Abstract

Understanding gas

desorption effects and laws of coal mass under

different conditions is essential for the effective exploration of

gas emission in underground coal mines, prediction and prevention

of coal and gas outburst, accurate detection of gas [coal methane

(CBM)] content in coal seams, and prediction of CBM productivity.

Using a self-developed test platform, we simulated gas adsorption

and desorption and performed physical simulation tests. Based on these

tests, we investigated the differences in the total amount of gas

desorbed, desorption rate, and initial amount of gas desorbed by long-flame

coal, coking coal, meager-lean coal, and anthracite on different scales

under different gas pressures. Two methods are used for compensating

gas loss, namely, the  method

and the power function method, as

stipulated in the current Standards for Determination of Gas Content

in Coal Seams in China. By combining these two methods, we analyzed

the applicability of these two compensation methods in coal on different

scales with varying degrees of metamorphism under gas pressures. The

results demonstrated that (1) under the same gas adsorption pressure,

the cumulative total amount of gas desorbed per unit mass within 90

min for the four kinds of coal samples increases with the degree of

metamorphism. Changes in the cumulative amount of gas desorbed per

unit mass and the desorption rate with the degree of metamorphism

vary with stages. Notably, a higher adsorption pressure leads to a

more obvious stage change. (2) Under the same gas adsorption pressure,

the cumulative total amount of gas desorbed per unit mass and the

desorption rate of coal with the same degree of metamorphism are inversely

proportional to the size of the coal sample. This indicates significant

scale effects. The larger the degree of metamorphism and gas adsorption

pressure, the more significant are the scale effects of gas desorption.

(3) For coal with the same degree of metamorphism, the higher gas

adsorption pressure leads to a larger cumulative total amount of gas

desorbed and a higher desorption rate throughout the desorption process

and a larger proportion of the cumulative amount of gas desorbed in

the initial stage. The smaller the size of the coal sample, the more

obvious the pressure effects of gas desorption are. (4) For coal samples

with the same degree of metamorphism, when the gas content in coal

seams is kept constant, the larger the size of the coal sample, the

smaller the actual gas loss is. Moreover, a higher gas content in

coal seams results in a greater gas loss and a larger calculation

error for gas loss. Compared with the

method

and the power function method, as

stipulated in the current Standards for Determination of Gas Content

in Coal Seams in China. By combining these two methods, we analyzed

the applicability of these two compensation methods in coal on different

scales with varying degrees of metamorphism under gas pressures. The

results demonstrated that (1) under the same gas adsorption pressure,

the cumulative total amount of gas desorbed per unit mass within 90

min for the four kinds of coal samples increases with the degree of

metamorphism. Changes in the cumulative amount of gas desorbed per

unit mass and the desorption rate with the degree of metamorphism

vary with stages. Notably, a higher adsorption pressure leads to a

more obvious stage change. (2) Under the same gas adsorption pressure,

the cumulative total amount of gas desorbed per unit mass and the

desorption rate of coal with the same degree of metamorphism are inversely

proportional to the size of the coal sample. This indicates significant

scale effects. The larger the degree of metamorphism and gas adsorption

pressure, the more significant are the scale effects of gas desorption.

(3) For coal with the same degree of metamorphism, the higher gas

adsorption pressure leads to a larger cumulative total amount of gas

desorbed and a higher desorption rate throughout the desorption process

and a larger proportion of the cumulative amount of gas desorbed in

the initial stage. The smaller the size of the coal sample, the more

obvious the pressure effects of gas desorption are. (4) For coal samples

with the same degree of metamorphism, when the gas content in coal

seams is kept constant, the larger the size of the coal sample, the

smaller the actual gas loss is. Moreover, a higher gas content in

coal seams results in a greater gas loss and a larger calculation

error for gas loss. Compared with the  method,

the power function method reveals

a smaller deviation between the calculated gas loss and the actual

gas loss, which is found to be more accurate. A larger size coal sample

results in higher accuracy in the calculated gas loss.

method,

the power function method reveals

a smaller deviation between the calculated gas loss and the actual

gas loss, which is found to be more accurate. A larger size coal sample

results in higher accuracy in the calculated gas loss.

Introduction

Gas coalbed methane (CBM) in coal seams is a clean form of energy. However, it is also associated with deleterious effects in coal mining. The research on gas desorption laws of coal mass and their influencing factors is a hotspot in the field of prevention and control of gas disasters and exploration and production of CBM in coal mines. This is of great practical significance in exploring gas emission in underground mines, predicting and preventing coal and gas outbursts, improving the evaluation accuracy of gas content in coal seams, and predicting CBM productivity.1−4

Coal is a type of porous solid medium, with complex characteristics and a complex surrounding environment. Different factors are potentially linked to the large difference in the characteristics of gas desorption from coal mass. Currently, studies on desorption laws of gas-bearing coal and their influencing factors have advanced. These studies mainly focus on the impact and laws of the degree of metamorphism, gas pressure, failure type of coal mass, size of coal samples, pore structure, and moisture on desorption effects of gas-bearing coal. Yang,5 Nie,6 Han,7 Feng,8 Qin,9 Liu,10 and Chen11 conducted gas desorption tests on different sizes of granular coal samples. The results revealed that the total amount of gas desorbed per unit mass and the gas desorption rate of coal at a given time decrease with an increase in the particle size of coal and remain unchanged after the coal particle size attains the limit. Ma12 and Zhang13 performed an adsorption–desorption experiment on 60–80 mesh granular coal and conducted the desorption process in four stages. Elsewhere, Ge,14 Li,15 and Yan16 explored differences in the desorption laws of bulk coal samples, columnar coal cores, and granular coal samples of anthracite. They found that the cumulative desorption rate, the cumulative amount of desorption, and desorption speed of the granular coal samples were larger compared to those of the columnar coal cores and bulk coal samples. Further, Cheng,17 Lin,18 Li,19 and Kang20 expounded mechanisms by which pore structures influence the rate and amount of gas desorption from the microperspectives of pore pattern and diameter. Wierzbicki21 reported that the cumulative amount and increment of the gas desorbed by granular coal increased with a temperature rise. The initial velocity of gas emission in the low-temperature environment was found to be much smaller than that in the normal-temperature environment.22 Also, Wang23 suggested that the loss of gas desorption is reduced by coring at a low temperature. With an increase in the degree of metamorphism of coal, the diffusion coefficient of methane first decreases and then gradually increases.24,25 Through analysis of the change laws of the Langmuir effective diffusion coefficient with the coal rank and their influencing factors, Yan26 found that a rise in the coal rank increased the development degree of micropores and gas desorption capacity. Wang,27 Gao,28 and Lin29 concluded a higher adsorption pressure of coal mass is related to the stronger movement of methane molecules, more favorable for gas desorption, and accelerates gas diffusion. Additionally, the high pressure increases the diffusion coefficient and the cumulative amount of gas desorption and diffusion. In general, different degrees of metamorphism of coal are associated with different structures of coal mass, environmental factors, and gas desorption laws.30−34 Through several tests and theoretical analyses, relevant scholars have established multiple empirical formulas reflecting gas desorption laws, for example, those described by Wendt, Barrel, Wang,35 Airy, and Bott.36 Scholars have verified and analyzed the applicability of the above empirical formulas for gas desorption laws through tests and theoretical analyses. Notably, a new model of gas desorption and diffusion was established. For instance, Li37 revealed that the tectonic coal accords with Wendt’s empirical formula in the initial stage of gas desorption. Also, Qi38 found that empirical formulas described by Wendt and Wang Youan are more accurate in the low-temperature environment. Li39 utilized singe-hole and double-hole models to establish a mode of dynamic gas diffusion in loaded coal and calculated diffusion coefficients of the coal samples with different particle sizes. Elsewhere, Liu10 and Wang41 constructed a gas desorption model considering the multiple diffusion coefficients. Collectively, the research results offer critical insights in determining the gas content in coal seams, prediction of gas emission from underground mines, prevention of gas disasters in coal mines, and exploration and production of CBM. However, most scholars used granular coal samples characterized by different particle sizes after artificial crushing and screening of the original coal mass. This distorts the original characteristics of the original coal mass and fails to simulate characteristics of the pore and fracture structures in the original underground coal mass. Some scholars have performed tests with large-scale coal samples and selected those exhibiting a single degree of metamorphism, which are not representative.

In coal seams, the gas content is a vital parameter for predicting

the amount of gas emission, estimation of gas resources, and prevention

of gas disasters during coal mining. Currently, the direct method

commonly used to measure the gas content in coal seams is directed

underground. With the direct method, gas content in coal seams is

measured in three parts, loss, measurable amount of desorption, and

residual amount. The loss is calculated based on desorption laws,

whereas the measurable amount of desorption and the residual amount

are the true readings. Therefore, to establish the gas content in

coal seams, the accuracy of the direct method is determined by the

accuracy of loss calculation. Practically, the exposure time of the

coal samples can be accurately evaluated.42 The desorption laws within the exposure time, that is, the accuracy

of the desorption model, are crucial in measuring the error of loss.

Based on the above reports, most desorption models integrate empirical

formulas. Also, the correlation coefficients for fitting gas desorption

models under different conditions are different. To improve the accuracy

of the assessment of gas content in coal seams, industries and academia

have extensively explored and reviewed models of loss calculation.43−47 In China, the national standard, Direct Method of Determining Coalbed

Gas Content in the Mine (GB/T23250-2009), indicate that the  method

and the power function method are

commonly applied to calculate gas loss.48 The standard also shows that with sampling methods, cuttings of

granular coal are collected from fixed points. A fixed-point sampler

is used to drill holes into coal seams or collect columnar coal cores

with a coal core sampler. Previous studies expressed both the

method

and the power function method are

commonly applied to calculate gas loss.48 The standard also shows that with sampling methods, cuttings of

granular coal are collected from fixed points. A fixed-point sampler

is used to drill holes into coal seams or collect columnar coal cores

with a coal core sampler. Previous studies expressed both the  method

and the power function method using

empirical formulas. Their applicability in the gas desorption of coal

drill cuttings (granular) and coal cores (columnar) samples under

different degrees of metamorphism and gas pressures differ, which

warrants further exploration.

method

and the power function method using

empirical formulas. Their applicability in the gas desorption of coal

drill cuttings (granular) and coal cores (columnar) samples under

different degrees of metamorphism and gas pressures differ, which

warrants further exploration.

Based on the current understanding,

there is no consensus on which

desorption law should be applied when calculating loss. Also, no systematic

study has explored gas desorption laws and differences between large-scale

coal samples through a reflection of the characteristics of the original

coal mass and small-scale granular coal samples after artificial crushing

and screening. Moreover, the applicability of two generally used methods

( method and power function method) for gas

loss calculation in the coal samples with different degrees of metamorphism,

gas pressures, and scales has not been systematically investigated.

In consequence, the methods that compensate for the gas content are

more erroneous and do not guarantee the accuracy of determining the

gas content.

method and power function method) for gas

loss calculation in the coal samples with different degrees of metamorphism,

gas pressures, and scales has not been systematically investigated.

In consequence, the methods that compensate for the gas content are

more erroneous and do not guarantee the accuracy of determining the

gas content.

On this basis, four types of coal samples with

different degrees

of metamorphism from different mining areas were used in tests. Desorption

tests under different gas pressures during adsorption were conducted

through the drilling of different sizes of columnar coal samples and

crushing and screening into different particle sizes of granular coal

samples. We aimed to explore the gas desorption laws of columnar coal

samples by approximately reflecting the original coal mass and their

differences in the desorption laws of granular coal samples. This

study explored and analyzed the applicability of the two methods for

compensating gas loss, the  method

and the power function method, in

coal with different scales, gas pressures, and degrees of metamorphism.

We expect that the findings will reveal desorption effects and laws

of multiscale gas-bearing coal with different degrees of metamorphism

and provide a basis for the selection of the optimal sampling method

for establishing the gas content in coal seams and the best method

for compensating the loss.

method

and the power function method, in

coal with different scales, gas pressures, and degrees of metamorphism.

We expect that the findings will reveal desorption effects and laws

of multiscale gas-bearing coal with different degrees of metamorphism

and provide a basis for the selection of the optimal sampling method

for establishing the gas content in coal seams and the best method

for compensating the loss.

Sample Preparation and Methods in Tests

Sample Collection and Preparation for Tests

The four types of coal samples with different degrees of metamorphism were collected for testing. They included anthracite from Jiaozuo Mining Area (Henan Province), meager-lean coal from Qinshui Coalfield (Shanxi Province), coking coal from Anyang Mining Area (Henan Province), and long-flame coal from Yujialiang Mining Area (Shaanxi Province), China. The collected samples were sealed with plastic films and transported to the laboratory. The columnar coal samples with two dimensions of 50 mm * 100 mm (diameter: 50 mm, height: 100 mm) and 37.5 mm * 75 mm (diameter: 37.5 mm, height: 75 mm) were drilled using a core-drilling machine (Figure 1a). The remaining coal samples were crushed and screened into granular coal samples with particle sizes of 1–3 and 0.5–1 mm (Figure 1b). We prepared 16 test samples. Table 1 displays the basic parameters of the four types of coal with different degrees of metamorphism.

Figure 1.

Coal samples used in tests.

Table 1. Basic Parameters of the Coal Samples in Tests.

| industrial analysis/% |

|||||

|---|---|---|---|---|---|

| coal number | degrees of metamorphism | coal structure | Mad | Aad | Vad |

| WYM | anthracite | native structure | 3.06 | 15.18 | 9.44 |

| PSM | meager-lean coal | native structure | 0.45 | 8.58 | 17.97 |

| JM | coking | native structure | 0.67 | 10.81 | 21.37 |

| CYM | long-flame coal | native structure | 6.41 | 1.90 | 38.16 |

Test Devices and Methods

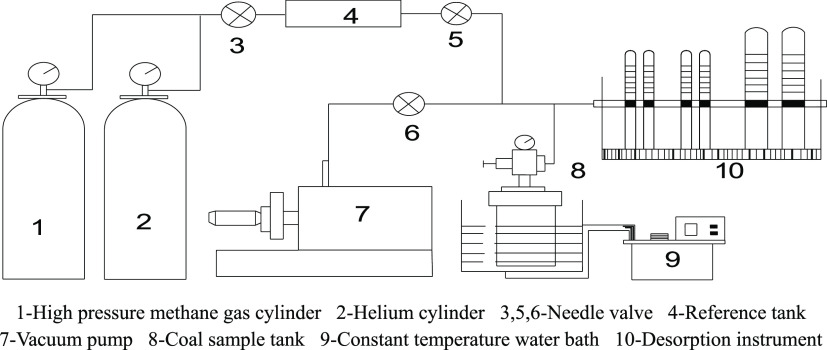

Following the requirements of test conditions, a set of adsorption and desorption test system (Figure 2) with temperature control functions was designed and installed independently and met the test requirements of columnar and granular coal samples simultaneously. The whole system mainly comprised four parts, a high-pressure gas-filling unit (1, 2, and 4), a gas adsorption–desorption unit (8 and 10), a constant-temperature regulating unit (9), and a vacuum degassing unit (7).

Figure 2.

Schematic diagram of the test device system.

Five major processes constituted this test: (i) dehydration of the coal samples, (ii) calibration of the dead-space volume, (iii) canning and degassing of the coal samples, (iv) gas (methane) adsorption of the coal samples under a high pressure, and (v) gas desorption under normal pressure. The pressures for adsorption equilibrium of the coal samples in the test were set at an equal gradient in the range of 0.5–3 MPa as follows: 0.5, 1, 1.5, 2, 2.5, and 3 MPa. The time of adsorption equilibrium of the columnar coal samples was longer than 4 d, whereas that of the granular coal samples was longer than 2 d. The temperature set in the test was 30 °C, and the coal samples were desorbed for 3 h.

Test Results and Discussion

Coal Rank Effects of Gas Desorption

The columnar coal samples with 50 mm * 100 mm dimensions and granular coal samples with a particle size of 1–3 mm of anthracite, meager-lean coal, coking coal, and long-flame coal with different degrees of metamorphism were selected. Based on the data of the desorption test recorded under the adsorption pressures of 1, 2, and 3 MPa within 90 min, we did a comparison and analysis of the change characteristics of the cumulative total amount of gas desorbed per unit mass and gas desorption rate with the degree of metamorphism. The effects of coal ranks and laws of gas desorption from coal mass were further revealed (Figures 3 and 4).

Figure 3.

Comparison of the cumulative amount of gas desorbed by coal with different degrees of metamorphism.

Figure 4.

Comparison of the gas desorption rates of coal with different degrees of metamorphism.

Based on the analysis of Figures 3 and 4, the coal with different degrees of metamorphism at the same scale exhibits the following characteristics in terms of the cumulative total amount of gas desorbed and the desorption rate.

-

(1)

Under the same adsorption pressure, according to the cumulative total amount of gas desorbed per unit mass within 90 min, anthracite, meager-lean coal, coking coal, and long-flame coal are ranked in descending order. That is, the cumulative total amount of gas desorbed increases with the degree of metamorphism. For instance, at an adsorption pressure of 3 MPa, the cumulative total amount of gas desorbed by the granular coal samples of anthracite, meager-lean coal, and coking coal within 90 min is 2.06, 1.61, and 1.45 times that of the granular coal samples of long-flame coal, respectively. This law was mainly determined by the adsorption capacity of coal with different degrees of metamorphism such that the greater the adsorption capacity, the larger the total amount of gas desorbed.

-

(2)

Under the same adsorption pressure, except for long-flame coal with a low degree of metamorphism, the other three types of coal with medium and high degrees of metamorphism show the following laws always. Particularly, anthracite, meager-lean coal, and coking coal are ranked in a descending order. This is according to the changes of the cumulative total amount of gas desorbed and the desorption rate with an increase in the degree of metamorphism in the entire desorption process. The desorption rates of coal with different degrees of metamorphism are largely different in the initial desorption stage. Later, the difference in desorption rates becomes increasingly small and the desorption rate tends to be approximate.

-

(3)

Compared to the other three types of coal with medium and high degrees of metamorphism, the cumulative amount of gas desorbed and the desorption rate of long-flame coal are larger in the initial stages. It takes less time to attain the maximum desorption. At a pressure of 3 MPa, the amount of gas desorbed by the granular coal samples of long-flame coal with a particle size of 1–3 mm in the first 3 and 5 min accounts for 67.0 and 68.5% of the total amount of gas desorbed within 90 min, respectively. Notably, under the same conditions, the amount of gas desorbed by anthracite in the first 3 and 5 min is 28.9 and 35.4% of the total amount of gas desorbed within 90 min, respectively. Such characteristics mainly are influenced by the development and good connectivity of pores and fractures in long-flame coal.

-

(4)

Considering the four types of coal with different degrees of metamorphism, the changes in their cumulative amount of gas desorbed and desorption rates with the degree of metamorphism in the whole desorption process are segmented. In the initial desorption stage, the cumulative amount of gas desorbed and the desorption rate of long-flame coal are large. They are larger compared to those of coking coal, meager-lean coal, and anthracite. Following an increase in the desorption time, the cumulative amount of desorption and desorption rates of long-flame coal is smaller than those of coal with medium and high degrees of metamorphism. A higher adsorption pressure implies that the phenomenon is more obvious. Figures 3a and 4a demonstrate that, under an adsorption pressure of 1 MPa, anthracite, long-flame coal, meager-lean coal, and coking coal are ranked in a descending order based on the cumulative amount of gas desorbed and desorption rate of the granular and columnar coal samples within 5 min of desorption time. Within 5–10 min, anthracite, meager-lean coal, long-flame coal, and coking coal are ranked in a descending order based on the cumulative amount of gas desorbed and desorption rate. An ascending order is found in long-flame coal, coking coal, meager-lean coal, and anthracite according to the cumulative amount of gas desorbed and desorption rate in more than 10 min. Figures 3c and 4b illustrate that, under an adsorption pressure of 3 MPa, long-flame coal, anthracite, meager-lean coal, and coking coal are ranked in a descending order based on the cumulative amount of gas desorbed and the desorption rate within 10 min. Within 10–20 min, the cumulative amount of gas desorbed and the desorption rate of anthracite are the largest, followed by long-flame coal and meager-lean coal. However, the smallest cumulative amount of gas desorbed and desorption rate are found in coking coal. Within 20–30 min, a descending order is found in anthracite, meager-lean coal, long-flame coal, and coking coal, whereas an ascending order is presented in long-flame coal, coking coal, meager-lean coal, and anthracite at a desorption time longer than 30 min. Such phenomena are mainly established by the adsorption capacity and development degree of pores and fractures in coal with different degrees of metamorphism. The development and good connectivity of pores and fractures in long-flame coal results are because the initial desorption capacity increases, whereas the desorption accelerates. However, the gas adsorption capacity eventually demonstrates that the total amount of desorption is small.

Scale Effects of Gas Desorption

The columnar coal samples with the dimensions of 37.5 mm * 75 mm and 50 mm * 100 mm and granular coal samples with the particle sizes of 0.5–1 and 1–3 mm of anthracite, meager-lean coal, and long-flame coal with different degrees of metamorphism were selected. This was followed by a comparison and analysis of the change characteristics of the cumulative amount of gas desorbed per unit mass and the gas desorption rate with the scale based on the desorption test data under adsorption pressures of 1 and 3 MPa (Figures 5 and 6). Then, scale effects and laws of gas desorption from coal mass were revealed.

Figure 5.

Comparison of the cumulative amount of gas desorbed between the columnar coal sample and granular coal samples.

Figure 6.

Comparison of the gas desorption rates between the columnar and granular coal samples.

Based on the analysis of Figures 5 and 6, the columnar and granular coal samples with different sizes exhibit the following characteristics of the cumulative amount of gas desorbed and desorption rates.

-

(1)

Under the same pressure of adsorption equilibrium, coal samples with the same degree of metamorphism, the cumulative amount of gas desorbed per unit mass, and the desorption rate have an inverse relationship with the sizes of the samples in the whole desorption process, and the maximum desorption is attained. That is, the smaller size implies a larger cumulative amount of desorption and desorption rates, demonstrating noticeable effects on the particle size. Among all the coal samples, the granular coal samples with a particle size of 0.5–1 mm exhibit the largest cumulative amount of gas desorbed and desorption rate, followed by the granular coal samples with a particle size of 1–3 mm. The columnar coal samples with the dimensions of 50 mm * 100 mm show the smallest cumulative amount of gas desorbed and desorption rate. Figures 5f and 6d demonstrates that, under an adsorption pressure of 3 MPa, the cumulative amounts of gas desorbed by the granular coal samples with a particle size of 0.5–1 mm for 40 min are 1.37, 1.68, and 1.87 times that of the granular coal samples with a particle size of 1–3 mm and columnar coal samples with the dimensions of 37.5 mm * 75 mm and 50 mm * 100 mm. Furthermore, its desorption rate is 1.27, 1.56, and 1.74 times that of the granular coal samples with the particle size of 1–3 mm and columnar coal samples with dimensions of 37.5 mm * 75 mm and 50 mm * 100 mm. The main reason for such particle size effects is that the fractures in the granular coal samples are more developed compared to the columnar coal samples due to artificial crushing. Also, the small particle size of granular coal makes the paths for desorbing gas adsorbed in the matrix become shorter and smoother.

-

(2)

Under the same adsorption pressure, an increase in the degree of metamorphism shows more noticeable particle size effects on the cumulative amount of gas desorbed and the desorption rate. Figure 5a,c,e illustrate that, under an adsorption pressure of 1 MPa and 10 min desorption time, differences exist between the cumulative amount of gas desorbed by long-flame coal and those of the particle size of 0.5–1 mm and the granular coal samples with the particle size of 1–3 mm and columnar coal samples with the dimensions of 37.5 mm * 75 mm and 50 mm * 100 mm. The differences are 0.13, 0.19, and 0.35 cm3/g. Under the same conditions, the cumulative amount of gas desorbed by meager-lean coal shows differences of 0.18, 0.28, and 0.48 cm3/g, while the cumulative amount of gas desorbed by anthracite demonstrates the differences of 0.36, 0.67, and 0.91 cm3/g, with that of the above granular coal samples and columnar coal samples.

-

(3)

For coal with the same degree of metamorphism, higher adsorption pressure depicts more significant effects of particle size on the cumulative amount of gas desorbed and desorption rate. Figure 5e,f show that, at an adsorption pressure of 1 MPa and 20 min desorption time, the differences between the cumulative amount of gas desorbed by anthracite with the particle size of 0.5–1 mm and the granular coal samples with the particle size of 1–3 mm and columnar coal samples with the dimensions of 37.5 mm * 75 mm and 50 mm * 100 mm are 0.39, 0.79, and 1.07 cm3/g. Under an adsorption pressure of 3 MPa, the differences are 1.87, 2.61, and 2.89 cm3/g, higher than those of particle size effects for gas desorption under an adsorption pressure of 1 MPa. Notably, meager-lean coal and anthracite show the same laws.

Pressure Effects of Gas Desorption

By selecting anthracite and long-flame coal with the particle sizes of 0.5–1 mm and the dimensions of 50 mm * 100 mm, we obtained data of the desorption test under the adsorption pressures of 0.5, 1, 1.5, 2, 2.5, and 3 MPa (Figures 7 and 8). The change characteristics of the cumulative amount of gas desorbed per unit mass and gas desorption rate with the adsorption pressure were compared and analyzed. Eventually, we revealed the pressure effects and laws of gas desorption from coal mass.

Figure 7.

Comparison of the amount of gas desorbed under different pressures of adsorption equilibrium.

Figure 8.

Comparison of the gas desorption rates under different pressures of adsorption equilibrium.

Based on the analysis of Figures 7 and 8, the coal samples exhibit the following characteristics in the cumulative amount of gas desorbed and the desorption rate under different adsorption pressures.

-

(1)

Higher the adsorption pressure in the whole desorption process implies that the cumulative amount of gas desorbed and the desorption rate are larger for coal with the same degree of metamorphism. To explain this, a higher adsorption pressure is related to a larger amount of adsorption of coal. When the equilibrium is damaged, a higher adsorption pressure results in a more violent movement of methane molecules, which becomes more conducive to gas desorption and accelerates gas desorption.29

-

(2)

Higher adsorption pressure causes a larger desorption rate and the cumulative amount of desorption in the initial desorption stage for coal with the same degree of metamorphism. Figures 7b and 8b demonstrate that, under 5 min of desorption, the cumulative amounts of gas desorbed per unit mass of the granular samples of anthracite with the particle size of 0.5–1 mm with an adsorption pressures of 3 MPa are 1.13, 1.22, 1.41, 1.62, and 2.33 times that of those under the pressures of 2.5, 2, 1.5, 1, and 0.5 MPa, respectively. Moreover, the desorption rate under the adsorption pressure of 3 MPa is 1.13, 1.21, 1.41, 1.63, and 2.33 times that of those under the pressures of 2.5, 2, 1.5, 1, and 0.5 MPa, respectively.

-

(3)

For coal samples with the same degree of metamorphism, smaller size of coal samples depicts more obvious pressure effects of gas desorption. That is, under the same difference of pressures for gas adsorption, the smaller size of coal samples is related to larger corresponding differences in the cumulative amount of gas desorbed and the desorption rate. Figure 7a,b demonstrates that, under the adsorption pressure of 3 MPa, the cumulative amount of gas desorbed per unit mass of the granular coal samples of anthracite with the particle size of 0.5–1 mm shows differences of 0.65, 1.19, 1.76, 2.24, and 3.09 cm3/g with those under 2.5, 2, 1.5, 1, and 0.5 MPa pressures in 10 min desorption time, respectively. Within 10 min, the cumulative amount of gas desorbed per unit mass of the columnar coal samples of anthracite with the dimensions of 50 mm * 100 mm under an adsorption pressure of 3 MPa shows differences of 0.40, 0.62, 0.90, 1.28, and 1.86 cm3/g with those under 2.5, 2, 1.5, 1, and 0.5 MPa pressures, respectively. Such differences are smaller than those of the granular coal samples with a particle size of 0.5–1 mm. Figure 8a,b illustrates the same characteristics in the desorption rate.

Discussion on Methods for Compensating the Gas Loss

The

accuracy of methods for loss calculation determines the accuracy

of measurement of the gas content in underground coal seams. In China,

the  method and power function methods complying

with the national standards48 are applied

to calculate the gas loss in the early stages of measurement. According

to the above desorption test data of gas-bearing coal, we compared

and analyzed the errors of the two methods under different scales,

degrees of metamorphism, and gas pressures. The applicability of the

two methods was also reviewed, which we believe can significantly

guide and improve the accuracy of establishing the gas content in

coal seams.

method and power function methods complying

with the national standards48 are applied

to calculate the gas loss in the early stages of measurement. According

to the above desorption test data of gas-bearing coal, we compared

and analyzed the errors of the two methods under different scales,

degrees of metamorphism, and gas pressures. The applicability of the

two methods was also reviewed, which we believe can significantly

guide and improve the accuracy of establishing the gas content in

coal seams.

The  method

is based on the linear relationship

between the cumulative amount V of gas desorbed and

the square root

method

is based on the linear relationship

between the cumulative amount V of gas desorbed and

the square root  of the total desorption time within

a certain

period after exposure of the coal samples, which is expressed as follows

of the total desorption time within

a certain

period after exposure of the coal samples, which is expressed as follows

| 1 |

where, t, t0, and V represent the gas desorption time (min), exposure time (min) of the coal samples, and the cumulative amount (cm3) of desorption within t, respectively, and Vs′ and K denote the amount (cm3) of gas desorbed within t0 and undetermined constant, respectively.

The power function method is to transmit

the measured data (t, Vt) into

the data of the desorption rate  and then calculate q0 and n by fitting through the formula.

and then calculate q0 and n by fitting through the formula.

| 2 |

where, qt, q0, and t denote the gas desorption rate at t, gas desorption rate when t = 0, and gas desorption time, respectively, and n represents the attenuation coefficient of the gas desorption rate and 0 < n < 1. The loss is calculated by the formula

| 3 |

where, Vs and T0 indicate the gas loss in the coal samples and exposure time of the coal samples, respectively.

Furthermore, we obtained the desorption data of anthracite, meager-lean coal, coking coal, and long-flame coal with the dimensions of 50 mm * 100 mm and the particle size of 0.5–1 mm under the adsorption pressures of 0.5, 1, and 3 MPa. Assuming that the exposure time is 2 min, the applicability and accuracy of the two methods in calculating gas loss were compared and analyzed (results are shown in Table 2).

Table 2. Gas Content Measurement Results of

Loss Using the  Method

and the Power Function Method.

Method

and the Power Function Method.

| loss

calculated (cm3/g) |

deviations (cm3/g) |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| coal number | size (mm) | pressure (MPa) | R12 | power function | R22 | actual loss (cm3/g) | power function | ||||

| WYM | 50*100 | 0.5 | 0.40 | 0.9940 | 0.64 | 0.9962 | 0.83 | 0.43 | 0.19 | ||

| 1 | 0.61 | 0.9969 | 0.91 | 0.9937 | 1.13 | 0.52 | 0.22 | ||||

| 3 | 0.92 | 0.9953 | 1.57 | 0.9949 | 1.98 | 1.06 | 0.41 | ||||

| 0.5–1 | 0.5 | 0.61 | 0.9989 | 0.95 | 0.9947 | 1.19 | 0.58 | 0.24 | |||

| 1 | 0.89 | 0.9960 | 1.36 | 0.9935 | 1.69 | 0.80 | 0.33 | ||||

| 3 | 1.96 | 0.9999 | 2.10 | 0.9958 | 2.60 | 0.64 | 0.50 | ||||

| PSM | 50*100 | 0.5 | 0.34 | 0.9982 | 0.35 | 0.9983 | 0.43 | 0.09 | 0.08 | ||

| 1 | 0.50 | 0.9960 | 0.59 | 0.9955 | 0.71 | 0.21 | 0.12 | ||||

| 3 | 0.85 | 0.9902 | 1.15 | 0.9964 | 1.42 | 0.57 | 0.27 | ||||

| 0.5–1 | 0.5 | 0.57 | 0.9982 | 0.64 | 0.9906 | 0.76 | 0.19 | 0.12 | |||

| 1 | 0.70 | 0.9931 | 0.82 | 0.9894 | 0.97 | 0.27 | 0.15 | ||||

| 3 | 1.22 | 0.9960 | 1.47 | 0.9970 | 1.80 | 0.58 | 0.33 | ||||

| JM | 50*100 | 0.5 | 0.30 | 0.9995 | 0.33 | 0.9968 | 0.41 | 0.11 | 0.08 | ||

| 1 | 0.48 | 0.9970 | 0.53 | 0.9929 | 0.65 | 0.17 | 0.12 | ||||

| 3 | 0.82 | 0.9987 | 1.11 | 0.9972 | 1.37 | 0.55 | 0.26 | ||||

| 0.5–1 | 0.5 | 0.48 | 0.9960 | 0.56 | 0.9964 | 0.68 | 0.20 | 0.12 | |||

| 1 | 0.60 | 0.9970 | 0.73 | 0.9929 | 0.88 | 0.28 | 0.15 | ||||

| 3 | 1.00 | 0.9991 | 1.42 | 0.9959 | 1.77 | 0.77 | 0.35 | ||||

| CYM | 50*100 | 0.5 | 0.20 | 0.9900 | 0.43 | 0.9915 | 0.54 | 0.34 | 0.11 | ||

| 1 | 0.22 | 0.9853 | 0.68 | 0.9941 | 0.88 | 0.66 | 0.2 | ||||

| 3 | 0.65 | 0.9859 | 1.96 | 0.9919 | 2.51 | 1.86 | 0.55 | ||||

| 0.5–1 | 0.5 | 0.22 | 0.9687 | 0.51 | 0.9897 | 0.65 | 0.43 | 0.14 | |||

| 1 | 0.27 | 0.9755 | 0.90 | 0.9915 | 1.13 | 0.86 | 0.23 | ||||

| 3 | 0.73 | 0.9880 | 2.28 | 0.9933 | 3.00 | 2.27 | 0.72 | ||||

Through analysis of the data in Table 2, the following understandings can be reached.

-

(1)

Under the same adsorption pressure, the actual loss of large-scale columnar coal samples is smaller than that of small-scale granular coal samples for the coal samples with the same degree of metamorphism. Besides, a higher pressure for gas adsorption, that is, a higher gas content in coal seams denotes a greater gas loss within the same exposure time for coal samples with the same degree of metamorphism and scale.

-

(2)

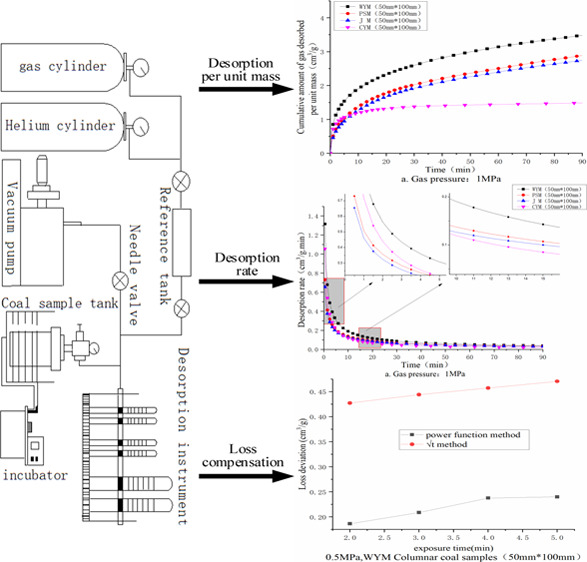

As shown in Figure 9, compared to the

method,

the deviation between the gas loss

calculated by fitting according to the power function method and the

actual gas loss is smaller, demonstrating a higher accuracy. Meanwhile,

gas desorption data in the initial stage should be selected when calculating

the gas loss using the

method,

the deviation between the gas loss

calculated by fitting according to the power function method and the

actual gas loss is smaller, demonstrating a higher accuracy. Meanwhile,

gas desorption data in the initial stage should be selected when calculating

the gas loss using the  method.

A longer time span of the selected

data would mean a larger error. Therefore, the gas desorption data

in the first 5 min were selected in this calculation, while those

in the first 20 min were selected for calculation using the power

function method.

method.

A longer time span of the selected

data would mean a larger error. Therefore, the gas desorption data

in the first 5 min were selected in this calculation, while those

in the first 20 min were selected for calculation using the power

function method. -

(3)

The accuracy of gas loss calculated by both the

method

and the power function method shows

noticeable effects on the particle size such that a larger size of

the coal sample implies a higher accuracy of gas loss calculation.

For anthracite under an adsorption pressure of 0.5 MPa, the deviations

of the gas loss of the columnar and granular coal samples calculated

by the

method

and the power function method shows

noticeable effects on the particle size such that a larger size of

the coal sample implies a higher accuracy of gas loss calculation.

For anthracite under an adsorption pressure of 0.5 MPa, the deviations

of the gas loss of the columnar and granular coal samples calculated

by the  method

are 0.43 and 0.58 cm3/g, while those calculated using the

power function method are 0.19

and 0.24 cm3/g as compared to the actual loss.

method

are 0.43 and 0.58 cm3/g, while those calculated using the

power function method are 0.19

and 0.24 cm3/g as compared to the actual loss. -

(4)

A higher adsorption pressure, that is, a higher gas content in coal seams, denotes a larger error of the calculated gas loss. For the meager-lean coal with the particle size of 0.5–1 mm, the deviations between the gas loss calculated with the

method

and the actual loss are 0.19, 0.27,

and 0.58 cm3/g under the adsorption pressures of 0.5, 1,

and 3 MPa. Under the same conditions, the deviations between the gas

loss calculated by the power function method and the actual loss are

0.12, 0.15, and 0.33 cm3/g.

method

and the actual loss are 0.19, 0.27,

and 0.58 cm3/g under the adsorption pressures of 0.5, 1,

and 3 MPa. Under the same conditions, the deviations between the gas

loss calculated by the power function method and the actual loss are

0.12, 0.15, and 0.33 cm3/g. -

(5)

Compared to the other coal samples with medium and high degrees of metamorphism, the error of the gas loss of long-flame coal calculated via the

method

is larger, especially under a higher

adsorption pressure. Similarly, by selecting the gas desorption data

in the first 5 min for calculation, the correlation coefficient after

fitting of the long-flame coal is smaller than those of the other

coal samples. At the same time, the deviation of gas loss under the

high adsorption pressure is larger. Under an adsorption pressure of

3 MPa, the deviation of gas loss of the columnar coal samples with

the dimensions of 50 mm * 100 mm from the actual loss is 1.86 cm3/g, whereas that of the granular coal samples with the particle

size of 1 mm is 2.27 cm3/g. When gas loss of long-flame

coal is calculated via the

method

is larger, especially under a higher

adsorption pressure. Similarly, by selecting the gas desorption data

in the first 5 min for calculation, the correlation coefficient after

fitting of the long-flame coal is smaller than those of the other

coal samples. At the same time, the deviation of gas loss under the

high adsorption pressure is larger. Under an adsorption pressure of

3 MPa, the deviation of gas loss of the columnar coal samples with

the dimensions of 50 mm * 100 mm from the actual loss is 1.86 cm3/g, whereas that of the granular coal samples with the particle

size of 1 mm is 2.27 cm3/g. When gas loss of long-flame

coal is calculated via the  method,

gas desorption data within a shorter

time span, for example, in the first 3 min, can be selected according

to the actual situations, thereby improving the accuracy of gas loss

calculation.

method,

gas desorption data within a shorter

time span, for example, in the first 3 min, can be selected according

to the actual situations, thereby improving the accuracy of gas loss

calculation. -

(6)

Based on the WY columnar coal sample desorption data under 0.5 MPa adsorption pressure, the deviation of the gas loss of the two compensation methods at different exposure times was compared and analyzed, so as to explore the influence of the exposure time on the accuracy of the compensation method.

Figure 9.

Comparison of the deviation of loss for different exposure times

As shown in Figure 9, regardless of the power function method

or the  method,

the gas loss deviation increases

with the increase of exposure time, that is, the longer the exposure

time, the lower the accuracy of the loss compensation method is.

method,

the gas loss deviation increases

with the increase of exposure time, that is, the longer the exposure

time, the lower the accuracy of the loss compensation method is.

Conclusions

-

(1)

The degree of metamorphism critically influences the amount of gas desorbed by coal and the desorption process. Under the same adsorption pressure, the cumulative total amount of gas desorbed per unit mass of the four types of coal samples increases with the degree of metamorphism. The changes in the cumulative amount of gas desorbed per unit mass and the desorption rate with the degree of metamorphism are segmented. The cumulative amount of gas desorbed and the desorption rate of anthracite, meager-lean coal, and coking coal with medium and high degrees of metamorphism increase with the degree of metamorphism. Notably, a descending order is reported in anthracite, meager-lean coal, and coking coal. However, the cumulative amount of gas desorbed and the desorption rate of long-flame coal with the low degree of metamorphism is large in the initial desorption stage but larger than those of coking coal, meager-lean coal, and even anthracite. Following desorption, the cumulative amount of gas desorbed and the desorption rate of long-flame coal are smaller than those of anthracite, meager-lean coal, and coking coal. A higher adsorption pressure implies more noticeable segmentation.

-

(2)

The columnar and granular coal samples exhibit noticeable differences in the characteristics of gas desorption. For coal with the same degree of metamorphism, the cumulative amount of gas desorbed per unit mass and the desorption rate of the columnar coal samples are significantly smaller than those of the granular coal samples in the whole desorption process before attaining maximum desorption under the same adsorption pressure. The smaller size is related to a larger desorption rate and the cumulative amount of gas desorbed, demonstrating noticeable scale effects. Of note, higher degrees of metamorphism and adsorption pressure imply that the scale effects of gas desorption become more significant.

-

(3)

The adsorption pressure plays a decisive role in the desorption rate and cumulative amount of desorption before the maximum adsorption is achieved. For coal with the same degree of metamorphism, a higher adsorption pressure means that the cumulative amount of gas desorbed and the desorption rate become larger in the whole desorption process. Similarly, a larger proportion of the cumulative amount of gas is desorbed in the initial stage. When the coal sample is smaller, more pressure effects of gas desorption are realized. Briefly, under the same difference in adsorption pressures, a smaller coal sample is associated with larger differences in the corresponding cumulative amount of gas desorbed and desorption rate.

-

(4)

The gas content in underground coal seams was established through the collection of columnar coal cores using the coal core sampler. The loss is smaller within the same exposure time. The loss calculation using the power function method is more accurate compared to the

method.

For coal samples with the same

degree of metamorphism, when the gas content in coal seams is the

same, the actual loss of large-scale columnar coal samples is smaller

than that of small-scale granular coal samples. A higher gas content

in coal seams implies a greater gas loss within the same exposure

time and a larger error of gas loss calculation. In comparison to

the

method.

For coal samples with the same

degree of metamorphism, when the gas content in coal seams is the

same, the actual loss of large-scale columnar coal samples is smaller

than that of small-scale granular coal samples. A higher gas content

in coal seams implies a greater gas loss within the same exposure

time and a larger error of gas loss calculation. In comparison to

the  method, the gas loss calculated by the

power function method depicts a smaller deviation with the actual

gas loss but with a higher accuracy. In addition, the accuracy of

the two calculation methods shows obvious effects of a particle size

such that the larger scale of the coal samples denotes a higher accuracy

of the gas loss calculation.

method, the gas loss calculated by the

power function method depicts a smaller deviation with the actual

gas loss but with a higher accuracy. In addition, the accuracy of

the two calculation methods shows obvious effects of a particle size

such that the larger scale of the coal samples denotes a higher accuracy

of the gas loss calculation.

Acknowledgments

This research was financially jointly supported by the National Science and Technology Major Project of China (grant no. 2011ZX05040005), Key Science and Technology Program of Henan Province (152102210105, 202102310221, and 202102310619), Program for Innovative Research Team at the University of Ministry of Education of China (IRT_16R22), Doctoral Foundation of Henan Polytechnic University (B2017-04), State Collaborative Innovation Center of Coal Work Safety and Clean-Efficience Utilization and National Coal Field Engineering Research Center for Gas Geology and Gas Control.

The authors declare no competing financial interest.

References

- Zhao W.; Cheng Y.; Jiang H.; Jin K.; Wang H.; Wang L. Role of the rapid gas desorption of coal powders in the development stage of outbursts. J. Nat. Gas Sci. Eng. 2016, 28, 491–501. 10.1016/j.jngse.2015.12.025. [DOI] [Google Scholar]

- Yang D. D.; Chen Y. J.; Tang J.; Li X. W.; Jiang C. L.; Wang C. J.; Zhang C. J. Experimental research into the relationship between initial gas release and coal-gas outbursts. J. Nat. Gas Sci. Eng. 2017, 50, 157–165. 10.1016/j.jngse.2017.12.015. [DOI] [Google Scholar]

- Yuan L. Theory and practice of integrated coal production and gas extraction. Int. J. Coal Sci. Technol. 2015, 2, 3–11. 10.1007/s40789-015-0065-2. [DOI] [Google Scholar]

- Xue S.; Yuan L. The use of coal cuttings from underground boreholes to determine gas content of coal with direct desorption method. Int. J. Coal Geol. 2017, 174, 1–7. 10.1016/j.coal.2017.03.007. [DOI] [Google Scholar]

- Yang Q. L. Experimental study on the rule of methane emission from coal dust. Saf. Coal Mine 1987, 18, 9–16. [Google Scholar]

- Nie B. S.; Yang T.; Li X. C.; Li L.; Lu H. Q. Research on diffusion of methane in coal particles. J. China Univ. Min. Technol. 2013, 42, 975–981. [Google Scholar]

- Han E. G.; LIU Z. W.; Ran Y. J.; Ma S. J.; Li Z. Q. Experimental study on the law of gas desorption and diffusion of different granularity coal. J. Saf. Sci. Technol. 2019, 15, 83–87. [Google Scholar]

- Feng Y.-Y.; Yang W.; Chu W. Coalbed methane adsorption and desorption characteristics related to coal particle size. Chin. Phys. B 2016, 25, 068102. 10.1088/1674-1056/25/6/068102. [DOI] [Google Scholar]

- Qin Y.-P.; Wang C.-X.; Wang J.; Yang X.-B. Mathematical model of gas emission in coal particles and the numerical solution. J. China Coal Soc. 2012, 37, 1466–1471. [Google Scholar]

- Liu Y. W.; Liu M. J. Effect of particle size on difference of gas desorption and diffusion between soft coal and hard coal. J. China Coal Soc. 2015, 40, 579–587. 10.13225/j.cnki.jccs.2014.0380. [DOI] [Google Scholar]

- Chen X. J.; Jia D. X.; Wang L. Study on Factors Affected to Coal Gas Desorption. Coal Sci. Technol. 2013, 41, 50–53. [Google Scholar]

- Ma D.-M.; Ma W.; Lin Y.-B. Desorption hysteresis characteristics of CBM. J. China Coal Soc. 2012, 37, 1885–1889. [Google Scholar]

- Zhang Z.; Qin Y.; Wang G. X.; Fu X. Numerical description of coalbed methane desorption stages based on isothermal adsorption experiment. Sci. China: Earth Sci. 2013, 56, 1029–1036. 10.1007/s11430-013-4597-2. [DOI] [Google Scholar]

- Ge Y.; Qin Y.; Fu X.; Luo B.; Sun H. Comparative experimental study of atmospheric pressure desorption and methane pressure desorption among coal samples of different particle sizes. J. China Univ. Min. Technol. 2015, 44, 673–678. [Google Scholar]

- Li Z. Q.; Cheng Q.; Liu Y. W.; Duan Z. P.; Song D. Y. Research on gas diffusion model and experimental diffusion characteristic of cylindrical coal. J. China Univ. Min. Technol. 2017, 46, 1033–1040. [Google Scholar]

- Yan J.; Wu L.; Wang J. Effect of particle size on methane desorption from different metamorphic coal samples. China Saf. Sci. J. 2018, 28, 95–101. 10.16265/j.cnki.issn1003-3033.2018.07.016. [DOI] [Google Scholar]

- Cheng Y.; Jiang H.; Zhang X.; Cui J.; Song C.; Li X. Effects of coal rank on physicochemical properties of coal and on methane adsorption. Int. J. Coal Sci. Technol. 2017, 4, 129–146. 10.1007/s40789-017-0161-6. [DOI] [Google Scholar]

- Lin B.; Li H.; Yuan D.; Li Z. Development and application of an efficient gas extraction model for low-rank high-gas coal beds. Int. J. Coal Sci. Technol. 2015, 2, 76–83. 10.1007/s40789-015-0057-2. [DOI] [Google Scholar]

- Li X. C.; Li Z. B.; Zhang L.; Gao J. X.; Nie B. S.; Meng Y. Y. Pore structure characterization of different coal rank coal samples and its effect on gas desorption and diffusion. J. China Coal Soc. 2019, 44, 142–156. [Google Scholar]

- Kang Z. Q.; Li X.; Li W.; Zhao J. Experimental research on the correlation between coal structure and methane adsorption/desorption law and its enlightenment. J. China Coal Soc. 2018, 43, 1400–1407. [Google Scholar]

- Wierzbicki M. The effect of temperature on the sorption properties of coal from upper silesian coal basin, Poland. Arch. Min. Sci. 2013, 58, 1163–1176. 10.2478/amsc-2013-0079. [DOI] [Google Scholar]

- Wang Y. B.; Li H. T.; Qi L. M. Study on gas desorption law of coal mass at low temperatures. China Coal 2011, 37, 103–104. [Google Scholar]

- Wang Z. F.; Kang B.; Yue G. W.; Xie C. Study on gas desorption characteristics of anthracite in low temperature environment. J. Henan Polytech. Univ., Nat. Sci. 2014, 33, 705–709. [Google Scholar]

- Meng Y.; Li Z. Experimental study on diffusion property of methane gas in coal and its influencing factors. Fuel 2016, 185, 219–228. 10.1016/j.fuel.2016.07.119. [DOI] [Google Scholar]

- Zhang D.; Cui Y.-J.; Li S.; Song W.; Lin W. Adsorption and diffusion behaviors of methane and carbon dioxide on various rank coals. J. China Coal Soc. 2011, 36, 1693–1698. [Google Scholar]

- Yan J.; Meng Z.; Li G. Diffusion characteristics of methane in various rank coals and the control mechanism. Fuel 2021, 283, 118959. 10.1016/j.fuel.2020.118959. [DOI] [Google Scholar]

- Wang L.; Zhang G.; Liu J.; Chen X.; Li Z. Effect of the Pore Structure on Adsorption and Diffusion Migration of Different Rank Coal Samples. Energy Fuels 2020, 34, 12486–12504. 10.1021/acs.energyfuels.0c02587. [DOI] [Google Scholar]

- Gao Z.; Ma D.; Chen Y.; Zheng C.; Teng J. Study for the Effect of Temperature on Methane Desorption Based on Thermodynamics and Kinetics. ACS Omega 2021, 6, 702–714. 10.1021/acsomega.0c05236. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lin C.; Jia T. R.; Zhou S. W.; Zhang Y. G. Diffusion characteristics of methane adsorption process in granular coal. Coal Geol. Explor. 2018, 46, 44–49. [Google Scholar]

- Li X.; Cao Z.; Xu Y. Characteristics and trends of coal mine safety development. Energy Sources, Part A 2020, 12, 1–19. 10.1080/15567036.2020.1852339. [DOI] [Google Scholar]

- Li X.; Chen S.; Wang E.; Li Z. Rockburst mechanism in coal rock with structural surface and the microseismic (MS) and electromagnetic radiation (EMR) response. Eng. Fail. Anal. 2021, 124, 105396. 10.1016/j.engfailanal.2021.105396. [DOI] [Google Scholar]

- Liu S.; Li X.; Wang D.; Zhang D. Experimental study on temperature response of different ranks of coal to liquid nitrogen soaking. Nat. Resour. Res. 2021, 30, 1467–1480. 10.1007/s11053-020-09768-3. [DOI] [Google Scholar]

- Si L.; Zhang H.; Wei J.; Li B.; Han H. Modeling and experiment for effective diffusion coefficient of gas in water-saturated coal. Fuel 2021, 284, 118887. 10.1016/j.fuel.2020.118887. [DOI] [Google Scholar]

- Si L.; Wei J.; Xi Y.; Wang H.; Wen Z.; Li B.; Zhang H. The influence of long-time water intrusion on the mineral and pore structure of coal. Fuel 2021, 290, 119848. 10.1016/j.fuel.2020.119848. [DOI] [Google Scholar]

- Wang Y. A.; Yang S. J. Some features of coal and gas outburst coal seams. J. China Coal Soc. 1981, 1, 47–53. [Google Scholar]

- Bolt B.; Innes J. Diffusion of carbon dioxide from coal. Fuel 1959, 38, 333–337. [Google Scholar]

- Li Y.-B.; Zhang Y.-G.; Zhang Z.-M.; Jiang B. Experimental study on gas desorption of tectonic coal at initial stage. J. China Coal Soc. 2013, 38, 15–20. [Google Scholar]

- Qi C. J.; Wang Z. F.; Xie C.; Yue G. W.; Li X. J. Study on Description of Empirical Formula on Gas Desorption of Coal Particles in Low Temperature Environment. Saf. Coal Mine 2016, 47, 29–32. [Google Scholar]

- Li C. W.; Xue H. L.; Liu W. B. Experimental study on gas diffusion in coal under stress. J. China Coal Soc. 2018, 43, 717–723. [Google Scholar]

- Wang D. K.; Wang H. L.; Wei J. P. Multi-diffusion coefficient model and diffusion parameter inversion of gas desorption for coal particles. J. Saf. Sci. Technol. 2016, 12, 10–15. [Google Scholar]

- Li C. W.; Wang Y. L.; Wang Q. J.; Gao X. Experimental study on accuracy of direct gas content determination. J. China Coal Soc. 2020, 45, 189–196. [Google Scholar]

- Qin Y. P.; Hao Y. G.; Liu P.; Wang J. Comparative analysis of coal particle gas dispersion model. Saf. Coal Mine 2015, 46, 144–147. 10.1002/9781119037699.ch6. [DOI] [Google Scholar]

- Liu P.; Qin Y.; Liu S.; Hao Y. Non-linear gas desorption and transport behavior in coal matrix: Experiments and numerical modeling. Fuel 2018, 214, 1–13. 10.1016/j.fuel.2017.10.120. [DOI] [Google Scholar]

- Li X.; Li Y.; Tang J. Determining the initial stage loss content of tectonic coal gas desorption via the Bayesian probability method. Nat. Hazards 2019, 97, 83–97. 10.1007/s11069-019-03627-y. [DOI] [Google Scholar]

- Saghafi A. Discussion on determination of gas content of coal and uncertainties of measurement. Int. J. Min. Sci. Technol. 2017, 27, 741–748. 10.1016/j.ijmst.2017.07.024. [DOI] [Google Scholar]

- Yang Z.; Qin Y.; Wang Z.; Wang G.; Wu C. Desorption-diffusion model and lost gas quantity estimation of coalbed methane from coal core under drilling fluid medium. Sci. China: Earth Sci. 2010, 53, 626–632. 10.1007/s11430-010-0027-x. [DOI] [Google Scholar]

- GB/T 23250-2009 The Direct Method of Determining Coalbed Gas Content in the Mine; General Administration of Quality Supervision and Inspection of China, Standardization Administration of China, 2009.