In recent years, the transition from analog to digital workflow has drastically increased in pace. The speed of this transition may be challenging for some faculty and dental students because of the steep learning curve associated with technology and the requirement of practitioners to adopt a new mind-set. Benefits of successfully implementing this new technology can include the reduction of overhead, an increase in the predictability of restorative outcomes, and ability to fabricate same-day restorations.1,2 At the forefront of this revolution is the implementation of CAD/CAM technology to digitally design and mill restorations (Fig. 1A,B).3

Figure 1.

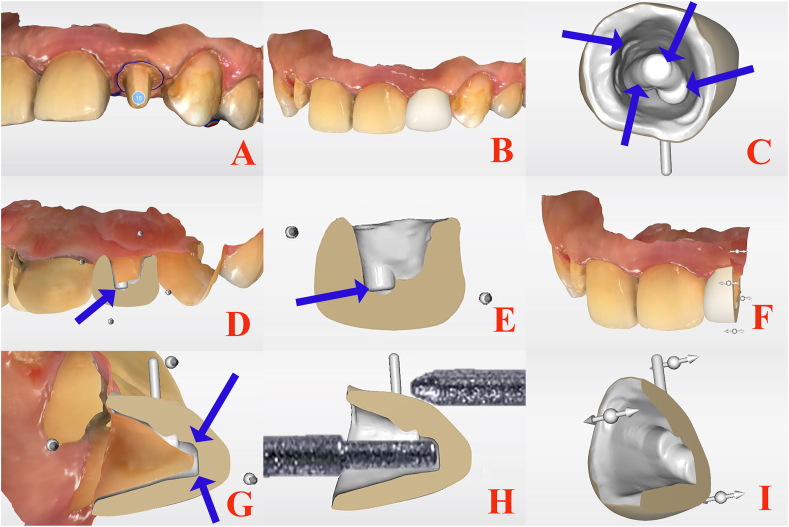

Digital workflow of the CAD/CAM crown. (A) Digital impression of the prepared tooth. (B) Digital design of proposed restoration. (C) Swirl marks on the internal surface indicating overmilling. (D, E, F, G, H, and I) Cross-sectional views of the prepared tooth, proposed restoration and overmilled areas.

When fabricating ceramic restorations for CAD/CAM production, the basic guidelines for tooth preparation are followed. Anterior teeth require a 2 mm incisal, 1.5 mm facial, and 1 mm lingual reduction while posterior teeth require a 2 mm occlusal and 1.5 mm axial reduction. For both anterior and posterior teeth, a uniform chamfer margin of 1 mm must be placed 360° around the tooth, prepared walls must be smooth, internal line angles must be rounded, and the preparation should be absent of undercuts. In addition to these basic preparation characteristics, CAD/CAM restorations require supplementary refinements to ensure compatibility with the selected milling unit. Anterior teeth, especially incisors, are an area where CAD/CAM milled restoration failures occur in high frequency. These teeth are taller and narrower than posterior teeth and require additional incisal edge thickness (faciolingually) of at least 1 mm to accurately reproduce the preparation for the intaglio surface of the restoration. Posterior teeth must also be refined to have flatter and broader 1 mm cusps to reduce the loss of excess material from CAD/CAM milling limitations.

These refinements are implemented to counteract CAD/CAM overmilling, or the excess removal of material on the internal surface of CAD/CAM milled restorations. Overmilling is a result of a milling machine's dimensional limitations caused by the size of its burs. Standard bur sizes in milling machines are normally 1.8 mm in diameter for the cylinder-pointed bur (external surface) and 1 mm or 1.3 mm in diameter for the step bur (internal surface). The consequence of points on the internal surface of the restoration that are narrower (<1 mm) than these measurements is overmilling. This excess reduction results in material thinning and ultimately restorative failure.

One of digital technology's main benefits is its ability to streamline formerly time-consuming analog processes. Labor intensive processes such as fabricating framework and metal components for porcelain fused to metal prosthesis via lost-wax techniques can be expedited. The multiple steps (waxing, investing, burnout, casting) of these prolonged methods can now be performed in a fraction of the time by using digital scanning, CAD/CAM fabricating, and milling technologies. Dimensional limitations are not seen by analog methods because of flowable nature of molten material during investing and casting steps. Though not ideal, analog methods can allow for a narrower (<1 mm) incisal edge to be fabricated with more promising results unlike CAD/CAM digital techniques. When using these new technologies, one must be familiar with their restrictions to produce successful restorations.

CAD/CAM milling deficiencies can be circumvented in many ways, most involving a wholistic restorative approach to yield successful treatment. Clinicians may lessen the probability of failure due to overmilling by being mindful of tooth preparation proportions and the milling machine's bur shape/diameter. Clinicians may also be more meticulous during the mill simulation step of fabrication (Fig. 1C–I). Checking the internal surface for swirl marks (the preliminary sign of overmilling) before milling begins may allow time for preparation refinement, crown adjustment (increase thickness, modify contours), or a change in the type of restorative material (composite resin with ceramic filler particlesc, zirconia). Milling machines with higher axis count should also be considered to yield the most accurate results.

The use of multi-axis milling machines has increased the effectiveness of CAD/CAM dentistry by increasing the accuracy of restorations, delivering them in a shorter period of time, and increasing patient satisfaction. However, they inherently have some limitations such as the size, cost, and type of milling machine (4-axis or 5-axis).4 These characteristics all contribute to how valuable of an asset a clinician deems their milling machine. While size and cost are important, the number of axis plays the most important role in restorative accuracy. Milling machines that have an increased number of axis are able to experience more accurate cutting because of their increased ability to move. In dentistry, 5-axis machines offer the most freedom to move making them capable of producing accurate restorations in a shorter amount of time. This high degree of movement also reduces the chances to produce “swirl marks”, resulting in more successful restorations with less overmilling.

A major threat to clinicians wishing to seek the benefits of CAD/CAM technology is their willingness to adapt a new way of thinking and obtain the required training to successfully implement these systems into their workflow. In the absence of these two fundamental attributes, clinicians can expect to see a decline in productivity, effectiveness of outcomes, and cost. It is recommended that inexperienced dentists should first become accustom to the basic components that drive this technology before implementing it.

Declaration of Competing Interest

The authors have no conflicts of interest relevant to this article.

Acknowledgments

This work is not supported by any grants from any institutions.

References

- 1.Unsal G.S., Turkyilmaz I. Improved reconstruction of an implant-retained auricular prosthesis using CAD/CAM technology. J Dent Sci. 2019;14:328–329. doi: 10.1016/j.jds.2019.02.002. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Zhivago P., Turkyilmaz I. A comprehensive digital approach to enhance smiles using an intraoral optical scanner and advanced 3-D sculpting software. J Dent Sci. 2021;16:784–785. doi: 10.1016/j.jds.2020.05.010. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Turkyilmaz I., Unsal G.S. Full-mouth rehabilitation of an elderly patient with Sjogren's syndrome by using implant-supported fixed dental prostheses including CAD/CAM frameworks. J Dent Sci. 2019;14:428–429. doi: 10.1016/j.jds.2019.06.004. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Al Hamad K.Q., Al-Rashdan R.B., Al-Rashdan B.A., Baba N.Z. Effect of milling protocols on trueness and precision of ceramic crowns. J Prosthodont. 2021;30:171–176. doi: 10.1111/jopr.13245. [DOI] [PubMed] [Google Scholar]