Abstract

The commercial demand for food products and dietary supplements has increased drastically in the last few decades. The packed food products and nutritional supplements have made a profound impact on the modern human lifestyle. Since ancient times, storage and long-term use of food products remain a significant challenge for humans. There are different parameters for the evaluation of food products and dietary supplements broadly categorized as quality control and quality assurance. On an average million tons of food, materials get spoiled daily worldwide due to lack of storage and transportation point out packaging systems inequalities. To ensure the quality of packed food products and nutritional supplements among available measures, packaging remained an important event and had been refined from time to time to provide a standard. Over a period, the packaging industry has evolved using modern technology from the conventional methods of new generation packaging, including glass, wood, and paper to most new biodegradable materials. The ancient pattern of packaging; manual packaging has been taken over by an automated system of packing, resulting in enhanced output with minimal chance of damage to valuable products for humanity. The article will emphasize new insights into current packaging system not only provide the quality of these products but also in aiming new heights beyond conventional technologies and consumer opinions. In the present study, we have given more emphasis on novel methods of packaging, the packaging materials, quality of packed products, and their impacts of food products on the environment.

Keywords: Food packaging, Synthetic materials, Biodegradable material, Edible packaging

Introduction

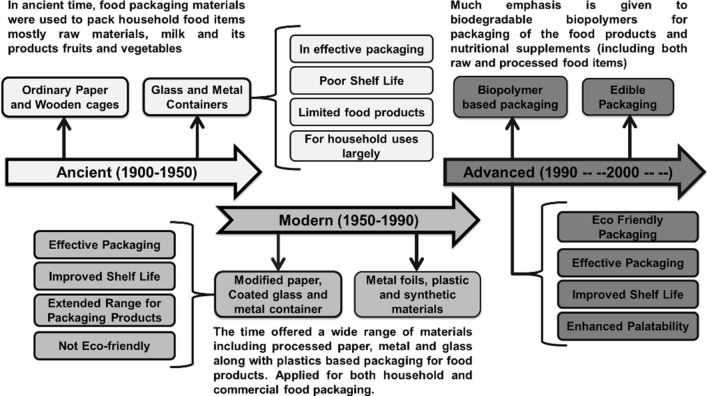

The packaging is one of the most crucial unit operations in the formulation of any commercial product to ensure product quality while transportation, storage, sale, and use (Abeer and Choudhary 2013). The first-ever principal of packaging designed to provide a physical appearance to the product in concern to the manufacturer and its storage for long term use (Risch 2009). Later on, the concept of packaging was not only restricted to the storage and transportation of the packed product but also to ensure the quality of the product, information of legal right from the manufacturer (copyright), providing information on product and marketing strategies (Amra et al. 2015). In the present scenario, packaging technology is more concerned with improving the shelf life of the product and ensuring its quality (Hotchkiss 1997). Moreover, in the last few decades, numerous developments have been made in the category of products associated with human health that includes pharmaceuticals, food products, and dietary supplements (Claudio 2012). The technology related to packaging is continuously evolving from old conventional methods to the novel advanced automated system to fulfill commercial demands. Food products and dietary supplements need additional protection beyond the prospect of transport and storage and more likely to their shelf life (Nitaigour 2014). The impact of these packaging materials on environmental is another important issue that made the necessity for adapting novel, safe technology such as biodegradable biopolymer packaging materials is receiving attention in recent years. Edible packaging is a newly emerged area in food packaging that offers effective means of safe packaging and environment friendly (Danijela et al. 2015). Figure 1 provides a detailed overview of various materials used during last century for various food products. Figure also highlights limitations and advantages of various materials use in food packaging. The use of conjugated polymers, including bio-conjugates along with nano-conjugate, provides additional properties to packaging material such as antimicrobial resistance ideal for the food industry (Alfadul and lneshwy 2010).

Fig. 1.

A detailed overview of food products packaging. The figure also depicts trends in food packaging; ancient, modern and advanced. The figure also provides detailed overview of limitations and advantage of various materials use in food packaging

Packaging of food products

Packaging plays an essential role in protecting and containing the products throughout their shelf life. Further-more, relevant product information about nutrition and its storage has become a crucial part of the packaging operation (Müller and Schmid 2019). However, the packaging methods and material often varies with products packed. In general, the packaging operations carry out to fulfill several objectives, including; physical and barrier protection, information transmission, transportation and marketing, anti-counterfeiting packaging, and security (anti-tampering). For food products, including fruits, vegetables, milk and milk products, meat, dry fruits, bakery products, sauces, etc. require more emphasis on shelf life and nutrition quality (Dobrucka and Cierpiszewski 2014). As the food product is much prone to microbial infection and growth, leading to the deterioration of product choice of packaging material becomes crucial. Certain food products such as fruits and vegetables require additional properties from the material used in packaging to control the maturation of packed products (Risch 2009). Milk products, meat, sauces, and bakery products select a packaging material not only to offer protection but also extend shelf life with sustained organoleptic properties as well (Table 1) (Risch 2009).

Table 1.

Trends in various materials used in the packaging of food products and dietary supplements

| Material used | Packaging product |

|---|---|

| Glass | Food product—milk and milk product, soft drink, sauce jam, jelly, beverages, edible oils. Dietary supplements—protein supplements, probiotics, nutraceutical formulations and vitamins |

| Type I and Type II | |

| Metal | Food products, soft drinks, milk products, beverages |

| Aluminum foil and cane | |

| Tinplate, Tin-free steel | Soft drinks, fruits juice, Food products large volume |

| Paper and Paperboard | Packing of variety of milk products, bakery products, fruits juices, dry fruits and dietary supplements- protein and vitamins |

| Kraft paper, grease proof paper Parchment paper and glassine | |

| White board, Fibre boards and solid boards | packaging of fruit juices and soft drinks, tea and cereals, fruit juices and soft drinks |

| Synthetic material | Food Product—Milk and milk product, soft drink, sauce jam, jelly, beverages, edible oils. Dietary supplements—protein supplements, probiotics, nutraceutical formulations and vitamins, snacks, dry fruits |

| Polyolefin, polyesters, polyvinyl chloride, polyamide, laminates and co-extrusions, ethylene vinyl alcohol | |

| Polyolefin, polyesters, polyvinyl chloride, polyamide, laminates and co-extrusions, ethylene vinyl alcohol | Food Product—Milk and milk Product, Soft Drink, Sauce Jam, Jelly, Beverages, Edible oils. Dietary Supplements—protein supplements, probiotics, nutraceutical formulations and vitamins, snacks, dry fruits, |

| Biodegradable and edible packaging | Food Product—milk and milk product, soft drink, sauce jam, jelly, beverages, edible oils. Dietary supplements—protein supplements, probiotics, nutraceutical formulations and vitamins, snacks, dry fruits |

| Polyhydroxyalkanoates (PHAs)-poly-3-hydroxybutyrate (PHB), polyhydroxyvalerate (PHV) and polyhydroxyhexanoate (PHH); Polylactic acid (PLA); Polybutylene succinate (PBS) and polycaprolactone (PCL) | |

| Chitin, chitosan, agar, carrageenan and alginate galactomannan, starch, corn zein and wheat gluten, WPC/WPI/WPHL | Edible food products, vitamins |

The most crucial aspect of any packaging operation is to ensure the product quality going to pack. The therapeutic formulations, food products, and dietary suppliants essentially require more attention while packaging to ensure their standard. There are different guidelines for the products which are not directly associated with human health. The food products and dietary supplements are more prone to bacterial contamination and, subsequently, microbial-based deterioration, hence the entire packaging operation designed to avoid these complications. This is more important to make a note here that these products necessarily evaluated for various quality control, and hence the packaging should not be a barrier (Gabriels and Lambert 2013). Further, the material used in packaging must be chosen to support these tests, keeping the integrity of the formulation. However, the packaging of products associated with human health, including therapeutic formulations, food products, and dietary supplements, has to ensure their quality of various national and international standard additions to generalized guidelines (Bailey 2020). The Indian Pharmacopeias (IP) takes all the measures for pharmaceutical and biopharmaceutical formulation in India, United States Pharmacopeias (USP) and British Pharmacopeias (BP) in the United States and the United Kingdom respectively. Further, these guidelines are reviewed from time to time to ensure the quality of the product packed (Marcus 2016).

Ancient and modern packaging system

The ancient packaging includes the use of wooden parts, especially Bamboo Baskets, Wooden Containers, and Jute Sacks, for the packaging of fruits and vegetables. The classical packaging of a manual option often gets failing to cover a large number of products (Knorr and Watzke 2019). Moreover, such opportunities are only applicable to those products which are having natural protection against influencing elements, including sunlight, moisture, pathogens, and pollutants. At present, these methods are hardly practiced anywhere. There are numerous facts, including inefficiency, short self-life, incompatibility to storage and transport led to developing a new option for packaging of food products and dietary supplements (Jones 2019). In contrast to the ancient mode of packaging, modern systems are the necessity of the current time. The diversity of available products and their consumption are two key factors that led to the development of the entire different industries for packaging. The modern packaging technology is associated with sophisticated and elegant packaging but also ensure preservation of product quality, enhanced the shelf life, ease transportation and storage (Theurich 2020). Further-more, modern packaging technology have already revolutionized the manufacturing and product availability across geographical boundaries. Novel packaging technology had made possible packaging of therapeutic formula food products and dietary supplements from a different origin, different physiochemical characteristic and different size and volume (Guillard et al. 2018). The significance of the packaging clearly indicates if the product is for use in space, underwater and varying geographical conditions without losing their therapeutic and nutritional value.

The material used in packaging

Paper and paperboard

The paper and paperboard are the oldest and most economical material practiced in the packaging. The paper and paperboard materials are a plant-derived cellulose product with some refinement accordingly to packaging conditions/requirements (Kirwan 2005). Paper based packing offer a broad spectrum of product packaging at a relatively low price value. The paper packaging which constitutes more than 30% of the global packaging market, and used for packing of food products, medicine and nutraceuticals. (Kirwan 2005). The most crucial feature associated with paper and paperboard packaging is their inert nature improves the shelf life of packed products. In-addition, paper and paperboard also offer an ease in recycling and remain environment-friendly. The paper and paperboard packaging include packing of a variety of milk products, bakery products, fruit juices, dry fruits, and dietary supplements- protein and vitamins. The standard paper cannot be used as such due to the reduced barrier to moisture, which further led to microbial contamination. Furthermore, the normal paper lacks mechanical strength necessarily required for transportation and storage. The overcome these complications different forms of paper and paperboard are, in practice, of packaging (Hotchkiss and Vecchio 1983). Among these modified forms of paper, Kraft paper which produced by sulfate treatment of ordinary paper for packaging of sugar, dried fruits, flour, and vegetables. The grease-proof paper ideal for those products which are much prone to moisture-based spoilage and produced by hydration of cellulose, leading to gelatinous nature and gelatinous fiber-packed densely to provide packaging to wrap snack foods, cookies, candy bars, and other oily foods, a use that is being replaced by plastic films (Ozakia et al. 2006). Depending on the demand and requirement, several categories of paper are being manufactured for packaging purposes only. The classification of paper used in food packaging is based on two major criteria 1; based on pulp or treatment, 2; based on shape and size of various materials. The details of paper used in food packaging give explored in Table 2.

Table 2.

List of various types of paper used in food packaging industry

| Types of Paper | Properties | Food products and dietary suppliant packed |

|---|---|---|

| Kraft paper |

Grade 1; refer to virgin kraft by paper industry and made from 100% unbleached sulphate pulp, or from a mixture of wood and bamboo pulp Grade 2; referred as bagasse, rice/wheat straw, grass, jute or a mixture of these with sulphate pulp Grade 3; produced from 100% waste paper or a mixture of waste paper and agricultural waste |

Flour, sugar, dried fruits and vegetables, sandwich wrapper, biscuit bag, chewing gum wrapper, frozen and non-frozen confection wrapper, salt, pepper, sugar packets and tea pouches |

| Bleached paper | Produced via a chemical process using chlorine, chlorine dioxide, hydrogen peroxide, ozone | Flour, sugar, and fruits and vegetables. |

| Greaseproof paper | It gives translucent and hydrated characteristics with oil and grease resistance. Producing via beating cellulose fiber to achieve water absorption capacity | Used for packaging of oil/fat rich food such as milk products |

| Glassine paper | A modified version of Greaseproof paper uses extreme hydration had been performed to develop a dense sheet with high density, transparency, smooth and glassy surface | Used for packaging of food rich in oil/fat rich food and protein as well. Milk products and meat. |

| Vegetable parchment paper | Manufactured by acid treatment and repeated washing with water allow partial solubilization and swelling of cellulosic fibres | Mainly for butter and food product rich in oil/fat, also slices of pastry or meat |

| Waxed paper | Any form of paper waxed restrict moisture exchange | Used for packaging of milk and juices |

| Sulfite paper | Sulfate paper is form of paper having a glazed surface to improve its appearance, wet strength and grease resistance | Confectionary and bakery products |

| Paperboard (Grammage with 250 gsm (gram per meter square)) | Paper bags; It could be grease resistant, kraft paper, recycled kraft, coated papers, wax impregnated, laminated | Paper bags are not used for primary packaging of food but mostly for grocery carry use |

| Newspaper; cellulose derived household paper including news papers | For wrapping freshly cooked non sticky food stuff such Roti/chapatti in India. Also use for wrapping of fruits and vegetables | |

| Composite cans; Generally made up of paper especially kraft type is the major layer in composite cans with polypropylene, high density polyethylene (HDPE) and aluminium | Used for a large variety of food products including refrigerated dough, snacks, frozen fruits, dried fruits, nuts, chips, powdered foods, dried meats, salt/spices, cookies/crackers and confectionary products | |

| Corrugated fibre board (CFB); Made up of craft paper with additional layers of corrugated material | CFB are used in the packaging of meat, fish, pizza, burgers, fast food, bread, poultry and French fries |

Another form of ordinary paper called glassine, produced by extreme hydration, provides gas resistance ideal for biscuits, cooking fats, fast foods, and baked goods. Parchment paper is an ideal packaging material for butter and lard produced by acid treatment yielding smooth and water-resistant paper. While paperboards are thicker, multi-layers designed for mechanical support to the package. There are different forms of cardboard available for packaging of food products, including Whiteboard produced from pulp with several bleaching followed by wax coating or polyethylene lamination ideal for ready-made food products (Marsh and Bugusu 2007). The solid boards are multilayered bleached, and laminated with polyethylene designed for mechanical strength for the packaging of fruit juices and soft drinks. Fiberboards are solid or corrugated ideal for bulk food product packaging, while Chipboard is very good for tea and cereal packaging as these is the recycled products of another paper (Biedermann et al. 2011). Paper packaging is extensive use for nonalcoholic beverages, including milk, fruit juices, and soft drink product. There are several reports demonstrated safety concerns and risks of toxicity as well. In the year 2004, Ozaki et al. carried out a study involving chemical analysis and genotoxicity of contaminants present in paper packaging. The research showed that dehydroabietic acid (DHA) and abietic acid (AA) could be toxic and may exert a genotoxic effect at higher concentrations (240 and 990 microns/g) of contaminant often reported in paper packaging. A risk of food contamination by the use of printed paper material in food packaging remains viable. Despite a few reported studies of toxicity associated paper in processed form is widely used for primary and secondary packaging of a variety of products including food products.

Glass

Glass container are one of the oldest methods and still practiced choice of food products packaging for a variety of products such as pharmaceuticals, nutraceutical, several food products and dietary supplements (Sorrentino et al. 2007). The glass manufacturing involves the use of silica as a critical element in glass material and sodium carbonate as a melting agent with the limestone/calcium carbonate and alumina as stabilizers. The cocktail allows melting as very high temperatures followed by molding of thick liquid (b The glasses are routinely recycled broken glass pieced accounts for as much as 60% of all raw materials in the glass manufacturing industry. Food products are regularly packed within glass containers with lubrication to remove lines and eliminate scratching or surface abrasion and line jams. The significant advantage of glass packaging is it does not impact odor to the product due to its chemical inertness nature (Majid et al. 2016). The other advantages glass packaging includes moisture resistance and adds up a pleasant physical appearance which was often used for marketing prospects. The packed food products in glass container sustain its freshness for an extended period without impairing taste or flavour (Fellows and Axtell 2002). The glass material is still the first choice for pharmaceutical and biopharmaceutical formulations as they offer thermal resistance to the packed product. Furthermore, chemical inertness of glass material resists ideal for medicinal products in liquid form against acid and base. More important glass materials are eco-friendly and easily recycled. The major limitation of glass packaging is its fragile nature, which is the main drawback in transportation and storage. For the pharmaceutical and biopharmaceutical packaging, a specially designed form of glass has been designed including Type I, Type II, Type III, and Type IV. Among this Highly Resistant Borosilicate (Type II) and Highly Resistant soda-lime glasses (Type I) is the first choice of the medicinal formulation, Shamblin et al. 1999).

Metal

Metal-based packaging is one of the most acceptable and versatile forms of packaging for different products. Metal-based packaging offers physical protection and recyclability (Yu 2001). The metals based packaging is eco-friendly practices for many decades. Among the metal-based packaging, aluminum and steel are more commonly used in packaging for various products, including food products and dietary supplements in different shapes and sizes. The first choice is aluminum which is available in forms such as cans, foil, and laminated paper or plastic packaging (Page 2003). Aluminum is manufactured from bauxite ore with a combination of alumina provides excellent mechanical strength ideal for transportation and storage. The aluminum packaging offers packages of milk products, soft drinks, beverages, fruit juices and protein supplements (Vermeiren and Devlieghere 1999). The advantage of aluminum containers in packing as it is resistant to moisture, air, odors, light, and microorganisms and offers unique flexibility and surface resilience, excellent malleability and formability, and outstanding embossing potential. An aluminum foil thin plated sheet is ideal for a soft drink and has proven its market value in the beverage industry. Moreover, the laminates and metalized films are conjugates of paper or plastic that provides measurable flexibility to the packed formulation (Singh et al. 2011). The high price of laminated aluminum typically used to package high-value foods such as dried soups, herbs, and spices. To be cost effective, a metalized film has been developed to resist moisture, oils, air and is mainly used for packaging snacks. The dietary supplements are routinely packed in aluminum containers and sustain their self-life for years without altering nutritional values (Dean 2007).

Steel

Steel is another option to provide a durable form of packaging for food products and dietary supplements. Sanders 1949 reviewed the potential of metals, including steel in food packaging. The metal, steel is produced from low-carbon steel called tinplate comprises coating both sides with thin layers of tin (Kamerud et al. 2013). Tin-plated steel offers to package to cans for drinks, processed foods, and aerosols; containers for powdered foods and sugar- or flour-based confections; and as package closures. Tin-plated steel provides resistance to gasses, water vapor, light, and odors. Further tinplate containers are widely practiced to pack sterile products after heat-treated and sealed hermetically. The tin-plated steel can be recyclable and eco-friendly minimizes pricing (Cooper et al. 2011). Tin-free steel is another metal available for the packaging of food products and dietary supplements. The steel coated with chrome oxide offers complete corrosion resistance. The physical protection, the thermal and chemical resistance of tin-free steel, has become famous for food cans, can ends, trays, bottle caps (Eliasson 1996). Another advantage of tin-free and tin-coated steel is to pack a large volume of food products and dietary supplements due to mechanical strength, which further can be optimized while designing containers (Grumetto et al. 2008). Compare to other materials used in food packaging percentage of steel is comparatively low; however, the higher recyclability of steel often cut down packaging cost. Like plastics, steel containers are associated with safety issues, and bisphenol A (BPA) is the most crucial contaminant considered in such packaging. Seltenrich, in 2015, explored approaches to reduce such pollutants in food products packed using steel and similar metal materials. Charbonneau (1997) studies how coated metal containers may react with food ingredients and result in serious health issues. Further, Stahl et al. (2017) reported migration of aluminum traces at the toxicological level from packed material to food might exert serious health complications.

Synthetic materials

Among synthetic material, plastics provide the most varied forms of packaging material for various types of formulations. The increasing interest of the packaging industry in the synthetic material is due to its versatile nature. The plastics are condensation products of various monomer units, including polyethylene, polypropylene, Polyethylene terephthalate, vinyl chloride, vinylidene chloride, styrene, ethylene, and vinyl alcohol and diamine and di-acid (Table 3) (Tang et al. 2012). The synthetic packaging material possesses several advantages over other existing equipment such as can be designed at the site of packaging, different forms of size and shape, and complete physical resistance. Further, these materials are comparatively cheap and provide ease in labeling, printing, and sealing (Vasile 2018). The number of products that are in the practice of packaging using synthetic material includes food products, jelly, jams, dry fruits, ready-made edible products, snacks, milk products, ice-cream, dietary supplements- proteins, edible oils, vitamins. The pharmaceutical dosage forms, including tablets, capsules, pills, ointments, paste, cream, eye drops, ear drops and injectable formulations (Andrady and Neal 2009). The major disadvantage of synthetic material is its disposal. The majority of synthetic materials which are in practice to pack food products and dietary suppliants fails to recycle naturally and need more emphasis to dispose of as part of solid waste management (Thompson et al. 2009).

Table 3.

List of various synthetic material used in packaging of food products and dietary supplements

| Synthetic material | Properties | Food products and dietary suppliant packed |

|---|---|---|

| Polyolefin | Condensation homo-polymer of ethylene (polyethylene) and propylene (polypropylene), thermal resistant, moisture and microbial protection | Food product—milk product, soft drink, sauce jam, jelly, dietary supplements—protein supplements, probiotic’s, nutraceutical formulations and vitamins, snacks, dry fruits |

| Polyesters |

Condensation homo-polymer of ethylene terephthalate (polyethylene terephthalate) Homo-polymer of Carbonate (Polycarbonate) Homo-polymer of Ethylene naphthalate (Polyethylene naphthalate), Chemical and thermal stability. Protection from moisture and microbes |

Food Product—milk and milk product, soft drink, sauce jam, jelly, beverages, edible oils. Dietary supplements—protein supplements, probiotics, nutraceutical formulations and vitamins, snacks, dry fruits |

| Homo-polymer of Carbonate (Polycarbonate) Homo-polymer of Ethylene naphthalate (Polyethylene naphthalate), Chemical and thermal stability. Protection from moisture and microbes | ||

| Polyvinyl chloride | Condensation homo-polymer of vinyl chloride, heavy, stiff, ductile, and a medium strong, chemicals resistance (acids, bases), grease, and oil; | Food product—milk and milk product, soft drink, sauce jam, jelly, beverages, edible oils. Dietary supplements—protein supplements, probiotics, nutraceutical formulations and vitamins, snacks, dry fruits |

| Polyvinylidene chloride | Addition polymer of vinylidene chloride, Heat sealable and serves as an excellent barrier to water vapor, gases, and fatty and oily products | Packaging of poultry, cured meats, cheese, snack foods, tea, coffee, and confectionary |

| Polystyrene | an addition polymer of styrene, is clear, hard, and brittle, low melting point | Lids, cups, plates, bottles, and food trays for various food products |

| Polyamide | Condensation reaction between di-amine and di-acid, chemical and thermal resistance to product | Food product—milk and milk product, soft drink, sauce, jam, jelly, beverages, edible oils. Dietary supplements—protein supplements, probiotics, nutraceutical formulations and vitamins, snacks, dry fruits |

| Ethylene vinyl alcohol | Co-polymer of ethylene and vinyl alcohol. an excellent barrier to oil, fat, and oxygen | Sauce, Jam, Jelly, Beverages, Edible oils. Dietary Supplements—protein supplements, probiotics, nutraceutical formulations and vitamins, snacks, dry fruits |

Plastics and derivatives

The plastic used in the packaging of food products and dietary supplements could be thermosets and thermoplastic nature. By and large, plastic-based polymers are relatively cheaper offer a low cost, ease of processability, formability, chemical resistance, lightweight, and a variety of physical properties (Marsh and Bugusu 2007). Further, composite polymers are becoming more popular nowadays in food packaging with predefined features. The conventional composite polymers are low density and high-density polyethylene (LDPE and HDPE), polypropylene (PP), polyethylene terephthalate (PET), ethylene vinyl alcohol (EVOH) copolymer, polyamide (PA), polystyrene (PS) and degradable ones as polyhydroxyalkanoates (polyhydroxy butyrate (PHB), poly(hydroxybutyrate-co-hydroxy valerate) (PHBV)), poly(lactic acid) (PLA), polycaprolactone (PCL), polyvinyl alcohol (PVOH) (Piringer 1994). Additionally, polyolefins and polyester are the most common plastic used in food packaging. Among the polyolefin category, Polyethylene and polypropylene represent essential players due to their lightweight, malleability, strength, stability, process ability, reusability, and resistance to chemicals and moisture (Jetten et al. 1999). In the current trend, polyethylene-based material is ideal for milk, juice, and water bottles, grocery, retail, and garbage bags, and bread and frozen food bags. Further, packaging requires heat resistance to opt for polypropylene-based materials (Claudio 2012).

Modern packaging system

In the current scenario, solid waste management is a significant challenge in concern of the environment, and plastic waste is a leading one. The increasing consumption of packaging material and failure in the natural recycling system, along with the cost factor of existing packaging materials, led us to find different options (Sharma et al. 2017). The incompatibilities associated with metal and glass material to pack small volumes of packages further trigger to search another feasible option (Müller and Schmid 2019). The use of biodegradable materials, edible packaging, and natural polymers are key packaging material for the future. The natural biopolymers derived from plants, animals, and microbes are replacing chemical-based equipment. There is much emphasis on developing packaging material compatible with food products and also eco-friendly (Wrona and Nerín 2020). The strict regulation further strengthens the packaging industry to create new, more productive and eco-friendly content not only for the food industry but for others as well.

Biodegradable materials

The biodegradable materials, often called biodegradable plastic has become more popular now a day as these products can be recycled using enzymatic reaction by microbial incorporation (Siracusaa et al. 2008). The biodegradable plastic comprised of two basic classes, one Bioplastics, whose building components are derived from renewable raw materials, and other plastics manufactured from the petrochemicals possess biodegradable additives, which further enhance biodegradation under natural conditions (Table 4) (Ioannis et al. 1998). The aromatic polyesters have emerged as one of the class of biodegradable material available for packaging. The aromatic polyesters are resistant to moisture and microbial contamination subsequently (Ioannis 1999). The available aromatic polyesters used in food packaging are natural polyhydroxyalkanoates (PHAs) such as poly-3-hydroxybutyrate (PHB), polyhydroxy valerate (PHV) and polyhydroxyalkanoate (PHH); Renewable such as a Polylactic acid (PLA); and purely Synthetic: Polybutylene succinate (PBS) and polycaprolactone (PCL) (Jin and Zhang 2008). Further, starch derivatives, cellulose esters, cellulose acetate, nitrocellulose, and celluloid are available biodegradable polymer for packaging. In addition to finding novel biodegradable material for packaging, more emphasis is given in recent times to develop plastic with a high proportion of additives for enhanced natural recycling. The products of poly-anhydride and polyvinyl alcohol have attended in current times to develop novel biodegradable material for the packaging industry (Cabedo et al. 2006). Though these materials are eco-friendly and offer easy recycling, there are several limitations associated with it. The primary issue with these novel materials is their manufacturing cost again, a very crucial factor for the final price of a product. Additionally, the essential requirement for packaging- physical protection, mechanical strength for transportation, and storage has to analyze. The material product compatibility is another crucial factor that needs to evaluate before commercial application. There is less evidence for the large-scale commercial claim of such products in the packaging of food products and dietary supplements (Estaca et al. 2014).

Table 4.

List of biodegradable polymer, nature and application in food packing industry

| Class of polymer | Nature of polymer | Application in food packaging |

|---|---|---|

| Natural Polymers | Starch | Wraps, cups, plates, trays, disposable dishes |

| Cellulose | Films, fresh food packaging, baked goods packaging | |

| Chitosan | Films for fresh fruits and vegetables | |

| Protein | Films, Coating on paper | |

| Synthetic biopolymers | Polyhydroxyalkanoates (PHA) | Cheese coatings, fast food plates, bottles, containers, sheets |

| Bacterial cellulose (BC) | Films | |

| Non-natural polymers | Poly(vinyl alcohol) (PVA) | Water-soluble films |

| Polylactide (PLA) | Paper coatings, films | |

| Polyglycolide (PGA) | Protective layer in multilayer packages, such as PETE bottles, cups, dishes, trays | |

| Poly(e-caprolactone) (PCL) | Foam trays, loose fill, film bags | |

| Poly(butylene succinate) (PBS) | Films, bags | |

| Poly(trimethylene terephthalate) (PTT) and derivatives | Films | |

| Poly(butylene adipate-co-terephthalate) (PBAT) | Films, blown bottles, disposable food bags, trays |

Edible packaging

Edible packaging is an attempt to develop packaging material of biological origin to pack food products and dietary supplements (Alves et al. 2010). The edible packaging not only provides an ideal material for the packaging of food products and nutritional supplements but also enhances the nutritional value of packed products. The edible packaging is a surface phenomenon that provides stability and aeration often require for various food products and dietary supplements. The biomaterial, including protein, lipids, and carbohydrates from plant, marine, and microbial sources, has shown tremendous potential in developing edible packaging. The edible packaging carries out by promoting coating or film around a food product and dietary suppliant with biomaterials (Guilbert et al. 1997). The biomaterials available for edible packaging include carbohydrates; polysaccharides—chitin, chitosan, agar, carrageenan, and alginate from marine sources and galactomannan, starch, corn zein and wheat gluten from plant origin (Tharanathan 2003). The animal origin biomaterials such as collagen, casein, and white protein concentrate/white protein isolate/while protein hydrolysate (WPC/WPI/WPHL has shown their potential as a material for edible packaging (Auras et al. 2004). Among film-forming biomaterial lipids from wax is ideal for designing food products and dietary supplements. The lipid film further stabilized by surfactant- lecithin, tween, spans and plasticizer- sorbitol, starch, corn syrup are generally from the biological origin (Rhima and Ng 2007). The edible packaging additionally incorporates nutritional additives including antioxidants, Nutraceutical, antimicrobial, flavors, and colors. The major challenges with edible packaging are shelf-life products, mechanical strength, and storage (Guilberta et al. 1997).

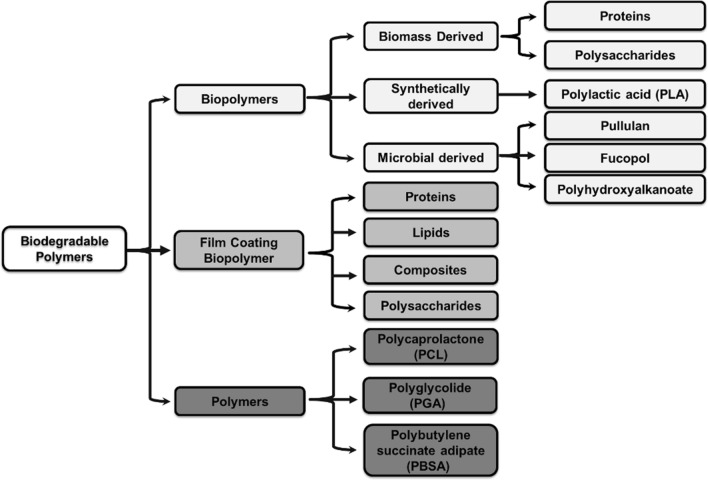

Polysaccharides are the most abundant carbohydrate polymers and associated with a wide range of ss polysaccharides derived from various sources, including animals, plants, algae, and microbes, offer a wide range of biodegradable coating material for safe packing in food and other products. The essential polysaccharides shown potential in good food packing are chitin, chitosan, starch, galactomannans, cellulose, carrageenan, and alginate with distinct physicochemical properties. For a material being used in the edible film, the coating requires specific membrane properties, and here, polysaccharides emerged as the most valuable natural polymer (Vasile 2018). Several research findings have demonstrated that polysaccharides derived from plant, animal, algae, and microbes possess excellent membrane properties, including biodegradable nature, antimicrobial, non-toxic, and highly transparent. Further, these polymers also exhibit superior mechanical properties, allow gaseous exchange, and maintain an adequate amount of water in packed food material (Mlalila et al. 2016). Polysaccharides precisely starch is ideal coating material for edible food packing as exhibit excellent mechanical properties, i.e., tensile strength. On the contrary, cellulose reported as a perfect candidate for film coating as it is highly sensitive to water resistance to fats and oil. The wide range of food products including fruits (apples, strawberries, cherries, mango, guavas, papaya, pear, and melon), milk products (cheese), vegetables and meat utilize polysaccharides based edible packing (Fig. 2) (Mangaraj et al. 2019).

Fig. 2.

Figure provide comprehensive details of various biodegradable polymer use in food packaging Industry. These biodegradable polymers derived from different sources including biomass, microbial and synthesis based

The materials/polymers used in edible packaging can be categories into four significant classes, including hydrocolloids, polypeptides, lipids, synthetic, and composite edible polymers (Siracusa et al. 2008). These polymers differ into physicochemical properties and hence had a full range of packaging spectrum. The hydrocolloids are the most abundant natural polymers derived from animals, plants, and microbes. For edible packaging or film coating, cellulose derivates such as hydroxypropyl cellulose (HPC), hydroxypropyl methylcellulose (HPMC), carboxymethylcellulose (CMC), or methylcellulose (MC) are widely used (Rydz et al. 2018). Compare to cellulose derivatives, peptides based coating, or edible packaging is limited. However, peptides based polymers possess additional properties such as antimicrobial and antioxidant ideal for many food products. Collagen, gelatin, and zein are a few examples of peptides based polymer used in food packaging. Mung beans are rich in protein and offer a film-forming tendency and excellent mechanical property (Mohanty and Swain 2017). Lipids offer another important class of natural polymer for film coating or edible packaging. Lipids derived polymer for edible packaging consists of acetylated monoglycerides, natural wax, and surfactants. Shellac resins, rosin and paraffin wax, are widely used lipid polymers for the coating to fruits and vegetables. The use of synthetic and composite polymers in edible packaging or film coating has a long list of compounds. These compounds synthesized with the use of natural polymers and or purely synthetic ones. The classic example of synthetic polymer widely used in film coating is polyvinyl acetate, a non-toxic and durable material. Further, biocompatible synthetic polymers such as polymethyl methacrylate (PMMA) have an advantage in food packaging as the least toxic nature (Schaefer and Cheung 2018).

Edible packaging, shelf life, and safety

The extended use of polymers, including both natural and synthetic in edible food packing, is widely accepted. However, safety issue remains a significant concern along with the shelf life of packed material. In a study, Maftoonazad and Badii, 2009 investigated the effect of edible food packing on the shelf life of product packed. The study demonstrates a wide range of characteristics, including barrier properties regulating the exchange of gases, i.e., CO2 and O2, moisture content, chemical and physicochemical stability are required to extend the shelf life of packed food products. It is evident that edible film coating allows additional properties to packed food, including antioxidants, flavor, color, and aided nutritional ingredients. The nature of the polymer used in food packaging also depends on the food material itself. For example, in fruits and vegetable, the packaging material control maturation of product packed. On the contrary, meat, milk products, dry fruits, and bakery products require a material offer antimicrobial property to extend shelf life. Guilbert et al. 1997 study nature and physicochemical properties of the polymer in edible food packaging. Additionally, polyethylene glycol (PEG) and poly (N-vinylpyrrolidone) are cellulose derivatives with increasing scope in film coating. For nutraceutical and dietary supplements, the researcher finds methacrylic acid, and methyl methacrylates are superior over natural and other synthetic polymers as protects formulation from damage caused by moisture, light, and air even though long history in coating and film-based packaging synthetic materials remain associated with environmental issues.

Packaging of food and dietary suppliants

The packaging of food products and dietary suppliants is quite different from pharmaceutical and biopharmaceutical formulation due to various factors. The key factors associated are shelf life, size, and volume of packed item consumption, ease of using the product, diversity of packed products, and cost as well (Holzapfel et al. 1995). These requirements led to the development of various packaging materials, including paper, paperboard, glass, metal, synthetic plastic, biodegradable materials, and edible packaging techniques. Several techniques and materials have been used in the last few decades to supply commercial demand under good manufacturing practices (GMP) (Guilberta et al. 1997). For food products and dietary supplements, paper packaging is most acceptable for a long time. As discussed earlier, there are several grades of paper developed for food packaging. The advantage of paper-based food packaging is low cost and safety. Milk and milk products and juices extinguished used paper-based packaging. Additionally, glass and metal-based packaging are more common for milk, juices, and soft drinks. The glass and metal-based packaging tackle limitations associated with paper-based packaging i.e., transportation issues (Puscaselu et al. 2019). Among metals used in food packaging, aluminum and tin in different forms are most common compare to other metals. The use of edible packaging is the most crucial aspect of modern-day packaging of food and food products. Film coating on fruits and vegetable utilizes a large number of biopolymers and synthetic compounds as well (Janjarasskul and Krochta 2010).

Environmental issues

The food industry has grown exponentially in the last few decades, and the impact of industrial development need to analyze (Marsh and Bugusu 2007). The materials used in the packaging of food products and dietary supplements are associated with adverse effects on the environment. The synthetic polymers, including plastics and specific use in the food packaging industry posed a burden on annual solid waste generation. Further, synthetic polymers specially designed for film coating; remain associated with several environmental issues (Table 5). The increasing solid waste is a significant challenge to a human in concern of the environment. The more critical, a synthetic material which constitutes more than 50% of packaging material alone in the food industry is needed to encounter first (Siracusa and Rosa 2018). The bio-degradable materials are the first choice for packaging need to explore and utilize a large scale. In the available packaging material paper, paperboard, glass, and metal are associated with minimal damage, and the latest inventions, including biodegradable materials and edible packaging, have been considered as the first choice of eco-friendly materials (Geueke et al. 2018).

Table 5.

List of materials used in food packaging industry and their Impact on Environment

| Material used | Impact on environment |

|---|---|

| Glass | Associated with pollution, recyclable economically and reusable |

| Type I and Type II | |

| Metal | Associated with pollution |

| Aluminum foil and cane | |

| Tinplate | Recyclable economically and |

| Tin-free steel | Reusable |

| Paper and paperboard | Biodegradable recyclable economically and reusable |

| Kraft paper, grease proof paper Parchment paper and glassine | |

| White board, Fibre boards and solid boards | Biodegradable recyclable economically and reusable |

| Synthetic material | Non-Biodegradable Recyclable with intense process, high expenditure associated with pollution |

| Polyolefins, polyesters polyvinyl chloride, polyamide, laminates and co-extrusions, ethylene vinyl alcohol | |

| Polyolefins, polyesters polyvinyl chloride, polyamide, laminates and co-extrusions, ethylene vinyl alcohol | Non-Biodegradable Recyclable with intense process, high expenditure associated with pollution |

| Biodegradable and edible packaging | Biodegradable And safe |

| Polyhydroxyalkanoates (PHAs)-poly-3-hydroxybutyrate (PHB), polyhydroxyvalerate (PHV) and polyhydroxyhexanoate (PHH); Polylactic acid (PLA); Polybutylene succinate (PBS) and polycaprolactone (PCL) | |

| Chitin, chitosan, agar, carrageenan and alginate galactomannan, starch, corn zein and wheat gluten, WPC/WPI/WPHL | Biodegradable And safe |

Regulation

The regulation of packaging of food products and dietary supplements is under Federal drug administration (FDA) (Ozaki et al. 2005). Additionally, each country has postulated rules and regulations for the safe and efficient practice of packaging operations using different materials. The European Food Safety Authority (efsa) is the governing body in European countries that regulates the use of various materials in the packaging industry, including the food industry. Both USFDA and efsa design policies for the materials that can be used in the packaging industry (Dimitriyevic 2015). These agencies also review the level of contaminants present in packaging material and impact on human health. In India, Food Safety and standard authority of India (FSSAI) is responsible for food product and dietary supplements, manufacturing and packaging. Food Safety and standard authority of India designed protocol and standard need to practice and refine legislation from time to time associated with food industries (EFSA 2008). Moreover, the Ministry of Commerce and Industry for the Department of Industrial policy and promotion with Pollution Control Board (CPCB) work together to ensure the legitimate practice of Industrial development without damage to the environment.

The prospect of food packaging

The massive rise in demand for food and food products resulted in the refinement of existing material and the development of more useful materials for food packaging. At the same time, innovations and new technologies in material science enhanced shelf life of packed food products (Biji et al. 2015). The edible packaging gained momentum in the last decade, and several polymers were developed to achieve new avenue in eco-friendly food packaging. The use of biopolymer and development of biodegradable polymers is one step towards eco-friendly food packaging and reduce the solid waste problem. The nanotechnology is another interdisciplinary area of modern science provides ease in developing composite material as per food packaging need (Sastry et al. 2013). The concept of active packaging is highly regarded in the case of food packaging as it allows for multiple benefits, including additional functional properties such as antibacterial and antioxidant. Such an effort may enhance the shelf life of the product and reduces food loss/spoilage. There is much effort in smart packaging or intelligence packaging that allows complete information of product, its shelf life, and active ingredient as well. By and significant primary emphasis will be to develop the packaging industry eco-friendly and deliver the active ingredient to the consumer as packed (Tharanathan et al. 2018).

Conclusion

The packaging of food products and dietary supplements is equally important as their formulation. The packaging not only provides physical protection but also to sustain the nutritional value of packed products. Additionally, transportation and storage of the full product define the efficiency of packaging technology and material used. The packed food products and dietary suppliant are an essential part of present human life and associated with health. To achieve efficient packaging, different techniques and packaging material has been used since ancient time. With the advancement of technology, the packaging system has redefined drastically from the old manual system to a highly efficient automated packaging system. In the last few decades, conventional packaging has adapted the novel technology with ease of generation of packaging materials. With the time and commercial demand paper, paperboard, glass, and metal material based packaging is switch over to the biodegradable material. The most advanced form of food packaging is edible packaging offers an eco-friendly means of food packaging. In recent times, material based packaging inventions are becoming popular not only to give fine-tune to the industry but also to improve the nutritional value of packed products and their shelf life. In this regard, a series of innovations and development made in the material used for food packaging from conventional to biodegradable materials. The regulatory authorities such as USFDA and efsa ensure the use of eco-friendly and biocompatible materials in food packaging on a global map. Still, many hurdles need to encounter to provide a more efficient packaging system to avoid loss of food products and dietary supplements and sustainable applications for humankind.

Acknowledgements

The author would like to acknowledge the Department of Biotechnology, Acharya Nagarjuna University, Guntur, Andhra Pradesh, India, for kind support and providing a facility for the study.

Compliance with ethical standards

Conflict of interest

The author declares no conflict of interest.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

M. K. Verma, Email: mahendraverma1980@gmail.com

S. Shakya, Email: phd1501261003@iiti.ac.in

P. Kumar, Email: kumar.ponnusamy@avalonu.org

J. Madhavi, Email: madhuu.bt@gmail.com

J. Murugaiyan, Email: Jayaseelan.m@srmap.edu.in

M. V. R. Rao, Email: reachdrmvrrao@gmail.com

References

- Abeer A, Choudhary R. Current practices in bread packaging and possibility of improving bread shelf life by nanotechnology. Int J Food Sci Nutr Eng. 2013;3(4):55–60. [Google Scholar]

- Ahmed T, Shahid M, Azeem F, Rasul I, Shah AA, Noman M, Hameed A, Manzoor N, Manzoor I, Muhammad S. Biodegradation of plastics: current scenario and future prospects for environmental safety. Environ Sci Pollut Res Int. 2018;25(8):7287–7298. doi: 10.1007/s11356-018-1234-9. [DOI] [PubMed] [Google Scholar]

- Alfadul SM, lneshwy A. A. Use of nanotechnology in food processing, packaging and safety: review. Afr J Food Agric Nutr Dev. 2010;10(6):2719–2739. [Google Scholar]

- Alves VD, Costa N, Coelhoso IM. Barrier properties of biodegradable composite films based on kappa-carrageenan/pectin blends and mica flakes. Carbohyd Polym. 2010;79:269–276. doi: 10.1016/j.carbpol.2009.08.002. [DOI] [Google Scholar]

- Amra B, Amra OS, Catic IS. Application of polymer nano-composite materials in food packaging. Croat J Food Sci Technol. 2015;7(2):86–94. doi: 10.17508/CJFST.2015.7.2.06. [DOI] [Google Scholar]

- Andrady AL, Neal MA. Applications and societal benefits of plastics. Philos Trans R Soc Lond B Biol Sci. 2009;364(1526):1977–1984. doi: 10.1098/rstb.2008.0304. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Auras R, Harte B, Selke S. Effect of water on the oxygen barrier properties of poly(ethylene terephthalate) and polylactide films. J Appl Polym Sci. 2004;92:1790–1803. doi: 10.1002/app.20148. [DOI] [Google Scholar]

- Bailey RL. Current regulatory guidelines and resources to support research of dietary supplements in the United States. Crit Rev Food Sci Nutr. 2020;60(2):298–309. doi: 10.1080/10408398.2018.1524364. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Biedermann M, Uematsu Y, Grob K. Mineral oil contents in paper and board recycled to paperboard for food packaging. Pack Technol Sci. 2011;24(2):61–73. doi: 10.1002/pts.914. [DOI] [Google Scholar]

- Biji KB, Ravishankar CN, Mohan CO, et al. Smart packaging systems for food applications: a review. J Food Sci Technol. 2015;52:6125–6135. doi: 10.1007/s13197-015-1766-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bintsis T. Microbial pollution and food safety. AIMS Microbiol. 2018;4(3):377–396. doi: 10.3934/microbiol.2018.3.377. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Cabedo L, Feijoo JL, Villanueva MP, Lagarón JM, Giménez E. Optimization of biodegradable nano-composites based on a PLA/PCL blends for food packaging applications. Macromol Symp. 2006;233(1):191–197. doi: 10.1002/masy.200690017. [DOI] [Google Scholar]

- Charbonneau JE. Recent case histories of food product-metal container interactions using scanning electron microscopy-x-ray microanalysis. Scanning. 1997;19(7):512–518. doi: 10.1002/sca.4950190710. [DOI] [PubMed] [Google Scholar]

- Claudio L. Our food: packaging and public health. Environ Health Perspect. 2012;120(6):A232–A237. doi: 10.1289/ehp.120-a232. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Cooper JE, Kendig EL, Belcher SM. Assessment of bisphenol A released from reusable plastic, aluminium and stainless steel water bottles. Chemosphere. 2011;85(6):943–947. doi: 10.1016/j.chemosphere.2011.06.060. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Danijela ZS, Vera LL, Senka ZP, Nevena MH. Edible films and coatings: sources, properties and application. Food Feed Res. 2015;42(1):11–22. doi: 10.5937/FFR1501011S. [DOI] [Google Scholar]

- Dean DA. Pharmaceutical packaging technology. Routledge, USA: Taylor and Francis Group; 2007. pp. 406–415. [Google Scholar]

- Dimitriyevic M, et al. Safety aspects of nanotechnology applications in food packaging. Proc Food Sci. 2015;5:57–60. doi: 10.1016/j.profoo.2015.09.015. [DOI] [Google Scholar]

- Dobrucka R, Cierpiszewski R. Active and intelligent packaging food: research and development—a review. Pol J Food Nutr Sci. 2014;64(1):7–15. doi: 10.2478/v10222-012-0091-3. [DOI] [Google Scholar]

- EFSA Scientific opinion of the panel on food additives, flavourings, processing aids and food contact materials on a request from european commission on safety of aluminium from dietary intake. EFSA J. 2008;754:1–34. doi: 10.2903/j.efsa.2008.754. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Eliasson A (1996) Packaging for better planet swedish innovations at the forefront of sustainable packaging. 25: 26–30

- Estaca JG, Lopez-de-Dicastillo C, Munoz PH, Catala R, Gavara R. Advances in antioxidant active food packaging. Trends Food Sci Technol. 2014;35(1):42–51. doi: 10.1016/j.tifs.2013.10.008. [DOI] [Google Scholar]

- Fellows P, Axtell B (2002). Appropriate food packaging: materials and methods for small businesses. Packaging materials. TOOL Publication, Amsterdam, Netherland, 193

- Gabriels G, Lambert M. Nutritional supplement products: does the label information influence purchasing decisions for the physically active? Nutr J. 2013;12:133. doi: 10.1186/1475-2891-12-133. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Geueke B, et al. Food packaging in the circular economy: overview of chemical safety aspects for commonly used materials. J Clean Prod. 2018;193:491–505. doi: 10.1016/j.jclepro.2018.05.005. [DOI] [Google Scholar]

- Grumetto L, Montesano D, Seccia S, Albrizio S, Barbato F. Determination of bisphenol A and bisphenol B residues in canned peeled tomatoes by reversed-phase liquid chromatography. J Agric Food Chem. 2008;56:10633–10637. doi: 10.1021/jf802297z. [DOI] [PubMed] [Google Scholar]

- Guilberta S, Gontardb N, Gorrisc GN. Prolongation of the shelf-life of perishable food products using biodegradable films and coatings. LWT Food Sci Technol. 1996;29(2):10–17. doi: 10.1006/fstl.1996.0002. [DOI] [Google Scholar]

- Guilberta S, Cuqa B, Gontard N. Recent innovations in edible and/or biodegradable packaging materials. Food Addit Contam. 1997;14(6–7):741–751. doi: 10.1080/02652039709374585. [DOI] [PubMed] [Google Scholar]

- Guillard V, Gaucel S, Fornaciari C, Angellier-Coussy H, Buche P, Gontard N. The next generation of sustainable food packaging to preserve our environment in a circular economy context. Front Nutr. 2018;5(121):2018. doi: 10.3389/fnut.2018.00121.eCollection. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Holzapfel WH, Geisen R, Schillinger U. Biological preservation of foods with reference to protective cultures, bacteriocins and food-grade enzymes. Int J Food Microbiol. 1995;24(3):343–362. doi: 10.1016/0168-1605(94)00036-6. [DOI] [PubMed] [Google Scholar]

- Hotchkiss JH. Food-packaging interactions influencing quality and safety. Food Addit Contam. 1997;14(6–7):601–607. doi: 10.1080/02652039709374572. [DOI] [PubMed] [Google Scholar]

- Hotchkiss JH, Vecchio AJ. Analysis of direct contact paper and paperboard food packaging for N-nitrosomorpholine and morpholine. J Food Sci. 1983;48(1):240–242. doi: 10.1111/j.1365-2621.1983.tb14833.x. [DOI] [Google Scholar]

- Huang Y, Mei L, Chen X, Wang Q. Recent developments in food packaging based on nanomaterials. Nanomaterials. 2018;8(10):E830. doi: 10.3390/nano8100830. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ioannis SA. Totally and partially biodegradable polymer blends based on natural and synthetic macromolecules: preparation, physical properties, and potential as food packaging materials. J Macromol Sci Part C Polym Rev. 1999;39(2):205–271. doi: 10.1081/MC-100101420. [DOI] [Google Scholar]

- Ioannis A, Biliaderisa CG, Ogawab H, Kawasakib N. Biodegradable films made from low-density polyethylene (LDPE), rice starch and potato starch for food packaging applications: part 1. Carbohyd Polym. 1998;36(2–3):89–104. [Google Scholar]

- Janjarasskul T, Krochta JM. Edible packaging materials. Ann Rev Food Sci Technol. 2010;1:415–448. doi: 10.1146/annurev.food.080708.100836. [DOI] [PubMed] [Google Scholar]

- Jetten J, de Kruijf N, Castle L. Quality and safety aspects of reusable plastic food packaging materials: a European study to underpin future legislation. Food Addit Contam. 1999;16(1):25–36. doi: 10.1080/026520399284299. [DOI] [PubMed] [Google Scholar]

- Jin T, Zhang H. Biodegradable polylactic acid polymer with nisin for use in antimicrobial food packaging. J Food Sci. 2008;73(3):M127–M134. doi: 10.1111/j.1750-3841.2008.00681.x. [DOI] [PubMed] [Google Scholar]

- Jones JM. Food processing: criteria for dietary guidance and public health? Proc Nutr Soc. 2019;78(1):4–18. doi: 10.1017/S0029665118002513. [DOI] [PubMed] [Google Scholar]

- Kamerud KL, Hobbie KA, Anderson KA. Stainless steel leaches nickel and chromium into foods during cooking. J Agric Food Chem. 2013;61(39):9495–9501. doi: 10.1021/jf402400v. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kirwan MJ. Paper and paperboard packaging technology. UK: Blackwell Publishing; 2005. [Google Scholar]

- Knorr D, Watzke H. Food processing at a crossroad. Front Nutr. 2019;6(85):2019. doi: 10.3389/fnut.2019.00085.eCollection. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Majid I, Nayik GA, Dar SM, Nanda V. Novel food packaging technologies: Innovations and future prospective. J Saudi Soc Agr Sci. 2018;17(4):454–462. doi: 10.1016/j.jssas.2016.11.003. [DOI] [Google Scholar]

- Mlalila N, Kadam DM, Swai H, Hilonga A. Transformation of food packaging from passive to innovative via nanotechnology: concepts and critiques. J Food Sci Technol. 2016;53(9):3395–3407. doi: 10.1007/s13197-016-2325-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Mangaraj S, Yadav A, Bal LM, et al. Application of biodegradable polymers in food packaging industry: a comprehensive review. J Pack Technol Res. 2019;3:77–96. doi: 10.1007/s41783-018-0049-y. [DOI] [Google Scholar]

- Marcus DM. Dietary supplements: What's in a name? What's in the bottle? Drug Test Anal. 2016;8(3–4):410–412. doi: 10.1002/dta.1855. [DOI] [PubMed] [Google Scholar]

- Marsh K, Bugusu B. Food packaging: role, materials, and environmental issues. Inst Food Technol. 2007;72(3):39–55. doi: 10.1111/j.1750-3841.2007.00301.x. [DOI] [PubMed] [Google Scholar]

- Mohanty F, Swain SK. Bionanocomposites for Food Packaging Applications. Nanotechnol Appl Food. 2017 doi: 10.1016/B978-0-12-811942-6.00018-2. [DOI] [Google Scholar]

- Müller P, Schmid M. Intelligent packaging in the food sector: a brief overview. Foods. 2019;8(1):E16. doi: 10.3390/foods8010016. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Nitaigour PM. Advances in packaging methods, processes and systems. Challenges. 2014;5:374–389. doi: 10.3390/challe5020374. [DOI] [Google Scholar]

- Ozaki A, Yamaguchi Y, Fujita T, Kuroda K, Endo G. Safety assessment of paper and board food packaging: chemical analysis and genotoxicity of possible contaminants in packaging. Food Addit Contam. 2005;22(10):1053–1060. doi: 10.1080/02652030500090885. [DOI] [PubMed] [Google Scholar]

- Ozakia A, Fujitaa T, Kurodab K, Endob G. Chemical analysis and genotoxicological safety assessment of paper and paperboard used for food packaging. Food Chem Toxicol. 2004;42(8):1323–1337. doi: 10.1016/j.fct.2004.03.010. [DOI] [PubMed] [Google Scholar]

- Ozakia A, Ooshimaa T, Moria Y. Migration of dehydroabietic and abietic acids from paper and paperboard food packaging into food-simulating solvents and Tenax TA. Food Addit Contam. 2006;23(8):854–860. doi: 10.1080/02652030600743813. [DOI] [PubMed] [Google Scholar]

- Page B, Edwards M, May N. Metal cans in Food packaging technology. London, U.K.: Blackwell Publishing, CRC Press; 2003. pp. 21–51. [Google Scholar]

- Piringer OG. Evaluation of plastics for food packaging. Food Addit Contam. 1994;11(2):221–230. doi: 10.1080/02652039409374220. [DOI] [PubMed] [Google Scholar]

- Puscaselu R, Gutt G, Amariei S. Rethinking the future of food packaging: biobased edible films for powdered food and drinks. Molecules. 2019;24(17):E3136. doi: 10.3390/molecules24173136s. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rhima JW, Ng PK. Natural biopolymer-based nano-composite films for packaging applications. Crit Rev Food Sci Nutr. 2007;47(4):411–433. doi: 10.1080/10408390600846366. [DOI] [PubMed] [Google Scholar]

- Risch SJ. Food packaging history and innovations. J Agric Food Chem. 2009;57:8089–8092. doi: 10.1021/jf900040r. [DOI] [PubMed] [Google Scholar]

- Rydz J, Musioł M, Zawidlak-Węgrzyńska B, Sikorska W. Present and future of biodegradable polymers for food packaging applications. Biopolym Food Des. 2018 doi: 10.1016/B978-0-12-811449-0.00014-1. [DOI] [Google Scholar]

- Sanders RK. Metal containers in the food packing industry. Research. 1949;2(11):519–523. [PubMed] [Google Scholar]

- Sastry RK, Anshul S, Rao NH. Nanotechnology in food processing sector-An assessment of emerging trends. J Food Sci Technol. 2013;50(5):831–841. doi: 10.1007/s13197-012-0873. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Schaefer D, Cheung WM. Smart packaging: opportunities and challenges. Procedia CIRP. 2018;72:1022–1027. doi: 10.1016/j.procir.2018.03.240. [DOI] [Google Scholar]

- Seltenrich N. A hard nut to crack: reducing chemical migration in food-contact materials. Environ Health Perspect. 2015;123(7):A174–A179. doi: 10.1289/ehp.123-A174. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Shamblin SL, Tang X, Chang L, Hancock BC, Pikal MJ. Characterization of the time scales of molecular motion in pharmaceutically important glasses. J Phys Chem B. 1999;103(20):4113–4121. doi: 10.1021/jp983964+. [DOI] [Google Scholar]

- Sharma C, Dhiman R, Rokana N, Panwar H. Nanotechnology: an untapped resource for food packaging. Front Microbiol. 2017;8(1735):2017. doi: 10.3389/fmicb.2017.01735.eCollection. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Singh A, Sharma PK, Malviya R. eco friendly pharmaceutical packaging material. World Appl Sci J. 2011;14(11):1703–1716. [Google Scholar]

- Siracusa V, Rosa MD (2018) Sustainable packaging; sustainable food systems from agriculture to industry. Academic Press, pp 275–307 10.1016/B978-0-12-811935-8.00008-1

- Siracusa V, Rocculi P, Romani S, Rosa M. Biodegradable polymers for food packaging: a review. Trends Food Sci Technol. 2008;19(12):634–643. doi: 10.1016/j.tifs.2008.07.003. [DOI] [Google Scholar]

- Sorrentino A, Gorrasi G, Vittoria V. Potential perspectives of bio-nano-composites for food packaging applications. Trends Food Sci Technol. 2007;18(2):84–95. doi: 10.1016/j.tifs.2006.09.004. [DOI] [Google Scholar]

- Stahl T, Falk S, Rohrbeck A, Georgii S, Herzog C, Wiegand A, Hotz S, Boschek B, Zorn H, Brunn H. Migration of aluminum from food contact materials to food-a health risk for consumers? Part I of III: exposure to aluminum, release of aluminum, tolerable weekly intake (TWI), toxicological effects of aluminum, study design, and methods. Environ Sci Eur. 2017;29(1):19. doi: 10.1186/s12302-017-0116-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Tang XZ, Kumar P, Alavi S, Sandeep KP. Recent advances in biopolymers and biopolymer-based nanocomposites for food packaging materials. Crit Rev Food Sci Nutr. 2012;52(5):426–442. doi: 10.1080/10408398.2010.500508. [DOI] [PubMed] [Google Scholar]

- Tharanathan RN. Review biodegradable films and composite coatings: past, present and future. Trends Food Sci Technol. 2003;14:71–78. doi: 10.1016/S0924-2244(02)00280-7. [DOI] [Google Scholar]

- Theurich MA. Are modern complementary food packaging, devices and teats compatible with international guidance on complementary feeding? J Hum Lact. 2020;36(1):29–33. doi: 10.1177/0890334419845643. [DOI] [PubMed] [Google Scholar]

- Thompson RC, Moore CJ, vom Saal FS, Swan SH. Plastics, the environment and human health: current consensus and future trends. Philos Trans R Soc Lond B Biol Sci. 2009;364(1526):2153–2166. doi: 10.1098/rstb.2009.0053. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Vasile C. Polymeric nano-composites and nano-coatings for food packaging: a review. Materials. 2018;11(10):E1834. doi: 10.3390/ma11101834. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Vermeiren L, Devlieghere F. Developments in the active packaging of foods. Trends Food Sci Technol. 1999;10(3):77–86. doi: 10.1016/S0924-2244(99)00032-1. [DOI] [Google Scholar]

- Wrona M, Nerín C. Analytical approaches for analysis of safety of modern food packaging: a review. Molecules. 2020;25(3):E752. doi: 10.3390/molecules25030752. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Yu L. Amorphous pharmaceutical solids: preparation, characterization and stabilization. Adv Drug Deliv Rev. 2001;48(1):27–42. doi: 10.1016/S0169-409X(01)00098-9. [DOI] [PubMed] [Google Scholar]