Abstract

In accordance with Article 6 of Regulation (EC) No 396/2005, the applicant Syngenta Crop Protection AG submitted a request to the competent national authority in Austria to set an import tolerance for the active substance azoxystrobin in mangoes and oil palm fruits imported from Brazil and Colombia, respectively. The data submitted in support of the request were found to be sufficient to derive maximum residue level (MRL) proposals for mangoes and oil palm fruits. Adequate analytical methods for enforcement are available to control the residues of azoxystrobin on the commodities under consideration at the validated limit of quantification (LOQ) of 0.01 mg/kg. Based on the risk assessment results, noting that an acute risk assessment was not deemed necessary for azoxystrobin, EFSA concluded that the long‐term intake of residues resulting from the uses of azoxystrobin according to the reported agricultural practices is unlikely to present a risk to consumer health.

Keywords: Azoxystrobin, mangoes, oil palm fruits, fungicide, MRL, consumer risk assessment

Summary

In accordance with Article 6 of Regulation (EC) No 396/2005, Syngenta Crop Protection AG submitted an application to the competent national authority in Austria (rapporteur Member State, RMS) to set import tolerances for the active substance azoxystrobin in mangoes and oil palm fruits. The RMS drafted an evaluation report in accordance with Article 8 of Regulation (EC) No 396/2005, which was submitted to the European Commission and forwarded to the European Food Safety Authority (EFSA) on 6 May 2021. The RMS proposed to establish maximum residue levels (MRLs) for mangoes imported from Brazil at the level of 4 mg/kg and for oil palm fruits imported from Colombia at the level of 0.03 mg/kg.

EFSA assessed the application and the evaluation report as required by Article 10 of the MRL regulation.

Based on the conclusions derived by EFSA in the framework of the renewal of approval of the active substance under Directive 91/414/EEC, the data evaluated under previous MRL assessments and the additional data provided by the RMS in the framework of this application, the following conclusions are derived.

The metabolism of azoxystrobin following foliar applications close to harvest was investigated in crops belonging to the group of fruit crops, cereals and pulses/oilseeds. Studies investigating the effect of processing on the nature of azoxystrobin (hydrolysis studies) demonstrated that azoxystrobin is stable. In rotational crops, the major residue identified was the parent compound. As the proposed uses of azoxystrobin are on imported commodities from permanently grown crops, investigations of residues in rotational crops are not required.

Based on the metabolic pattern identified in metabolism studies and on the results of hydrolysis studies, the residue definition for enforcement and risk assessment in all plant commodities following foliar application was proposed as ‘azoxystrobin’. This residue definition is also deemed appropriate for the post‐harvest use on mangoes.

EFSA concluded that for the crops assessed in this application, the metabolism of azoxystrobin and the possible degradation in processed products has been sufficiently addressed and that the previously derived residue definitions are applicable.

Sufficiently validated analytical methods based on high‐performance liquid chromatography with tandem mass spectroscopy (HPLC‐MS/MS) are available to quantify residues in the crops assessed in this application according to the enforcement residue definition. The methods enable quantification of residues at or above 0.01 mg/kg in the crops assessed (LOQ).

The available residue trials are sufficient to derive MRL proposals of 4 mg/kg for mangoes and of 0.03 mg/kg for oil palm fruits.

A peeling factor for mangoes was derived from residues in whole fruits and pulps after post‐harvest use and it is recommended to be included in Annex VI of Regulation (EC) No 396/2005 as follows:

-

–

mangoes, peeling factor: 0.02

Kernel meal derived from imported oil palm fruits cannot be excluded to be used for feed purposes. A potential carry‐over into food of animal origin was assessed. The calculated livestock dietary burden exceeded the trigger value of 0.1 mg/kg dry matter (DM) for all animal species. However, the contribution of azoxystrobin residues in the by‐product under consideration in this MRL application to the total livestock exposure was insignificant and the calculated livestock dietary burden resulted to be the same as in the previous assessment. Therefore, a modification of the existing MRLs for commodities of animal origin was considered unnecessary and the conclusion reached in the framework of the MRL review confirmatory data assessment remains valid.

The toxicological profile of azoxystrobin was assessed in the framework of the EU pesticides peer review and the data were sufficient to derive an acceptable daily intake (ADI) of 0.2 mg/kg body weight (bw) per day. An acute reference dose (ARfD) was deemed unnecessary.

The consumer risk assessment was performed with revision 3.1 of the EFSA Pesticide Residues Intake Model (PRIMo). The estimated chronic exposures were compared with the ADI of azoxystrobin. The estimated long‐term dietary intake was up to 22% of the ADI (Dutch toddler). The contribution of residues expected in the mangoes does not exceed 0.01% of the ADI (IE, adult) and that in oil palm fruits remains below 0.004% of the ADI (Dutch child). A short‐term (acute) risk assessment was not required since no ARfD has been considered necessary for azoxystrobin.

EFSA concluded that the reported uses of azoxystrobin on mangoes and oil palm fruits will not result in a consumer exposure exceeding the toxicological reference value, and therefore, it is unlikely to pose a risk to consumers’ health.

EFSA proposes to amend the existing MRLs as reported in the summary table below.

Full details of all end points and the consumer risk assessment can be found in Appendices B–D.

| Codea | Commodity | Existing EU MRL (mg/kg) | Proposed EU MRL (mg/kg) | Comment/justification |

|---|---|---|---|---|

| Enforcement residue definition: Azoxystrobin | ||||

| 0163030 | Mangoes | 0.7 | 4 | The submitted data are sufficient to derive an import tolerance (Brazilian GAP). Risk for consumers unlikely. MRL set in the country of origin for the post‐harvest use is 6 mg/kg. |

| 0402030 | Oil palms fruits | 0.01* | 0.03 | The submitted data are sufficient to derive an import tolerance (Colombian GAP). Risk for consumers unlikely. |

MRL: maximum residue level; NEU: northern Europe; SEU: southern Europe; GAP: Good Agricultural Practice.

Indicates that the MRL is set at the limit of analytical quantification (LOQ).

Commodity code number according to Annex I of Regulation (EC) No 396/2005.

Assessment

The European Food Safety Authority (EFSA) received an application to set an import tolerance for the active substance azoxystrobin in mango and oil palm fruits. The detailed description of the existing uses of azoxystrobin authorised in Brazil in mangoes and in Colombia in oil palm fruits, which are the basis for the current MRL application, are reported in Appendix A.

Azoxystrobin is the ISO common name for methyl (2E)‐2‐(2‐{[6‐(2‐cyanophenoxy)pyrimidin‐4‐yl]oxy}phenyl)‐3‐methoxyacrylate (IUPAC). The chemical structures of the active substance and its main metabolites are reported in Appendix E.

Azoxystrobin was evaluated for renewal of the approval in the framework of Directive 91/414/EEC1 with United Kingdom designated as rapporteur Member State (RMS) for the representative uses as a foliar treatment on cereals and brassica vegetables. The renewal assessment report (RAR) prepared by the RMS has been peer reviewed by EFSA (EFSA, 2010). The decision on the renewal of azoxystrobin entered into force on 1 January 2012. The approval is restricted to uses as fungicide only.

The EU MRLs for azoxystrobin are established in Annexes II of Regulation (EC) No 396/20052. The review of existing MRLs according to Article 12 of Regulation (EC) No 396/2005 (MRL review) has been performed (EFSA, 2013) and the proposed modifications have been implemented in the MRL legislation. After completion of the MRL review, EFSA has issued several reasoned opinions on the modification of MRLs for azoxystrobin. The proposals from these reasoned opinions have been considered in recent MRL regulation(s). Also certain Codex maximum residue limits (CXLs) have been taken over in the EU MRL legislation.3

In accordance with Article 6 of Regulation (EC) No 396/2005, Syngenta Crop Protection AG submitted an application to the competent national authority in Austria (newly appointed rapporteur Member State, RMS) to set import tolerances for the active substance azoxystrobin in mangoes and oil palm fruits. The RMS drafted an evaluation report in accordance with Article 8 of Regulation (EC) No 396/2005, which was submitted to the European Commission and forwarded to the EFSA on 6 May 2021. The RMS proposed to establish maximum residue levels (MRLs) for mango imported from Brazil at the level of 4 mg/kg and for oil palm fruits imported from Colombia at the level of 0.03 mg/kg.

EFSA based its assessment on the evaluation report submitted by the EMS (Austria, 2021), the renewal assessment report (RAR) (and its addendum) (United Kingdom, 2009a,b) prepared under Directive 91/414/EEC, the Commission review report on azoxystrobin (European Commission, 2015), the conclusion on the peer review of the pesticide risk assessment of the active substance azoxystrobin (EFSA, 2010), the reasoned opinion on the MRL review according to Article 12 of Regulation (EC) No 396/2005 (EFSA, 2013), as well as the conclusions from previous EFSA opinions on azoxystrobin (EFSA, 2016a,b, 2020, 2021).

For this application, the data requirements established in Regulation (EU) No 544/20114 and the guidance documents applicable at the date of submission of the application to the RMS are applicable (European Commission, 1996, 1997a, 1997b, 1997c, 1997d, 1997e, 1997f, 1997g, 2010, 2017, 2020, 2021; OECD, 2011, 2013). The assessment is performed in accordance with the legal provisions of the Uniform Principles for the Evaluation and the Authorisation of Plant Protection Products adopted by Commission Regulation (EU) No 546/20115.

A selected list of end points of the studies assessed by EFSA in the framework of this MRL application including the end points of relevant studies assessed previously is presented in Appendix B.

The evaluation report submitted by the RMS (Austria, 2021) and the exposure calculations using the EFSA Pesticide Residues Intake Model (PRIMo) are considered as supporting documents to this reasoned opinion and, thus, are made publicly available as background documents to this reasoned opinion.

1. Residues in plants

1.1. Nature of residues and methods of analysis in plants

1.1.1. Nature of residues in primary crops

The metabolism of azoxystrobin in primary crops belonging to the groups of fruit crops (grapes), cereals/grass (wheat) and pulses/oilseeds (peanuts) has been investigated in the framework of the EU pesticides peer review (EFSA, 2010). All metabolism studies assessed in this framework were performed with foliar applications.

The metabolism pattern was similar in all plant groups with the parent azoxystrobin being the major compound, accounting for 17–43% total radioactive residue (TRR) in cereal grain and straw, 35–65% TRR in grapes and 14–48% TRR in peanut hulls and hay. Consequently, the residue definition for enforcement and risk assessment in all plant commodities following foliar application was proposed as azoxystrobin (EFSA, 2010, 2013).

The uses under assessment in the present opinion are a foliar use on palm oil fruits and a combined foliar and subsequent post‐harvest treatment on mangoes. It is to be noted that no studies investigating the metabolism of azoxystrobin following post‐harvest treatment are available. Considering that azoxystrobin was applied close to harvest in the foliar metabolism studies when the mature commodity was present at application, the MRL review (EFSA, 2013) considered that the results of the available studies cover the post‐harvest good agricultural practices (GAPs).

Therefore, for the intended uses, the metabolic behaviour in primary crops is sufficiently addressed and further data were not required for the intended uses.

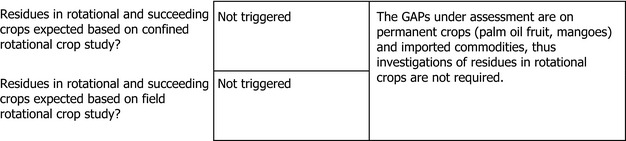

1.1.2. Nature of residues in rotational crops

As the uses under assessment are on permanent crops and represent applications for imported commodities, investigations of residues in rotational crops are not required.

1.1.3. Nature of residues in processed commodities

The effect of processing on the nature of azoxystrobin was investigated in the framework of the EU pesticides peer review (EFSA, 2010). These studies showed that azoxystrobin is hydrolytically stable under standard processing conditions.

1.1.4. Methods of analysis in plants

Analytical methods for the determination of azoxystrobin residues in plant commodities were assessed during the EU pesticides peer review and during the MRL review of azoxystrobin (EFSA, 2010, 2013).

An analytical method using high‐performance liquid chromatography with tandem mass spectrometry detection (HPLC‐MS/MS) was concluded to be sufficiently validated for the determination of azoxystrobin in dry, high acid‐, high water‐ and high oil‐content matrices and hops, with a limit of quantification (LOQ) of 0.01 mg/kg (EFSA, 2010, 2013).

In this application, a comprehensive cross‐validation study was provided to assess extraction efficiency for representatives from each major crop group and a difficult matrix (hops) by using three solvent systems, namely that of the QuEChERS method, the methods used for enforcement and for the residue trials and the method from the metabolism studies. Extraction efficiency when using the solvents of all four methods in the new study ranged between 90% and 103% for the major crop groups (Austria, 2021).

With reference to the guidance on extraction efficiency (European Commission, 2017) and considering the crops under assessment, it has to be noted that mangoes and oil palm fruits are representatives for the metabolism group of ‘fruits and fruiting vegetables’ whereby they represent ‘high‐water content’ and ‘high oil content commodity’, respectively, regarding the analytical methods. The summary table of available primary crop metabolism studies in the evaluation report which details the total radioactive residues and the extractable radioactive residues from the metabolism data provide the information for pulses/oilseeds and cereals, however, does not include a fruit crop. Furthermore, the specific %TRR of parent azoxystrobin in the various solvents seems not to be reported (Austria, 2021).

It can be concluded from the available data that extraction efficiency for the crops under assessment is partially demonstrated. EFSA, therefore, recommends reconsidering this further in the framework of the peer review for the renewal of approval of the active substance.

Additionally, in this application, the results of the validation of the multi‐residue analytical method DFG S19 using HPLC‐MS/MS and its ILV were provided. The LOQ of 0.01 mg/kg for the determination of residues of azoxystrobin was validated in high water content, high acid content, high oil content and dry/high starch content commodities (Austria, 2021).

The crops under consideration belong to the high‐water and high‐oil content commodity groups, and sufficiently validated analytical methods are available to control azoxystrobin residues in palm oil fruits and mangoes. New data submitted in the current MRL application have been assessed by the RMS and confirm this conclusion (Austria, 2021).

1.1.5. Storage stability of residues in plants

The storage stability of azoxystrobin in plants stored under frozen conditions was investigated in the framework of the EU pesticides peer review and the MRL review (EFSA, 2010, 2013).

The MRL review referred to the assessment of the peer review where storage stability of azoxystrobin was demonstrated for a period of 24 months at –18°C in commodities with high water content (bananas, peaches, tomatoes, cucumbers, lettuces, carrots) and high oil content (soybean meal, oilseed rape, pecan, peanuts) commodities (EFSA, 2013).

This result also applies to the crops assessed in the framework of this application.

1.1.6. Proposed residue definitions

Based on the metabolic pattern identified in metabolism studies and on the results of hydrolysis studies, the residue definition for enforcement and risk assessment in all plant commodities following foliar application was proposed as azoxystrobin (EFSA, 2010, 2013).

The residue definition for enforcement set in Regulation (EC) No 396/2005 is identical with the above‐mentioned residue definition.

Although the available metabolism studies were all performed with foliar applications and the residue definitions are therefore applicable for the foliar use on oil palm fruits, EFSA concluded that the results of the metabolism studies considering foliar application close to harvest also cover post‐harvest uses (EFSA, 2013). Therefore, these residue definitions are deemed appropriate for the post‐harvest use on mangoes too.

1.2. Magnitude of residues in plants

1.2.1. Magnitude of residues in primary crops

In support of the authorised uses in Brazil and Colombia, the applicant submitted residue trials on mangoes and palm oil fruits. The samples were analysed for the parent compound according to the residue definitions for enforcement and risk assessment.

According to the assessment of the RMS, the analytical methods used were sufficiently validated and fit for purpose (Austria, 2021).

According to the RMS, extraction efficacy of the HPLC‐MS/MS method used for the residue trials has been assessed (see also Section 1.1.4) (Austria, 2021).

The samples of these residue trials were stored under conditions for which integrity of the samples has been demonstrated.

Mangoes

In support of the import tolerance application, the applicant submitted four residue trials performed on mangoes. All trials were performed in Brazil during the growing season of 2020, in accordance with the two authorised GAPs, each of which represents a combination of a foliar use with a post‐harvest treatment (broadcast foliar treatment combined after 7 days from harvest of the fruits with either post‐harvest dip or post‐harvest spray treatment).

Mango fruit samples were collected from the field at a PHI of 7 days after the last of four foliar applications (to the critical foliar GAP for mangoes of 4 × 120 g a.i./ha) and subsequently either subjected to a dip or spray post‐harvest treatment with a suspension concentrate formulation nominally containing 239 g azoxystrobin/L of formulated product (Austria, 2021).

The single dip or the single spray post‐harvest application was compliant with the maximum nominal concentration of 120 g/hL of the reported GAP. Following post‐harvest treatments, mango fruits were collected at 0, 21 and 42 days. The whole samples were separated into peel and pulp fractions after removal of the stones (Austria, 2021).

It is noted that mango is a minor crop worldwide and that a minimum of four trials are required for post‐harvest treatments according to the guidance document SANTE/2019/12752 (European Commission, 2020). Therefore, the four trials submitted to support the combined foliar plus post‐harvest GAPs were considered as sufficient.

Regardless to the type of post‐harvest application, dip or spray, residues in treated fruits were on the same range. EFSA concludes that an MRL proposal of 4 mg/kg can be derived for the authorised combined foliar and post‐harvest uses of azoxystrobin on mango fruits based on the provided trials. The tolerance established for azoxystrobin in Brazil6 for foliar or post‐harvest uses on mangoes is 6 mg/kg.

Oil palm fruits

In support of the authorised outdoor foliar GAP on oil palm fruits, five trials were performed on oil palm trees in Colombia during the 2018 growing season. All trials were performed with six instead of five applications which was considered as a deviation within acceptable tolerance (± 25%) by the RMS (Austria, 2021).

EFSA concludes that the available trials are sufficient to derive an MRL proposal of 0.03 mg/kg on oil palm fruits for the use reported in the product label in Colombia. Information on an MRL set for azoxystrobin on oil palm fruits established in Colombia is not set.

1.2.2. Magnitude of residues in rotational crops

As the use under assessment is an import tolerance application on permanent crops (mangoes and oil palm tree), investigations of residues in rotational crops are not required.

1.2.3. Magnitude of residues in processed commodities

As residues of azoxystrobin exceeding 0.1 mg/kg in oil palm fruits are not expected, and a chronic exposure does not exceed 10% of the ADI in mangoes, investigations on the effect of industrial processing are in principal not required (European Commission, 1997d).

Nevertheless, two processing studies in treated palm oil fruits demonstrated that processing to mesocarp meal and mesocarp oil leads to a concentration of residues whereby processing to kernel meal and kernel oil leads to a reduction of residues (Austria, 2021). For mesocarp meal, a high variability of individual processing factors is observed (Table B.1.2.3). Anyway, the number of processing studies is insufficient to derive robust processing factors recommended to be included in Annex VI of Regulation (EC) No 396/2005. If risk managers wish to derive robust processing factors, which allow enforcement of azoxystrobin residues in oil palm fruit processed products, further processing trials would be required.

For mangoes, the separation of fruits into peel and pulp allowed derivation of an overall peeling factor of 0.02 for the post‐harvest treatment, regardless from the tested withholding period of day 0, 21 and 42, from the four submitted residue trials (see Table B.1.2.3). The quality of the processing studies is acceptable, and the number of trials is sufficient to derive a robust peeling factor which is recommended for inclusion in Annex VI of Regulation (EC) No 396/2005.

1.2.4. Proposed MRLs

The available data are considered sufficient to derive MRL proposals as well as risk assessment values for oil palm fruits and mangoes imported from Colombia and Brazil, respectively (see Appendix B.1.2.1).

In Section B.1.2.1, EFSA assessed whether residues in mangoes and oil palm fruit resulting from the uses authorised in Brazil and Colombia are likely to pose a consumer health risk.

2. Residues in livestock

Kernel meal derived from imported oil palm fruits cannot be excluded to be used for feed purposes. Hence, it was necessary to update the previous dietary burden calculation for livestock to estimate whether the import tolerance under evaluation would have an impact on the residues expected in food of animal origin (Austria, 2021).

EFSA updated the calculations performed in the previous assessment (EFSA, 2021), adding the input values for palm kernel meal. As the indicative PF derived for this processed commodity indicate a reduction of azoxystrobin concentrations in palm kernel meal, the default processing factor for this by‐product was replaced in the calculations by a tentative PF of 0.3 (see Section B.1.2.3).

The input values for the exposure calculations for livestock are presented in Appendix D.1. The results of the dietary burden calculation are presented in Section B.2.

The calculated dietary burden resulted to be the same as in the assessment of the MRL review confirmatory data and a previous import tolerance application on sugar beets (EFSA, 2020, 2021). Consequently, a change of the existing MRLs in products of animal origin is not necessary and the conclusion of the article 12 confirmatory data assessment remains valid.

The applicant has submitted the result of the validation for an alternative analytical method (RAM 399/01 using HPLC‐MS/MS). The method is sufficiently validated on milk, eggs, muscle, fat, kidney and liver to an LOQ of 0.01 mg/kg. An ILV is also available. The validation of multi‐residue analytical method DFG S19 has been proven a not suitable method for the determination of residues of azoxystrobin in animal (Austria, 2021).

3. Consumer risk assessment

The toxicological reference value for acceptable daily intake (ADI) of 0.2 mg/kg bw per day assessed in the framework of the EU pesticides peer review is applicable. The derivation of an acute reference dose (ARfD) was considered not necessary (European Commission, 2015).

In the framework of the assessment of confirmatory data following the MRL review (EFSA, 2020, 2021) a comprehensive consumer risk assessment for azoxystrobin was performed by EFSA taking into account the input values previously considered for the consumer risk assessment of azoxystrobin, the updated risk assessment values assessed as confirmatory data (for lettuces and other salad plants) and the safe CXLs and their associated risk assessment values (for prickly pears/cactus fruits and sugarcane; FAO, 2017). This consumer risk assessment was performed with the most recent version of the EFSA Pesticide Residues Intake Model (PRIMo Rev. 3.1) (EFSA, 2018, 2019).

This previous consumer risk assessment was updated in the context of an import tolerance application on sugar beet (EFSA, 2021) and is now revised considering the risk assessment values derived from the residue trials submitted in support of this MRL import tolerance application for mangoes and oil palm fruits. The input values used to perform the consumer risk assessment are reported in Appendix D.2.

The estimated chronic exposures were compared with the ADI of azoxystrobin. The outcome of the calculations is reported in Appendix B.3. The estimated long‐term dietary intake was up to 22% of the ADI (Dutch toddler). The contribution of residues expected in mangoes (intended import tolerance) to the overall long‐term exposure does not exceed 0.01% of the ADI (IE, adult) and that in oil palm fruits (intended import tolerance) remains below 0.004% of the ADI (Dutch child). More details of the contribution of the residues are included in Appendix B.3. A short‐term (acute) risk assessment was not required since no ARfD has been considered necessary for azoxystrobin.

EFSA concluded that the consumer intake of residues of azoxystrobin resulting from the existing uses and the import of commodities resulting from the authorised use on mangoes in Brazil and oil palm fruits in Colombia are unlikely to present a risk to consumer health.

It is noted that the uncertainty in the consumer risk assessment related to the calculated consumer exposure to livestock metabolites L1, L4, L9 and K1 (conjugate of L1) highlighted in the framework of the MRL review of the confirmatory data is still valid (EFSA, 2020, 2021).

For further details on the exposure calculations, a screenshot of the report sheet of the PRIMo is presented in Appendix C.

4. Conclusion and Recommendations

The data submitted in support of this MRL application were found to be sufficient to derive an MRL proposal for mangoes and oil palm fruits imported from Brazil and Colombia, respectively.

EFSA concluded that the notified uses (import tolerances) of azoxystrobin in mangoes and oil palm fruits will not result in a consumer exposure exceeding the toxicological reference value and therefore is unlikely to pose a risk to consumers’ health.

The MRL recommendations are summarised in Appendix B.4.

Abbreviations

- a.s.

active substance

- ADI

acceptable daily intake

- ARfD

acute reference dose

- BBCH

growth stages of mono‐ and dicotyledonous plants

- bw

body weight

- CAS

Chemical Abstract Service

- CF

conversion factor for enforcement to risk assessment residue definition

- CS

capsule suspension

- CV

coefficient of variation (relative standard deviation)

- CXL

Codex maximum residue limit

- DAR

draft assessment report

- DAT

days after treatment

- DM

dry matter

- DP

dustable powder

- DS

powder for dry seed treatment

- EC

emulsifiable concentrate

- EDI

estimated daily intake

- EMS

evaluating Member State

- FAO

Food and Agriculture Organization of the United Nations

- FID

flame ionisation detector

- GAP

Good Agricultural Practice

- GC

gas chromatography

- GC‐FID

gas chromatography with flame ionisation detector

- GC‐MS

gas chromatography with mass spectrometry

- GC‐MS/MS

gas chromatography with tandem mass spectrometry

- GC‐NPD

gas chromatography with nitrogen/phosphorous detector

- GS

growth stage

- HPLC

high performance liquid chromatography

- HPLC‐MS

high performance liquid chromatography with mass spectrometry

- HPLC‐MS/MS

high performance liquid chromatography with tandem mass spectrometry

- HR

highest residue

- IEDI

international estimated daily intake

- IESTI

international estimated short‐term intake

- ILV

independent laboratory validation

- ISO

International Organisation for Standardisation

- IUPAC

International Union of Pure and Applied Chemistry

- LC

liquid chromatography

- MRL

maximum residue level

- MS

Member States

- MS

mass spectrometry detector

- MS/MS

tandem mass spectrometry detector

- MW

molecular weight

- NEU

northern Europe

- NPD

nitrogen/phosphorous detector

- OECD

Organisation for Economic Co‐operation and Development

- PBI

plant back interval

- PF

processing factor

- PHI

preharvest interval

- PRIMo

EFSA) Pesticide Residues Intake Model

- QuEChERS

Quick, Easy, Cheap, Effective, Rugged, and Safe (analytical method)

- RA

risk assessment

- RAC

raw agricultural commodity

- RD

residue definition

- RMS

rapporteur Member State

- SANCO

Directorate‐General for Health and Consumers

- SC

suspension concentrate

- SEU

southern Europe

- SL

soluble concentrate

- SP

water‐soluble powder

- STMR

supervised trials median residue

- TAR

total applied radioactivity

- TRR

total radioactive residue

- UV

ultraviolet (detector)

- WHO

World Health Organization

Appendix A – Summary of intended GAP triggering the amendment of existing EU MRLs

1.

| Crop and/or situation | NEU, SEU, MS or country | F G or Ia | Pests or group of pests controlled | Preparation | Application | Application rate per treatment | PHI (days)d | Remarks | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Typeb | Conc. a.s. | Method kind | Range of growth stages and seasonc | Number min–max | Interval between application (days) min–max | g a.s./hL min–max | Water (L/ha) min–max | Rate min–max | Unit | ||||||

| Oil palm fruit | Colombia | F | Bud rot of palms (Phytophthora palmivora) | SE | 322 g/L | Foliar treatment – broadcast spraying | – | 5 | 28 | – | – | 64.4 | g a.i./ha | 60 | 200 mL product/ha with application volume of 300 mL of water per palm, targeted at two points on buds |

| Mango | Brazil | F+I | Anthracnose (Colletotrichum gloeosporioides) | SC | 200 g/L + 239 g/L | Foliar spraying + Post‐harvest dip | – | 4 + 1 | 14 (field use) | 6–20e | 600–1,000 | 60–120 + 60–120 | g a.s/ha g a.s./hL | 0 Po‐use | Combined foliar and post‐harvest use. Fruits shall be harvested with a PHI of 7 days prior to the Po‐use. |

| Mango | Brazil | F+I | Anthracnose (Colletotrichum gloeosporioides) | SC | 200 g/L + 239 g/L | Foliar spraying + Post harvest Spray | – | 4 + 1 | 14 (field use) | 6–20e | 600–1,000 | 60–120 + 60‐120 | g a.s./ha g a.s./hL | 0 Po‐use | |

MRL: maximum residue level; GAP: Good Agricultural Practice; NEU: northern European Union; SEU: southern European Union; MS: Member State; a.s.: active substance; xx: formulation type.

Outdoor or field use (F), greenhouse application (G) or indoor application (I).

CropLife International Technical Monograph no 2, 7th Edition. Revised March 2017. Catalogue of pesticide formulation types and international coding system.

Growth stage range from first to last treatment (BBCH Monograph, Growth Stages of Plants, 1997, Blackwell, ISBN 3‐8263‐3152‐4), including, where relevant, information on season at time of application.

PHI – minimum preharvest interval.

Calculated based on the GAP spray volume range of 600–1000 L/ha.

Appendix B – List of end points

B.1. Residues in plants

B.1.1. Nature of residues and methods of analysis in plants

B.1.1.1. Metabolism studies, methods of analysis and residue definitions in plants

| Primary crops (available studies) | Crop groups | Crop(s) | Application(s) | Sampling (DAT) | Comment/Source |

|---|---|---|---|---|---|

| Fruit crops | Grapes | Foliar: 250 + 1,000 + 1,000 + 250 g/ha | 21 | Radiolabelled azoxystrobin: 14C‐pyrimidinyl 14C‐cyanophenyl 14C‐phenylacrylate EFSA (2010) | |

| Cereals/grass | Wheat | Foliar: 2 × 500 g/ha; BBCH 30‐31 and 59‐61 | Forage: 13 Grain, straw: 61‐62 | Radiolabelled azoxystrobin: 14C‐pyrimidinyl 14C‐cyanophenyl 14C‐phenylacrylate EFSA (2010) | |

| Foliar: 1 × unknown; BBCH 71 | 28 | Radiolabelled azoxystrobin: 14C‐pyrimidinyl EFSA (2010) | |||

| Pulses/oilseeds | Peanuts | Foliar: 850 + 850 + 300 g/ha | 10 | Radiolabelled azoxystrobin: 14C‐pyrimidinyl 14C‐cyanophenyl 14C‐phenylacrylate EFSA (2010) |

| Rotational crops (available studies) | Crop groups | Crop(s) | Application(s) | PBI (DAT) | Comment/Source |

|---|---|---|---|---|---|

| Root/tuber crops | Radish | Bare soil: 2.2 kg/ha | 30, 200, 365 | Radiolabelled azoxystrobin: 14C‐pyrimidinyl 14C‐cyanophenyl 14C‐phenylacrylate EFSA (2010) | |

| Leafy crops | Lettuce | ||||

| Cereal (small grain) | Wheat |

| Processed commodities (hydrolysis study) | Conditions | Stable? | Comment/Source |

|---|---|---|---|

| Pasteurisation (20 min, 90°C, pH 4) | Yes | EFSA (2010) | |

| Baking, brewing and boiling (60 min, 100°C, pH 5) | Yes | ||

| Sterilisation (20 min, 120°C, pH 6) | Yes |

B.1.1.2. Stability of residues in plants

| Plant products (available studies) | Category | Commodity | T (°C) | Stability period | Compounds covered | Comment/Source | |

|---|---|---|---|---|---|---|---|

| Value | Unit | ||||||

| High water content | Bananas | –18 | 24 | Months | Azoxystrobin | EFSA (2010) | |

| Peaches | –18 | 24 | Months | Azoxystrobin | EFSA (2010) | ||

| Tomatoes | –18 | 24 | Months | Azoxystrobin | EFSA (2010) | ||

| Cucumbers | –18 | 24 | Months | Azoxystrobin | EFSA (2010) | ||

| Lettuces | –18 | 24 | Months | Azoxystrobin | EFSA (2010) | ||

| Carrots | –18 | 24 | Months | Azoxystrobin | EFSA (2010) | ||

| High oil content | Oilseed rape | –18 | 24 | Months | Azoxystrobin | EFSA (2010) | |

| Pecan | –18 | 24 | Months | Azoxystrobin | EFSA (2010) | ||

| Peanuts | –18 | 24 | Months | Azoxystrobin | EFSA (2010) | ||

| Dry/High starch | Cereal grain | –18 | 24 | Months | Azoxystrobin | EFSA (2010) | |

| High acid content | Grapes | –18 | 24 | Months | Azoxystrobin | EFSA (2010) | |

| Apples | –18 | 24 | Months | Azoxystrobin | EFSA (2010) | ||

| Oranges | –18 | 24 | Months | Azoxystrobin | EFSA (2010) | ||

| Others | Cereal straw | –18 | 24 | Months | Azoxystrobin | EFSA (2010) | |

B.1.2. Magnitude of residues in plants

B.1.2.1. Summary of residues data from the supervised residue trials

| Commodity | Region/a | Residue levels observed in the supervised residue trials (mg/kg) | Comments/Source | Calculated MRL (mg/kg) | HRb (mg/kg) | STMRc (mg/kg) | CFd |

|---|---|---|---|---|---|---|---|

| Oil palm fruits | CO | 3 × < 0.010; 0.011; 0.018 | Residue trials on oil palm fruits performed with six instead of five applications. This is considered acceptable based on 25% tolerance (and considering that the 1st application is expected to have less impact on the final residue) Austria (2021). | 0.03 | 0.018 | 0.010 | n/a |

| Mangoes | BR | Mo: 1.66; 2.16; 2.31; 2.54 | Residue trials on mangoes compliant with GAP (Foliar spray and post‐harvest spray). MRL proposal based on the mean residue + 4 × SD (EFSA, 2015)7 | 4.0 | 2.54 | 2.24 | n/a |

| BR | Mo: 1.67; 1.93; 2.11; 2.67 | Residue trials on mangoes compliant with GAP (Foliar spray and post‐harvest dip). MRL proposal based on the mean residue + 4 × SD (EFSA, 2015)7 | 4.0 | 2.67 | 2.02 | n/a |

MRL: maximum residue level; GAP: Good Agricultural Practice; Mo: monitoring; RA: risk assessment.

Indicates that the MRL is proposed at the limit of quantification.

NEU: Outdoor trials conducted in northern Europe, SEU: Outdoor trials conducted in southern Europe, EU: indoor EU trials or Country code: if non‐EU trials. CO: Columbia; BR. Brazil.

Highest residue. The highest residue for risk assessment refers to the whole commodity and not to the edible portion.

Supervised trials median residue. The median residue for risk assessment refers to the whole commodity and not to the edible portion.

Conversion factor to recalculate residues according to the residue definition for monitoring to the residue definition for risk assessment.

B.1.2.2. Residues in rotational crops

B.1.2.3. Processing factors

| Processed commodity | Number of valid studiesa | Processing Factor (PF) | CFP b | Comment/Source | |

|---|---|---|---|---|---|

| Individual values | Median PF | ||||

| Oil palm fruit, mesocarp meal | 2 | 0.083, 2.12 | 1.5 | 1 | Tentativec Austria (2021) |

| Oil palm fruit, mesocarp oil | 2 | 1.43, 2.84 | 2.1 | 1 | |

| Oil palm fruit, kernel meal | 2 | 0.23, 0.28 | 0.3 | 1 | |

| Oil palm fruit, kernel oil | 2 | 0.23, 0.28 | 0.3 | 1 | |

| Mango, peeled (whole fruit to pulpd) at day of dip post‐harvest treatment | 4 | 0.005; 0.01; 0.036; 0.036 | 0.02 | 1 | Residues in the pulp following the foliar applications at PHI of 7 where always < LOQ of 0.01 mg/kg (Austria, 2021) |

| Mango, peeled (whole fruit to pulpd) at day of spray post‐harvest treatment | 4 | 0.004; 0.006; 0.017; 0.019 | 0.01 | 1 | |

| Mango, peeled (whole fruit to pulpd) 21 days after dip post‐harvest treatment | 4 | 0.01; 0.013; 0.017; 0.036 | 0.02 | 1 | |

| Mango, peeled (whole fruit to pulpd) 21 days after spray post‐harvest treatment | 4 | 0.008; 0.01; 0.022; 0.03 | 0.02 | 1 | |

| Mango, peeled (whole fruit to pulpd) 42 days after dip post‐harvest treatment | 4 | 0.0037; 0.011; 0.023; 0.027 | 0.02 | 1 | |

| Mango, peeled (whole fruit to pulpd) 42 days after spray post‐harvest treatment | 4 | 0.007; 0.01; 0.0144; 0.024; | 0.01 | 1 | |

PF: processing factor.

Studies with residues in the RAC at or close to the LOQ were disregarded (unless concentration may occur).

Conversion factor for risk assessment in the processed commodity is not applicable.

A tentative PF is derived based on a limited data set.

The individual peeling factors represent a mean of two measurements of residues ranging from the LOQ of 0.01 mg/kg up to 0.07 mg/kg.

B.2. Residues in livestock

Dietary burden calculation according to OECD, 2013.

| Relevant groups (subgroups) | Dietary burden expressed in | Most critical subgroupa | Most critical commodityb | Trigger exceeded (Y/N) | Previous assessment (EFSA, 2021) | |||

|---|---|---|---|---|---|---|---|---|

| mg/kg bw per day | mg/kg DM | mg/kg bw per day | ||||||

| Median | Maximum | Median | Maximum | Maximum | ||||

| Cattle (all) | 0.46 | 0.59 | 12.0 | 15.4 | Dairy cattle | Citrus, dried pulp | Y | 0.59 |

| Cattle (dairy only) | 0.46 | 0.59 | 12.0 | 15.4 | Dairy cattle | Citrus, dried pulp | Y | 0.59 |

| Sheep (all) | 0.10 | 0.23 | 2.85 | 5.79 | Lamb | Rye, straw | Y | 0.23 |

| Sheep (ewe only) | 0.10 | 0.19 | 2.85 | 5.79 | Ram/Ewe | Rye, straw | Y | 0.19 |

| Swine (all) | 0.20 | 0.25 | 8.76 | 10.6 | Swine (breeding) | Citrus, dried pulp | Y | 0.25 |

| Poultry (all) | 0.05 | 0.10 | 0.66 | 1.42 | Poultry layer | Wheat, straw | Y | 0.10 |

| Poultry (layer only) | 0.05 | 0.10 | 0.66 | 1.42 | Poultry layer | Wheat, straw | Y | 0.10 |

| Fish | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. |

bw: body weight; DM: dry matter; n.a.: not applicable.

When one group of livestock includes several subgroups (e.g. poultry ‘all’ including broiler, layer and turkey), the result of the most critical subgroup is identified from the maximum dietary burdens expressed as ‘mg/kg bw per day’.

The most critical commodity is the major contributor identified from the maximum dietary burden expressed as ‘mg/kg bw per day’.

B.3. Consumer risk assessment

Short‐term (acute) risk assessment:

not relevant since no ARfD has been considered necessary (European Commission, 2015).

B.4. Recommended MRLs

| Codea | Commodity | Existing EU MRL (mg/kg) | Proposed EU MRL (mg/kg) | Comment/justification |

|---|---|---|---|---|

| Enforcement residue definition: Azoxystrobin | ||||

| 0163030 | Mangoes | 0.7 | 4 | The submitted data are sufficient to derive an import tolerance (Brazilian GAP). Risk for consumers unlikely. MRL set in the country of origin for the post‐harvest use is 6 mg/kg. |

| 0402030 | Oil palms fruits | 0.01* | 0.03 | The submitted data are sufficient to derive an import tolerance (Colombian GAP). Risk for consumers unlikely. |

MRL: maximum residue level; NEU: northern Europe; SEU: southern Europe; GAP: Good Agricultural Practice.

Indicates that the MRL is set at the limit of analytical quantification (LOQ).

Commodity code number according to Annex I of Regulation (EC) No 396/2005.

Appendix C – Pesticide Residue Intake Model (PRIMo)

1.

Appendix D – Input values for the exposure calculations

D.1. Livestock dietary burden calculations

| Feed commodity | Median dietary burden | Maximum dietary burden | ||

|---|---|---|---|---|

| Input value (mg/kg) | Comment | Input value (mg/kg) | Comment | |

| Risk assessment residue definition: azoxystrobin | ||||

| Barley straw | 2.3 | STMR (EFSA, 2013) | 5.5 | HR (EFSA, 2013) |

| Beet, sugar tops | 0.21 | STMR (EFSA, 2013) | 0.38 | HR (EFSA, 2013) |

| Cabbage, heads leaves | 0.03 | STMR (EFSA, 2013) | 0.17 | HR (EFSA, 2013) |

| Kale leaves (forage) | 1.04 | STMR (EFSA, 2013) | 3.5 | HR (EFSA, 2013) |

| Oat straw | 2.3 | STMR (EFSA, 2013) | 5.5 | HR (EFSA, 2013) |

| Rye straw | 3.85 | STMR (EFSA, 2013) | 10.1 | HR (EFSA, 2013) |

| Triticale straw | 3.85 | STMR (EFSA, 2013) | 10.1 | HR (EFSA, 2013) |

| Wheat straw | 3.85 | STMR (EFSA, 2013) | 10.1 | HR (EFSA, 2013) |

| Carrot culls | 0.06 | STMR (EFSA, 2013) | 0.11 | HR (EFSA, 2013) |

| Potato culls | 0.02 | STMR (EFSA, 2013) | 0.03 | HR (EFSA, 2013) |

| Swede roots | 0.05 | STMR (EFSA, 2013) | 0.10 | HR (EFSA, 2013) |

| Turnip roots | 0.06 | STMR (EFSA, 2013) | 0.11 | HR (EFSA, 2013) |

| Barley grain | 0.10 | STMR (EFSA, 2013) | 0.10 | STMR (EFSA, 2013) |

| Bean seed (dry) | 0.01 | STMR (EFSA, 2013) | 0.01 | STMR (EFSA, 2013) |

| Corn, field (Maize) grain | 0.01 | STMR (EFSA, 2013) | 0.01 | STMR (EFSA, 2013) |

| Corn, pop grain | 0.01 | STMR (EFSA, 2013) | 0.01 | STMR (EFSA, 2013) |

| Cowpea seed | 0.01 | STMR (EFSA, 2013) | 0.01 | STMR (EFSA, 2013) |

| Lupin seed | 0.01 | STMR (EFSA, 2013) | 0.01 | STMR (EFSA, 2013) |

| Oat grain | 0.10 | STMR (EFSA, 2013) | 0.10 | STMR (EFSA, 2013) |

| Pea (Field pea) seed (dry) | 0.01 | STMR (EFSA, 2013) | 0.01 | STMR (EFSA, 2013) |

| Rye grain | 0.08 | STMR (EFSA, 2013) | 0.08 | STMR (EFSA, 2013) |

| Soybean seed | 0.05 | STMR (EFSA, 2013) | 0.05 | STMR (EFSA, 2013) |

| Triticale grain | 0.08 | STMR (EFSA, 2013) | 0.08 | STMR (EFSA, 2013) |

| Wheat grain | 0.08 | STMR (EFSA, 2013) | 0.08 | STMR (EFSA, 2013) |

| Beet, sugar dried pulp | 1.35 | STMR (EFSA, 2021) | 1.35 | STMR (EFSA, 2021) |

| Beet, sugar ensiled pulp | 1.35 | STMR (EFSA, 2021) | 1.35 | STMR (EFSA, 2021) |

| Beet, sugar molasses | 1.35 | STMR (EFSA, 2021) | 1.35 | STMR (EFSA, 2021) |

| Brewer's grain dried | 0.33 | STMR (EFSA, 2013) × default PF (3.3) | 0.33 | STMR (EFSA, 2013) × default PF (3.3) |

| Canola (Rape seed) meal | 0.11 | STMR (EFSA, 2013) × default PF (2) | 0.11 | STMR (EFSA, 2013) × default PF (2) |

| Citrus dried pulp | 47.5 | STMR (EFSA, 2013) × default PF (10) | 47.5 | STMR (EFSA, 2013) × default PF (10) |

| Corn, field milled by‐pdts | 0.01 | STMR (EFSA, 2013)b | 0.01 | STMR (EFSA, 2013)b |

| Corn, field hominy meal | 0.01 | STMR (EFSA, 2013)b | 0.01 | STMR (EFSA, 2013)b |

| Corn, field gluten feed | 0.01 | STMR (EFSA, 2013)b | 0.01 | STMR (EFSA, 2013)b |

| Corn, field gluten, meal | 0.01 | STMR (EFSA, 2013)b | 0.01 | STMR (EFSA, 2013)b |

| Distiller's grain dried | 0.25 | STMR (EFSA, 2013) × default PF (3.3) | 0.25 | STMR (EFSA, 2013) × default PF (3.3) |

| Flaxseed/Linseed meal | 0.04 | STMR (EFSA, 2016b) × default PF (2) | 0.04 | STMR (EFSA, 2016b) × default PF (2) |

| Lupin seed meal | 0.01 | STMR (EFSA, 2013) × default PF (1.1) | 0.01 | STMR (EFSA, 2013) × default PF (1.1) |

| Palm, kernel meal | 0.01 | STMR × PFa (see Appendix B.1.2.1) | 0.01 | STMR × PFa (see Appendix B.1.2.1) |

| Potato process waste | 0.3 | STMR (EFSA, 2013) × default PF (20) | 0.3 | STMR (EFSA, 2013) × default PF (20) |

| Potato dried pulp | 0.57 | STMR (EFSA, 2013) × default PF (38) | 0.57 | STMR (EFSA, 2013) × default PF (38) |

| Rape meal | 0.11 | STMR (EFSA, 2013) × default PF (2) | 0.11 | STMR (EFSA, 2013) × default PF (2) |

| Rice bran/pollard | 0.61 | STMR (EFSA, 2013) × PF (1.2) | 0.61 | STMR (EFSA, 2013) × PF (1.2) |

| Safflower meal | 0.04 | STMR (EFSA, 2016b) × default PF (2) | 0.04 | STMR (EFSA, 2016b) × default PF (2) |

| Soybean meal | 0.07 | STMR (EFSA, 2013) × default PF (1.3) | 0.07 | STMR (EFSA, 2013) × default PF (1.3) |

| Soybean hulls | 0.65 | STMR (EFSA, 2013) × default PF (13) | 0.65 | STMR (EFSA, 2013) × default PF (13) |

| Sunflower meal | 0.02 | STMR (EFSA, 2013) × default PF (2) | 0.02 | STMR (EFSA, 2013) × default PF (2) |

| Wheat gluten meal | 0.14 | STMR (EFSA, 2013) × default PF (1.8) | 0.14 | STMR (EFSA, 2013) × default PF (1.8) |

| Wheat milled by‐pdts | 0.13 | STMR × PF (1.7) (EFSA, 2013) | 0.13 | STMR × PF (1.7) (EFSA, 2013) |

STMR: supervised trials median residue; HR: highest residue; PF: processing factor.

For palm kernel meal, the default processing factor was replaced by tentative PF of 0.3 calculated in Section B.1.2.3.

For maize/corn by‐products, no default processing factor was applied because residues are expected to be below the LOQ (EFSA, 2013). Concentration of residues in these commodities is therefore not expected.

D.2. Consumer risk assessment

| Commodity | Chronic risk assessment | |

|---|---|---|

| Input value (mg/kg) | Comment | |

| Grapefruits | 4.90 | STMR (EFSA, 2013) |

| Oranges | 4.75 | STMR (EFSA, 2013) |

| Lemons | 4.90 | STMR (EFSA, 2013) |

| Limes | 4.90 | STMR (EFSA, 2013) |

| Mandarins | 4.90 | STMR (EFSA, 2013) |

| Almonds | 0.01 | STMR (EFSA, 2013) |

| Brazil nuts | 0.01 | STMR (EFSA, 2013) |

| Cashew nuts | 0.01 | STMR (EFSA, 2013) |

| Chestnuts | 0.01 | STMR (EFSA, 2013) |

| Coconuts | 0.01 | STMR (EFSA, 2013) |

| Hazelnuts/cobnuts | 0.01 | STMR (EFSA, 2013) |

| Macadamia | 0.01 | STMR (EFSA, 2013) |

| Pecans | 0.01 | STMR (EFSA, 2013) |

| Pine nut kernels | 0.01 | STMR (EFSA, 2013) |

| Pistachios | 0.44 | STMR (EFSA, 2013) |

| Walnuts | 0.01 | STMR (EFSA, 2013) |

| Apricots | 0.74 | STMR (EFSA, 2013) |

| Cherries (sweet) | 0.74 | STMR (EFSA, 2013) |

| Peaches | 0.74 | STMR (EFSA, 2013) |

| Plums | 0.74 | STMR (EFSA, 2013) |

| Table grapes | 0.72 | STMR (EFSA, 2016a) |

| Wine grapes | 0.72 | STMR (EFSA, 2016a) |

| Strawberries | 1.30 | STMR (EFSA, 2013) |

| Blackberries | 1.03 | STMR (EFSA, 2013) |

| Dewberries | 1.03 | STMR (EFSA, 2013) |

| Raspberries (red and yellow) | 1.03 | STMR (EFSA, 2013) |

| Blueberries | 1.03 | STMR (EFSA, 2013) |

| Cranberries | 0.23 | STMR (EFSA, 2013) |

| Currants (red, black and white) | 1.03 | STMR (EFSA, 2013) |

| Gooseberries (green, red and yellow) | 1.03 | STMR (EFSA, 2013) |

| Rose hips | 1.03 | STMR (EFSA, 2013) |

| Mulberries (black and white) | 1.03 | STMR (EFSA, 2013) |

| Azarole/Mediterranean medlar | 1.03 | STMR (EFSA, 2013) |

| Elderberries | 1.03 | STMR (EFSA, 2013) |

| Carambolas | 0.02 | STMR (EFSA, 2013) |

| Passion fruits/maracujas | 1.10 | STMR (EFSA, 2013) |

| Prickly pears/cactus fruits | 0.04 | STMR (FAO, 2017) |

| Bananas | 0.03 | STMR*PeF (EFSA, 2013) |

| Mangoes | 0.04 | STMR*PeF(0.02) (see Appendices B.1.2.1; B.1.2.3) |

| Papayas | 0.10 | STMR (EFSA, 2013) |

| Potatoes | 2.30 | STMR (FAO, 2013) |

| Cassava roots/manioc | 0.23 | STMR (EFSA, 2013) |

| Sweet potatoes | 0.23 | STMR (EFSA, 2013) |

| Yams | 0.23 | STMR (EFSA, 2013) |

| Arrowroots | 0.23 | STMR (EFSA, 2013) |

| Beetroots | 0.23 | STMR (EFSA, 2013) |

| Carrots | 0.23 | STMR (EFSA, 2013) |

| Celeriacs/turnip‐rooted celeries | 0.23 | STMR (EFSA, 2013) |

| Horseradishes | 0.23 | STMR (EFSA, 2013) |

| Jerusalem artichokes | 0.23 | STMR (EFSA, 2013) |

| Parsnips | 0.23 | STMR (EFSA, 2013) |

| Parsley roots/Hamburg roots parsley | 0.23 | STMR (EFSA, 2013) |

| Radishes | 0.30 | STMR (EFSA, 2013) |

| Salsifies | 0.23 | STMR (EFSA, 2013) |

| Swedes/rutabagas | 0.23 | STMR (EFSA, 2013) |

| Turnips | 0.23 | STMR (EFSA, 2013) |

| Garlic | 2.20 | STMR (EFSA, 2013) |

| Onions | 2.20 | STMR (EFSA, 2013) |

| Shallots | 2.200 | STMR (EFSA, 2013) |

| Spring onions/green onions and Welsh onions | 2.20 | STMR (EFSA, 2013) |

| Tomatoes | 0.35 | STMR (EFSA, 2013) |

| Sweet peppers/bell peppers | 0.71 | STMR (EFSA, 2013) |

| Aubergines/egg plants | 0.35 | STMR (EFSA, 2013) |

| Okra/lady's fingers | 0.35 | STMR (EFSA, 2013) |

| Cucumbers | 0.17 | STMR (EFSA, 2013) |

| Gherkins | 0.17 | STMR (EFSA, 2013) |

| Courgettes | 0.17 | STMR (EFSA, 2013) |

| Melons | 0.17 | STMR (EFSA, 2013) |

| Pumpkins | 0.17 | STMR (EFSA, 2013) |

| Watermelons | 1.00 | MRL (EFSA, 2013) |

| Broccoli | 1.20 | STMR (EFSA, 2013) |

| Cauliflowers | 1.20 | STMR (EFSA, 2013) |

| Brussels sprouts | 1.20 | STMR (EFSA, 2013) |

| Head cabbages | 1.20 | STMR (EFSA, 2013) |

| Chinese cabbages/pe‐tsai | 1.04 | STMR (EFSA, 2013) |

| Kales | 1.04 | STMR (EFSA, 2013) |

| Kohlrabies | 1.20 | STMR (EFSA, 2013) |

| Lamb's lettuce/corn salads | 3.40 | STMR (EFSA, 2020, 2021) |

| Lettuces | 3.40 | STMR (EFSA, 2020, 2021) |

| Escaroles/broad‐leaved endives | 3.40 | STMR (EFSA, 2020, 2021) |

| Cress and other sprouts and shoots | 3.40 | STMR (EFSA, 2020, 2021) |

| Land cress | 3.40 | STMR (EFSA, 2020, 2021) |

| Roman rocket/rucola | 3.40 | STMR (EFSA, 2020, 2021) |

| Red mustards | 3.40 | STMR (EFSA, 2020, 2021) |

| Baby leaf crops (including brassica species) | 3.40 | STMR (EFSA, 2020, 2021) |

| Spinaches | 3.90 | STMR (EFSA, 2013) |

| Purslanes | 3.90 | STMR (EFSA, 2013) |

| Chards/beet leaves | 3.90 | STMR (EFSA, 2013) |

| Witloofs/Belgian endives | 0.05 | STMR (EFSA, 2013) |

| Chervil | 23 | STMR (EFSA, 2013) |

| Chives | 23 | STMR (EFSA, 2013) |

| Celery leaves | 23 | STMR (EFSA, 2013) |

| Parsley | 23 | STMR (EFSA, 2013) |

| Sage | 23 | STMR (EFSA, 2013) |

| Rosemary | 23 | STMR (EFSA, 2013) |

| Thyme | 23 | STMR (EFSA, 2013) |

| Basil and edible flowers | 23 | STMR (EFSA, 2013) |

| Laurel/bay leaves | 23 | STMR (EFSA, 2013) |

| Tarragon | 23 | STMR (EFSA, 2013) |

| Beans (with pods) | 1.04 | STMR (EFSA, 2013) |

| Beans (without pods) | 1.04 | STMR (EFSA, 2013) |

| Peas (with pods) | 1.04 | STMR (EFSA, 2013) |

| Peas (without pods) | 1.04 | STMR (EFSA, 2013) |

| Lentils (fresh) | 1.04 | STMR (EFSA, 2013) |

| Asparagus | 0.01 | STMR (EFSA, 2013) |

| Cardoons | 1.98 | STMR (EFSA, 2013) |

| Celeries | 1.98 | STMR (EFSA, 2013) |

| Florence fennels | 2.20 | STMR (EFSA, 2013) |

| Globe artichokes | 1.80 | STMR (EFSA, 2013) |

| Leeks | 2.20 | STMR (EFSA, 2013) |

| Rhubarbs | 0.10 | STMR (EFSA, 2013) |

| Beans | 0.01 | STMR (EFSA, 2013) |

| Lentils | 0.01 | STMR (EFSA, 2013) |

| Peas | 0.01 | STMR (EFSA, 2013) |

| Lupins/lupini beans | 0.01 | STMR (EFSA, 2013) |

| Linseeds | 0.02 | STMR (EFSA, 2016b) |

| Peanuts/groundnuts | 0.01 | STMR (EFSA, 2013) |

| Poppy seeds | 0.06 | STMR (EFSA, 2013) |

| Sunflower seeds | 0.04 | STMR (EFSA, 2013) |

| Rapeseeds/canola seeds | 0.06 | STMR (EFSA, 2013) |

| Soyabeans | 0.05 | STMR (EFSA, 2013) |

| Mustard seeds | 0.06 | STMR (EFSA, 2013) |

| Cotton seeds | 0.01 | STMR (EFSA, 2013) |

| Safflower seeds | 0.02 | STMR (EFSA, 2016b) |

| Borage seeds | 0.02 | STMR (EFSA, 2016b) |

| Gold of pleasure seeds | 0.06 | STMR (EFSA, 2013) |

| Oil palm fruit | 0.01 | STMR (see Appendix B.1.2.1) |

| Barley | 0.05 | STMR (FAO, 2013) |

| Maize/corn | 0.01 | STMR (EFSA, 2013) |

| Oat | 0.05 | STMR (FAO, 2013) |

| Rice | 0.52 | STMR (EFSA, 2013) |

| Rye | 0.08 | STMR (EFSA, 2013) |

| Sorghum | 1.85 | STMR (FAO, 2013) |

| Wheat | 0.08 | STMR (EFSA, 2013) |

| Coffee beans | 0.01 | STMR (FAO, 2013) |

| Hops (dried) | 3.93 | STMR (EFSA, 2013) |

| Sugar beet roots | 1.35 | STMR (EFSA, 2021) |

| Sugar canes | 0.02 | STMR (FAO, 2017) |

| Chicory roots | 0.03 | STMR (EFSA, 2013) |

| Swine: Muscle/meat | 0.01 | STMR (EFSA, 2013 based on CXL) |

| Swine: Fat tissue | 0.01 | STMR (EFSA, 2013 based on CXL) |

| Swine: Liver | 0.01 | STMR (EFSA, 2013 based on CXL) |

| Swine: Kidney | 0.01 | STMR (EFSA, 2013 based on CXL) |

| Bovine: Muscle/meat | 0.01 | STMR (EFSA, 2013 based on CXL) |

| Bovine: Fat tissue | 0.01 | STMR (EFSA, 2013 based on CXL) |

| Bovine: Liver | 0.01 | STMR (EFSA, 2013 based on CXL) |

| Bovine: Kidney | 0.01 | STMR (EFSA, 2013 based on CXL) |

| Sheep: Muscle/meat | 0.01 | STMR (EFSA, 2013 based on CXL) |

| Sheep: Fat tissue | 0.01 | STMR (EFSA, 2013 based on CXL) |

| Sheep: Liver | 0.01 | STMR (EFSA, 2013 based on CXL) |

| Sheep: Kidney | 0.01 | STMR (EFSA, 2013 based on CXL) |

| Goat: Muscle/meat | 0.01 | STMR (EFSA, 2013 based on CXL) |

| Goat: Fat tissue | 0.01 | STMR (EFSA, 2013 based on CXL) |

| Goat: Liver | 0.01 | STMR (EFSA, 2013 based on CXL) |

| Goat: Kidney | 0.01 | STMR (EFSA, 2013 based on CXL) |

| Poultry: Muscle/meat | 0.01 | STMR (EFSA, 2013 based on CXL) |

| Poultry: Fat tissue | 0.01 | STMR (EFSA, 2013 based on CXL) |

| Poultry: Liver | 0.01 | STMR (EFSA, 2013 based on CXL) |

| Milk: Cattle | 0.01 | STMR (EFSA, 2013 based on CXL) |

| Milk: Sheep | 0.01 | STMR (EFSA, 2013 based on CXL) |

| Milk: Goat | 0.01 | STMR (EFSA, 2013 based on CXL) |

| Eggs: Chicken | 0.01 | STMR (EFSA, 2013 based on CXL) |

STMR: supervised trials median residue; PeF: Peeling factor; CXL: Codex maximum residue limit.

Appendix E – Used compound codes

1.

| Code/Trivial namea | IUPAC name/SMILES notation/InChiKeyb | Structural formulac |

|---|---|---|

| Azoxystrobin | methyl (2E)‐2‐(2‐{[6‐(2‐cyanophenoxy)pyrimidin‐4‐yl]oxy}phenyl)‐3‐methoxyacrylate O=C(OC)\C(=C\OC)c1ccccc1Oc1cc(Oc2ccccc2C#N)ncn1 WFDXOXNFNRHQEC‐GHRIWEEISA‐N |

|

| L1 | methyl (2E)‐2‐(2‐{[6‐(2‐ cyanophenoxy)pyrimidin‐4‐yl]oxy}‐xhydroxyphenyl)‐3‐methoxyprop‐2‐enoate Refers to a non‐determined mixture of isomers with hydroxyl group in one of the alternative positions. Name and codes of one of the compounds are given for illustrative purposes. methyl (2E)‐2‐(2‐{[6‐(2‐cyanophenoxy)pyrimidin‐4‐yl]oxy}‐4‐hydroxyphenyl)‐3‐methoxyprop‐2‐enoate O=C(OC)\C(=C\OC)c1ccc(O)cc1Oc1cc(Oc2ccccc2C#N)ncn1 YGORCRAVOJDUML‐SFQUDFHCSA‐N |

|

| L4 | S‐(2‐cyano‐x‐hydroxyphenyl)cysteine Refers to a non‐determined mixture of isomers with hydroxyl group in one of the alternative positions. Name and codes of one of the compounds are given for illustrative purposes. S‐(2‐cyano‐4‐hydroxyphenyl)cysteine O=C(O)C(N)CSc1ccc(O)cc1C#N HHJSURCWSNDRKW‐UHFFFAOYSA‐N |

|

| L9 | 2‐{[6‐(2‐cyanophenoxy)pyrimidin‐4‐ yl]oxy}‐x‐hydroxybenzoic acid Refers to a non‐determined mixture of isomers with hydroxyl group in one of the alternative positions. Name and codes of one of the compounds are given for illustrative purposes. 2‐{[6‐(2‐cyanophenoxy)pyrimidin‐4‐yl]oxy}‐4‐hydroxybenzoic acid O=C(O)c1ccc(O)cc1Oc1cc(Oc2ccccc2C#N)ncn1 KBPYPCVAGBHCJS‐UHFFFAOYSA‐N |

|

| K1 | 4‐{[6‐(2‐cyanophenoxy)pyrimidin‐4‐ yl]oxy}‐3‐[(1E)‐1,3‐dimethoxy‐3‐oxoprop1‐en‐2‐yl]phenyl glucopyranuronic acid Refers to a non‐determined mixture of isomers with glucopyranuronic acid moiety in one of the alternative positions. Name and codes of one of the compounds are given for illustrative purposes. 3‐{[6‐(2‐cyanophenoxy)pyrimidin‐4‐yl]oxy}‐4‐[(1E)‐1,3‐dimethoxy‐3‐oxoprop‐1‐en‐2‐yl]phenyl L‐glucopyranosiduronic acid N#Cc1ccccc1Oc1cc(ncn1)Oc1cc(O[C@H]2OC([C@H](O)C(O)C2O)C(=O)O)ccc1C(=C\OC)/C(=O)OC BPMGKBSQEJFZIY‐SFQUDFHCSA‐N |

|

IUPAC: International Union of Pure and Applied Chemistry; SMILES: simplified molecular‐input line‐entry system; InChiKey: International Chemical Identifier Key.

The metabolite name in bold is the name used in the conclusion.

ACD/Name 2019.1.3 ACD/Labs 2019 Release (File version N05E41, Build 111418, 3 September 2019).

ACD/ChemSketch 2019.1.3 ACD/Labs 2019 Release (File version C05H41, Build 111302, 27 August 2019).

Suggested citation:EFSA (European Food Safety Authority) , Bellisai G, Bernasconi G, Brancato A, Carrasco Cabrera L, Ferreira L, Giner G, Greco L, Jarrah S, Kazocina A, Leuschner R, Magrans JO, Miron I, Nave S, Pedersen R, Reich H, Ruocco S, Santos M, Scarlato AP, Theobald A, Vagenende B and Verani A, 2021. Reasoned Opinion on the setting of import tolerances for azoxystrobin in mangoes and oil palm fruits. EFSA Journal 2021;19(8):6821, 30 pp. 10.2903/j.efsa.2021.6821

Requestor: European Commission

Question number: EFSA‐Q‐2021‐00263

Declarations of interest: The declarations of interest of all scientific experts active in EFSA's work are available at https://ess.efsa.europa.eu/doi/doiweb/doisearch.

Acknowledgements: EFSA wishes to thank Stathis Anagnos, Laszlo Bura, Andrea Mioč, Marta Szot, Aikaterini Vlachou for the support provided to this scientific output.

Adopted: 5 August 2021

Notes

Council Directive 91/414/EEC of 15 July 1991 concerning the placing of plant protection products on the market. OJ L 230, 19.8.1991, p. 1–32.

Regulation (EC) No 396/2005 of the Parliament and of the Council of 23 February 2005 on maximum residue levels of pesticides in or on food and feed of plant and animal origin and amending Council Directive 91/414/EEC. OJ L 70, 16.3.2005, p. 1–16.

For an overview of all MRL Regulations on this active substance, please consult: https://ec.europa.eu/food/plant/pesticides/eu-pesticides-database/active-substances/?event=search.as

Commission Regulation (EU) No 544/2011 of 10 June 2011 implementing Regulation (EC) No 1107/2009 of the European Parliament and of the Council as regards the data requirements for active substances. OJ L 155, 11.6.2011, p. 1–66.

Commission Regulation (EU) No 546/2011 of 10 June 2011 implementing Regulation (EC) No 1107/2009 of the European Parliament and of the Council as regards uniform principles for evaluation and authorisation of plant protection products. OJ L 155, 11.6.2011, p. 127–175.

Brazilian Health Regulatory Agency (Anvisa) monograph on azoxystrobin (available online, https://www.gov.br/anvisa/pt-br)

References

- Austria , 2021. Evaluation report on the setting of import tolerance for azoxystrobin in oil palm fruits and mango. April 2021, revised in May 2021, 92 pp.

- EFSA (European Food Safety Authority), 2010. Conclusion on the peer review of the pesticide risk assessment of the active substance azoxystrobin. EFSA Journal 2010;8(4):1542, 110 pp. 10.2903/j.efsa.2010.1542 [DOI] [Google Scholar]

- EFSA (European Food Safety Authority), 2013. Reasoned opinion on the review of the existing maximum residue levels (MRLs) for azoxystrobin according to Article 12 of Regulation (EC) No 396/2005. EFSA Journal 2013;11(12):3497, 97 pp. 10.2903/j.efsa.2013.3497 [DOI] [Google Scholar]

- EFSA (European Food Safety Authority), 2015. Residues trials and MRL calculations Proposals for a harmonised approach for the selection of the trials and data used for the estimation of MRL, STMR and HR. September 2015.

- EFSA (European Food Safety Authority), 2016a. Reasoned opinion on the modification of the existing maximum residue levels for azoxystrobin in grapes. EFSA Journal 2016;14(2):4415, 17 pp. 10.2903/j.efsa.2016.4415 [DOI] [Google Scholar]

- EFSA (European Food Safety Authority), 2016b. Reasoned opinion on the modification of the existing maximum residue levels for azoxystrobin in various crops. EFSA Journal 2016;14(5):4459, 17 pp. 10.2903/j.efsa.2016.4459 [DOI] [Google Scholar]

- EFSA (European Food Safety Authority), Brancato A, Brocca D, Ferreira L, Greco L, Jarrah S, Leuschner R, Medina P, Miron I, Nougadere A, Pedersen R, Reich H, Santos M, Stanek A, Tarazona J, Theobald A and Villamar‐Bouza L, 2018. Guidance on use of EFSA Pesticide Residue Intake Model (EFSA PRIMo revision 3). EFSA Journal 2018;16(1):5147, 43 pp. 10.2903/j.efsa.2018.5147 [DOI] [PMC free article] [PubMed] [Google Scholar]

- EFSA (European Food Safety Authority), Anastassiadou M, Brancato A, Carrasco Cabrera L, Ferreira L, Greco L, Jarrah S, Kazocina A, Leuschner R, Magrans JO, Miron I, Pedersen R, Raczyk M, Reich H, Ruocco S, Sacchi A, Santos M, Stanek A, Tarazona J, Theobald A and Verani A, 2019. Pesticide Residue Intake Model‐ EFSA PRIMo revision 3.1 (update of EFSA PRIMo revision 3). EFSA supporting publication 2019;EN‐1605, 15 pp. 10.2903/sp.efsa.2019.en-1605 [DOI]

- EFSA (European Food Safety Authority), Anastassiadou M, Bernasconi G, Brancato A, Carrasco Cabrera L, Ferreira L, Greco L, Jarrah S, Kazocina A, Leuschner R, Magrans JO, Miron I, Nave S, Pedersen R, Reich H, Rojas A, Sacchi A, Santos M, Stanek A, Theobald A, Vagenende B and Verani A, 2020. Reasoned opinion on the evaluation of confirmatory data following the Article 12 MRL review and modification of the existing maximum residue levels for azoxystrobin. EFSA Journal 2020;18(8):6231, 42 pp. 10.2903/j.efsa.2020.6231 [DOI] [PMC free article] [PubMed] [Google Scholar]

- EFSA (European Food Safety Authority), Anastassiadou M, Bernasconi G, Brancato A, Carrasco Cabrera L, Ferreira L, Greco L, Jarrah S, Kazocina A, Leuschner R, Magrans JO, Miron I, Nave S, Pedersen R, Reich H, Rojas A, Sacchi A, Santos M, Scarlato AP, Theobald A, Vagenende B and Verani A, 2021. Reasoned Opinion on the setting of import tolerance for azoxystrobin in sugar beet roots. EFSA Journal 2021;19(2):6401, 29 pp. 10.2903/j.efsa.2021.6401 [DOI] [PMC free article] [PubMed] [Google Scholar]

- European Commission , 1996. Appendix G. Livestock feeding studies. 7031/VI/95‐rev 4, 22 July 1996.

- European Commission , 1997a. Appendix A. Metabolism and distribution in plants. 7028/VI/95‐rev.3, 22 July 1997.

- European Commission , 1997b. Appendix B. General recommendations for the design, preparation and realization of residue trials. Annex 2. Classification of (minor) crops not listed in the Appendix of Council Directive 90/642/EEC. 7029/VI/95‐rev. 6, 22 July 1997.

- European Commission , 1997c. Appendix C. Testing of plant protection products in rotational crops. 7524/VI/95‐rev. 2, 22 July 1997.

- European Commission , 1997d. Appendix E. Processing studies. 7035/VI/95‐rev. 5, 22 July 1997.

- European Commission , 1997e. Appendix F. Metabolism and distribution in domestic animals. 7030/VI/95‐rev. 3, 22 July 1997.

- European Commission , 1997f. Appendix H. Storage stability of residue samples. 7032/VI/95‐rev. 5, 22 July 1997.

- European Commission , 1997g. Appendix I. Calculation of maximum residue level and safety intervals. 7039/VI/95 22 July 1997. As amended by the document: classes to be used for the setting of EU pesticide maximum residue levels (MRLs). SANCO 10634/2010, finalised in the Standing Committee on the Food Chain and Animal Health at its meeting of 23–24 March 2010.

- European Commission , 2010. Classes to be used for the setting of EU pesticide Maximum Residue Levels (MRLs). SANCO 10634/2010-rev. 0, Finalised in the Standing Committee on the Food Chain and Animal Health at its meeting of 23–24 March 2010.

- European Commission , 2015. Review report for the active substance azoxystrobin. Finalised in the Standing Committee on the Food Chain and Animal Health at its meeting on 17 June 2011 in view of the approval of azoxystrobin as active substance in accordance with Regulation (EC) No 1107/2009. SANCO/11027/2011-Rev. 3, 20 March 2015.

- European Commission , 2017. Technical Guideline on the Evaluation of Extraction Efficiency of Residue Analytical Methods. SANTE 2017/10632, Rev. 3, 22 November 2017.

- European Commission , 2020. Technical guidelines on data requirements for setting maximum residue levels, comparability of residue trials and extrapolation on residue data on products from plant and animal origin. SANTE/2019/12752, 23 November 2020.

- European Commission , 2021. Guidance Document on Pesticide Analytical Methods for Risk Assessment and Post‐approval Control and Monitoring Purposes. SANTE/2020/12830, Rev.1 24. February 2021.

- FAO (Food and Agriculture Organization of the United Nations), 2013. Azoxystrobin. In: Pesticide residues in food – 2013. Report of the Joint Meeting of the FAO Panel of Experts on Pesticide Residues in Food and the Environment and the WHO Expert Group on Pesticide Residues. FAO Plant Production and Protection Paper 220.

- FAO (Food and Agriculture Organization of the United Nations), 2017. Azoxystrobin. In: Pesticide residues in food – 2017. Report of the Joint Meeting of the FAO Panel of Experts on Pesticide Residues in Food and the Environment and the WHO Expert Group on Pesticide Residues. FAO Plant Production and Protection Paper 233.

- OECD (Organisation for Economic Co‐operation and Development), 2011. OECD MRL calculator: spreadsheet for single data set and spreadsheet for multiple data set, 2 March 2011. In: Pesticide Publications/Publications on Pesticide Residues. Available online: http://www.oecd.org

- OECD (Organisation for Economic Co‐operation and Development), 2013. Guidance document on residues in livestock. In: Series on Pesticides No 73. ENV/JM/MONO(2013)8, 4 September 2013.

- United Kingdom , 2009a. Draft assessment report on the active substance azoxystrobin prepared by the rapporteur Member State United Kingdom in the framework of Council Directive 91/414/EEC, May, 2009. Available online: www.efsa.europa.eu

- United Kingdom , 2009b. Final addendum to the assessment report on the active substance azoxystrobin prepared by the rapporteur Member State United Kingdom in the framework of Council Directive 91/414/EEC, compiled by EFSA, December, 2009. Available online: www.efsa.europa.eu