials are explored to see the feasibility and comparison so that the best material can be used for the cage. Comparison for these materials is given in Table 2.

Table 2.

Comparative study of various materials for their properties, depth of immersion and metacentric heights.

| Material | Density (kg/m cube) | Weight in (kg) | Height Submerged (M) | Meta Centre (M) |

|---|---|---|---|---|

| PVC Sheets | 1380 | 880.71 | 0.0935 | 11.81 |

| Bakelite | 1350 | 861.57 | 0.0914 | 11.8 |

| Aluminum | 2810 | 1793.34 | 0.19 | 10.136 |

| HDPE | 970 | 619.05 | 0.066 | 11.94 |

| Nylon | 1150 | 733.93 | 0.0779 | 11.91 |

| Cast iron | 7130 | 4548.9 | 0.48 | 8.83 |

| Steel | 8050 | 5135.9 | 0.545 | 8.4 |

Depth of Immersion of Rectangular CSB is found to be equal to 0.196 m and the metacentric heigh is found to be equal to 10.136 m. The schematic representation of the rectangular CSB is shown in Fig. 2, Fig. 3, Fig. 4, Fig. 5, Fig. 6.

Fig. 2.

Rectangular CSB - front view.

Fig. 3.

Rectangular CSB - top view.

Fig. 4.

Rectangular CSB - bottom view.

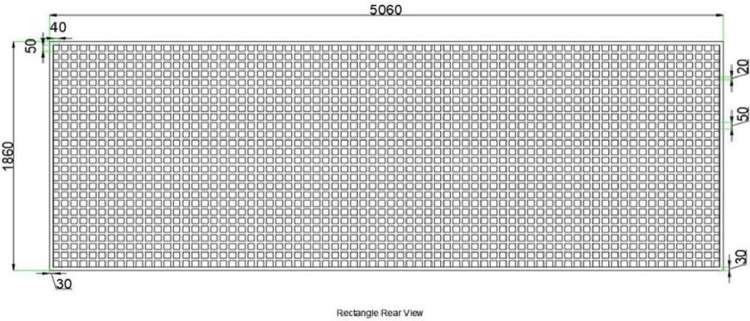

Fig. 5.

Rectangular CSB - rear View.

Fig. 6.

Rectangular CSB - side view.

Non-return flaps

Flaps are installed in front of both the sections of CSB. In total there are eight flaps. Size of flap is 0.9m x 0.45m. Two flaps are provided adjacent to each other, one move clockwise and another move anticlockwise. Distance between two pair of flaps is 0.236m. Flaps are 0.45m above and below of bins and are aligned at center of bin. Flaps are tightly fixed with bin with help of two hinges, one at top and other at bottom. Hinges are 0.1 m above with bottom of flaps and 0.1 m below top of flaps.

Flaps open only in one way i.e., parallel to the horizontal section of bin in inward direction. When wave of force greater than 27.388Kg for rectangular CSB, hit the flaps it will open inward with help of this wave force. Waves bring all the floating materials along with it. When wave hit and open the flaps, materials which wave carry get inside the bin. Hinges used are self-closing hydraulic hinges, therefore after the wave hit the flaps it gets closed automatically, trapping all waste inside the bins. Flaps remain close till the next wave hit the flaps.

Next wave prevents waste material inside the bin to get out, therefore waste is trapped inside bin when flaps are closed as well as when flaps are opened. Material used for flaps will of same material as that of bins i.e., if bins is of aluminum then flaps made are also made of aluminum. A schematic diagram of non-return flaps is given in the Fig. 7.

Fig. 7.

Schematic diagram of non-return flaps for rectangular CSB.

Model construction

Initially, a 3D drawing of different section with help of AutoCAD is made. Each section is drawn separately. A model for rectangular CSB using 3D printing machine with the scale factor of 1:12.5 is also made. The filament used for model is Flash forge – ABS Black. It took fifty hours to print the 3D model. Printed 3D model has fourteen different parts. These fourteen different parts are attached together to get final model of rectangular CSB. The photographs of the model are shown in Fig. 8 and Fig. 9.

Fig. 8.

3D sketches of rectangular CSB (scale factor – 1:12.5).

Fig. 9.

Photographs of the 3D model of rectangular CSB.

When compared with all the materials, it is found that the Aluminum is the most suitable material for rectangular CSB. The tentative cost for the rectangular CSB in the study is found to be equal to INR 4L including material, labor and transportation cost (Fig. 9).

Merits of the CSB

The coastal sea bin will be stationed in the coastal waters where there is natural swelling of water as it is near land. Since it is an immobile equipment, there will not be any power consumption in this method, waste will be collected in the coastal bin because of the natural direction and force of the swelling wave water. It is not entirely in coastal waters the waves will not have completely formed their crescent shape which will invariably lead to uniformity in the opening of the non-return flaps. There will be no harm to the aquatic life and the environment as there will be no emissions of any sort in the water or air.

The CSB is placed partially in water, and it is perforated from the rear side, there is minimum danger to the aquatic life which may happen to get trapped in the cage. CSB is portable and easy to handle. The length of the cage can also be changed as per requirements at the time of manufacturing.

The structure is designed such that it can float in sea water and maintain its equilibrium when approached by swelling waves, however in case of rough winds when the waves tend to be irregular this sea bin can be anchored to the bottom of the sea floor. After extensive literature review, it was found that there has not been a sea water cleaning equipment near the coastal waters due to the action of the waves. However, in a country like India this becomes necessary as the waste disposed via the rivers accumulates back the sea sore due to the action of the waves.

Conclusion

Ocean trash is one of the world's biggest pollution problems. Effects of dumping trash have adverse effects on aquatic life and on human beings. Some of the effects include water pollution, loss in biodiversity, destruction of habitats for water animals, endangerment of species, destruction of coral reefs, effects on aquatic plants, health effects and many more.

In this age where conventional sources of energy are getting scarce, a self-sustaining design which consumed less energy is required. Taking into consideration this perspective a rectangular CSB which is nothing but a cage like structure is introduced in this study. It will have non returning flaps on one side and a net on the opposite side, the non-return flaps will be positioned facing the direction of the waves and thus open inwards due to the wave forces and trap the floating sea garbage which travelled along with the waves. The waves can further progress through the cage openings. A comprehensive and detailed study is done where the different properties of materials were studied. A 3D model with the scale factor of 1:12.5 is made. If it is installed in water just where the waves are about to form, it can easily withstand those wave forces and due to the ergonomically stable design, toppling of the cage is unlikely.

Limitations: The simulation model is prepared with the detailed calculations. But it is not tested for the controlled scenario also.

Supplementary material and/or Additional information: [OPTIONAL. We also give you the option to submit both supplementary material and additional information. Supplementary material relates directly to the work that you have submitted and can include extensive excel tables, raw data etc. We would also encourage you to include failed methods or describe adjustments to your methods that did not work. Additional information can include anything else that is not directly related to your method, e.g. more general background information, useful links etc. Introduction is not a section included in the MethodsX format. This information could be moved to the end under Additional Information.

Acknowledgement

[OPTIONAL. This is where you can acknowledge colleagues who have helped you that are not listed as co-authors, and funding. MethodsX is a community effort, by researchers for researchers. We highly appreciate the work not only of authors submitting, but also of the reviewers who provide valuable input to each submission. We therefore publish a standard "thank you" note in each of the articles to acknowledge the efforts made by the respective reviewers.]

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- 1.Sheavly S.B., Register K.M. Marine Debris & Plastics: Environmental Concerns, Sources, Impacts and Solutions. Journal of Polymers and the Environment. 2007;15(4):301–305. [Google Scholar]

- 2.Weiss K.R. The pileup of plastic debris is more than ugly ocean litter. Knowable Magazine. 2017 [Google Scholar]

- 3.Moore C.J, Leicester M.K., Weisberg S.B. A Comparison of Plastic and Plankton in the North Pacific Central Gyre. Marine Pollution Bulletin. 2001;42(12):1297–3000. doi: 10.1016/s0025-326x(01)00114-x. [DOI] [PubMed] [Google Scholar]

- 4.Jenna R.J., Roland G., Theodore R.S., Mirium P., Anthony A., Ramani N., Kara L. Plastic waste inputs from land into the ocean. Science. 2015;347(6223):768–771. doi: 10.1126/science.1260352. [DOI] [PubMed] [Google Scholar]

- 5.Simon M. Ocean Cleanup’s New Plastic-Catcher … Kinda Already Exists? Wired. 2019 [Google Scholar]

- 6.Fang J., Wong K.V. An Advanced VOF Algorithm for Oil Boom Design. Int. J. Model. and Simulation. 2006;26(1):36–44. [Google Scholar]

- 7.Rafaela G.G., Marta A.M., Rodrigo P., Nascimento A., Victor J.R., Duarte A.J., Clissa P.B., Sabri Saeed Sanabani S.S. Bacterial community composition and potential pathogens along the Pinheiros River in the southeast of Brazil. Scientific Reports. 2020;10(9331) doi: 10.1038/s41598-020-66386-y. [DOI] [PMC free article] [PubMed] [Google Scholar]