Abstract

1-MCP (1-methylcyclopropene) is a simple synthetic hydrocarbon molecule that interacts with the ethylene receptor and inhibits the response of fruit or plant to ethylene. 1-MCP has opened new opportunities in handling harvested crops and serves as a powerful tool to learn about plant response to ethylene (Watkins and Miller, 2006). 1-MCP is manufactured by Agrofresh and known by its commercial name SmartfreshSM.

Keywords: Ripening inhibition, Ethylene, Fruit, Postharvest, Storage

Background

Application of 1-MCP can serve as a powerful tool to examine the response of the plant to ethylene. The commercial production of 1-MCP by Agrofresh allows simple practice of this treatment, especially postharvest. The application of 1-MCP to plants, fruit or vegetable was mentioned in many articles but was not described in detail. This was the motivation to provide the following protocol. In this protocol tomatoes served as candidates for the treatment.

Materials and Reagents

Hand gloves (latex or nitrile)

Rubber septa (for the volumetric flask) (Sigma-Aldrich, catalog number: Z553964)

Syringe 10 ml (OMG, catalog number: OMG-W-10M)

Needle 0.60 x 30 mm (Pic, catalog number: 03.070140.300.800)

Weighing papers for the 1-MCP powder (Whatman, catalog number: 28414662)

Freshly harvested tomatoes (any type and origin)

1-MCP powder (Agrofresh Inc.) containing 0.14% 1-MCP as active ingredient

Tap water

Equipment

30 L airtight HDPE plastic barrel wide mouth and cover with lid equipped with flexible latex hose or rubber septa (Chen Samuel chemicals, catalog number: 0100230)

Brand volumetric flask 1,000 ml (Sigma-Aldrich, catalog number: Z326828)

Benchtop weight scales with 0.01 g resolution (Vibra, catalog number: AJ-3200CE)

Procedure

-

Preparation of 1-MCP gas stock (1,000 ppm or 0.1%)

Gently pour 0.82 g of 1-MCP powder into the 1,000 ml volumetric flask and close tightly with the rubber septa.

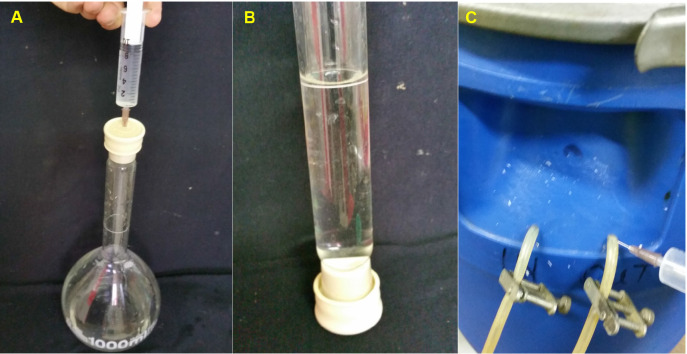

Inject a volume of 50 ml of water into the closed flask (5 times, 10 ml of water) and dissolve the powder to release the 1-MCP gas (Figure 1A).

Turn the volumetric flask upside down to check that the gas volume is 1,000 ml otherwise add water up to the marked line (Figure 1B).

-

1-MCP treatment.

Place the tomatoes (It is recommended not to exceed over one third of the barrel volume) inside the barrel and close the lid tightly. You can use wrapped plastic or other solution to prevent any gas leakage. The tomatoes and the barrel should be placed in a 20-25 °C room.

-

To apply 1 ppm of 1-MCP: injection of 30 ml of 1,000 ppm 1-MCP in 30 L barrel will give a concentration of 1 ppm 1-MCP to the tomatoes.

C1 x V1 = C2 x V2; 1,000 (ppm) x V1 (ml) = 1 (ppm) x 30,000 (ml)

Where, C1 = the concentration of 1-MCP gas stock in the volumetric flask (ppm); V1 = the unknown volume of the 1-MCP gas stock sample that should inject into the Barrel (ml); C2 = the wanted concentration of 1-MCP in the barrel (ppm); V2 = the volume of the barrel (ml).

The application of 1-MCP: Inject 10 ml of water into the volumetric flask (1-MCP) through the septa, draw up 10 ml of 1-MCP gas and inject immediately into the closed barrel through the flexible latex hose or the septa (Figure 1C).

Repeat step 2c two more times until injecting a total of 30 ml 1-MCP gas into the barrel.

Incubate for 24 h.

Open the barrel and air the tomatoes for at least 2 h to allow the tomatoes to adjust to the atmospheric environment. It is possible to measure ethylene levels and/or carbon dioxide in the barrel before opening.

As a control, untreated tomatoes should be placed in similar conditions without 1-MCP or any other gas treatment (Figure 2).

Figure 1. Preparation of 1-MCP gas stock and application to the tomato fruit.

A. Injection of water into the volumetric flask through the rubber septa; B. Volumetric flask filled with water up to the marked line to allow accurate volume of gas; C. Injection of 1-MCP gas through flexible latex hose into the closed barrel with tomatoes inside (Pictures: Dan Gamrasni).

Figure 2. The effect of 1-MCP treatment on the color change of tomatoes (Lycopersicon esculentum cv. Ailsa Craig) harvested at different ripening stages (mature green, breaker or early orange) 48 h after the end of the treatment .

(Picture: Dario Breitel)

Notes

The volume of the tomatoes should not exceed one third of the barrel to prevent CO2 accumulation if quicklime is not available, otherwise use bigger barrel (200 L) or do the treatment to smaller samples of tomatoes in few barrels.

To prevent carbon dioxide accumulation due to fruit respiration in the closed barrel, it is possible to add 0.5 kg of quicklime (known as burnt lime) that will spontaneously react with CO2 from the air (you can keep this powder in any paper bag).

It is possible to use the 1-MCP stock solution up to 2 weeks keeping the volumetric flask upside down at low temperature (4 °C).

Acknowledgments

The protocol was adapted from Gamrasni et al. (2010), and was similarly applied in Breitel et al. (2016).

We would like to thank RIMI and Agrofresh Inc. for the supply of 1-MCP.

Citation

Readers should cite both the Bio-protocol article and the original research article where this protocol was used.

References

- 1.Breitel D. A., Chappell-Maor L., Meir S., Panizel I., Puig C. P., Hao Y., Yifhar T., Yasuor H., Zouine M., Bouzayen M., Granell Richart A., Rogachev I. and Aharoni A.(2016). AUXIN RESPONSE FACTOR 2 intersects hormonal signals in the regulation of tomato fruit ripening. PLoS Genet 12(3): e1005903. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Gamrasni D., Ben-Arie R. and Goldway M.(2010). 1-Methylcyclopropene(1-MCP) application to Spadona pears at different stages of ripening to maximize fruit quality after storage . Postharvest Biol Technol 58(2):104-112. [Google Scholar]

- 3.Watkins C. B. and Miller W. B.(2006). A summary of physiological processes or disorders in fruits, vegetables and ornamental products that are delayed or decreased, increased, or unaffected by application of 1-methylcyclopropene(1-MCP).