ABSTRACT

Successful implementation of cooling strategies obviously depends on identifying effective interventions, but in industrial settings, it is equally important to consider feasibility and economic viability. Many cooling interventions are available, but the decision processes affecting adoption by end-users are not well elucidated. We therefore arranged two series of meetings with stakeholders to identify knowledge gaps, receive feedback on proposed cooling interventions, and discuss factors affecting implementation of heat-health interventions. This included four meetings attended by employers, employees, and health and safety officers (n = 41), and three meetings attended primarily by policy makers (n = 74), with feedback obtained via qualitative and quantitative questionnaires and focus group discussions. On a 10-point scale, both employers and employees valued worker safety (9.1 ± 1.8; mean±SD) and health (8.5 ± 1.9) as more important than protecting company profits (6.3 ± 2.3). Of the respondents, 41% were unaware of any cooling strategies at their company and of those who were aware, only 30% thought the interventions were effective. Following presentation of proposed interventions, the respondents rated “facilitated hydration”, “optimization of clothing/protective equipment”, and “rescheduling of work tasks” as the top-three preferred solutions. The main barriers for adopting cooling interventions were cost, feasibility, employer perceptions, and legislation. In conclusion, preventing negative health and safety effects was deemed to be more important than preventing productivity loss. Regardless of work sector or occupation, both health and wealth were emphasized as important parameters and considered as somewhat interrelated. However, a large fraction of the European worker force lacks information on effective measures to mitigate occupational heat stress.

List of abbreviations: OH-Stress: Occupational heat stress; WBGT: Wet Bulb Globe Temperature

KEYWORDS: Occupational medicine, occupational hygiene, heat action plans, cooling interventions, climate change, human adaptation

Introduction

The societal challenge related to rising environmental temperatures includes negative health [1] and productivity effects provoked by occupational heat-stress (OH-stress): the combined effect of environmental heat stress and internal metabolic heat production, consequent of physical exertion [2–4]. Avoiding exposure or limiting physical activities that elevate endogenous heat production may protect the general population and particularly vulnerable citizens (e.g. elderly, children, diseased) against heat-wave morbidity and mortality [5]. However, for working people, such strategies are incompatible with maintained productivity, often directly affecting individual income [6]. Prompted by global warming, but already relevant within current climatic conditions, it is becoming increasingly important to identify interventions and strategies that are effective, economically-viable for industries to adopt and feasible for workers to implement [7–10]. However, despite OH-Stress becoming increasingly more recognized as a threat to both health and productivity, employers, employees, and health practitioners regularly report a lack of knowledge concerning the availability and effectiveness of cooling methods to mitigate OH-Stress [11–14].

Although the motivations of employers and employees to combat OH-Stress will often complement one another, there is a possibility for potential conflicts of interests to arise and differences in desired outcomes. For example, interventions effective in terms of health prevention (such as longer or more frequent breaks or lowering of intensity) may clash with maintained productivity [15]. However, some interventions may help to protect both worker health and productivity, such as optimizing hydration [16–18], working in the shade or shifting work hours [4], or lowering of the environmental heat load via air-conditioning or facilitated air flow [19]. Finally, some interventions, although highly effective for mitigating negative heat effects when tested in laboratory experiments or evaluated in ecological settings, may in practice be unfeasible to implement in practice or only applicable for some industries [9]. For example, air-conditioning is excessively costly, energy-consuming and not applicable for outdoor settings [20]; the time required for personal pre-cooling strategies can outweigh their cooling benefits and specialized cooling personal protective clothing/equipment, such as water-perfused clothing [21], can be highly costly and restrictive.

Currently, the European HEAT-SHIELD project (https://www.heat-shield.eu/) has been charged by the European Commission to protect workers in key European industries (agriculture construction, manufacturing, transport and tourism) from the negative effects of OH-Stress [22]. Accordingly, the purpose of the present investigation was to assess the current level of knowledge pertaining to OH-Stress as well as discus industry specific solutions on hydration and cooling interventions with end-users with feedback collected via quantitative and qualitative questionnaires and focus group discussion from seven meetings across Europe.

Methods

Stakeholder meetings

The qualitative and quantitative research methods used to collect feedback in the present study were approved by the National Committee on Health Research Ethics (protocol number: 55907_v3_02012017). In total seven meetings were held around Europe: four meetings attended primarily by employers, employees and health and safety officers in Florence, Italy; Tønder, Denmark; Rome, Italy; Nicosia, Cyprus; and three meetings attended primarily by policy makers in Ljubljana, Slovenia; Athens, Greece; and Sankt Augustin, Germany. The primary purpose of these meetings was to present the main recommendations created by the HEAT-SHIELD team for combatting OH-Stress and to receive direct feedback from a range of stakeholders. These recommendations were produced for each of the five key European industries of interest (agriculture, construction, manufacturing, tourism and transport) based upon original HEAT-SHIELD research [3,4,16,23–25], an extensive review of the literature [9] and expert knowledge. For ease of translation, these recommendations have been summarized in Figure 1, but further information is available on the HEAT-SHIELD website (https://www.heat-shield.eu/) and weather warning platform (https://heatshield.zonalab.it/) [26]. The presentations were specifically tailored to the audience of each meeting, i.e. focused on the occupations and industries represented at the specific meetings. All meeting attendees were specifically invited to select for the most relevant and experienced stakeholders, and to ensure a variety of employees, health officers, trade union representatives, professionals responsible for control and vigilance within the work place, senior management, and policy makers, working with or within the agriculture, construction, manufacturing, transport and tourism sectors. All meetings were undertaken in the native language of the host country and facilitated by HEAT-SHIELD research-team members.

Figure 1.

HEAT-SHIELD recommendations to combat occupational heat stress

The locations for the meetings were selected based on previous connections with stakeholders and health officials via the HEAT-SHIELD network. In particular, the Italian meetings were undertaken with the Italian Institute for Insurance against Accidents at Work; the Danish meeting was undertaken with Hydro-Extrusion (an aluminum melting and manufacturing company); the Cypriot meeting was in collaboration with Ministry of Agriculture, Natural Resources and Environment; the Slovenian meeting was in collaboration with the Clinical Institute for Occupational, Traffic and Sport Medicine, the Slovenian Environment Agency, the Slovene Chamber of Agriculture and Forestry – Institute of Agriculture and Forestry Maribor, the Association of Trade Unions of Slovenia, the Chamber of Safety and Health at Work, Legal-Information Center for NGOs, the Chamber of Tourism and Catering, Youth Union No Excuse – Youth Association for Sustainable Development, Greenpeace CEE Slovenia; the German meeting was in collaboration with Institute for Occupational Safety and Health of the German Social Accident Insurance; and the Athens meeting was in collaboration with Greek Ministry of Labor in Athens with the participation of the National Meteorological Service, the Ministry of Health, the General Confederation of Greek Workers, the Public Power Corporation, the Association of Greek Industrialists and the Technical Chamber of Greece.

At the meetings targeted toward employers, employees and health and safety workers (Florence, Tønder, Rome and Nicosia), a pre-presentation questionnaire was disseminated before the presentation of the HEAT-SHIELD recommendations, in order to assess the attendees’ unbiased current state of knowledge concerning OH-Stress. Similarly, at these locations, a post-presentation questionnaire was collected immediately following the presentation. This was then followed by a round-table discussion on OH-Stress, facilitated by a local HEAT-SHIELD researcher, during which everyone in attendance were able to voice their thoughts and opinions regarding OH-Stress in their native language to elaborate on the qualitative feedback and put forward any additional comments pertaining OH-Stress in general. While the round-table discussion transpired, a HEAT-SHIELD researcher who was fluent in the native language transcribed key notes from the conversation. As the second round of meetings in Ljubljana, Athens, and Sankt Augustin consisted primarily of people higher up in organizational ranks (e.g. policy makers), the pre and post-presentation questionnaires were not given; however, key notes were transcribed in the same fashion as the first round of meetings, and a list was given at the start of the meeting in order to record the occupation and employer of each attendee.

Questionnaire construction

In order to help standardize feedback between stakeholder meetings, two questionnaires (Appendix 1), one for before the meeting and one for after, were created in advance. These questionnaires were developed by the HEAT-SHIELD research team, created to get feedback on the primary questions of interest, and based on previous experience on collecting qualitative feedback [27] and assessment of OH-Stress effects via quantitative questionnaires [14]. The questionnaires were originally prepared in English (Appendix 1) and subsequently translated into the language of the host country by native speakers.

Data collation and analysis

Following the completion of the meetings, the answers to the questionnaires, as well as the transcribed round-table discussion notes, were translated into English and delivered to the lead author for synthesis. The numeric scores from the questionnaires were then compiled and descriptive analysis was used to calculate the frequency of the specific qualitative answers given. Additionally, notes and summaries from the round-table discussion sessions of the meeting were coded for common patterns and then these codes were subsequently compiled to form reoccurring relevant themes associated with OH-Stress. Following the identification of these themes, the lead author verified the primary themes with the hosting HEAT-SHIELD researchers in order to confirm and make a consensus on the primary concerns raised at each meeting.

In order to determine whether respondent scores differed by occupation, a Kruskal-Wallis test was performed (5 levels: employees, health and safety officers, management, researchers, other). Similarly, Kruskal-Wallis tests were employed to determine whether some reasons for combating OH-Stress were viewed as more important than others (7 seven levels: question 1, 2, 3, 4, 5, 6, 7). In the event a of a significant difference on the Kruskal-Wallis test, individual scores were compared using Mann-Whitney tests. The chance of making a type 1 error was maintained at 5% for all statistical tests and all statistics were performed using Graph Pad Prism (Version 8.0, Graph Pad Software, La Jolla, CA). All data are presented as mean (±SD).

Results

First round meetings and respondents

The number of respondents, their length of employment, the degree to which they considered OH-Stress to be a threat, and their evaluation of the reasons for combatting OH-Stress, broken down by meeting and primary occupation, are displayed in Table 1. Approximately one third of our respondents worked in health and safety positions, one third in management positions, and one third in employee, occupational research or other positions. Additionally, 18% of the respondents listed some type of health and safety responsibilities as a secondary role within their organization. Overall, the average meeting participant had been working in their industry for 15 ± 10 years, with the shortest employment period being 1 year and the longest being 33 years.

Table 1.

Questionnaire respondents, primary occupations, perceived threat of occupational heat strain, and reasons to combat occupational heat strain

| Respondents |

Perceived threat of OH-Stress |

#Reasons to combat OH-Stress |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Participants (%) |

Years of experience (SD) | Hot months per year (SD) | *Effect on performance (SD) | Minimize heat-related health-risks hazards (SD) | Minimize impact on well-being (SD) | For safety reasons (SD) | Regulation compliance (SD) | Productivity maintenance (SD) | Protect individual productivity (SD) | Protect company productivity (SD) | |

| Total | 41 (100) | 15.3 (9.8) | 3.2 (2.3) | 2.1 (0.9) | 9.1 (1.8) | 8.5 (1.9) | 8.2 (2.4) | 7.4 (2.5) | 7.0 (2.1) | 6.3 (2.3) | 6.3 (2.3) |

| By location | |||||||||||

| Florence | 11 [24] | 20.8 (10.1) | 3.2 (0.7) | 1.9 (0.6) | 9.6 (0.5) | 8.6 (2.5) | 8.0 (2.5) | 6.3 (3.6) | 6.1 (1.6) | 5.7 (2.5) | 5.3 (2.8) |

| Tønder | 8 [9] | 10.3 (10.9) | 4.9 (3.7) | 2.8 (1.2) | 7.8 (2.1) | 8.7 (1.2) | 8.0 (2.2) | 6.0 (0.0) | 7.3 (1.5) | 3.5 (0.7) | 3.3 (0.6) |

| Rome | 14 [28] | 13.6 (8.2) | 1.9 (1.2) | 1.9 (0.6) | 9.5 (0.8) | 8.7 (1.1) | 9.2 (0.9) | 8.2 (1.7) | 7.5 (1.7) | 6.4 (2.3) | 6.6 (1.4) |

| Nicosia | 8 [9] | 16.8 (9.2) | 4.0 (2.3) | 2.0 (1.0) | 8.8 (3.2) | 8.0 (2.8) | 6.0 (3.8) | 7.4 (2.6) | 7.1 (3.2) | 7.5 (1.7) | 7.9 (1.8) |

| By primary occupation | |||||||||||

| Health and safety | 14 [28] | 17.2 (9.5) | 3.0 (1.7) | 1.8 (0.6) | 9.8 (0.4) | 8.5 (1.8) | 9.0 (1.2) | 8.2 (2.0) | 7.3 (2.0) | 5.9 (2.3) | 6.3 (1.9) |

| Management | 13 [17] | 13.8 (9.8) | 2.8 (1.7) | 2.1 (0.9) | 8.7 (2.8) | 8.6 (2.7) | 7.2 (3.6) | 6.8 (2.9) | 6.1 (2.5) | 6.8 (2.4) | 6.6 (2.7) |

| Employee | 6 [32] | 11.7 (12.4) | 5.2 (4.4) | 2.8 (1.4) | 7.8 (2.1) | 8.7 (1.2) | 8.0 (2.2) | 6.0 (0.0) | 7.3 (1.5) | 3.5 (0.7) | 3.3 (0.6) |

| Researcher | 5 [37] | 17.5 (11.6) | 3.1 (1.3) | 2.3 (0.5) | 10.0 (0.0) | 9.3 (1.0) | 9.3 (0.5) | 9.0 (1.4) | 7.0 (2.2) | 7.3 (2.1) | 7.3 (2.1) |

| Other | 3 [2] | 17.0 (4.2) | 1.7 (0.5) | 2.0 (1.0) | 8.7 (0.6) | 7.0 (1.0) | 8.3 (0.6) | 5.0 (3.0) | 9.0 (0.0) | 7.5 (0.7) | 7.5 (0.7) |

OH-Stress: Occupational heat stress

*Performance impact scores: 1-No/minimal effect; 2-The heat mildly affects my health and performance; 3-The heat moderately affects my health and performance; 4-The heat greatly affects my health and performance.

#Level of importance to combat occupational heat strain on a scale from 1 to 10; 1 being not important and 10 being most important.

Respondents’ perceptions of occupational heat strain

On average, the respondents believed that hot weather affected workers’ performance for 3.2 ± 2.3 months per year (Table 1) and this did not differ between occupations (p = 0.36). One individual stated that heat affected their work performance all 12 months of the year, but that individual worked as an aluminum extrusion worker, requiring them to work around hot metals and machinery year-round. During the hot months, the average score of the respondents on a four-point scale was ~2, corresponding with a response of “The heat has mild influence on my health and performance” (Table 1), and did not differ between occupations (p = 0.51).

Overall, protecting the health and safety of the workers was scored as more important than protecting either company productivity or being compliant with internal or governmental regulations (p < 0.001) and this did not differ between occupations (p = 0.18; Table 1). Specifically, on a ten-point scale, where 1 denoted low-priority and 10 denoted high-priority, to minimize heat-health hazards (9.1 ± 1.8), minimize impact on wellbeing and reduce heat-related symptoms (8.5 ± 1.9) and for safety reasons (8.2 ± 2.4) scored higher than questions about protecting company income (p < 0.05) but did not differ between each other (p > 0.05). These answers were followed by being in compliance with national regulations (7.4 ± 2.5). Finally, productivity reasons scored the lowest with prevent loss of productivity (7.0 ± 2.1), benefit personal income (6.3 ± 2.3) and benefit the company’s income (6.3 ± 2.3).

Respondents’ knowledge and attitude toward cooling interventions

Before the HEAT-SHIELD presentation, 59% of the respondents stated that they were aware of guidelines or some safety measures to combat heat stress, whereas 41% reported being unaware of any protective measures. Collectively, 30% of workers believed the measures their companies currently employed were effective, 21% thought these methods were partially effective, and 48% either thought these methods were ineffective or elected not to answer.

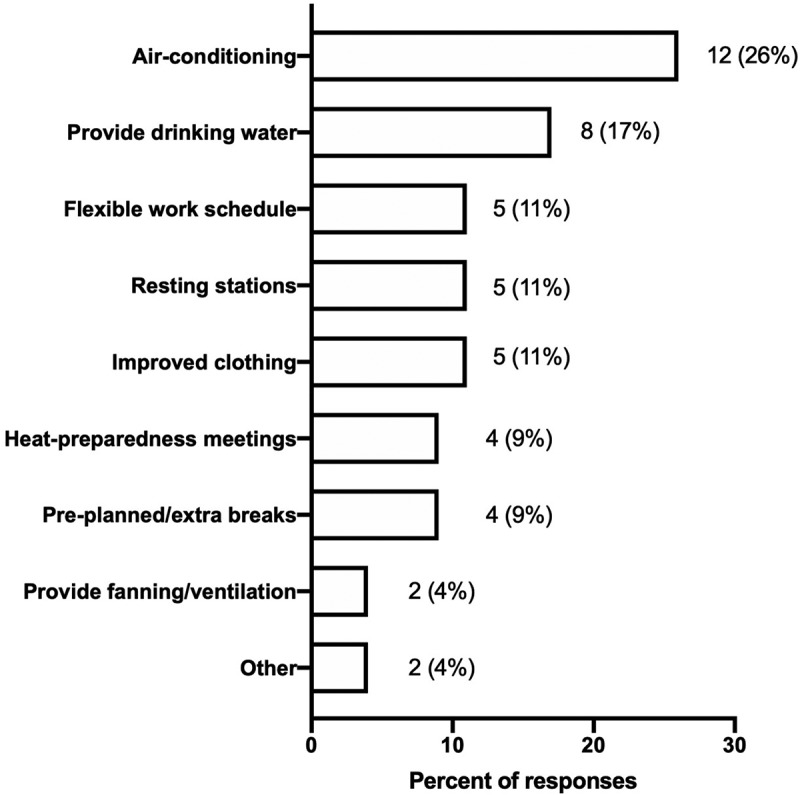

Of the interventions reported as currently being used at their work place (Figure 2), the most common responses were air-conditioner use (26%); followed by provision of drinking water (17%); and modification of work schedule, creation of cooling stations, and improving the heat transfer capabilities of workers’ clothing or protective equipment (11%). The two scores counted as “other” with only one vote each were “risk management plan” and “company policy on working outdoors in the heat”.

Figure 2.

Absolute and percent of total answers given to the question: “What heat prevention actions does your company use during hot periods?”

Answers given to the question “What other interventions could be useful?” are presented in Table 2. The most commonly stated intervention was to provide more drinking water, followed by providing additional breaks and refraining from working outdoors during the hottest hours, then improve the thermal qualities of the building’s employees worked in, such as by improving insulation, opening doors and windows or tinting the windows.

Table 2.

What other interventions could be useful?

| Intervention | Frequency of answer |

|---|---|

| Make drinking water available | 5 |

| Planned breaks | 3 |

| Refrain from working outdoors in the hottest hours | 3 |

| Better insulate old buildings, tint windows, etc | 2 |

| Comprehensive risk assessment of heat stress for all tasks with each industry | 1 |

| Have social security set up for workers who cannot work because of the heat | 1 |

| Inform the workers about the signs/symptoms and health affects of heat illness | 1 |

| Not having to wear helmets | 1 |

| Suck the heat out of the top of the building | 1 |

| Add more radiant heat screens | 1 |

| Better helmets | 1 |

| Surveillance of health indicators | 1 |

| Provide saline supplementation | 1 |

| Plan interventions | 1 |

| Improve canteen controls to stop food spoilage | 1 |

| Air conditioning sanitation and revision | 1 |

| Evaluate personal protective equipment being used | 1 |

| Better clothing | 1 |

| Shading | 1 |

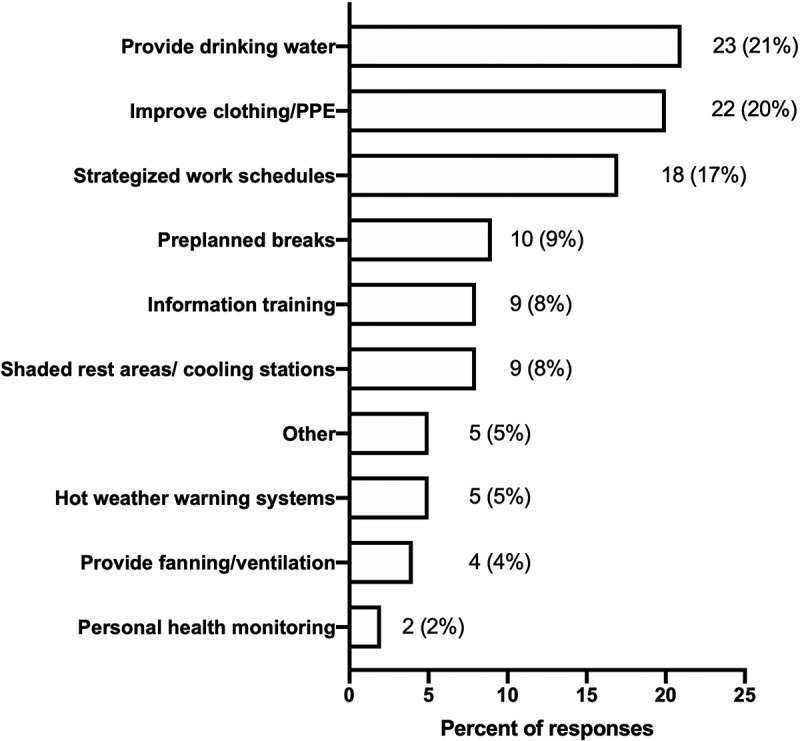

Following the HEAT-SHIELD presentation, the respondents’ selections of the best/most effective cooling interventions for combatting heat stress following the information dissemination are displayed in Figure 3. There was relative agreement between respondents as providing drinking water (21%), improving the thermal qualities of clothing and personal protective equipment (20%) and strategizing the work schedules (17%; i.e. either starting the work shift earlier, taking breaks in the hottest part of the day, or planning the hardest activities for the coolest time of day and vice-versa) all received ~20% of the votes cast. Other interventions which were not included in the figure having only received 1 vote each included: “comprehensive risk assessment”, “enforcing heat-health procedures”, “not having to wear helmets”, “moral rewards” and “safety measures”.

Figure 3.

Absolute and percent of total answers given to the question: “What are the three best interventions for combatting heat stress?”. PPE: personal protective equipment

Of the interventions listed in Figure 3 and outlined above, 56% reported being aware of all presented interventions, 28% reported being unaware of some or all of the available improvements to clothing which were possible, 8% reported being unaware of weather warning systems, 6% were unaware of the effectiveness of adding preplanned breaks to the work day and one person stated that they were unaware of the use of nanotechnology, even though this was not one of the interventions presented. Additionally, when asked if the respondents disagreed with any of the interventions presented, 88% said no, two people disagreed with changing the work hours, one person disagreed with improving clothing, one disagreed with preplanned breaks, and one disagreed with providing drinking water.

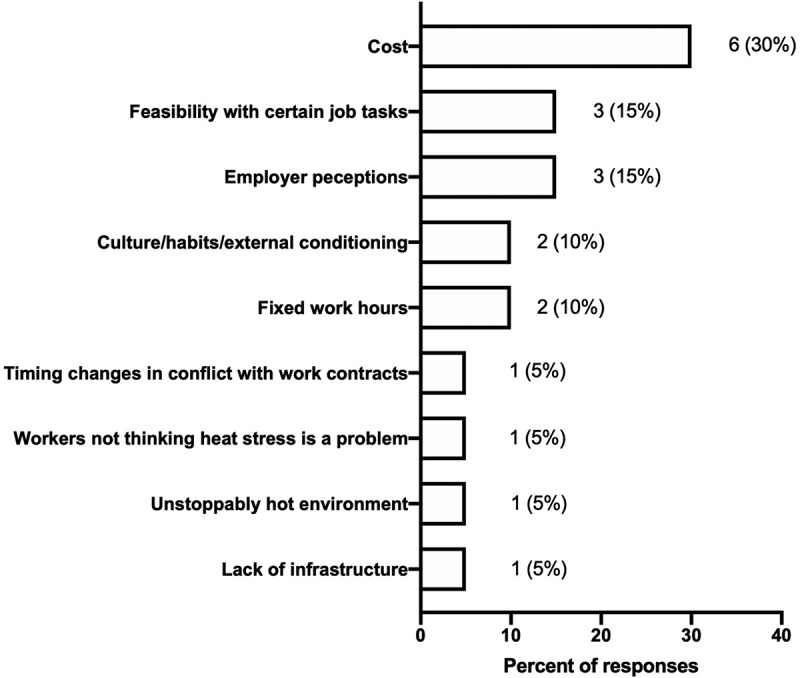

Perceived barriers to implementation

When asked if the respondents saw any perceived barriers to the adoption of the interventions that were proposed, 57% reported no perceived barriers. Of the 14 who did report perceived barriers (Figure 4), cost was the most common (30%), followed by feasibility with certain job tasks and employer perceptions (15% each), and then cultural habits and fixed work hours (10% each).

Figure 4.

Absolute and percent of total answers given to the question: “What barriers do you think exist that would prevent the implementation of the proposed cooling interventions”

In terms of issues surrounding legislation, during the focus group discussion following the Nicosia meeting, a representative for the Cyprus Ministry of Labor, stated that Cyprus had released “Heat Stress Safety Decree”, which implements work-rest cycles based upon the prevailing weather conditions. However, worker union representatives countered that many of the employers in the Cypriot agricultural industry were either unaware or neglected these policies and that workers often had to work continuously without a break or any provided cooling interventions; despite environmental conditions warranting extended breaks according to the government policy.

Finally, the respondents’ answers for what other information about occupational heat related injuries they felt they were missing are displayed in Table 3. The main answers provided were asking for information on less studied sectors, the various different factors that put certain people at greater risk for heat illnesses as well as how heat illness is confounded by other predisposing conditions, heat health warning systems, what health metrics could be monitored to ensure worker safety, and how heat affects fatigue and cognition.

Table 3.

What further information about the effects of heat stress on work performance would you want from future meetings?

| Answer | Frequency of response |

|---|---|

| Information on understudied sectors | 3 |

| Interplay between heat stress and confounding factors (e.g. medical conditions, habits [smoking and nutrition] and drug use, sex | 3 |

| More about weather warning systems | 2 |

| Monitorable health metrics | 2 |

| Information on how heat affects fatigue and cognition | 2 |

| Information regarding heat stroke | 1 |

| Considerations of local health unit supervisors | 1 |

| How the body responds to heat stress | 1 |

| Information on and dissemination to underrepresented workers (immigrants, those on small farms) | 1 |

| Cost/benefit analysis of interventions | 1 |

| What is being done outside of Europe | 1 |

| More information on occupational research | 1 |

Second round meetings: Ljubljana

This expert group meeting was attended by 31 stakeholders, primarily responsible for health and safety policy, A characteristic point from the Slovenian meeting, was a discussion of employers being unaware that the poor working conditions stemming from occupational heat stress will decrease performance and will therefore negatively affect the company’s productivity and profits. In another example, some workers reported that managers encouraged them to minimize water intake during work in order to prevent productivity losses associated with toilet breaks but neglecting the negative consequences of dehydration. Also, construction workers were said to often not be aware of the serious health concerns cause by solar radiation exposure. Further, some workers were under the impression that sweating was not good for their health, and because of this, consciously limited the amount of fluids they consumed in a day. Solutions were also proposed on how these issues could be addressed, including providing warnings for heat waves in the media, companies, trade unions, etc. and adding the dangers of heat to the primary education system, in order for the general public (but especially those working jobs involving manual labor) to start protecting and taking care of themselves during periods of hot weather. Additionally, both managers and employees are often unaware of both the threat OH-Stress poses, as well as how to best combat it. For example, it was discussed that the forecasting of heat waves in Slovenia is as good as in other European countries, but awareness is not. Also, in the Slovenian meeting it was discussed that current legislation prevents the introduction of certain solutions that would make sense (e.g. trees around factories in the industrial zone which would provide shading and lower that radiative thermal load placed upon the building). Further, the role of the economy, extra costs, and cost-benefit ratios are so strong that implementation of measures to reduce heat stress is feasible only through new legislation. Therefore, legislation needs further support from researchers to be able to make evidence-based decisions; otherwise, it will be very difficult to protect outdoor workplaces.

Second round meetings: Athens

This expert group meeting was attended by 21 representatives, primarily concerned on health and safety topics in regard to occupational environments, including special focus on tourism and agriculture industries. The presentations were well received, with much interest in the HEAT-SHIELD project and discussions of potential future collaborations. Specifically, certain approaches were discussed that could be used to downscale the weather forecast of the Greek National Meteorological Service to the workplace level. An important concern raised during the meeting, was the use of thermal indices to provide guidelines on protecting workers against heat-related diseases. The International Organization for Standardization standard 7243:2016 recommends the Wet Bulb Globe Temperature (WBGT) for assessing the heat stress in occupational settings. However, directly measuring WBGT involves specialized instruments requiring equipment which is not used at weather stations and knowledge about other factors such as the clothing and metabolic rate of employees. Importantly, it was emphasized by representatives from the Greek Ministry for Labor and the Greek Ministry of Health that WBGT stations are very expensive for a small company to afford and the index may be difficult to interpret for normal workers and company managers. Therefore, we have both developed methods to calculate WBGT in indoor (tourism) and outdoor (agriculture) environments and the HEAT-SHILED project have developed color codes that translate the index to overall heat risk categories (see www.heat-shield.eu).

Second round meetings: Sankt Augustin

This meeting was attended by 12 stakeholders. The mandate of the Institute for Occupational Safety and Health of the German Social Accident Insurance is to prevent occupational accidents, accidents on the way to and from work, occupational diseases and work-related hazards as well as to ensure effective first aid. This expert group meeting was primarily concerned on health and safety topics in regard to indoor environments, including the inside of transport and other professional vehicles, as well as the interior environments of manufacturing and construction buildings and factories. Some information that was highlighted as particularly useful was the cooling solutions offered. As well, it was mentioned the physiological evidence supporting these interventions was particularly appreciated, as the German Social Accident Insurance had previously, in some instances, provided information to interested parties, which differed from the HEAT-SHIELD guidelines. For example, one member had stated that they previously discouraged the ingestion of cold fluids based on the assumption that the body “would have to expend additional energy to warm the fluid, thereby causing the person to tire faster”. Indeed, these types of anecdotal or assumed knowledge have been encountered at the meetings at all levels of employment (i.e. from the workers to the policy administrators). Items of concern raised by the committee primarily centered around cooling options available to those in the transport industry. From their studies, the only reliably effective cooling method for inside vehicles which they had found to make a reliable difference was the use of air-conditioning. This issue raises two primary concerns: 1) the use of air-conditioning uses a considerable amount of energy, therefore creating more exhaust, releasing more carbon dioxide, thereby worsening the overall problem of climate change and 2) because of this higher energy consumption, many companies had begun removing the air conditioning systems from their vehicles in order to improve their “bottom line” by saving on fuel costs. This was a particular issue for garbage trucks, where the doors had either been removed or were being opened on a regular basis to let the workers out. Because of this, cooling the truck cabins with air-conditioning was very difficult, ineffective and costly. In terms of our suggestion of ensuring vehicles use window tinting, which can reduce solar radiation by 30%, the committee was skeptical, stating that they had found this method to be largely ineffective at lowering the actual temperature within their vehicles. Another option discussed was incorporating electrical fans in the seats of the vehicles, which the committee said was occasionally done but not very often. Additionally, the committee challenged our recommendation to modify the work hours to cooler times of the day, as much of the transport industry and other driving-related industries (such as garbage collection) relies upon very tight, inflexible schedules.

Discussion

This paper provides detailed information on knowhow and attitudes toward combating negative effects of OH-Stress on health and productivity with quantitative as well as qualitative feedback from industrial managers, safety officers, employees, occupational health advisors and policy makers across Europe. Heat stress was generally considered as a moderate problem and seasonal issue that typically lasted for approximately three months of the year; however, in some settings, heat stress was considered a year-round issue. Approximately 25% of all attendees were unaware of solutions to combat heat stress, but the majority of all attendees considered protecting the health of the workers was the most important reason for combatting heat stress. However, maintaining productivity, protecting the economy and complying with legislation were also scored as moderately important. After presenting scientific-based recommendations, providing drinking water, improving the thermal properties of work attire (clothing and personal protective clothing/equipment), and changing workers’ work schedules were the highest-rated recommendations. More than half of the respondents did not think there were any major barriers to enacting the recommendations, however, the barriers that were identified included cost, lack of feasibility with certain tasks, and employer perceptions/reluctance were most commonly reported. Finally, attendees reported wishing for even more information concerning OH-Stress. Collectively, these findings suggest that those working in managerial and health and safety positions in companies do believe heat stress is a problem, are willing to combat it and primarily simply lacking the knowledge for how to best combat this issue.

Perceptions toward heat stress

Only 14% of respondents reported that heat stress was not an issue at their workplace. This is in agreement with an Australian study where data was collected at an annual national conference for occupational hygienists, and therefore, the perspective toward OH-Stress from multiple industries could be investigated simultaneously. In total, there were 180 respondents, who were primarily hygienists (n = 89), occupational consultants (n = 48) and occupational health and safety managers (n = 5) and who worked with mining, manufacturing, energy delivery, construction and national defense. In that study, it was observed that 90% of their respondents were concerned about the hazards of heat stress in the workplace [14]. Further, 7% of their respondents said that heat stress was “always” an issue, 37% said “often” and 44% said “sometimes”. These numbers are again very similar to the present data, wherein 44% of respondents thought heat stress was an issue 1–3 months of the year and 38% though heat stress was an issue 4–6 months of the year, with no differences between meeting locations, despite vastly different weather conditions. The similarity in findings between our meeting locations, as well as compared to the Australian study, may provide further evidence toward the importance of acclimatizing to the local thermal conditions [28], as well as recent research demonstrating how perceptions to the heat change between people from different geographical locations [29,30]. In the present study, we did not ask for the respondents’ gender, however, this may be an interesting question for future questionnaires as men (66%) are more likely to consider heat as a non-threat compared to women (25%) [13].

Regarding motivations for combatting heat stress, no differences were found between occupations (i.e. employee, manager, or health and safety representative), but reasons that had to do with worker health and safety scored higher than those for protecting worker or company productivity. Previous research has identified lack of autonomy to use the toilet as a contributing factor to workplace dehydration [31], suggesting some employers/managers prioritize worker productivity over their health. These finding are supported by comments from the Slovenian meeting that indicated managers were discouraging their workers from drinking water, so that the workers did not need to use the toilet, and therefore would not reduce their work productivity. Alternatively, the rest of our results generally did not support this notion, possibly due to participant selection bias, as most of the respondents were from larger companies with well-educated workers, resources to spend on cooling interventions and an interest in how heat affects workers (as they sent representatives to the meetings). It is also important to note that by comparing motivations for combatting heat stress, it may create a false dichotomy, where one has to prioritize either worker health or productivity; whereas, in reality, a healthy worker is a productive worker. Therefore, it should not be lost that, when providing recommendations, it should be stressed that using cooling interventions will improve both worker health and productivity.

Cooling interventions

In the present study, 41% of the respondents stated that they were unaware of any guidelines or safety measures to combat heat stress, before the presentation of our proposed interventions. These values are lower than previous investigations, such the Australian study, wherein 59% of the respondents indicated that there were hot weather plans or heat stress policies currently available in their workplaces or workplaces where they consult [14], whereas in California, 91% of respondents from the agricultural industry had received training on heat related illness [13]. This discrepancy in results may be due perceptions of California and Australia being traditionally hot places, whereas Europe, especially Northern and central Europe, is typically regarded as having more temperate weather, and as such, the population in general may be less concerned about the effects of heat on their health.

In the present study, results of the pre-presentation questionnaires indicated a difference in what cooling interventions respondents were aware of, which they used, and following the information, which interventions they thought would be most effective. The most commonly reported interventions they were aware of were rescheduling working hours, providing drinking water to workers, following local guidelines and improving the thermal qualities of clothing and protective equipment. In contrast, the interventions most used were using air-conditioning, providing drinking water, modifying the work schedule, providing cooling stations and improving the thermal qualities of clothing. Moreover, following the presentation of our recommendations, the top-rated interventions by far were provision of drinking water, improving the thermal qualities of clothing, and optimizing the work schedules.

Our findings agree with the above presented Australian study in which provision of cool drinking water (97.2%), heat stress related training (76%), shady rest area (68.9%), rescheduling work time (67.2%), using electric fans (52.2%), stopping outdoor work in extreme heat (41.7%) were the most commonly reported heat mitigation strategies [14]. It is interesting to observe that although the respondents did not list air-conditioning as one of the known heat-health guidelines in the pre-presentation questionnaire, nor did they think it was an optimal option, it was one of the single most-used interventions. Also stated in the pre-presentation questionnaire, 30% of the respondents thought that the current practices were effective, 21% thought they were partially effective and 48% thought the current methods were ineffective. In another HEAT-SHIELD study [30], migrants tended to express more satisfaction than native workers with measures adopted in the workplace – possibly on account of negative previous experiences with health and safety systems in their countries of origin. Also, our findings contrast with previous Australian findings in which 50% of the occupational hygienists were strongly satisfied with the measures currently being taken to combat heat stress and only 19% were unsatisfied [14].

In general, the efficiency of different cooling solutions is highly dependent on the specific scenario and, particularly for occupational settings, it is clear that one size does not fit all. Thus, the effectiveness will change with the environmental conditions and the practical implementation potential will depend on the industrial settings and feasibility for the individual worker [1]. Although beyond the scope of this paper, a detailed consideration of factors that contribute to a successful cooling intervention can be found in the umbrella review our cooling recommendations were based on [9]. Accordingly, the implementation of the top three cooling recommendations will differ by job site. For example, in indoor locations, “provide drinking water” could be as simple as making sure water coolers are distributed throughout the worksite; whereas in agricultural fields, where resource accessibility is limited, “provide drinking water” may take the form of providing workers with water bladders in back packs, water bottles, or establishing shaded water catches at specific locations throughout the fields. Alternatively, “improve clothing/personal protective equipment” might be to wear light, breathable, sun-reflective clothing in outdoor agricultural settings; whereas in a manufacturing shop, “improve clothing/personal protective equipment” may be to invest in coveralls with built in ventilation patches. As such, cooling interventions will work best when individualized with the help of a knowledgeable practitioner, however, resources that provide individualized recommendations, such as the HEAT-SHIELD weather warning platform, may help for those without access to trained personnel.

Barriers to adoption

In the post-presentation feedback, respondents seemed generally supportive of the proposed cooling measures as 57% of respondents reported foreseeing no perceived barriers to adoption. For the 43% who foresaw some barriers, the most commonly reported were cost, feasibility with certain job tasks, employer perceptions, cultural habits and fixed work hours. These contrasted with findings from the Australian study, wherein the most common reasons given for why the recommendations may not be adopted were lack of awareness (68%), lack of training (56%), lack of management commitment (52%), low compliance and implementation of heat stress prevention programs (40%), lack of financial resources to bring in engineering controls (37%), and lack of specific heat-related guidelines and regulations (37%) [14]. Similarly, in a pair of studies on Californian agriculture workers, heat prevention barriers may also include lack of training and management commitment, low compliance and implementation of heat prevention policies, and lack of financial resources [32,33].

An additional barrier to adoption, highlighted particularly by the Slovenian meeting was a lack of information dissemination, where for example, heatwave forecasting was on par with the rest of Europe, however disseminating information on how to deal with heatwaves was not. To this end, one of the primary outcome goals of HEAT-SHIELD was to create an occupational heat health warning platform for Europe (heatshield.zonalab.it), which provides personalized heat-stress risk forecast [26]. In this way, not only are workers informed about the upcoming weather, but they are also given warnings about how this may affect their health and comfort, and given advise on how to best combat the threat of hot weather. Additionally, in the meeting in Sankt Augustin, it was highlighted that in many transport-related occupations, such as waste disposable, general delivery, and particularly fresh produce delivery due to the logistics of cooling and transporting fresh food, adjusting work schedules is just not possible.

Missing information and future research

In the post-presentation questionnaire of the present study, the main answers provided were asking for information on less studied sectors, the various different factors that put certain people at greater risk for heat illnesses as well as how heat illness is confounded by other predisposing conditions, heat health warning systems, what health metrics could be monitored to ensure worker safety, and how heat affects fatigue and cognition. This is consistent with previous work with Australian occupational hygienists, where 61% of respondents thought that there was a need to increase heat-related training in the workplace [14]. Specifically in that study, the methods reported for how to improve the mitigation of OH-Stress included hydration maintenance, self-pacing, heat acclimatization, identifying early symptoms of heat illness, impact of personal protective equipment on human body heat balance maintenance, individual heat risk factors e.g. predisposing medical conditions, lifestyle, fitness level, annual training prior to hot seasons [14].

Dissonance between legislation and practise

In the Australian study [14], the authors noted that providing drinking water to workers was required by national regulatory bodies but that according to the health and safety specialists surveyed in their study, this often was not the case. This finding was similarly supported by both the meeting in Slovenia and Cyprus, where regulators would state that legislation was in place to protect the workers, but worker representatives countered by stating that these guidelines often were not enforced. We believe this observation, in combination with concerns raised in both this and previous studies that employers may be hesitant to implement cooling interventions due to cost concerns, highlights that further research is needed to demonstrate that protecting workers’ health will be beneficial to company productivity and therefore incentivize adherence via economic incentives.

At the Slovenian meeting, it was discussed that the role of the economy, extra costs, and cost-benefit ratios are so strong that implementation of measures to reduce heat stress is feasible only through new legislation. Similar observations have been made in Australia [14], wherein the federal government has no specific guidelines to counteract heat stress, but some non-governmental institutions [34] and trade unions [35] have made specific heat stress management guidelines themselves. However, it was noted that as these recommendations were not legally binding and that there was no way to enforce these recommendations, adherence by companies to these recommendations were unlikely [33,36].

Governments, however, can encourage healthy heat-defense behaviors through other means than just enacting legislative punishments. For example, in Italy, there is the possibility for companies to apply for the Ordinary Redundancy Fund, provided by the National Social Welfare Institution, in order to provide monetary support in the case of extreme temperatures. The Ordinary Redundancy Fund in the construction sector, for example, can be requested in the most critical climatic conditions, that is when the heat or cold is prohibitive.

One of the most commonly recommended heat action policies is the adoption of environmental condition-dependent work-rest cycles (such as the NIOSH guidelines [37] and/or full cessation of work past a given temperature, such as 37°C [35]. During the focus group discussion in Cyprus, federal policy makers noted that they employed mandatory environmental condition-dependent work rest cycles; however, an agricultural union representative argued that, due to limited governmental enforcement, these guidelines were largely ignored. Similar observations have been made in Australia, where it was observed that despite unions recommending to cease all work above a temperature of 37°C [35], only 40% of occupational hygienists questioned reported ceasing outdoor work as a possible method to mitigate occupational heat stress [14]. There are also multiple reasons why a worker may not be able to cease work when it’s hot, for example due to the immediacy of the task, like emergency responders (particularly firefighters). For others, such as miners, the job may be initiated at temperatures that already surpass absolute “cease work” values, or else require encapsulating personal protective equipment that limits heat loss, rendering the thermal load unbearable at any ambient temperature, such as firefighters, hazardous materials responders, and agricultural chemical sprayers. Taken collectively, these findings demonstrate that absolute adherence to strict work-rest-stop cycles may not be overly useful, and rather, more flexible alternative cooling options that better fit the companies need should be available.

Studied occupations

In the present study, the main industries of interest were agriculture, construction, manufacturing, tourism and transport, as these industries make up ~50% of the European economy. Of note, the meetings held in Italy, carried out in collaboration with the Italian Institute for Insurance against Accidents at Work, primarily involved managers, workers’ safety representatives and prevention doctors working with construction and agriculture sectors. In Italy, more evidence relating to the effects of heat on workers concerns the construction sector, in addition to the fact that in the last 10 years, during the summer season, the media often reported cases of occupational accidents, including fatalities, related to heat stroke. This is supported by a recent study where the authors found that construction workers showed the highest risk of injuries on hot days [38]. For this reason, Italian companies are mandated to perform a risk assessment of OH-Stress and provide “effective” OH-Stress prevention measures during the summer, however, no specific measures are mandatory. Some such measures that are regularly employed include the creation of shady areas for workers to rest and the continuous measurement of the air temperature in the workplace. On the other hand, there are still very important gaps in the agricultural sector where, also due to the greater precariousness of workers and the presence of very small companies (most of the companies are made up of between 1 and 3 workers), measures aimed at reducing the effects of heat in the workplace are not yet widely adopted.

In a recent systematic review investigating the effect of occupational heat stress on worker health and productivity, in which it was observed that workers who worked only one shift in the heat were four times more likely to experience occupational heat strain compared to those not exposed to the heat, 111 studies were found, in 30 countries including 447 million workers from 40 occupations, including industrial workers (36%), miners (13%), agricultural workers (11%), farmers (7%), construction workers (6%) and electrical workers (3%) [2]. These occupations differed from another recent systematic review of systematic reviews investigating the level evidence existing in the literature pertaining to cooling interventions to help mitigate occupational heat strain, which found that the only occupations for which cooling interventions had been analyzed for were military, firefighters, and emergency responders [9]. These systematic reviews demonstrate that presently there is a discrepancy between the occupations that are known to be at risk for occupational heat strain and those that interventions have been actively investigated. It is interesting, therefore, that one study on Australian occupational hygienists reported that the industrial sectors that had hot weather plans or polices were the mining (62%), manufacturing (25%), electricity, gas and water (9%), construction (8%), and defense (3%), with agriculture and forestry workers notably being absent [14].

Limitations

A limitation to the present study was the relatively small number of respondents, particularly for the questionnaire feedback, compared to previous studies with similar designs to the present study [11,13,14]. However, this was partially by design and due to the invitation only recruitment in the present study to ensure a relatively heterogeneous sampling, which consisted of occupations ranging from manual laborers to policy makers and members of parliament. Although our study may have lacked ideal respondent numbers, it is impactful for the diversity of persons represented. Further, it is likely that some of the differences we observed, relative to other studies, were likely due to geographical and/or cultural reasons, as perceptions toward heat are well known to differ by culture [29,30]

Conclusions

Representatives from five primary industries across Europe believed that heat stress was a concern in the workplace. However, these representatives either lacked information on how to combat heat stress or else did not think the interventions they had access to were effective. Further, what generally fueled their motivations for combatting heat stress was concern over the workers’ well-being, rather than to protect company productivity and income. Following an information session where HEAT-SHIELD researchers presented our proposed interventions for combatting OH-Stress, the representatives believed that the best recommended cooling interventions were to provide drinking water, improve the thermal properties of workers’ clothes/protective equipment, and to reschedule the workday so that the hardest tasks occurred at the coolest times of the day. While the majority of respondents saw no perceived barriers to implementing the proposed interventions in the workplace, the most common reasons that were provided included cost, feasibility, and cultural norms. Collectively, these findings indicate that, when modified to adjust for the local working conditions, as can be done by the online HEAT-SHIELD weather platform, our proposed interventions will likely be beneficial to employers but need to be disseminated effectively to be appropriately used.

Appendix 1.1. Pre-presentation questionnaire

| Q1. What is your role and area within the company/organization? E.g. manufacturer, laborer, management, etc. |

| Q2. Do you have any additional roles or titles within the company? E.g. union representative, shop steward, etc. |

| Q3. How many years of experience do you have with the company? |

| Q4. Are you aware of local (company) or national “heat-prevention-plans” (procedures initiated when it is hot)? If yes, briefly describe: |

| Q5. How many months each year is heat in the workplace a problem? |

| Q6. How often do you think high temperatures affects your personal productivity during the hot months of the year? Select one: i) No/minimal influence in limited period of year; ii) Moderate influence (mainly peak summer); iii) High impact (during major part of summer). |

| Q7. How often do you think high temperatures affects your company’s productivity during the hot months of the year? Select one: i) No/minimal influence in limited period of year; ii) Moderate influence (mainly peak summer); iii) High impact (during major part of summer). |

| Q8. How many days per year would you estimate you are affected by high temperatures at work? Give number: |

| Q9. When it does get hot, how much do you feel the affects your health and performance? Select: i) No/minimal effect; ii) The heat mildly affects my health and performance; iii) The heat moderately affects my health and performance; iv) The heat greatly affects my health and performance. |

| Q10. Does the company implement heat prevention actions during hot periods? List types of actions implemented. |

| Q11. List any additional actions/procedures/solutions you find relevant to adopt during hot periods. |

| Q12. Please rank (score from 1 [low] to 10 [high]) the importance of the listed factors in relation to implementing heat-prevention-procedures: i) Prevent loss of productivity (individual or company capacity); ii) Prevent/minimize risk of heat-health hazards; iii) Comply with company or national regulations; iv) For safety reasons; v) Minimize impact on well-being i.e. reduce heat-related symptoms (such as thirst, thermal discomfort etc.); vi) Benefit income (my individual piecework rate); vii) Benefit income (company economy) |

| Q13. List and rank any additional factors: |

| Q14. The currently implemented heat prevention actions, are they effective? Please explain their impact. |

Appendix 1.2. Post-presentation questionnaire

| Q1. Were there any of the proposed solutions or procedures for heat prevention that you disagreed with or did not understand the rationale behind/need to implement them? If yes briefly describe which: |

| Q2. List the top-three heat-prevention procedures or solutions (either some of the presented or you own best advice for others): |

| Q3. Were there any of the proposed solutions or procedures that you were unaware of (or did not find relevant or feasible to use) before the presentation that you would now consider using or suggest others to use for future practice? If yes briefly describe which: |

| Q4. Do you see any barriers that might preclude you or your company from implementing new or already identified solutions? If yes, please list the main issues you see: |

| Q5. Is there any general or specific information you are aware of concerning heat stress – recommendations or practices you think would be valuable to share – that you feel were not included in the presentation? If yes, briefly describe which: |

| Q6. Is there any information about heat stress that you would like to know more about that you feel was not covered in this presentation? If yes, briefly describe which: |

Funding Statement

The study has received funding from the European Union’s Horizon 2020 research and innovation program under the grant agreement No 668786.

Disclosure statement

No potential conflict of interest was reported by the authors.

References

- [1].Faulkner S, Broekhuijzen I, Raccuglia M, et al. Identification of the threshold ambient temperature above which pre-cooling has a performance benefit for time trials in the heat. J Sci Cycl Pulianas. 2018;7:36–37. [Google Scholar]

- [2].Flouris AD, Dinas PC, Ioannou LG, et al. Workers’ health and productivity under occupational heat strain: a systematic review and meta-analysis. Lancet Planet Health. 2018;2:e521–e531. [DOI] [PubMed] [Google Scholar]

- [3].Ioannou LG, Tsoutsoubi L, Samoutis G, et al. Time-motion analysis as a novel approach for evaluating the impact of environmental heat exposure on labor loss in agriculture workers. Temperature. 2017;4:330–340. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [4].Morabito M, Messeri A, Crisci A, et al. Heat-related productivity loss: benefits derived by working in the shade or work-time shifting. Int J Product Perform Manag ahead-of-print. 2020. DOI: 10.1108/IJPPM-10-2019-0500. [DOI] [Google Scholar]

- [5].CDC . Extreme heat [Online]. Cent Dis Control Prev. 2019. [cited 2020 Feb 20]. Available from: https://www.cdc.gov/Features/trackingheat/ [Google Scholar]

- [6].Venugopal V, Chinnadurai JS, Lucas RAI, et al. Occupational heat stress profiles in selected workplaces in India. Int J Environ Res Public Health. 2016;13:89. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [7].Gaglio B, Shoup JA, Glasgow RE.. The RE-AIM framework: A systematic review of use over time. Am J Public Health. 2013;103:e38–e46. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [8].Hosokawa Y, Casa DJ, Trtanj JM, et al. Activity modification in heat: critical assessment of guidelines across athletic, occupational, and military settings in the USA. Int J Biometeorol. 2019;63:405–427. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [9].Morris NB, Jay O, Flouris AD, et al. Sustainable solutions to mitigate occupational heat strain – an umbrella review of physiological effects and global health perspectives. Environ Health. 2020;19:95. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [10].Rychetnik L, Frommer M, Hawe P, et al. Criteria for evaluating evidence on public health interventions. J Epidemiol Community Health. 2002;56:119–127. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [11].Bach AJE, Maley MJ, Minett GM, et al. Occupational cooling practices of emergency first responders in the United States: A survey. Temperature. 2018;5:348–358. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [12].Pogačar T, Črepinšek Z, Bogataj LK, et al. Comprehension of climatic and occupational heat stress amongst agricultural advisers and workers in Slovenia. Acta Agric Slov. 2017;109:545–554. . [Google Scholar]

- [13].Stoecklin-Marois M, Hennessy-Burt T, Mitchell D, et al. Heat-related illness knowledge and practices among california hired farm workers in the MICASA study. Ind Health. 2013;51:47–55. [DOI] [PubMed] [Google Scholar]

- [14].Xiang J, Hansen A, Pisaniello D, et al. Perceptions of workplace heat exposure and controls among occupational hygienists and relevant specialists in Australia. PloS One. 2015;10. DOI: 10.1371/journal.pone.0135040 [DOI] [PMC free article] [PubMed] [Google Scholar]

- [15].Kjellstrom T, Freyberg C, Lemke B, et al. Estimating population heat exposure and impacts on working people in conjunction with climate change. Int J Biometeorol. 2018;62:291–306. [DOI] [PubMed] [Google Scholar]

- [16].Piil JF, Lundbye-Jensen J, Christiansen L, et al. High prevalence of hypohydration in occupations with heat stress—perspectives for performance in combined cognitive and motor tasks. Plos One. 2018;13:e0205321. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [17].Shirreffs SM. The importance of good hydration for work and exercise performance. Nutr Rev. 2005;63:S14–21. [DOI] [PubMed] [Google Scholar]

- [18].Wittbrodt MT, Millard-Stafford M. Dehydration impairs cognitive performance: a meta-analysis. Med Sci Sports Exerc. 2018;50:2360–2368. [DOI] [PubMed] [Google Scholar]

- [19].Jay O, Hoelzl R, Weets J, et al. Fanning as an alternative to air conditioning – A sustainable solution for reducing indoor occupational heat stress. Energy Build. 2019;193:92–98. [Google Scholar]

- [20].Davis LW, Gertler PJ. Contribution of air conditioning adoption to future energy use under global warming. Proc Natl Acad Sci. 2015;112:5962–5967. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [21].Yang Y, Stapleton J, Diagne BT, et al. Man-portable personal cooling garment based on vacuum desiccant cooling. Appl Therm Eng. 2012;47:18–24. [Google Scholar]

- [22].Nybo L, Kjellstrom T, Bogataj LK, et al. Global heating: attention is not enough; we need acute and appropriate actions. Temperature. 2017;4:199–201. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [23].Piil JF, Christiansen L, Morris NB, et al. Direct exposure of the head to solar heat radiation impairs motor-cognitive performance. Sci Rep. 2020;10:7812. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [24].Piil JF, Lundbye-Jensen J, Trangmar SJ, et al. Performance in complex motor tasks deteriorates in hyperthermic humans. Temperature. 2017;4:420–428. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [25].Piil JF, Mikkelsen CJ, Junge N, et al. Heat acclimation does not protect trained males from hyperthermia-induced impairments in complex task performance. Int J Environ Res Public Health. 2019;16:716. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [26].Morabito M, Messeri A, Noti P, et al. An occupational heat–health warning system for Europe: the HEAT-SHIELD platform. Int J Environ Res Public Health. 2019;16:2890. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [27].Nybo L, May M. Effectiveness of inquiry-based learning in an undergraduate exercise physiology course. Adv Physiol Educ. 2015;39:76–80. [DOI] [PubMed] [Google Scholar]

- [28].Tustin AW, Lamson GE, Jacklitsch BL, et al. Evaluation of occupational exposure limits for heat stress in outdoor workers — United STATES, 2011–2016. Morb Mortal Wkly Rep. 2018;67:733–737. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [29].Havenith G, Griggs K, Qiu Y, et al. Higher comfort temperature preferences for anthropometrically matched Chinese and Japanese versus white-western-middle-European individuals using a personal comfort/cooling system. Build Environ. 2020;183:107162. [Google Scholar]

- [30].Messeri A, Morabito M, Bonafede M, et al. Heat stress perception among native and migrant workers in italian industries—case studies from the construction and agricultural sectors. Int J Environ Res Public Health. 2019;16:1090. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [31].Nerbass FB, Pecoits-Filho R. Can your work affect your kidney’s health? Rev Environ Health. 2019;34:441–446. [DOI] [PubMed] [Google Scholar]

- [32].Lam M, Krenz J, Palmández P, et al. Identification of barriers to the prevention and treatment of heat-related illness in Latino farmworkers using activity-oriented, participatory rural appraisal focus group methods. BMC Public Health. 2013;13:1004. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [33].Riley K, Delp L, Cornelio D, et al. From agricultural fields to urban asphalt: the role of worker education to promote california’s heat illness prevention standard. NEW Solut J Environ Occup Health Policy. 2012;22:297–323. . [DOI] [PubMed] [Google Scholar]

- [34].Di Corleto R, Firth I, Maté J. A guide to managing heat stress: developed for use in the Australian environment. Aust Inst Occup Hygienists. 2013. [Google Scholar]

- [35].Construction A. . Forestry, mining and energy union (CFMEU)(2012) inclement weather—heat policy. 2013. [Google Scholar]

- [36].Nevarez J. OSHA compliance issues: OSHA heat stress fatality investigation of a Latino landscaping worker. J Occup Environ Hyg. 2013;10:D67–D70. [DOI] [PubMed] [Google Scholar]

- [37].Jacklitsch B, Williams J, Musolin K, et al. NIOSH criteria for a recommended standard: occupational exposure to heat and hot environments. Dep Health Hum Serv Cent Dis Control Prev Natl Inst Occup Saf Health DHHS NIOSH Publ. p. 2016–2106. 192, [date unknown]. . [Google Scholar]

- [38].Marinaccio A, Scortichini M, Gariazzo C, et al. Nationwide epidemiological study for estimating the effect of extreme outdoor temperature on occupational injuries in Italy. Environ Int. 2019;133:105176. [DOI] [PubMed] [Google Scholar]